Polyurethane sandwiched tire and preparation method thereof

A polyurethane and tire technology, applied in tire parts, tires, tire sidewalls, etc., can solve problems such as poor tire elasticity, achieve high resilience and excellent performance, eliminate assembly work, and reduce rubber components and load-carrying cross-sectional area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

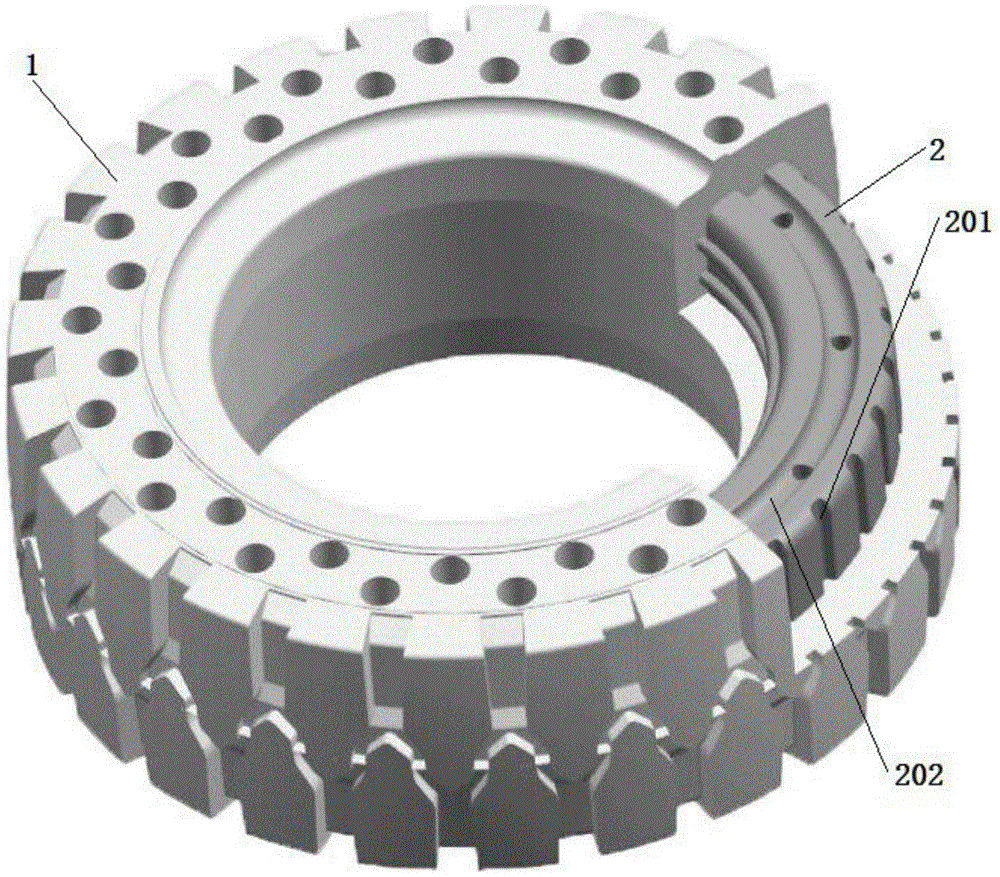

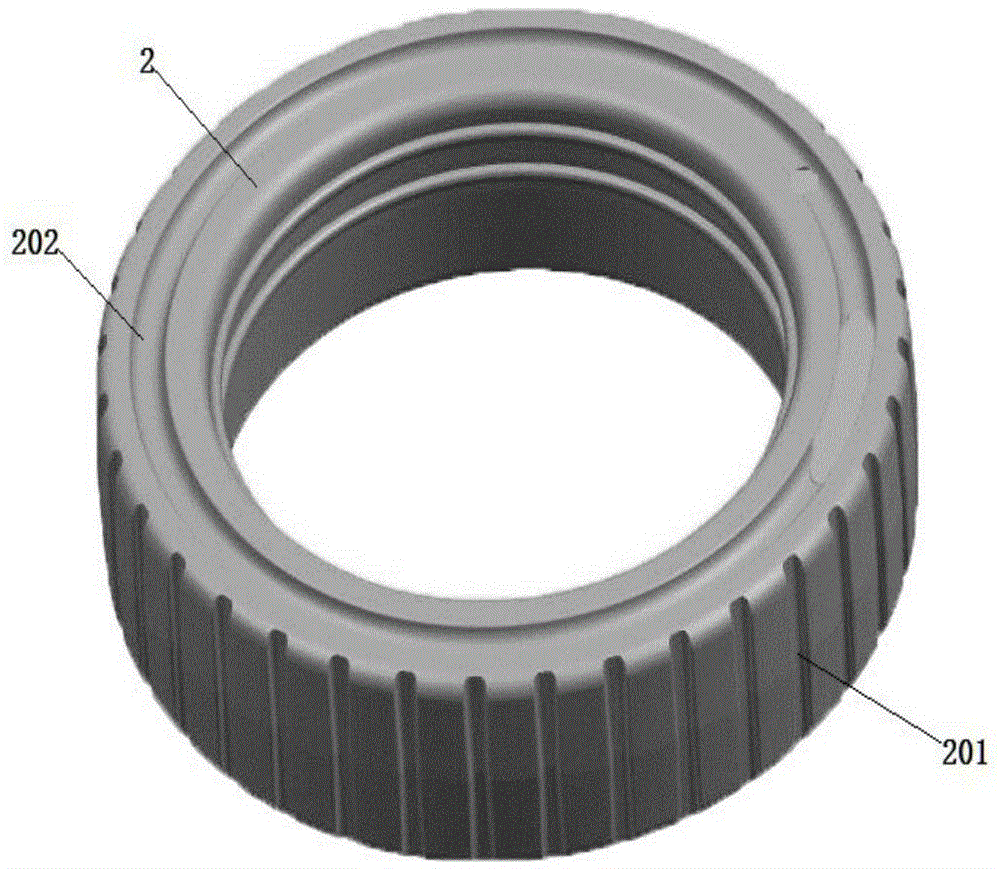

[0043] A polyurethane sandwich tire, such as figure 1 with figure 2 As shown, it includes a cover tire 1 and an inner tube 2 wrapped inside the cover tire. The Shore hardness of the cover tire 1 is greater than the Shore hardness of the inner tube 2. The groove 201 with a vertical direction and a semicircular cross section is provided with ribs 101 corresponding to the groove 201 with the same number, equal length and semicircular cross section on the inner tread of the tire. The ribs 101 of the tire cover are placed in the inner tube groove 201 and bonded together. That is, wave-type semicircular bonding is used to increase the bonding area between the inner tube and the outer tire, strengthen the adhesive force, and disperse the force direction of the inner tube. When the outer tire is in contact with the ground, the outer tire is transmitted to the vertical upward effect of the inner tube. The force is distributed to different directions, reducing the damage to the inner...

Embodiment 2

[0045] A polyurethane sandwich tire, such as figure 1 with figure 2 As shown, it includes a cover tire 1 and an inner tube 2 wrapped inside the cover tire. The Shore hardness of the cover tire 1 is greater than the Shore hardness of the inner tube 2. The groove 201 with a vertical direction and a semicircular cross section is provided with ribs 101 corresponding to the groove 201 with the same number, equal length and semicircular cross section on the inner tread of the tire. The ribs of the cover tire are placed in the groove of the inner tube and bonded together.

[0046] And, the sidewall two sides of described cover tire all are provided with a circle of shock-absorbing buffer hole 103 perpendicular to the traveling direction, described shock-absorbing buffer hole 103 is circular, and described shock-absorbing buffer hole 103 is " V " along the sidewall. Glyph distribution. The main function is; because high-hardness polyurethane has high support and tensile strength, ...

Embodiment 3

[0048] A polyurethane sandwich tire, such as Figure 1~4 As shown, it includes a cover tire 1 and an inner tube 2 wrapped inside the cover tire. The Shore hardness of the cover tire 1 is greater than the Shore hardness of the inner tube 2. The groove 201 with a vertical direction and a semicircular cross section is provided with ribs 101 corresponding to the groove 201 with the same number, equal length and semicircular cross section on the inner tread of the tire. The ribs of the cover tire are placed in the groove of the inner tube and bonded together.

[0049] And, the sidewall two sides of described cover tire all are provided with a circle of shock-absorbing buffer hole 103 perpendicular to the traveling direction, described shock-absorbing buffer hole 103 is circular, and described shock-absorbing buffer hole 103 is " V " along the sidewall. Glyph distribution.

[0050] Furthermore, the inner tire sidewall is provided with an annular groove 202, which is bonded to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com