Steel nuclear power containment circular seam submerged arc automatic horizontal welding process

A technology for containment and nuclear power steel, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unstable welding product quality, easily affected by the skill level and experience of welders, and poor welding environmental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can obviously be implemented in many other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

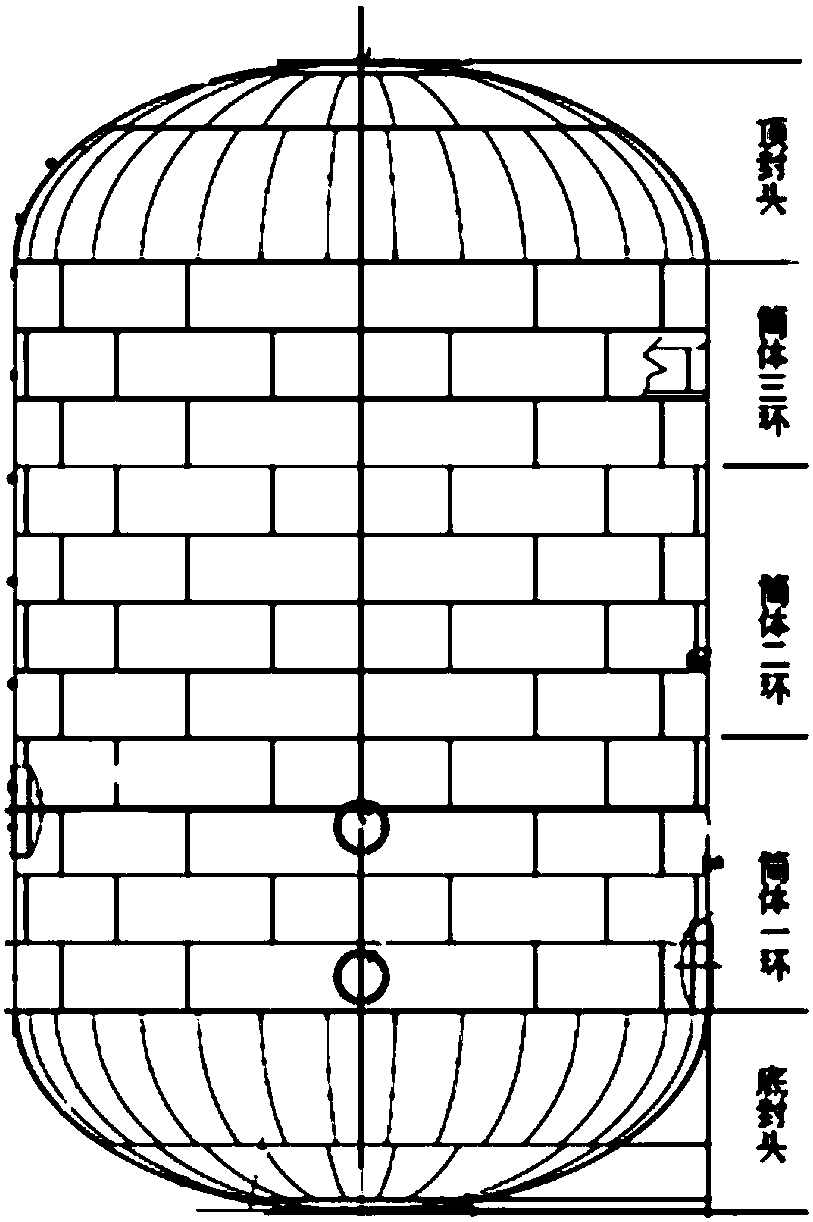

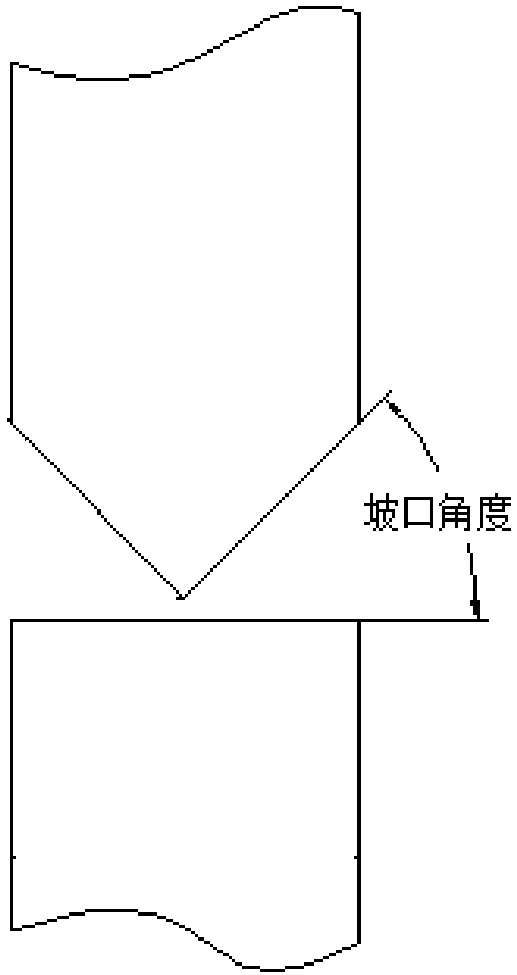

[0026] Such as figure 1 As shown, the nuclear power containment includes modules such as the bottom head, the first ring of the cylinder, the second ring of the cylinder, the third ring of the cylinder, and the top seal. The length of the annular seam between the cylinders is about 1500m. The bottom head or top is also welded by two different parts, and the length of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com