Printing and dyeing wastewater treatment method

A technology for printing and dyeing sewage and treatment methods, which is applied in the direction of reducing water/sewage treatment, textile industry wastewater treatment, etc., can solve the problems of low efficiency, iron/water micro-electrolysis hardening, iron rust consumption, etc. The method is simple and easy to implement, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

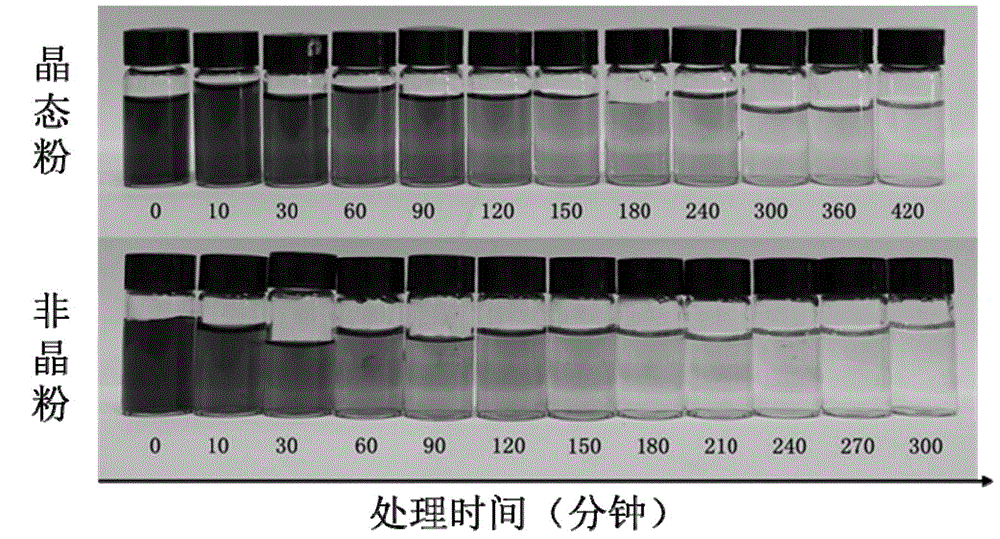

[0033] In this embodiment, the printing and dyeing sewage is direct blue 2B dye water with a concentration of 200mg / L, and the iron-based amorphous alloy powder Fe 78 Si 9 B 13 , Iron-based crystalline alloy powder Fe 78 Si 9 B 13 , and commercial iron powder to treat the printing and dyeing sewage respectively.

[0034] (1) Iron-based amorphous alloy powder Fe 78 Si 9 B 13 preparation

[0035] Fe 78 Si 9 B 13 Is a component with a strong ability to form amorphous, the iron-based amorphous alloy powder Fe 78 Si 9 B 13 The preparation method is as follows:

[0036] (1) Fe 78 Si 9 B 13 Preparation of master alloy

[0037] Fe, Si and B elements with a purity of not less than 99% (weight percent) are used in the atomic ratio of 78:9:13, and the prepared raw material mixture is smelted in an electric arc furnace with an argon atmosphere adsorbed by titanium. More than 3 times, mix evenly, and obtain the master alloy ingot after cooling;

[0038] (2) Fe 78 Si 9...

Embodiment 2

[0058] In this example, using Fe 77 Si 9 B 13 La 1 The iron-based amorphous alloy powder is used to treat the printing and dyeing wastewater.

[0059] Iron-based amorphous alloy powder Fe in the present embodiment 77 Si 9 B 13 La 1 The preparation method is basically the same as that in Example 1, except that the raw materials Fe, Si, B and La elements are dosed according to the atomic ratio of 77:9:13:1.

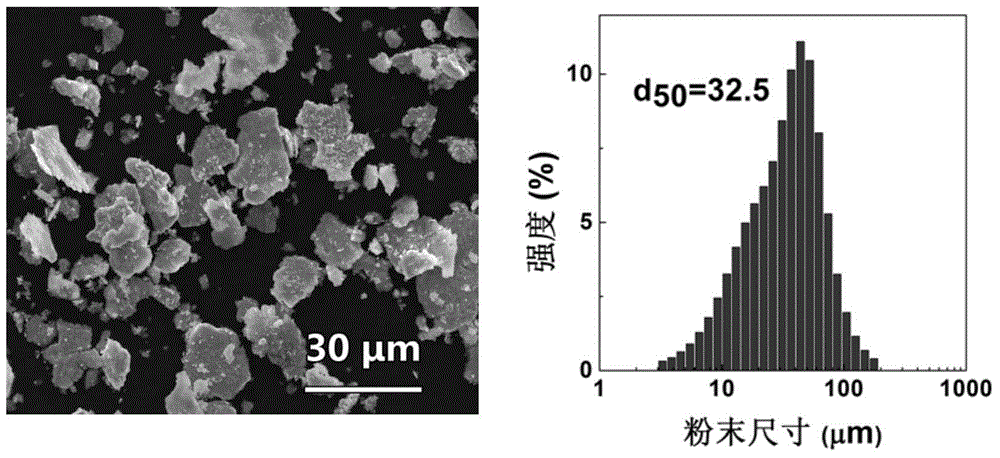

[0060] Similar to Example 1, to Fe 77 Si 9 B 13 La 1 The iron-based amorphous alloy powder was subjected to scanning electron microscope experiment and particle size analysis. like Image 6 As shown, the iron-based amorphous alloy powder is a uniform fine powder with an average particle size of 29.2 μm.

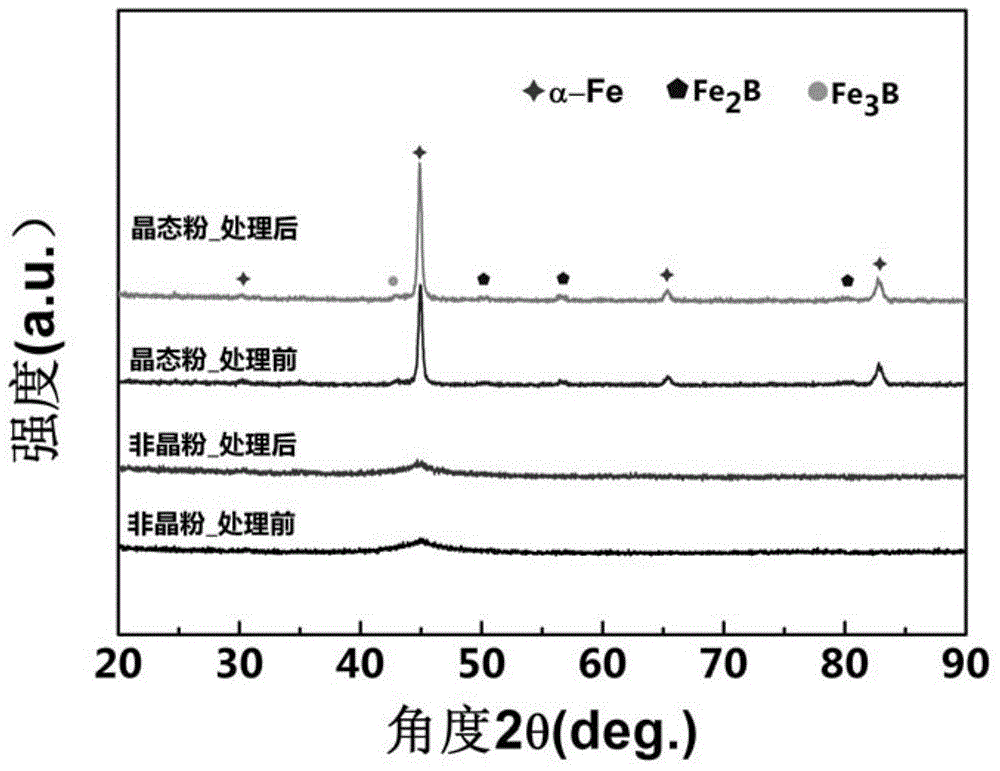

[0061] Similar to Example 1, the XRD figure of the iron-based amorphous alloy powder in the present embodiment shows that this alloy is an amorphous alloy, such as Figure 7 shown.

[0062] According to the method for processing printing and dyeing sewage in...

Embodiment 3-7

[0064] In embodiment 3-7, utilize Fe 73 Si 7 B 17 Mo 3 , Fe 73 Si 7 B 17 Nb 1 Gd 2 , Fe 75 Si 9 B 13 Nb 2 Tb 1 , Fe 75 Si 9 B 13 Tm 3 , Fe 77 Si 9 B 13 Y 1 The iron-based amorphous alloy powder is used to treat the printing and dyeing wastewater.

[0065] Iron-based amorphous alloy powder Fe in the present embodiment 73 Si 7 B 17 Mo 3 , Fe 73 Si 7 B 17 Nb 1 Gd 2 , Fe 75 Si 9 B 13 Nb 2 Tb 1 , Fe 75 Si 9 B 13 Tm 3 , Fe 77 Si 9 B 13 Y 1 The preparation method is basically the same as in Example 1, except that each element is dosed according to the atomic ratio of the corresponding molecular formula. The average particle sizes of the five powders are all between 20 and 40 μm.

[0066] Similar to Example 1, the XRD patterns of the iron-based amorphous alloy powders in Examples 3-7 show that these alloys are amorphous alloys, such as Figure 9 shown.

[0067] According to the method for processing printing and dyeing sewage in Example 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com