Low-temperature lithium iron phosphate lithium-ion power battery

A lithium iron phosphate, power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor low temperature performance, and achieve the effect of improving low temperature performance, stable structure, and expanding use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: 36Ah lithium iron phosphate lithium ion power battery

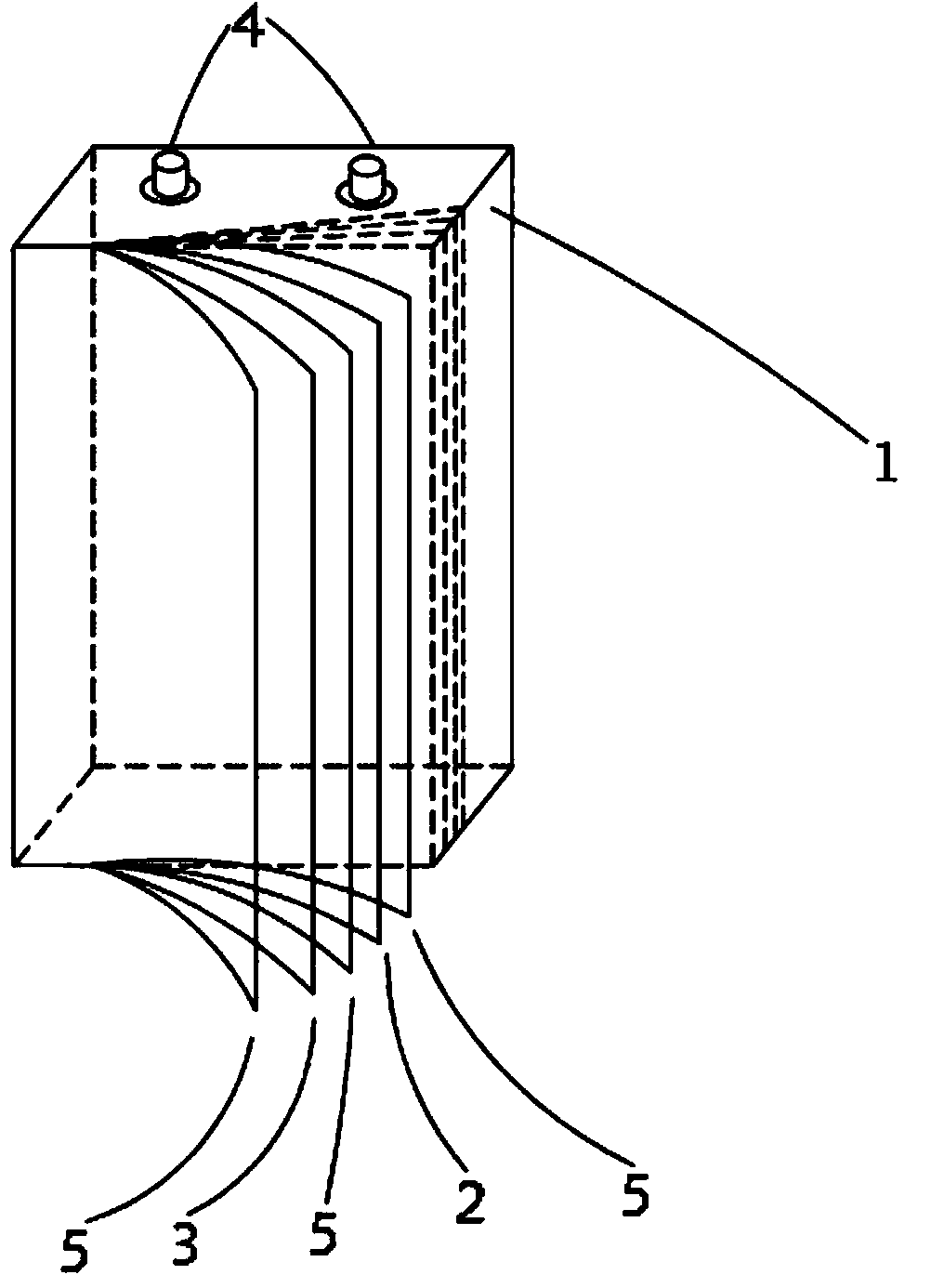

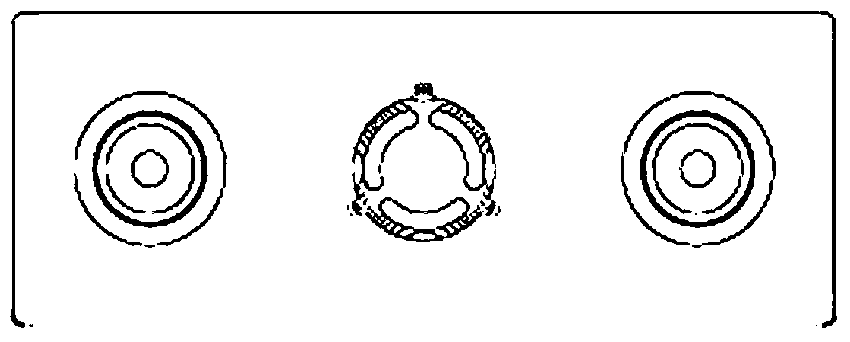

[0053] like figure 1 , 2 , 3, the lithium iron phosphate lithium ion power battery of the present invention includes a positive electrode sheet 2, a negative electrode sheet 3, a diaphragm 5, an electrolyte (not marked), a casing 1, a cover plate (not marked) and a pole 4, and the battery size It is 36mm×130mm×155mm.

[0054] Positive electrode sheet: The thickness of the positive electrode sheet is 145±2μm; the positive electrode active material is nano-sized lithium iron phosphate coated with a discontinuous graphene structure; the median particle size of the nano-sized lithium iron phosphate is 5-10nm, and the graphene is 3-8 layers of multilayer graphene, the coating area accounts for 40%-70% of the total surface area of the lithium iron phosphate material; the binder is polyvinylidene fluoride; the conductive agent is a mixture of acetylene black and carbon nanotubes (CNT) , The weight percentage...

Embodiment 2

[0060] Example 2: 50Ah lithium iron phosphate lithium ion power battery

[0061] The battery is the same as in Embodiment 1, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, a casing, a cover plate, and a pole. The size of the battery in this embodiment is 45mm×120mm×187mm.

[0062] Positive electrode sheet: the thickness of the positive electrode sheet is 144±2μm; the positive electrode active material is nano-sized lithium iron phosphate coated with a discontinuous graphene structure; the median particle size of the nano-sized lithium iron phosphate is 5-10nm, and the graphene is 3-8 layers of multi-layer graphene, the coating area accounts for 40%-70% of the total surface area of the lithium iron phosphate material. The binder is polyvinylidene fluoride; the conductive agent is a mixture of acetylene black and carbon nanotubes (CNT), and the weight percentage of acetylene black and CNT is 50%: 50%; the weight percentage of po...

example 2

[0067] The battery of Example 2 was tested: after the battery was fully charged at room temperature, it was stored at -40°C±2°C for 20 hours, and then at the same temperature, it was charged with 3I 3 (A) Current discharge until the end-of-discharge voltage is 2.0V, and the discharge capacity is 93.2% of the rated capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com