Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1221results about How to "High reusability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lactobacillus helveticus microcapsule, preparation and use thereof

InactiveCN101323850AOvercoming the problem of low survival rate of freeze-dryingImprove efficiencyMilk preparationMetabolism disorderFreeze-dryingDietary supplement

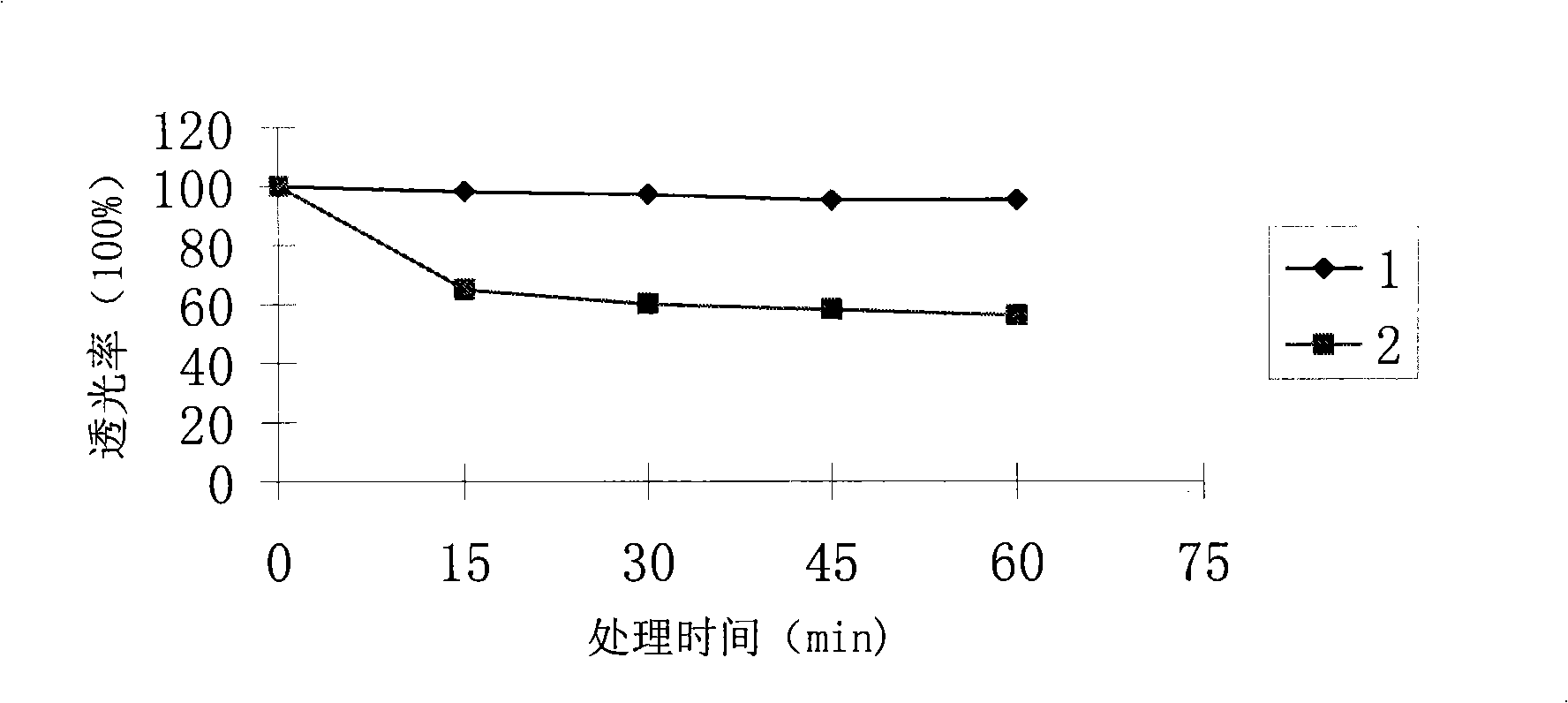

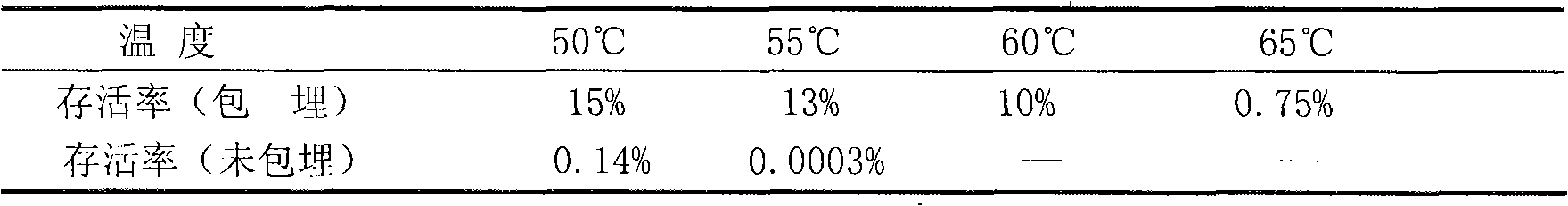

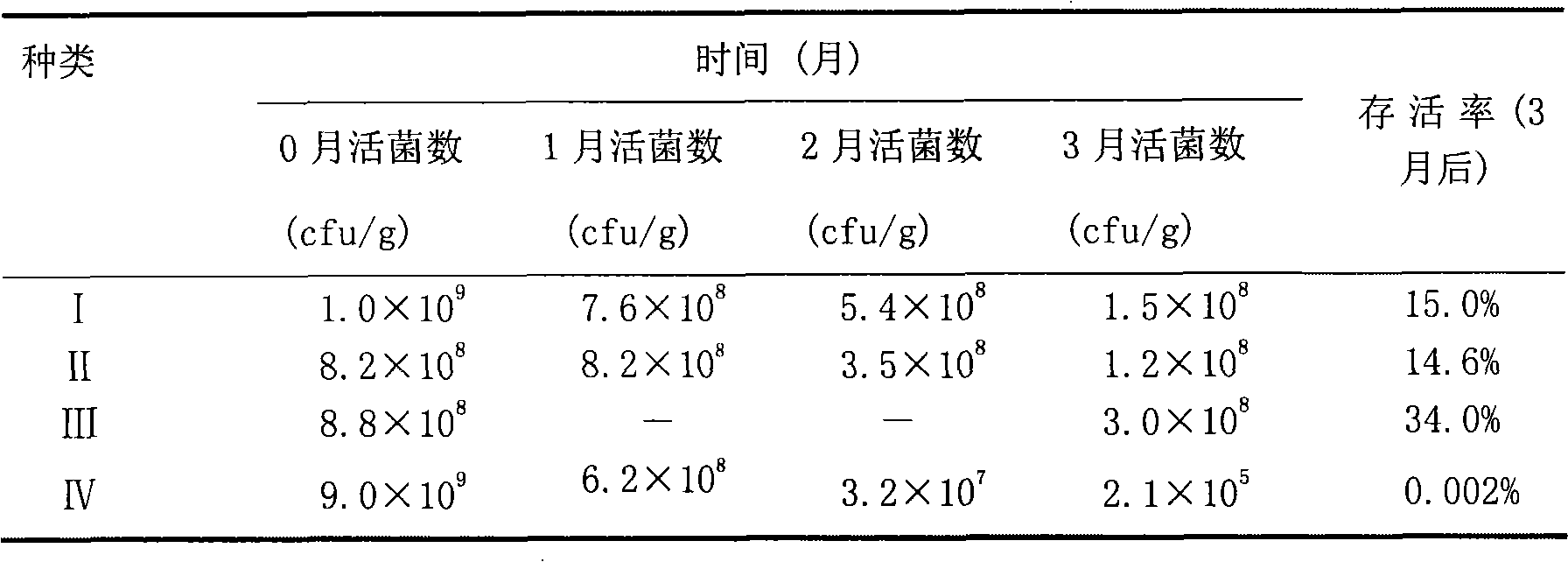

The invention provides a lactobacillus helveticus microcapsule as well as the preparation and application thereof, pertaining to the embedding technology of lactobacillus helveticus and aiming at microencapsulating the lactobacillus helveticus so as to solve the problems of low embedding efficiency and embedding yield in single-layer or double-layer embedment. The technical proposal adopted by the invention is that isolated soy protein, microporous starch and sodium alginate are respectively taken as the first, the second and the third layers of wall materials for microencapsulation; the three-layer embedment is carried out to the lactobacillus helveticus for the first time, wherein, in the process of preparing bacterial suspension, an orthogonal optimization protective agent is adopted to improve the livability after freeze drying. The microcapsule of the invention has strong heat resistance and acid resistance, solves the inactivation problem caused by gastric acid, digestive enzyme and antibiotic, etc. to active bacillus, is capable of releasing when reaching large intestine, and balances intestinal flora. The reusability of fermented milk is good. The lactobacillus helveticus used by the invention enriches the variety of probiotic bacteria microcapsule and is a good dietary supplement.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

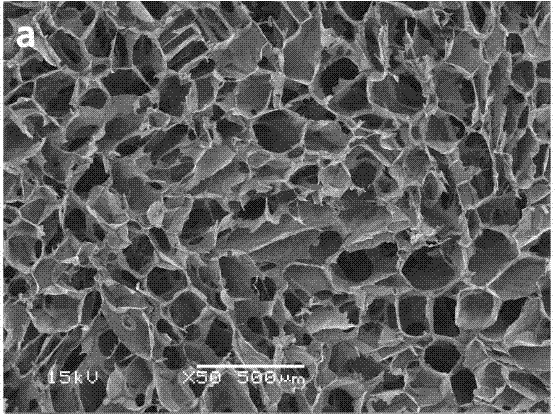

Method for preparing seaweed cellulose aerogel oil absorption material

ActiveCN103980530AEnsure thoroughnessFast oil absorptionOther chemical processesCelluloseUltimate tensile strength

The invention discloses a method for preparing a seaweed cellulose aerogel oil absorption material and relates to a method for preparing an oil absorption material. The method comprises the following steps: I, purifying seaweed cellulose; II, preparing seaweed nano cellulose microfibril in a mechanical colloid milling mode; III, preparing seaweed cellulose aerogel; and IV, performing hydrophobic modification on the seaweed cellulose aerogel. The seaweed cellulose aerogel oil absorption material prepared by using the method is natural and pollution-free and has the advantages of high oil absorption efficiency, , good strength, simple secondary treatment and the like, and is an important development direction of novel aerogel oil absorption materials.

Owner:HARBIN INST OF TECH

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

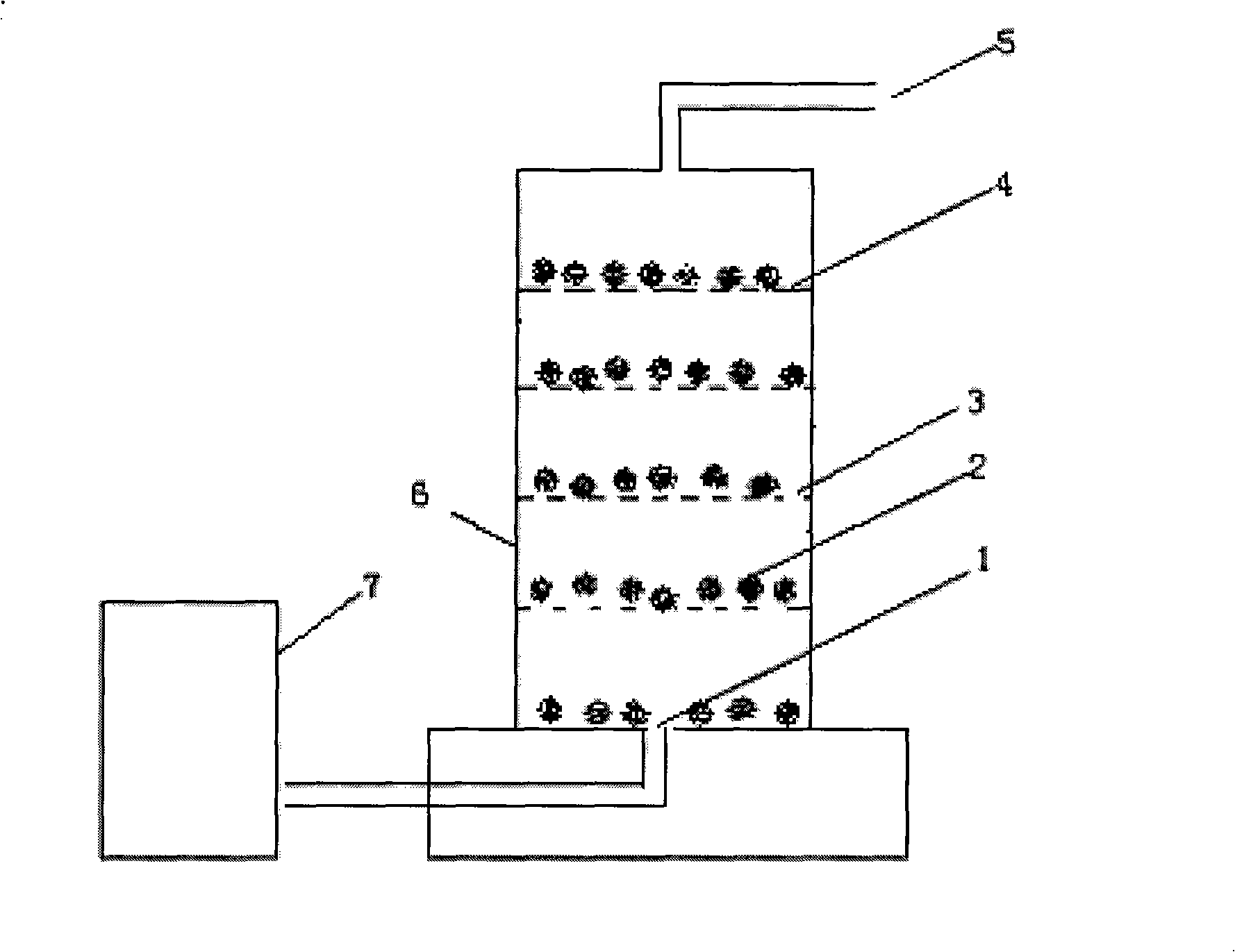

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

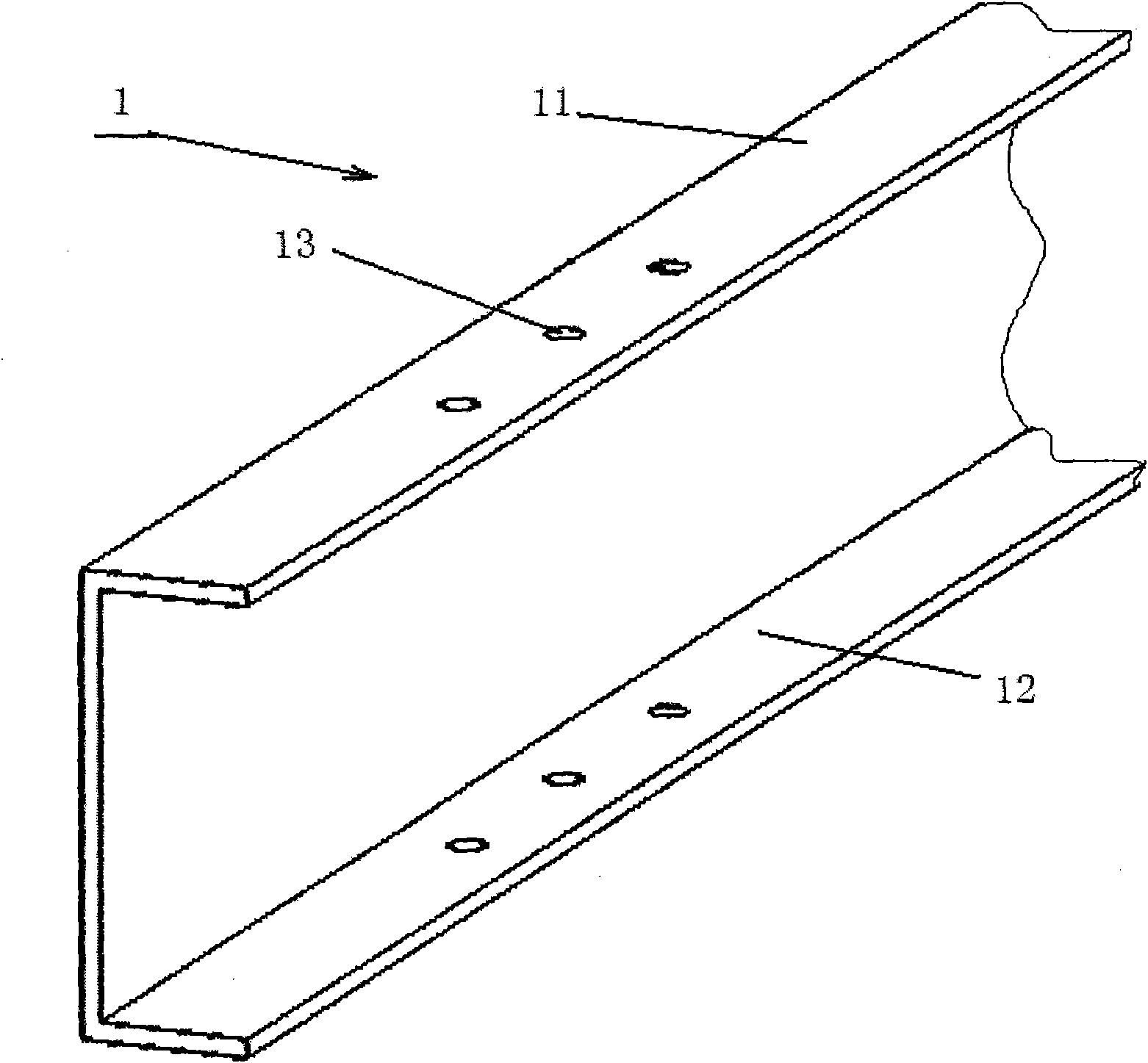

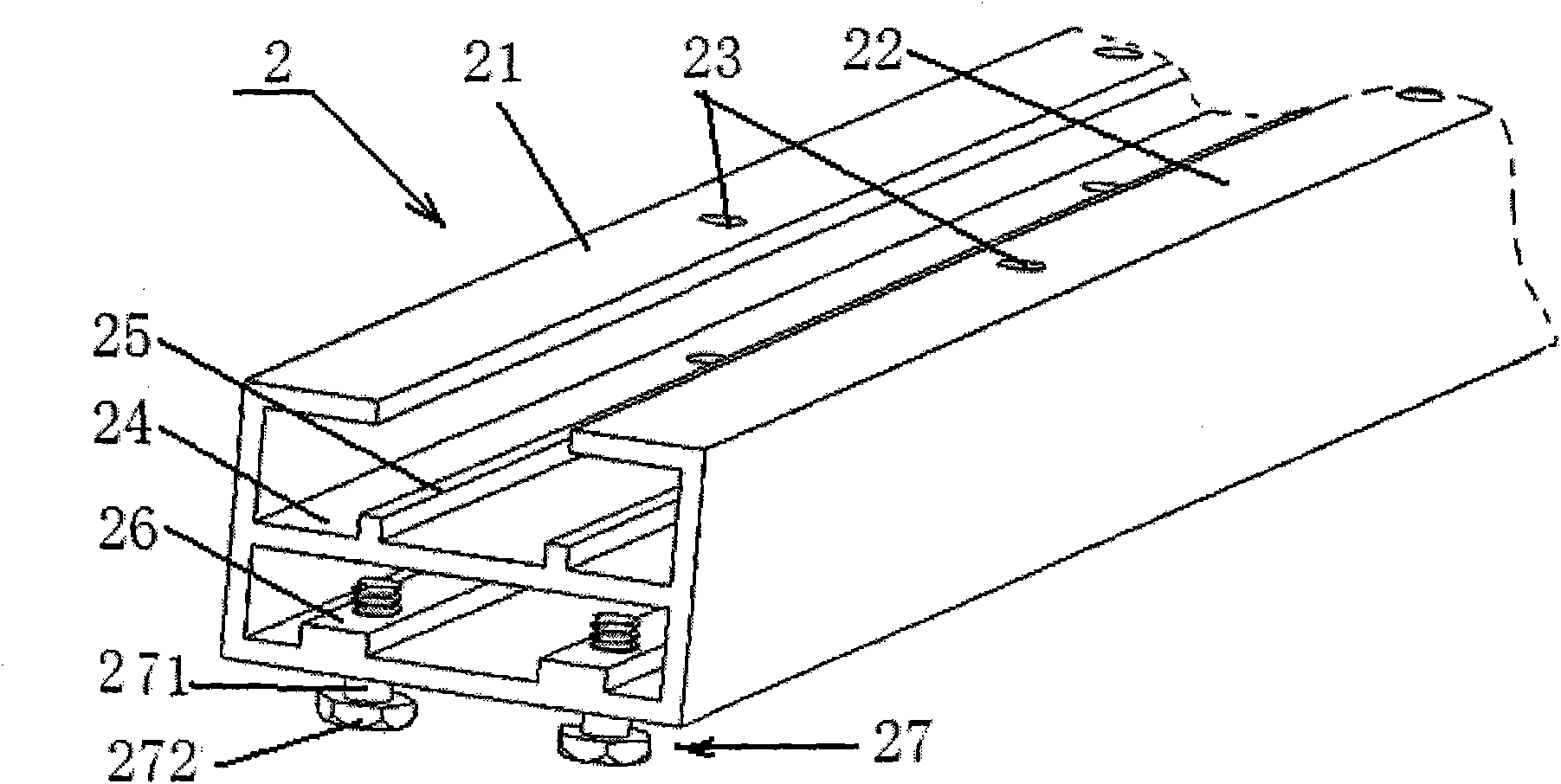

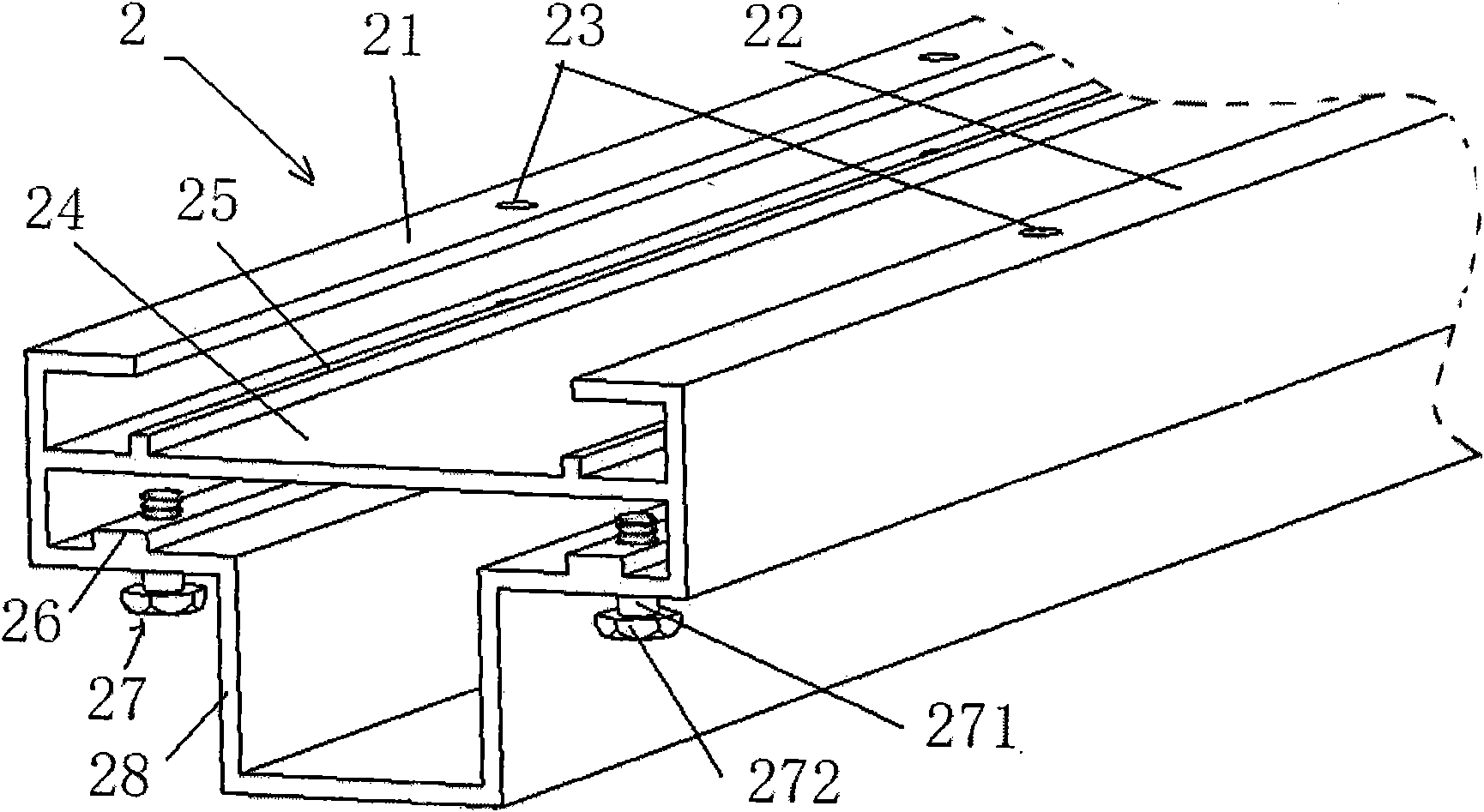

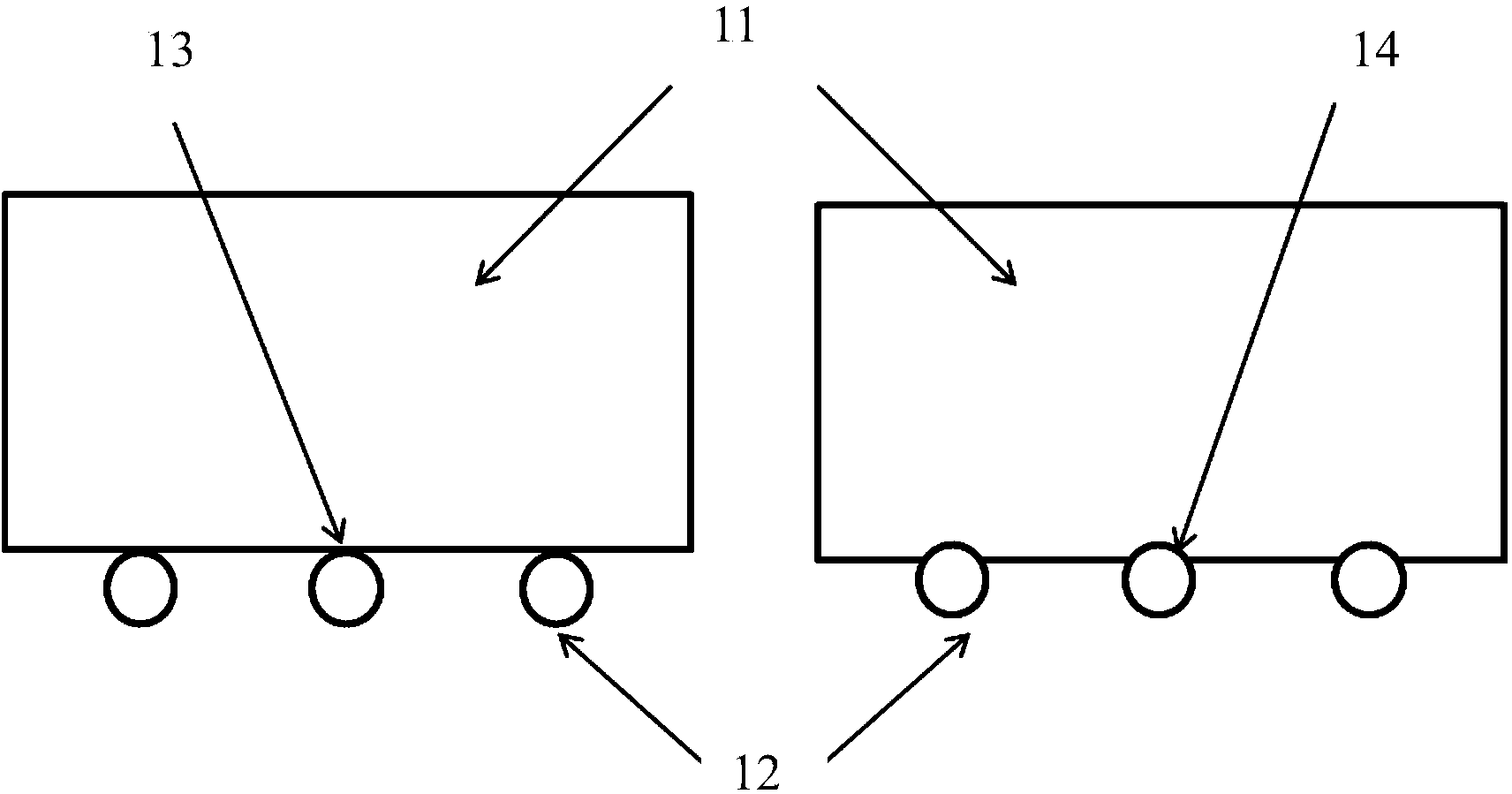

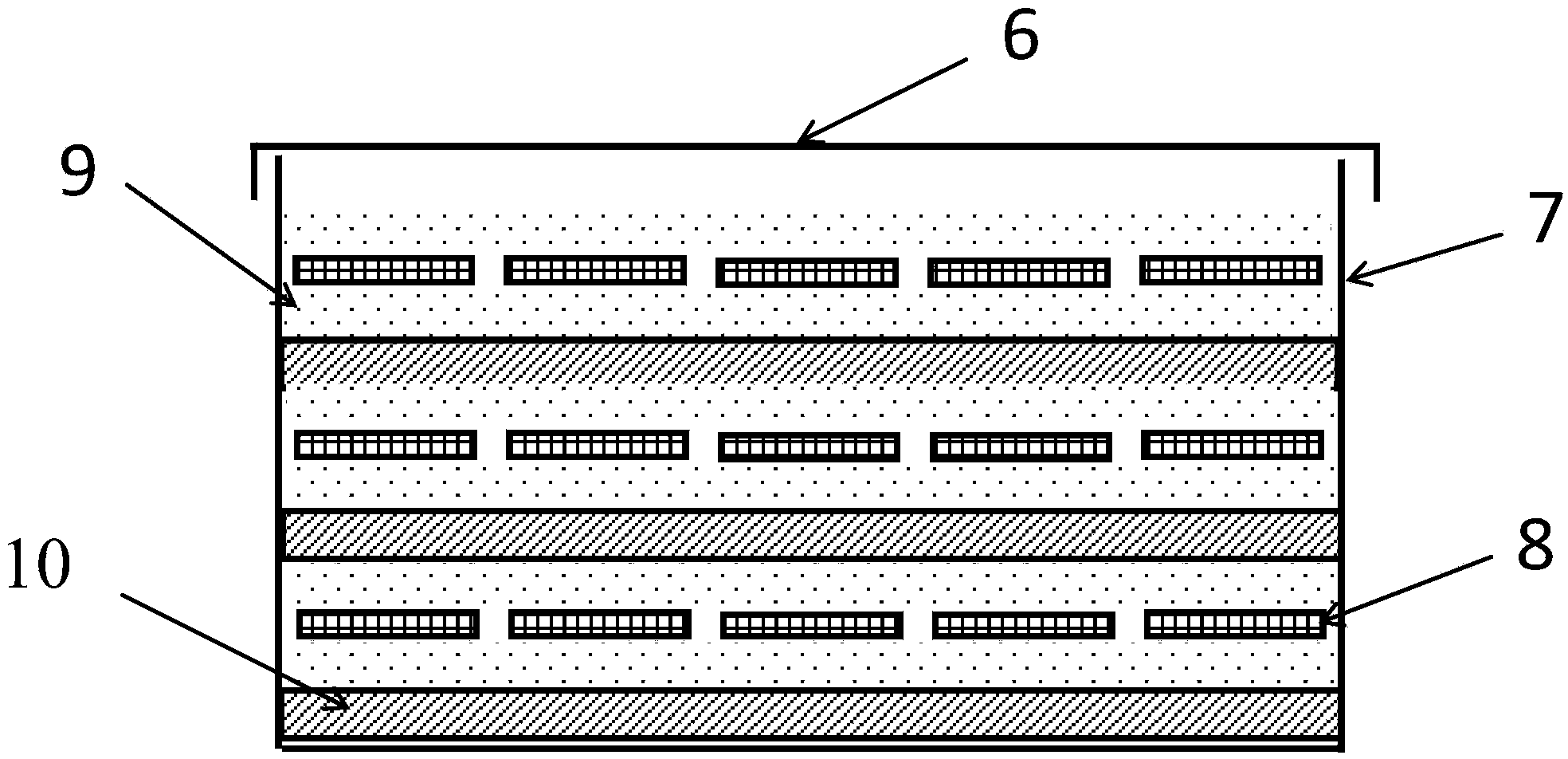

Support keel of integrated ceiling, unit buckle, electrical appliance module and installation method thereof

InactiveCN102041864AStrong keel structureSimple installation structureCeilingsCovering/liningsEngineeringComputer module

The invention discloses a support keel of an integrated ceiling, a unit buckle, an electrical application module and an installation method thereof. The support keel comprises main keels and auxiliary keels, wherein the bottom end of each main keel is provided with a horizontal connecting edge, each auxiliary keel is slotted at the top, provided with inner turnups, and connected with the main keel through bolts, and the bottom surface of each auxiliary keel is provided with a mounting part. Four sides of the buckle and a face cover board of the electrical application module are secondary edgefolds in the same direction, and each second edgefold is provided with a connecting part which is movably connected with the mounting part of each auxiliary keel. The installation method comprises the steps of: a, installing at least two keels under a ceiling through suspenders and suspending rods; b, fixing a plurality of the auxiliary keels under the main keel at intervals through bolts; c, hanging the connecting parts of each unit buckle and / or electrical face cover board on the mounting part of each auxiliary keel and moving to a determined position; and d, fixing an electrical main engine of the electric module above the auxiliary keels opposite to the position of the electrical face cover board. The invention has the advantages of convenience of installation, maintenance and detachment and strong bearing capacity.

Owner:上海指顶集成电气有限公司

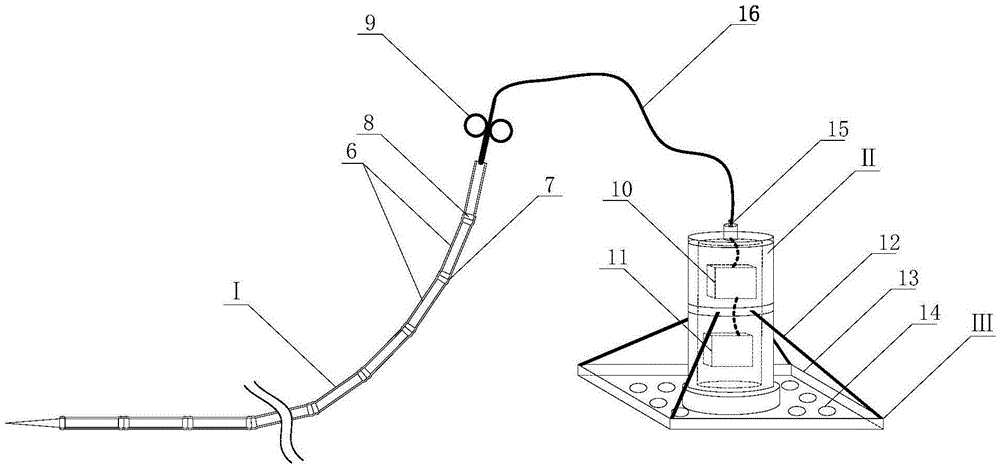

Two-degrees-of-freedom supporting system for wind tunnel test of airplane

InactiveCN102175420ASmall frictional dampingProtection securityAerodynamic testingDisc brakeLinear displacement

The invention provides a two-degrees-of-freedom supporting system for a wind tunnel test of an airplane. The entire system comprises a rotating module (rotary table bearing for simulating pitching movement of the airplane), a translational module (linear guide rail for simulating plunging motion of the airplane), measuring modules (an angular displacement meter and a linear displacement meter formeasuring angular displacement and linear displacement), protecting modules (a disc brake and a shock absorber for limiting and protecting a test model) and an interface module (a shaft connected with the test model). The system is connected with an airplane module through a connecting module, and two degrees of freedom including pitching and plunging can be provided to simulate the flying pitching and plunging movement of the airplane; the angular displacement meter and the linear displacement meter can be used for measuring an attack angle and plunging displacement; a disc brake braking device can be used for limiting the pitching movement of the airplane model; and the shock absorber is used for limiting the plunging displacement of the airplane model and can be used for reducing an impact load, so that the test model is protected.

Owner:BEIHANG UNIV

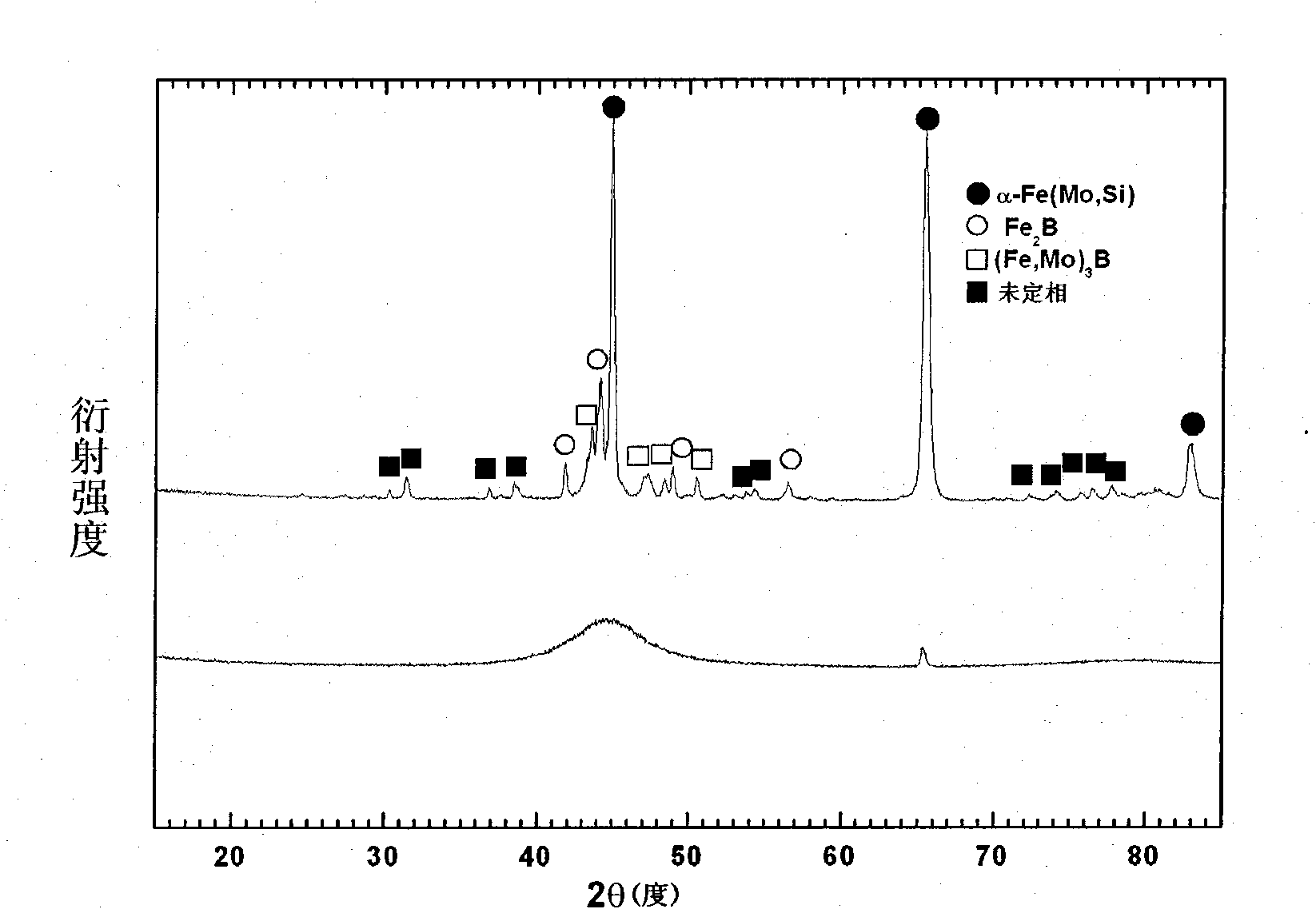

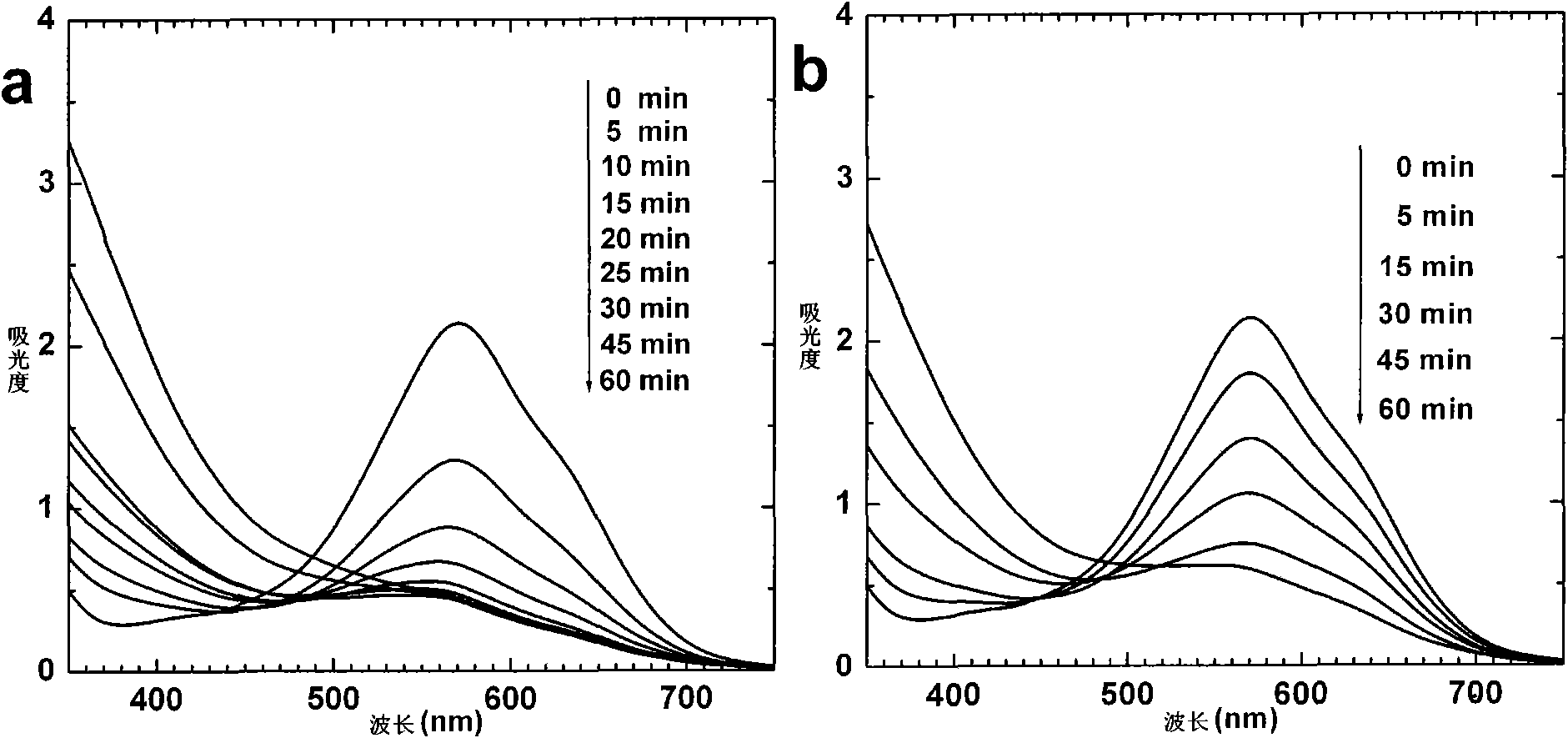

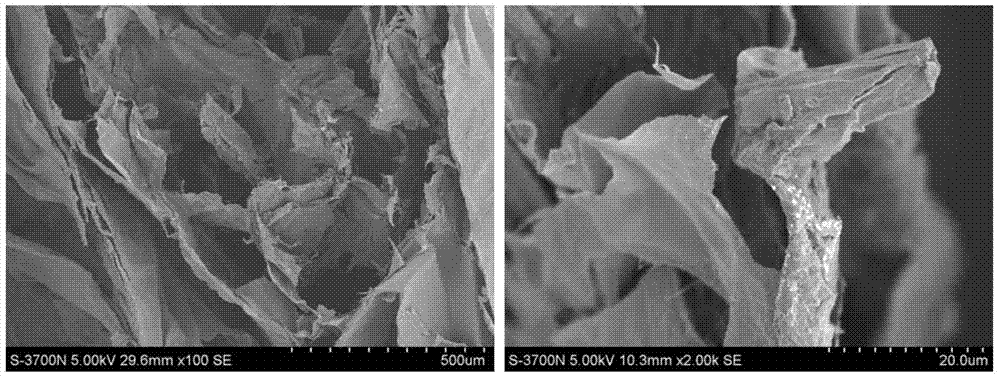

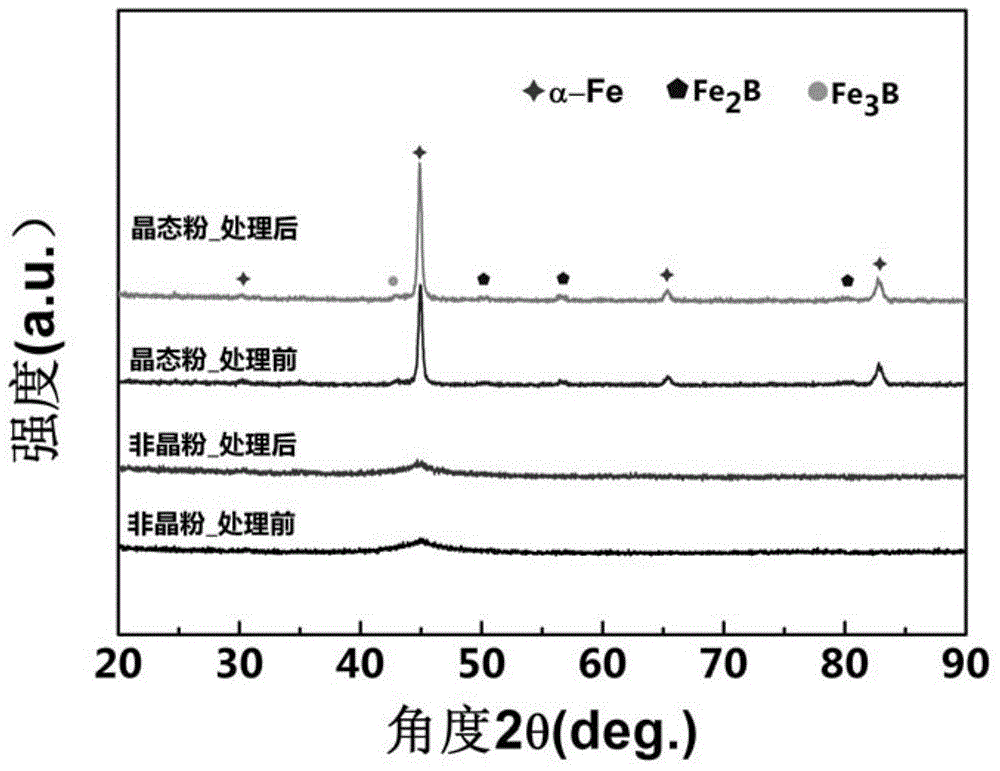

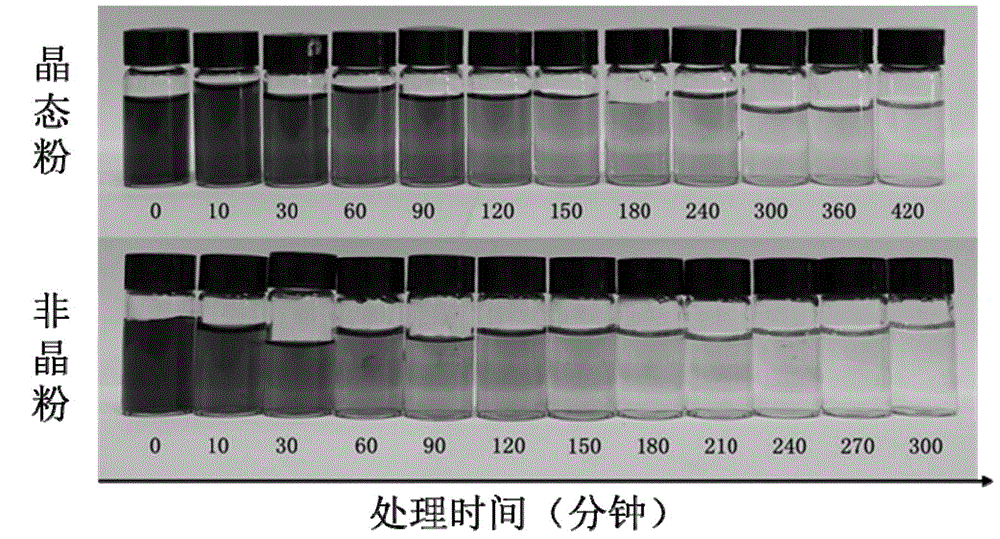

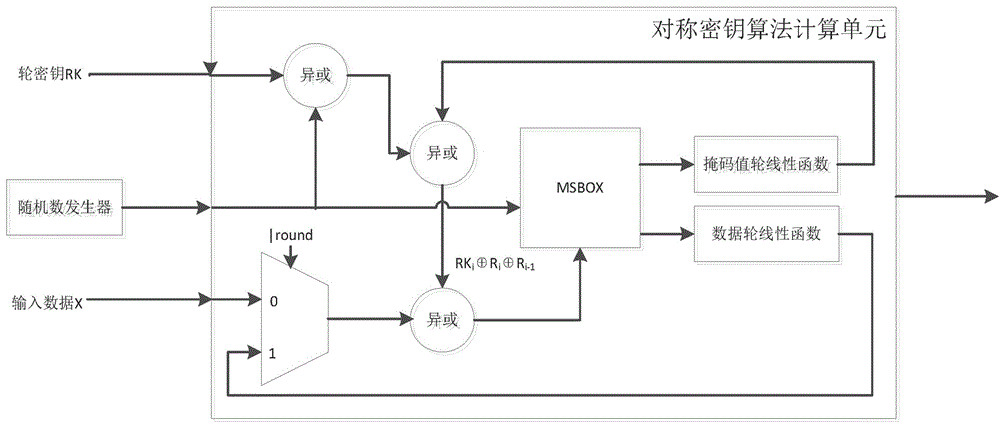

Ferrum-based amorphous alloy strip for treating printing and dyeing wastewater and preparation method thereof

ActiveCN102070236AAchieve amorphizationRetain color removal abilityWaste water treatment from textile industryWater/sewage treatment by reductionIron powderDyeing wastewater

The invention relates to a ferrum (Fe)-based amorphous alloy material, in particular to a Fe-based amorphous alloy strip for treating printing and dyeing wastewater and a preparation method thereof. According to the conventional literatures and technical data, an alloy component with Fe-based amorphous alloy strip forming capacity is selected; and general requirements show that the selected alloy component comprises more than 50 percent of Fe atoms, preferably 60 to 85 percent, so the reduction decoloring capacity of the Fe atoms is exerted. The amorphous alloy strip is obtained by adding a small amount of other elements and performing rapid solidification by using melt spinning equipment. The decrystallization of zero-valent Fe is realized by preprocessing technology; the decoloring capacity of the Fe atoms is kept; the rusting consumption of the Fe in the wastewater treatment process is effectively reduced; the strip is repeatedly and persistently utilized on the premise of guaranteeing the decoloring rate; the technical defects and the application defects in the conventional method for treating the printing and dyeing wastewater by using reducing Fe powder or waste cast Fe scraps are overcome; and the Fe-based amorphous alloy strip relates to the field of potential application of decrystallization technology in the industrial field, and has an extremely high application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Catalyst for wet oxidation technique and preparation method thereof

InactiveCN101185887AHigh catalytic activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActive componentSalt solution

The invention relates to a catalyst which is used for wet air oxidation technique and the preparation method in the field of environmental protection technology. The catalyst uses Gamma-Al2O3 as a vector and the oxide of transition metal Mn or Mn and rear earth element M or the oxide of the M as active components, wherein, M is one or two kinds in La and Ce and the loading of each metal relative to Gamma-Al2O3 vector is 5wt to 8wt percent. The catalyst takes Gamma-Al2O3 as the vector, is cleaned and roasted to be a consistent weight; the obtained Gamma-Al2O3 vector is immersed into the metallic salt solution of the rear earth element M and the transition metal Mn; the loading of each metal relative to the vector is 5wt to 8wt percent; the mixture after being immersed and dried is roasted in air to get the catalyst used in the wet air oxidation. The invention does not use expensive precious metal materials and greatly reduces the cost of the catalyst; at the same time, the catalytic activity of the catalyst is enhanced; the operation condition is improved; and the reaction time is shortened.

Owner:SHANGHAI JIAO TONG UNIV

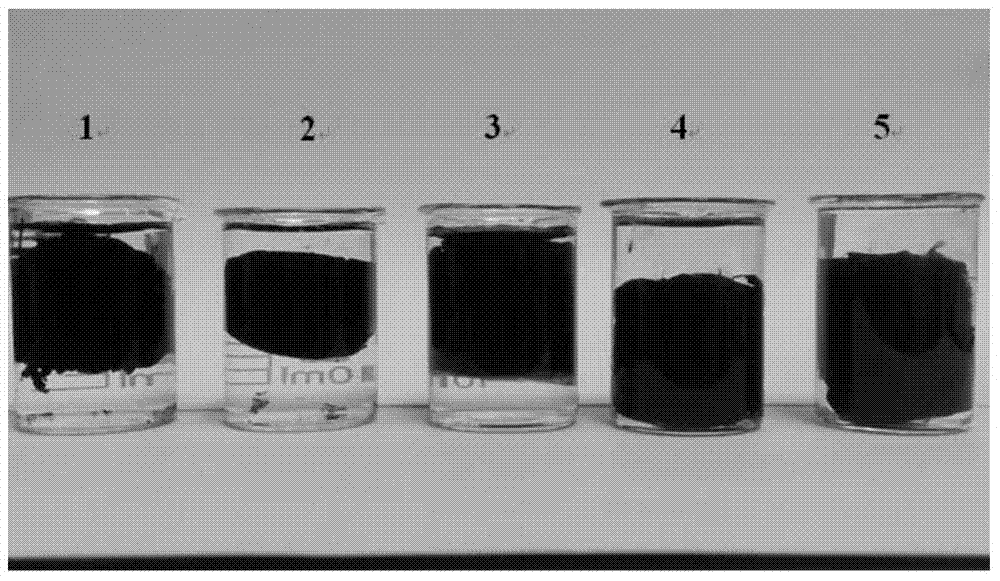

Graphene sponge used for enriching heavy metals or removing pollutants in water and preparation method of graphene sponge

ActiveCN104759253ASimple preparation processEasy to getOther chemical processesAlkali metal oxides/hydroxidesAtherion elymusSorbent

The invention discloses a graphene sponge used for enriching heavy metals or removing pollutants in water and a preparation method of the graphene sponge. The preparation method comprises the following steps: ultrasonically uniformly mixing oxidized graphene and a sodium alginate solution with a mass ratio of 1:0.1-1:10, adding an alkaline substance to adjust a pH value to be 8-10; sealing at the temperature of 60-150 DEG C to perform heating reaction for 0.5h-10h to obtain graphene hydrogel; and adding a calcium ion solution in the obtained graphene hydrogel, washing respectively with acid and water, and then drying to obtain a target product. According to the preparation method, the preparation process is simple, the raw material ingredients are relatively simple and are easily available, secondary pollution is avoided, the popularization is easy, and large-batch production can be performed; the prepared graphene sponge is relatively disperse and porous, and is large in specific surface area so that the adsorption capacity to the pollutants is increased. The problem that solid-liquid separation is difficultly performed by adopting a nanometer adsorbing agent is solved. The graphene sponge can be used for adsorbing organic pollutants and heavy metal ions in water, and can also be used for enriching trace heavy metals in water.

Owner:INST OF ANALYSIS GUANGDONG ACAD OF SCI (CHINA NAT ANALYTICAL

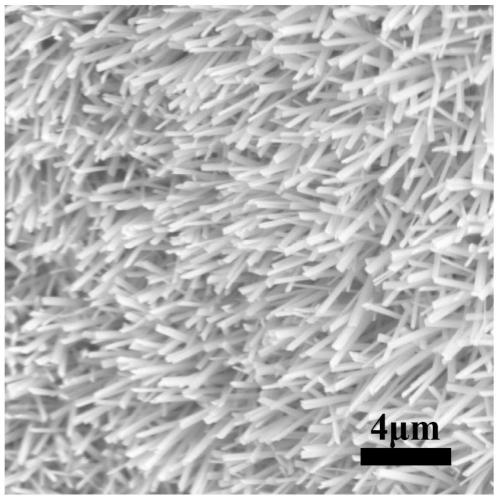

Molybdenum doped iron/nickel lamellar array @ nickel foam base composite electrode material and preparing method and application thereof

ActiveCN108754532AImprove stabilityMake up for deficienciesElectrodesNickel substrateComposite electrode

The invention discloses a molybdenum doped iron / nickel lamellar array @ nickel foam base composite electrode material and a preparing method and application thereof. The material uses foamed nickel asa substrate, an iron / nickel lamellar thermometal hydroxide (FeNi-LDHs) array grows on the surface of the foamed nickel, and the metal molybdenum is doped into the array. According to the preparing method of the material, a hydrothermal method is adopted for directly growing FeNi-LDHs nanosheet arrays on the foamed nickel substrate, then the FeNi-LDHs array is used as a substrate to dope metal Moon the surface of the array through the hydrothermal method, and finally high temperature carbonization and revivification are carried out to obtain the electrode material with the electro-catalytic property. The composite material is stable in performance under the alkaline condition, the high reutilization degree is achieved, the large electrochemical active area is achieved, and the material catalytic activity is greatly improved; and the preparing method is simple in preparing process, low in sintering temperature, low in energy consumption in the preparing process and favorable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

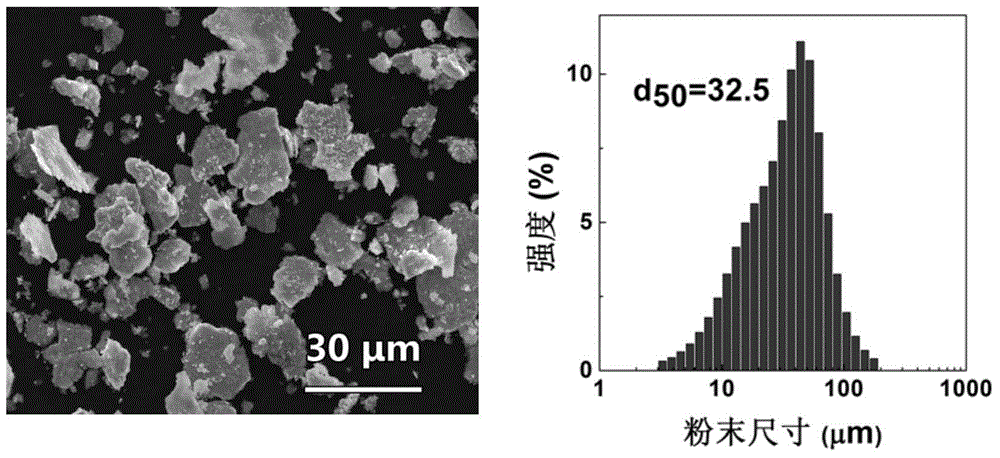

Printing and dyeing wastewater treatment method

ActiveCN105314726AHigh reactivityReduce rust consumptionWaste water treatment from textile industryWater/sewage treatment by reductionIron based alloySewage

The invention provides a printing and dyeing wastewater treatment method. An iron-base alloy raw material being capable of forming an amorphous alloy strip is employed in the method and is processed to form an iron-base amorphous alloy strip. The iron-base amorphous alloy strip then is embrittled and smashed to obtain iron-base amorphous alloy powder. The iron-base amorphous alloy powder is used in printing and dyeing wastewater treatment. Compared with the prior art, the iron-base amorphous alloy powder has a high specific surface area and can form a nano porous structure on surface when being reacted with printing and dyeing wastewater. The nano porous structure can not only increase the specific surface area of the iron-base amorphous alloy further but also has the effects of adsorb azo dyes and reaction products during a reaction process, thereby increasing efficiency of the iron-base amorphous alloy powder in printing and dyeing wastewater treatment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

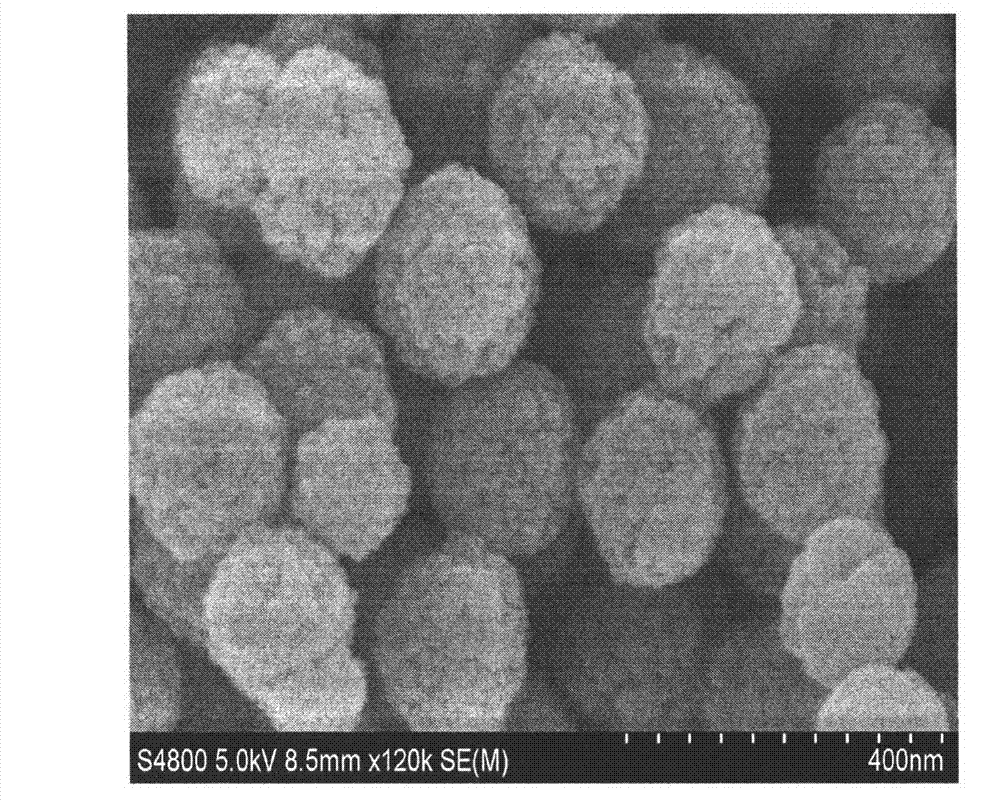

RAFT (Reversible addition-fragmentation chain transfer) polymerization preparation method of magnetic mesoporous molecular imprinted hybrid silicon spheres

InactiveCN102964542AReasonable workmanshipEasy to implementOther chemical processesWater/sewage treatment by magnetic/electric fieldsPerturbateurs endocriniensSolvent

The invention relates to a preparation method of magnetic mesoporous molecular imprinted hybrid silicon spheres. The preparation method comprises the following steps: firstly preparing Fe3O4 magnetic microspheres by adopting a solvothermal method, then coating mesoporous silica on the surfaces of the Fe3O4 magnetic microspheres through a sol-gel method and finally synthesizing the magnetic mesoporous molecular imprinted hybrid silicon spheres on the surfaces of the magnetic mesoporous silicon spheres by utilizing an RAFT (reversible addition-fragmentation chain transfer) molecular imprinting technology. The prepared magnetic mesoporous molecular imprinted hybrid silicon spheres can be used for selectively removing alkylphenol in drinking water. The preparation method disclosed by the invention has the advantages that the preparation method of the magnetic mesoporous molecular imprinted hybrid silicon spheres is reasonable in process and easy to implement; when the materials are used for removing alkylphenol type endocrine disruptors, the materials have good chemical stability and reusability and are easy to realize active adsorption, identification and separation against the alkylphenol; and according to the preparation method, the properties of magnetic mesoporous microspheres and a molecular imprinted polymer can be combined into a whole, the using efficiency of the molecular imprinting technology can be greatly improved and the range of molecular imprinting applications can be further expanded.

Owner:TIANJIN POLYTECHNIC UNIV

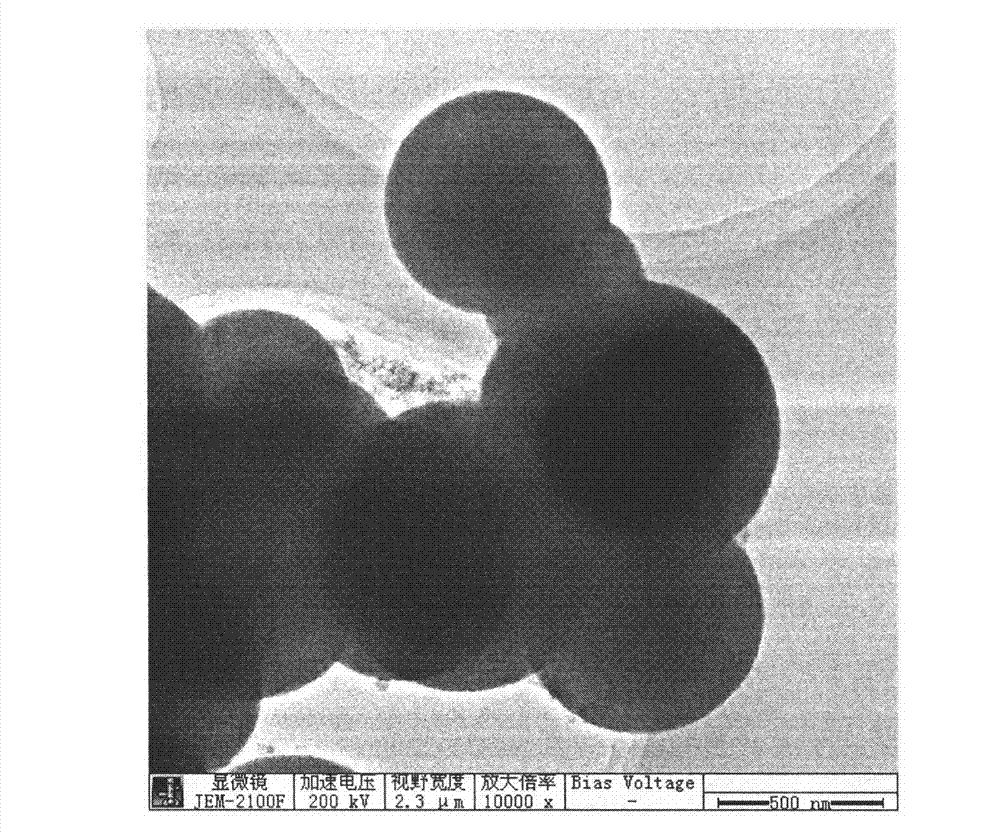

Preparation method of magnetic functionalized graphene oxide based molecularly imprinted hybrid material

ActiveCN102977247AEasy to implementGood chemical stabilityOther chemical processesAlkali metal oxides/hydroxidesPerturbateurs endocriniensEndocrine disruptor

The invention relates to a preparation method of a magnetic functionalized graphene oxide based molecularly imprinted hybrid material. The preparation method comprises the following steps: firstly, loading Fe3O4 magnetic nanoparticles on the surface of graphene oxide by chloroformylation reaction; and synthesizing the magnetic functionalized graphene oxide based molecularly imprinted hybrid material on the surface of the magnetic functionalized graphene oxide serving as a carrier by utilizing a molecular imprinting technology. The prepared magnetic functionalized graphene oxide based molecularly imprinted hybrid material can be used for selectively removing estrogen in drinking water. The preparation method of the magnetic functionalized graphene oxide based molecularly imprinted hybrid material has the advantages that the process is reasonable and easy to implement; when being used for removing endocrine disruptors, the material has good chemical stability and reusability, and active adsorption, identification and separation of the estrogen are easily carried out; and the preparation method has strong magnetic response, preordainment, identity and practicality, and can greatly improve the using efficiency of the molecular imprinting technology and expand the range of molecular imprinting applications.

Owner:TIANJIN POLYTECHNIC UNIV

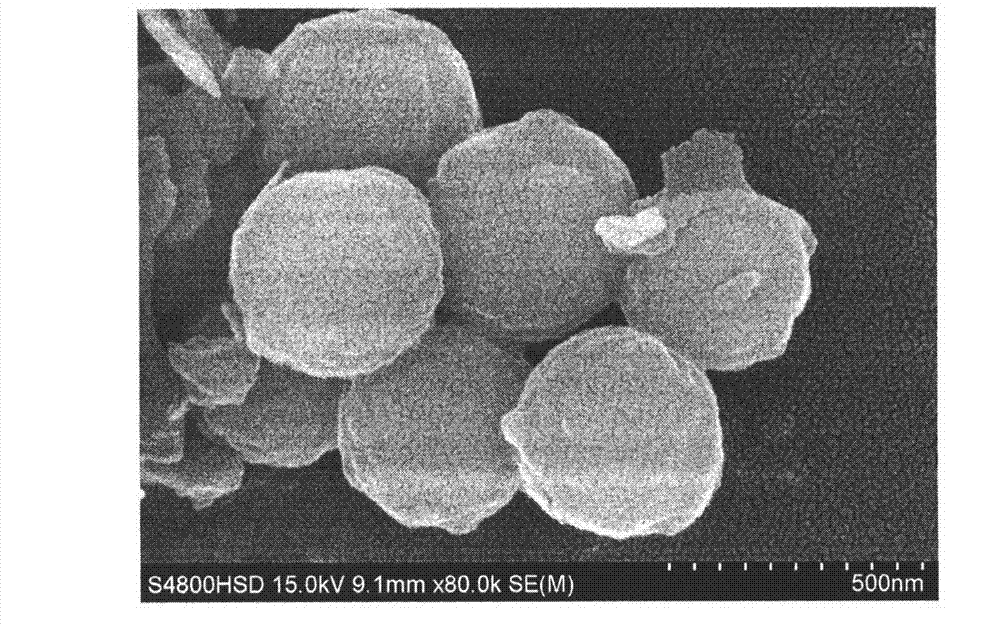

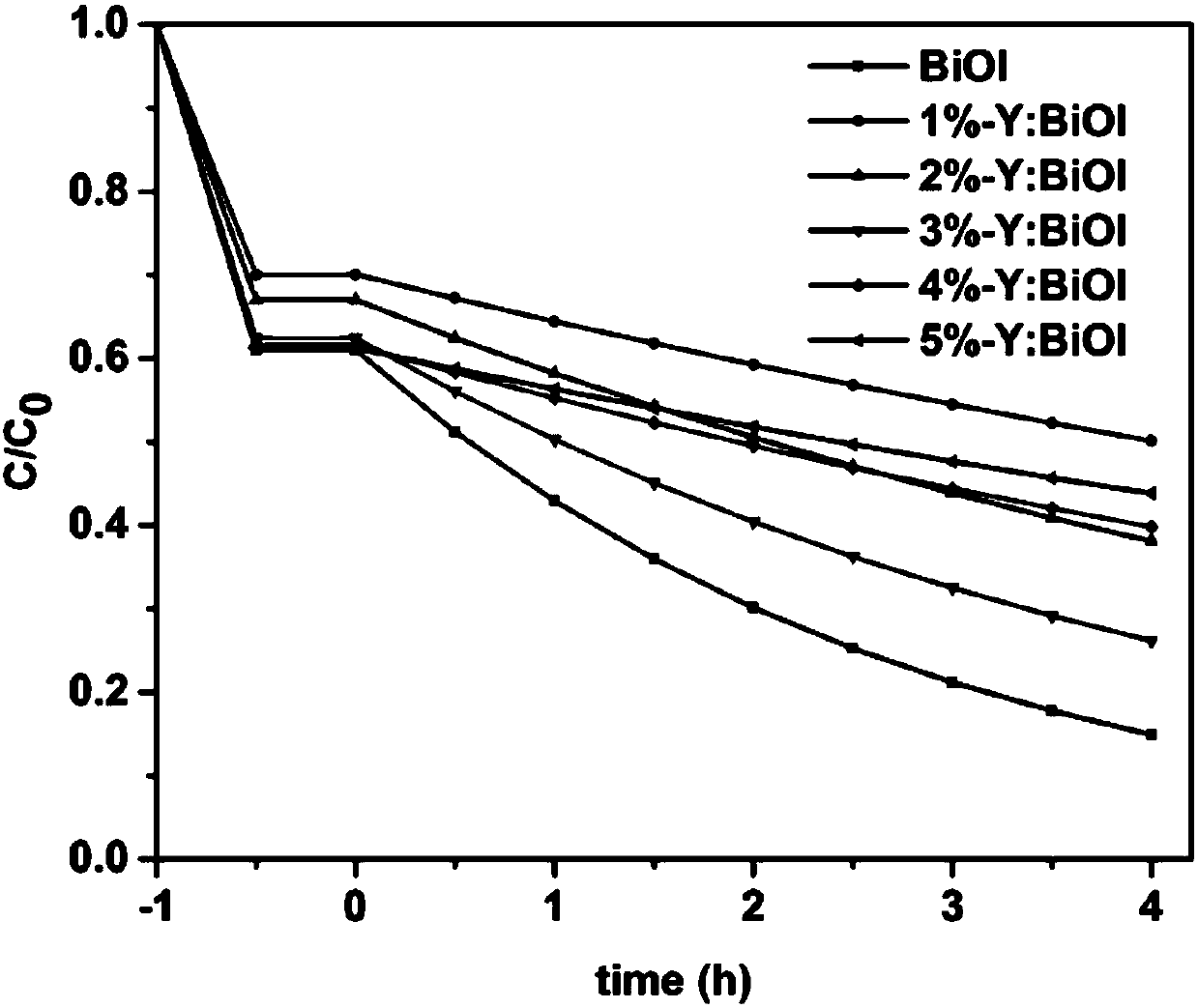

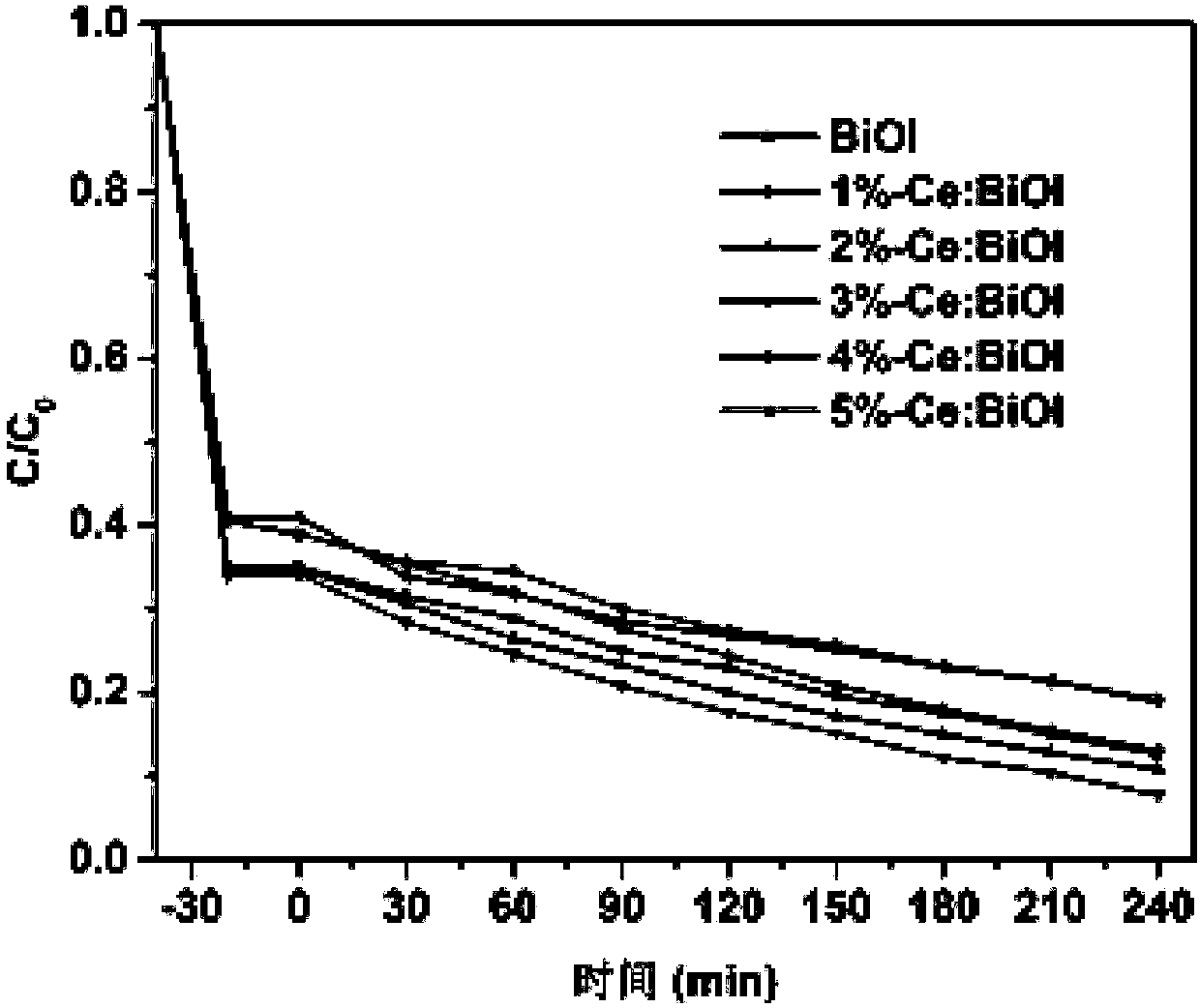

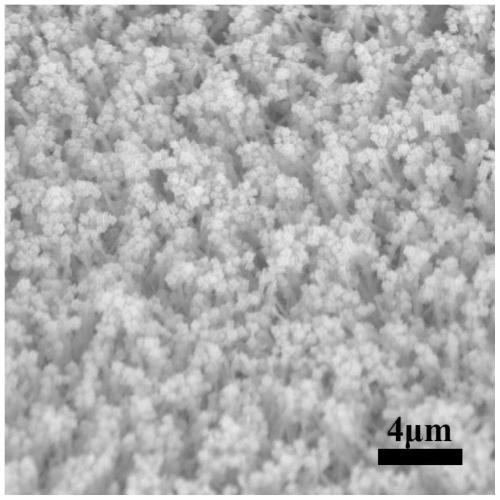

Preparation method of rare-earth element doped modified hollow microsphere bismuth oxyiodide photocatalyst

InactiveCN107597150ABroad absorption spectrumPromote absorptionPhysical/chemical process catalystsWater/sewage treatment by irradiationRare-earth elementNitrate

The invention relates to a preparation method of a rare-earth element doped modified hollow microsphere bismuth oxyiodide photocatalyst. The preparation method comprises the following steps: adding bismuth nitrate pentahydrate and nitrate of a rare-earth element into a solvent and sufficiently dissolving to obtain a bismuth nitrate solution containing the rare-earth element; under magnetic stirring, dropwise adding a potassium iodide solution at a uniform speed drop by drop; after finishing dropwise adding, continually carrying out the magnetic stirring to obtain a precursor solution; puttingthe precursor solution into a reaction kettle to react by adopting a solvothermal method; after finishing the reaction, cooling a product to room temperature and taking out the product; washing, drying in vacuum and grinding to obtain the rare-earth element doped modified hollow microsphere bismuth oxyiodide photocatalyst. The method provided by the invention is simple and feasible and has the characteristics of simple process, good experiment reproducibility, low production cost and the like; the prepared rare-earth element doped composite photocatalyst has good photocatalytic degradation performance on organic pollutant and a good application prospect.

Owner:DONGHUA UNIV

Seabed lateral deformation and sliding observation device and method

ActiveCN105301193AObvious lateral deformationTest accurateMaterial analysisOcean bottomMeasurement device

The invention provides a seabed lateral deformation and sliding observation device and method. The seabed lateral deformation and sliding observation device comprises an auxiliary ship and a seabed observation system, wherein the auxiliary ship is provided with an offshore drilling rig and a lifting device, and the seabed observation system is provided with a displacement measurement device, a data acquisition sealing cabin and a subsidence prevention frame. The displacement measurement device is of a rod joint combination structure with a cable, each joint point is provided with a three-axis acceleration sensor, and the displacement deviation of each joint point can be calculated according to the posture change of the corresponding three-axis acceleration sensor. The method includes the steps that the auxiliary ship is utilized for drilling a target point position so that the seabed observation system can be arranged, the seabed lateral deformation and sliding are observed and recorded through the displacement measurement device in the seabed observation system, fishing and recycling are conducted after the in-situ observation cycle is ended, and the deformation amount and the deformation process of seabed soil can be obtained by analyzing data. The seabed lateral deformation and sliding observation device and method provide a new thought and a new method for seabed lateral deformation and sliding observation and have the advantages of being long in observation cycle, capable of being repeatedly used, wide in observation range, high in accuracy and the like.

Owner:OCEAN UNIV OF CHINA

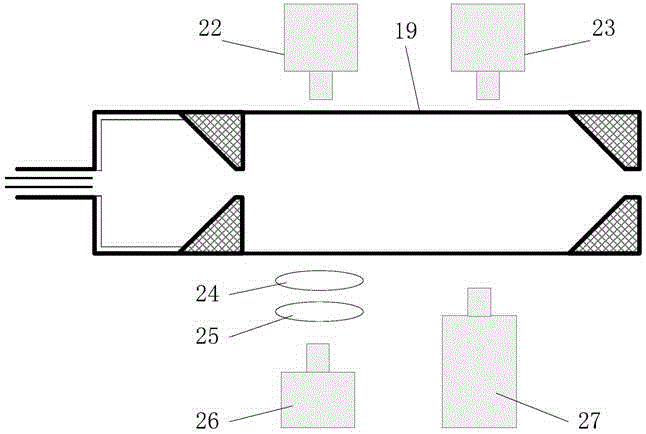

Micrometer order solid particle ignition burning test device under jet stream condition

ActiveCN105388248AEvaluate combustion efficiencyMonitor combustionChemical analysis using combustionRamjetHigh energy

The embodiment of the invention provides a micrometer order solid particle ignition burning test device under a jet stream condition. The device comprises four parts of a gas generator part, an afterburning chamber part, a sampling part and an observing part; the test device can change the ratio of fuel to an oxidant in the gas generator and realize stable controllable adjustment on mass and flow of solid particles, thus realizing the simulation of a working environment in the afterburning chamber of a ramjet of a solid rocket under different working conditions; a test process is monitored in real time by equipment such as a sensor and a high speed camera, a burnt product of the high energy solid particles is sampled in the test process, research on an ignition burning process of the micrometer order high energy solid in the afterburning chamber is realized, the test preparation time is shorter, the expense cost is lower, more observing methods can be used for a burning process in the afterburning chamber, more test data are obtained, the test system is good in reutilization, and engineering reference value of the obtained test data is high.

Owner:NAT UNIV OF DEFENSE TECH

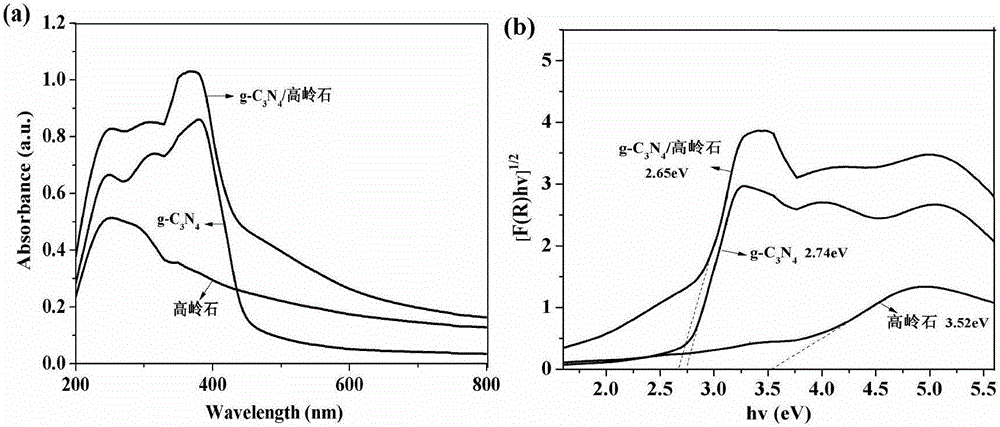

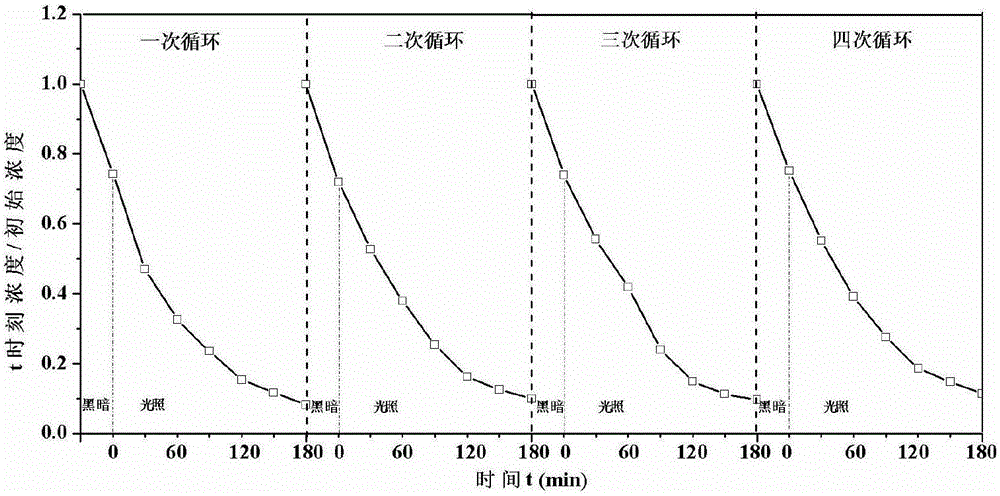

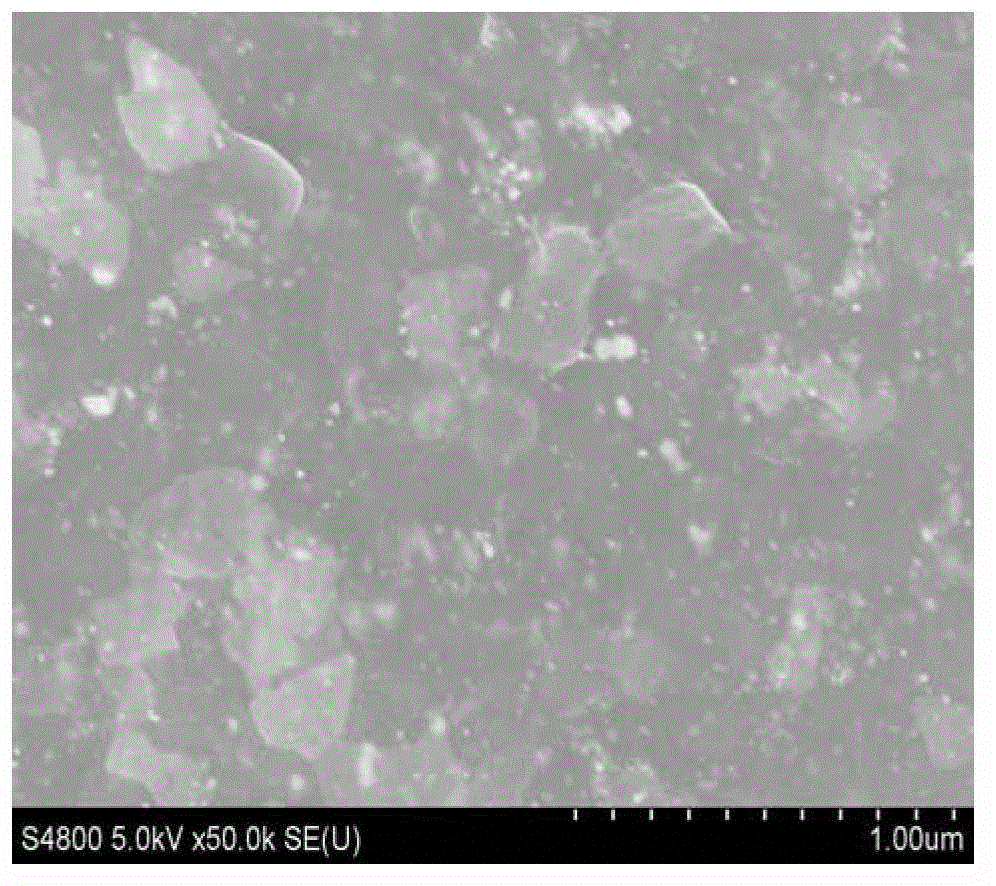

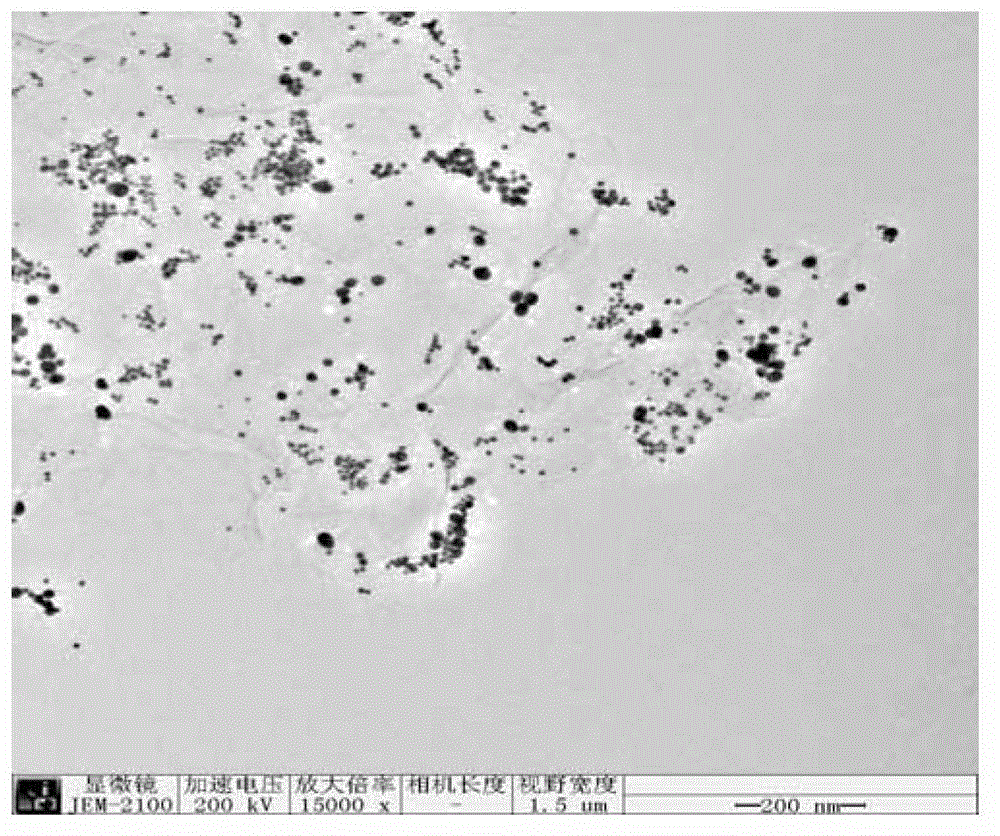

G-c3n4/kaolinite composite photocatalyst and preparation method thereof

InactiveCN106111174ALow application costIn situ assemblyPhysical/chemical process catalystsKaoliniteWastewater

The invention relates to a g-C3N4 / kaolinite photocatalyst and a preparation method thereof and belongs to the fields of nonmetallic mineral material deep-processing and environmental engineering. On the basis of a stratified structure and adsorption characteristics of kaolinite and chemical impregnation and calcination control technologies, piece-to-piece assembly of g-C3N4 and kaolinite is realized, and a kaolinite based composite photocatalytic material with high activity is prepared. With the adoption of the method, compositing of kaolinite and g-C3N4 is realized, g-C3N4 agglomeration and photon-generated carrier recombination are effectively inhibited, and pollutant adsorption and capture performance of the material and dispersibility of the catalyst are improved through a carrier effect of the kaolinite. The composite photocatalytic material has excellent photocatalytic activity under visible light, has low production cost, and is environment-friendly in a use process, thereby having great potential application value in the field of advanced treatment of organic wastewater.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

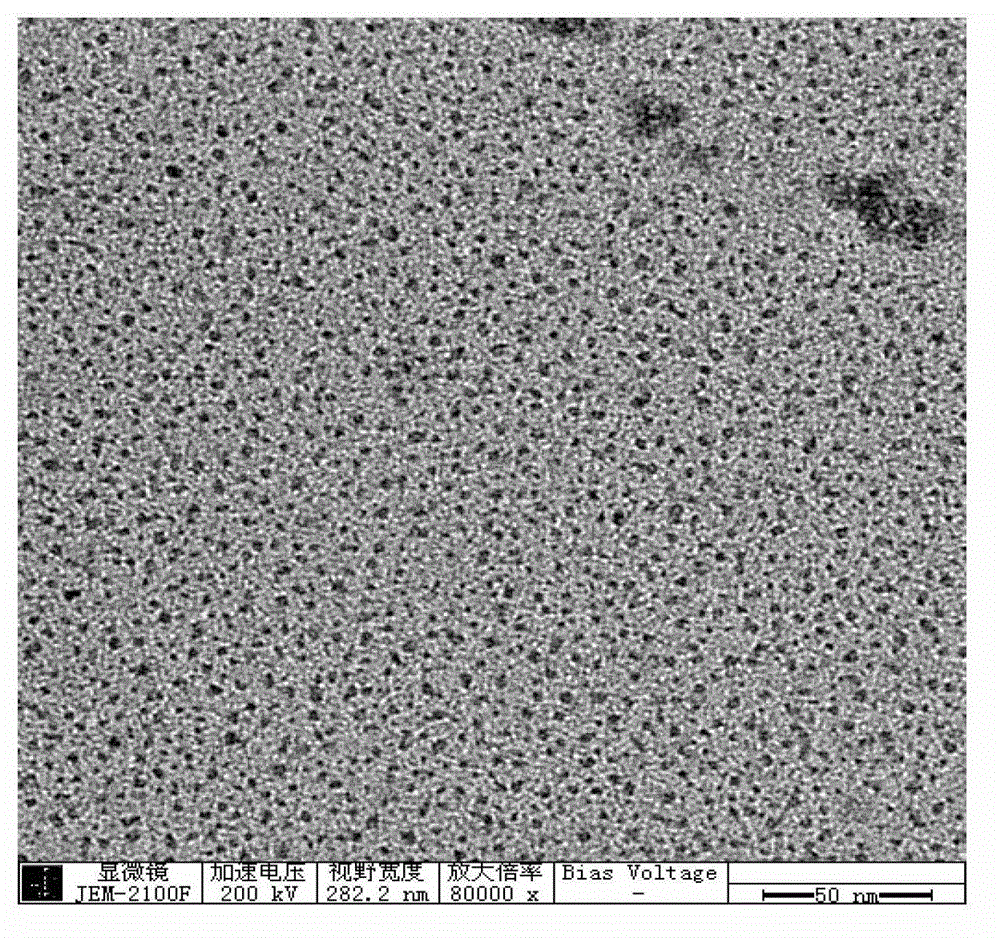

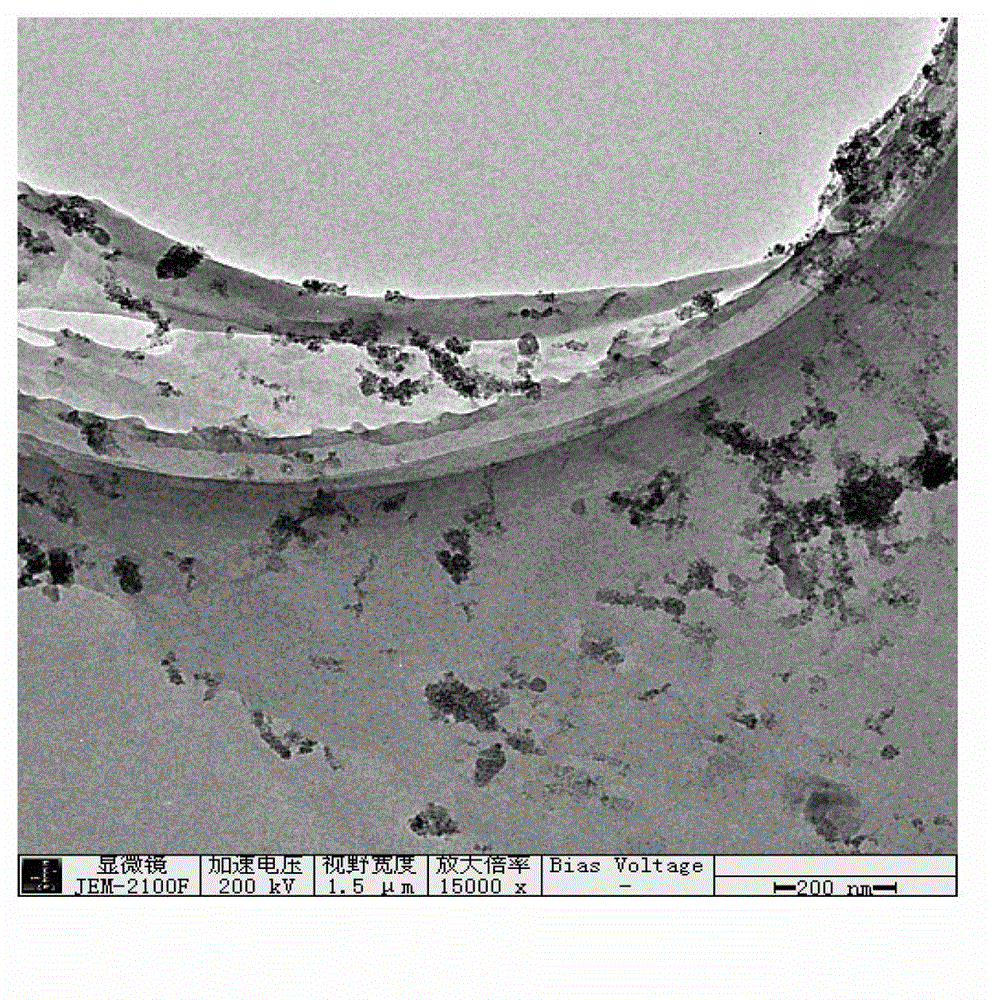

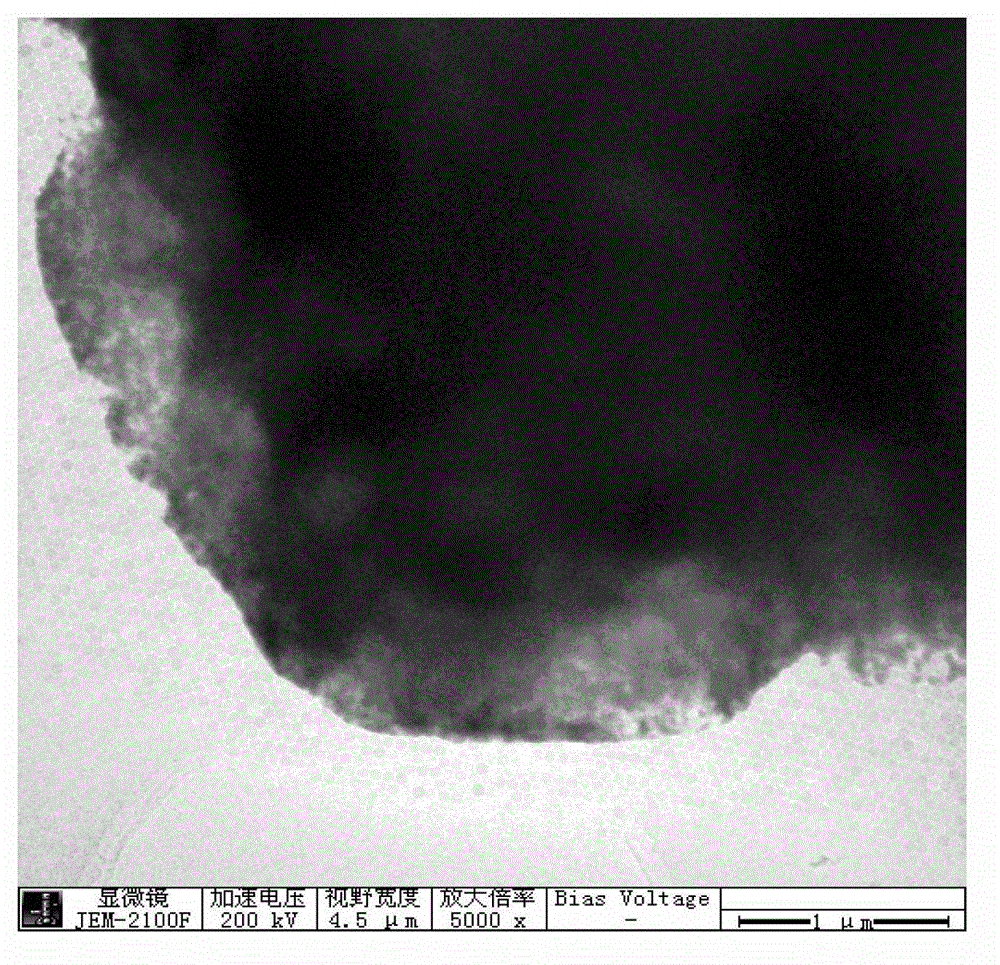

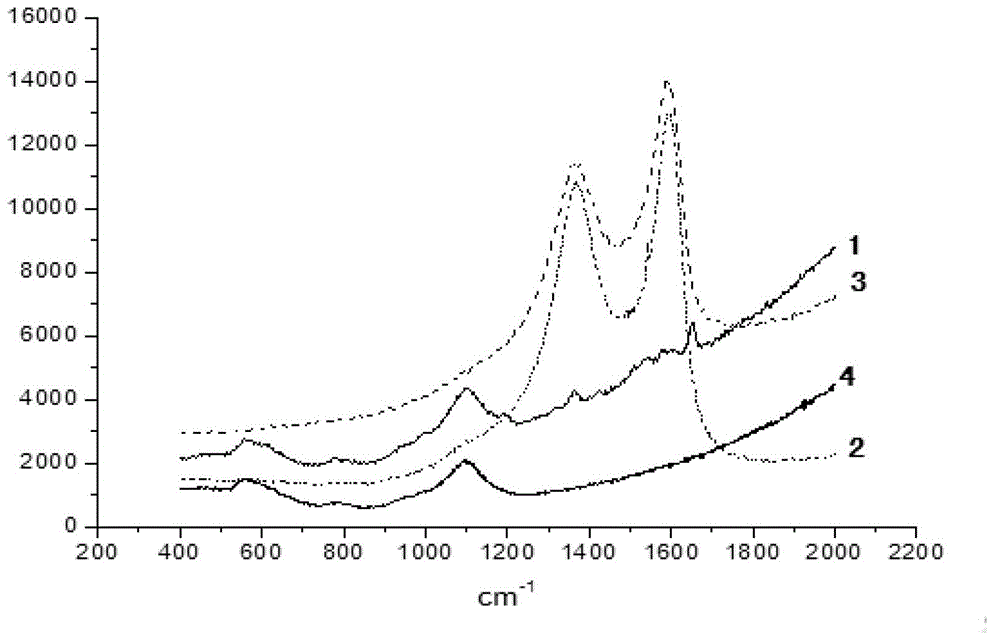

Method for manufacturing graphene/gold surface-enhanced Raman spectrum substrate

InactiveCN102914500AHigh reusabilityLow costRaman scatteringChemical industrySurface-enhanced Raman spectroscopy

The invention discloses a method for manufacturing a graphene / gold surface-enhanced Raman spectrum substrate and relates to a method for manufacturing a surface-enhanced Raman spectrum substrate. The problems that gold nanoparticles of the conventional precious metal surface-enhanced Raman spectrum substrate are not fully utilized and precious metal substrates are insufficient are solved. The method comprises the following steps of: 1, preparing a graphene oxide aqueous solution; 2, preparing a hydrogen tetrachloroaurate hydrate aqueous solution, a sodium citrate aqueous solution and a silver nitrate solution; 3, preparing a graphene / gold composite material; 4, preparing a graphene / gold composite material suspension; and 5, erecting the treated substrate in the graphene / gold composite material suspension, and obtaining the graphene / gold surface-enhanced Raman spectrum substrate after the reaction is finished. According to the graphene / gold surface-enhanced Raman spectrum substrate, the repeated utilization of gold nanoparticles is improved, so that the cost is reduced, and the substrate has high enhancement of the surface Raman spectrum; and moreover, the method is applied to the field of chemical industry.

Owner:HEILONGJIANG UNIV

Preparation method of hydrogenation catalyst with X/Ni/A1 hydrotalcite as precursor

InactiveCN102407121AHigh reactivityRaw materials are cheap and easy to getOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrotalciteMetallurgy

The invention discloses a preparation method of hydrogenation catalyst with X / Ni / A1 hydrotalcite as precursor. The invention comprises adopting coprecipitation method to prepare X / Ni / A1 hydrotalcite with laminated structure, roasting at high temperature to produce X / Ni / A1 containing composite metal oxide, reducing by high temperature hydrogenation to obtain X / Ni / A1 containing hydrogenation catalyst with high dispersion and large specific surface area, in the presence of X / Ni / A1 containing composite metal oxide and under proper reaction conditions, making generation of gamma-valerolactone by levulinic acid hydrogenation with good effect. The catalyst of the invention has easily obtained and low cost raw materials, simple and feasible production techniques, large specific surface area and easily separated product.

Owner:SOUTH CHINA UNIV OF TECH

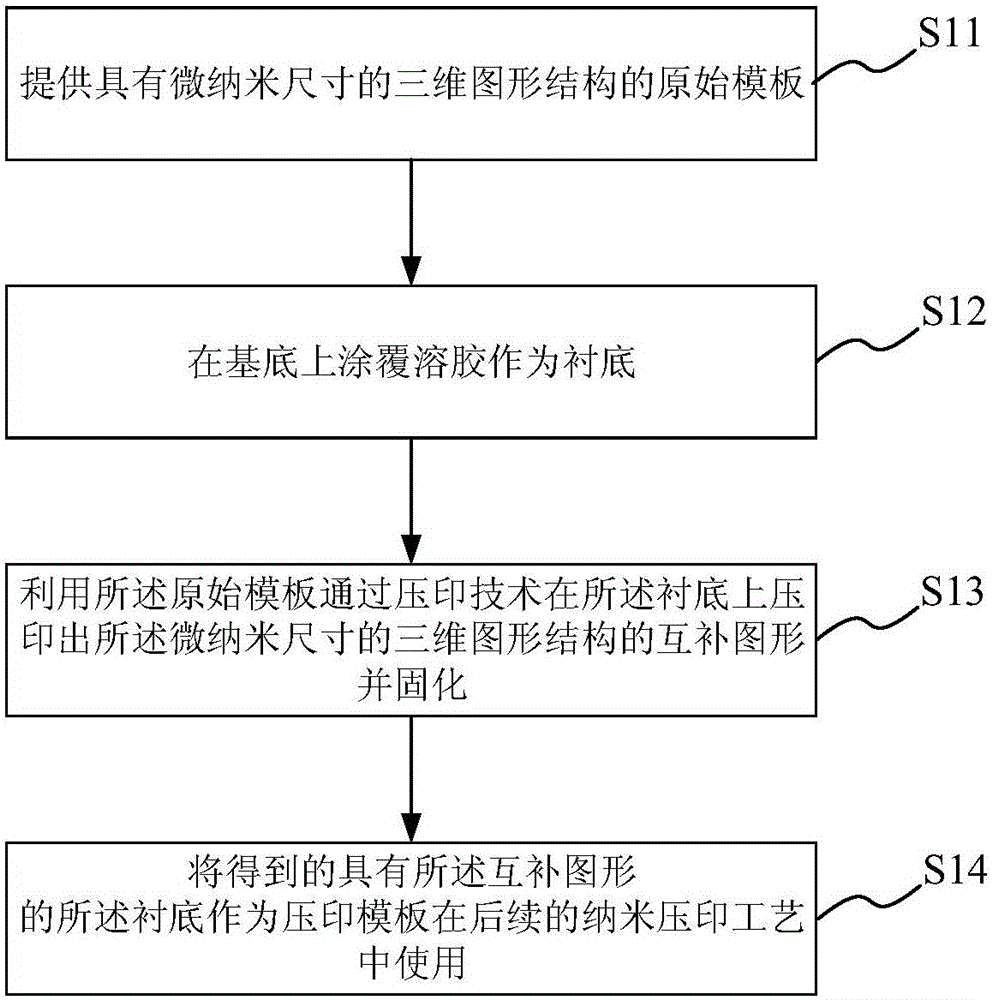

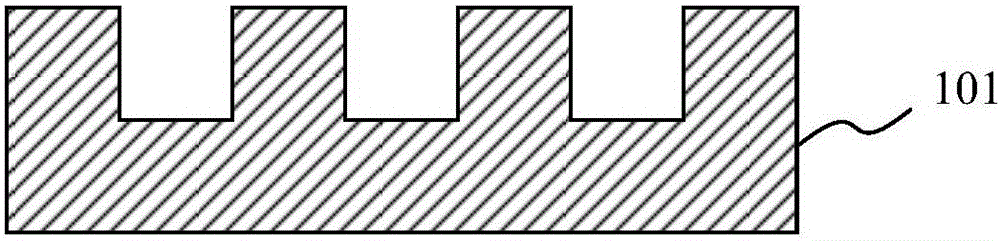

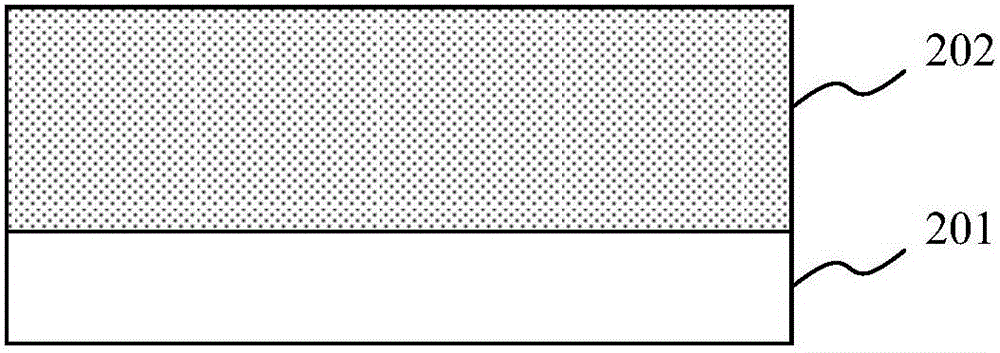

Preparing method for nanoimprint template

InactiveCN105824190AGood repeatabilityFast preparationPhotomechanical apparatusMicro nanoRepeatability

The invention provides a preparing method for a nanoimprint template .The method includes the following steps that a micro-nano original template of a three-dimensional graph structure is provided; a base is coated with sol to serve as a substrate; a complementary graph of the micro-nano three-dimensional graph structure is imprinted on the substrate with the original template through an imprinting technology; the obtained substrate with the complementary graph is used as the template in the follow-up nanoimprint process .The preparing method for the nanoimprint template is high in repeatability, capable of preparing the inorganic template fast at low cost on a large scale and capable of being used in the processes of ultraviolet imprinting and thermal imprinting, the prepared template is high in mechanical strength and reutilization, conformality in the follow-up imprinting process is good, a base material with a higher depth ratio can be obtained by using the template as a mask plate after etching, and the problem that the structure is shallow after etching when photoresist serves as the mask plate can be solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

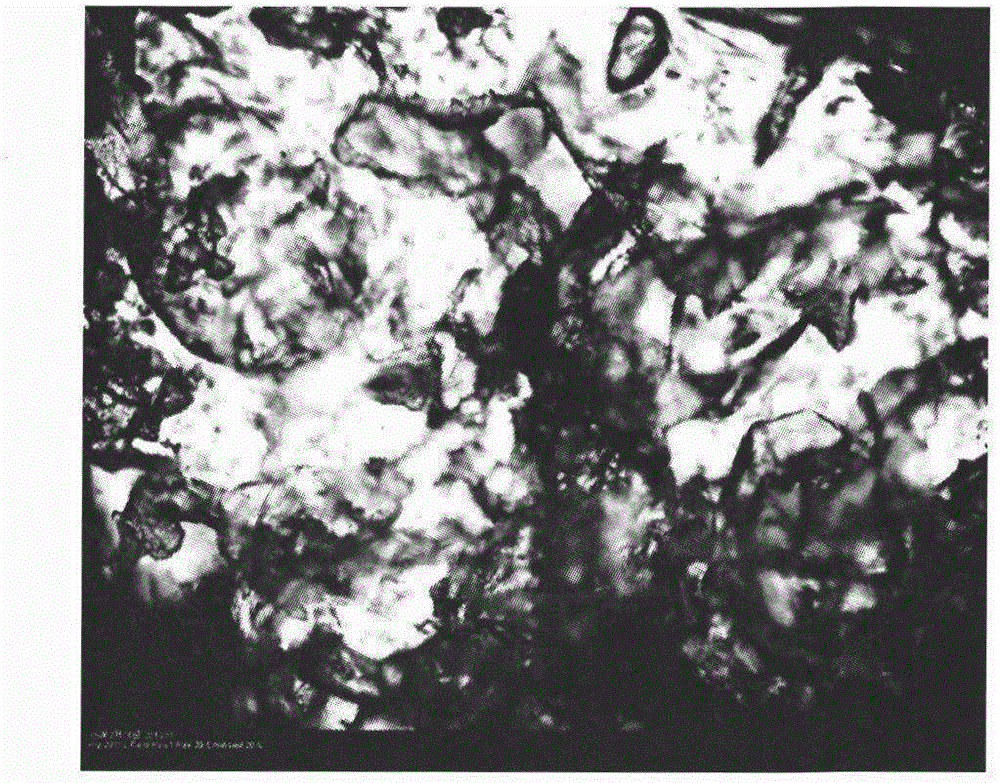

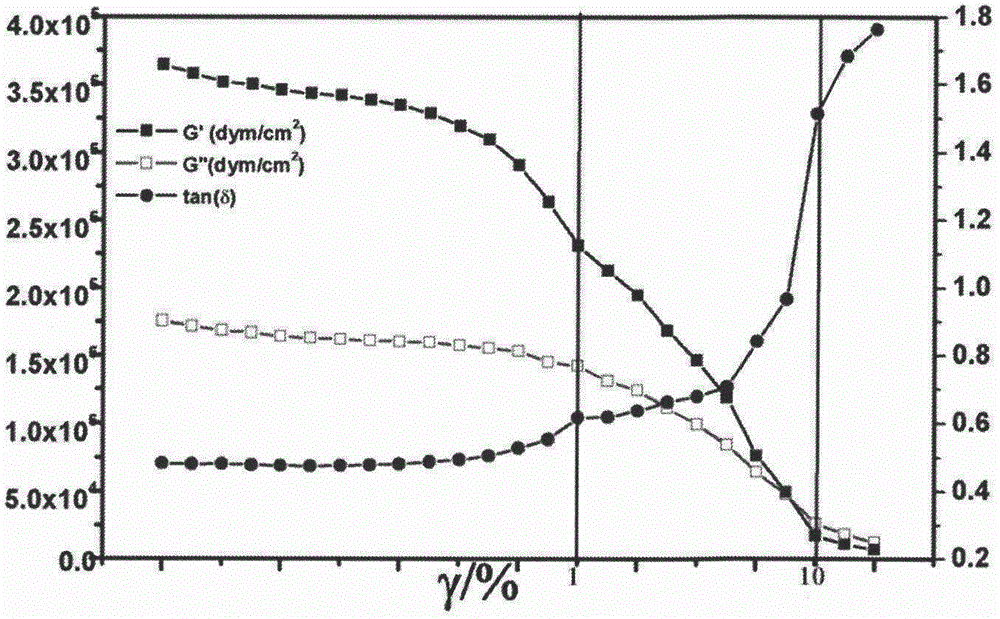

Self-healing liquid crystalline elastomer based on chitin-type liquid crystal and preparation method of self-healing liquid crystalline elastomer

InactiveCN104530315AReduce crackingImprove performanceLiquid crystal compositionsLiquid crystallinePolymer science

The invention discloses a self-healing liquid crystalline elastomer based on a chitin-type liquid crystal and a preparation method of the self-healing liquid crystalline elastomer. According to the self-healing liquid crystalline elastomer disclosed by the invention, the chitin-type liquid crystalline elastomer with the self-healing capability is constructed by introducing a reversible covalent-multiple hydrogen bond; due to self-healing introduction, cracks in the material can be remarkably reduced, the comprehensive performances and the reusability of the material are improved, and the service life of the material is prolonged. The preparation method comprises the following steps: firstly, selecting proper reaction materials and reaction paths, synthesizing a monomer containing the multiple hydrogen bond and a side group, with a large volume, containing a mesogenic unit, carrying out reaction on the monomer and the side group by virtue of a liquid crystalline monomer with connection of a short spacer and a double bond under the proper reaction conditions to design and synthesize a chitin-type effect polymer, regulating the dosage of a hydrogen bond crosslinking agent, and preparing the chitin-type self-healing liquid crystalline elastomers in different crosslinking degrees under the condition without influencing the liquid crystallinity.

Owner:XIANGTAN UNIV

Preparing method of R-Fe-B sintered magnet

ActiveCN103646772AReduce processing costsImprove uniformityInorganic material magnetismInductances/transformers/magnets manufactureAcid washingDysprosium

The invention relates to a preparing method of an R-Fe-B sintered magnet. The preparing method of the R-Fe-B sintered magnet comprises, firstly utilizing a conventional method to prepare the R-Fe-B sintered magnet, and cleaning the sintered magnet through the steps such as oil removing, acid-washing and water deionization; secondly, bespreading metal Dy (dysprosium) at the bottom of a material box in any shape, and then filling the inside of the material box with zirconia, silicon dioxide or aluminium oxide powder; thirdly, inserting the sintered magnet into the powder in a direction perpendicular to a magnetizing direction, or placing the metal Dy plate, high-melting-point powder particles, the sintered magnet and high-melting-point powder particles sequentially inside the material box in a layered mode, wherein the bottom end of the magnet is not in contact with the Dy particles at the bottom of the material box, and adjacent magnets are not in contact with each other; finally, putting the material box inside the sintering furnace, and performing heat treatment in vacuum or Ar (argon) protective atmosphere at the temperature of 750-1000 DEG C and enabling the Dy to enter the inside of the sintered magnet along a grain boundary through diffusion. By means of the preparing method of the R-Fe-B sintered magnet, the processing cost of the Dy is greatly reduced, the process is simplified, and the coercivity of the magnet after heat treatment is greatly improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

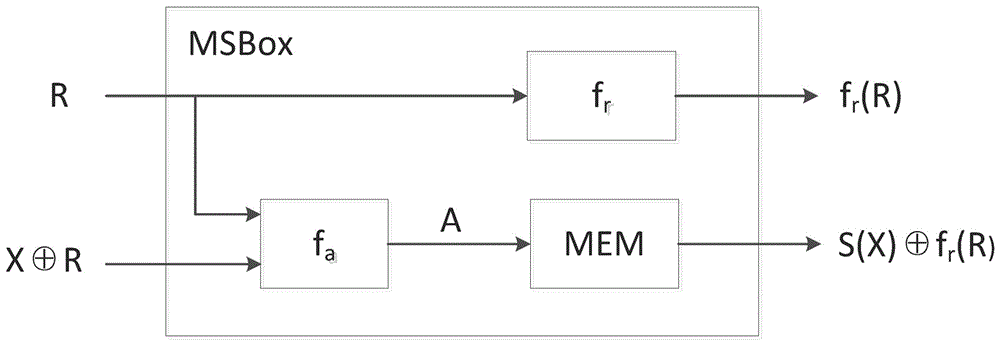

Mask S box, packet key calculation unit, apparatus and corresponding construction method

ActiveCN106788974AHigh reusabilityIncreased complexityEncryption apparatus with shift registers/memoriesDigital data processing detailsS-boxComputer module

The present invention discloses a mask S box, a packet key calculation unit, an apparatus and corresponding construction method. The mask S box comprises an input module, an address mapping processing module, and an output module. The input module receives and uses a random number and input data masked by the random number as two inputs of the mask S box. The address mapping processing module performs one-to-one mapping on the two inputs and corresponding storage addresses in a memory of the mask S box. The output module performs linear processing on the random number by using a linear equation so as to obtain and uses the random number after linear conversion as one output of the mask S box. The storage address is obtained after the random number undergone linear conversion masks the output of the original S box, and is used as another output of the mask S box. The mask S box is safe, and further, the mask S box is easy to implement, is low in power consumption and small in area, and is optimized and expanded to realize the anti-high order DPA encryption device.

Owner:SHENZHEN STATE MICRO TECH CO LTD

Preparation method of magnetic composite catalyst Ag/HNTs/Fe3O4

InactiveCN103638944AHigh catalytic activityGood magnetic response propertiesMetal/metal-oxides/metal-hydroxide catalystsNanotubeReducing agent

The invention relates to a preparation method of magnetic composite catalyst Ag / HNTs / Fe3O4, and belongs to the technical field of environmental function material preparation; a simple and effective chemical reduction method is used to prepare a Fe3O4 / Halloysite Nanotubes (HNTs / Fe3O4) magnetic composite material, then a silver nitrate solution and ammonia are mixed into a fresh silver ammonia solution as an oxidizing agent, glucose is used as a reducing agent, Ag nanoparticles are deposited on the magnetic composite material by a silver mirror reaction to prepare the magnetic composite catalyst Ag / HNTs / Fe3O4, and the magnetic composite catalyst Ag / HNTs / Fe3O4 is used for catalytic degradation of p-nitrophenol in a water solution.

Owner:JIANGSU UNIV

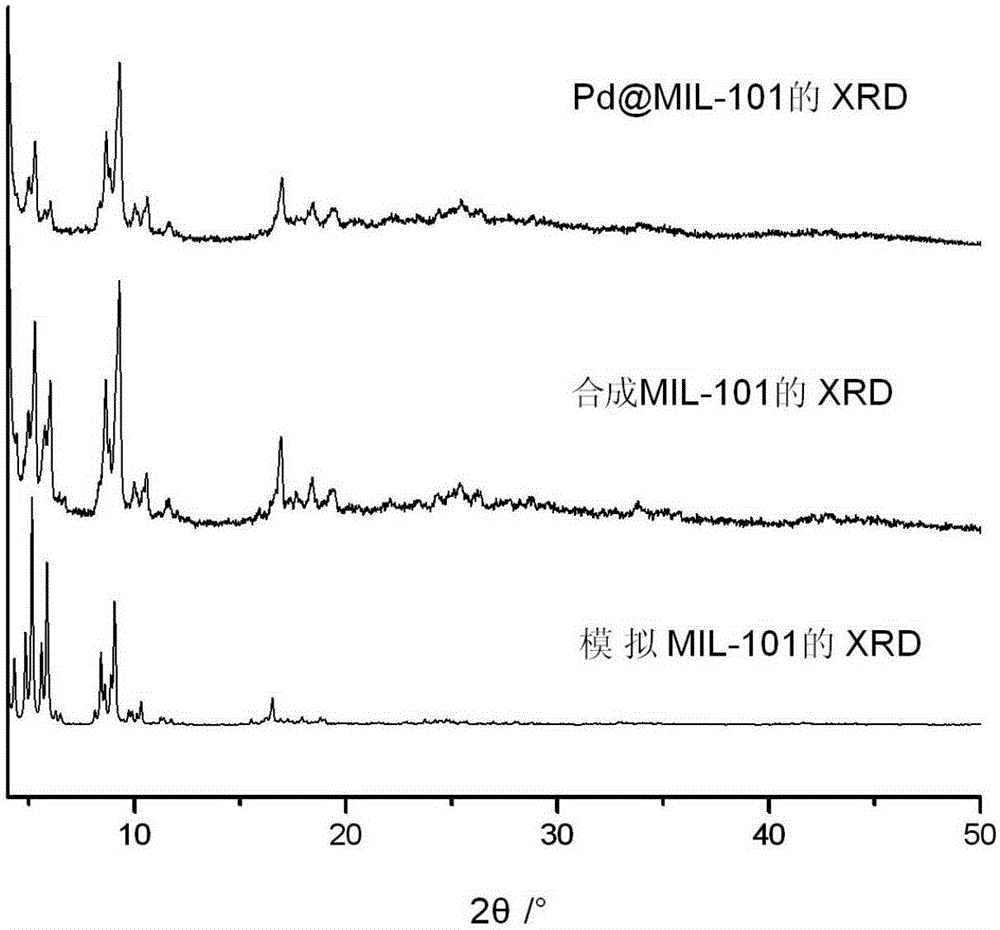

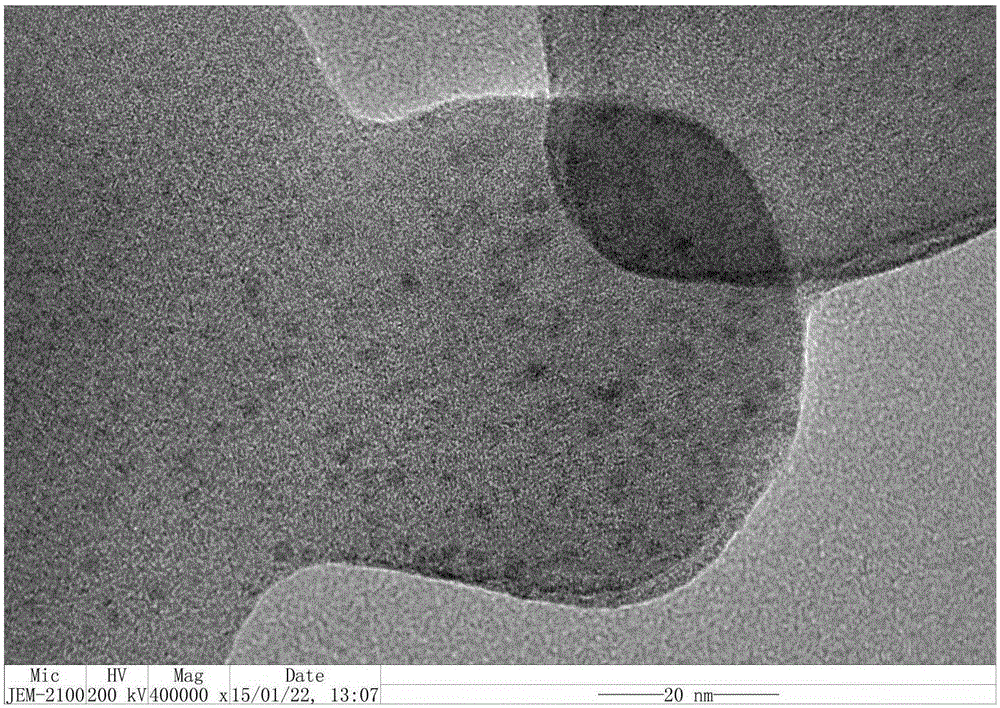

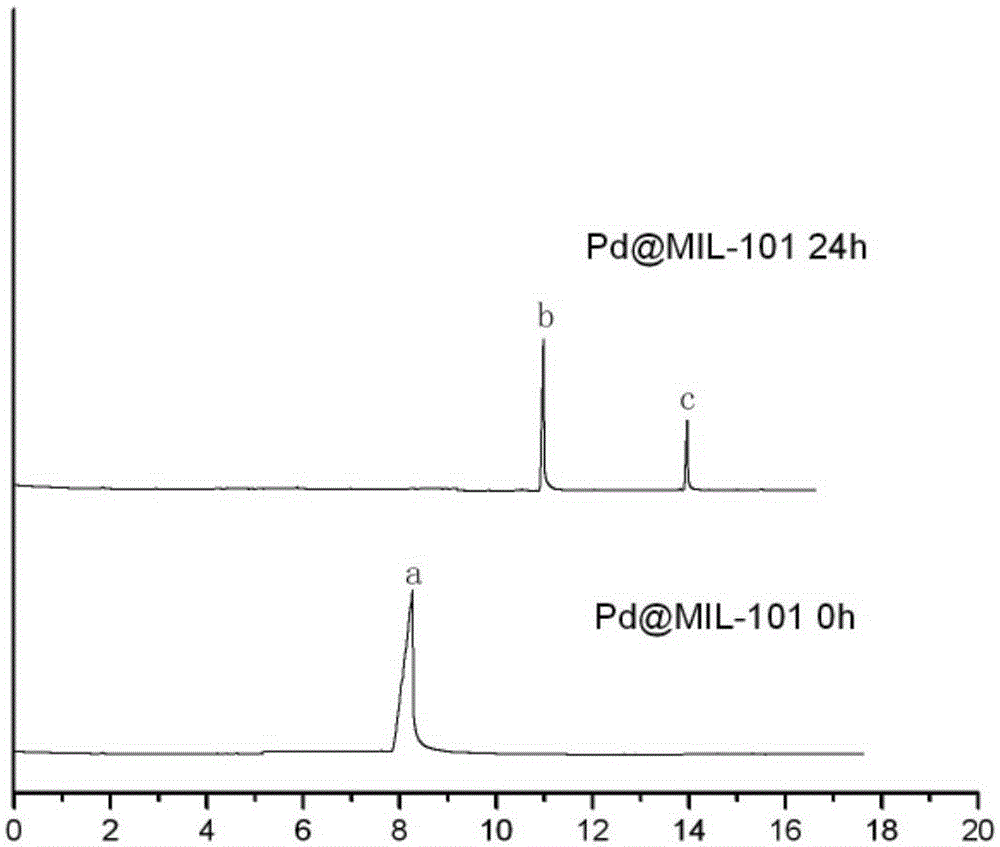

Pd @MIL-101 composite and preparation method and application thereof

ActiveCN105233872AEasy to separate and purifyHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsIce water1,4-Dibromobenzene

The invention relates to a Pd @MIL-101 composite and a preparation method and application thereof. According to the adopted technical scheme, palladium chloride is added to methyl alcohol while sodium chloride is added, ultrasonic dispersion is conducted, stirring is conducted for 10-20 hours, and sodium tetrachloropalladate is obtained; a sodium tetrachloropalladate solution is dropwise added into MIL-101 crystals slowly, pd<2+>@MIL-101 is obtained; a methanol solution of asaturated sodium borohydride is added to the pd<2+>@MIL-101, reduction is conducted under the condition of ice-water bath, and the Pd @MIL-101 composite is obtained. The synthesized Pd @MIL-101 composite has special selectivity catalytic activity for phenylboronic acid and 1,4-dibromo-benzene in a suzuki reaction, and the yield of an intermediate product 4-bromobiphenyl is effectively raised.

Owner:芜湖数字信息产业园有限公司

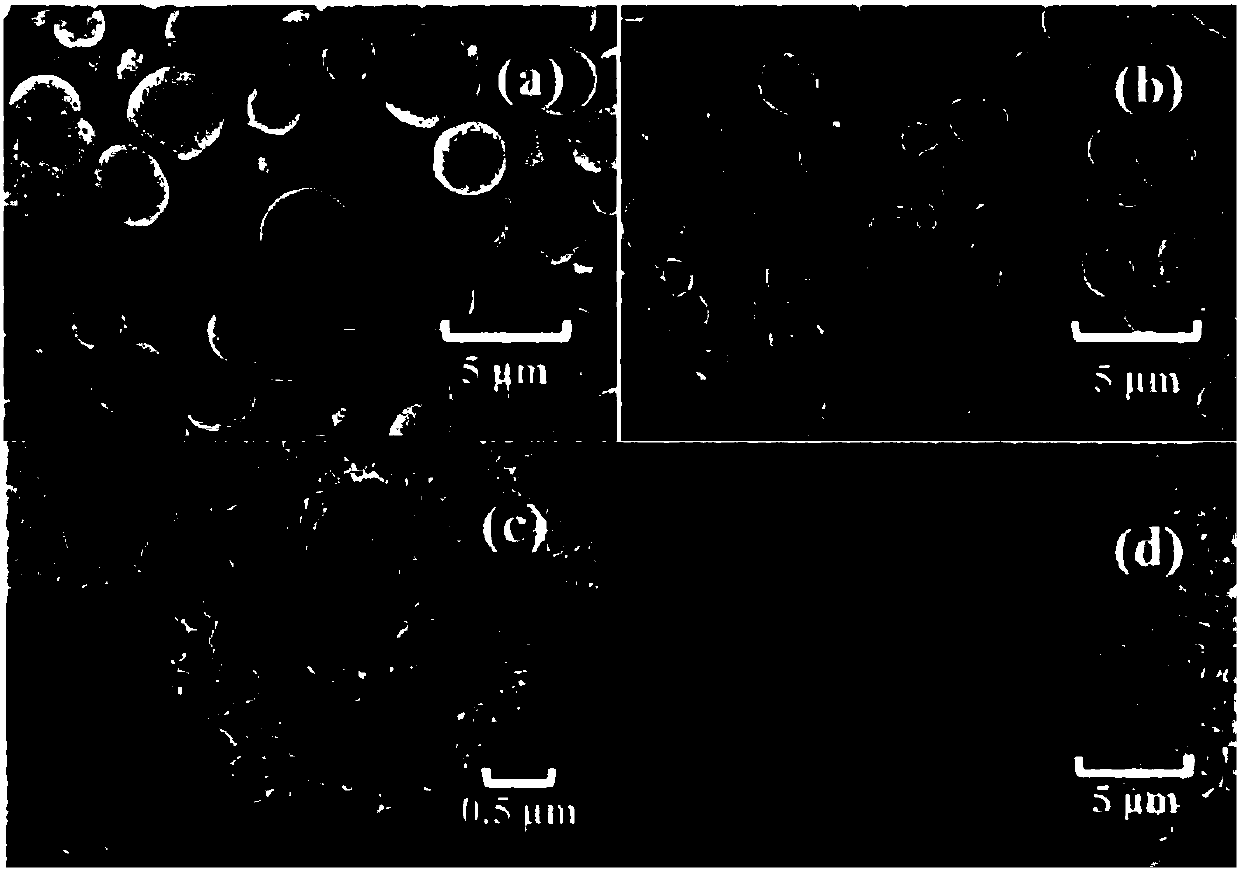

Oil-water separation type sodium alginate/graphene oxide composite aerogel and preparation method thereof

InactiveCN106853296AEasy to separateImprove separation efficiencyAerogel preparationLiquid separationOxide compositeGraphite oxide

The invention relates to an oil-water separation type sodium alginate / graphene oxide composite aerogel and a preparation method thereof. The preparation method of the oil-water separation type sodium alginate / graphene oxide composite aerogel comprises the following steps: preparing a sodium alginate / graphene oxide mixed solution, preparing an uncrosslinked sodium alginate / graphene oxide composite aerogel, and preparing the oil-water separation type sodium alginate / graphene oxide composite aerogel. The oil-water separation type sodium alginate / graphene oxide composite aerogel has a highly porous structure, a complete three-dimensional network and a high separation efficiency, has a separation rate of above 99.9%, has high salt resistance, is suitable for being used in high-salinity sea environments, and also has the advantages of good elasticity, high mechanical strength, oil pollution resistance, realization of almost no reduction of the separation efficiency after reuse 40 times or more, and good reuse ability.

Owner:FUJIAN AGRI & FORESTRY UNIV

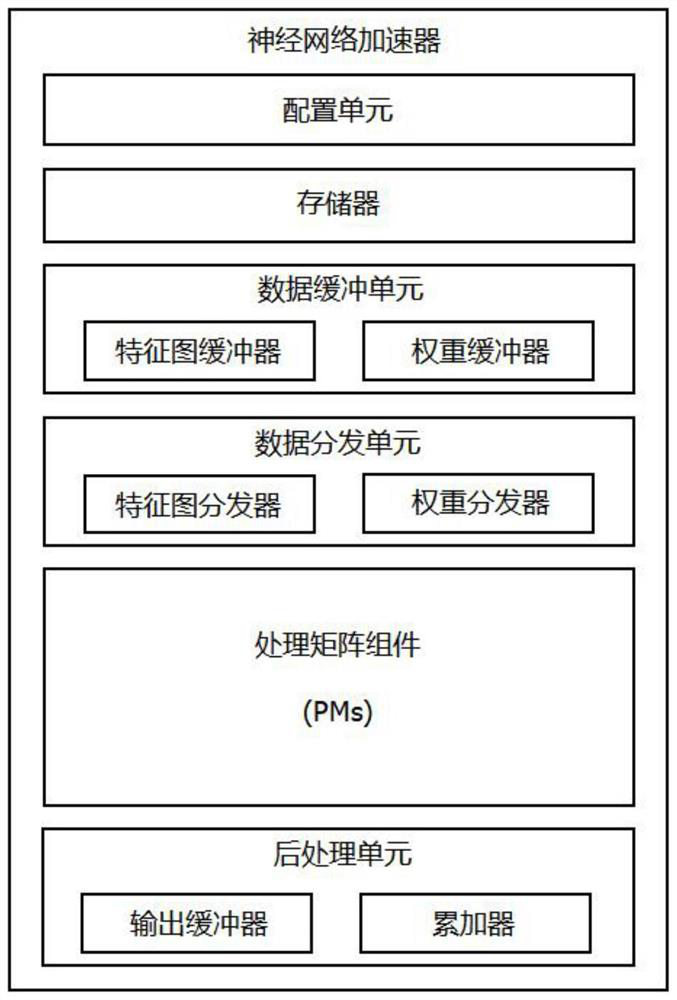

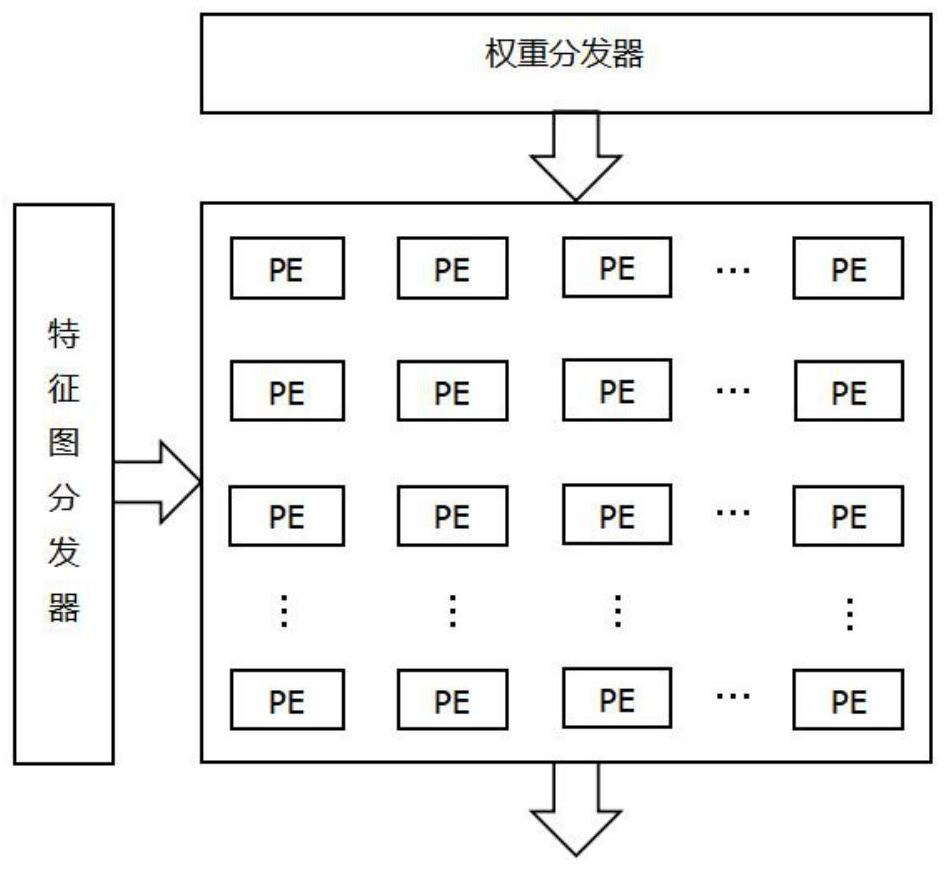

Neural network accelerator suitable for edge equipment and neural network acceleration calculation method

ActiveCN111667051ARealize multiplexingImprove reuse rateDigital data processing detailsNeural architecturesMultiplexingProcessing element

The invention discloses a neural network accelerator suitable for edge equipment and a neural network acceleration calculation method, and relates to the technical field of neural networks. The network accelerator comprises a configuration unit, a data buffer unit, a processing matrix component (PMs) and a post-processing unit, and a main controller writes feature parameters of different types ofnetwork layers into a register of the configuration unit to control the mapping of different network layer operation logics to the processing matrix hardware, so as to realize the multiplexing of theprocessing matrix component, i.e., the operation acceleration of different types of network layers in the neural network is realized by using one hardware circuit without additional hardware resources; and the different types of network layers comprise a standard convolution layer and a pooling network layer. The multiplexing accelerator provided by the invention not only ensures the realization of the same function, but also has the advantages of less hardware resource consumption, higher hardware multiplexing rate, lower power consumption, high concurrency, high multiplexing characteristic and strong structural expansibility.

Owner:上海赛昉科技有限公司

Method for preparing 2,5-furandicarboxylic acid by supported bifunctional catalyst by catalyzing fructose

ActiveCN105418561AAcidicHas catalytic oxidation propertiesOrganic chemistryMolecular sieve catalystsFructoseCatalytic oxidation

The invention provides a method for preparing 2,5-furandicarboxylic acid by catalyzing fructose with a supported bifunctional catalyst. According to the method, a supported heteropolyacid salt is taken as a catalyst; and the catalyst disclosed by the invention is the bifunctional catalyst, and has acidity and catalytic oxidation performance. The fructose and biomass materials rich in the fructose can be efficiently catalyzed to dewater and prepare HMF; and meanwhile, 2,5-furandicarboxylic acid can be prepared by in-situ catalytic oxidation of the HMF at high selectivity. The catalyst is convenient to recycle and good in reusability, so that a foundation is laid for efficient preparation of the 2,5-furandicarboxylic acid.

Owner:NANJING UNIV OF TECH

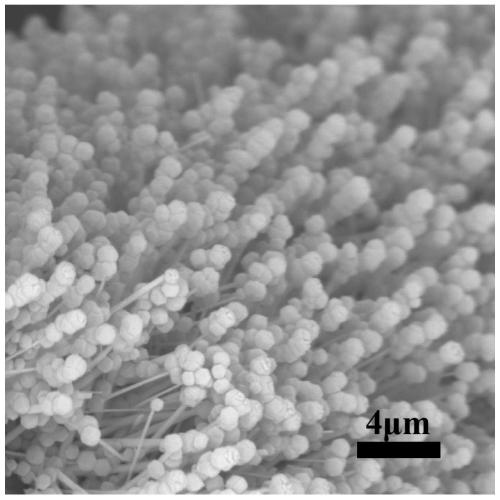

MOF compounded copper-based nanorod array@foam copper based composite electrode material, preparation method and application thereof

ActiveCN110331414AImprove stabilityMake up for deficienciesOrganic-compounds/hydrides/coordination-complexes catalystsNanotechnologyComposite electrodeDehydration

The invention discloses a MOF compounded copper-based nanorod array@foam copper based composite electrode material, a preparation method and application thereof. The MOF compounded copper-based nanorod array@foam copper based composite electrode material is characterized in that foam copper is adopted as the substrate, and a MOF compounded copper hydroxide nanorod array grows on the surface of thefoam copper, wherein the MOF is ZIF-67. The preparation method includes: directly growing the nanorod array of Cu(OH)2 on the foam copper substrate by in-situ synthesis, then adopting the Cu(OH)2 nanorod array as the substrate for template orientated growth of MOF particles on the surface, and finally performing dehydration treatment to obtain the electrode material with electrocatalytic performance. The composite material has stable performance in an alkaline condition, has high reusability and large electrochemical active area, and the catalytic activity of the material is greatly improved.The preparation method has the characteristics of simple preparation process, low sintering temperature, and low energy consumption in the preparation process, and is convenient for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

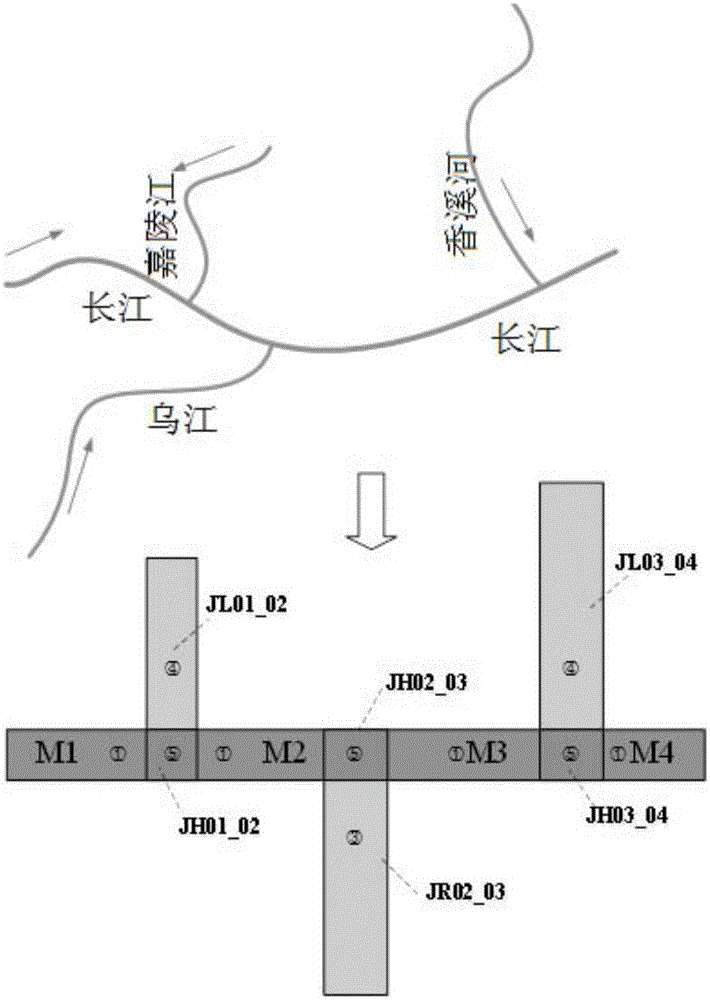

Drawing and coding method for large-scale complex river network massive fine regular grids of river basin

ActiveCN106202265AAvoid the problem of fine massive mesh drawingAvoid drawingGeographical information databasesSpecial data processing applicationsRegular gridRiver network

The invention discloses a drawing and coding method for large-scale complex river network massive fine regular grids of a river basin. The method comprises the steps of S1, identifying structure layers and boundary range layers of a river basin water system body; S2, obtaining river reaches of rivers of a river basin water system segment by segment; S3, drawing two-dimensional regular grids of the rivers and coding the grids in the rivers; S4, carrying out two-dimensional compilation on the two-dimensional regular grids, thereby obtaining an integrated grid; S5, carrying out one-dimensional compilation on the integrated regular grid; and S6, establishing one-dimensional grid relationships. According to the method, on the basis of an existing massive regular grid method and tool, the large-scale massive grids are increased, reduced and coarsened simply and effectively, the grids are drawn once and can be used for life, and the data support is provided for calculation of values based on the regular grids.

Owner:WUHAN UNIV

Amphoteric-cellulose-based composite material and application thereof

InactiveCN103497476ALarge specific surface areaImprove adsorption performanceOther chemical processesWater contaminantsComposite materialCellulose

The invention discloses an amphoteric-cellulose-based composite material and application thereof. Quaternary ammonium-sulfonic acid cellulose serves as a carrier, grapheme oxide and chitosan are loaded in a blending manner, binding force among the three is utilized, and a quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material is obtained through freeze drying. The quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material comprises, by weight, 5-8 parts of quaternary ammonium-sulfonic acid cellulose, 0.5-3 parts of grapheme oxide and 0.5-3 parts of chitosan, is safe, non-poisonous and good in biocompatibility and degradability, has an orderly three-dimensional porous structure, good mechanical strength and efficient adsorption capability, can be used for water absorption and oil removal and processing of heavy metal ion waste water and organic waste water, and hopefully serves as a filtering material such as an air purification material and a medical adsorption material for use.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com