Multifunctional inherent-flame-retardant viscose blended yarn, fabric and yarn preparation method

A technology of blended yarn and flame-retardant viscose fiber, which is applied in textiles, fabrics, textiles, and papermaking. It can solve the problems of low tensile strength of fabrics, low fiber strength, and easy pilling, and achieve low fabric cost and protection. Excellent performance, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Based on the above-mentioned multifunctional intrinsically flame-retardant viscose blended yarn, the present invention also provides a preparation method. Described preparation method comprises the steps:

[0061] According to the percentage by weight, the flame-retardant viscose fiber, aramid fiber, and antistatic fiber are mixed, and the yarn is spun through a combination of manual and automatic configuration to obtain a single-ply yarn of 20-60s;

[0062] Two-fold twisting is performed on the obtained single-ply yarn of 20-60s to obtain double-ply multi-functional intrinsically flame-retardant viscose blended yarn of 20-60s.

[0063] Therefore, through two-for-one twisting, the multifunctional intrinsically flame-retardant viscose blended yarn of the present invention has the least damage, the least hairiness, and excellent strength performance.

[0064] Based on the above-mentioned multifunctional intrinsically flame-retardant viscose blended yarn, the present inve...

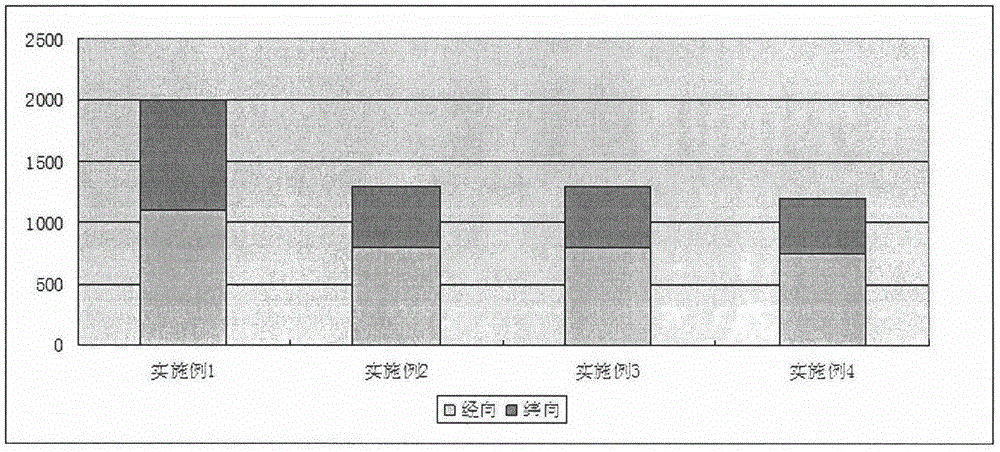

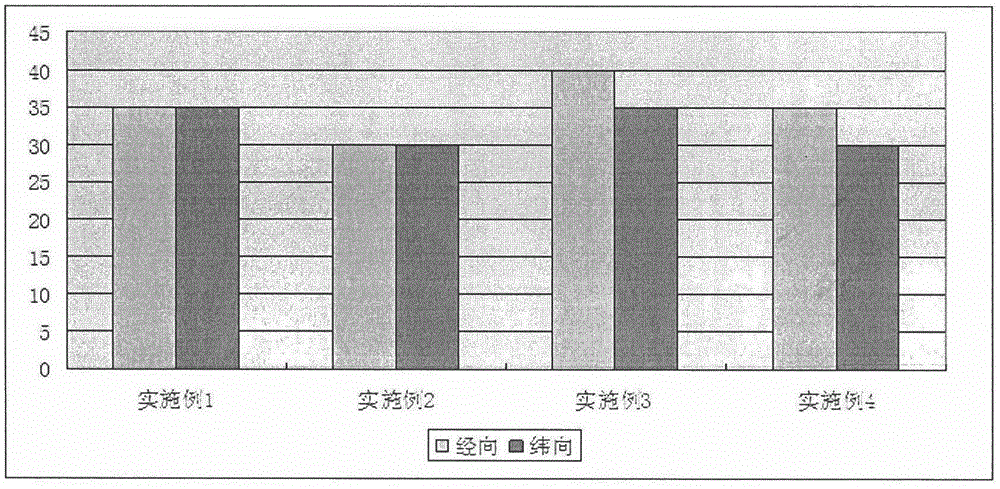

Embodiment 1

[0073] A viscose blended yarn comprising 50 wt% flame retardant viscose fiber and 50 wt% aramid was prepared. In the present embodiment, the mixed strip made is made into 25 strands, and the warp and weft yarns all use this yarn. Warp and weft yarns are used in 2 / 1 twill on rapier looms. The fabric structure is 75 warp yarns / inch*55 weft yarns / inch, and the basis weight is 250g / cm 2 . The fabric made as above is subjected to water setting finishing to obtain the final finished fabric.

Embodiment 2

[0075] A viscose blended yarn comprising 55 wt% flame retardant viscose fiber, 25 wt% meta-aramid, 18 wt% para-aramid and 2 wt% antistatic fiber was prepared. In the present embodiment, the mixed strip thus made is made into 40 strands, and the warp and weft yarns all use this yarn. Warp and weft yarns are used in 2 / 1 twill on rapier looms. The fabric structure is 90 warp yarns / inch*60 weft yarns / inch, and the basis weight is 180g / cm 2 . The fabric made as above is subjected to water setting finishing to obtain the final finished fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com