Temple device for towel loom

A technology for towel looms and temples, which is applied in textiles, textiles, papermaking, and auxiliary equipment for weaving. It can solve problems such as frequent maintenance, fabric surface damage, and short service life of parts, so as to reduce use and maintenance costs. Effect of improving fabric quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

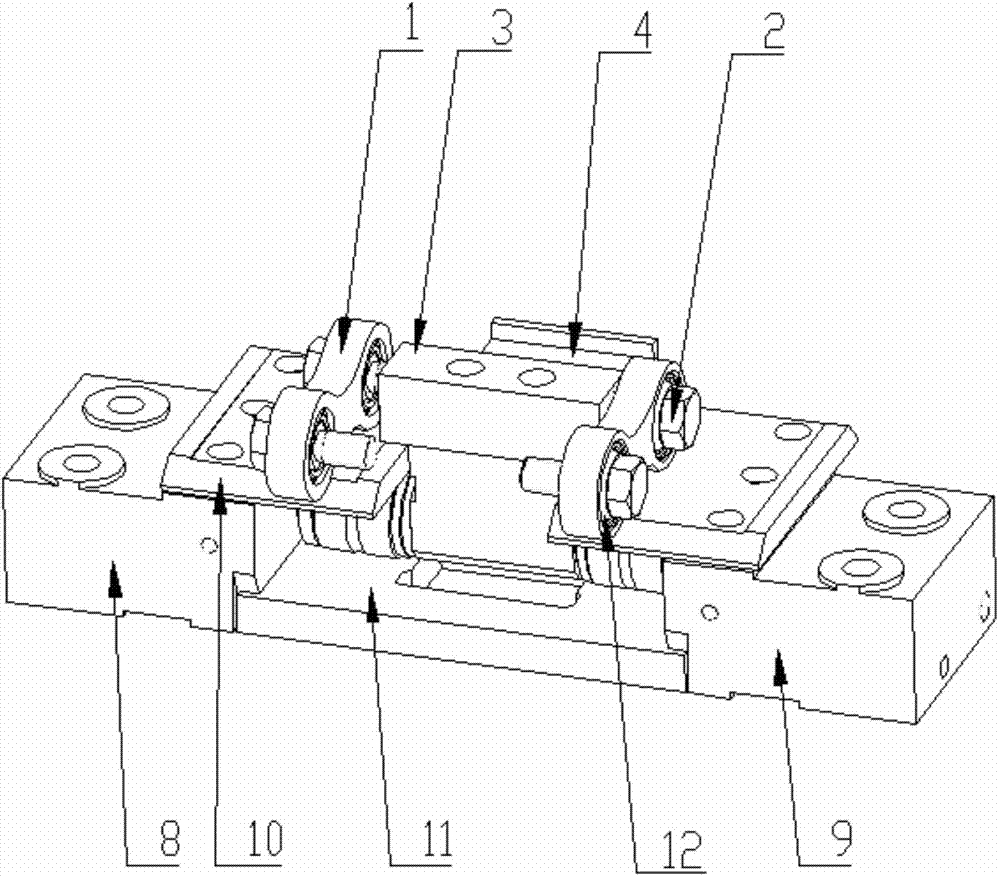

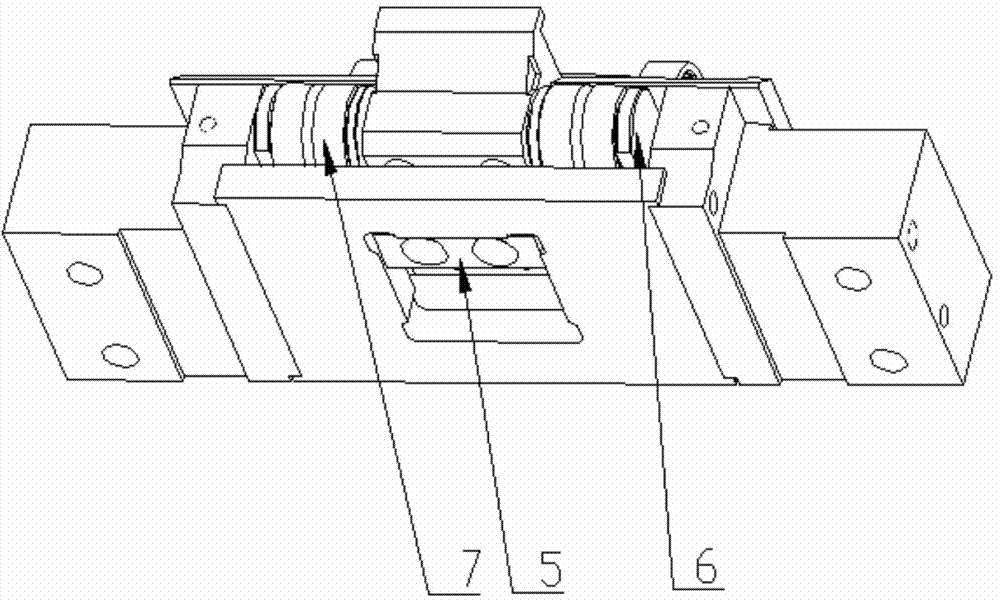

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

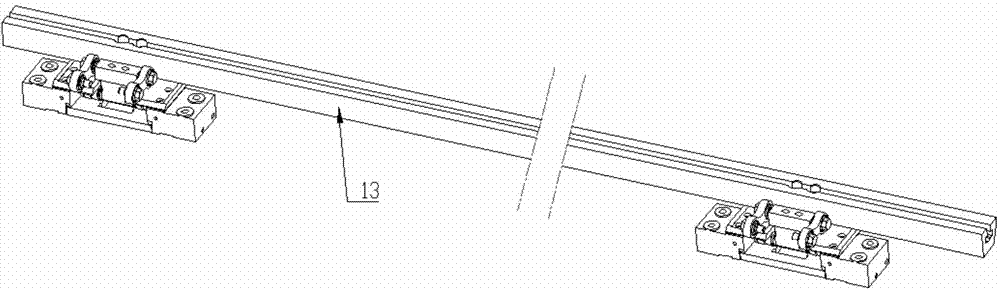

[0021] combine as Figure 1 to Figure 5 , a temple device for a towel loom, comprising a reciprocating part and a fixed part, the reciprocating part reciprocates along the fixed part, and the reciprocating part includes a push arm 1, a push block 3, and a slider holder 4 , sliding limit block 5, slide bar pin 6, needle roller bearing 7 and sliding seat 13, the both sides of described push block 3 are respectively provided with a push arm 1, and the inner hole of described push arm 1 is provided with centripetal Joint bearing 12, one end of push arm 1 is connected with push block 3 by follower pin 2, and the other end of push arm 1 is connected with the power output end of loom raising mechanism; Described push block 3, slide seat 13 are connected with slide seat respectively The holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com