Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1305 results about "Reciprocating compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

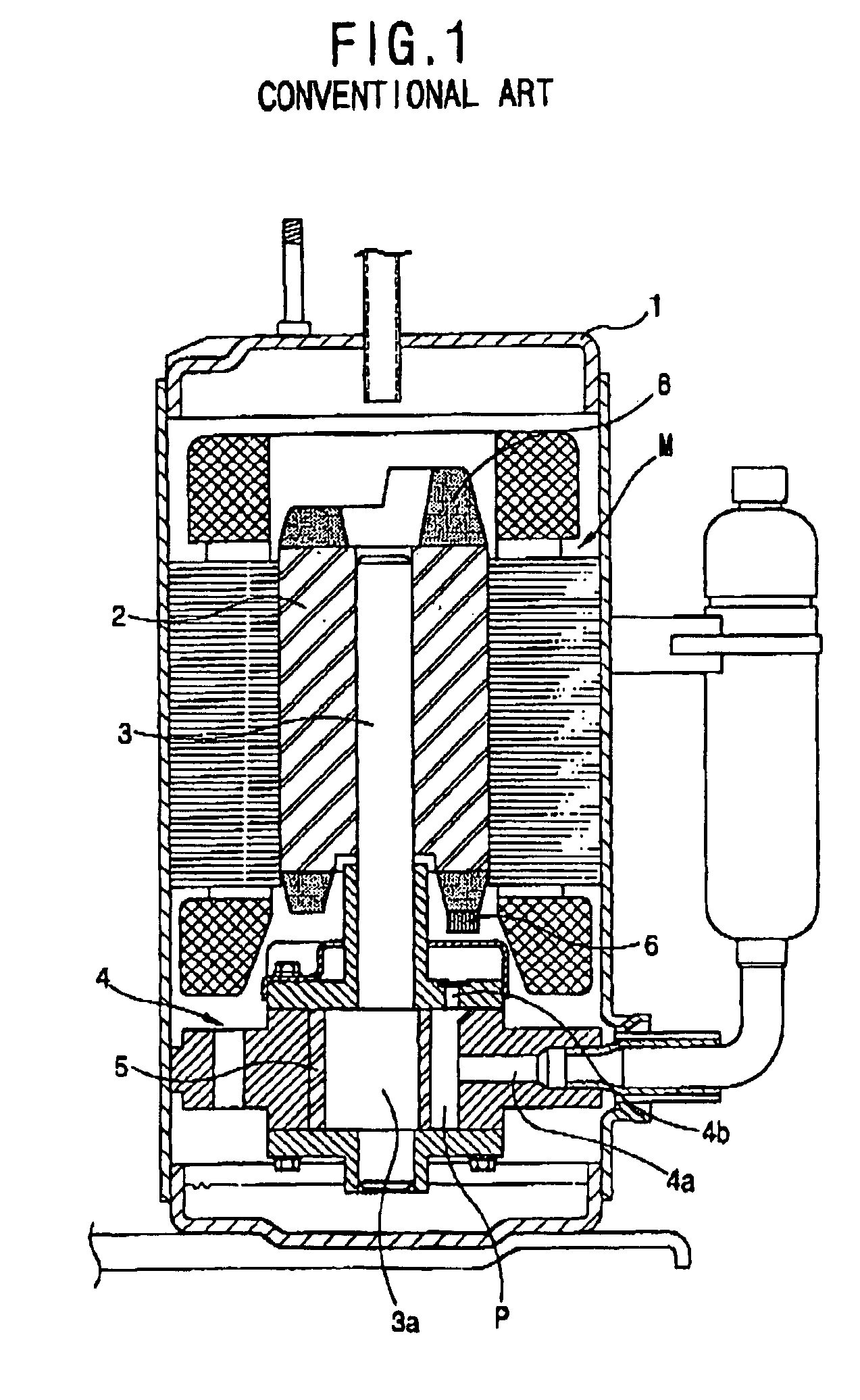

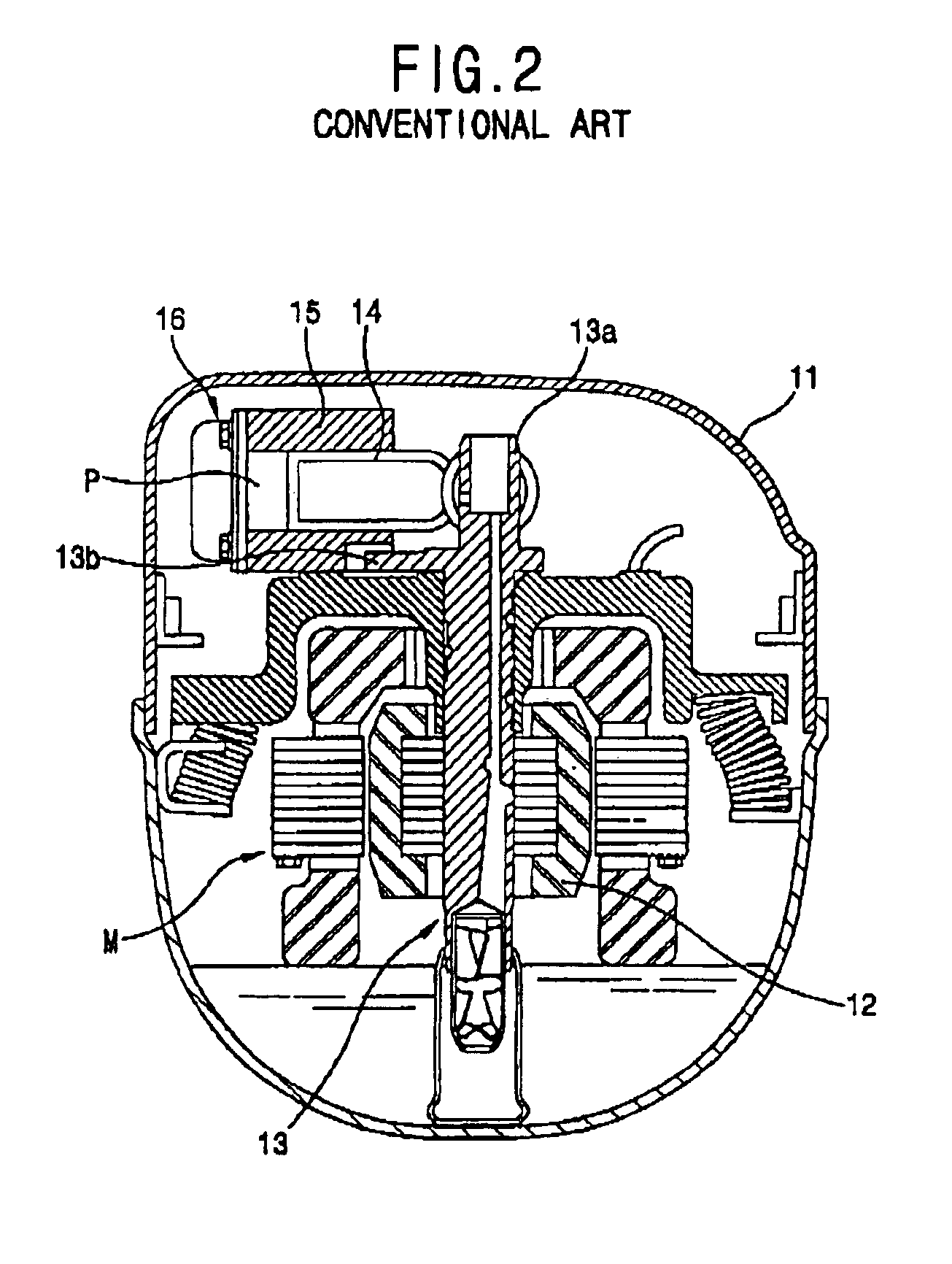

A reciprocating compressor or piston compressor is a positive-displacement compressor that uses pistons driven by a crankshaft to deliver gases at high pressure. The intake gas enters the suction manifold, then flows into the compression cylinder where it gets compressed by a piston driven in a reciprocating motion via a crankshaft, and is then discharged. Applications include oil refineries, gas pipelines, chemical plants, natural gas processing plants and refrigeration plants. One specialty application is the blowing of plastic bottles made of polyethylene terephthalate (PET).

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

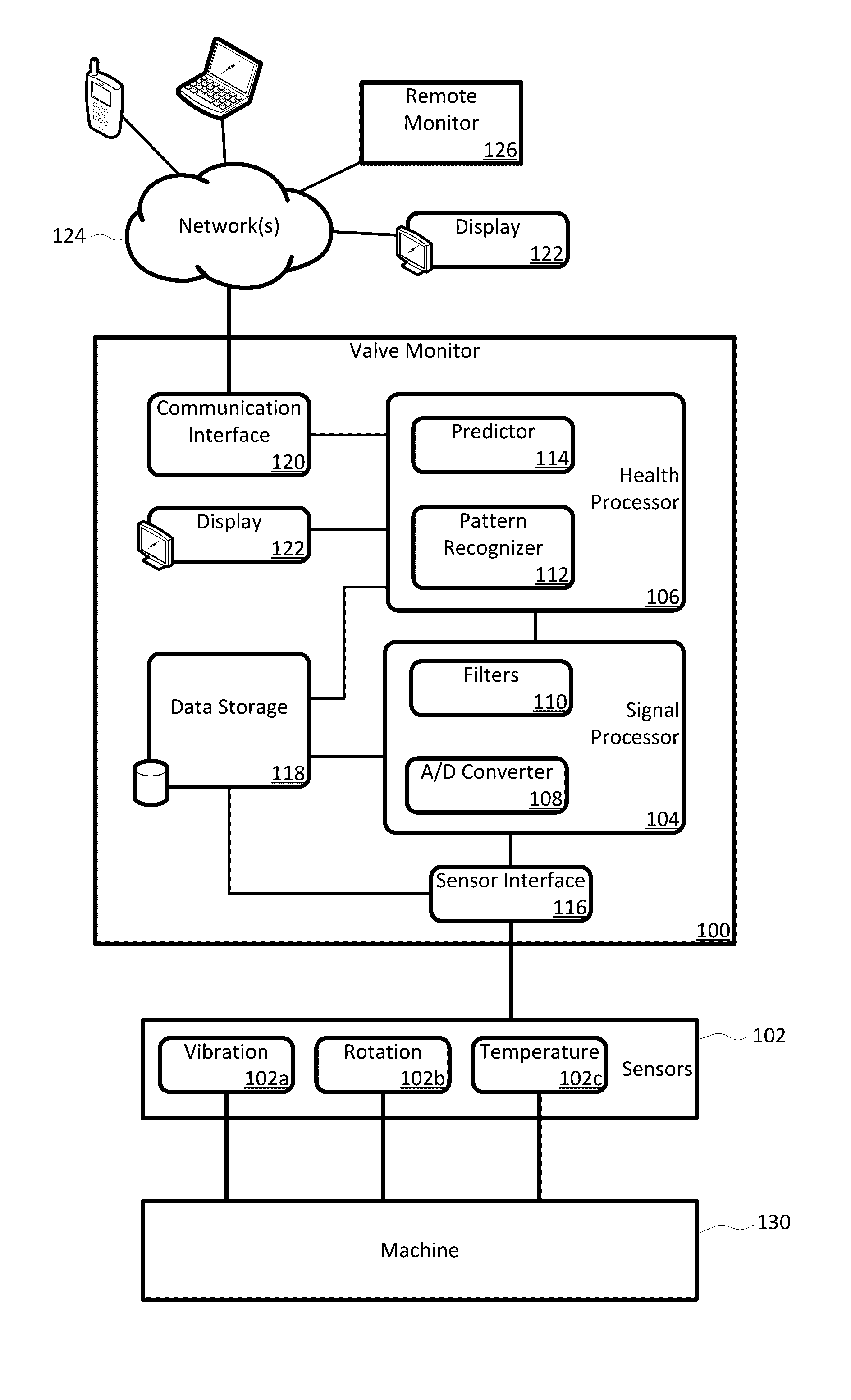

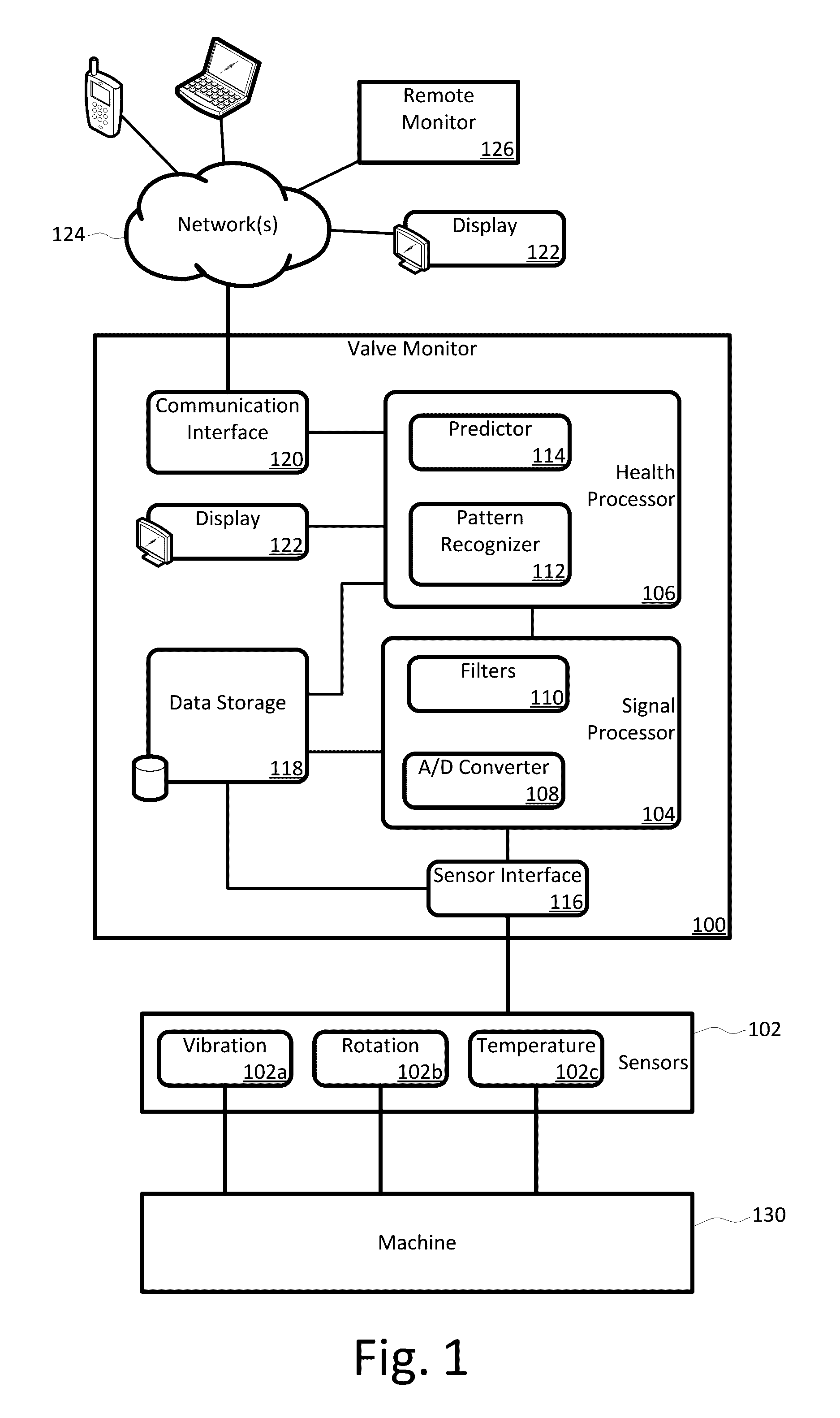

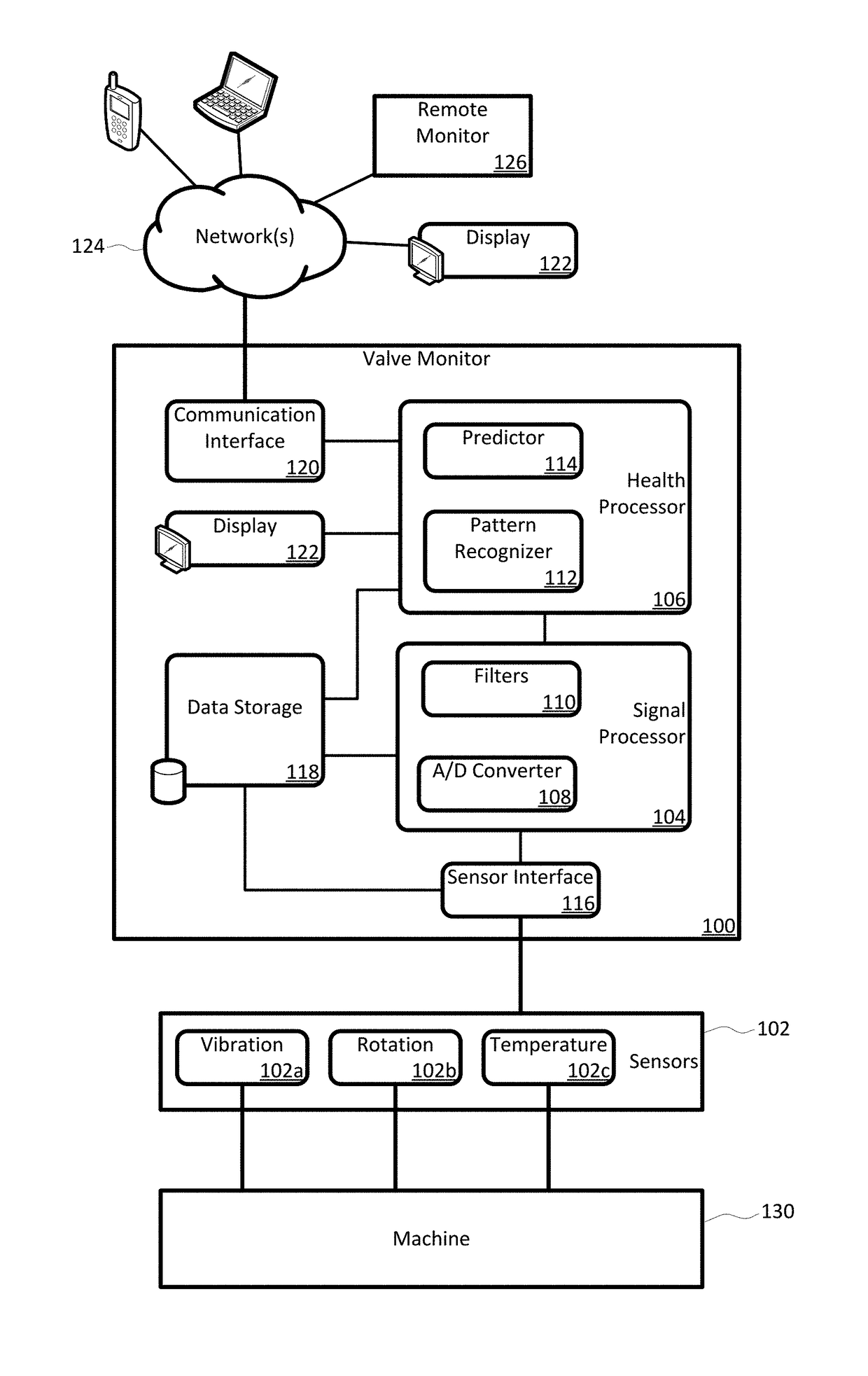

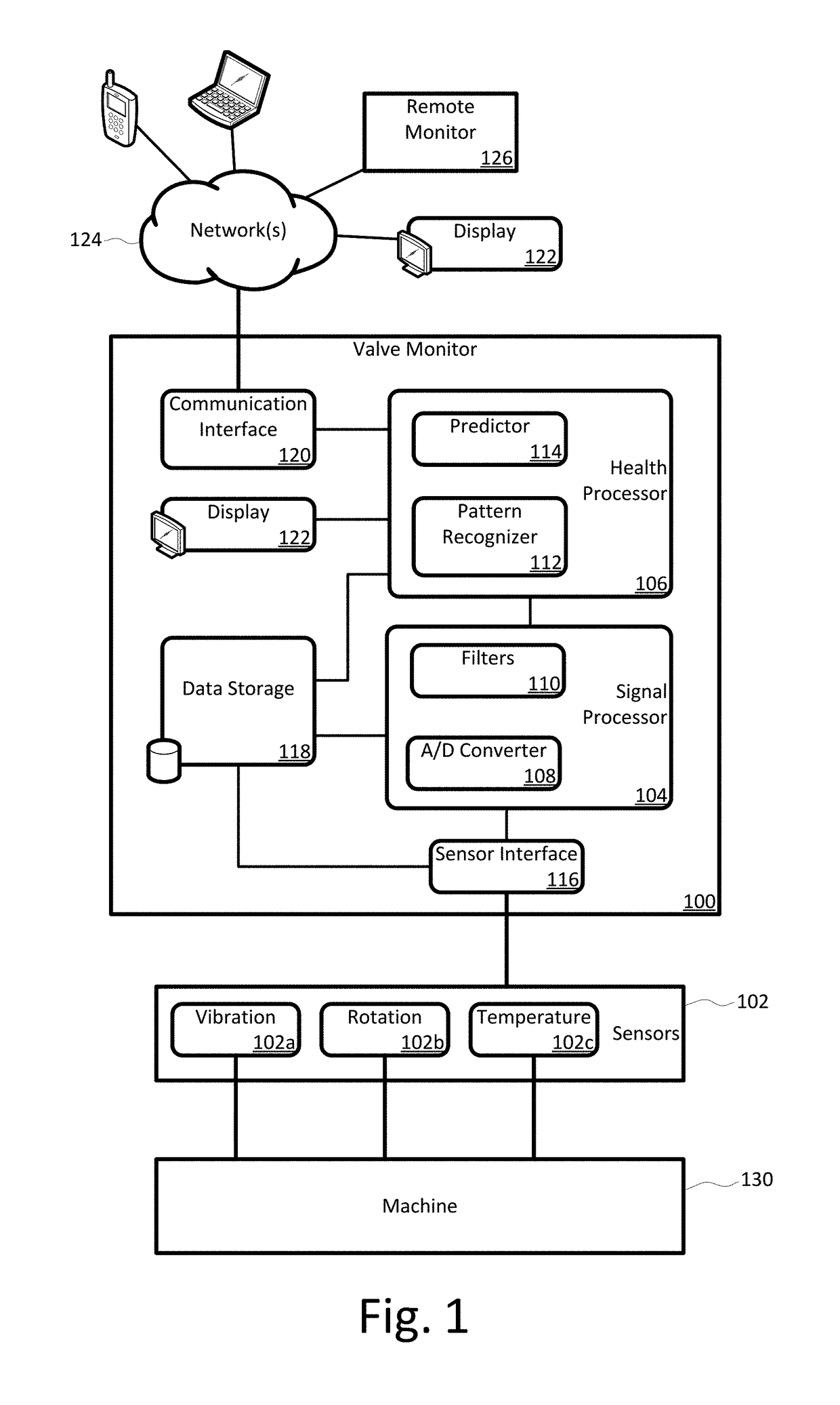

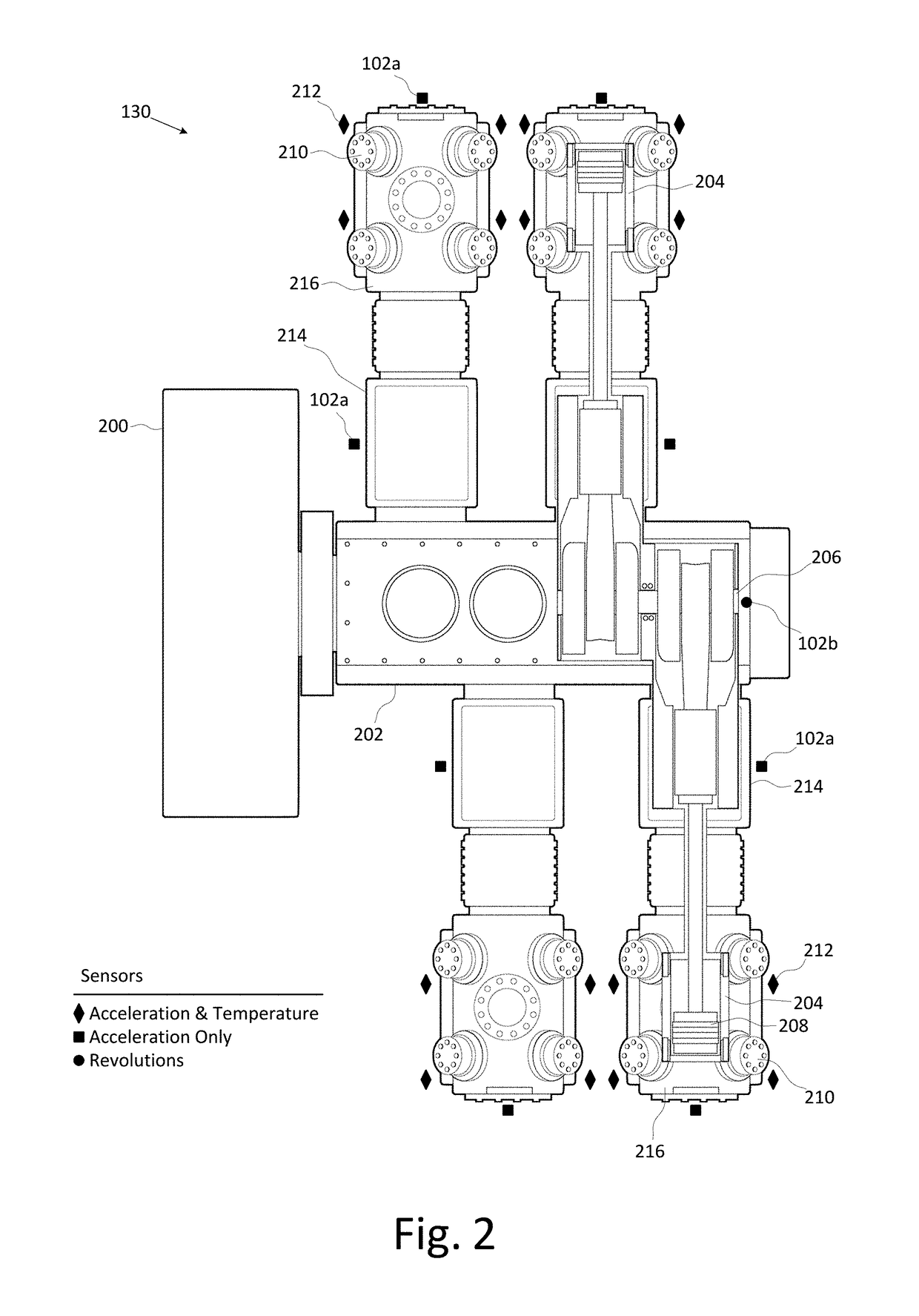

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

Removable compressor grouting formula

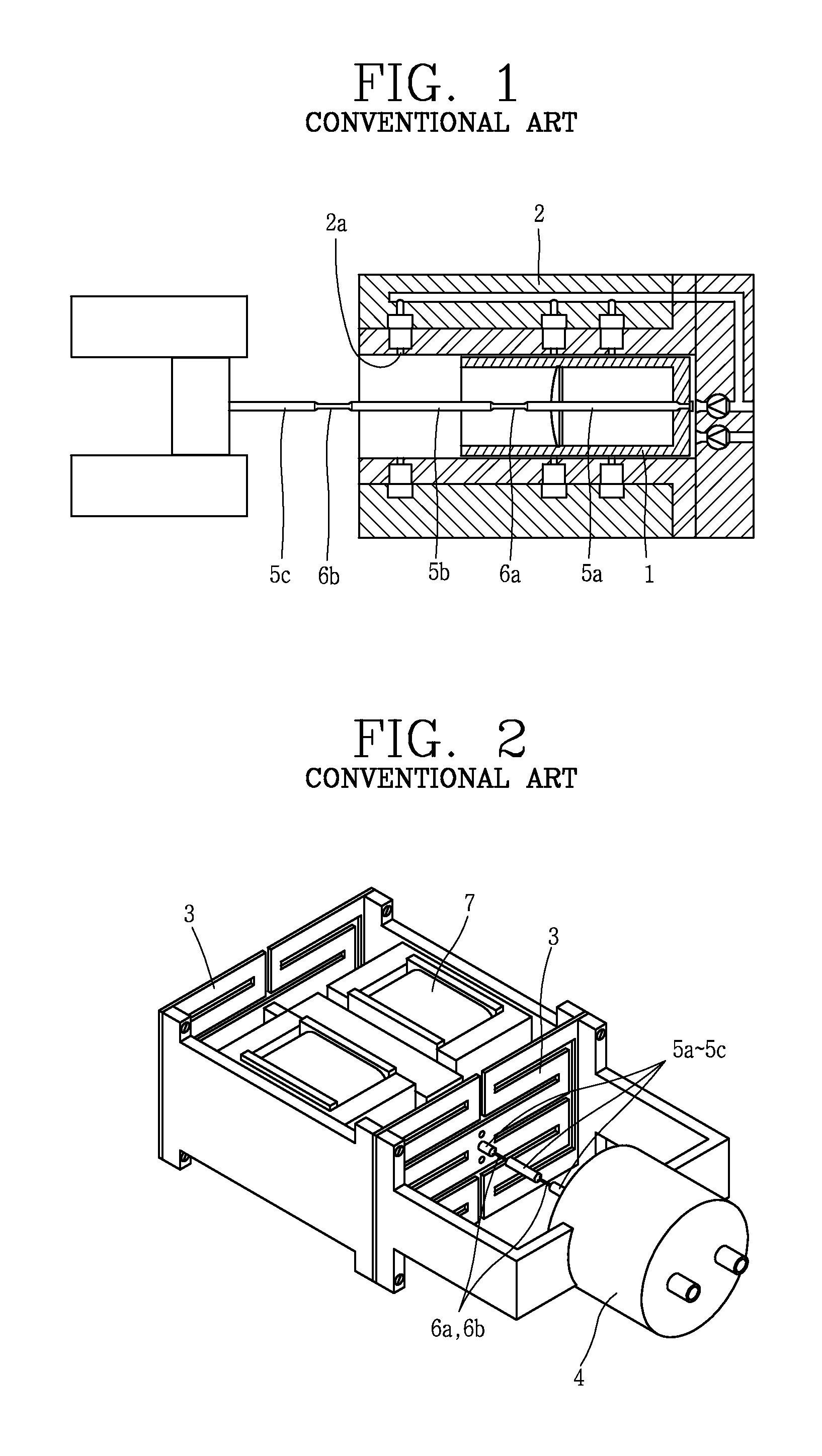

InactiveCN107859053AGuaranteed installation requirementsHigh reusabilityFoundation engineeringEngineeringNatural gas

The invention belongs to the industry of natural gas, and particularly relates to a removable compressor grouting formula, which is applied to a skid-mounted unit of a reciprocating compressor. The removable compressor grouting formula adopts the following technical scheme that the removable compressor grouting formula is characterized in that a new grouting material of the skid-mounted unit of the reciprocating compressor is adopted, the material is prepared in the step of mixing cement with sand according to the proportion of 11:16, the grouting material can flow to all bottom surfaces of askid base by using a proper amount of water, and a short curing period can be guaranteed. A pipeline which is connected with the unit is removed when the whole skid-mounted unit of the reciprocating compressor needs to be moved, and one corner of the bottom skid-mounted unit is pulled by using a crane or a jack, so that the whole skid-mounted unit is separated from a foundation. According to the removable compressor grouting formula, the reuse of equipment is greatly increased, so that the cost is reduced, the waste of resources is reduced, and the original zero feasibility can become feasible.

Owner:JEREH OIL & GAS ENG

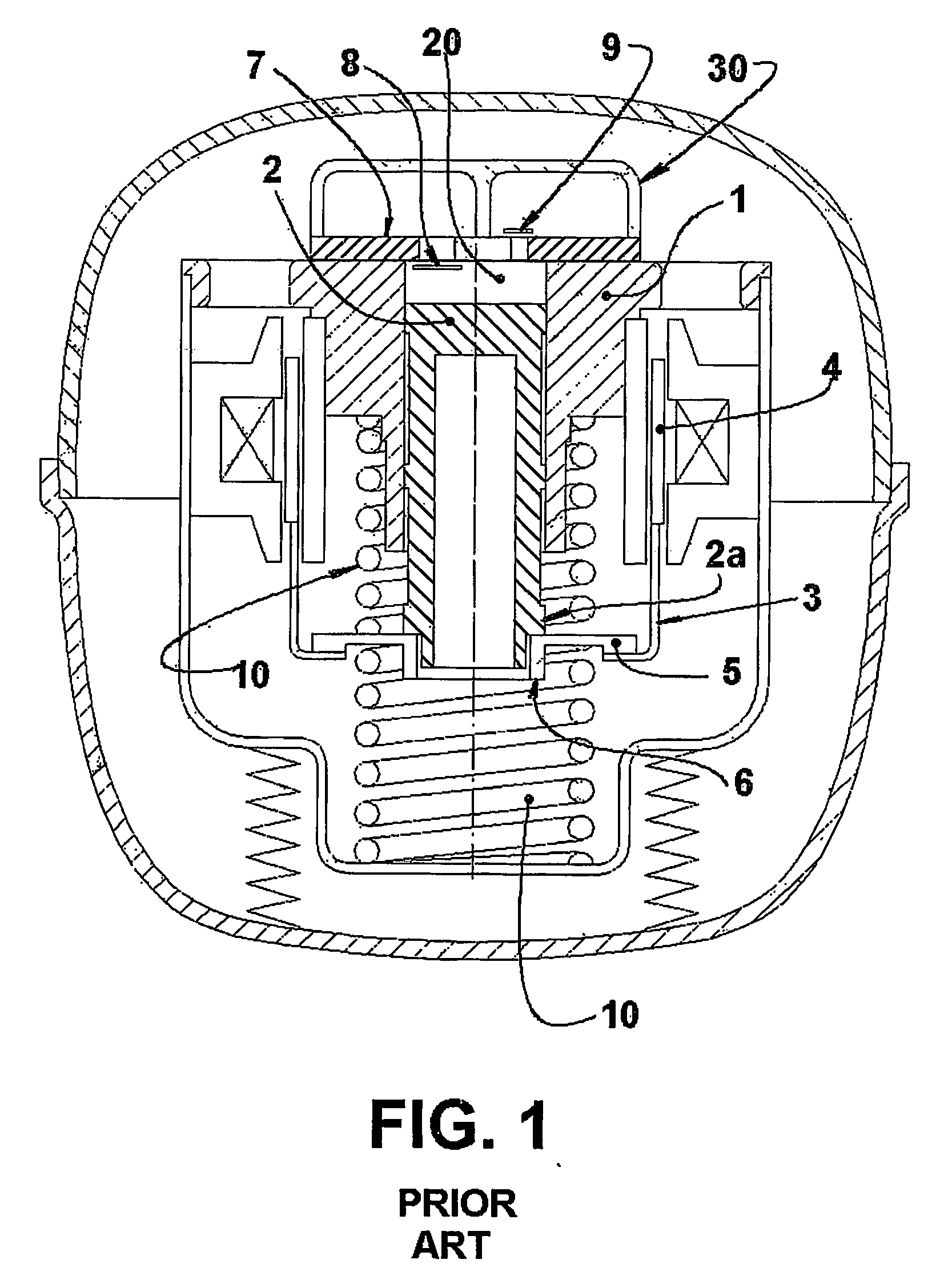

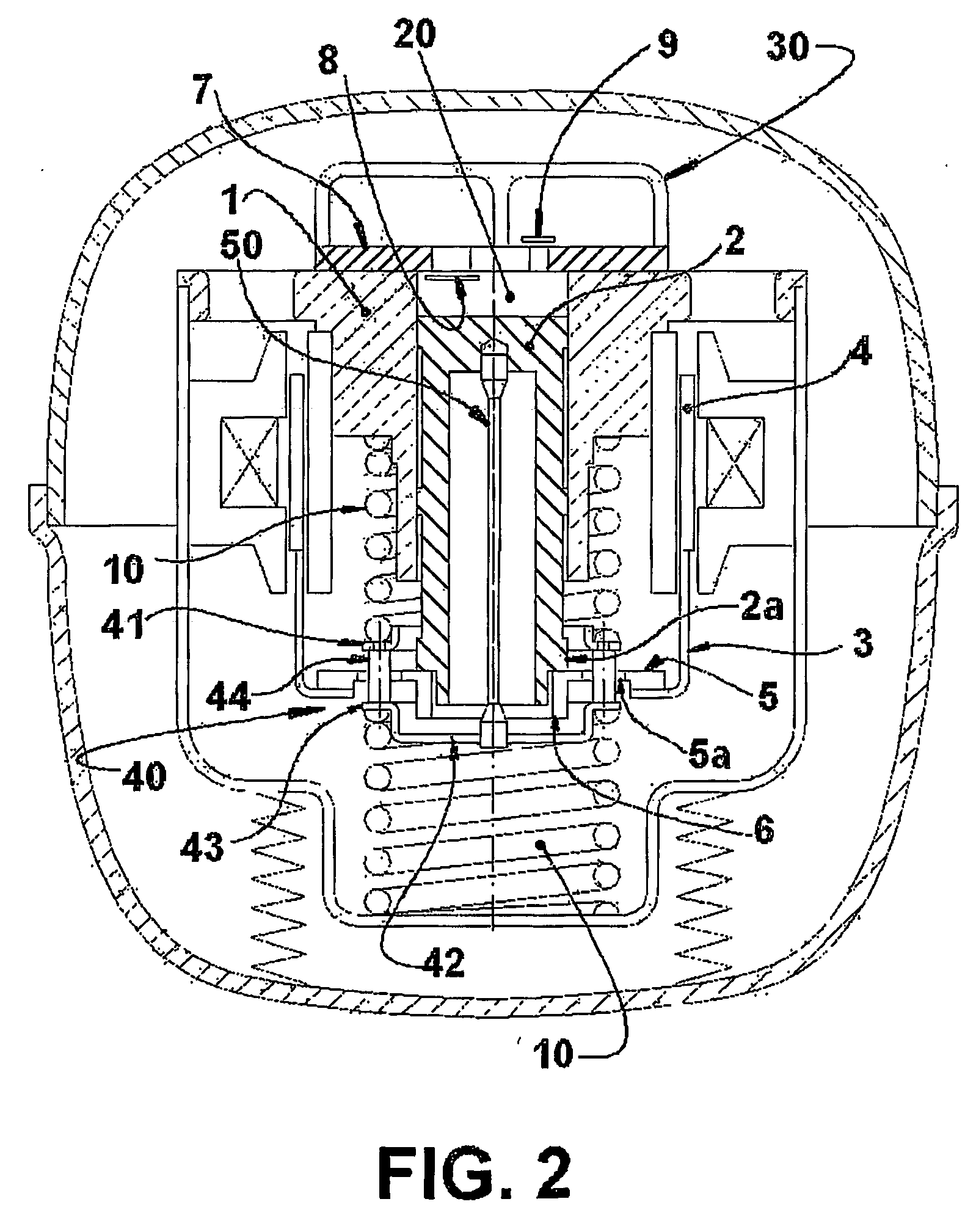

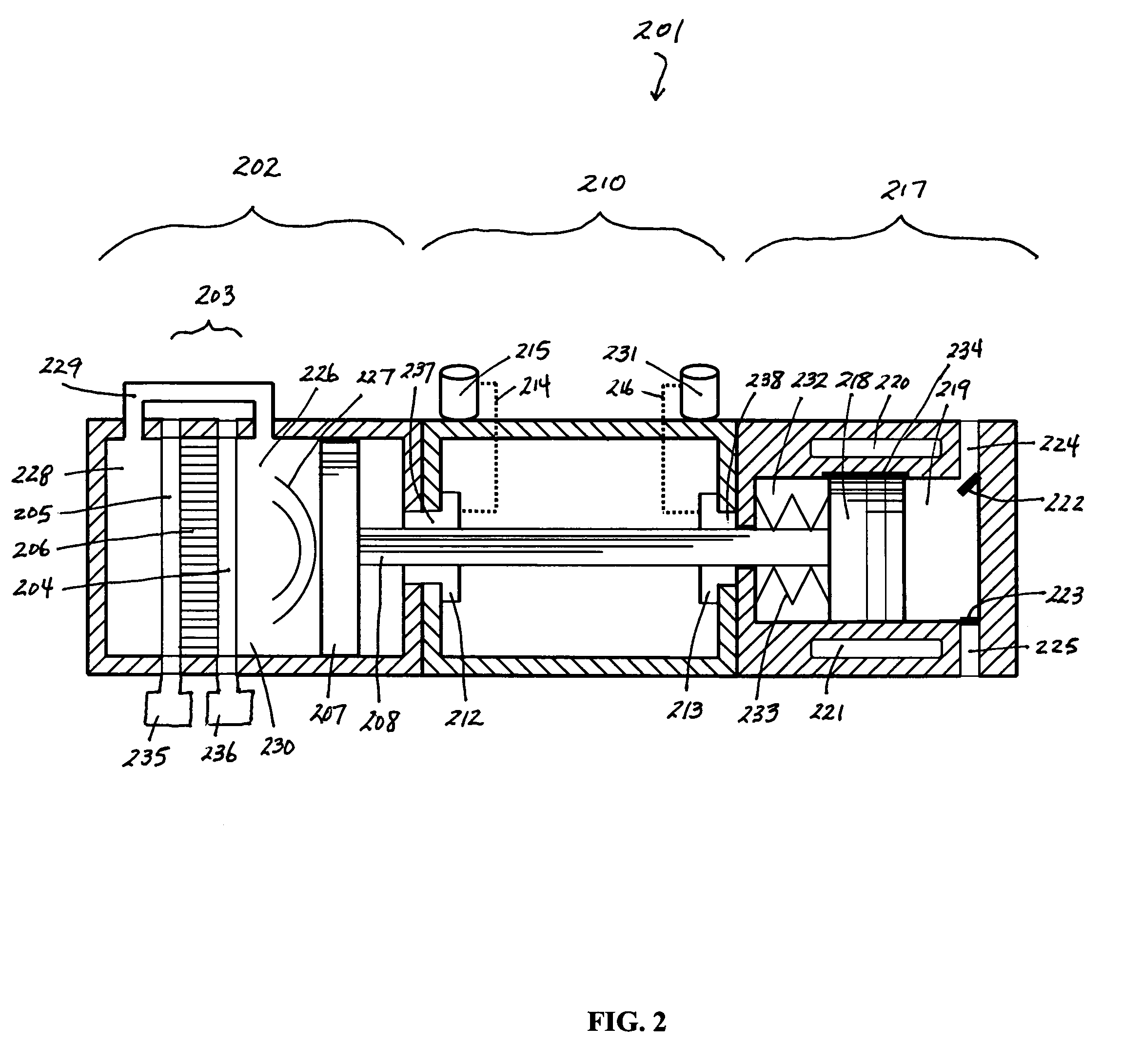

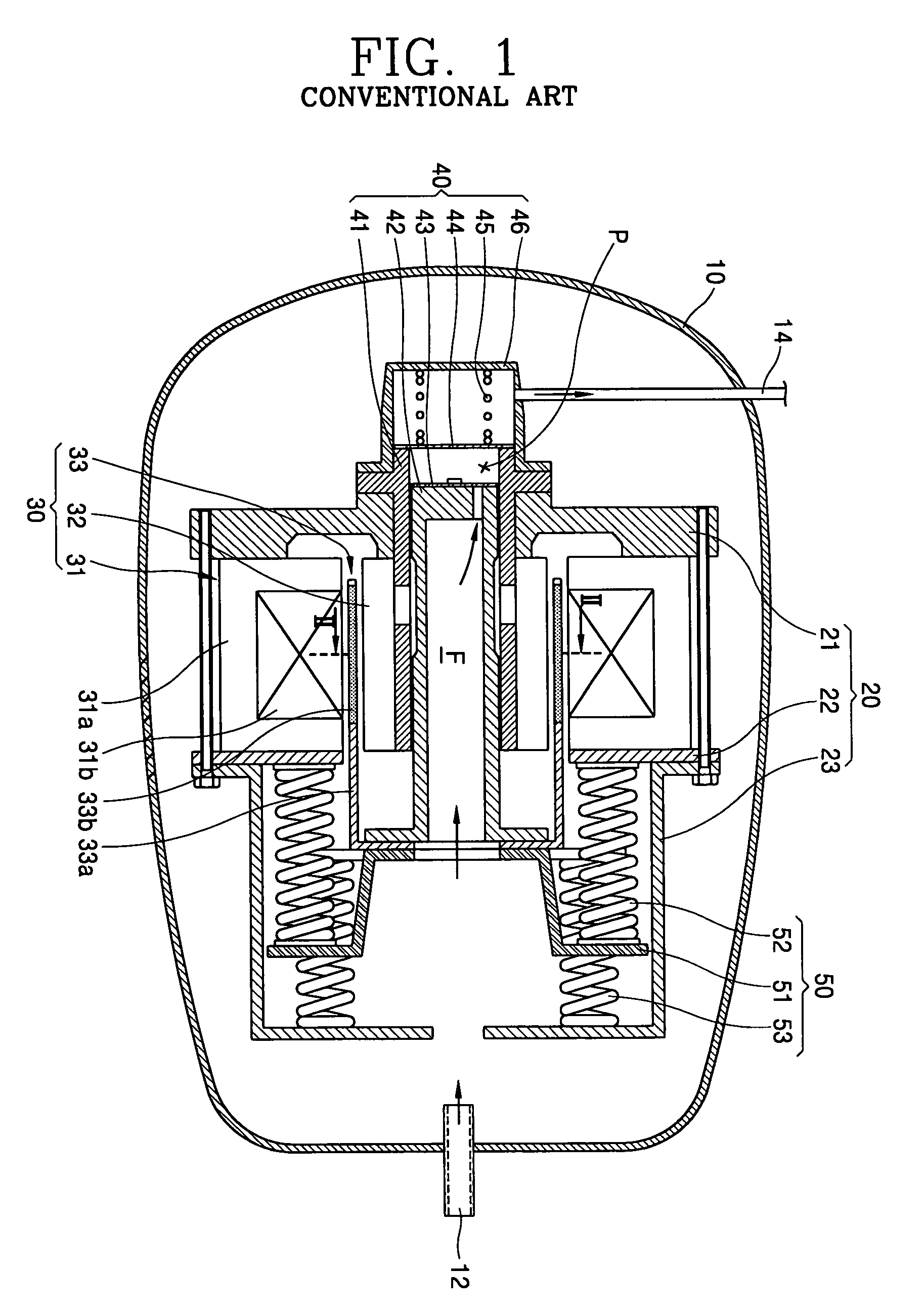

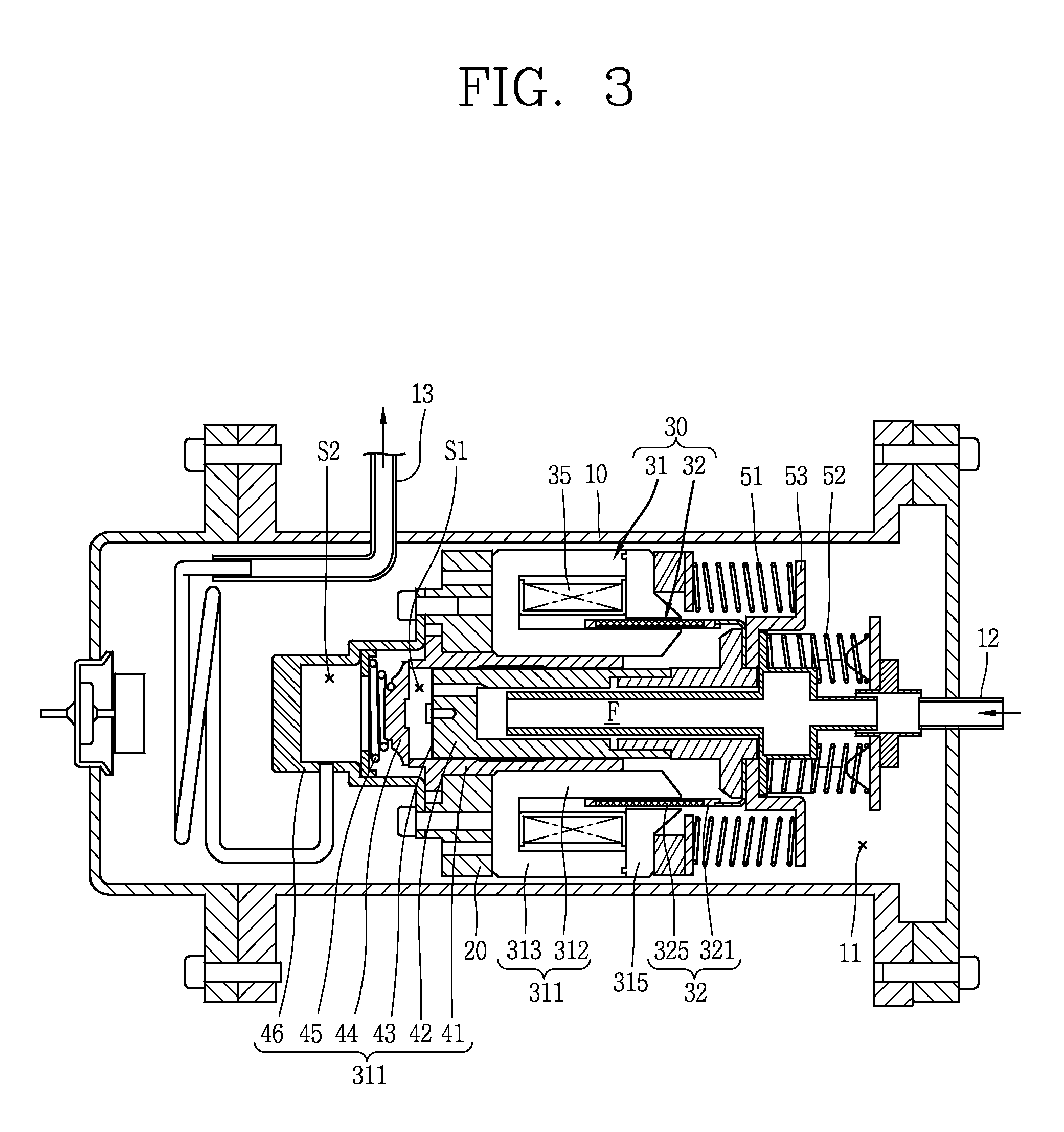

Reciprocating compressor driven by a linear motor

InactiveUS20050123422A1Easy constructionMinimizes lateral forcePositive displacement pump componentsPiston pumpsAxial displacementReciprocating motion

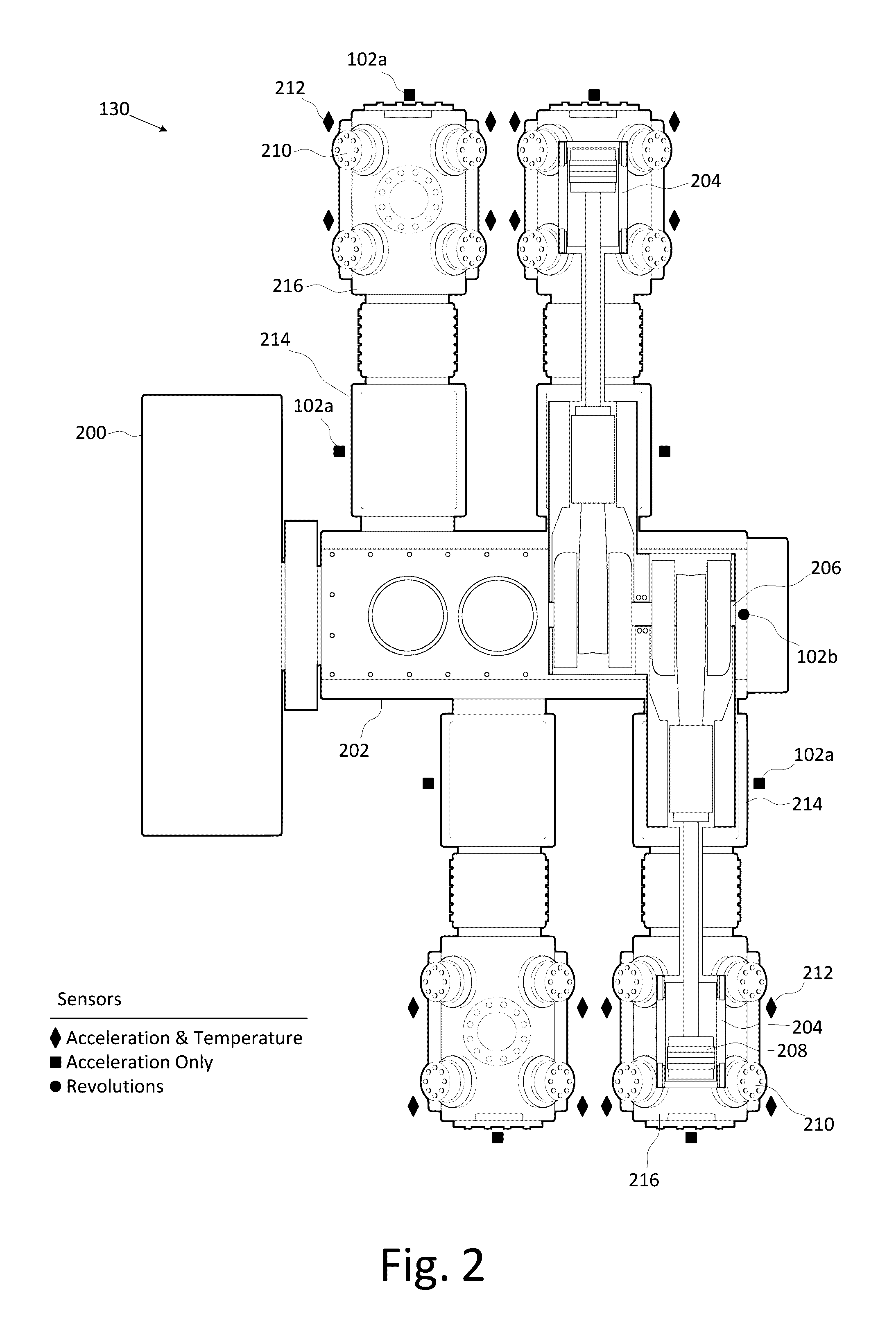

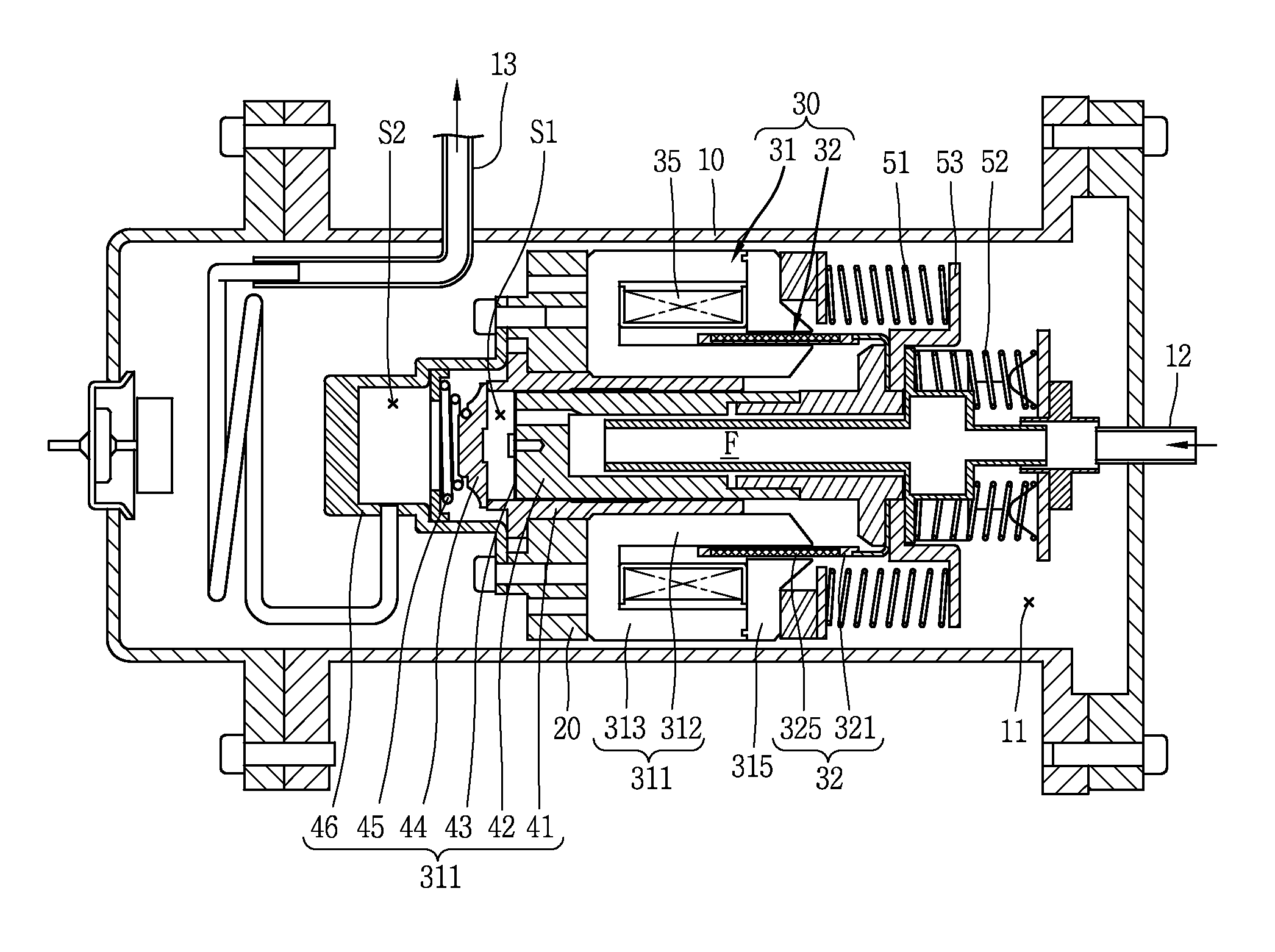

A reciprocating compressor driven by a linear motor, comprising a shell, within which are mounted: a reference assembly formed by a motor and a cylinder (1); a resonant assembly formed by a piston (2) reciprocating inside the cylinder (1), and by an actuating means (3) operatively coupling the piston (2) to the motor; two spring means (10) mounted to the resonant assembly and to the reference assembly and which are elastically and axially deformed in the displacement direction of the piston (2); a mounting element (40) coupling an end of one spring means (10) to an end of the other spring means (10); and a coupling element (50) mounted to the piston (2) and to the mounting element (40), which is axially displaced together with the piston (2) and displaced freely and transversally to the displacement direction of the piston (2), said coupling element (50) transmitting the axial forces between the piston (2) and the mounting element (40) and minimizing the application of radial forces to the piston (2).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

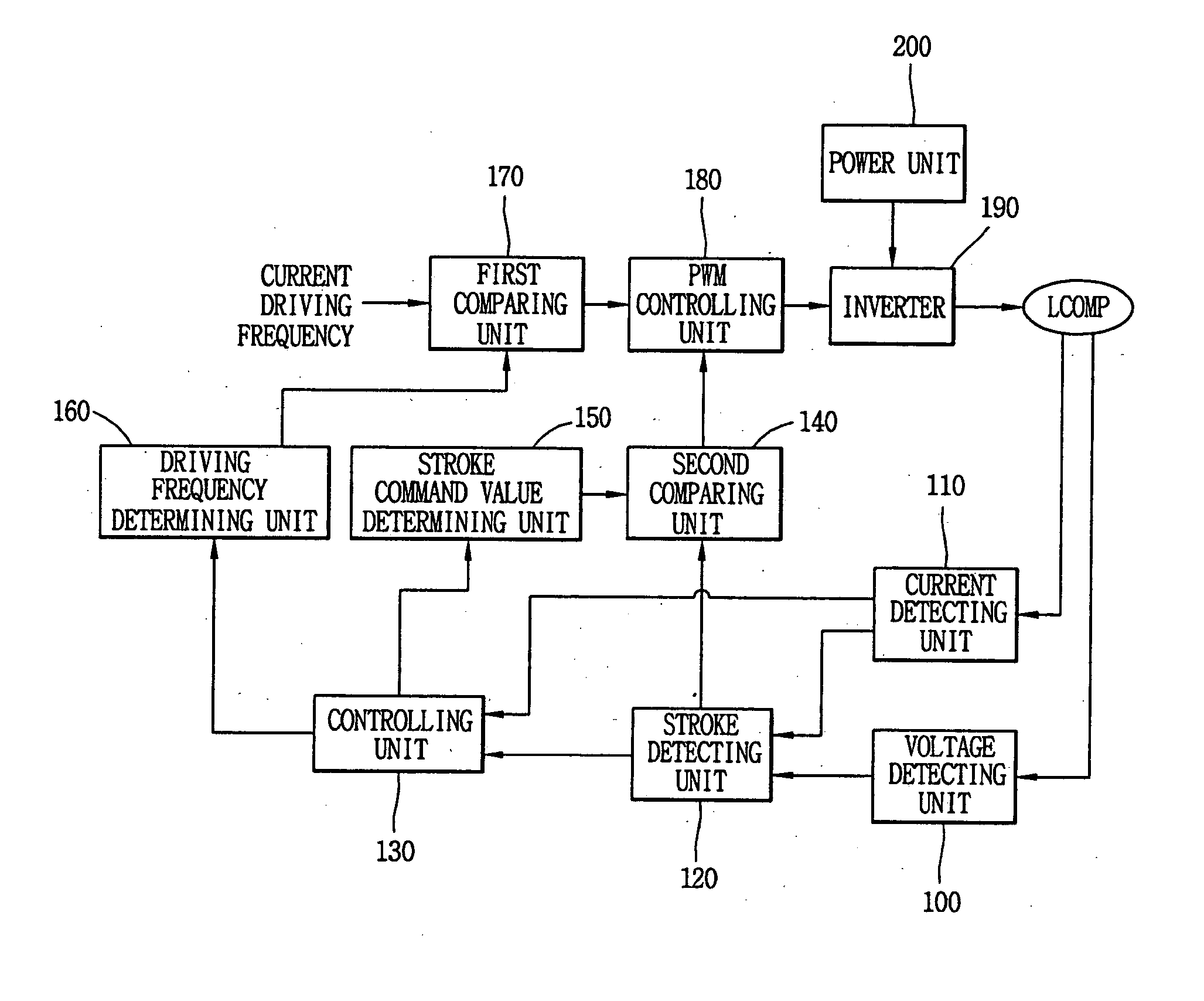

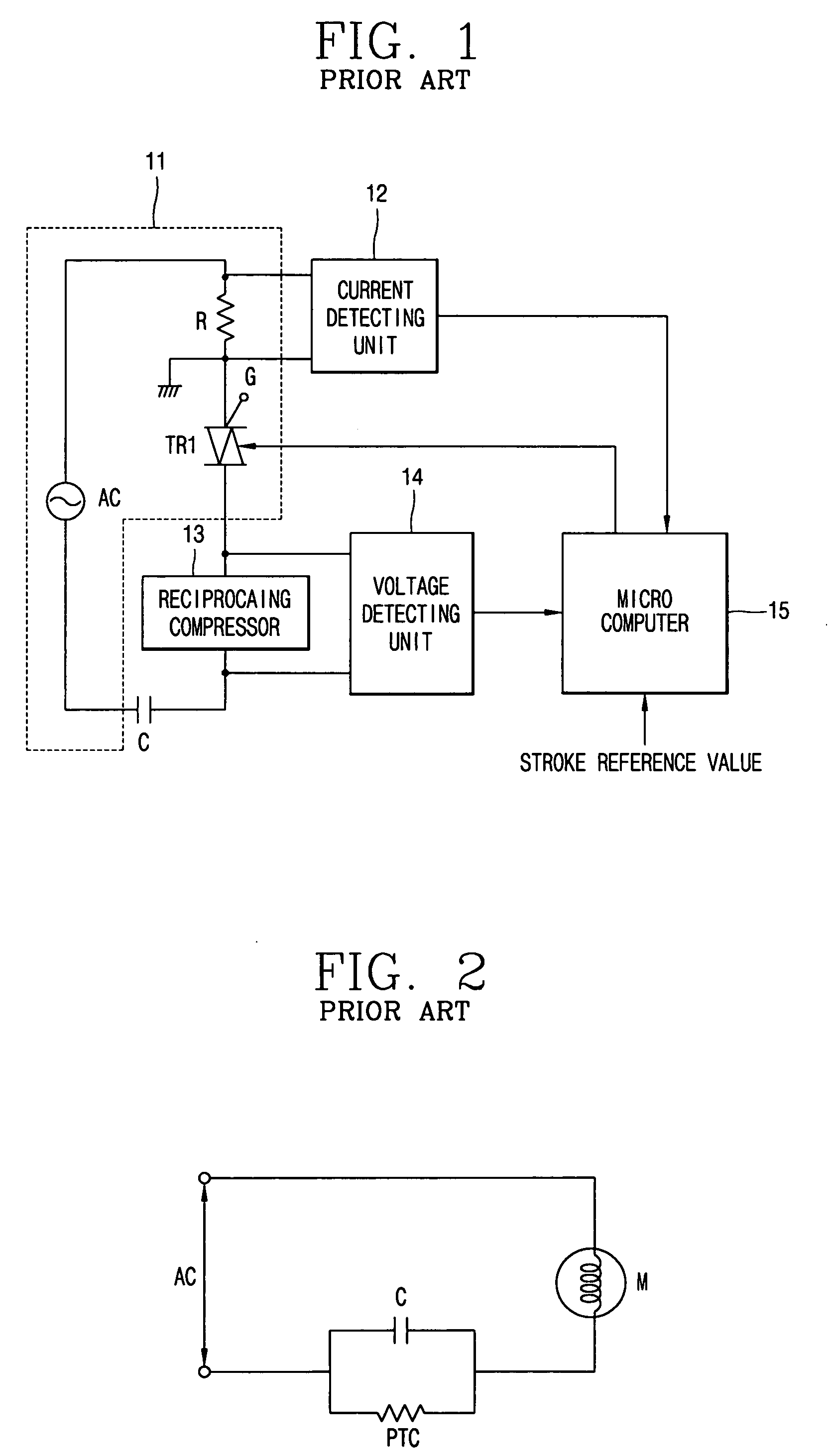

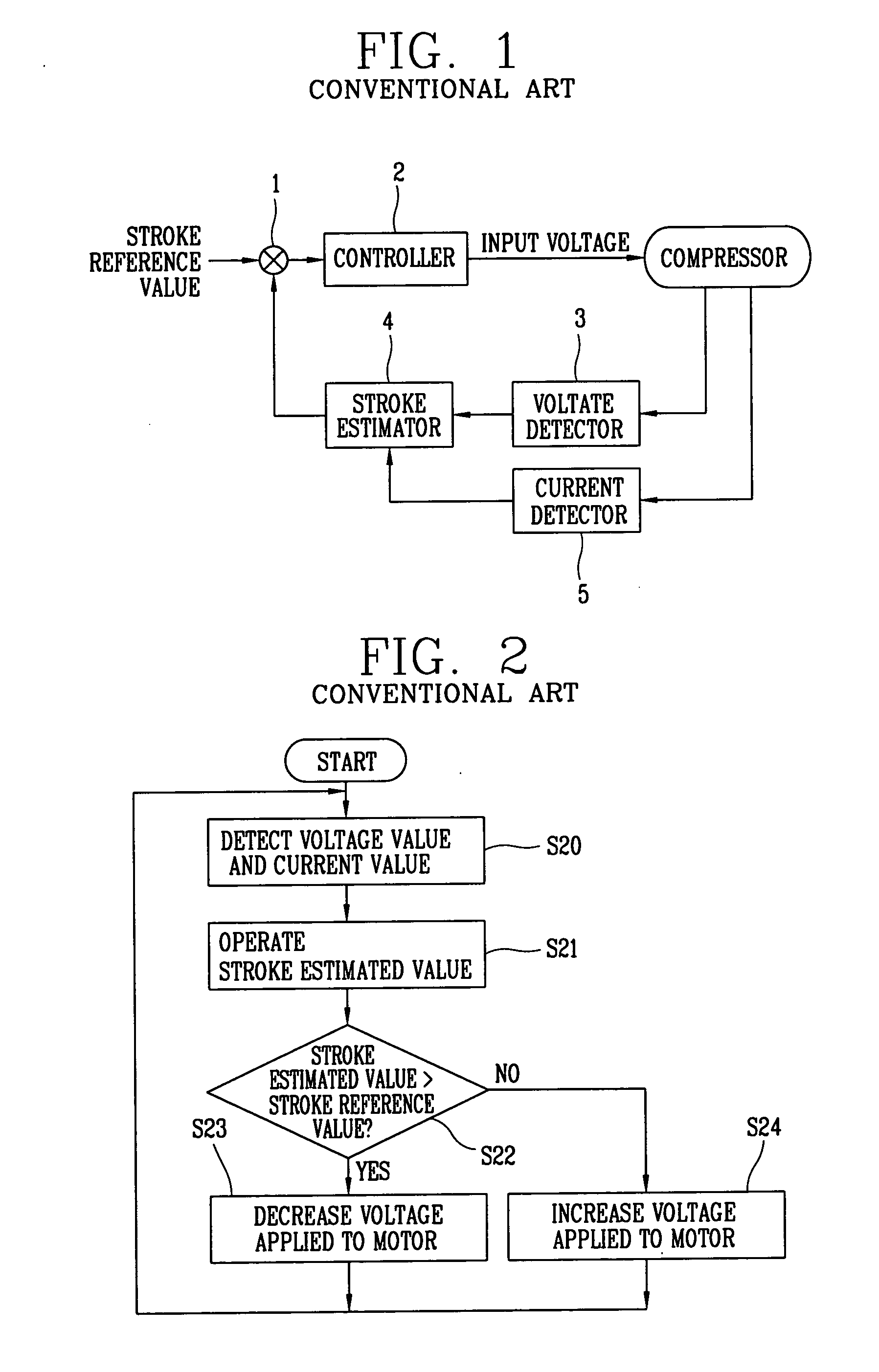

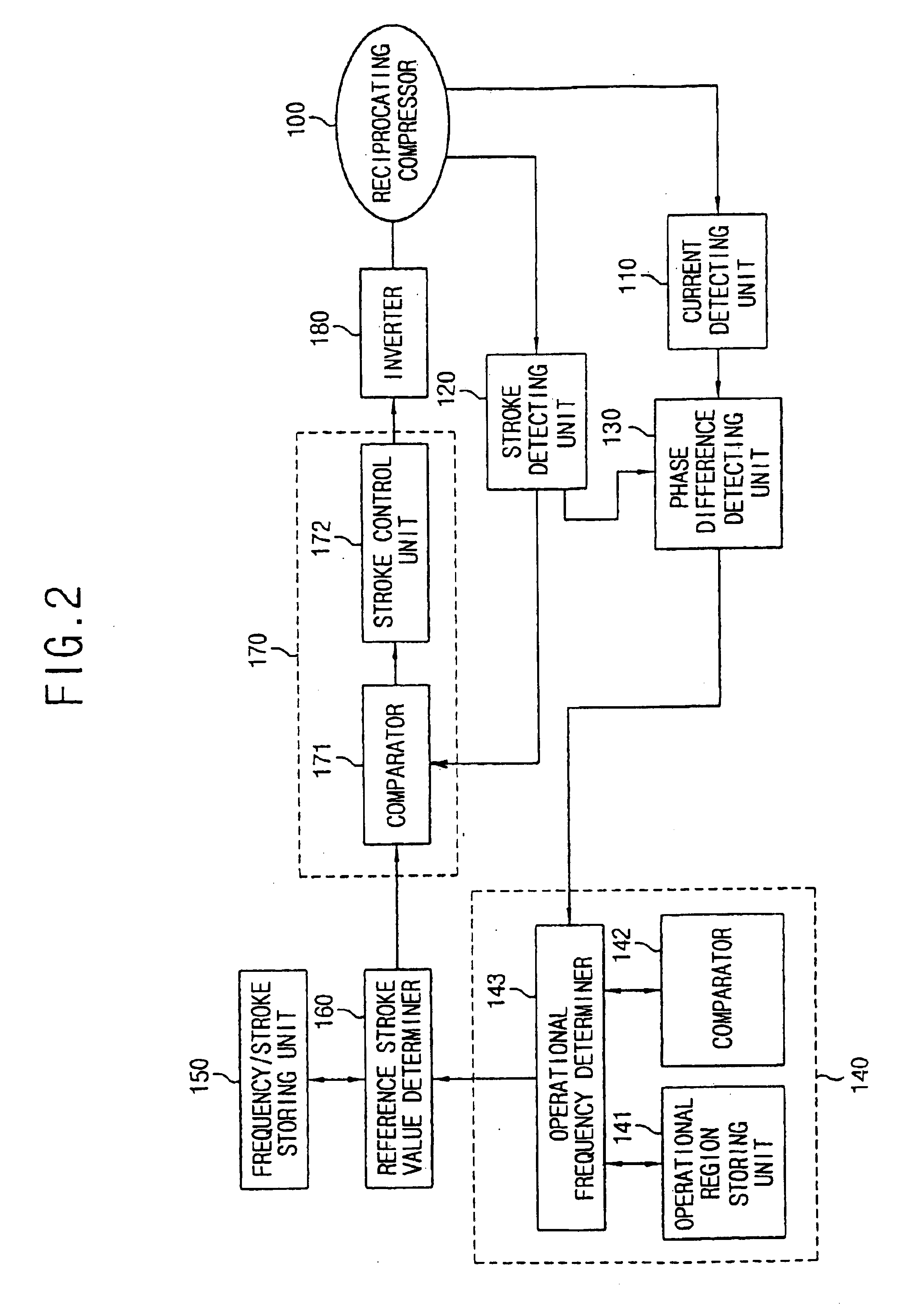

Apparatus for controlling driving of reciprocating compressor and method thereof

ActiveUS20060228224A1Improve efficiencyLow efficiencyMotor/generator/converter stoppersDC motor speed/torque controlControl signalPhase difference

Disclosed are an apparatus for controlling a driving of a reciprocating compressor capable of enhancing an efficiency by differently controlling a frequency and a stroke voltage according to a load size and capable of reducing consumption power, and a method thereof. The apparatus comprises a controlling unit for judging a load size by comparing a phase difference between a detected current and a stroke with a reference phase difference, and outputting a frequency control signal and a stroke control signal according to the judged load size.

Owner:LG ELECTRONICS INC

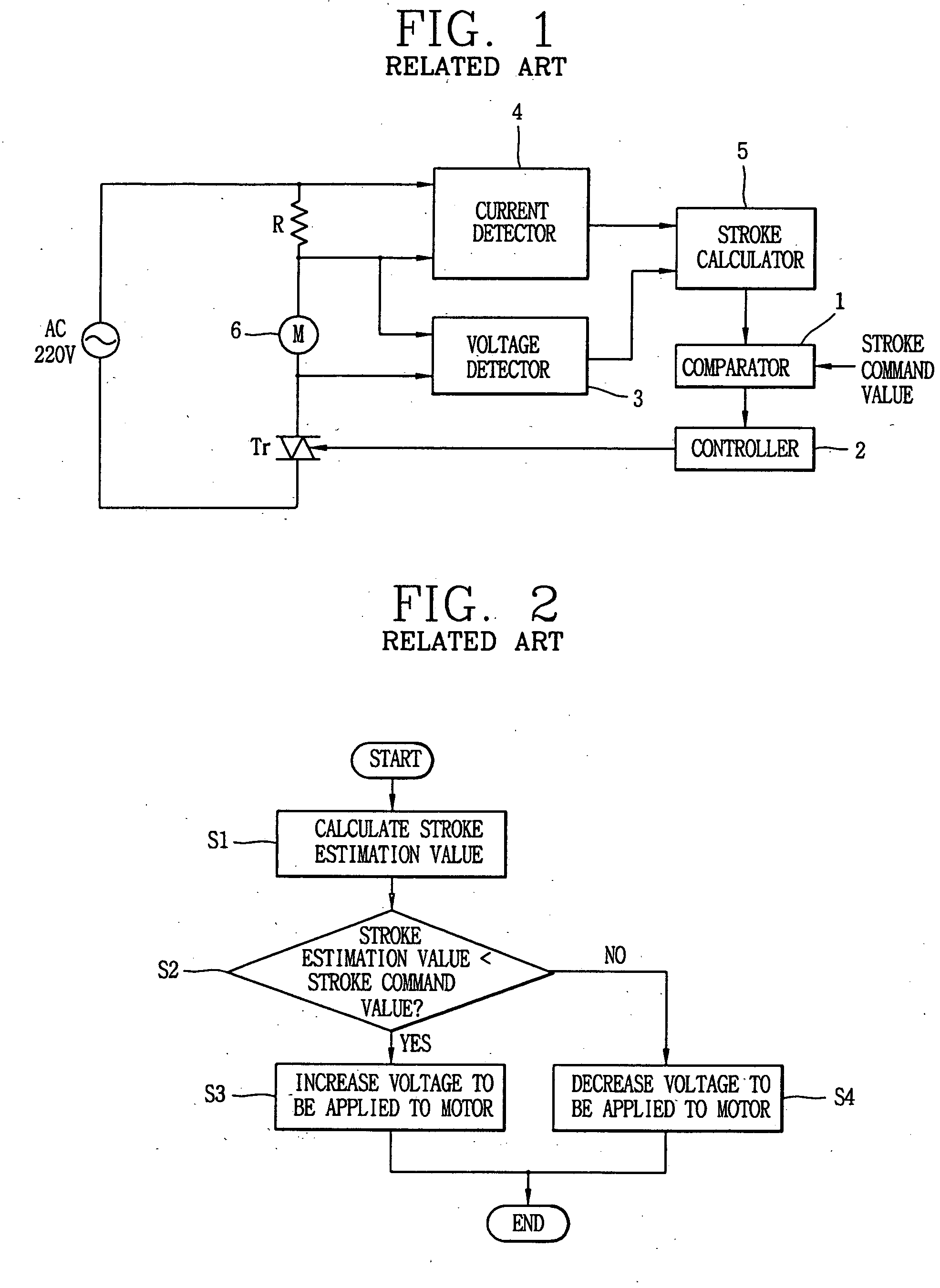

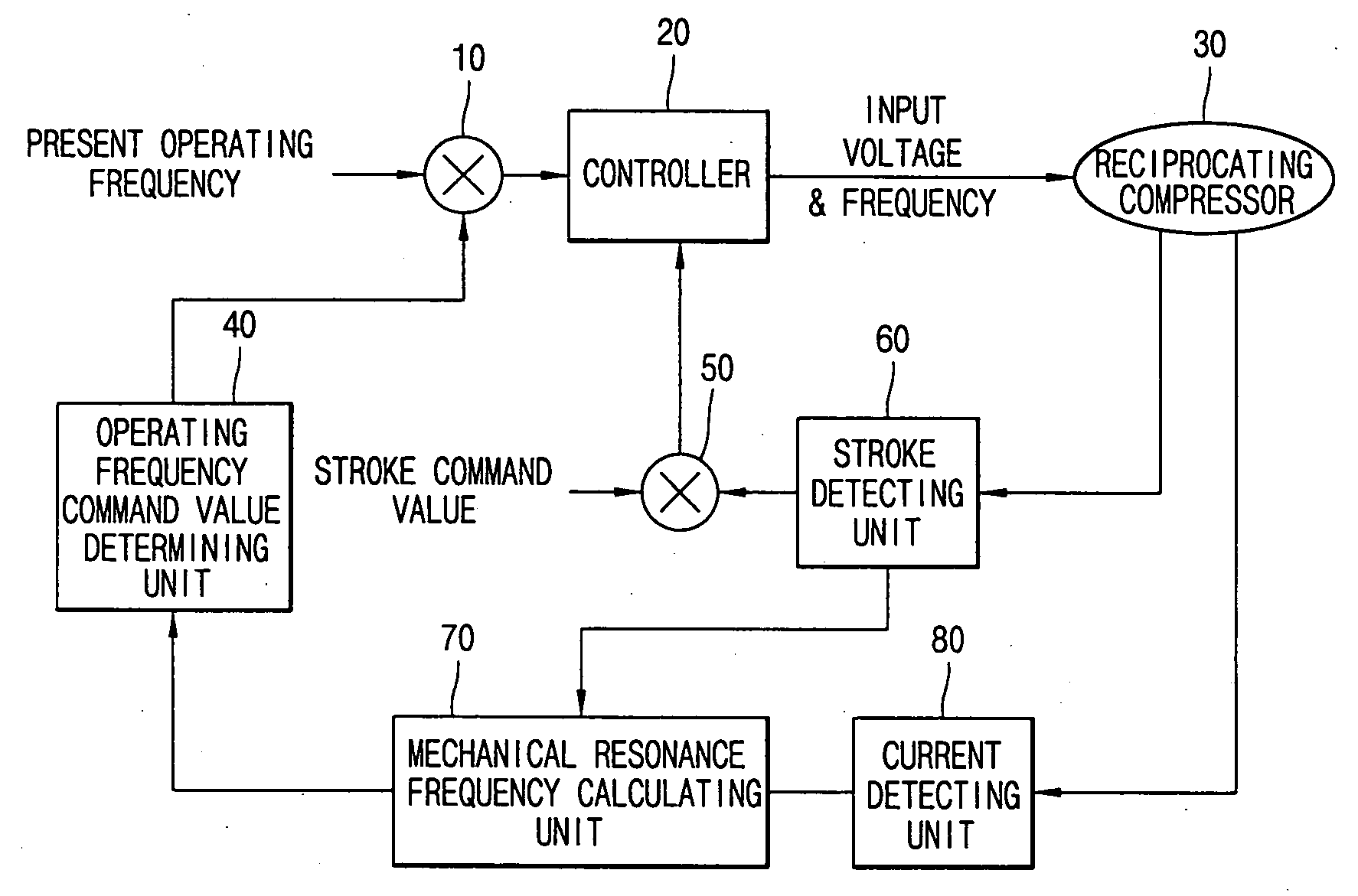

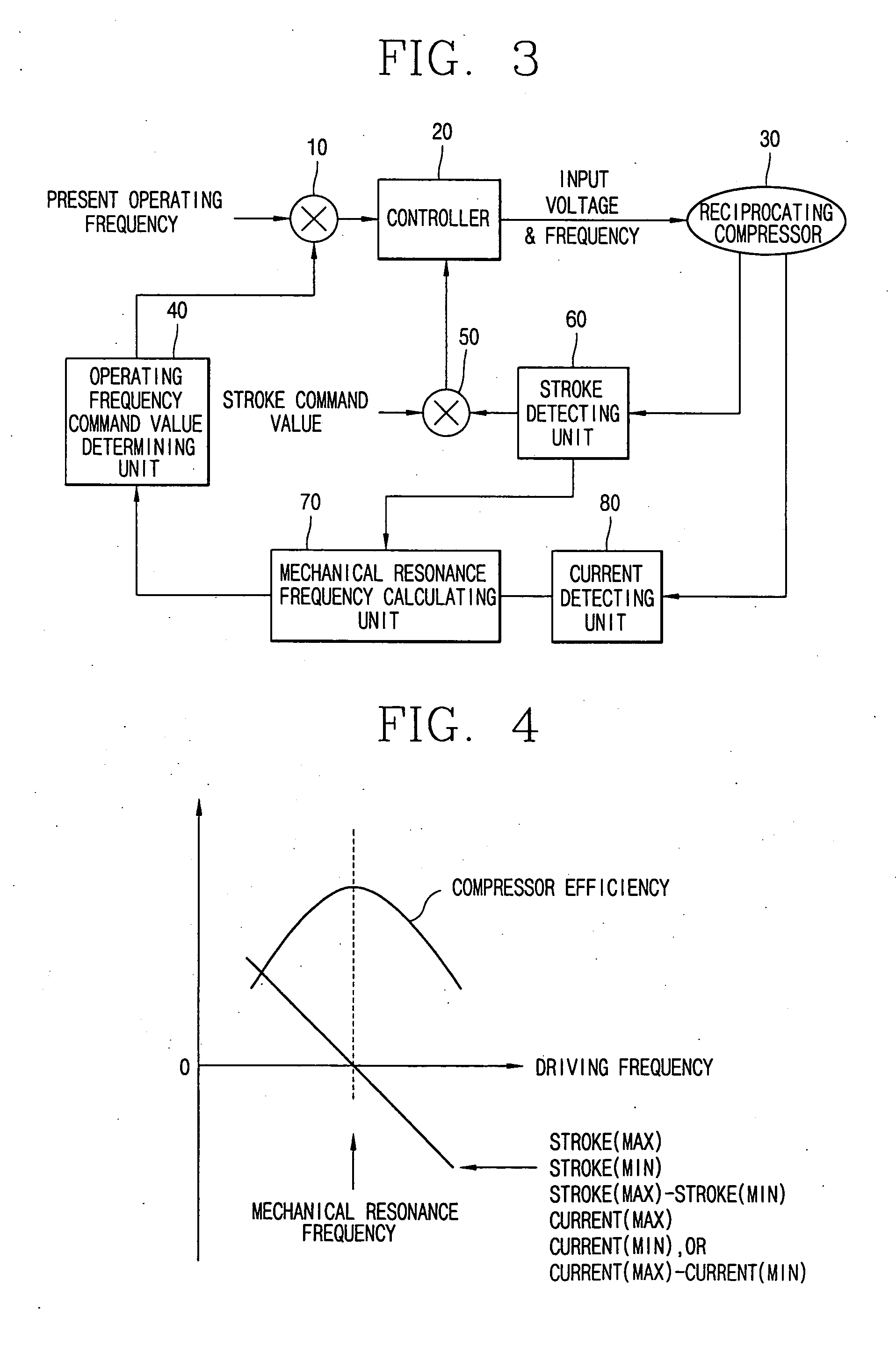

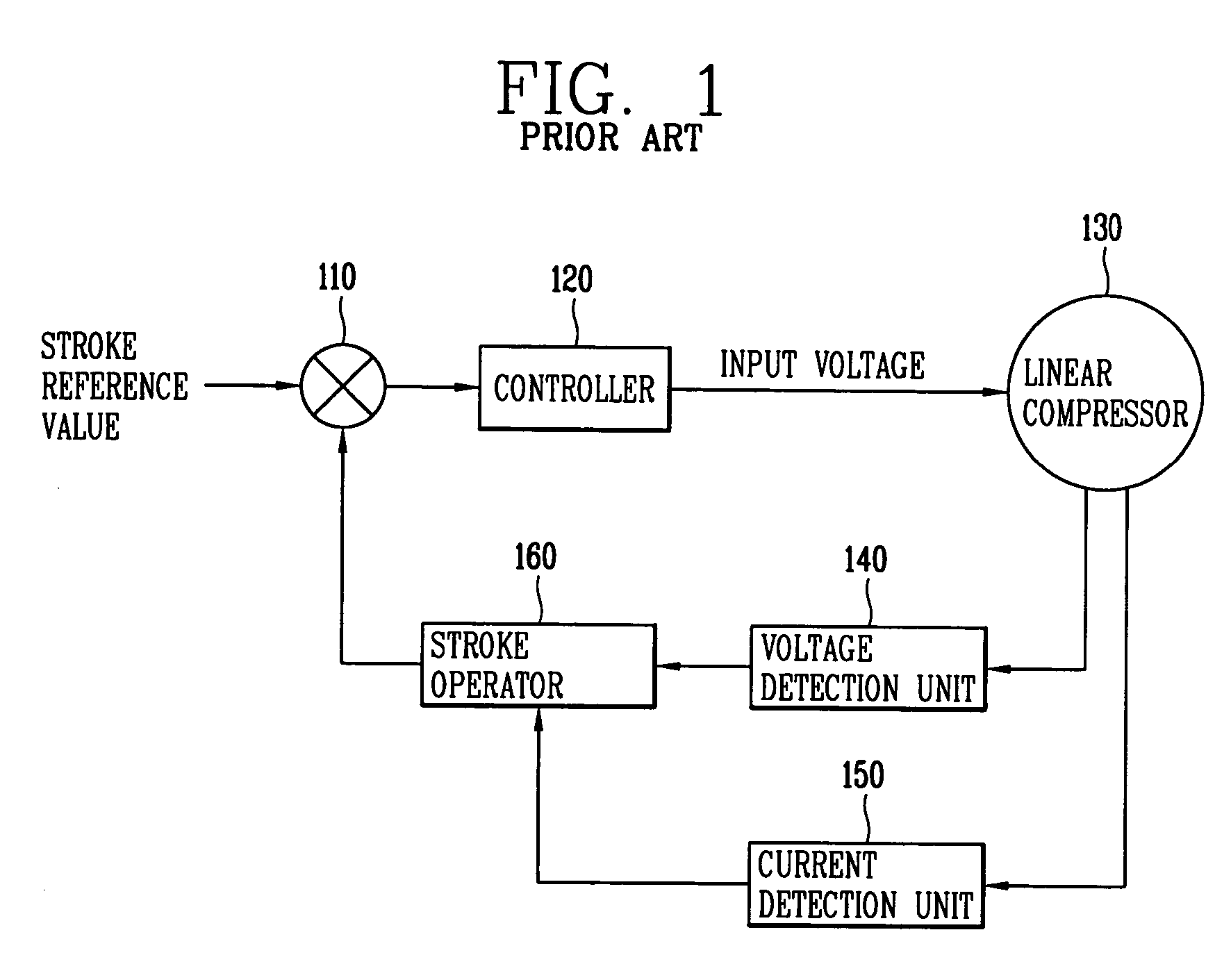

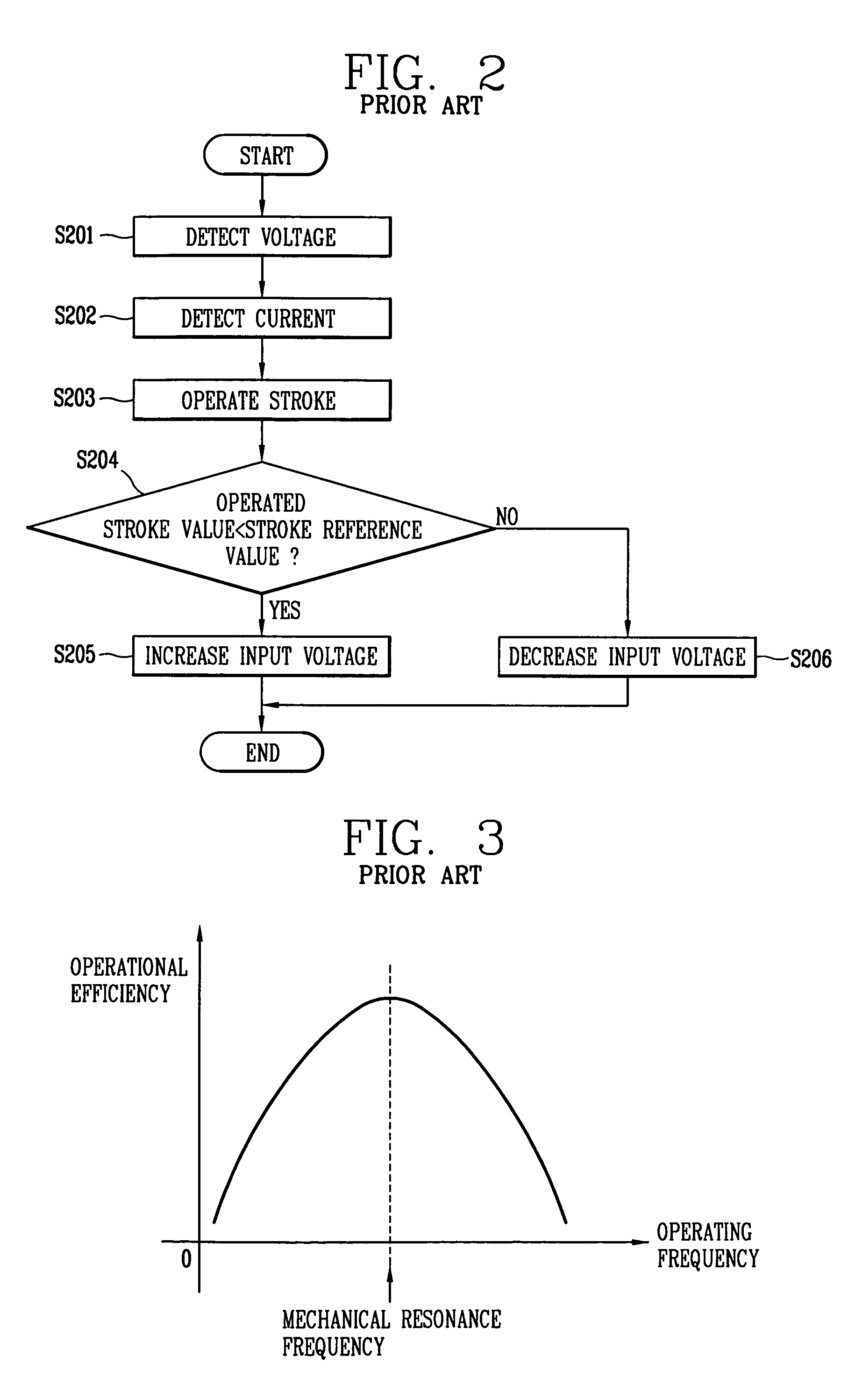

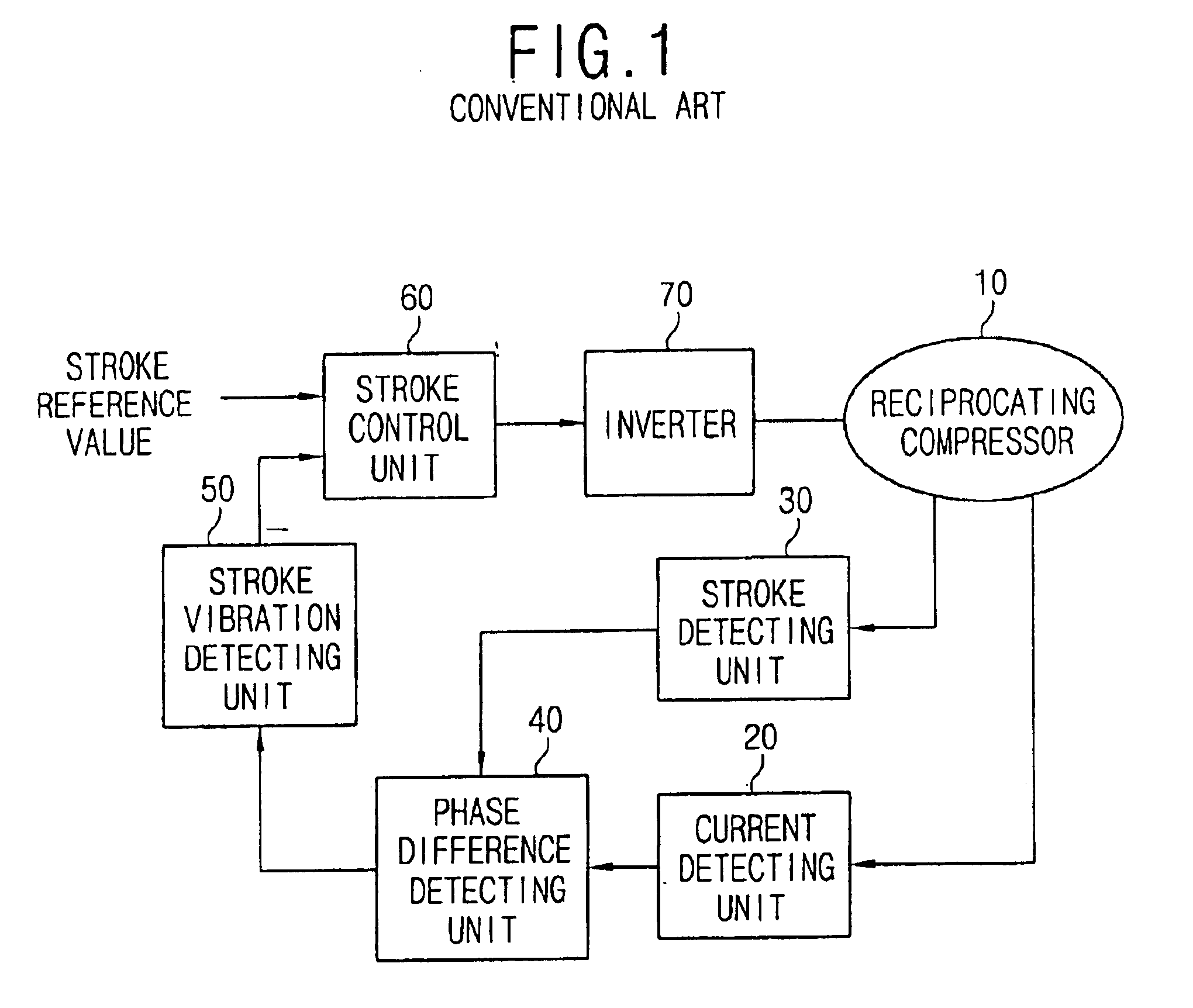

Apparatus and method for controlling operation of reciprocating compressor

ActiveUS20050111987A1Easy to operateAC motor controlDC motor speed/torque controlEngineeringMechanical resonance

The present invention relates to an apparatus and method for controlling operation of a reciprocating compressor. The operating efficiency of the compressor can be improved by performing the steps of: detecting a current and a stroke applied a compressor; a calculating a mechanical resonance frequency by using the detected current and stroke; and determining an operating frequency command value by adding or subtracting the present operating frequency so as to be within a predetermined range of the calculated mechanical resonance frequency and then driving the compressor by the operating frequency command value.

Owner:LG ELECTRONICS INC

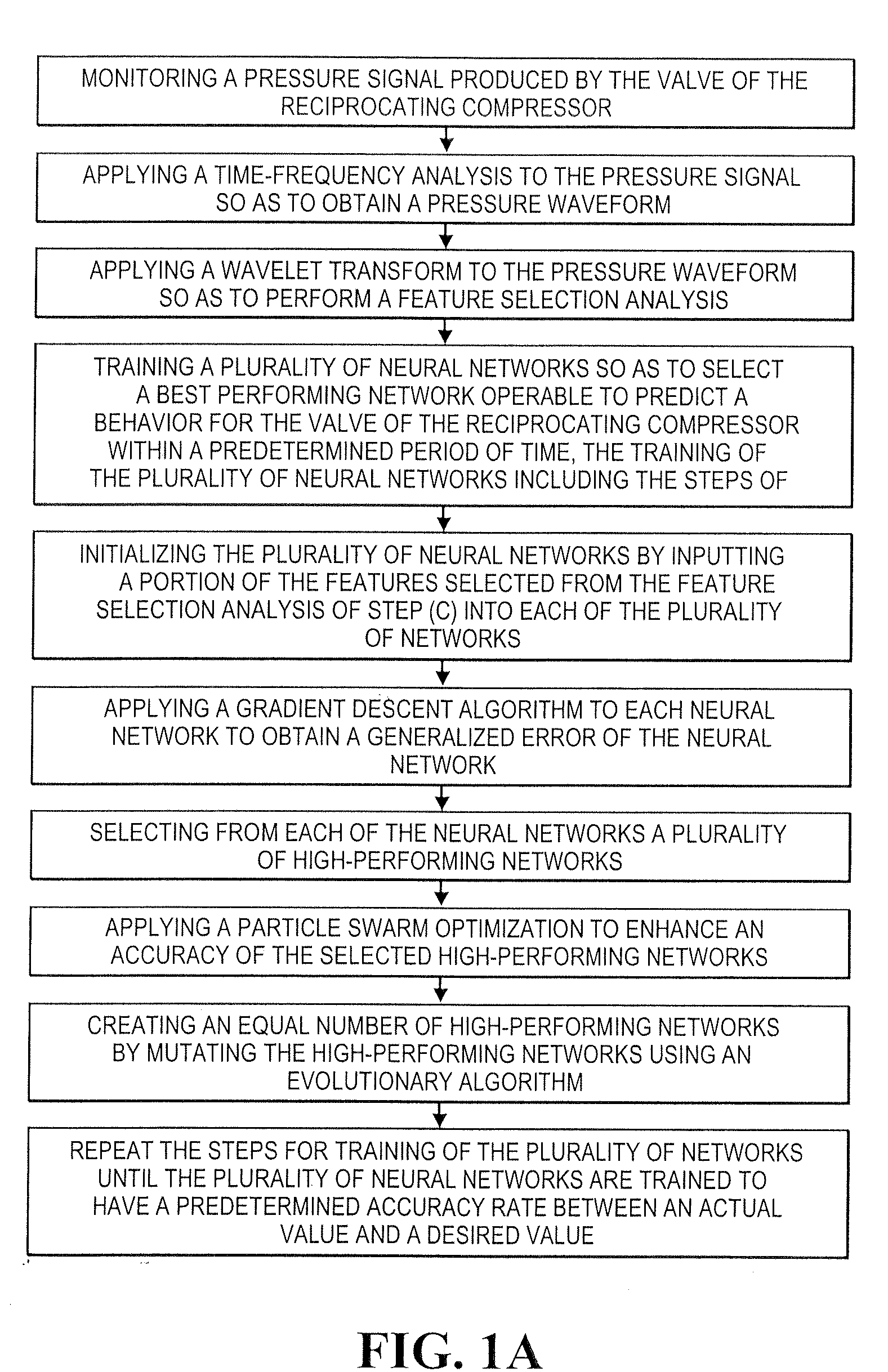

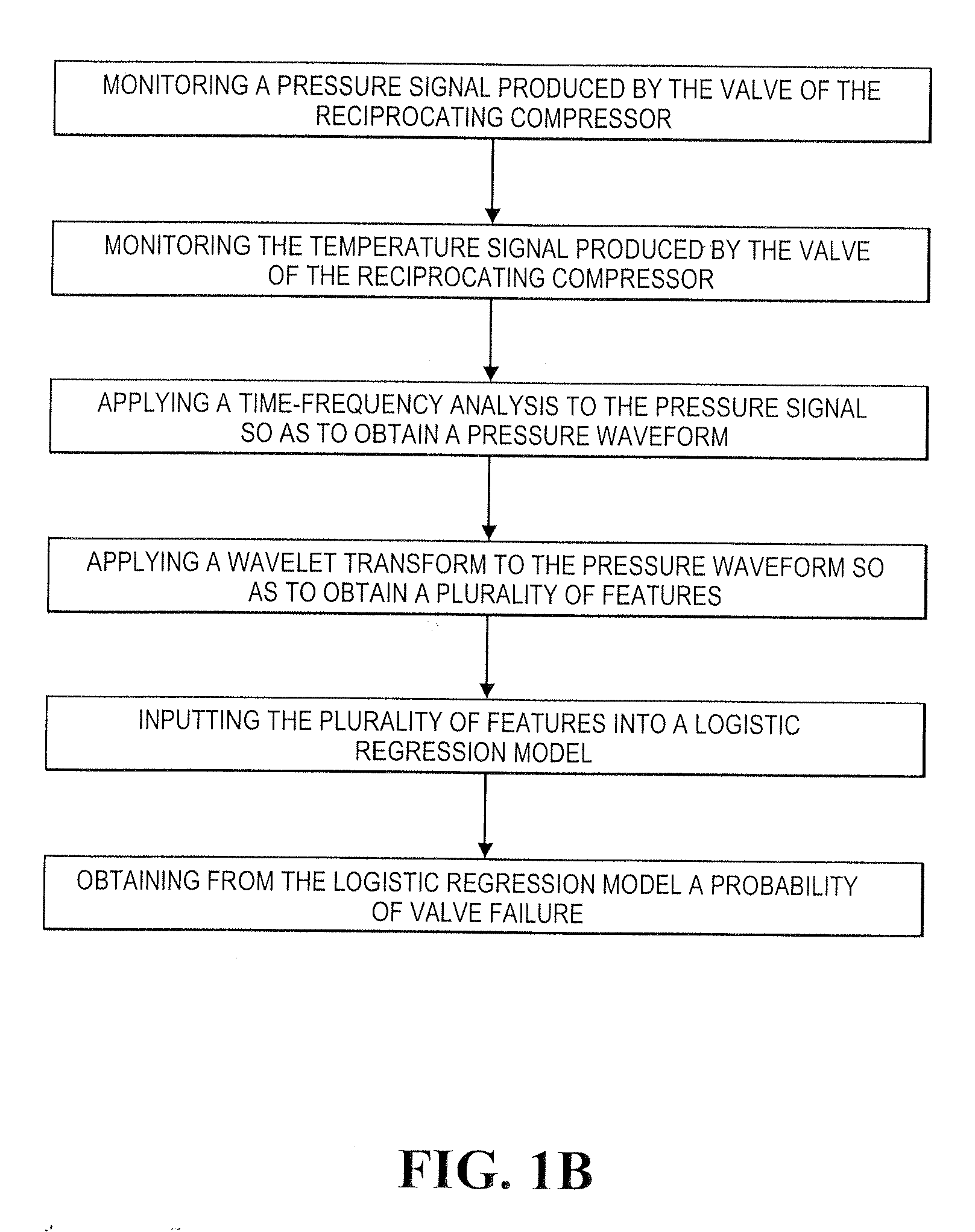

Computer program and method for detecting and predicting valve failure in a reciprocating compressor

Embodiments of the present invention provide a method implemented by a computer program for detecting and identifying valve failure in a reciprocating compressor and further for predicting valve failure in the compressor. Embodiments of the present invention detect and predict the valve failure using wavelet analysis, logistic regression, and neural networks. A pressure signal from the valve of the reciprocating compressor presents a non-stationary waveform from which features can be extracted using wavelet packet decomposition. The extracted features, along with temperature data for the valve, are used to train a logistic regression model to classify defective and normal operation of the valve. The wavelet features extracted from the pressure signal are also used to train a neural network model to predict to predict the future trend of the pressure signal of the system, which is used as an indicator for performance assessment and for root cause detection of the compressor valve failures.

Owner:UNIVERSITY OF MISSOURI

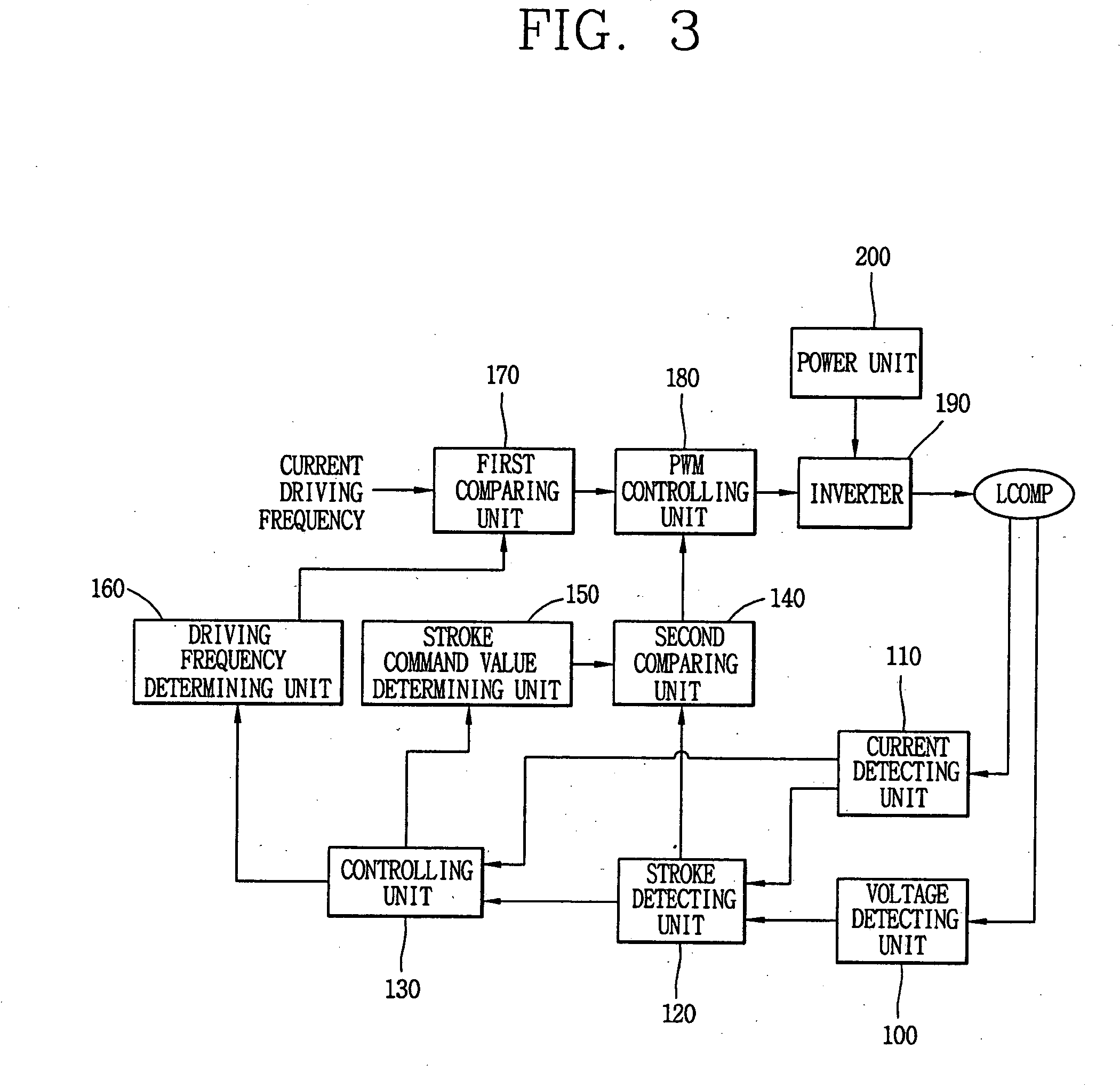

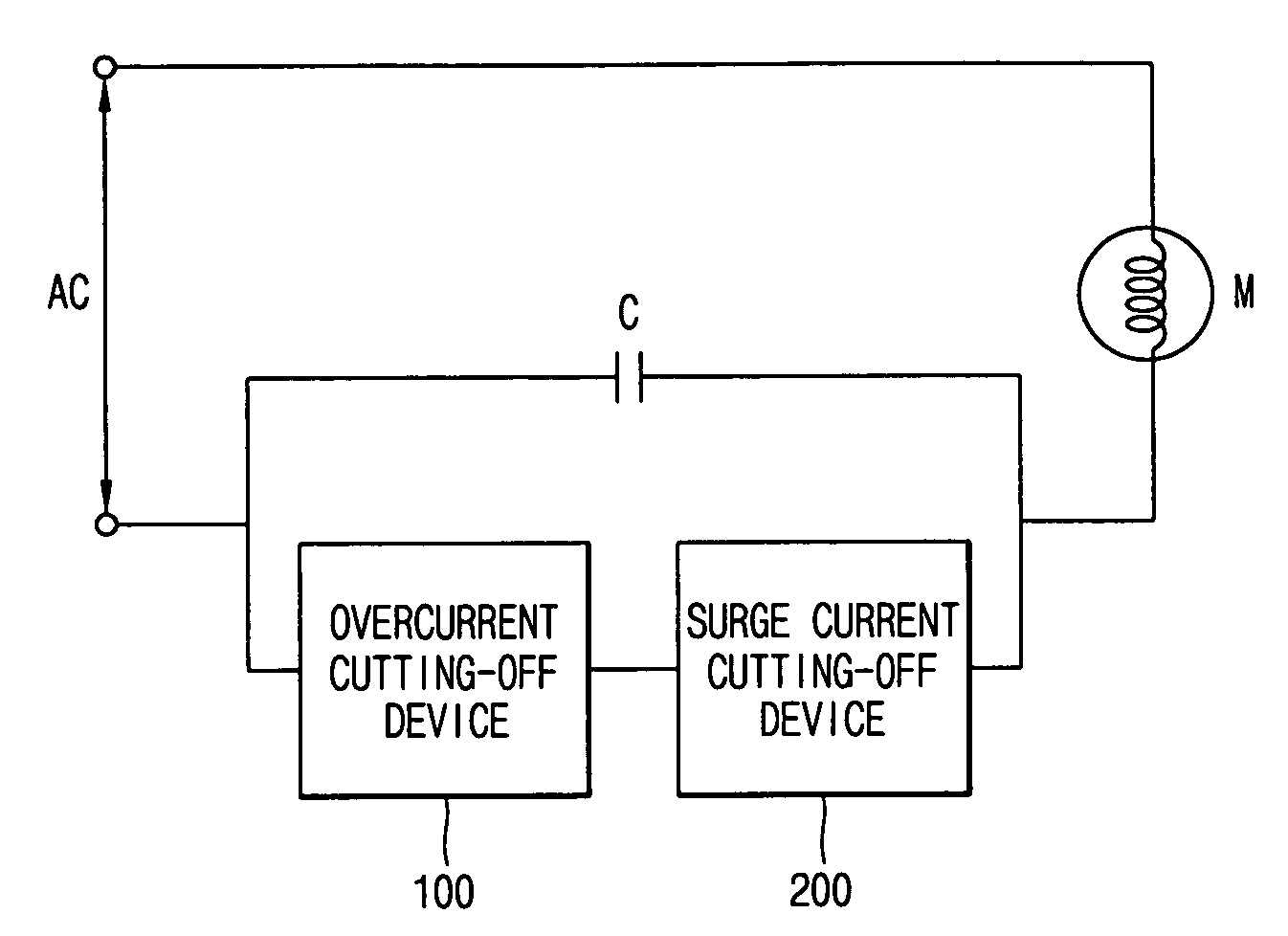

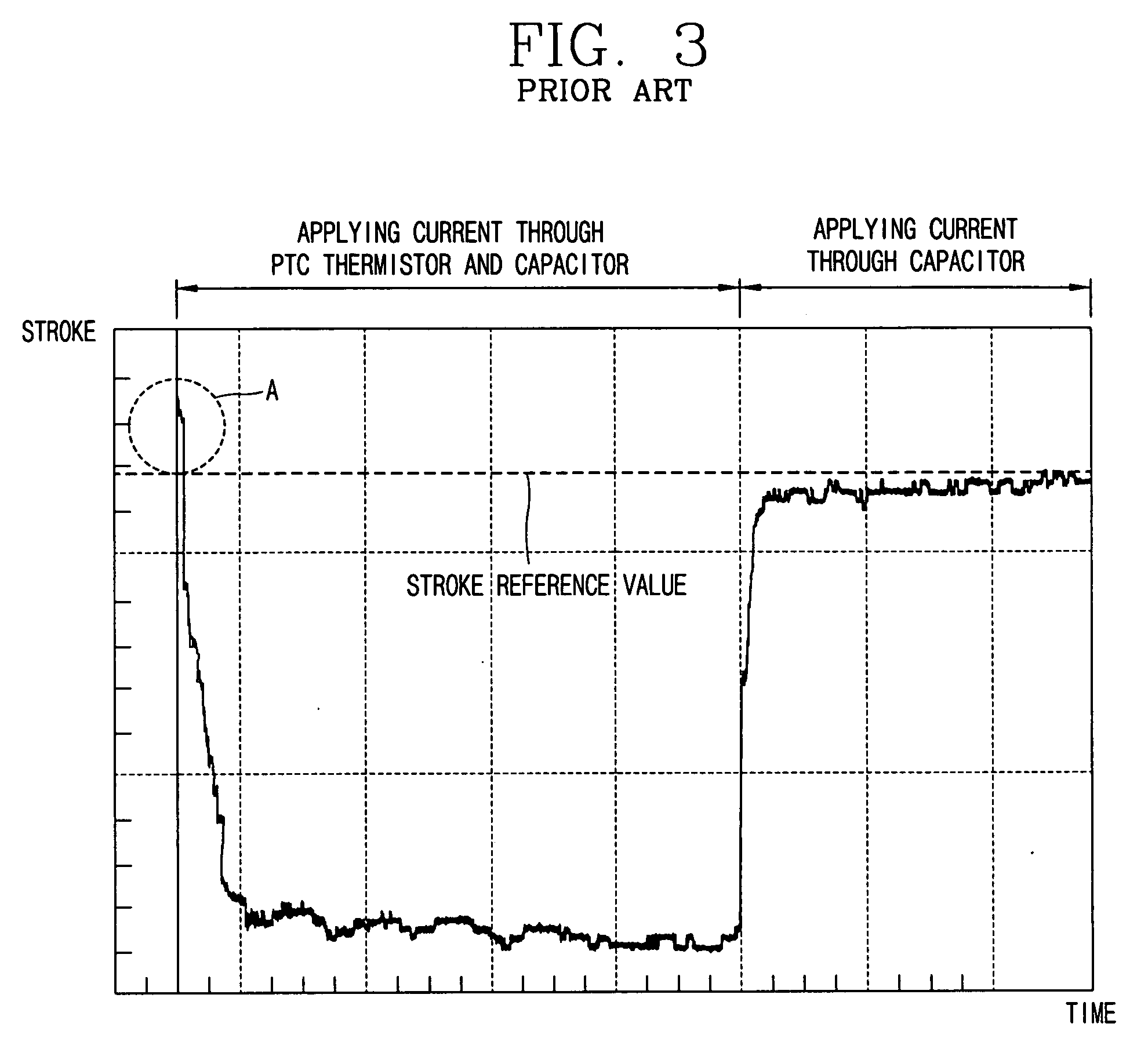

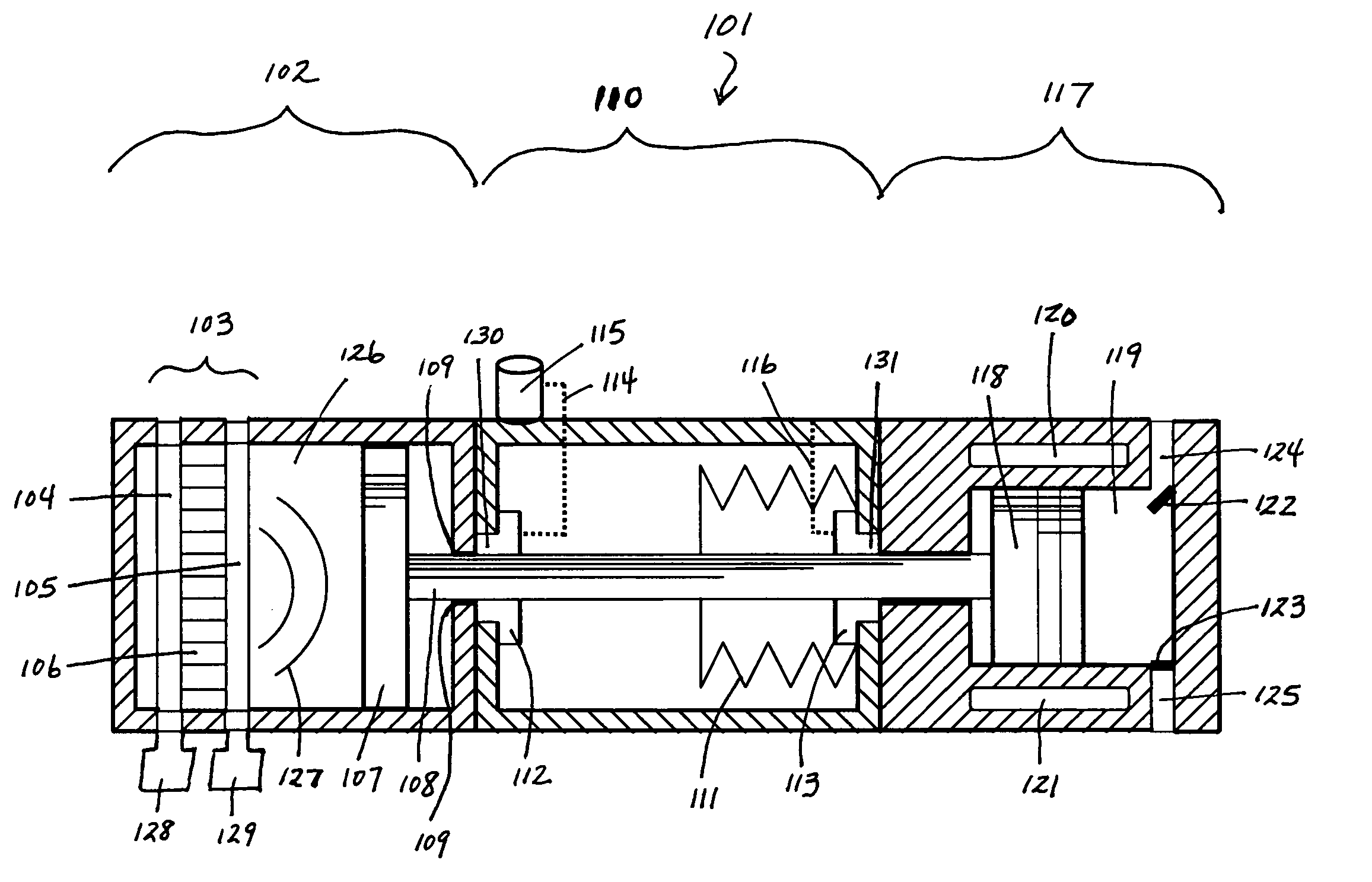

Apparatus for controlling operation of reciprocating compressor

InactiveUS20050053471A1Operation efficiency can be improvedTotal current dropSingle-phase induction motor startersDC motor speed/torque controlInductanceElectrical current

An apparatus for controlling an operation of a reciprocating compressor includes a inductance increasing device connected to a motor of the reciprocating compressor, so that a surge current generated when power is applied to the reciprocating compressor at an initial stage is reduced and thus an initial stroke of the reciprocating compressor is reduced. Accordingly, operational efficiency of the reciprocating compressor is improved.

Owner:LG ELECTRONICS INC

Thermoacoustic driven compressor

The present disclosure details a thermoacoustic driven compressor having a pressurized housing, which contains within a thermoacoustic engine and a working gas, coupled to a positive displacement reciprocating compressor. The thermoacoustic driven compressor generates scalable compressed air from a given heat source.

Owner:ENOVA

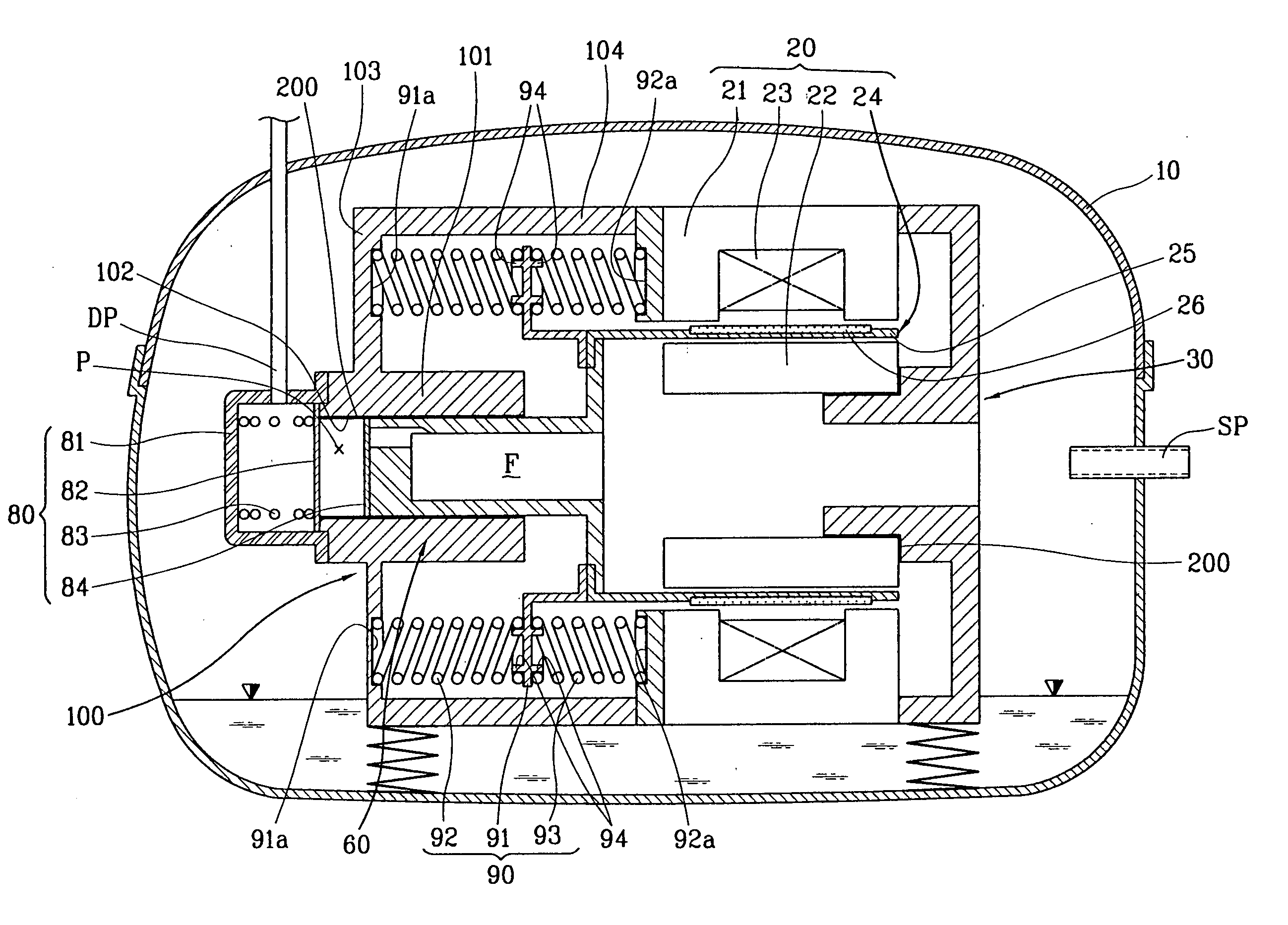

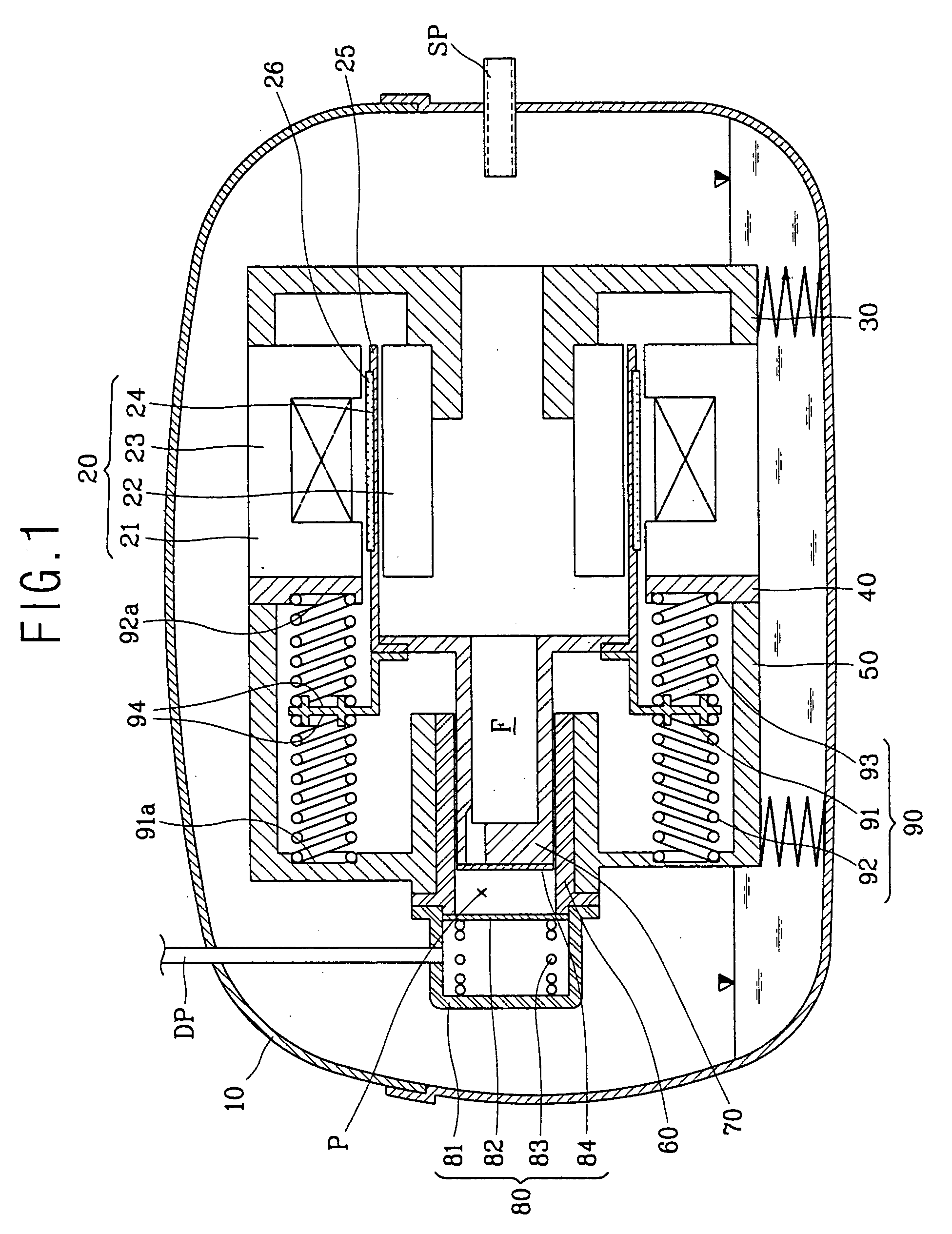

Abrasion preventive structure of reciprocating compressor

In an abrasion preventive structure of a reciprocating compressor, by forming a coating layer made of Ni—P alloy material having high hardness onto the surface of a frame at which front (92) and rear (93) resonance springs are contacted or spring mounting grooves (91a, 92a) of a spring supporting rod (91) or spring fixation protrusions or the inner circumference of a cylinder built-in type frame, although each resonance spring (92, 93) is rotated while repeating compression / relaxation, it is possible to prevent abrasion of the spring mounting grooves (91a, 92a) or the spring fixation protrusions, and accordingly reliability of the compressor can be improved.

Owner:LG ELECTRONICS INC

Apparatus for preventing abrasion in reciprocal compressor

InactiveUS20050142007A1Avoid scratchesPositive displacement pump componentsPlungersInterior spaceRelative motion

The present invention discloses an apparatus for preventing abrasion in a reciprocal compressor, including a cylinder, a reciprocal motor having a stator and a mover, and generating a linear reciprocation driving force, a piston inserted into an inside space of the cylinder to be linearly movable, a piston rod coupled to the piston to be movable in the radial direction of the piston, and coupled to the mover of the reciprocal motor, for transmitting the linear reciprocation driving force of the reciprocal motor to the piston, and a concentricity control means coupled to a junction between the piston and the piston rod, for fixing the piston and the piston rod in the axial direction, and allowing a relative motion thereof in the radial direction. The apparatus for preventing abrasion in the reciprocal compressor prevents abrasion from being generated between the cylinder and the piston due to processing errors and assembly errors of components of the reciprocal compressor.

Owner:LG ELECTRONICS INC

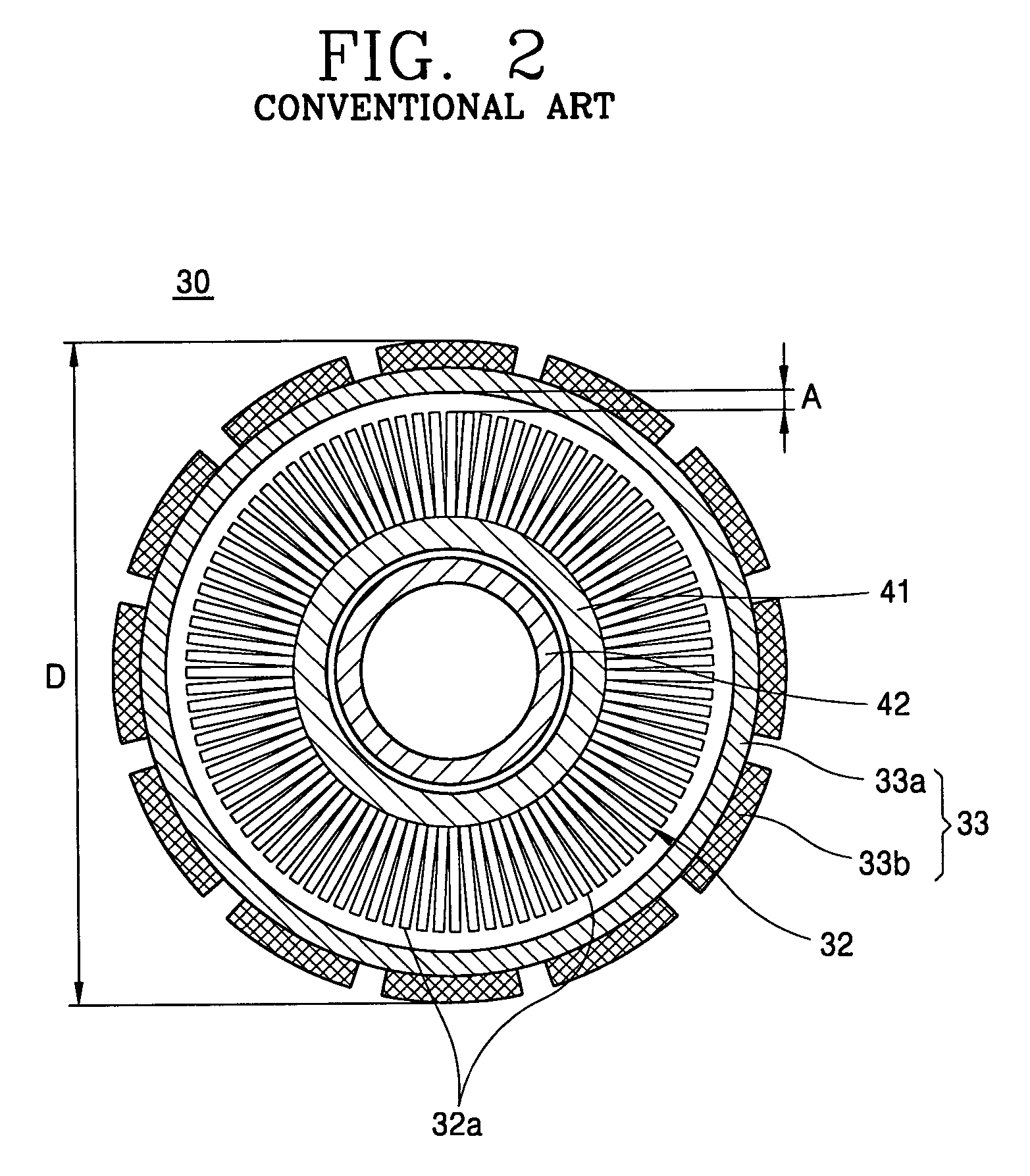

Reciprocating compressor

InactiveUS20060018771A1Reduce in quantityImprove workabilityPiston pumpsDynamo-electric machinesEngineeringMagnet

A reciprocating compressor includes: a cylinder installed inside a casing and having a space therein; a piston disposed inside the cylinder; an inner stator fixed at an outer circumference of the cylinder; a magnet fixed at an outer circumference of the inner stator; and an outer stator disposed to maintain a certain distance from an outer circumference of the magnet. Accordingly, the number of components is reduced thus to reduce a manufacturing cost, and performance can be also improved.

Owner:LG ELECTRONICS INC

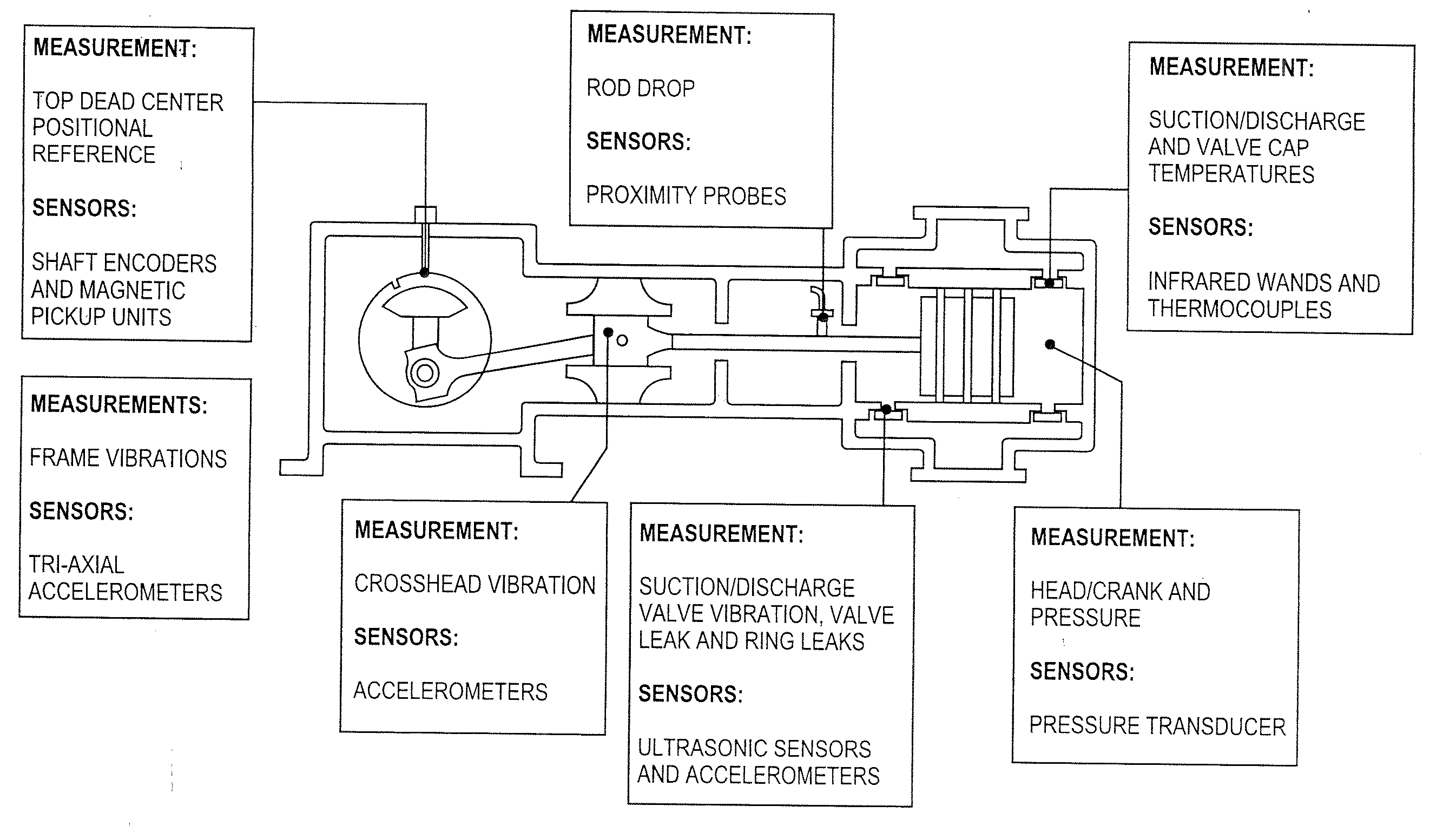

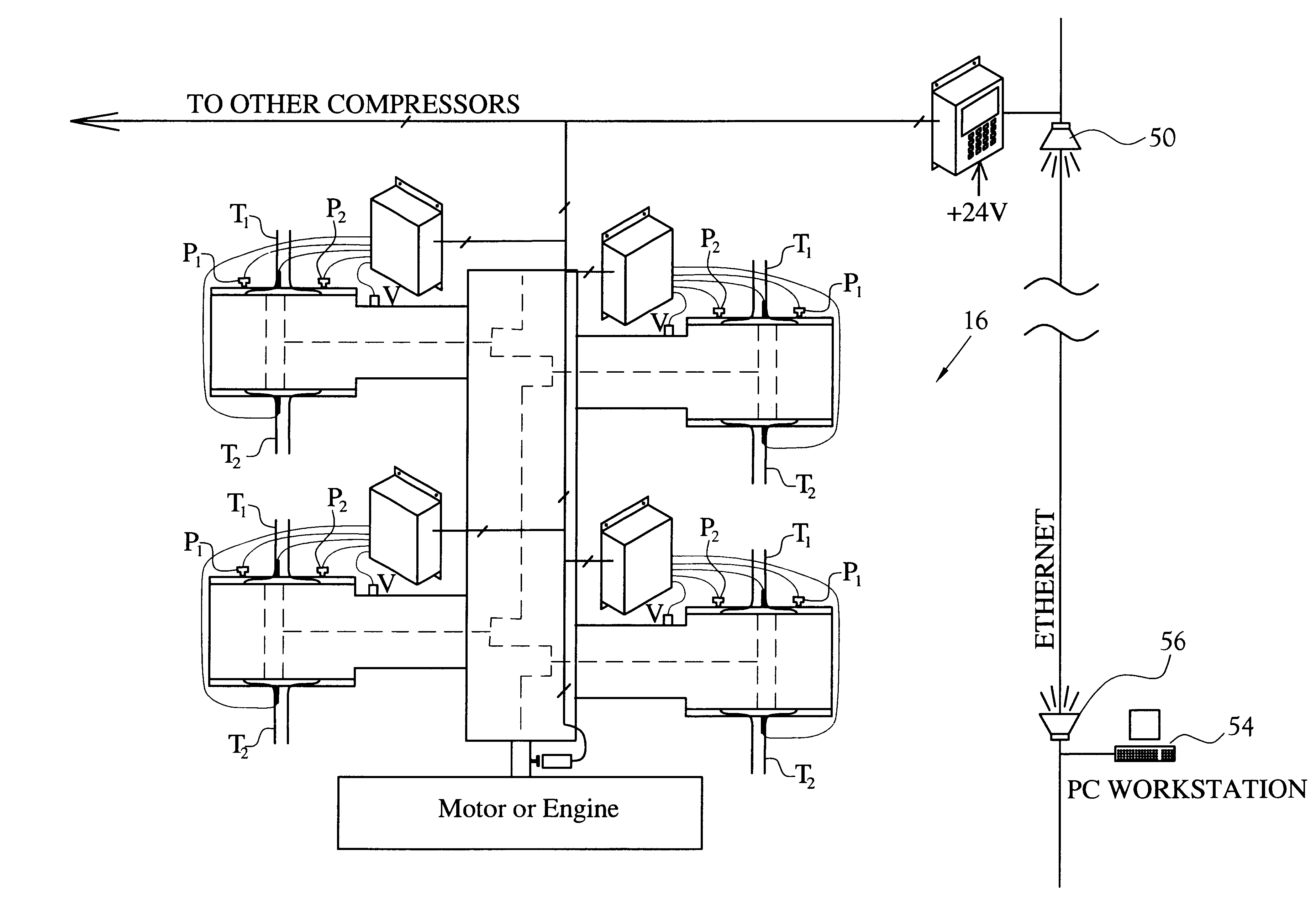

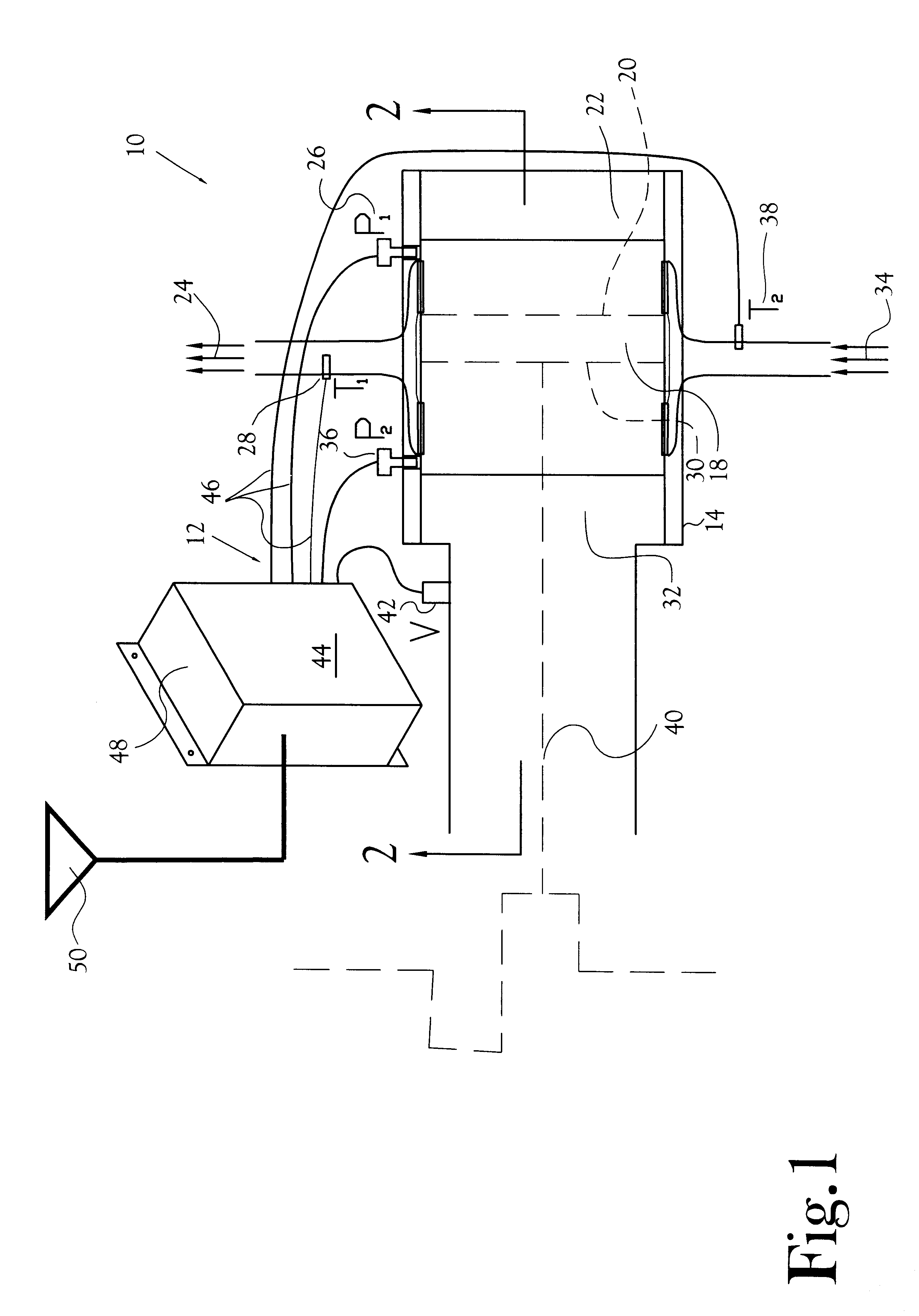

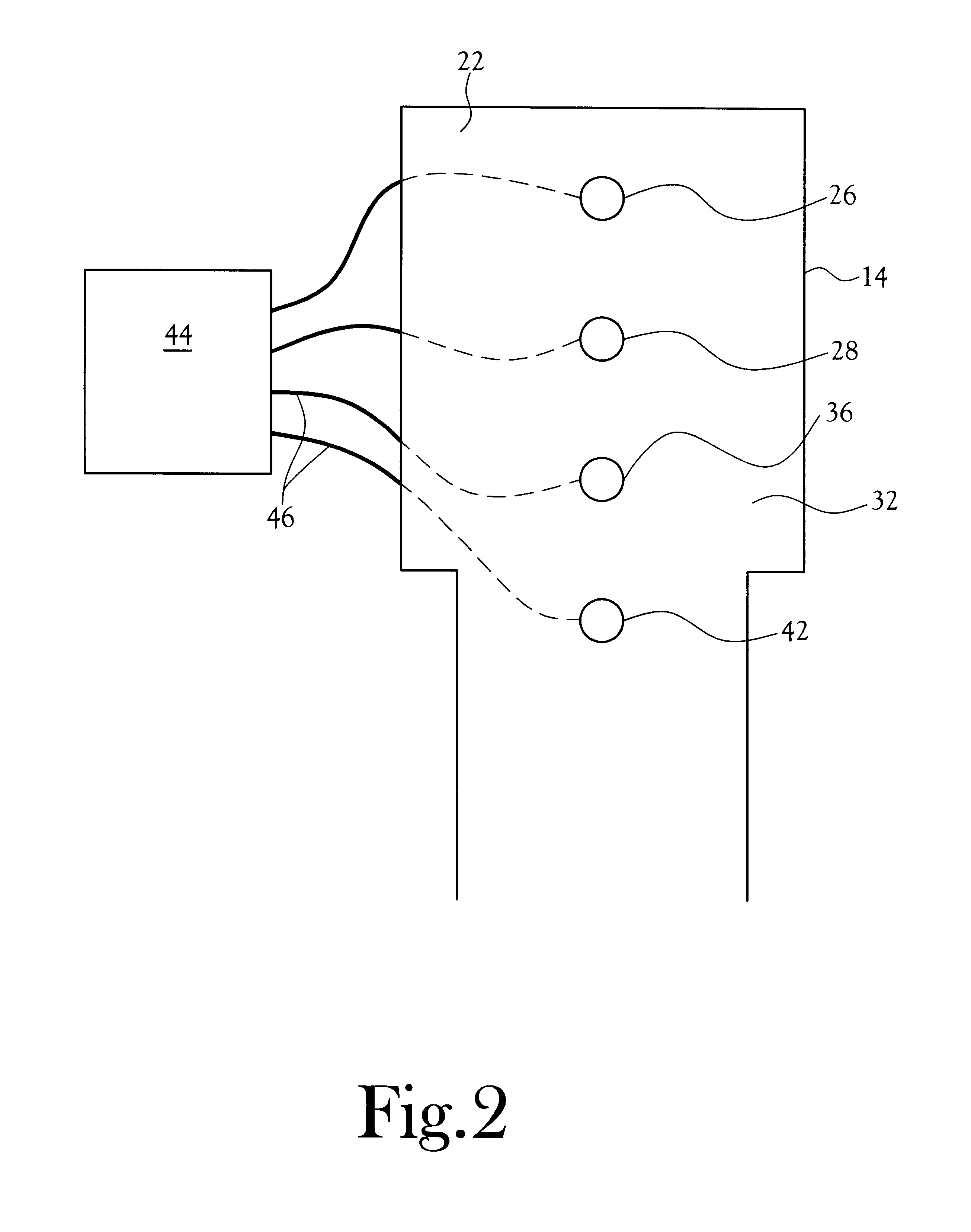

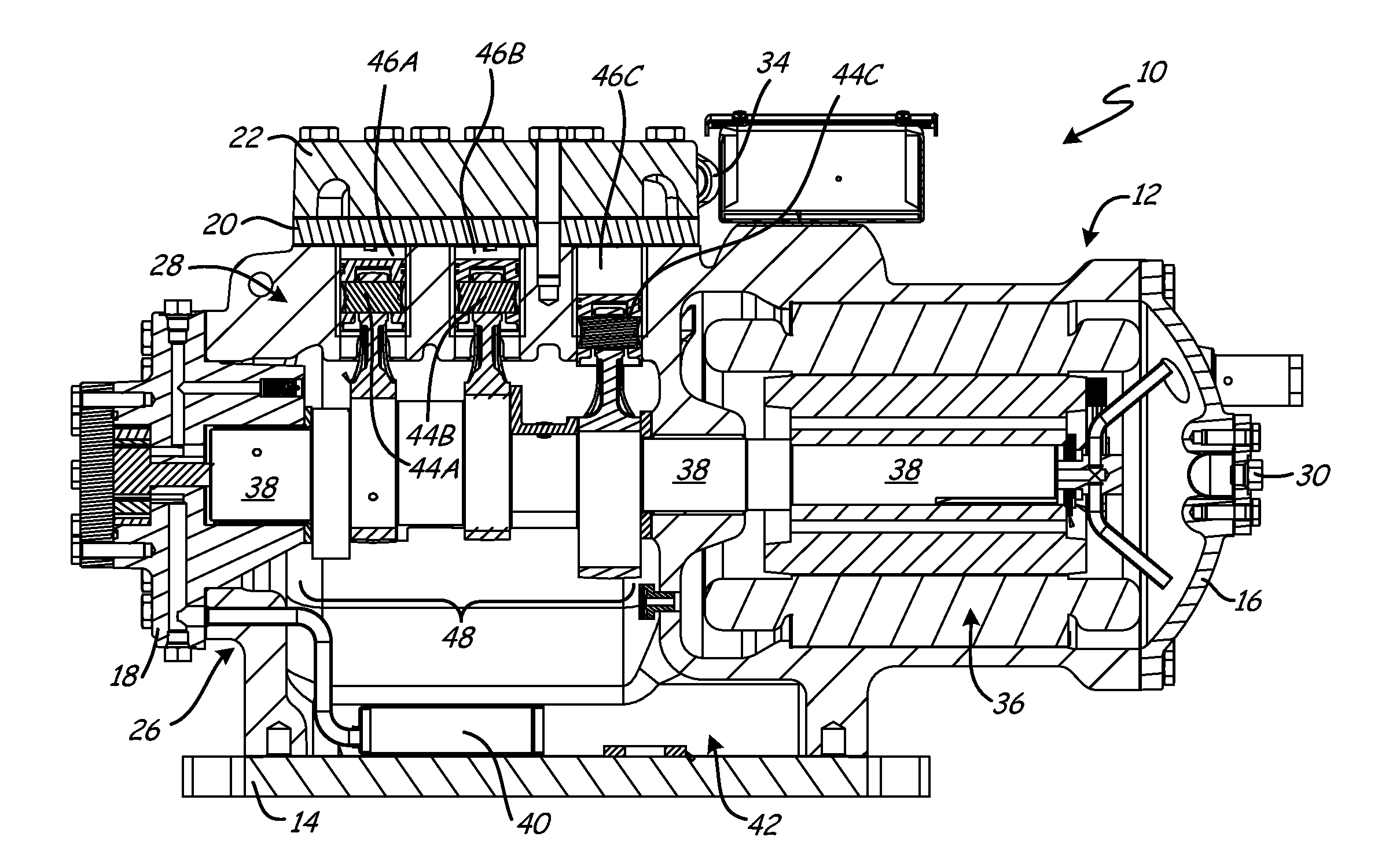

Method and apparatus for continuously monitoring parameters of reciprocating compressor cylinders

InactiveUS6292757B1Continuous monitoringAnalogue computers for vehiclesInternal-combustion engine testingEngineeringVolume Curve

An apparatus and method for continuously monitoring selected parameters of reciprocating compressor cylinders is disclosed, the apparatus includes a plurality of sensors positioned to monitor selected parameters within the cylinder on either side of the piston, with the selected parameters including pressures on each side of the piston for each cycle, temperatures of the gas entering and exiting the cylinder, and vibrations of components such as a piston shaft within the cylinder. A calculator means in close proximity to the cylinder receives the signals from the sensors and analyzes the signals for each cycle of the piston. Output signals proportional to the monitored signals are transmitted to a remotely located computer. The output signals include pressure versus volume curves for each cylinder volume, horsepower consumed by the cylinder, inlet suction and outlet discharge gas temperatures of the gases moved through the cylinder, and compression and tension stress on the piston rod. Computer analyses compare monitored signals to pre-selected ranges of operating parameters to provide alarm signals to alert operators of the performance and mechanical conditions within the monitored reciprocating compressor cylinder. A method of operation for continuously monitoring selected parameters of reciprocating compressor cylinders is also disclosed.

Owner:WINDROCK

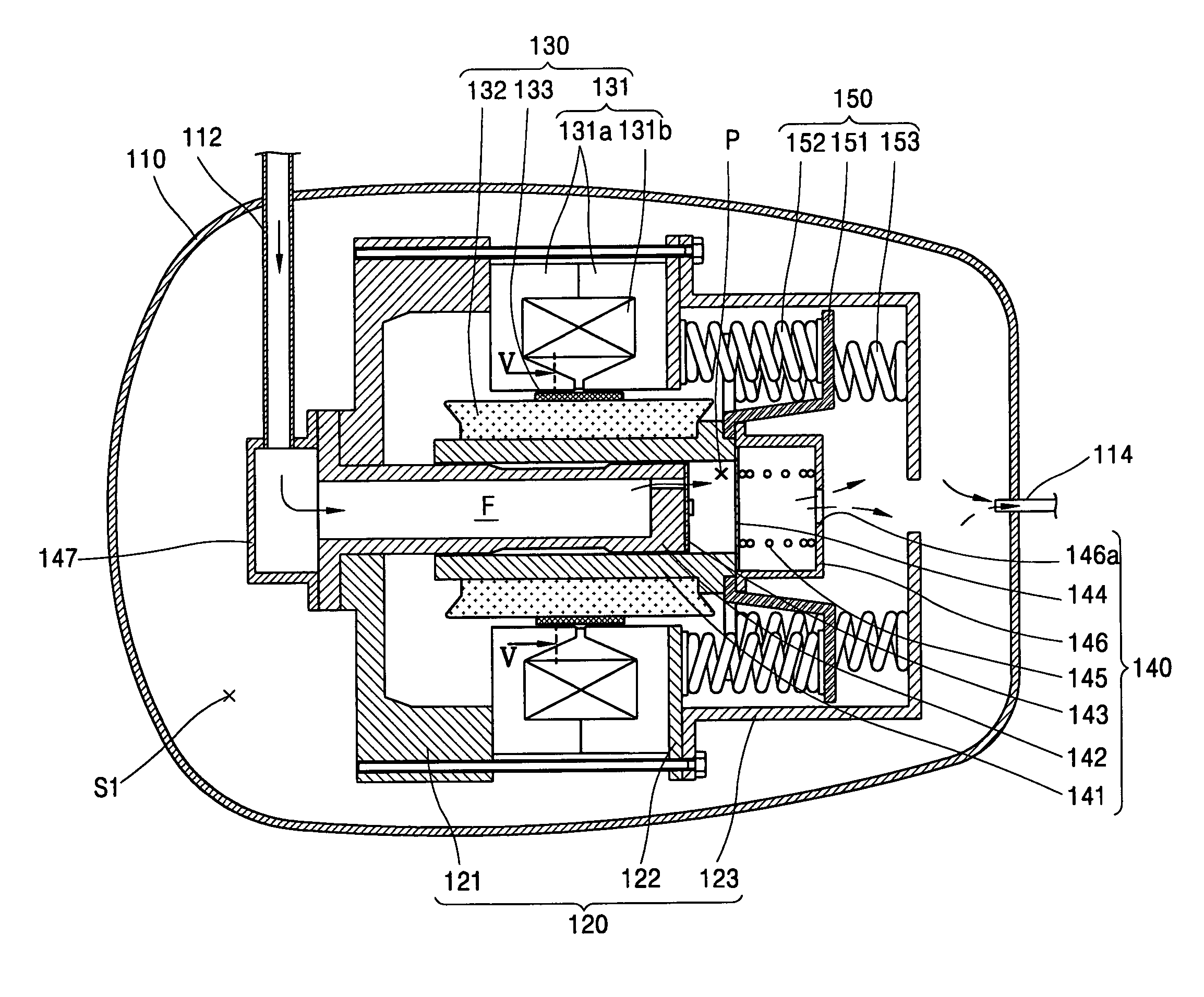

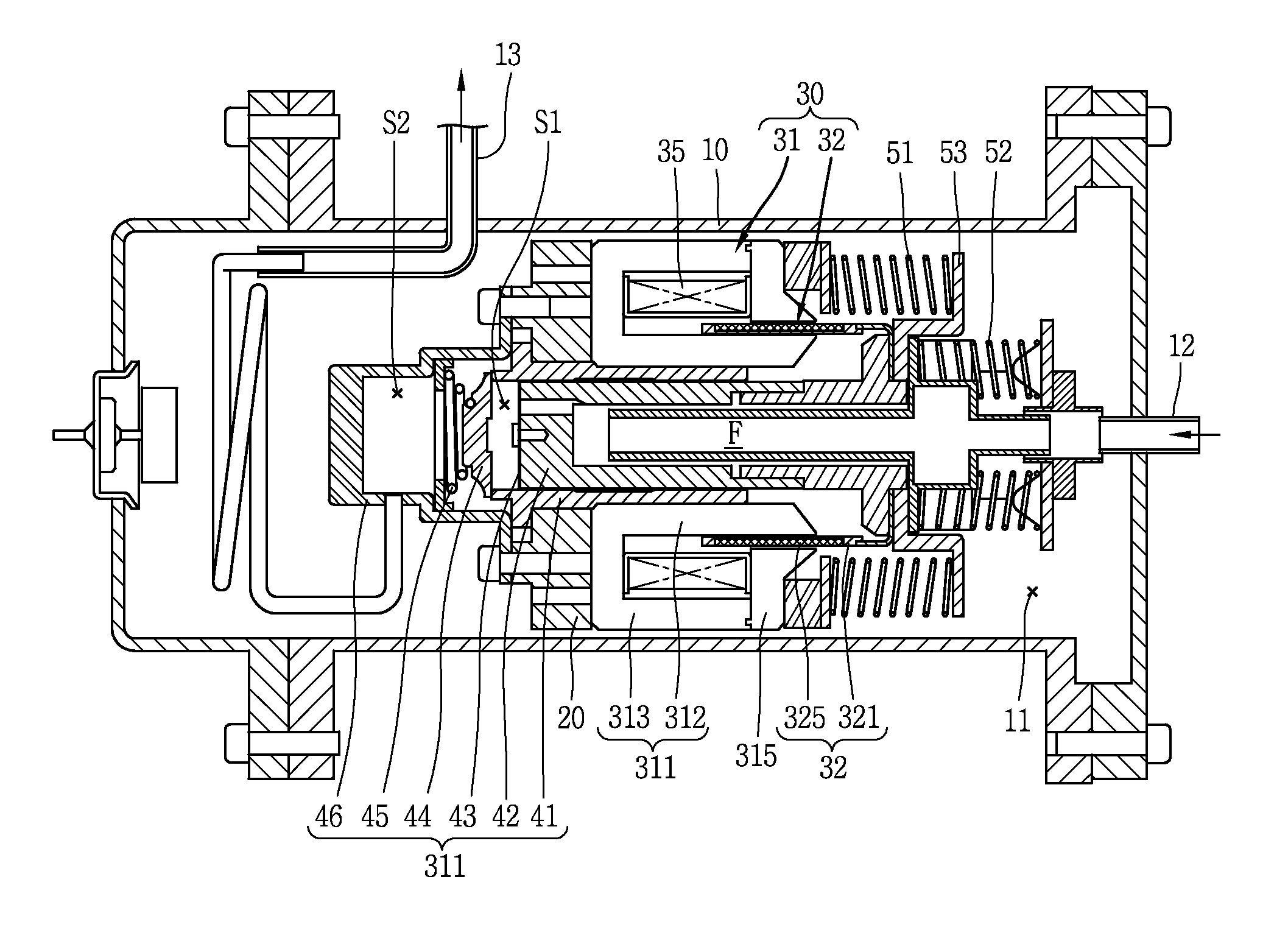

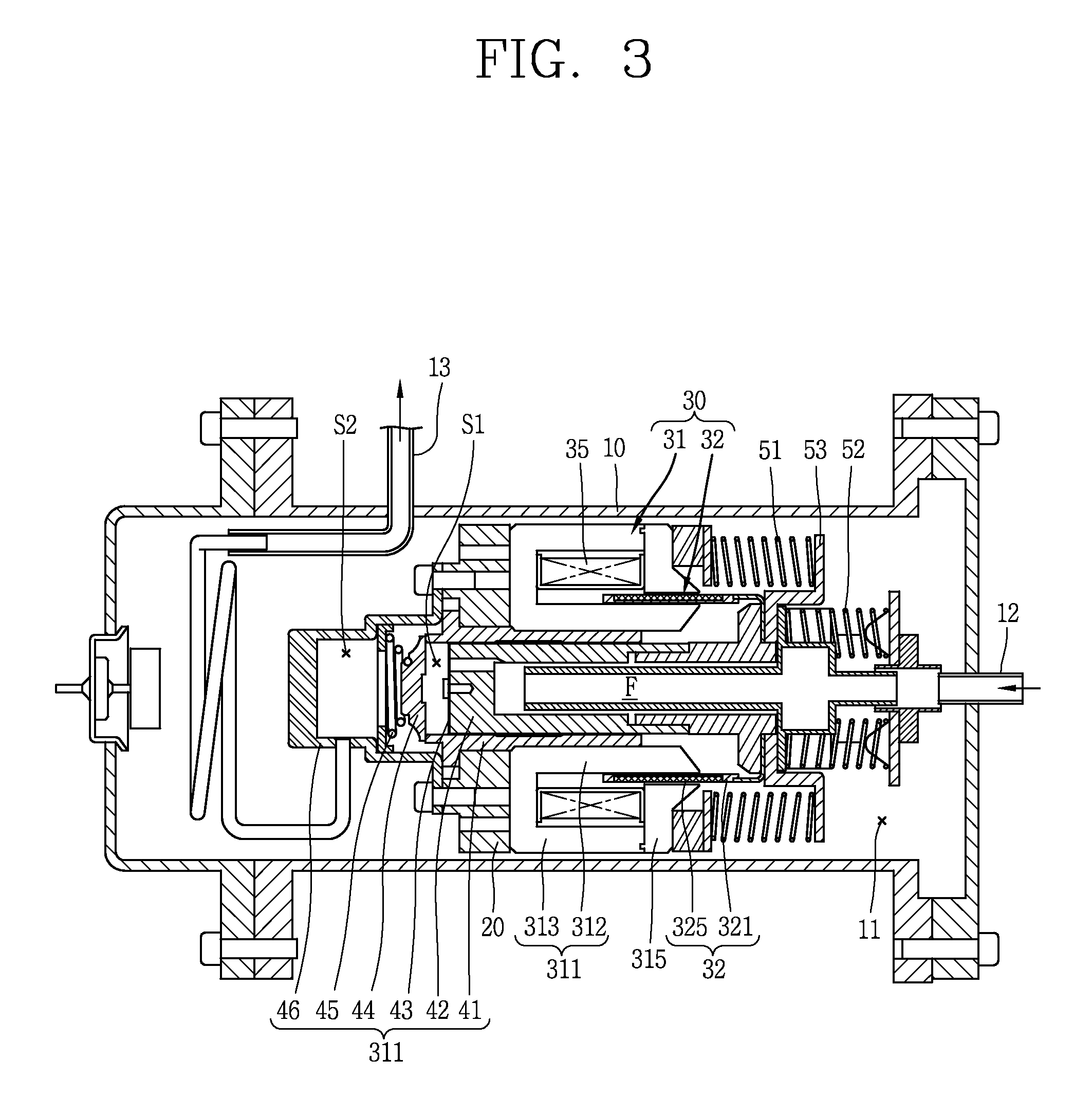

Reciprocating compressor

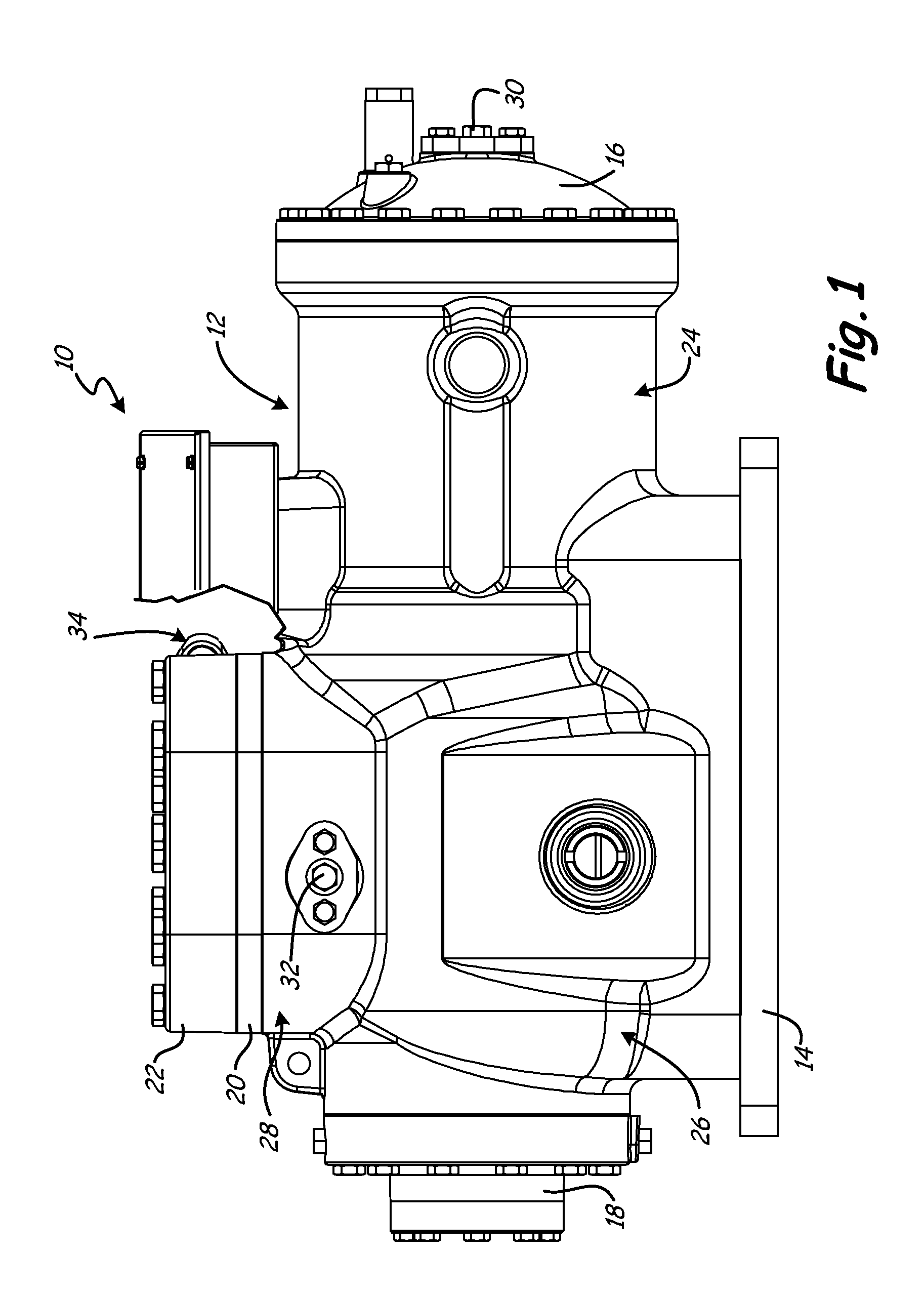

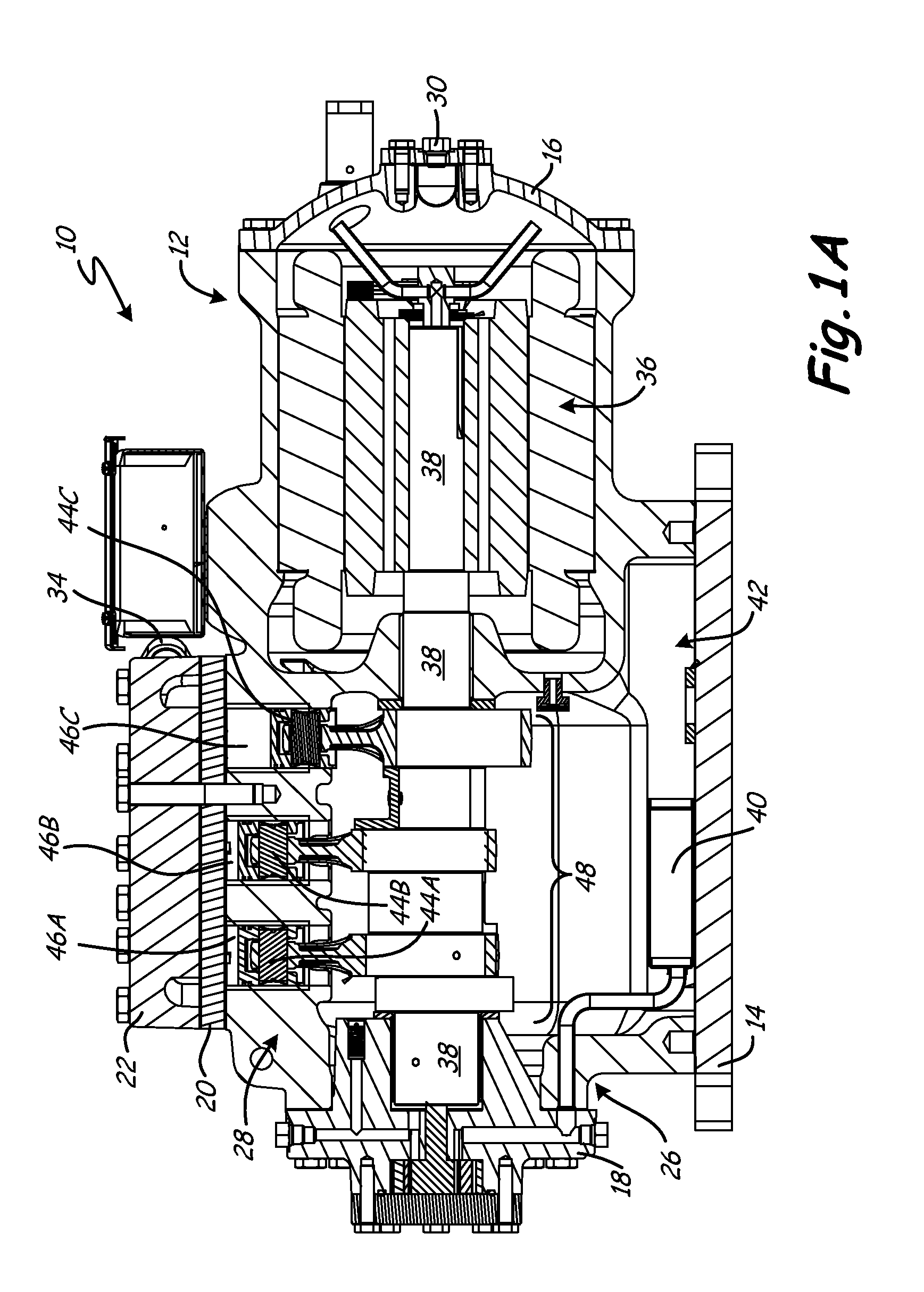

InactiveUS20060210411A1Reduce widthMaintain concentricityPiston pumpsPositive-displacement liquid enginesReciprocating motionEngineering

A reciprocating compressor includes a driving unit (16) having an outer stator (26) and an inner stator disposed at a predetermined air gap there between, and a moving member positioned between the outer stator (26) and the inner stator (28) and linearly and reciprocally moved; a compression unit (18) having a cylinder (38) fixed at an inner circumferential surface of the inner stator (28) and a piston (22) linearly moved in the cylinder (38) by being connected to the moving member, a support portion (20) supporting the compression unit (18) and the driving unit (16); and a resonant spring unit positioned (24) at a rear portion of the driving unit (16), disposed at the support portion (20), and inducing a resonant movement of the piston (22). Therefore, a resonant spring (62,64) of the compressor can be moved horizontally and straight forwardly by reducing a torsion moment of the resonant spring (62,64), a width of the compressor can be reduced, and a concentricity of a driving unit (16) and a compression unit can be maintained.

Owner:LG ELECTRONICS INC

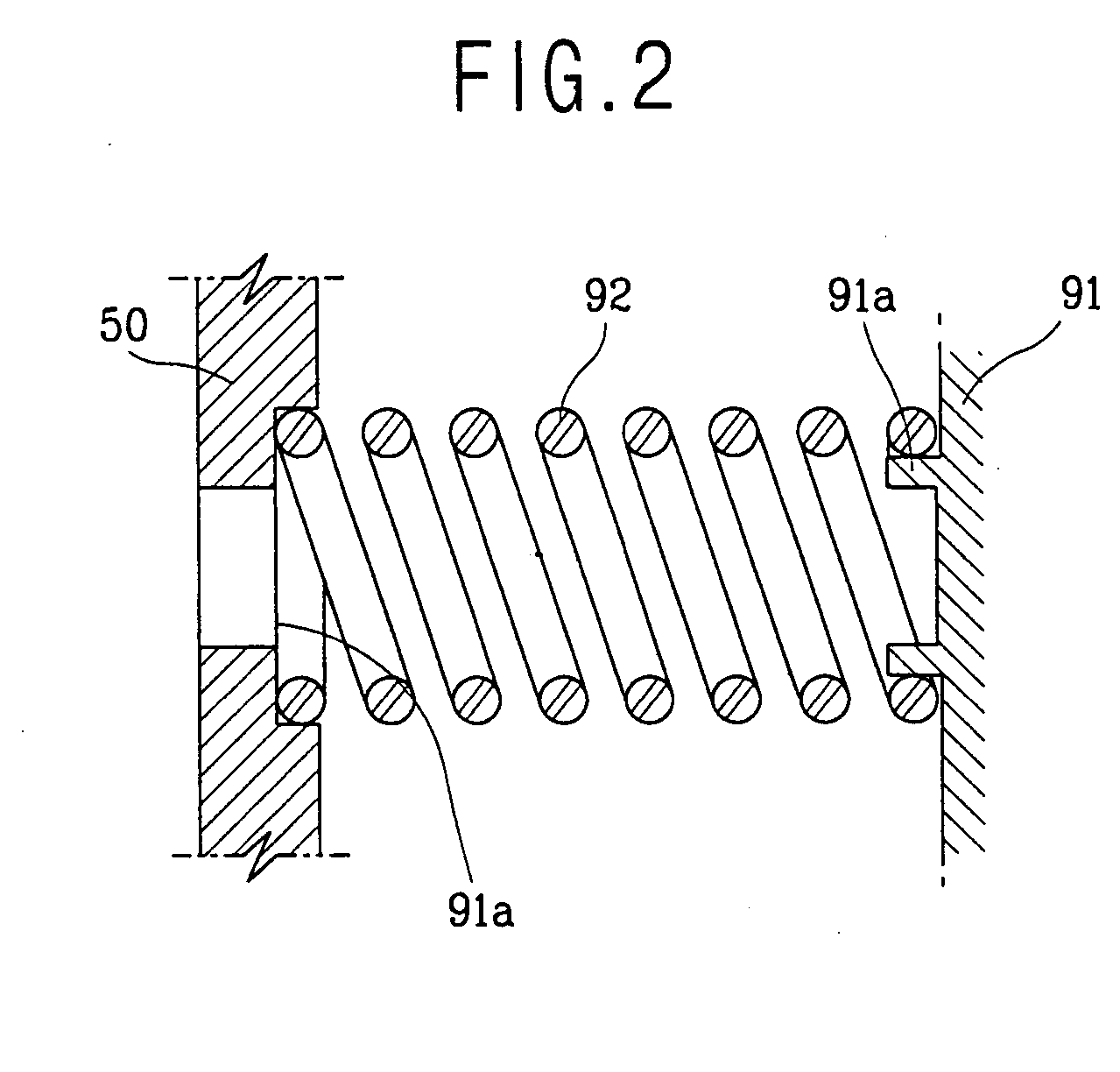

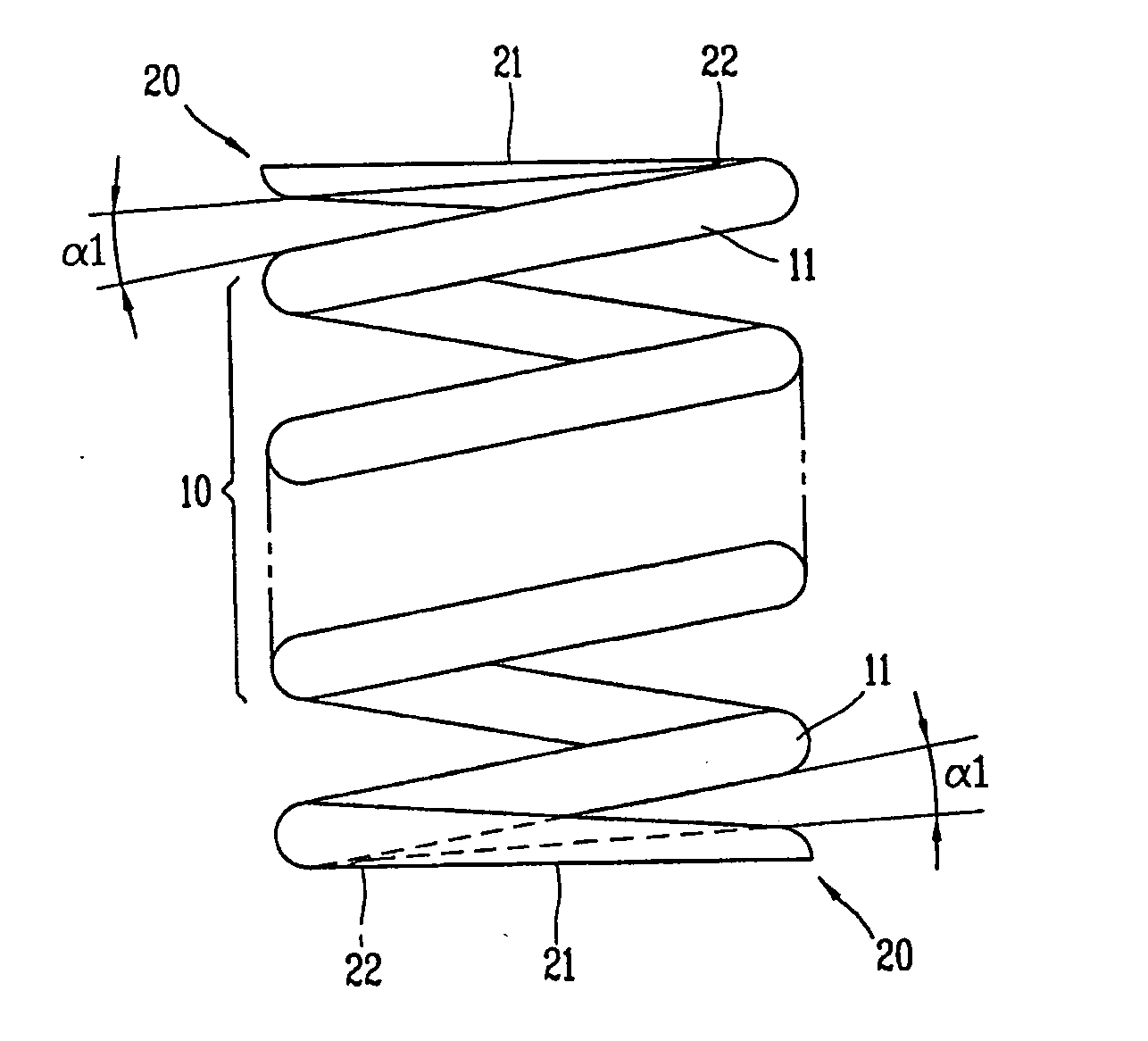

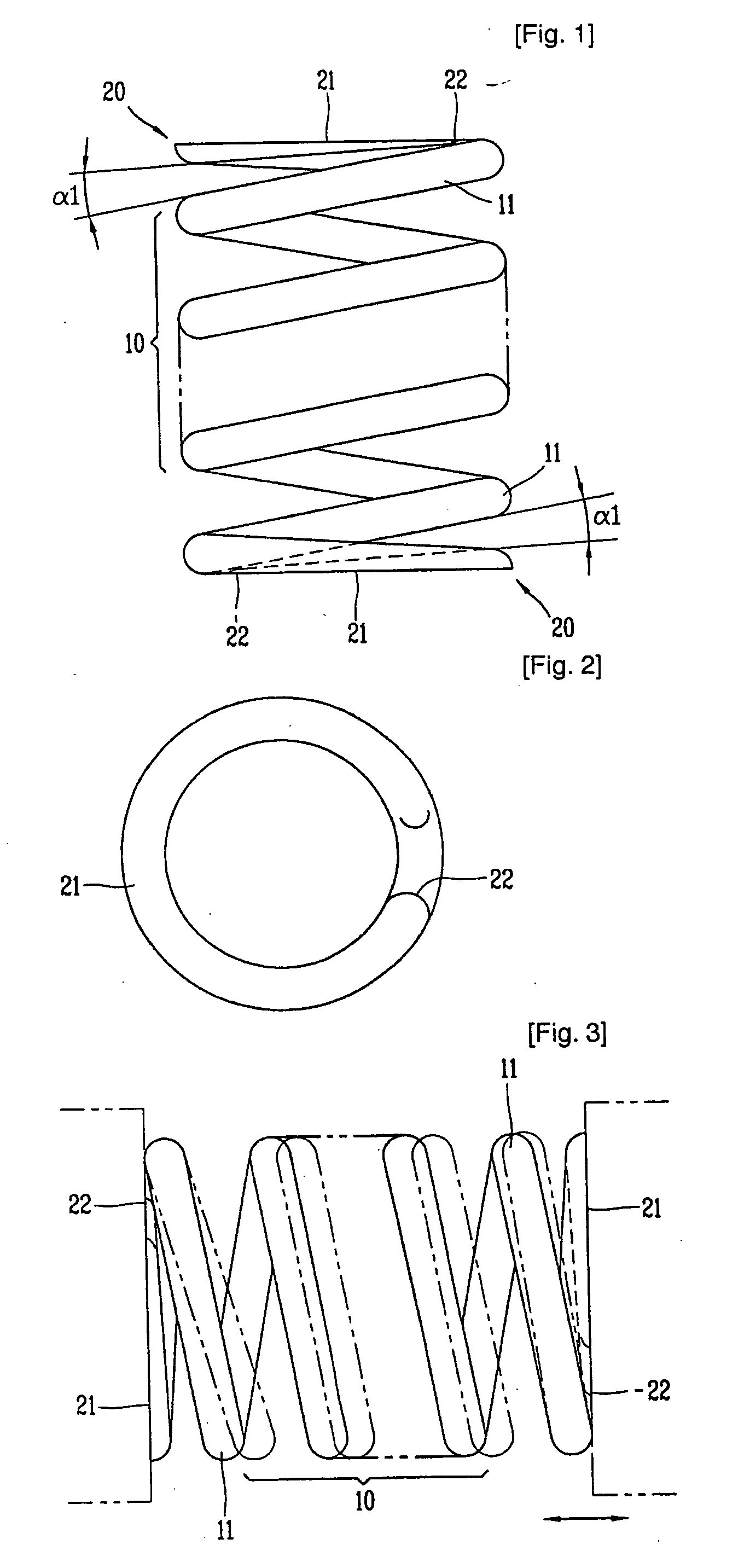

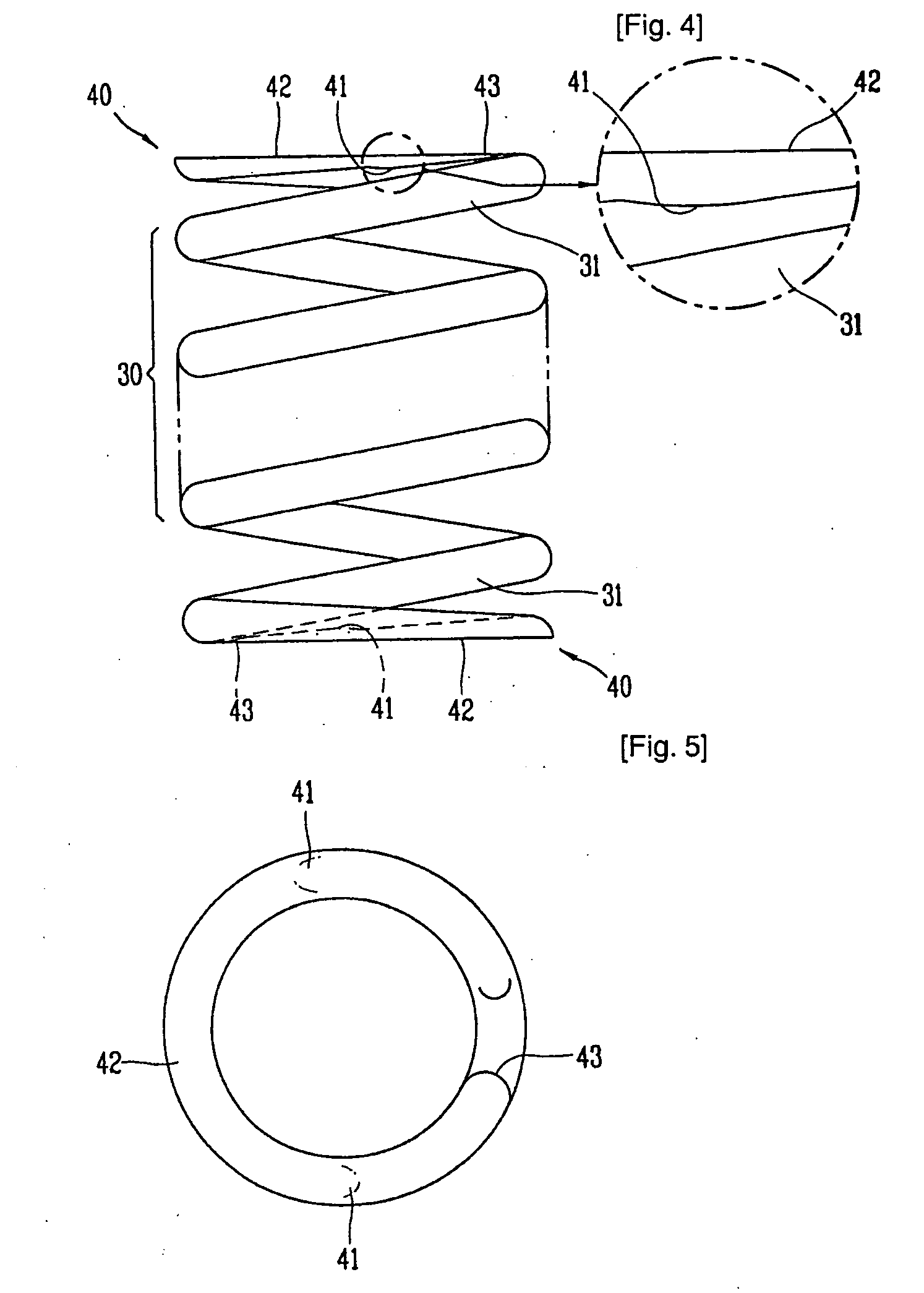

Coil spring and reciprocating compressor having the same

InactiveUS20060061024A1Minimizing friction noiseFriction minimizationLighting and heating apparatusPiston pumpsCoil springEngineering

A coil spring in accordance with the present invention includes inner coils formed as a wire is wound plural times; and an inflection portion having a nonlinear shape and formed at an outer circumferential surface of the end coil, which is positioned toward the inner coil. When connected to other component and is constricted and relaxed to absorb an impact or a vibration transmitted from the outside, the coil spring minimizes friction generated between itself and other components so that reliability of a reciprocating compressor having the coil spring can be improved.

Owner:LG ELECTRONICS INC

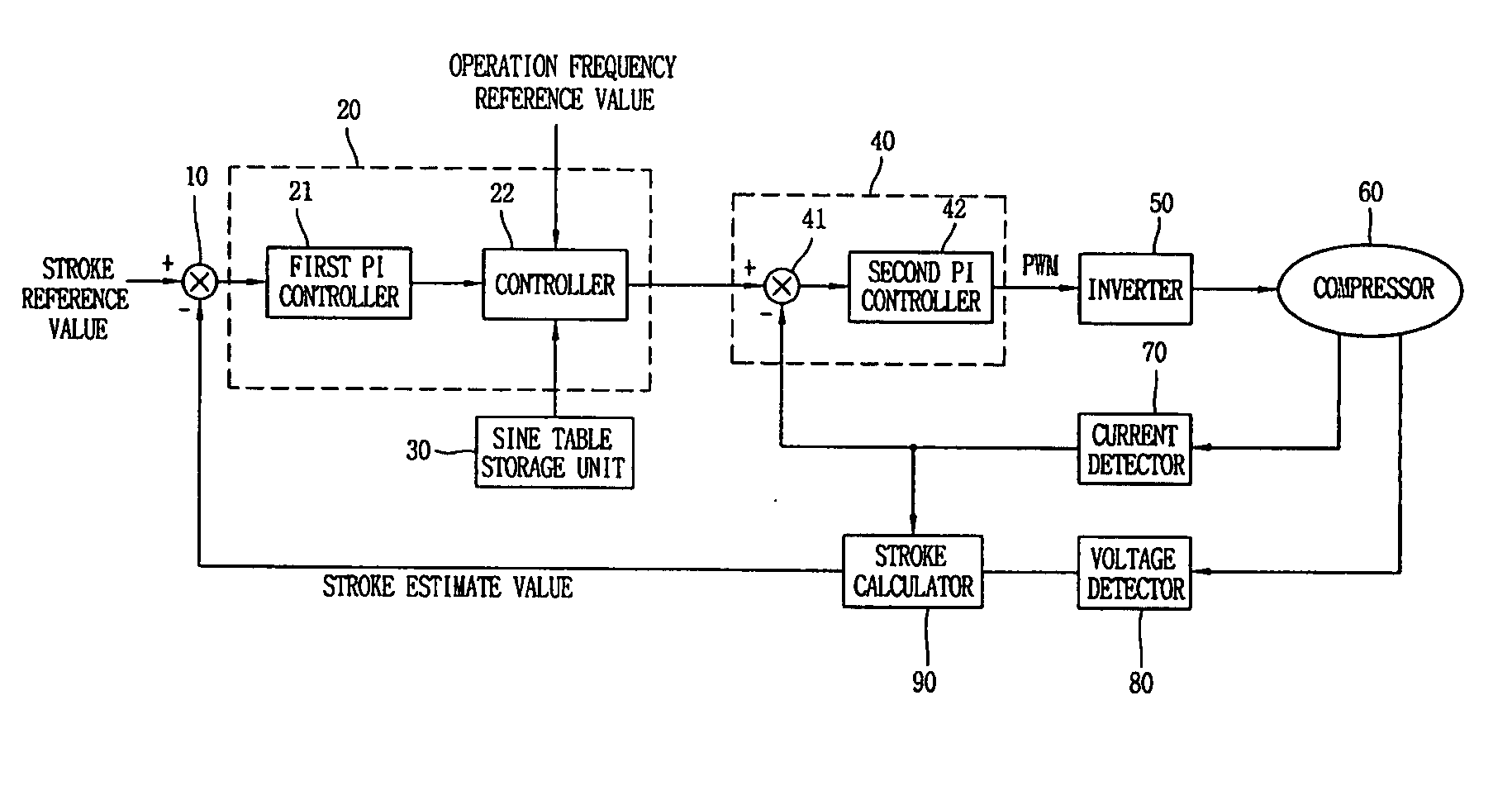

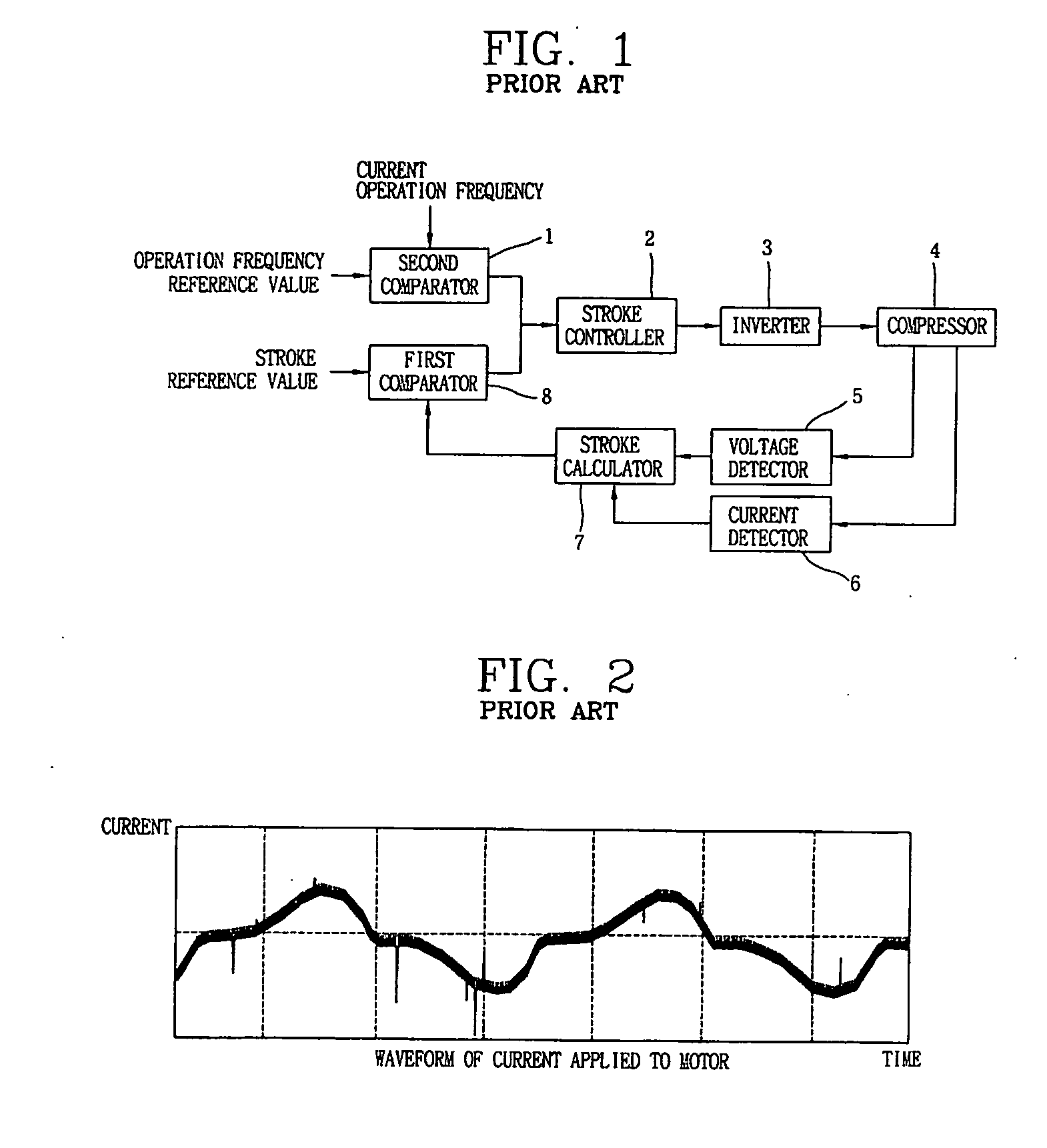

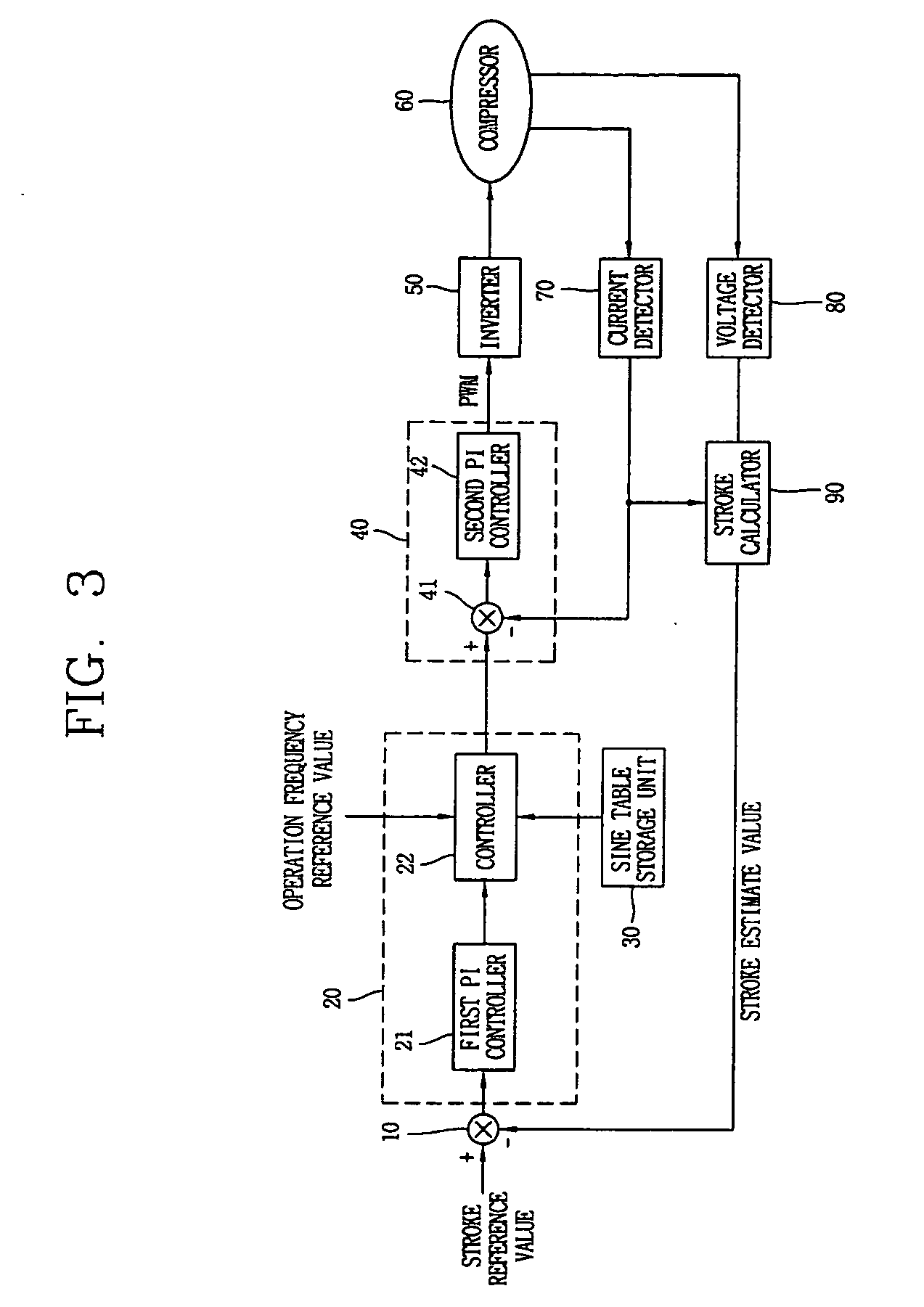

Apparatus and method for controlling operation of reciprocating compressor

InactiveUS20060251523A1Inhibit currentAvoid distortionExternal parameterAC motor controlControl theoryCurrent amplitude

An apparatus and method for controlling the operation of a reciprocating compressor are capable of preventing distortion of a current applied to the reciprocating compressor by generating a current amplitude value for compensating a difference value between a stroke reference value of the reciprocating compressor and a stroke estimate value and outputting the current amplitude value in a form of a sine wave to the reciprocating compressor. The apparatus for controlling an operation of a reciprocating compressor generates a current amplitude value for compensating a difference value between a stroke reference value and a stroke estimate value of the reciprocating compressor and outputs the current amplitude value in a sine wave form to the reciprocating compressor.

Owner:LG ELECTRONICS INC

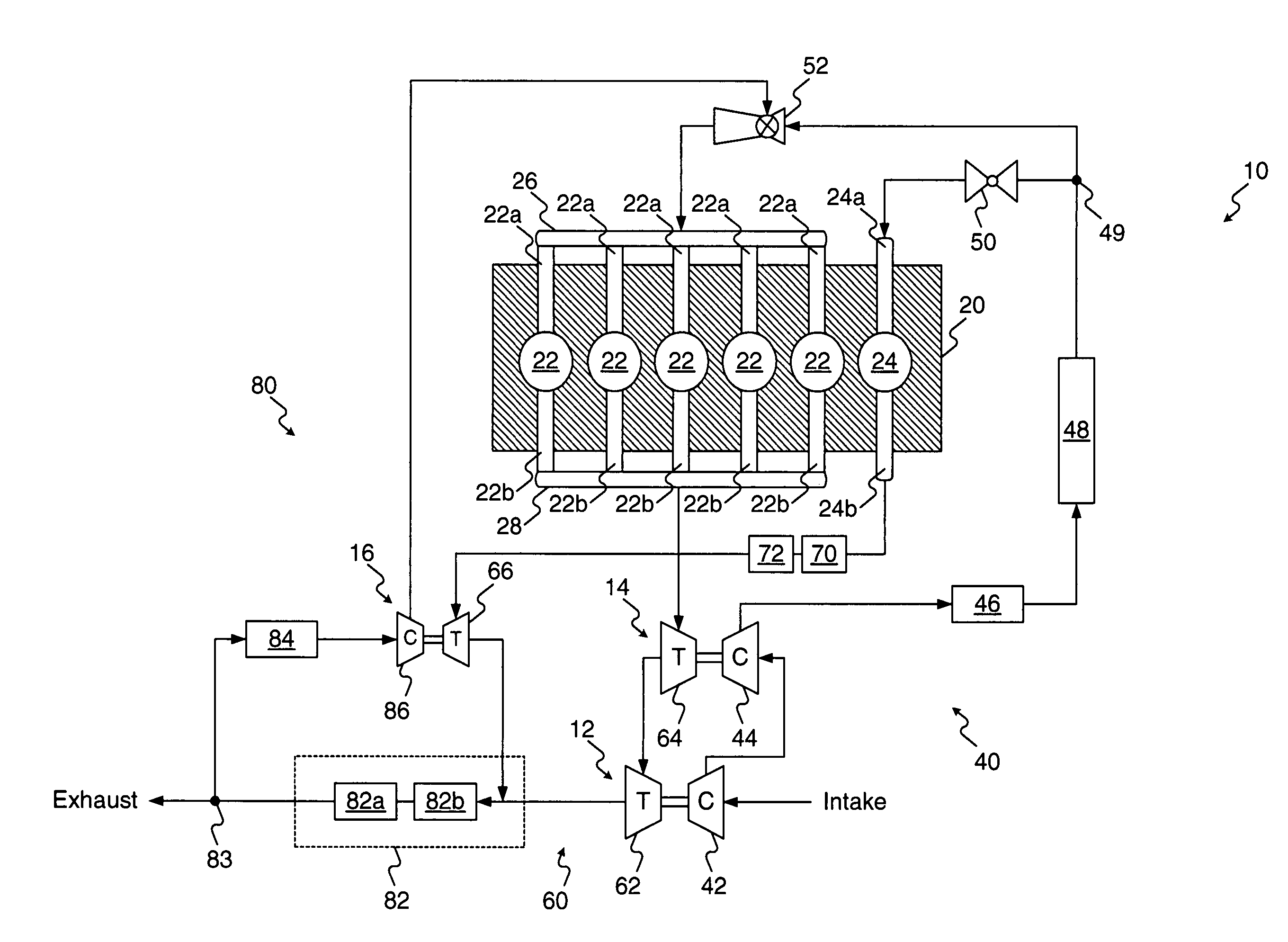

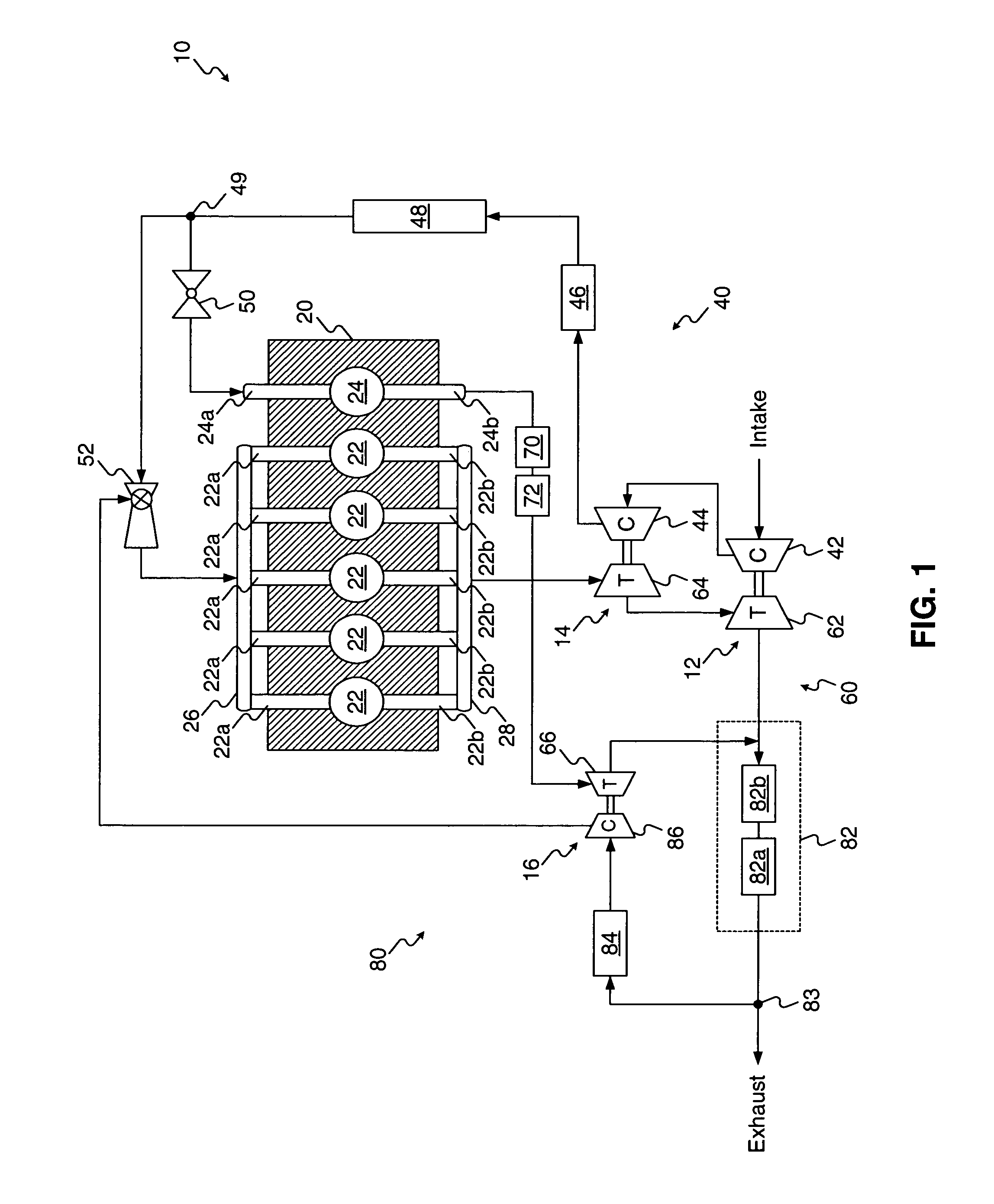

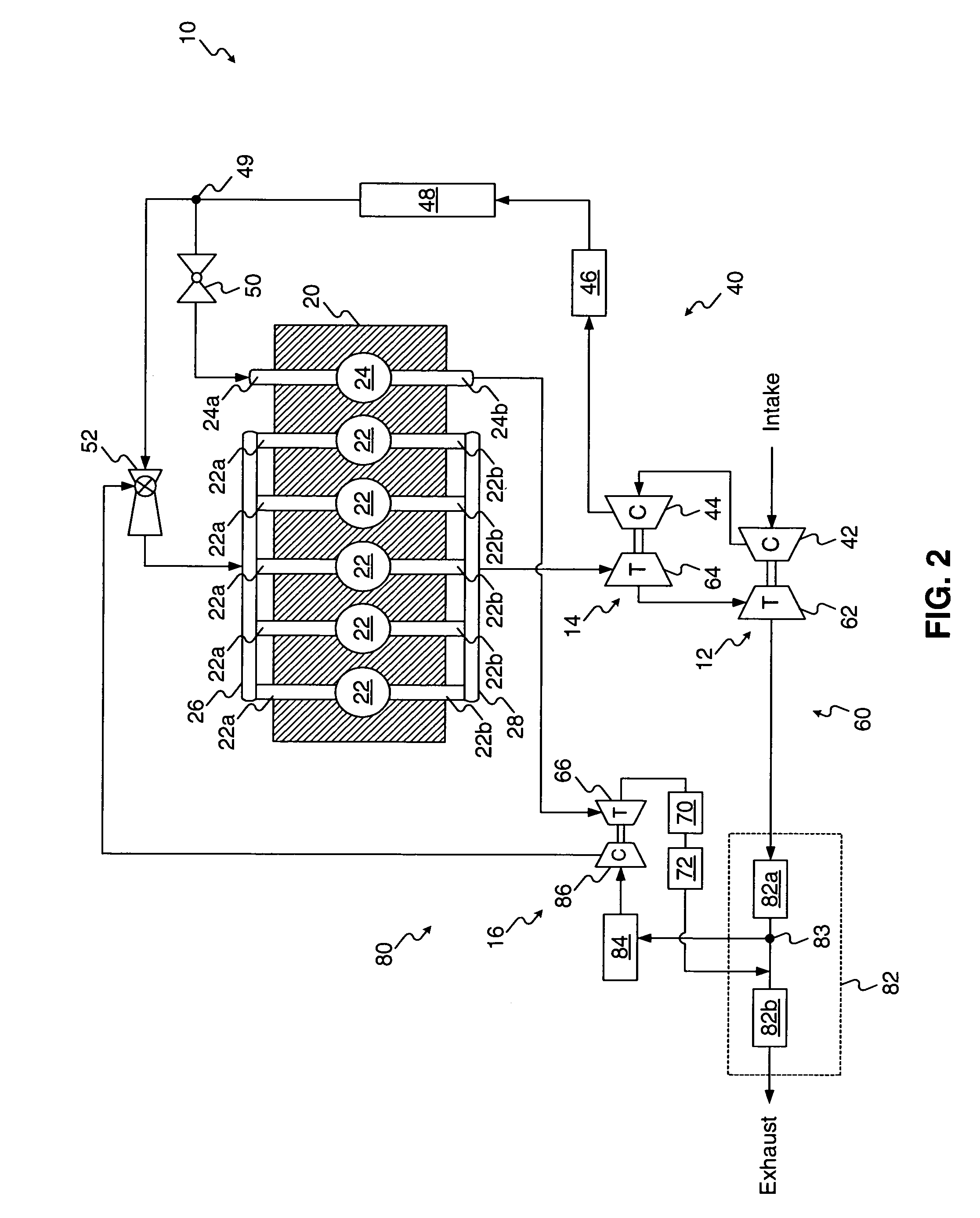

Turbocharged exhaust gas recirculation system

InactiveUS7490462B2Non-fuel substance addition to fuelInternal combustion piston enginesParticulatesExhaust fumes

An exhaust recirculation system includes a power source including at least one cylinder outputting exhaust gas and a particulate reducing device fluidly connected to at least one exhaust duct of the power source. The particulate reducing device is configured to reduce an amount of particulates in the exhaust gas. The exhaust recirculation system also includes a recirculation compressor configured to receive and compress at least a portion of the exhaust gas. An intake duct of the at least one cylinder of the power source is fluidly connected to the recirculation compressor to receive the compressed reduced-particulate exhaust gas.

Owner:CATERPILLAR INC

Compressor valve health monitor

ActiveUS9759213B2Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

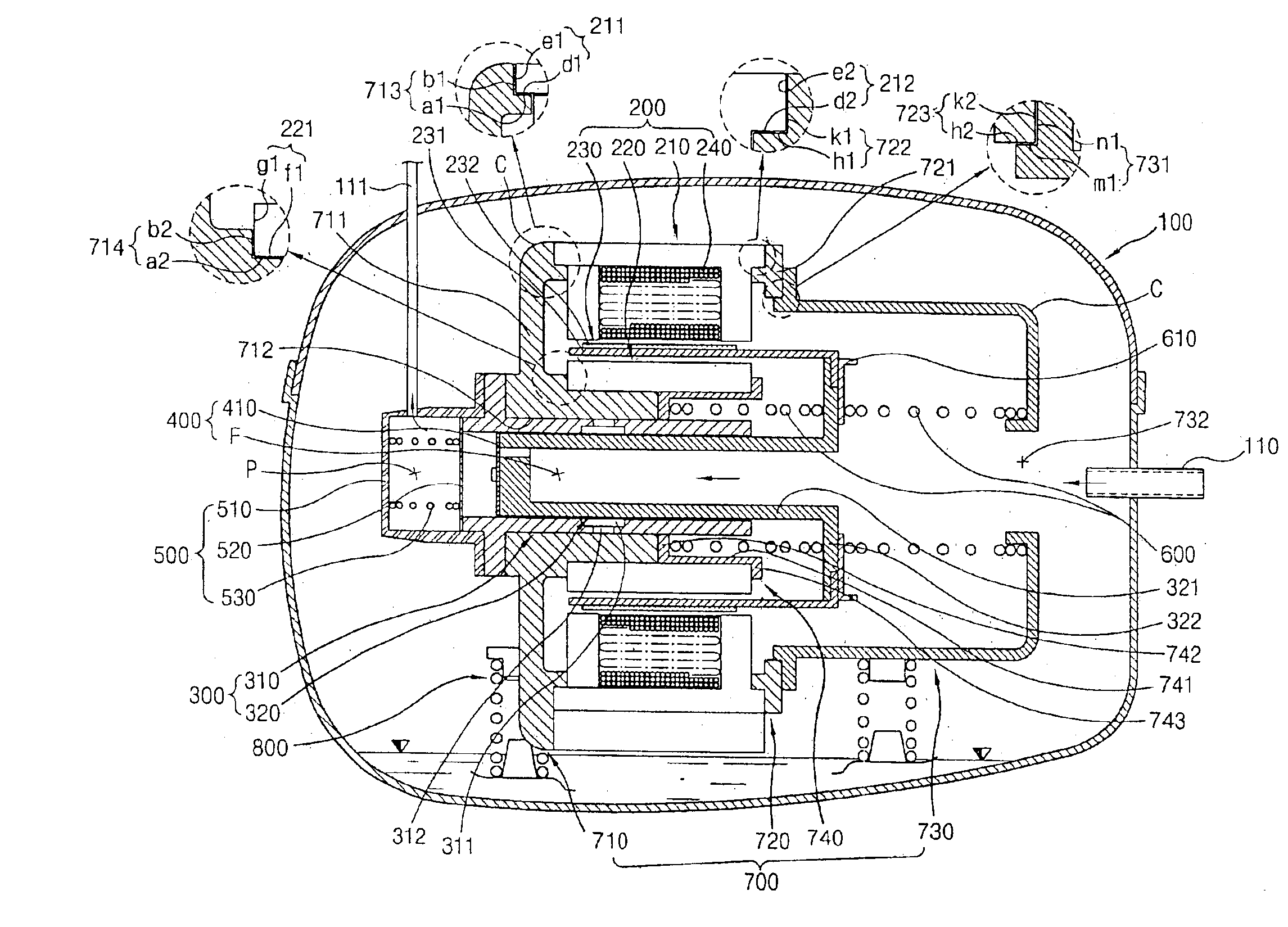

Multi-stage reciprocating compressor

InactiveUS20110171044A1Positive displacement pump componentsMulti-stage pumpsWorking fluidCylinder head

A multi-stage reciprocating compressor includes a cylinder block and a cylinder head. The cylinder block defines a low stage cylinder and a high stage cylinder. The cylinder head is secured to the cylinder block overlying the low and high stage cylinders. The cylinder head defines a mid-stage plenum which is in fluid communication with the low stage cylinder and the high stage cylinder for communicating a working fluid discharged from the low stage cylinder to the high stage cylinder.

Owner:CARRIER CORP

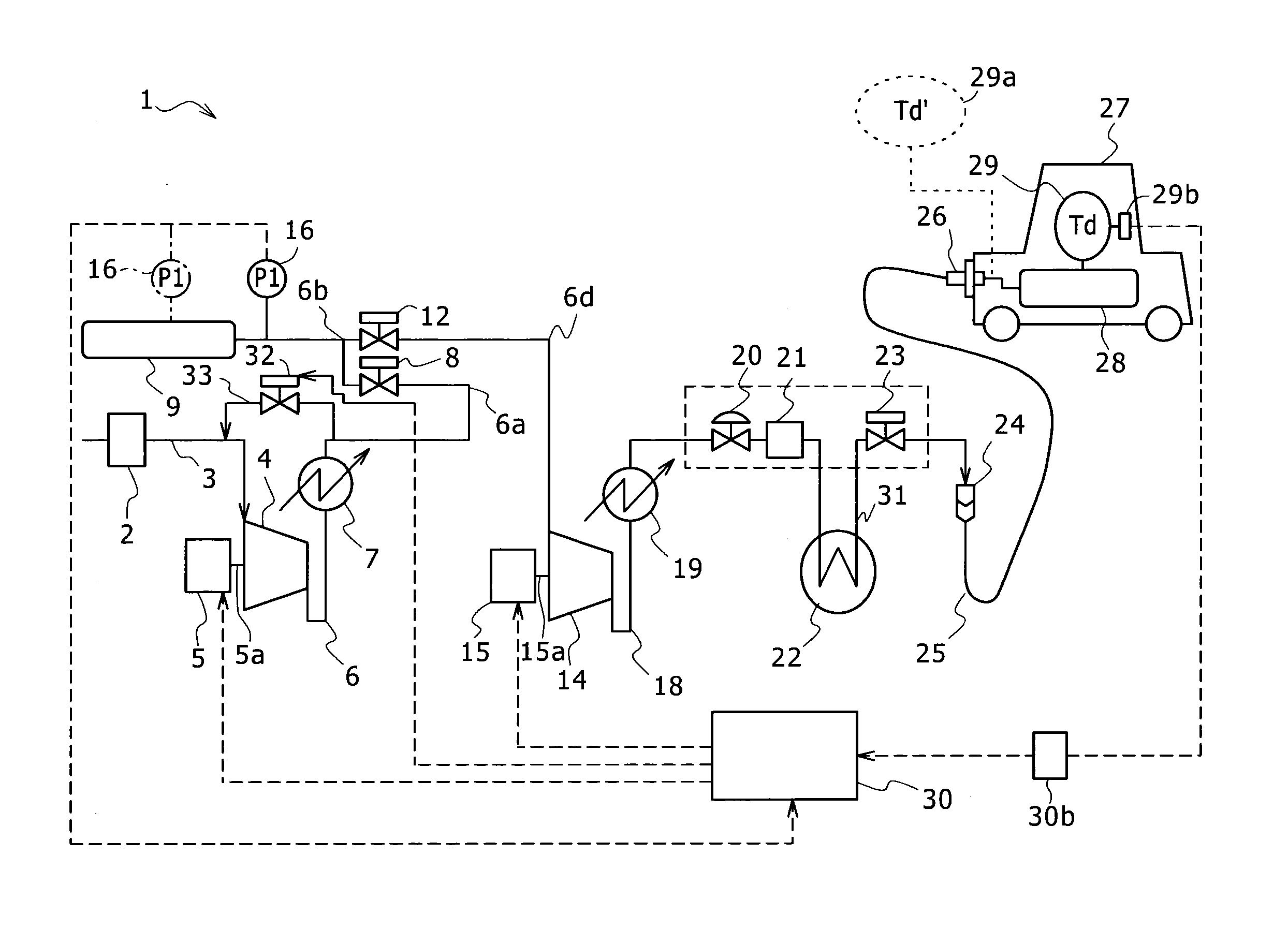

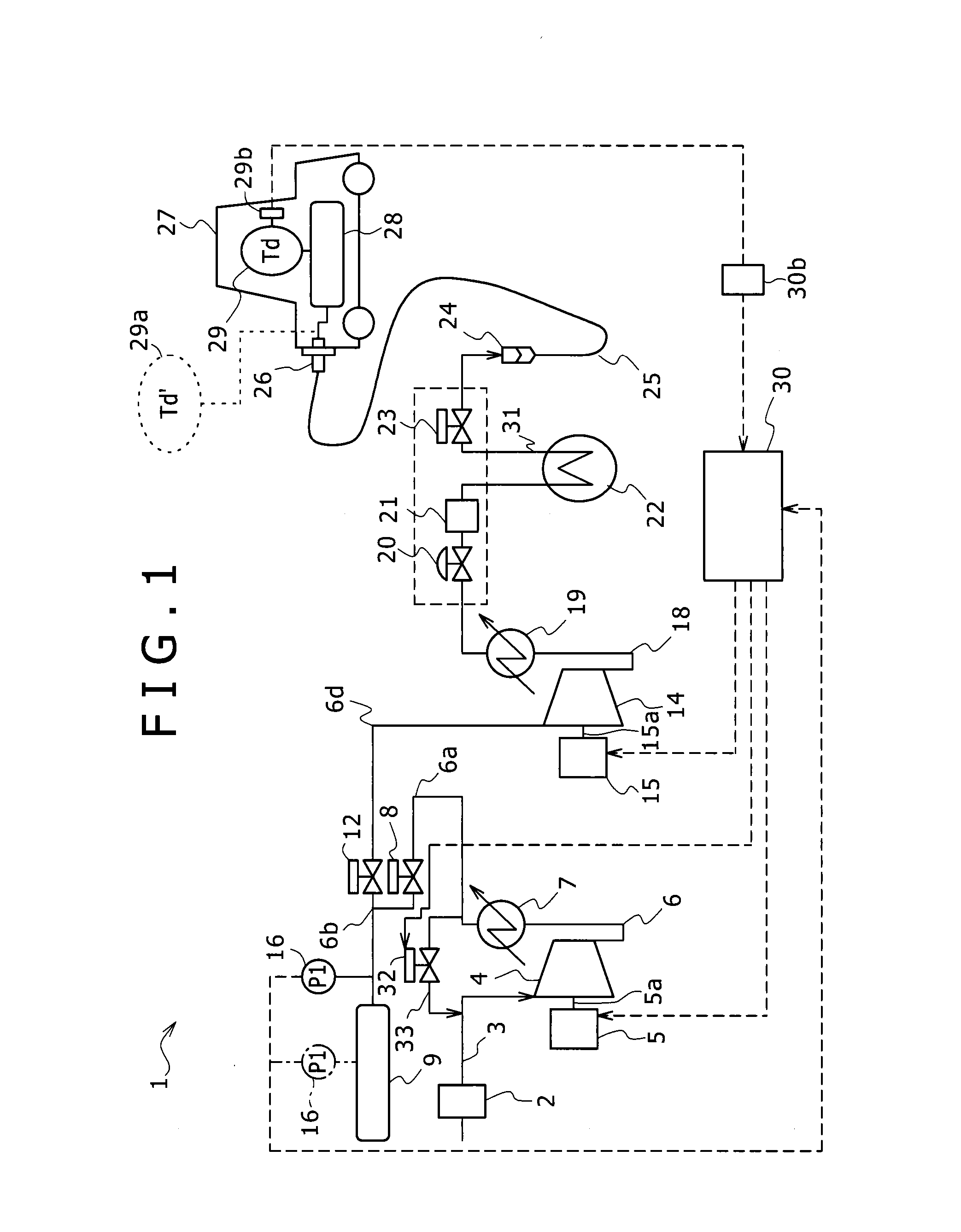

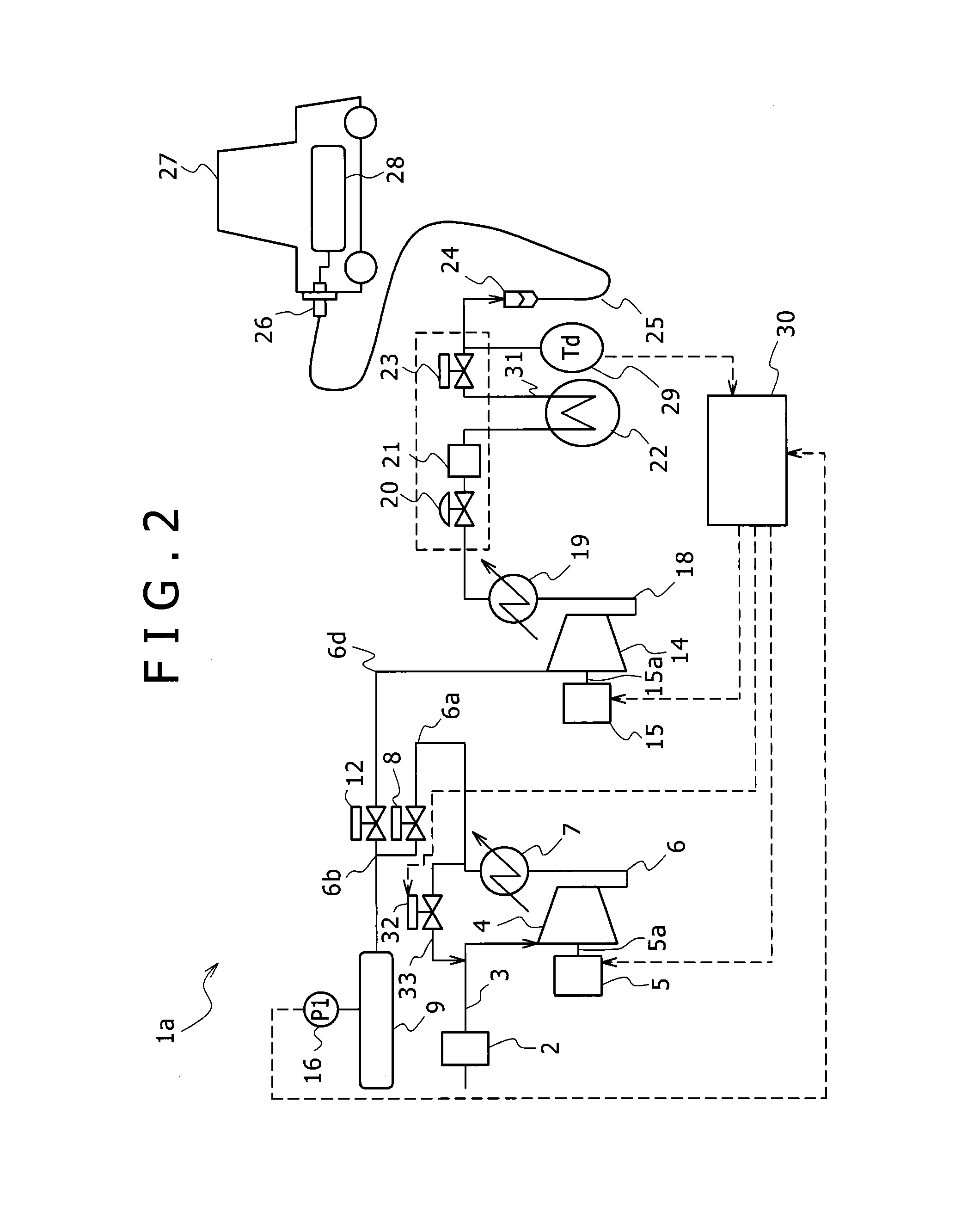

Hydrogen station

ActiveUS20140196814A1Easy to controlSuppresses internal temperature riseVessel mounting detailsGas handling applicationsEngineeringHydrogen supply

Provided is a hydrogen station that supplies hydrogen to an external hydrogen tank, the hydrogen station including: a reciprocating compressor that is driven by a driver of which revolution is controllable; a cooling device that is capable of cooling hydrogen supplied from the reciprocating compressor to the hydrogen tank; a temperature sensor that detects an internal temperature of the hydrogen tank or a temperature of the hydrogen supplied to the hydrogen tank; and a control unit that controls the revolution of the driver based on the temperature detected by the temperature sensor.

Owner:KOBE STEEL LTD

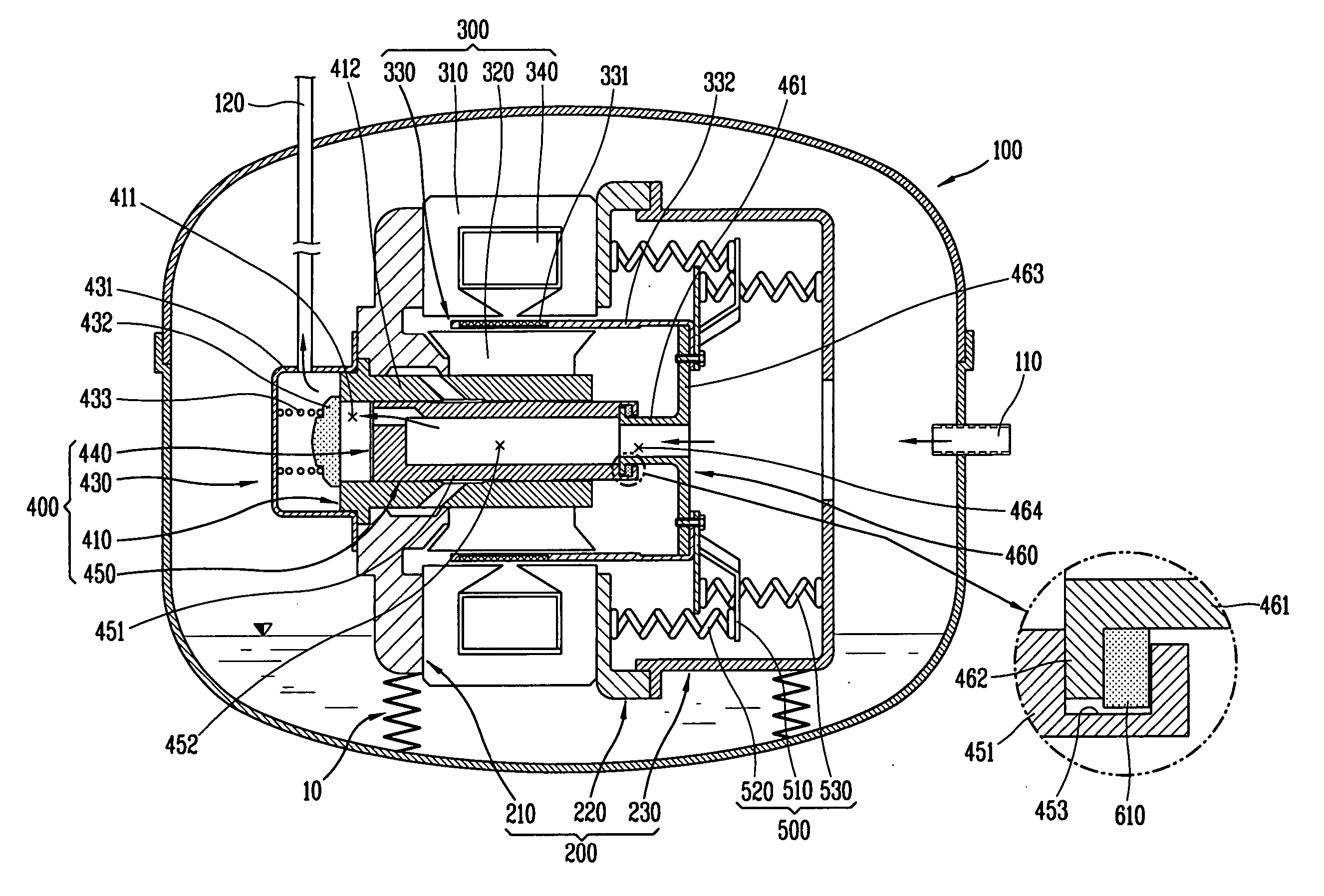

Reciprocating compressor with gas bearing

ActiveUS20130058815A1Reduce material costsLow costPositive displacement pump componentsPiston pumpsCoil springEngineering

A reciprocating compressor with a gas bearing is configured to support a portion between a cylinder and a piston by the gas bearing and induce a resonating motion of the piston by the use of compression coil springs. Therefore, a proper resonating motion of a vibrating body can be induced by the use of the gas bearing, without using plate springs, and accordingly manufacturing costs and the number of assembly processes can be reduced and the installation direction of the compressor can be freely designed.

Owner:LG ELECTRONICS INC

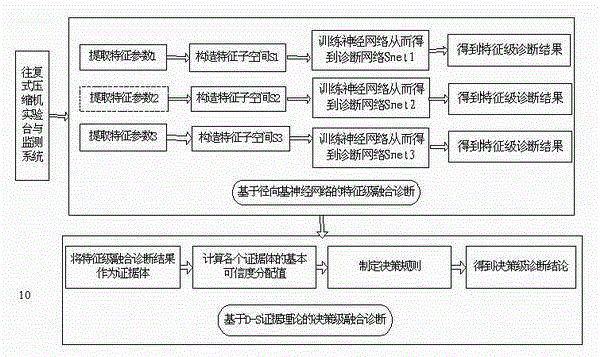

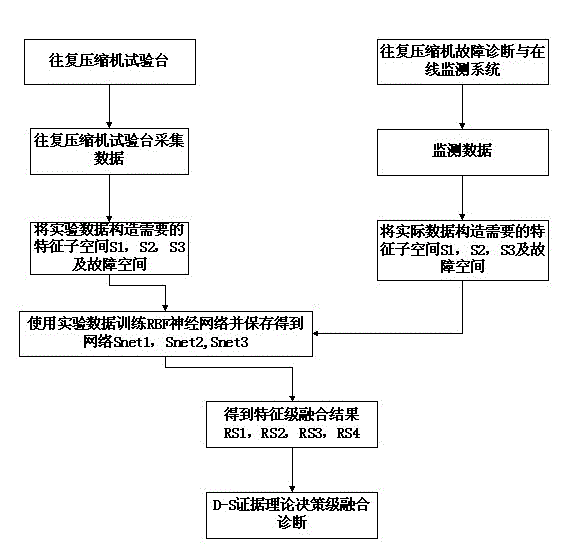

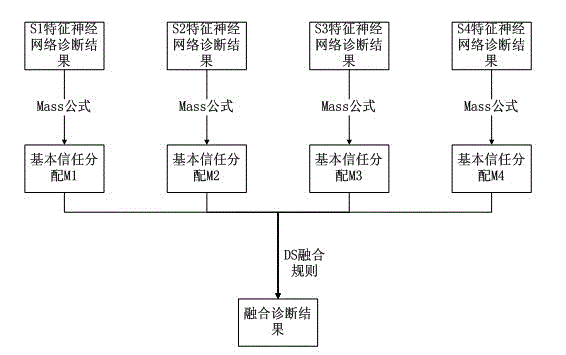

Reciprocating-type compressor fault diagnosis method based on multi-sensor information fusion

ActiveCN103147972APump testingPositive-displacement liquid enginesControl engineeringMultiple sensor

The invention discloses a reciprocating-type compressor fault diagnosis method based on multi-sensor information fusion, and the method is characterized by comprising the following steps of 1, collecting data; 2, constructing a fault characteristic sub-space and a fault space; 3, obtaining a fault diagnosis network; 4, acquiring characteristic fusion diagnosis results; and 5, carrying out D-S evidence theory decision-level fusion diagnosis, and giving out a decision-level diagnosis result. The method has the advantages of convenience in application, high diagnosis accuracy and applicability to a production site of reciprocating-type compressors of petroleum chemical industrial enterprises.

Owner:BEIJING UNIV OF CHEM TECH

Reciprocating compressor

InactiveUS20130058816A1Well formedImprove compressor performancePositive displacement pump componentsPiston pumpsRefrigerantMechanical engineering

A reciprocating compressor comprises a cylinder having a cylinder side gas flow path for guiding refrigerant discharged to the discharge space to an inner circumferential surface of the cylinder and a piston having a piston side gas flow path communicating with the cylinder side gas flow path to distribute and supply the refrigerant guided through the cylinder side gas flow path between the cylinder and the piston. Also, an outlet of the gas flow path is formed in the piston and an inlet of the gas flow path is formed in the cylinder.

Owner:LG ELECTRONICS INC

Apparatus and method for controlling operation of reciprocating compressor

InactiveUS20050158178A1Operation efficiency can be improvedCompressorExternal parameterMechanical resonanceOperating frequency

Disclosed are an apparatus and a method for controlling an operation of a reciprocating compressor which can improve operational efficiency of the reciprocating compressor. The apparatus for controlling the operation of the reciprocating compressor includes a resonance frequency operation unit for operating a mechanical resonance frequency of the reciprocating compressor, an operating frequency reference value generation unit for comparing the operated mechanical resonance frequency with a current operating frequency of the reciprocating compressor, and generating an operating frequency reference value according to the comparison result, and a controller for controlling a motor of the reciprocating compressor according to the generated operating frequency reference value.

Owner:LG ELECTRONICS INC +1

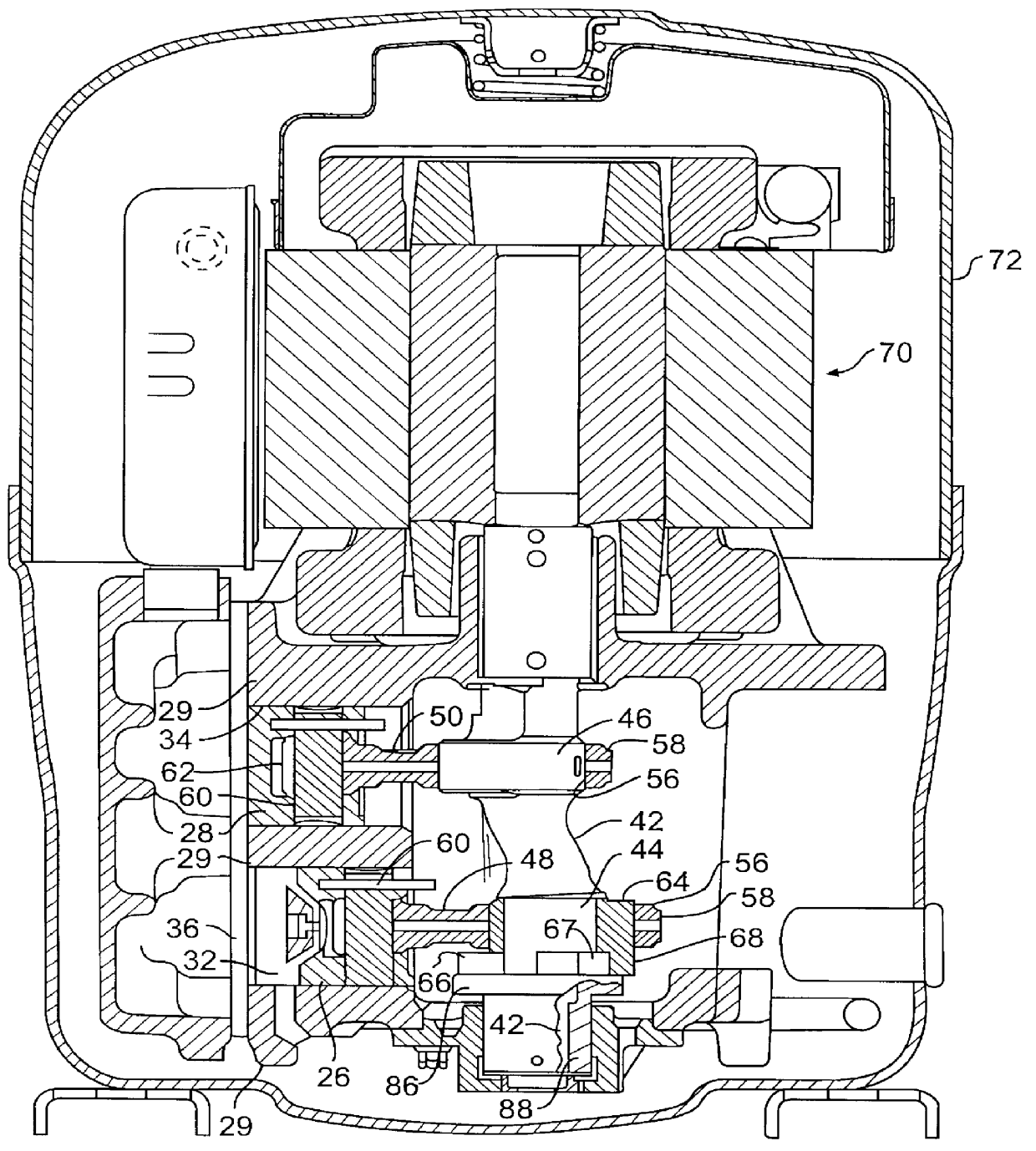

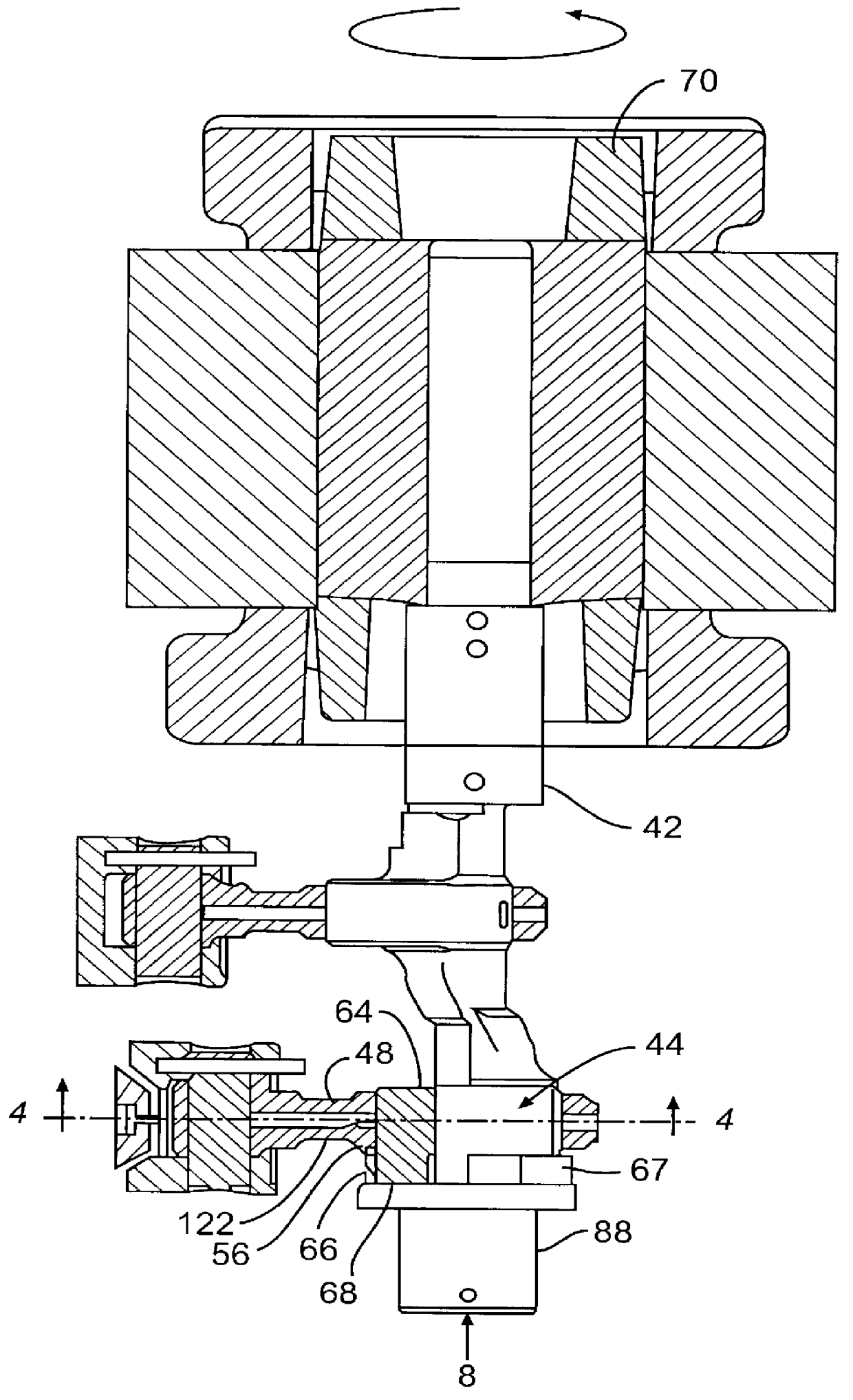

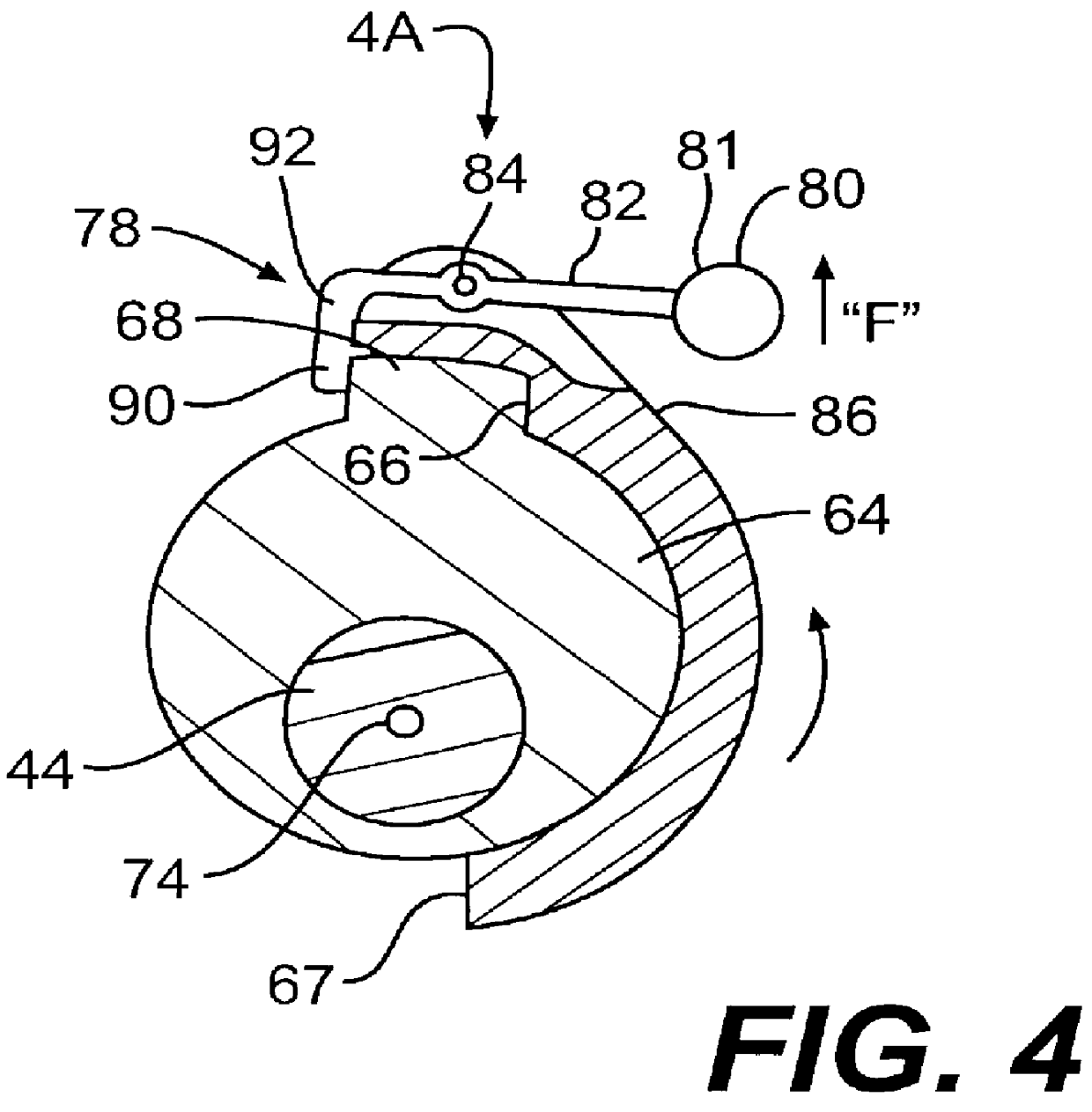

Adjustable crankpin throw structure having improved throw stabilizing means

InactiveUS6092993ACancel noiseReduce capacityFlexible member pumpsWorking fluid for enginesCrankpinCam

A stabilizing structure for a throw adjusting eccentric cam in a two-stage reciprocating compressor is provided. The compressor includes a block that has at least one cylinder with an associated compression chamber and piston, a crankshaft that includes an eccentric crankpin, and a reversible motor for rotating the crankshaft in a forward and a reverse direction. An eccentric, two position cam is rotatably mounted over the crankpin. The cam rotates to and operates at a first position relative to said crankpin when the motor is running in the forward direction and rotates to and operates at a second position relative to said crankpin when the motor is running in the reverse direction. The combined eccentricities of the crankpin and the cam cause the piston to have a first stroke when the motor operates in the forward direction and a second stroke when the motor operates in the reverse direction. There is also provided a control for selectively operating the motor either in the forward direction or in the reverse direction.

Owner:BRISTOL COMPRESSORS INT

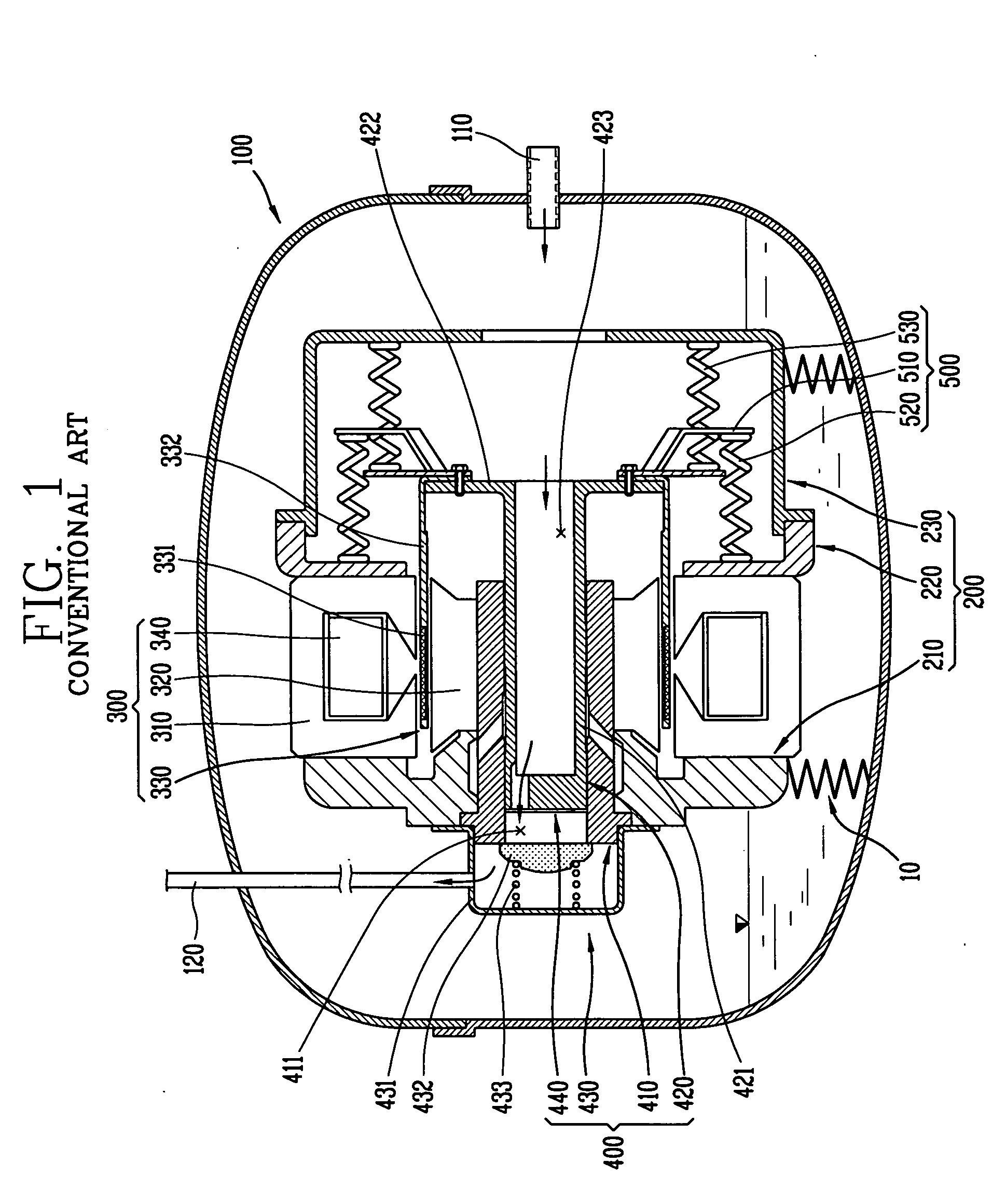

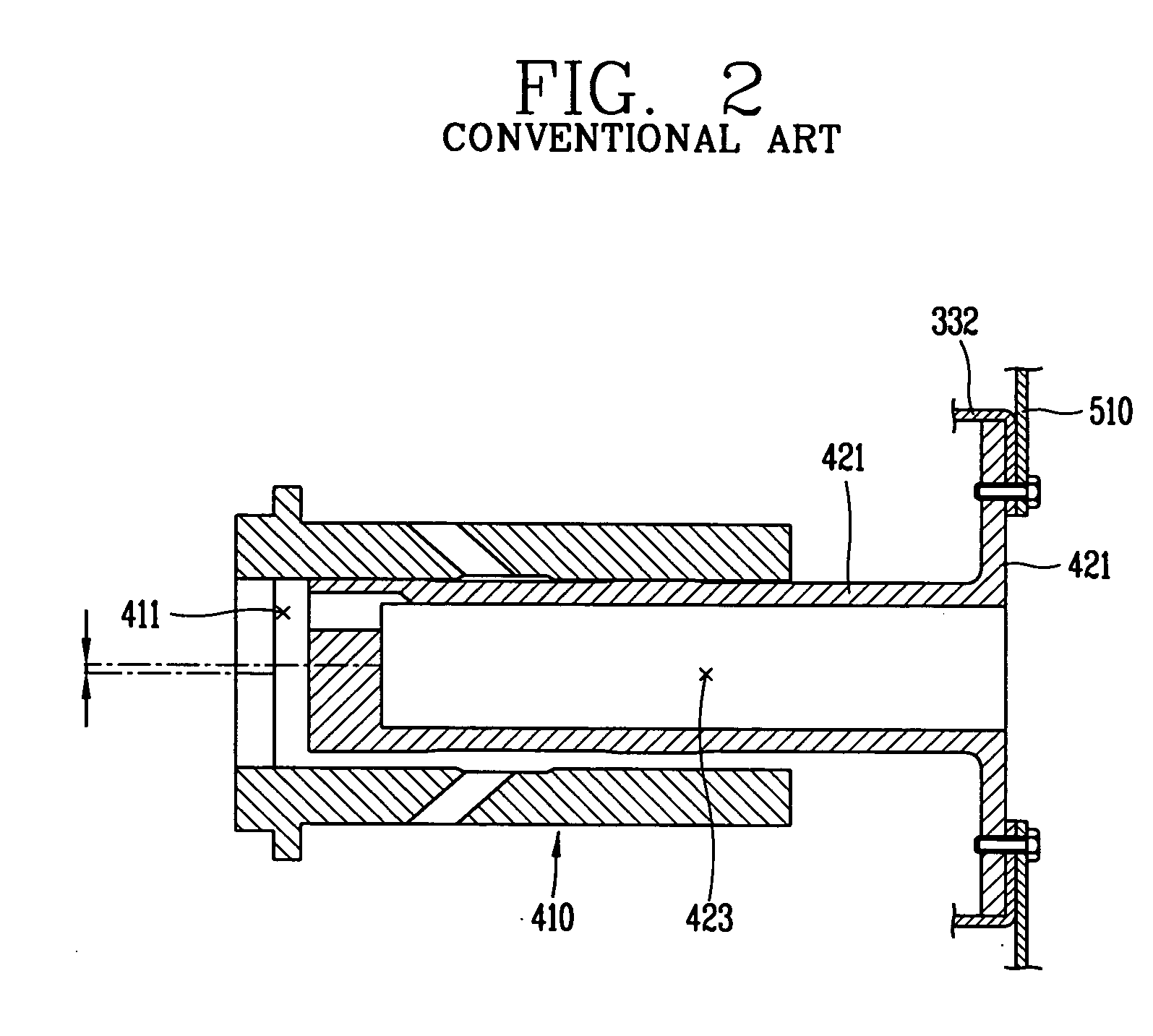

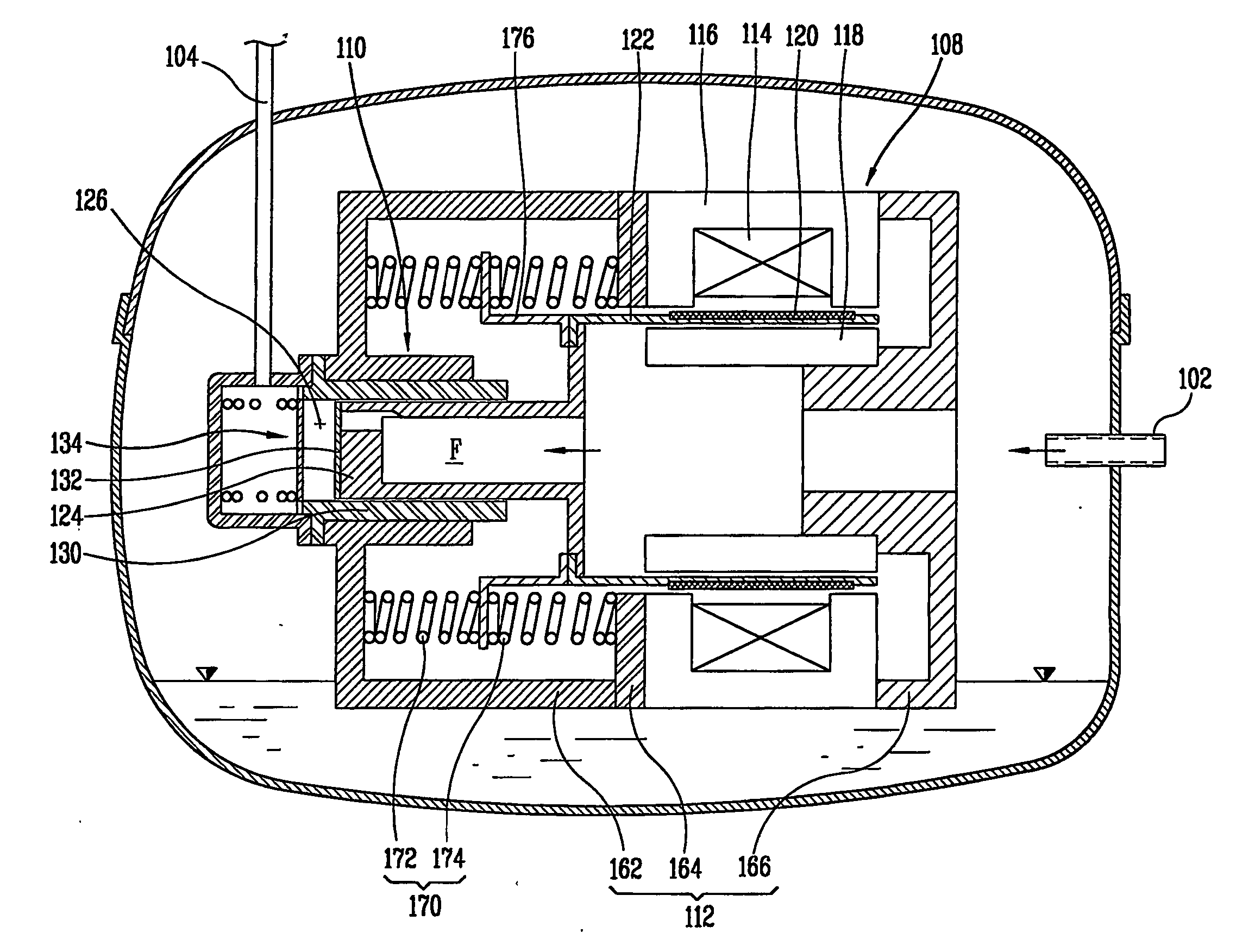

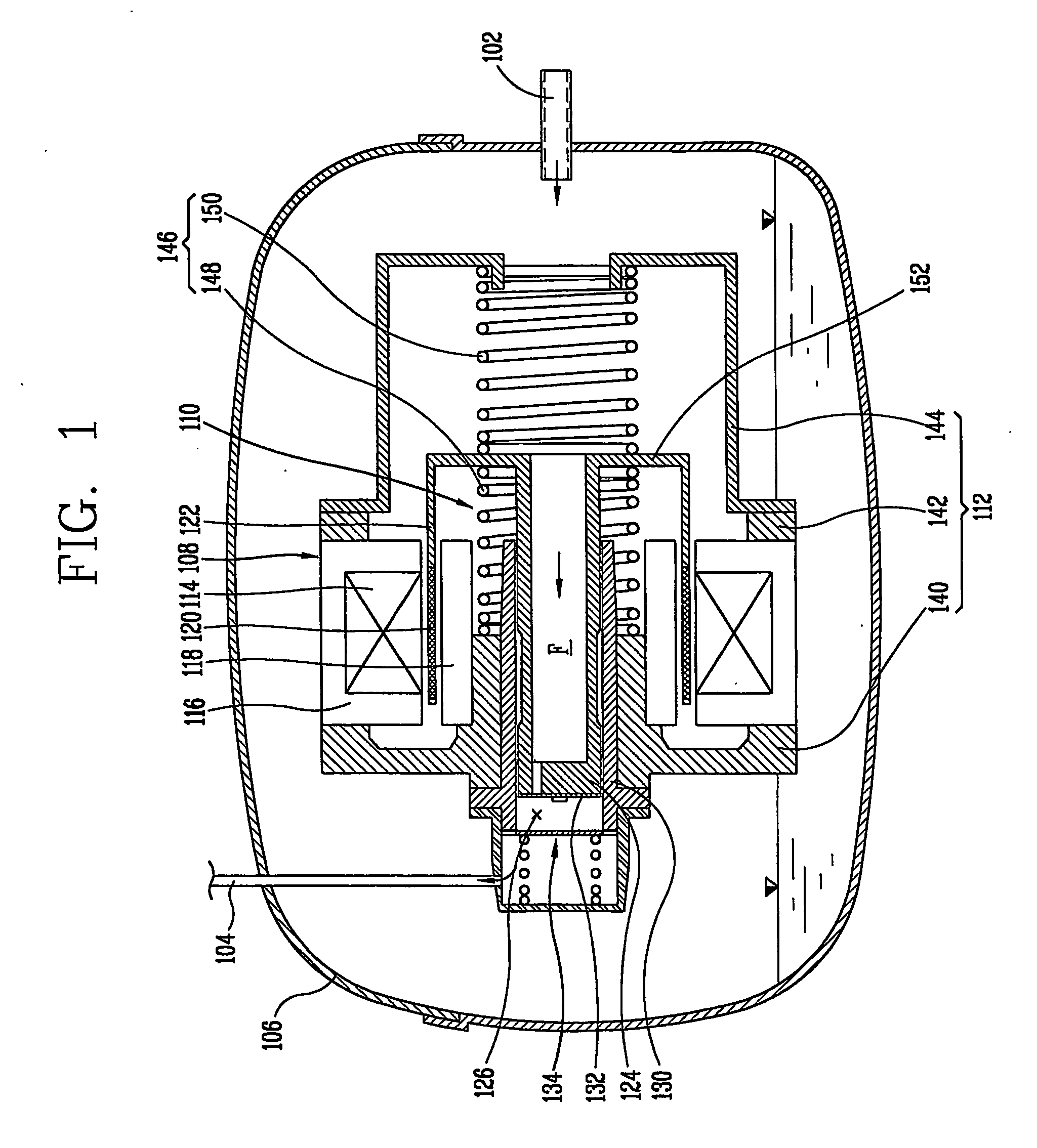

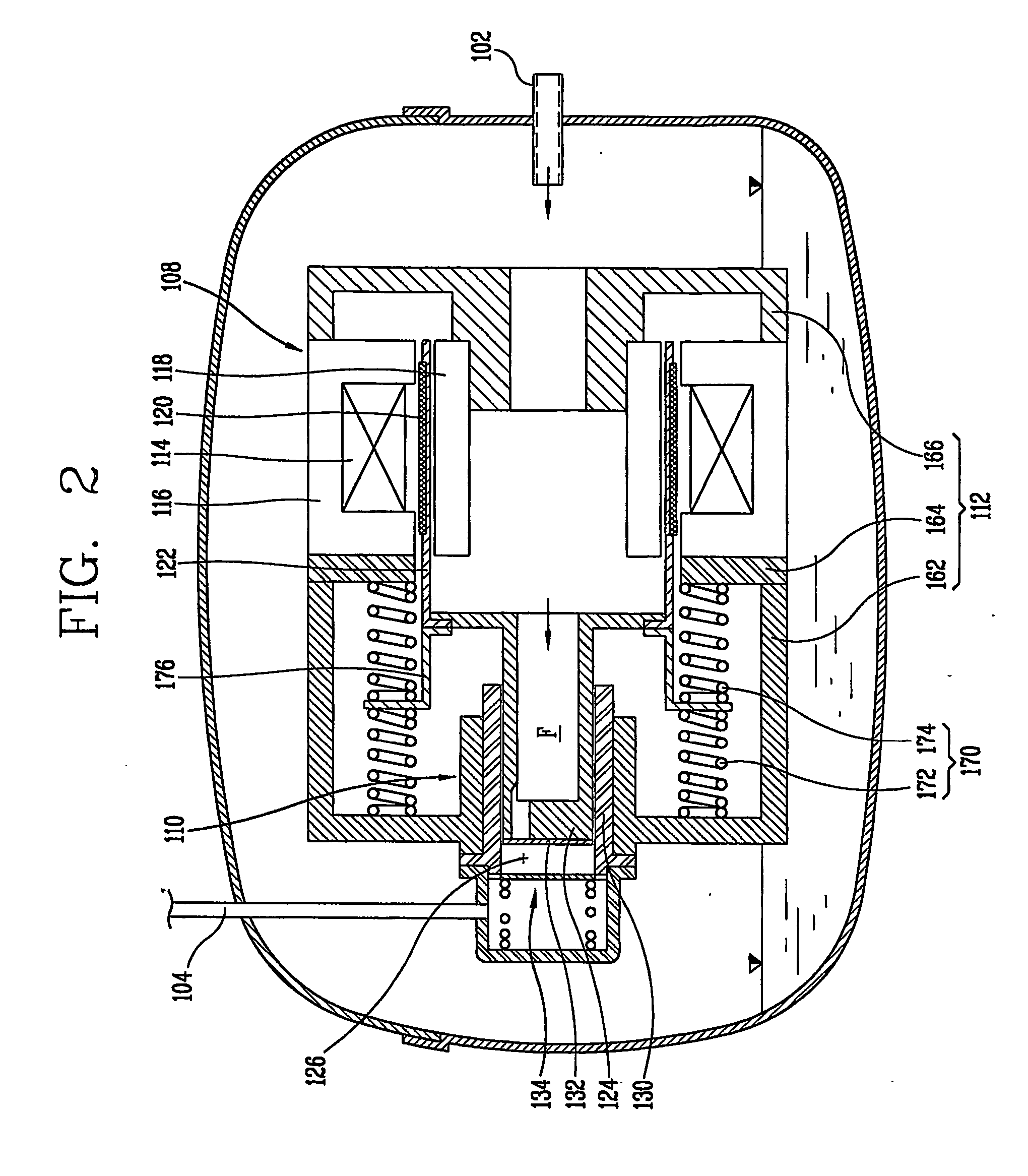

Reciprocating compressor having reduced vibration

InactiveUS6881042B2Easy to controlVibration minimizationPositive displacement pump componentsPiston pumpsResonanceElectric machine

A reciprocating compressor includes: a reciprocating motor, an outer stator and an inner stator provided with at least one step portion at both sides thereof, and an armature linearly moving therebetween; a compression unit having a cylinder and a piston inserted in the cylinder to receive a linear and reciprocal driving force of the reciprocating motor and compress a gas; a suction unit sucking a gas into the compression unit; a discharge unit discharging the gas compressed in the compression unit to outside the container; a resonance spring unit elastically supporting the piston and the armature; and a frame unit supporting the compression unit and the reciprocating motor. Because stable driving is achieved in its operation, generation of vibration and noise can be minimized, heightening reliability. In addition, the amount of gas discharge can be accurately controlled.

Owner:LG ELECTRONICS INC

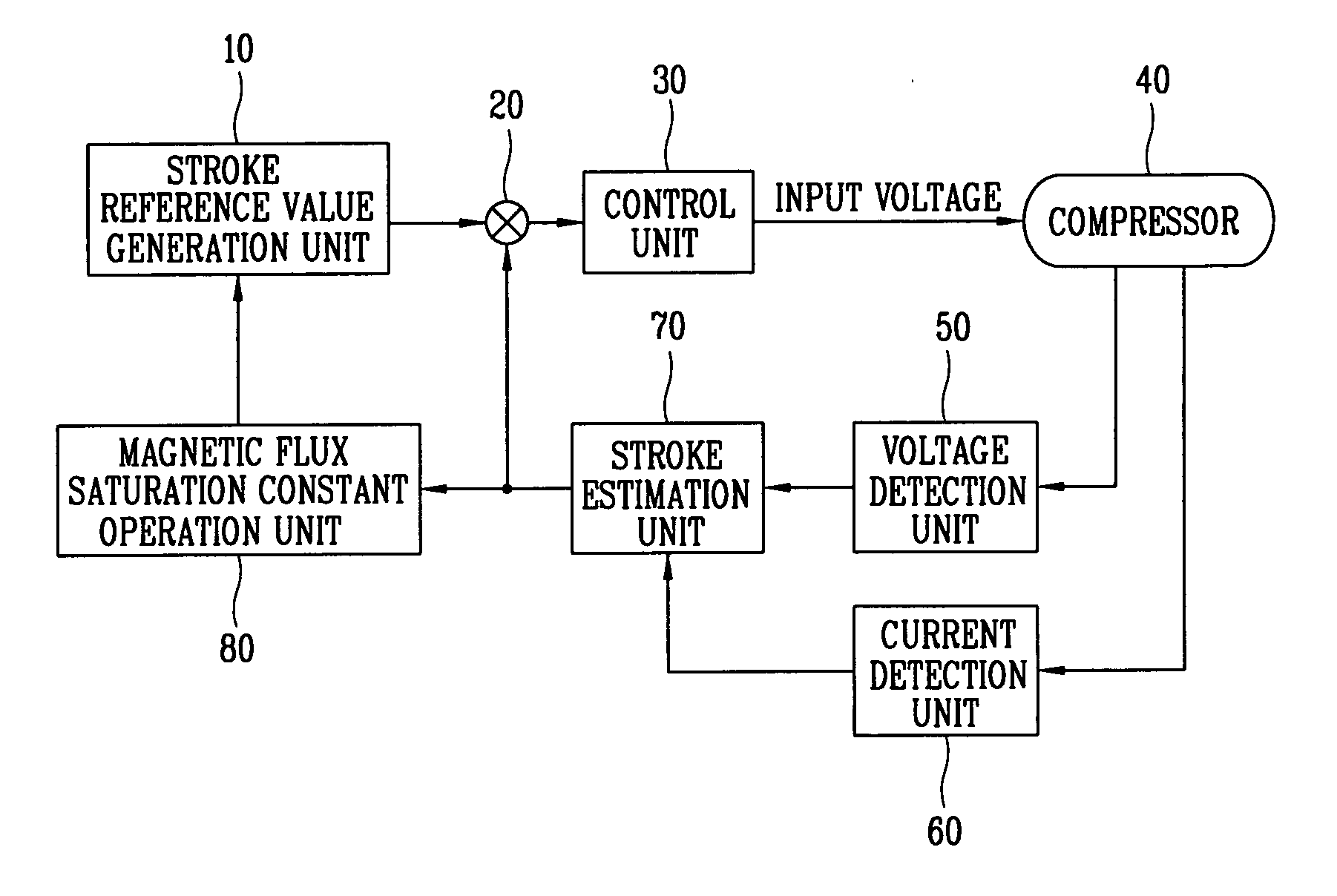

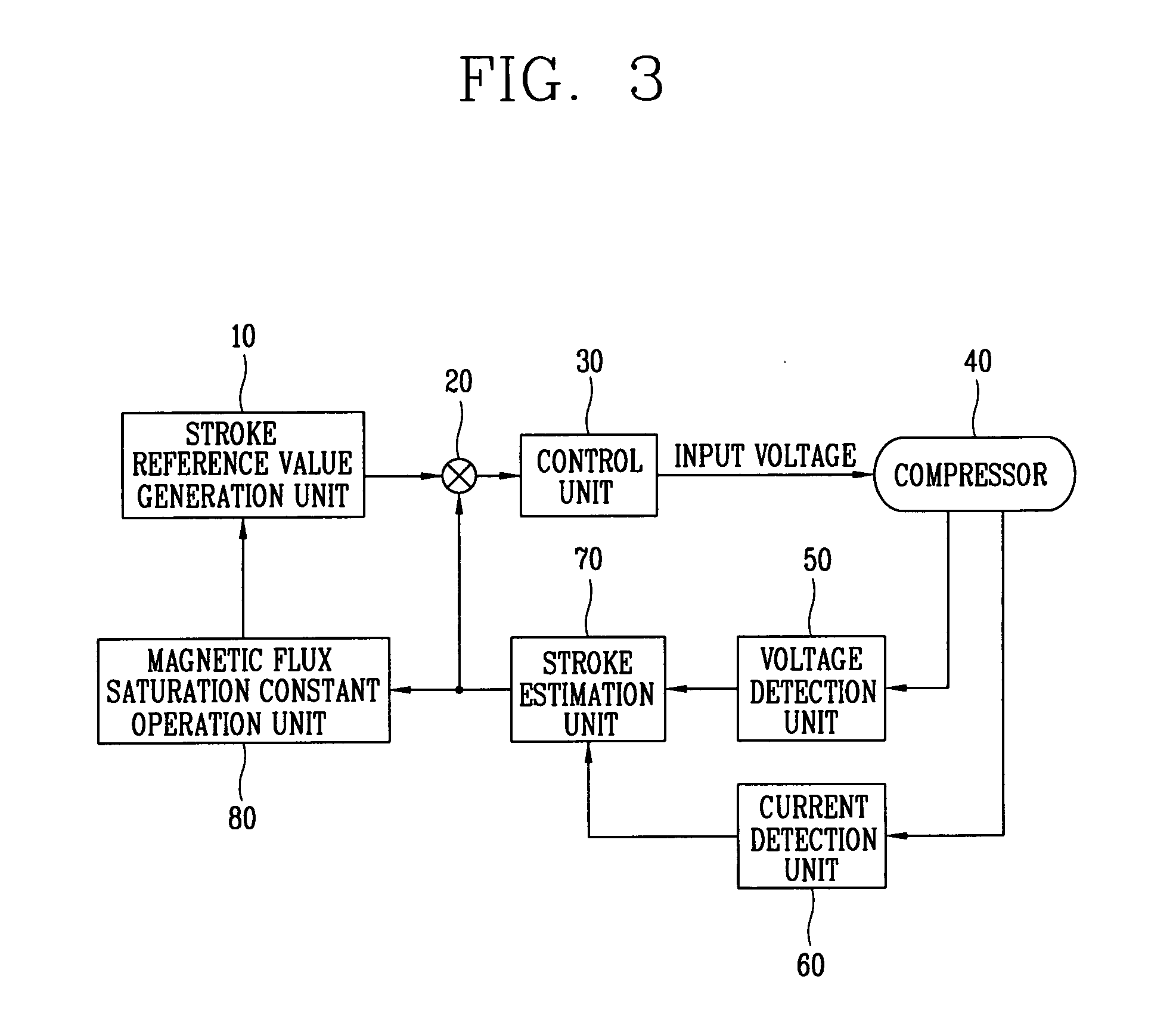

Apparatus for controlling operation of reciprocating compressor, and method therefor

ActiveUS20050141998A1Reduce errorsAvoid oversaturationDC motor speed/torque controlTemperatue controlMagnetic fluxVoltage

The present invention discloses an apparatus for controlling an operation of a reciprocating compressor and a method therefor which can reduce errors in an operation of a stroke estimated value of the reciprocating compressor, by previously preventing over-saturation of a magnetic flux density generated in a coil of a motor. The apparatus for controlling the operation of the reciprocating compressor includes a magnetic flux saturation constant operation unit for operating a magnetic flux saturation constant of a motor of the reciprocating compressor on the basis of a stroke estimated value of the reciprocating compressor, a stroke reference value generation unit for generating an increased or decreased stroke reference value by increasing or decreasing a predetermined stroke reference value on the basis of the magnetic flux saturation constant, and a control unit for controlling a voltage applied to the motor of the reciprocating compressor on the basis of the generated stroke reference value.

Owner:LG ELECTRONICS INC

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

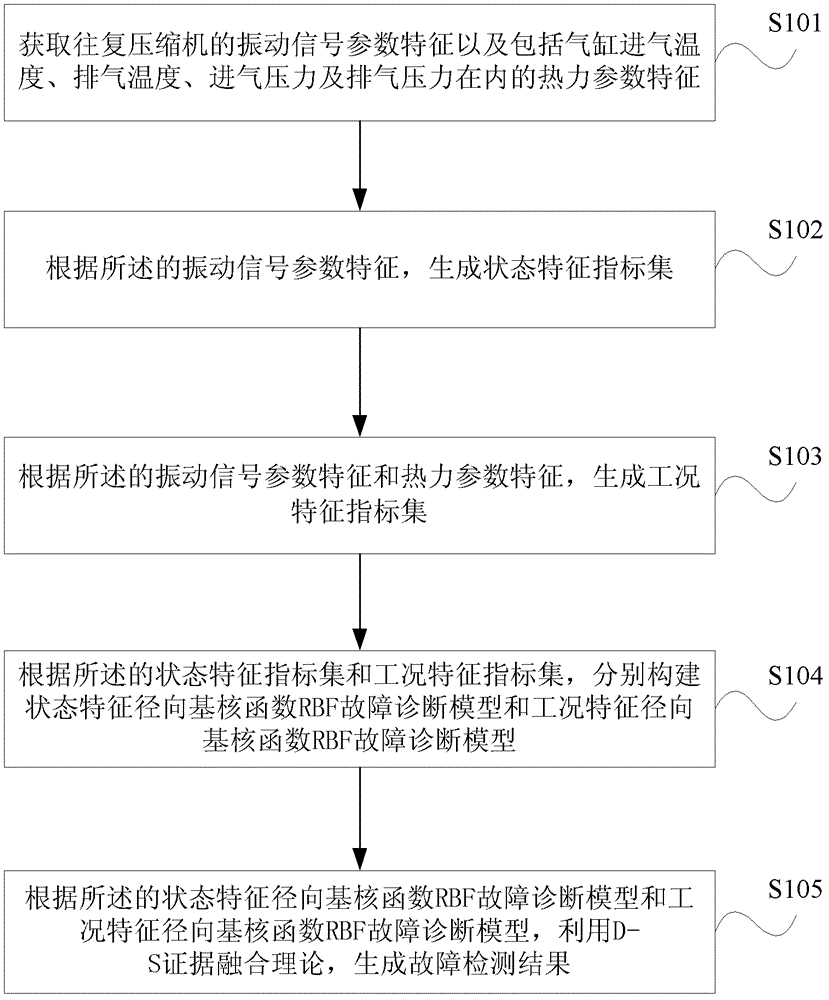

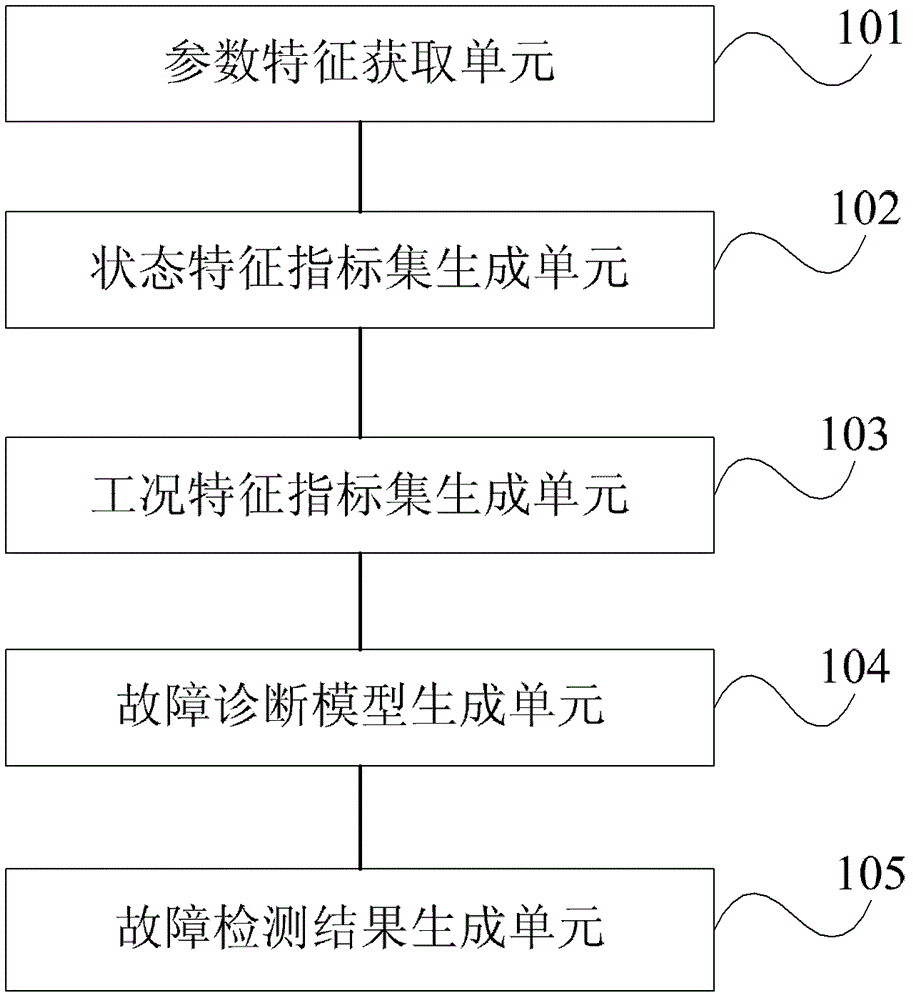

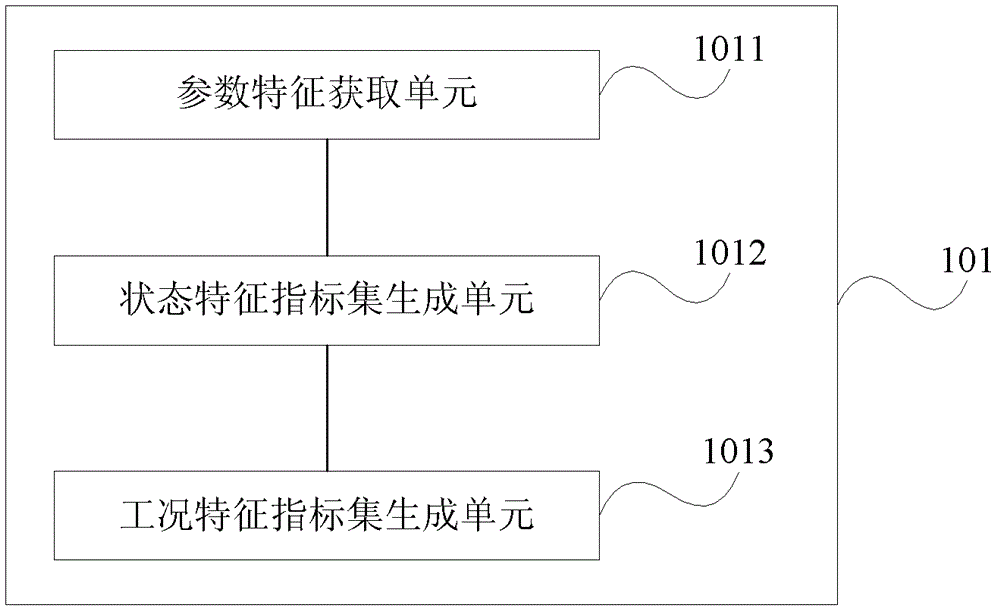

Fault detection method and device of reciprocating compressor

InactiveCN102797671ASimple and fast operationLow costPump testingPositive-displacement liquid enginesEngineeringInlet pressure

The invention discloses a fault detection method and a fault detection device of a reciprocating compressor. The method comprises the following steps of acquiring vibration signal parameter characteristics of the reciprocating compressor and thermal parameter characteristics comprising an air inlet temperature, an exhaust temperature, air inlet pressure and exhaust pressure of a cylinder; generating a state characteristic index set according to the vibration signal parameter characteristics; generating a working condition characteristic index set according to the vibration signal parameter characteristics and the thermal parameter characteristics; constructing a state characteristic radial basis function (RBF) fault diagnosis model and a working condition characteristic RBF fault diagnosis model respectively according to the state characteristic index set and the working condition characteristic index set; and generating a fault detection result by using a D-S evidence fusion theory according to the state characteristic RBF fault diagnosis model and the working condition characteristic RBF fault diagnosis model. By the method and the device, monitoring information of two detection means are fused, so that the accuracy rate of a judgment conclusion is remarkably improved; and the method and the device are easy and convenient to operate, low in cost, high in accuracy rate and easy to popularize and apply.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

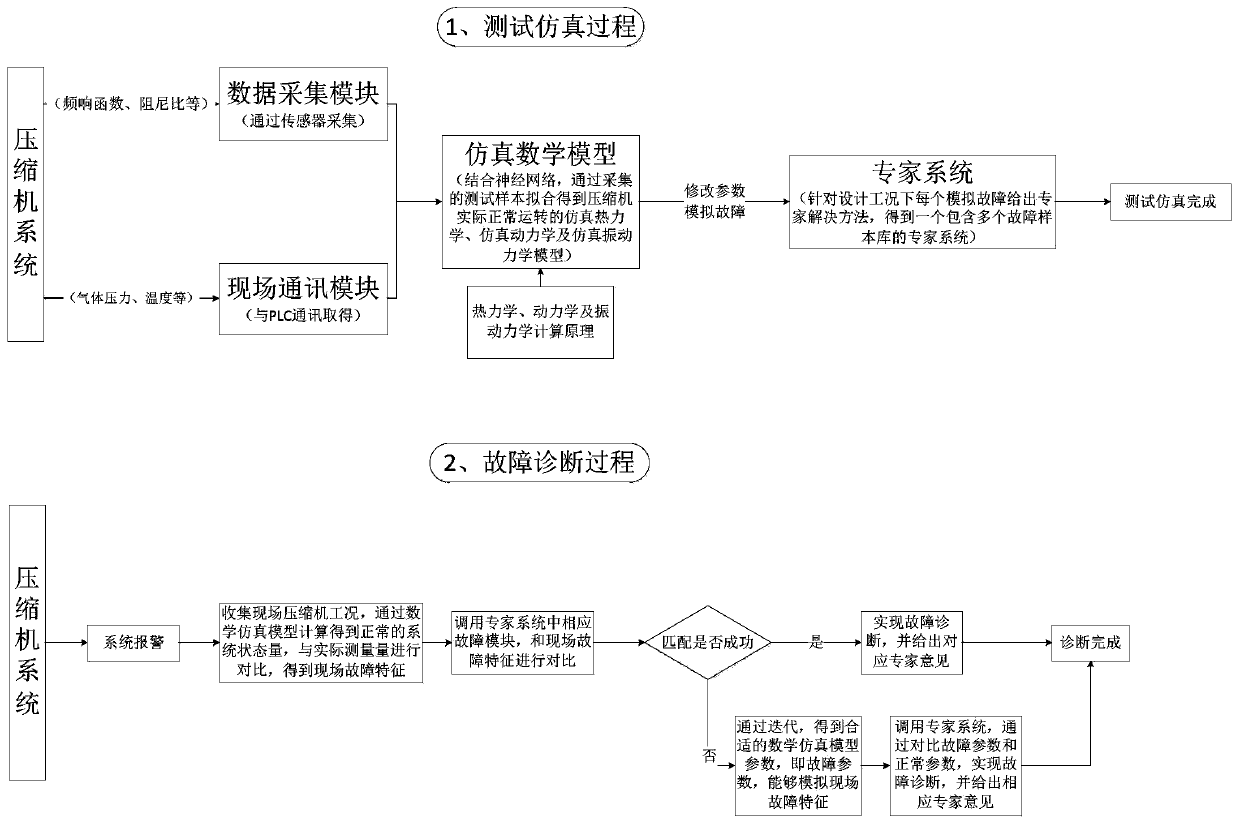

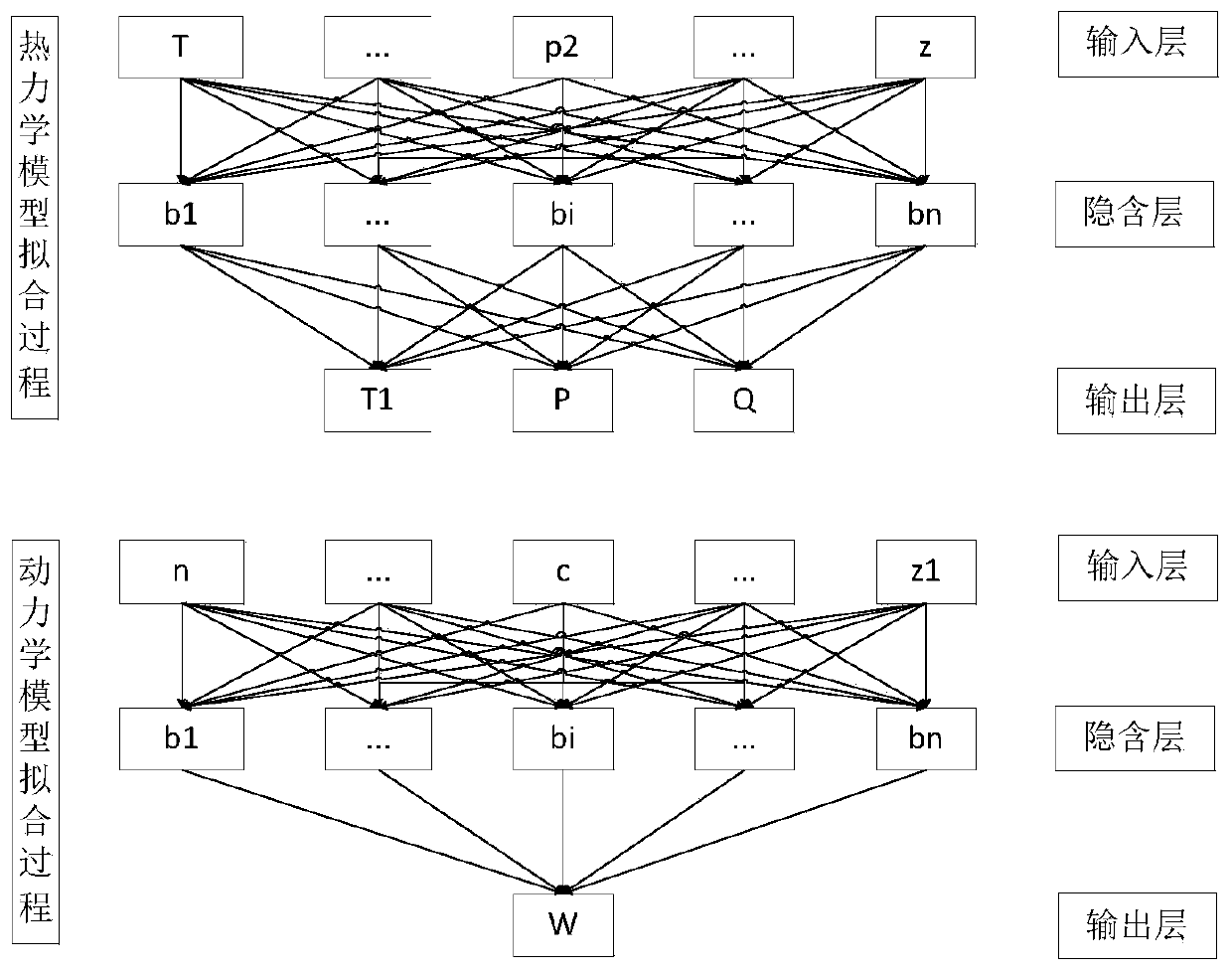

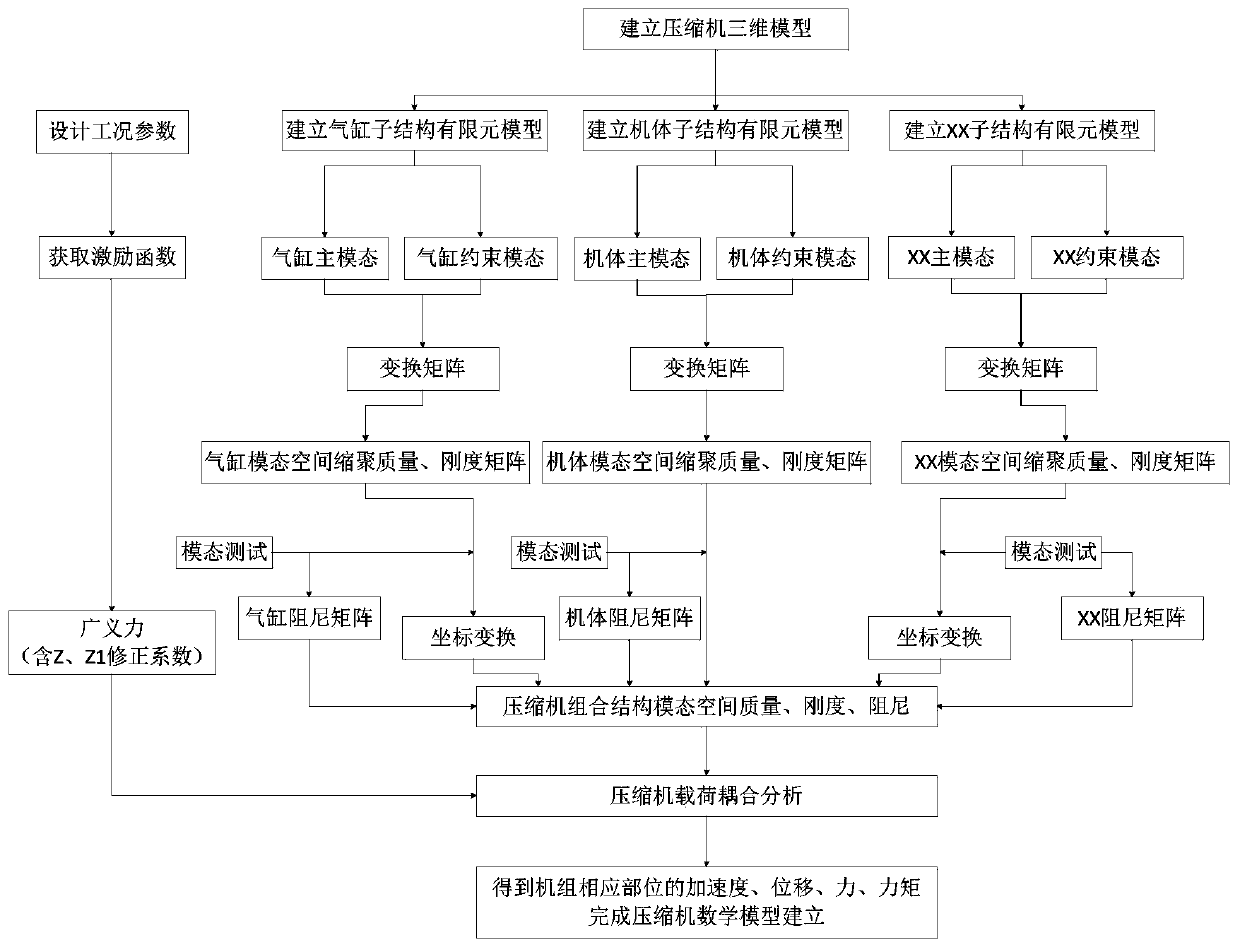

Reciprocating compressor fault diagnosis system and method based on neural network algorithm

ActiveCN109779894AImprove simulation accuracyImprove accuracyPump testingNeural architecturesSimulationData collecting

The invention discloses a reciprocating compressor fault diagnosis system and method based on a neural network algorithm. The reciprocating compressor fault diagnosis system and method based on the neural network algorithm comprises a field communication module, a data collecting module, a simulation model based on neural networks, an expert system module based on standard fault characteristics, afault diagnosis main machine and an upper computer. According to the reciprocating compressor fault diagnosis system and method based on the neural network algorithm, the neural network algorithm isutilized, measured compressor system status parameters are combined, and thus simulation models in all working conditions are acquired; compressor faults are simulated by changing system parameters tocalculate and obtain the standard fault characteristics, after the abnormal operation of the compressor occurs, through the comparison with the standard fault characteristics, fault parts can be accurately located, and elimination methods can be brought; and the diagnosis success rate is high, and real-time monitoring analysis of high precision equipment is not needed, and the diagnosis cost is lowered.

Owner:XI AN JIAOTONG UNIV

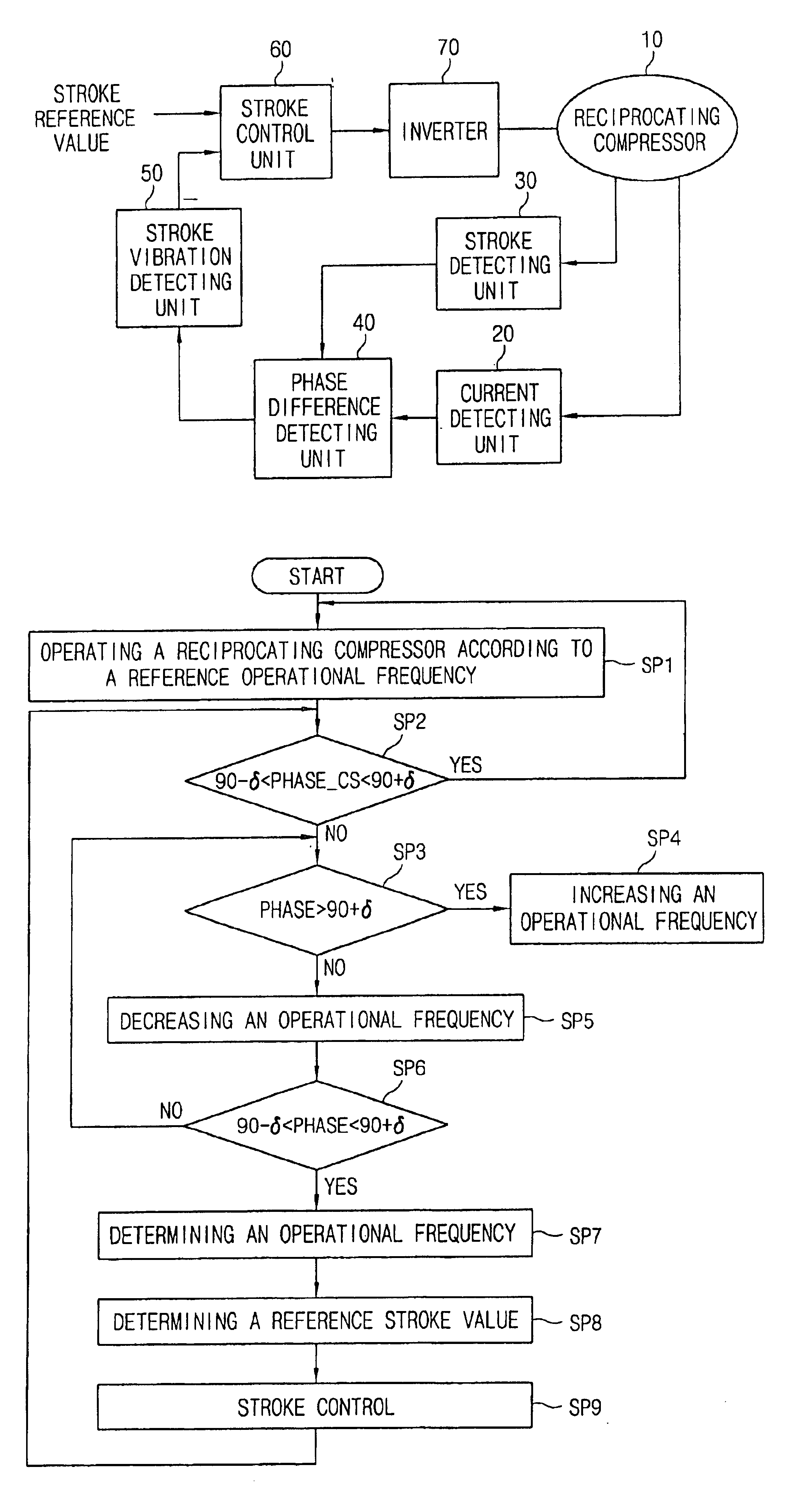

Stroke control apparatus of reciprocating compressor and method thereof

InactiveUS6851934B2Easy to operateAC motor controlFlexible member pumpsPhase differenceControl signal

In a stroke control apparatus of a reciprocating compressor and a method thereof, the stroke control apparatus of the reciprocating compressor includes a reciprocating compressor, a current detecting unit for detecting a current flowing in a motor of the reciprocating compressor, a stroke detecting unit for detecting a piston stroke by using a voltage and a current applied to the motor of the reciprocating compressor, a phase difference detecting unit for detecting a phase difference by receiving the piston stroke from the stroke detecting unit and the motor current from the current detecting unit, an operational frequency determining unit for determining an operational frequency corresponded to an operation region according to the detected phase difference, a frequency / stroke storing unit for storing a piston stroke value by the determined operational frequency, a reference stroke value determining unit for determining a reference stroke value corresponded to the determined operational frequency by using the stroke value pre-stored in the frequency / stroke storing unit, a control unit for comparing the reference stroke value with a present piston stroke value after a certain time point and outputting a stroke control signal according to the comparison result and an inverter for varying an operational frequency and a voltage applied to the motor of the reciprocating compressor according to the stroke control signal of the control unit.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com