Method for producing powder-coated aluminum alloy section

The technology of an aluminum alloy profile and production method is applied in the direction of surface coating liquid devices, coatings, electrolytic coatings, etc., which can solve the problems of affecting the use effect and poor performance of aluminum alloy materials, so as to increase the uniformity, Improve the quality and processing performance, increase the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

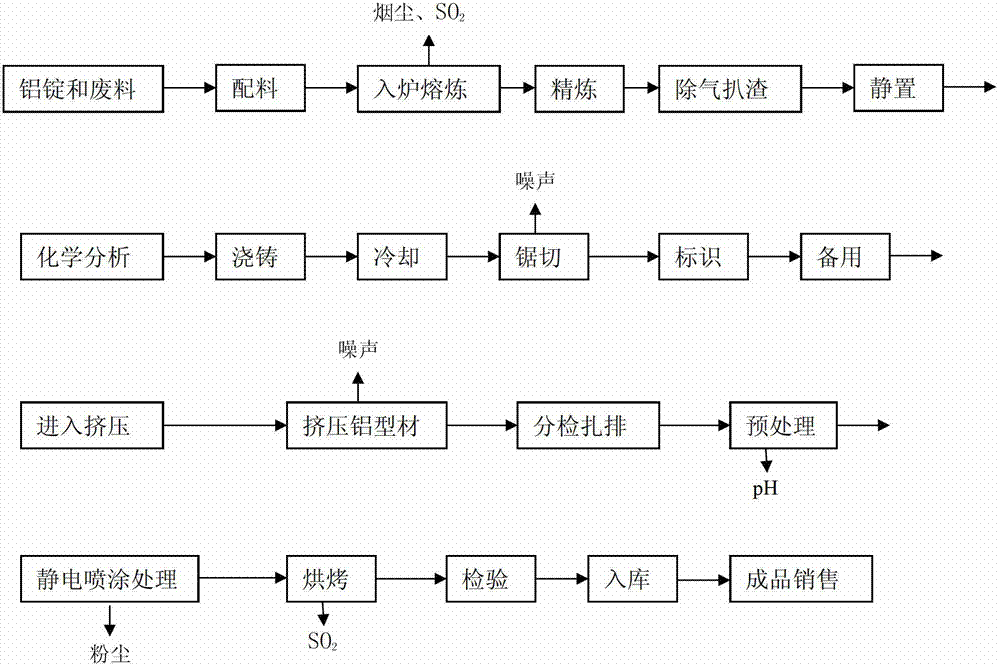

Method used

Image

Examples

Embodiment 1

[0026] (1) Aluminum ingots and other raw material ingredients

[0027] According to the following raw materials by weight: 60 aluminum ingots, 40 reclaimed aluminum profile waste products and other waste aluminum, 7 nanometer ceramic powder for proportioning;

[0028] (2) Melting and casting aluminum alloy round ingot

[0029] First put aluminum ingots, recycled aluminum profile waste and other waste aluminum into the smelting furnace for smelting, the temperature is controlled at 720°C, and when it becomes molten, add nano-ceramic powder to spread it evenly, and then put in an appropriate amount of AlTiB grains The refiner is refined, and finally the impurities and gas in the melt are effectively removed by degassing and slag removal;

[0030] (3) Casting and sawing

[0031] Before casting, let the smelted aluminum liquid stand for 25 minutes, pass the aluminum liquid through the water hole of the smelting furnace and enter the crystallizer through the aluminum tank, cast t...

Embodiment 2

[0043] (1) Aluminum ingots and other raw material ingredients

[0044] According to the following raw materials by weight: 70 aluminum ingots, 30 recycled aluminum profile waste products and other waste aluminum, 10 boron carbide, and 10 nanometer ceramic powders, the mass percentages of each element are: Si ≤ 0.25%, Mg 2.2 -2.8%, Fe ≤0.40%, Cu ≤0.10%, Mn ≤0.10%, Cr 0.15-0.35%, Zn ≤0.10%, other elements total ≤0.15, and the rest is Al;

[0045] (2) Melting and casting aluminum alloy round ingot

[0046] First put aluminum ingots, recycled aluminum profile waste and other waste aluminum into the melting furnace for smelting, the temperature is controlled at 750 ° C, when it becomes molten, add boron carbide and nano-ceramic powder to spread it evenly, and then put in an appropriate amount AlTiB grain refiner is used for refining, and finally the impurities and gases in the melt are effectively removed by degassing and slag removal;

[0047] (3) Casting and sawing

[0048] Be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com