Submerged flow pushing device based on rail-abutted single pulley sliding

A submersible flow propeller, slip-type technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

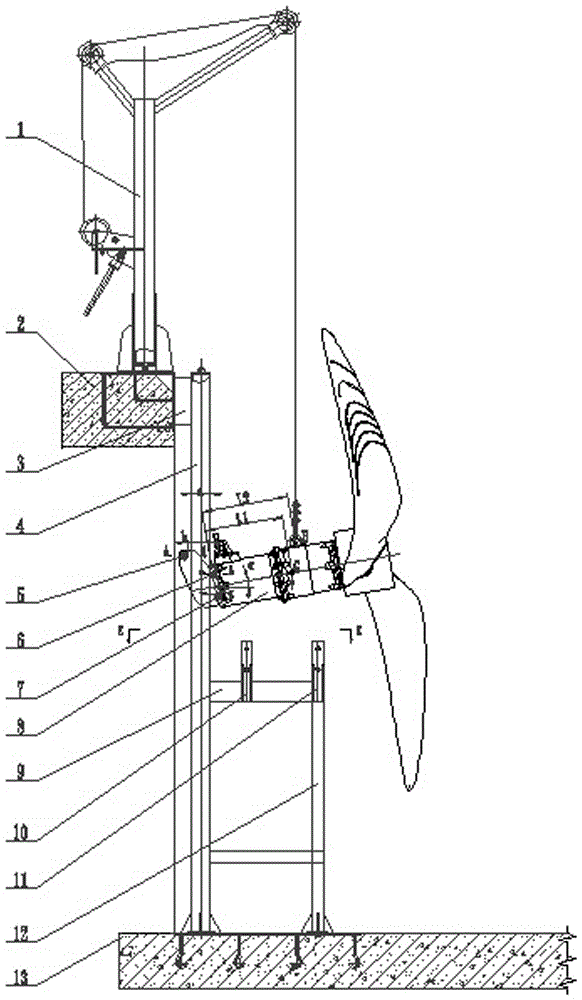

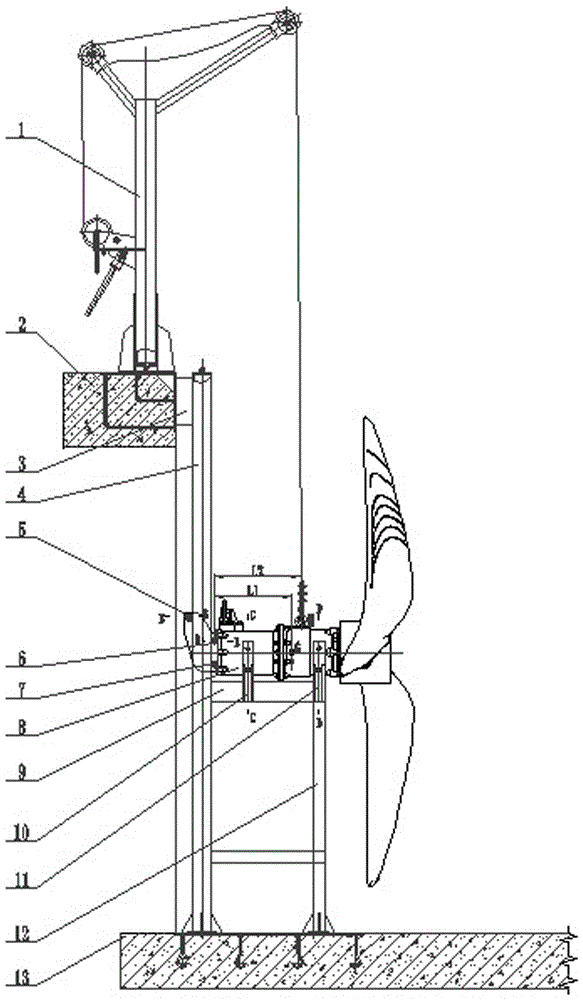

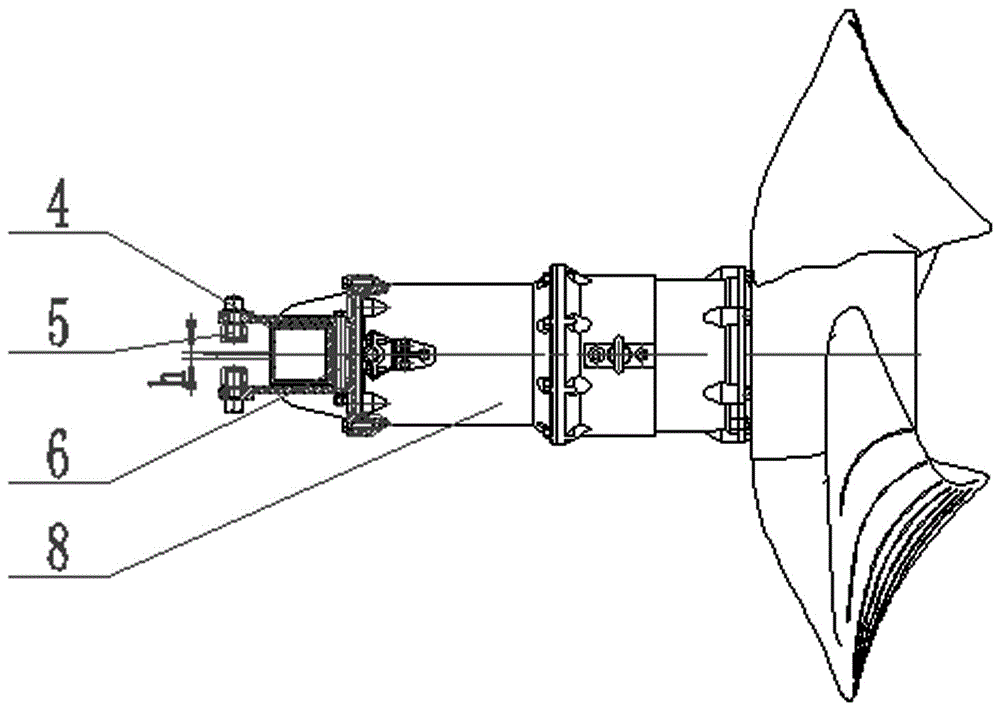

[0039] The implementation of the invention will be further described below in conjunction with the accompanying drawings:

[0040] figure 1 , 2, 3, 4, 5, 6, 7, 8, and 14, a single-wheel rail sliding submersible flowmaker, which includes a lifting device 1, a pool surface installation base 2, a connecting plate 3, and a sliding guide rail 4. Limit pulley 5, rail pulley 6, load pulley 7, submersible thruster host 8, coupling seat beam 9, front coupling seat 10, rear coupling seat 11, coupling seat support 12, pool bottom installation base 13, lifting The device 1 is fixedly installed on the installation foundation 2 of the pool surface, and is mainly used for lifting the flow booster to move up and down along the guide rail. The sliding guide rail 4 is installed vertically, and the upper end is fixed to the connecting plate 3, and the connecting plate 3 is connected to the pool surface. The foundation 2 is pulled and fixed, the lower break is fixed to the installation foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com