Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

269 results about "Ball diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A men's ball is about 9.55 inches (24.26 cm) in diameter and a women's ball is about 9.23 inches (23.44 cm) in diameter. The baskets are placed at the end line of each court and are 10 feet above the floor. The metal rim of the hoop is 18 inches in diameter, which is about double in diameter of the ball itself.

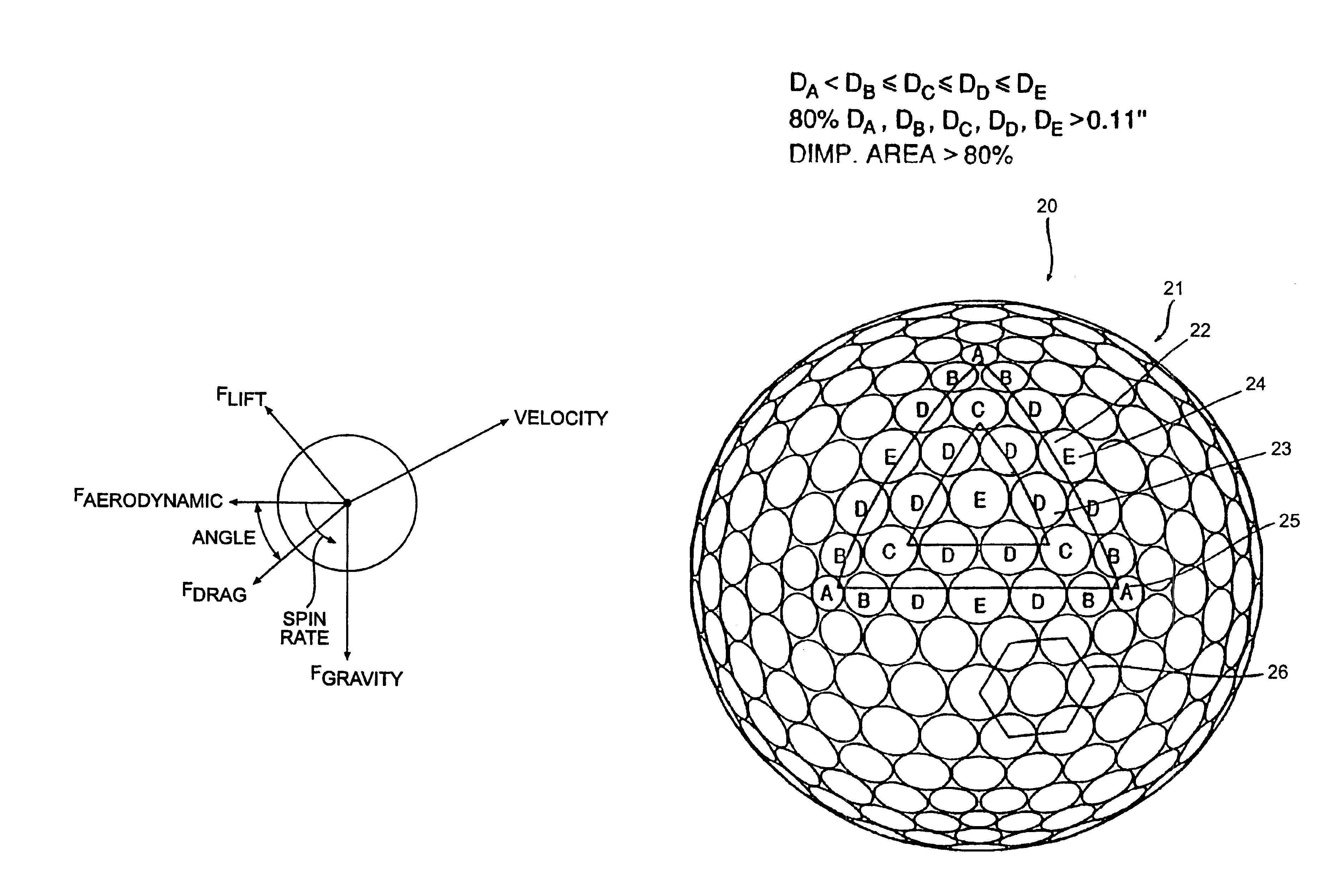

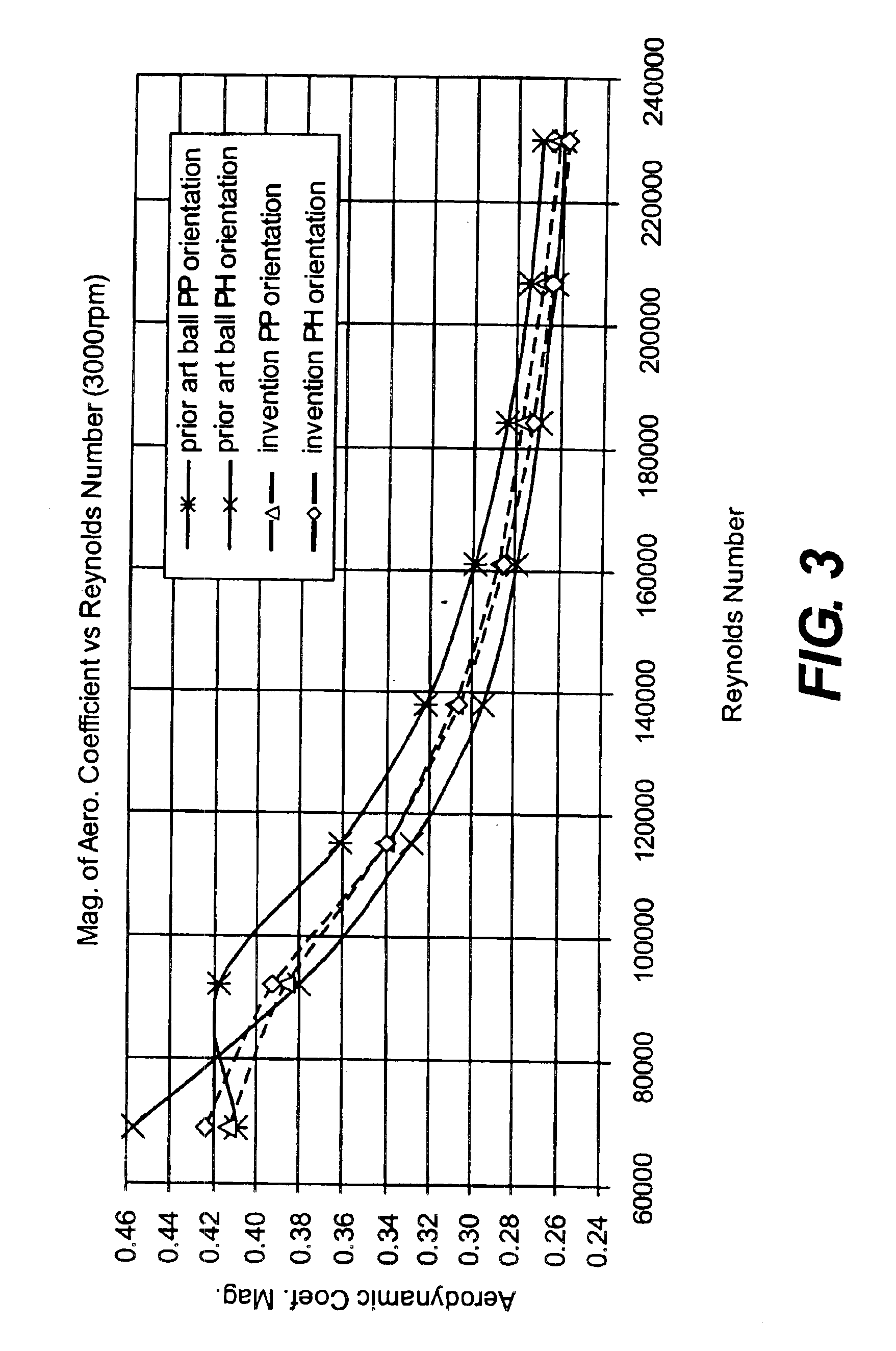

Golf ball with improved flight performance

A golf ball with aerodynamic coefficient magnitude and aerodynamic force angle, resulting in improved flight performance, such as increased carry and flight consistency regardless of ball orientation. In particular, the present invention is directed to a golf ball having increased flight distance as defined by a set of aerodynamic requirements, at particular spin ratios and Reynolds Numbers. The invention is also directed toward golf balls with dimple diameters of greater than 6.5 percent of the ball diameter and dimples with a profile defined by a catenary curve.

Owner:ACUSHNET CO

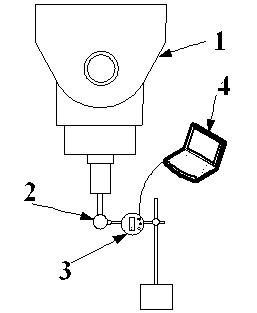

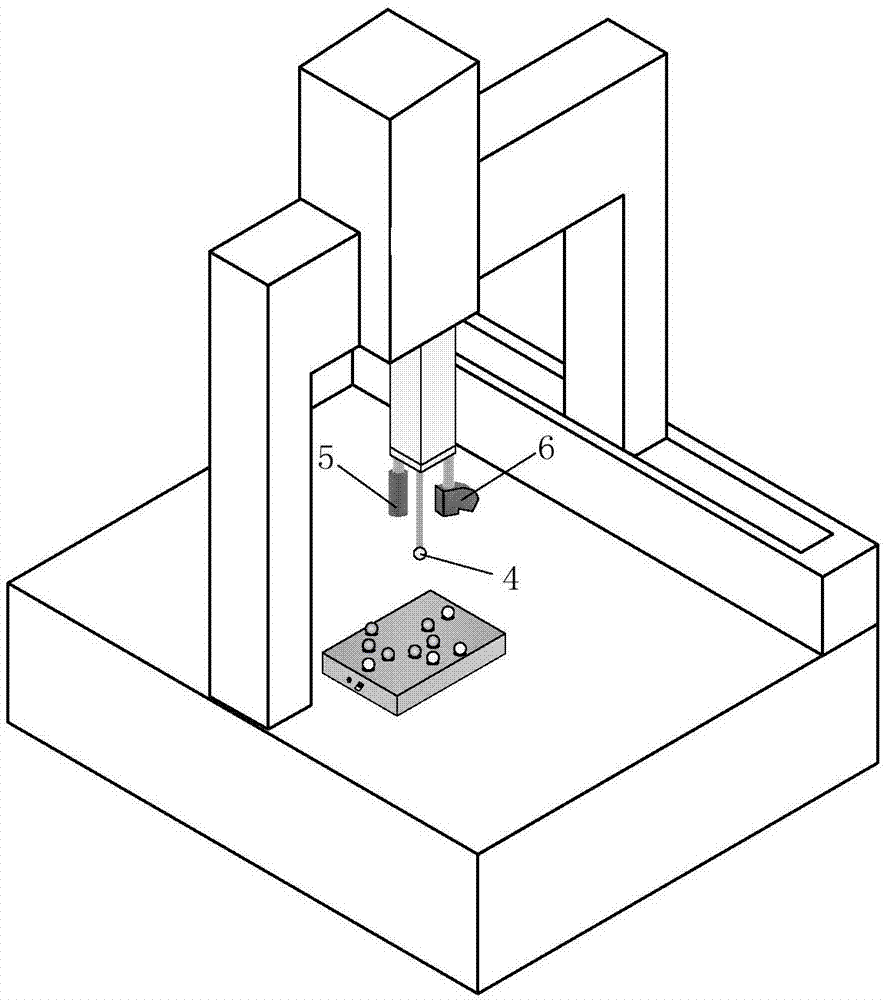

Method for detecting linkage accuracy of C-shaft of multi-shaft linkage double-pendulum numerical control milling machine

ActiveCN103273379AAcquisition is fast and efficientFast and effective analysisMeasurement/indication equipmentsNumerical controlMeasuring instrument

The invention discloses a method for detecting the linkage accuracy of a C-shaft of a multi-shaft linkage double-pendulum numerical control milling machine. The method comprises the following steps that a standard linkage ball is installed on a machine tool spindle, and the working length L and the linkage ball diameter D of the standard linkage ball are set in a machine tool system; a digital display dial indicator used for data collection and data output is arranged on a machine tool bed frame, and after a measuring head of the digital display dial indicator makes contact with the standard linkage ball, the measuring head is pressed inward by a certain distance d, and the current position of the digital display dial indicator is reset to zero; a machine tool RTCP motion mode is switched on, and the C-shaft is made to rotate around the center of the standard linkage ball; the digital display dial indicator is used for collecting displacement deviation delta 1 generated between the standard linkage ball and the measuring head in the rotation process, and the value of the displacement deviation delta 1 at a certain rotation angle is the linkage accuracy of the C-shaft at the angle. The method for detecting the linkage accuracy of the C-shaft of the multi-shaft linkage double-pendulum numerical control milling machine is more rapid and effective in data collection and data analysis, and can serve as a basis for accuracy compensation of a C-shaft of a follow-up machine tool; a large number of trial cuts does not need to be conducted, a three-coordinate measuring instrument does not need to be arranged for special inspection, and therefore cost is low and efficiency is high.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

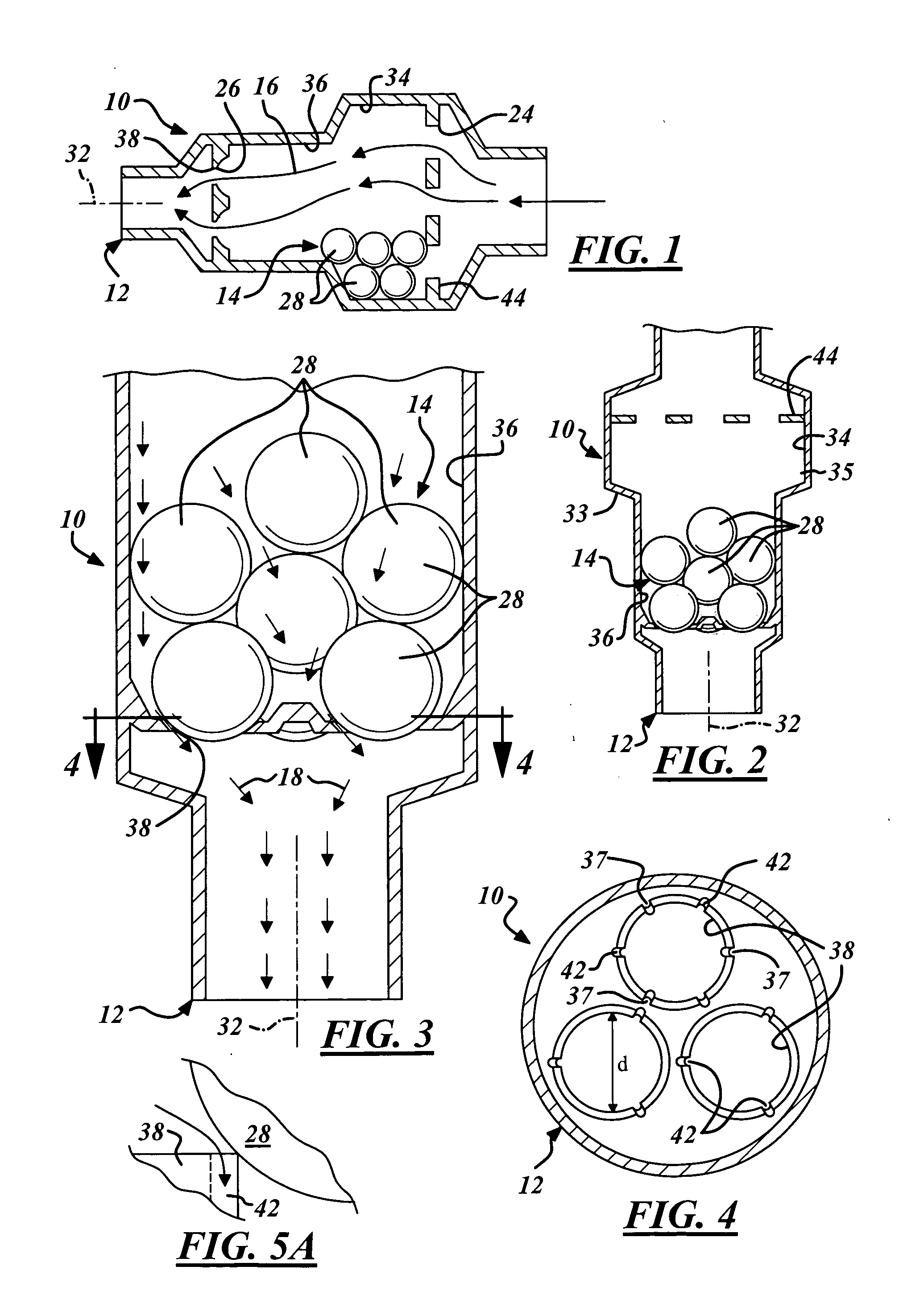

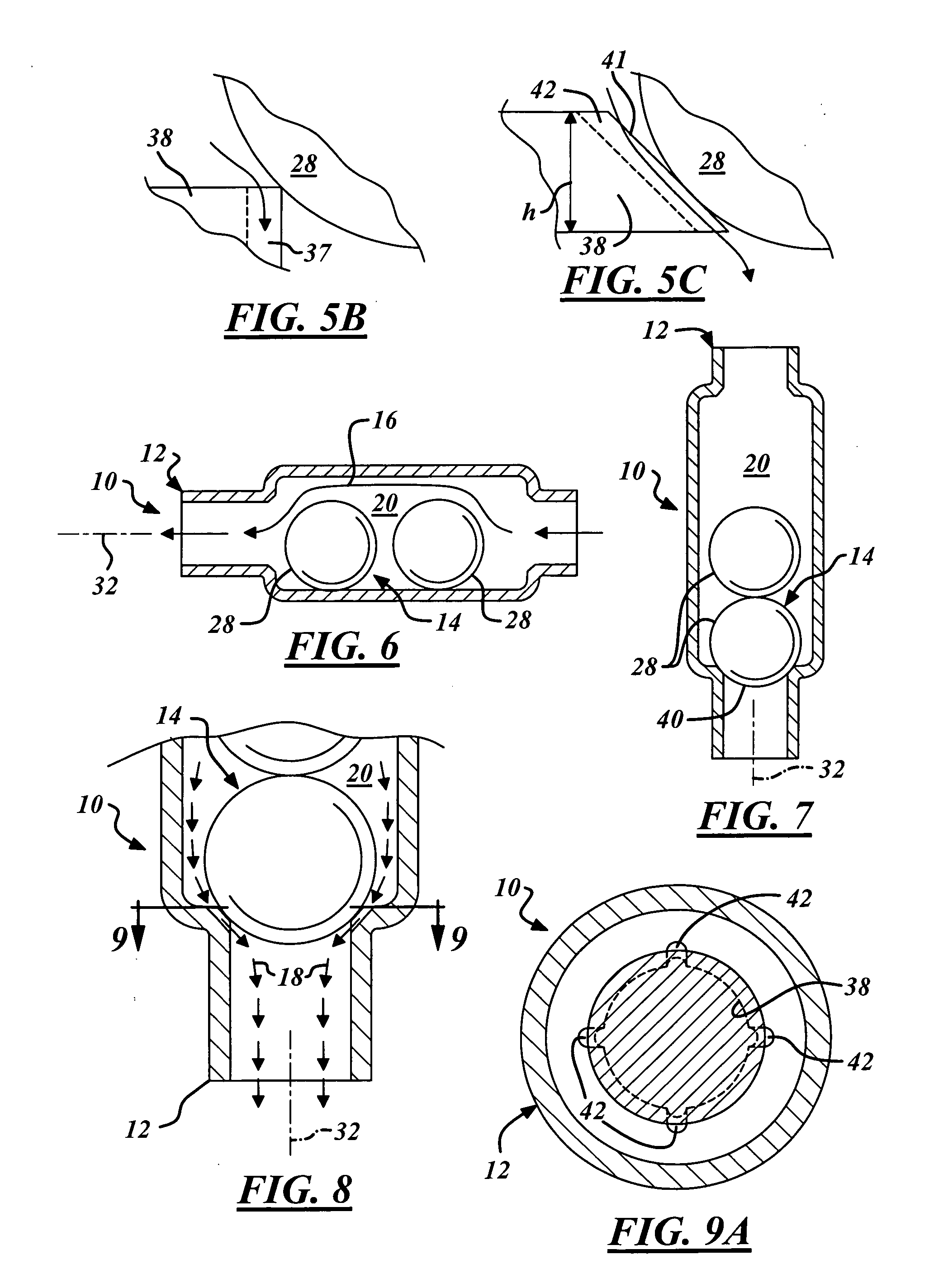

Resistive shunt valve

InactiveUS20060089589A1Avoid problemsMinimize occlusionWound drainsIntravenous devicesEngineeringCatheter

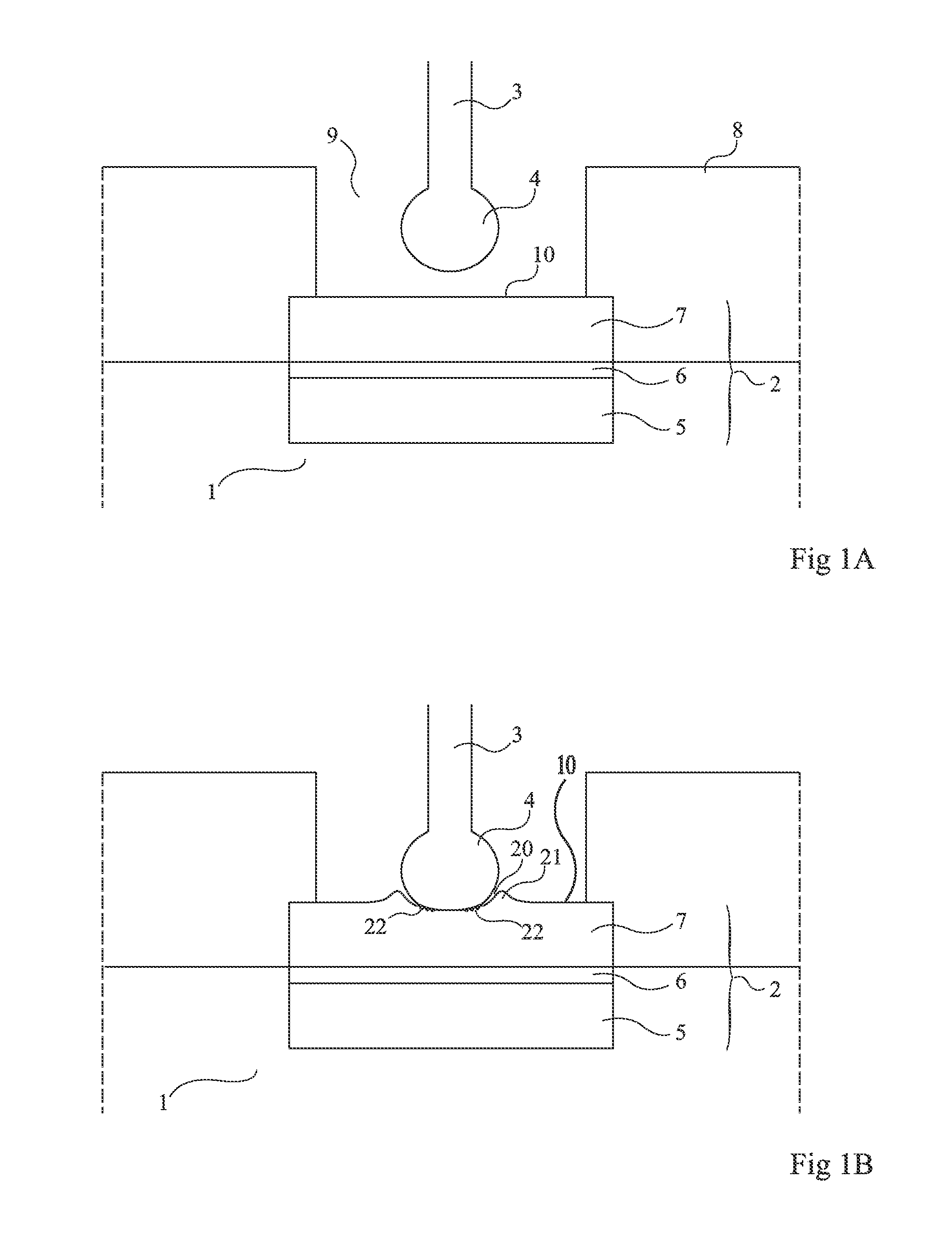

A resistive shunt valve (RSV) for draining cerebrospinal fluid. The RSV is comprised of a conduit housing and a valve member. The conduit housing is adapted for continuously conveying a flow of cerebrospinal fluid (CSF) with the valve member metering the flow of CSF therethrough. The valve member has a plurality of balls and at least one valve seat, with the number of balls being greater than the number of valve seats. The balls register within the valve seats in the direction of CSF flow. Small notches or irregularities are provided in the valve seats. Metering of CSF can be controlled by the housing diameter, ball diameter, number of balls, ball weight, irregularity of the valve seats, surface characteristics of the ball, and ball material.

Owner:PORTNOY HAROLD D

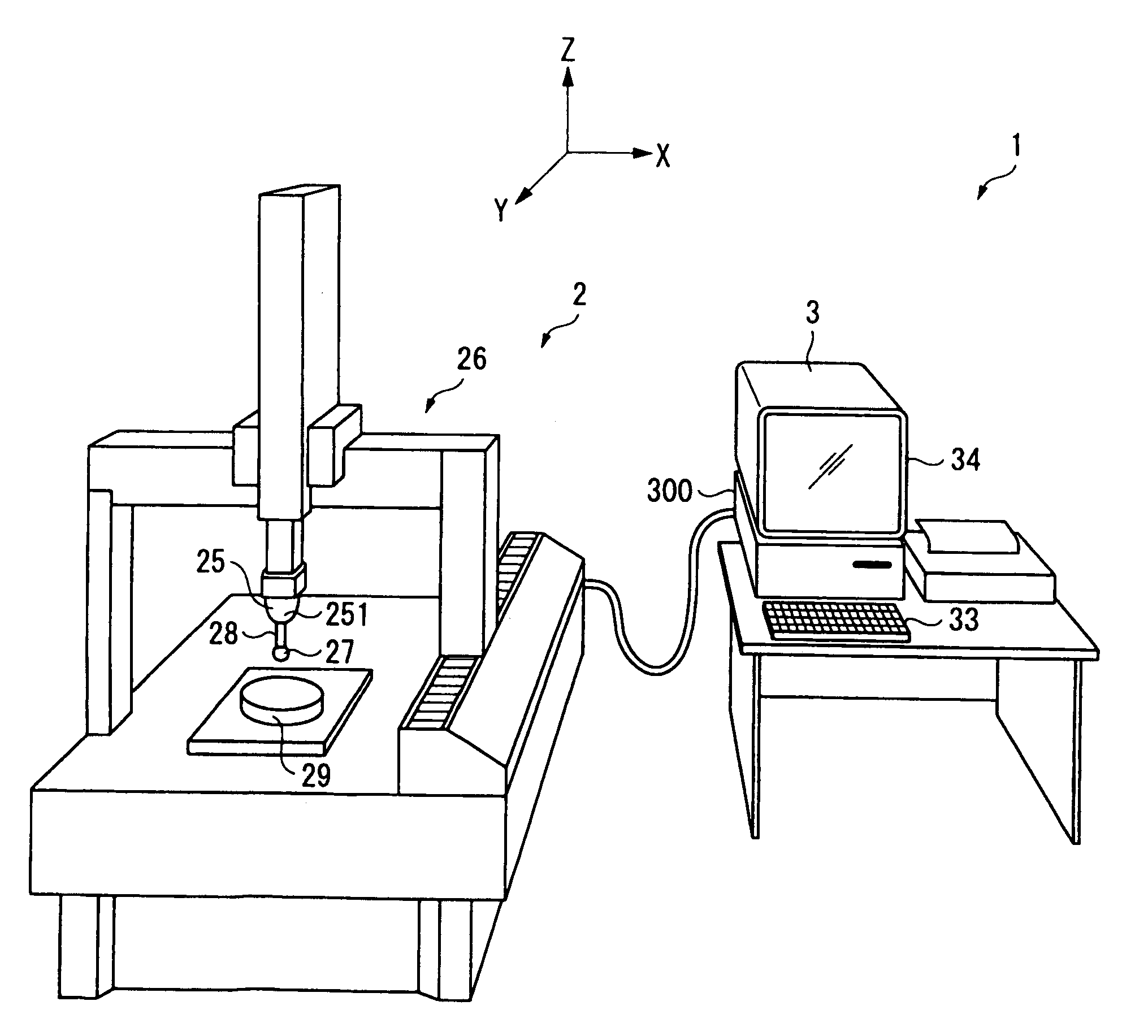

Corrected ball diameter calculating method and form measuring instrument

ActiveUS20100250178A1Amount of calculationReduce the amount of calculationMechanical counters/curvatures measurementsMechanical diameter measurementsMeasuring instrumentEngineering

A corrected ball diameter calculating method includes: preparing a reference gauge that has at least one reference peripheral surface of an outer peripheral surface and an inner peripheral surface; valuing of diameter values of the reference peripheral surface at a plurality of different height positions from a bottom surface of the reference gauge; calculating calibrated diameter values per each of the height positions; placing the reference gauge on the rotary table and causing the stylus tip to touch a plurality of measurement sites on the reference peripheral surface at each of the height positions to calculate measured diameter values that are diameter values of a circle passing through the neighborhood of center points of the stylus tip; and calculating the corrected ball diameters per each of the height positions from the calibrated diameter values and the measured diameter values that are calculated per each of the height positions.

Owner:MITUTOYO CORP

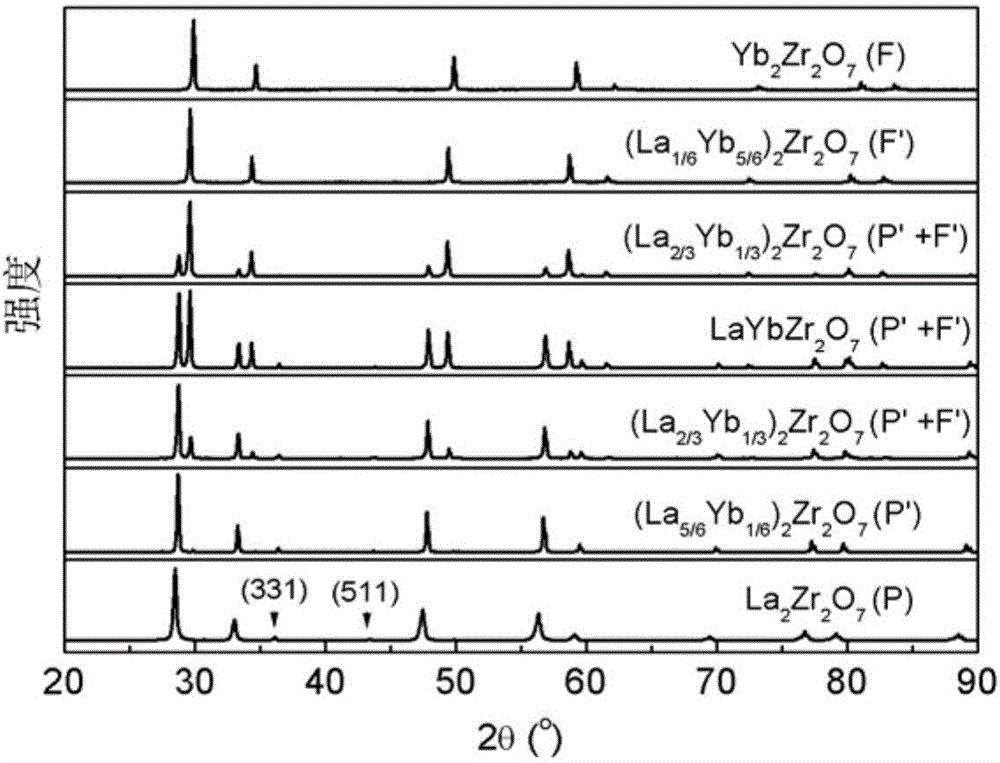

Thermal barrier coating material of eutectic structure and method for manufacturing thermal spraying powder particles by utilizing material

ActiveCN104891990AOvercoming problems such as failureImprove toughnessAir atmosphereThermal spraying

The invention relates to a thermal barrier coating material of a eutectic structure and a method for manufacturing thermal spraying powder particles by utilizing the material, which belongs to the technical field of high temperature-resistant ceramic materials. The structural formula of the material is (Ln11-xLn2x)2Zr2O7, and the material comprises two elements Ln1 and Ln2 in the form of metal oxides of at least two metals selected from La, Ce, La, Pr, Nd, Sm, Gd, Dy, Ho, Yb, Y and Sc, wherein the content x of the two elements is larger than or equal to 0.2 and smaller than or equal to 0.8. Raw materials are subjected to ball milling and then are mixed up, dried and pressed into blanks. After reacting with one another in an air atmosphere at 1500 DEG C to 1650 DEG C for a certain period of time, the materials form the (Ln11-xLn2x)2Zr2O7 eutectic material having two crystalline phases. Synthesized materials are ground to be fine and then mixed with a binder and a dispersing agent for ball-milling operation. After the spray granulation process, microspheres of 30 to 60 [mu]m in ball diameter can be obtained for preparing a heat-insulating coating through the plasma thermal-spraying process. The thermal barrier coating prepared by the above method is low in heat conductivity coefficient and high in toughness. The coating deterioration defect due to the growth and the sintering of crystal grains in a high-temperature working environment for a long term can be overcome.

Owner:TSINGHUA UNIV

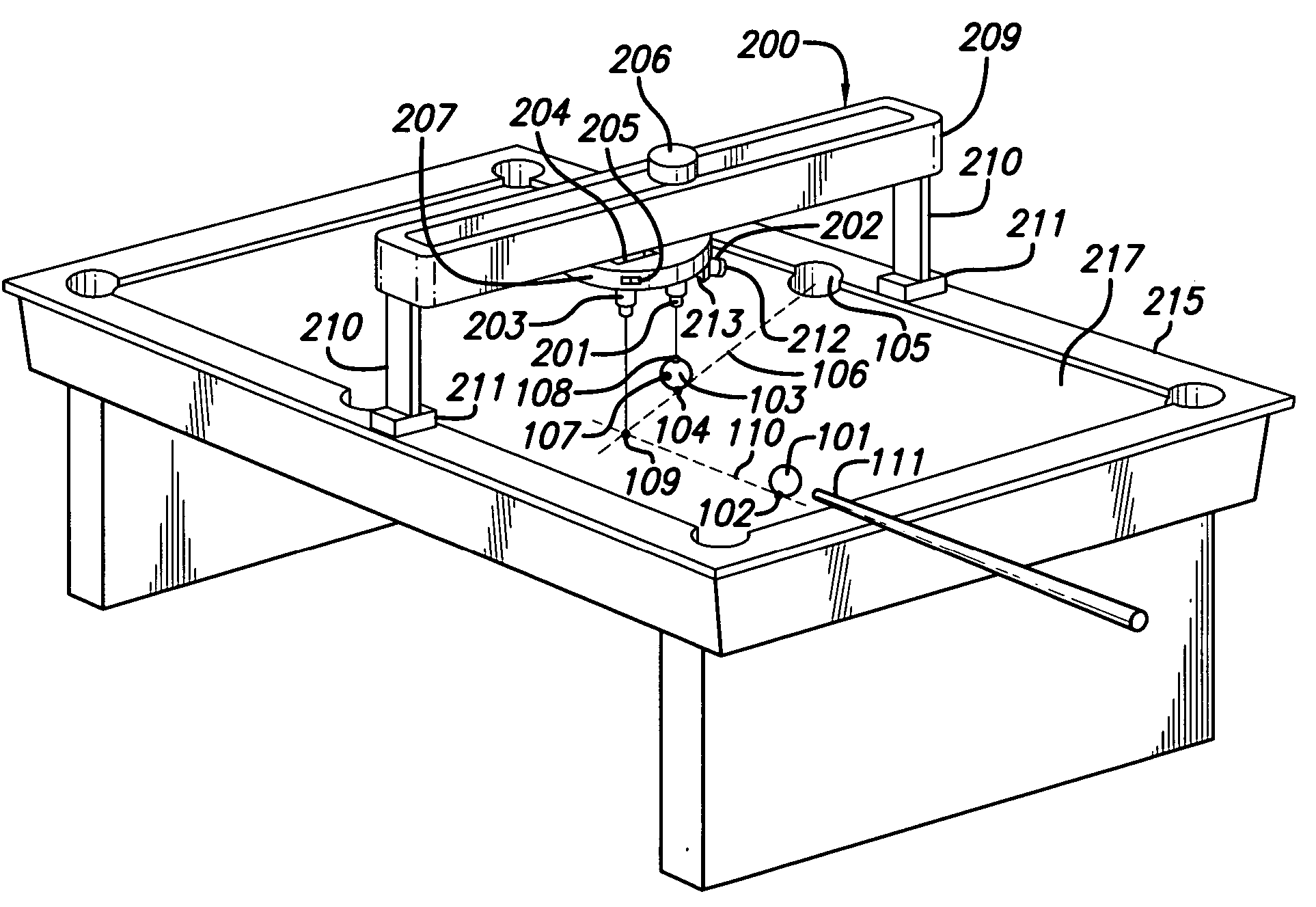

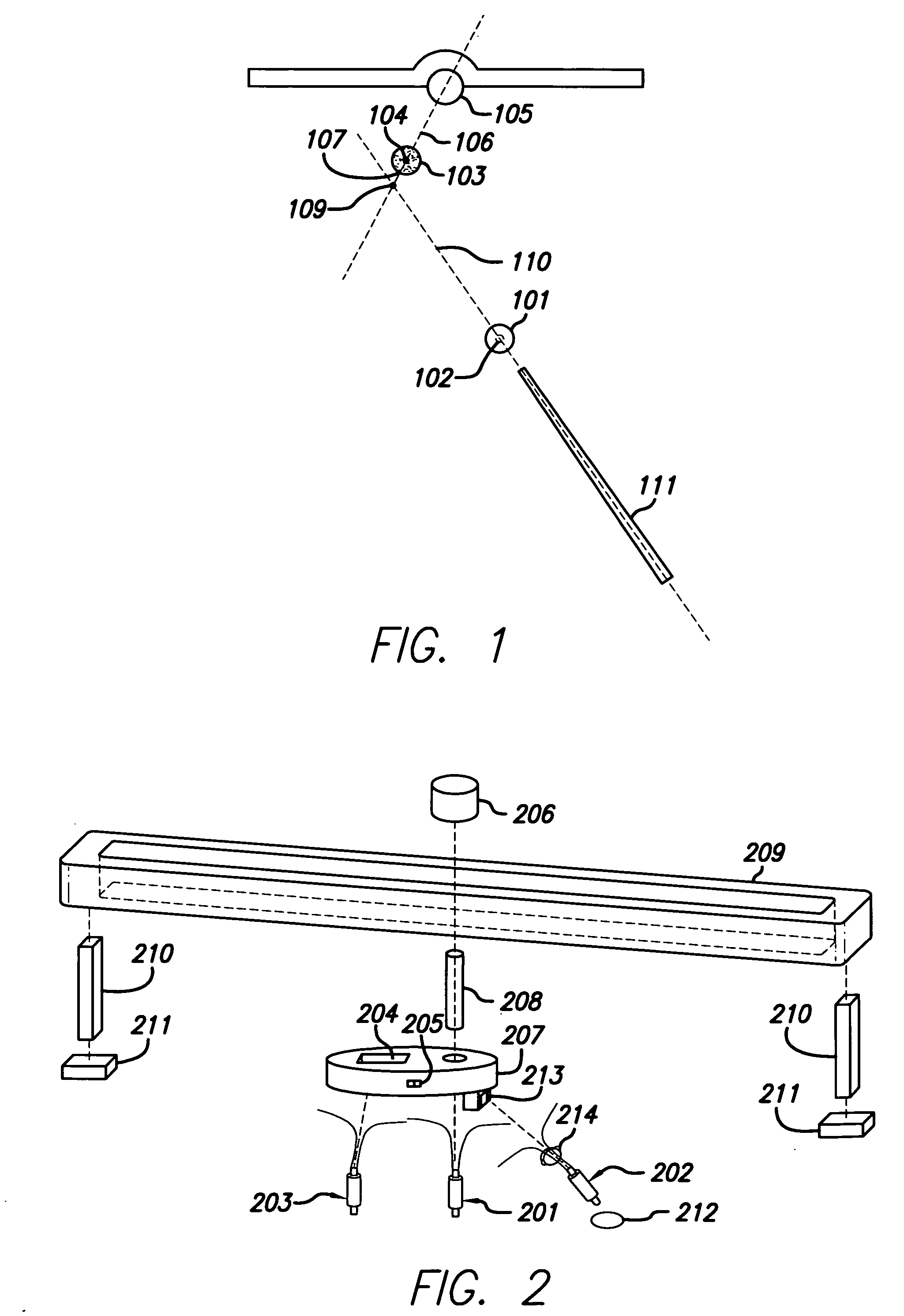

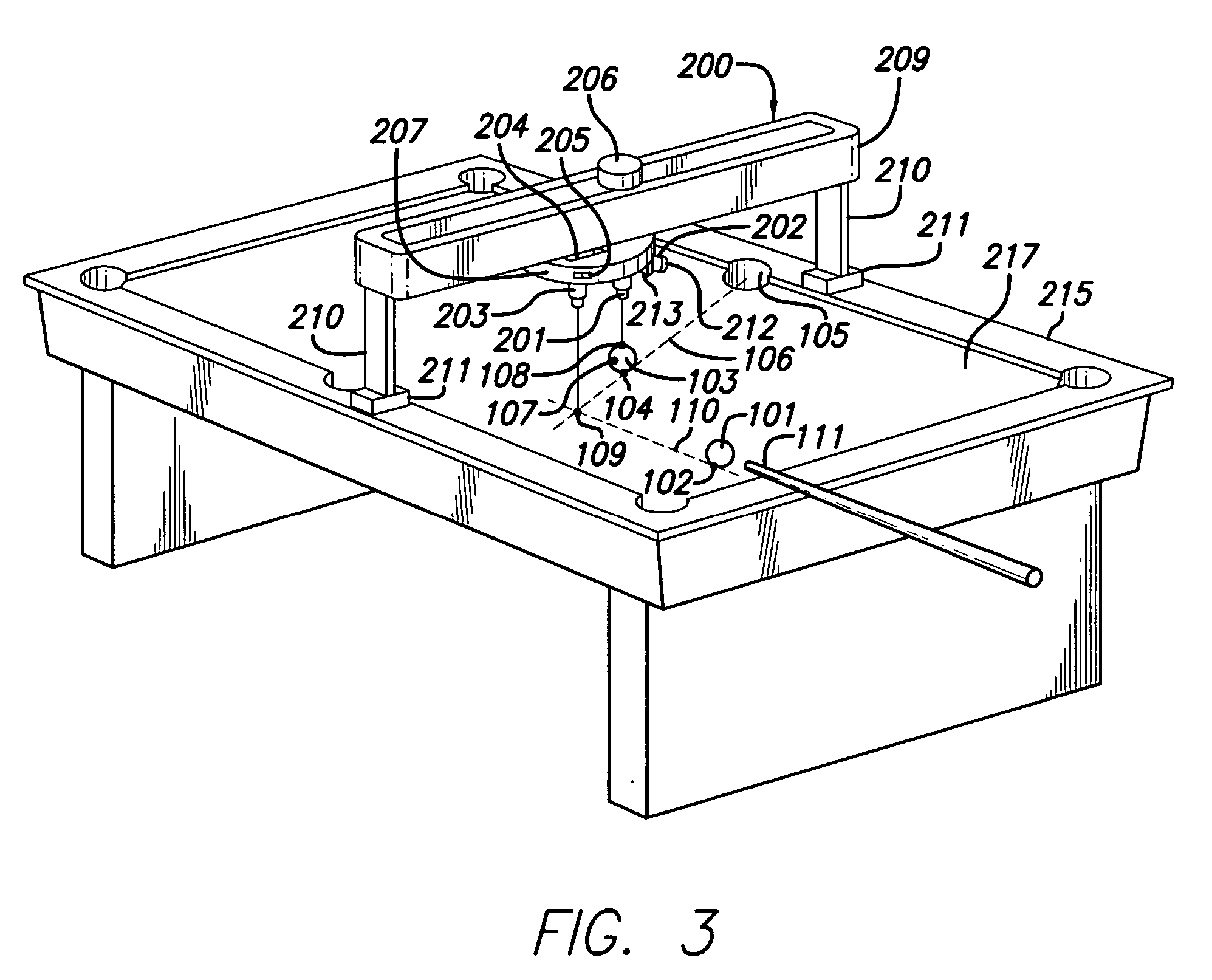

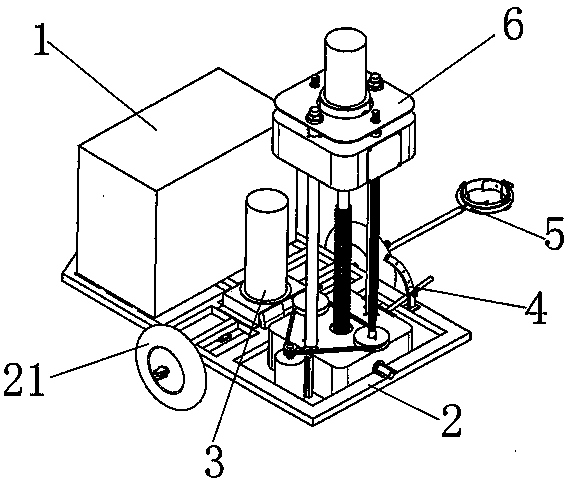

Laser light aiming trainer for the game of pool and similar games

A method of conditioning participants in games of billiards or the like to visualize the geometry underlying the pocketing of an object ball as the result of impact by a cue ball through the employment of a training device adapted to be positioned above the playing surface. The device includes a base member rotatable in a horizontal plane, said base member housing three laser light-emitting sources, the first of which is focused downwardly to illuminate a selected object ball, the second of which downwardly projects a line path from the illuminated object ball to the designated pocket, and the third of which is directed downwardly to emit a beam focused on the “aim spot,” said first and third laser light emitting sources being positioned perpendicular to the playing surface, parallel to each other, and spaced one object ball diameter apart, whereby when the propelled cue ball rolls over the “aim spot,” it impacts the proximate object ball causing it to travel along the illuminated line path to the designated target.

Owner:EVERS EDWARD E

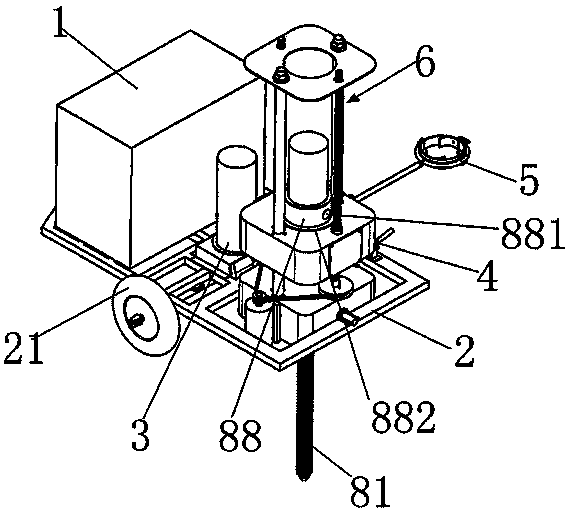

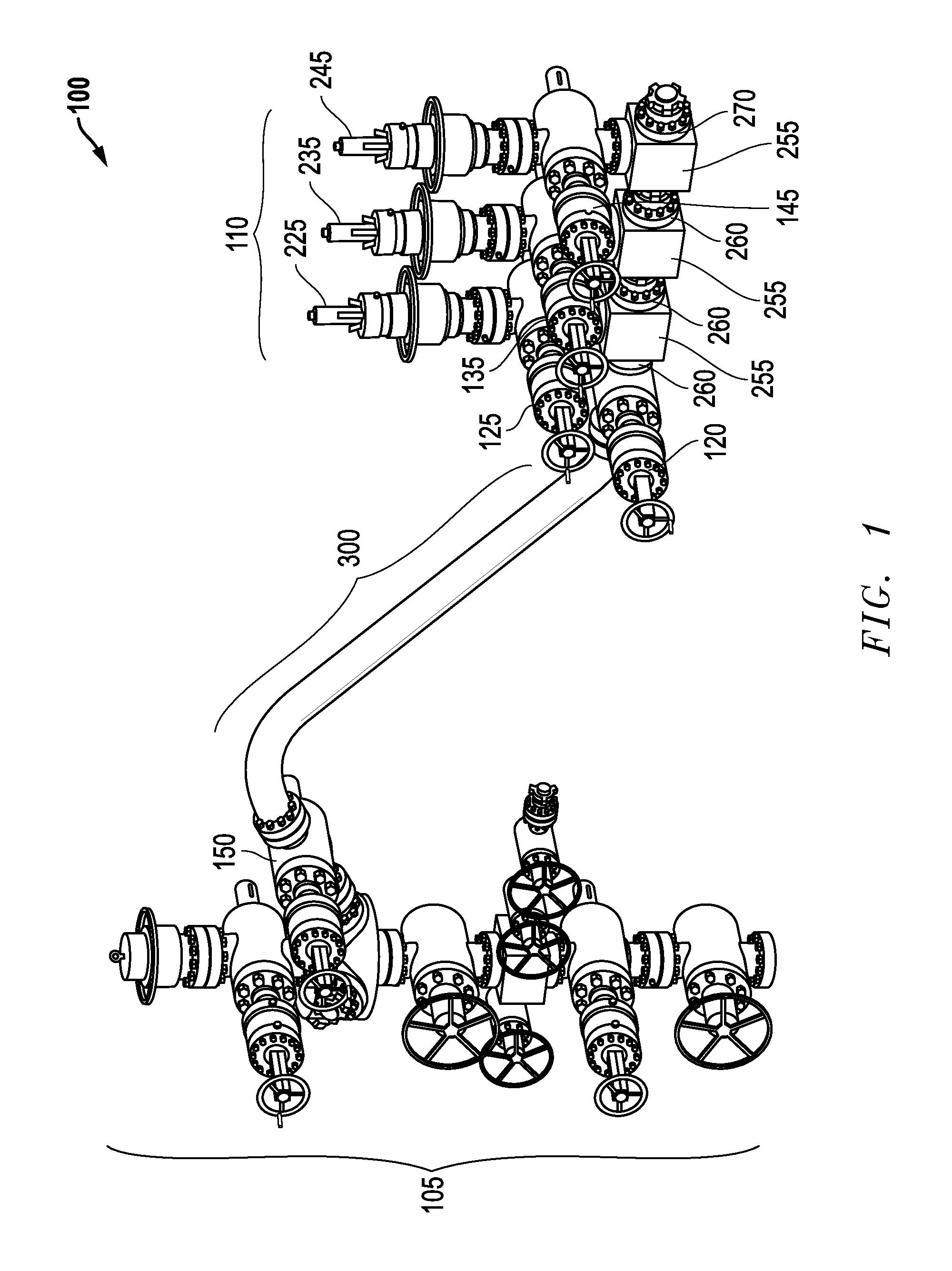

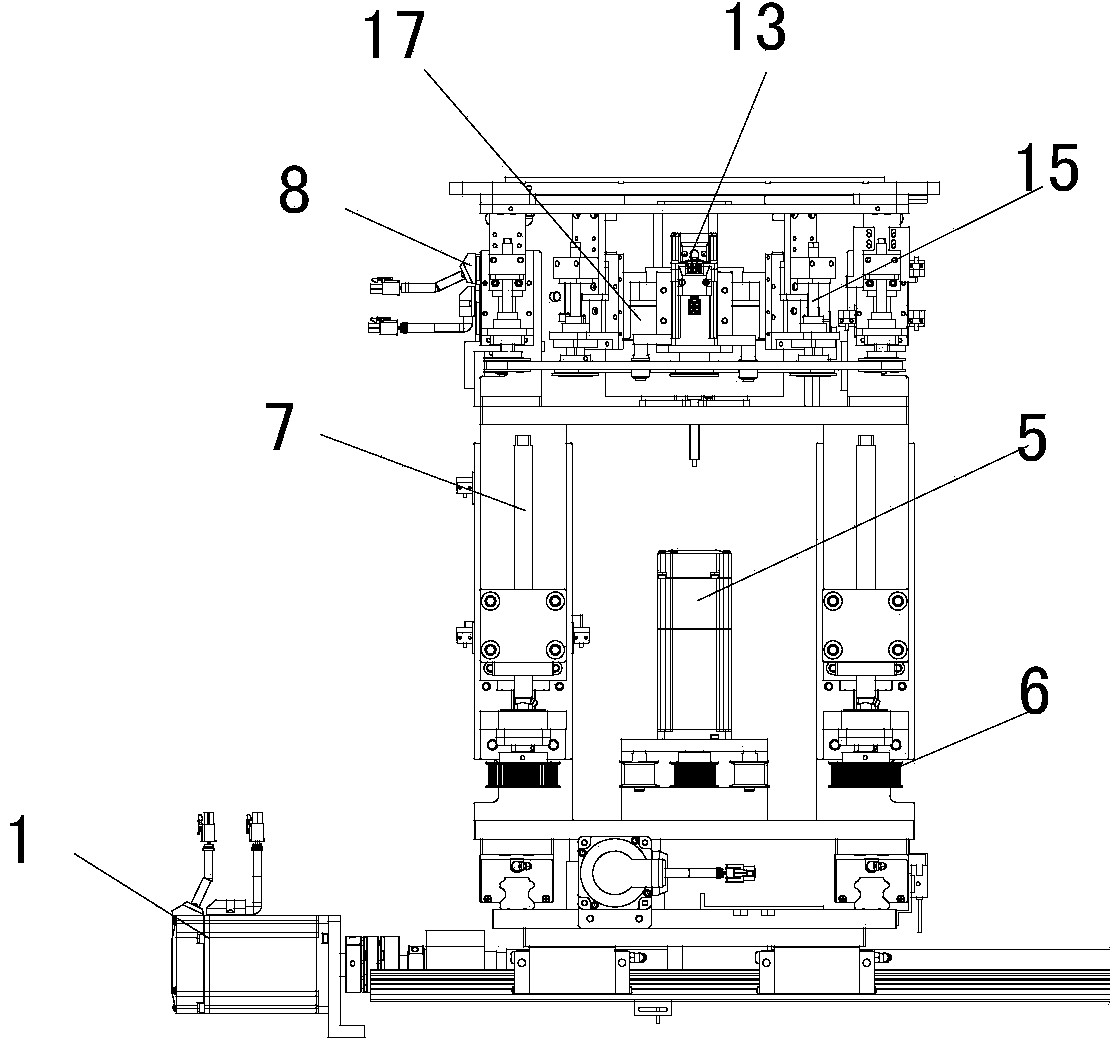

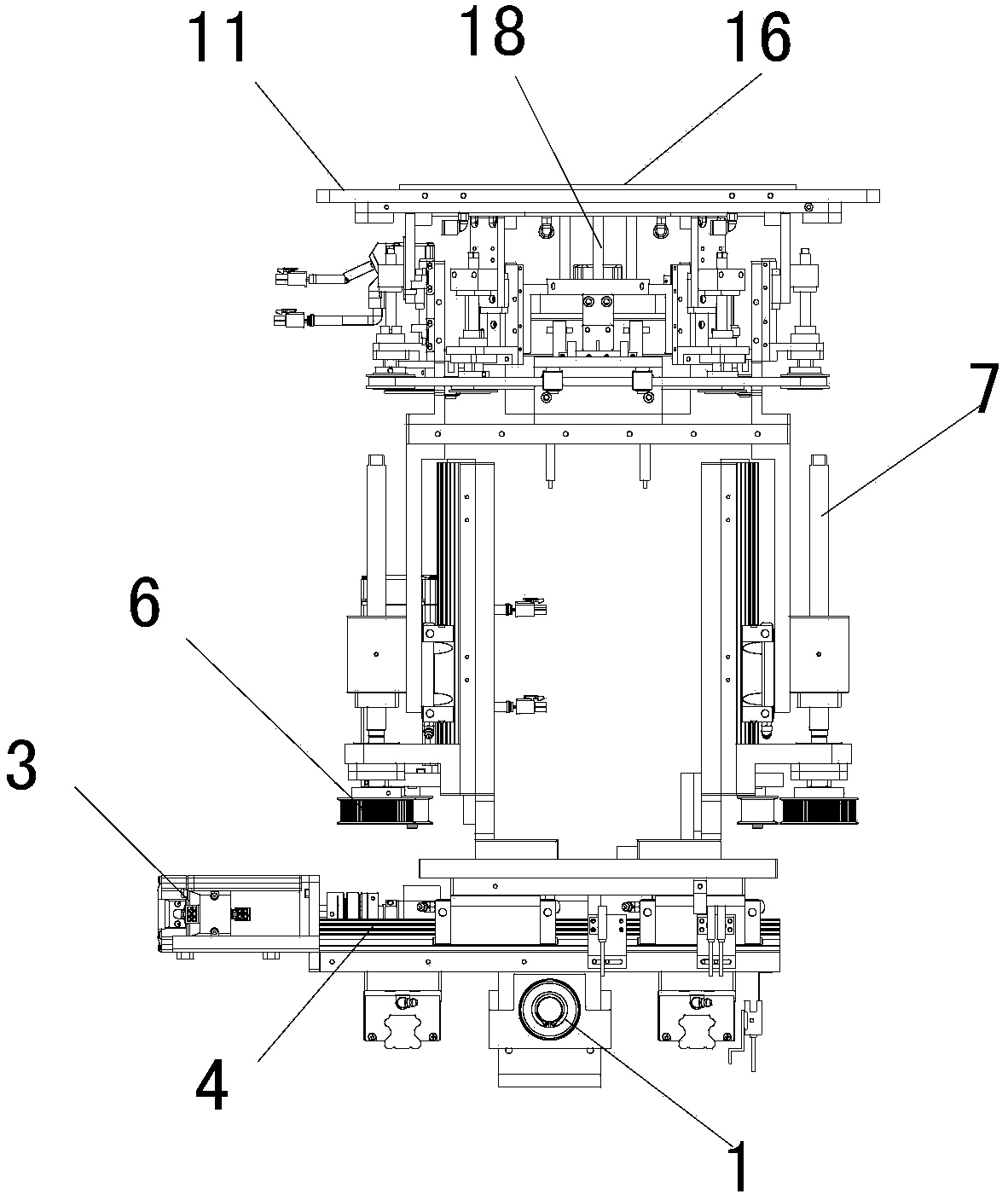

Earth ball shape and size adjustable small-sized tree mover

InactiveCN104170701AEasy to control automaticallySimple structureForestryAutomatic controlEngineering

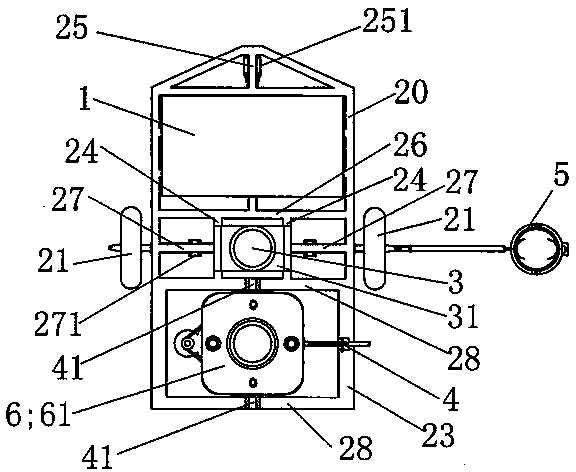

The invention discloses an earth ball shape and size adjustable small-sized tree mover which comprises a generator, a trolley, a first drive device, an earth ball taper angle adjusting device, an earth ball diameter adjusting device and a tree moving working device, wherein the generator, the first drive device, the earth ball taper angle adjusting device, the earth ball diameter adjusting device and the tree moving working device are arranged on the trolley; a multi-head reamer of the tree moving working device works to dig out a tree. The small-sized tree mover has the advantages that the structure is simple; the automatic control of procedure is easy to realize; the operation is convenient; suitability for nursery stock of different breast diameters can be realized; the shape and size of an earth ball can be adjusted conveniently; the earth ball cutting speed is high; the work efficiency is high; the earth ball quality is high; guarantee is provided for the transplanting survival rate of the nursery stock.

Owner:KUNMING UNIV

Desert green planting structure and method

ActiveCN103718883AImprove survival rateSolve the problem of lack of water and fertilizerRoot feedersReceptacle cultivationGround planeSeedling

The invention provides a desert green planting structure and method which are particularly suitable for planting bare-rooted seedlings, shrubs and the dungarunga, the soil ball diameter of the shrubs and the dungarunga is lower than 50cm, and the shrubs and the dungarunga are suitable for being planted in the desert. The structure comprises a planting bag, a planting matrix, an irrigating device and a plant. The planting bag is filled with the planting matrix which completely buries the root of the plant. The irrigating device is arranged inside the planting bag and used for being connected with an irrigating water pipe, the tail end of the lower portion of the irrigating device faces the root of the plant, and the top end of the upper portion of the irrigating device is exposed out of the ground plane of the desert soil. According to the desert green planting structure and method, the plant can be planted in the desert conveniently and rapidly, the planting survival rate of plants in the desert area is improved, meanwhile, the irrigating efficiency can be improved, and irrigation water is saved.

Owner:BEIJING ORIENT LANDSCAPE

Copper wire receiving pad

ActiveUS20130001777A1Prevent penetrationSemiconductor/solid-state device detailsSolid-state devicesCopper wireProtection layer

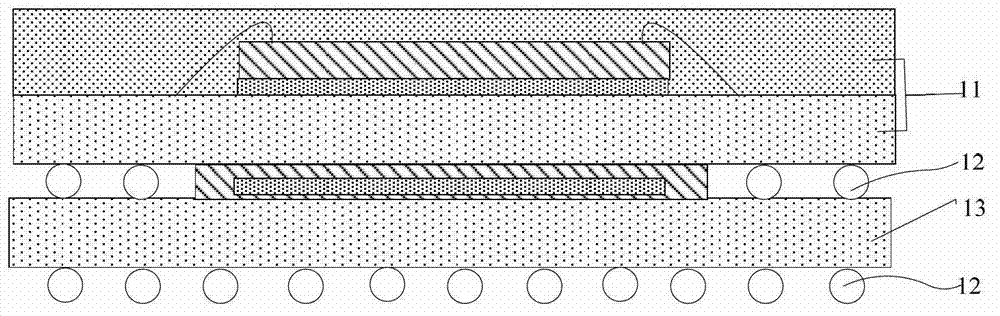

On embodiment is directed to a welding pad capable of receiving a ball-shaped copper wire at its end, including a first copper pad coated with a protection layer and topped with a second pad containing aluminum having dimensions smaller than those of the first pad and smaller than the ball diameter once said ball has been welded to the welding pad.

Owner:STMICROELECTRONICS (GRENOBLE 2) SAS

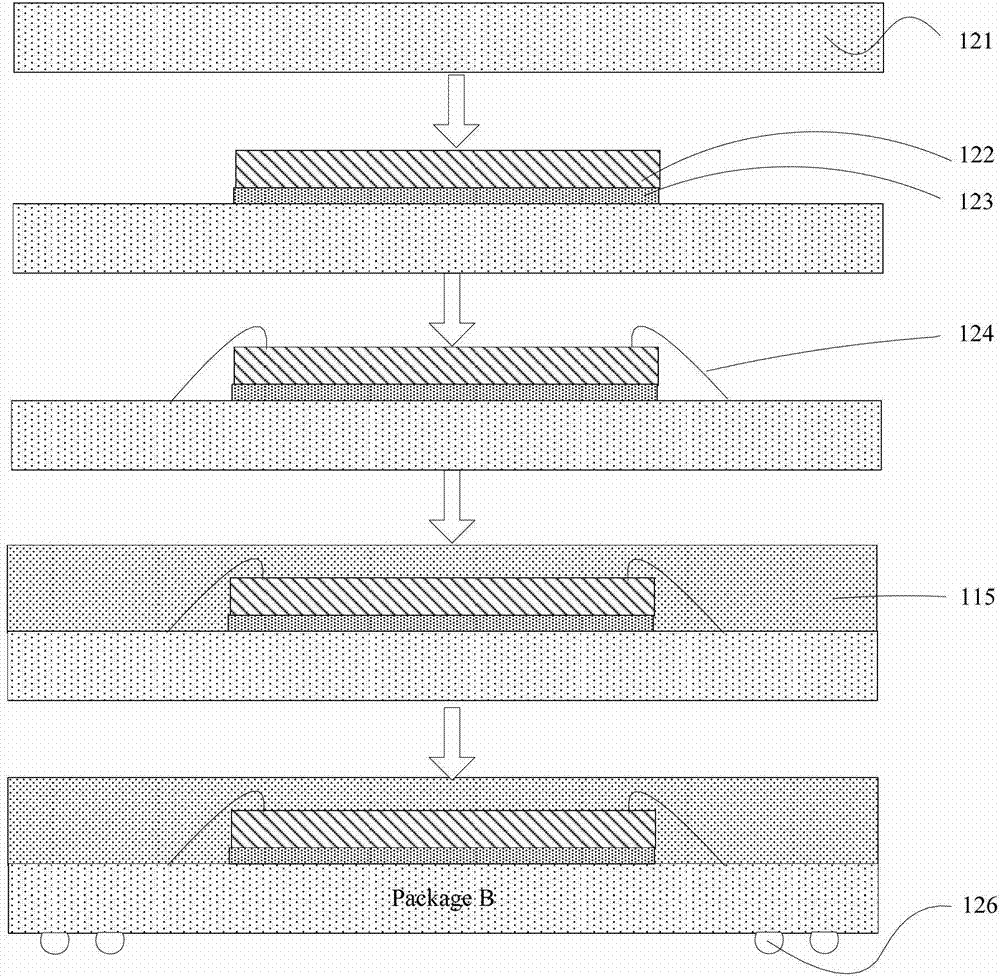

Fine spacing laminated packaging structure containing copper pillar and packaging method

InactiveCN103400823ASmall diameterOmit complex processSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

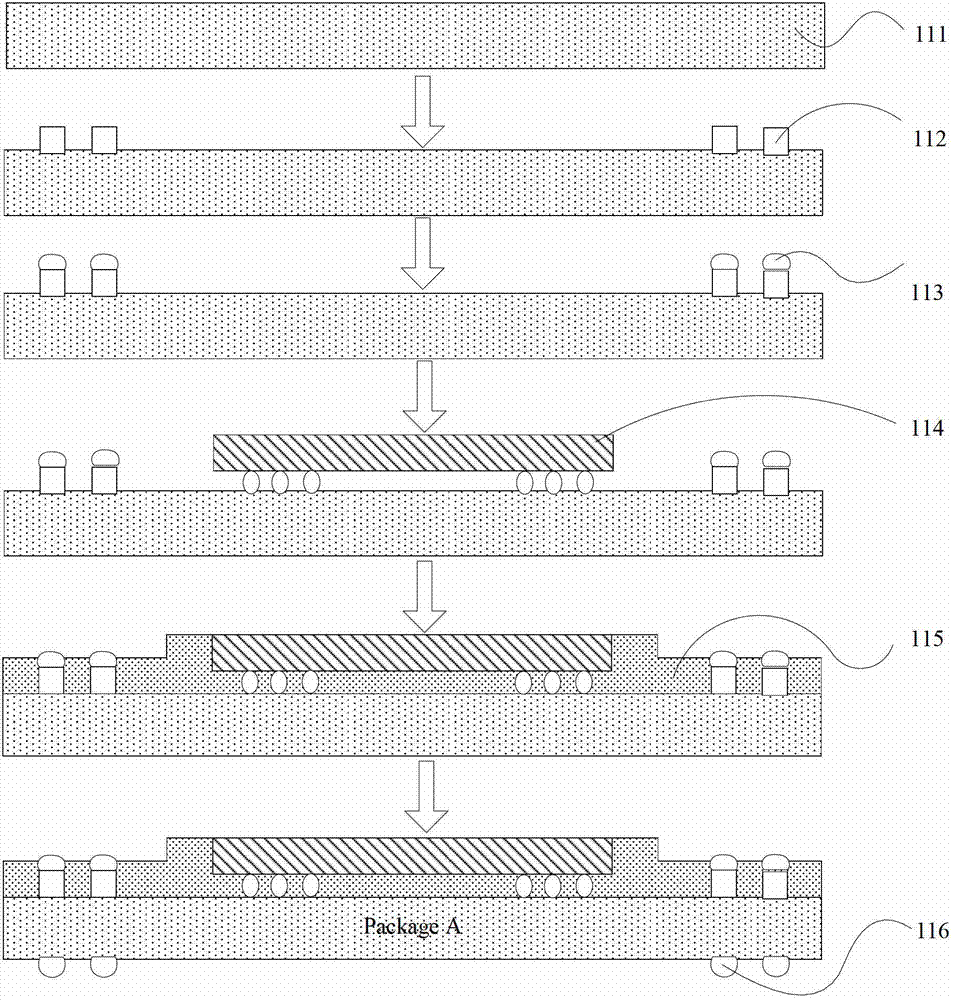

The invention provides a fine spacing laminated packaging structure containing a copper pillar, which comprises a lower packaging body and an upper packaging body, wherein the lower packaging body comprises a lower substrate, and a first chip is installed at a chip packaging area of the upper surface of the lower substrate and is electrically connected with the lower substrate; a welding area of the upper surface of the lower substrate is provided with the copper pillar, and a first welding ball is arranged on the copper pillar; the first welding ball and the upper surface of the lower substrate are pre-packaged by a packaging material, and the top of the first welding ball shows the packaging material of the upper surface of the lower substrate; the upper packaging body comprises an upper substrate, and a second chip is installed at the upper surface of the upper substrate and is electrically connected with the upper substrate; a welding area of the lower surface of the upper substrate is provided with a second welding ball. The upper substrate and the lower substrate are mutually connected through the butting joint of the second welding ball and the first welding ball. The packaging structure adopts the copper pillar so that the ball diameter of the welding balls can be shortened, and therefore the purpose of fine spacing packaging is achieved. As the copper pillar is manufactured in a welding line way, the complex electroplating process is omitted. The fine spacing laminated packaging structure has the advantages of simplicity in manufacture, low cost and the like.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

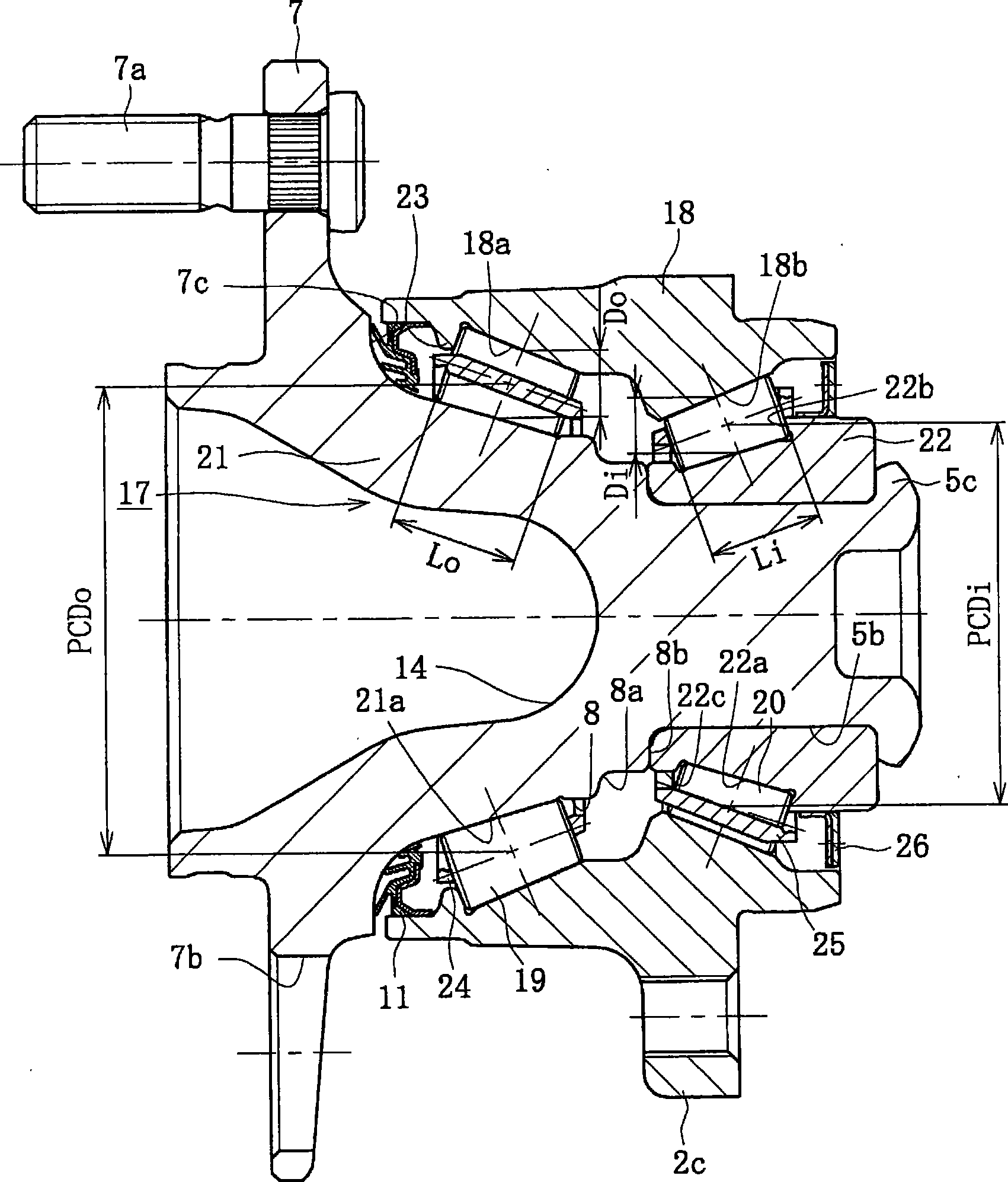

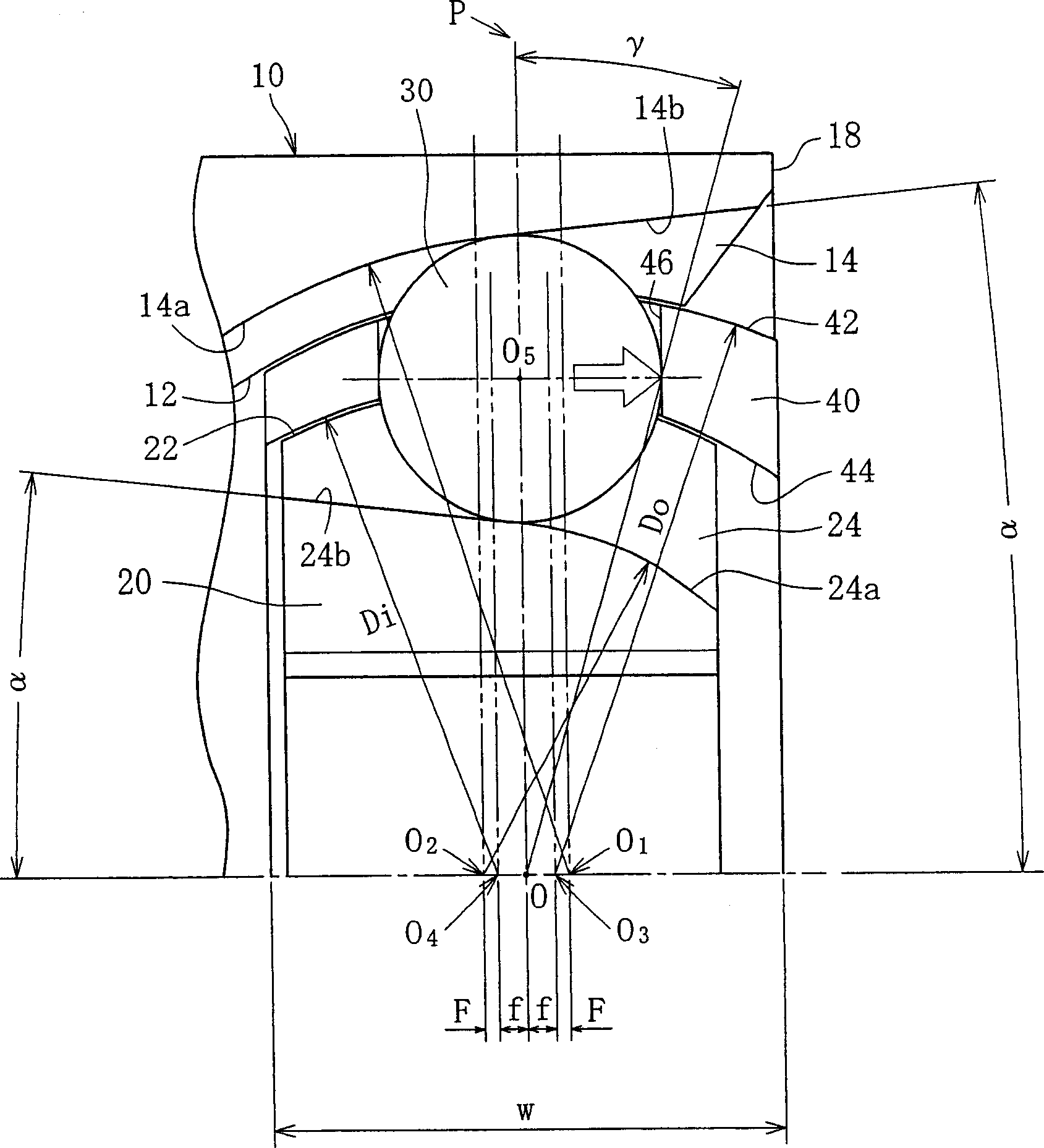

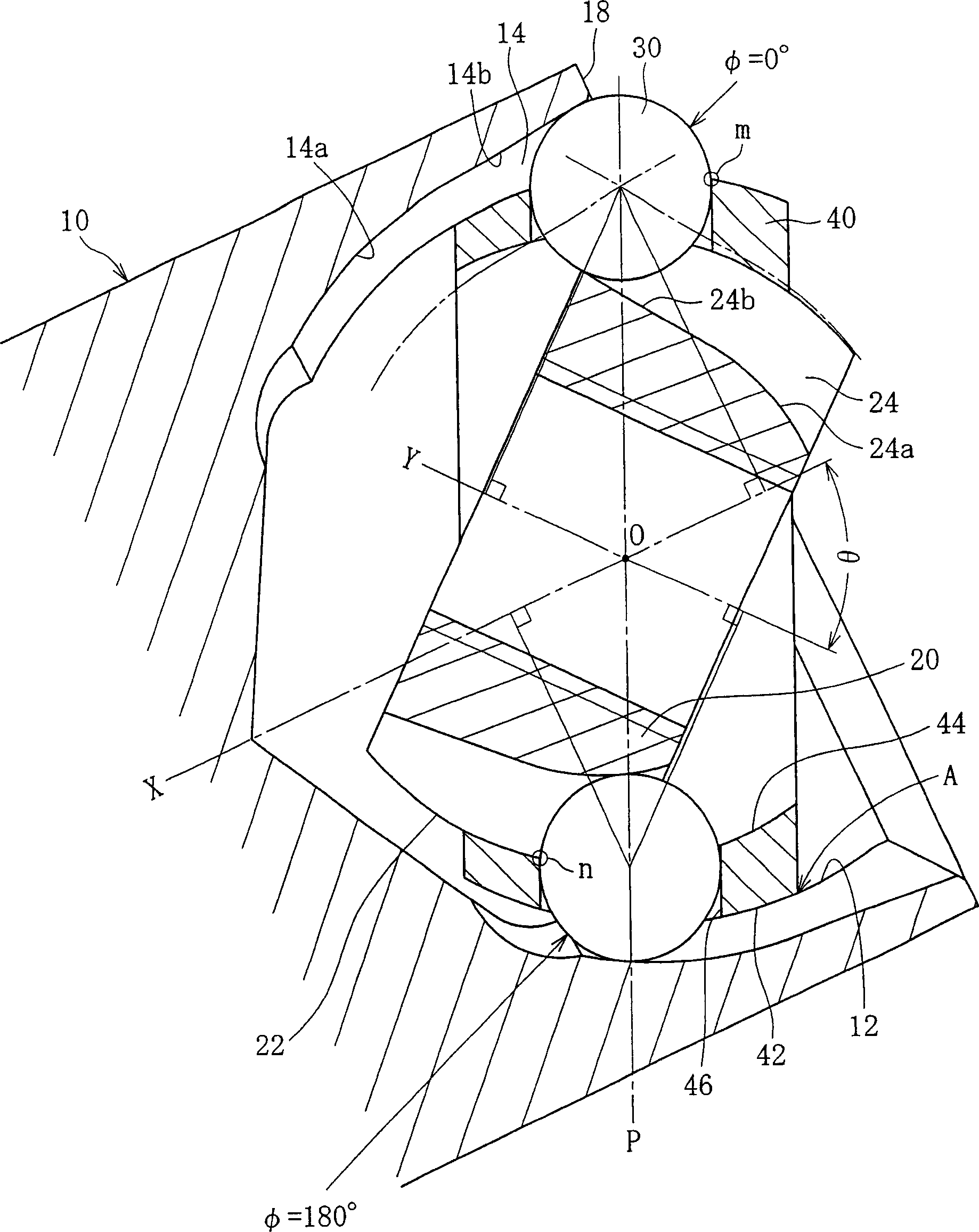

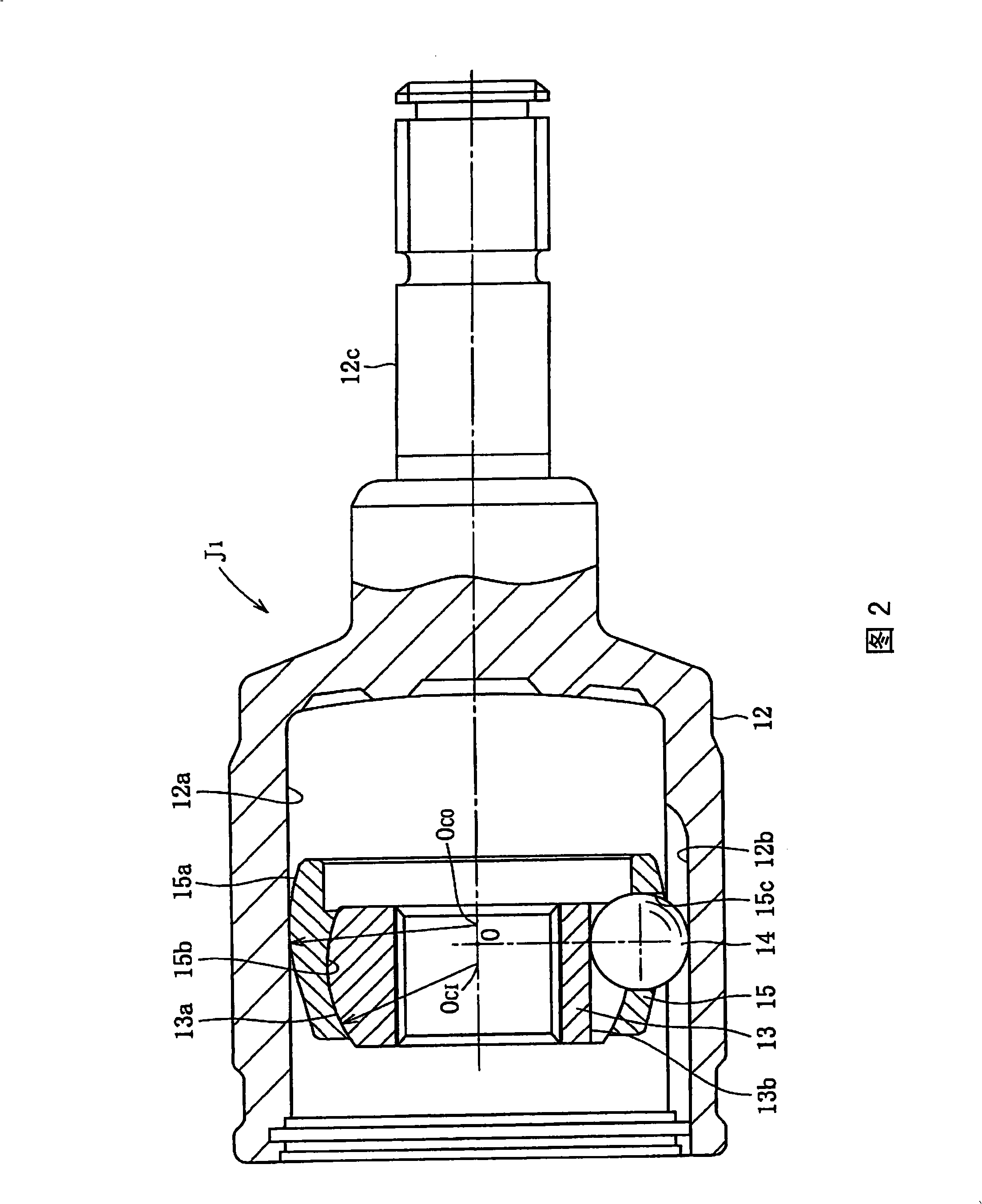

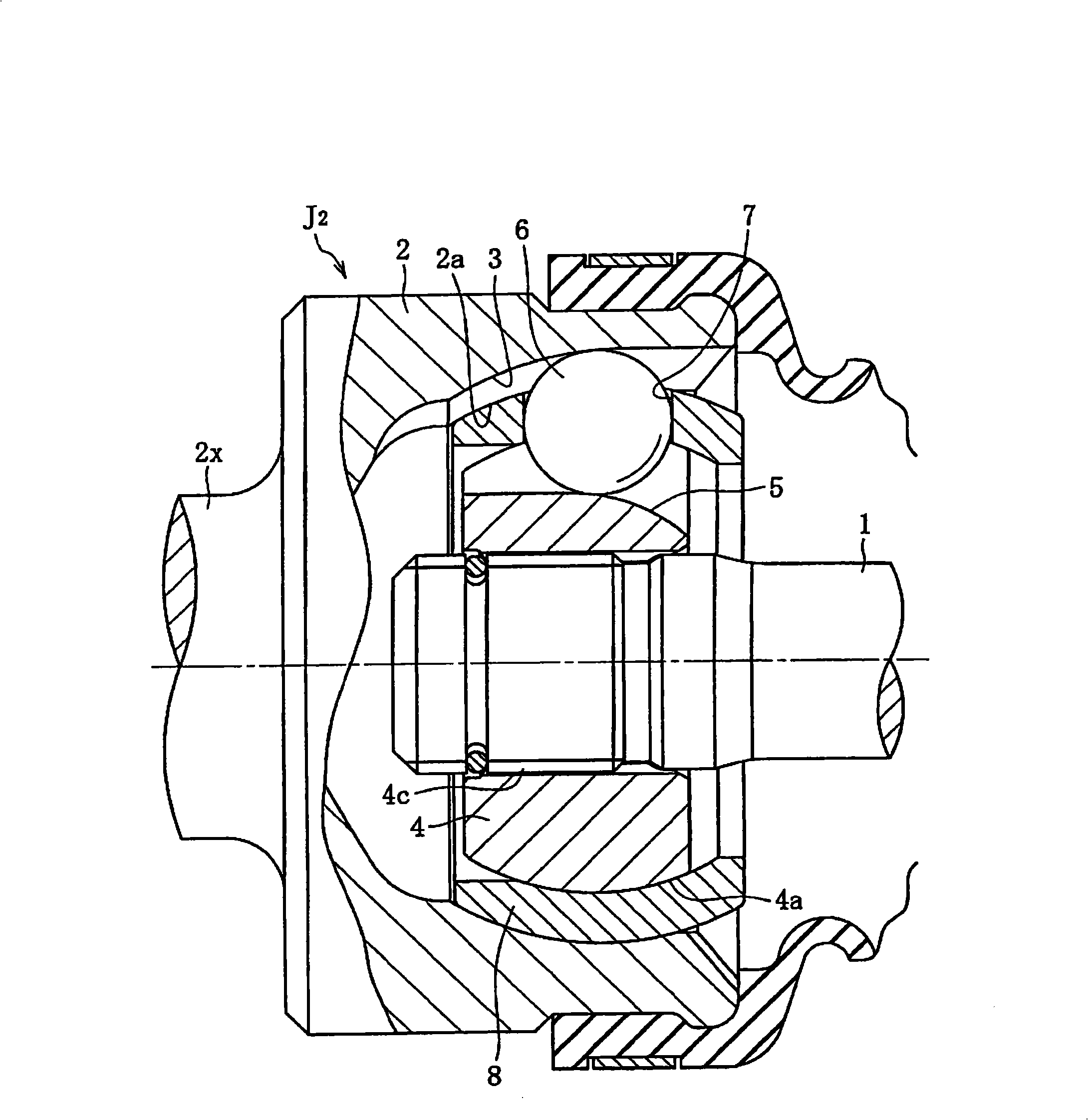

Fixed-type constant-velocity universal joint

ActiveUS20060217207A1Easy to disassembleImprove workabilityYielding couplingRotary machine partsUniversal jointEngineering

Internal dimensions for fixed-type constant velocity universal joints are defined to optimize the geometry of the components of the joints and to readily achieve a larger operating angle of the joints. In the joint, the track grooves of an outer ring and an inner ring are tapered by an angle not exceeding 12°. The ratio (f / PCR) of the cage offset amount f to PCR is greater than 0 and smaller than or equal to 0.12. The ratio (Do / d) of the cage outer diameter (Do) to the ball diameter (d), the ratio (t / d) of the cage wall thickness (t) to the ball diameter (d), and the ratio (w / d) of the cage width (w) to the ball diameter (d) are such that 3.9≦Do / d≦4.1, 0.31≦t / d≦0.34, and 1.8≦w / d≦2.0, respectively. The end of the spherical outer surface of the cage adjacent to the open end is axially extended, and the end of the spherical inner surface of the cage adjacent to the open end is tapered so that the tapered surface has an increasing diameter toward the end of the spherical outer surface adjacent to the open end. Part of the spherical outer surface of the cage is cut on the open end side of pockets, and the outer diameter of the cage across the two opposing planer cut faces is smaller than the spigot diameter of the outer ring.

Owner:NTN CORP

Proximity communication package for processor, cache and memory

ActiveUS8102663B2Reduce toppingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCapacitive coupling

A “sombrero” bridge transports signal communication between a processor and one or more cache memories. The bridge surrounds the processor's perimeter, and includes an aperture opposite the processor through which power and data can be provided to the processor from another device. The bridge exchanges signals with the cache memories via capacitively coupled proximity connections. The bridge communicates with the processor via conductive (e.g. wire) connections and optionally proximity connections. Spacing between opposing pads of the proximity connection(s) between the bridge and the cache memories can be provided by recesses in a surface of the cache memory, corresponding recesses in an opposing surface of the bridge, and a ball for each matching pair of corresponding cache memory and bridge recesses. The ball fits in and between the recesses of the matching pair. The recess depths and ball diameter(s) constrain a minimum distance between opposing pads of the proximity connection(s).

Owner:ORACLE INT CORP

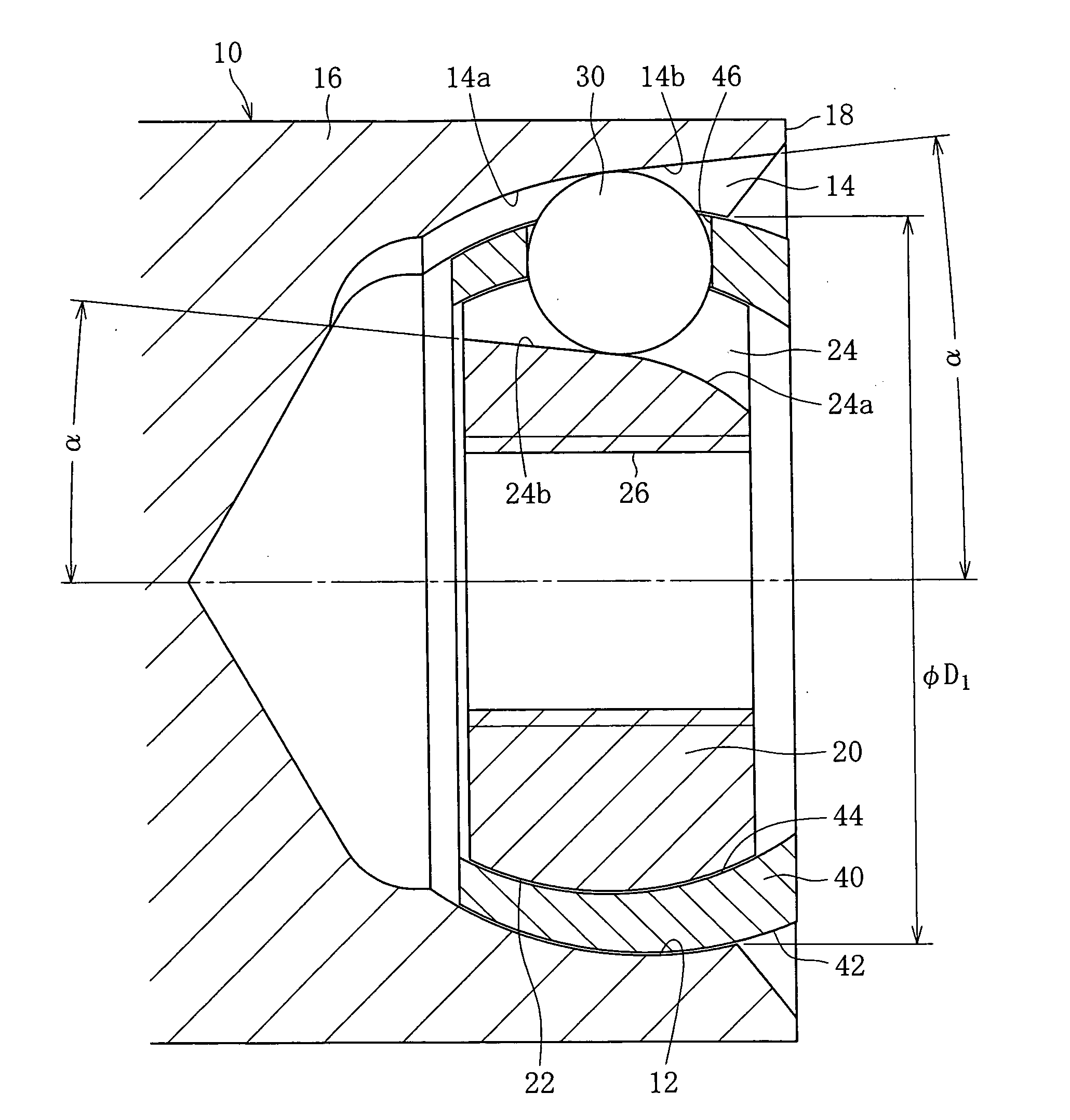

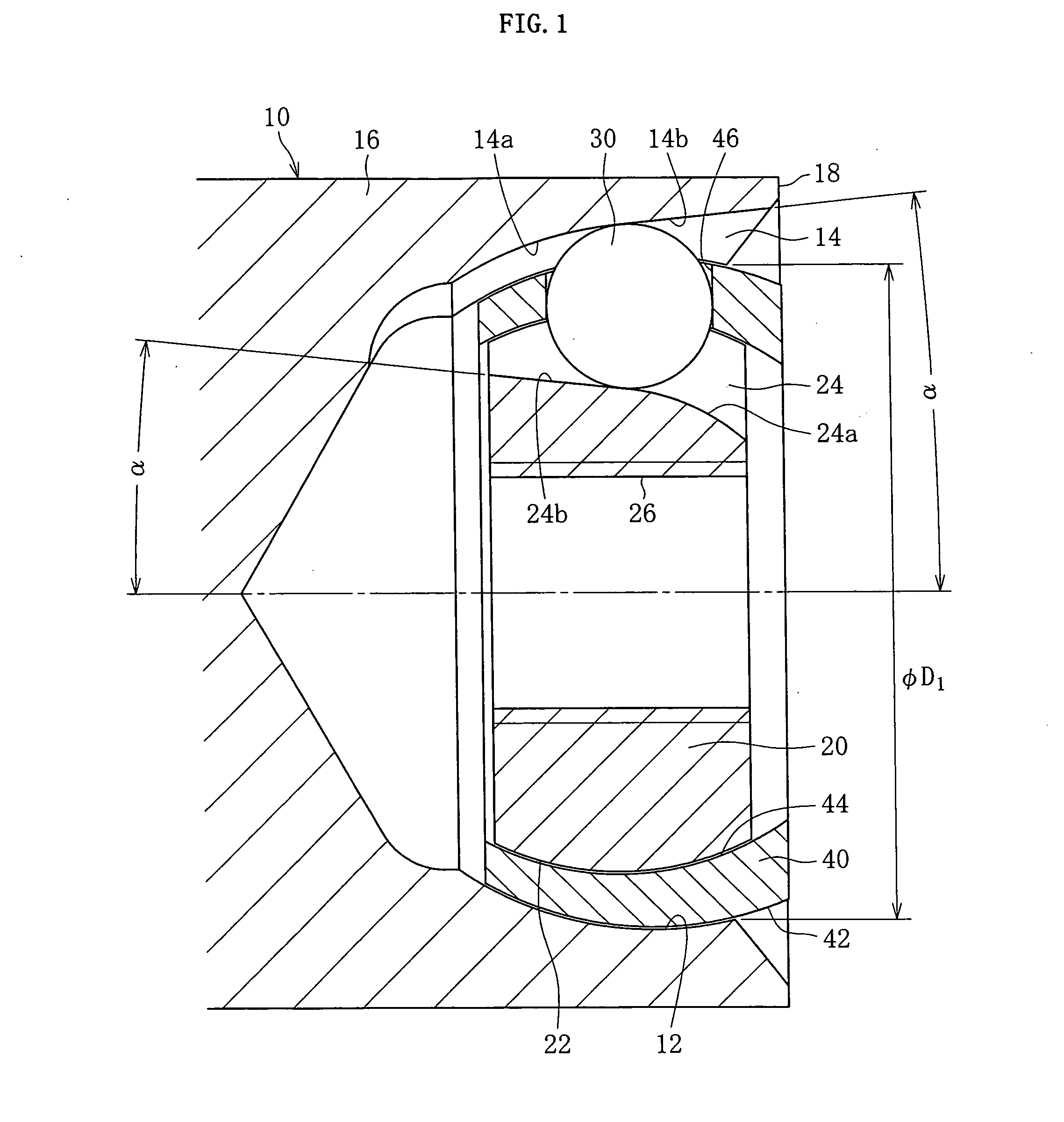

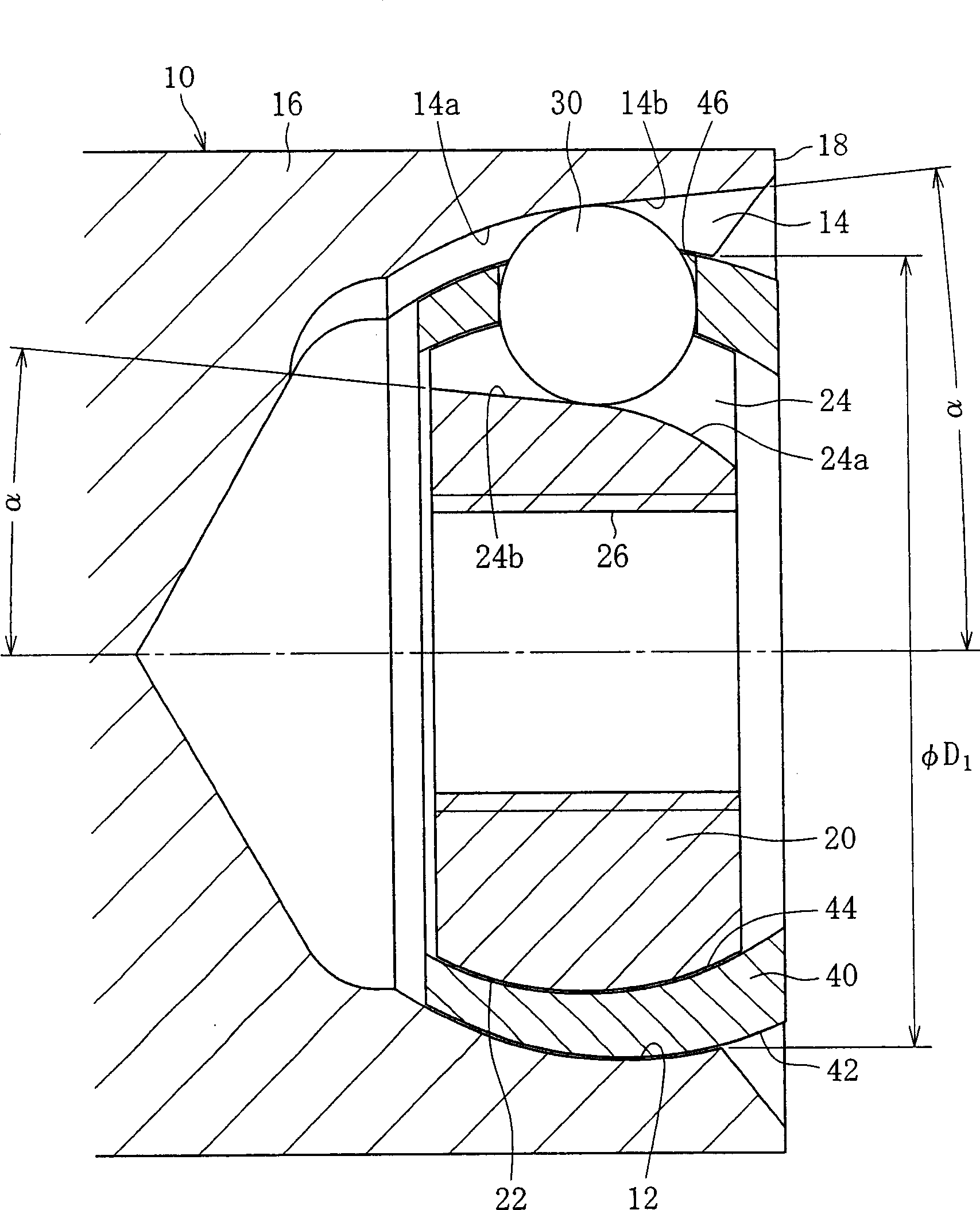

Bearing apparatus for supporting pinion shaft

InactiveUS20070104403A1Improve carrying capacityLarge contact angleShaftsBall bearingsBall bearingRolling-element bearing

A bearing apparatus for supporting a pinion shaft comprises a pair of rolling bearings which rotatably support a pinion shaft to a case and are arranged side by side in a shaft direction between a pinion gear arranged at one end of the pinion shaft, and a companion flange attached outside the other end thereof. The rolling bearing on a companion flange side comprises an angular ball bearing, and a radius of curvature Ri of an inner ring raceway, a radius of curvature Ro of an outer ring raceway, and a ball diameter Bd of the rolling bearing may satisfy a relationship given by equations of Ri<Ro, 0.502×Bd≦Ri≦0.512×Bd, and 0.510×Bd≦Ro≦0.520×Bd.

Owner:JTEKT CORP

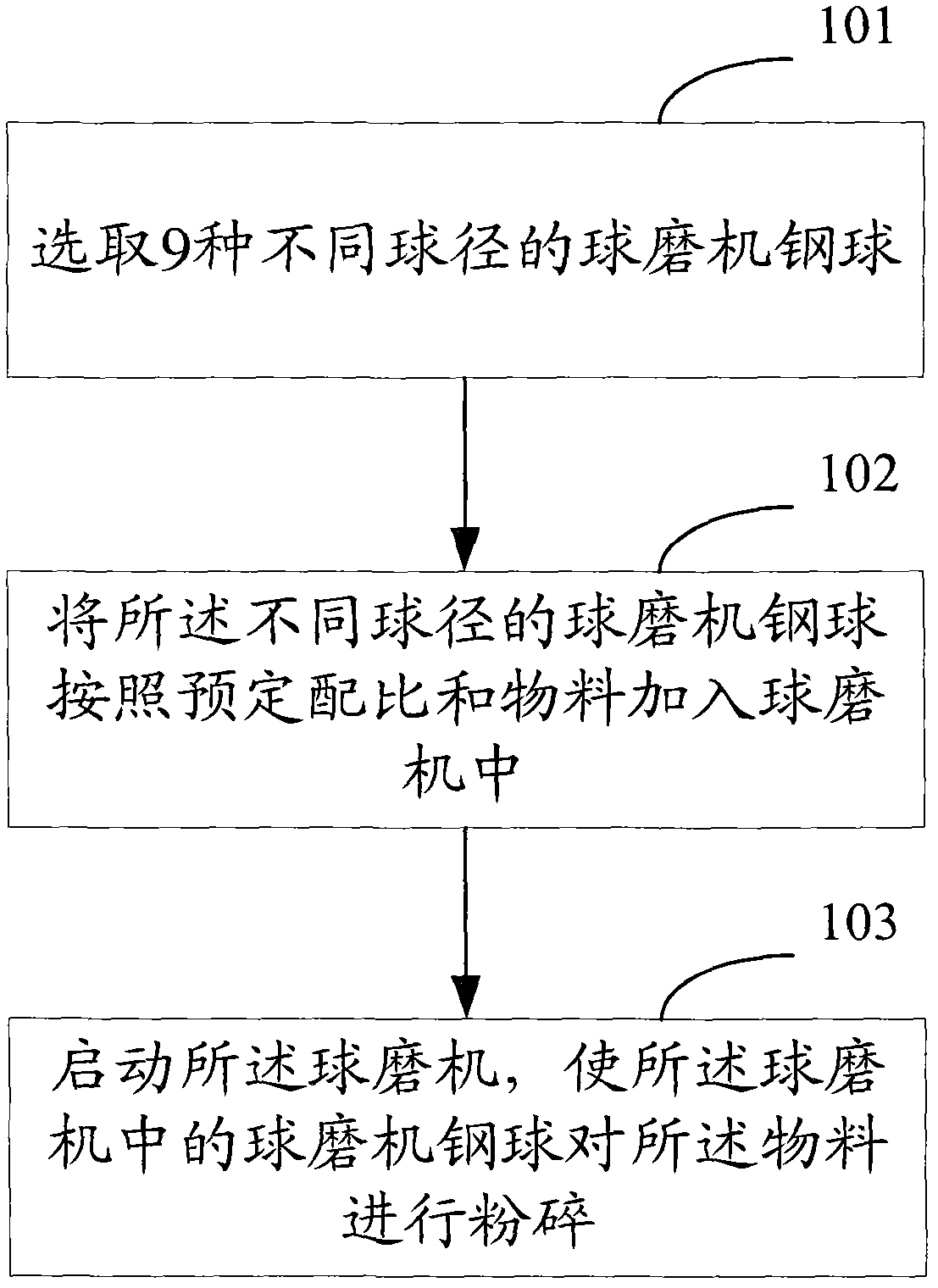

A kind of ball mill less ball milling method

InactiveCN102284325AIncrease impactIncreased grinding contact areaGrain treatmentsSteel ballSteel mill

The invention discloses a fewer ball milling method for a ball mill, which is applied to a ball mill which uses steel mill balls to crush materials. The method comprises the following steps of: selecting 9 kinds of steel mill balls with different ball diameters; adding steel mill balls with different ball diameters into the ball mill with materials according to a preset proportion; starting the ball mill to ensure that the steel mill balls in the ball mill crush the materials. According to the fewer ball milling method for the ball mill, the steel balls in the steel tank of the ball mill are mixed reasonably according to a certain proportion in nine specifications with ball diameters from 20 to 90mm, so that the impact force can be intensified by big balls, and the grinding contact area can be increased by small balls; and the big balls and the small balls are cooperated one another in cascade, so that the grinding effect of the steel mill balls is sufficiently played, and the grinding efficiency is greatly improved.

Owner:宁国市锦宏耐磨材料有限公司

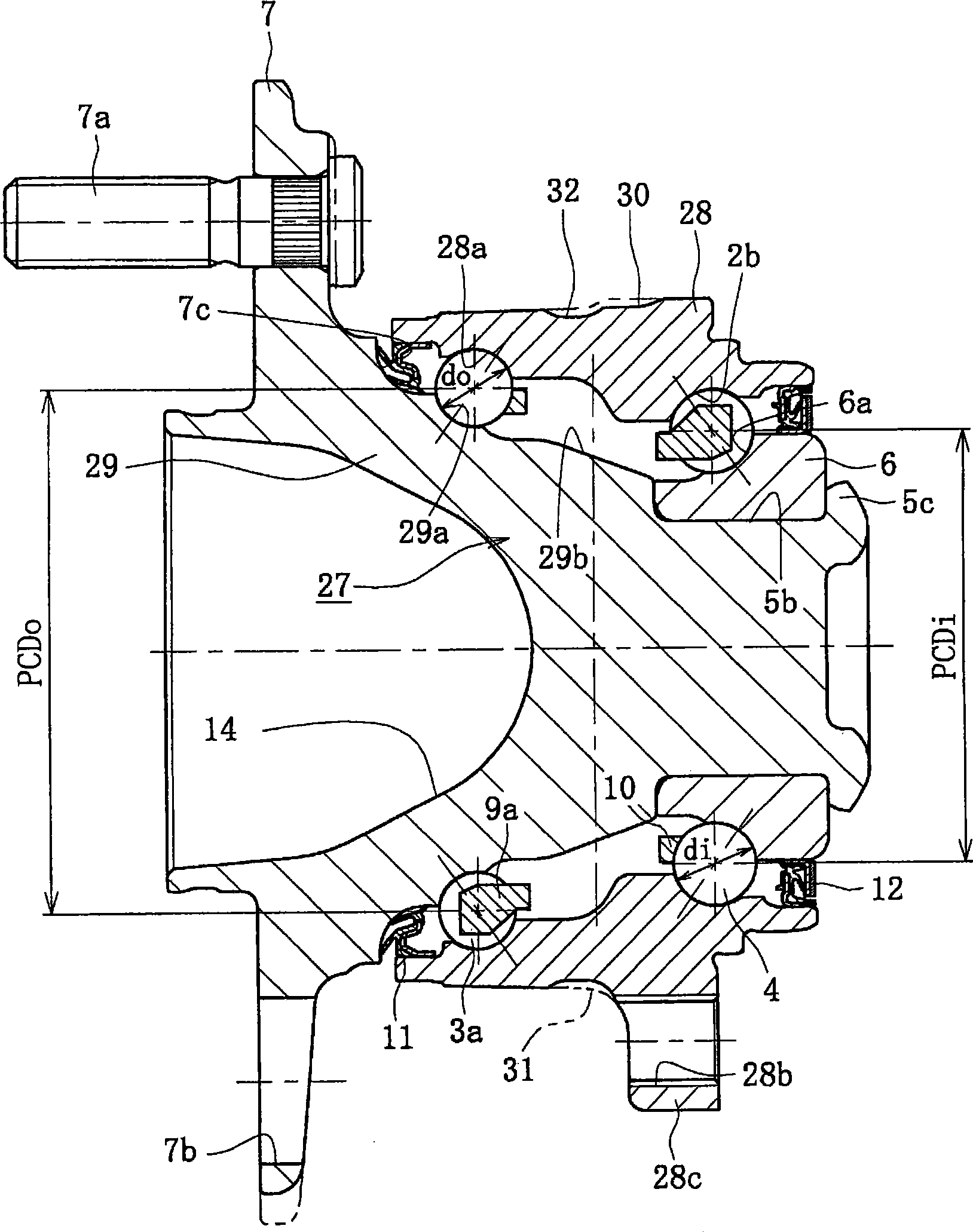

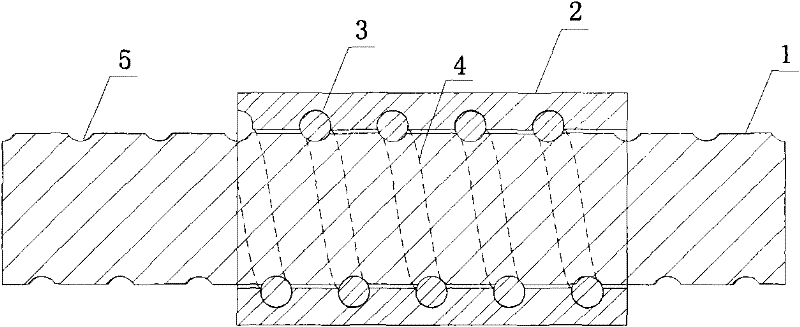

Bearing device for wheel

ActiveCN101512170AIncrease stiffnessReduce weightRoller bearingsBearing componentsBall diameterFlange

To provide a wheel bearing device which is made light and compact while increasing the rigidity of a bearing. In the wheel bearing device, a pitch circle diameter PCDo of a ball group 3 located close to a wheel mounting flange 7, out of double row ball groups 3, 4, is set to be larger than a pitch circle diameter PCDi of the ball group 4 located far from the wheel mounting flange 7. A ball diameter do of the ball group 3 located close to the wheel mounting flange 7 is set to be larger than a ball diameter di of the ball group 4 located far from the wheel mounting flange 7, the ball number of the former is set to be more than that of the latter. A mortary recessed portion 14 is formed in the end on the outer side of a hub ring 5. The depth of the mortary recessed portion 14 reaches the vicinity of at least shaft portion 8, and the shell of the hub ring 5 is shaped with its thickness approximately uniform. This solves conflicting problems on the device which is lighter / compacter as well as highly rigid.

Owner:NTN CORP

Fixed-type constant-velocity universal joint

Internal dimensions for fixed-type constant velocity universal joints are defined to optimize the geometry of the components of the joints and to readily achieve a larger operating angle of the joints. In the joint, the track grooves of an outer ring and an inner ring are tapered by an angle not exceeding 12 DEG . The ratio (f / PCR) of the cage offset amount f to PCR is greater than 0 and smaller than or equal to 0.12. The ratio (Do / d) of the cage outer diameter (Do) to the ball diameter (d), the ratio (t / d) of the cage wall thickness (t) to the ball diameter (d), and the ratio (w / d) of the cage width (w) to the ball diameter (d) are such that 3.9<=Do / d<=4.1, 0.31<=t / d<=0.34, and 1.8<=w / d<=2.0, respectively. The end of the spherical outer surface of the cage adjacent to the open end is axially extended, and the end of the spherical inner surface of the cage adjacent to the open end is tapered so that the tapered surface has an increasing diameter toward the end of the spherical outer surface adjacent to the open end. Part of the spherical outer surface of the cage is cut on the open end side of pockets, and the outer diameter of the cage across the two opposing planer cut faces is smaller than the spigot diameter of the outer ring.

Owner:NTN CORP

Silicon-silicon oxide-carbon composite material, lithium ion secondary battery anode material, preparation methods of two and application of composite material

ActiveCN103915609AImprove first-time efficiencyImprove cycle performanceCell electrodesSecondary cellsCarbon compositesLithium

The invention provides a silicon-silicon oxide-carbon composite material, a lithium ion secondary battery anode material, preparation methods of the two materials and application of the composite material. The provided silicon-silicon oxide-carbon composite material successively comprises hard carbon particles and a second amorphous carbon layer along the ball diameter direction; the hard carbon particle inside comprises first particles each coated with a first amorphous carbon layer in a dispersion manner; and the first particle is silicon oxide particle and inside comprises simple-substance silicon particles in a dispersion manner. The silicon-silicon oxide-carbon composite material is applied to prepare the lithium ion secondary battery anode material. The lithium ion secondary battery anode material disclosed by the invention is large in charge / discharge capacity, high in first efficiency and long in capacity conservation rate after being recycled for a long time, and has wide market application prospect.

Owner:宁波杉杉硅基材料有限公司

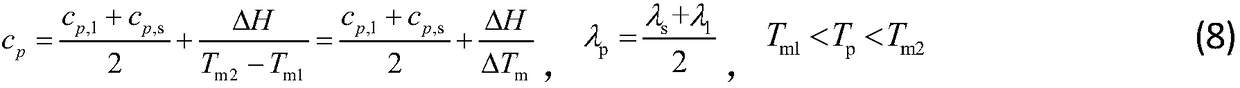

Packed bed heat storage device and preparation method of heat storage ball

ActiveCN108534578AIncrease heat storage rateHigh heat storage densityHeat storage plantsHeat exchange apparatusOptimal combinationBall diameter

The invention discloses a two-layer variable ball diameter packed bed heat storage device and provides a preparation method of a heat storage ball. A large-diameter heat storage ball is arranged on the upper layer of the packed bed heat storage device, and a small-diameter heat storage ball is arranged on the lower layer of the packed bed heat storage device. The packed bed heat storage structurecomprehensively considers two important evaluation indexes of the heat storage device, namely heat storage rate and heat storage density, the maximum heat storage rate of the packed bed heat storage device serves as a design principle, and an optimal combination of diameters of the heat storage balls in the packed bed is obtained by virtue of an optimization design, so that the heat storage devicehas optimal heat storage performance. According to the preparation method of the heat storage ball provided by the invention, the heat storage ball with advantages of high heat storage density, excellent heat-conducting property, high mechanical strength, excellent sealing property and simple preparation process can be prepared.

Owner:XI AN JIAOTONG UNIV

Method for preparing resin-based ball charcoal

The invention relates to a preparation method of ball carbon. Linear phenolic resin, alcohol and formamine are mixed and dissolved into isotrope solution substance according to a mass ratio that is 100:40 to 180:4 to 16. The mass of the phenolic resin is used as a standard, the 100 parts of the phenolic resin is added with pretreating material, the mass of which is 15 to 30 parts, the mixed liquid which is mixed by the phenolic resin and the pretreating material is stirred and heat-preserved for 30 to 150 minutes under 40 DEG C to 60 DEG C; then the mixed liquid is added into water solution which includes 0.5 to 5wt percent of dispersant, is stirred and heated to 110 DEG C to 140 DEG C at a heating rate of 0.5 to 10 DEG C / min, is heat-preserved for 0.5 to 2 hours, and then is cooled, filtered and dried, thereby gaining a resin-covered spherule. The invention has the advantages that the method and the technology are simple, the output is large, and the controllability of the ball diameter is high. The invention is suitable for carbon spherule, the producing diameter of which is 0.3mm to 2mm.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

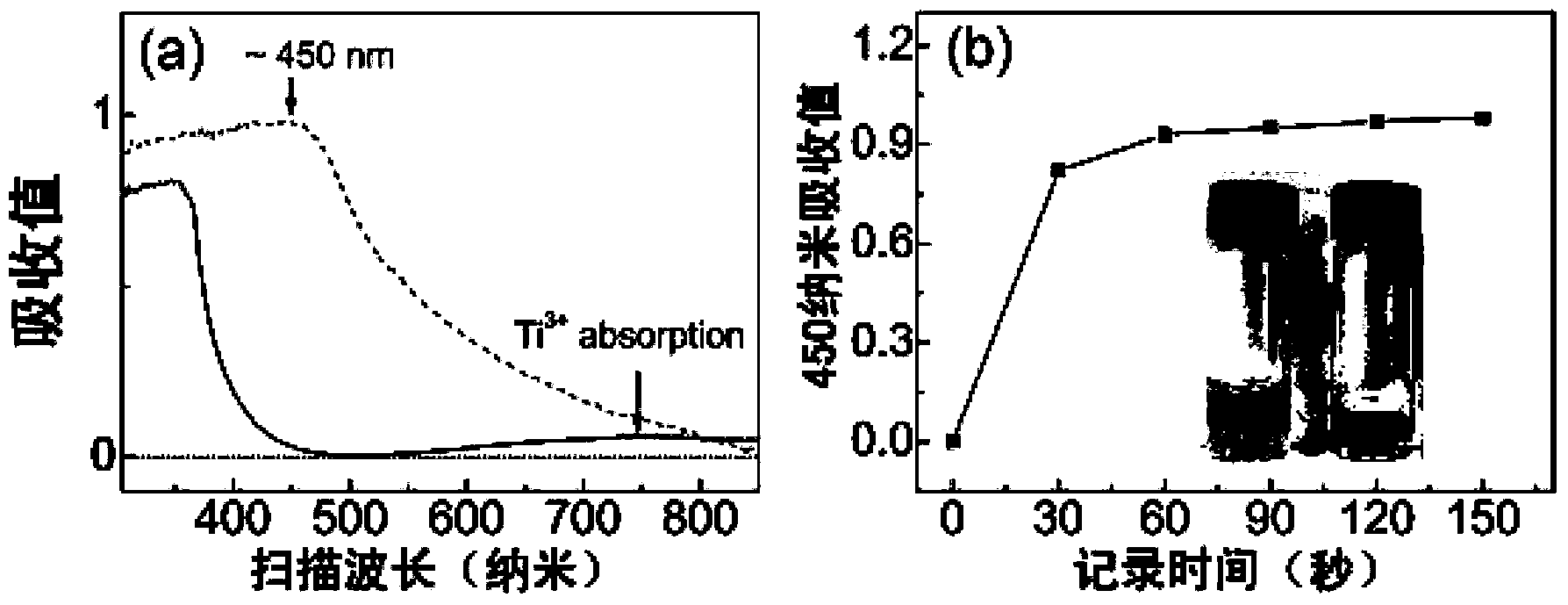

Nanometer blue titanium dioxide colloid and preparation method and application thereof

ActiveCN103482698ARealize sensitiveEasy to detectMicrobiological testing/measurementColor/spectral properties measurementsEnvironmental resistanceUltraviolet

The invention discloses nanometer blue titanium dioxide colloid and a preparation method and application thereof. The colloid is a nanometer blue titanium dioxide ball, wherein the ball diameter is 20-40nm and the ball is composed of tetravalent titanium ions and trivalent titanium ions according to an atomic percent ratio of 51%: 49%. The preparation method comprises the following steps: firstly, mixing white rutile phase titanium dioxide powder with deionized water according to a weight ratio of (1-10): 1, uniformly stirring to obtain emulsion, and then, irradiating the emulsion by using laser with a wavelength of ultraviolet, power of 0.5-4.5W, frequency of 8-12Hz and a pulse width of 4-8ns for 10-30min to prepare a target product. An aqueous solution of the target product can be used as a detection reagent to detect glucose through a colorimetric method, or a mixed solution of the aqueous solution of the target product, glucose oxidase and a phosphate buffer solution is used as the detection reagent to detect glucose through the colorimetric method; and when used for detection, the target product has the advantages of simple process, good quickness and sensitivity, low detection cost, short time, environmental protection and the detection accuracy is hardly influenced by external factors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

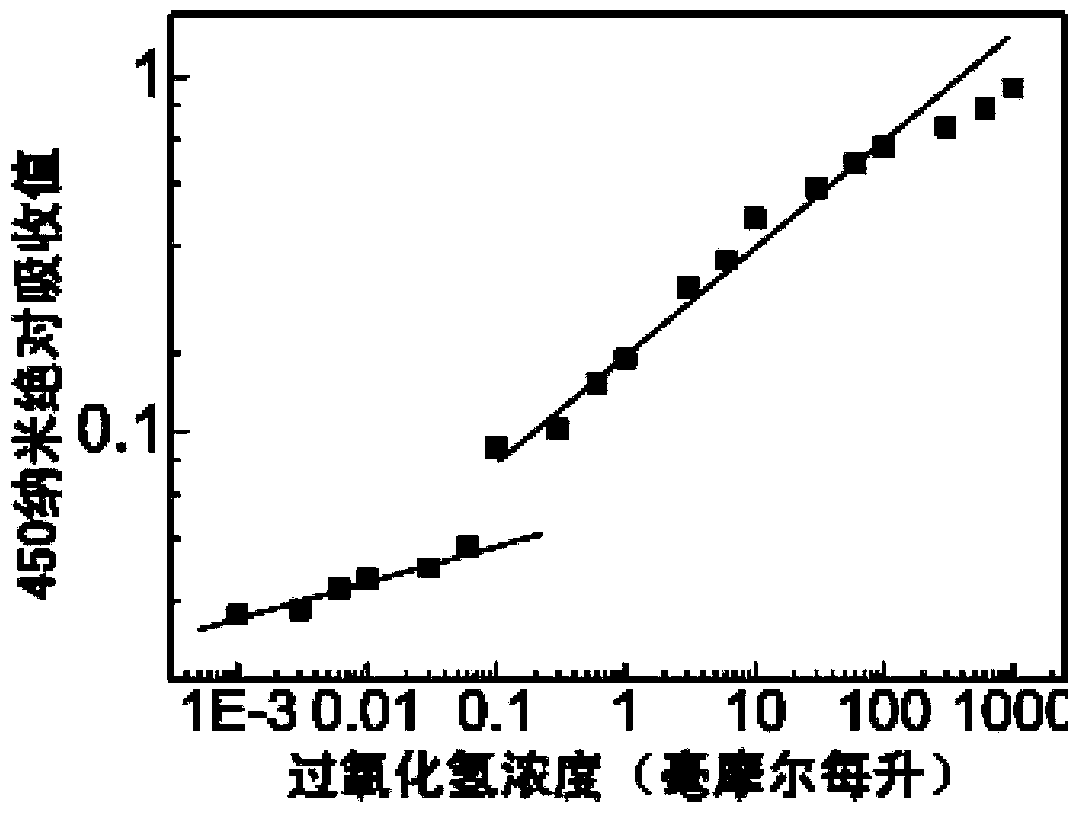

Ball injector system apparatus and method

A ball launching system includes a ball launcher with a removable ball pod and sleeve assembly that retains balls prior to injection. An interchangeable ball pod with a chamber corresponding to the ball diameter, fits into a pod sleeve and comprise the ball pod and sleeve assembly. The ball launcher further includes a housing with a moveably disposed piston that engages with the ball thereby launching it. The housing also includes a thru hole through which the piston may travel to externally indicate its position within the housing. The ball launching system also includes a control system having control inputs, which may be located remote to the ball launcher. By applying a pre-determined sequence of control inputs, the piston may engage with the balls retained in the ball pod and sleeve assembly to force the balls to be launched from the ball launcher.

Owner:VAULT PRESSURE CONTROL LLC

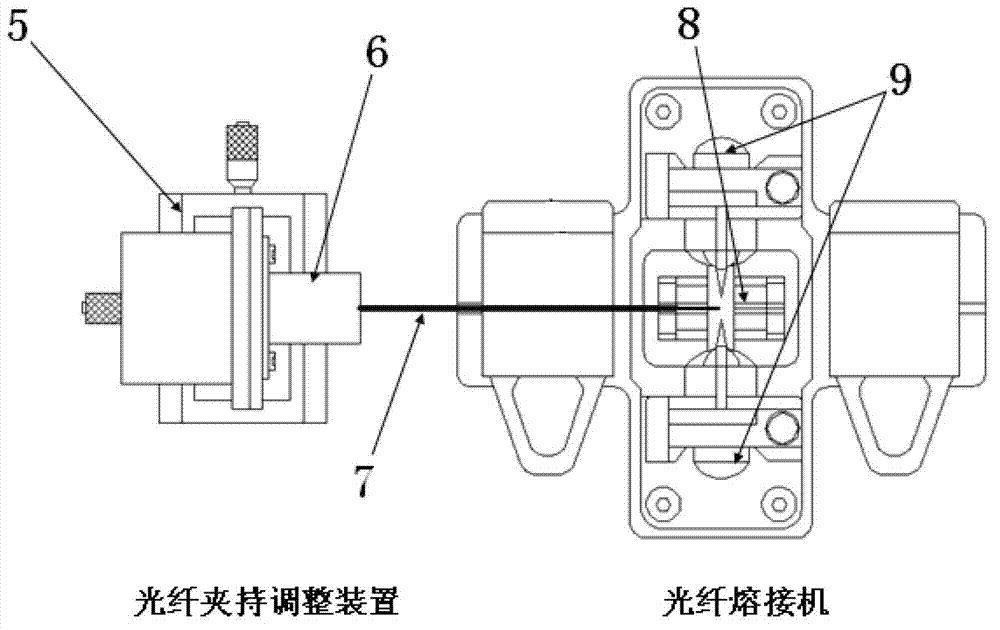

Preparation method of contact-type optical fiber micro probe based on optical fiber tapering technology

ActiveCN103197380ASmall diameterRealize true 3D shape measurementUsing optical meansCoupling light guidesMicrometerEngineering

The invention discloses a preparation method of a contact-type optical fiber micro probe based on an optical fiber tapering technology. Through the optical fiber tapering technology, the diameter of a single mode fiber is attenuated to be in a range of less than 40 micrometers. Then, the single mode fiber after being attenuated is accurately put into a V-type groove in an optical fiber welding machine, and at the same time, the tapered portion of the optical fiber is placed on a discharging region of the optical fiber welding machine. The tapered portion of the optical fiber is heated and fired through the optical fiber welding machine, and the optical fiber is evenly rotated until the end of a tapering optical fiber is melted to be a high-quality micro probe ball. In the process of firing of the optical fiber, process control parameters of the optical fiber welding machine are reasonably arranged based on a taguchi method, the optical fiber is rotated to overcome the impact caused by gravity, and accordingly the micro probe ball which is small in ball diameter, good in sphericity and small in eccentricity is obtained on the end portion of the tapering optical fiber. The micro probe ball and the tapering optical fiber form the contact-type optical fiber probe.

Owner:HEFEI UNIV OF TECH

Crankshaft of automobile engine

An engine crankshaft of automobile is prepared from cast iron material. It features that material intensifying process is applied on said cast iron material i.e. utilizing isothermal hardening heat treatment to process normal graphite cast iron to be austenit-bainite graphite cast iron and making cast-state blank bailing grade be 1-2 grade as well as making graphite ball diameter be above 6grade.

Owner:CHERY AUTOMOBILE CO LTD

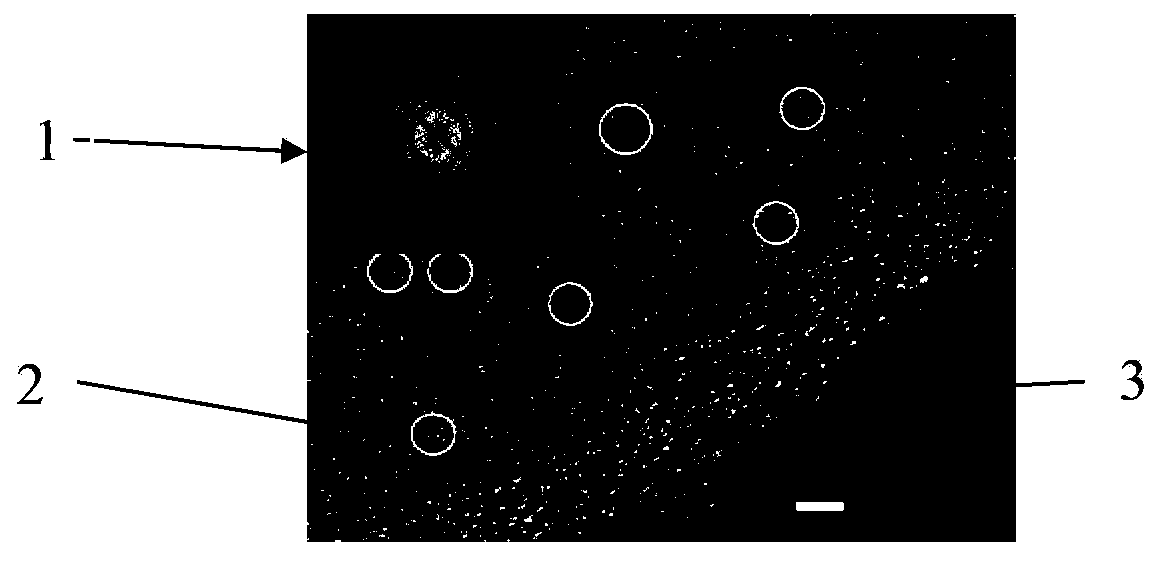

Ordered spherical large mesoporous material alpha-Fe*O*

InactiveCN101172645APrevent collapseHigh crystallinityStannous chlorideMaterials preparationEngineering

The invention relates to an ordered ball type big mesoporous Alpha-Fe2O3 material, belonging to the technical filed of material preparation. The ball type big mesoporous Alpha-Fe2O3 material with an aperture diameter of 37 plus or minus 3nm and an aperture wall of 12 plus or minus 2nm, which orderly extends along the three-dimensional direction, is obtained by taking the polymethacrylic methyl rosmarinate milk-globule the ball diameter of which is 71 plus or minus 5nm and the colloidal crystals which are closely accumulated and distributed along the three-dimensional direction as templates, and through dipping the templates by the ethanol-water mixture of FeC2O4.2H2O, and then removing the PMMA templates through heating, solidifying and roasting. The structure and the magnetic performance of the big mesoporous are determined into a novel ordered ball type big mesoporous Alpha-Fe2O3 material through SEM, TEM, XRD and N2 adsorption test and squid. The material of the invention has the advantages of crystal aperture wall, particular ball type big mesoporous and weak ferromagnetism. The material can be used for preparing for catalyst and sensor.

Owner:YUNNAN NORMAL UNIV

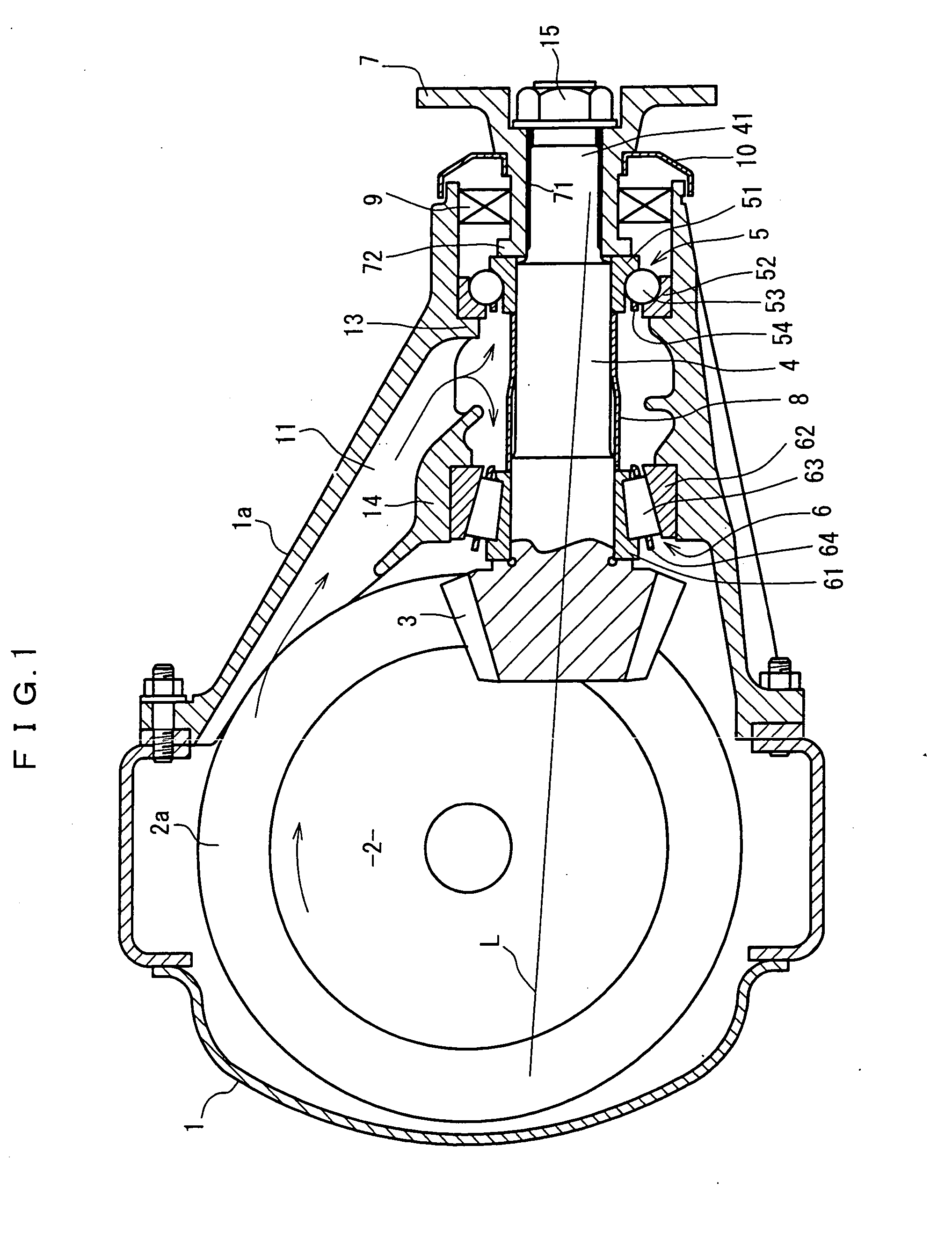

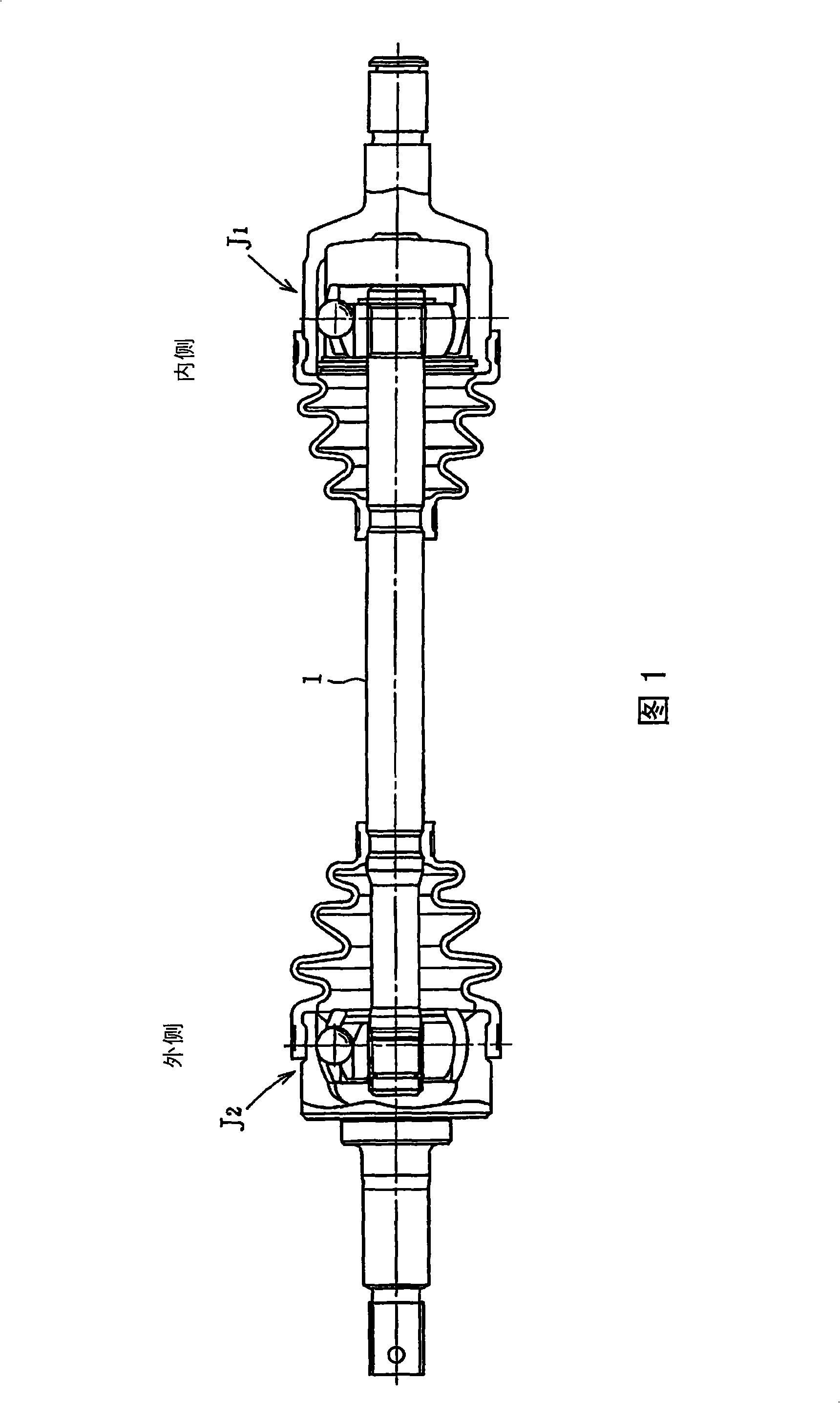

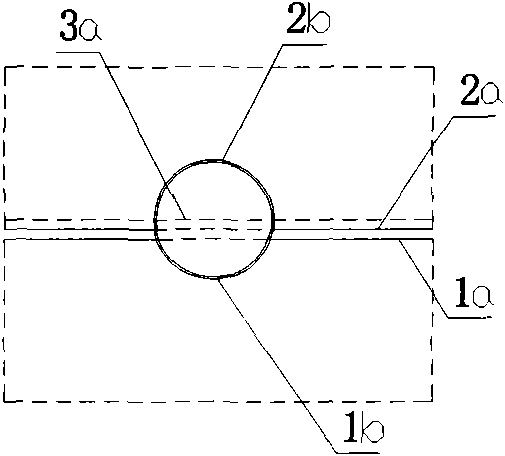

Sliding-type constant velocity universal joint

ActiveCN101268294ADepth does not changeYielding couplingRotary machine partsUniversal jointTorque transmission

The present invention provides a light and compact slide-type constant velocity universal joint that can have a maximum operating angle of 30 DEG or more through optimization of a ball contact angle relative to ball grooves, a ball contact ratio, and a cage offset amount. The present invention is the slide-type constant velocity universal joint including an outer ring 12 in which six linear ball grooves 12b are formed on a cylindrical inner circumferential surface 12a in an axial direction, an inner ring 13 on which six linear ball grooves 13b are formed on a spherical outer circumferential surface 13a in the axial direction and a connecting hole for connecting a shaft is formed in a center section, six torque transmission balls 14 disposed on ball tracks formed by a pair composed of the a ball groove 12b on the outer ring 12 and a ball groove 13b on the inner ring 13, and a cage 15 having pockets 15c for storing the torque transmission balls 14, a convex spherical outer circumferential surface 15a that is in contact with and guided by the inner circumferential surface 12a of the outer ring 12, and a concave spherical inner circumferential surface 15b that is in contact with and guided by the outer circumferential surface 13a of the inner ring 13 and in which a spherical surface center O C0 of the outer circumferential surface 15a and a spherical surface center O CI of the inner circumferential surface 15b are offset to opposite sides of a pocket center O in the axial direction. In the slide-type constant velocity universal joint, a ratio of ball diameter to outer ring outer diameter is 0.21 to 0.25, a ratio of ball pitch diameter to outer ring outer diameter is 0.64 to 0.68, a contact angle of the ball groove is 30 DEG to 35 DEG , a contact ratio of the ball groove is 1.02 to 1.08, and a ratio of cage offset amount to ball pitch diameter is 0.07 to 0.09.

Owner:NTN CORP

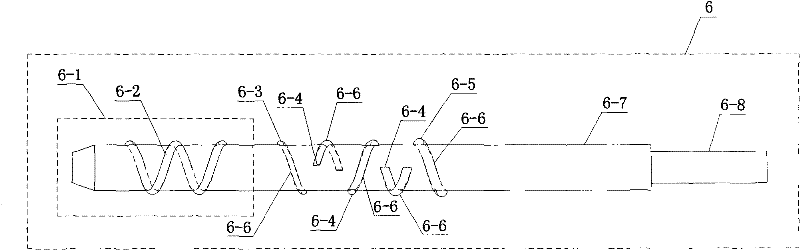

Ball nut with deep groove track and manufacturing method thereof

The invention discloses a ball screw cap with a deep groove track and a manufacturing method thereof. After the ball screw cap is separated from a ball lead screw, balls on the inner circle surface of the ball screw cap is still limited in the deep groove track and are prevented from being scattered, so that the ball screw cap is convenient to be screwed out of and into the ball lead screw. The manufacturing method of the ball screw cap comprises the following steps of: drilling a hole on a blank with the conventional technology to form an inner circle surface; processing the inner circle surface with a turning method or a whirling method to form a spiral groove of which the depth is greater than the ball radius, the opening is a little smaller than the ball diameter, the normal section bottom side is a circular arc and the upper part is rectangular; introducing a spiral cutting tool into the spiral groove for cutting to form a deep groove track; and performing thermal treatment and surface treatment on the deep groove track.

Owner:朱豪东

Method for preparing titanium alloy TA15 metal balls by employing plasma auxiliary rotating electrode

The invention relates to a method for preparing titanium alloy TA15 metal balls by employing a plasma auxiliary rotating electrode centrifugal process. In a sealed container protected by inert gas, a glow discharge plasma arc is generated between a plasma auxiliary electrode and a consuming electrode made of a rotating cylinder titanium alloy TA15. The high temperature caused by the plasma arc forms droplets on a section of the titanium alloy TA15 electrode, close to the plasma arc, and the droplets are thrown out by centrifugal force. The droplets of the titanium alloy TA15 is air cooled and solidified into a ball shape in the inert gas environment of the sealed container, thus, the titanium alloy TA15 metal balls are obtained. The method can obtain titanium alloy TA15 metal balls with the average sphere diameter between 0.1mm and 1.5 mm and good monodispersity by changing process parameters. The prepared powder metal balls have the advantages of good sphericity, lower proportion of abnormal granule and controllable ball diameter and can be used in the field of laser solid forming to prepare special components of aviation spacecraft.

Owner:张建利

Carrying platform for wafer-level ball mounter

InactiveCN103794541AHigh precisionLow costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringManipulator

A carrying platform for a wafer-level ball mounter comprises a bottom X-axis movement system, a bottom Y-axis movement system, a bottom Z-axis movement system, an outer-circle Z-axis movement mechanism, an inner-circle Z-axis movement mechanism, wafer supporting columns, an outer carrying platform circle and an inner carrying platform circle. Vacuum absorption holes are formed in the outer carrying platform circle, the inner carrying platform circle and the wafer supporting columns respectively. According to the carrying platform for the wafer-level ball mounter, a high-precision lead screw is adopted for driving, and therefore the carrying platform has high precision and high stability; the smallest ball diameter phi of the wafer-level ball mounter can be 0.1mm. According to the carrying platform, a inner and outer circle carrying platform structure and a wafer supporting column structure are adopted, automatic wafer feeding and discharging can be performed through mechanical arms, the automation degree of equipment is improved to the maximum extent, the production efficiency is improved, and the stability of products is improved. By replacing a jig, the carrying platform can correspond to wafers being six inches, eight inches and twelve inches, and is high in applicability.

Owner:SHANGHAI WEISONG IND AUTOMATION

Multi-ball board standard for multi-sensor measurement system and joint error detection method

ActiveCN106871949AOptimize layoutLow processing and assembly costsInstrumentsComputer scienceBall diameter

The invention relates to a multi-ball board standard for a multi-sensor measurement system. The multi-ball board standard comprises a board body. Standard balls are distributed on the upper surface of the board body according to a topological structure. The topological structure comprises primary nodes extending along a regular square or octagonal path. The primary nodes at least derive out secondary nodes. Two adjacent upper-level nodes constitute a derivative group and derive out two lower-level nodes. The two upper-level nodes in each derivative group derive out respective lower-level nodes at equal distances along the directions of rays which take the two upper-level nodes as the endpoints and form an angle of 135 degrees with the connecting line of the two upper-level nodes. The invention further relates to a joint error detection method comprising the following steps: standard balls are numbered using the 10-ball standard of the invention; actual values, including the diameter of the standard balls, are measured; sensors sample the standard balls in sequence according to a sampling path; the center coordinates of the standard balls and the measured value of ball diameter are calculated; and each joint error is calculated, and whether each joint error is qualified or not is judged.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

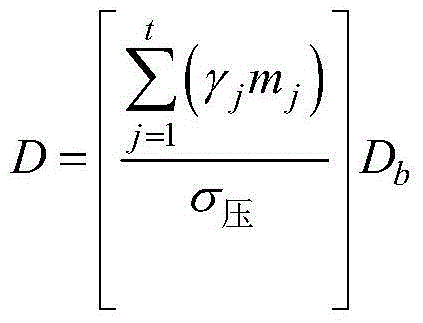

Method for determining diameter of mineral steel ball harder than gangue mineral and used for grinding valuable mineral

ActiveCN104668056AAchieve recyclingReasonable particle size compositionMaterial strength using tensile/compressive forcesGrain treatmentsSteel ballEmpirical formula

The invention relates to a method for determining the diameter of a mineral steel ball harder than gangue mineral and used for grinding valuable mineral, belonging to the ore grinding field of mineral separation. According to the method, first, the uniaxial compressive strength sigma pressure of minerals and the Moh's hardness mj of each pure mineral are detected; then the relative ratio gamma j of each pure mineral to the main pure minerals is detected; finally, each process parameter of a kominuter and the detected sigma pressure, mj and gamma j are substituted into a steel ball diameter calculation formula, so that the diameter of the steel ball is calculated. The defect in diameter calculation of the steel ball by a traditional empirical formula and a semi-theoretical formula for the ball diameter is overcome; when the steel ball diameter calculated with the method is applied to a ball mill, the particle size composition of ore grinding products is more reasonable, the content of course-level hard-to-grind particles can be reduced, the content of easily-argillitized serpentinite and talc over crushing particles can also be obviously reduced, and the content of the medium easy-to-separate particles is greatly increased, so that the metal recovery rate is effectively improved, and the recycle of the valuable minerals is realized.

Owner:KUNMING UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com