Method for preparing sensor by using polyurethane package fiber grating

A fiber grating, polyurethane technology, applied in the field of optical fiber communication and light sensing, can solve the problems of measurement error, the influence of the temperature center wavelength is not eliminated, the reliability, stability and sensitivity are difficult to meet the engineering requirements, to overcome the problems. Affinity problem, strong overall structure, simple packaging method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

[0025] A method for preparing a sensor with a polyurethane-encapsulated optical fiber grating, using polyurethane as the packaging material, comprising the following steps:

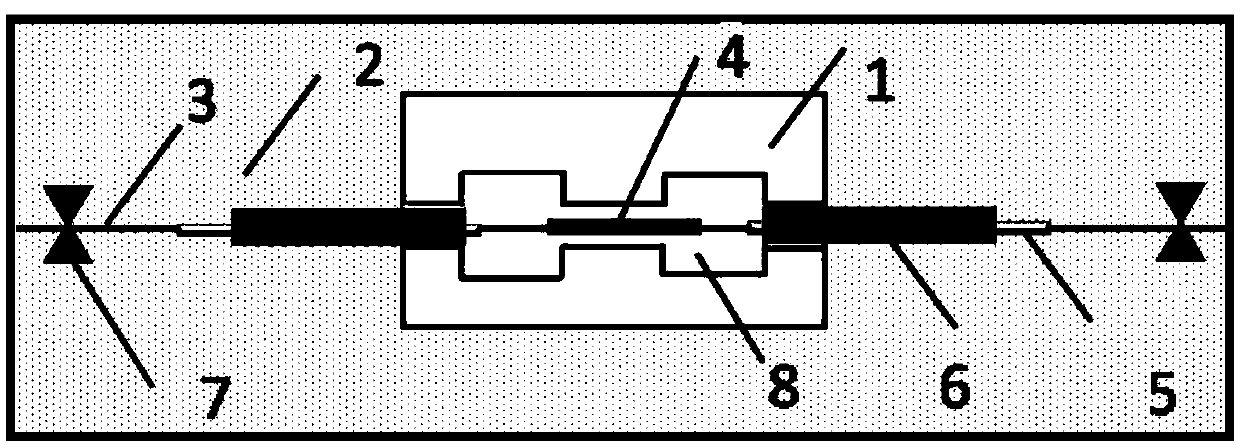

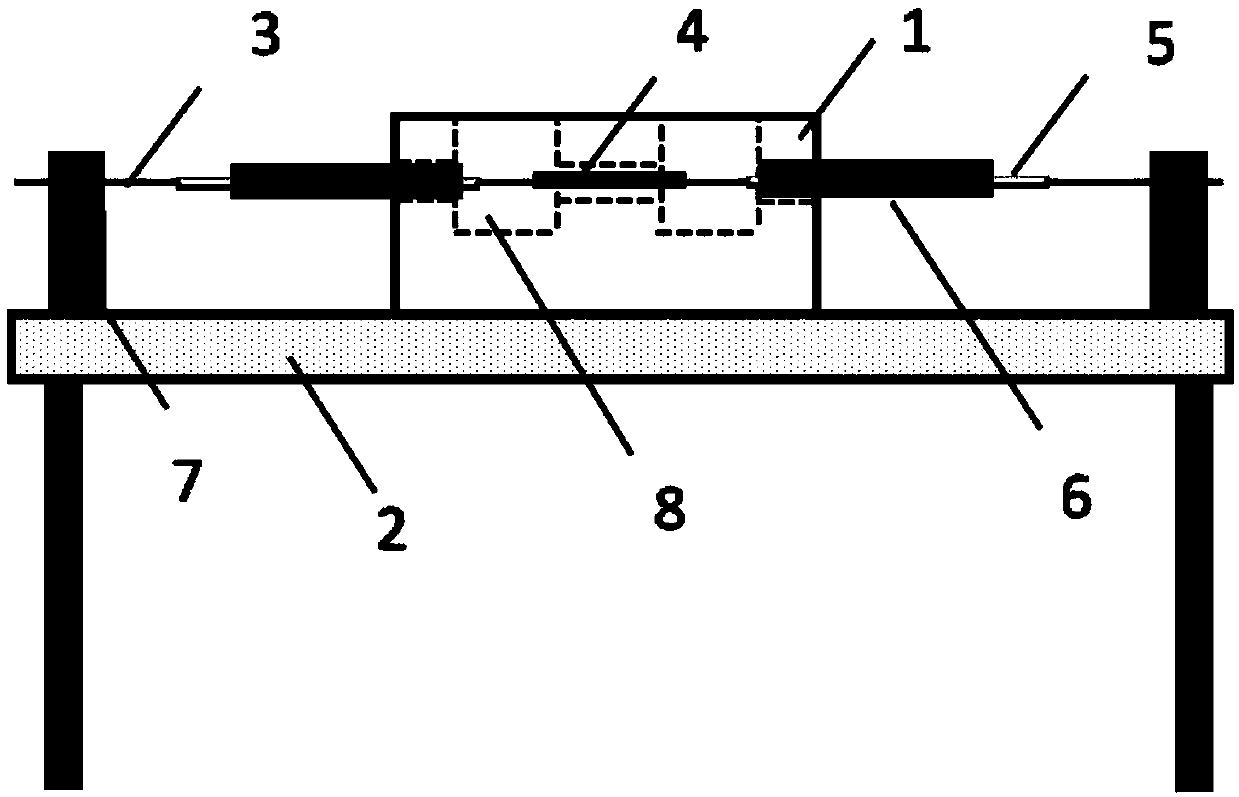

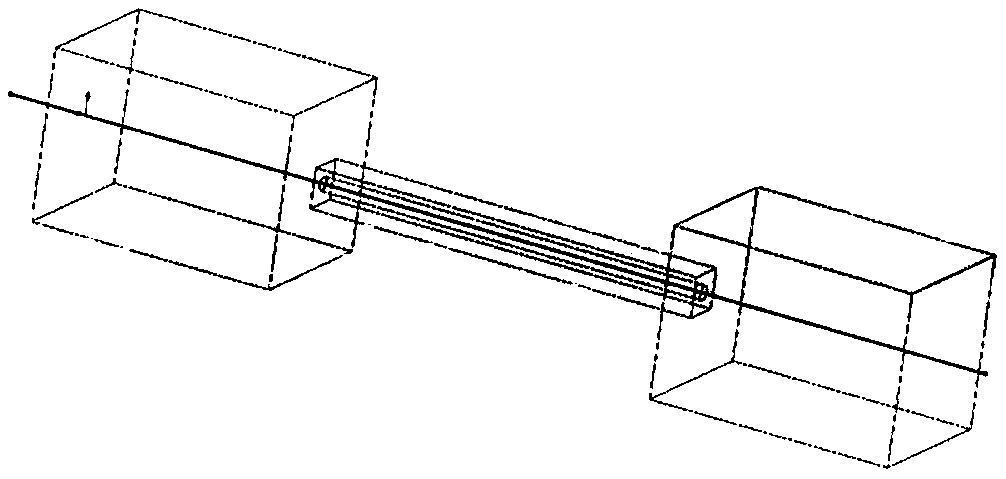

[0026] In the first step, the packaging mold 1 is placed flat on the optical fiber platform 2, such as figure 1 with figure 2 shown. The packaging mold 4 is pre-coated with a release agent. The special packaging mold 1 is a rectangular structure. The packaging mold 1 is provided with a dumbbell-shaped cavity, and the two ends of the spline are rectangular parallelepiped. 6mm, the middle is a connecting strip with a length of 40mm, a width of 3mm, and a height of 3mm. The cavity is left with a threading hole with a length of 5mm and a diameter of 4mm from the edge of the mold; the material of the packaging mold 4 is high temperature resistant polytetrafluoroethylene.

[0027] In the second step, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com