Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "High deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

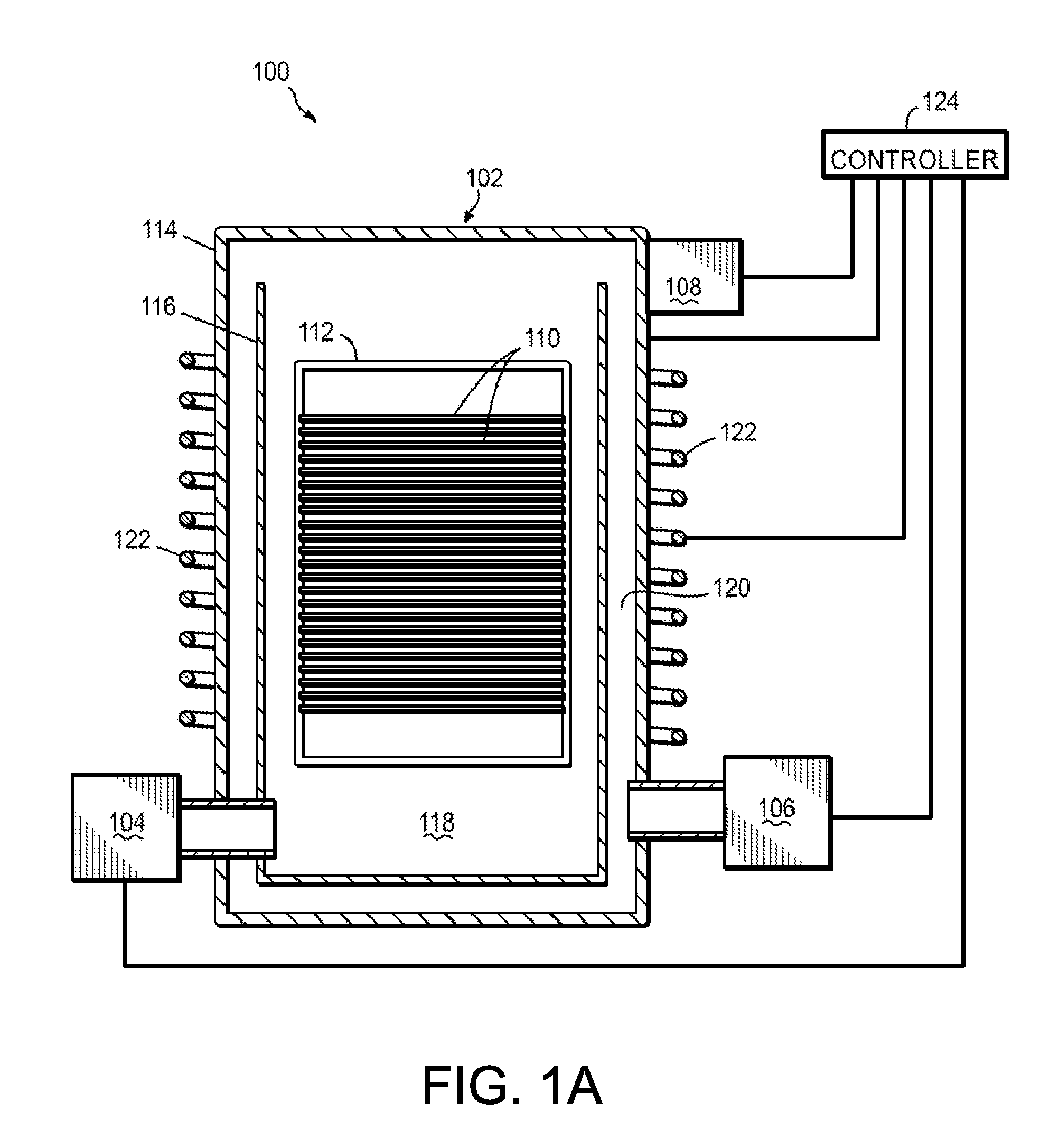

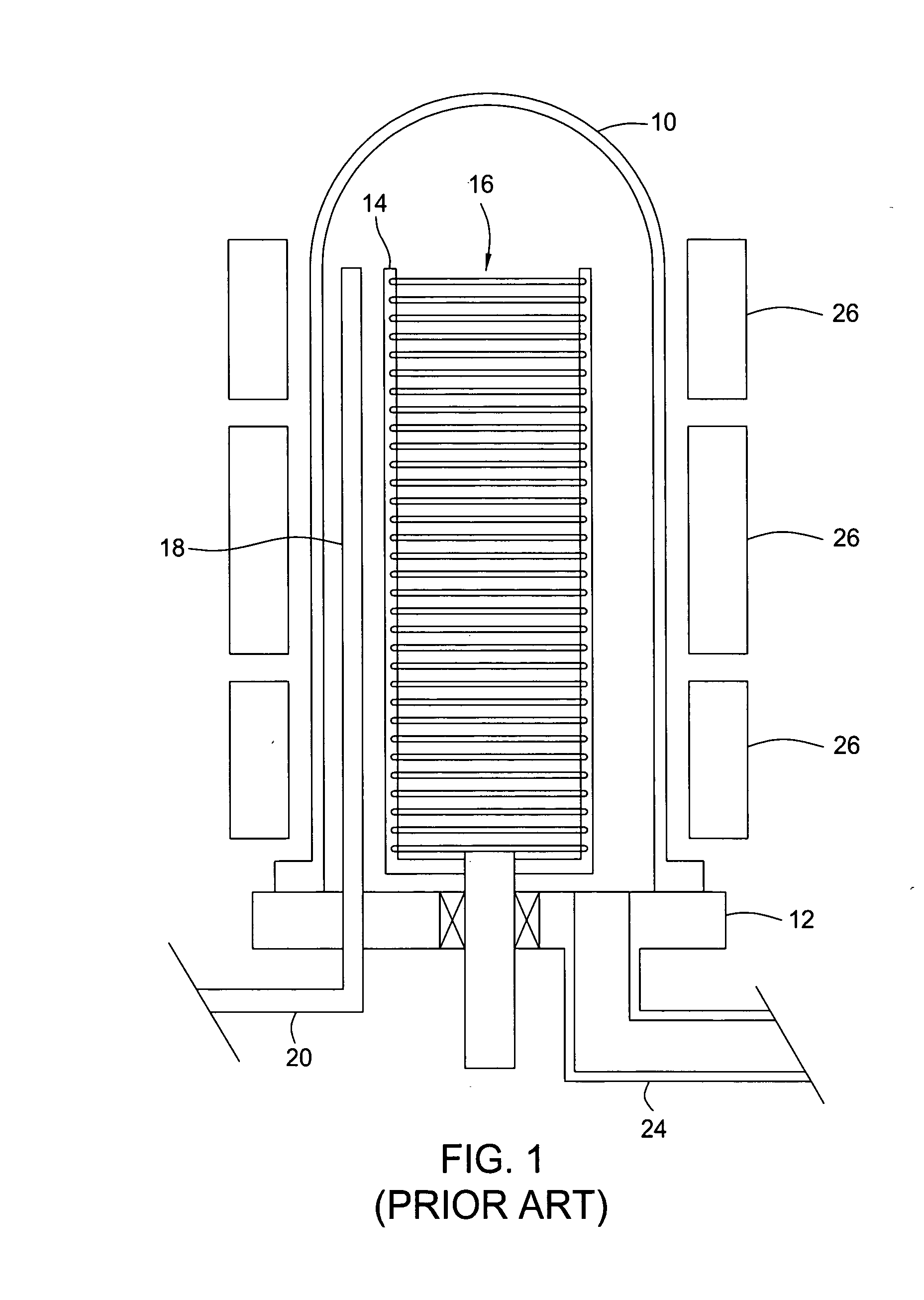

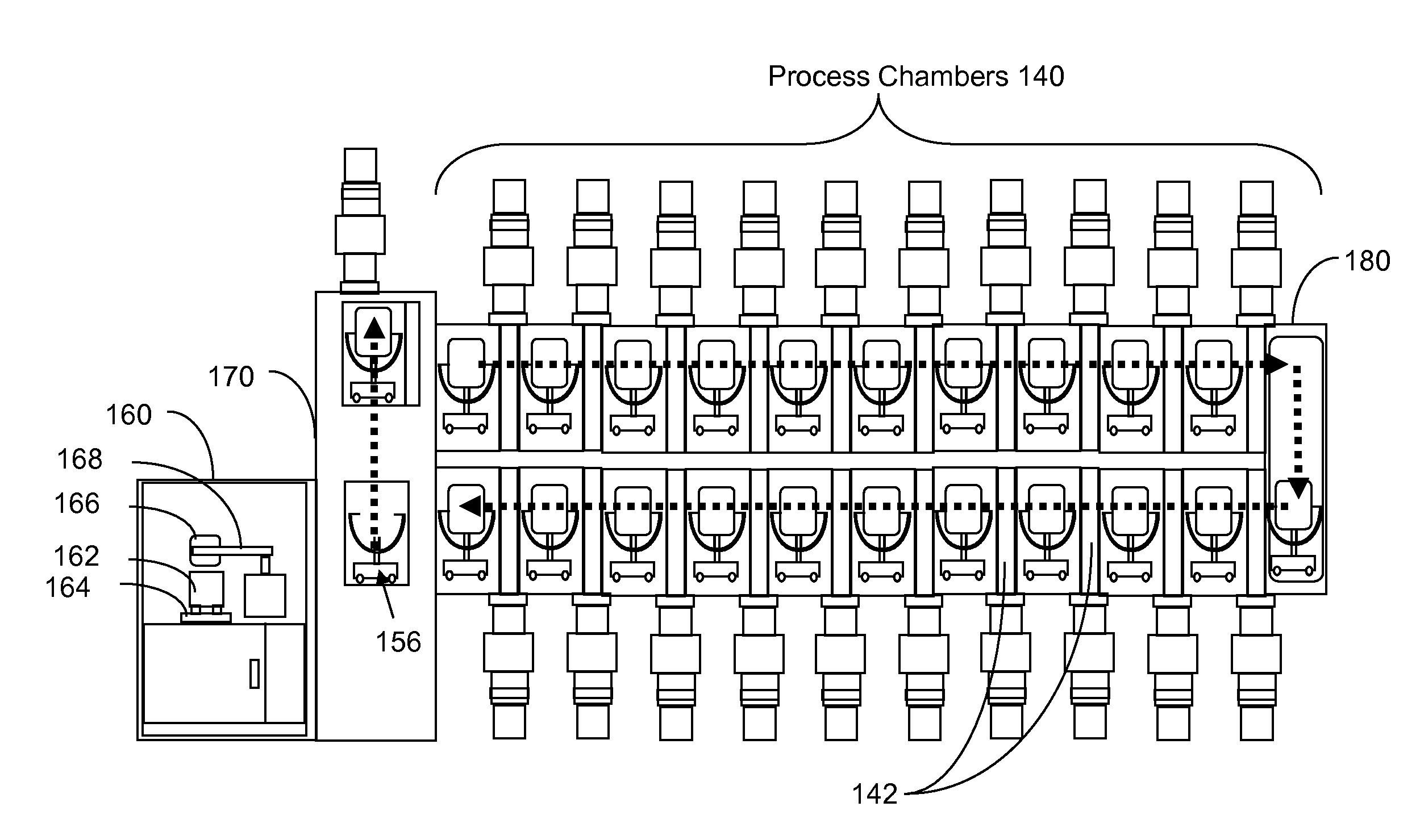

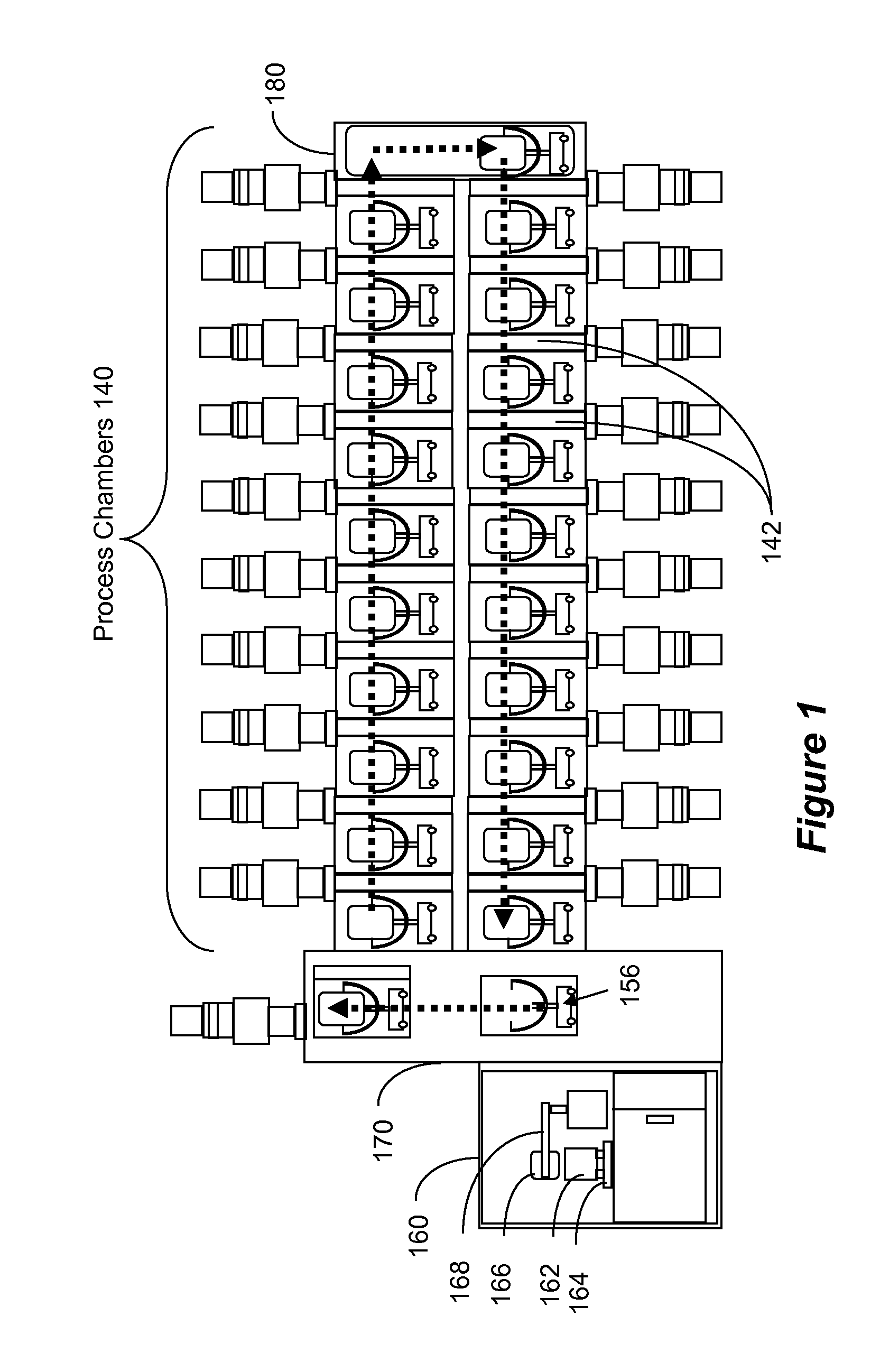

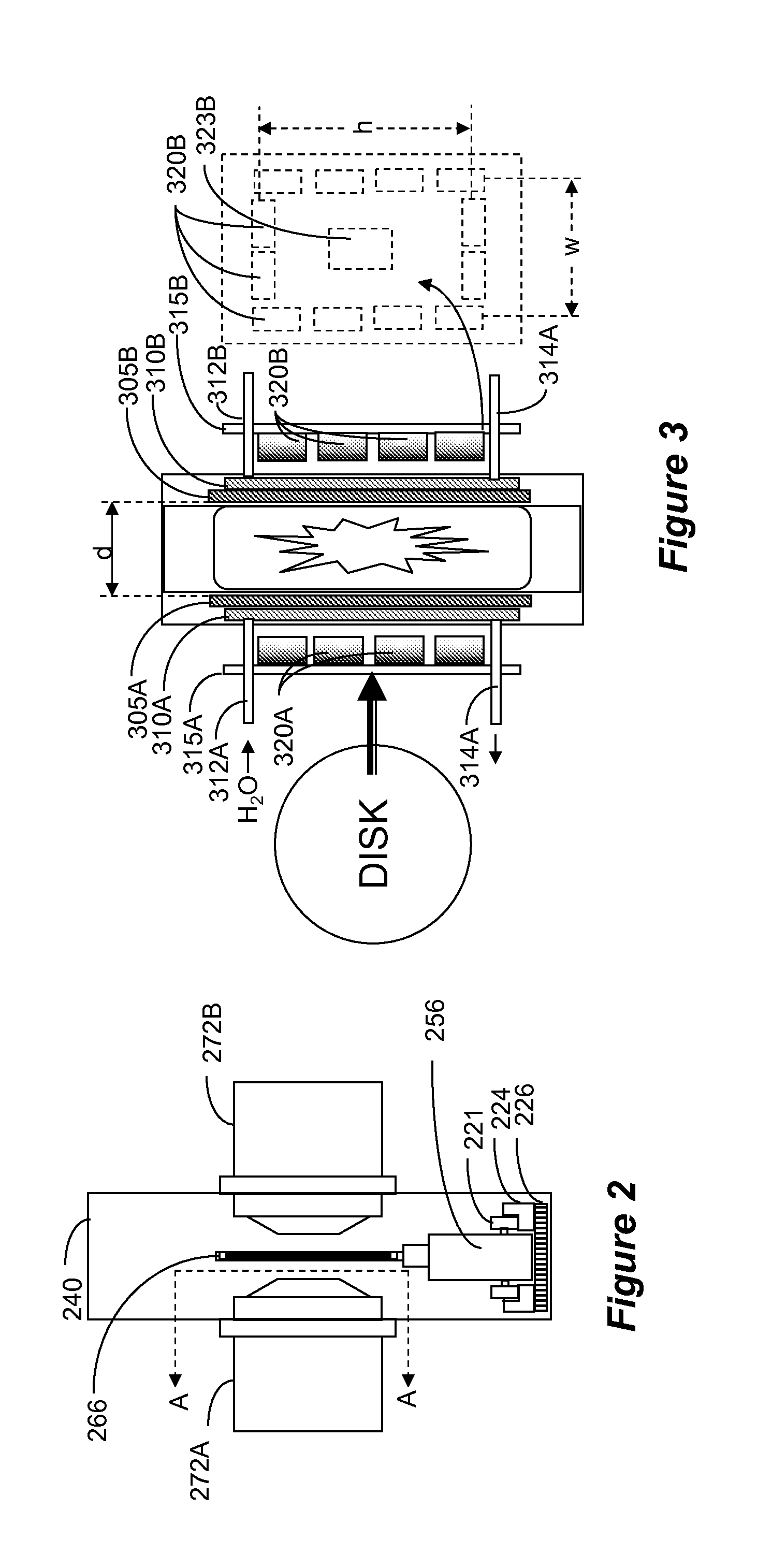

In-situ hybrid deposition of high dielectric constant films using atomic layer deposition and chemical vapor deposition

InactiveUS20090246971A1Cost-effectiveHigh deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHigh dielectric permittivity

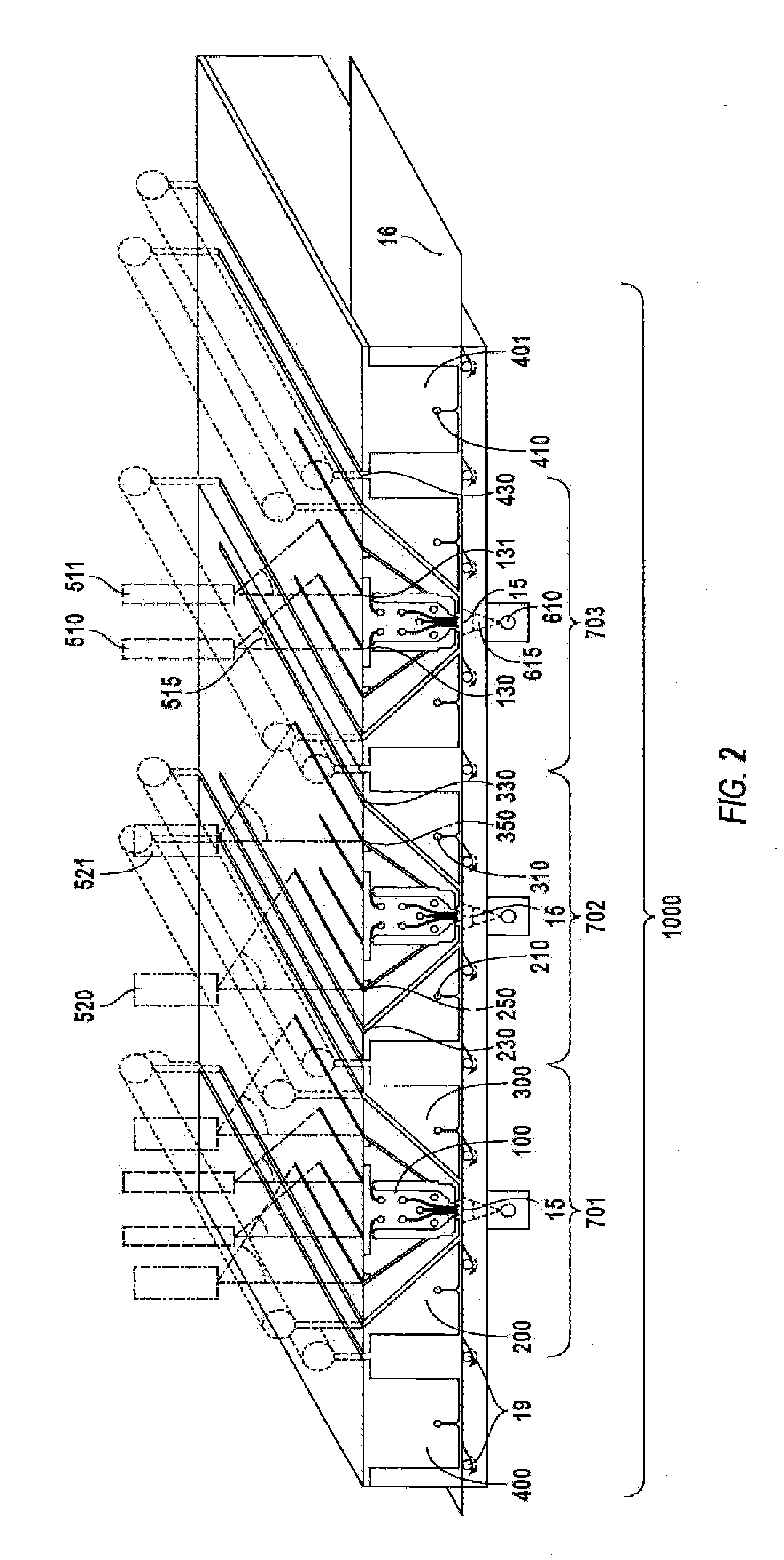

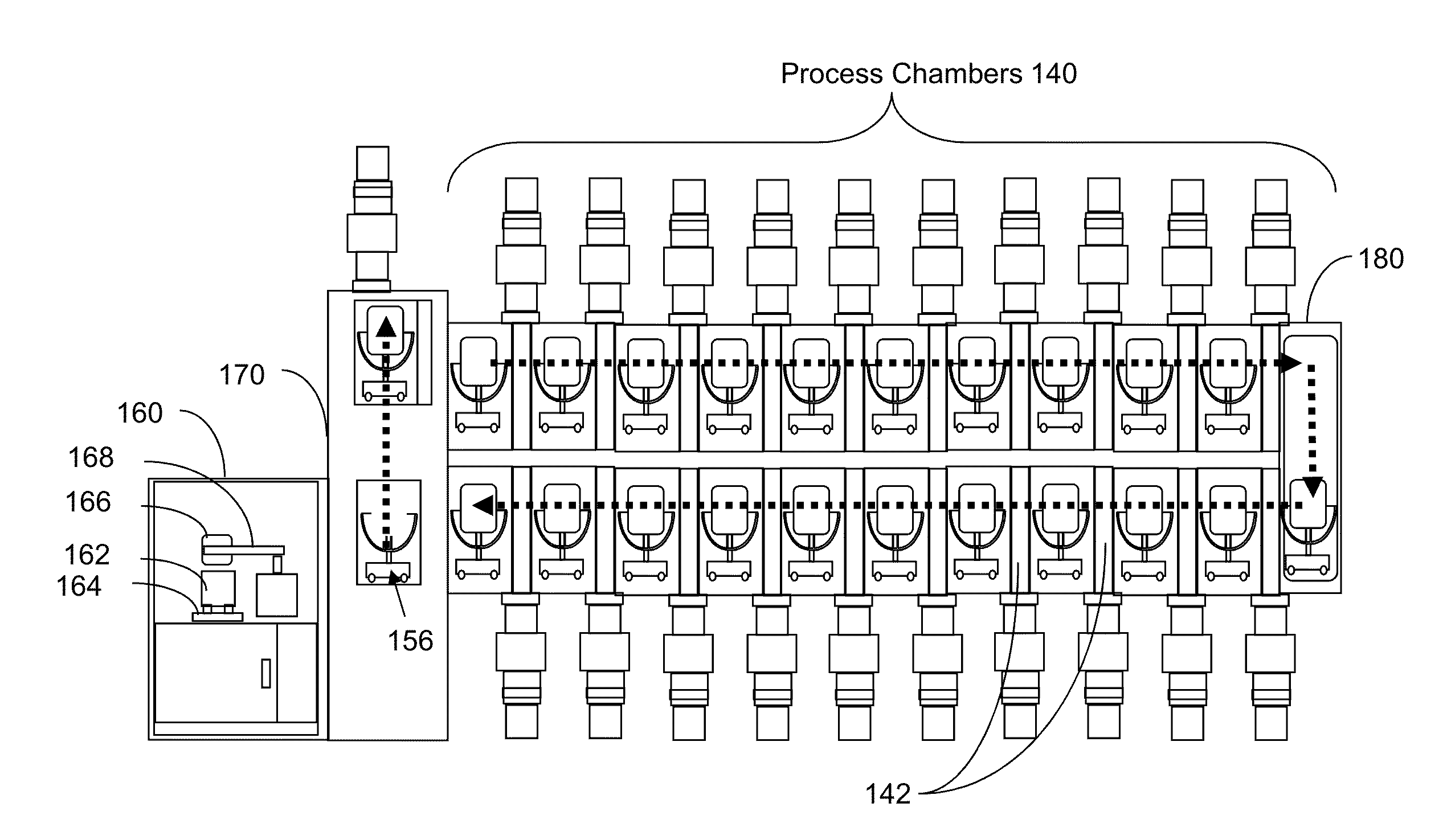

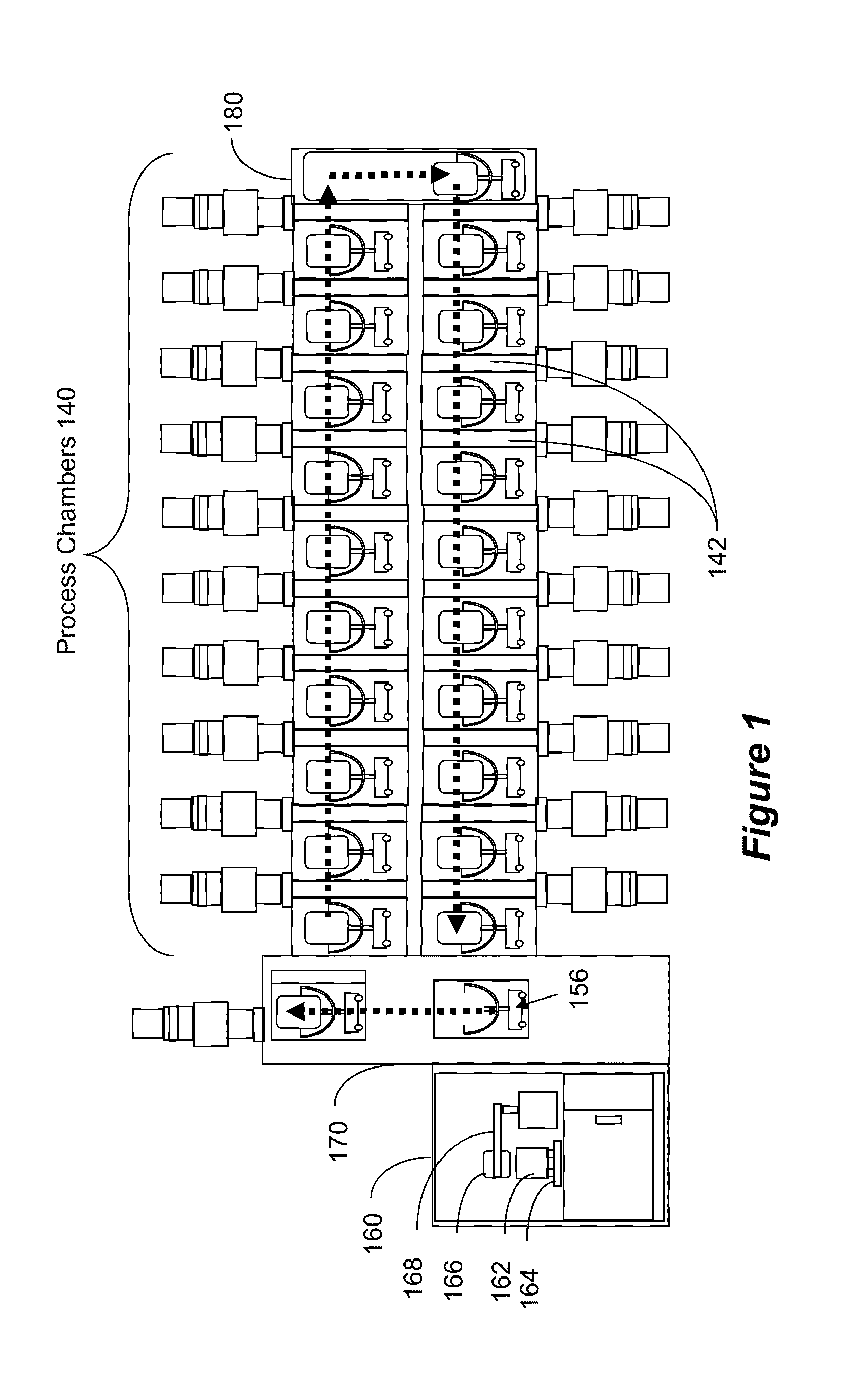

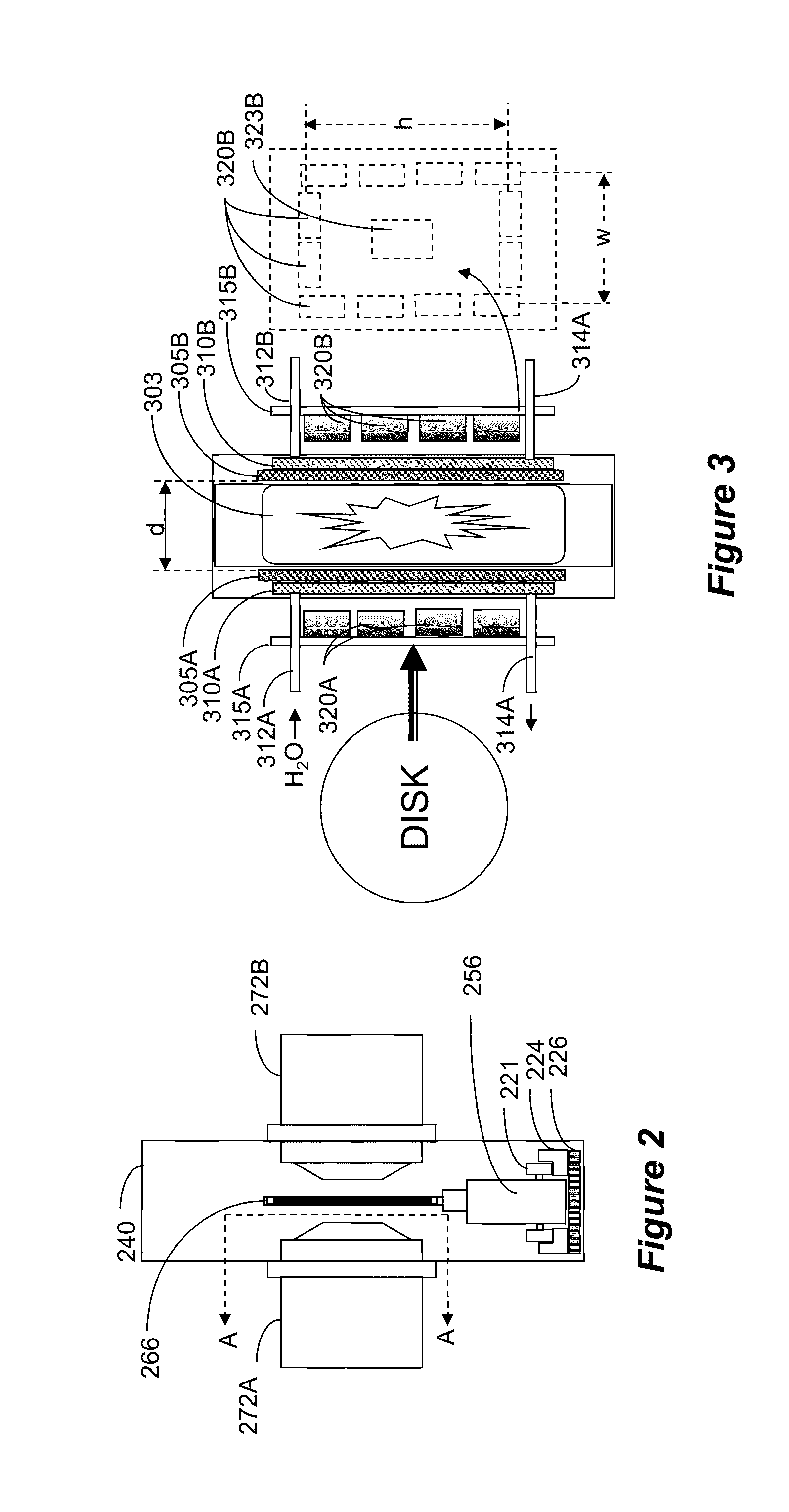

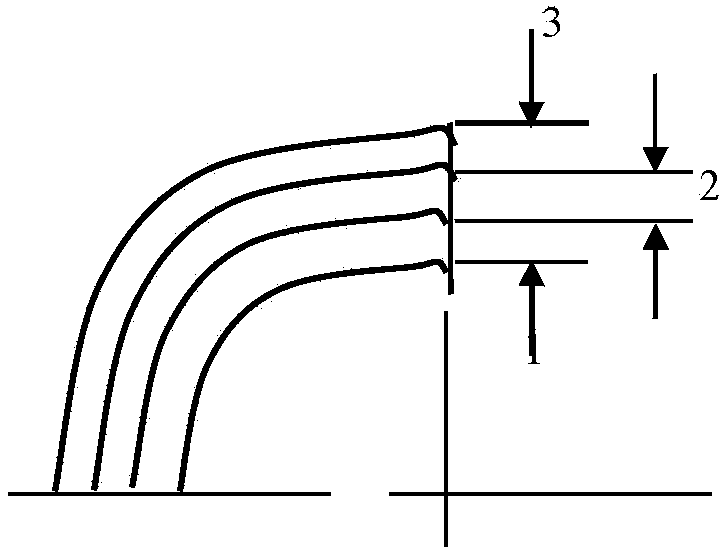

An in-situ hybrid film deposition method for forming a high-k dielectric film on a plurality of substrates in a batch processing system. The method includes loading the plurality of substrates into a process chamber of the batch processing system, depositing by atomic layer deposition (ALD) a first portion of a high-k dielectric film on the plurality of substrates, after depositing the first portion, and without removing the plurality of substrates from the process chamber, depositing by chemical vapor deposition (CVD) a second portion of the high-k dielectric film on the first portion, and removing the plurality of substrates from the process chamber. The method can further include alternatingly repeating the deposition of the first and second portions until the high-k dielectric film has a desired thickness. The method can still further include pre-treating the substrates and post-treating the high-k dielectric film in-situ prior to the removing.

Owner:TOKYO ELECTRON LTD

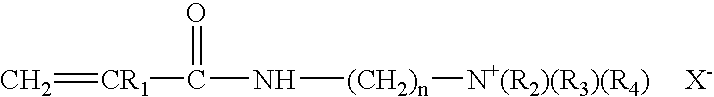

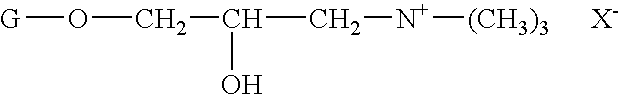

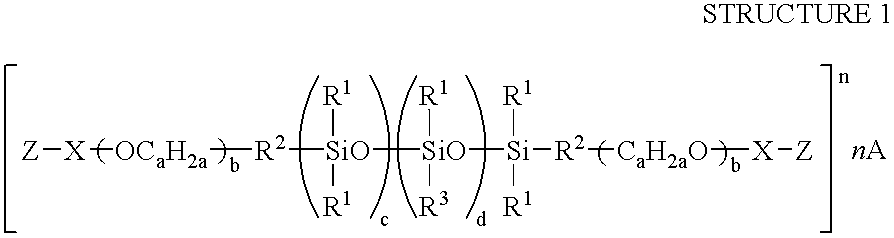

Liquid laundry detergent comprising cationic silicone block copolymers

InactiveUS7273837B2Increase deposition rateGood colorInorganic/elemental detergent compounding agentsCationic surface-active compoundsAminosilochromeCationic polymerization

The invention is directed to a liquid laundry detergent composition comprising at least one detergent ingredient selected from the group consisting of anionic surfactant, zwitterionic surfactant, amphoteric surfactant, and mixtures thereof; a coacervate phase forming cationic polymer; and one or more fabric care ingredients selected from the group consisting of one or more cationic silicone polymers comprising one or more polysiloxane units and one or more nitrogen moieties; one or more amino silicone polymers; one or more nitrogen-free silicone polymers; and mixtures thereof; and a liquid carrier for providing cleaning and fabric care benefits. A process for preparing such compositions, a method for treating substrates, a method for providing certain fabric care benefits and the use of such compositions are also described.

Owner:THE PROCTER & GAMBLE COMPANY +1

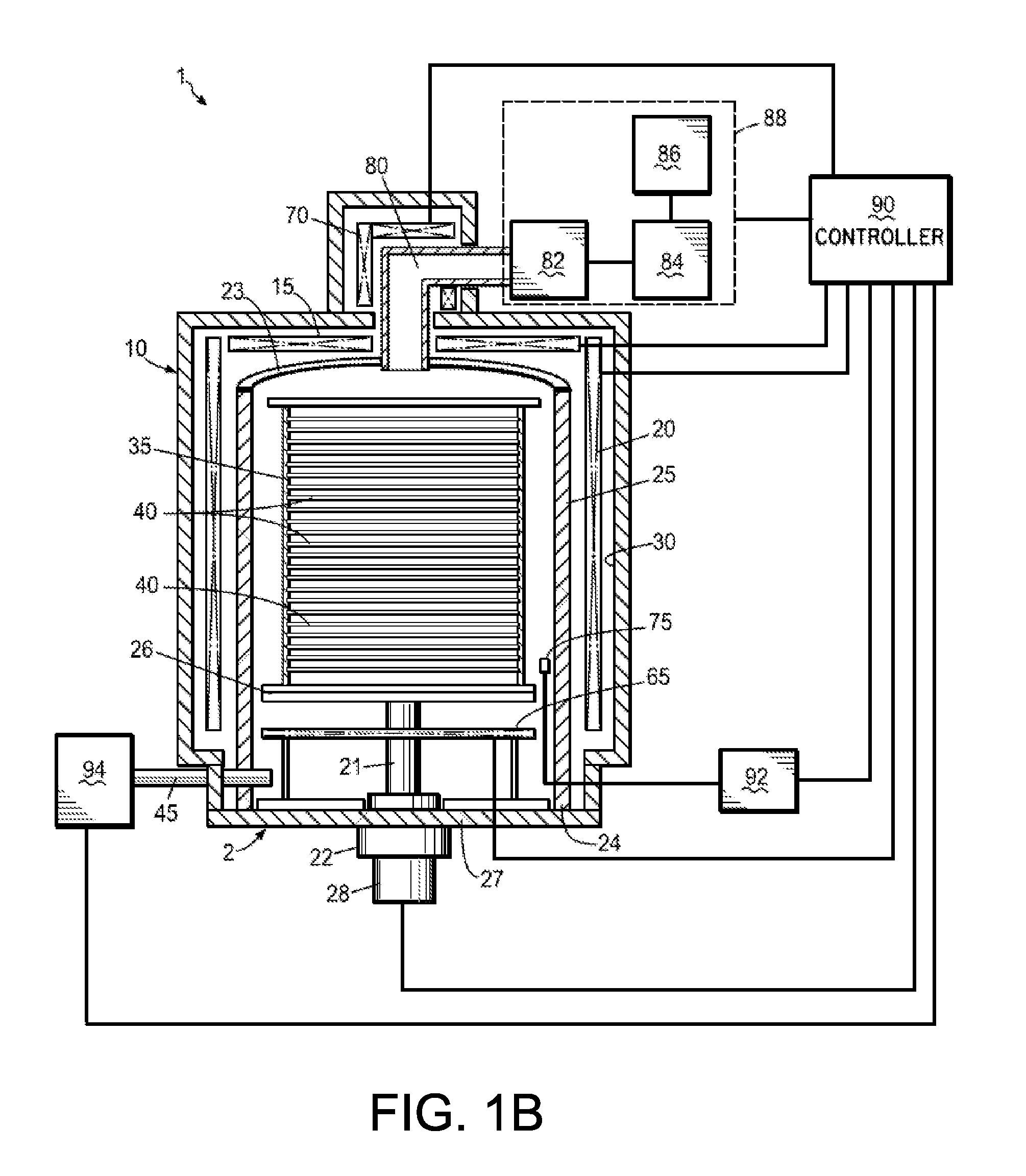

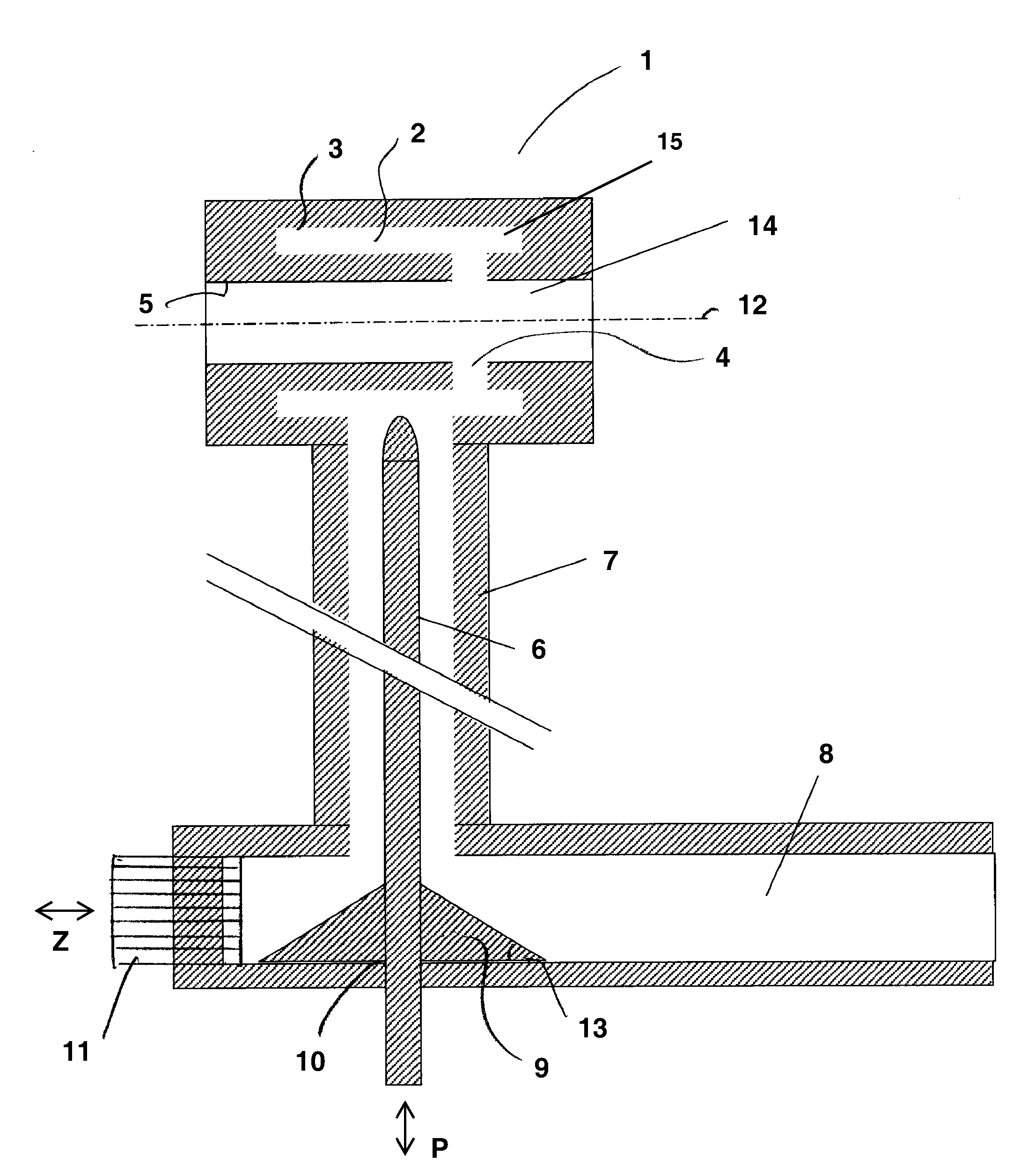

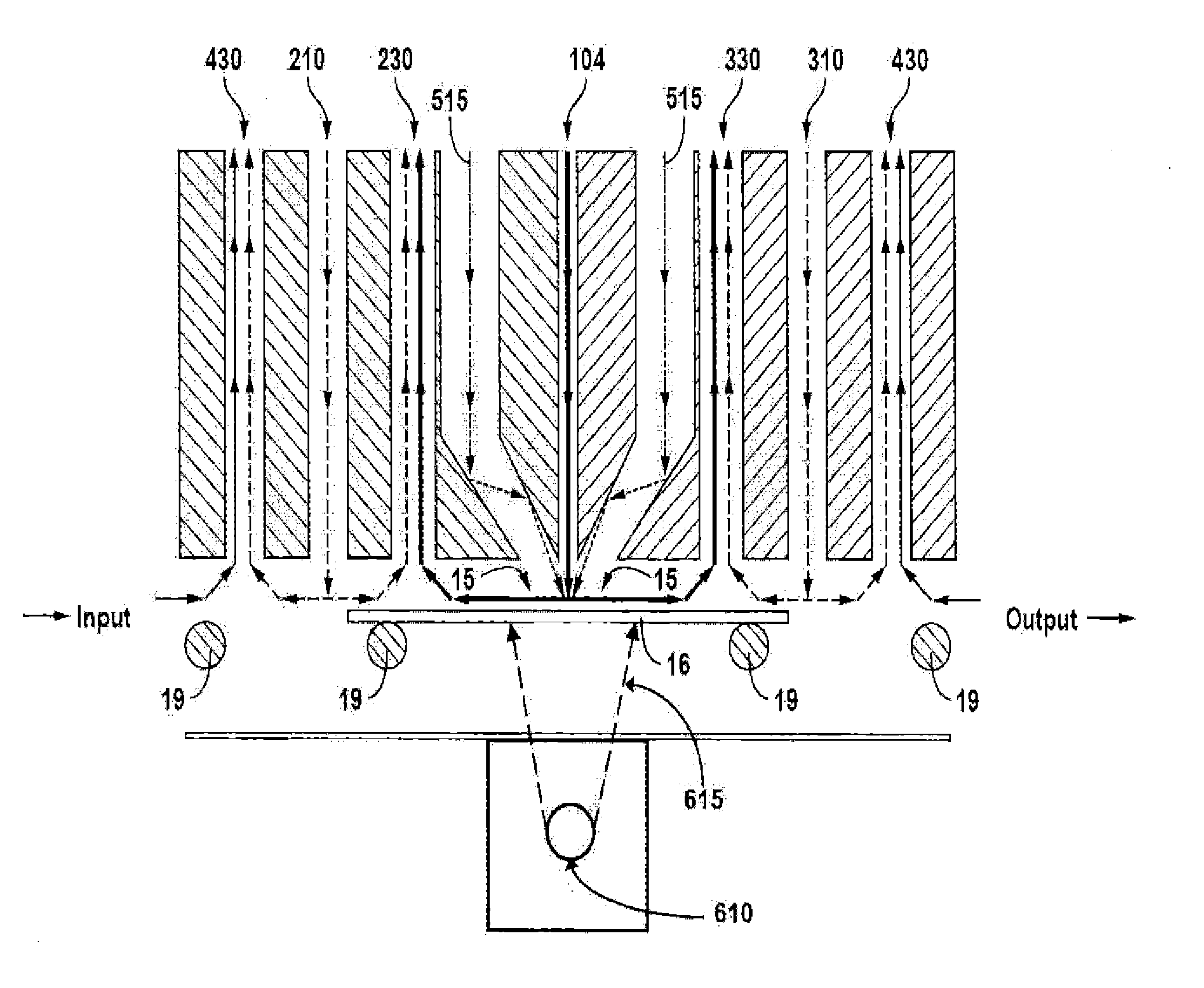

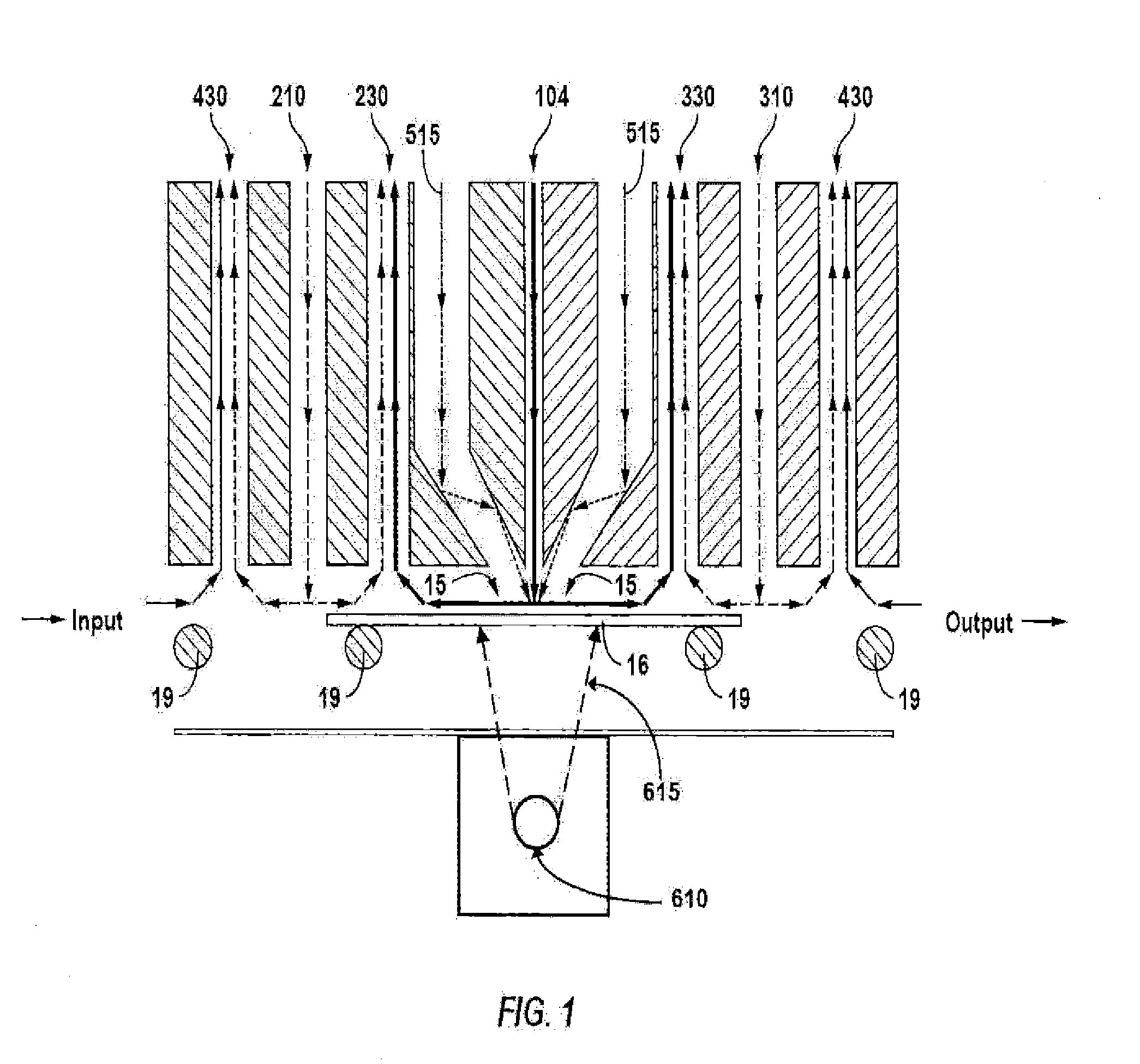

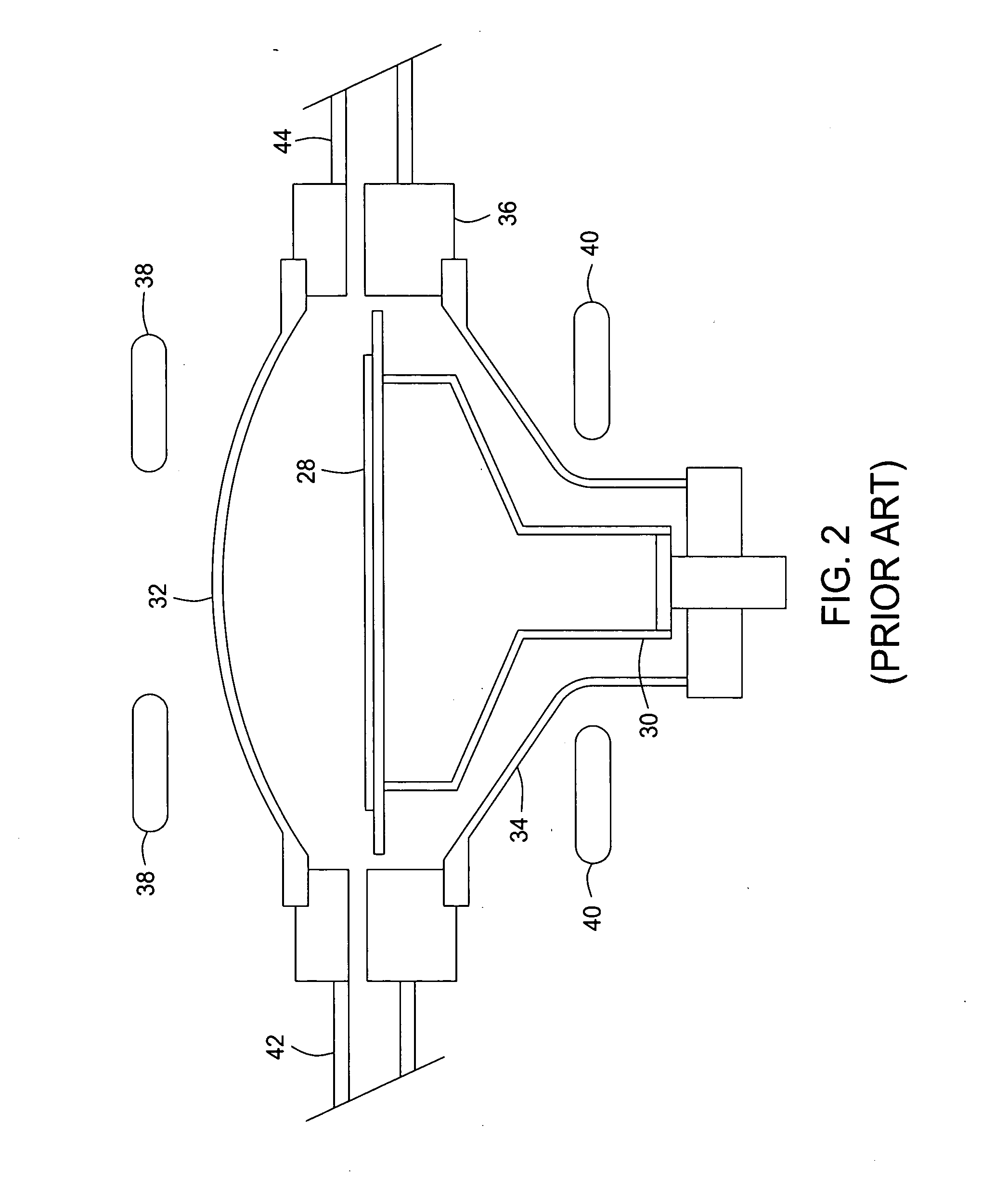

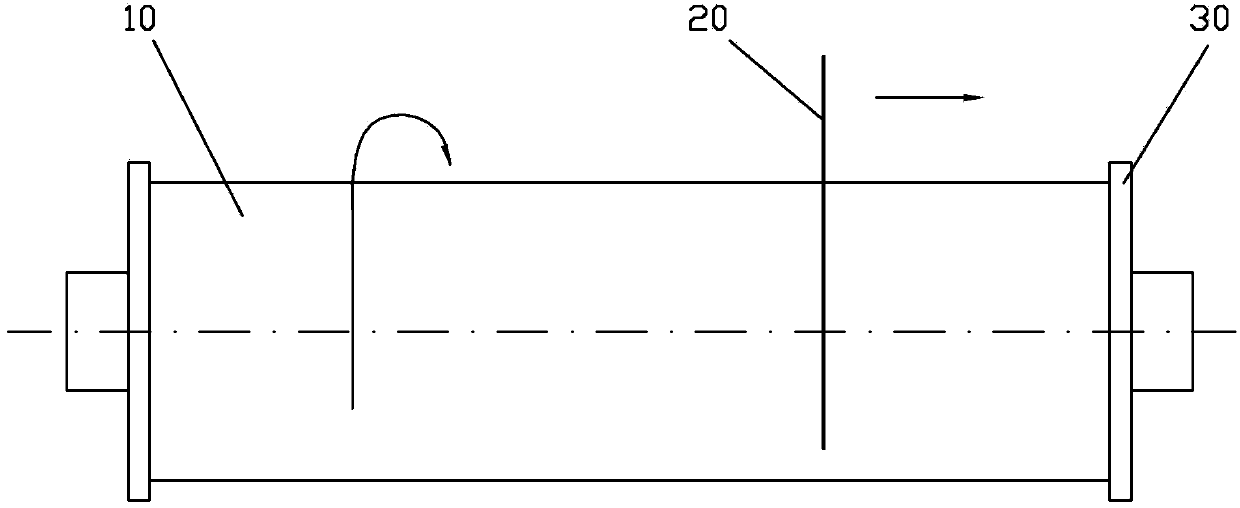

Apparatus for Effecting Plasma Chemical Vapor Deposition (PCVD)

ActiveUS20070289532A1Increase power levelIncrease deposition rateGlass making apparatusElectric discharge tubesChemical vapor depositionSilicon dioxide

The present invention relates to an apparatus for carrying out a plasma chemical vapor deposition process by which one or more layers of doped or undoped silica can be deposited on the interior of an elongated glass substrate tube. The present invention further relates to a method for manufacturing an optical fiber using such an apparatus.

Owner:DRAKA COMTEQ BV

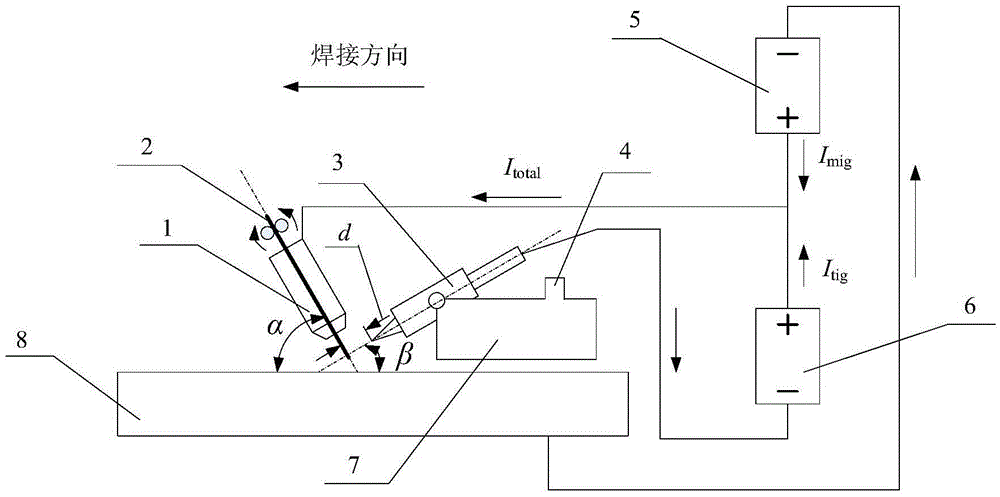

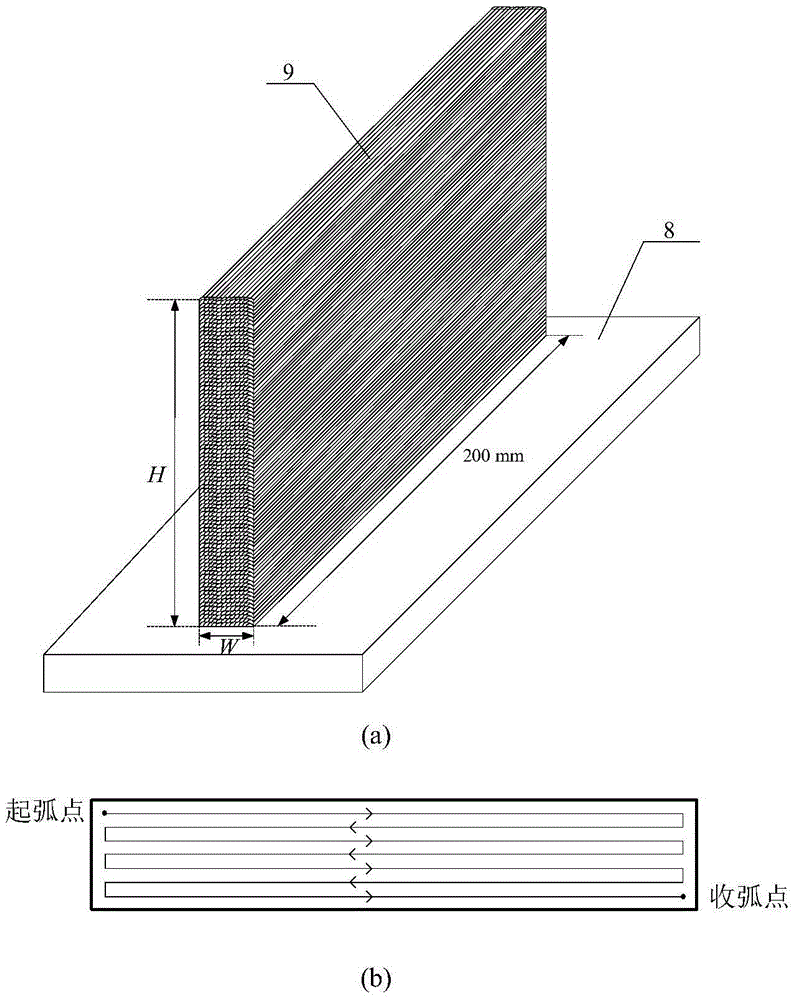

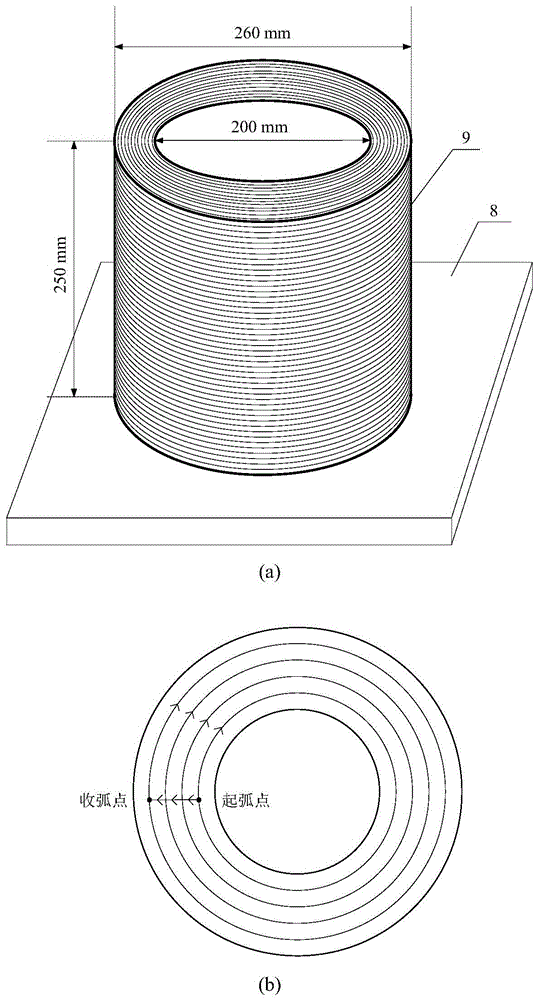

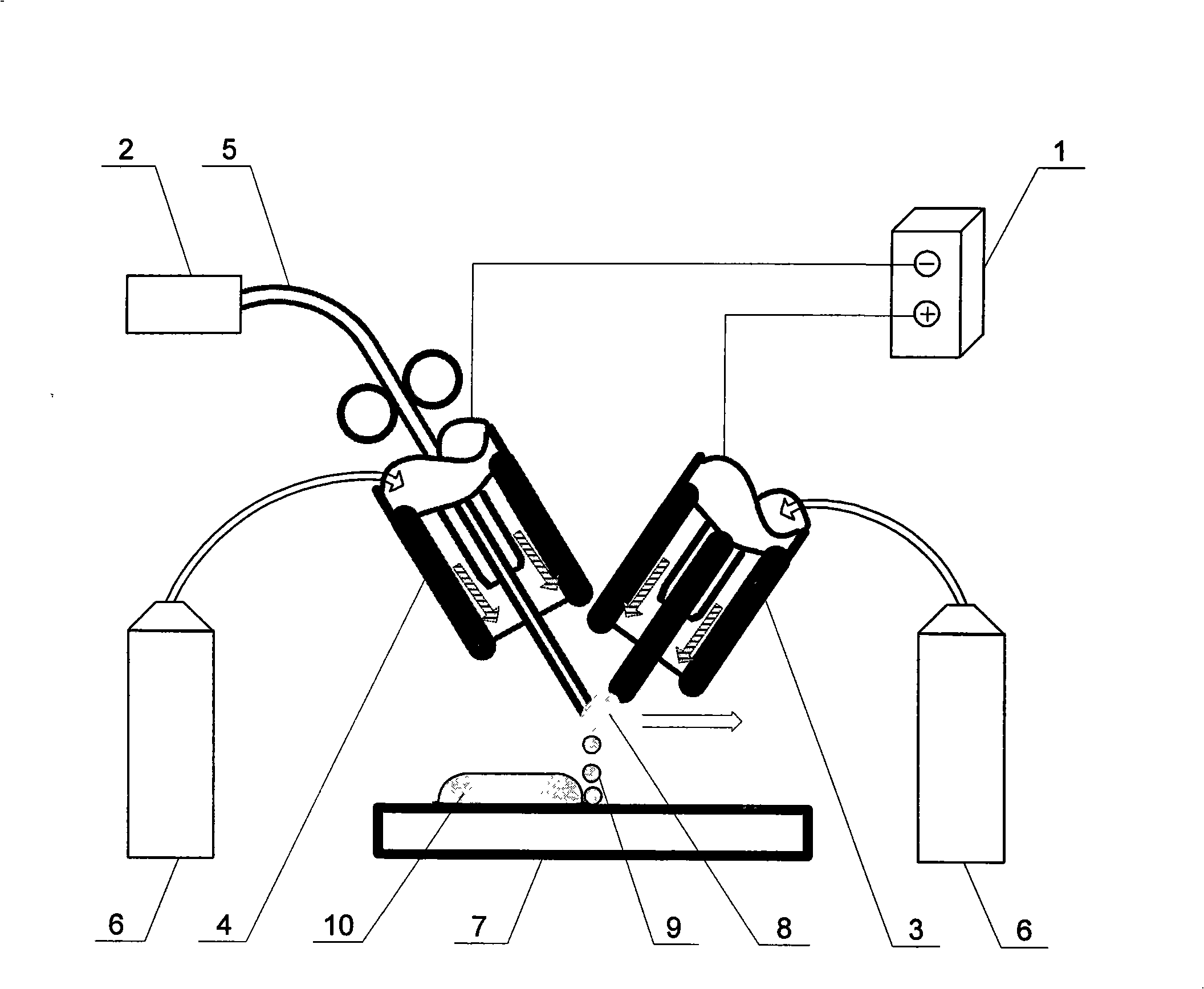

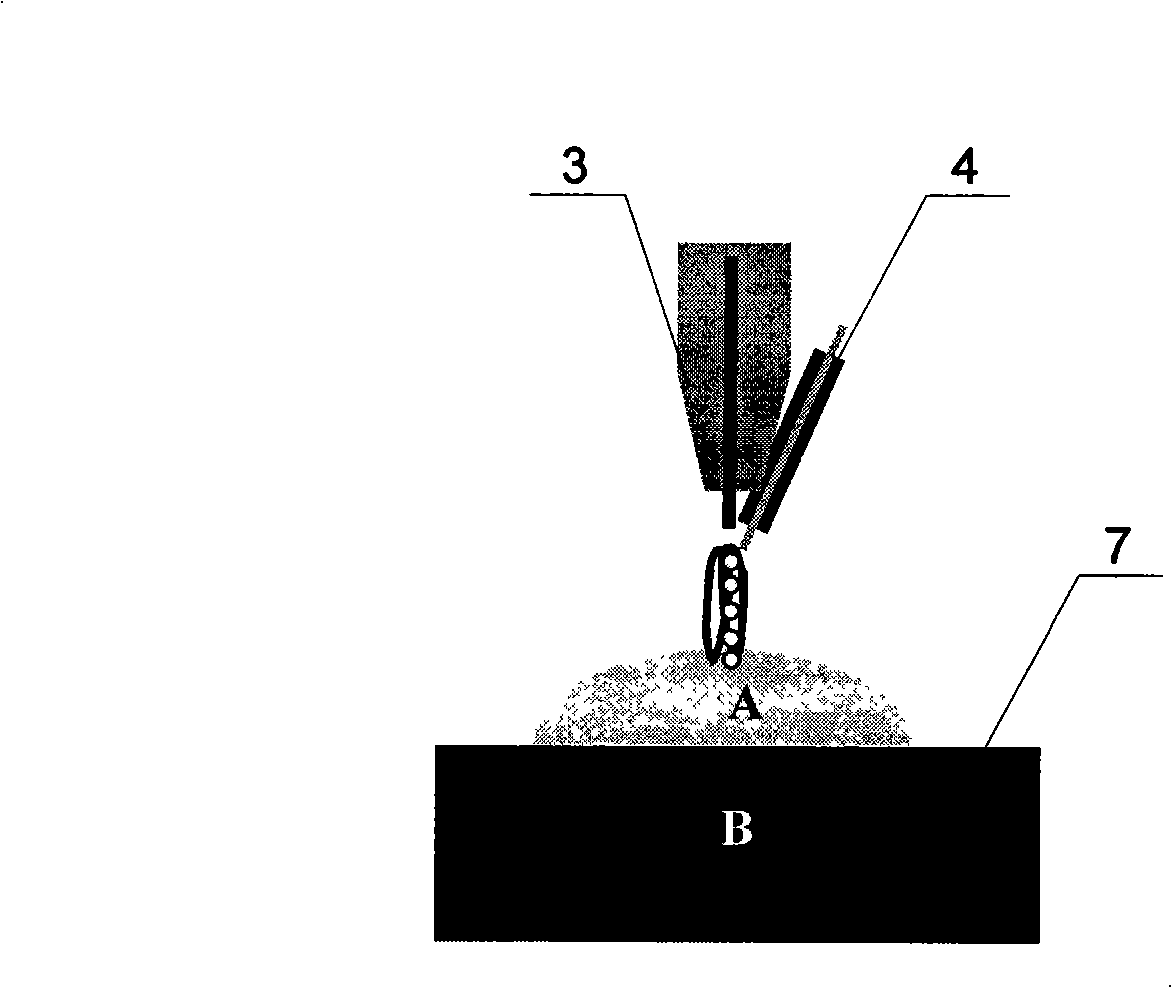

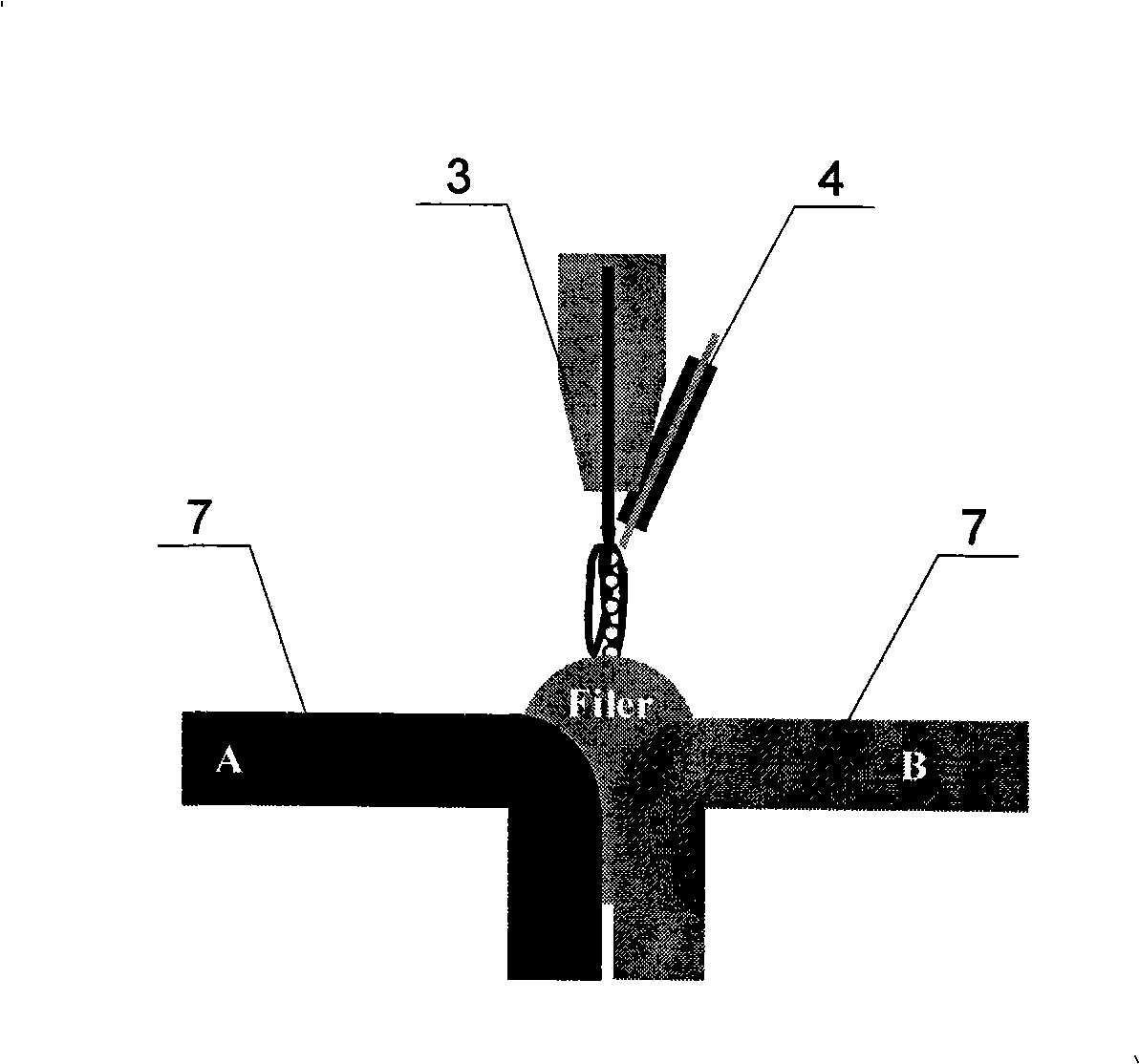

Material increase manufacturing method for titanium alloy shape part by using double-arc hybrid heat source

InactiveCN105458470AImprove deposition rate and welding speedAvoid overheatingArc welding apparatusWelding/soldering/cutting articlesElectric arcPower flow

The invention relates to a material increase manufacturing method for a titanium alloy shape part by using a double-arc hybrid heat source. The method comprises the following steps: MIG welding and TIG welding are originally combed, a welding wire as a melting electrode is sent out by an MIG welding gun and is subjected to surfacing on a base plate; an MIG power anode is connected with a TIG power anode, and an MIG power cathode is connected with the base plate, the MIG welding gun is connected with the MIG power anode, and a TIG welding gun is connected with a TIG power cathode; the MIG welding gun is in the front, and the TIG welding gun is in the back; the current of the welding wire is shunted through a TIG welding circuit, so that the current passing through the welding wire is large, and the current passing through a weldment is small. After the base plate completes a first surfacing layer, a hybrid welding gun is increased by a story height, and a second layer of shape part is welded; the above process is repeated, so that the titanium alloy shape part is formed by overlaying plurality of surfacing layer. The method has the advantages of being high in metal deposition rate, high in welding speed, less in weldment heat input, good in structural and mechanical properties of the shape part and low in cost and solves the problems of lager heat input, low welding speed, poor welding quality and low efficiency during material increase manufacturing of the traditional titanium alloy single TIG arc wire feeding.

Owner:JIANGSU UNIV OF SCI & TECH

Method and apparatus for depositing a thin film

InactiveUS20120237695A1Improve abilitiesHigh deposition rateRadiation applicationsFinal product manufactureReactive gasLength wave

A substrate is brought into close proximity with one or more gas injectors to deposit a thin film. As the substrate is moved horizontally along a predefined direction, it is injected with reactive gases and pyrolytically heated with a heating light focused on the substrate. To prevent photolytic reactions, the heating light source is preferably on the side of the substrate opposite to the side where the reactive gases are deposited. In some embodiments, this heating light source is supplemented by heating light sources on the same side of the substrate as the deposited reactive gases. The heating light source(s) has a wavelength to optimize absorption by the substrate or the deposited film layer.

Owner:2 PYE SOLAR

PVD-based metallization methods for fabrication of interconnections in semiconductor devices

ActiveUS7964504B1High deposition rateHigh ionizationElectric discharge tubesVacuum evaporation coatingIonizationEtching

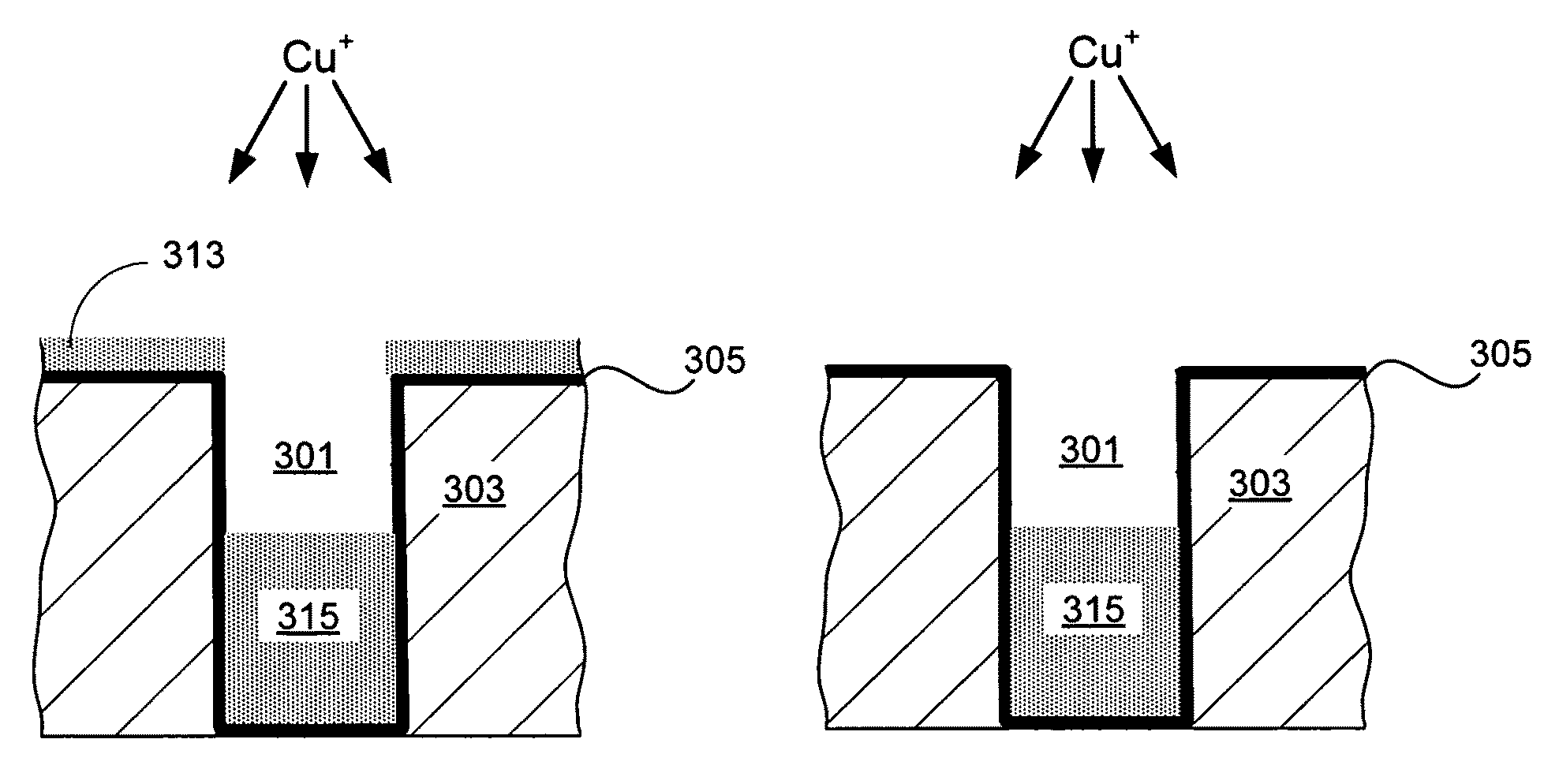

Recessed features on a Damascene substrate are filled with metal using plasma PVD. Recessed features having widths of less than about 300 nm, e.g., between about 30-300 nm can be filled with metals (e.g., copper and aluminum), without forming voids. In one approach, the deposition is performed by exposing the substrate to a high-density plasma characterized by high fractional ionization of metal. Under these conditions, the metal is deposited within the recess, without forming large overhang at the opening of the recess. In some embodiments, the metal is deposited within the recess, while diffusion barrier material is simultaneously etched from the field region. In a second approach, recessed features are filled by performing a plurality of profiling cycles, wherein each cycle includes a net etching and a net depositing operation. Etching and depositing parameters are adjusted such that the recessed features are filled without forming overhangs and voids.

Owner:NOVELLUS SYSTEMS

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

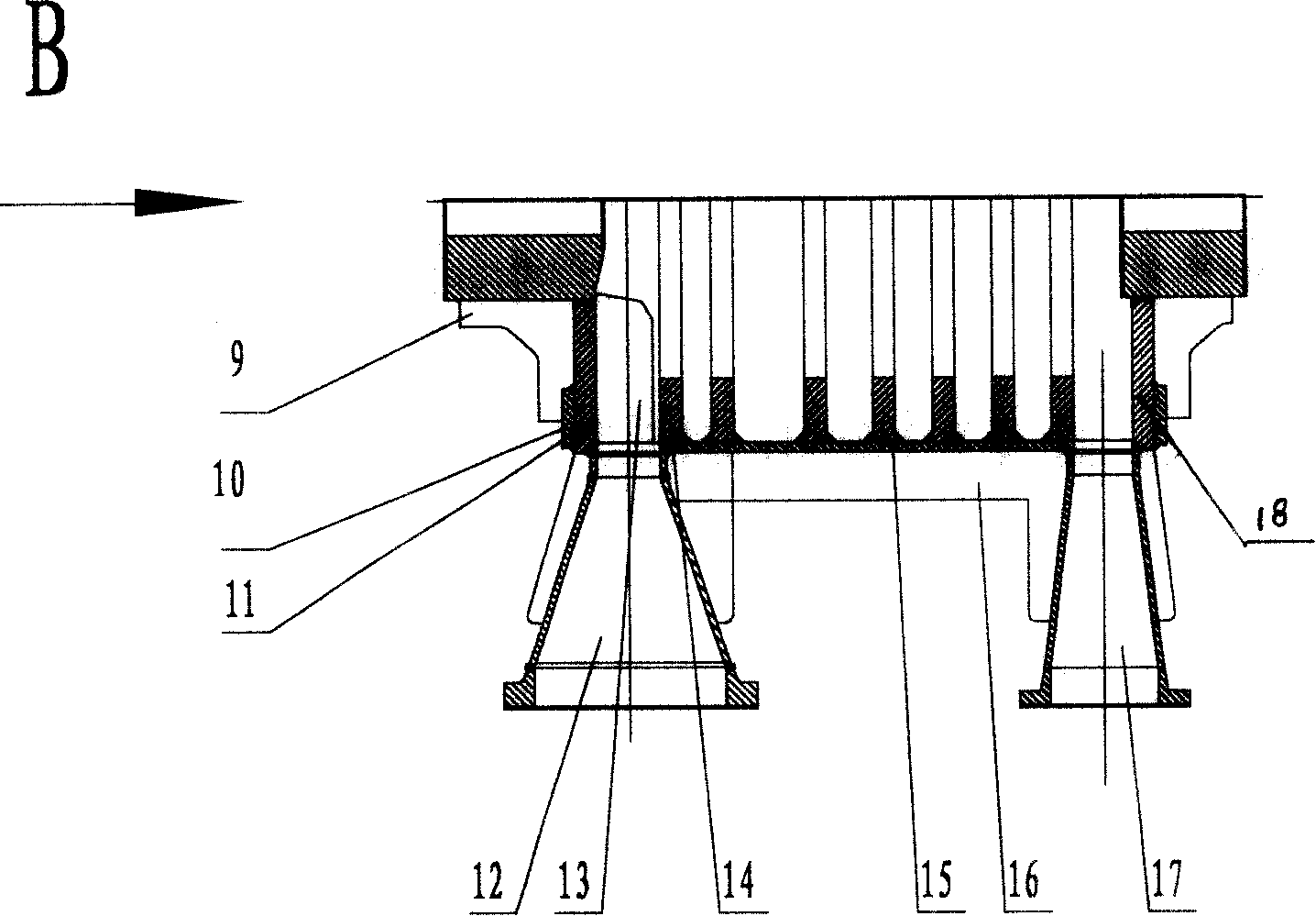

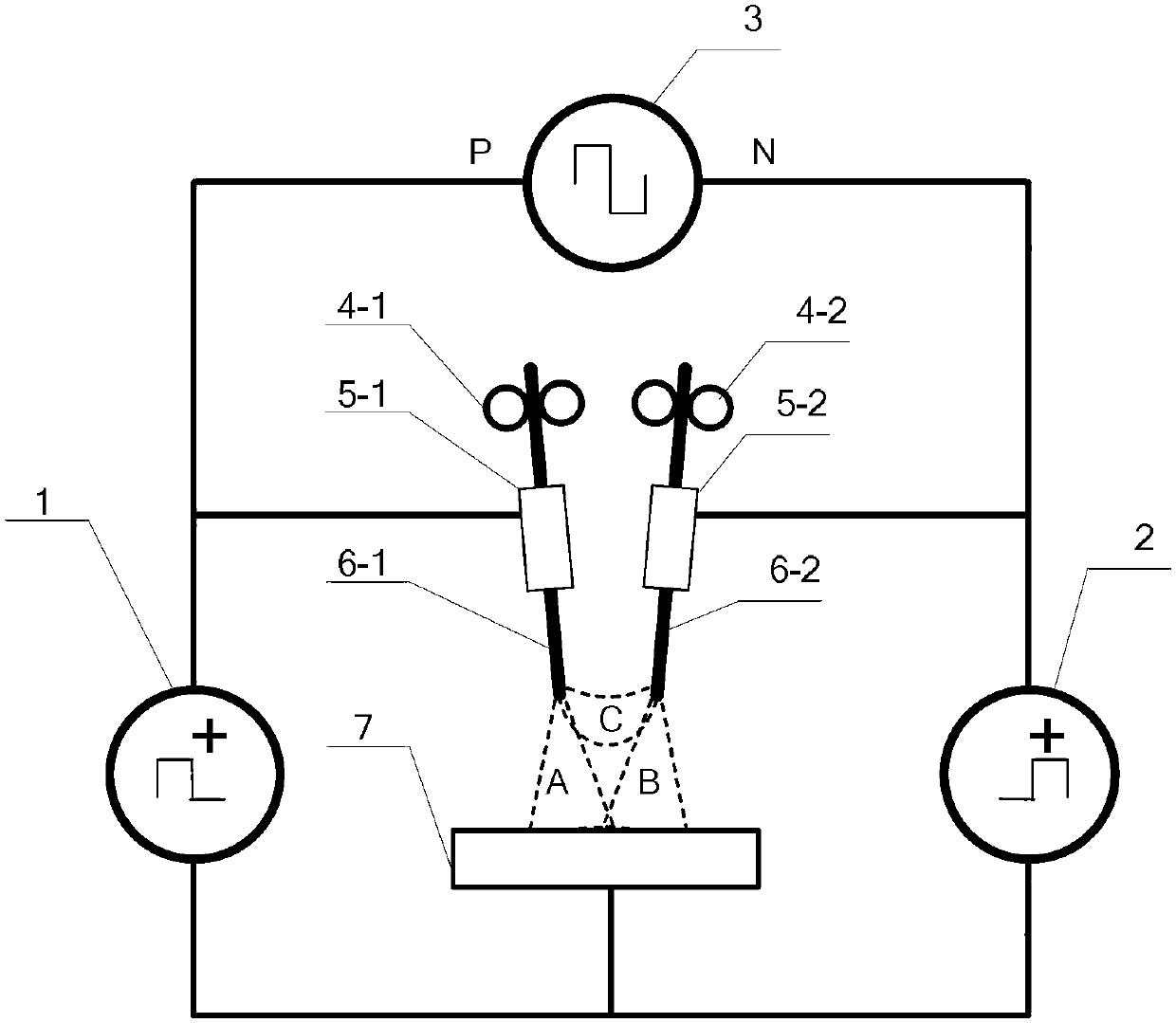

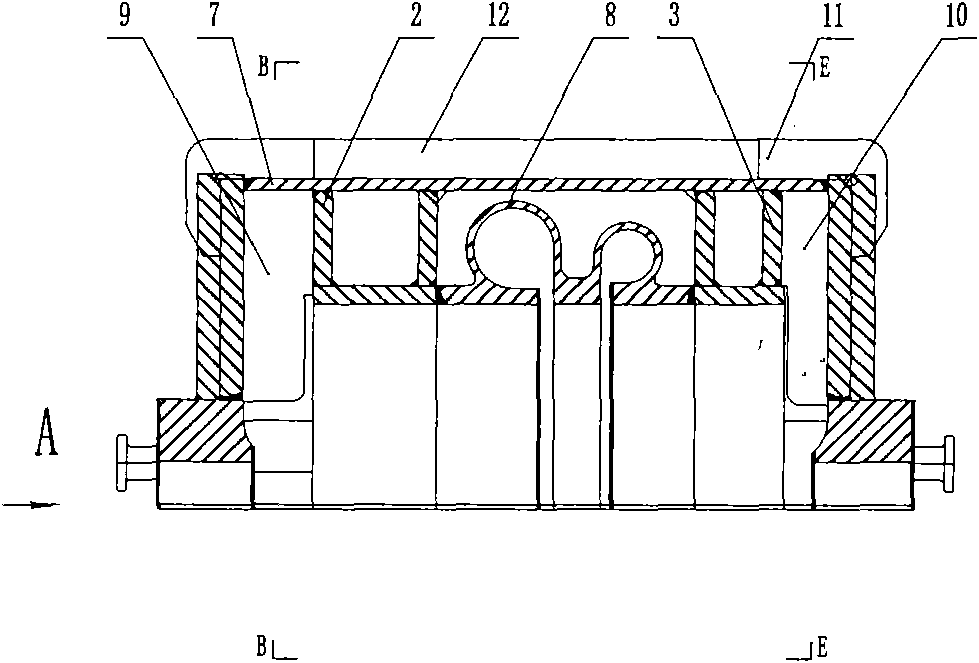

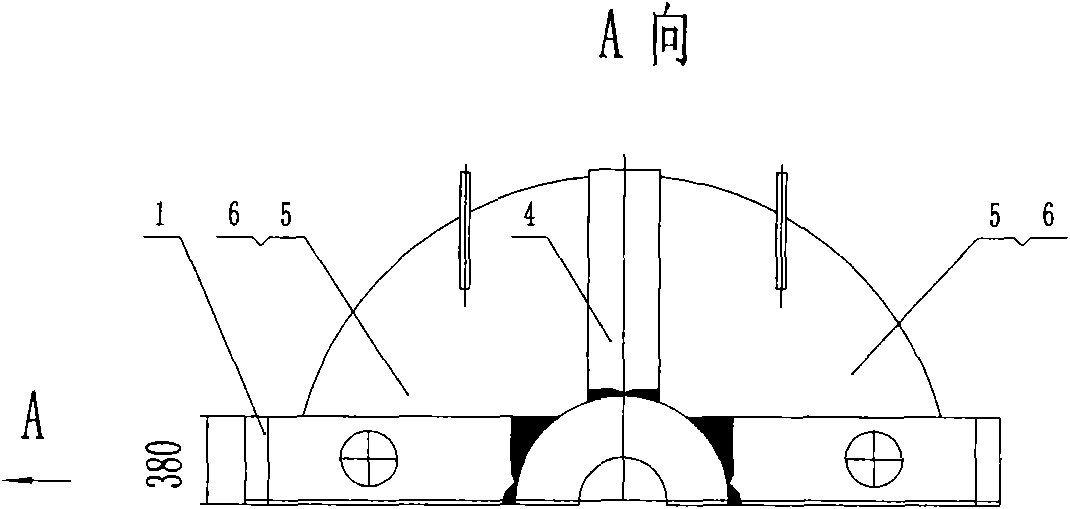

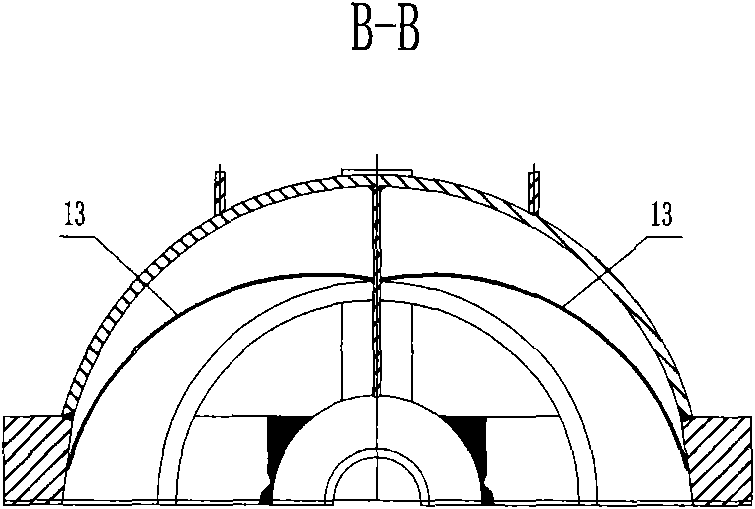

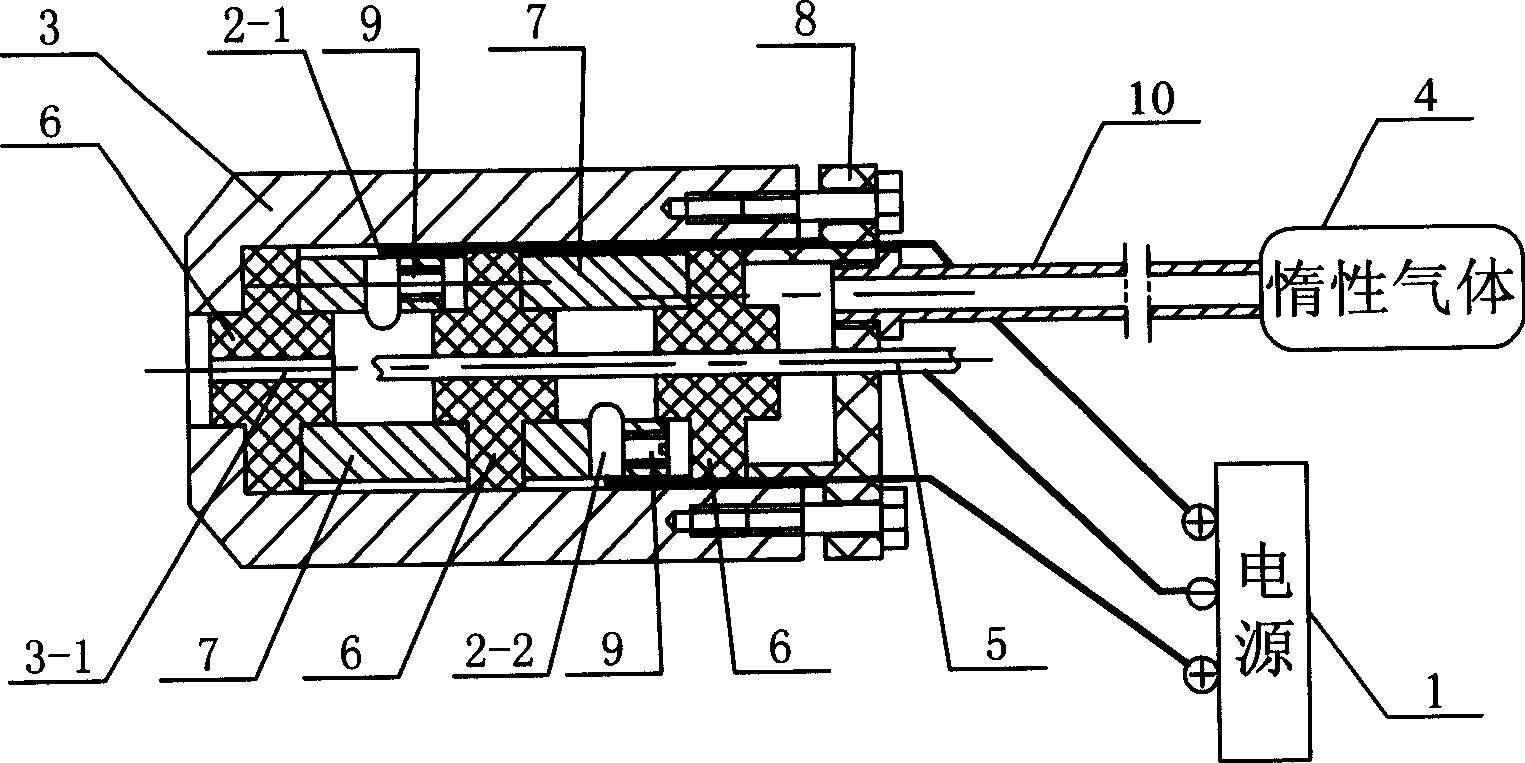

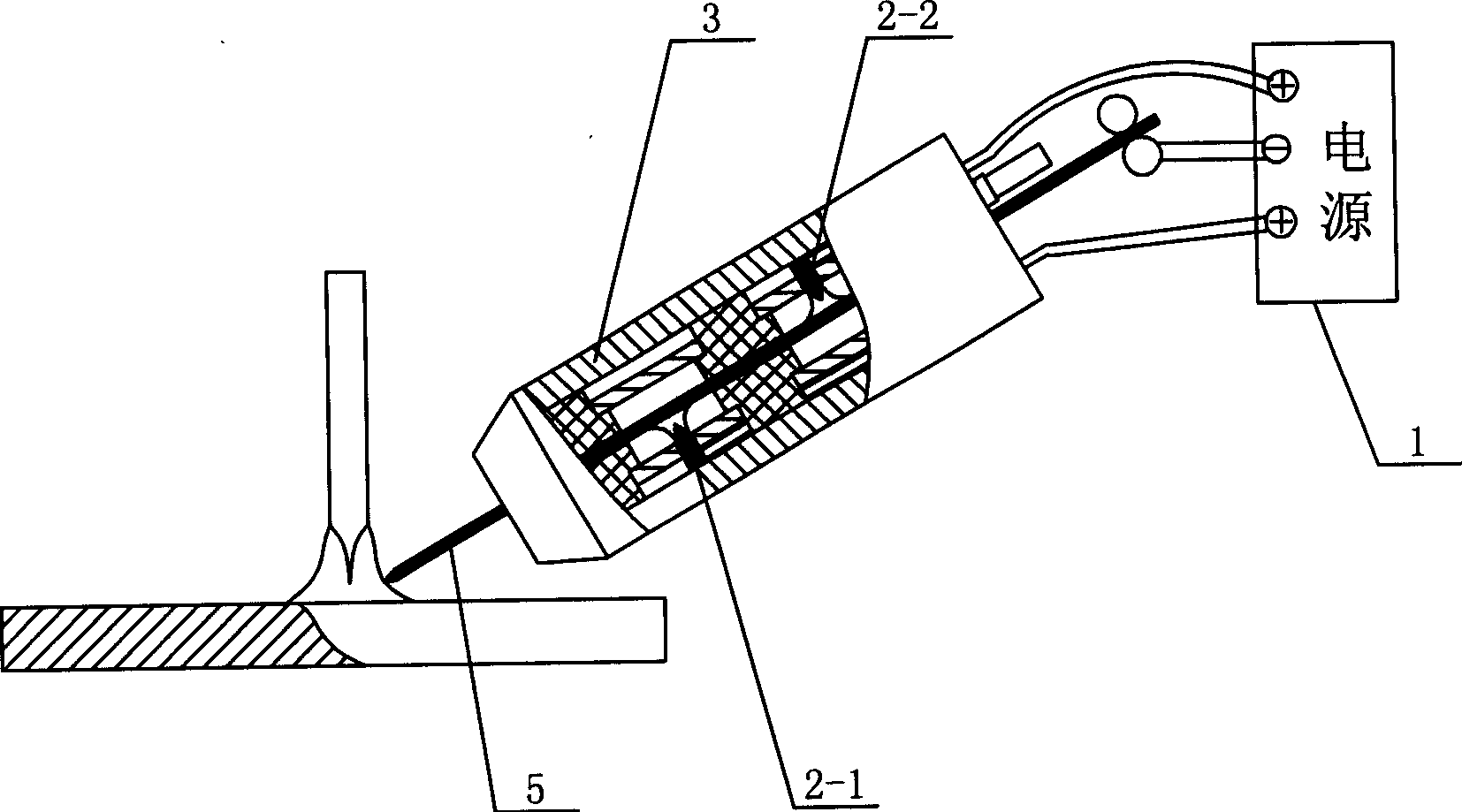

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

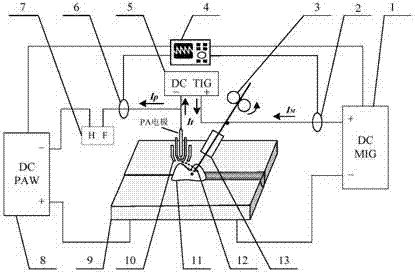

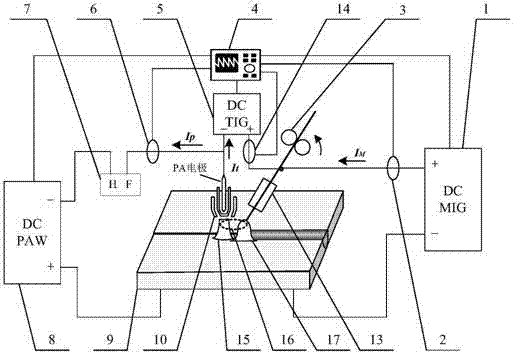

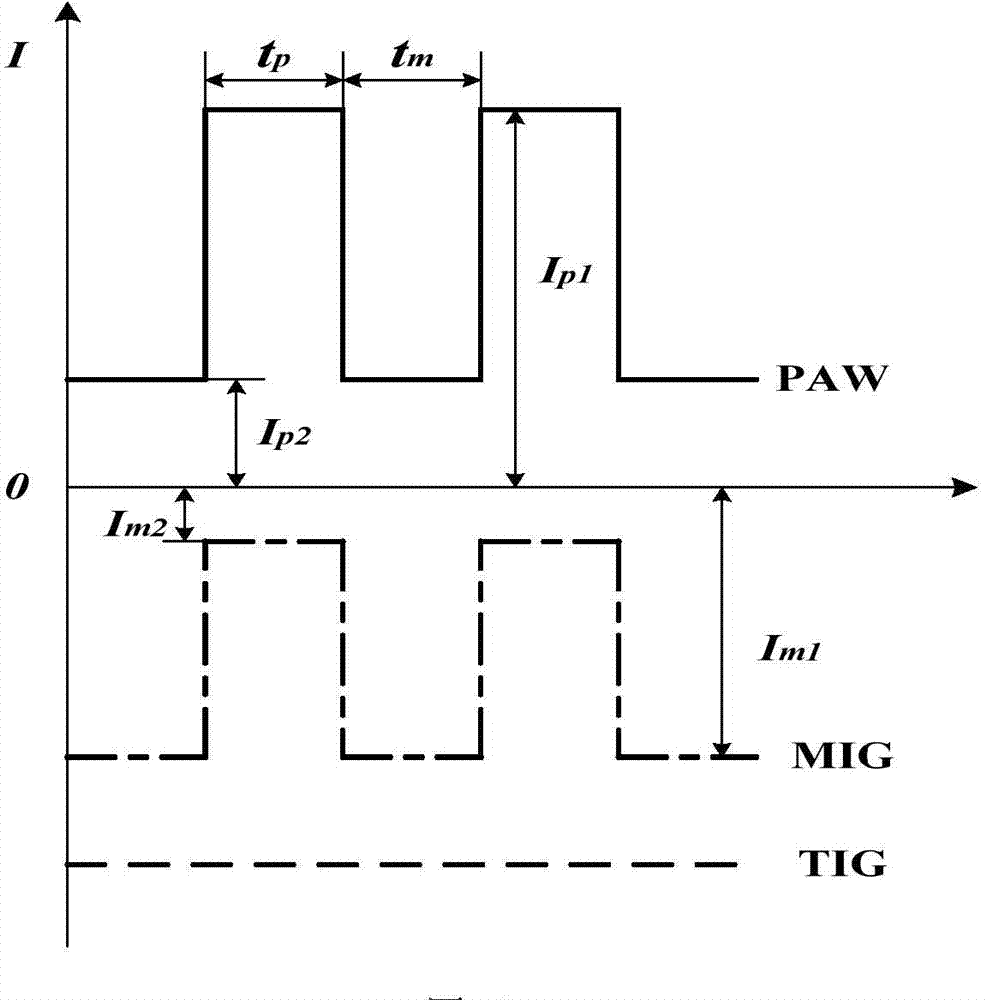

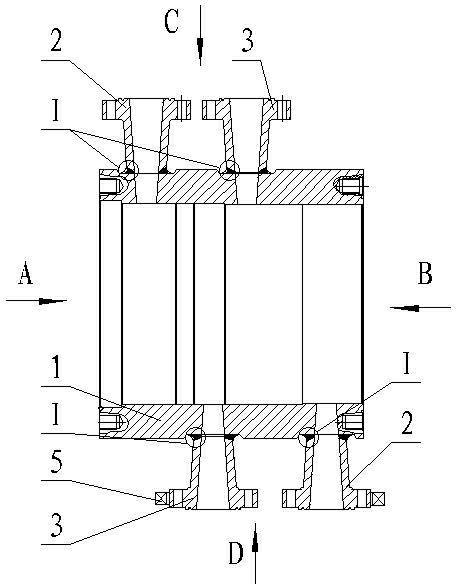

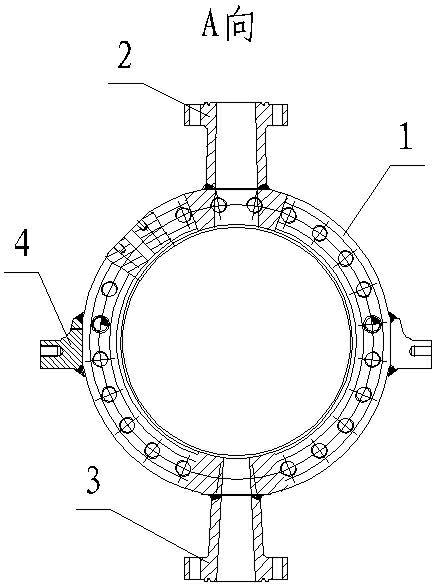

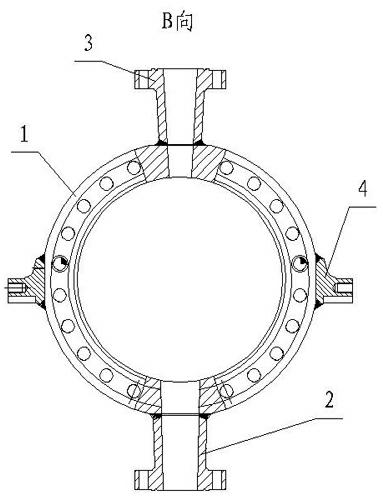

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

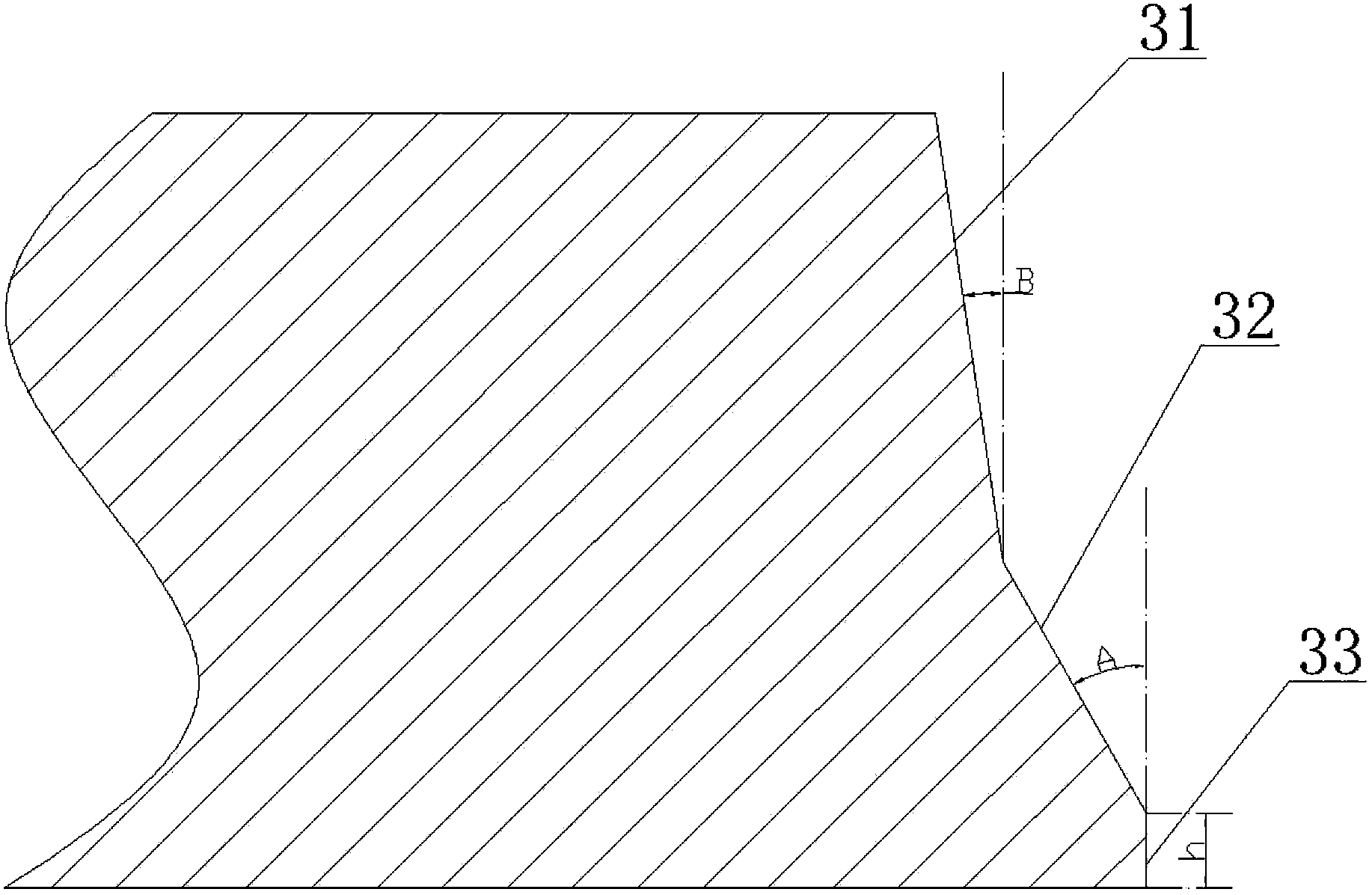

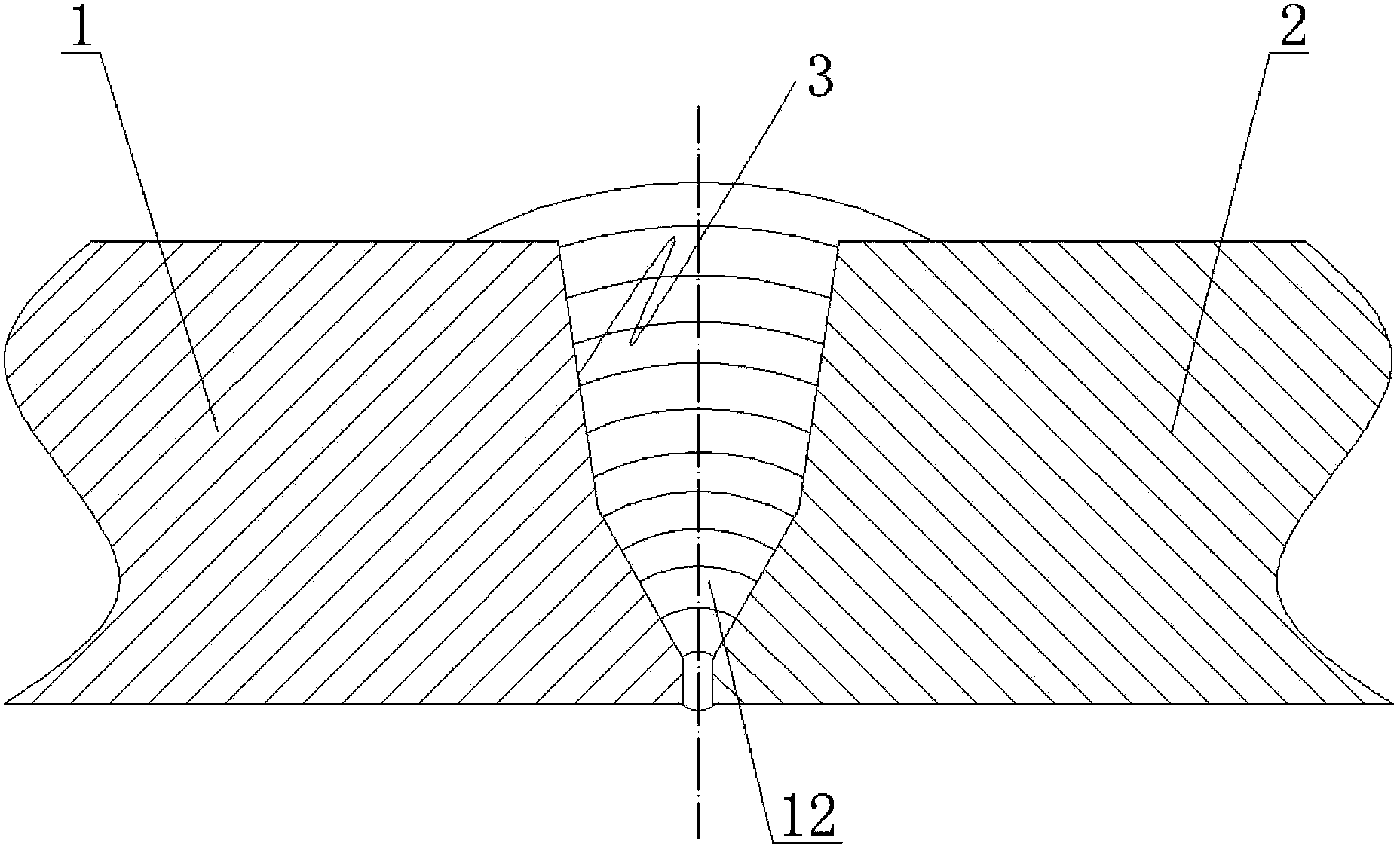

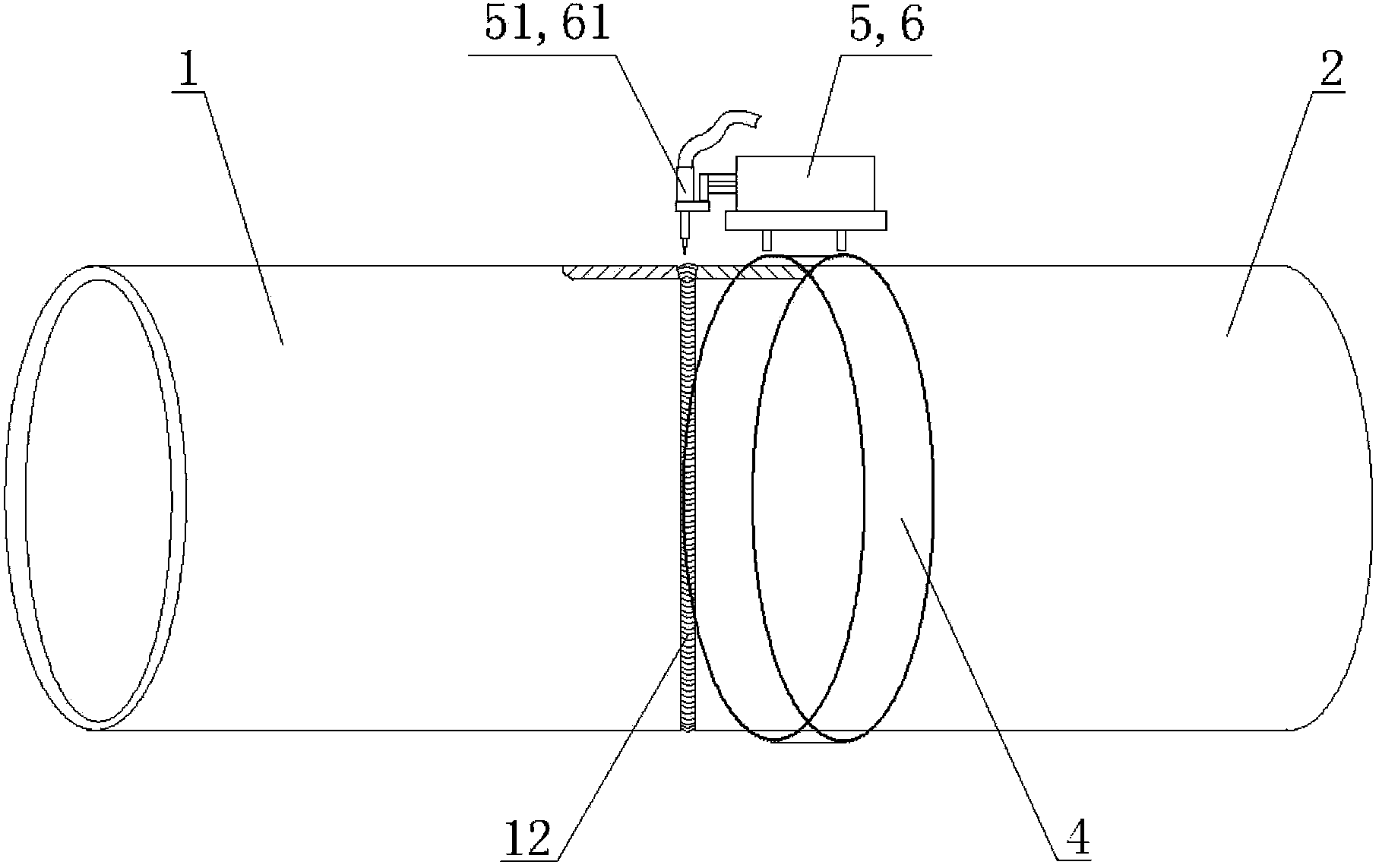

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

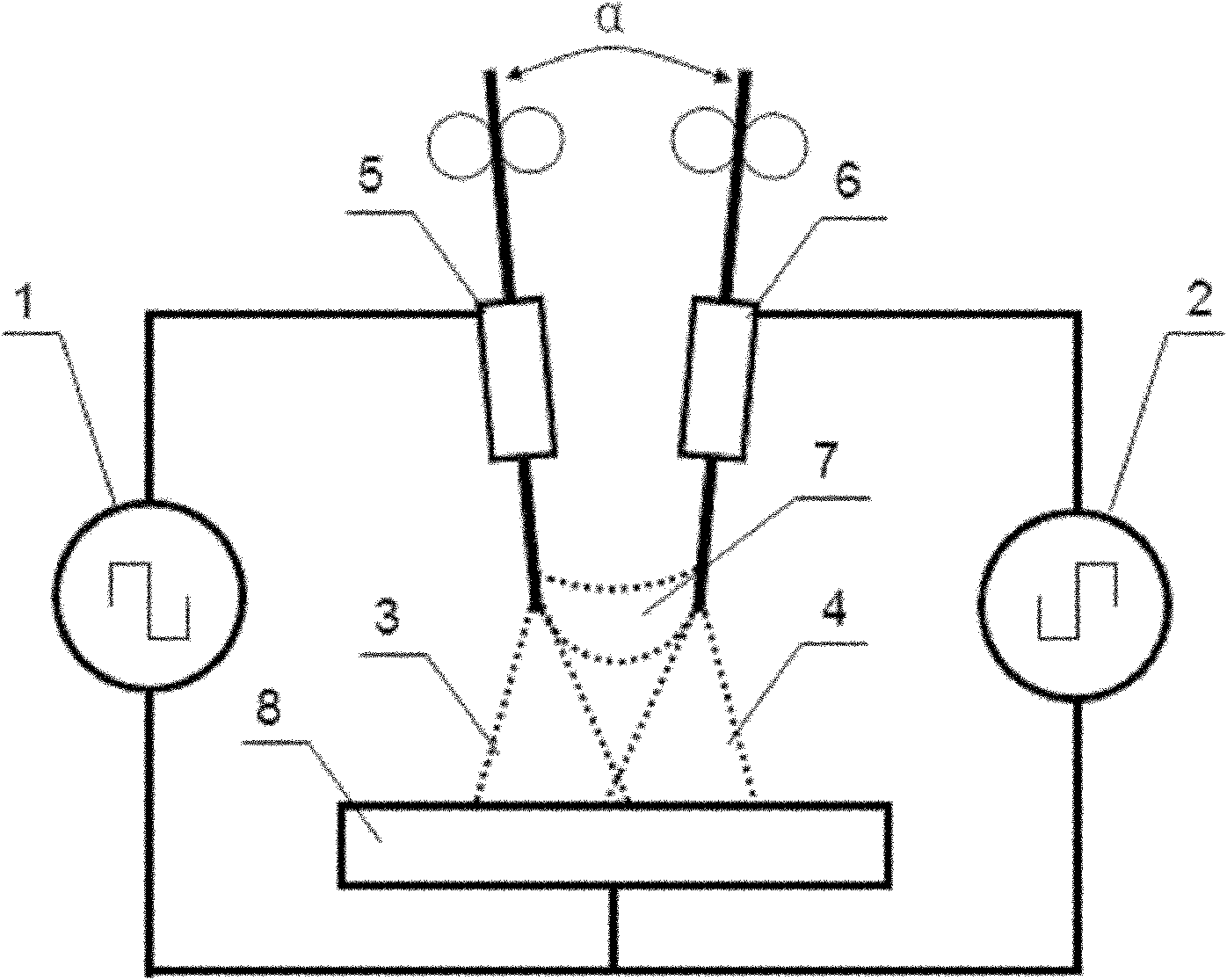

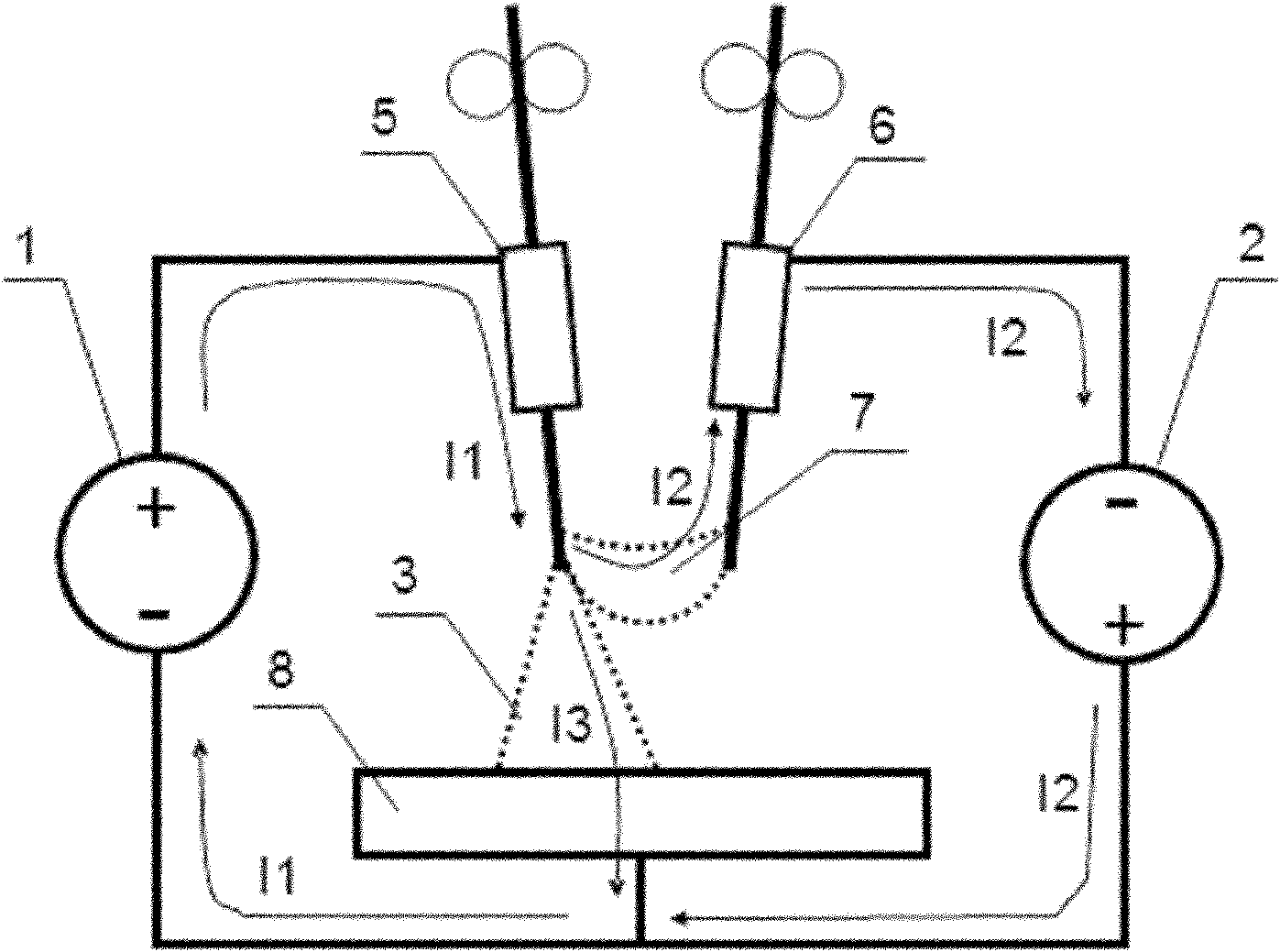

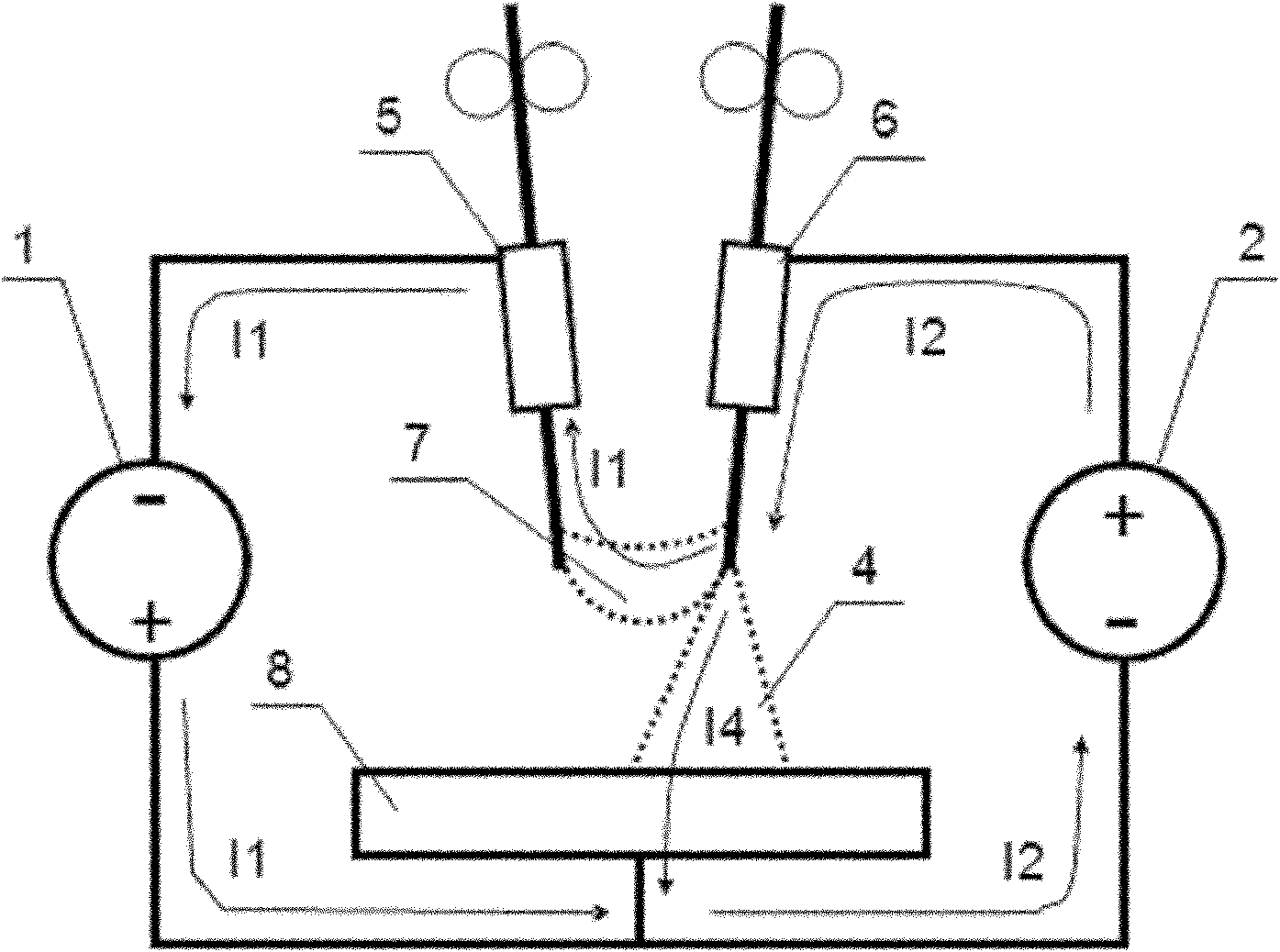

Dynamic twin-wire three-arc welding method

ActiveCN102069265AReduce welding heat inputAvoid electromagnetic interferenceArc welding apparatusPhase differenceEngineering

The invention provides a dynamic twin-wire three-arc welding method, belonging to the technical field of welding. The invention solves the problem that contradictions exist between improvement of deposition rate and reduction of heat input in the existing arc welding methods. The method is characterized in that a wire feeder is adopted to automatically feed a first welding wire and a second welding wire into two welding wire tips respectively and the included angle between the two welding wires is ensured to be 0-90 degrees; one output end of a first variable polarity power source is connected with one welding wire tip; one output end of a second variable polarity power source is connected with the other welding wire tip; after being connected with each other, the other output end of the first variable polarity power source and the other output end of the second variable polarity power source are connected with a workpiece to be welded; and the phase difference between output signals of the first variable polarity power source and the second variable polarity power source is 180 degrees. The welding method is efficient.

Owner:SHENZHEN RILAND IND

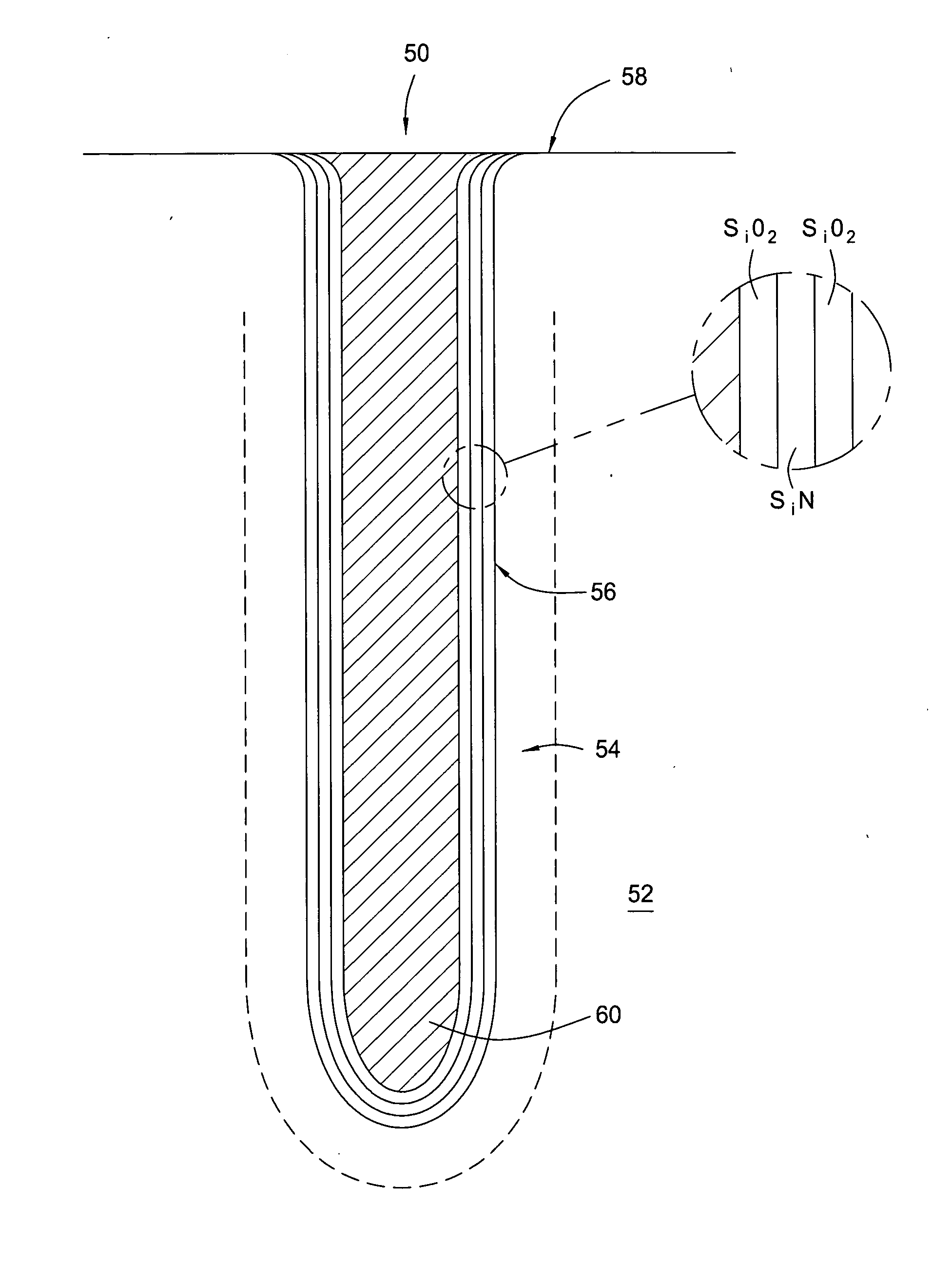

Process sequence for doped silicon fill of deep trenches

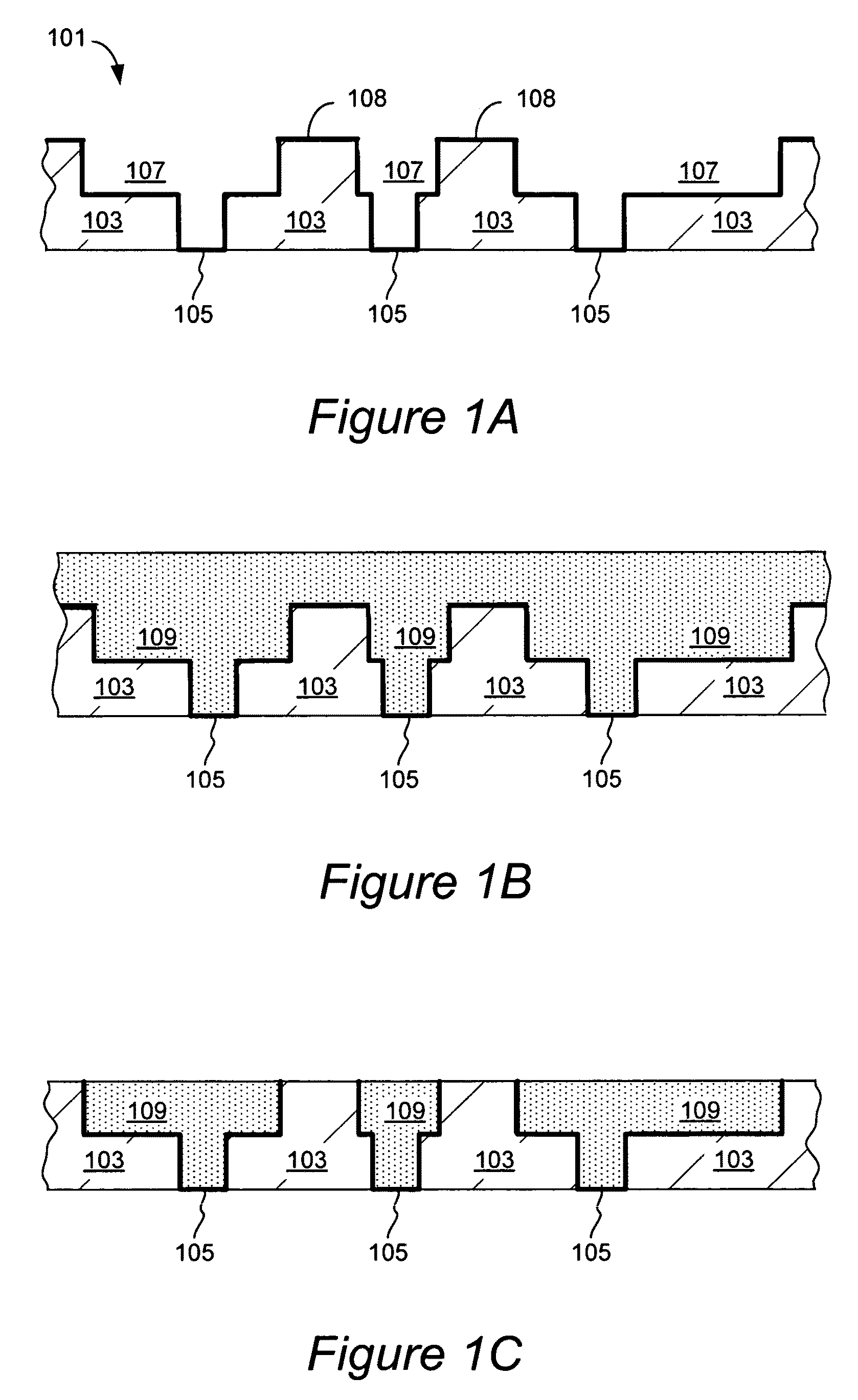

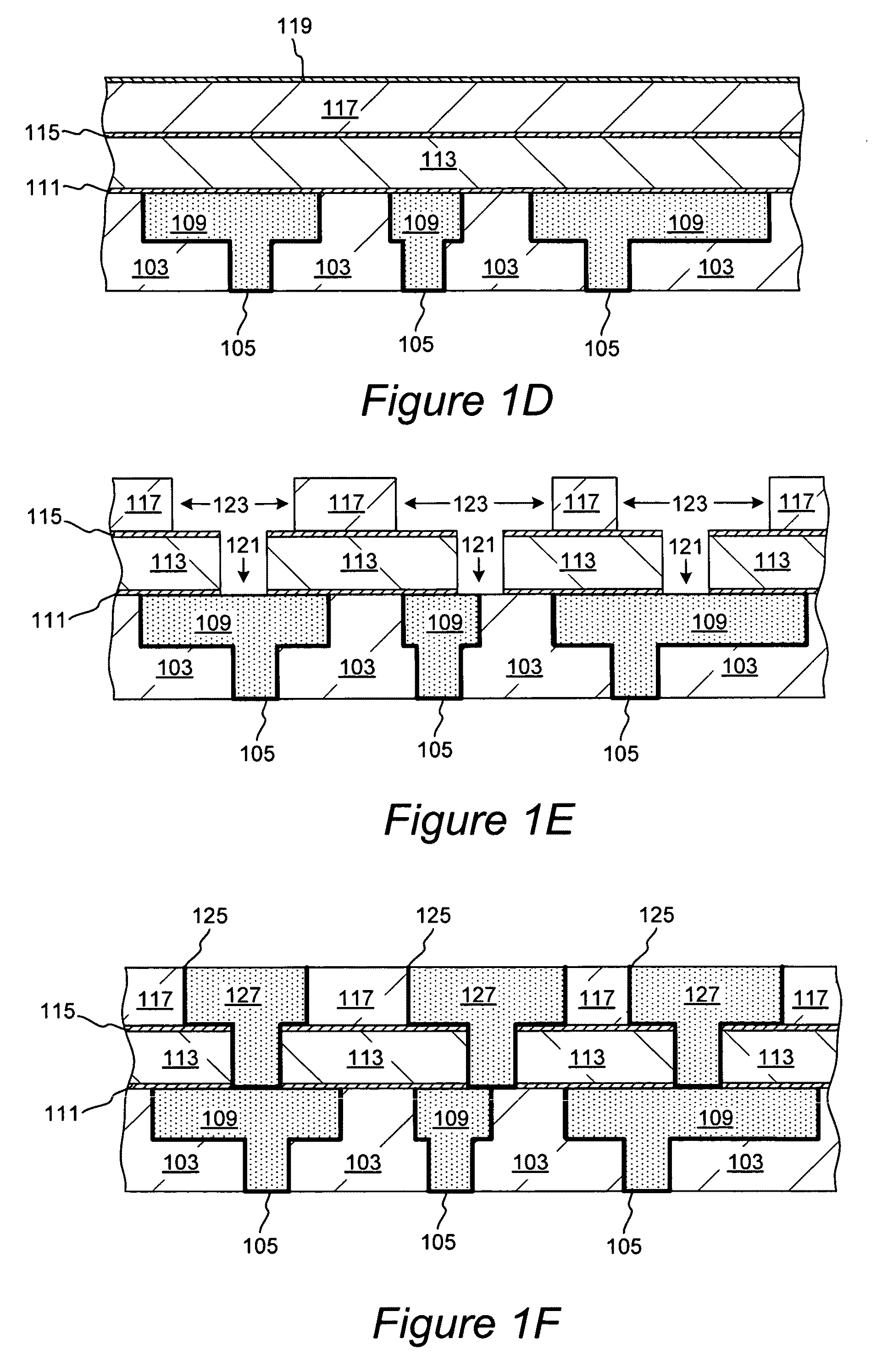

InactiveUS20060128139A1Increase deposition rateShort staySolid-state devicesSemiconductor/solid-state device manufacturingDopantFirst Fill

A method for void free filling with in-situ doped amorphous silicon of a deep trench structure is provided in which a first fill is carried out in at a temperature, pressure and dopant to silane ratio such that film deposition occurs from the bottom of the trench upwards. By way of this first fill, step coverages well in excess 100% are achieved. In the second fill step, deposition is carried out under changed conditions so as to reduce the impact of dopant on deposition rate, whereby trench fill is completed at a deposition rate which exceeds the deposition rate of the first fill. In an application of this method to the formation of deep trench capacitor structures, the intermediate steps further including the capping of the void free filled trench with a thick layer of amorphous silicon, planarization of the wafer thereafter, followed by a thermal anneal to re-distribute the dopant within the filled trench. Thereafter, additional steps can be performed to complete the formation of the capacitor structure.

Owner:APPLIED MATERIALS INC

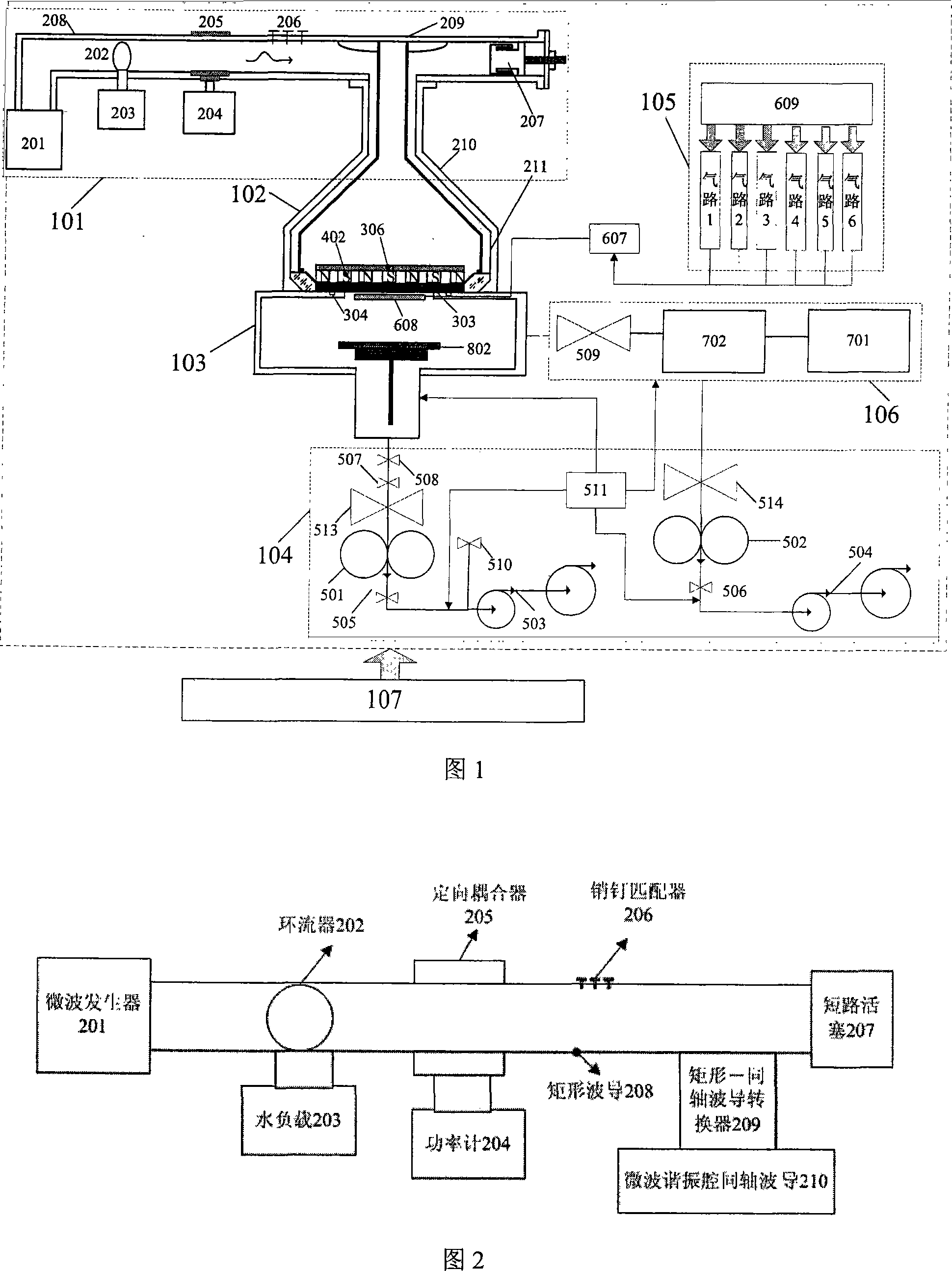

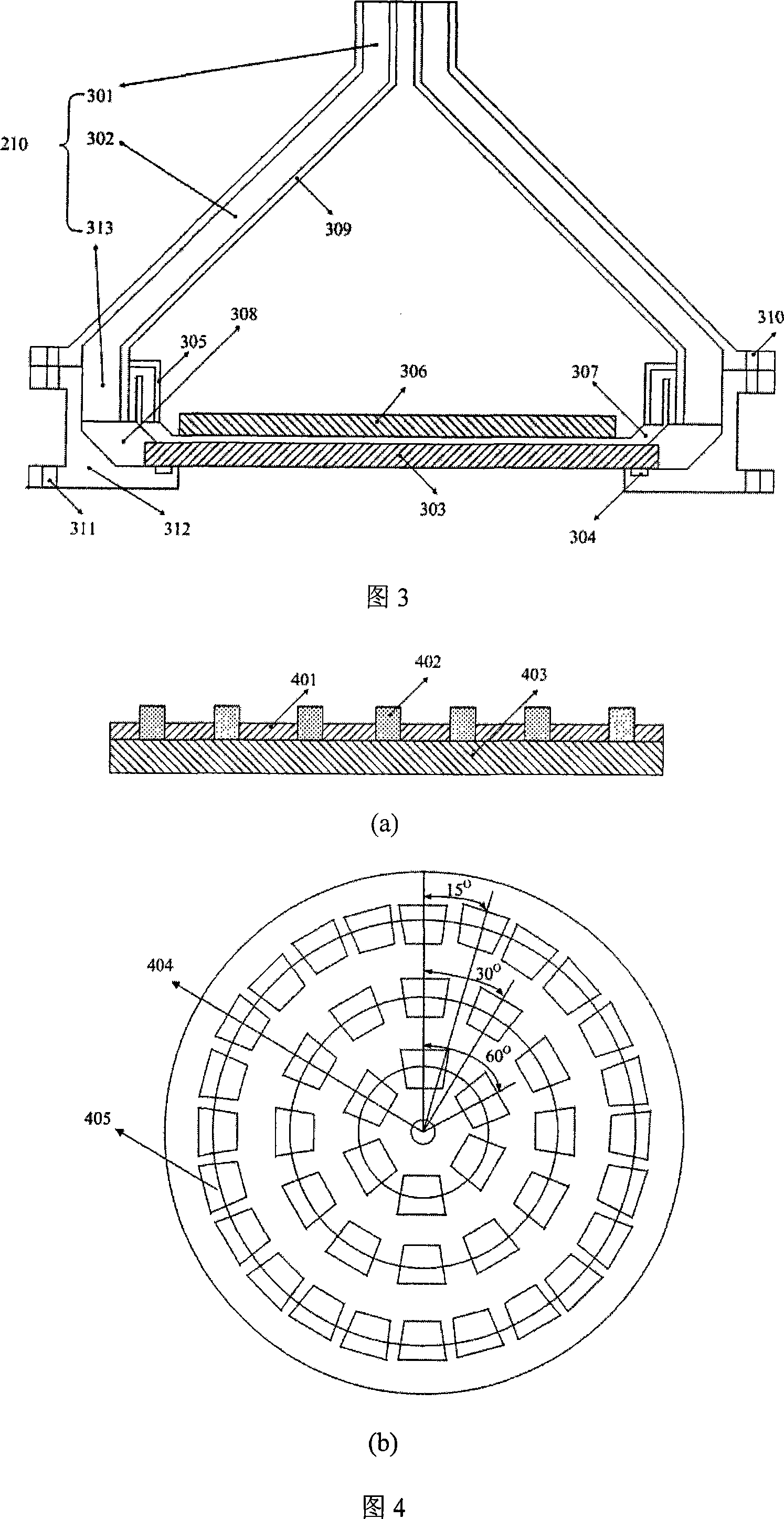

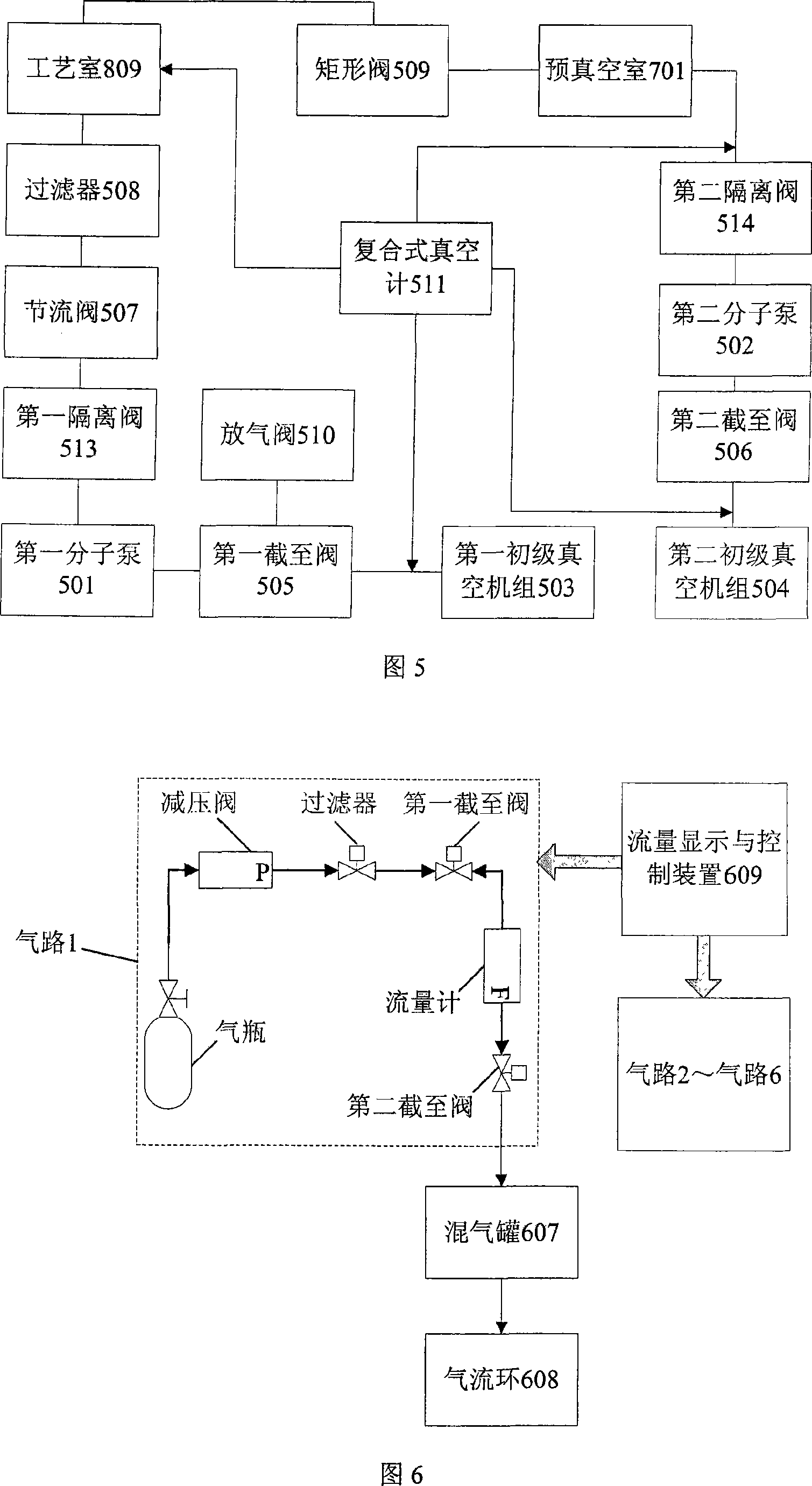

Microwave electron cyclotron resonance plasma chemistry gas phase sedimentation device

InactiveCN101144155AReduce volumeReduce power consumptionChemical vapor deposition coatingGas phaseMicrowave resonance

The present invention discloses microwave electron cyclotron resonance plasma body chemical vapor deposition equipment, which comprises a microwave power source and a transmission system 101, a microwave resonance cavity 102, a coating chamber and a specimen stage system 103, a vacuum system 104, a gas circuit system 105, an automatic sheet transmission system 106, and a controlling system 107, wherein, magnetic field devices 306 which are lined at equal intervals are arranged in the microwave resonance cavity; the specimen stage system is arranged inside the coating chamber; the microwave resonance cavity, the vacuum system, and the automatic sheet transmission system are respectively connected with a coating chamber 809, the microwave power source and the transmission system are connected with the microwave resonance cavity; a controlling software is solidified in the host computer of the controlling system; the working states of the microwave power source and the transmission system, the coating chamber and the specimen stage system, the vacuum system, and the gas circuit system are respectively controlled through interfaces, and thus the deposition technological process of a film is completed. The present invention has the advantages that the big area uniformity is good, the deposition rate is high, the automaticity and the production efficiency are high, the reliability is good, the power loss is small, and the stability and the repeatability are good.

Owner:XIDIAN UNIV

Multi-state double-wire electrical arc welding device and welding method

ActiveCN103341681AFlexible adjustment ratioGuaranteed PenetrationArc welding apparatusWelding power supplyPulse power supply

The invention provides a multi-state double-wire electrical arc welding device and welding method to solve the problem that in an existing electrical arc welding method, due to the fact that a fixed proportional relationship exists between the welding wire deposition rate and the weld heat input, contradictions exist between welding wire deposition rate increase and weld heat input reduction, and belongs to the technical field of consumable electrode electrical arc welding. The device comprises a first direct-current pulse power supply, a second direct-current pulse power supply, a welding power supply with the alterable polarity, a first wire sending mechanism, a second wire sending mechanism, a first contact tube, a second contact tube, a first welding wire and a second welding wire. In the welding process, the first direct-current pulse power supply, the first welding wire and a workpiece to be welded form a left electrical arc welding circuit, the second direct-current pulse power supply, the second welding wire and the workpiece to be welded form a right electrical arc welding circuit, and the welding power supply with the alterable polarity, the first welding wire and the second welding wire form a shunt circuit. The multi-state double-wire electrical arc welding device and welding method are used for electrical arc welding.

Owner:HARBIN INST OF TECH

Horizontally laid large-section aluminum bus welding construction method

ActiveCN102126072AHigh deposition rateLower the temperature of the molten poolWelding accessoriesAluminiumEngineering

In order to solve the problems of welding deformation and hot cracks in the process of welding large-section aluminum buses and improve welding efficiency, the invention provides a horizontally laid large-section aluminum bus welding construction method. In the method, aluminum buses to be welded are paired and fixed, and arranged in a welding pool crystallization tank with a heater, semi-automatic metal inert-gas (MIG) double pulse argon arc welding is adopted, and an aluminum bar serving as a welding material is directly inserted into the welding pool for welding simultaneously; before welding, two ends of welding positions of the buses are pre-heated at the temperature of between 150 and 250DEG C; and in the welding process, the temperature of the welding positions of the aluminum buses is always kept in a range of 150-250DEG C. Compared with the prior art, the method has the advantages that: the temperature of the welding pool can be reduced and the welding speed can be improved by filling the welding material; and the crystallization tank heats the welding positions in the welding process, so that air holes of welding lines are reduced and the welding deformation and hot cracks are reduced.

Owner:CHINA CHEM ENG SECOND CONSTR +1

Welding process of heat-resistant steel cylindrical housing

InactiveCN102463406AShorten welding cycleStable deliveryArc welding apparatusShielding gasEngineering

The invention relates to a welding technology in an equipment manufacturing industry, discloses a welding professional technology for welding a housing of a BCL cylindrical centrifugal compressor and specifically relates to a welding process of the cylindrical housing of the centrifugal compressor made of chrome molybdenum heat-resistant steel 20CrMo material. Gas shielded welding is adopted, and the adopted welding wire trade name is CHW-55B2; the diameter of welding wires is phi 1.2mm; the polarity of a power supply is direct current electrode positive; and the welding process comprises pre-welding treatment, welding process and post-welding treatment, wherein the process parameters of the welding process are as follows: welding current is 150-230A, welding voltage is 25-30V, shielding gas is mixed gas comprising 80% by volume of Ar and 20% by volume of CO2, welding speed is 100-200mm / min, dry extension is 10-15mm and gas flow rate is 15-20L / min. According to the welding process provided by the invention, the welding wires can be fed automatically during the welding process and a welding rod does not need to be changed; and as heat is centralized in the gas shielded welding of an MAG (metal active gas) consumable electrode, the welding process has the advantages of narrow heat affected zone, small deformation, aesthetic shape, good quality, fast welding speed, high welding efficiency and the like.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

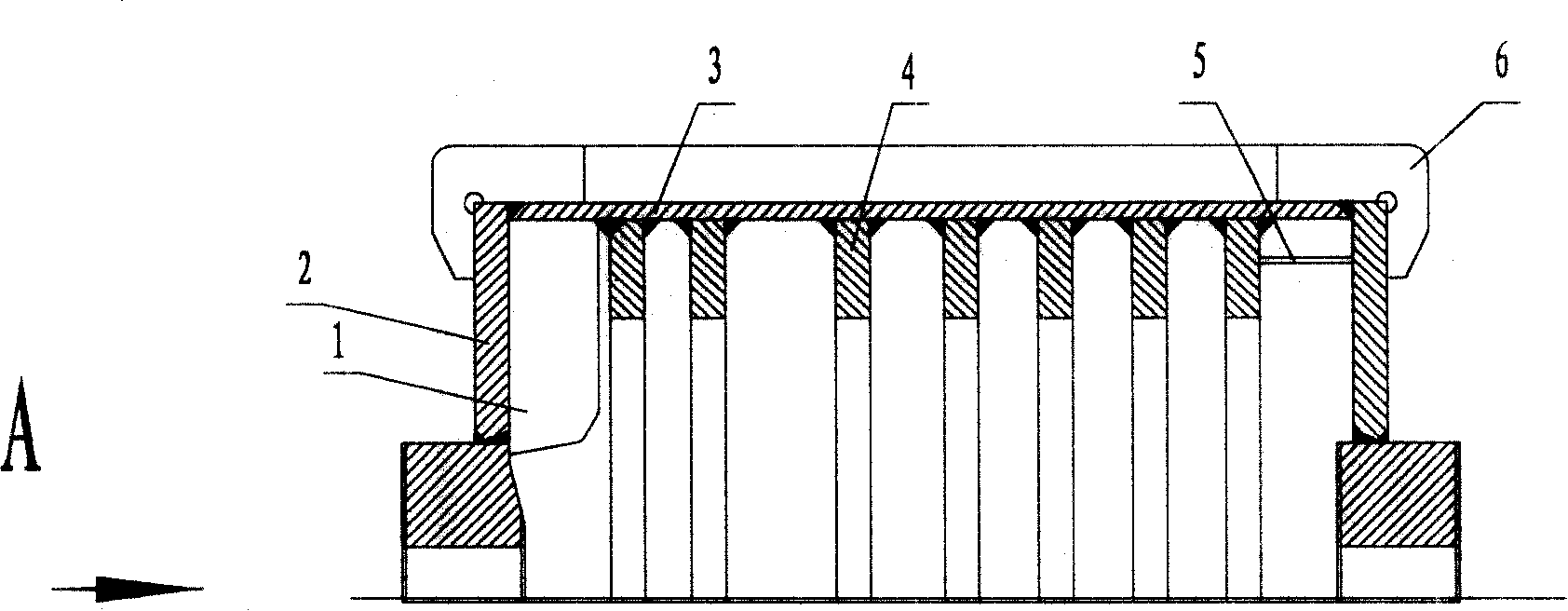

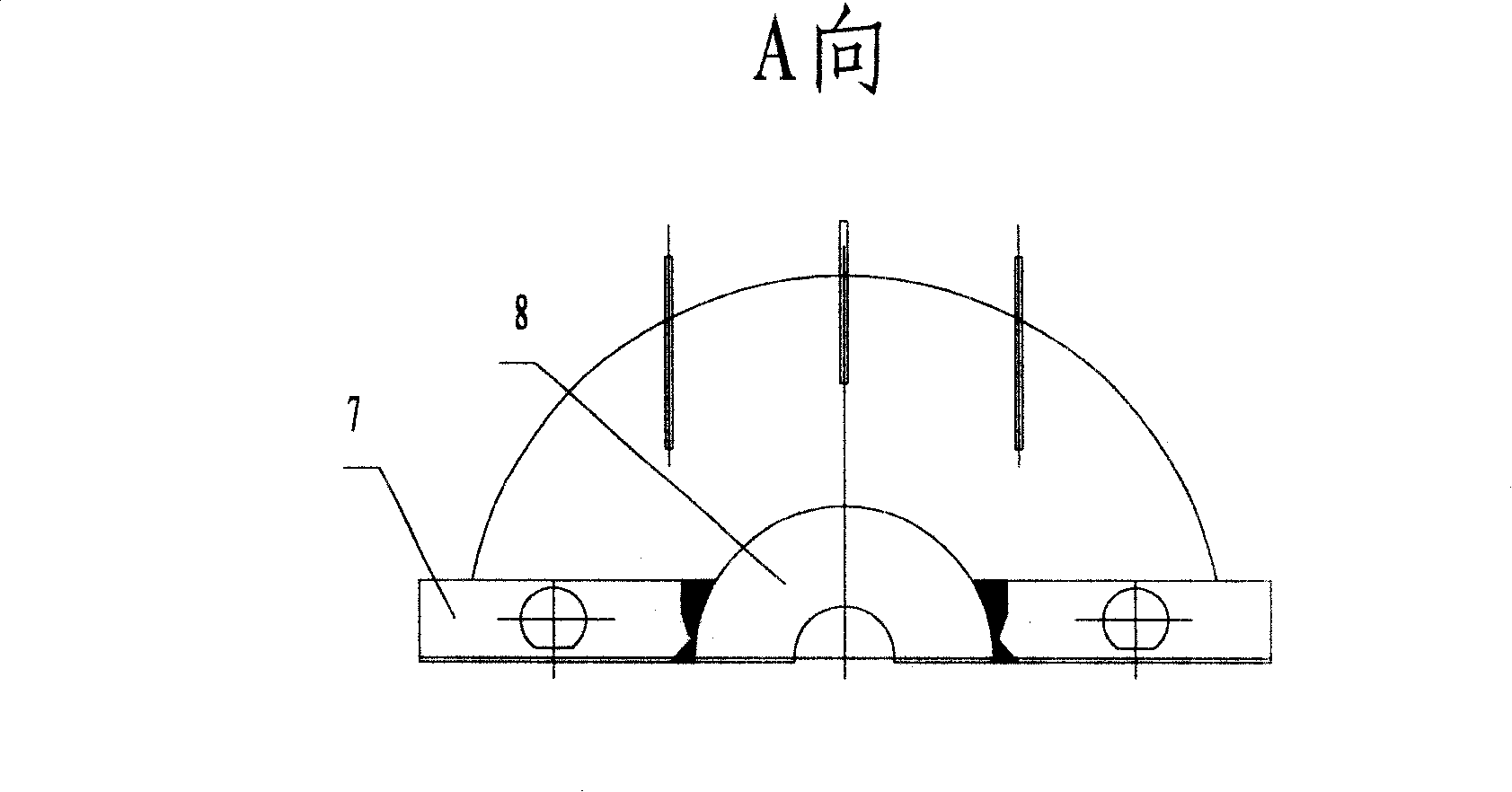

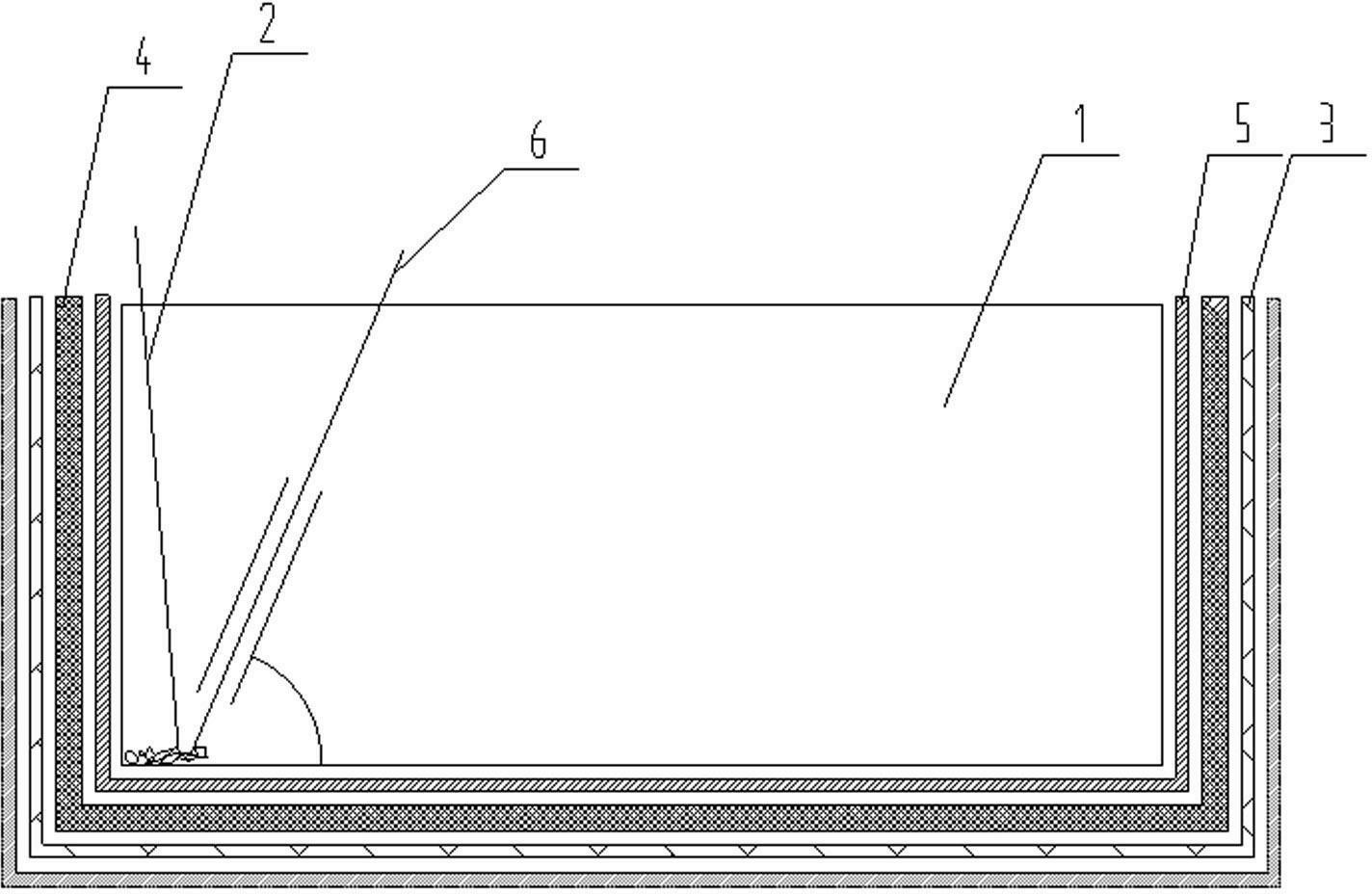

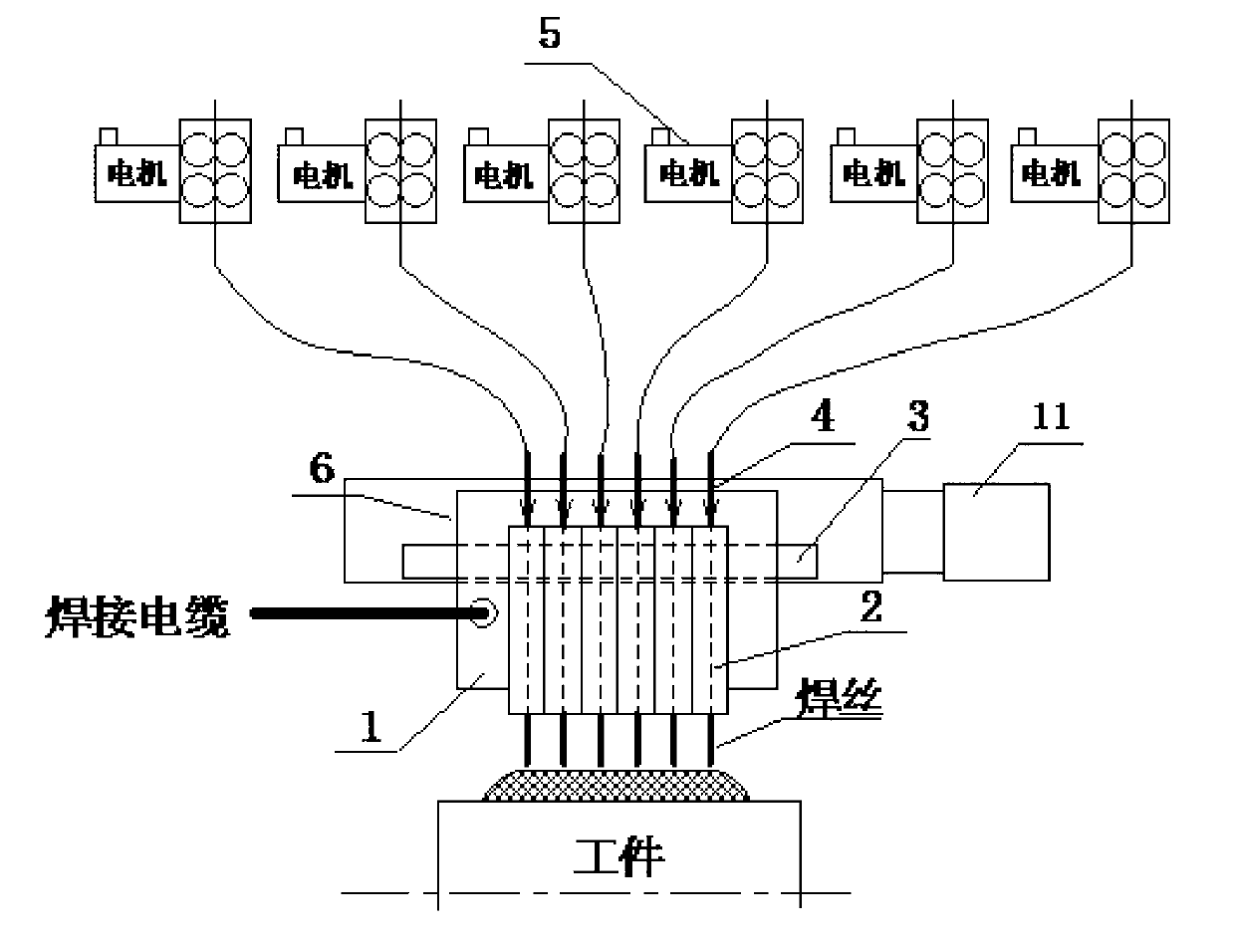

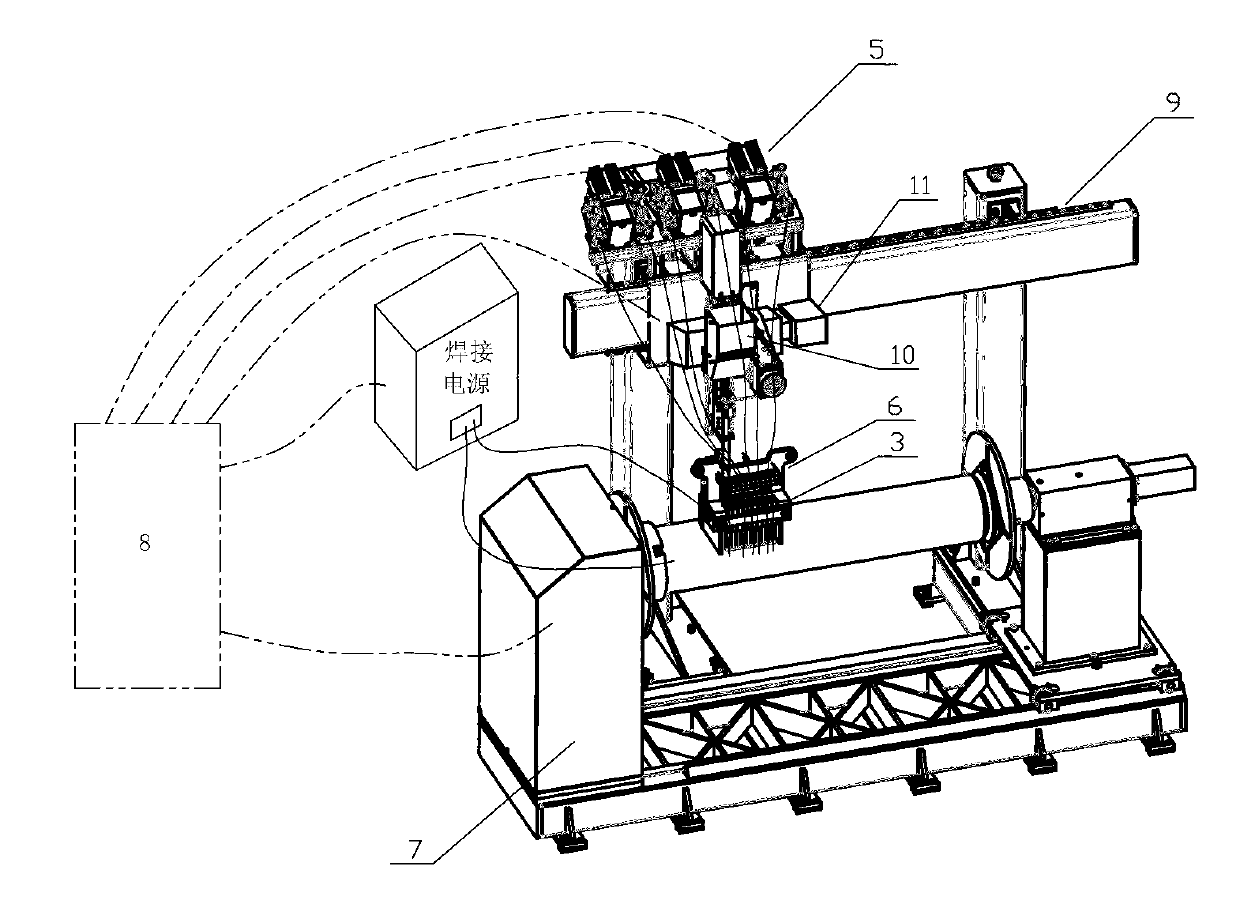

Multi-wire bead welding system and process thereof

ActiveCN103273169AConvenient sourceEasy parallel arrangementElectrode supporting devicesLap jointEngineering

The invention discloses a multi-wire (solid or flux-cored) bead welding system adopting an inert gas protection or submerged arc method, and a process of the multi-wire bead welding system. The multi-wire bead welding system and the process of the multi-wire bead welding system are used for replacing surfacing with band-electrode to obtainer higher production efficiency. The multi-wire bead welding system comprises a welding gun swing mechanism (11), a multi-wire welding gun (6), a wire-feeding pipe (4) and at least two wire-feeding machines (5). Compared with traditional bead welding, the multi-wire bead welding is higher in deposition rate. Due to the fact that a lap joint area of multi-wire bead welding is soother than that of traditional bead welding, the machining time needed to obtain a smooth surface is largely shortened. A machine head of the multi-wire bead welding system can swing in the welding process, the fusion ratio between bead welding materials and wood is improved while a wider weld joint is obtained, and the unique swing function can guarantee a bead welding layer to be more uniform.

Owner:AMET WELDING AUTOMATION TECH BEIJING +1

Method and apparatus to produce high density overcoats

InactiveUS20120152726A1High deposition rateHigh qualityCellsElectric discharge tubesCarbon atomHigh density

A deposition system is provided, where conductive targets of similar composition are situated opposing each other. The system is aligned parallel with a substrate, which is located outside the resulting plasma that is largely confined between the two cathodes. A “plasma cage” is formed wherein the carbon atoms collide with accelerating electrons and get highly ionized. The electrons are trapped inside the plasma cage, while the ionized carbon atoms are deposited on the surface of the substrate. Since the electrons are confined to the plasma cage, no substrate damage or heating occurs. Additionally, argon atoms, which are used to ignite and sustain the plasma and to sputter carbon atoms from the target, do not reach the substrate, so as to avoid damaging the substrate.

Owner:INTEVAC

Welding process of megaton ethane compressor casing

ActiveCN101890557AShorten welding cycleQuality assuranceWelding/cutting media/materialsSoldering mediaShielding gasWeld seam

The invention relates to a welding technology in the equipment manufacture industry and relates a special welding technology of an MCL (Mean Control Limit) type horizontally-split centrifugal compressor welder casing, in particular to a welding technology of a megaton ethane centrifugal compressor welder casing with forgeable pieces of 16 Mn and Q345R and ZQ230-450 materials. Gas shielded welding is adopted to weld the welder casing with the forgeable pieces of 16 and the Q345R low alloyed steel, and an electrode in a brand of H08Mn2SiS with a diameter shown in the specification, power supply polarity of DCRP (Direct Current Reverse Polarity) is adopted and comprises fore-welding treatment, welding process and post-welding treatment, wherein the welding process comprises the following process parameters: a welding current is 250-280 A, a welding voltage is 28-32 V, a protective mixed gas comprises 80 percent by volume of Ar and 20 percent by volume of CO2, a welding speed is 280-320 mm / min, the dry extension is 20-25 mm, and the gas flow is 15-20 L / min. The invention can solve the problems of welding deformation, layered tearing, low welding efficiency, and the like and ensure the welding seam strength by selecting an MAG (Metal Active Gas) shielded welding material with similar chemical contents and matched strength with a welder casing material.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Method for raising common steel antibiotic and rust resisting performance

InactiveCN101067196AImprove adhesion strengthHigh deposition rateVacuum evaporation coatingSputtering coatingFood sectorCopper

The process of raising antibiotic and antirust performance of common steel product belongs to the field of material surface treating technology. The process includes: grinding and polishing the surface of steel product to mirror finishing, ion plating to deposit Ni-Cr film, and implanting Cu or Ag ion. The ion plating and the ion implanting make the common steel product possess both antibiotic performance and antirust performance. Thus treated steel may be used in door handle, kitchenware, household appliance, etc.

Owner:SHANGHAI JIAO TONG UNIV

Double-wire underwater wet welding device and method

InactiveCN104400181AStable combustionIndependently adjustable welding parametersElectrode supporting devicesElectric arcBase metal

The invention relates to a double-wire underwater wet welding device and a double-wire underwater wet welding method. The welding device comprises a master welding gun power supply, a slave welding gun power supply, a master wire conveyor, a slave wire conveyor, a master welding gun and a slave welding gun, wherein the master welding gun and the slave welding gun are respectively connected to the master welding gun power supply and a slave welding gun power supply, a master welding wire and a slave welding wire are respectively conveyed to the end parts of the master and slave welding guns through the master and slave wire conveyors, the master welding gun and the slave welding gun are respectively arranged to form a certain angle with a workpiece to be welded, and a certain distance is kept between the front end of the master welding gun and the front end of the slave welding gun. According to the double-wire underwater wet welding device and method, the two welding wires in the master and slave welding guns are heated mutually, and the energy of electric arc is fully used, so that the deposition rate is greatly improved, and the problem that the underwater wet welding molten bath and the base metal cannot be fully fused is overcome.

Owner:HARBIN INST OF TECH AT WEIHAI

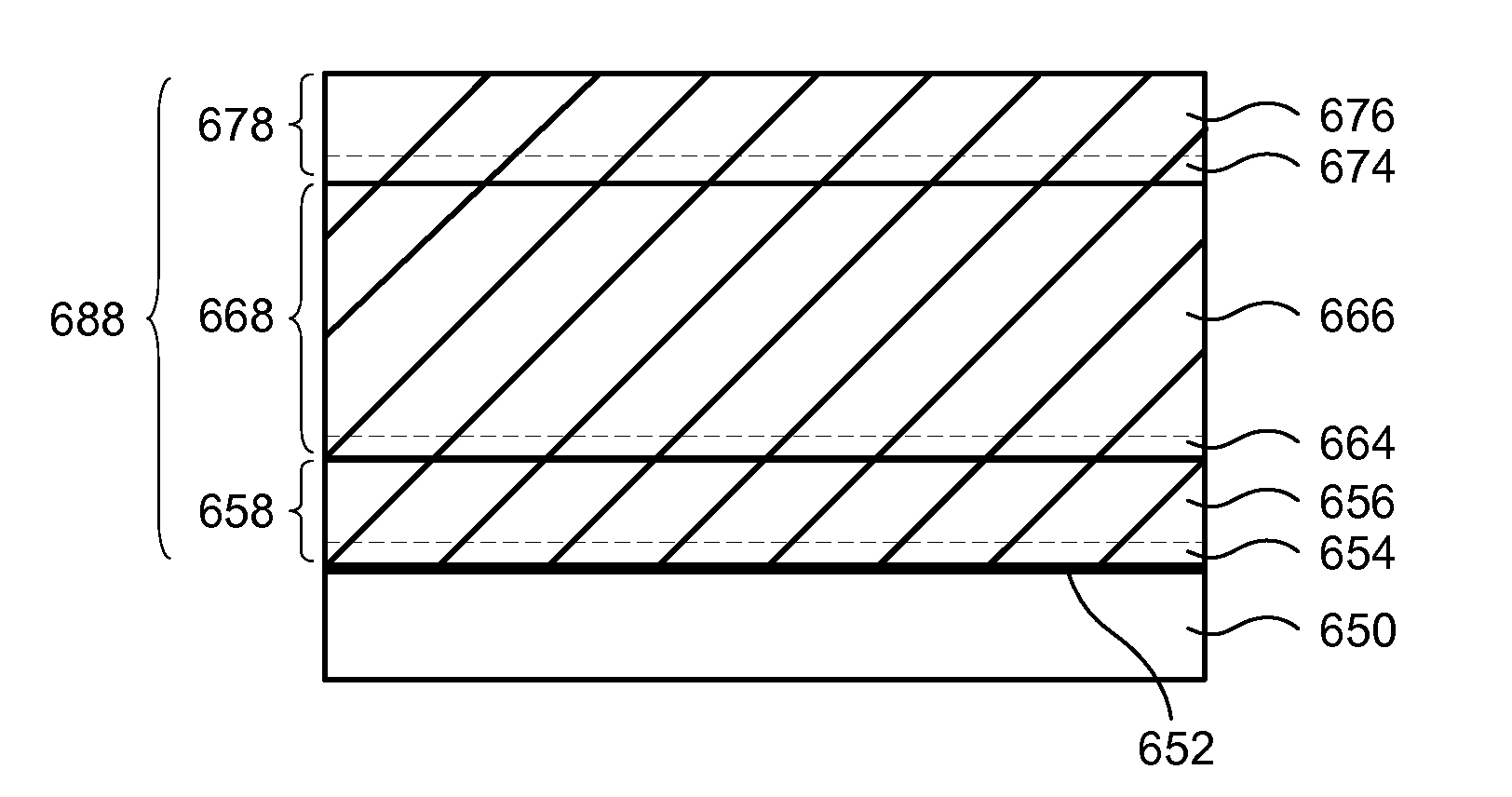

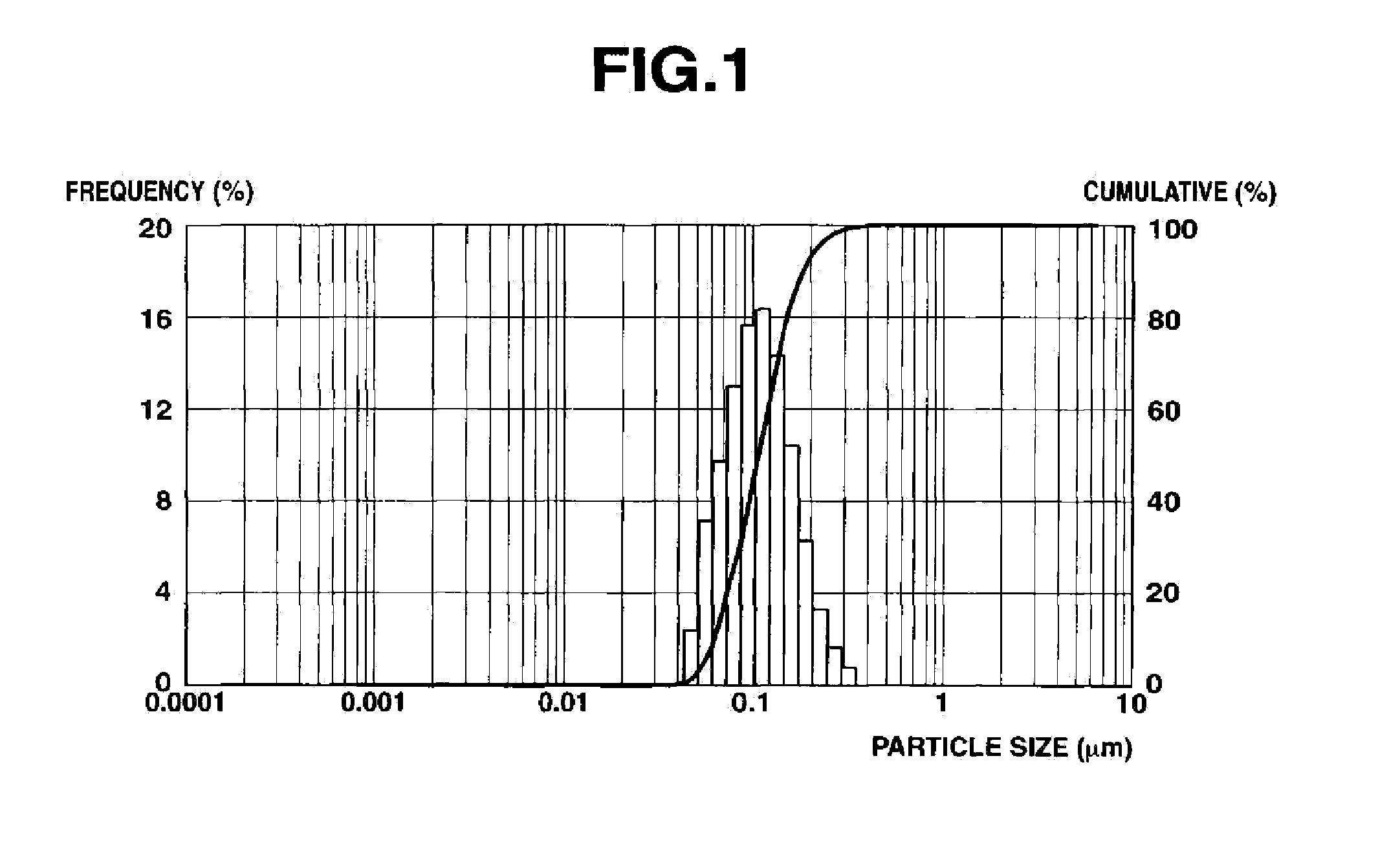

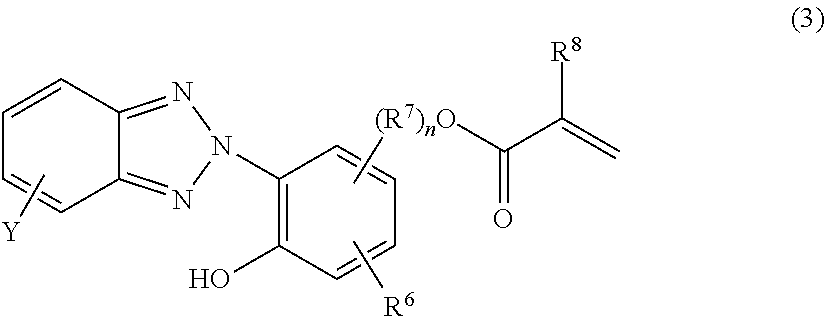

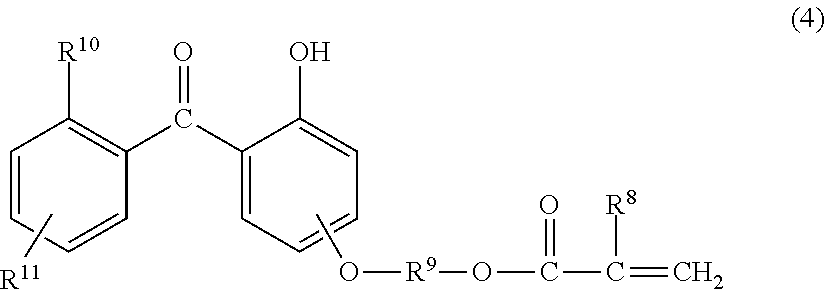

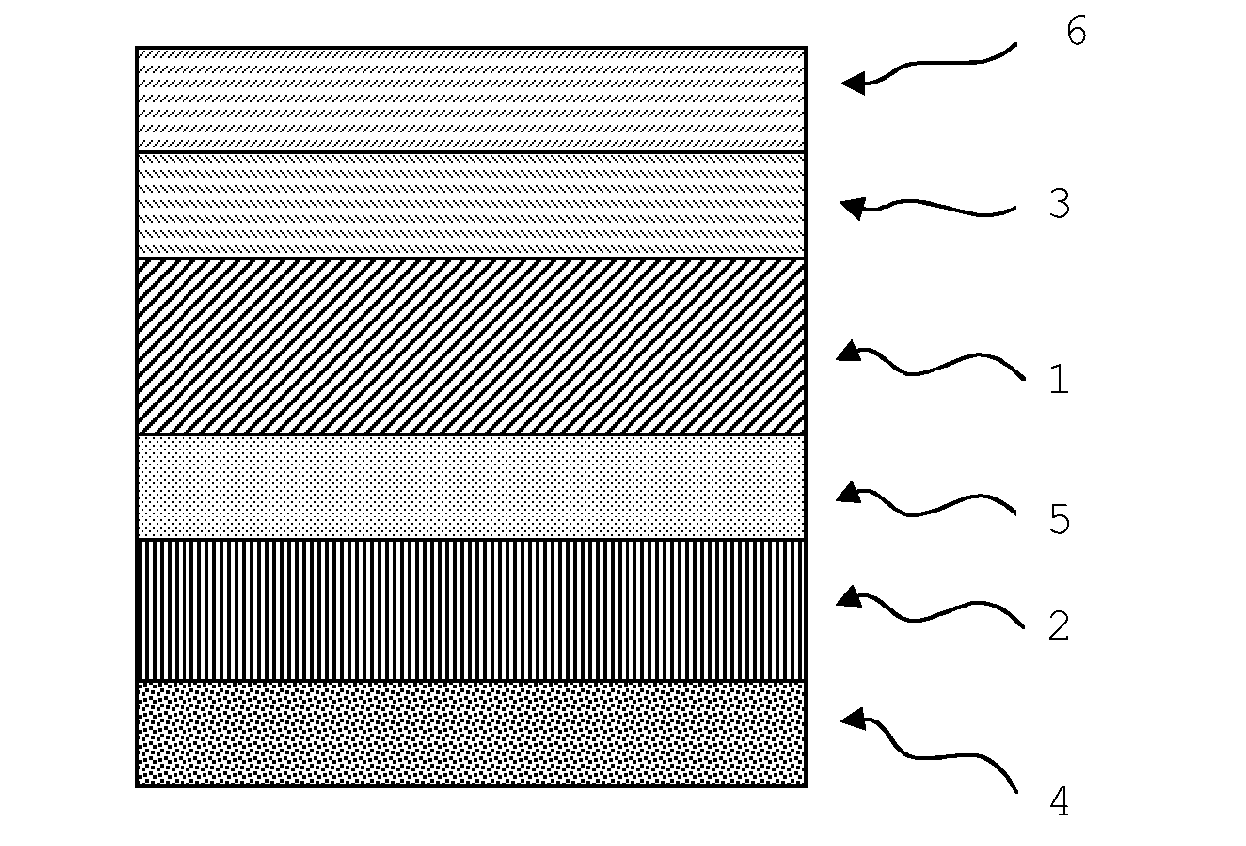

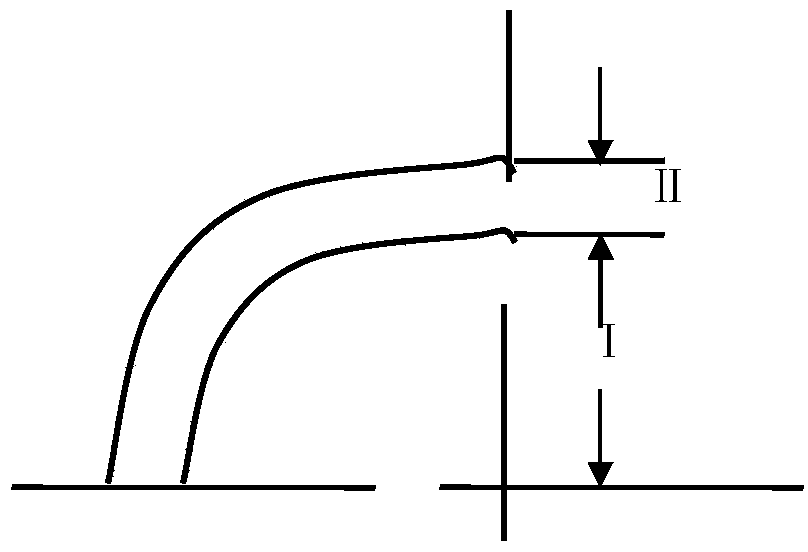

Organic resin laminate

ActiveUS20120263933A1Solve the lack of durabilitySolve the lack of resistanceMaterial nanotechnologySynthetic resin layered productsAcrylic resinCoating system

An organic resin laminate comprising an organic resin substrate and a multilayer coating system thereon has UV-shielding property and high mar resistance. The multilayer coating system includes an outermost layer (I) resulting from plasma polymerization of an organosilicon compound, a lower layer (II) of a silicone coating composition comprising composite oxide nanoparticle dispersion, silicone resin, curing catalyst, and solvent, and optionally a bottom layer (III) of acrylic resin.

Owner:EXATEC LLC +1

Low-dust environment-protection carbon-steel electric welding bar

InactiveCN1404960AImprove protectionSave resourcesWelding/cutting media/materialsSoldering mediaManganeseEngineering

The low-dust environment-protecting type carbon steel electric welding rod is made up by using reduced ilmenite, rutile, mica, white mud, medium manganese, marble, clay, pyrauxite, feldspar, wollastonite and natural cereal skin as main raw material. Said electric welding rod possesses excellent welding property, high deposition rate, can reduce welding smoke and dust, and is favorable for protecting environment, and its cost is low.

Owner:魏玉刚

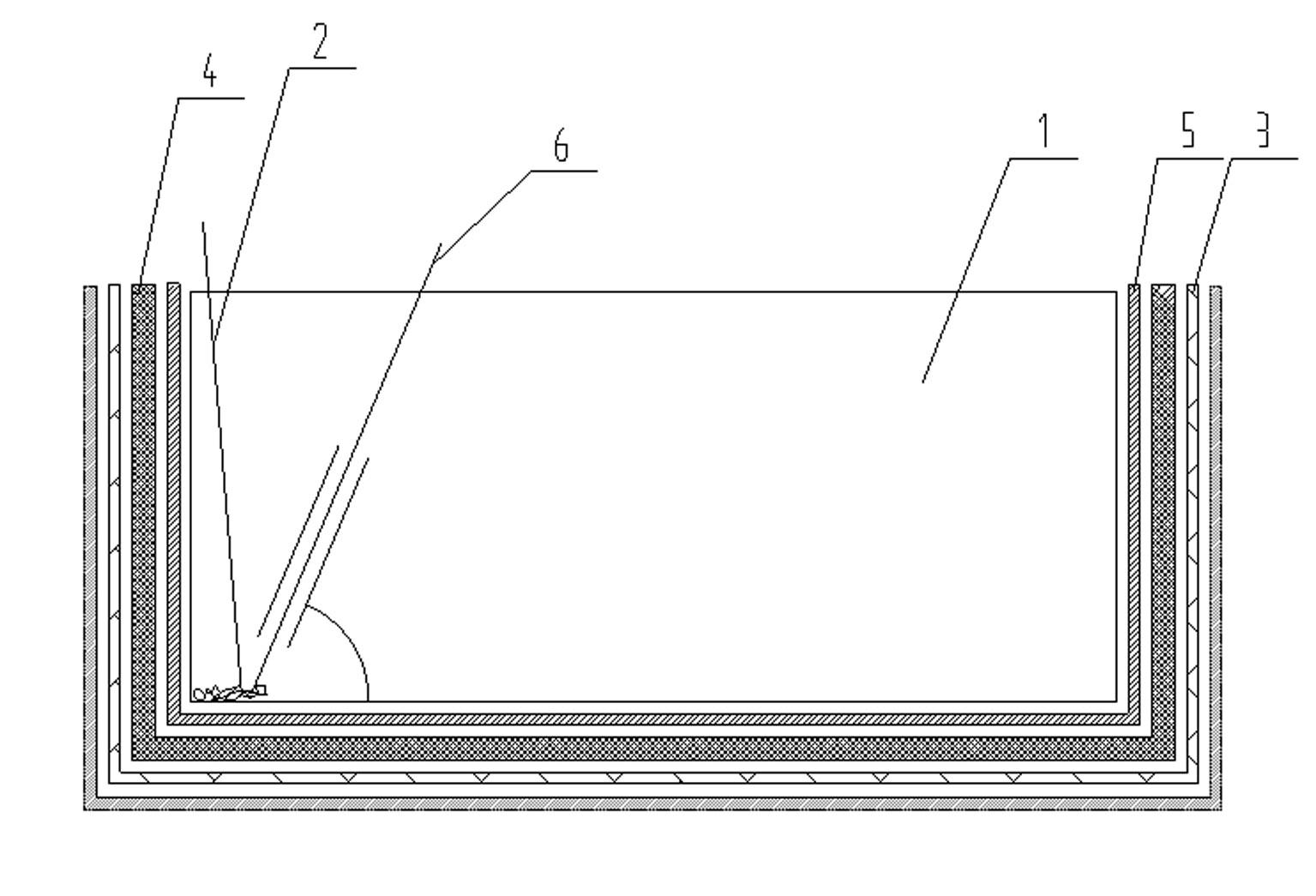

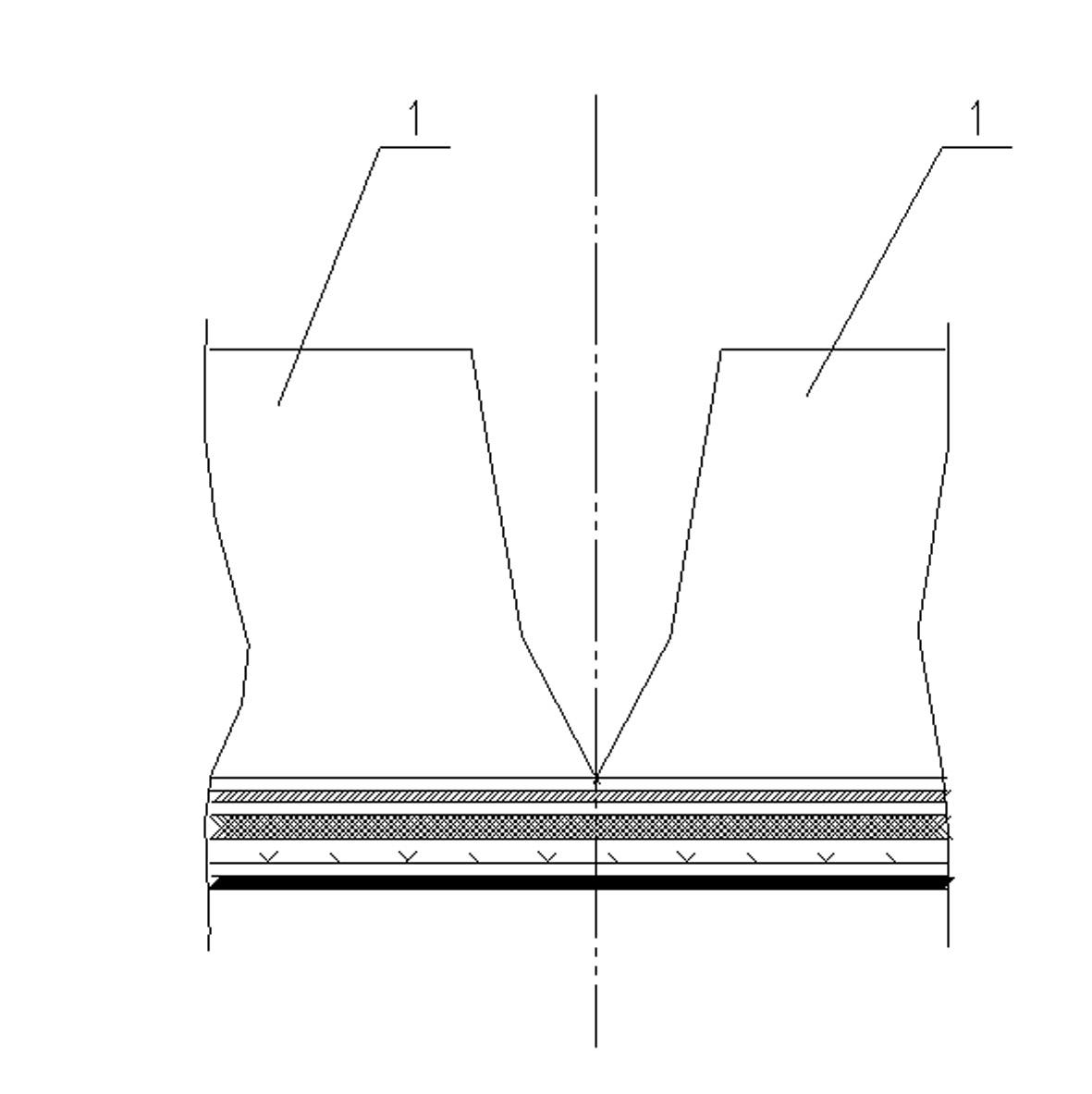

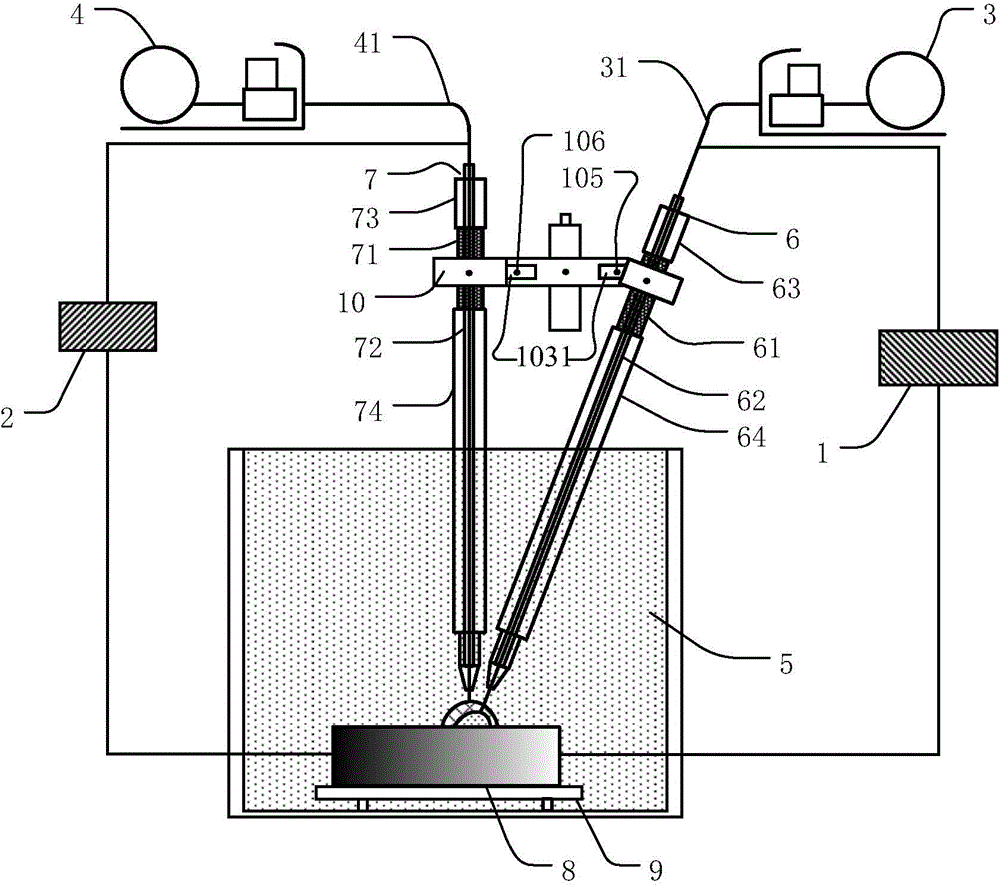

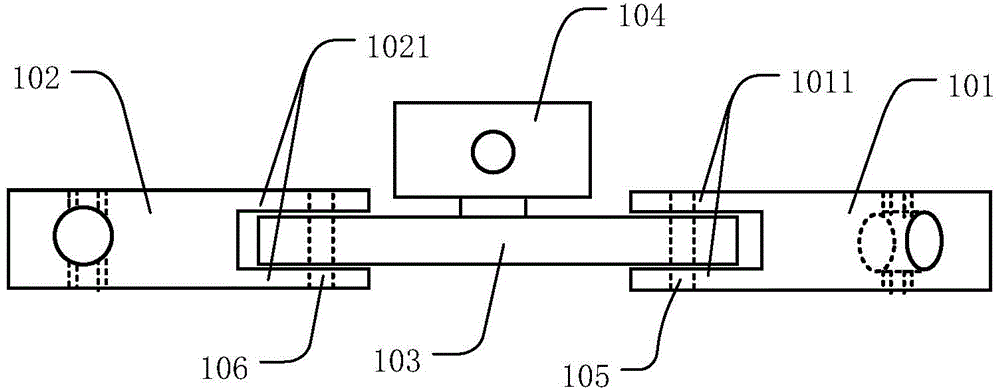

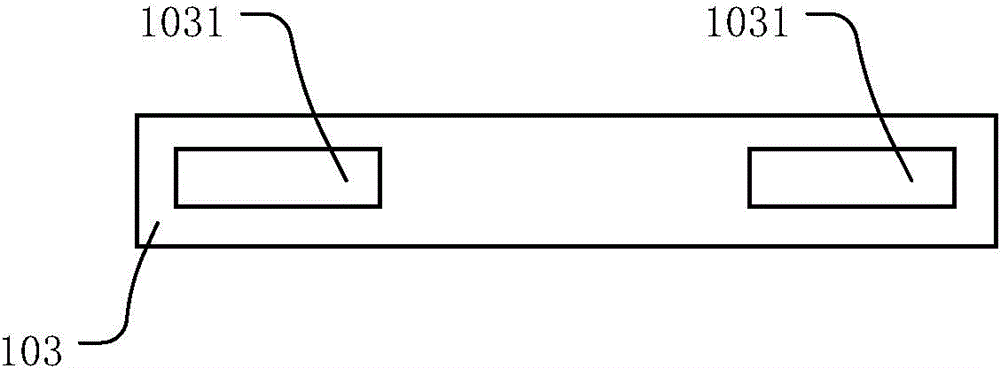

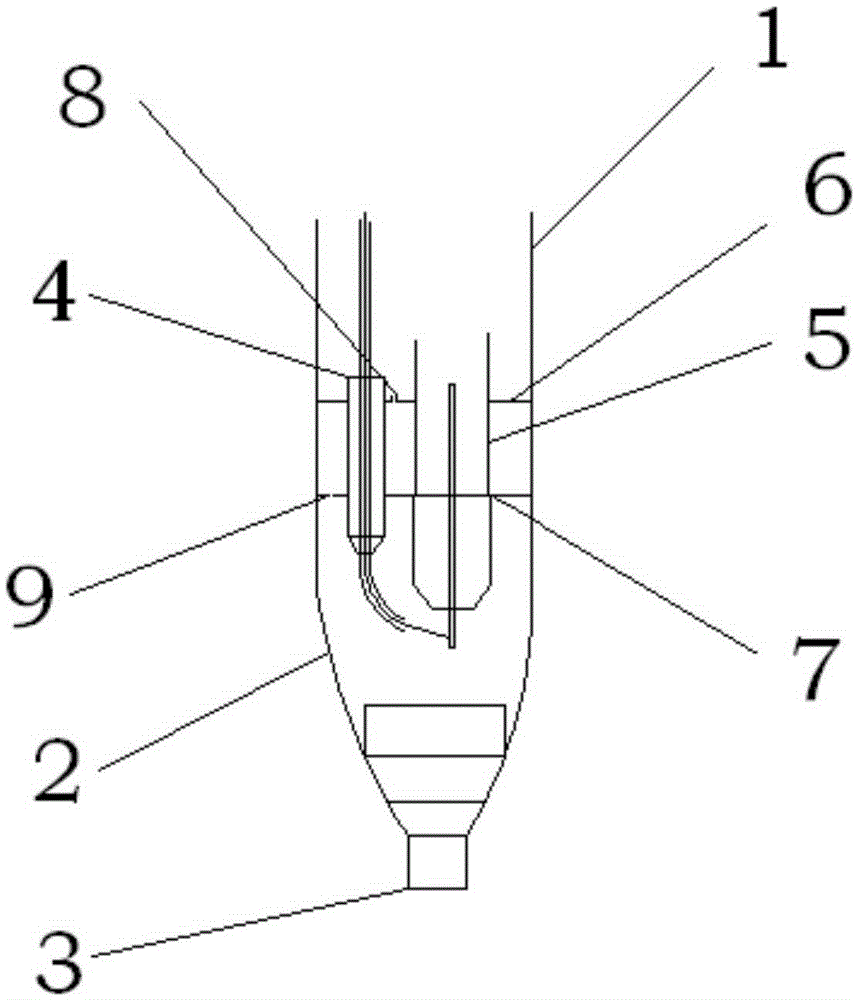

3D printing device and method for molten metal

The invention relates to a 3D printing device and method for molten metal, and belongs to the technical field of 3D printing. The 3D printing device comprises a casing, a first nozzle, a melting-electrode welding electrode and a non-melting-electrode welding electrode, wherein the first nozzle is connected with one end of the casing; a cavity is formed in the middle part of the casing; a first sealing plate and a second sealing plate are arranged in the casing; the melting-electrode welding electrode and the non-melting-electrode welding electrode are positioned in the cavity of the casing; the melting-electrode welding electrode and the non-melting-electrode welding electrode penetrate through the two sealing plates to be arranged; the first sealing plate is provided with a gas inlet, and the second sealing plate is provided with a gas outlet; the gas inlet and the gas outlet are used for allowing noble gases to circulate. According to the 3D printing device and method disclosed by the invention, a wire material extruding hot melting forming manner and a melting forming manner based on fusion welding are creatively combined, high temperature generated by welding arcs enables high-melting-point metal wires to be melted to obtain molten metal, and under the extruding action of the inside pressure of the casing and the nozzle, the molten metal stably and quickly flows out, so that the 3D printing is realized.

Owner:SHANDONG UNIV

Submerged arc welding process

The invention discloses a process for carrying out submerged arc welding on two plates with thicknesses of no more than 14 mm. The process comprises the following steps: after one part to be welded forms a groove, checking an assembling clearance between the two plates and making the assembling clearance satisfy requirements, fixing a gasket on the back face of an abutted part; enabling a variable speed submerged arc welding trolley to move along a welding joint at a constant speed; controlling a welding wire to swing backwards relative to the trolley in a reciprocating way at a constant speed in the direction of the welding joint when the welding wire on the trolley moves at the constant speed with the trolley; controlling the swinging amplitude of the welding wire, so that the swinging arc of the welding wire always falls within a range of a molten pool; and adjusting the height of the welding wire so as to guarantee that an electric arc can directly act upon the root of the groove when the welding wire is positioned at a swinging arc front point. According to the invention, the desired welding current is reduced, linear energy is also reduced, the expansion stress of the welding joint is reduced and cracks are uneasy to generate on a welding joint terminal; moreover, as the two sides of the side wall of the groove can be continuously heated by the electric arc, the deposition rate is increased, the production efficiency is increased, the electric quantity and the consumption of the welding material are reduced and the production cost is reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

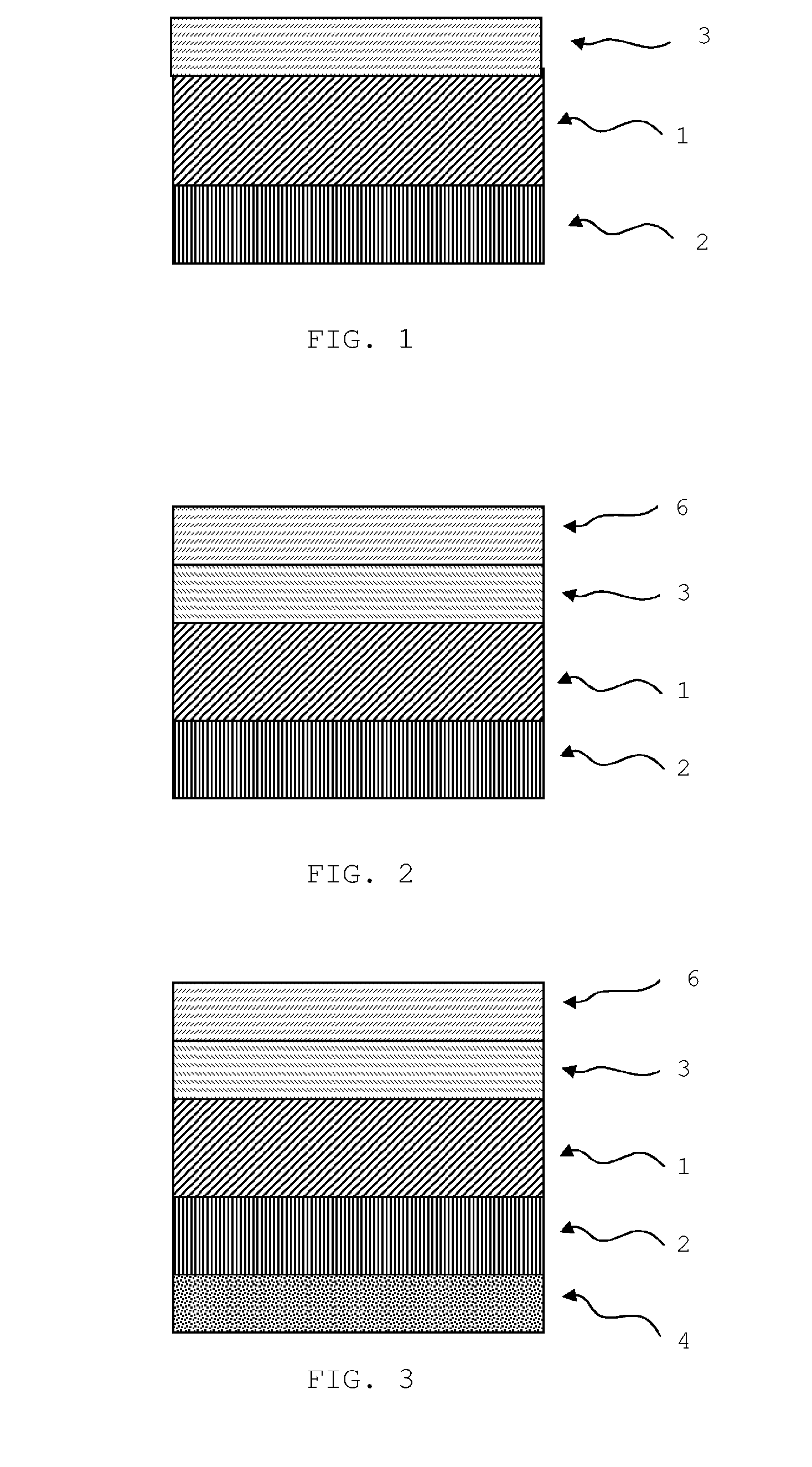

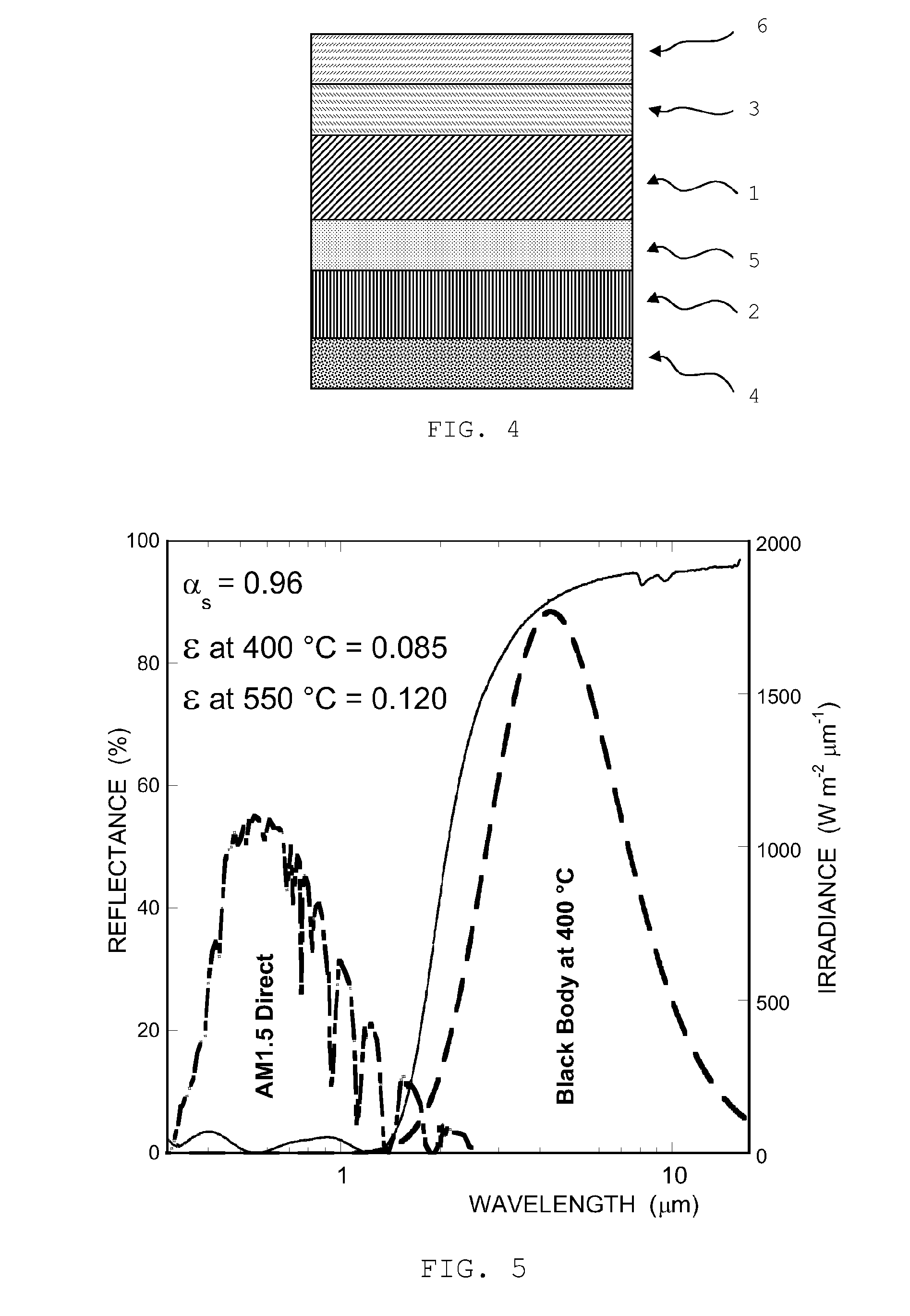

Solar selective absorber based on double nitride composite material and process for its preparation

ActiveUS20140130794A1Improve performanceIncrease absorbanceMirrorsSolar heat devicesThin membraneAbsorption layer

A thin-film spectrally selective coating for receiver tube of vacuumed type for use in thermodynamic solar installations and operating both at medium temperature (up to 400° C.) and at high temperature (up to 550° C.), coating where the optically absorbing layer is a multilayer of cermet material of type: WyN—AlNx or MoyN—AlNx, material prepared with reactive co-sputtering technique from an Al target and a W or Mo target, process conducted under a transition regimen, under PFM (Plasma Emission Monitoring) or CVM (Cathode Voltage Monitoring) monitoring for the sole Al target, with inletting near the Al target of a N2 amount adequate for obtainment of a high-transparency, high growth rate sub-stoichiometric ceramic AlN and with inletting near the W or Mo target of a N2 amount adequate for obtainment of the sole W2N or Mo2N phase, phase very stable at high temperature, such as to make the cermet material as close as possible to the formulation W2N—AlNx or Mo2N—AlNx (with x comprised between 0.90 and 1.00, preferably 0.95) and, therefore, cermet material employable at least up to the temperature of 550° C.

Owner:ENTE PER LE NUOVE TECH LENERGIA E LAMBIENTE ENEA

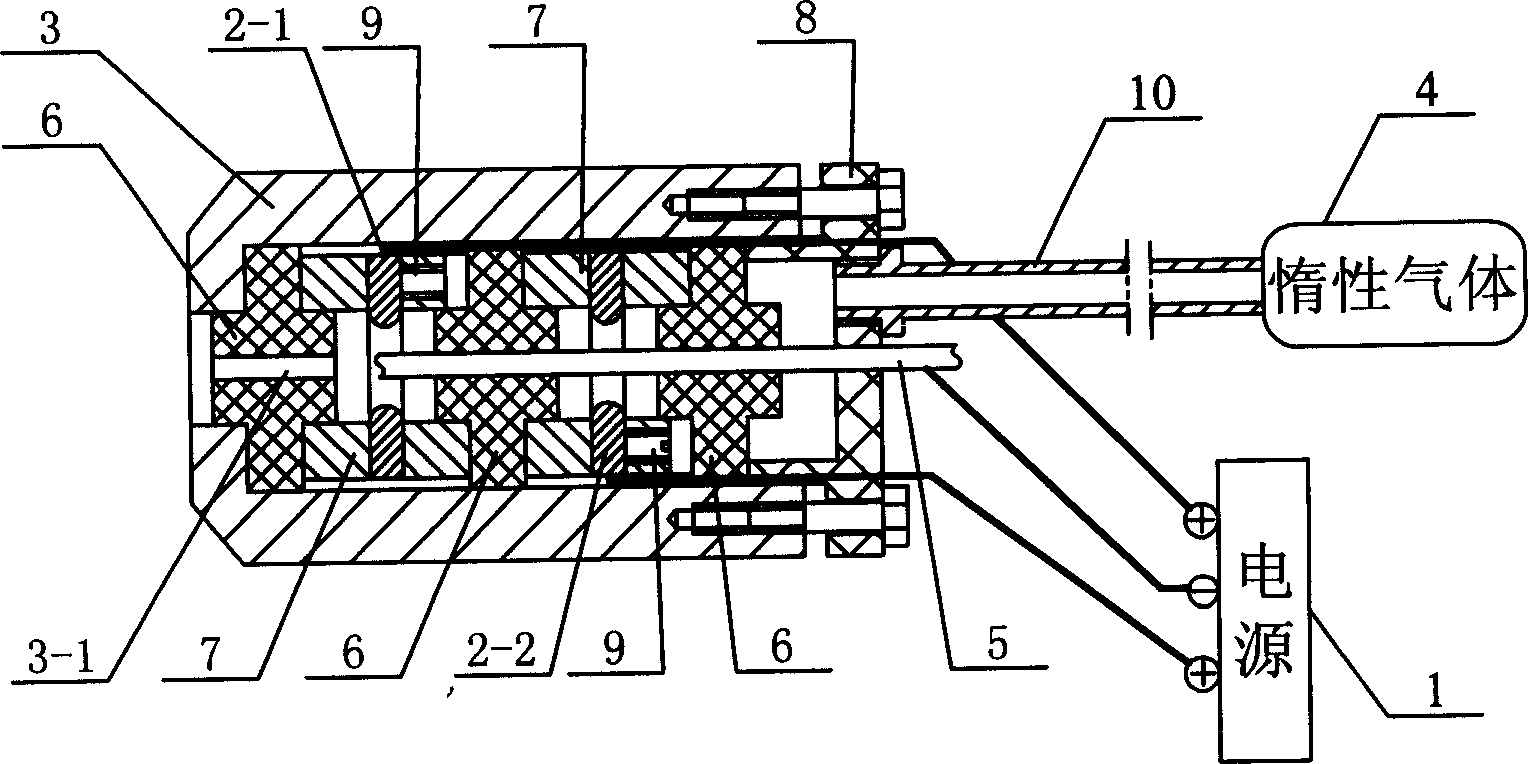

Catelectrode atomization type preweld cleaning equipment for aluminum alloy welding wire

InactiveCN1593830AAdjust cleaning depthPrevent regenerationArc welding apparatusCurrent sourceInert gas

The invention makes public a kind of negative electrode atomization cleaning device which is used to clean the aluminum alloy welding thread before welding. The device consists of current source, at least two tungsten electrodes, tube, shell body, and inert gas container. Through the sealed body is thread bore. And the two electrodes are inside the body, separate each other above the thread bore and connect respectively to positive outing end. Lumen of the body connects to the inert gas container by tube. The two tungsten electrodes strike fire respectively with aluminum alloy welding thread and produce mini electric arc to clean the oxidation film covering the welding thread. The invention uses the negative atomization phenomenon of aluminum alloy welding to clean the welding thread before melting it by mini arc. The invention is a cleaning method going with welding, can clean more completely than previous method. It also can heat the welding thread in advance so can improve the welding efficiency.

Owner:HARBIN INST OF TECH

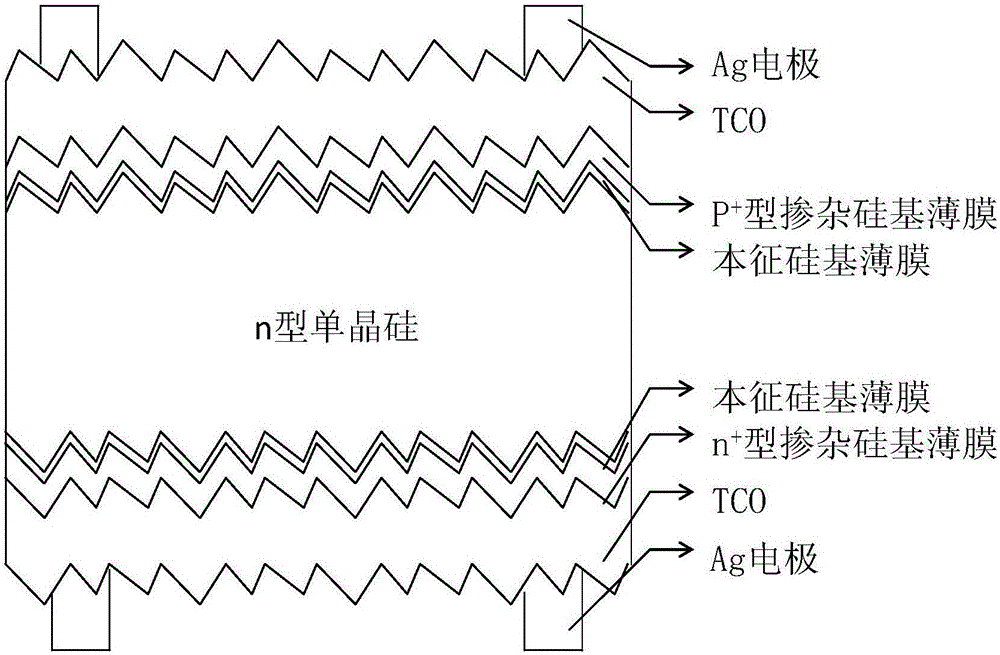

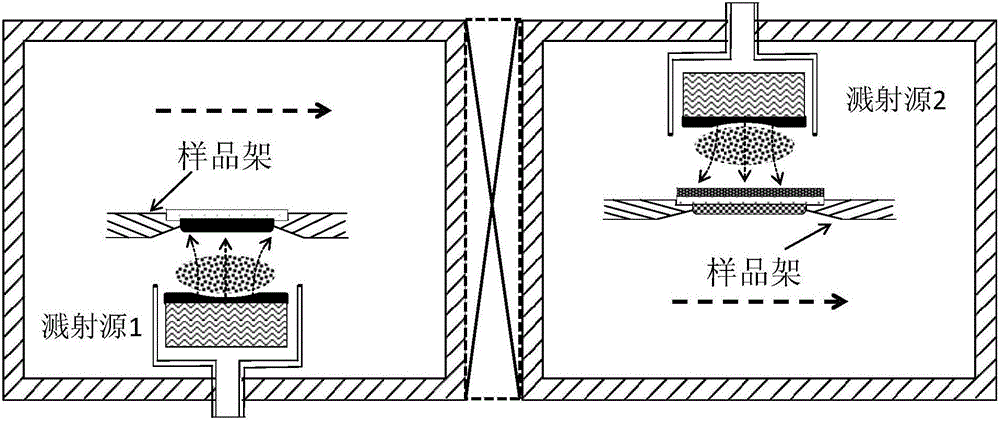

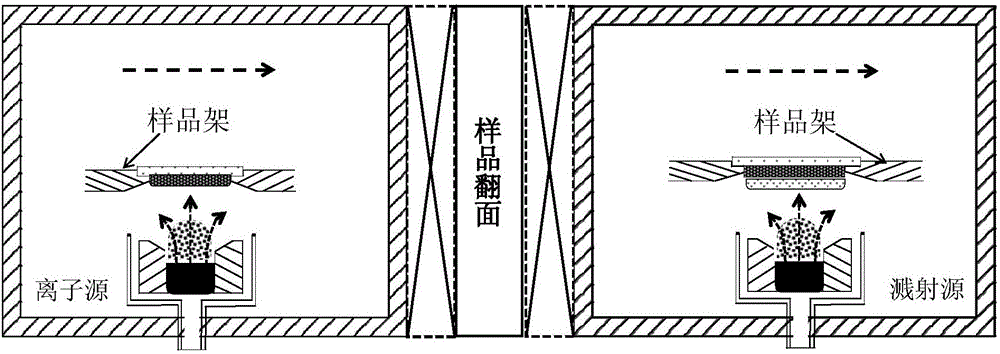

Film plating device for preparing TCO (Transparent Conductive Oxide) film and film plating method

ActiveCN106340570AAvoid damageHigh deposition rateFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionDeposition process

The invention provides a film plating device for preparing a TCO film and a film plating method. The film plating device integrates an ion film plating source with a sputtering film plating source in the same vacuum equipment. Characteristics of ion film plating and sputtering film plating are combined effectively, TCO films of different optical and electrical properties are prepared continuously under the condition that the films are not exposed in the atmosphere according to different requirements for the TCO films of devices, a high deposition speed is obtained, and damage on a substrate and the device surface caused in the film deposition process is reduced. The device and method are especially suitable for preparing the TCO films continuously in the front and back sides of high-efficiency film silicon / crystalline silica heterojunction solar cells with low loss as well as preparing different TCO films continuously in different film solar cells; and the device and method are suitable for different TCO materials with different performances.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Method and apparatus to produce high density overcoats

InactiveUS20140102888A1High deposition rateHigh qualityCellsElectric discharge tubesCarbon atomHigh density

A deposition system is provided, where conductive targets of similar composition are situated opposing each other. The system is aligned parallel with a substrate, which is located outside the resulting plasma that is largely confined between the two cathodes. A “plasma cage” is formed wherein the carbon atoms collide with accelerating electrons and get highly ionized. The electrons are trapped inside the plasma cage, while the ionized carbon atoms are deposited on the surface of the substrate. Since the electrons are confined to the plasma cage, no substrate damage or heating occurs. Additionally, argon atoms, which are used to ignite and sustain the plasma and to sputter carbon atoms from the target, do not reach the substrate, so as to avoid damaging the substrate.

Owner:INTEVAC

Method for repairing open arc welding and surfacing of continuous casting roller of continuous casting fan-shaped section

A method for repairing open arc welding and surfacing of a continuous casting roller of a continuous casting fan-shaped section includes the following steps of (1) welding material selection, (2) open arc welding and surfacing processing and (3) roller surface welding. By means of the method for repairing open arc welding and surfacing, a surfacing layer of the continuous casting roller has high anti-stripping performance, good abrasion resistance, good fatigue resistance and good machinable performance, production efficiency is high due to surfacing, the requirement for multiple times of surfacing repairing can be met, and the service life of the continuous casting roller after surfacing repairing is not shorter than that of an original roller.

Owner:上海一钢机电有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com