Extrusion grade thermoplastic polyurethane elastomer and manufacturing method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polyurethane, can solve the problems of the narrow range of thermoplastic polyurethane hardness and the inability to meet the demand, and achieve the effect of good extrusion flow performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

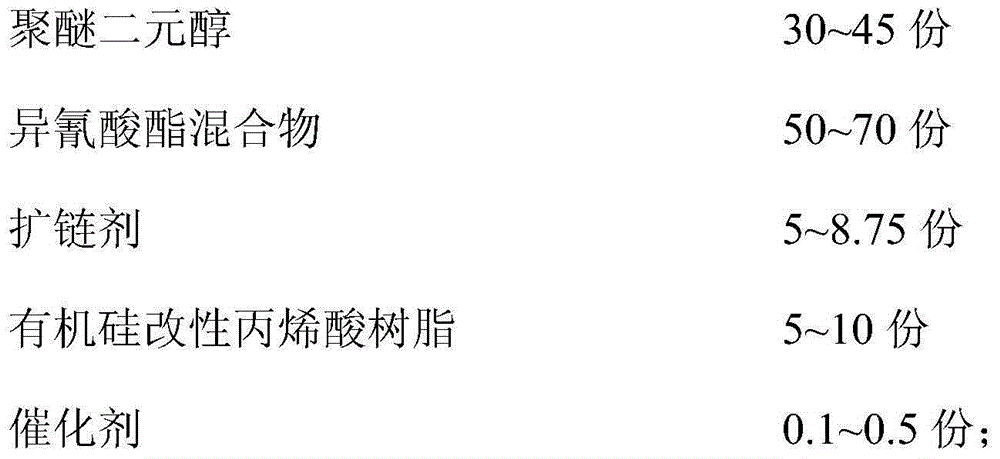

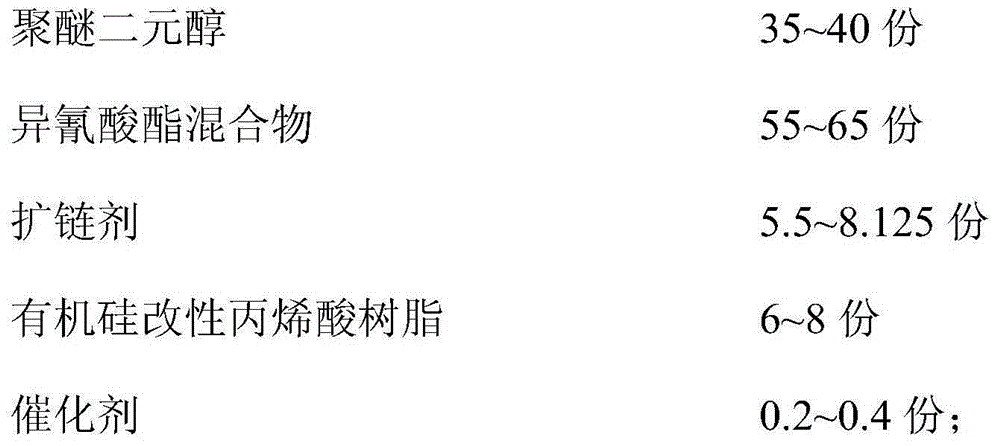

Method used

Image

Examples

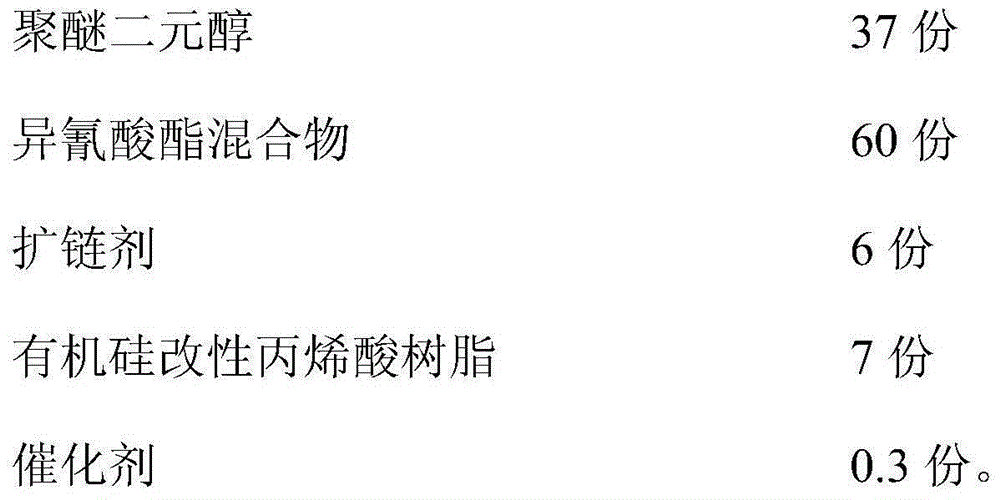

Embodiment 1

[0044] (1) Weigh 37 parts of polyoxytetramethylene glycol into the reactor, control the stirring rate at 1300r / min, vacuum dehydrate at 90°C for 2h, then add 0.3 part of the catalyst stannous octoate to it, and ultrasonically treat it for 45min. It is mixed evenly to form a mixture A;

[0045] (2) Weigh 60 parts of isocyanate mixture (wherein, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate in the isocyanate mixture is 1.5:1; and R is 1.04) and 6 parts of chain extender (wherein, two The molar ratio of phenylsilanediol and ethylene glycol is 4:1), add water to melt at 60°C, add to mixture A, stir at 100°C for 50min, then add 7 parts of silicone modified acrylic resin at 100°C After stirring for 15 minutes, add it into a twin-screw extruder to extrude and granulate to obtain product B;

[0046] Wherein, the temperature of the feeding section of the twin-screw extruder is set at 135°C, the temperature of the mixing section is set at 165°C, and the temp...

Embodiment 2

[0050] (1) Weigh 40 parts of polyepoxide propylene glycol into the reactor, control the stirring rate to 1000r / min, vacuum dehydrate at 80°C for 3h, then add 0.2 part of the catalyst dibutyltin dilaurate to it, and ultrasonically treat it for 60min Mix it evenly to form a mixture A;

[0051] (2) Weigh 65 parts of isocyanate mixture (wherein, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate in the isocyanate mixture is 1:1; and R is 1.02) and 8.125 parts of chain extender (wherein, two The molar ratio of phenylsilanediol and ethylene glycol is 3:1) add water to melt at 50°C, add to mixture A, stir at 90°C for 60min, then add 8 parts of silicone modified acrylic resin at 90°C After stirring for 30 minutes, add it into a twin-screw extruder to extrude and granulate to obtain product B;

[0052] Wherein, the temperature of the feeding section of the twin-screw extruder is set at 130°C, the temperature of the mixing section is set at 160°C, and the tempera...

Embodiment 3

[0056] (1) Weigh 35 parts of polyepoxide propylene glycol into the reactor, control the stirring rate at 1500r / min, vacuum dehydrate at 100°C for 1h, and then add the catalyst bis(dodecylsulfide)dibutyltin 0.4 part, ultrasonically treated for 30 minutes to make it evenly mixed to form mixture A;

[0057] (2) Weigh 55 parts of isocyanate mixture (wherein, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate in the isocyanate mixture is 2:1; and R is 1.1) and 5.5 parts of chain extender (wherein, two The molar ratio of phenylsilanediol and ethylene glycol is 7:1), add water to melt at 70°C, add to mixture A, stir at 110°C for 30min, then add 6 parts of silicone modified acrylic resin at 110°C After stirring for 10 minutes, add it into a twin-screw extruder to extrude and granulate to obtain product B;

[0058] Wherein, the temperature of the feeding section of the twin-screw extruder is set at 140°C, the temperature of the mixing section is set at 170°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com