Preparation method of contact-type optical fiber micro probe based on optical fiber tapering technology

A contact type, optical fiber fusion splicer technology, applied in the coupling of optical waveguides, the use of optical devices, measuring devices, etc., can solve the problems of inability to meet the three-dimensional micro-nano measurement technology, unfavorable for mass production, complex preparation methods, etc. Small diameter, improved measurement capability, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

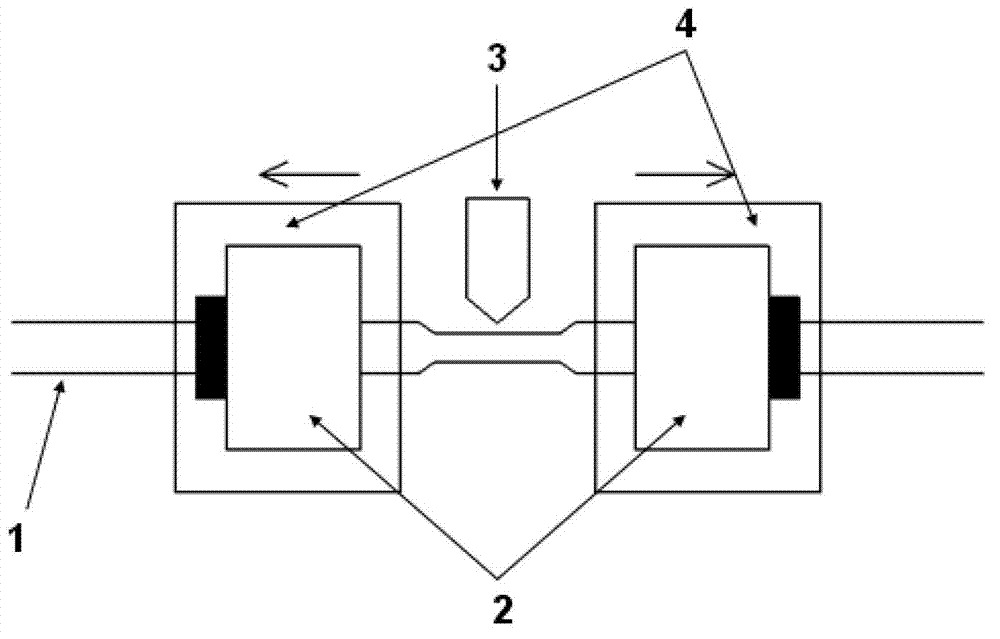

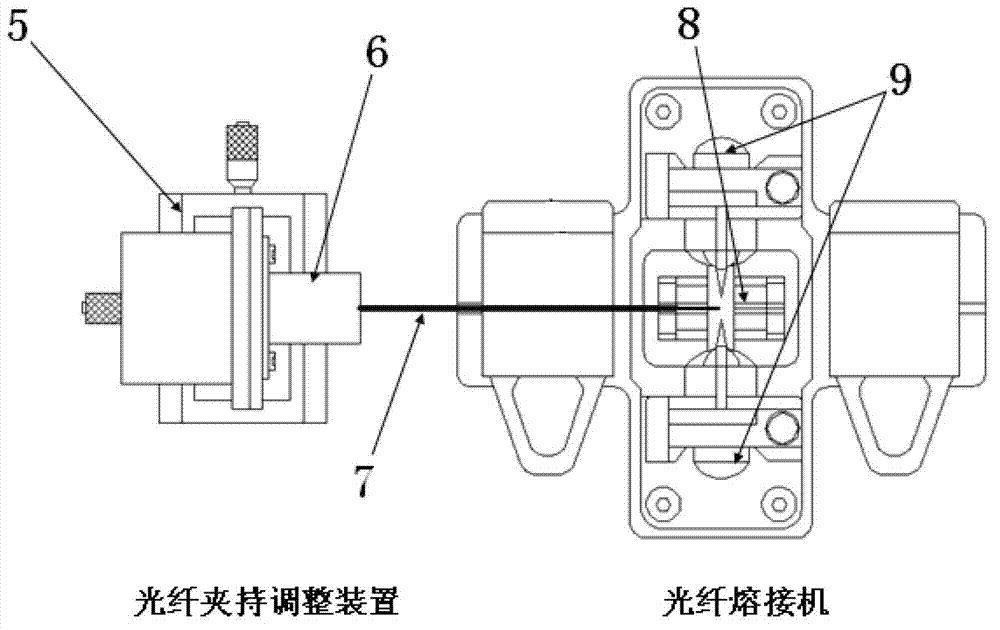

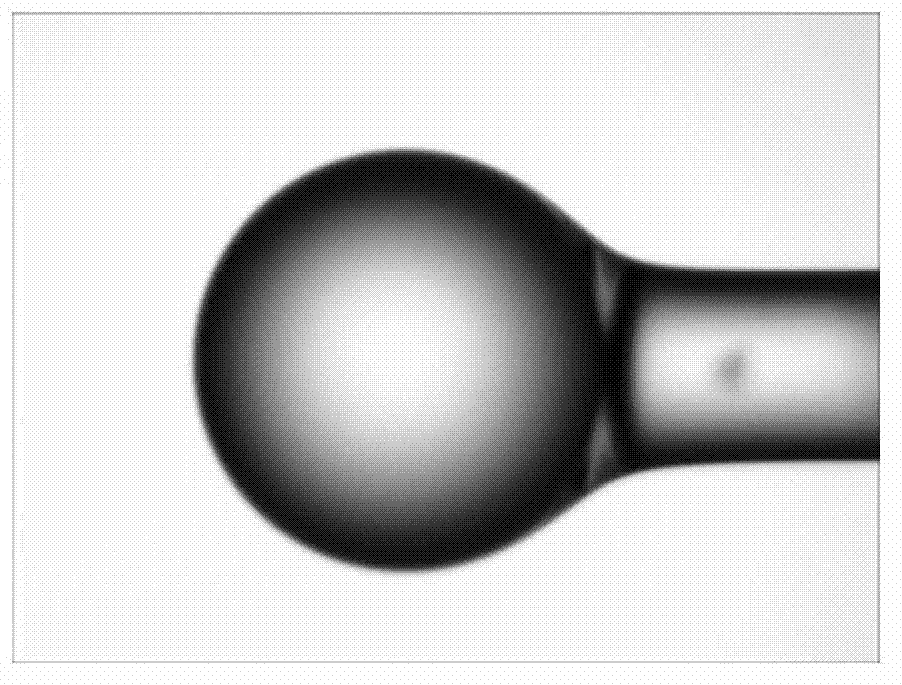

[0021] A preparation method of a contact optical fiber microprobe based on optical fiber tapering technology. A contact optical fiber microprobe is prepared by selecting a single-mode fiber material. The optical fiber is accurately placed in the V-shaped positioning groove of the optical fiber fusion splicer, so that the tapered single-mode optical fiber is placed in the discharge area of the optical fiber fusion splicer, and the electric spark discharge of the optical fiber fusion splicer is used to control the taper. The single-mode fiber is preliminarily fired and optimized for the tapered part. During the whole firing process, the tapered single-mode fiber is rotated to overcome the influence of gravity, so that the end of the single-mode fiber after the tapered A micro-probe with small diameter, good sphericity, and small eccentricity is obtained. The contact-type optical fiber micro-probe is composed of the micro-probe and the tapered single-mode optical fiber. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com