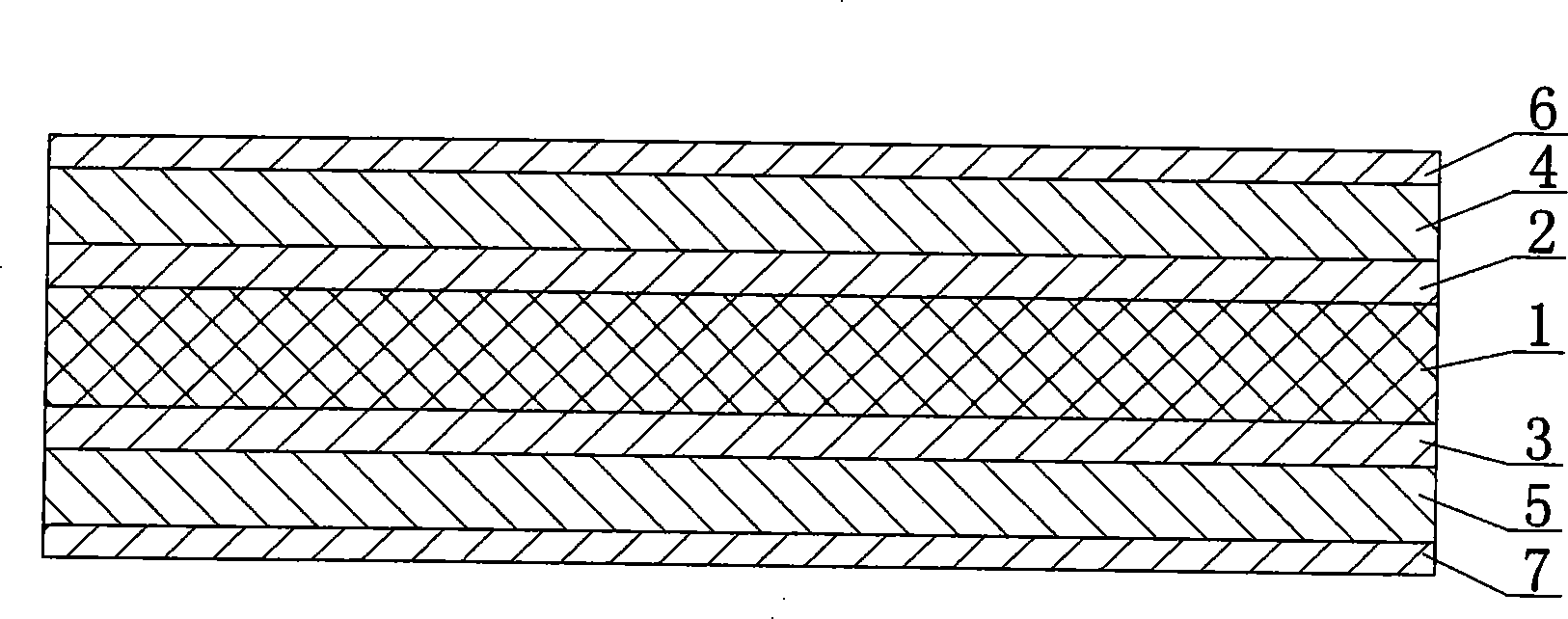

Method for preparing polytetrafluoroethylene spatial structure building film material

A polytetrafluoroethylene and architectural membrane technology, which is applied in textiles and papermaking, fiber processing, singeing, etc., can solve the problems of reducing strength and softness, difficulty in weaving glass fiber yarns, etc., and reduce the decrease in tensile strength. , Improve self-cleaning and anti-ultraviolet function, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Low-temperature singeing treatment of glass fiber cloth: the singeing treatment is carried out on the impregnation equipment, and the weight of the base fabric is 660g / m 2 . The glass fiber cloth roll is fixed on the transmission shaft of the impregnation equipment. The three drying areas of the oven are 6 meters high, and each 2 meters is 1 area. The set temperature of the first zone of the oven is 180°C, and the set temperature of the second and third zones is 280°C. The glass fiber cloth is coiled after being singed in the oven at a line speed of 3 m / min, and the dust attached to the surface of the glass fiber cloth is removed. Wetting agent and other organic components can improve the adhesion of PTFE;

[0019] (2) Dipping and drying treatment to form the bottom layer: the bottom layer impregnating agent is proportioned by weight percentage: 97% of polytetrafluoroethylene emulsion with a solid content of 60%, 1.8% of hydrophilic nano silicon dioxide, 0.7% of or...

Embodiment 2

[0025] (1) Low-temperature singeing treatment of glass fiber cloth: singeing treatment is carried out on impregnation equipment. Base fabric weight 450g / m 2 . The glass fiber cloth roll is fixed on the transmission shaft of the impregnation equipment. The three drying areas of the oven are 6 meters high, and each 2 meters is 1 area. The set temperature of the first zone of the oven is 200°C, and the set temperature of the second and third zones is 280°C. The glass fiber cloth is coiled after being singed in the oven at a line speed of 3.5 m / min, and the dust attached to the surface of the glass fiber cloth is removed. Wetting agent and other organic components can improve the adhesion of PTFE;

[0026](2) Dipping and drying treatment to form the bottom layer: the bottom layer impregnating agent is proportioned by weight percentage: 98% of polytetrafluoroethylene emulsion with a solid content of 60%, 1% of hydrophilic nano silicon dioxide, 0.5% of organic thickener, Silane c...

Embodiment 3

[0032] (1) Low-temperature singeing treatment of glass fiber cloth: singeing treatment is carried out on impregnation equipment. Base fabric weight 330g / m 2 . The glass fiber cloth roll is fixed on the transmission shaft of the impregnation equipment. The drying area of the oven is 6 meters high, and every 2 meters is a zone. The set temperature of the first section of the oven is 180°C, and the set temperature of the second and third sections is 260°C. The glass fiber cloth is coiled after being singed in the oven at a line speed of 4 m / min, and the surface of the glass fiber cloth is removed. The attached wetting agent and other organic components can improve the adhesion of PTFE;

[0033] (2) Dipping and drying treatment to form the bottom layer: the bottom layer impregnating agent is proportioned by weight percentage: 98.5% of polytetrafluoroethylene emulsion with a solid content of 60%, 0.8% of hydrophilic nano silicon dioxide, 0.3% of organic thickener, Silane coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com