Pd @MIL-101 composite and preparation method and application thereof

A composite material and reaction technology, used in the preparation of halogenated hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve the problems of selectivity, difficult to protect catalysts, difficult to produce, etc., and achieve convenient purification and separation. The effect of reusability and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

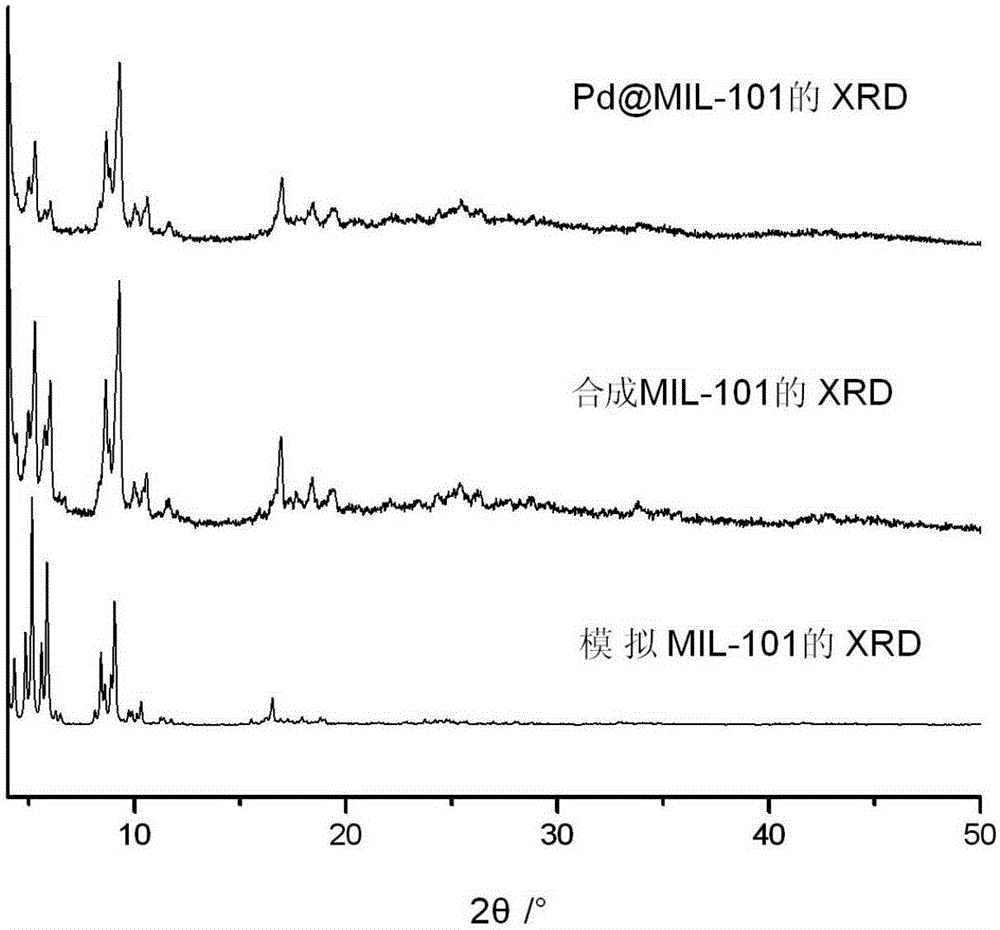

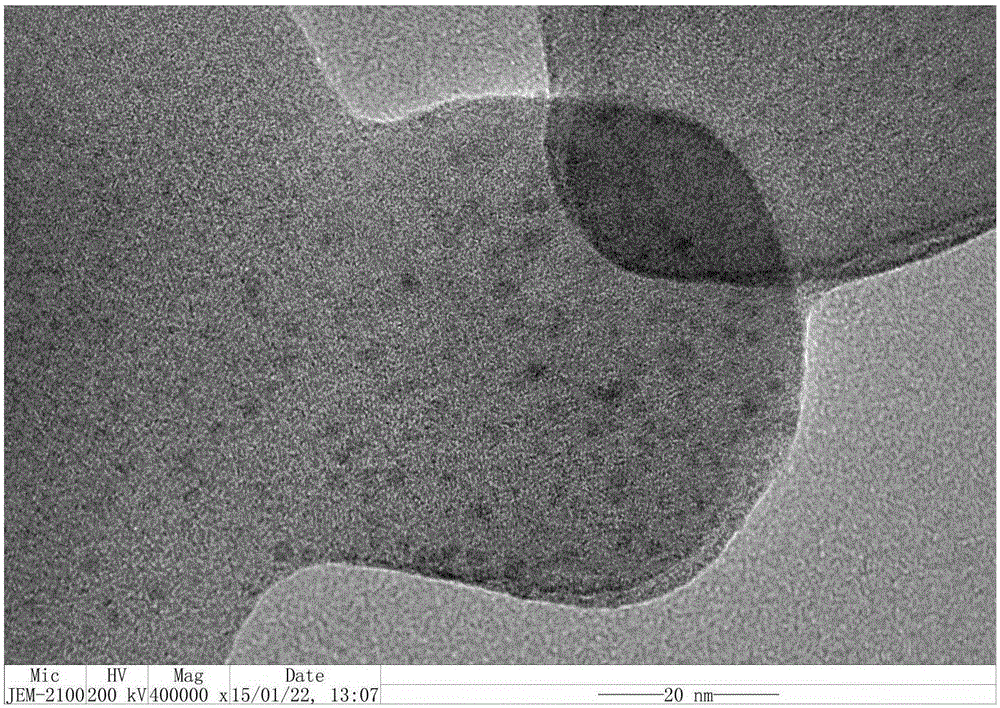

[0021] Embodiment 1PdMIL-101 composite material

[0022] (1) Preparation method

[0023] 1. Preparation of MIL-101 crystals: Weigh 4g of chromium nitrate nonahydrate and 1.312g of terephthalic acid in a 100mL hydrothermal synthesis reactor, add 540mL of acetic acid (99.5%) and 50mL of sub-boiling distilled water at the same time, and use a stirring rotor to Sealed and stirred for 30 minutes, after stirring evenly, the rotor was taken out, and the hydrothermal synthesis reaction kettle was placed in an oven at 200°C for 8 hours of reaction. After the reaction, remove the liquid in the solution, wash the solid particles with 10 mL of water and 10 mL of ethanol three times each, put the washed solid into 50 mL of N,N'-dimethylformamide (DMF), and statically Place overnight, and obtain MIL-101 crystals after filtration.

[0024] 2. Activation of MIL-101 crystals: put the MIL-101 crystals into a vacuum drying oven at 150° C. for 12 hours in vacuum to obtain activated MIL-101 crys...

Embodiment 2

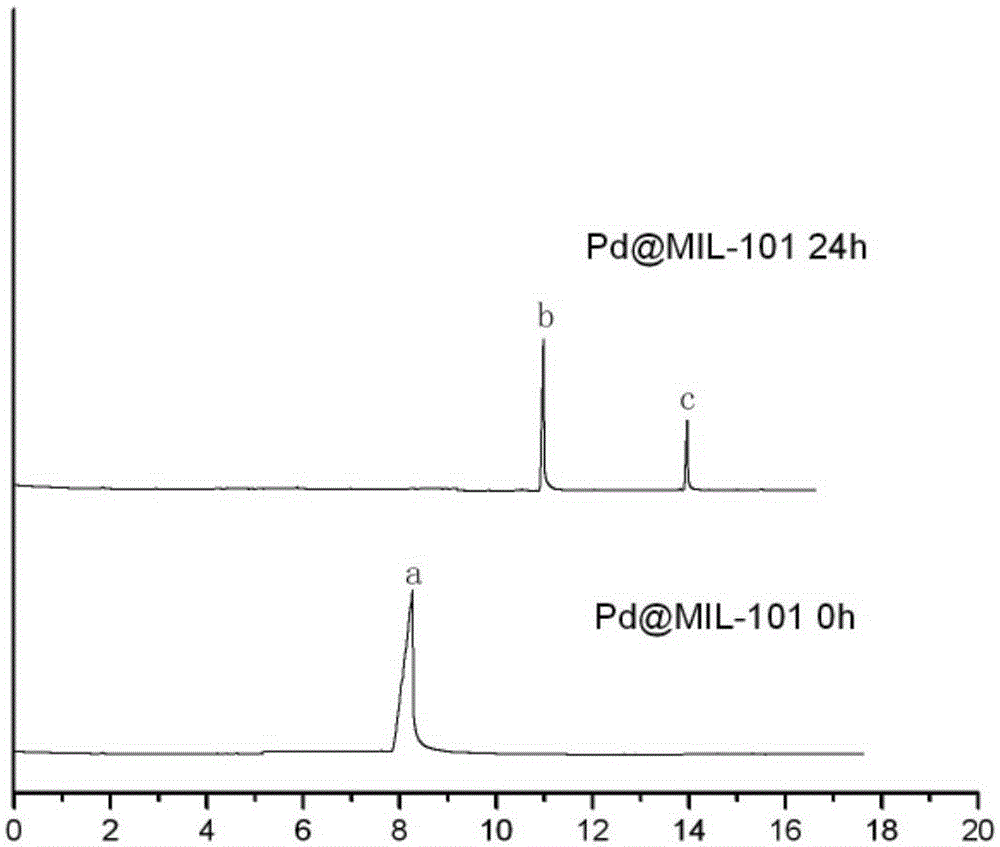

[0030] The selective catalysis of embodiment 2PdMIL-101 composite material to the reaction of phenylboronic acid and 1,4-dibromobenzene

[0031] The method is as follows: Weigh 3mmol (0.1825g) of phenylboronic acid, 3mmol (0.4146g) of potassium carbonate and 1.5mmol (0.354g) of 1,4-dibromobenzene, and dissolve them in 10mL of methanol solution to obtain a mixed solution; Add 53mgPdMIL-101 composite material (1.44mgPd) prepared in Example 1 and 1.44mg pure palladium nanoparticles respectively, then respectively place them in 10mL eggplant-shaped reaction bottles, install the reaction device, and first extend the long needle into the liquid surface Next, pass nitrogen gas for 10 minutes to eliminate the oxygen contained in the solution, then pull out the needle to make the whole reactor airtight, and finally insert a needle above the condenser tube for full nitrogen protection, react at a temperature of 80°C, and react for 24 hours. Get the reaction solution and carry out gas ch...

Embodiment 3

[0036] Embodiment 3PdMIL-101 composite material repeatability test

[0037] After the reaction of Example 2 was completed, the PdMIL-101 composite material was isolated, and the experiment of Example 2 was repeated 4 times. By repeating the test, the yield of the PdMIL-101 composite material for the first four times of the reaction has little change, and has good catalytic activity and selectivity. The yield was 13.26%. It proves that the PdMIL-101 composite material synthesized by the present invention has good reusability, is easy to separate from reactants, and does not interfere with the entire reaction system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com