Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Optimizing components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

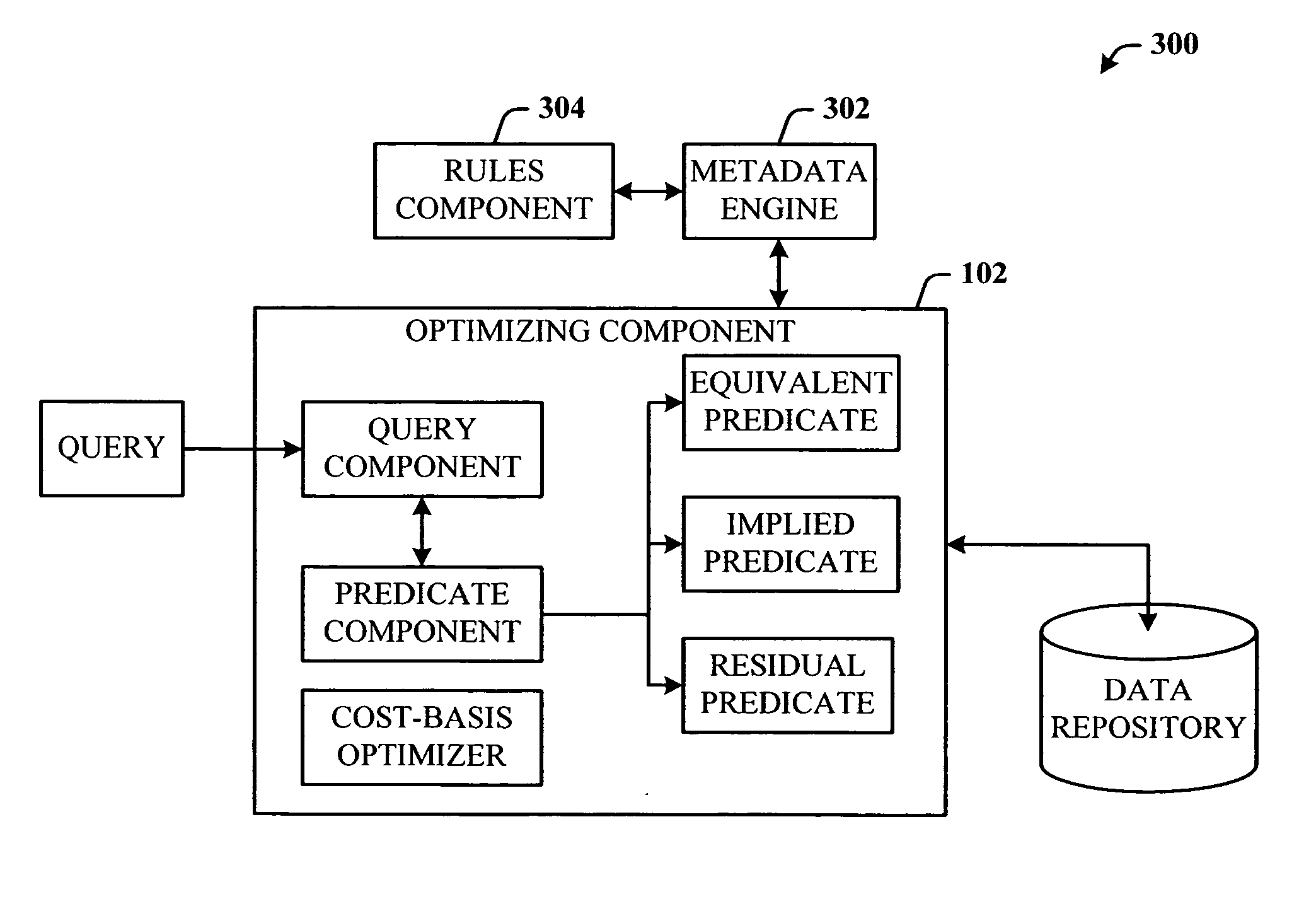

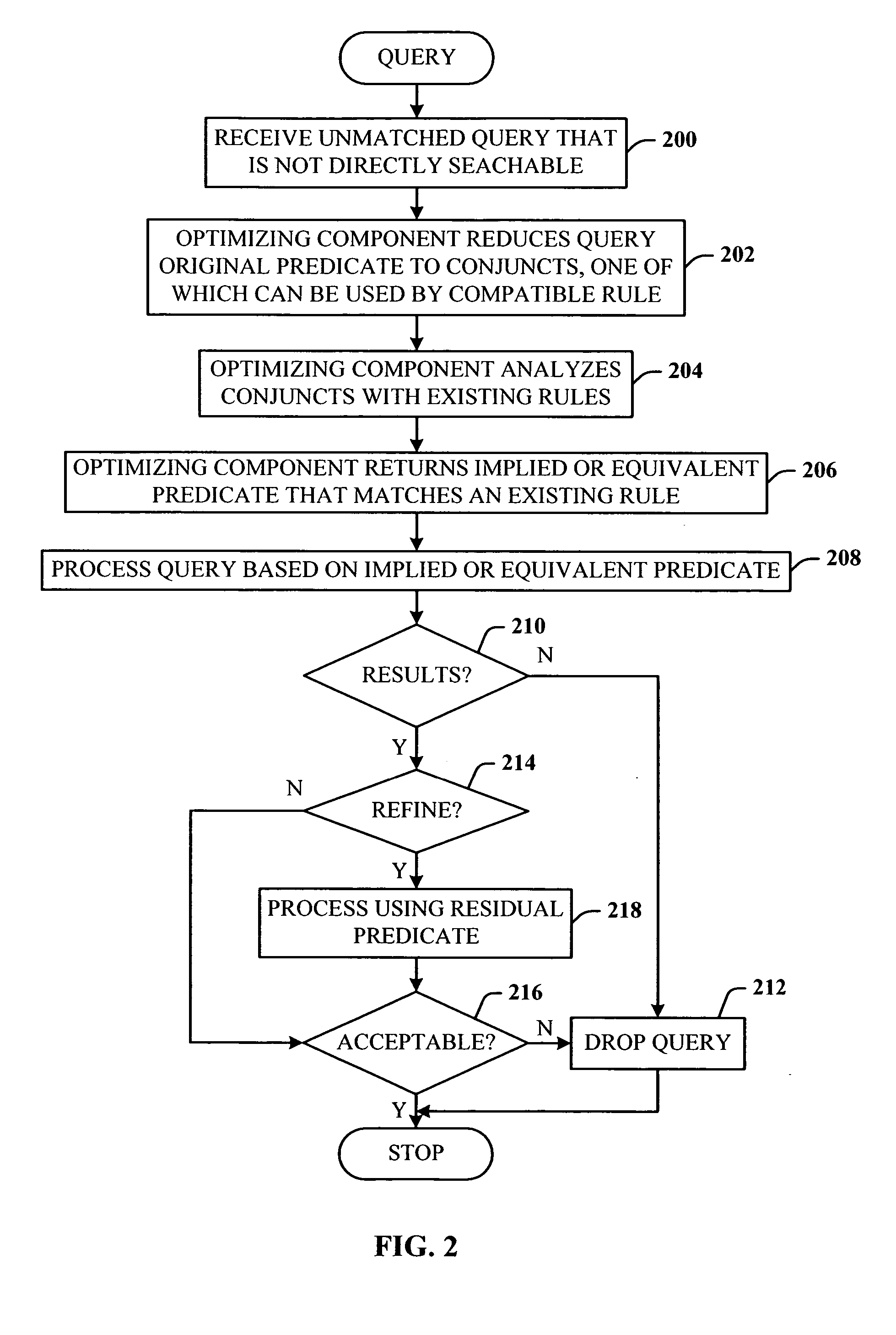

Query optimizer using implied predicates

InactiveUS20050210023A1Optimizing componentsEasy to compareDigital data information retrievalNatural language data processingQuery optimizationMulti valued

Improved query optimizer using implied predicates. The system facilitates allowing a query optimizing component to introduce into a query, extra predicates that facilitate the following: render the same results as the original query; are used as dictated by rules passed to the optimizing component—these rules specify whether the new predicate is an equivalence (that will substitute the old predicate) or an implication (in which the old predicate is preserved); are considered as cost-based alternatives, and discarded if not useful; are tied to index utilization; and can consider both standard and multi-valued indices.

Owner:MICROSOFT TECH LICENSING LLC

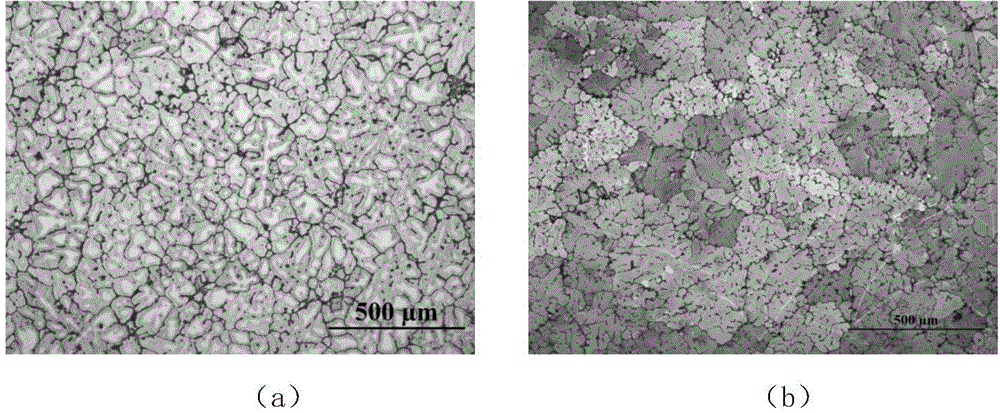

High-strength cast Mg alloy containing rare-earth and preparing process thereof

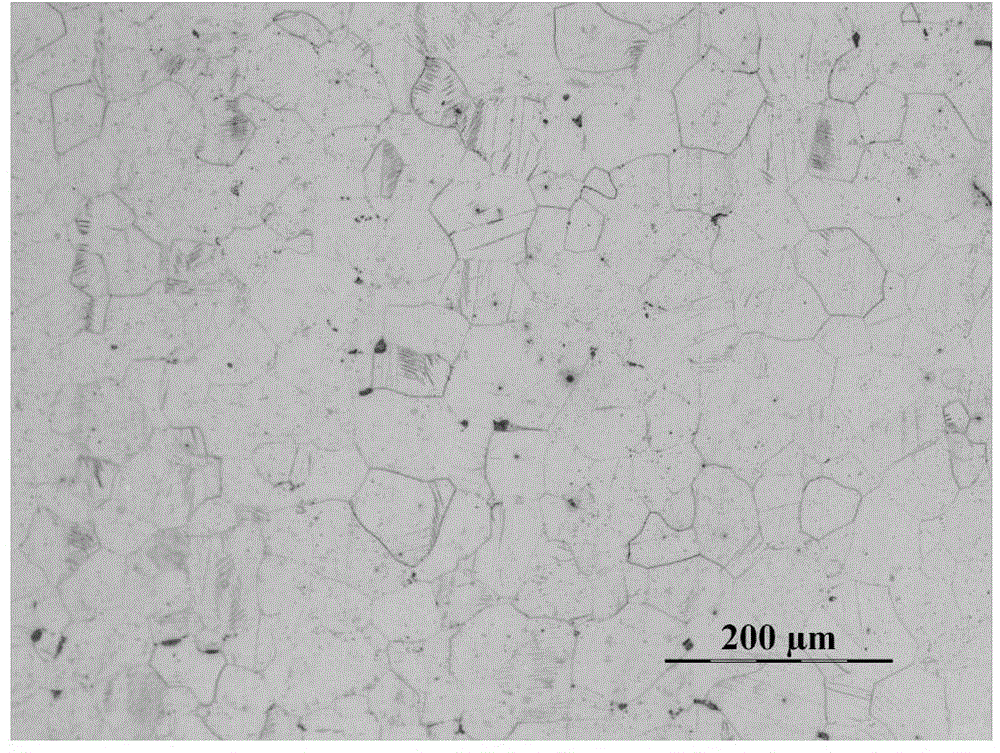

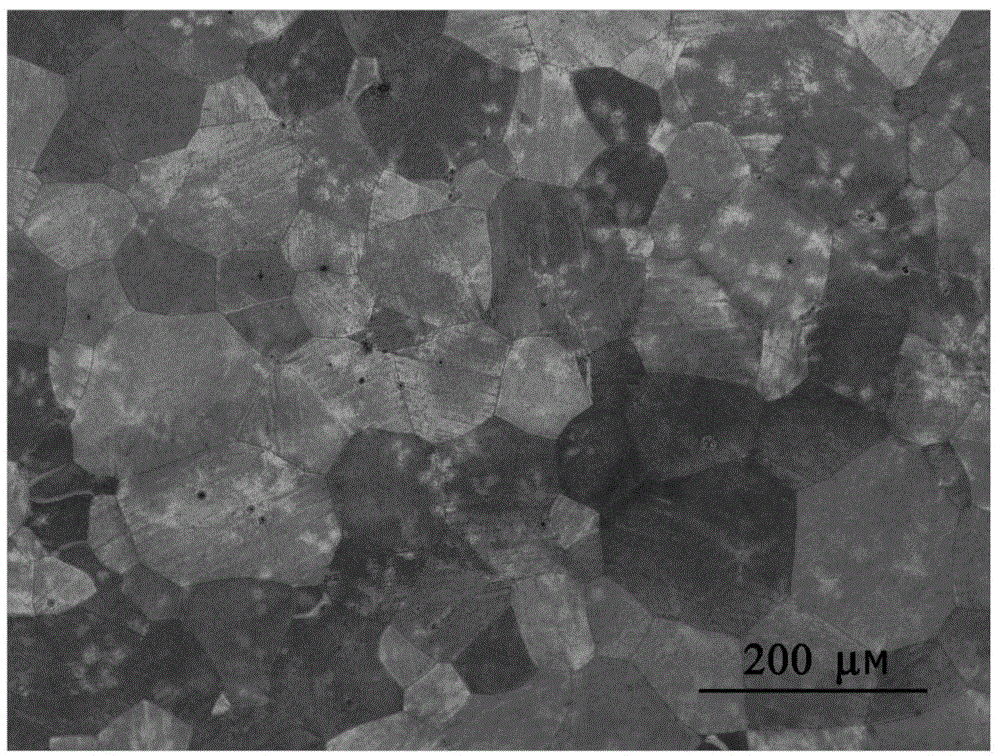

A high-strength cast RE-contained Mg-alloy contains Nd (2.5-3.6 Wt%), Zr (0.35-0.8), Zn (0-0.4), Ca (0-0.5), impurities (0-0.02) and Mg (rest). It is prepared through smelting Mg, adding Nd, Zr and Ca in Mg-Nd, Mg-Zr and Mg-Ca alloy mode, adding Zn, solution treating at 525-540 deg.C for 4-12 hr, quenching in water and ageing at 200 deg.C for 12-20 hr. It has high strength, hardness and high-temp creep performance.

Owner:SHANGHAI JIAO TONG UNIV

Light-weight and high-strength cast aluminum lithium alloy and preparation method thereof

The invention discloses a light-weight and high-strength cast aluminum lithium alloy and a preparation method thereof. The alloy consists of Li, Cu, Mg, Zn, Zr, Ti, Mn, Ce and impurity elements in specific percentages by weight as well as the balance of Al. During preparation, an aluminum alloy is obtained by smelting Al-Li, Al-Cu, Al-Zr, Al-Ti-B, Al-Mn, Al-Ce intermediate alloy, pure aluminum, pure Zn and Pure Mg, and then is subjected to two-stage solid solution heat treatment of 400-450 DEG C / 8-10h and 510-540 DEG C / 20-28h, and one-stage aging treatment of (120-190) DEG C* (30-48) h is carried out after hardening treatment to obtain the light-weight and high-strength cast aluminum lithium alloy. The mechanical properties such as room temperature strength, hardness, rigidity and breaking tenacity of the prepared aluminum lithium alloy are superior to those of a traditional business aluminum alloy, and the aluminum lithium alloy is also low in cost.

Owner:SHANGHAI JIAO TONG UNIV

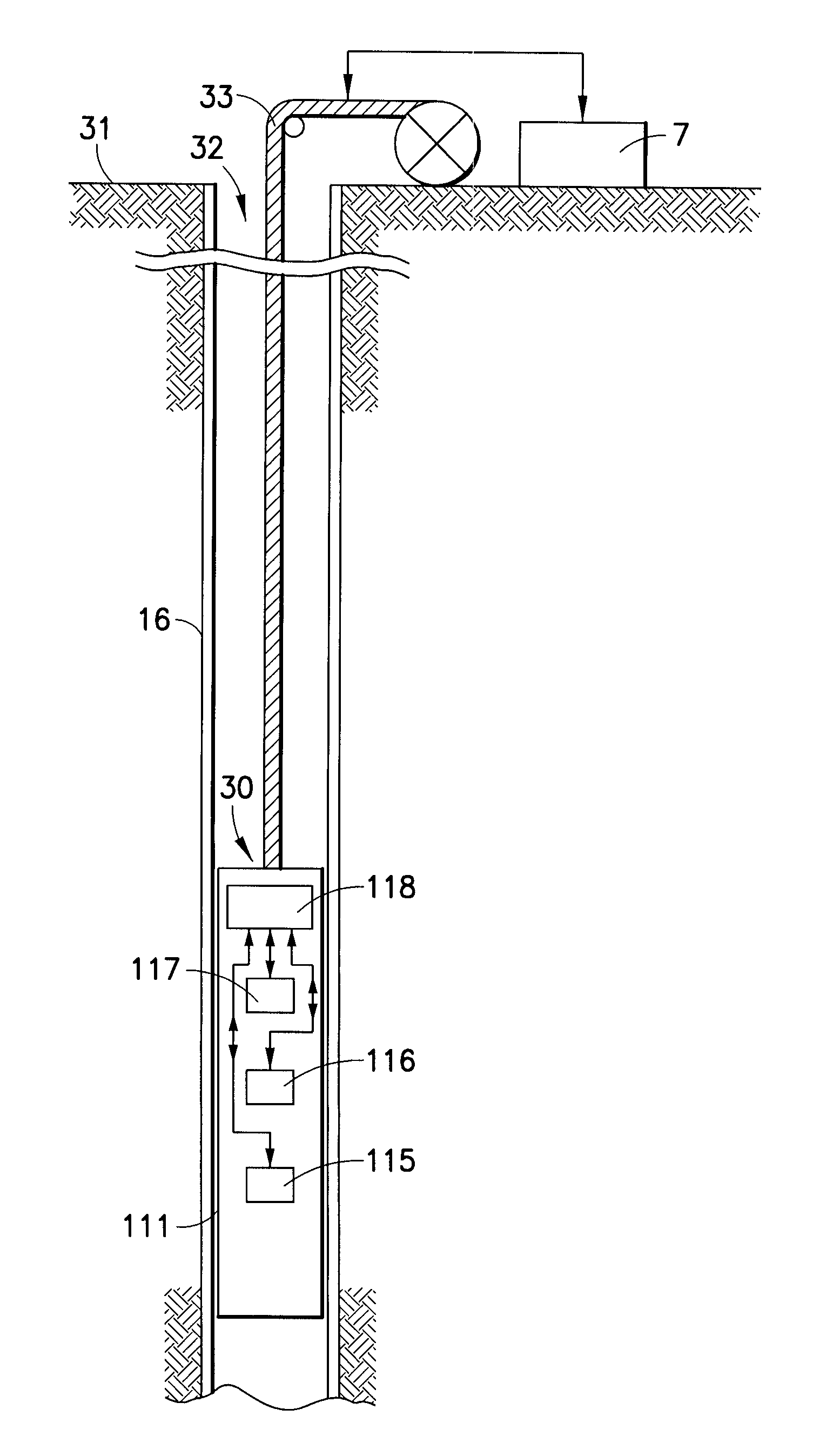

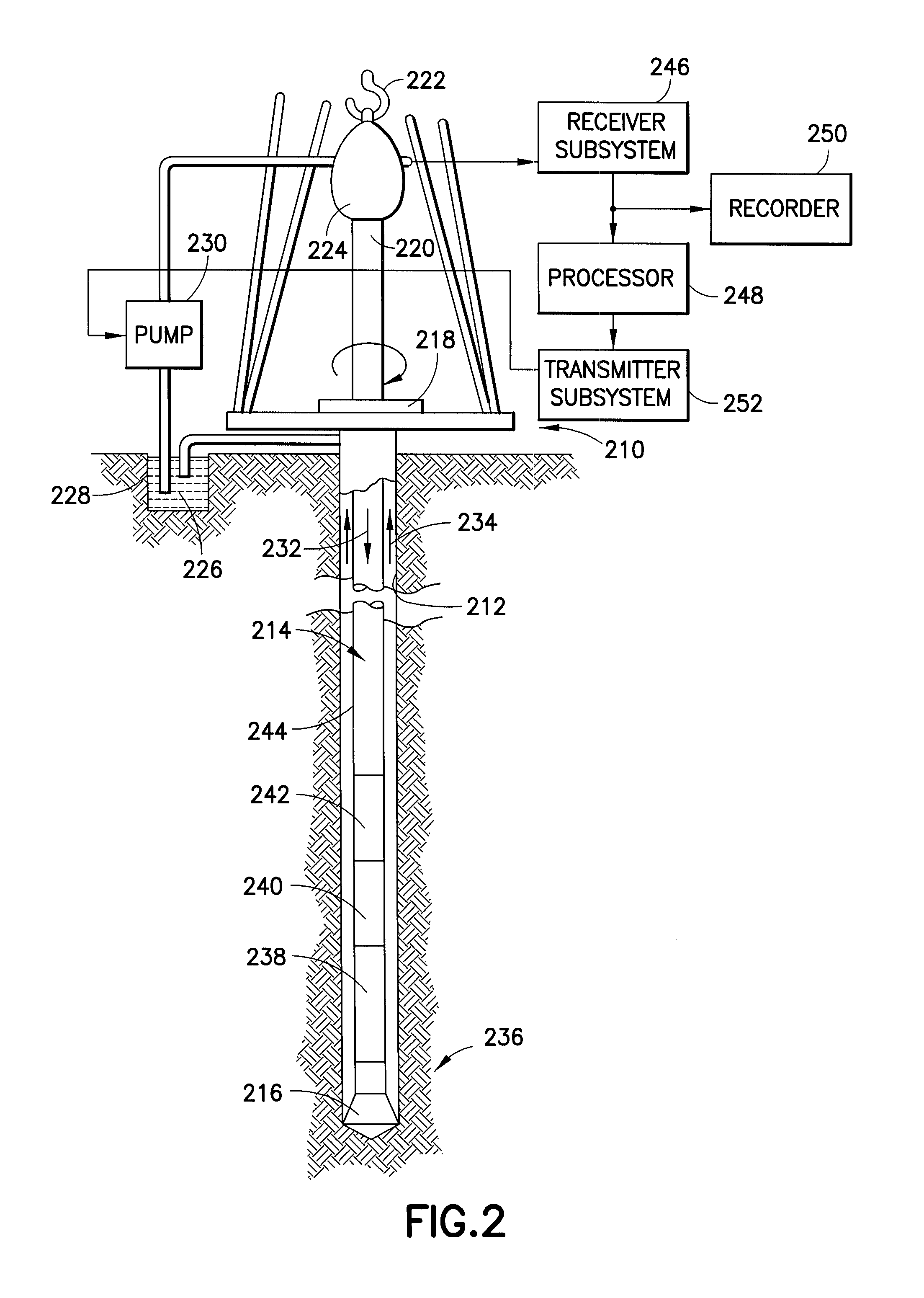

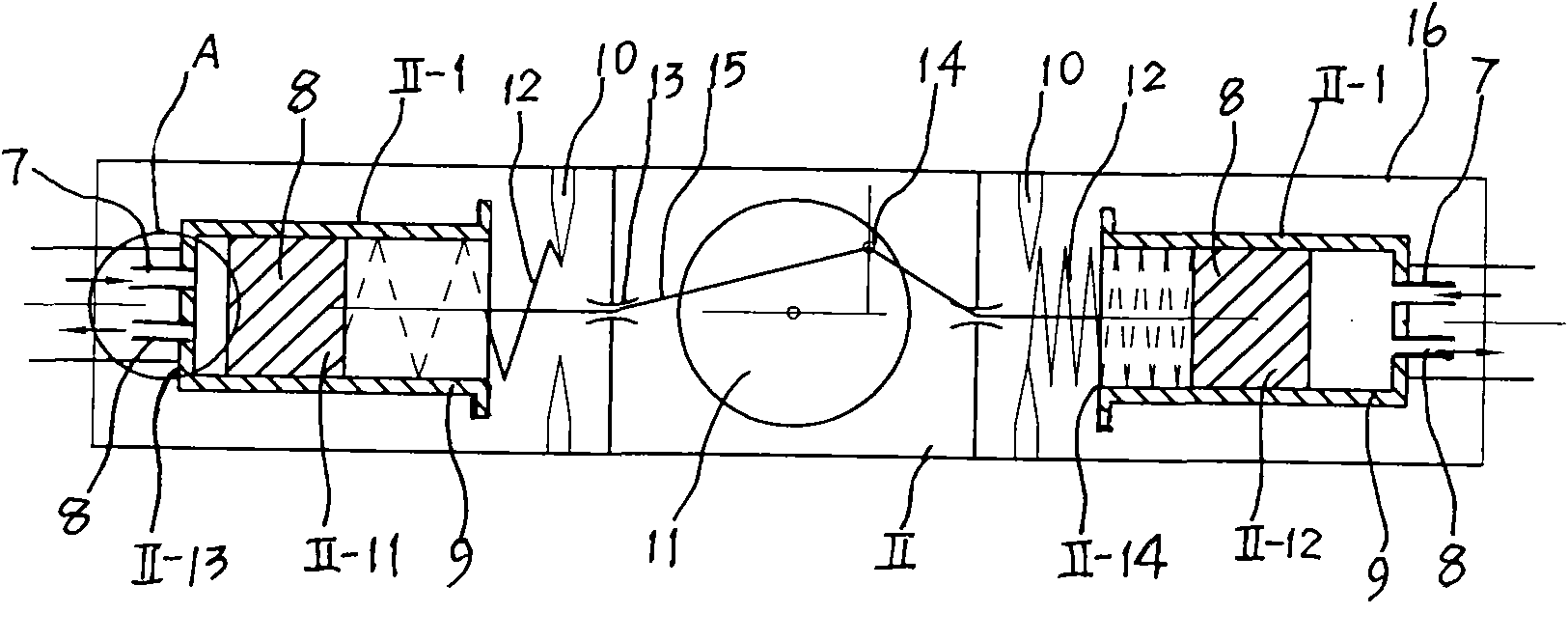

Well logging method for determining formation characteristics using pulsed neutron capture measurements

ActiveUS7408150B1Repeatable smooth behaviorPoorly repeatable resultNuclear radiation detectionFrequency spectrumNeutron capture

A method for determining thermal capture cross-sections of formations surrounding an earth borehole, including the following steps: providing a logging device that is moveable through the borehole; transmitting, from the logging device, bursts of neutrons into the formations; detecting, at the logging device, resultant gamma ray counts, and deriving a measurement spectrum from the gamma ray counts; deriving a forward model comprising a combination of model exponential components having respective model decay times and model amplitudes; deriving an error function that depends on comparison between the forward model and the measurement spectrum; and determining, by regularized inversion, optimized exponential components of the model that substantially minimize the error function; the optimized exponential components being indicative of the thermal capture cross-sections of the formations.

Owner:SCHLUMBERGER TECH CORP

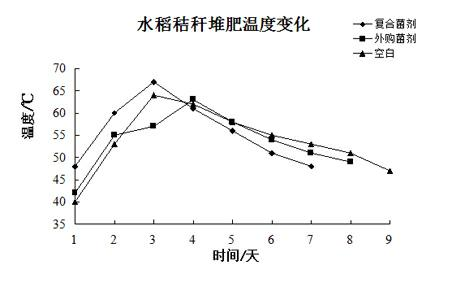

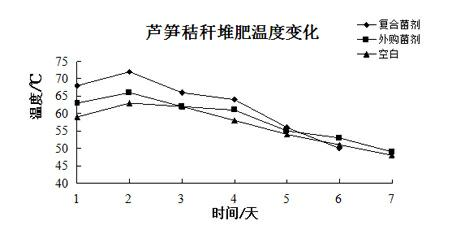

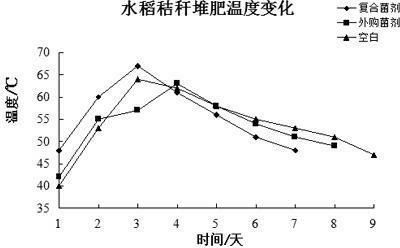

Efficient straw degrading composite fungicide and organic fertilizer preparing method thereof

ActiveCN102676492AFully degradedIncrease productivityBio-organic fraction processingMicroorganism based processesInsect pestFermentation

The invention relates to an efficient straw degrading composite fungicide (JFB-1) and an organic fertilizer preparing method thereof. The composite fungicide comprises composite bacteria and a carrier, wherein the carrier is wheat bran, and the composite bacteria include composite bacteria I, composite bacteria II, composite bacteria III and auxiliary bacteria. The composite bacteria I, II and III account for 1-1.5% of the weight of straws, wherein the composite bacteria I account for 20-25%, the composite bacteria II account for 45-50%, the composite bacteria III account for 30-35%, and the composite bacteria are added uniformly in compost fermentation so as to effectively improve the maturation speed and the quality of an organic fertilizer. The fungicide is fully mixed with straws of rice, asparagus and other crops to carry out compost fermentation, the straws can be degraded rapidly through the synergistic effect of the bacteria, the degradation efficiency is improved, the degradation time is shortened, and insect pests are effectively killed and are rapidly transformed into the organic fertilizer for improving soil. The efficient straw degrading composite fungicide can be used for effectively solving the problem of land occupation caused by landfill, or the problems of fire, traffic dangers, environment pollution and the like caused by burning.

Owner:SHANGHAI JIAO TONG UNIV

Polyamide-imide copolymer film and method of preparing polyamide-imide copolymer

ActiveUS20140243482A1Improve mechanical propertiesExcellent optical propertiesNon-linear opticsPolymer sciencePolyamide-imide

Disclosed herein is a polyamide-imide copolymer film, comprising a copolymer resin in which a unit structure derived from TFDB (2,2′-bistrifluoromethyl-4,4′-biphenyl diamine), a unit structure derived from 6FDA (4,4′-(hexa-fluoroisopropylidene)diphthalic anhydride), a unit structure derived from BPDA (3,3′,4,4′-biphenyltetracarboxylic dianhydride) and a unit structure derived from TPC (terephthaloyl chloride or 1,4-benzenedicarbonyl chloride) are copolymerized, wherein the copolymer resin has a weight average molecular weight of 10,000˜400,000.

Owner:KOLON IND INC

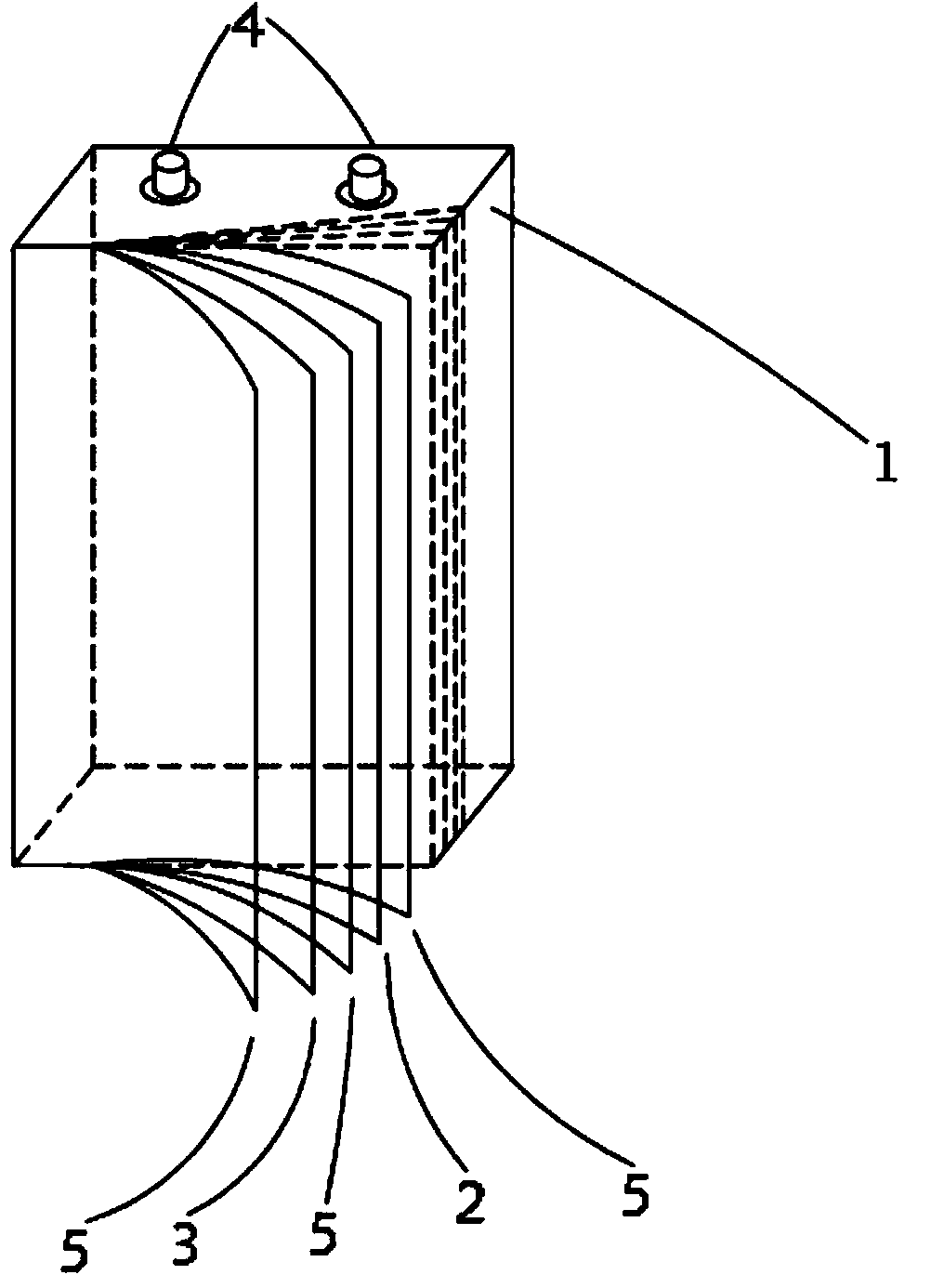

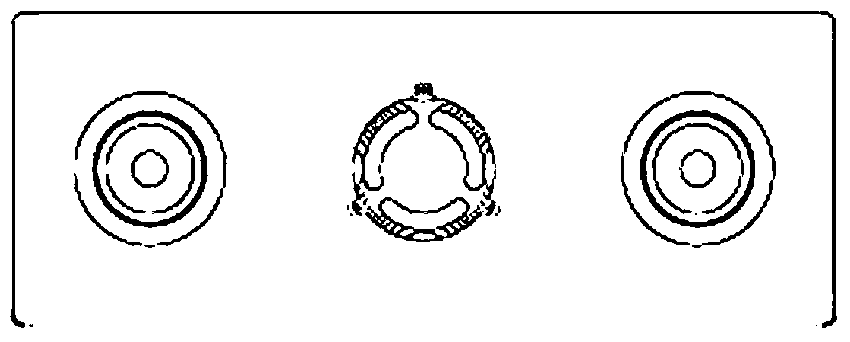

Low-temperature lithium iron phosphate lithium-ion power battery

InactiveCN103715452AImprove electronic conductivityIncrease migration rateCell electrodesSecondary cellsPower batteryLithium iron phosphate

The invention provides a low-temperature lithium iron phosphate lithium-ion power battery. The low-temperature lithium iron phosphate lithium-ion power battery comprises a positive plate, a negative plate, a membrane, electrolyte, a shell, a cover plate and a post terminal, wherein positive materials in the positive plate comprise a positive active material, a binding agent and a conductive agent, the positive active material is lithium iron phosphate which is subjected to nanocrystallization and is coated with a discontinuous graphene structure, the median diameter of the nanocrystallization lithium iron phosphate is 5-10nm, the graphene is 3-8 layers of multilayer graphene, and the coating area accounts for 40%-70% of the total surface area of the lithium iron phosphate material. The low-temperature lithium iron phosphate lithium-ion power battery has the advantages that the problem that the lithium iron phosphate lithium-ion power battery has poor low-temperature property is solved, the low-temperature lithium iron phosphate lithium-ion power battery has relatively excellent low-temperature property under the condition that other performance indexes are not lowered, the application range of the lithium iron phosphate lithium-ion power battery is greatly expanded, and the lithium iron phosphate lithium-ion power battery facilitates the popularization of electric cars in low-temperature areas and the normal use of the electric cars in cold winter.

Owner:SHANDONG WINA GREEN POWER TECH

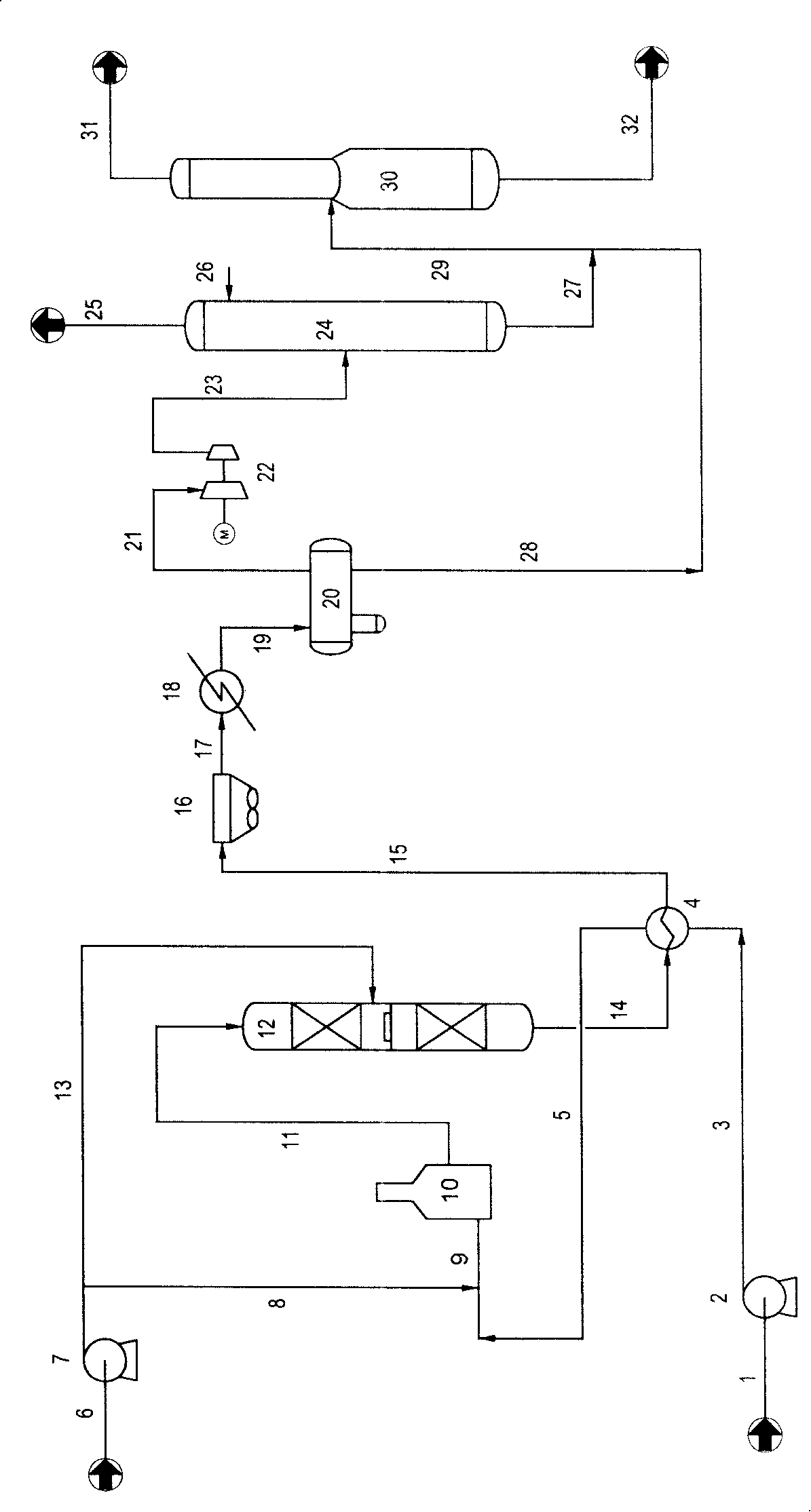

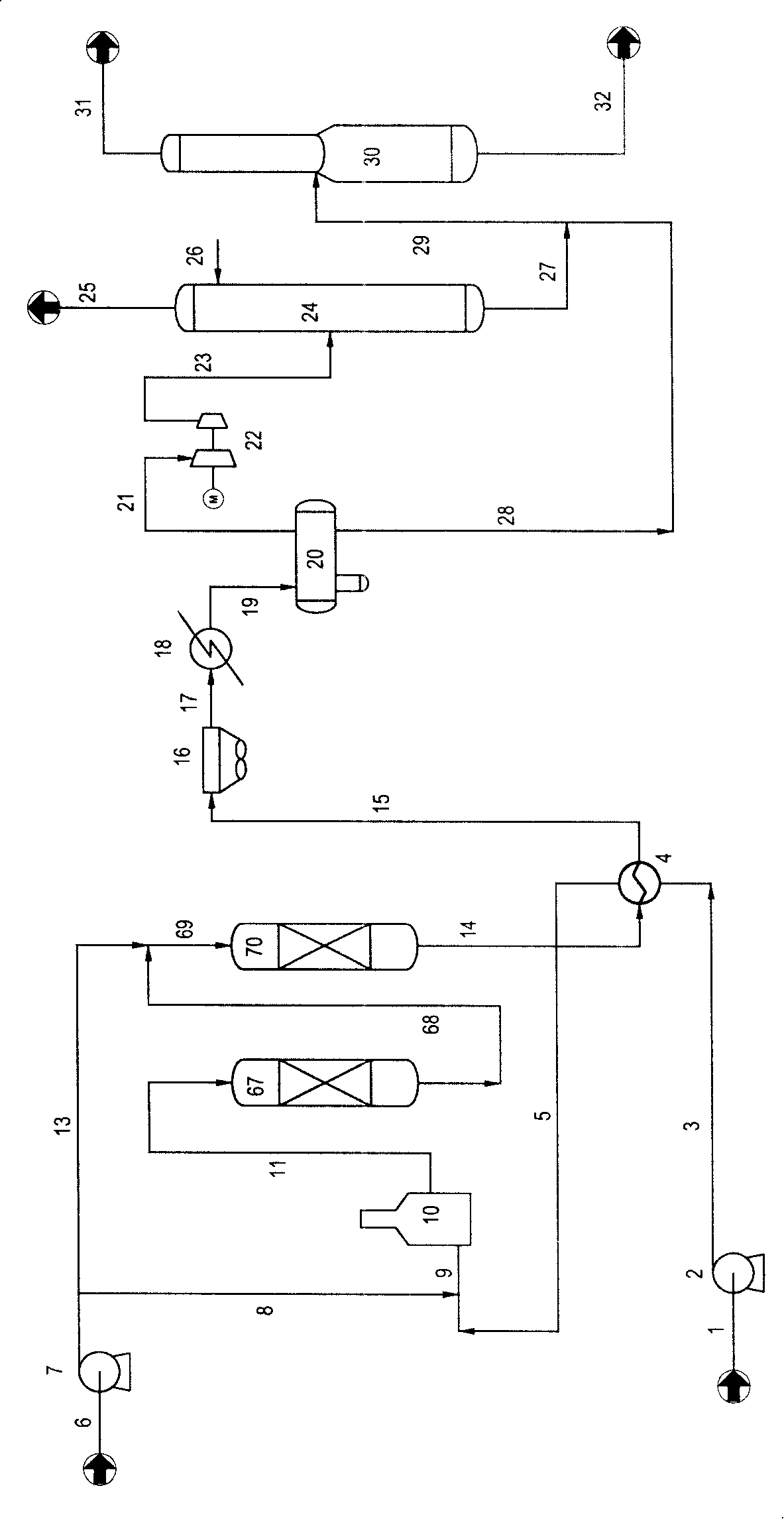

Catalyst continuous reproducible low octane rating gasoline modifying method

The invention discloses a catalyst continuous regeneration low-octane gasoline upgrading method. The low-octane gasoline raw material and the light hydrocarbon raw material are mixed, then enter into a gasoline upgrading reactor, contact and react with the upgrading catalyst in the reactor, the reactant is separated to obtain dry gas, liquefied gas and upgrading gasoline products; the deactivated catalyst in the reaction system is lifted and conveyed to a regeneration system, contacts with the regeneration gas to be burned in a regenerator, the burned regeneration catalyst is lifted and conveyed to the reaction system. The method greatly improves the octane value of the gasoline, and the olefin content in the upgrading gasoline is very low; the continuous regeneration of the deactivated catalyst ensures that the activity and the selectivity of the catalyst in the reactor are both maintained at higher levels; compared with the conventional reactor switching regeneration way, the dry gas yield of the upgrading reaction is obviously decreased, the upgrading gasoline and the liquefied gas as the target products are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

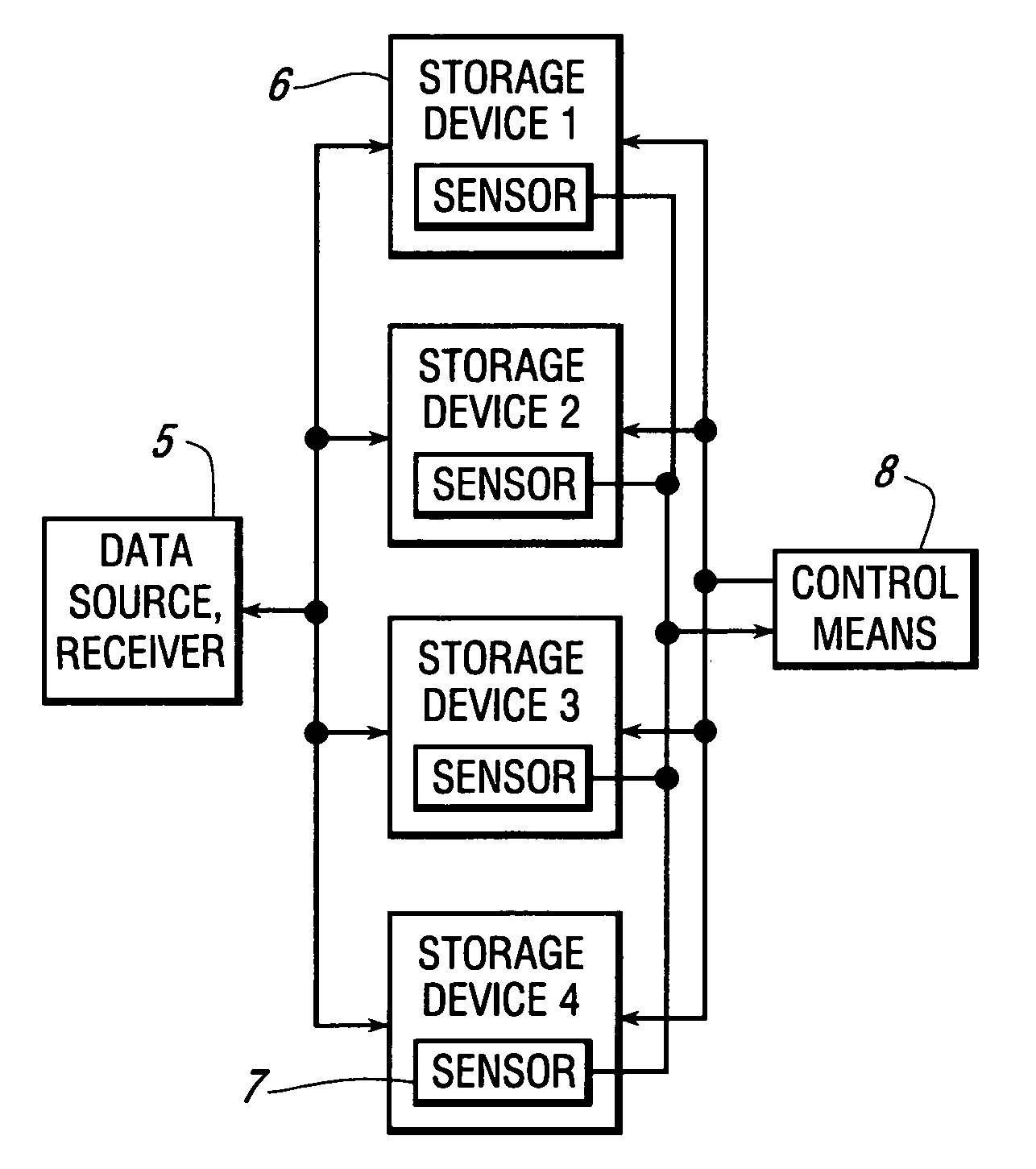

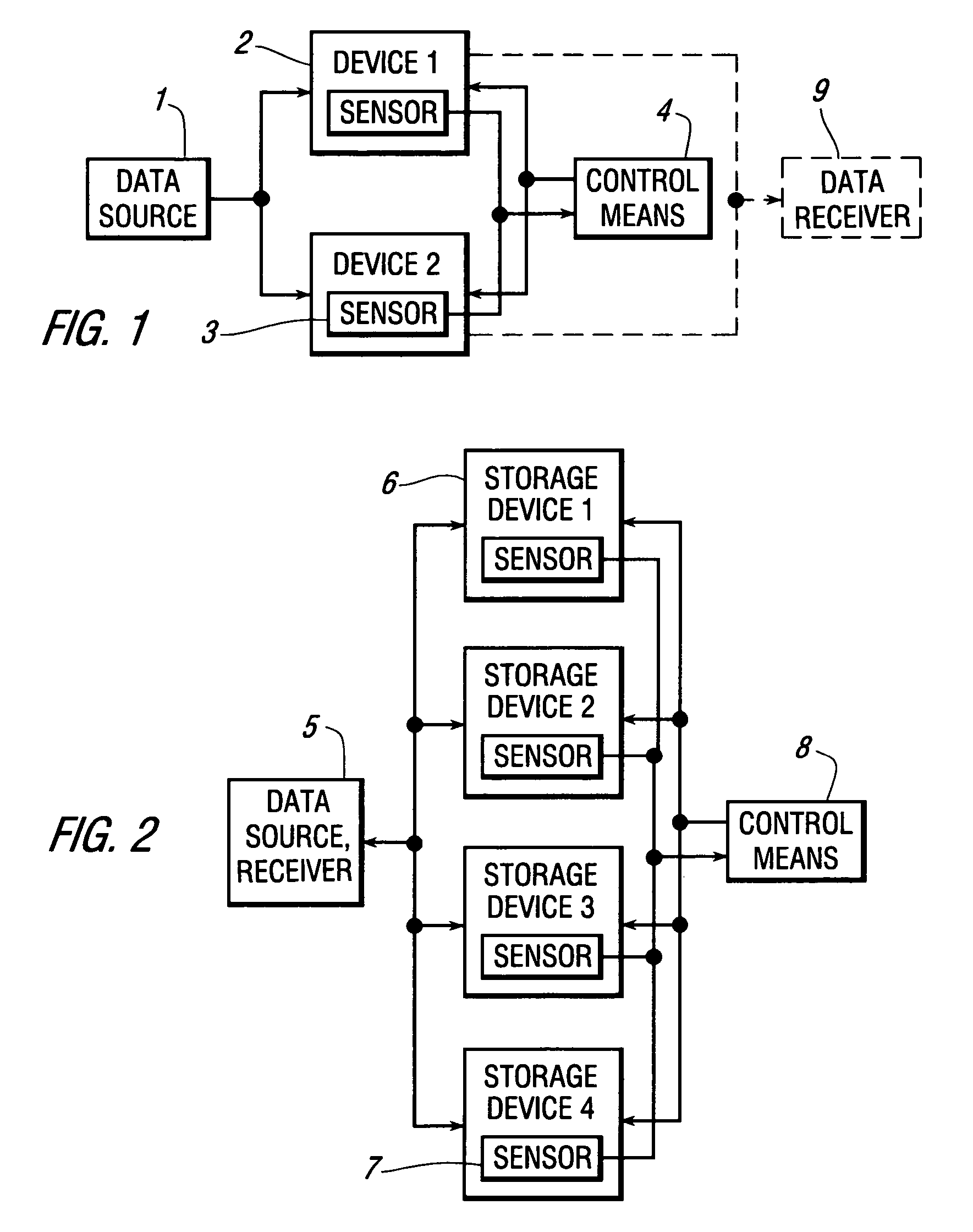

Apparatus and method for achieving thermal management through the allocation of redundant data processing devices

InactiveUS20070011288A1Improve efficiencyIncrease costDigital data processing detailsDigital computer detailsData storeOperating temperature

Data processing devices arranged in a redundant manner, with each of the devices including a thermal sensor measuring its operating temperature, are allocated so that data is processed by the coolest available device. In one form of the invention, the same data is stored in two data storage devices to be retrieved from the device having a cooler operating temperature. When the data is to be stored, it may further be stored in the coolest one of a number of storage devices. In other forms of the invention, the data processing devices are, for example, adapter circuits or computer systems accessed by a server.

Owner:IBM CORP

Operation technology used for maintaining direct motion of large blast furnace through low-heat state strength coke

InactiveCN108359760AImprove responseBreaking the hot state strength must be greater than 60%Blast furnace detailsAir volumeSlag

The invention discloses an operation technology used for maintaining direct motion of a large blast furnace through low-heat state strength coke. Local coal is used, the heat state strength of the coke is 29.8%, the O / C is 4.142, oxygen enrichment is maintained to be 15500+ / -100 m<3> / h, the oxygen enrichment rate is 4.5%-5%, the top temperature is 105+ / -5 DEG C, PT ranges from 1490 DEG C-1510 DEGC, Si ranges from 0.5-0.7, and the fuel ratio ranges from 541 kg / t-557 kg / t. The operation technology comprises the following steps that (1) the coke ratio is reduced, the blowing-in area is adjustedfrom 0.34 m<2> to 0.311 m<2>, and the air speed is 265+ / -5 m / s; (2) according to a charging rule, the air volume is reduced to 4000 Nm<3> / min,and the material speed per batch is 44+ / -1; (3) accordingto a heating rule, the molten iron temperature is 1490 DEG C+ / -10 DEG C; (4) according to a slagging rule, the blast-furnace slag basicity ranges from 1.1-1.5; and (5) according to a tapping deslagging rule, the iron notch depth is 3600 mm-3800 mm, the mud ramming quantity is 200 kg-250 kg, and the mud emitting rate is smaller than 1%. According to the new technology, the large blast furnace completely uses the low-heat state strength coke, by increasing oxygen enrichment and decreasing the air quantity, the coal gas component is improved, the bosh coal gas quantity is decreased, the blast furnace pressure difference is reduced, the air feeding rule, the charging rule, the heat rule and the slagging rule are adjusted, the direct motion of the furnace condition is maintained, a foothold iskept at the local coal resource, and the competitive power is improved.

Owner:XINJIANG BAYI IRON & STEEL

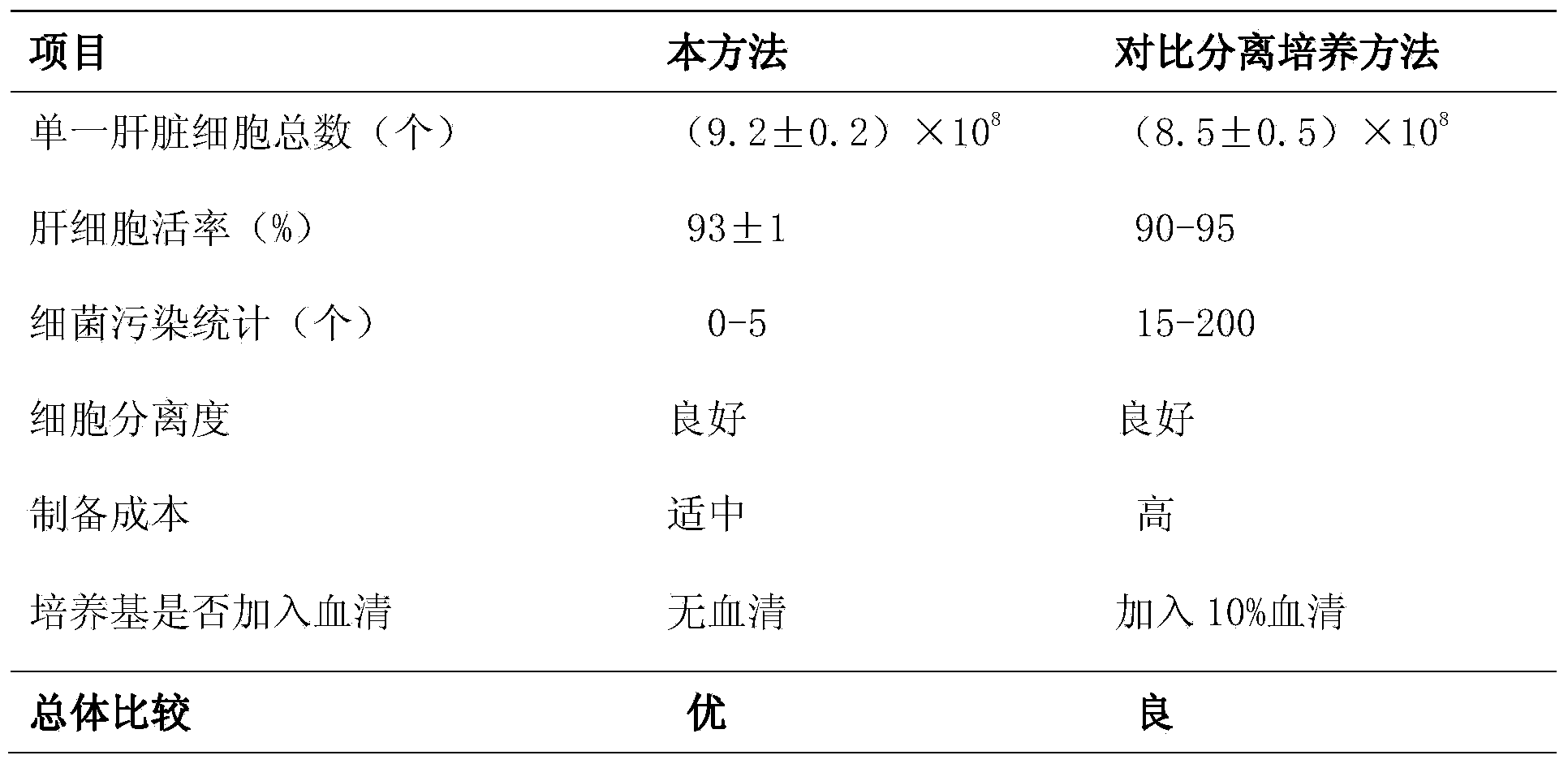

Method for separating and culturing primary chicken hepatocytes

InactiveCN103525756AExtend incubation timeWell differentiatedArtificial cell constructsVertebrate cellsBioproductsEthylene Glycol Tetraacetic Acid

The invention discloses a method for separating and culturing primary chicken hepatocytes. According to the method, EGTA (Ethylene Glycol Tetraacetic Acid) with low hepatotoxicity is added into a perfusate A to loosen the junction between hepatocytes, so that the dispersion degree of the to-be-separated hepatocytes is increased; double resistance is added into the perfusate A, a perfusate B and D-Hanks flushing fluid, so that the pollution is further prevented; and circulating perfusion digestion is adopted during digestion perfusion, so that the perfusion cost is greatly reduced. A serum-free cultural method of the chicken hepatocytes is established; compared with a traditional serum cultural method, the method disclosed by the invention has the same effect on the aspects of cell quantity, activity, function and the like, so that the problems caused by the existence of serum are solved and a foundation is laid for the substance metabolism study and biological product preparation on the basis of the chicken hepatocyte culture.

Owner:NANJING AGRICULTURAL UNIVERSITY

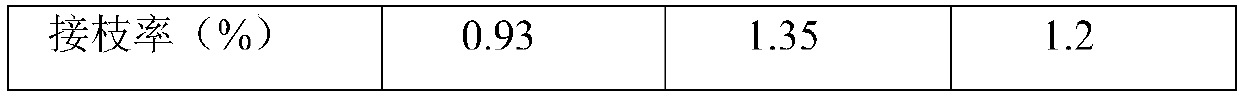

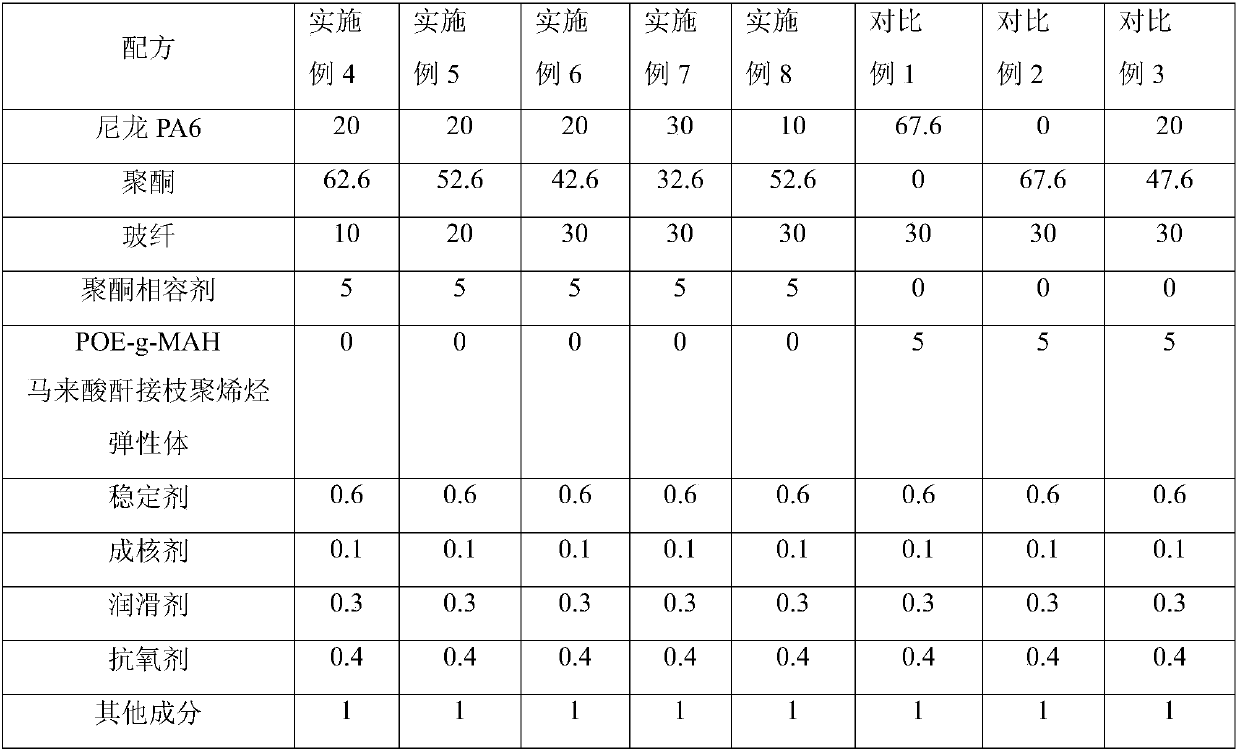

Nylon/polyketone alloy material and preparation method thereof

InactiveCN107652658AImprove thermal stabilityGood compatibility and dispersionGlass fiberAntioxidant

The invention discloses a nylon / polyketone alloy material and a preparation method thereof. The nylon / polyketone alloy material comprises, by weight, 10-50 parts of nylon resin, 40-80 parts of polyketone resin, 10-30 parts of glass fibers, 0.1-0.2 part of initiator, 1-3 parts of maleic anhydride, 2-6 parts of comonomer, 0.2-1 part of antioxidant, 0.2-0.8 part of stabilizer, 0.3-0.6 part of lubricant and 0.1-0.5 part of nucleating agent. The nylon / polyketone alloy material improves the performance of nylon materials and thermal stability of polyketone materials, can substitute for glass fiber reinforced nylon, reinforced PPS and POM and is applied to extremely harsh environments.

Owner:安徽科高新材料有限公司

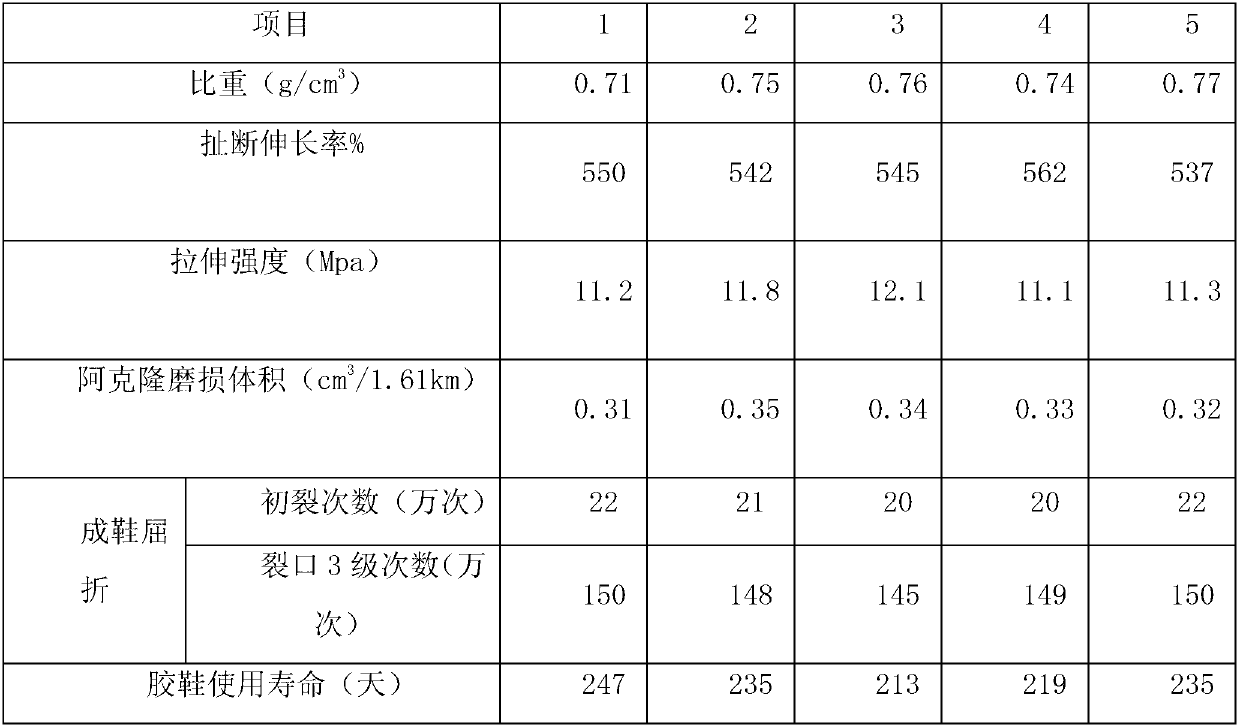

Light anti-slipping high-wear-resistance rubber material for sole and preparation method thereof

The invention relates to a rubber composite material and particularly relates to a light anti-slipping high-wear-resistance rubber material for a sole and a preparation method thereof. The light anti-slipping high-wear-resistance rubber material for the sole is prepared from the following raw materials in parts by weight: 55-75 parts of EVA (Ethylene Vinyl Acetate), 8-25 parts of NR (Natural Rubber), 8-25 parts of SBR (Styrene Butadiene Rubber), 2-6 parts of CaCO3, 2-6 parts of wear-resisting agent, 1-5 parts of ZnO, 1-5 parts of ZnST, 0.5-2.5 parts of ST, 0.5-1.5 parts of DCP (Dibasic Calcium Phosphate) and 1.2-2.5 parts of AC (Azodicarbonamide). Compared with the prior art, the components and the ratios of all raw materials are optimized and the light anti-slipping high-wear-resistance rubber material has the advantages of light weight, anti-slipping performance and wear resistance under the synergistic effect of the components with the ratios. The light anti-slipping high-wear-resistance rubber material is particularly suitable for manufacturing a light and anti-slipping sneaker sole.

Owner:MAOTAI FUJIAN SOLES CO LTD

High-magnesium aluminum alloy state rolling preparation process

ActiveCN109332384ASmall thickness limitSimple production processTemperature control deviceMetal rolling arrangementsHigh magnesiumMechanical property

The invention discloses a high-magnesium aluminum alloy state rolling preparation process, and relates to the technical field of aluminum alloy machining. The process aims to solve the problems that in an existing high-magnesium aluminum alloy machining hardening mode, the thickness and the width of a plate are limited, a stretcher with larger tensile force is needed during the tensile strength, and too many machining procedures are adopted. The process mainly comprises the steps of material proportioning, smelting, casting, soaking, sawing, surface milling, preheating, hot rolling and the like, reasonable selection of alloy components, and casting and smelting parameters is achieved, two-stage uniform heat treatment is adopted, and different hot rolling process parameters and the like areselected according to different Mg contents, so that a high-magnesium aluminum alloy plate material with excellent performance is obtained. According to the high-magnesium aluminum alloy state rolling preparation process, cold rolling is not needed, limitation to the thickness and the width is small, and stretching machining strengthening is not needed so that the production process can be simplified, the cost can be saved, and the production efficiency can be improved; and the performance of the rolled plate can be directly controlled through hot rolling, the plate can be made into hot rolled tissue, the production process is simpler and more efficient, and then the high-magnesium aluminum alloy plate material with good mechanical property and good corrosion resistance is obtained.

Owner:广西南南铝加工有限公司

High-strength martensite PH stainless steel material and preparation method thereof

The invention discloses a high-strength martensite PH stainless steel material, and belongs to the field of martensite stainless steel materials. The high-strength martensite PH stainless steel material is prepared from, by weight, 0.05% of C or less, 12.25%-13.25% of Cr, 7.50%-8.50% of Ni, 2.00%-2.50% of Mo, 0.90%-1.35% of Al and the balance Fe. The invention further discloses a preparation method of the stainless steel material. The components of the material are improved and simpler, a proper amount of Cr, Ni, Mo and Al is added, the novel preparation method is adopted, indoor temperature performance:tensile strength Rm is larger than or equal to 1,560 Mpa, and the yield strength Rp0.2 is larger than or equal to 1,460 Mpa; the transverse tensile elongation A is larger than or equal to 10.0%, the percentage reduction Z of area is larger than or equal to 45.0%, and the impulse test Aku is larger than or equal to 39 J; the longitudinal tensile elongation A is larger than or equal to 10.0%, the percentage reduction Z of area is larger than or equal to 35.0%, and the impulse test Aku is larger than or equal to 23 J; the performance of the martensite PH stainless steel material is obviously improved, and the needs of aerospace materials are met.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

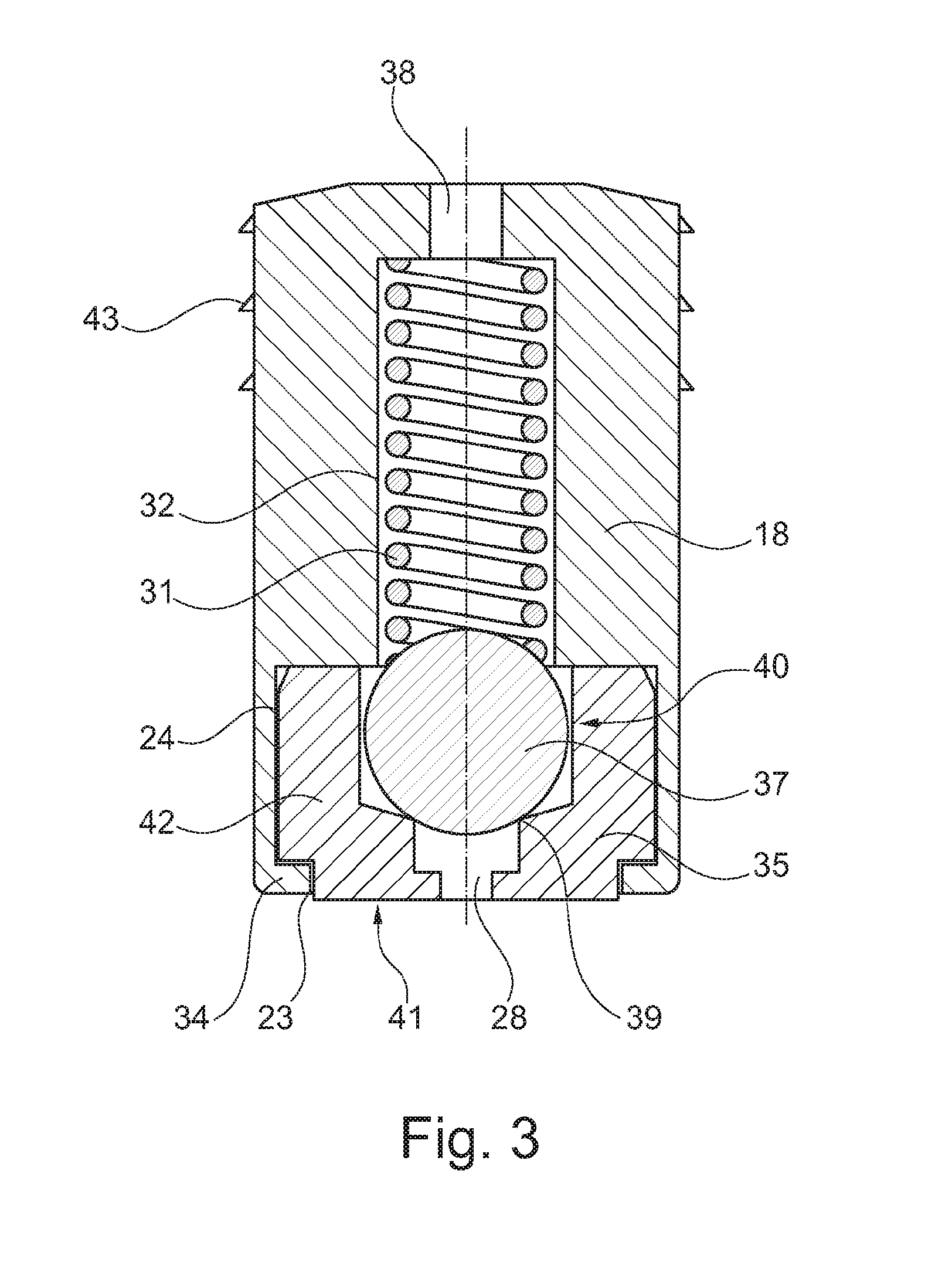

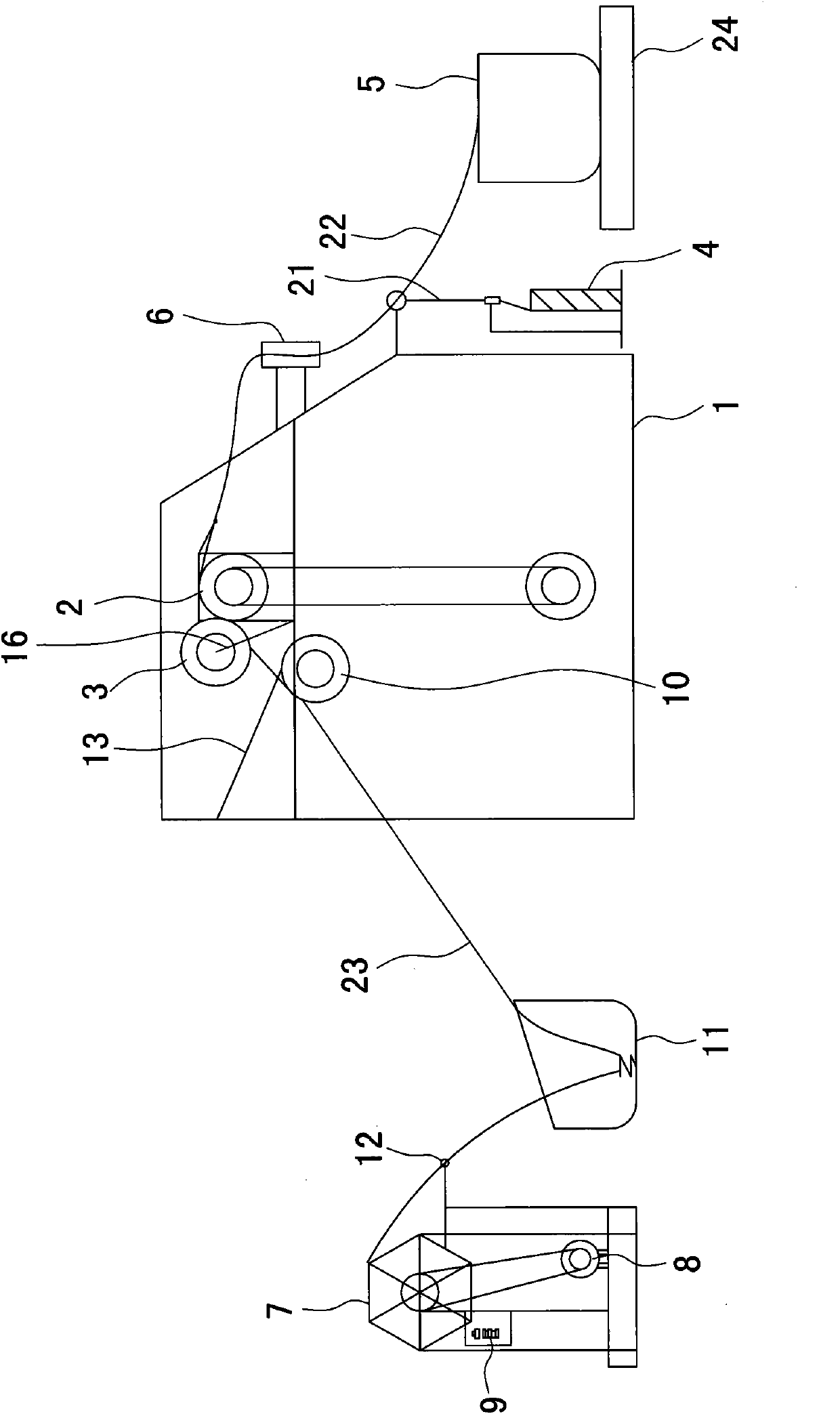

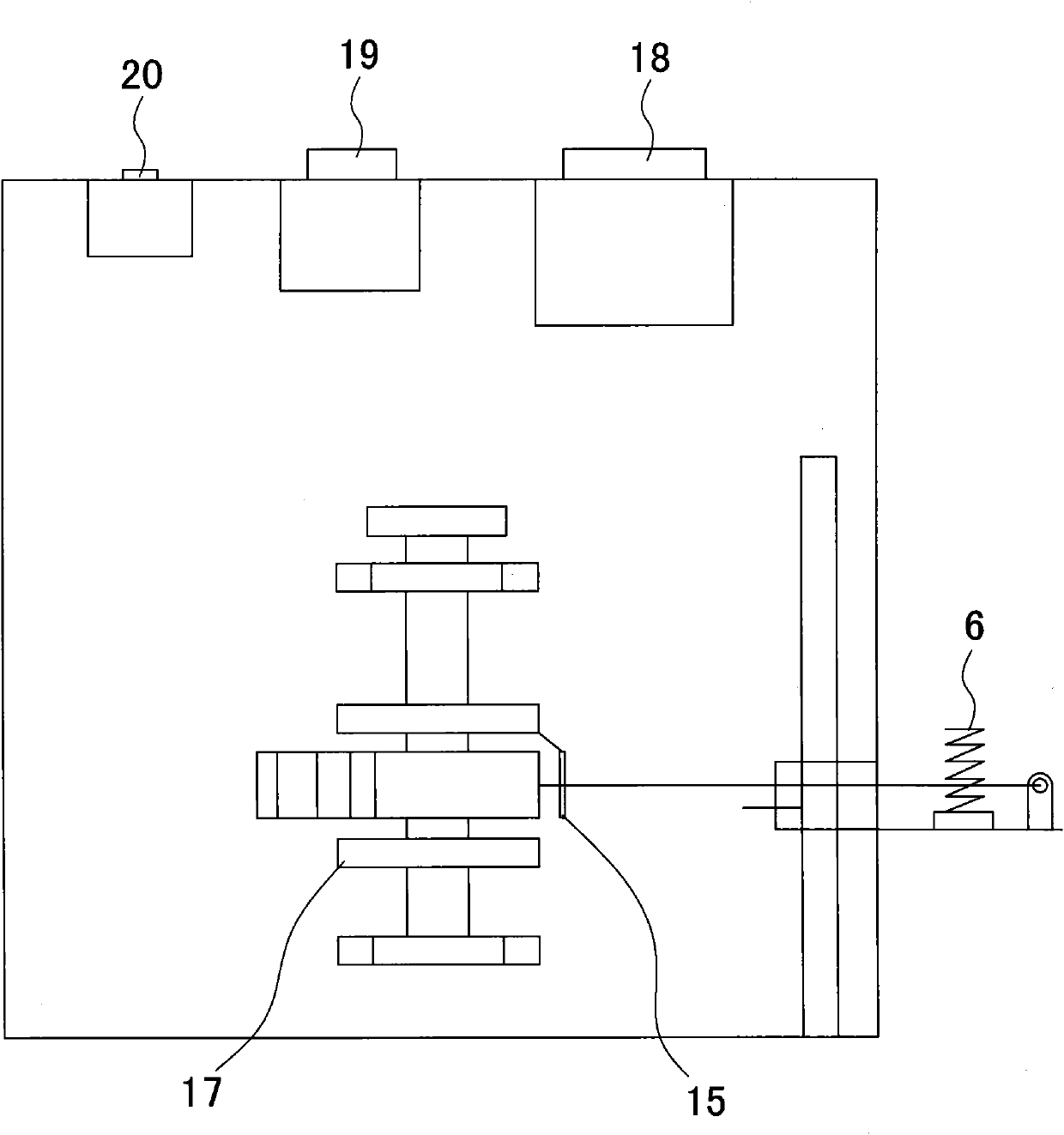

Hydraulic tensioning device for a traction mechanism drive

The invention relates to a hydraulic tensioning device, which is used in traction drives of internal combustion engines and which comprises a piston (19) that is supplied with a hydraulic fluid. The piston is movably guided in a linear manner in a cylinder and is spring-loaded against a traction means. The hydraulic fluid can flow into a pressure chamber (17) via a non-return valve or out of the pressure chamber (17) via a pressure-relief valve (20), depending on an adjustment movement direction of the piston (19). For this purpose, the pressure-relief valve (20) is inserted in a central receiving area (16) of the piston (19) on the pressure-chamber side as a valve group (21) which can be mounted upstream and comprises a pot-shaped valve housing (18) and into which a guide element (25) with a corresponding valve seat (29), a valve element designed as a valve plate (30), and a pressure spring (31) are integrated.

Owner:SCHAEFFLER TECH AG & CO KG

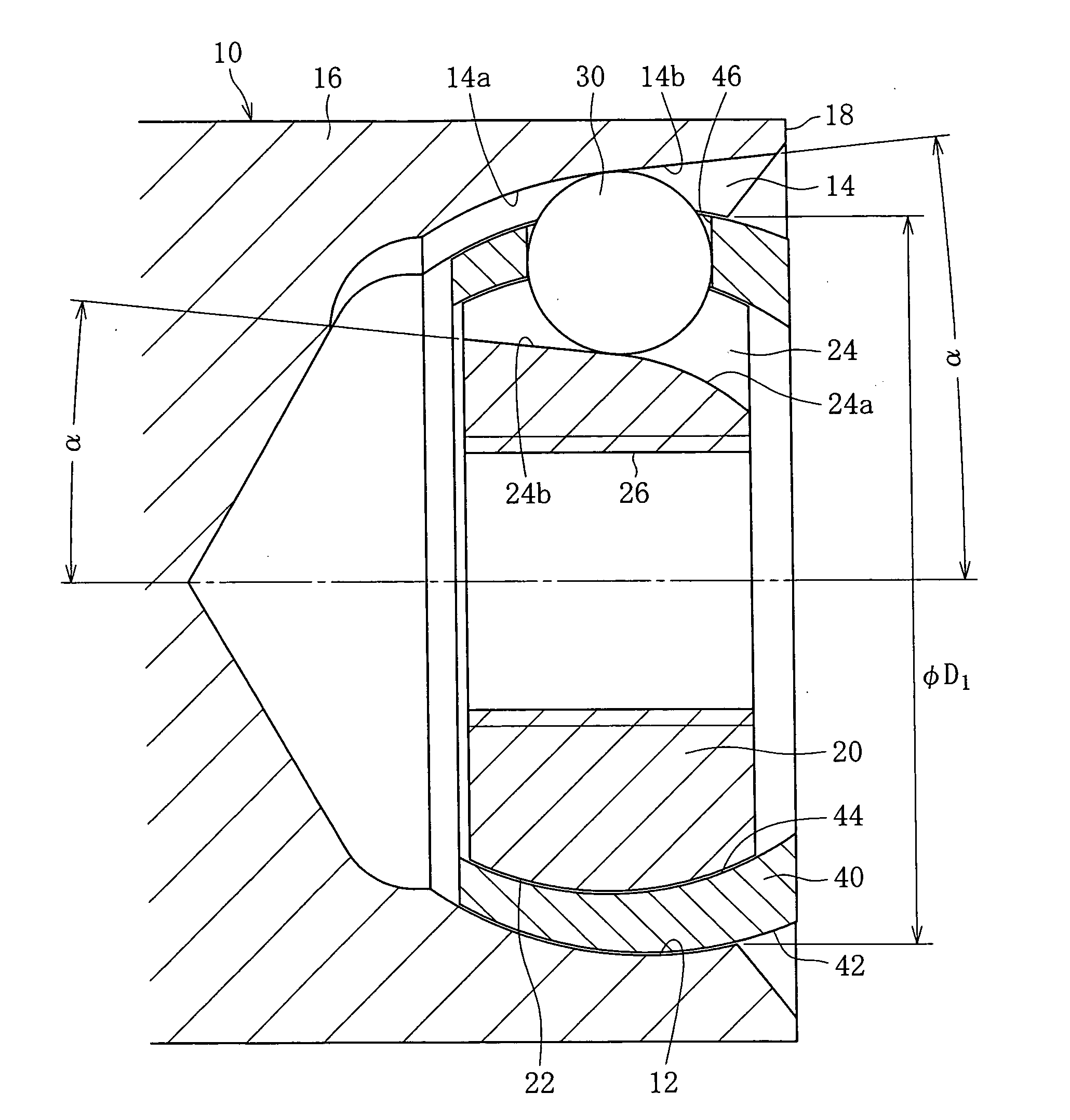

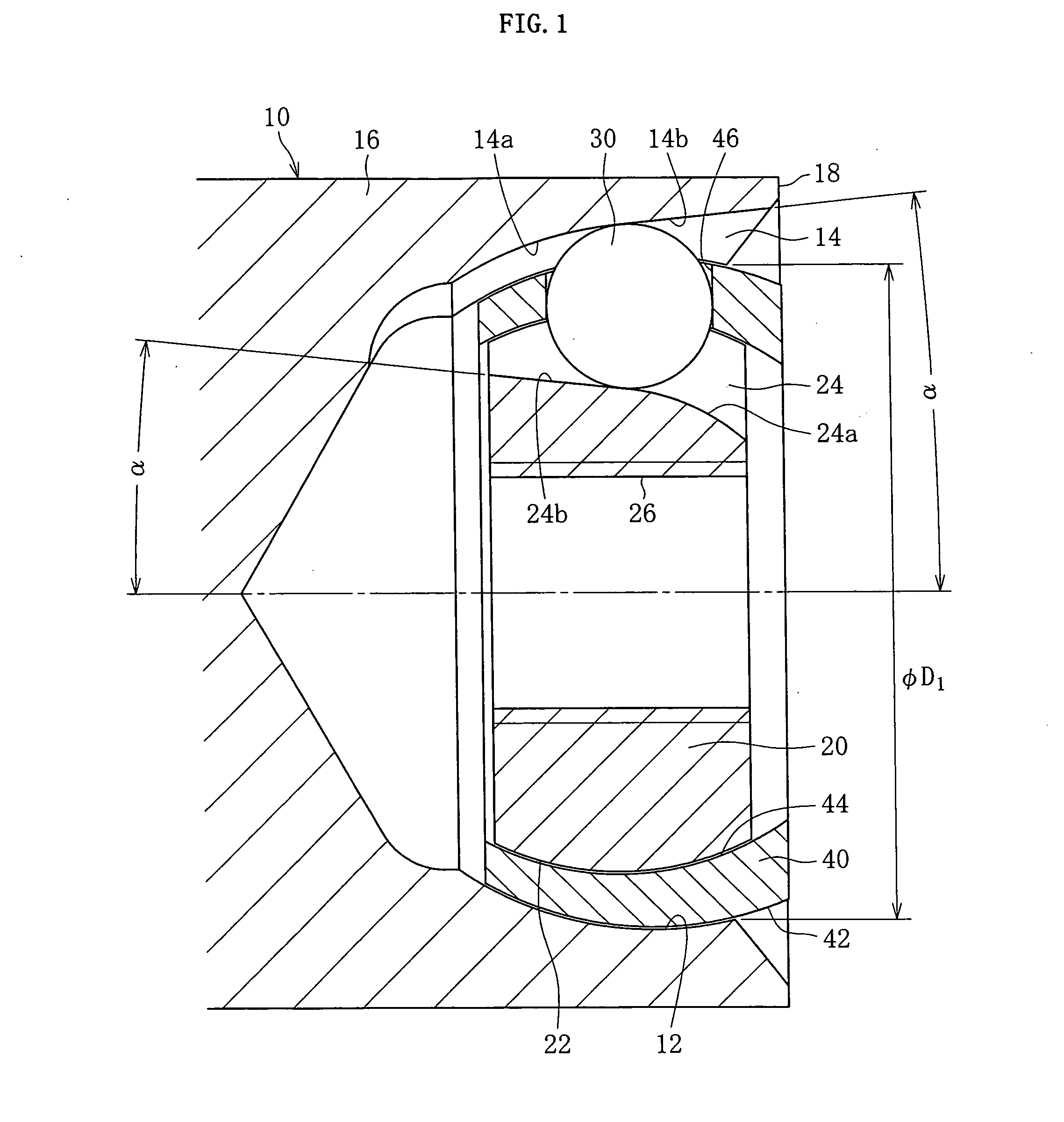

Fixed-type constant-velocity universal joint

ActiveUS20060217207A1Easy to disassembleImprove workabilityYielding couplingRotary machine partsUniversal jointEngineering

Internal dimensions for fixed-type constant velocity universal joints are defined to optimize the geometry of the components of the joints and to readily achieve a larger operating angle of the joints. In the joint, the track grooves of an outer ring and an inner ring are tapered by an angle not exceeding 12°. The ratio (f / PCR) of the cage offset amount f to PCR is greater than 0 and smaller than or equal to 0.12. The ratio (Do / d) of the cage outer diameter (Do) to the ball diameter (d), the ratio (t / d) of the cage wall thickness (t) to the ball diameter (d), and the ratio (w / d) of the cage width (w) to the ball diameter (d) are such that 3.9≦Do / d≦4.1, 0.31≦t / d≦0.34, and 1.8≦w / d≦2.0, respectively. The end of the spherical outer surface of the cage adjacent to the open end is axially extended, and the end of the spherical inner surface of the cage adjacent to the open end is tapered so that the tapered surface has an increasing diameter toward the end of the spherical outer surface adjacent to the open end. Part of the spherical outer surface of the cage is cut on the open end side of pockets, and the outer diameter of the cage across the two opposing planer cut faces is smaller than the spigot diameter of the outer ring.

Owner:NTN CORP

High-strength and high-modulus casting Mg-RE alloy and preparation method thereof

The invention provides a high-strength and high-modulus casting Mg-RE alloy and a preparation method thereof. The Mg-RE alloy comprises 2-4wt% of Nd, 1-3wt% of Li, 0.2-0.6wt% of Zn, 2-4wt% of Al, the balance of Mg and inevitable impurities, wherein the total content of Si, Fe, Cu and Ni in the impurities is smaller than 0.02wt%. The preparation method of the Mg-RE alloy includes the sequential steps of vacuum melting and heat treatment. Compared with the prior art, the preparation method has the advantages that the components of the alloy and the heat treatment process are optimized, the optimized alloy component proportion of the alloy is obtained by studying different component proportions of the alloy elements of Nd, Zn, Li and Al, and therefore compared with an existing alloy, the alloy has the better overall performance of room-temperature strength and elasticity modulus under the component proportion and the heat treatment process.

Owner:SHANGHAI JIAO TONG UNIV

System, method & computer program product

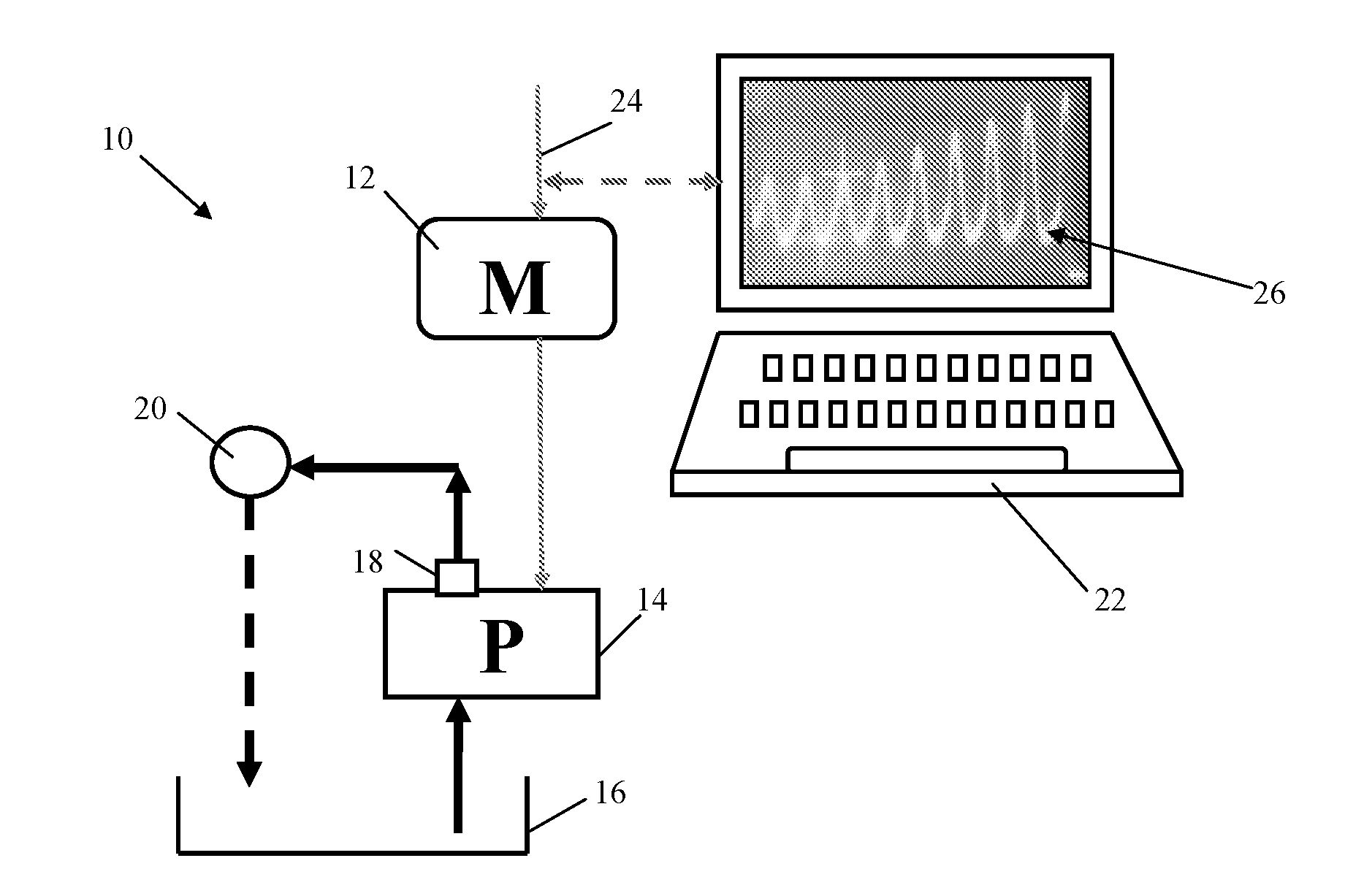

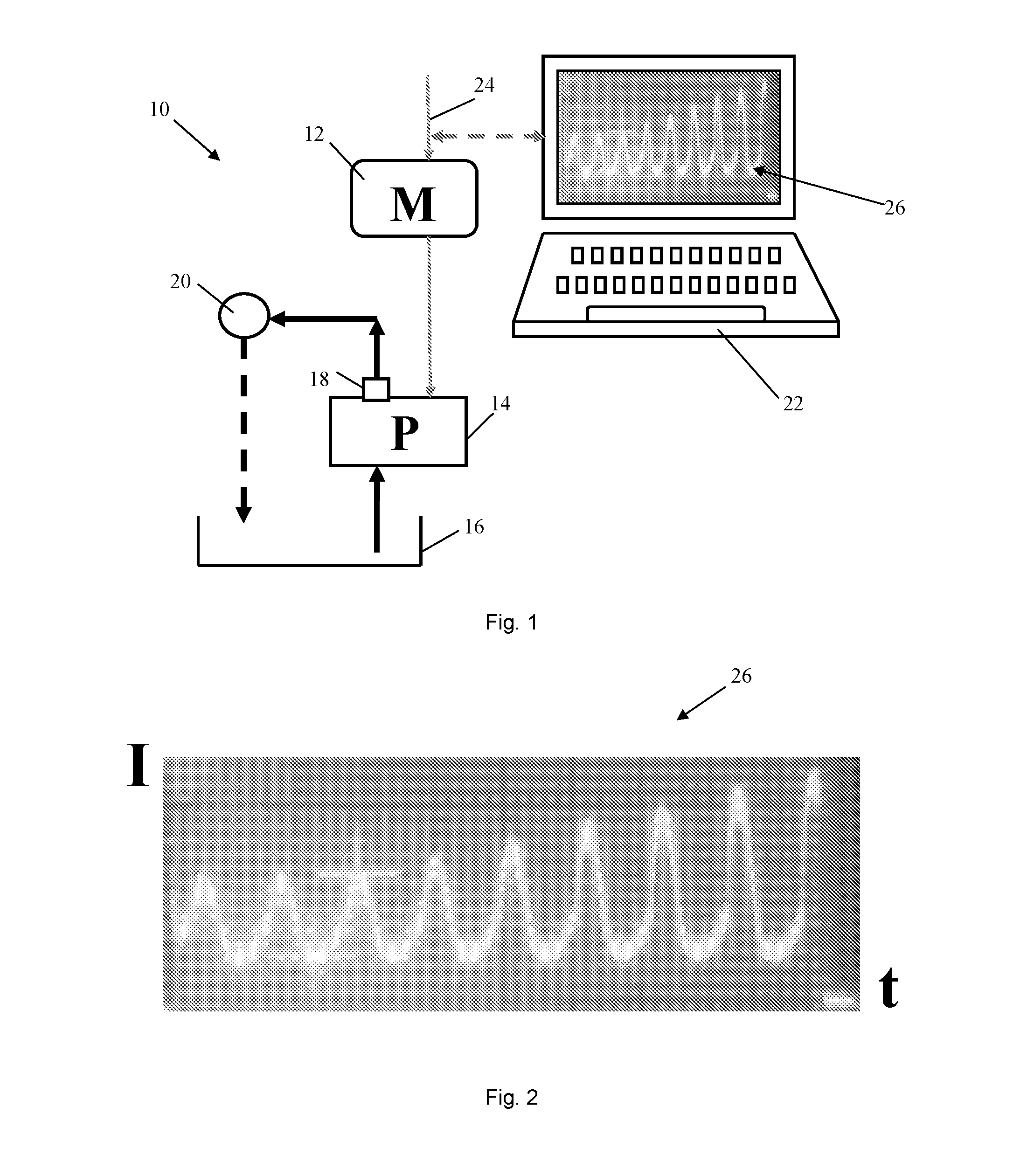

ActiveUS20160208983A1Low costReduce complexityDC motor speed/torque controlLubricating pumpsPower flowEngineering

A lubrication system comprising a motor, a positive displacement pump driven by the motor, a lubricant container in fluid communication with the positive displacement pump and at least one lubricant outlet in fluid communication with the lubricant container. The positive displacement pump is arranged to carry out at least one discharge stroke to dispense lubricant from the at least one lubricant outlet when the lubrication system is in use. The lubrication system also comprises a control unit that is arranged to determine an amount of lubricant that is dispensed from the lubricant container via the at least one lubricant outlet when the lubrication system is in use. The control unit is arranged to monitor current supplied to the motor to obtain a motor current signal, and to determine a number of the discharge strokes from the motor current signal.

Owner:OSAKEYHTIO SKF

Locale vehicle made emulsification blasting agent underwater demolition

The invention relates to a field vehicle-made emulsion explosive suitable for underwater blasting, belonging to a technical field for preparing the emulsion explosive. The emulsion explosive is mainly prepared by applying water-phase materials of ammonium nitrate, sodium nitrate and perchlorate water; oil-phase materials of emulsifier and diesel oil; density modifier of glass or plastic hollow bead; and dry powder of coarse aluminum powder and fine aluminum powder. Compared with traditional emulsion explosive, the field vehicle-made emulsion explosive of the invention has the advantages of high detonation velocity, big power and good water-resistant performance; the emulsion explosive is beneficial to solve the problem that the existing emulsion explosive is unsuitable for underwater blasting; the emulsion explosive has high application value in a large-scale underwater blasting project.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD +1

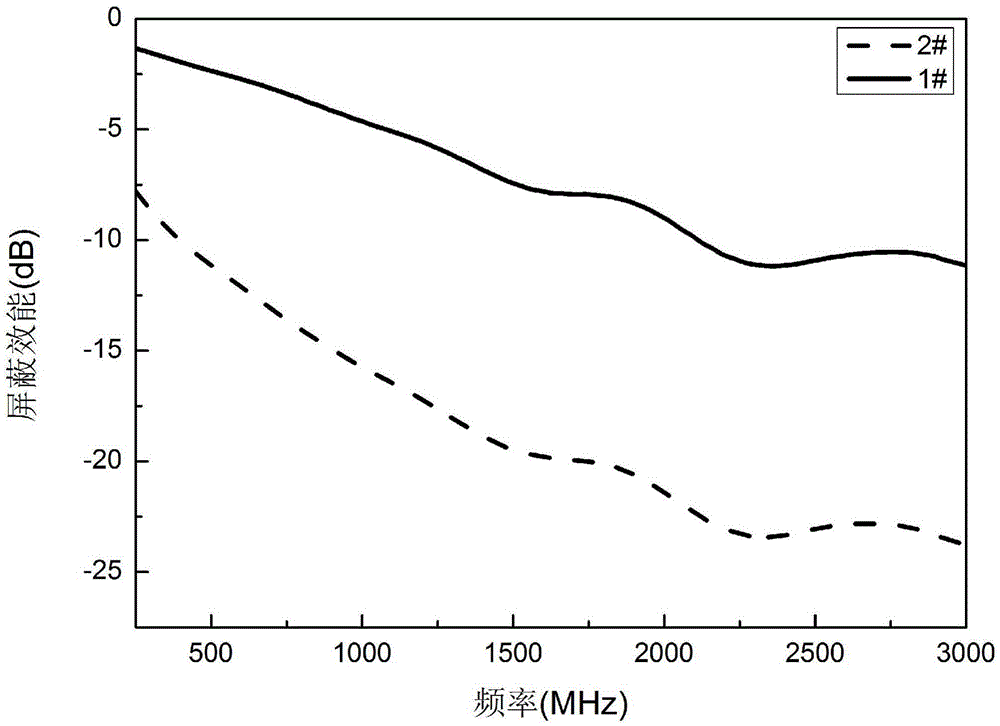

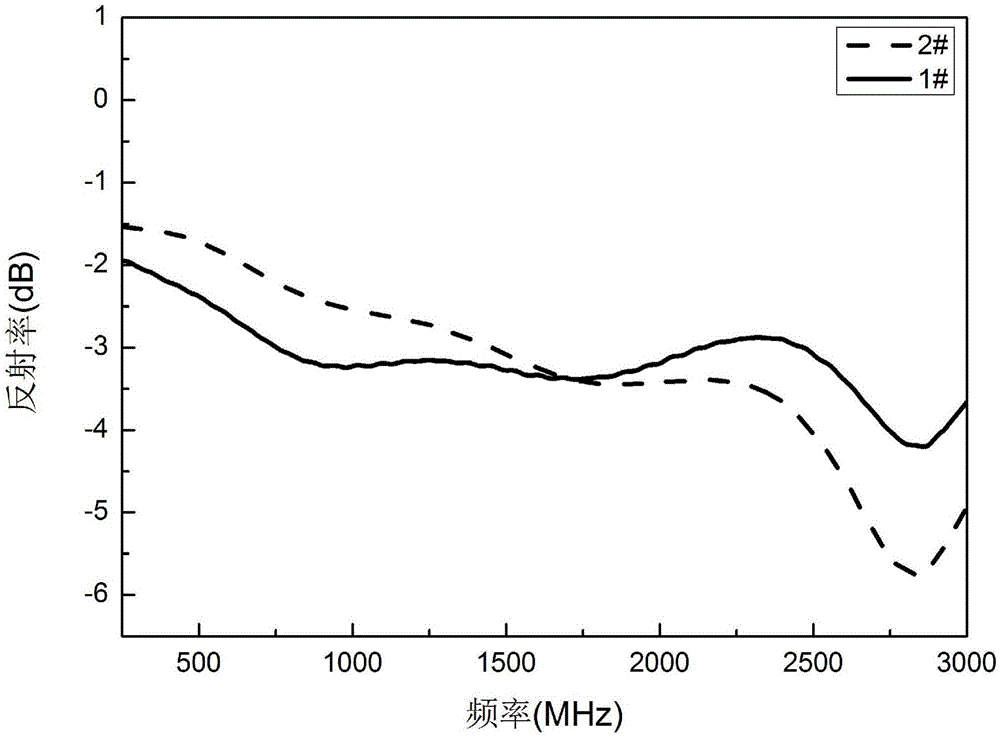

Noise suppression piece and preparation method thereof

ActiveCN105537581APromote absorptionOptimizing componentsTransportation and packagingMetal-working apparatusSolventNoise suppression

The invention discloses a noise suppression piece which comprises the following components in percentage by weight: 35-60 weight percent of flat soft magnetic alloy powder, 5-20 weight percent of a binder and 30-50 weight percent of a solvent. The invention further discloses a preparation method of the noise suppression piece. The noise suppression piece prepared by the method has the characteristics that the electromagnetic performance can be controlled, the noise suppression piece has multiple functions, the magnetic conductivity and the shielding demand can be met, the electromagnetic wave absorption effect can be improved, and the absorption band is broadened.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Tube seedling slow growth conservation method for anoectochilus roxburghii germplasm

InactiveCN109329048ALower culture temperatureReduce light intensityHorticulture methodsPlant tissue cultureEcologyAnoectochilus roxburghii

The invention provides a tube seedling slow growth conservation method for anoectochilus roxburghii germplasm. The method comprises the following steps: S1, material drawing and sterilization of explants; S2, inoculation and induction; S3, subculture multiplication; S4, low-temperature stress treatment of tube seedlings; S5, slow growth conservation of the tube seedlings; S6, rejuvenation of the tube seedlings; S7, rooting of the tube seedlings; S8, transplantation. The method effectively slows the growth speed of the tube seedlings by changing microenvironment conditions for the growth of germplasm materials, prolongs the subculture cycle, ensures that the germplasm preservation time reaches 3 to 4 years, is stable in inheritable character, high in germplasm survival rate and obvious in rejuvenation effect, and has important significance on further protection of the anoectochilus roxburghii resource and research, development and utilization of anoectochilus roxburghii.

Owner:谭兴江

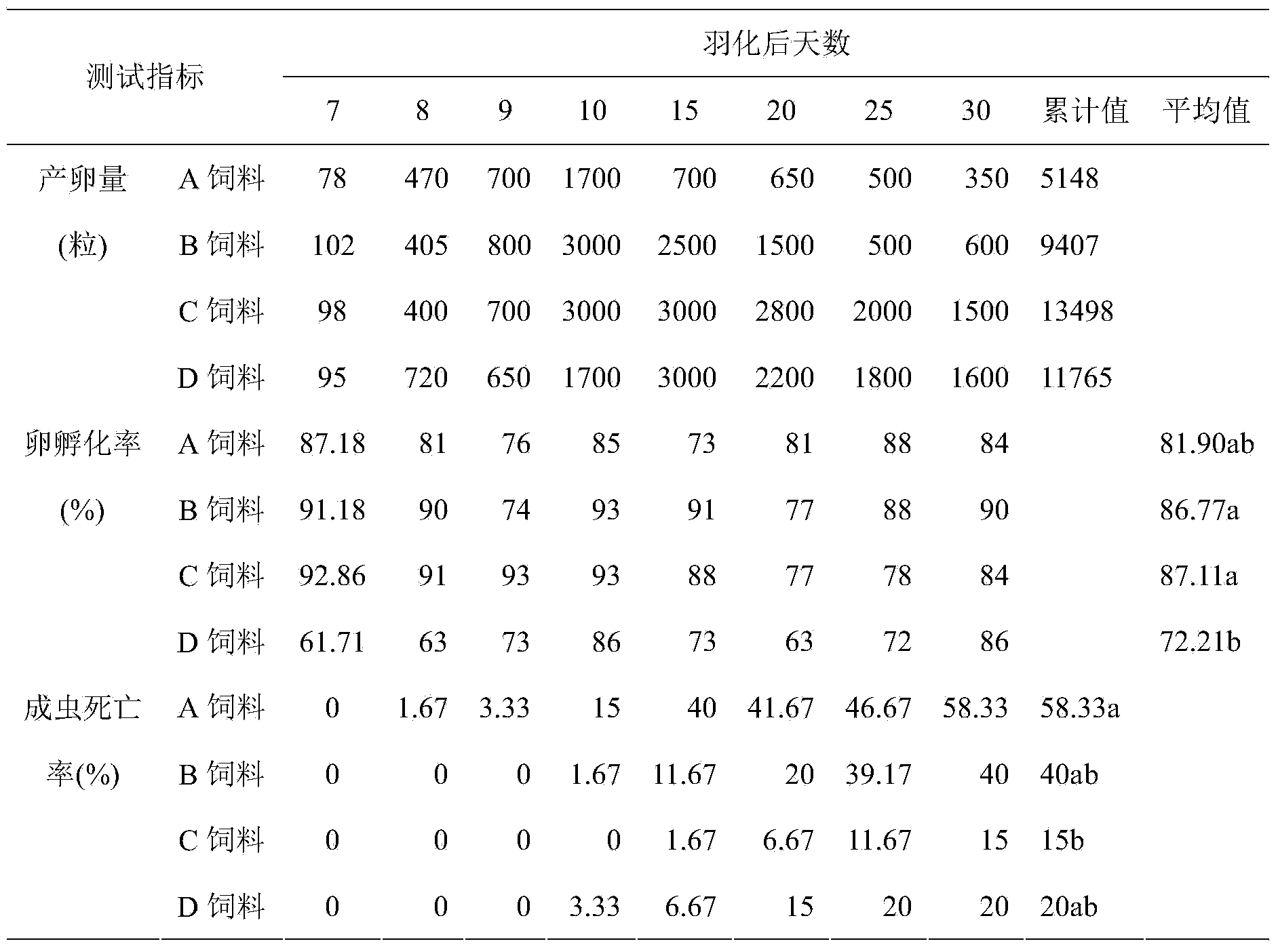

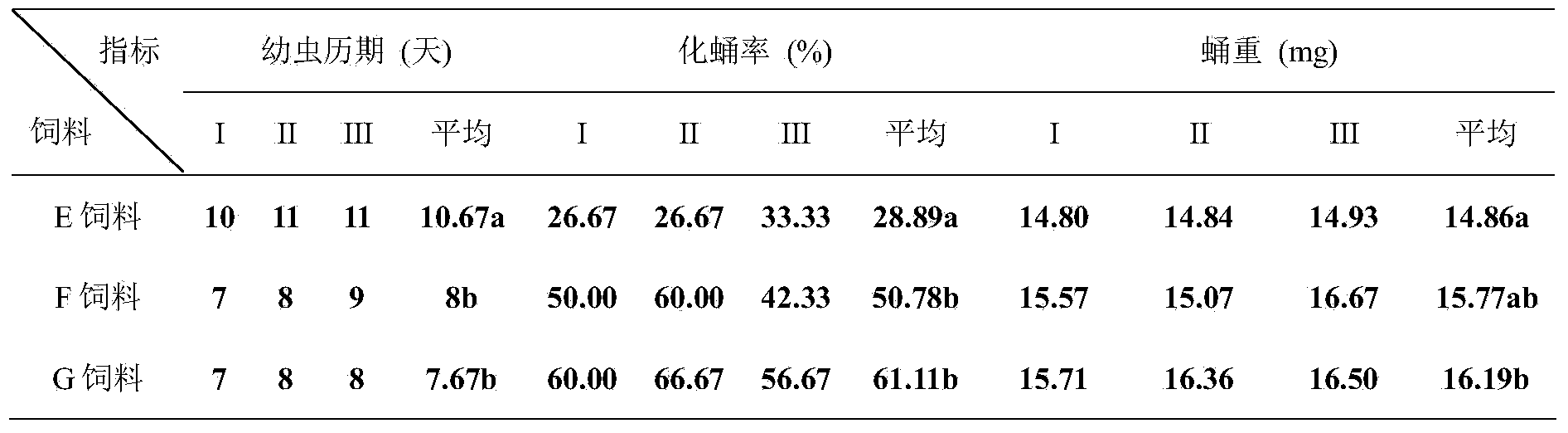

Bactrocera dorsalis large-scale feeding method

The invention relates to the field of plant protection, and specifically relates to a bactrocera dorsalis large-scale feeding method. The method comprises the following steps: adults are fed, wherein a modified artificial feed comprises yeast paste and sucrose with a mass ratio of 1:8; eggs are collected; larva are fed, wherein the larva are fed by using an artificial feed in which a mass ratio of corn flour to yeast powder is 19:7; and pupa are managed. The method has the advantages of high egg production amount, high egg hatching rate, high pupation rate and high eclosion rate.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

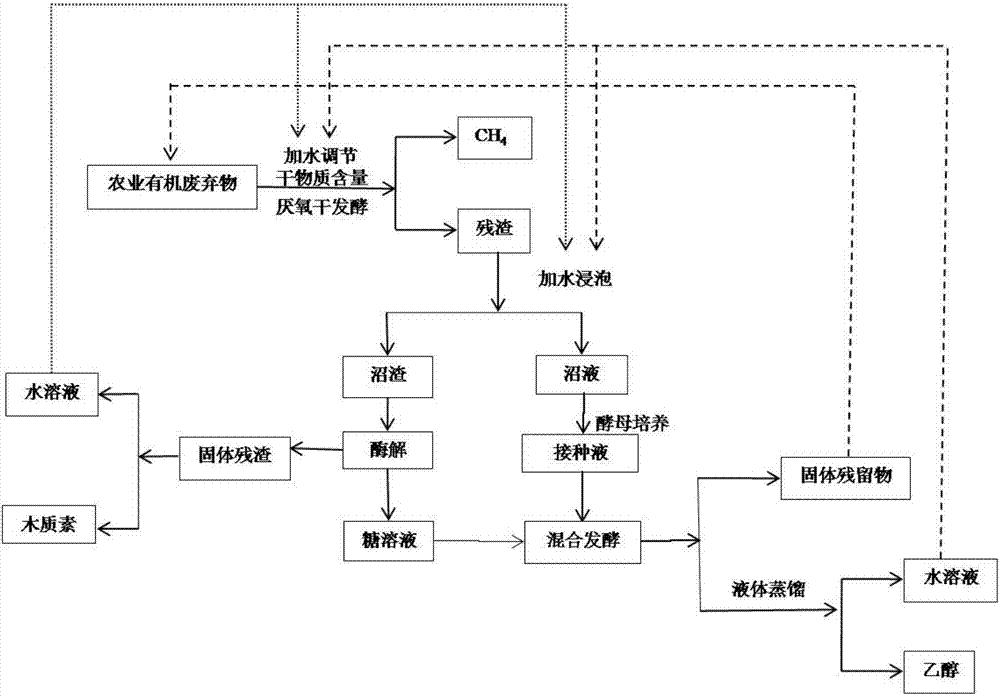

Resource utilization method of agricultural organic waste

InactiveCN107083401AImprove the level of cleanlinessImprove composition and structureBiofuelsMicroorganism based processesChemistryBrown iron oxide

The invention discloses a resource utilization method of agricultural organic waste. The method comprises the steps that iron oxide is added into the agricultural organic waste, anaerobic dry fermentation is conducted to generate biogas, and residues are subjected to water washing and then separated into biogas slurry and biogas residues; the biogas slurry serves as a culture solution to culture saccharomyces cerevisiae, and inoculation fluid is obtained; the biogas residues are converted into dissolved sugar through cellulase and separated into solid residues and a sugar solution; the inoculation fluid and the sugar solution are mixed and fermented, the solid residues in a product are used for serving as raw materials for anaerobic dry fermentation, liquid is subjected to distillation, and ethyl alcohol is obtained; the solid residues are used for producing lignin. Accordingly, the organic waste can be efficiently converted into three products of methane, ethyl alcohol and lignin, the efficient utilization of resources and additional value promotion are achieved, the technology greening and cleanliness levels are high, and no waste discharge exists in the whole technology.

Owner:HEFEI UNIV OF TECH

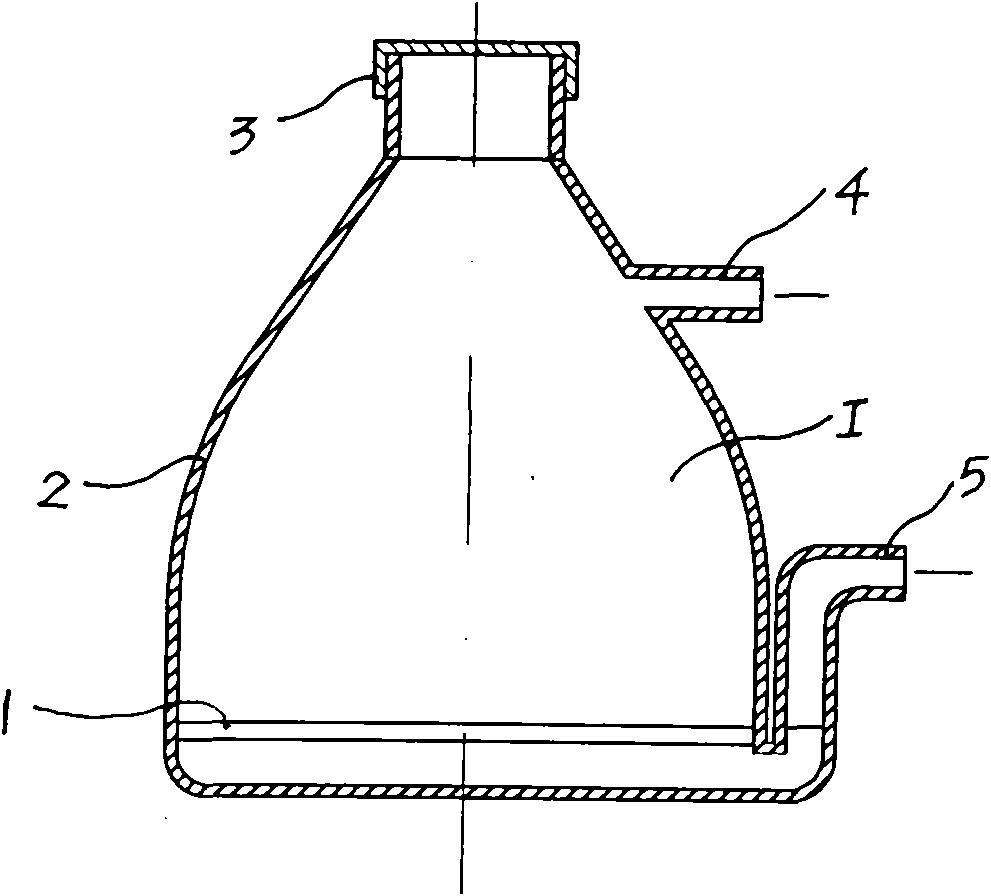

Internal circulation gas-lift type cell culture apparatus

InactiveCN101899392AOptimizing componentsReasonable structural designBioreactor/fermenter combinationsBiological substance pretreatmentsPlant tissueCulture fluid

The invention relates to an internal circulation gas-lift type cell culture apparatus which is mainly suitable for cell culture of tissues in agriculture and forestry. The invention is characterized in that a cell culture bottle is provided with an air disperser, a culture bottle bleeder hole and a culture bottle air inlet, wherein the air disperser and the culture bottle air inlet are positionedat the middle lower part of the bottle body, and the culture bottle bleeder hole is positioned at the middle upper part of the bottle body; an internal gas circulation mechanism is arranged in the cell culture apparatus and comprises a transmission fixed seat, a wearproof rope, a pair of piston bodies which are installed in opposite directions, a pair of return springs and a pair of return springclamps; the internal gas circulation mechanism is connected with the cell culture bottle; and each piston body is provided with a piston air inlet and a piston air outlet. The invention has reasonable structural design, and gas in the cell reactor is circulated into the culture fluid through a minitype one-way piston pump, so that the cells of the plant tissues in the cell culture bottle are in the gas-lift culture state; and the apparatus is easy to disassemble and assemble, can not be affected by damage and replacement, and has the advantages of low cost and easy popularization.

Owner:ZHEJIANG FORESTRY ACAD

Zirconia fiber board and preparation method

The invention belongs to the technical field of refractory materials, and provides a zirconia fiber board and a preparation method. The zirconia fiber board comprises raw materials as follows: zirconia fibers with diameters ranging from 3 mu m to 5 mu m, hollow zirconia spheres with the granularity larger than 0.045 mm and smaller than or equal to 0.075 mm, zirconia composite micro-powder with the granularity smaller than or equal to 0.003 mm as well as a stabilizer; the zirconia fiber board further comprises small organic matter spheres with the granularity larger than 0.045 mm and smaller than or equal to 0.075 mm, organic matter micro-powder with the granularity smaller than or equal to 0.045 mm as well as a binding agent, wherein the zirconia fibers and the hollow zirconia spheres are used as base bodies; the hollow zirconia spheres and the small organic matter spheres are constructed into a three-dimensional framework structure in a zirconia fiber board green body; the zirconia composite micro-powder is used as a matrix. According to the zirconia fiber board and the preparation method, problems that zirconia fiber boards prepared with a wet method are low in strength, severe to pulverize at high temperatures and short in service life when used as thermal interface materials are solved, the cost is reduced, the efficiency is increased, the energy is saved, and the consumption is reduced.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

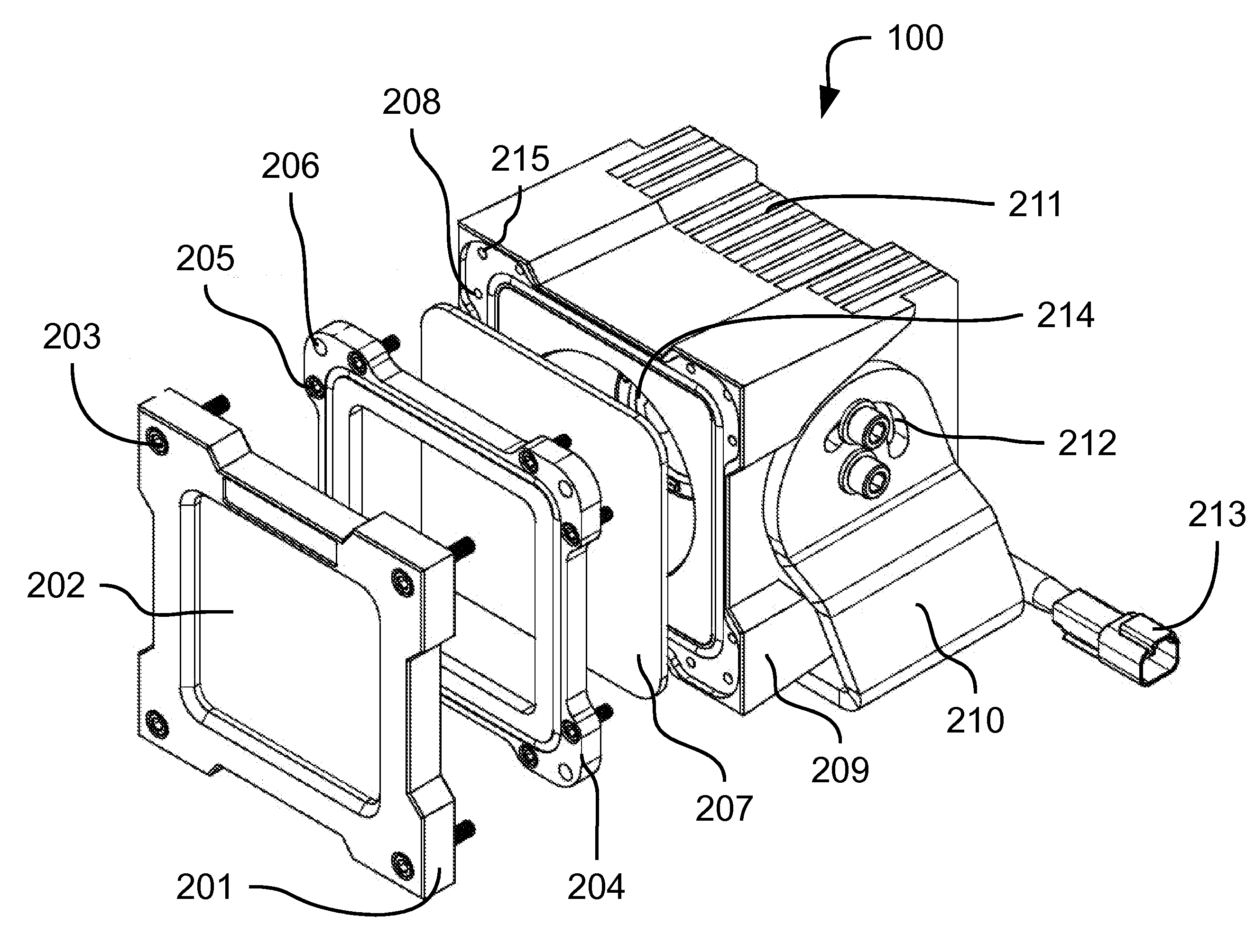

Rugged Lighting System

ActiveUS20150362155A1Optimizing componentsImprove efficiencyMechanical apparatusPoint-like light sourceOptical ModuleLuminosity

A new and innovative, rugged lighting system is provided. The problem of achieving a lighting system that optimizes ruggedness, luminosity, energy and thermal efficiency, versatility, and unbundling of key components is solved. Embodiments of the present invention include a rugged lighting system comprising a housing unit with a body with integrally formed back, sides, and a front with an opening to provide access to the interior of the housing unit; a first lens configured to substantially cover the opening; a first lens bezel configured to removeably attach to the housing unit over the first lens; a second lens configured for placement over the first lens; and a second lens bezel configured to removeably attach to the housing unit over the first lens bezel. Various embodiments further include a light module within the housing unit with a light emitting diode (LED) mounted to an electronics module having a printed circuit board for operating the LED.

Owner:INDUSTRALIGHT

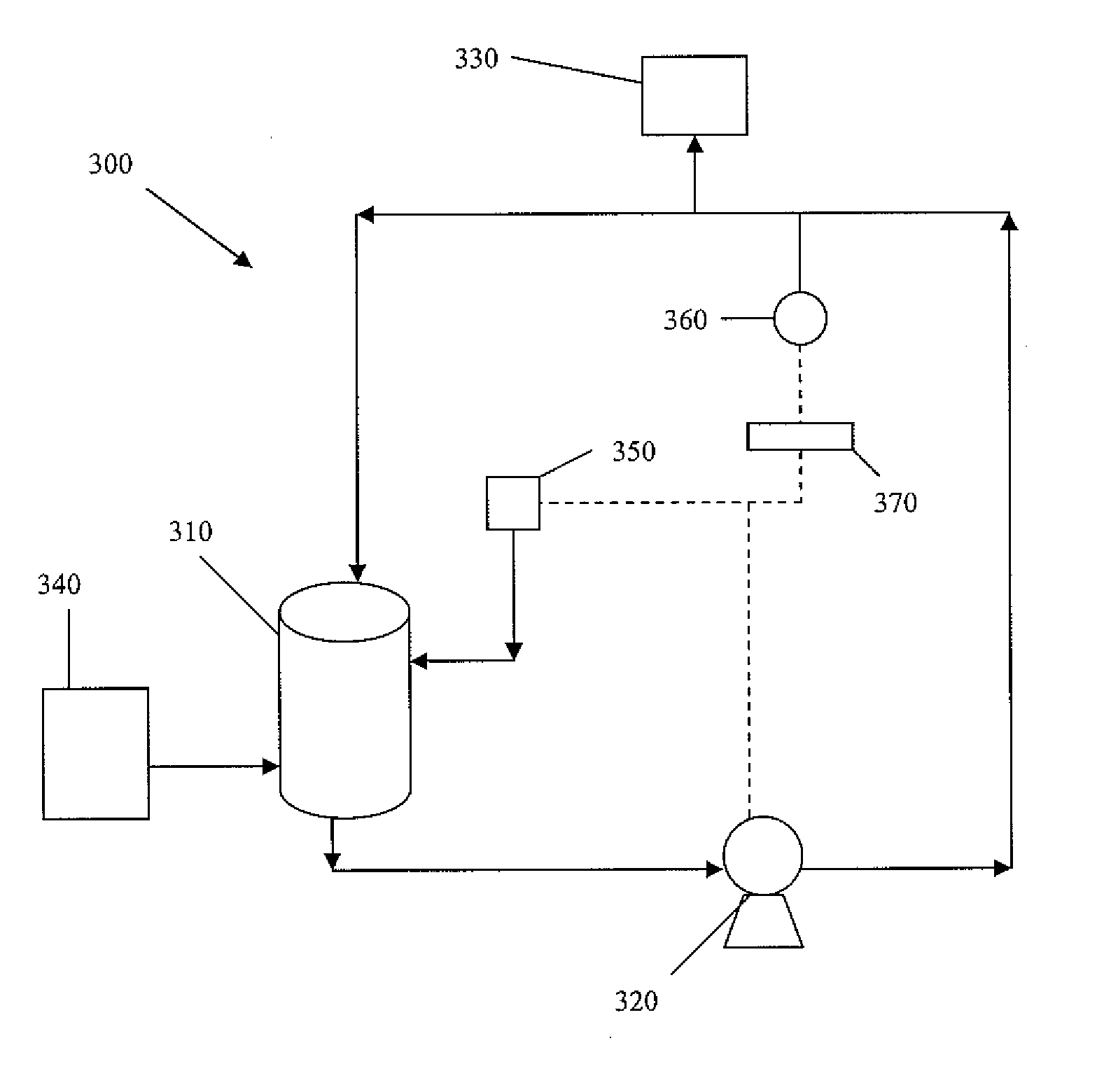

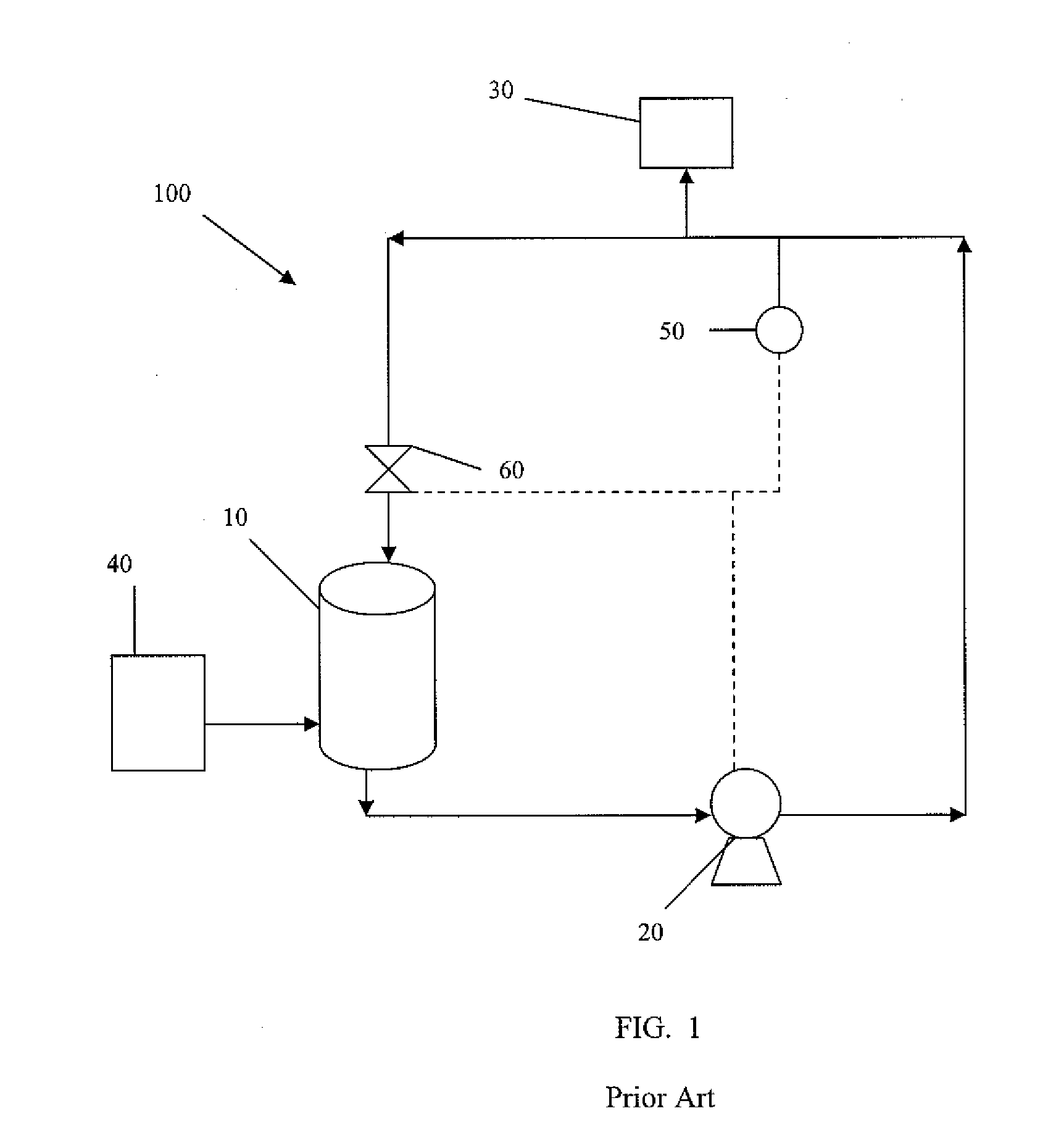

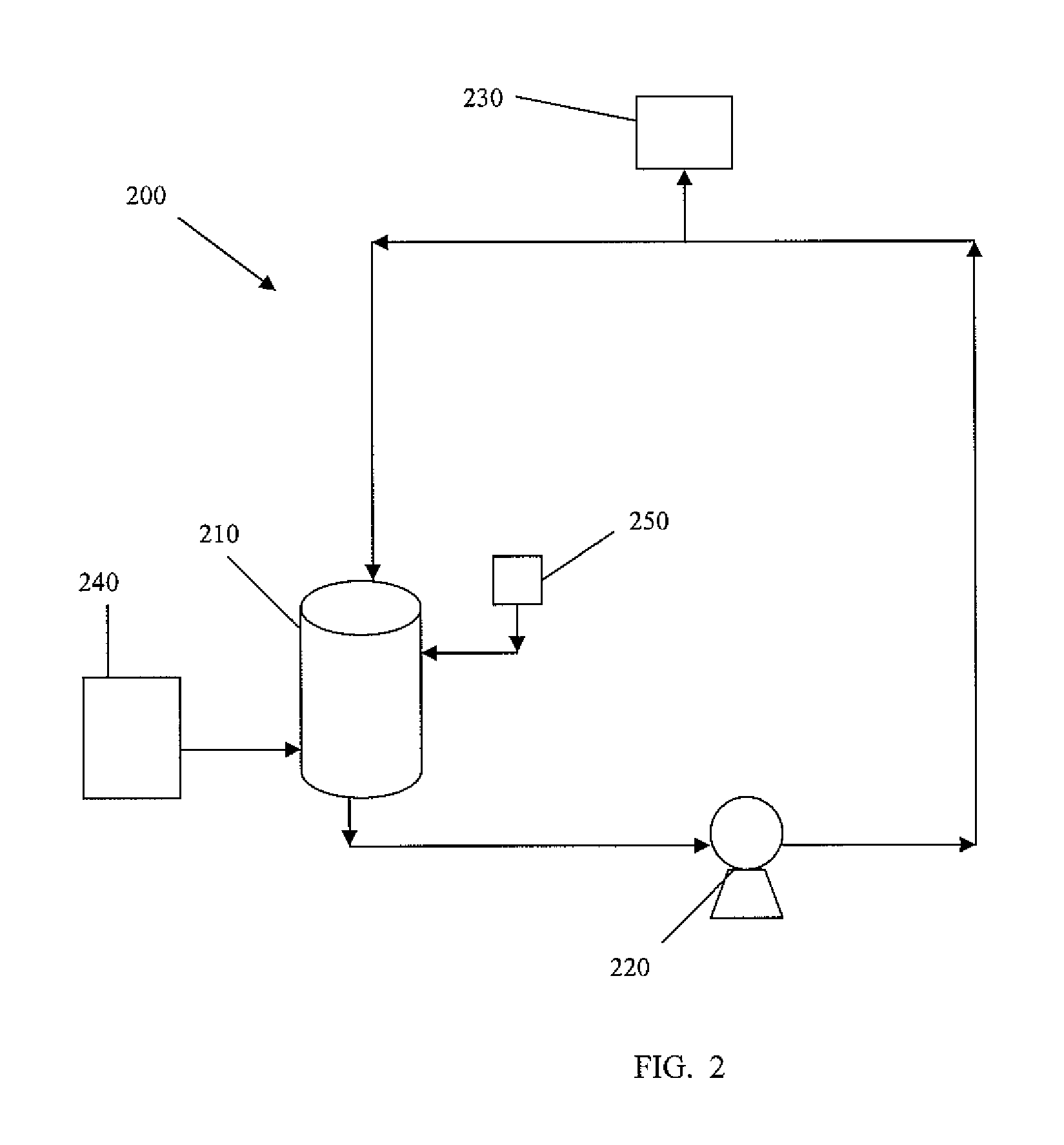

Method and Apparatus for Dispensing Liquid with Precise Control

InactiveUS20070215639A1Optimizing componentsImprove system performanceLarge containersLiquid transferring devicesCompound (substance)Engineering

The present invention provides methods and apparatus combining a pressure vessel and a centrifugal pump to accurately and efficiently control pressure and flow rate of liquid in a liquid dispense system. The present invention particularly relates to the accurate and efficient control of pressure and flow rate of liquids, such as high purity chemicals or slurries used in semiconductor manufacturing processes.

Owner:AIR LIQUIDE ELECTRONICS US LP

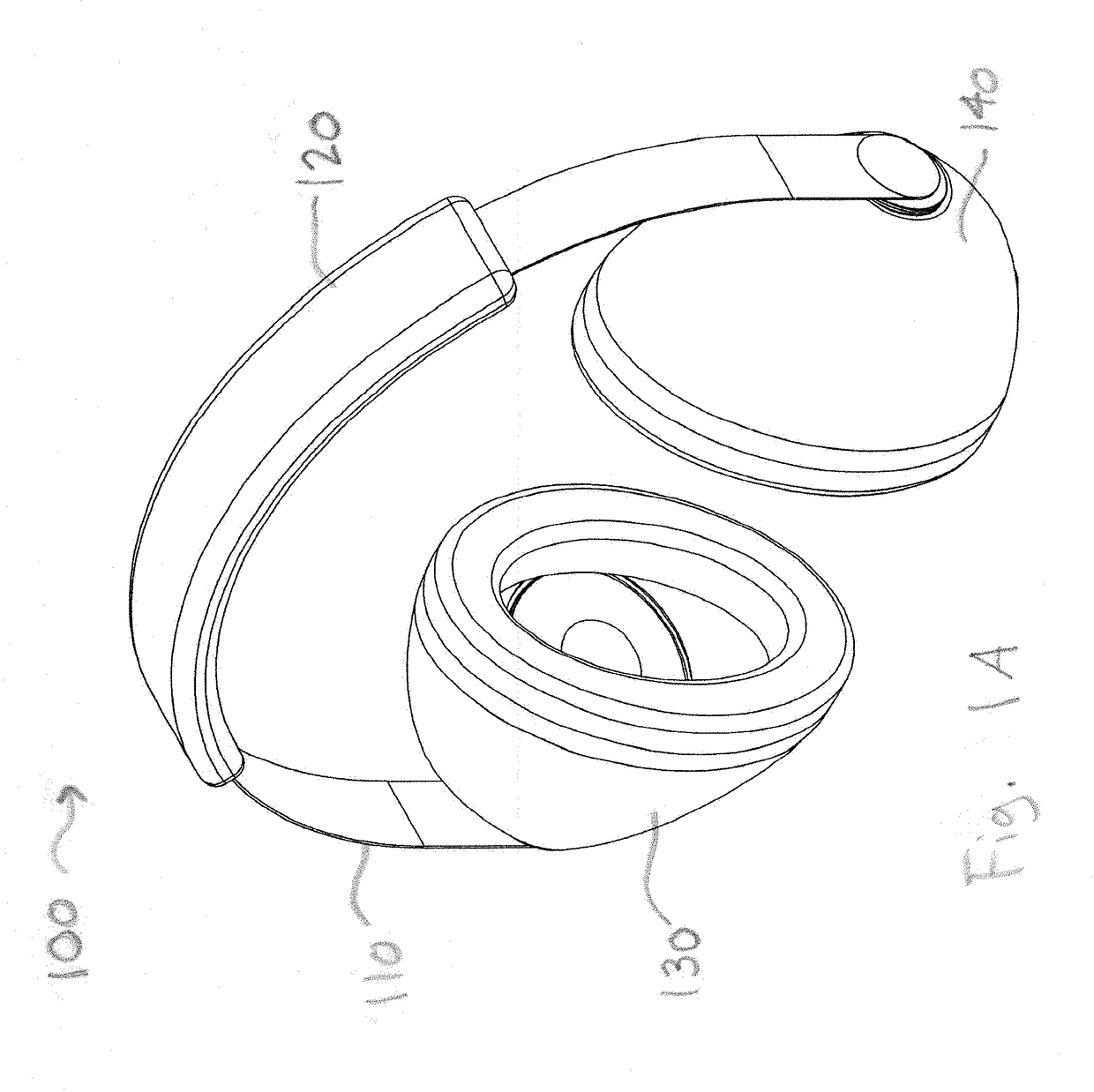

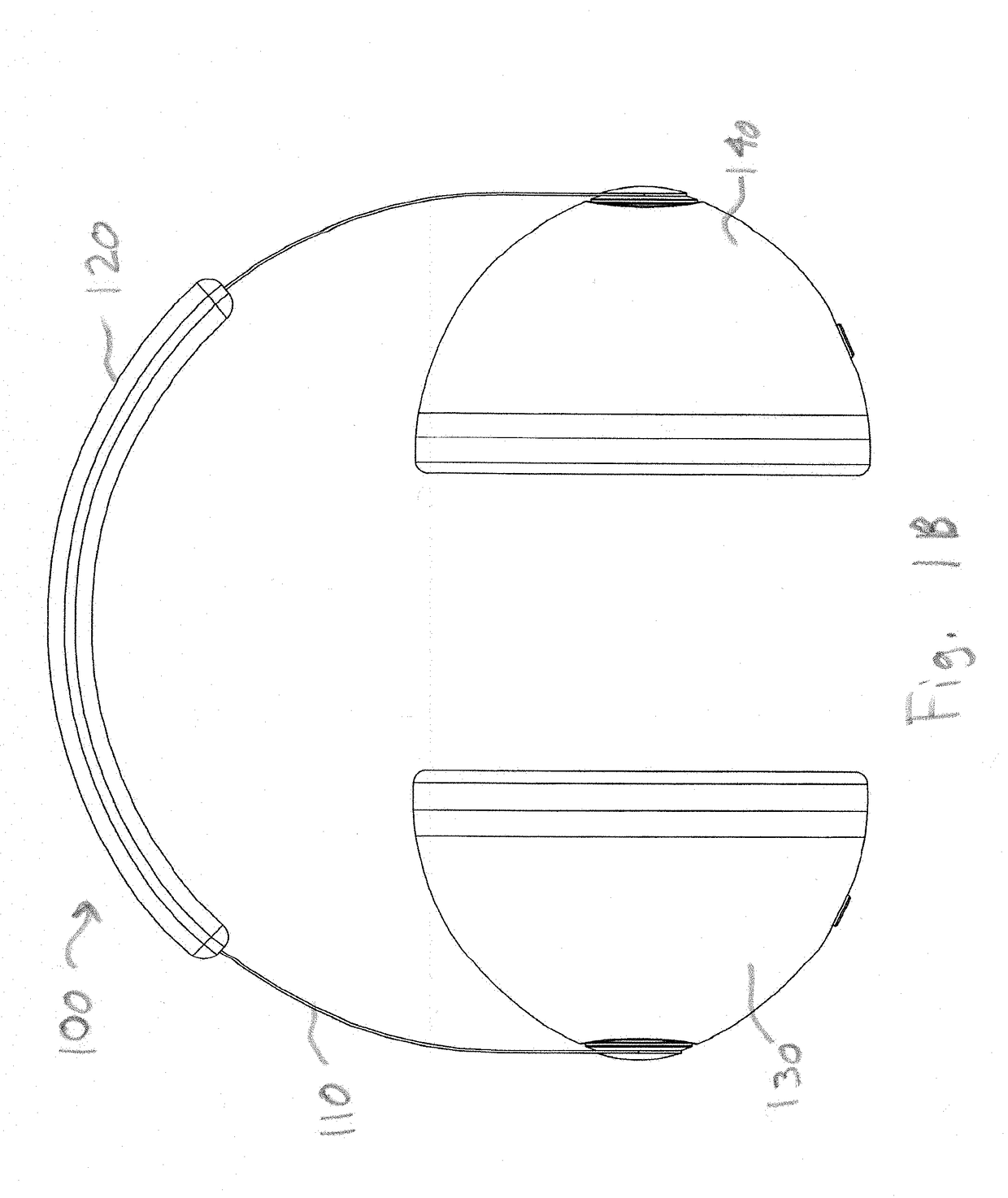

Headphone attachment mechanism

InactiveUS20180316999A1Optimize movement and efficiencyImprove abilitiesSupra/circum aural earpiecesEarpiece/earphone manufacture/assemblyEngineeringHeadphones

Devices and methods described herein relate to novel and improved headphone designs that can optimize component movement, efficiency, and / or performance. Headphone designs described herein allow components to freely move in many directions, which can provide users with an increased ability to optimize component positioning and / or performance. Additionally, headphone embodiments described herein can provide a novel manner to foster component adjustability, which also improves headphone efficiency and comfort. This component adjustability allows headphones to provide adjustable shapes and / or sizes, which helps to facilitate the transition to users of different sizes. Embodiments according to the present disclosure can also include headphones with removable components. For example, the headband can be removable from other headphone components. This can allow headphone components to be exchanged for similar components. In addition, removable individual components can provide headphone users with increased mobility and / or flexibility.

Owner:BELLAS KIMON

Preparation method and device of composite textured yarn

The invention discloses a processing method and a device of composite textured yarn, the device comprises a rack, a heating deformation mechanism arranged on the rack, a yarn guide mechanism arranged on one side of the rack, a yarn coiling mechanism arranged on the other side of the rack, wherein the heating deformation mechanism comprises a driving wheel and a matched yarn pressing wheel, the driving wheel and the yarn pressing wheel are arranged at the left and the right, the yarn pressing wheel is higher than the driving wheel, the connecting line of shaft centers forms an included angle of 20-40 degrees with the horizontal line, and heating devices are arranged on two sides of the driving wheel; the wire guide mechanism comprises a detwisting bobbin creel, a cocoon cooking pot and a tensioner; the yarn coiling mechanism comprises a yarn holding tool, a winding motor connected with the yarn holding tool and a speed regulator; and a special-shaped yarn guide wheel, a yarn storage device and a yarn guide device are sequentially arranged between the heating deformation mechanism and the yarn coiling mechanism. The processing method and the device can carry out composite deformation processing on the yarn with different components, completely realize the winding without tension, realize the continuous production of the composite textured yarn and keep the deformation effect.

Owner:SUZHOU INST OF TRADE & COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com