Light anti-slipping high-wear-resistance rubber material for sole and preparation method thereof

A rubber material, high wear-resistant technology, applied in the field of rubber composite materials, can solve the problems of inability to meet strenuous exercise, poor shock absorption, heavy quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

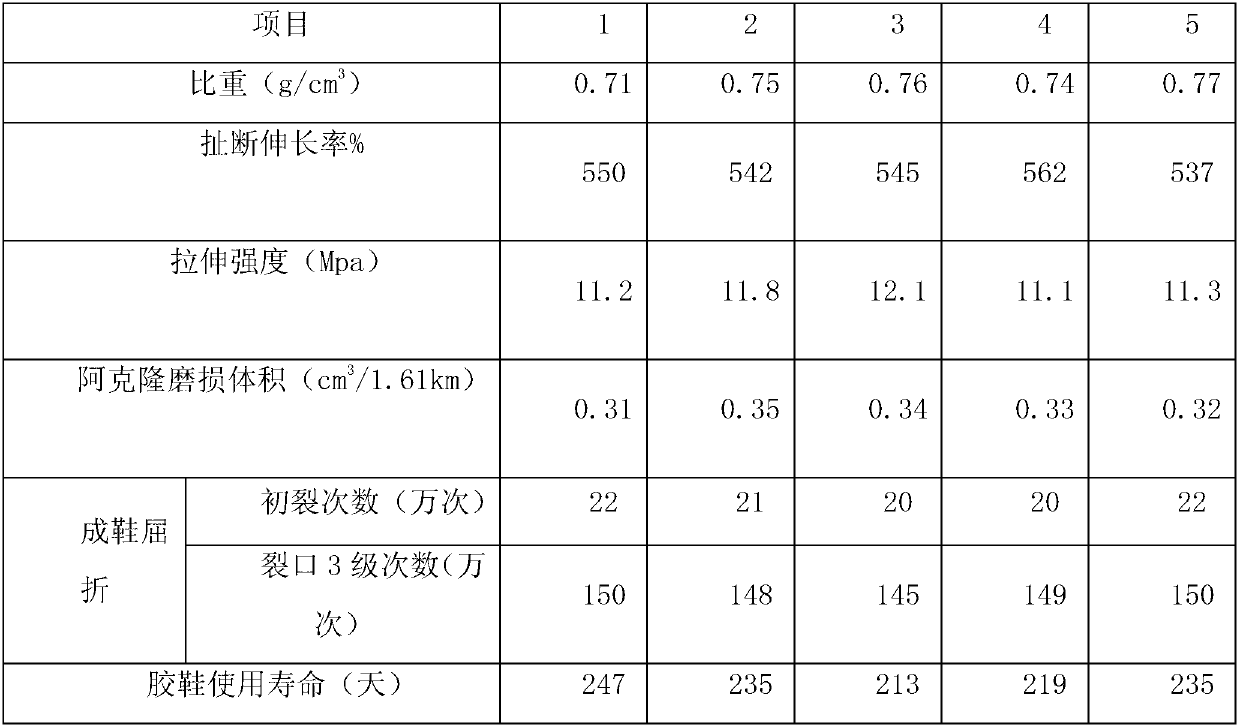

Examples

Embodiment 1

[0044] The formula of this embodiment is as follows (note: each raw material is by weight)

[0045] EVA: 65

[0046] NR: 15

[0047] SBR: 15

[0048] CaCO3:4

[0049] Si-69 wear agent: 4

[0050] ZnO: 3

[0051] ZnST: 3

[0052] ST: 1.5

[0053] DCP: 1

[0054] AC: 1.8.

[0055] The preparation method is as follows:

[0056] First mix other raw materials except DCP and AC for banburying, add DCP and AC 5 minutes before the end of banburying, granulate after the end of banburying, and then one-time injection molding to obtain the light weight non-slip and high wear-resistant rubber Material.

[0057] During banburying, control temperature is 125 ℃, banburying time is 18min.

[0058] During one injection molding, the control temperature is 185°C and the time is 4min.

Embodiment 2

[0060] The formula of this embodiment is as follows (note: each raw material is by weight):

[0061] EVA: 60

[0062] NR: 10

[0063] SBR: 20

[0064] CaCO3:5

[0065] AG-209 wear agent: 3

[0066] ZnO: 2

[0067] ZnST: 4

[0068] ST: 2

[0069] DCP: 0.8

[0070] AC: 1.5.

[0071] The preparation method is as follows:

[0072] First mix other raw materials except DCP and AC for banburying, add DCP and AC 4 minutes before the end of banburying, granulate after the end of banburying, and then make the above-mentioned light weight non-slip and high wear-resistant rubber by one injection molding Material.

[0073] During banburying, control temperature is 120 ℃, banburying time is 20min.

[0074] During one injection molding, the temperature is controlled at 180°C and the time is 5 minutes.

Embodiment 3

[0076] The formula of this embodiment is as follows (note: each raw material is by weight):

[0077] EVA: 70

[0078] NR: 20

[0079] SBR: 10

[0080] CaCO3:3

[0081] Si-69 wear agent: 5

[0082] ZnO: 4

[0083] ZnST: 2

[0084] ST: 1

[0085] DCP: 1.2

[0086] AC: 2.

[0087] The preparation method is as follows:

[0088] First mix other raw materials except DCP and AC for banburying, add DCP and AC 6 minutes before the end of banburying, granulate after banburying, and then make the above-mentioned light weight non-slip and high wear-resistant rubber by one injection molding Material.

[0089] During banburying, control temperature is 135 ℃, banburying time is 12min.

[0090] During one-time injection molding, the temperature is controlled at 195°C and the time is 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com