Formula and production technology of polyurethane low-speed solid tire

A solid tire, production process technology, used in special tires, tire parts, transportation and packaging, etc., can solve the problems of inability to replace at any time, oil resistance, short rubber life, etc., to solve the problem of blocks and cracks, product performance The effect of stability and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

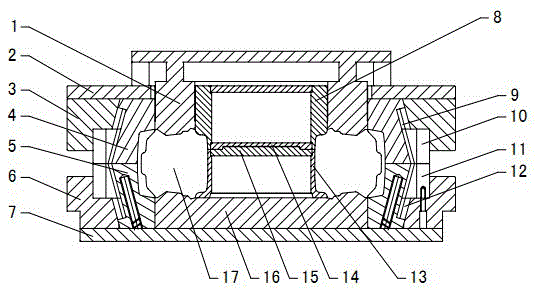

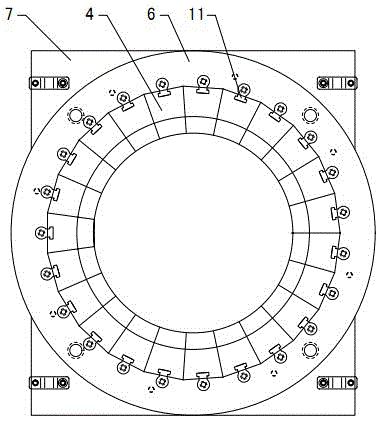

Image

Examples

Embodiment 1

[0034] 1) Heat 1,000 grams of polyester polyol 218 to 115°C for 4 hours for vacuum dehydration, add 200 grams of TDI T100 when the temperature is lowered to 70°C, control the temperature at 80°C, and mix for 2.5 hours to obtain a prepolymer;

[0035] 2) Warm 20 grams of BD14 to 100°C for 4 hours for vacuum dehydration, heat 20 grams of DMEP for 4 hours to 100°C for vacuum dehydration, then lower them to room temperature and mix them with 60 grams of DMTDA to prepare the curing agent component;

[0036] 3) Add the prepolymer and curing agent components prepared in step (1) and step (2) into tanks A and B of the pouring machine, and mix and inject the prepolymer and curing agent components at a weight ratio of 12:1 The tire is poured into the mold, put it in an oven at 110°C for 4 hours to be vulcanized, and then it can be demoulded. Later, after 16 hours of secondary vulcanization in the oven at 110°C, the product performance will be stable.

[0037] The solid tire prepared in ...

Embodiment 2

[0039] 1) Heat 1,200 grams of polyester polyol to 115°C for 4 hours for vacuum dehydration, lower it to 70°C, add 210 grams of TDI T100, control the temperature at 80°C, and mix for 2.5 hours to obtain a prepolymer;

[0040] 2) Heat 20 grams of BD14 to 100°C for 4 hours for vacuum dehydration, heat 40 grams of DMEP to 100°C for 4 hours and vacuum dehydrate for 4 hours, then lower them to room temperature and mix them with 60 grams of DMTDA to prepare the curing agent component;

[0041] 3) Add all the prepolymer and curing agent components prepared in step (1) and step (2) into tanks A and B of the pouring machine, mix the prepolymer and curing agent components and inject them into the tire casting mold, and put It can be released from the mold after being vulcanized in an oven at 110°C for 4 hours, and the performance of the product will be stable after secondary vulcanization in an oven at 110°C for 16 hours.

[0042] The solid tire prepared in this example was tested for pe...

Embodiment 3

[0044] 1) Heat 1,300 grams of polyester polyol to 115°C for 4 hours in vacuum dehydration, then lower it to 70°C, add 240 grams of TDI T100, control the temperature at 80°C, and mix for 2.5 hours to obtain a prepolymer;

[0045] 2) Heat 20 grams of BD14 to 100°C for 4 hours for vacuum dehydration, heat 60 grams of DMEP to 100°C for 4 hours and vacuum dehydrate for 4 hours, then lower them to room temperature and mix them with 60 grams of DMTDA to prepare the curing agent component;

[0046] 3) Add all the prepolymer and curing agent components prepared in step (1) and step (2) into tanks A and B of the pouring machine, mix the prepolymer and curing agent components and inject them into the tire casting mold, and put It can be released from the mold after being vulcanized in an oven at 110°C for 4 hours, and the performance of the product will be stable after secondary vulcanization at 110°C in an oven for 16 hours.

[0047] Performance tests were performed on the solid tire pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com