Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Stannous chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

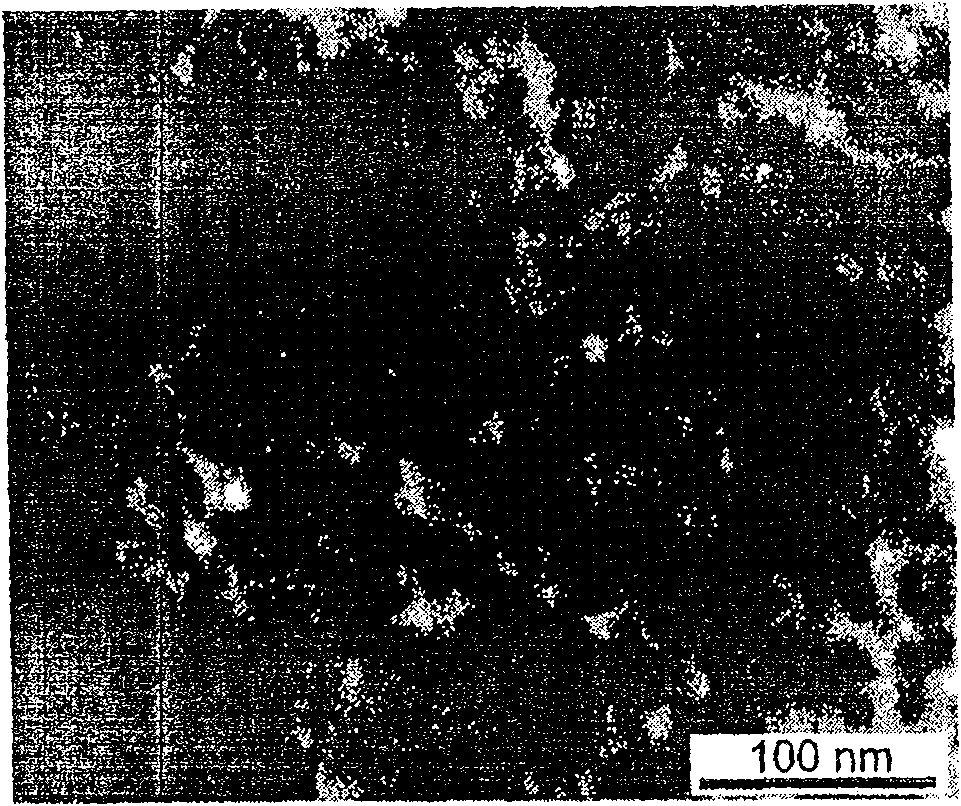

Ordered spherical large mesoporous material alpha-Fe*O*

InactiveCN101172645APrevent collapseHigh crystallinityStannous chlorideMaterials preparationEngineering

The invention relates to an ordered ball type big mesoporous Alpha-Fe2O3 material, belonging to the technical filed of material preparation. The ball type big mesoporous Alpha-Fe2O3 material with an aperture diameter of 37 plus or minus 3nm and an aperture wall of 12 plus or minus 2nm, which orderly extends along the three-dimensional direction, is obtained by taking the polymethacrylic methyl rosmarinate milk-globule the ball diameter of which is 71 plus or minus 5nm and the colloidal crystals which are closely accumulated and distributed along the three-dimensional direction as templates, and through dipping the templates by the ethanol-water mixture of FeC2O4.2H2O, and then removing the PMMA templates through heating, solidifying and roasting. The structure and the magnetic performance of the big mesoporous are determined into a novel ordered ball type big mesoporous Alpha-Fe2O3 material through SEM, TEM, XRD and N2 adsorption test and squid. The material of the invention has the advantages of crystal aperture wall, particular ball type big mesoporous and weak ferromagnetism. The material can be used for preparing for catalyst and sensor.

Owner:YUNNAN NORMAL UNIV

Preparation method of stannous chloride

InactiveCN102849788AReduce the temperatureReduce volatilityStannous chloridePhysical chemistryReaction temperature

The invention relates to a preparation method of stannous chloride, and belongs to the technical field of inorganic stannum preparation. The method comprises the following steps: carrying out one-step synthesis of a stannous chloride solution through applying supersonic waves having frequencies of 20-30kHZ to raw materials comprising metallic stannum flowers and hydrochloric acid having a concentration of 25-34wt%, and concentrating and crystallizing to obtain colorless and transparent stannous chloride crystals. The method provided by the invention, which introduces the supersonic waves to the reaction process, overcomes disadvantages of high reaction temperature, large hydrochloric acid volatilization amount and long reaction time of present stannous chloride preparation technologies, has the advantages of low cost, low acid consumption, fast reaction rate, less hydrochloric acid volatilization and easy industrialization, and has a bright application prospect.

Owner:YUNNAN TIN

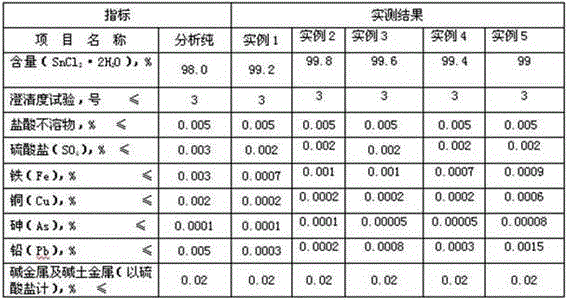

Preparation method of reagent-grade stannous chloride dehydrate crystals

ActiveCN105481005AMeet the needs of industries with high quality requirementsIncrease productivityStannous chlorideFiltrationTin

The invention provides a method for preparing reagent-grade stannous chloride dehydrate crystals from industrial-grade raw materials. The method comprises the following steps: melting industrial tin ingots and quenching the molten industrial tin ingots into tin flower; then enabling reaction between filtered industrial hydrochloric acid and tin hydroxide to produce stannic chloride pentahydrate; adding the tin flower into the stannic chloride pentahydrate solution; enabling heat-insulating reaction for 12-18 h at 100-105 DEG C; when the mass concentration of quadrivalent tin in the solution is detected to be less than 0.01%, concentrating under reduced pressure till the specific weight of the solution is 2.0-2.4; filtering the solution into a cooling device to be cooled for 12-20 h at 0-10 DEG C; then discharging; carrying out vacuum suction filtration and centrifugal separation to obtain the required reagent-grade stannous chloride dehydrate crystals. The preparation method is short in process route, simple to operate, easy for processing parameter control and relatively high in production efficiency; the obtained product can meet the standards of the reagent-grade (high-purity) stannous chloride dehydrate crystals without crushing or screening, and can satisfy the requirements of industries (such as chemical analysis, catalytic synthesis and PCB colloid-Pd sensitization) which demand much on the quality of stannous chloride.

Owner:GUANGDONG GUANGHUA SCI TECH

Preparation method of premium-grade stannous chloride from low-tin waste residues

The invention discloses a preparation method of premium-grade stannous chloride from low-tin waste residues. The invention comprises the following steps: preparing a reaction solution, introducing chlorine, settling, settling for a second time, filtrating, concentrating, freeze crystallization and solid-liquid separation, wherein the obtained solid is the premium-grade stannous chloride. According to the invention, low-tin waste residues produced in tin manufacturing process are used as raw materials, various indexes of the stannous chloride product are controlled through acidity, concentration and time, and multiple setting, filtering and concentrating are performed to remove impurities, so as to obtain premium-grade stannous chloride products. The preparation method disclosed by the invention is simple in process, low in cost and environmentally friendly, provides a new way for recycling of low-tin waste residues produced in a tin manufacturing process and satisfies requirements of circular economy.

Owner:广西华锡集团股份有限公司

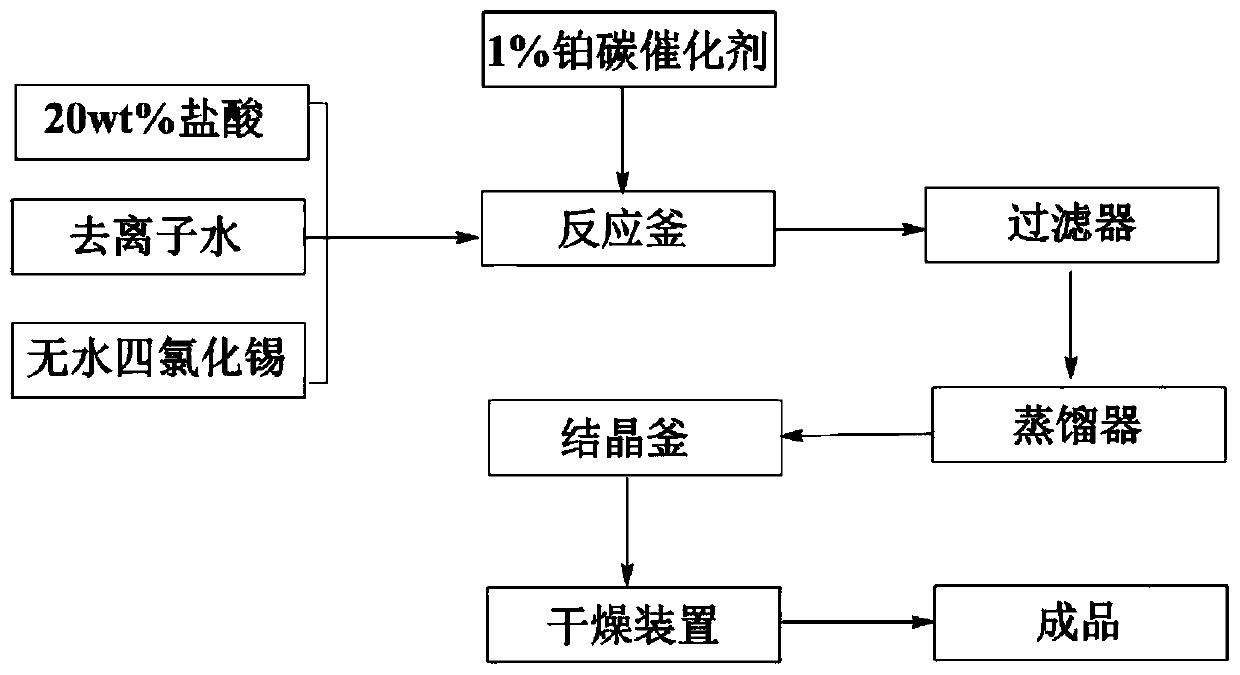

Preparation method of toothpaste-grade tin chloride

ActiveCN103539198ACompliant with Addition CriteriaQuality improvementStannous chlorideFiltrationDistillation

The invention discloses a preparation method of a toothpaste-grade tin chloride. The preparation method comprises the following steps: (i) synthetic reaction and primary filtration: adding deionized water, anhydrous tin tetrachloride and metallic tin into a reaction kettle according to a molar ratio of (4-8): 1: (1-1.2), and then adding concentrated hydrochloric acid to carry out synthetic reaction and primary filtration; (ii) purification and secondary filtration: adding excessive sulfuric acid into a purifying kettle, and then adding an appropriate amount of toothpaste-grade strontium chloride to carry out purification and secondary filtration; (iii) carrying out distillation and crystallization; (iv) carrying out vacuum drying, thus obtaining a finished product of dry white crystal toothpaste-grade tin chloride. The preparation method disclosed by the invention is stable in process, easy to control, low in cost and little in three wastes; the synthesized toothpaste-grade tin chloride is stable in quality and accords with addition standards of toothpaste.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Chlorine introducing method and device for producing stannous chloride by liquid chlorine

ActiveCN102126747AIncrease gasification rateImprove the efficiency of chlorine reactionStannous chlorideBuffer tankChloride

The invention relates to a chlorine introducing method and a chlorine introducing device, in particular to a chlorine introducing method and a chlorine introducing device for producing stannous chloride by liquid chlorine. The method comprises the following steps of: introducing liquid chlorine into a coiled tube to be heated and gasified, introducing chlorine to a chlorine introducing tank for use, and heating the coiled tube by external hot water at the temperature of between 40 and 60 DEG C. The device comprises a liquid chlorine cylinder, the toiled tube, a heating water tank and a chlorine buffer tank, wherein the coiled tube is arranged in the heating water tank; an inlet of the coiled tube is communicated with the liquid chlorine cylinder, and an outlet of the coiled tube is communicated with the chlorine buffer tank; and the chlorine buffer tank is communicated to the chlorine introducing tank. In the method and the device, an operating mode of the natural gasification of the liquid chlorine is changed, and the liquid chlorine is introduced into the coiled tube in liquid mode and is heated by utilizing the coiled tube to accelerate the gasification speed of the liquid chlorine and improve the efficiency of a chlorination reaction in stannous chloride production; and the requirement of the production on the speed of a chlorine introducing reaction can be met only by opening one cylinder of liquid chlorine (one ton / cylinder), and the reliability of safety performance of the liquid chlorine during use is enhanced.

Owner:广西华锡集团股份有限公司

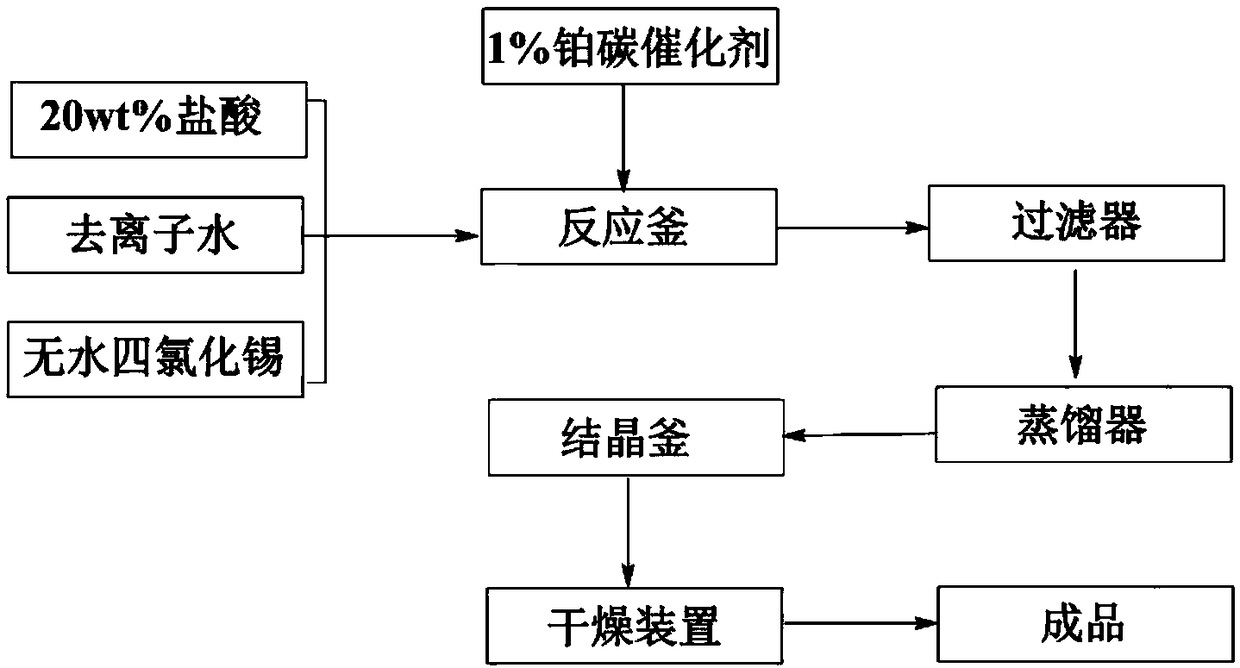

Synthetic method of stannous chloride

ActiveCN108341427AOvercome the problem of slow responseEffectively remove the interference of product qualityStannous chlorideTetrachlorideHydrogen

The invention discloses a synthetic method of stannous chloride. The method comprises the following steps: by using anhydrous stannic tetrachloride and hydrochloric acid with concentration of 20 wt% as raw materials, adding a precious metal catalyst, heating to 110 to 140 DEG C, introducing hydrogen with the pressure intensity of 1.5 to 3MPa, performing heat insulation reaction for 2 to 6 hours at125 to 135 DEG C, and performing press filtration to obtain a stannous chloride solution and a dilute hydrochloric acid solution with required concentrations; then performing concentration and crystallization to obtain a stannous chloride crystal. According to the synthetic method of stannous chloride disclosed by the invention, by using hydrogen as a reducing agent, a catalyst can be reacted andrecycled for being reused, and the phenomenon that tin is used as the reducing agent in a conventional process is avoided, so that the interference of impurity elements carried by metal tin on the quality of a product is effectively eliminated. The method disclosed by the invention has the advantages of stable process, strong operability, low cost, environment-friendly property, high security andthe like, and can be applied to industrial popularization.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD +1

Preparation method of anhydrous stannous chloride

ActiveCN101665267ATechnically feasibleReasonable workmanshipStannous chlorideInorganic tin compoundVacuum drying

The invention relates to a preparation method of anhydrous stannous chloride, in particular to a large-scale production method of anhydrous stannous chloride, belonging to the technical field of the chemical engineer. The method of the invention is to use SnCl2.2H2O as raw material to perform two-stage drying, wherein in the first stage, the first stage drying is performed at normal pressure whilethe heating temperature is controlled to less than 130 DEG C, then organic dispersant is added, the second stage drying adopts vacuum drying, the drying temperature is controlled to 90-110 DEG C andthe vacuum degree is controlled to less than 0.075MPa. The invention has simple process flow and high product purity and is easy to control; and the method can use common chemical equipment and effectively solve the problem of equipment corrosion. The main content of the product prepared by the method is not less than 99% and the solution obtained by dissolving the product in hydrochloric acid solution is clear.

Owner:云南锡业锡化工材料有限责任公司

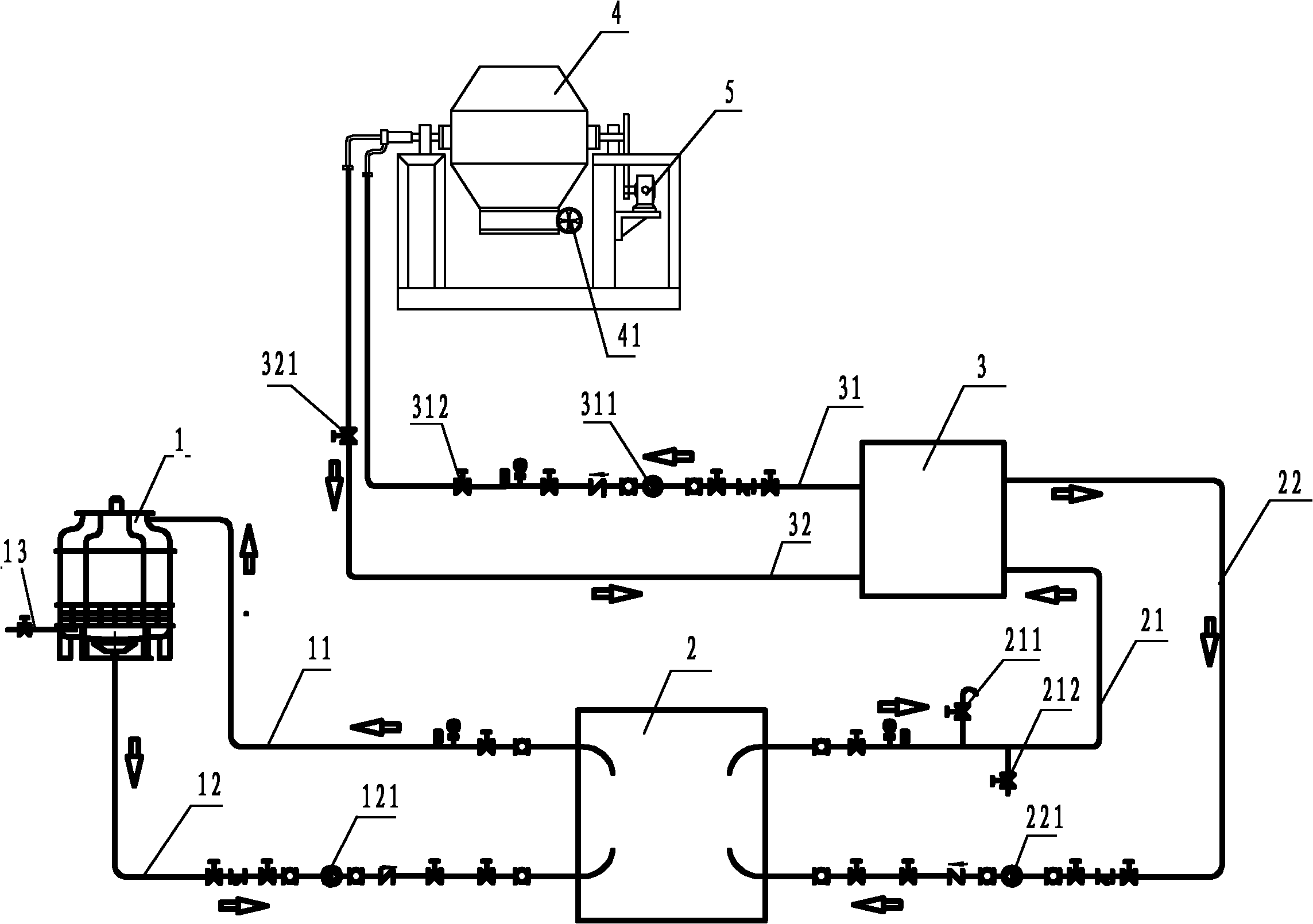

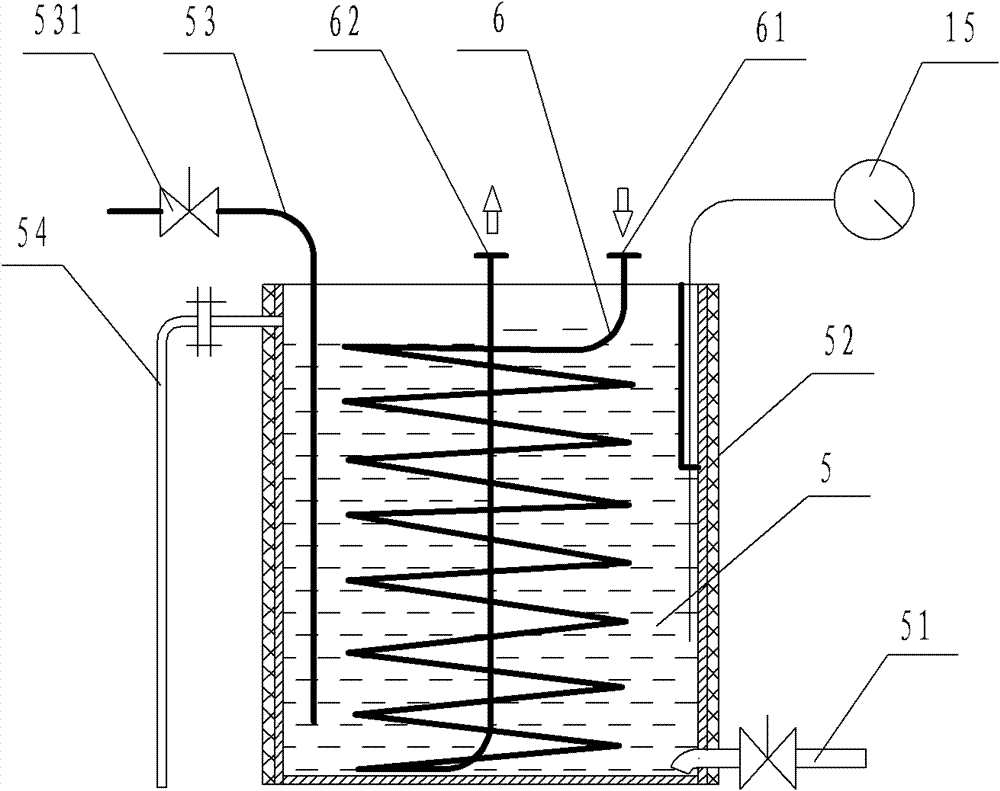

Dynamic crystallization technological method and device for stannous chloride solution

ActiveCN102120609AImprove crystallization efficiencyShorten crystallization timeStannous chlorideSlurryTemperature difference

The invention relates to a dynamic crystallization technological method and device for a stannous chloride solution. The technological method comprises the following steps of: A, adding a stannous chloride concentrated solution into rotation equipment with a clamping sleeve; B, introducing a coolant into the clamping sleeve of the rotation equipment; C, starting the rotation equipment, controlling the rotation speed of the rotation equipment to be 2-5r / min, and controlling the temperature difference between the stannous chloride concentrated solution and the coolant in the whole crystallizing process to be 5-10 DEG C, and D, ending crystallization when the concentration temperature T of stannous chloride is not more than 10 DEG C, stopping introduction of the coolant and the rotation equipment, spinning to dry slurry crystal in the rotation equipment in a centrifuger, and packaging to obtain a product of the stannous chloride. In the invention, the traditional static crystallization mode of the stannous chloride solution is changed into a dynamic crystallization mode, and the advantages of improved production efficiency, high crystallization rate, uniform particle sizes of stannous chloride crystals and simplified crystallization production process are achieved.

Owner:广西华锡集团股份有限公司

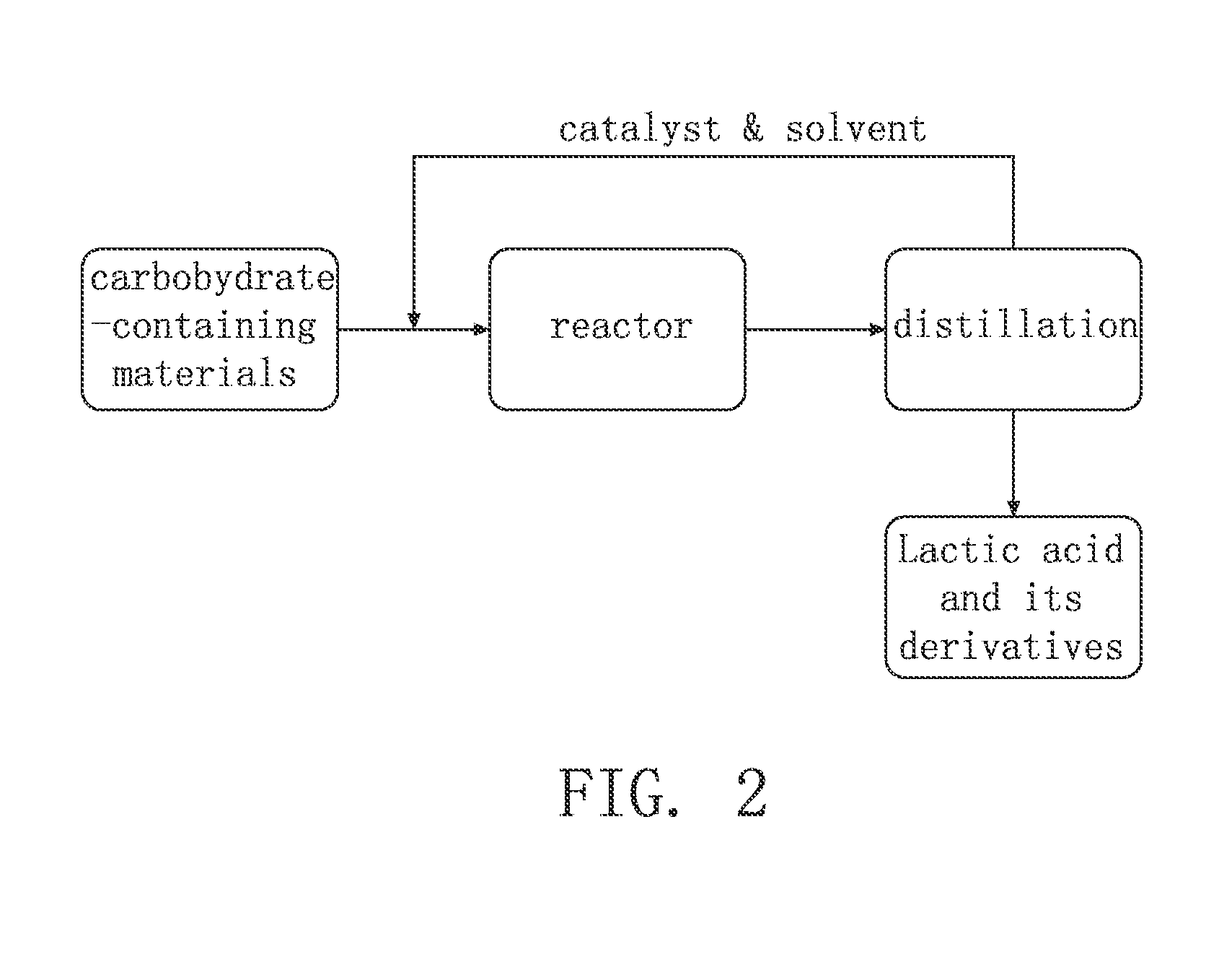

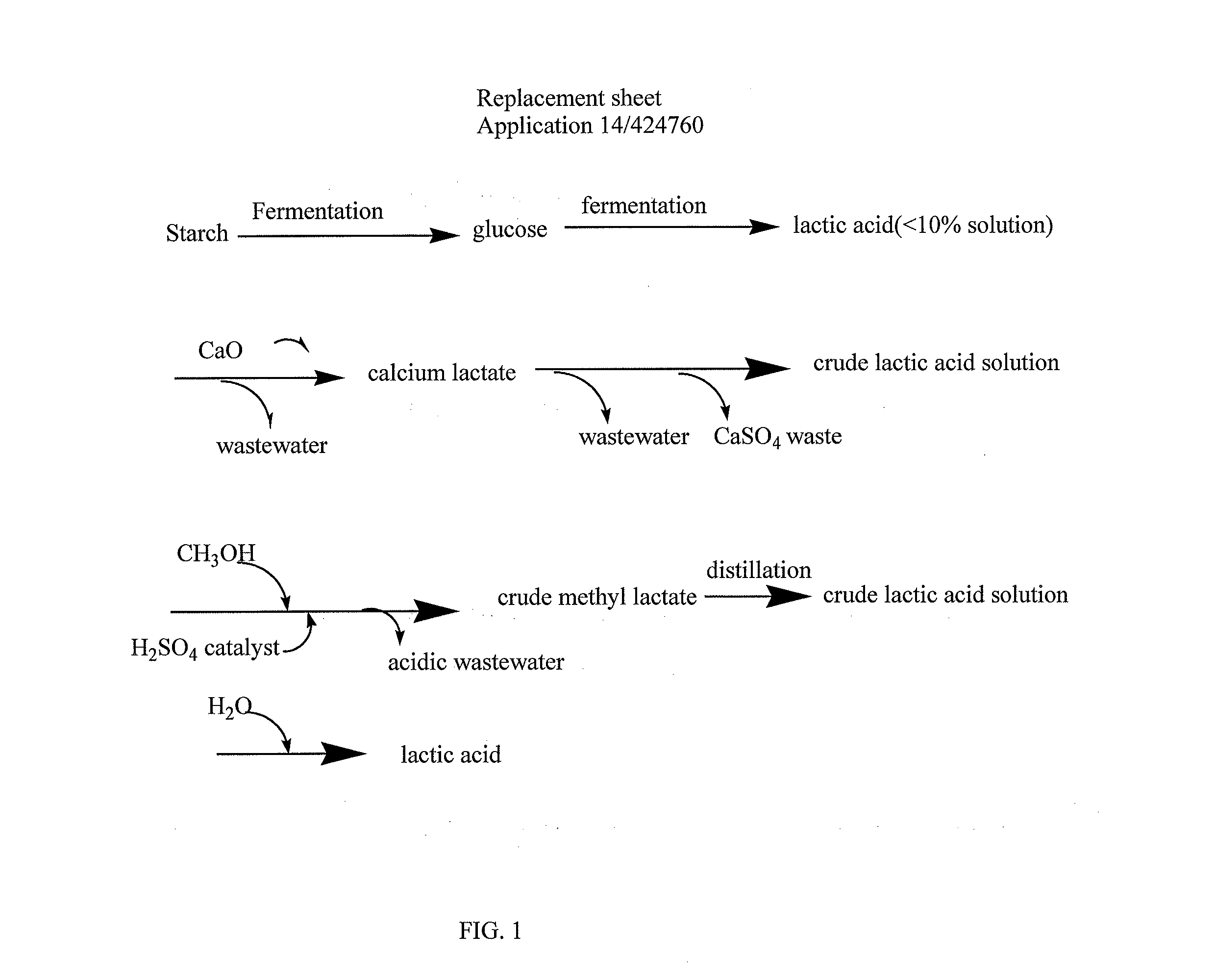

Method for synthesis of lactic acid and its derivatives

ActiveUS8835670B2Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

Method for Synthesis of Lactic Acid and Its Derivatives

ActiveUS20140058130A1Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

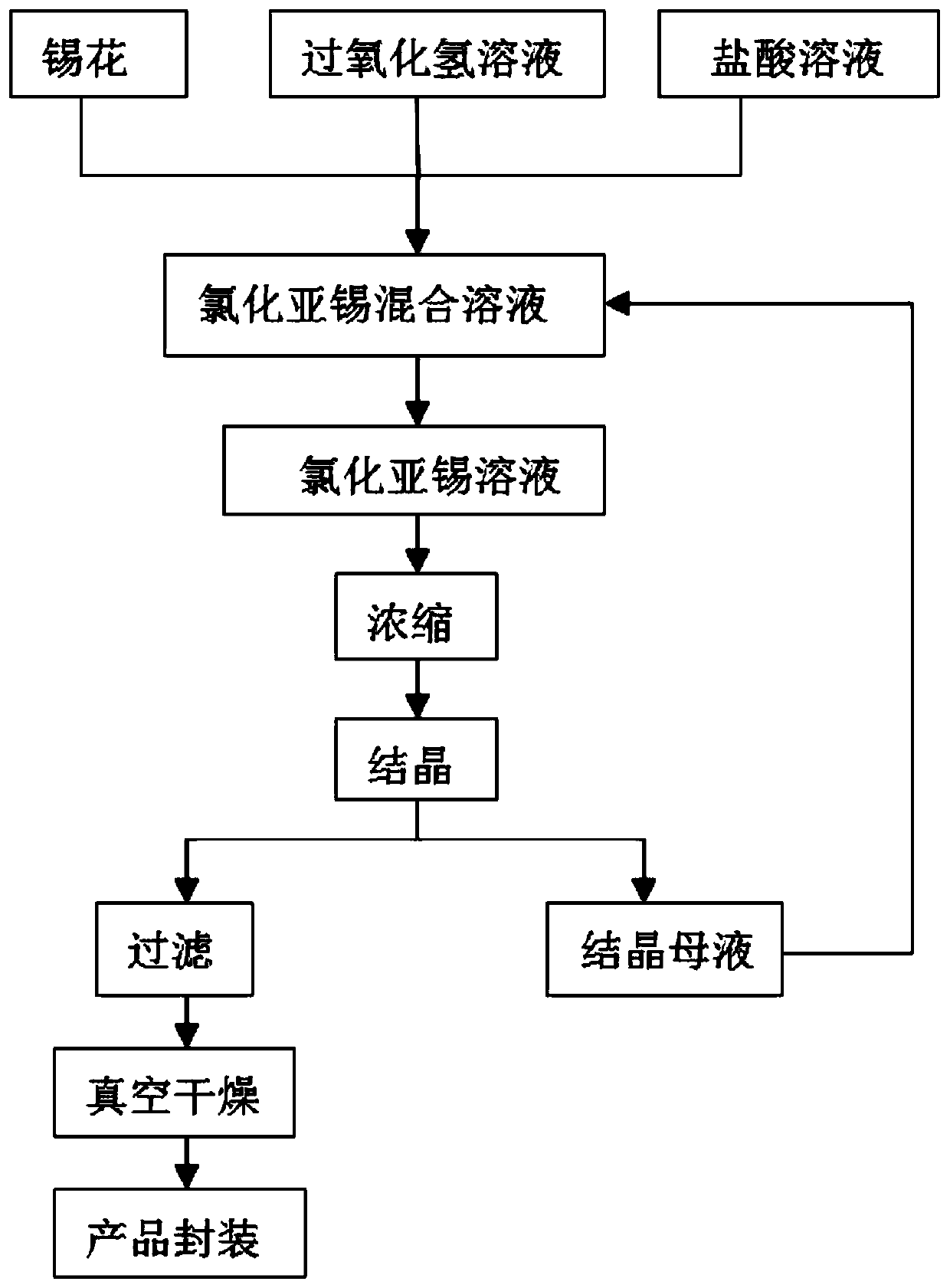

Stannous chloride dehydrate and preparation method thereof

ActiveCN110563029ASimple process routeIncreased process safetyStannous chlorideHydrogen peroxideMetal

The invention discloses a preparation method of stannous chloride dehydrate. The method comprises the following steps: 1, adding a hydrochloric acid solution and metallic tin into a reactor; controlling the reaction temperature to be 40-70 DEG C; dropwise adding a hydrogen peroxide solution to dissolve metallic tin, adding metallic tin, reducing Sn<4+>, filtering, adjusting the pH value of an obtained filtrate to 0.5-1.5, concentrating the filtrate, adding metallic tin into the filtrate at the same time, inhibiting Sn<2+> oxidation, and stopping concentration when the density of the filtrate reaches 2.0-2.3 g / mL so as to obtain a concentrated solution; and crystallizing the concentrated solution at 0-5 DEG C, separating out precipitated stannous chloride crystals, and drying to obtain stannous chloride dehydrate. The preparation method disclosed by the invention is simple in process route, can remarkably improve the reaction rate, shorten the reaction time, and effectively reduce the temperature required by the reaction; concentrated hydrochloric acid and chlorine are not needed in the reaction process; the preparation method is environment-friendly, high in process safety and highin product purity.

Owner:昆明先导新材料科技有限责任公司

The manufacture method of anhydrous stannous chloride

ActiveCN101665267BTechnically feasibleReasonable workmanshipStannous chlorideInorganic tin compoundVacuum drying

The invention relates to a method for producing an inorganic tin compound, in particular to a method for large-scale production of anhydrous stannous chloride, which belongs to the technical field of chemical industry. The method of the present invention uses SnCl 2 2H 2O as the raw material to dry in two stages, the first stage controls the heating and concentration temperature to be less than 130°C under normal pressure, adds an organic dispersant, and the second stage is vacuum-dried to control the drying temperature The temperature is 90-110°C, and the vacuum degree is lower than 0.075MPa. The invention has simple technological process, is easy to control, has high product purity, can utilize ordinary chemical equipment, and effectively solves the problem of equipment corrosion. The main content of the product prepared by the method is more than 99%, and the solution is clear after being dissolved in hydrochloric acid solution.

Owner:云南锡业锡化工材料有限责任公司

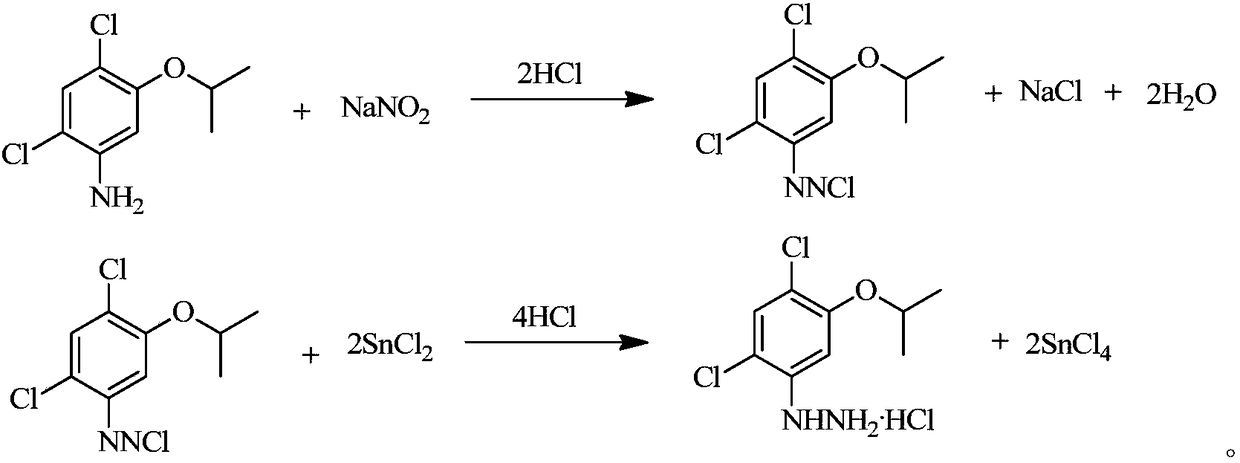

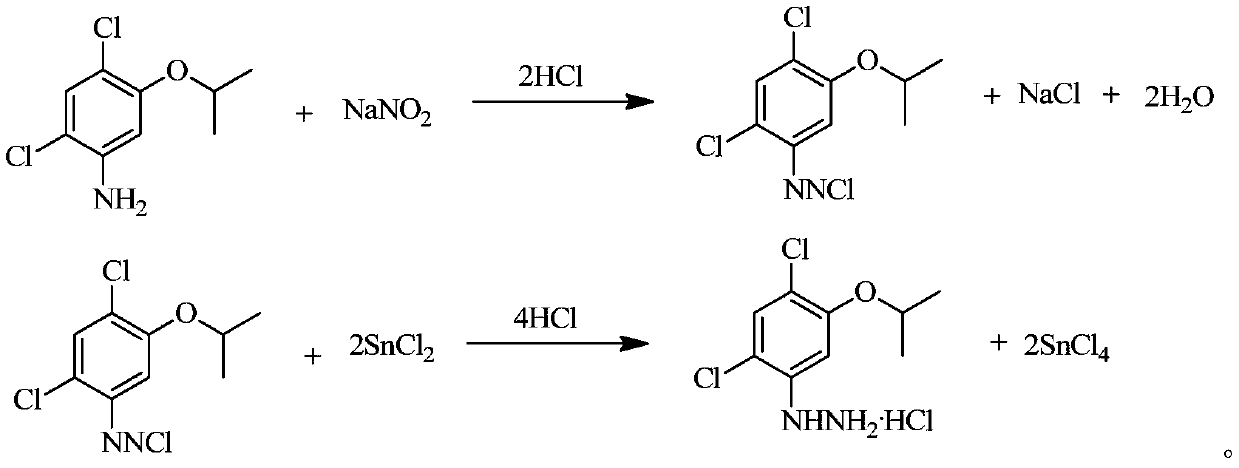

Method for reducing stannic chloride

The invention discloses a method for reducing stannic chloride. Aluminum particles are taken as a reducing agent in the method. The method comprises the following specific steps: adding diluted hydrochloric acid solution of stannic chloride generated by reducing diazonium salt with stannous chloride into a corrosion-resistant device provided with a tail gas air induction emptying system and a stirrer; starting stirring; slowly heating up and slowly adding the aluminum particles at the temperature of 20-55 DEG C for reaction; centrifugally drying after no divalent stannum is detected in the solution; and obtaining simple substance stannum after the reaction is finished. According to the method, the disadvantages in the prior art are overcome, and the method is simpler, convenient and environment-friendly, low in cost and high in yield and is more beneficial to reducing stannic chloride in industrial production.

Owner:HEFEI XINGYU CHEM

A kind of preparation method of reagent grade stannous chloride dihydrate crystal

ActiveCN105481005BMeet the needs of industries with high quality requirementsIncrease productivityStannous chlorideFiltrationTin(II) chloride

The invention provides a method for preparing reagent-grade stannous chloride dehydrate crystals from industrial-grade raw materials. The method comprises the following steps: melting industrial tin ingots and quenching the molten industrial tin ingots into tin flower; then enabling reaction between filtered industrial hydrochloric acid and tin hydroxide to produce stannic chloride pentahydrate; adding the tin flower into the stannic chloride pentahydrate solution; enabling heat-insulating reaction for 12-18 h at 100-105 DEG C; when the mass concentration of quadrivalent tin in the solution is detected to be less than 0.01%, concentrating under reduced pressure till the specific weight of the solution is 2.0-2.4; filtering the solution into a cooling device to be cooled for 12-20 h at 0-10 DEG C; then discharging; carrying out vacuum suction filtration and centrifugal separation to obtain the required reagent-grade stannous chloride dehydrate crystals. The preparation method is short in process route, simple to operate, easy for processing parameter control and relatively high in production efficiency; the obtained product can meet the standards of the reagent-grade (high-purity) stannous chloride dehydrate crystals without crushing or screening, and can satisfy the requirements of industries (such as chemical analysis, catalytic synthesis and PCB colloid-Pd sensitization) which demand much on the quality of stannous chloride.

Owner:GUANGDONG GUANGHUA SCI TECH

Method for reducing lead content in stannous chloride

The invention discloses a method for reducing lead content in stannous chloride. The method comprises the following steps of (1) dissolution: dissolving stannous chloride in water and preparing into a stannous chloride solution; (2) adjustment of a pH value: adjusting a pH value of the stannous chloride solution to 8-9 with an alkaline solution and heating to a temperature of 60-80 DEG C with stirring; (3) lead removal: dropwise adding a certain amount of a barium chloride-sodium carbonate solution into the stannous chloride solution with the pH value adjusted, controlling a reaction end point to a natural pH value, wherein a ratio of the amount of barium chloride to that of lead ions in stannous chloride is 20-60:1; and a ratio of the amount of substance of sodium carbonate to that of barium and lead ions is 13:12; and (4) solid-liquid separation: separating the stannous chloride solution with the lead removed by centrifugation and removing the precipitate. Lead content of high lead stannous chloride is reduced to below 0.005% through a barium carbonate co-precipitation method, thereby producing low lead stannous pyrophosphate. The lead content of the product can reach an industrial standard.

Owner:广西华锡集团股份有限公司

Method for preparing stannous chloride crystals by utilizing PCB tin stripping waste liquid

InactiveCN112499670AReduce pollutionReduce manufacturing costPhotography auxillary processesStannous chlorideTetrachloridePhysical chemistry

The invention relates to the technical field of preparation methods of stannous chloride crystals, and provides a method for preparing stannous chloride crystals by utilizing PCB tin stripping waste liquid, which comprises the following steps: washing tin hydroxide solids recovered from the PCB tin stripping waste liquid, dissolving tin hydroxide into a tin tetrachloride solution by using hydrochloric acid, reducing the stannous chloride solution the stannous chloride solution through a diaphragm electrolysis method, further purifying and concentrating the stannous chloride solution under reduced pressure, performing cooling to obtain clean and white stannous chloride crystals, and stannous chloride prepared through the method is free of caking, good in liquidity and free of crushing and screening. According to the method, the stannic chloride solution is reduced into the stannous chloride solution through diaphragm electrolysis, a traditional process for reducing the stannous chloridesolution mainly through a metallic tin ingot is replaced, expensive metallic tin is saved, and the production efficiency is greatly improved.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

Hydrothermal synthesis method of stannous oxide nanosheet

InactiveCN110040768AEfficient preparationLow costMaterial nanotechnologyStannous chlorideSTANNOUS OXIDEFiltration

The invention discloses a hydrothermal synthesis method of stannous oxide nanosheet. 0.677-1 g of stannous chloride and 0.24-0.5 g of sodium hydroxide are respectively dispersed in mixed solutions ofethanol and deionized water to obtain a solution A and a solution B, mixing and stirring the solution A and the solution B for 2.5 h to obtain a milky yellowish colloidal product; and the obtained milky yellowish colloidal product is placed in a reactor for reaction at 120 DEG C for 8 h, pumping filtration is carried out, the product is alternately washed with deionized water and ethanol for threetimes, a small part of a sample at an upper layer is white, most of the sample at a lower layer is black, and the black sample at the lower layer is placed into a baking box for drying to obtain nano-flake stannous oxide. The hydrothermal synthesis method of the stannous oxide nanosheet of the invention is high in efficiency, low in cost, environmentally friendly and easy in storage.

Owner:HENAN NORMAL UNIV

The synthetic method of stannous chloride

ActiveCN108341427BOvercome the problem of slow responseEffectively remove the interference of product qualityStannous chlorideTetrachlorideHydrogen

The invention discloses a synthetic method of stannous chloride. The method comprises the following steps: by using anhydrous stannic tetrachloride and hydrochloric acid with concentration of 20 wt% as raw materials, adding a precious metal catalyst, heating to 110 to 140 DEG C, introducing hydrogen with the pressure intensity of 1.5 to 3MPa, performing heat insulation reaction for 2 to 6 hours at125 to 135 DEG C, and performing press filtration to obtain a stannous chloride solution and a dilute hydrochloric acid solution with required concentrations; then performing concentration and crystallization to obtain a stannous chloride crystal. According to the synthetic method of stannous chloride disclosed by the invention, by using hydrogen as a reducing agent, a catalyst can be reacted andrecycled for being reused, and the phenomenon that tin is used as the reducing agent in a conventional process is avoided, so that the interference of impurity elements carried by metal tin on the quality of a product is effectively eliminated. The method disclosed by the invention has the advantages of stable process, strong operability, low cost, environment-friendly property, high security andthe like, and can be applied to industrial popularization.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD +1

Application of tin hemispheres in preparation of tin chemical products

InactiveCN106882836AReduce labor intensityFlat surfaceTin organic compoundsFoundry mouldsIngotChemical products

The application of tin hemispheres in the preparation of tin chemical products is to make tin ingots into hemispherical tin raw materials for the synthesis of tin-containing chemical products. The invention can reduce friction and corrosion of equipment, reduce equipment investment, reduce labor intensity of workers, reduce energy consumption, improve production efficiency and product quality stability.

Owner:YUNNAN TIN

Method for synthesis of lactic acid and its derivatives and catalyst for preparing same

ActiveUS20150329458A1Cheap preparationImprove reaction speedCobalt halidesCarboxylic acid esters preparationPolymer scienceAlcohol

The present disclosure provides a catalyst for preparing lactic acid and derivatives thereof, comprising at least one of metallic compounds MXn, wherein M is selected from Na, K, Mg, Ca, Sr, Ba, Al, Ga, In, Sn, Sb, Bi, Cr, Mn, Fe, Co, Ni and Zn, and n is an integer of 1 to 6. The present disclosure further provides a method for synthesis of lactic acid and derivatives thereof, wherein at least one raw material including carbohydrates, at least one alcohol, at least one of the aforesaid catalysts and at least one solvent are heated to react to prepare lactic acid and derivatives thereof.

Owner:MICROVAST POWER SYST CO LTD

Preparation method of toothpaste-grade tin chloride

ActiveCN103539198BCompliant with Addition CriteriaQuality improvementStannous chlorideFiltrationDistillation

The invention discloses a preparation method of a toothpaste-grade tin chloride. The preparation method comprises the following steps: (i) synthetic reaction and primary filtration: adding deionized water, anhydrous tin tetrachloride and metallic tin into a reaction kettle according to a molar ratio of (4-8): 1: (1-1.2), and then adding concentrated hydrochloric acid to carry out synthetic reaction and primary filtration; (ii) purification and secondary filtration: adding excessive sulfuric acid into a purifying kettle, and then adding an appropriate amount of toothpaste-grade strontium chloride to carry out purification and secondary filtration; (iii) carrying out distillation and crystallization; (iv) carrying out vacuum drying, thus obtaining a finished product of dry white crystal toothpaste-grade tin chloride. The preparation method disclosed by the invention is stable in process, easy to control, low in cost and little in three wastes; the synthesized toothpaste-grade tin chloride is stable in quality and accords with addition standards of toothpaste.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Ordered spherical large mesoporous material alpha-Fe2O3

The invention relates to an ordered spherical large mesoporous α-Fe2O3 material, which belongs to the technical field of material preparation. The present invention adopts colloidal crystals closely packed and arranged in the three-dimensional direction of polymethyl methacrylate milk balls with a ball diameter of 71±5nm as a template, impregnates the template with an ethanol-water mixed solution of FeC2O4 2H2O, heats and solidifies, and roasts to remove PMMA template, obtained spherical large mesoporous α-Fe2O3 material with pore diameter of 37±3nm, pore wall of 12±2nm, and orderly extension in three-dimensional direction. After SEM, TEM, XRD, N2 adsorption experiments and superconducting quantum interferometer to determine its large mesoporous structure and magnetic properties, it is a new type of ordered spherical large mesoporous α-Fe2O3 material. The material of the invention has the advantages of crystalline hole walls, special spherical large mesopore network and weak ferromagnetic properties, and can be used to prepare catalysts and sensors.

Owner:YUNNAN NORMAL UNIV

Dynamic crystallization technological method and device for stannous chloride solution

ActiveCN102120609BImprove crystallization efficiencyShorten crystallization timeStannous chlorideChlorideSlurry

Owner:GUANGXI HUAXI GRP CO LTD

Method for preparing high-grade stannous chloride by utilizing low-tin waste slag

The invention discloses a preparation method of premium-grade stannous chloride from low-tin waste residues. The invention comprises the following steps: preparing a reaction solution, introducing chlorine, settling, settling for a second time, filtrating, concentrating, freeze crystallization and solid-liquid separation, wherein the obtained solid is the premium-grade stannous chloride. According to the invention, low-tin waste residues produced in tin manufacturing process are used as raw materials, various indexes of the stannous chloride product are controlled through acidity, concentration and time, and multiple setting, filtering and concentrating are performed to remove impurities, so as to obtain premium-grade stannous chloride products. The preparation method disclosed by the invention is simple in process, low in cost and environmentally friendly, provides a new way for recycling of low-tin waste residues produced in a tin manufacturing process and satisfies requirements of circular economy.

Owner:GUANGXI HUAXI GRP CO LTD

A kind of stannous chloride dihydrate and preparation method thereof

ActiveCN110563029BSimple process routeIncreased process safetyStannous chlorideHydration reactionReaction rate

The invention discloses a preparation method of stannous chloride dihydrate, which comprises the following steps: adding hydrochloric acid solution and metal tin into a reactor, controlling the reaction temperature at 40-70° C., and then dropping hydrogen peroxide solution to make Metal tin is dissolved, then metal tin is added to reduce Sn 4+ , then filter, adjust the pH value of the filtrate to 0.5-1.5, then concentrate the filtrate, and at the same time add metal tin to the filtrate to inhibit Sn 2+ Oxidize, when the density of the filtrate reaches 2.0~2.3g / mL, stop the concentration to obtain a concentrated solution; place the concentrated solution to crystallize at 0~5℃, separate the precipitated stannous chloride crystals, and dry to obtain chlorine dihydrate stannous. The preparation method of the invention has a simple process route, significantly improves the reaction rate, shortens the reaction time, and effectively reduces the temperature required for the reaction, does not need to use concentrated hydrochloric acid and chlorine in the reaction process, is environmentally friendly, and has high process safety. High purity.

Owner:昆明先导新材料科技有限责任公司

A method for reducing lead content in tin protochloride

The invention discloses a method for reducing lead content in stannous chloride. The method comprises the following steps of (1) dissolution: dissolving stannous chloride in water and preparing into a stannous chloride solution; (2) adjustment of a pH value: adjusting a pH value of the stannous chloride solution to 8-9 with an alkaline solution and heating to a temperature of 60-80 DEG C with stirring; (3) lead removal: dropwise adding a certain amount of a barium chloride-sodium carbonate solution into the stannous chloride solution with the pH value adjusted, controlling a reaction end point to a natural pH value, wherein a ratio of the amount of barium chloride to that of lead ions in stannous chloride is 20-60:1; and a ratio of the amount of substance of sodium carbonate to that of barium and lead ions is 13:12; and (4) solid-liquid separation: separating the stannous chloride solution with the lead removed by centrifugation and removing the precipitate. Lead content of high lead stannous chloride is reduced to below 0.005% through a barium carbonate co-precipitation method, thereby producing low lead stannous pyrophosphate. The lead content of the product can reach an industrial standard.

Owner:GUANGXI HUAXI GRP CO LTD

Method for preparing stannous chloride by recycling diluted hydrochloric acid tail gas

PendingCN112374535ASolve environmental pressureChemical industryStannous chloridePhysical chemistryTin(II) chloride

The invention discloses a method for preparing stannous chloride by recycling diluted hydrochloric acid tail gas, which comprises the steps of adding hydrochloric acid and tin into a concentrated hydrochloric acid reactor, heating, reacting to form stannous chloride liquid, and gradually concentrating; generating dilute hydrochloric acid tail gas mixed by HCl steam and water vapor through reaction, entering a heat exchanger, feeding cold dilute acid salt in a cold dilute hydrochloric acid storage tank into the heat exchanger at the same time so as to obtain hot dilute hydrochloric acid by heating cold dilute hydrochloric acid through the hot dilute hydrochloric acid tail gas, feeding into a hot dilute hydrochloric acid heat preservation storage tank to be stored for standby application, and condensing the diluted hydrochloric acid tail gas and returning to a cold diluted hydrochloric acid storage tank for later use; and pumping the hot diluted hydrochloric acid in the hot diluted hydrochloric acid heat preservation storage tank into a diluted hydrochloric acid reactor, adding tin into the diluted hydrochloric acid reactor for reaction to prepare a stannous chloride solution, pumping the stannous chloride solution into a concentrated hydrochloric acid reactor for concentration after the reaction is completed, and then discharging, cooling and crystallizing to obtain stannous chloride crystals. The method can directly recycle dilute hydrochloric acid tail gas to prepare stannous chloride, and is energy-saving, environment-friendly and efficient.

Owner:云南锡业锡化工材料有限责任公司

Method for chlorination and dehydrogenation of ethane

ActiveUS10138181B2Simple processLow costCatalyst activation/preparationHydrocarbonsMetal chlorideLiquid state

The present invention relates to a method for chlorination and dehydrogenation of ethane, comprising: mixing and reacting a low-melting-point metal chloride with C2H6, such that the low-melting-point metal chloride is reduced to a liquid-state low-melting-point metal, and the C2H6 is chlorinated and dehydrogenized to give a mixed gas containing HCl, C2H6, C2H4, C2H2 and C2H3Cl. In the method, the low-melting-point metal chloride is used as a raw material for chlorination and dehydrogenation, and the low-melting-point metal produced after the reaction is used as an intermediate medium. The method has the characteristics of simple process, low cost and high yield. Moreover, some acetylene and vinyl chloride can be produced as by-products at the same time when the ethylene is produced, by controlling the ratio of ethane to the chloride as desired in production.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

Chlorine introducing method and device for producing stannous chloride by liquid chlorine

ActiveCN102126747BIncrease gasification rateImprove the efficiency of chlorine reactionPressure vesselsContainer discharging from pressure vesselsBuffer tankChloride

The invention relates to a chlorine introducing method and a chlorine introducing device, in particular to a chlorine introducing method and a chlorine introducing device for producing stannous chloride by liquid chlorine. The method comprises the following steps of: introducing liquid chlorine into a coiled tube to be heated and gasified, introducing chlorine to a chlorine introducing tank for use, and heating the coiled tube by external hot water at the temperature of between 40 and 60 DEG C. The device comprises a liquid chlorine cylinder, the toiled tube, a heating water tank and a chlorine buffer tank, wherein the coiled tube is arranged in the heating water tank; an inlet of the coiled tube is communicated with the liquid chlorine cylinder, and an outlet of the coiled tube is communicated with the chlorine buffer tank; and the chlorine buffer tank is communicated to the chlorine introducing tank. In the method and the device, an operating mode of the natural gasification of the liquid chlorine is changed, and the liquid chlorine is introduced into the coiled tube in liquid mode and is heated by utilizing the coiled tube to accelerate the gasification speed of the liquid chlorine and improve the efficiency of a chlorination reaction in stannous chloride production; and the requirement of the production on the speed of a chlorine introducing reaction can be met only by opening one cylinder of liquid chlorine (one ton / cylinder), and the reliability of safety performance of the liquid chlorine during use is enhanced.

Owner:GUANGXI HUAXI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com