Preparation method and device of composite textured yarn

A deformation device and technology of textured yarn, applied in the direction of textiles, papermaking, yarn, etc., can solve the processing method of single silk textured silk and synthetic fiber composite, no component, shape controllable real silk/synthetic fiber composite textured yarn and Problems such as its processing device, to achieve a good effect of heating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

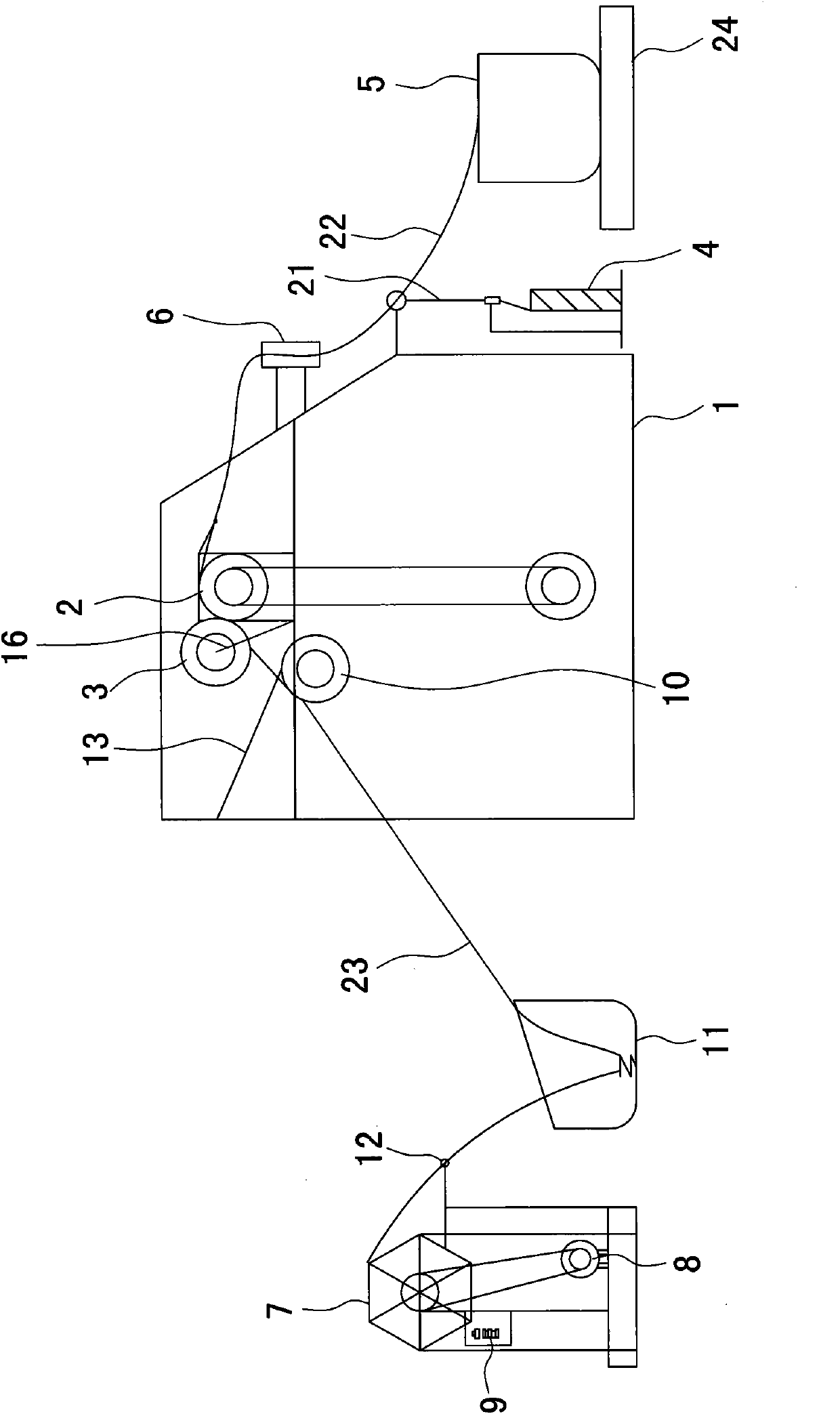

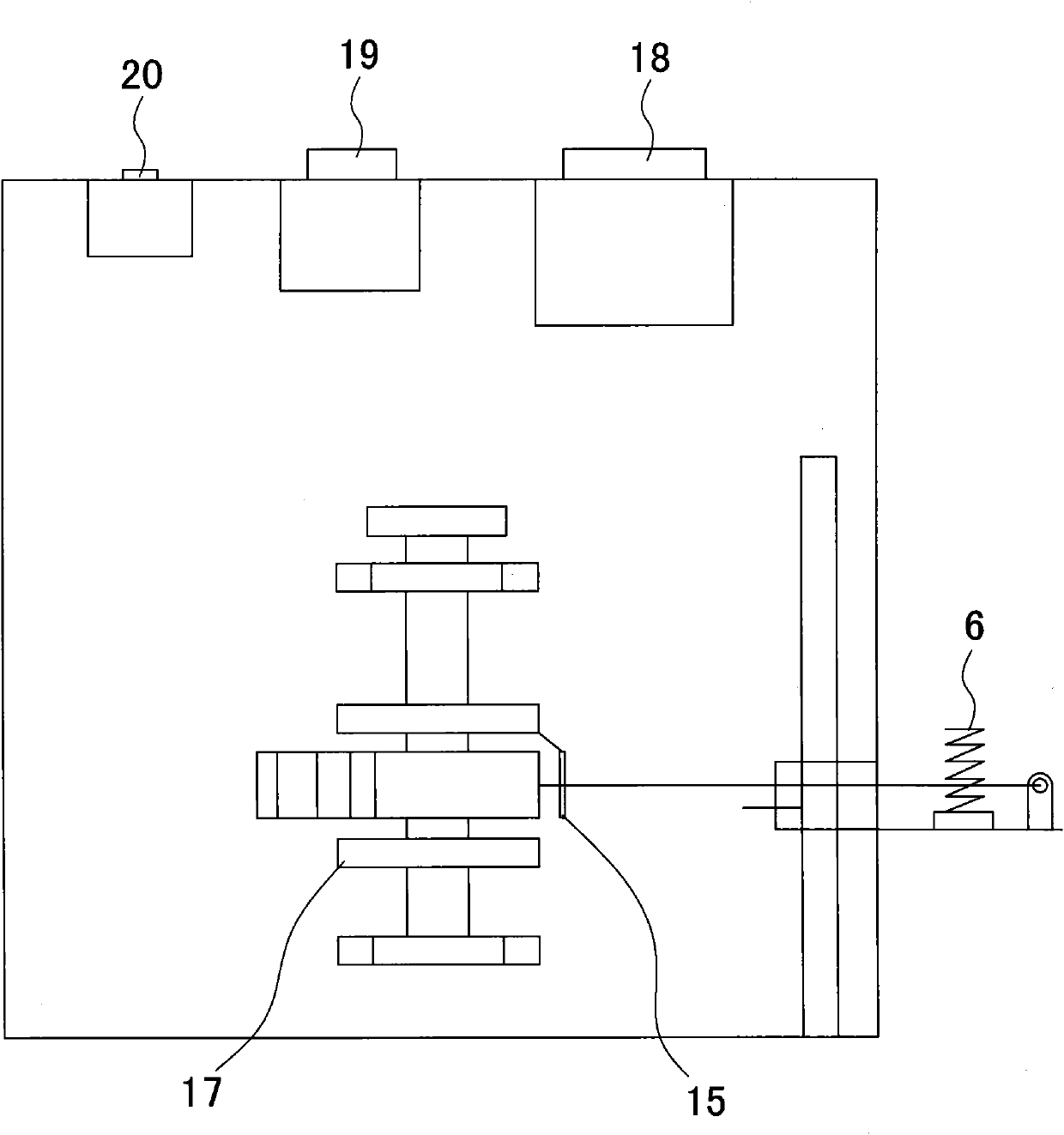

[0039] Embodiment one: see Figure 1~2 As shown, a processing device for composite textured yarn includes a frame 1, a heating deformation mechanism arranged on the frame, a wire guide mechanism arranged on one side of the frame, and a wire winding mechanism arranged on the other side of the frame, The heating and deformation mechanism includes a driving wheel 2 and a matching pressing wheel 3, the driving wheel and the pressing wheel are arranged on the left and right, and the pressing wheel is higher than the driving wheel, and the angle between the axis connecting line and the horizontal line is 20-40 degrees , heating devices are provided on both sides of the drive wheel;

[0040] The wire guide mechanism includes a bobbin frame 4, a cocoon cooking pot 5, and a tensioner 6; the wire winding mechanism includes a zipper 7, a winding motor 8 connected with the zipper, and a governor 9; A special-shaped wire guide wheel 10, a wire storage device 11 and a wire guide device 12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com