G-c3n4/kaolinite composite photocatalyst and preparation method thereof

A technology of photocatalyst and kaolinite, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of separation of unfavorable interfaces combined with photogenerated carriers, unsatisfactory photocatalytic performance under visible light, Complex process and other issues, to achieve the effect of inhibiting the recombination of photogenerated carriers, good reusability, and inhibiting self-agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The specific implementation steps are as follows:

[0017] (1) Take 4g of dicyandiamide in 50mL of distilled water, stir and disperse at 60°C for 30 minutes until the dicyandiamide is completely dissolved, then slowly add 2g of kaolinite, continue stirring for 12h, then dry in an oven at 60°C, and grind 97% pass through 200 mesh sieve to get g-C 3 N 4 / Kaolinite precursor.

[0018] (2) the g-C described in step (1) 3 N 4 / The kaolinite precursor was calcined twice: the first closed calcining temperature was 550°C, the calcining time was 4h, and the heating rate was 2.3°C / min, and the second open calcining temperature was 500°C, the calcining time was 2h, and the heating rate was 5°C / min. Finally, the g-C of the visible light response is obtained 3 N 4 / kaolinite composite photocatalytic material.

[0019] According to the above process conditions, pure g-C was prepared simultaneously 3 N 4 as a control sample.

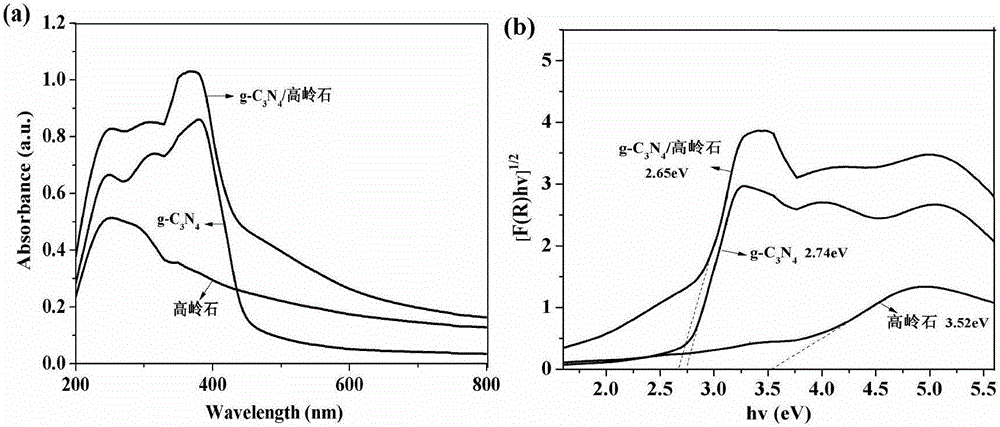

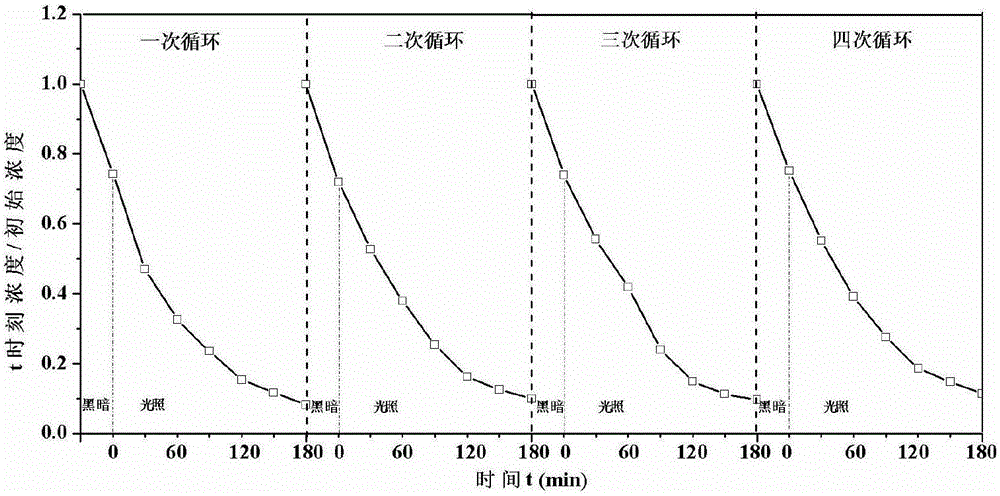

[0020] The g-C that embodiment 1 prepares 3 N...

Embodiment 2

[0022] The steps are the same as those in Example 1, except that the amount of distilled water in step (1) is 75ml, the dipping temperature is 50°C, the amount of dicyandiamide is 3g, the reaction time of stirring and dipping is 24h, and the drying temperature is 70°C; in step (2), g-C 3 N 4 / The kaolinite precursor was calcined at a temperature of 550°C with a cover for one time, the calcining time was 2 hours, and the heating rate was 5°C / min, and the second open calcining temperature was 550°C, the calcining time was 3 hours, and the heating rate was 10°C / min.

Embodiment 3

[0024] The steps are the same as those in Example 1, except that the amount of distilled water in step (1) is 100ml, the dipping temperature is 70°C, the amount of dicyandiamide is 5g, the reaction time of stirring and dipping is 18h, and the drying temperature is 50°C; in step (2), g-C 3 N 4 / The kaolinite precursor was calcined at a temperature of 600°C for one cover, for a calcination time of 3 hours, and a heating rate of 7.5°C / min, and for the second open calcination temperature of 450°C, for a calcination time of 1 hour, and a heating rate of 7.5°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com