Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Shorten welding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

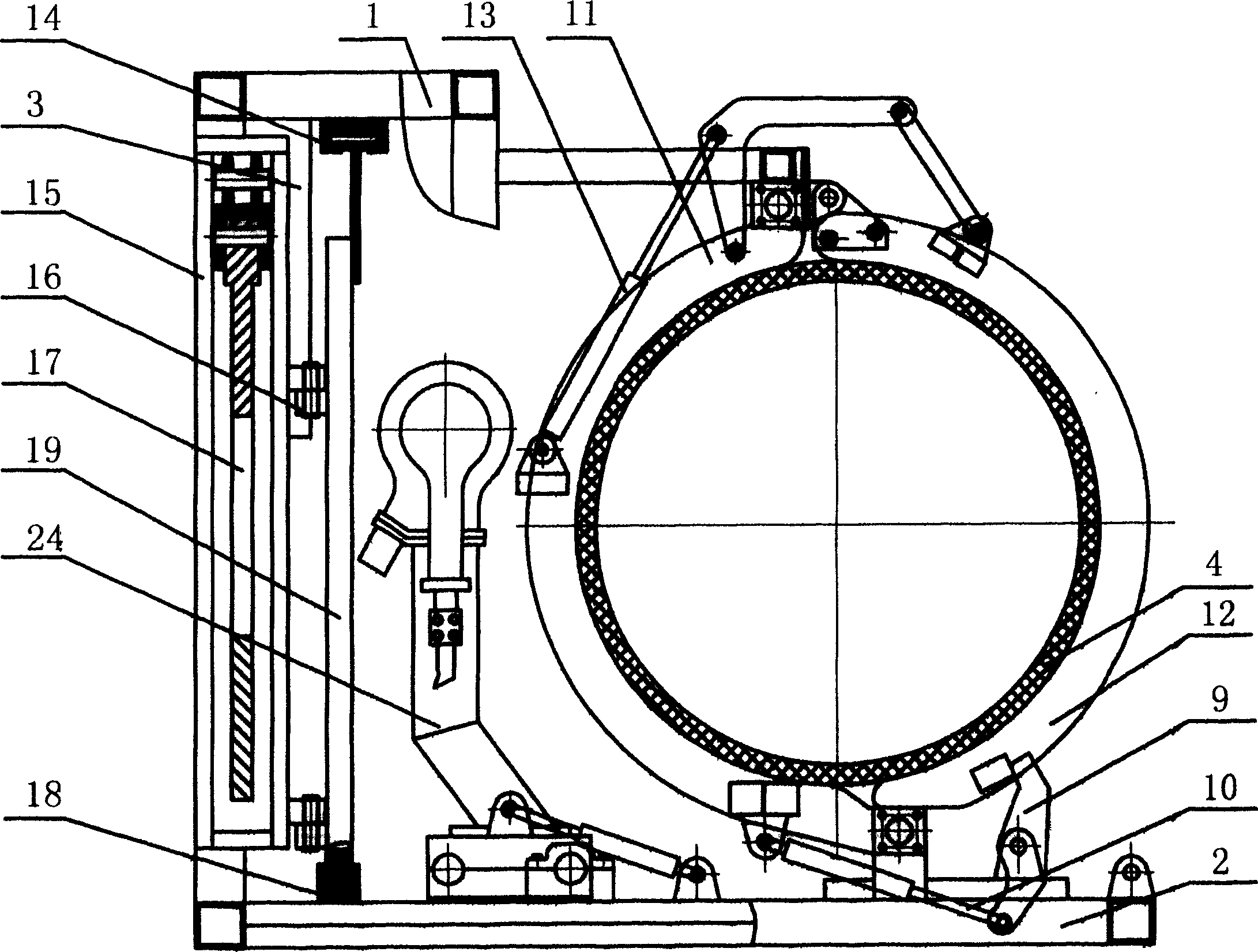

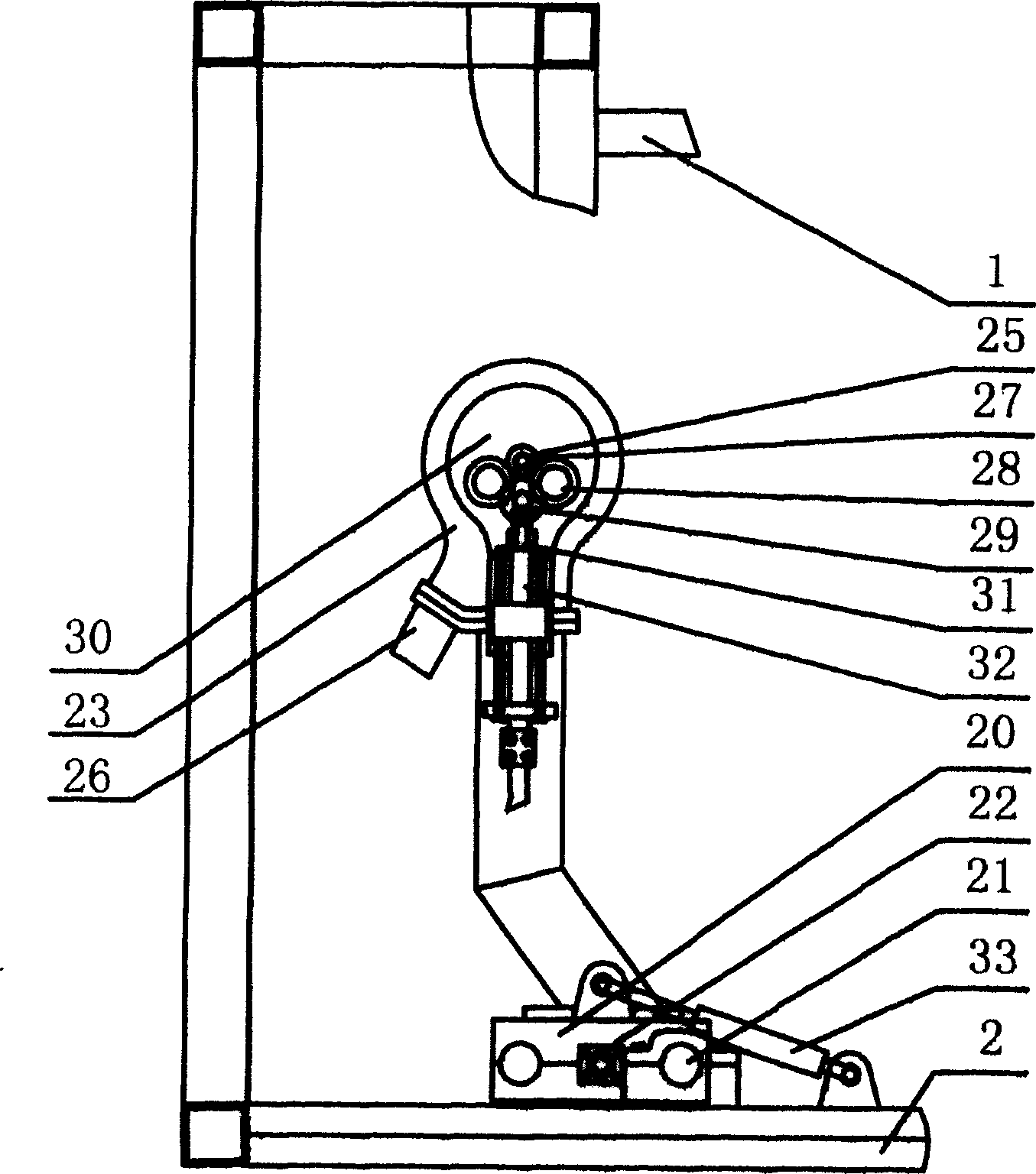

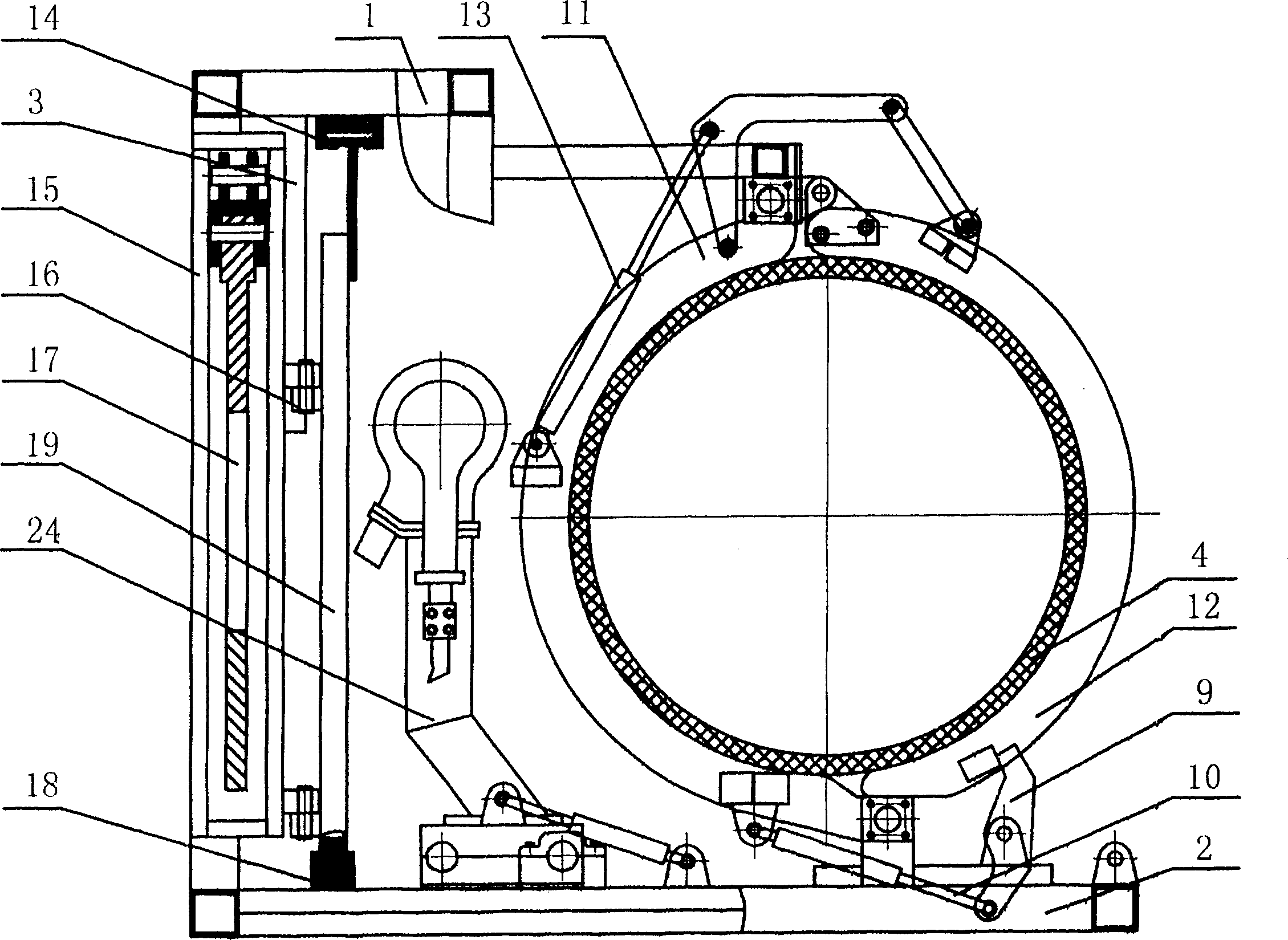

Heat melting butt joint welder for plastic pipe

ActiveCN1586869AMonitor and adjust temperature in real timeReal-time monitoring and adjustment of welding pressureThermoplasticBlade plate

The present invention relates to heat melting butt jointing welder for plastic pipe and belongs to the field of plastic pipe welding apparatus making technology. The heat melting butt jointing welder includes mainly frame comprising upper frame with controller, lower frame, etc.; clamping mechanism comprising fixed clamps, movable clamps, etc.; cutting mechanism comprising sliding track with turning cylinder, sliding seat with translation cylinder, cutting motor with reducing box, cutting board with lathe tool, etc.; and heating mechanism comprising upper sliding seat, lower sliding seat, heating board sliding body, heating board holder with heating board, etc. The present invention has reasonable design and compact integral structure, and may be used in completing clamping, cutting, heating and butt jointing of different kinds of plastic pipes, especially plastic pipes of caliber as great as 800-2000 mm.

Owner:ZHEJIANG ZHONGYUAN FENGYE PIPES +2

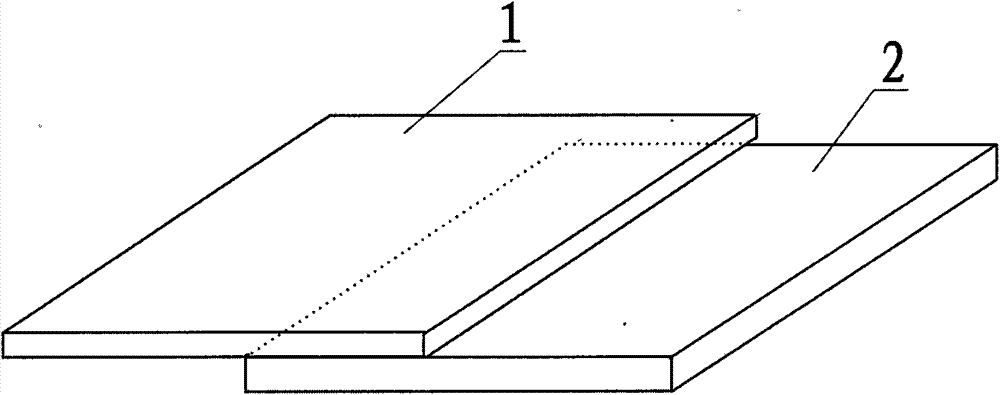

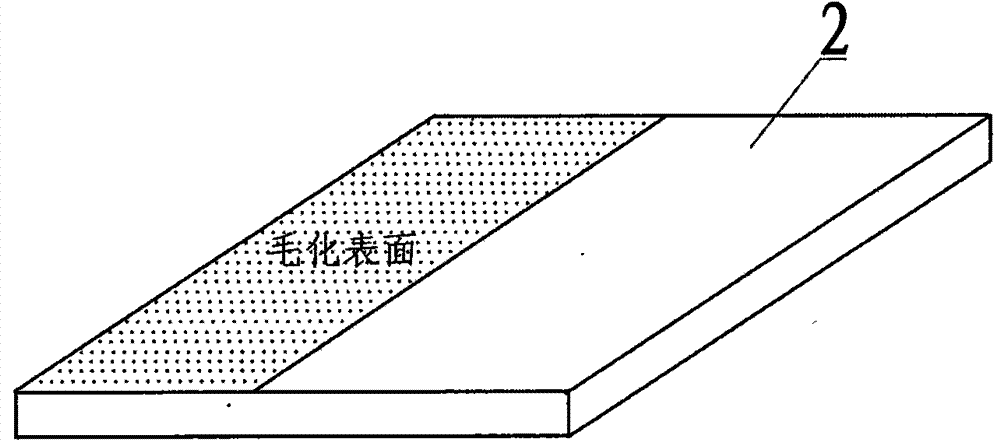

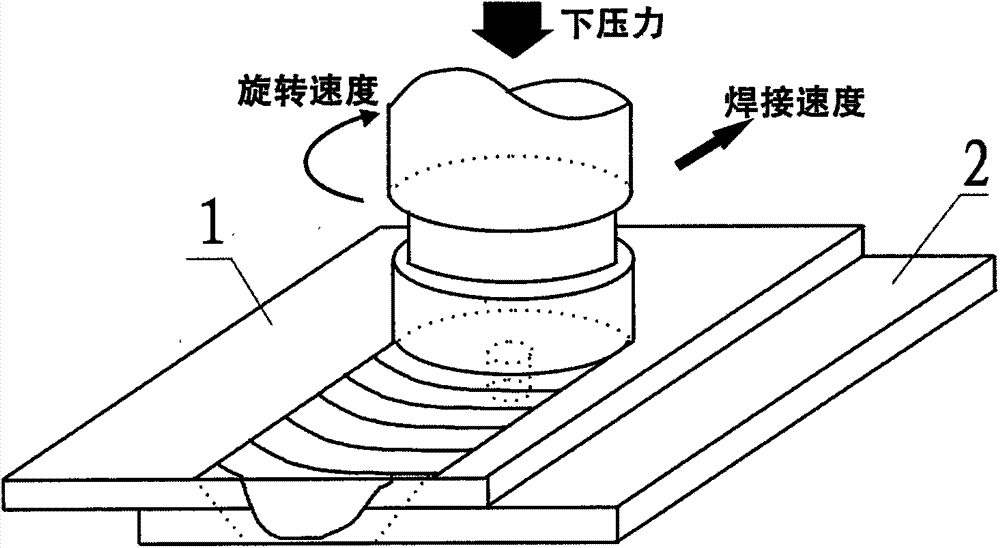

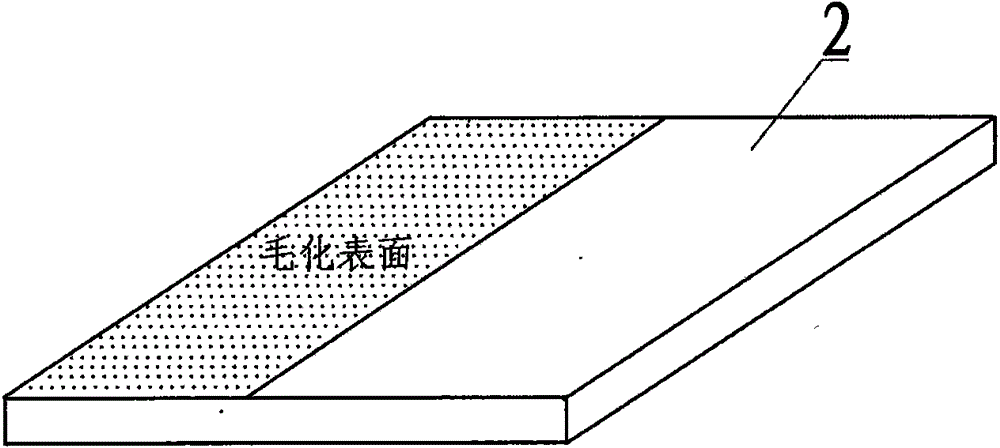

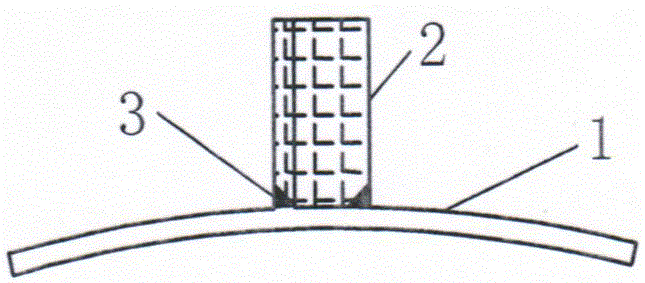

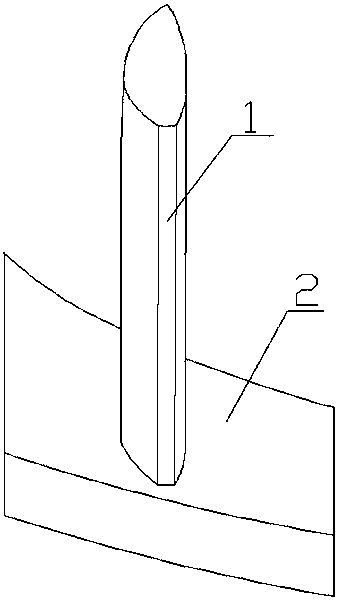

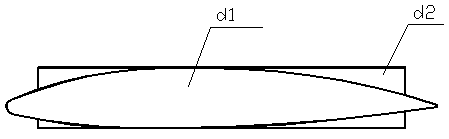

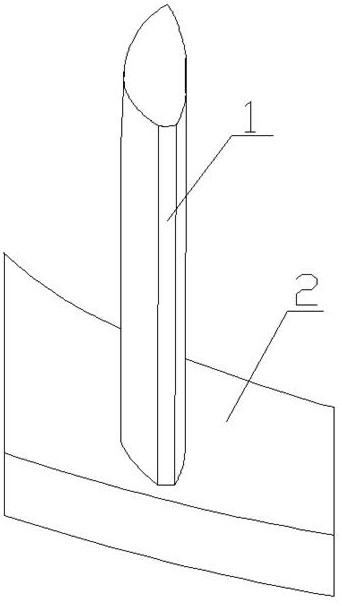

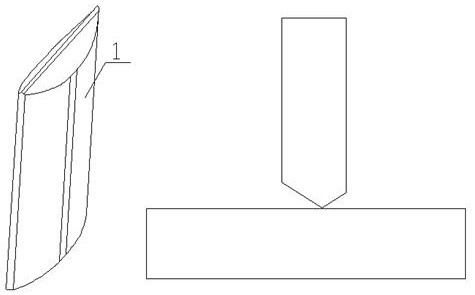

Steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection

InactiveCN103894724AImprove mechanical propertiesReliable strengthWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingSheet steel

The invention relates to a steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection. A fine convex-concave structure is obtained on the surface of a lap connection position of a steel plate through a roughing method, heat is generated through friction and plastic deformation of a stirring head and an aluminum plate, softened aluminum alloy is combined with the convex-concave structure of the surface of the roughed steel plate, the effective combination area is increased, a brittle intermetallic compound is suppressed from being formed between aluminum and steel, and effective and high-quality lap connection is formed between the steel plate and the aluminum plate. An aluminum steel dissimilar connector with beautiful formed welding joints, a good mechanical property and reliable strength is finally obtained, the welding operation process is simple, the welding cycle is effectively shortened, and automation is achieved easily.

Owner:HARBIN INST OF TECH

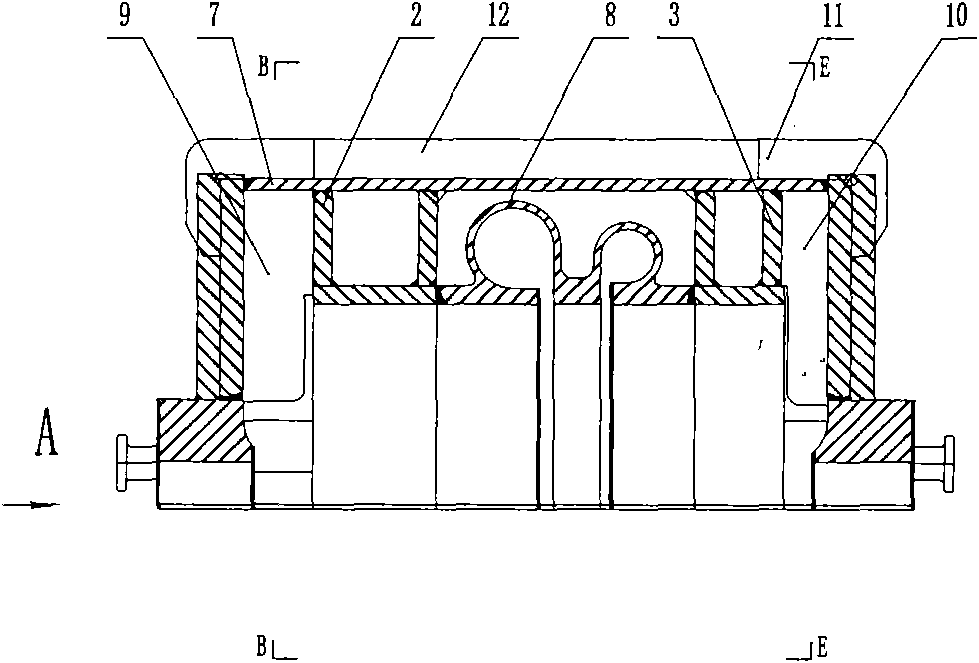

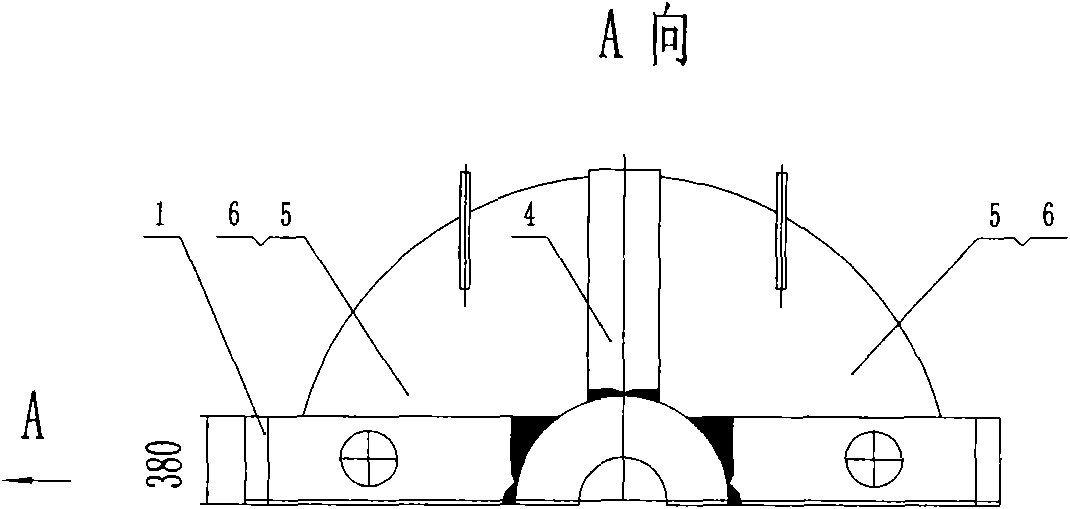

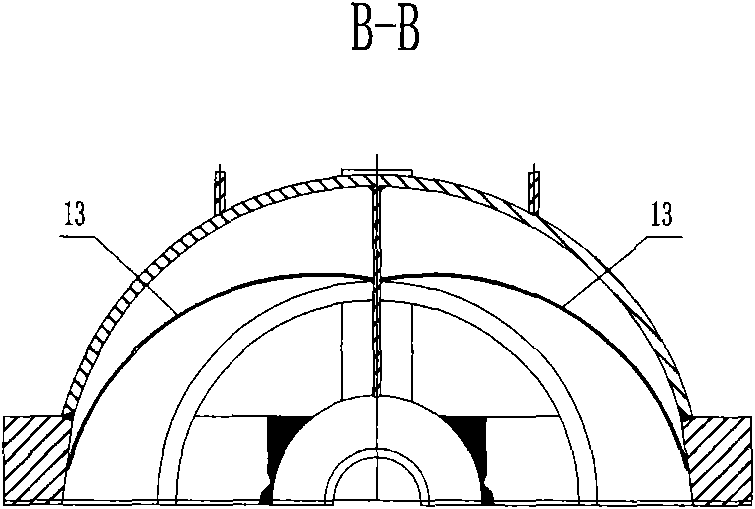

Welding process of heat-resistant steel cylindrical housing

InactiveCN102463406AShorten welding cycleStable deliveryArc welding apparatusShielding gasEngineering

The invention relates to a welding technology in an equipment manufacturing industry, discloses a welding professional technology for welding a housing of a BCL cylindrical centrifugal compressor and specifically relates to a welding process of the cylindrical housing of the centrifugal compressor made of chrome molybdenum heat-resistant steel 20CrMo material. Gas shielded welding is adopted, and the adopted welding wire trade name is CHW-55B2; the diameter of welding wires is phi 1.2mm; the polarity of a power supply is direct current electrode positive; and the welding process comprises pre-welding treatment, welding process and post-welding treatment, wherein the process parameters of the welding process are as follows: welding current is 150-230A, welding voltage is 25-30V, shielding gas is mixed gas comprising 80% by volume of Ar and 20% by volume of CO2, welding speed is 100-200mm / min, dry extension is 10-15mm and gas flow rate is 15-20L / min. According to the welding process provided by the invention, the welding wires can be fed automatically during the welding process and a welding rod does not need to be changed; and as heat is centralized in the gas shielded welding of an MAG (metal active gas) consumable electrode, the welding process has the advantages of narrow heat affected zone, small deformation, aesthetic shape, good quality, fast welding speed, high welding efficiency and the like.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

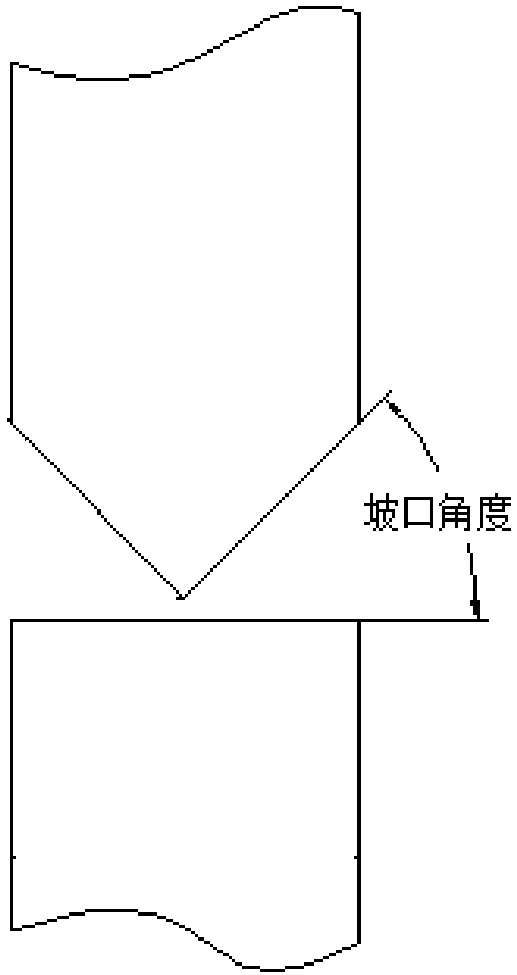

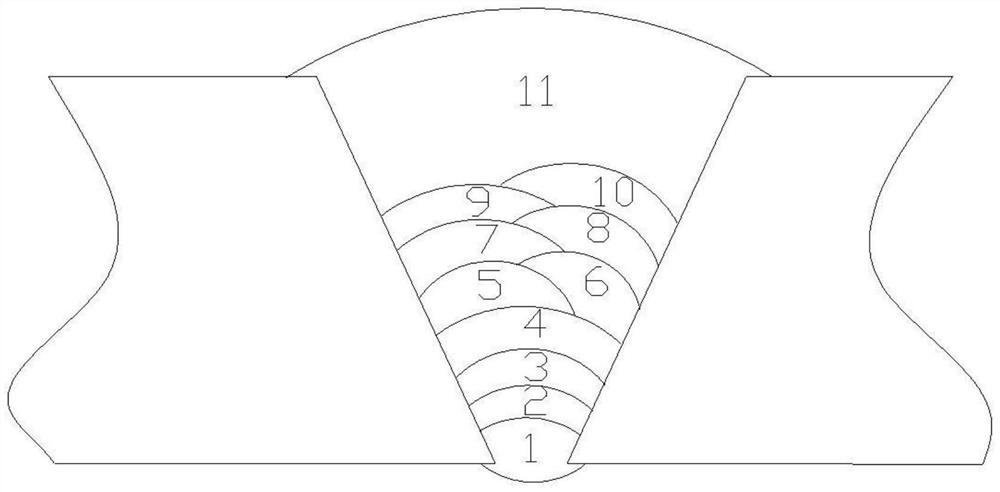

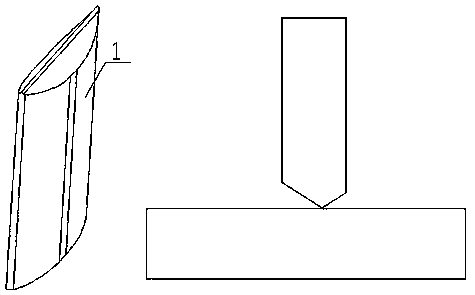

Narrow gap groove of steel containment vessel of nuclear power station and automatic welding method thereof

ActiveCN103394796AReduce fillingReduce welding costsNuclear energy generationArc welding apparatusNuclear powerStructural engineering

The invention discloses a narrow gap groove of a steel containment vessel of a nuclear power station and an automatic welding method of the narrow gap groove of the steel containment vessel of the nuclear power station. The narrow gap groove of the steel containment vessel of the nuclear power station comprises an upper groove, a lower groove and a bottom truncated edge, the top of the lower groove is connected to the bottom of the upper groove, and the bottom truncated edge is arranged at the bottom of the lower groove in a protruding mode. A pulse MAG automatic welding technology is adopted by the automatic welding method of the narrow gap groove. Compared with the prior art, due to the fact that the narrow gap groove is adopted on the steel containment vessel of the nuclear power station, filling volume for welding deposited metal is reduced, and welding cost is reduced; due to the fact that the pulse MAG automatic welding technology is used, multi-layer single-pass welding of the narrow gap groove is achieved, welding efficiency is improved, and the welding period of each welded junction is shortened.

Owner:中广核工程有限公司 +1

Welding process of megaton ethane compressor casing

ActiveCN101890557AShorten welding cycleQuality assuranceWelding/cutting media/materialsSoldering mediaShielding gasWeld seam

The invention relates to a welding technology in the equipment manufacture industry and relates a special welding technology of an MCL (Mean Control Limit) type horizontally-split centrifugal compressor welder casing, in particular to a welding technology of a megaton ethane centrifugal compressor welder casing with forgeable pieces of 16 Mn and Q345R and ZQ230-450 materials. Gas shielded welding is adopted to weld the welder casing with the forgeable pieces of 16 and the Q345R low alloyed steel, and an electrode in a brand of H08Mn2SiS with a diameter shown in the specification, power supply polarity of DCRP (Direct Current Reverse Polarity) is adopted and comprises fore-welding treatment, welding process and post-welding treatment, wherein the welding process comprises the following process parameters: a welding current is 250-280 A, a welding voltage is 28-32 V, a protective mixed gas comprises 80 percent by volume of Ar and 20 percent by volume of CO2, a welding speed is 280-320 mm / min, the dry extension is 20-25 mm, and the gas flow is 15-20 L / min. The invention can solve the problems of welding deformation, layered tearing, low welding efficiency, and the like and ensure the welding seam strength by selecting an MAG (Metal Active Gas) shielded welding material with similar chemical contents and matched strength with a welder casing material.

Owner:SHENYANG BLOWER WORKS GROUP CORP

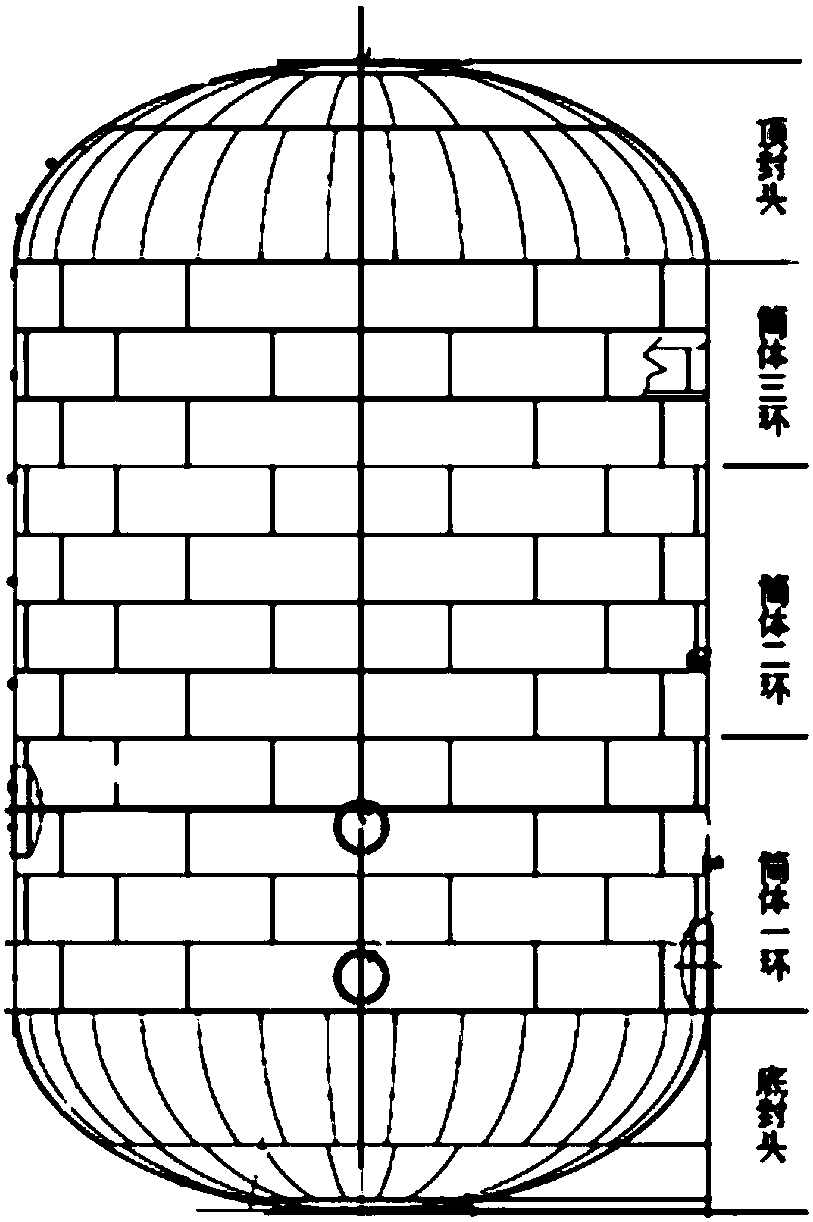

Steel nuclear power containment circular seam submerged arc automatic horizontal welding process

InactiveCN107617803AQuality improvementShorten welding cycleArc welding apparatusNuclear powerEngineering

The invention provides a steel nuclear power containment circular seam submerged arc automatic horizontal welding process. By means of the process, the quality of welded products is stable. The process comprises the steps of (1) determining pre-welding grooves and preparing welding materials; (2) assembling welded parts within the assembly interval range of 0-10 mm and the alignment tolerance range of 0-7 mm; (3) preheating a weld joint between the welded parts at the preheating temperature greater than or equal to 75 DEG C, wherein the preheating width on the two sides of the weld joint is greater than or equal to twice as thick as the welded parts and is greater than or equal to 100 mm; (4) conducting backing welding on the grooves and the truncated edge of the root of the weld joint between the welded parts to form a backing welding pass, conducting multi-layer and multi-pass welding pass filling welding on the grooves on the front side and the back side to form filling welding passes, conducting multi-layer and multi-pass covering welding on the grooves on the front side and the back side to form covering welding passes, controlling the temperature between welding layers to be93-200 DEG C in the welding process and taking measures to control welding deformation in the welding process; and (5) conducting weld joint detection and determining whether the weld joint is qualified.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

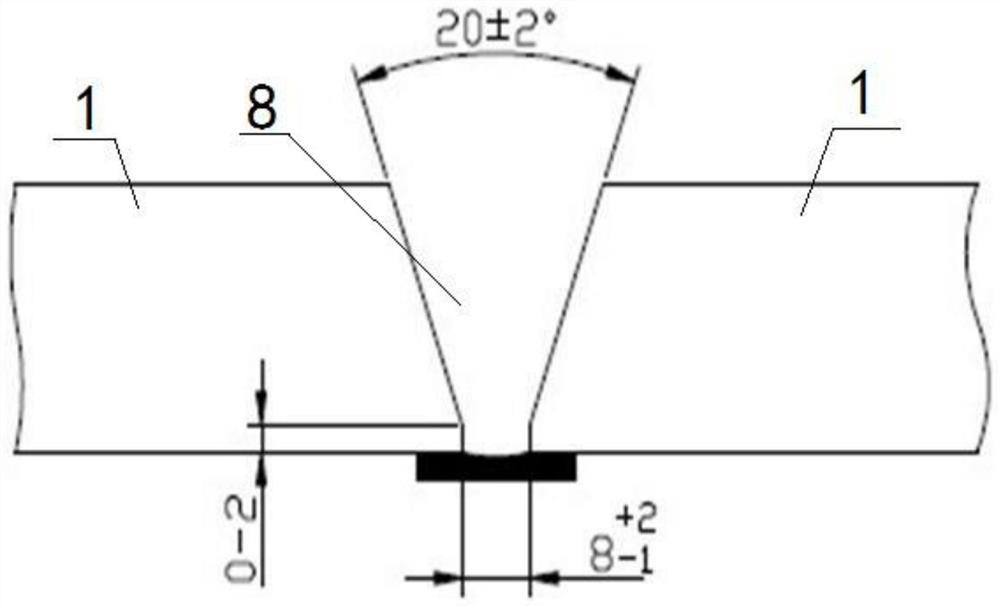

One-time forming welding method for hull structure panel

PendingCN112589233AShorten welding cycleImprove construction efficiencyWelding accessoriesHull structureSteel plates

The invention discloses a one-time forming welding method for a hull structure panel. The one-time forming welding method comprises the following steps that a vertical electro-gas welding machine andwelding accessories are installed; the positions of a front welding wire and a back welding wire of the vertical electro-gas welding machine in the weld groove are adjusted according to the plate thickness of the to-be-welded structure panel, so that the back welding wire keeps a first distance from the root of the weld groove, and a second distance is kept between the front welding wire and the back welding wire; the vertical electro-gas welding machine is started; the front welding wire swings back and forth in the depth direction of the weld joint; the back welding wire does not move; and the front welding wire and the back welding wire are molten simultaneously to form a molten pool, so that the weld joint is formed once. According to the method, single-pass efficient welding can be conducted on the steel plate with the thickness of 38 mm to 84 mm; the weld joint formed at a time can meet related technical index requirements; the welding period of the super-large-thickness high-strength steel plate can be effectively shortened; and the construction efficiency and quality are improved.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

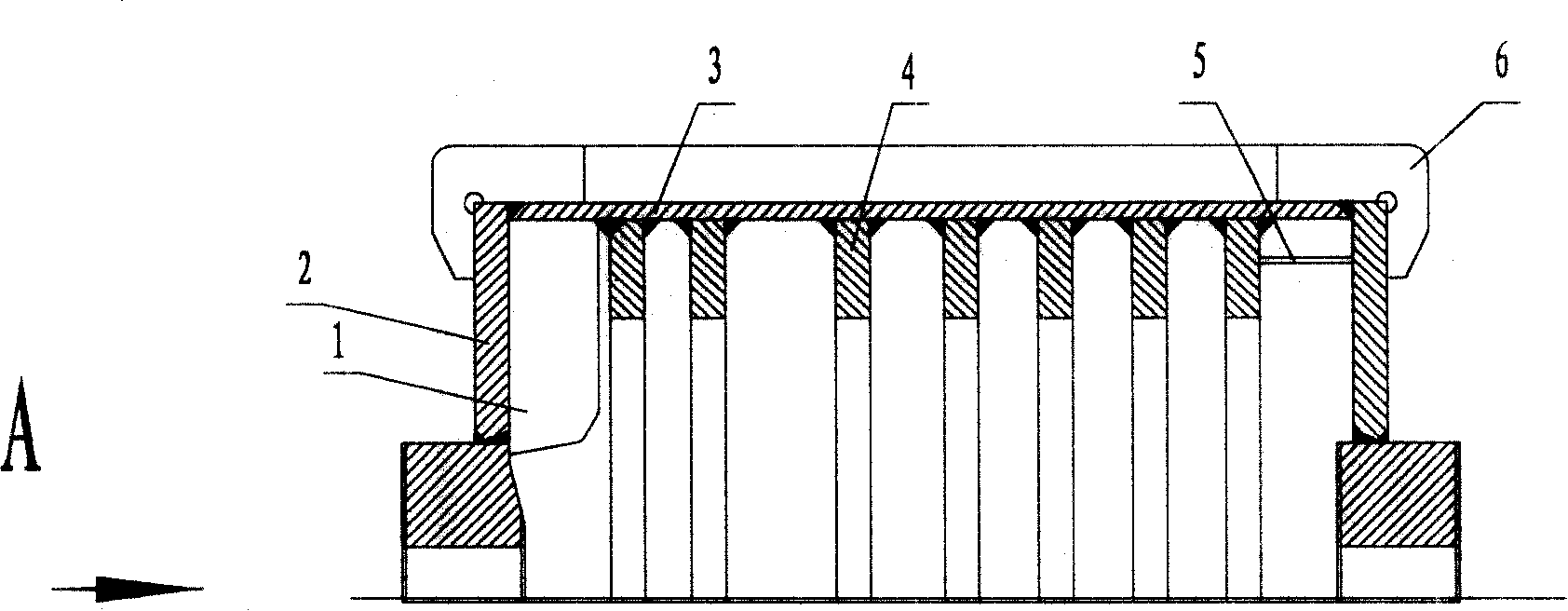

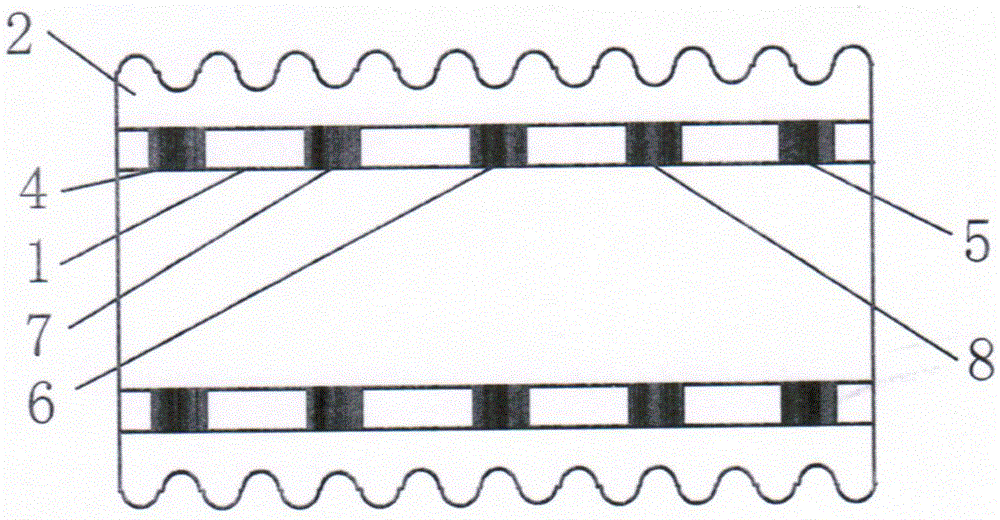

Welding process of dual-face water cooling wall for boiler

The invention relates to the technical field of water cooling wall processing, and particularly discloses a welding process of a dual-face water cooling wall for a boiler. The welding process comprises the following specific steps that round steel and flat steel are subjected to heat treatment; before welding, rust and oil dirt on pipes, the flat steel and the round steel are ground away till themetal luster is exposed, and the joints of all the pipes, the flat steel and the round steel are ground to be level; the width and the side deflection of the flat steel are subjected to finishing according to the outer diameter of the pipes; the pipes, the flat steel and the round steel enter an MPM automatic welding machine to be welded and arranged; welding slag sundries are cleared away, and welding seam defects are ground; and pipe row correction is carried out. According to the welding process of the dual-face water cooling wall, through the MPM automatic welding machine, the flat steel on the vertical faces of the pipes is firstly welded, then the round steel on the horizontal faces of the pipes is welded, no manpower is needed for welding, and the welding automation degree reaches 99%; and meanwhile, the welding period is shortened, the welding quality is improved, pipe deformation is reduced, the cost and work difficulty are reduced, and the market competitiveness of products is improved.

Owner:NANTONG GANGHUA BOILER CO LTD

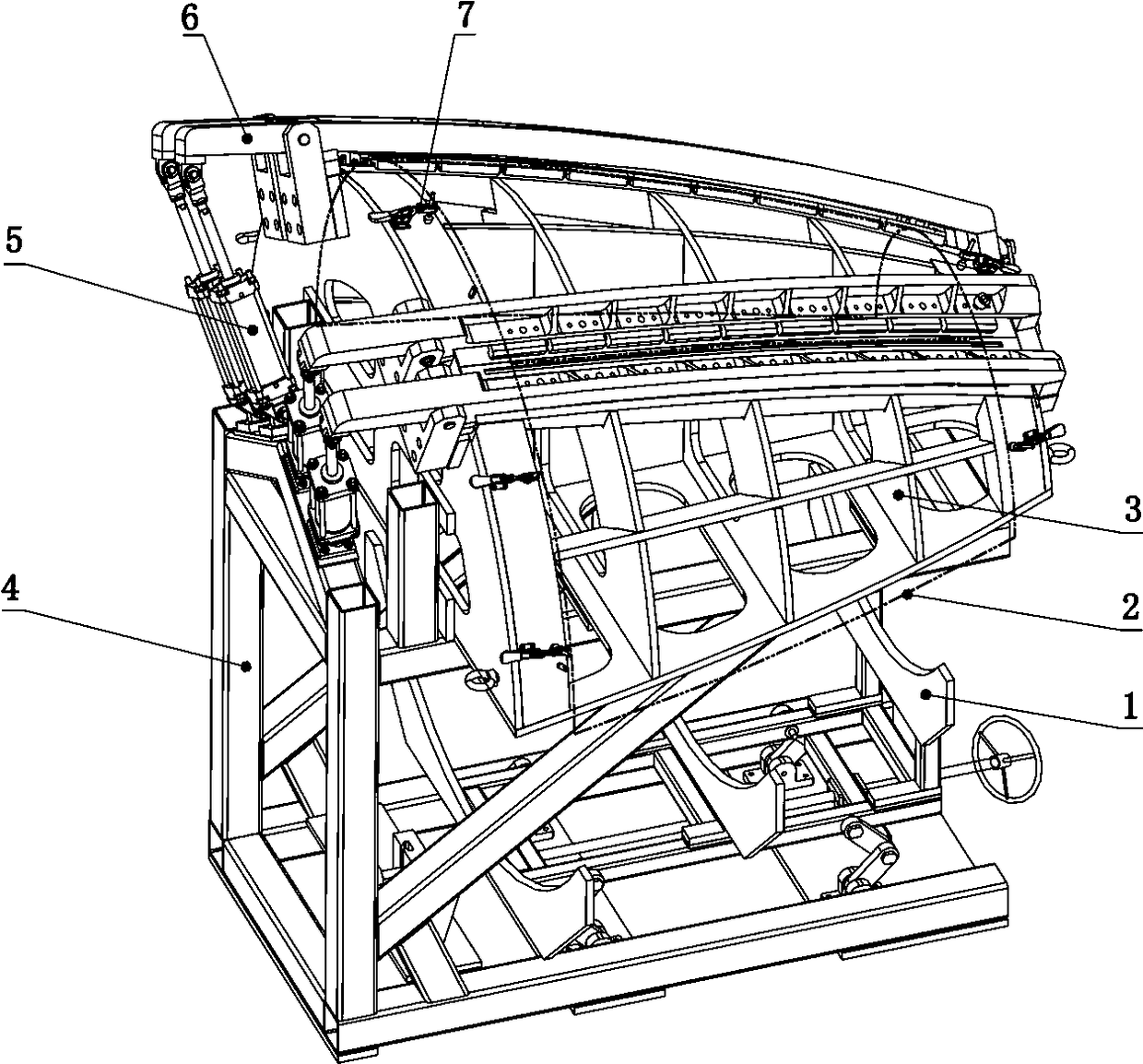

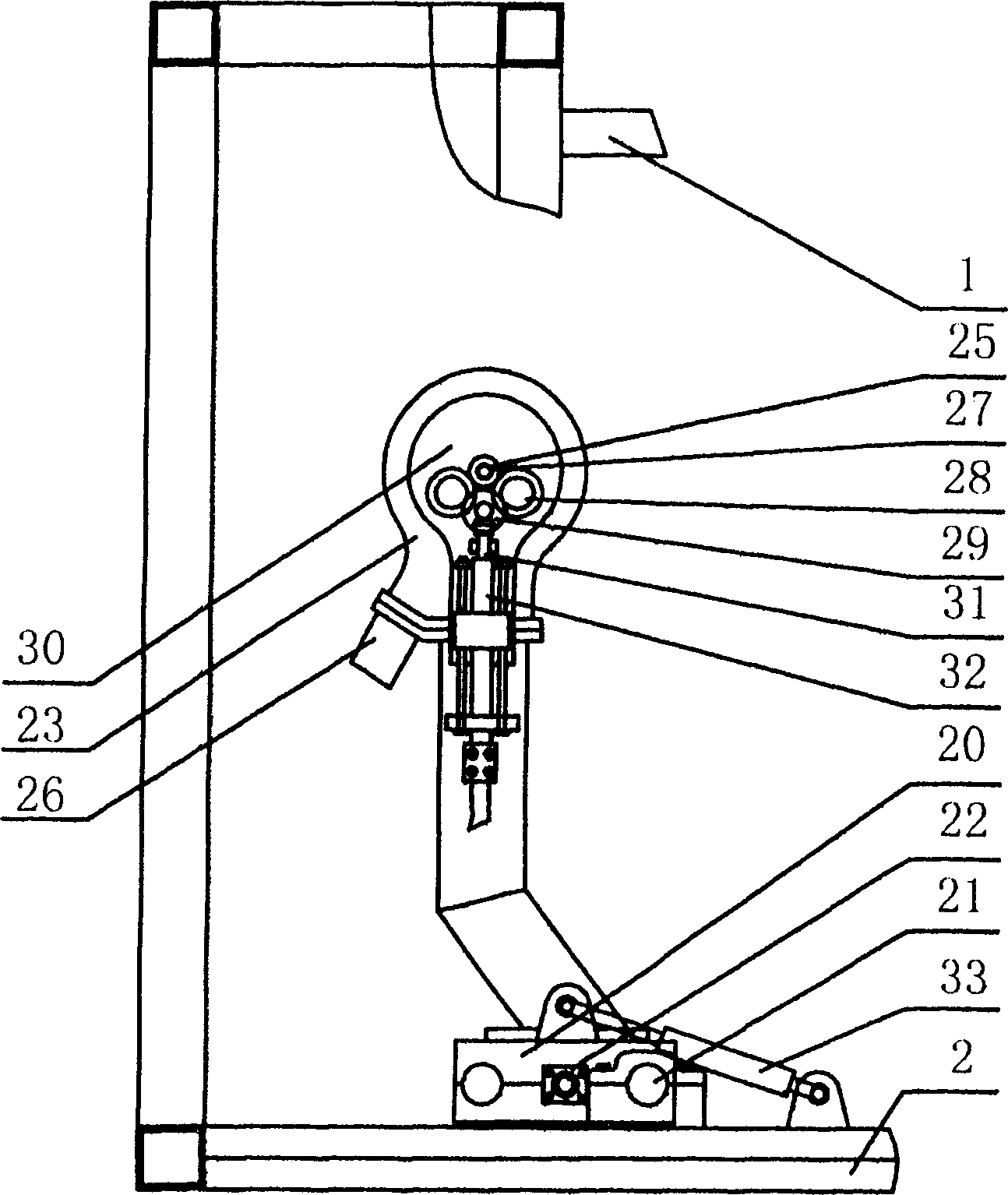

Laser welding tool for engine hood of large aircraft

PendingCN108687452AAutomated mobileAvoid disassemblyWelding/cutting auxillary devicesAuxillary welding devicesLaserWelding process

The invention relates to a laser welding tool for an engine hood of a large aircraft. The laser welding tool comprises a supporting frame, a mold frame, a cylinder, a transverse beam and a mold bracket; the mold frame, the cylinder and the mold bracket are mounted on the supporting frame; the mold bracket is mounted at the bottom of the supporting frame, and the mold frame is arranged above the mold bracket correspondingly; and the cylinder is mounted on the supporting frame, the transverse beam is rotatably mounted on the mold frame through a rotating seat, one end of the transverse beam is connected with the cylinder to form a lever structure with the rotating seat as the pivot, and the other end of the transverse beam is detachably connected with the mold frame. The laser welding tool is simple in construction, reasonable in structure and convenient to use and is used for clamping and disassembling of parts in the laser welding process of the engine hood of the large aircraft, the laser welding tool is high precision, accurate in positioning and low in damage to the parts, and the transverse beam does not need to be disassembled repeatedly, the time is reduced, and the processing efficiency is high.

Owner:CHENGDU HONGXIA TECH CO LTD

Steel Surface Texturization Assisted Friction Stir Welding Method for Aluminum-Steel Dissimilar Material Lap Joints

InactiveCN103894724BImprove mechanical propertiesReliable strengthWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingSheet steel

The invention relates to a steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection. A fine convex-concave structure is obtained on the surface of a lap connection position of a steel plate through a roughing method, heat is generated through friction and plastic deformation of a stirring head and an aluminum plate, softened aluminum alloy is combined with the convex-concave structure of the surface of the roughed steel plate, the effective combination area is increased, a brittle intermetallic compound is suppressed from being formed between aluminum and steel, and effective and high-quality lap connection is formed between the steel plate and the aluminum plate. An aluminum steel dissimilar connector with beautiful formed welding joints, a good mechanical property and reliable strength is finally obtained, the welding operation process is simple, the welding cycle is effectively shortened, and automation is achieved easily.

Owner:HARBIN INST OF TECH

Hot-melting and cold-pressing welding machine and welding method thereof

The invention relates to a hot-melting and cold-pressing welding machine. The hot-melting and cold-pressing welding machine includes a frame, wherein the frame is provided with three layers of bedplates; two gas storage tanks are mounted on the bedplate on the first layer; the bedplate on the second layer is located above the bedplate on the first layer; a workpiece positioning mechanism, a guide rail carrying the workpiece positioning mechanism, and a station driving cylinder driving the workpiece positioning mechanism to perform translational motions are mounted on the bedplate on the second layer; the bedplate on the third layer is located above the bedplate on the second layer, and a lifting type hot-melting mechanism and a lifting type cold-pressing mechanism are arranged in sequence on the bedplate on the third layer in the translation direction of the workpiece positioning mechanism. A pressure head of the original hot-riveting welding machine has the heating and pressing functions, so that heating and pressing can be carried out at the same time and completed through one step; in the hot-melting welding machine, heating and pressing are updated into two different procedures, so as to achieve great improvements in various aspects; the hot-melting and cold-pressing welding machine has a high heating speed, so that the product welding cycle is shortened by 50 percent, which completely meets the production requirements; the welding effect is good, the phenomena of ineffective or misplaced welding seldom occur, and the product rejection rate is greatly reduced; faults can be easily detected, so that the maintenance is convenient.

Owner:重庆平伟科技(集团)有限公司

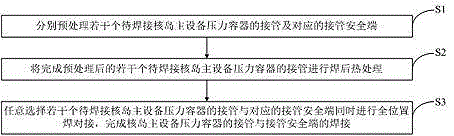

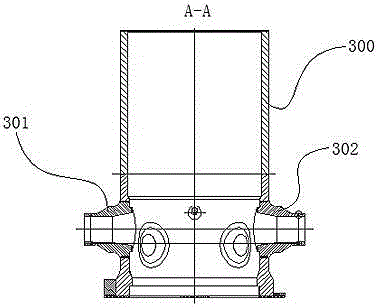

Nickel-base welding wire dissimilar metal cold wire TIG all-position welding method

InactiveCN105195869AGuarantee welding qualityShorten welding cycleArc welding apparatusWelding/soldering/cutting articlesSlagEngineering

The invention discloses a nickel-base welding wire dissimilar metal cold wire TIG all-position welding method used in a welding process of a connection pipe of a main device pressure container in a nuclear island and a connection pipe safety end, and comprising the steps: pre-processing a plurality of to-be-welded connection pipes of the main device pressure container in the nuclear island and the corresponding connection pipe safety ends; and randomly selecting the plurality of to-be-welded connection pipes of the main device pressure container in the nuclear island and the corresponding connection pipe safety ends for performing all-position welding butting joint simultaneously so as to finish the welding of the connection pipes of the main device pressure container in the nuclear island and the corresponding connection pipe safety ends. According to the method disclosed by the invention, the welding period is short, and welding defects of air holes, slag inclusion, non-fusing and the like can be effectively avoided simultaneously.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN100493795CRealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

Permanent locating segment assembling and welding method for rack and leg of drilling platform

InactiveCN104999187AReduce labor intensityReduce welding stressWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a permanent locating segment assembling and and welding method for a rack and a leg of a drilling platform. The method comprises the following steps: at first, an angular heating sheet is utilized to preheat both a leg and a rack; then assembling and welding permanent locating segments in sequence; after finish of permanent locating segment welding, carrying out after-heating; and after completion of after-heating, conducting pre-heating, welding and after-heating on product seams. The rack is inserted into the leg in a penetrating manner, and the connecting part of the leg and the rack is subjected to welding combination through permanent locating segment welding points. The method has the positive results that firstly, the welding stress and the welding deformation are reduced, and the welding quality and precision are improved; secondly, the welding efficiency is improved and the welding period is shortened; and thirdly, the labor intensity of workers is reduced. The method is suitable for rack and leg welding.

Owner:BOHAI SHIP HEAVY IND CO LTD

Method for improving thick plate vertical butt welding efficiency

PendingCN114309891AShorten welding cycleImprove welding efficiencyElectrode supporting devicesWelding accessoriesButt weldingThick plate

The invention discloses a method for improving the welding efficiency of vertical butt welding of thick plates. The method comprises the following steps of pretreatment before welding; the CO2 gas shielded welding machine is started, backing welding and filling welding are conducted on a welding seam between the two to-be-welded structural panels, and when the distance between the surface of the welding seam of the filling layer and the front faces of the to-be-welded structural panels is 10-15 mm, welding work of CO2 gas shielded welding is ended; an electro-gas welding machine is installed and adjusted; and the electro-gas welding machine is started, cosmetic welding is conducted on the unwelded groove between the two to-be-welded structural panels, and in the welding process, a welding wire swings in a reciprocating mode in the width direction of the unwelded groove, and meanwhile, the welding wire automatically walks upwards according to molten pool forming till welding is completed. According to the method, steel plates with the thickness of 35 mm-50 mm can be efficiently welded, formed welding seams can meet relevant technical index requirements, and the thick plate vertical butt joint welding efficiency can be effectively improved.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Electro-gas welding method for 42-50 mm high-strength steel plate for ship body

PendingCN114101867ASave electricityShorten welding cycleWelding accessoriesShielding gasStructural engineering

The invention relates to the field of ship manufacturing, and discloses an electro-gas welding method for a 42-50mm high-strength steel plate for a ship body, which comprises the following steps of: arranging a single-sided V-shaped groove at a welding position; the back of the weld joint is welded and fixed with a steel plate; a gasket is installed on the back face of the welding groove, and the gasket is tightly attached to the steel plate through a wooden wedge; a welding guide rail and a welding trolley are installed on the front face of the welding groove in the direction parallel to the welding groove; the angle of a welding gun is adjusted, the angle between the welding gun and the surface of the workpiece to be welded is 10-15 degrees, the flow of protective gas is 35 L / min, the welding current is 450-470 A, the welding voltage is 40-44 V, the welding speed is 4 + / -1 cm / min, and the front face and the back face of a welding seam are formed at a time. On the premise that preheating is not conducted before welding, electro-gas welding of the 42-50 mm high-strength steel plate for the ship body can be met, the purpose of outdoor efficient welding construction is achieved, the welding period is shortened, the welding seam quality is improved, and the post-welding grinding time is shortened.

Owner:CHINA SHIPPING IND JIANGSU

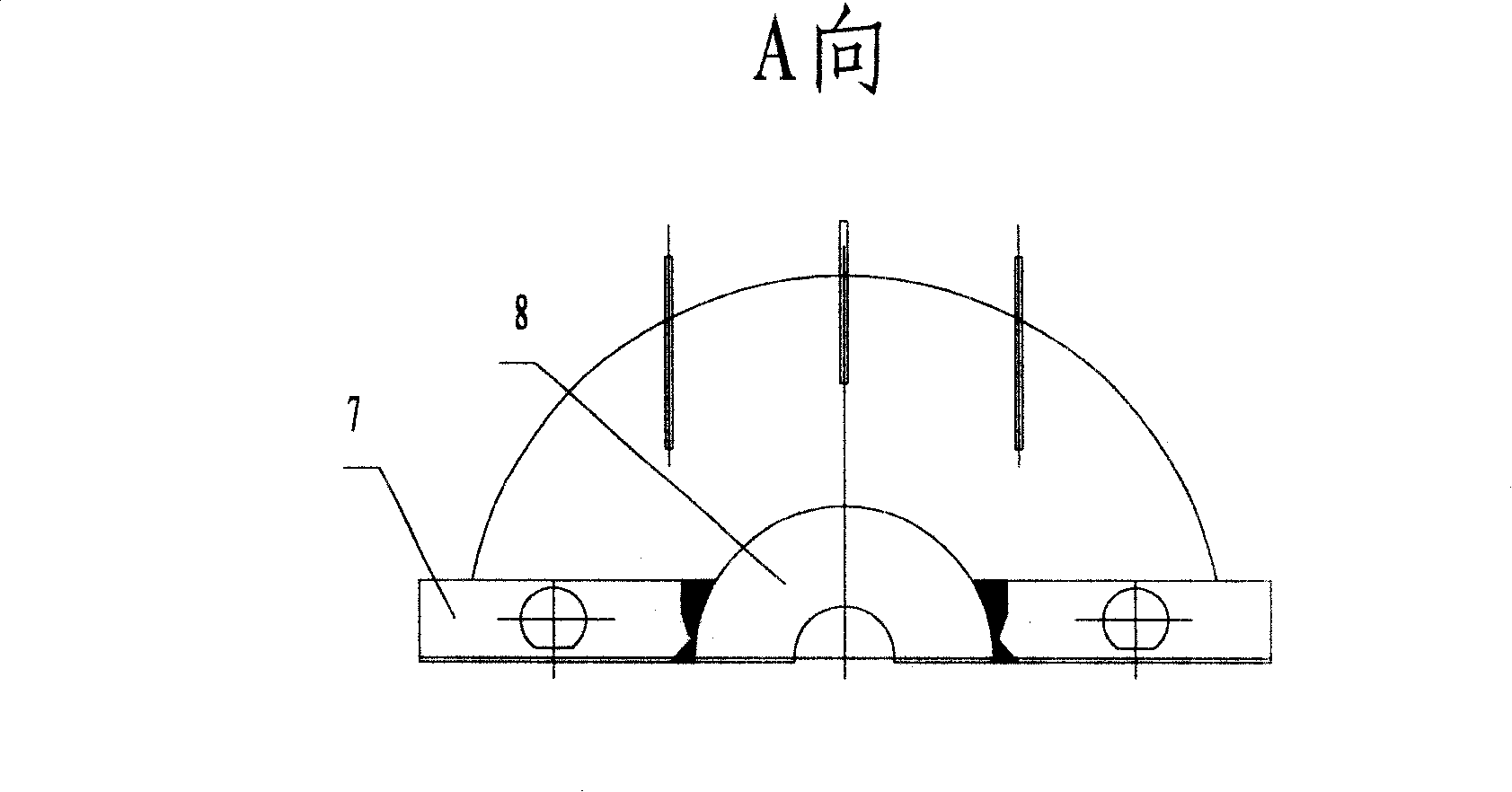

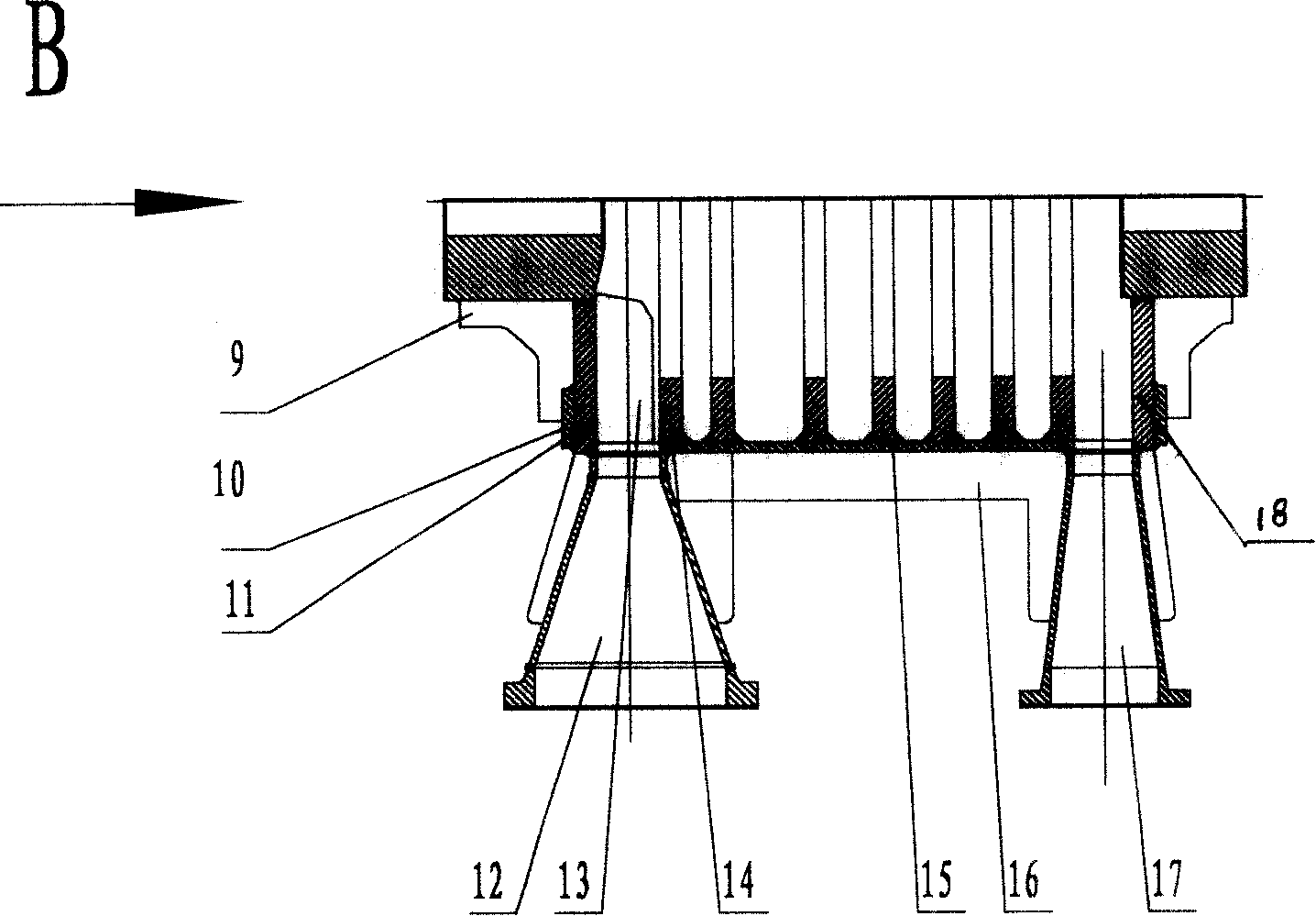

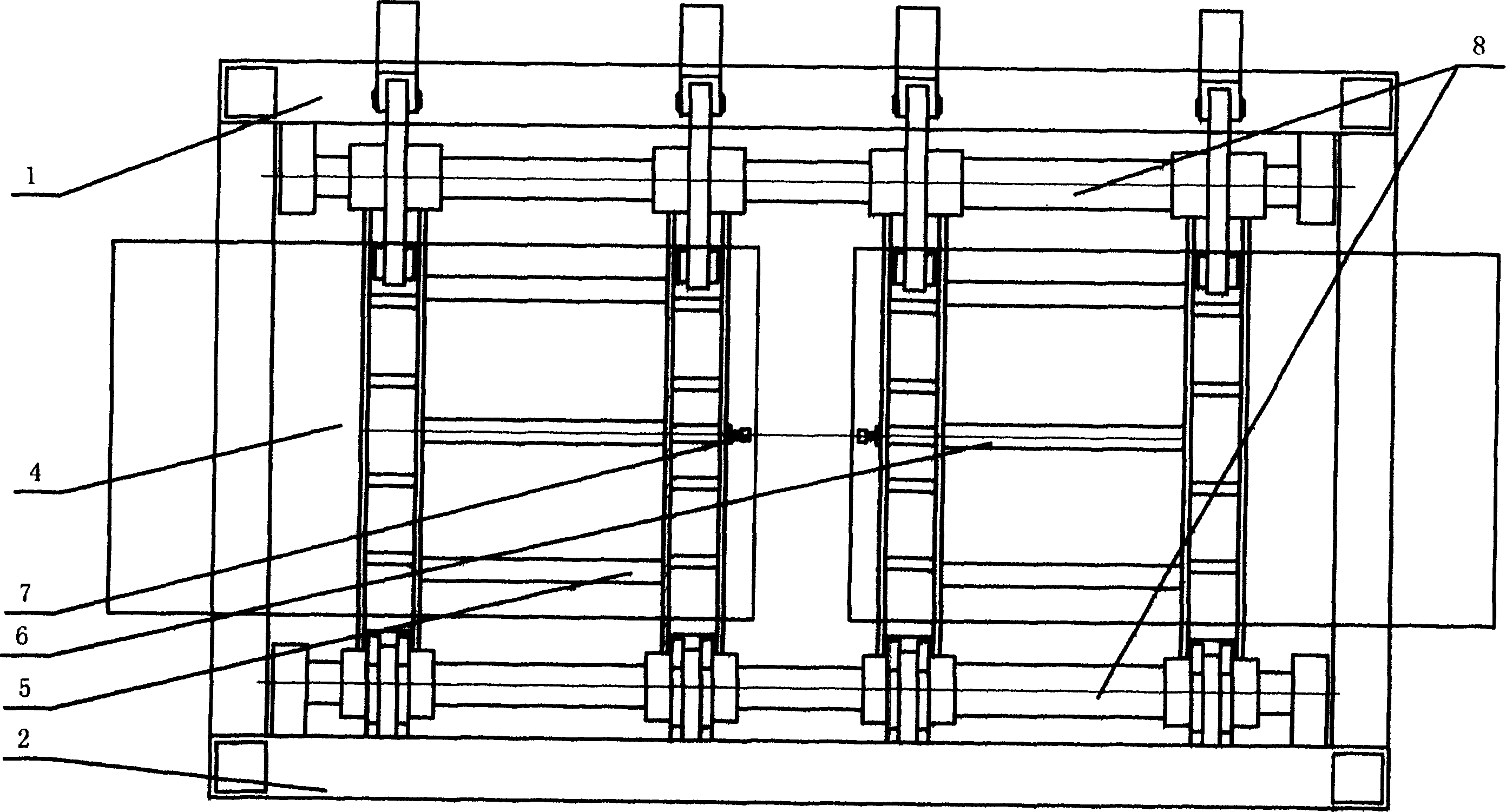

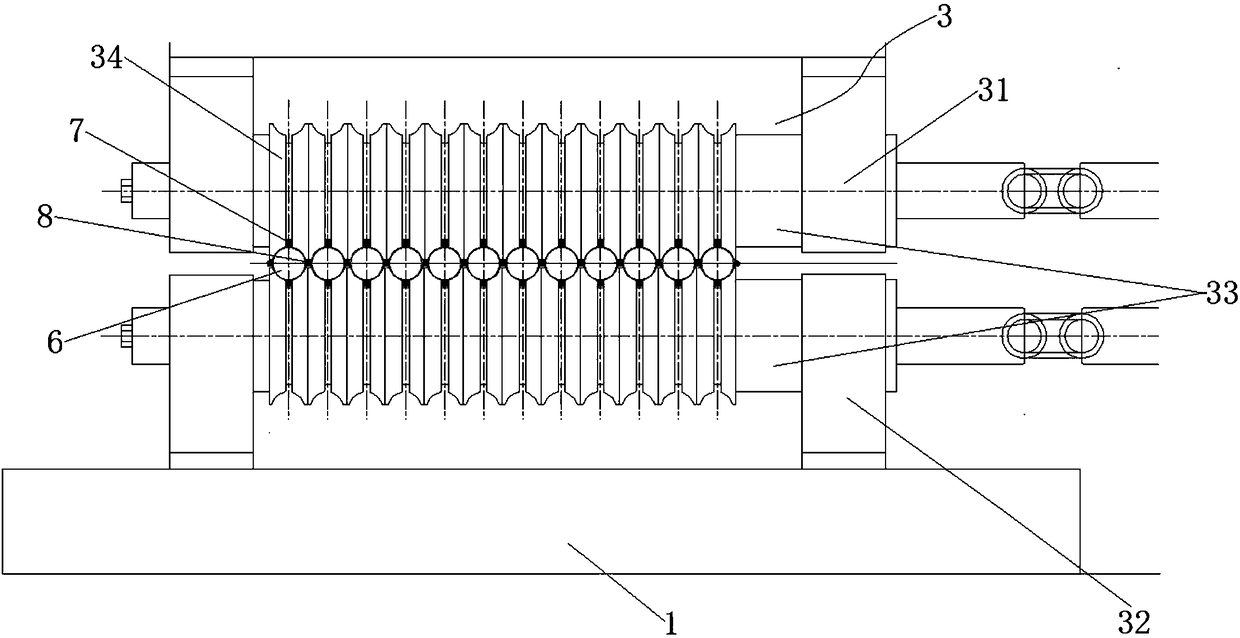

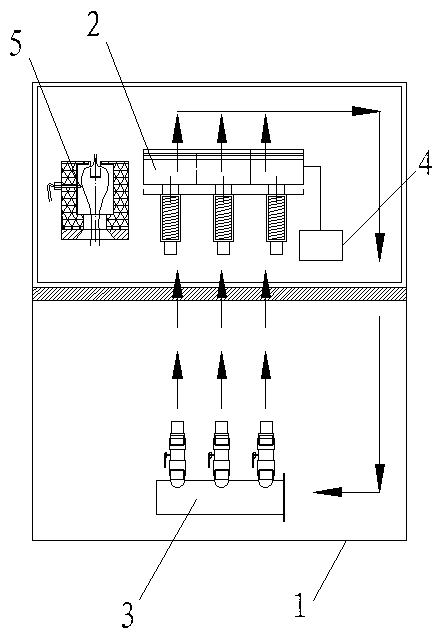

Automatic welding device for double-sided water-cooled wall welding

ActiveCN108247182ACompact structureReasonable arrangementTubular articlesWelding accessoriesElectrical controlEngineering

The invention relates to the technical field of welding equipment, and particularly discloses an automatic welding device for double-sided water-cooled wall welding. The automatic welding device comprises a machine frame, lifting mechanisms, rolling wheel conveying mechanisms, welding mechanisms and an electric control mechanism; and the lifting mechanisms are installed on the inner side above themachine frame, the rolling wheel conveying mechanisms are arranged on the lifting mechanisms, the welding mechanisms are arranged on conveying routes of the rolling wheel conveying mechanisms, and the lifting mechanisms, the rolling wheel conveying mechanisms and the welding mechanisms are controlled by the electrical control mechanism. The automatic welding device has the advantages of being compact in structure and reasonable in arrangement; the welding device is mainly used for welding double-sided water cooling walls in a boiler; the conveying mechanisms of a welding machine is provided with grooving rolling wheels so as to weld flat steels on vertical surfaces of pipes directly, welding do not need to be carried out manually, the automation degree reaches 99%, meanwhile, the weldingperiod is shortened, and the welding quality is improved, the deformation of the pipe is reduced, cost and working difficulty are reduced, and the market competitiveness of a product is improved.

Owner:NANTONG GANGHUA BOILER CO LTD

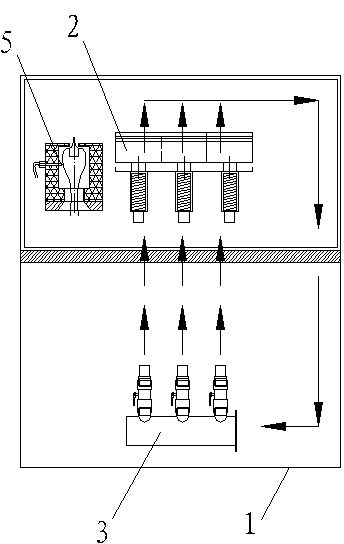

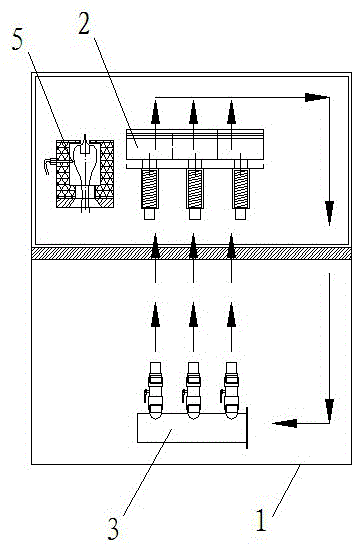

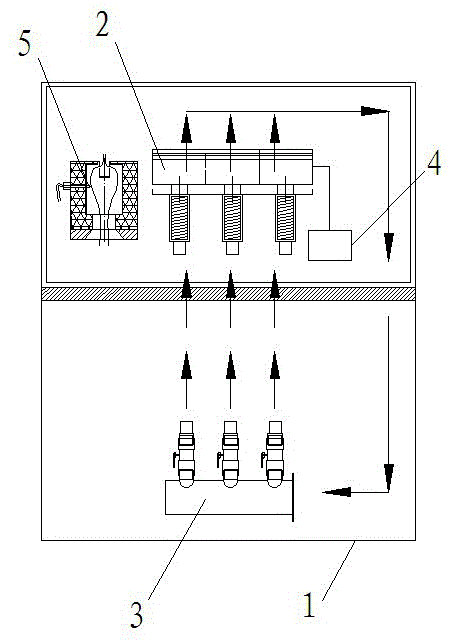

Spot welder hot air circulating system

ActiveCN103128466AImprove thermal efficiencySmall fluctuations in soldering temperatureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInhaled air

The invention discloses a spot welder hot air circulating system which comprises a welding box, a heating device and an air blower. The heating device and the air blower are arranged in the welding box, the heating device is arranged on an air outlet of the air blower, and an air inlet of the air blower is used for inhaling air inside the welding box. The spot welder hot air circulating system has the advantages of being high in heat efficiency, energy-saving and environment-friendly, and small in welding temperature fluctuation at the same time, effectively guaranteeing quality and stability of products, shortening welding cycle, and improving welding reliability.

Owner:KUSN WANSHENG ELECTRONICS

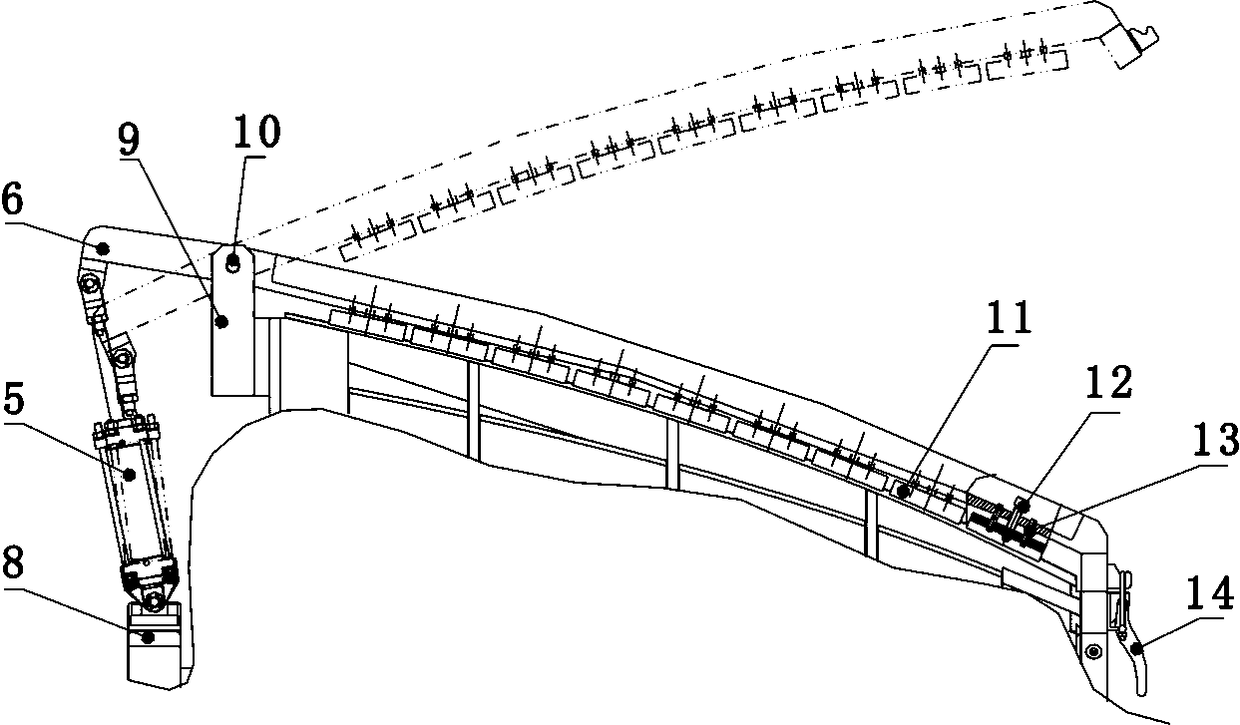

Assembling method for inner arc frame and outer arc frame of slab continuous casting fan-shaped section

ActiveCN112157365ASoldering is easyShorten welding cycleWelding apparatusStructural engineeringMechanical engineering

The invention discloses an assembling method for an inner arc frame and an outer arc frame of a slab continuous casting fan-shaped section. The assembling method comprises the steps that 1, a robot isadopted for batch surfacing of seat blocks; 2, a plurality of second marks are arranged on a welding platform in the length direction of a main board according to the positions of limiting parts andthe actual welding positions of the seat blocks and the main board, a first positioning component used for positioning the seat blocks is fixed to each second mark, and a first cushion block used forsupporting the main board to form an interval space between the main board and the welding platform is fixed on the welding platform; 3, the main board is placed on the first cushion block, the main board is adjusted to enable the wide edge of the main board to abut against a limiting component, and after the main board abuts against the first positioning components and the seat blocks, the main board and the seat blocks are welded; and 4, the main board is placed on second positioning components, a head frame is placed on a second cushion block, and the head frame and the main board are welded. The method has the advantages that the welding assembly technological process is simplified, the assembly efficiency is improved, and the pre-welding assembly precision is improved.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Water turbine volute welding method

ActiveCN105537787BImprove welding qualityImprove the one-time pass rate of weldingWelding apparatusWater turbineEngineering

The invention discloses a water turbine volute welding method. The water turbine volute welding method comprises the steps that firstly, positioning sections of a water turbine volute are adjusted and positioned, and positioned welding is conducted on circular seams of volute branch pipe sections; secondly, one side or two sides of each positioning section are welded to the circular seam of the volute branch pipe section adjacent to the positioning section, then the circular seam of the volute branch pipe section adjacent to the positioning section and the circular seam of the next volute branch pipe section are welded, and afterwards the upper butterfly edge and the lower butterfly edge of the positioning section are welded, or the circular seam of the next volute branch pipe section and the circular seam of the volute branch pipe section after the next volute branch pipe section are welded at the same time; thirdly, the upper butterfly edge and the lower butterfly edge of the next volute branch pipe section are welded, or the circular seam of the volute branch pipe section after the next volute branch pipe section and the circular seam of another volute branch pipe section are welded at the same time, and the other volute branch pipe sections are welded in the same way. By the adoption of the water turbine volute welding method, the welding ventilation condition is effectively guaranteed, the welding construction environment is remarkably improved, and the welding quality of the water turbine volute is stabilized.

Owner:CHINA THREE GORGES CORPORATION +1

Heat melting butt joint welder for plastic pipe

ActiveCN1272161CMonitor and adjust temperature in real timeReal-time monitoring and adjustment of welding pressureThermoplasticBlade plate

The present invention relates to heat melting butt jointing welder for plastic pipe and belongs to the field of plastic pipe welding apparatus making technology. The heat melting butt jointing welder includes mainly frame comprising upper frame with controller, lower frame, etc.; clamping mechanism comprising fixed clamps, movable clamps, etc.; cutting mechanism comprising sliding track with turning cylinder, sliding seat with translation cylinder, cutting motor with reducing box, cutting board with lathe tool, etc.; and heating mechanism comprising upper sliding seat, lower sliding seat, heating board sliding body, heating board holder with heating board, etc. The present invention has reasonable design and compact integral structure, and may be used in completing clamping, cutting, heating and butt jointing of different kinds of plastic pipes, especially plastic pipes of caliber as great as 800-2000 mm.

Owner:ZHEJIANG ZHONGYUAN FENGYE PIPES +2

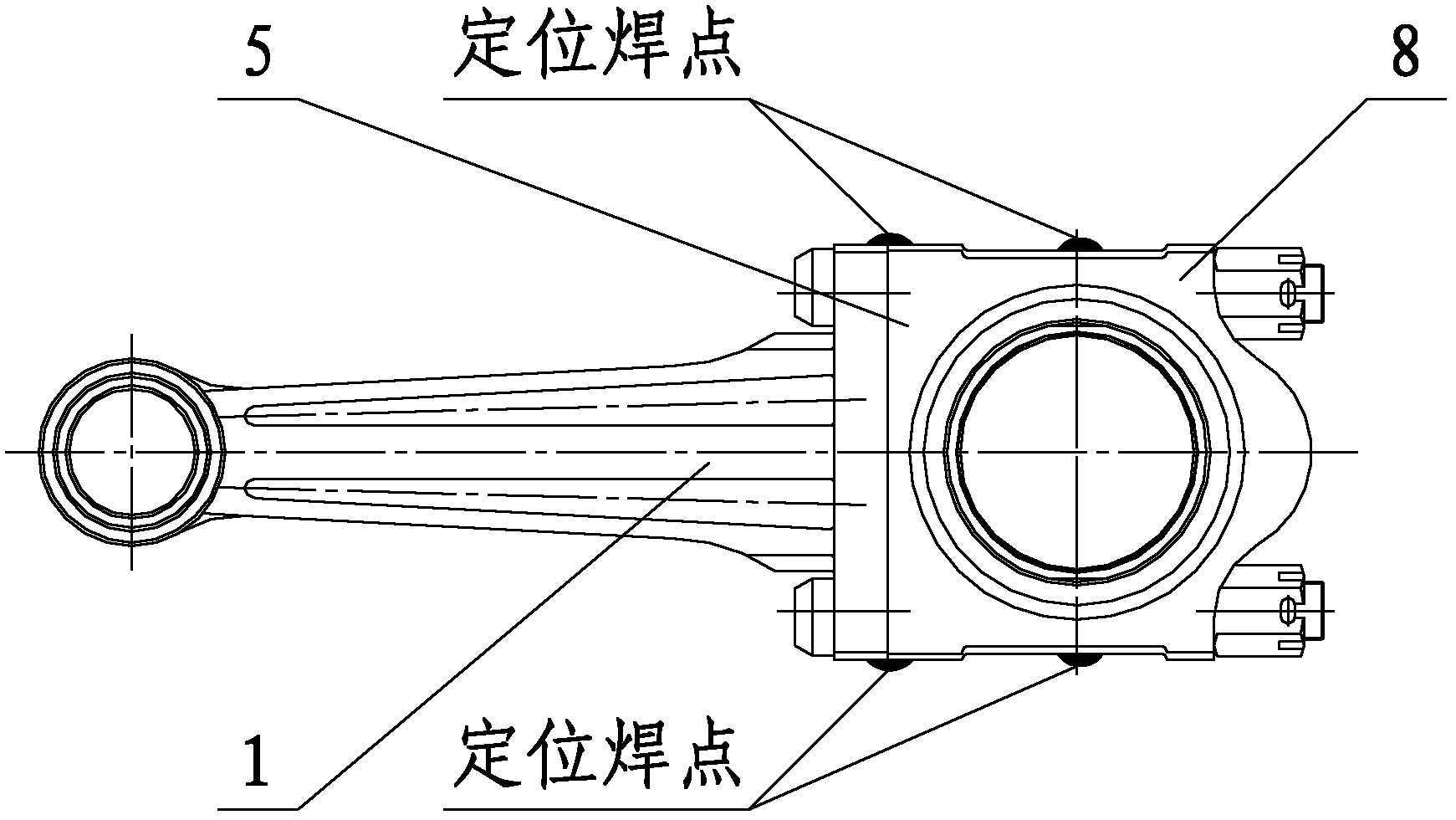

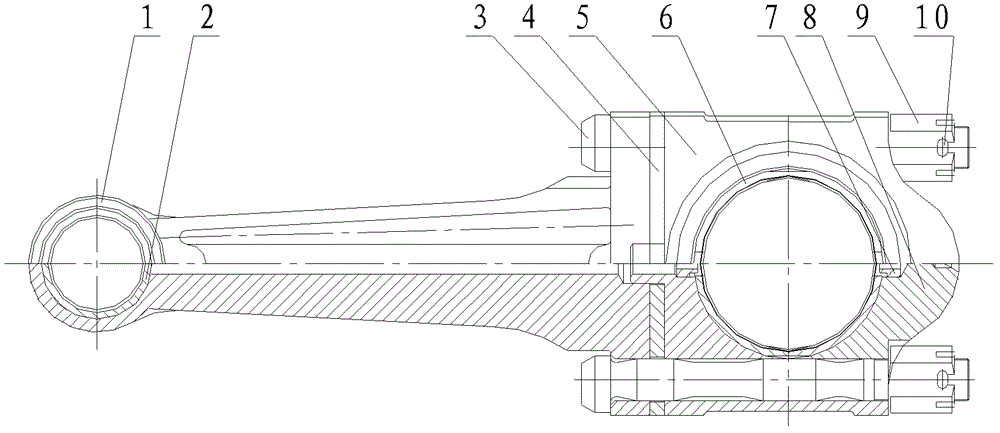

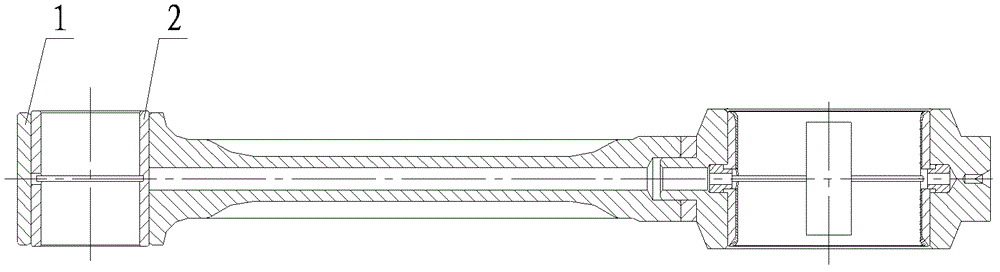

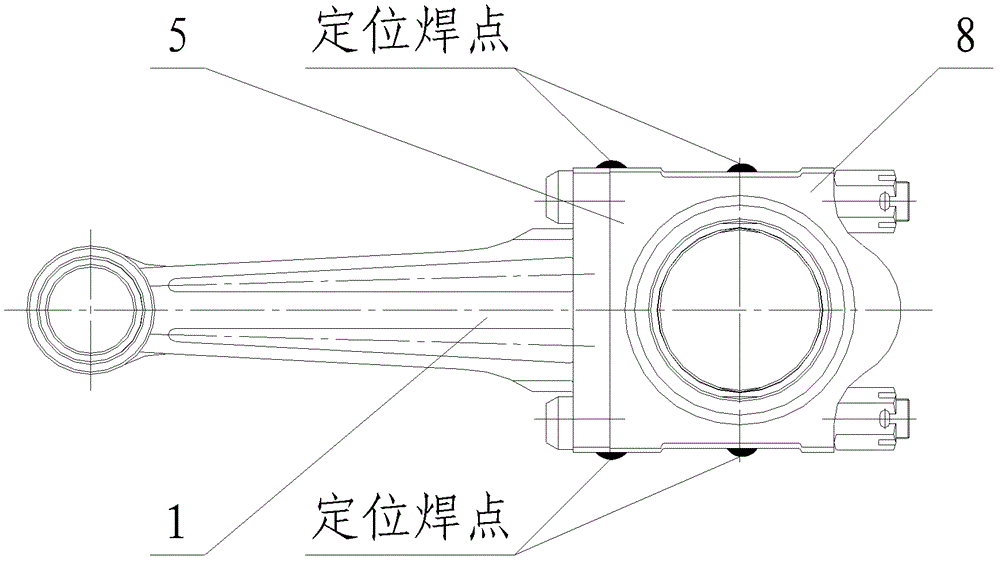

Fixed-position welding process for casting titanium alloy connecting rod

ActiveCN103143821AStable deliveryShorten welding cycleConnecting rod bearingsBearing assemblyPower flowShielding gas

The invention relates to a fixed-position welding technique for use in the device manufacturing industry, which relates to a professional welding technique for a connecting rod in a reciprocating compressor, in particular to a fixed-position welding process for casting a titanium alloy connecting rod by using ZTC4. The fixed-position welding technique comprises the following steps of: casting a titanium alloy connecting rod by using ZTC4 in manual tungsten electrode argon arc welding, wherein a welding wire is a TA1 pure titanium welding wire, the diameter of the welding wire is phi2.4 millimeters, and the polarity of a power supply belongs to direct-current positive connection; and processing bolt holes in both sides of the connecting rod, and then removing a fixed-position welding spot by processing, wherein process parameters of a welding process are that the welding current is 170-180A; the welding voltage is 12-14V; the protective gas is 99.9% Ar gas; the diameter of a tungsten electrode is 2.4 millimeters; and the gas flow is 10-15L / min. According to the fixed-position welding technique, fixed-position welding is adopted for ensuring the accuracy requirement of connecting rod processing, so that the processing technical requirements, processing accuracy requirement and processing quality requirement of the titanium alloy connecting rod are met, welding is qualified at one time, the manufacturing quality of the reciprocating compressor is enhanced, the production efficiency is increased, and the manufacturing cost of the titanium alloy connecting rod is reduced.

Owner:沈阳鼓风机集团往复机有限公司

Thick section and narrow gap T-shaped welding method

ActiveCN111408825ASimplify welding trajectoryReduce cleanupElectrode supporting devicesElectrode accessoriesOne passThick plate

The invention discloses a thick section and narrow gap T-shaped welding method, which relates to the technical field of production and manufacture of thick plate and ultra-thick plate welding in the hydropower industry. According to the invention, the butt groove between a special-shaped structure thick plate and a flat thick plate is changed first, that is, the range of 60mm above the welding endof the special-shaped thick plate is processed into a rectangular structure, and the arc weld bead is changed into a straight weld bead, which can simplify the robot welding trajectory and reduce theprogramming difficulty; and the welding surface of the rectangular structure is set as an oblique welding surface with a certain slope, the welding groove between the special-shaped thick plate and the flat thick plate is designed into an I-shaped narrow gap groove structure, and the original multilayer and multi-pass welding is changed into one layer and one pass; and therefore, the welding process is simplified, the probability of non-fusion among the weld beads and the cleaning times of the weld beads are reduced, and the welding efficiency is improved.

Owner:DONGFANG ELECTRIC MACHINERY

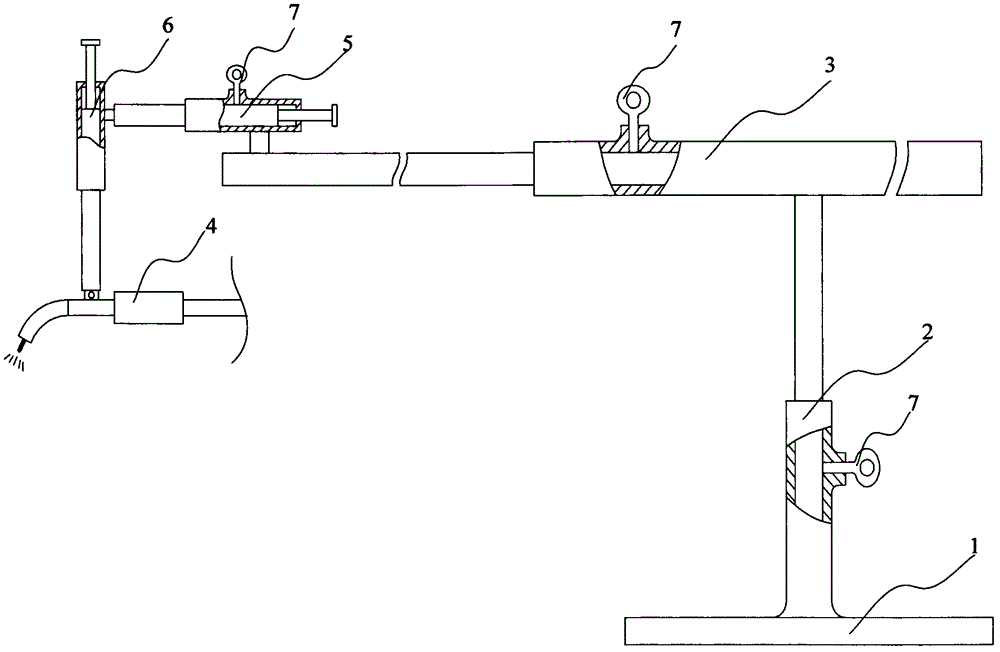

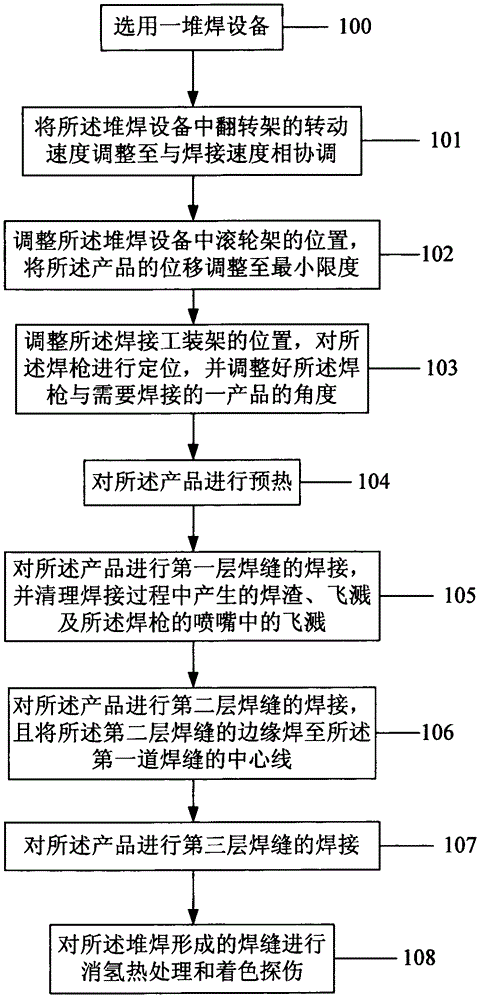

Welding tool frame for carbon dioxide gas shielded welding and its welding method

ActiveCN102581452BReduce labor intensityReduce radiationElectrode supporting devicesDye penetrant inspectionPetroleum engineering

The invention discloses a welding tooling support for carbon dioxide arc welding. The welding tooling support comprises a base and an adjusting device for adjusting a welding torch, wherein one end of the adjusting device is fixed on the base, and the other end of the adjusting device is connected with the welding torch. The invention further discloses a welding method in which the welding tooling support is utilized. The welding method comprises step 1 adjusting the position of the welding tooling support, positioning the welding torch, and adjusting an angle formed by the welding torch and a product to be welded; step 2 preheating the product; step 3 subjecting the product to surfacing; and step 4 subjecting welding seams formed by surfacing to hydrogen relief heat treatment and dye penetrant inspection. The welding tooling support for carbon dioxide arc welding reduces labor intensity of welders and improves welding quality and production efficiency. According to the welding method, short time is required, continuous welding is achieved, time of replacing welding electrodes is decreased, and welding cycle is shortened.

Owner:SHANGHAI BOILER WORKS

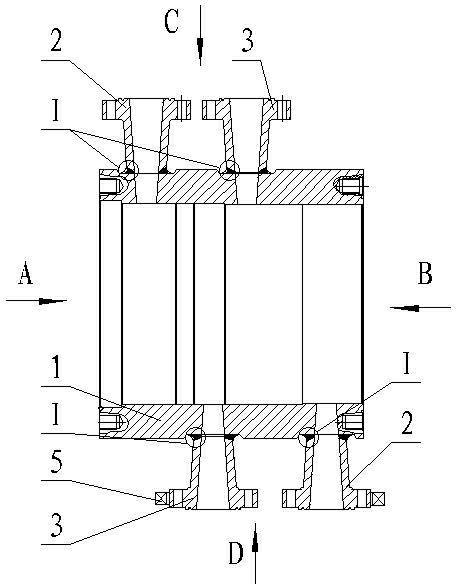

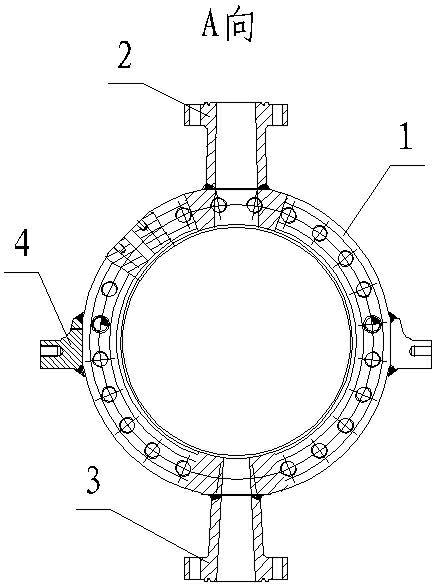

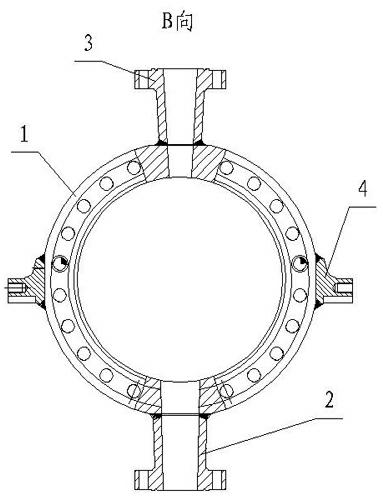

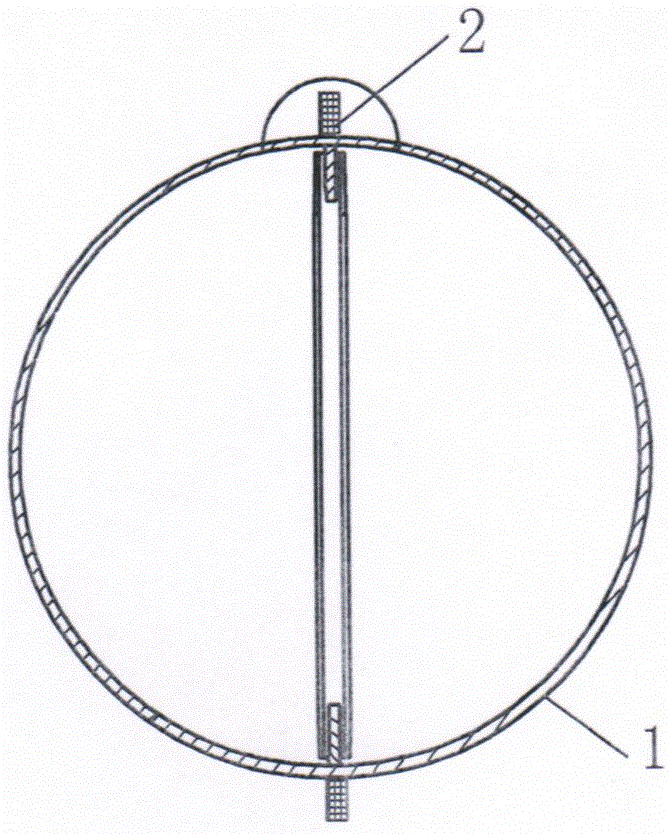

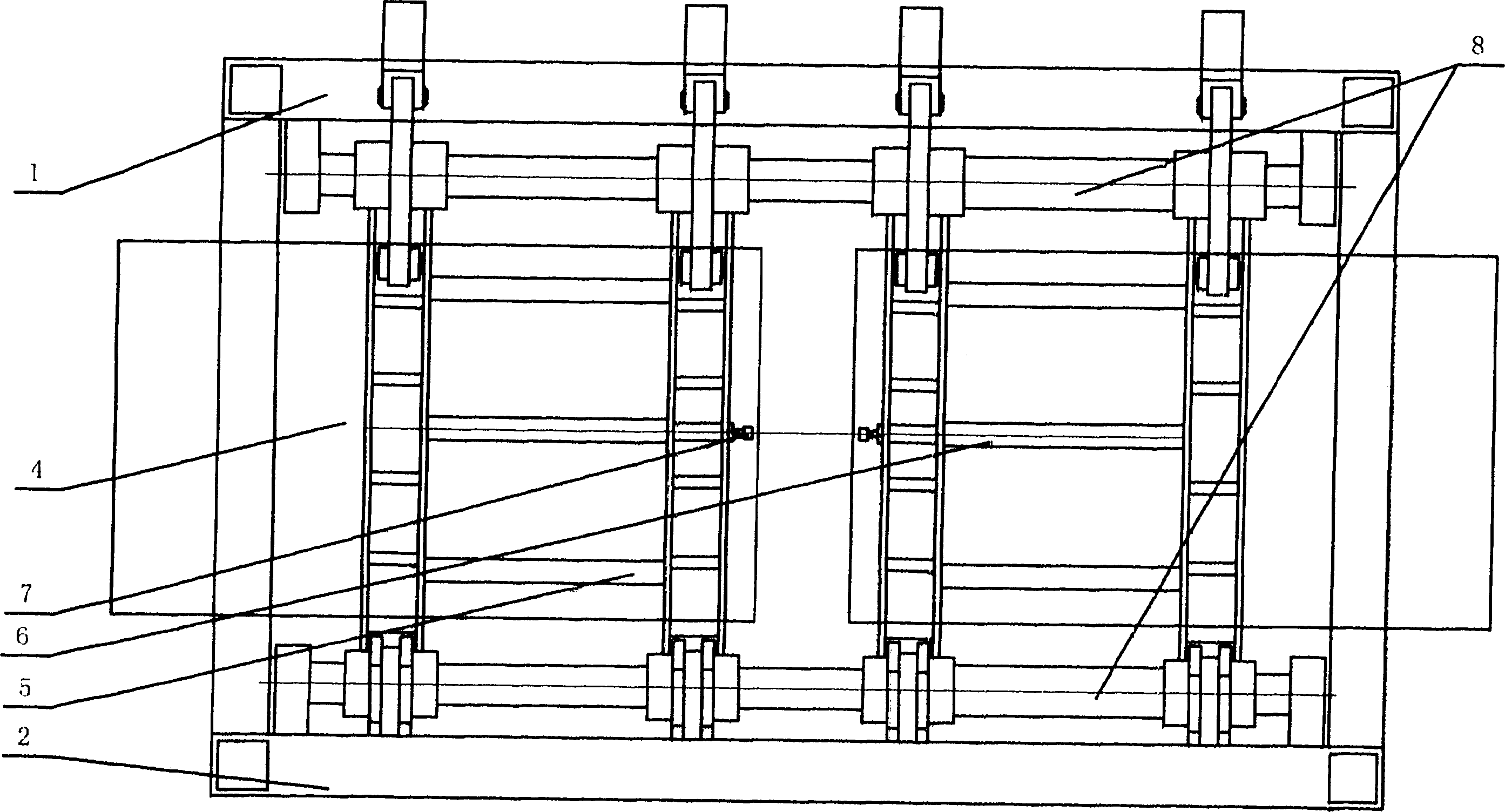

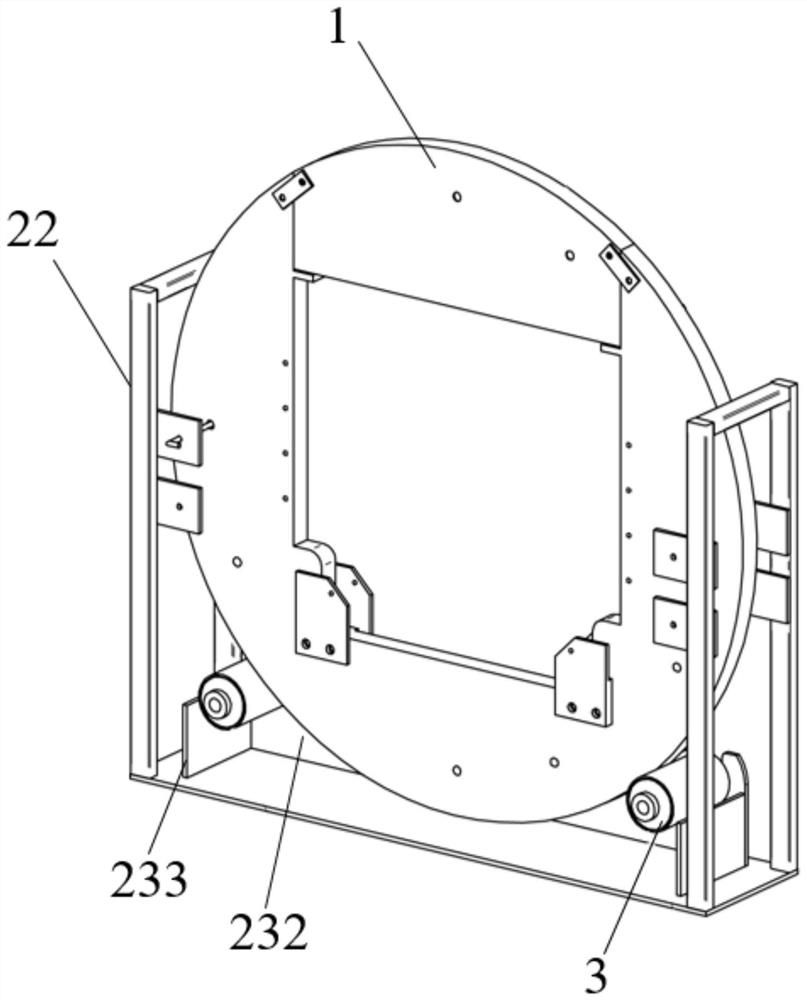

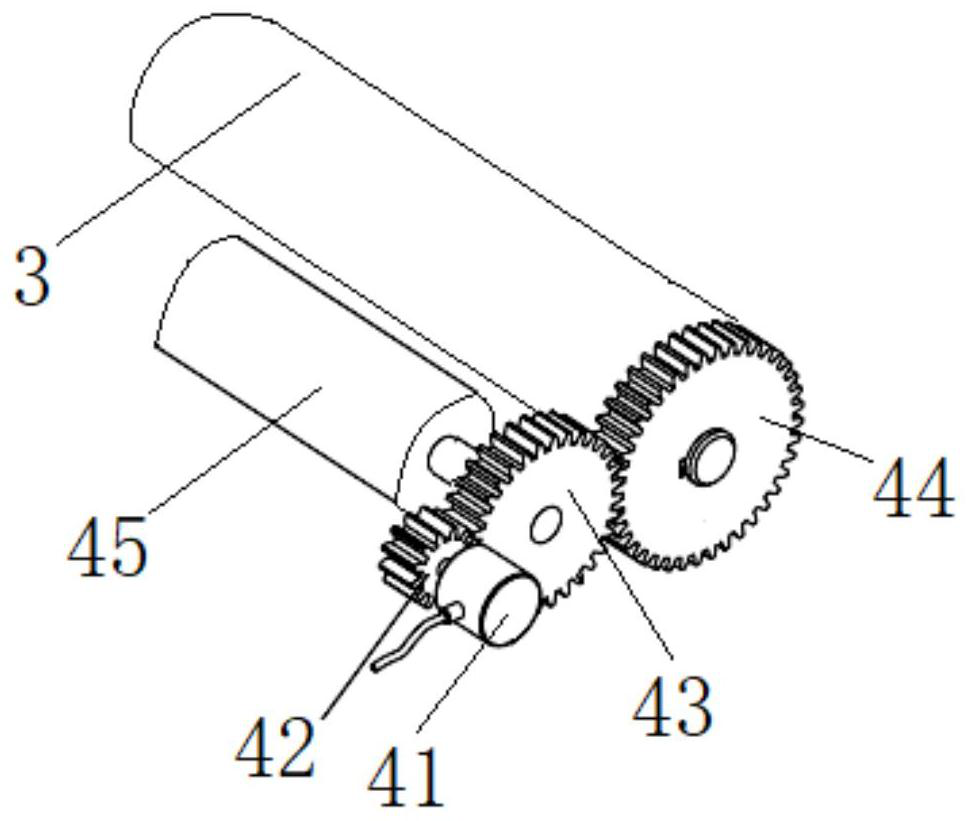

Rotary turnover device and method for heavy product

PendingCN113977181AShorten welding cycleReduce turning timeWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringSupport plane

The invention relates to a rotary turnover device and method for a heavy product, belongs to the technical field of turnover of heavy products, and solves the problems of low turnover efficiency and poor safety of the heavy product in the prior art. The device comprises a round wheel assembly, a supporting frame and a plurality of carrier rollers, the carrier rollers are arranged on the supporting frame and rotationally connected with the supporting frame, the round wheel assembly is arranged in the supporting frame and located above the carrier rollers, the cylindrical surface of the round wheel assembly makes contact with the cylindrical surfaces of the carrier rollers, the round wheel assembly is provided with through holes, the heavy products are arranged in the through holes, and when the carrier rollers are rotated, the round wheel assembly drives the heavy products to turn over. The rotary turnover device is high in heavy product overturning efficiency and good in safety.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A positioning welding process for a cast titanium alloy connecting rod

ActiveCN103143821BStable deliveryShorten welding cycleConnecting rod bearingsBearing assemblyShielding gasTitanium alloy

The invention relates to a fixed-position welding technique for use in the device manufacturing industry, which relates to a professional welding technique for a connecting rod in a reciprocating compressor, in particular to a fixed-position welding process for casting a titanium alloy connecting rod by using ZTC4. The fixed-position welding technique comprises the following steps of: casting a titanium alloy connecting rod by using ZTC4 in manual tungsten electrode argon arc welding, wherein a welding wire is a TA1 pure titanium welding wire, the diameter of the welding wire is phi2.4 millimeters, and the polarity of a power supply belongs to direct-current positive connection; and processing bolt holes in both sides of the connecting rod, and then removing a fixed-position welding spot by processing, wherein process parameters of a welding process are that the welding current is 170-180A; the welding voltage is 12-14V; the protective gas is 99.9% Ar gas; the diameter of a tungsten electrode is 2.4 millimeters; and the gas flow is 10-15L / min. According to the fixed-position welding technique, fixed-position welding is adopted for ensuring the accuracy requirement of connecting rod processing, so that the processing technical requirements, processing accuracy requirement and processing quality requirement of the titanium alloy connecting rod are met, welding is qualified at one time, the manufacturing quality of the reciprocating compressor is enhanced, the production efficiency is increased, and the manufacturing cost of the titanium alloy connecting rod is reduced.

Owner:沈阳鼓风机集团往复机有限公司

A spot welding machine hot air circulation system

ActiveCN103128466BImprove thermal efficiencySmall fluctuations in soldering temperatureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInhaled air

The invention discloses a spot welder hot air circulating system which comprises a welding box, a heating device and an air blower. The heating device and the air blower are arranged in the welding box, the heating device is arranged on an air outlet of the air blower, and an air inlet of the air blower is used for inhaling air inside the welding box. The spot welder hot air circulating system has the advantages of being high in heat efficiency, energy-saving and environment-friendly, and small in welding temperature fluctuation at the same time, effectively guaranteeing quality and stability of products, shortening welding cycle, and improving welding reliability.

Owner:KUSN WANSHENG ELECTRONICS

Thick Section Narrow Gap T-Type Welding Method

ActiveCN111408825BSimplify welding trajectoryReduce cleanupElectrode supporting devicesElectrode accessoriesThick plateStructural engineering

The invention discloses a thick-section narrow-gap T-shaped welding method, and relates to the technical field of production and manufacturing of thick plate and ultra-thick plate welding in the hydropower industry. The present invention firstly changes the butt joint groove between the special-shaped thick plate and the plane thick plate, that is, processes it into a rectangular structure within 60mm above the welding end of the special-shaped thick plate, and changes the arc-shaped weld bead into a straight weld bead, which can Simplify the welding trajectory of the robot and reduce the difficulty of programming. The welding surface of the rectangular structure is set as a beveled welding surface with a certain slope, and the welding groove between the special-shaped thick plate and the flat thick plate is designed as an I-shaped narrow gap groove structure. The original multi-layer and multi-pass welding is changed to one layer and one, which simplifies the welding process, reduces the probability of non-fusion between weld beads and the number of weld bead cleaning, and improves welding efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com