Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about "Copper chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

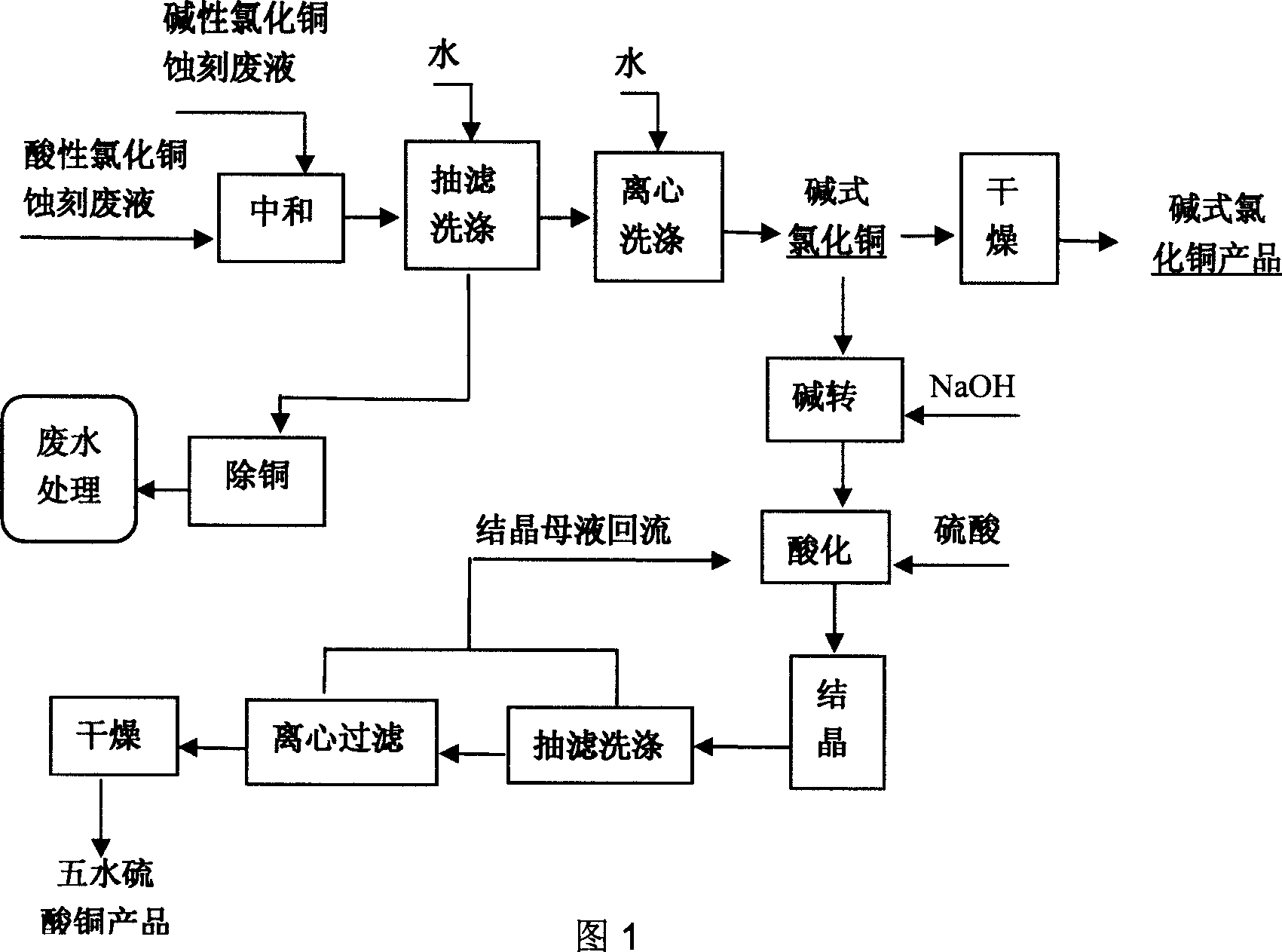

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

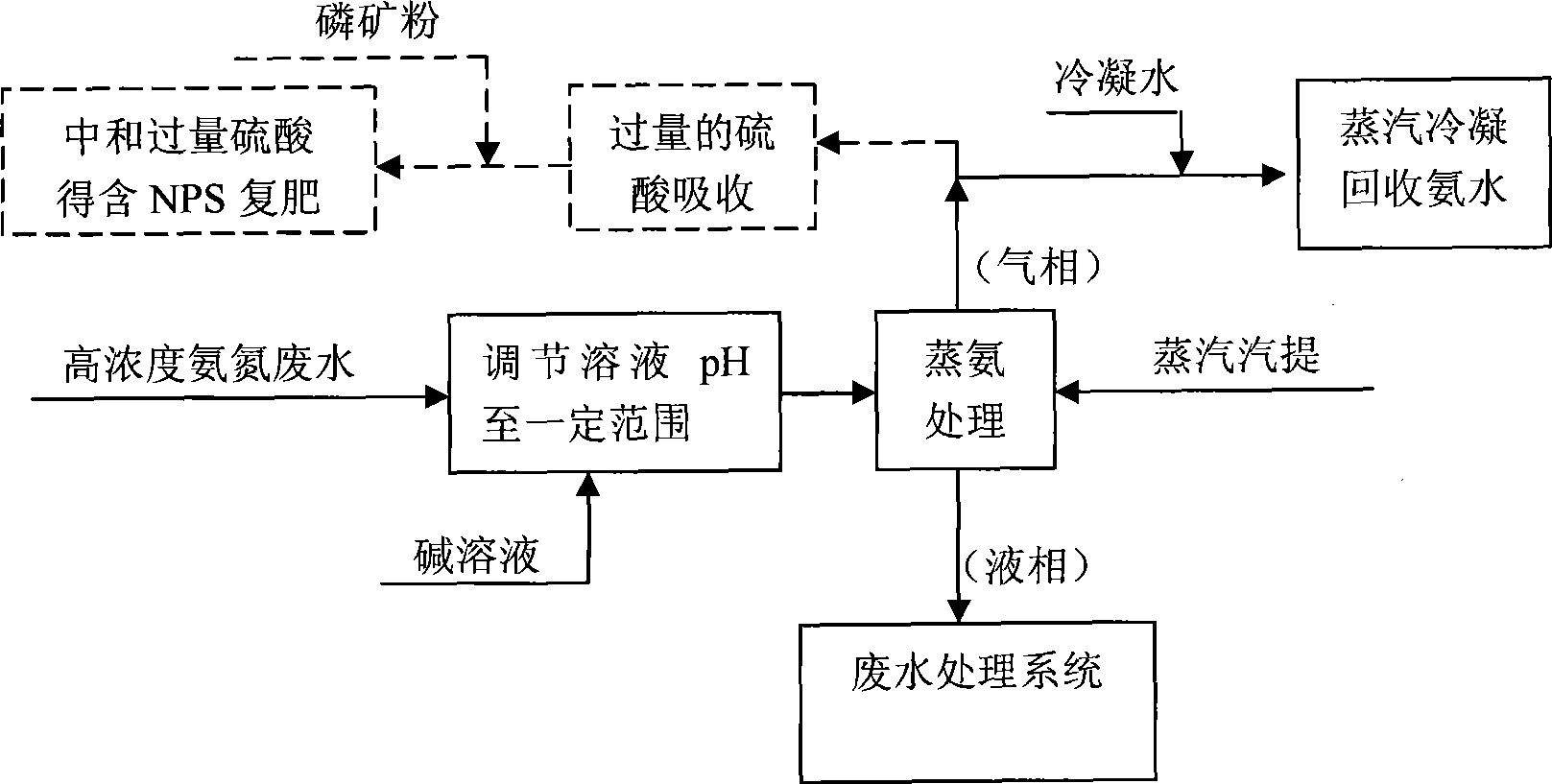

Method for recovery processing of ammonia nitrogen from printed circuit board waste liquid

ActiveCN101391799ARealize resource utilizationEasy to handleClimate change adaptationSewage/sludge fertilisersHigh concentrationLiquid waste

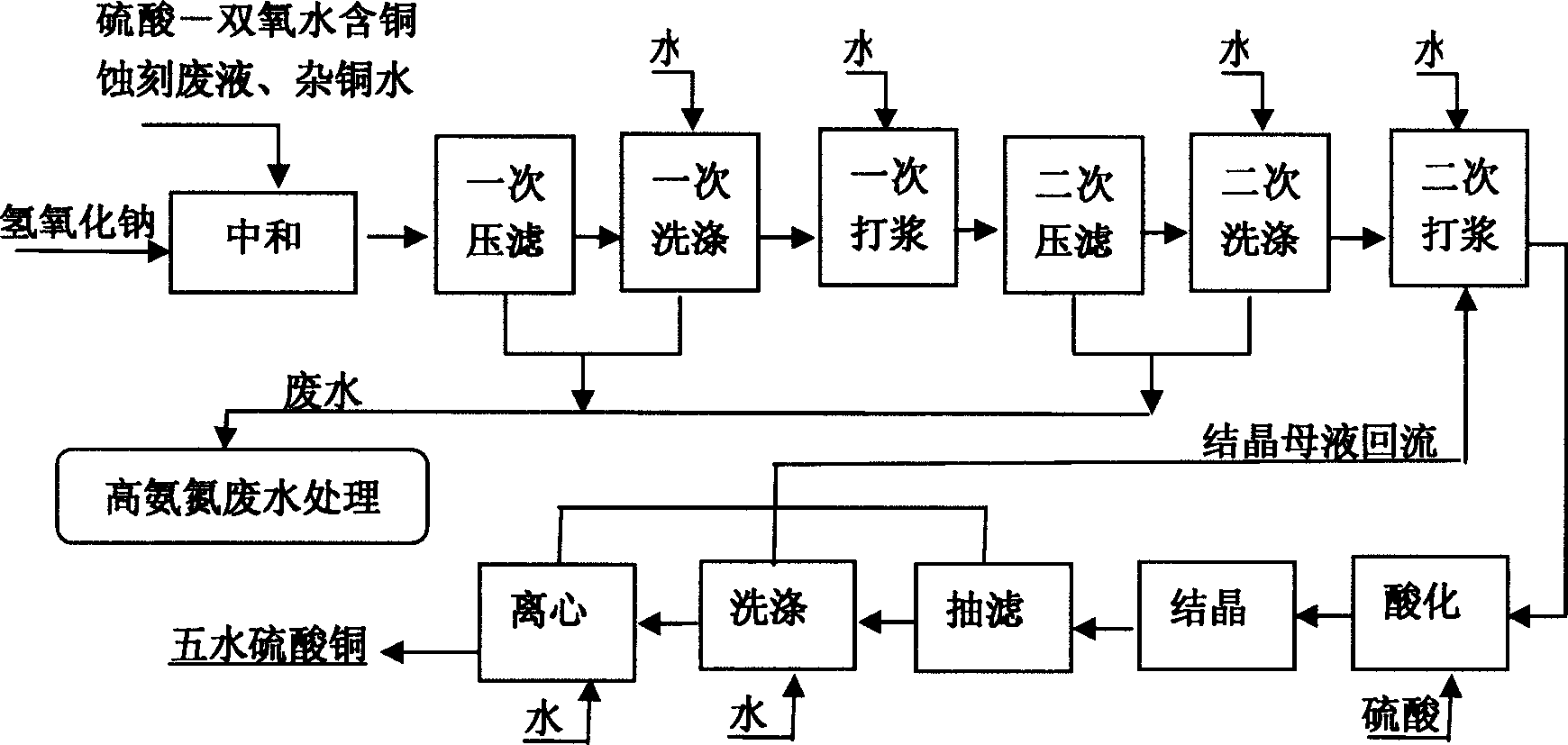

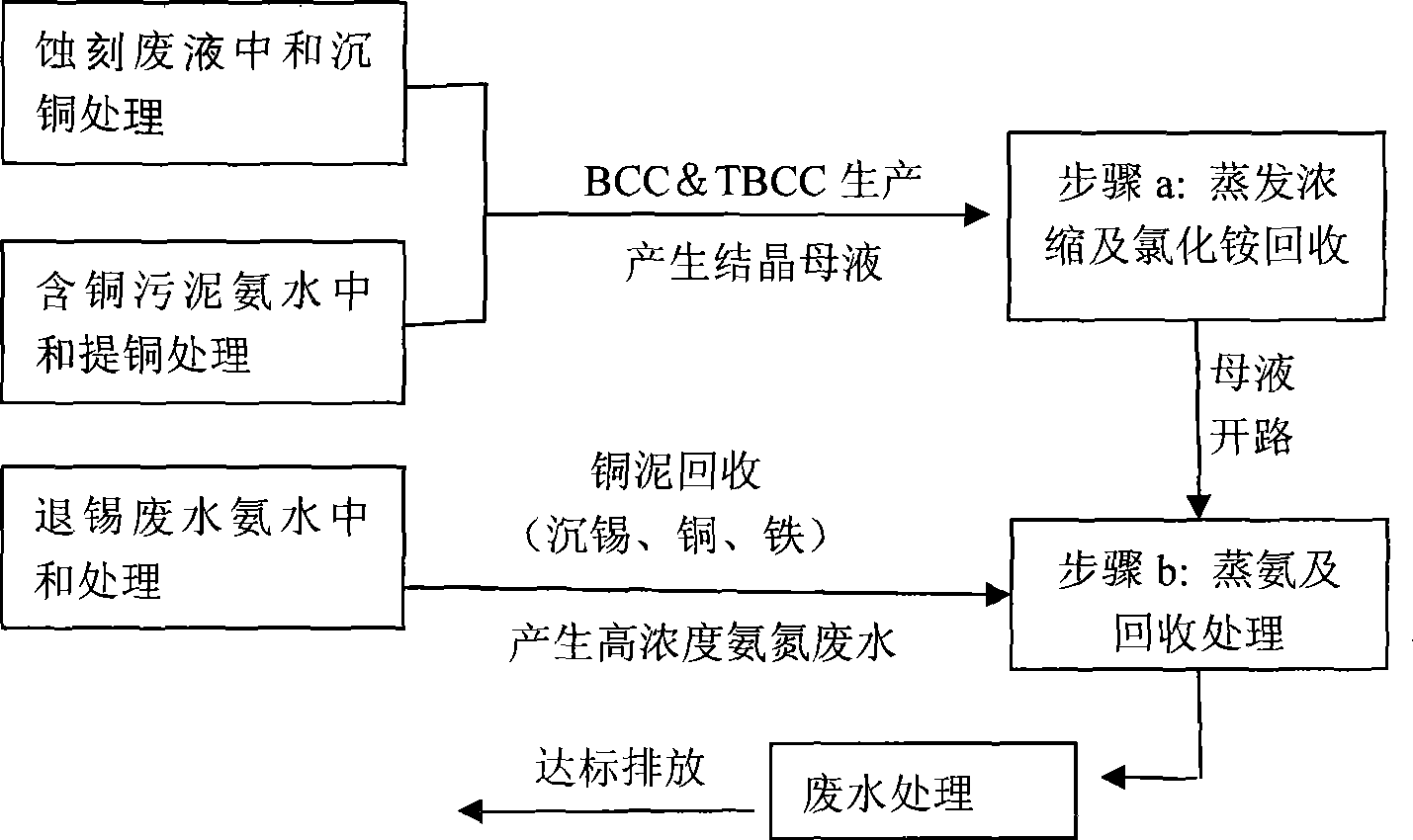

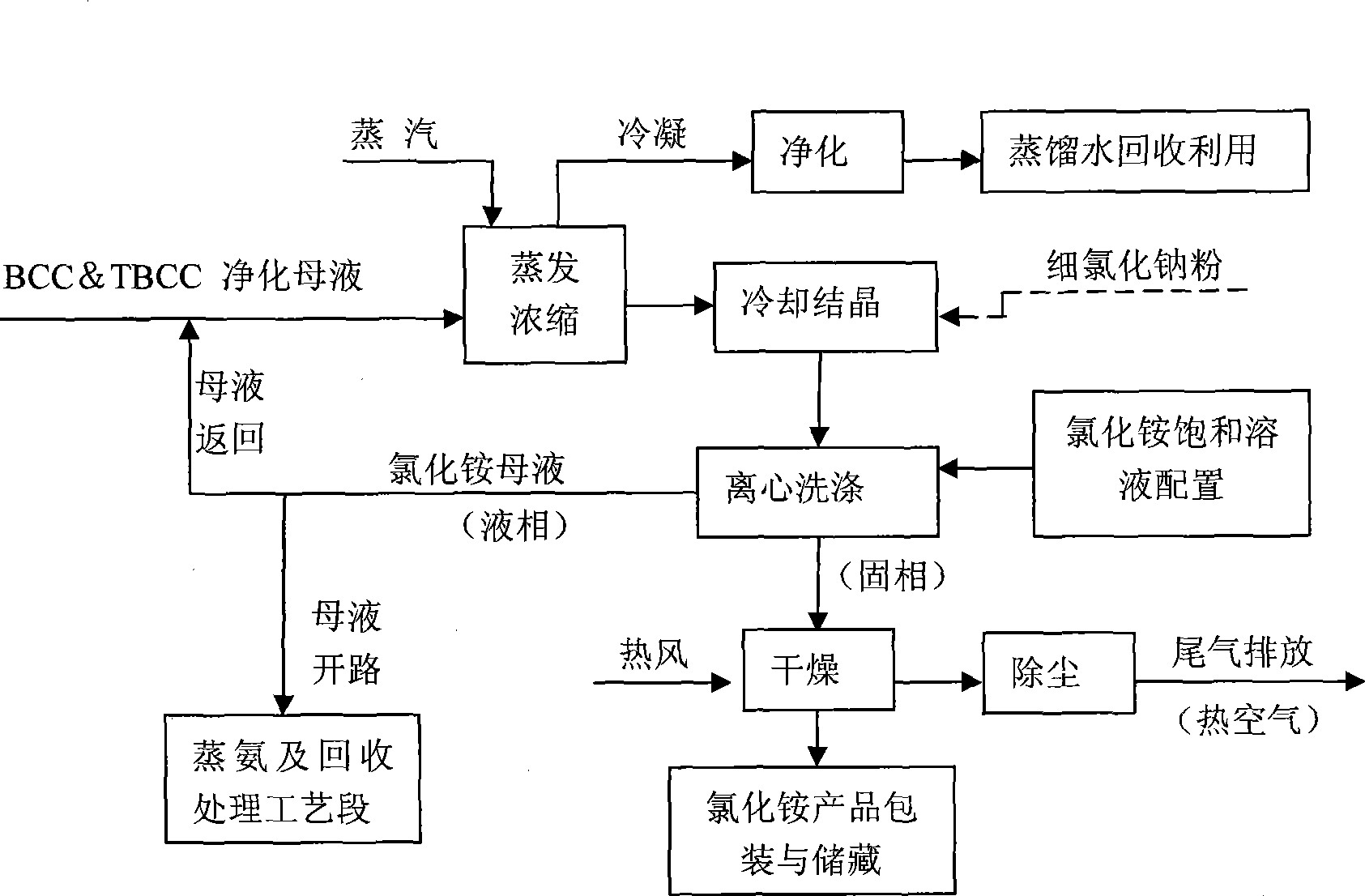

The invention relates to a method for recycling ammonian in ammonian waste water with high concentration, in particular to a method for recycling ammonian in printed wiring board waste water; crystallization mother liquid containing ammonium chloride with high concentration which is generated from processes such as producing alkaline copper chloride, Alpha crystallization type alkaline copper, blue vitriod and the like by using wiring board etching waster water, firstly is evaporated, concentrated and crystallized by one or two combination in multiple effect evaporation technique of mechanical compression, evaporating and compression with heat so as to recycle most ammonium chloride; secondly, Ph is adjusted and ammonian is evaporated so as to recycle ammonia or ammonium sulphate; ammonian waste water generated from removing tin water from ammonia and recycling tin mud are treated by evaporating ammoniac after directly adjusting Ph; and the residual sewage is further treated in the sewage treatment system. By using the method, both of the removal rates of ammonian waste water for wiring board and the recovery rate of ammonia are more than 99.8 percent; the method has good treatment effect, high efficiency, little amount of steam usage, low running cost, and good popularization and application prospect.

Owner:深圳市宝安东江环保技术有限公司

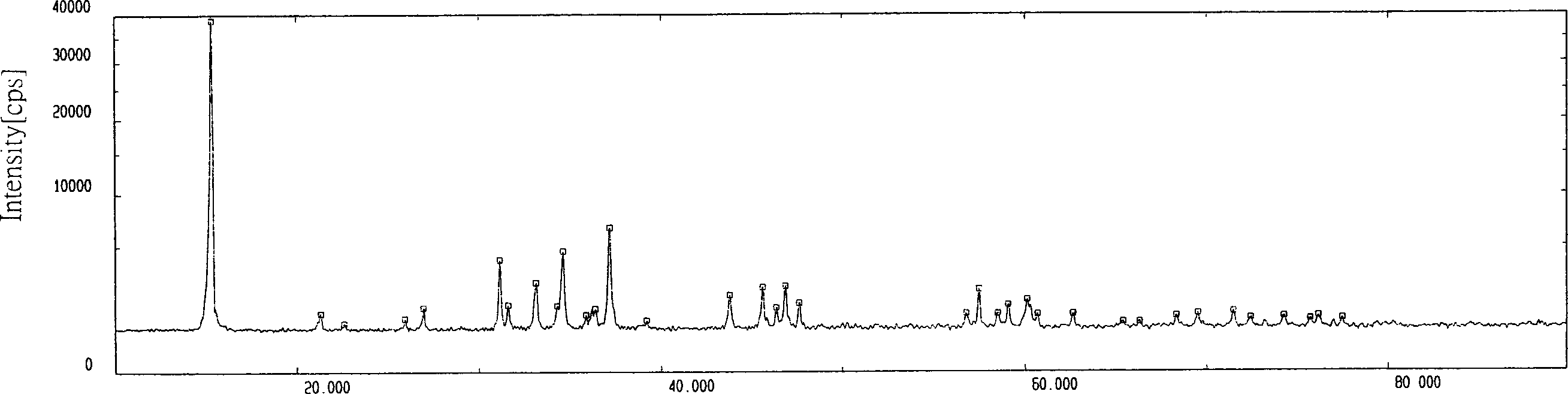

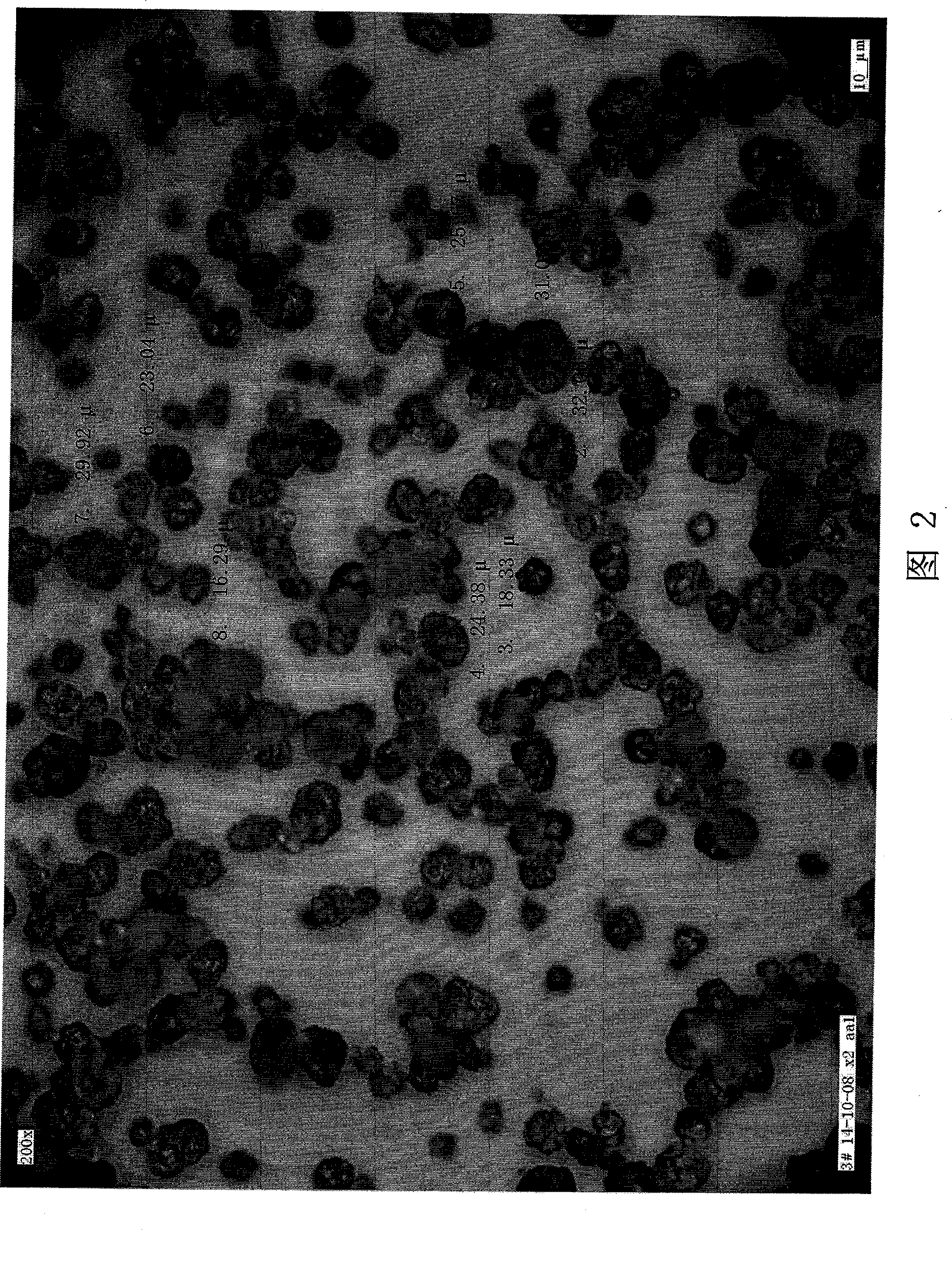

Method for producing tribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Botallackite preparation method and uses thereof

ActiveCN1880225AHigh yieldQuality improvementAnimal feeding stuffAccessory food factorsSal ammoniacCopper chloride

A method for preparation and use of sloping atacamite belonging to the area of fine chemical engineering, the characters of which consist in the process steps as follows: preheating the ammonium chloride solution, copper chloride solution and ammonial solution to 65-100 degree centigrade separately; the concentration of ammonium chloride solution is 5-25%, the concentration of copper in copper chloride solution is 100-200g / L, the content of ammonial in ammonial solution is 5-20%; adding ammonium chloride solution to reactor equipped agitating device, at the same time, adding copper chloride solution and ammonial solution with the mole proportion of 2:3 to undergo neutralizing reaction during agitation for deposit of sloping atacamite. The invention has simple process, high reaction sensitivity and low cost; the sloping atacamite produced in the method has high yield, excellent quality, stable property and is suitable for mass production. So the sloping atacamite can be used for feed addictive on a large scale for the stable property

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

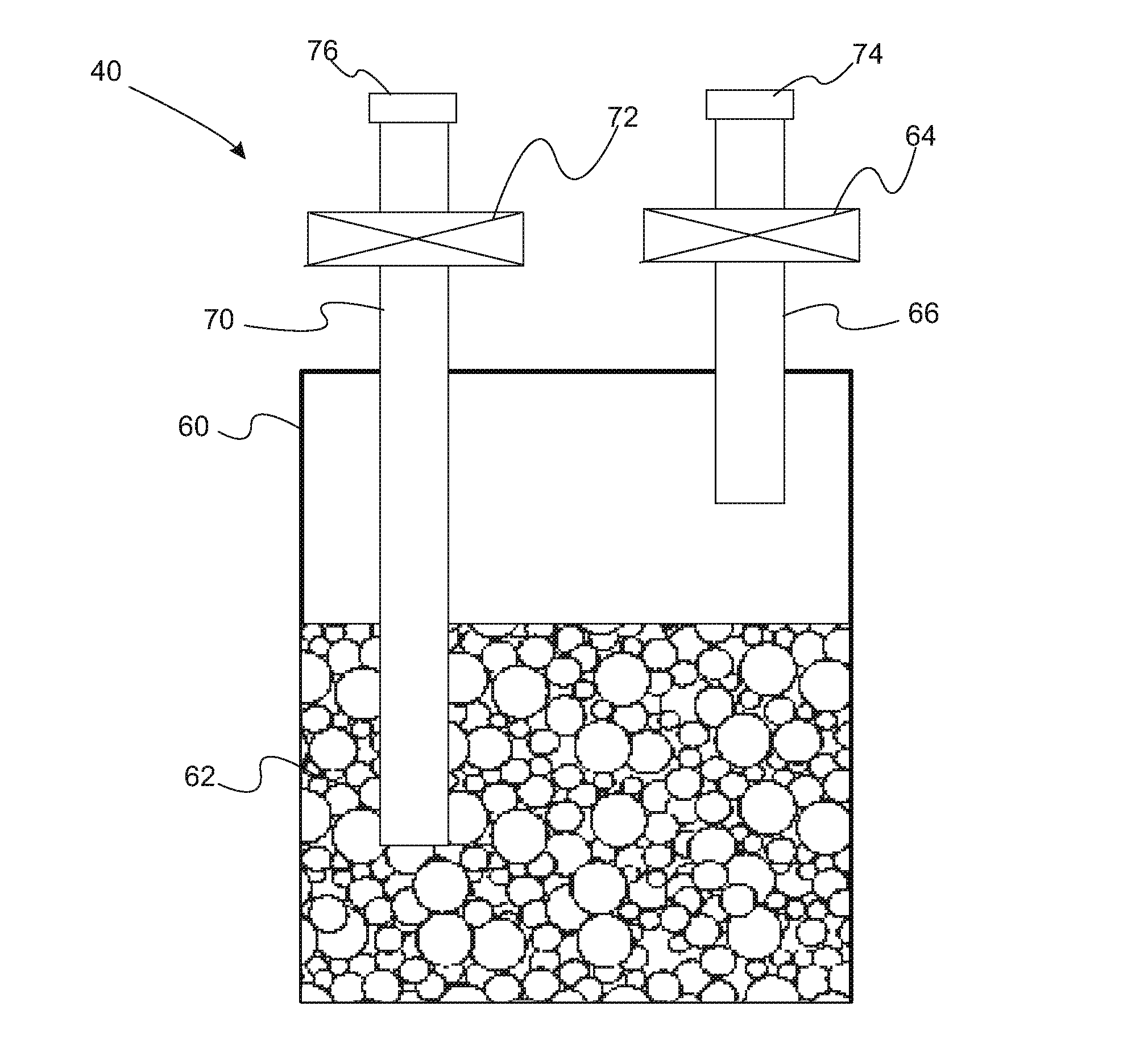

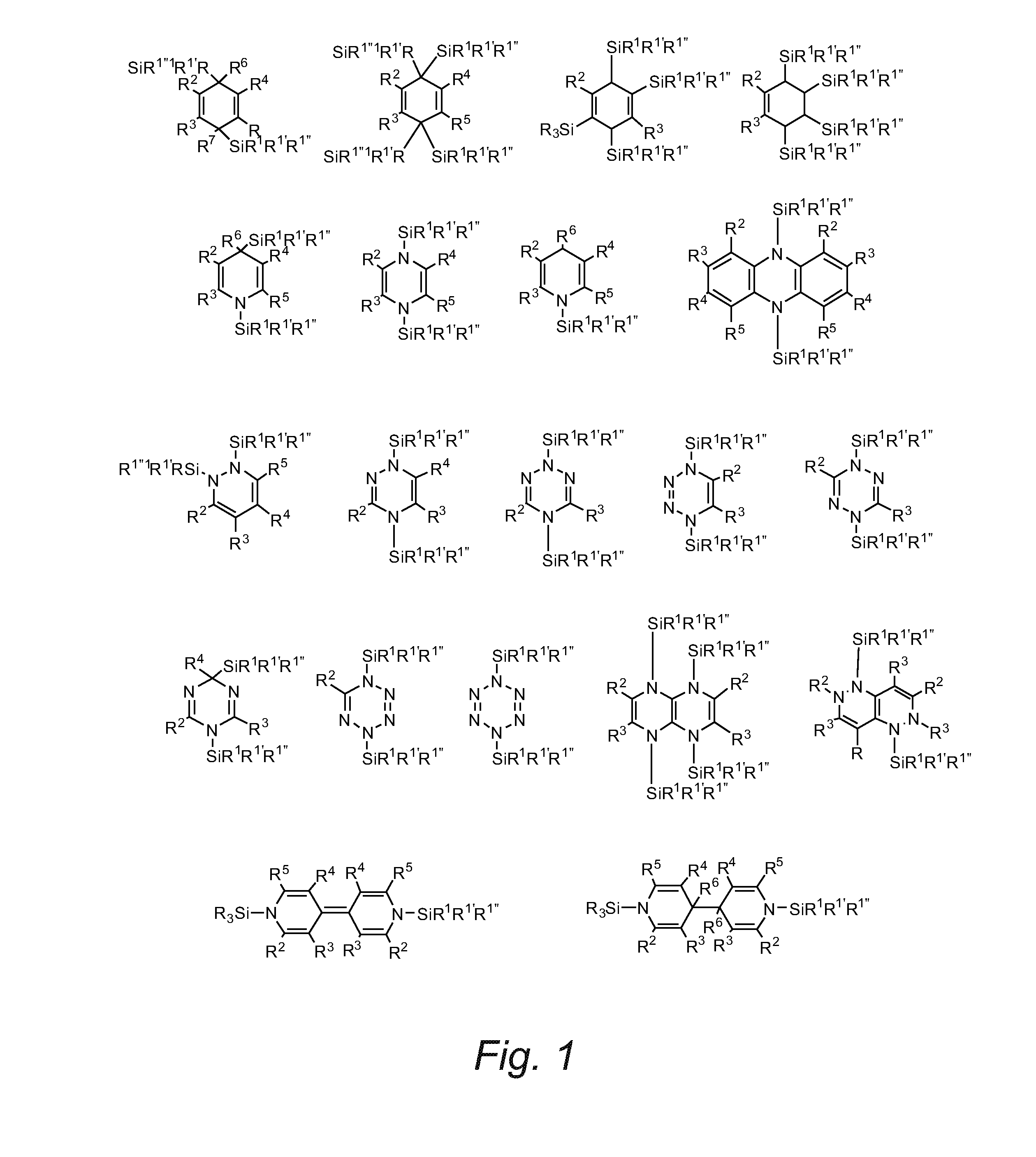

Bis(trimethylsilyl) six-membered ring systems and related compounds as reducing agents for forming layers on a substrate

ActiveUS20150004314A1Solve problemsGroup 4/14 element organic compoundsPipe supportsTrimethylsilylChemical compound

A first compound having an atom in an oxidized state is reacted with a bis(trimethylsilyl) six-membered ring system or related compound to form a second compound having the atom in a reduced state relative to the first compound. The atom in an oxidized state is selected from the group consisting of Groups 2-12 of the Periodic Table, the lanthanides, As, Sb, Bi, Te, Si, Ge, Sn, and Al.

Owner:WAYNE STATE UNIV

Basic copper chloride production method

ActiveCN103351020AImprove recycling effectSimplified processing stepsCopper chloridesAmmoniacal nitrogenTribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Recovery method for mother liquor after copper chloride hydroxide production by etching waste liquor

ActiveCN102320703AEfficient recyclingHigh purityMultistage water/sewage treatmentCopper chloridesAmmoniacal nitrogenCopper chloride

The invention discloses a recovery method for mother liquor after copper chloride hydroxide production by etching waste liquor, which is characterized in that the mother liquor of the etching waste liquor after the copper chloride hydroxide production is firstly neutralized, precipitated and filtered, the rest liquor sequentially passes through an ion exchanger filled with ion exchange resin and ion exchange resin fibers, then, the exchange liquor is evaporated, evaporation mother liquor and condensed water are obtained, ammonium chloride is obtained after evaporation mother liquor cooling, and ammonia nitrogen contained in the condensed water is removed through an efficient ammonia nitrogen regeneration reactor. In the second exchange liquor treated by the recovery method, the copper content is less than 5mug / L, and the content of the ammonia nitrogen passing through the efficient ammonia nitrogen regeneration reactor is less than 10mg / L. The etching waste liquor treated by the method has the advantages that copper ions are recovered in the form of copper chloride hydroxide, the ammonia is recovered in the forms of ammonia chloride and ammonia water, the waste water can also reach the industrial application standard to be cyclically utilized, and the goal of zero waste emission is realized.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

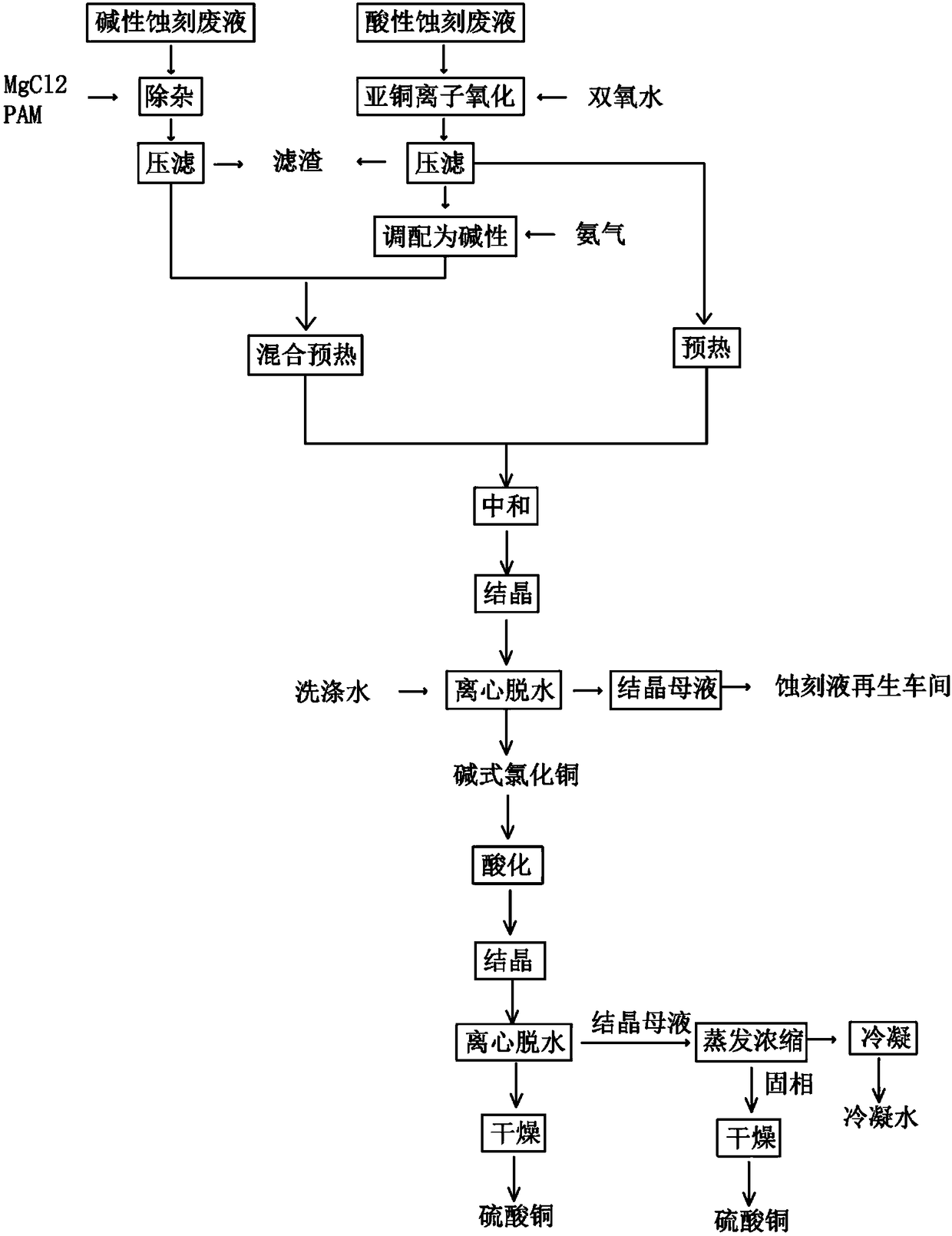

Comprehensive recycling process of copper-containing etching waste solution

InactiveCN108249472AHigh recovery rateEfficient removalCopper chloridesCopper sulfatesCopper chlorideChloride

The invention discloses a recycling process of a copper-containing etching waste solution. The recycling process comprises the following steps: removing mechanical particles and arsenic in an alkalinewaste solution by virtue of magnesium chloride, PAM and a press filtering machine, removing the mechanical particles and oil contaminants in an acid waste solution by virtue of a press filtering machine, neutralizing the acid waste solution and alkaline waste solution to obtain alkaline copper chloride, or acidifying by using sulfuric acid to obtain copper sulfate; and when the alkaline waste solution is insufficient, introducing ammonia gas into the acid waste solution with the mechanical particles and the oil contaminants removed by virtue of the press filtering machine, adjusting the solution to be alkaline, and then performing the neutralization reaction to obtain alkaline copper chloride or copper sulfate. The comprehensive recycling process is simple, low cost, capable of massivelytreating the etching waste solution, and capable of recycling the copper and realizing the safety up-to-standard treatment of the etching waste solution.

Owner:韶关鹏瑞环保科技有限公司

Method for producing cuprous chloride form deposed copper chloride fluid of etching board

A process for preparing cuprous chloride from the used etching liquid of copper chloride includes adding copper oxide to said used etching liquid, filtering, heating the clear solution, stirring while filling SO2 gas, cooling, filtering to obtain crystals, washing with diluted hydrochloric acid and then with alcohol, and drying.

Owner:RUANSHI CHEM WUJIANG CITY

Preparation and use of crystal basic copper chloride containing iron

ActiveCN101434405AImprove liquidityGrowth inhibitionAnimal feeding stuffCopper chloridesCopper chlorideMoisture resistance

The invention discloses a preparation method of ferrous crystalline caustic soda type copper chloride, and the function thereof, wherein, the preparation method comprises the steps of: a. taking and preheating an ammonium chloride solution, a ferrous copper chloride solution and hartshorn or copper chloride ammonia liquor respectively; b. putting the preheated ammonium chloride solution, the ferrous copper chloride solution and the hartshorn or the copper chloride ammonia liquor in a reaction container to carry out synthetic reaction to generate the ferrous crystalline caustic soda type copper chloride; and c. stopping charging when the ferrous crystalline caustic soda type copper chloride grows certain grain diameter, discharging part of the material from the bottom, discharging the precipitate in the material, washing, filtering and centrifugalizing the material to obtain the ferrous crystalline caustic soda type copper chloride. The ferrous crystalline caustic soda type copper chloride prepared by the method can be used as the copper-iron micronutrient element additive of animal feed and is characterized by moisture resistance, no agglomeration, good fluidity, stable chemical property, easy mixing with feed, low price, low additive cost, soluble subacidity, easy absorption and utilization, and the like.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

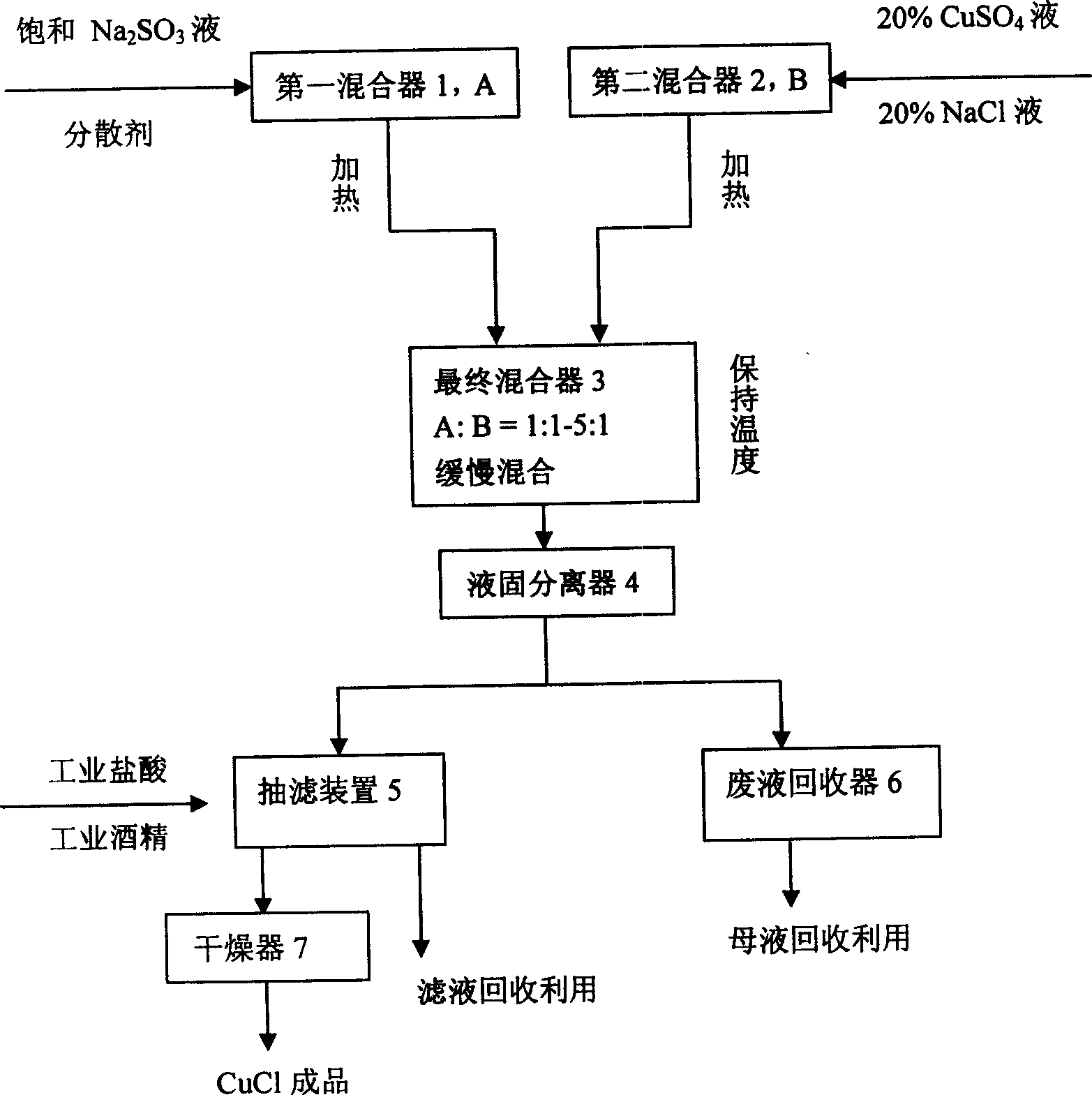

Preparation method of high activity cuprous chloride catalyst used for organic silicon monomer synthesis

A coprous chloride catalyst used for preparing organosilicon monomer with high activity, selectivity and output rate is prepared through reduction reaction for reducing the mixed solution of Cu and Cl ions by SO3 solution while adding disperser for controlling the granularity and form of product, liquid-solid separation, acid washing, alcohol washing, filtering washing and drying.

Owner:TSINGHUA UNIV

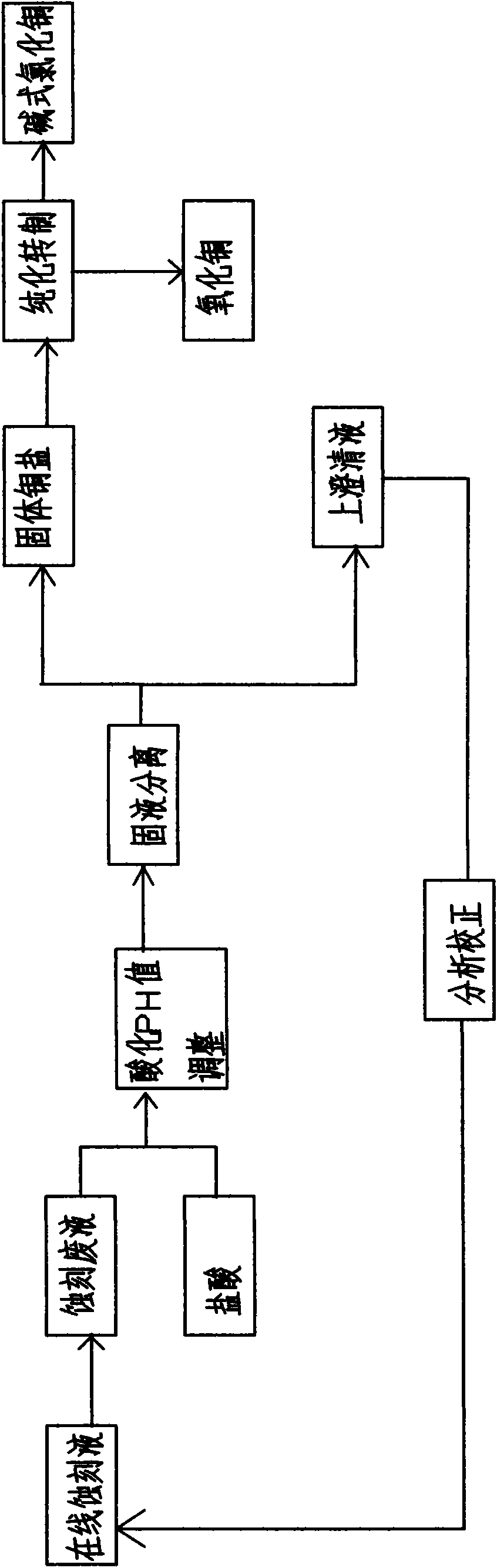

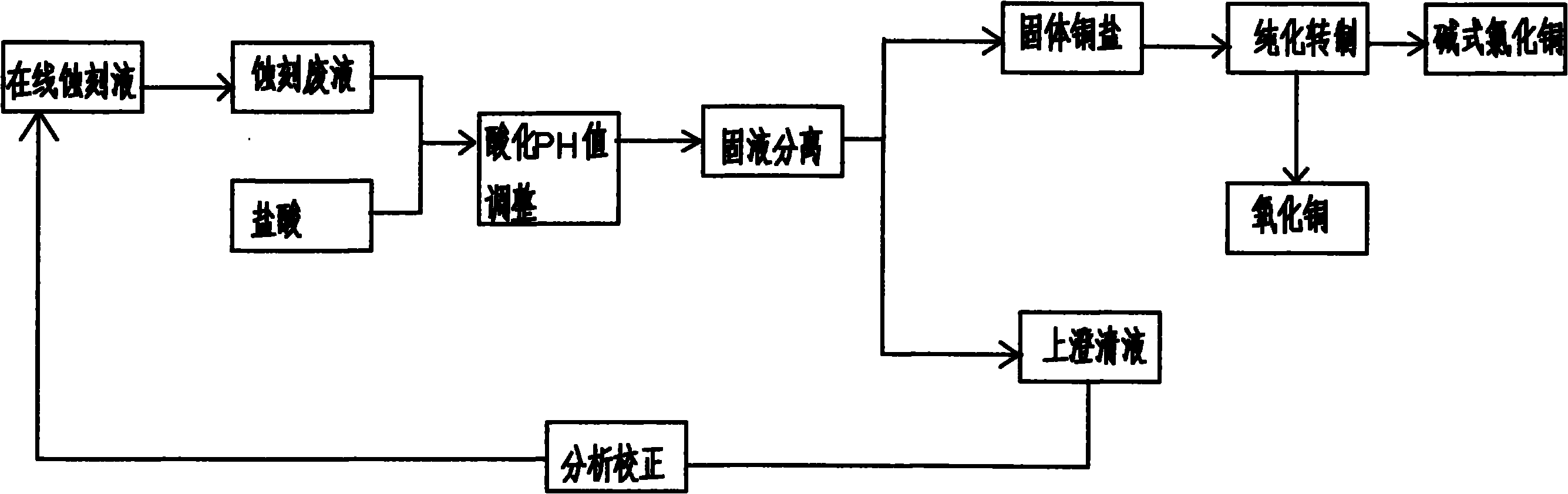

Process for recycling alkali waste etching liquid

InactiveCN101935121AReduce processing costsReduce manufacturing costMultistage water/sewage treatmentCopper chloridesWater dischargeWastewater

The invention discloses a process for recycling alkali waste etching liquid. The process comprises the following steps of: acidizing and regulating the pH value; separating solid and liquid; purifying and converting; and recycling supernatant liquid. By adopting the process for recycling the waste alkali etching liquid, copper ions in the waste alkali etching liquid can be recovered, and the supernatant liquid can be recycled; the process has zero waste water discharge, thereby reducing the production cost of enterprises; and the waste liquid can be utilized 100 percent to guarantee no pollution.

Owner:昆山联鼎环保科技有限公司

Novel growth method of two-dimensional organic polymer through two-dimensional crystal surface catalysis

ActiveCN107936261AUniform thicknessShape is easy to controlCopper chloridesCopper foilTwo dimensional crystal

The invention provides a novel growth method of a two-dimensional organic polymer through two-dimensional crystal surface catalysis. A solid-liquid interface rapid preparation method is adopted to directly prepare a two-dimensional cuprous chloride nano-crystal material which has template and catalysis effects on a copper foil substrate; 1,3,5-tribromobenzene and p-phenylenediamine are used as monomer molecules; polymerization reaction is directly carried out on the surface of a two-dimensional cuprous chloride nano-crystal which is used as a catalyst, so as to obtain the two-dimensional organic polymer. According to the method disclosed by the invention, the two-dimensional organic polymer is prepared from specific monomers by utilizing surface-catalyzed reaction and two-dimensional organic polymerization reaction types are widened.

Owner:射阳县新港污水处理有限公司

Static pressure hydrothermal and hydrolytic preparing technology for cuprous chloride crystal

A process for preparing the cuprous chloride crystal by static-pressure hydrothermal hydrolysis includes such steps as dissolving copper sulfate and sodium chloride in solvent, regulating its acidity, adding excessive red copper powder, boiling while reflux reaction, adding hydrochloric acid to dissolve generated cuprous chloride crystals, filtering to remove residual copper powder, adding water heating to 105-150 deg.c in sealed state, static-pressure hydrothermal hydrolyzing, filtering, washing and drying.

Owner:ZHEJIANG UNIV

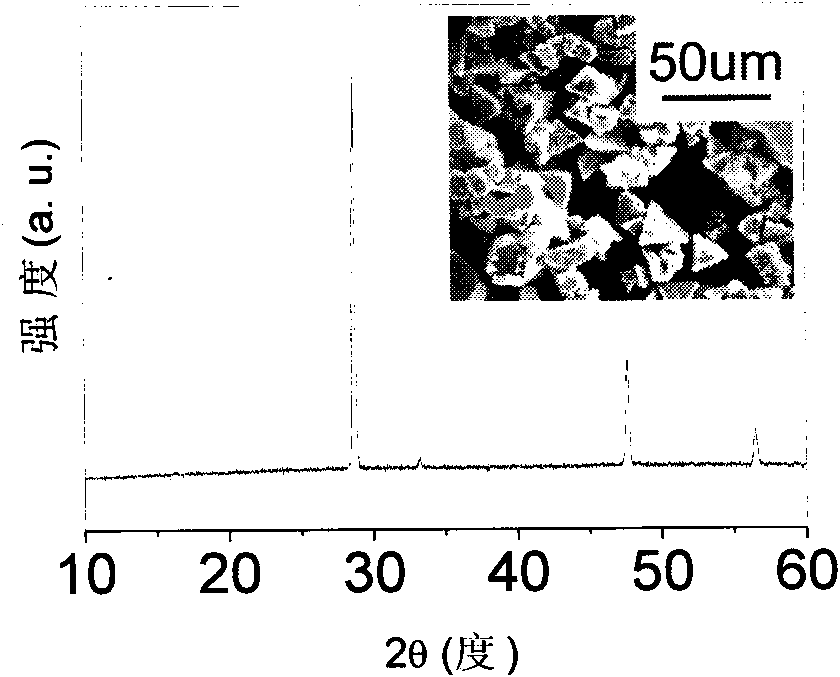

Water heating reduction method preparing process for cuprous chloride

InactiveCN101070181ANo emissionsSimple preparation processCopper chloridesCopper chlorideCuprous chloride

The invention is a kind of preparation craft of copper chloride crystal by hydrothermal reduction method, confect bluestone and sodium chloride into mixed water solution, transmit them into pressure and resistant autoclave, add reducer of formaldehyde which then is heated to temperature of 130 degree C-170 degree C closely, make them react for 3-12 hours by hydrothermal reduction method and form copper chloride crystal, cool it and then filter, absterge and dry the filtered crystal according to general method, then get product wanted. In the course of preparing copper chloride crystal in the invention, it uses formaldehyde as reducer, liquor and formaldehyde reducer reacts in the close autoclave directly by hydrothermal reduction method, form product wanted of copper chloride crystal for one step. The preparation craft is simple and easy to control, save water and energy, there is no harmful gas and liquid to discharge, the mother liquor filtered copper chloride crystal can be used circulatoryly after being disposalled, and it has double superiority of environmental protection and energy-conservation.

Owner:YANCHENG TEACHERS UNIV

Comprehensive utilization method of waste liquor in production of basic cupric carbonate

ActiveCN103449501AAchieve reuseRealize recycling of resourcesCopper chloridesCopper nitratesSulfate radicalsIndustrial waste water

The invention discloses a comprehensive utilization method of waste liquor in the production of basic cupric carbonate and relates to the field of treatment methods of industrial wastewater. The invention aims at providing a comprehensive utilization method of waste liquor in the production of basic cupric carbonate, and in particular relates to a method for reusing sodium bicarbonate in the waste liquor. The waste liquor in the production of the basic cupric carbonate is the waste liquor generated after the basic cupric carbonate is produced by a reaction between an acidic copper chloride solution or an acidic copper sulfate solution and a sodium carbonate solution. The comprehensive utilization method of the waste liquor in the production of the basic cupric carbonate mainly comprises the following steps: adding a little distilled water into a reaction kettle as a base solution; when the reaction temperature rises to 35-90 DEG C, starting a stirring device, and adding the waste liquor containing sulfate radicals or chlorine and the acidic copper solution into the reaction kettle for reaction, wherein the pH value during the addition of the solutions is controlled to be 3-6; and filtering, washing, drying and sieving reaction products to obtain the basic copper salt. The method disclosed by the invention is simple to operate, easy to control reaction conditions, and widely applicable to the recycling and reusing of the waste liquor in the production of basic cupric carbonate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Preparation method of copper chloride hydroxide

ActiveCN101717110AHigh purityImprove protectionAnimal feeding stuffCopper chloridesResource utilizationCopper chloride

The invention discloses a preparation method of copper chloride hydroxide. The method comprises the following steps: adding copper hydroxide slurry in copper chloride solution according to a ratio of 2.5-3.5:1, reacting under the condition that the temperature is 80-160 DEG C, the pH value is 4-9 and the pressure is 0-600kPa, obtaining the reaction product after the reaction; and rinsing, centrifuging and drying the reaction product to obtain copper chloride hydroxide. The method of the invention has simple and safe operation, less waste discharge, lower production cost, more complete resource utilization and less environmental pollution.

Owner:昕嘉生物技术(长沙)有限公司

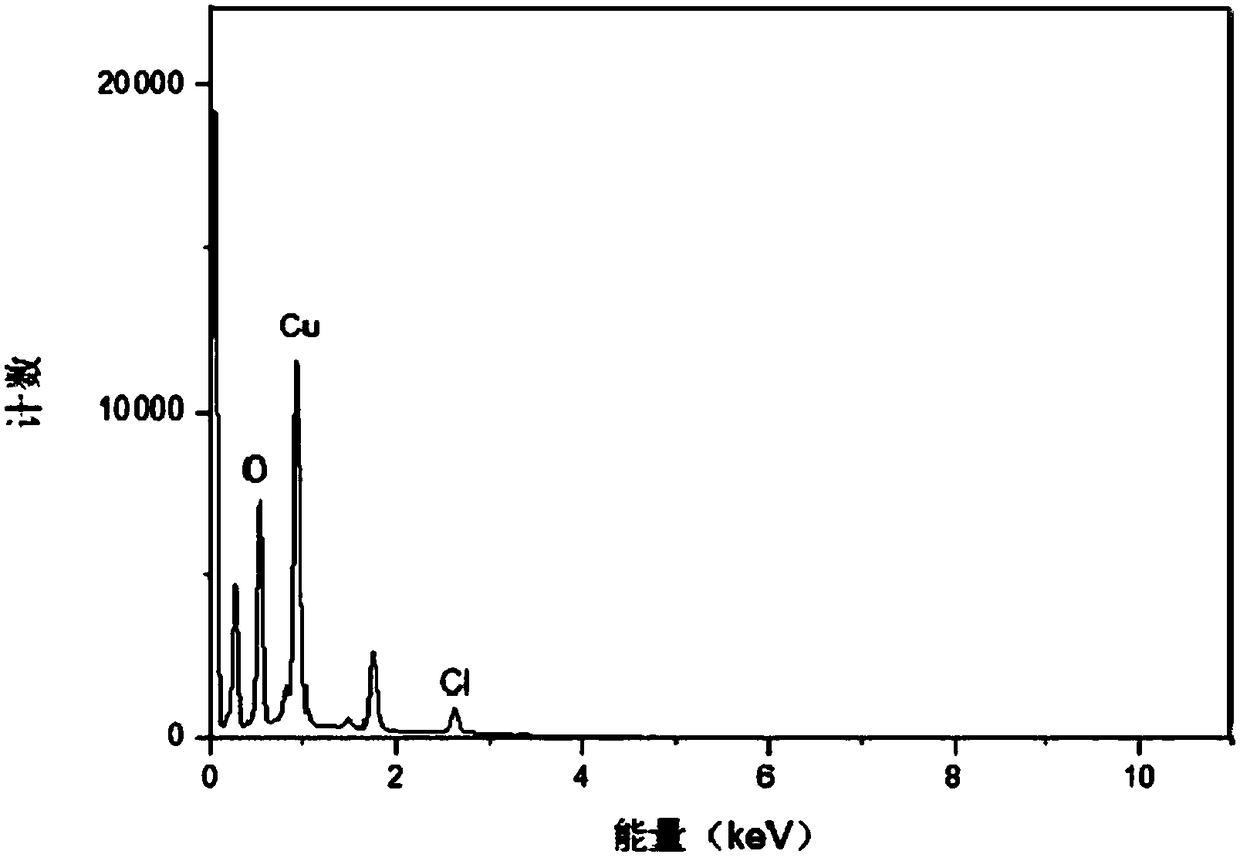

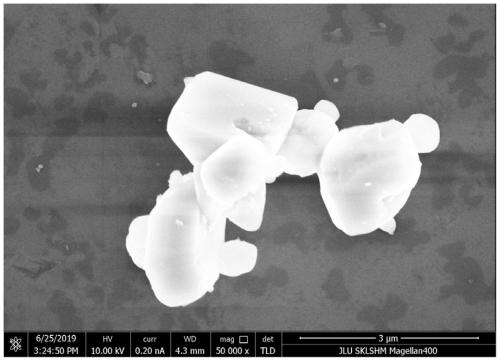

Copper hydroxychloride nanosheet and preparation method thereof

InactiveCN108358234AEasy to shapeHigh purityNanotechnologyCopper chloridesChemical reactionHexamethylenetetramine

The invention discloses a copper hydroxychloride nanosheet and a preparation method thereof, and belongs to the technical field of IB family hydroxychloride nanomaterials. The copper hydroxychloride nanosheet is lamellar and is of a lamellar structure, and the surface of the nanosheet is flat and smooth. The preparation method comprises the following steps: firstly mixing and stirring copper nitrate and hexamethylenetetramine, then adding sodium chloride, and continuously stirring; then carrying out a sealing reaction at the temperature of 95 to 135 DEG C in a reaction still for 2 to 8 h; andfinally carrying out washing, drying and grinding to obtain the light-green powder-like hydroxychloride nanosheet. A sealing high-temperature heating method with the reaction still is adopted firstly,so that the synthesized copper hydroxychloride nanosheet is high in purity, smooth in surface and complete in appearance; and copper hydroxychloride is an extremely important raw material for synthesizing copper oxide and copper chloride, and also can serve as a nutrient element additive of animal feeds and a catalyst of chemical reactions.

Owner:JILIN UNIV

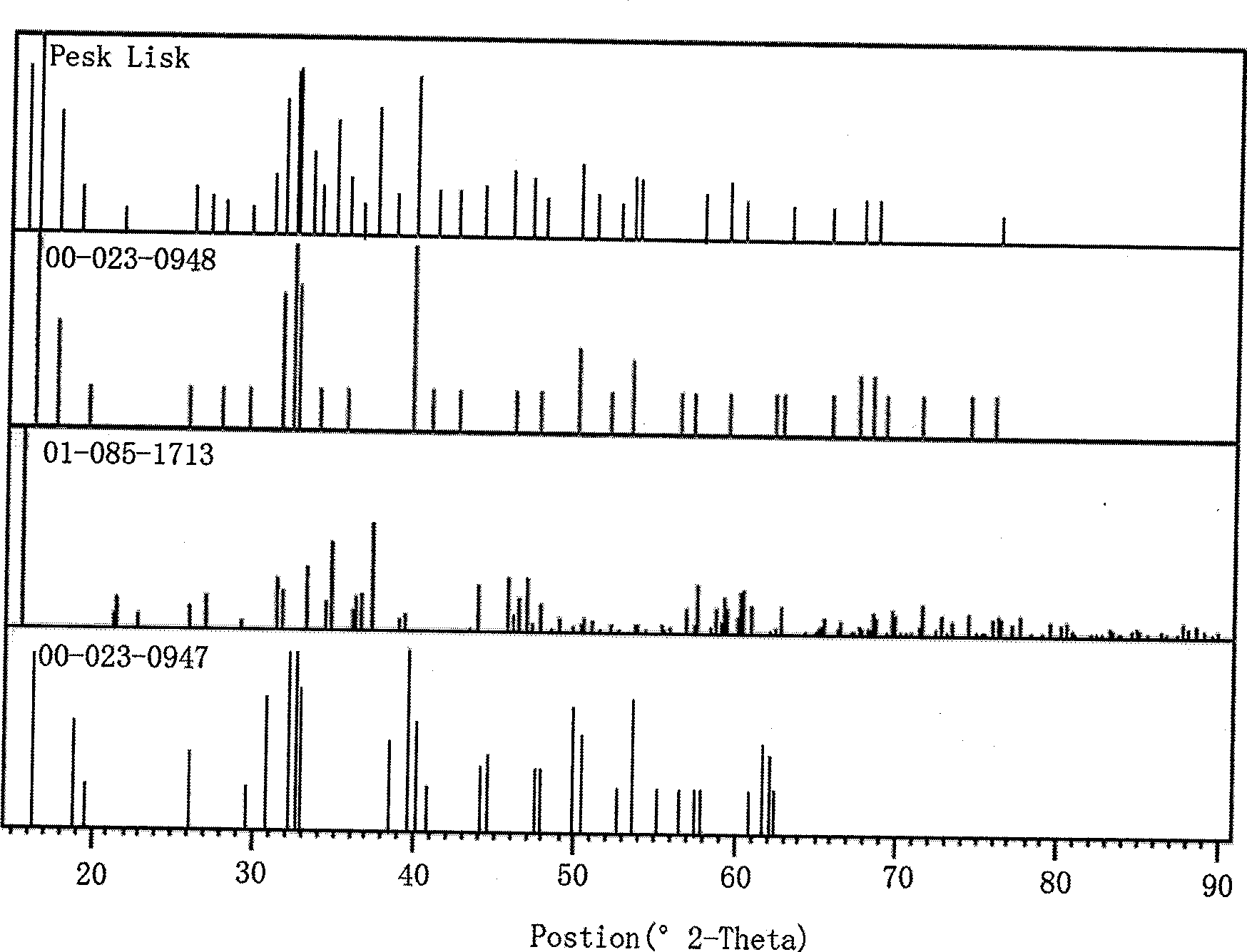

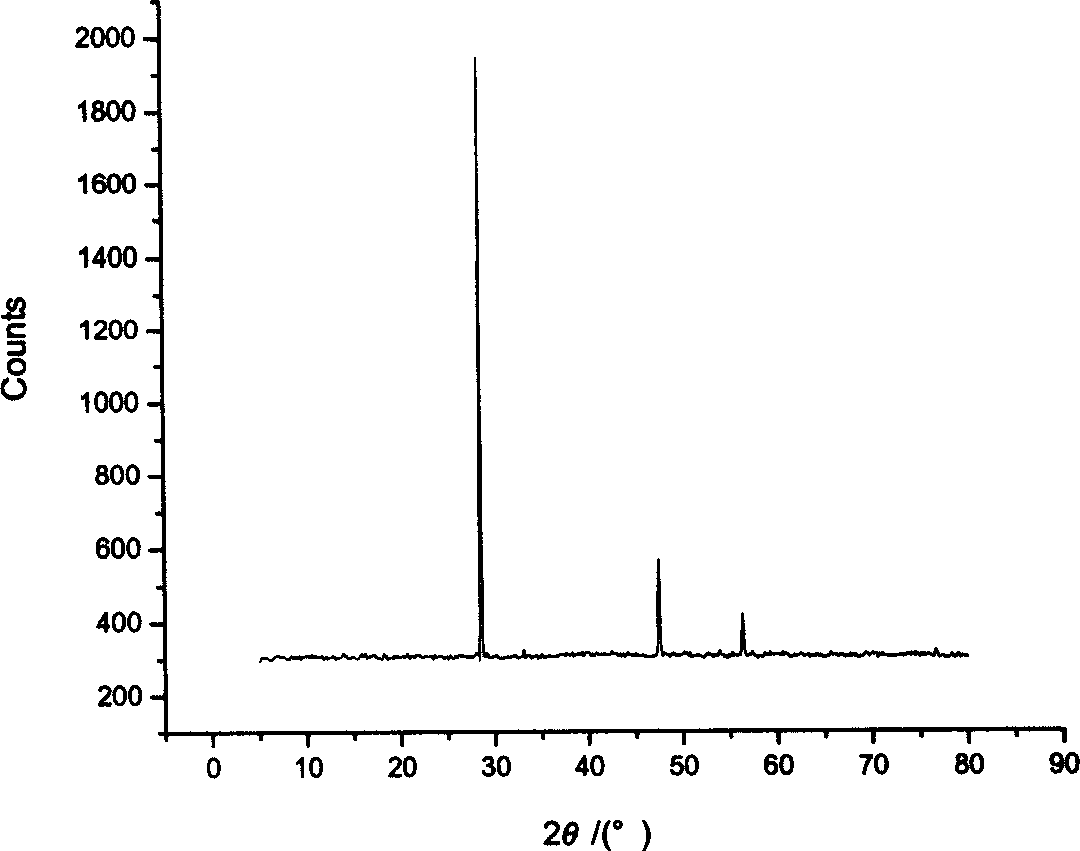

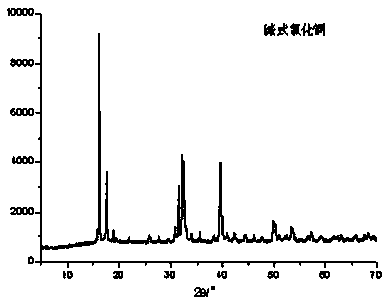

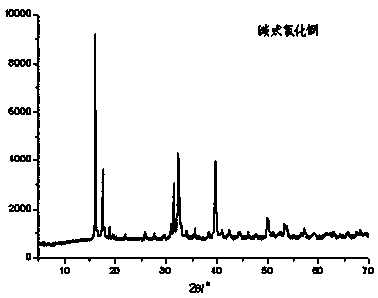

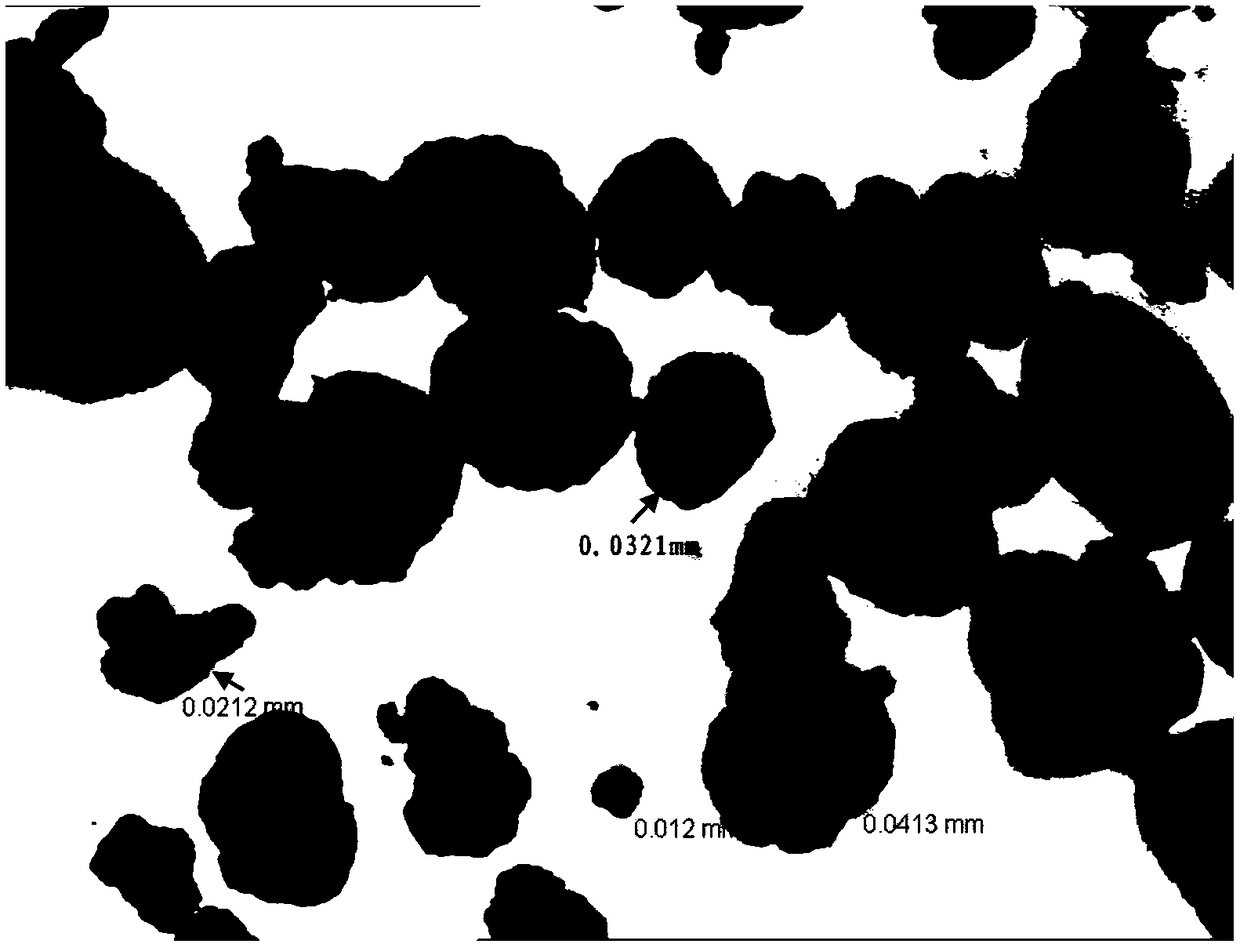

Production method of tribasic copper chloride

ActiveCN103818944AAchieve preparationHigh purityCopper chloridesTribasic copper chlorideCopper chloride

The invention discloses a novel production method of tribasic copper chloride. The production method is that 0.1-8% of sodium salt is added during the production process of tribasic copper chloride, so that prepared tribasic copper chloride is alpha-crystal form-oriented. The production method overcomes the defect that alpha-crystal form tribasic copper chloride is difficult to prepare in the prior art.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

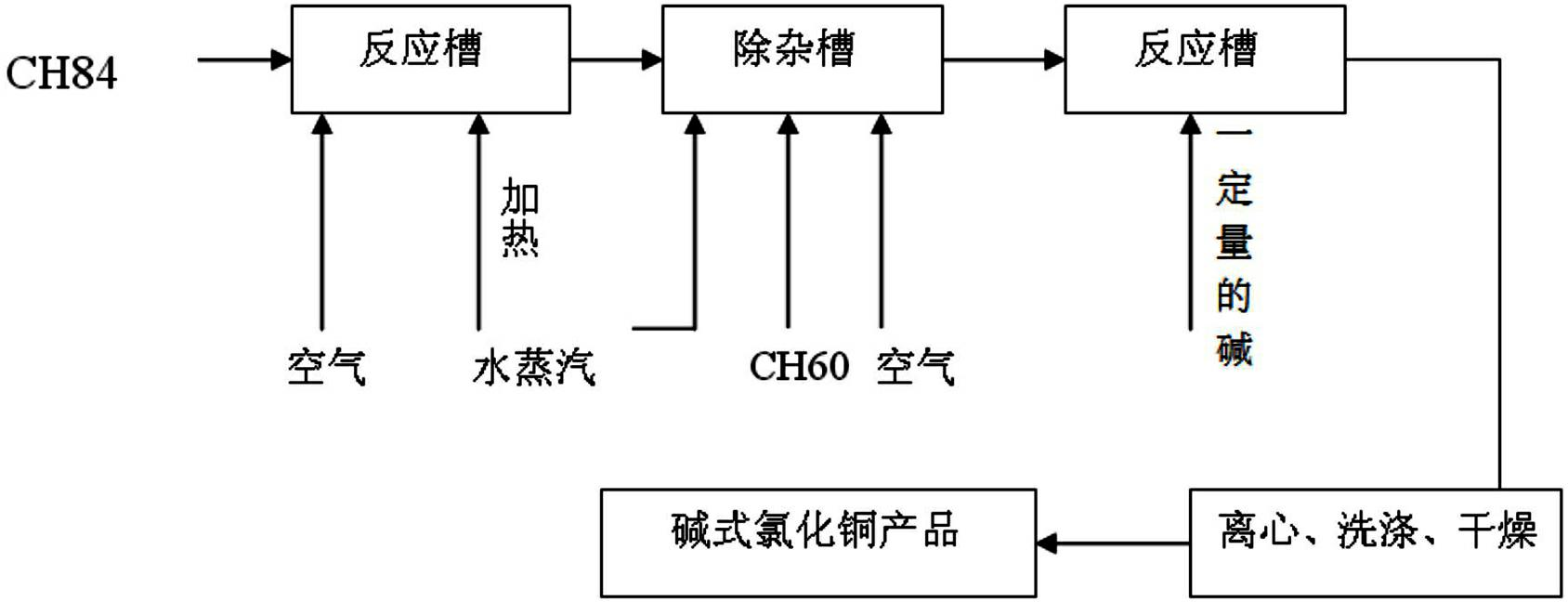

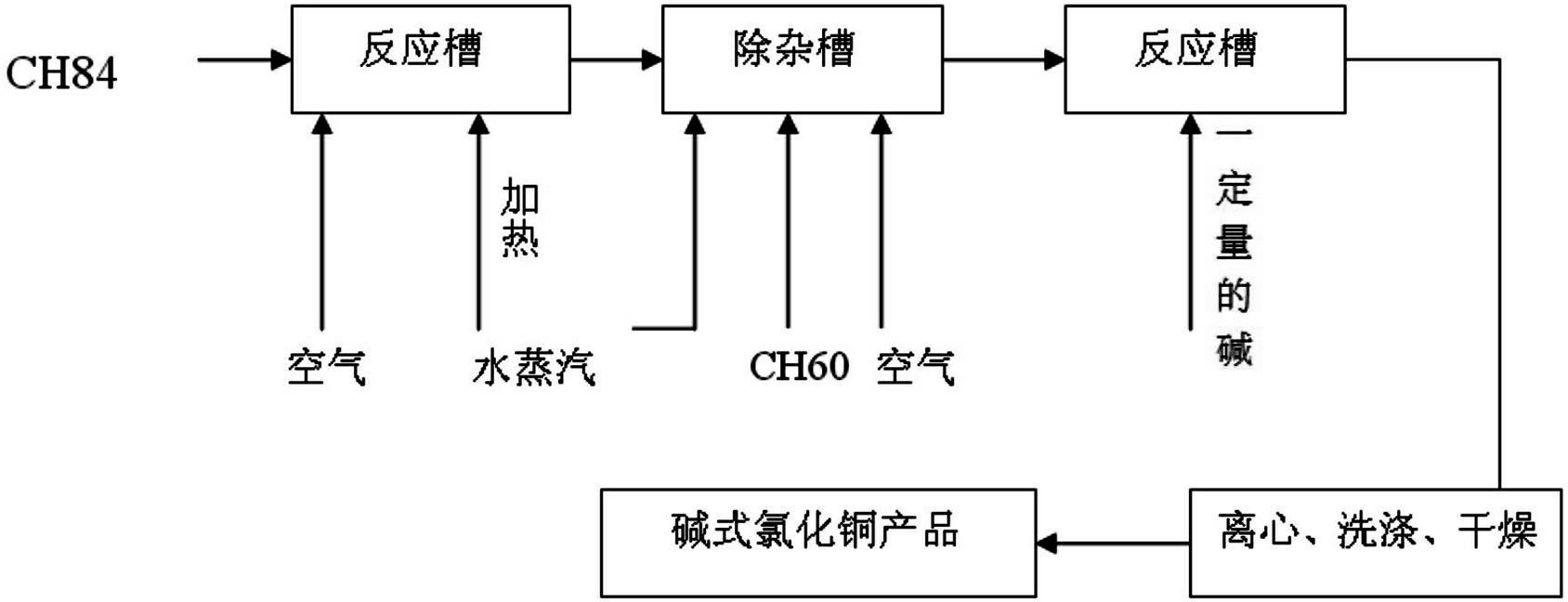

Method for producing cupric chloride basic by using scrap copper

InactiveCN102432058AEfficient recyclingReduce wasteCopper chloridesCupric chlorideProcess engineering

The invention discloses a method for producing cupric chloride basic by using scrap copper, which comprises the steps of: at first, adding the scrap copper into a reaction liquid containing hydrochloric acid, then heating the reaction liquid in a reaction kettle, performing a copper-dissolving reaction at a certain temperature and removing impurities after reaction to obtain a cupric chloride solution; performing a secondary reaction by using the cupric chloride solution prepared and alkali, wherein the molar ratio of cupric chloride and alkali is 1: (0.1-3); preparing a cupric chloride basic solution after reaction; and washing, centrifuging and drying to obtain the end product of cupric chloride basic. The method provided by the invention has the advantages of simple technological steps, low cost, ecological and environmental friendliness, stable product quality and good product safety and the like.

Owner:XINGJIA BIO ENG CO LTD

Production method for basic copper chloride

The invention discloses a production method for basic copper chloride. The production method comprises the following steps: respectively preheating an acid etching waste liquid and a basic etching waste liquid to 43-55 DEG C, further mixing the waste liquids in the presence of a basic copper chloride crystal seed, enabling the mixture to react under conditions that the temperature is 68-72 DEG C and the rotation speed is 65-85 r / minute, so as to obtain a mixed liquid with basic copper chloride, and filtering the mixed liquid, thereby obtaining basic copper chloride, wherein the addition amountof the basic copper chloride crystal seed is 70-100 Kg / 15m<3>. A basic copper chloride product produced by using the method is dark green and uniform in granule, and in addition, the content of copper in the basic copper chloride product is greater than or equal to 58.5 w / %, and the basic copper chloride product is applicable to industrial production.

Owner:东莞市恒建环保科技有限公司

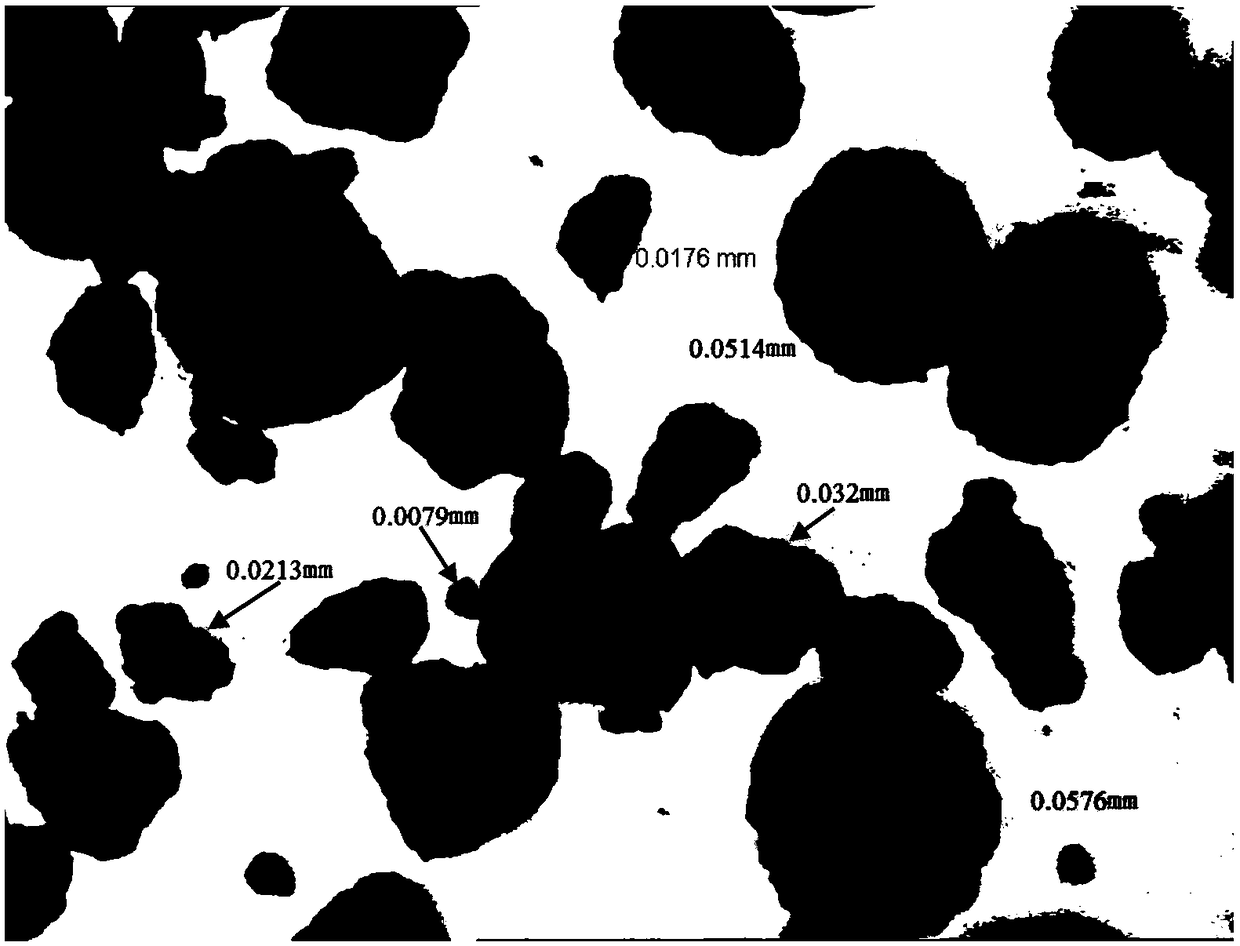

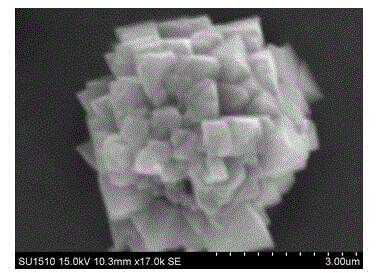

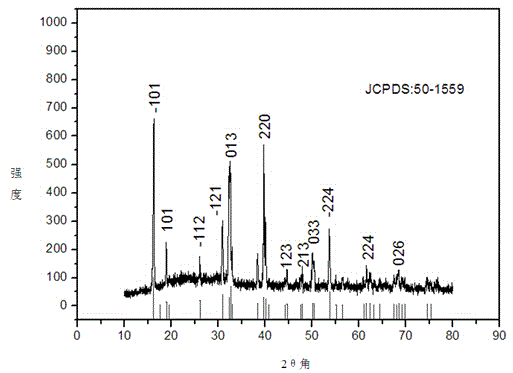

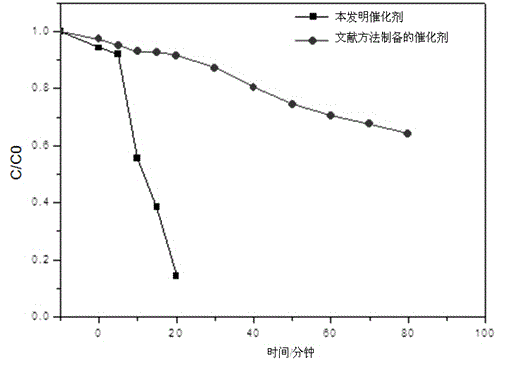

Preparation method of novel flower-like basic copper chloride catalyst

InactiveCN104874411ASimple methodHigh catalytic activityPhysical/chemical process catalystsCopper chloridesPtru catalystAqueous sodium hydroxide

The invention discloses a preparation method of a novel flower-like basic copper chloride catalyst. The preparation method comprises the following steps: preparing a sodium hydroxide aqueous solution, namely preparing the sodium hydroxide aqueous solution with the concentration being 0.32-0.8mol / L; dissolving at the room temperature: adding copper chloride and 30% hydrogen peroxide to the sodium hydroxide aqueous solution to prepare a mixed solution with a copper chloride concentration being 0.154-0.164mol / L, and with the ratio of the additive amount of the 30% hydrogen peroxide to the volume of the sodium hydroxide aqueous solution being 1:(1-25); and carrying out hydrothermal reaction, namely adding the mixed solution to a polytetrafluoroethylene lining, carrying out hydrothermal reaction at the constant temperature of 80-140 DEG C for 18-24 hours, centrifuging, washing and drying. The method is simple and feasible, and easy to promote, compared with methods reported by documents, the method has the advantages that the flower-like basic copper chloride catalyst with high activity can be prepared, and can be used for catalytic degradation of organic pollutants.

Owner:宁晟智能环保科技(南京)有限公司

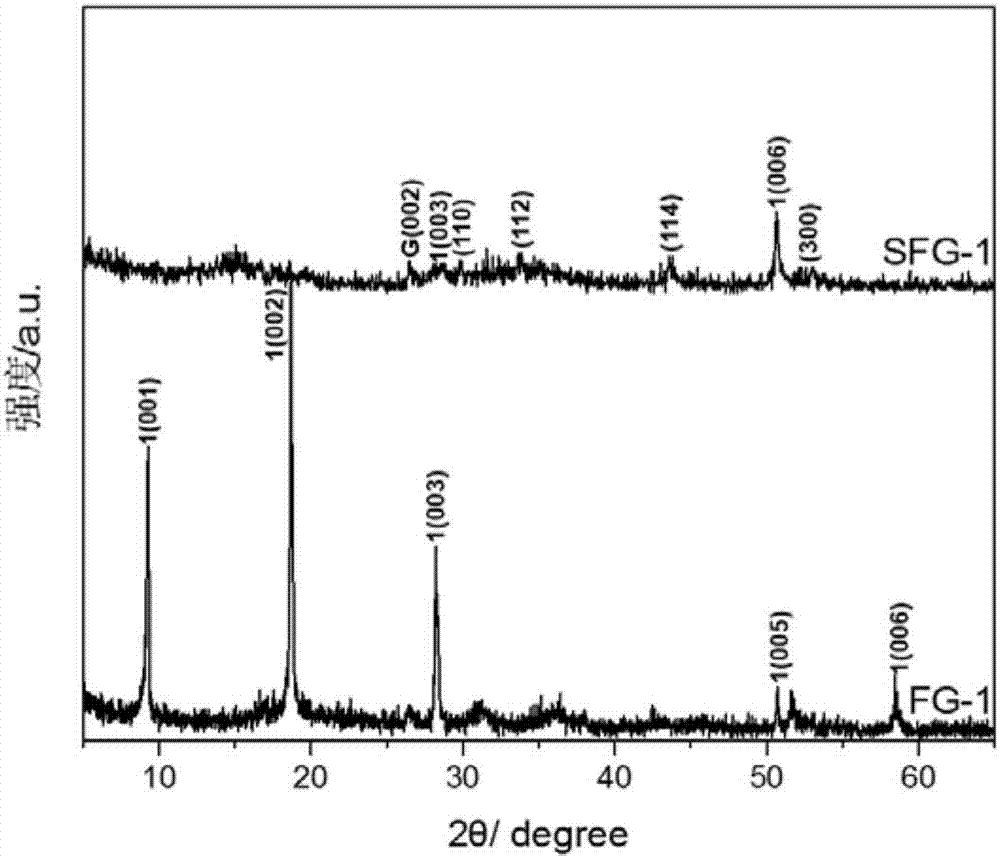

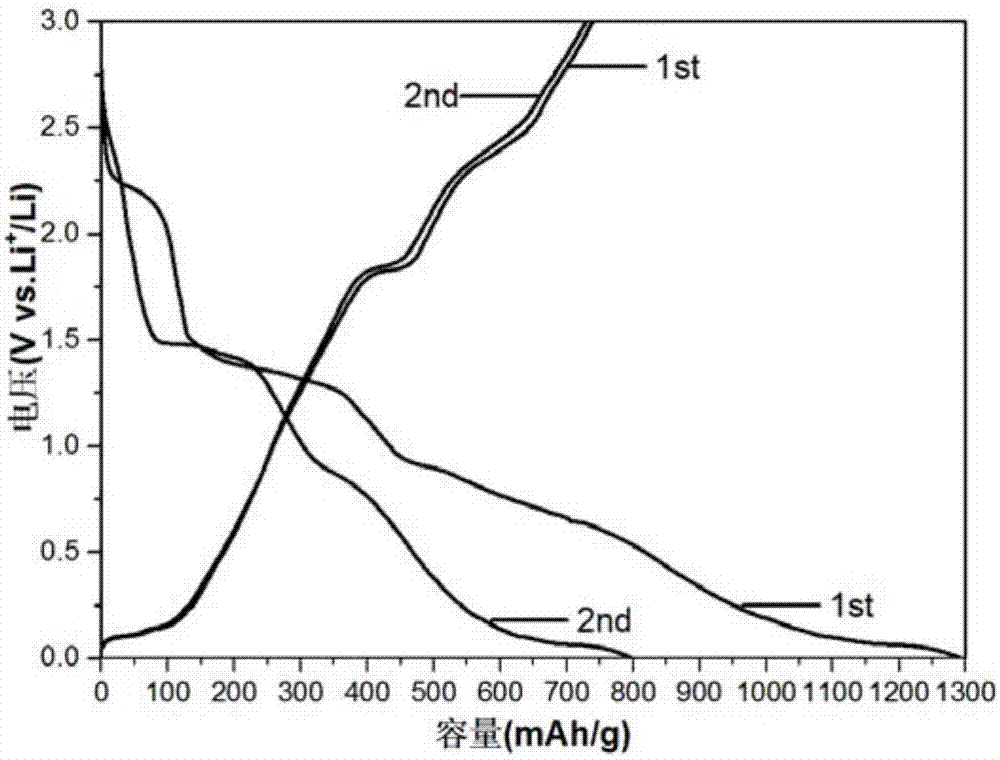

Graphite intercalation compound preparation method

The invention discloses a graphite intercalation compound preparation method. The method includes: mixing graphite with metal halides in air, sealing in a reactor, heating to a certain temperature, keeping the temperature for a period of time to allow the metal halides to diffuse to graphite intercalation so as to form a graphite intercalation compound with the metal halides as an intercalator, and converting the metal halide type intercalator into metal sulfide or metal phosphide to obtain a graphite intercalation compound with the metal sulfide / phosphide as the intercalator, so that the metal sulfide / phosphide can exist in graphite intercalation in a molecular level. Insertion of different substances in graphite intercalation can be realized, so that different characteristics of products can be achieved; a preparation process has advantages of low material consumption, low energy consumption, product quality stability, high technical repeatability and the like, the method is suitable for large-scale industrial production, and final products are applied to fields of next-generation energy storage materials, solar cell materials, electro-catalysis and the like.

Owner:HUNAN UNIV

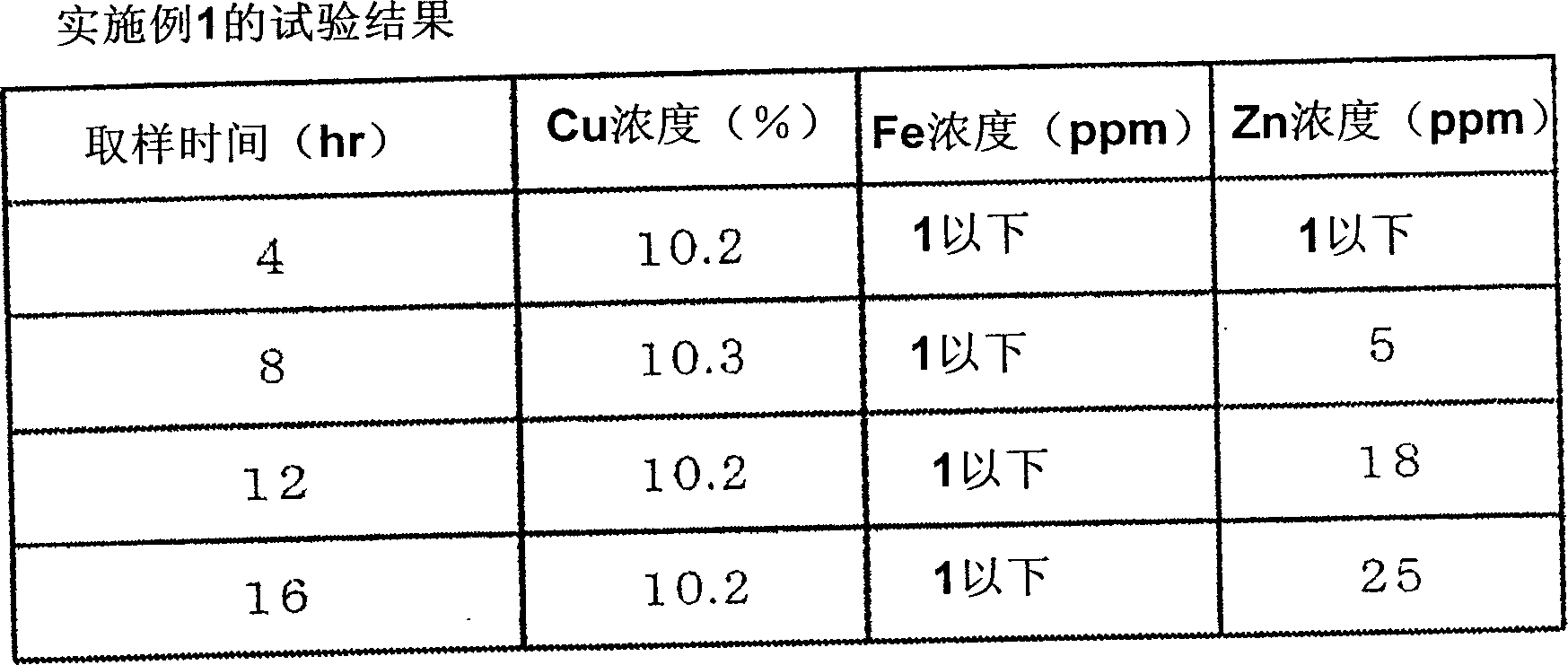

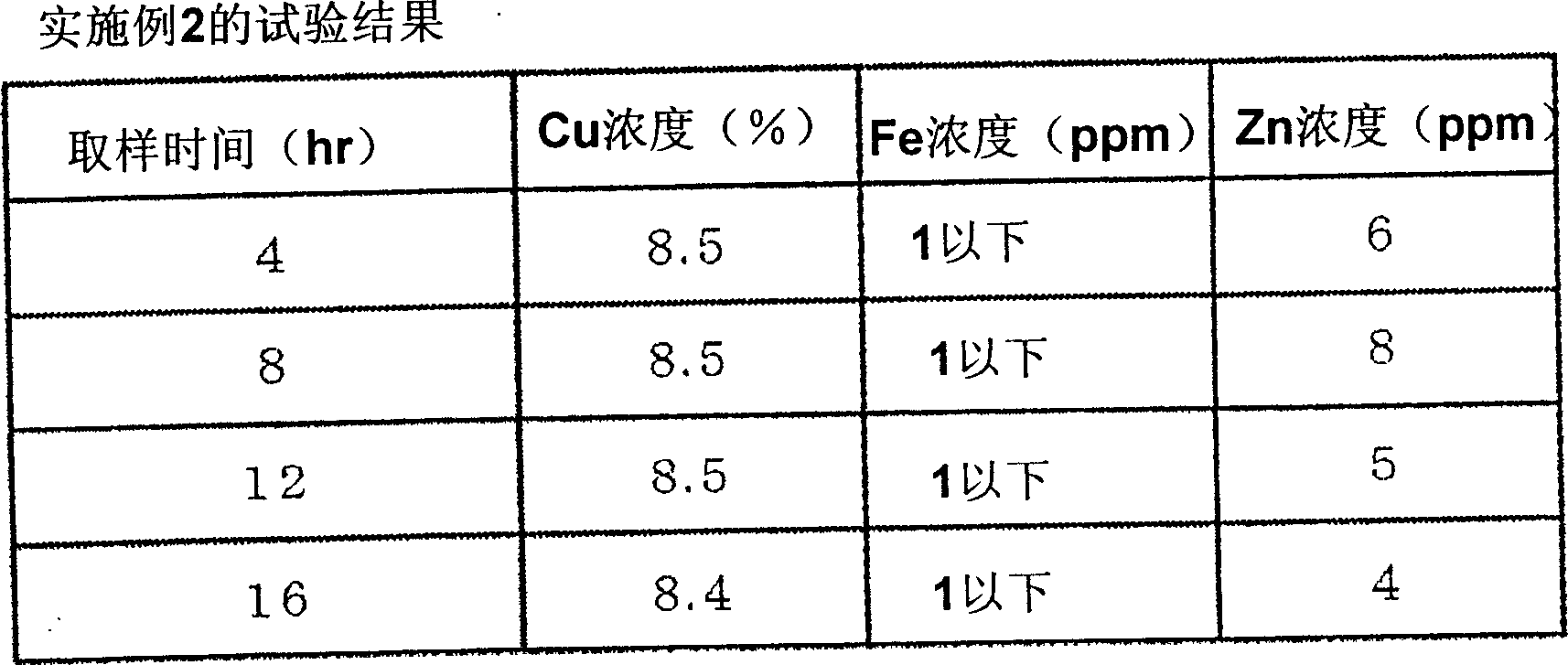

Refining method for copper chloride etching waste liquid and refined copper chloride solution

The invention is to refine a copper chloride etching waste liquid after etching a copper material by removing impurity metals other than copper which is effective metal with a simple operation. An anionic complex of metal, such as zinc and iron, is known to be removed by bringing the same into contact with a weak anionic exchange resin. The copper which is the effective metal in the copper chloride waste liquid is said to exist as the anionic complex. The inventor found that the anionic complex of the copper in the copper chloride etching waste liquid is substantially not adsorbed even if the complex is brought into contact with the strong or weak basic anionic exchange resin. Accordingly, by bringing the copper chloride etching waste liquid into contact with these anion exchange resins, the anionic complex of the iron or the zinc is adsorbed in the resins and is thereby removed but since the copper remains as it is in the liquid, the copper chloride etching waste liquid can be refined.

Owner:TOAGOSEI CO LTD

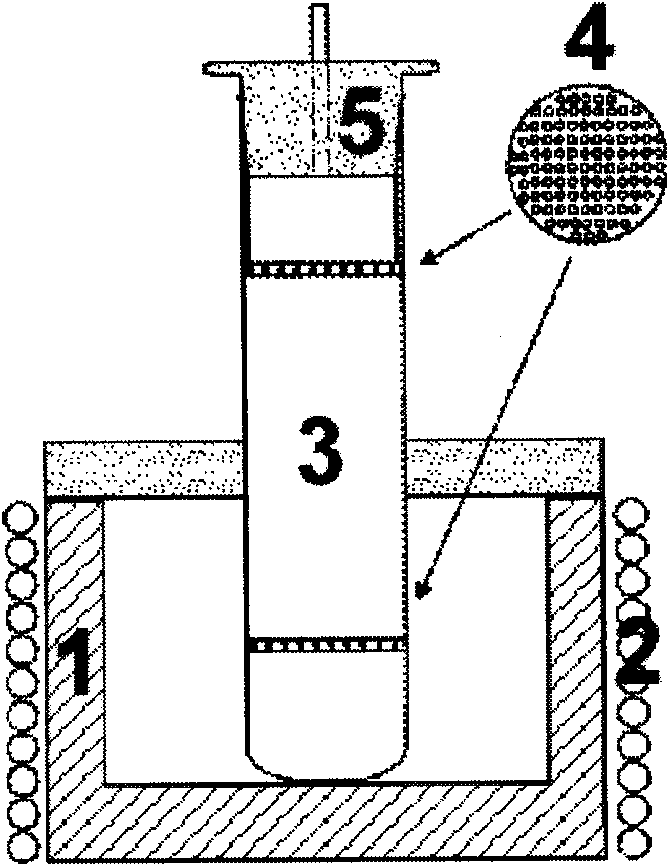

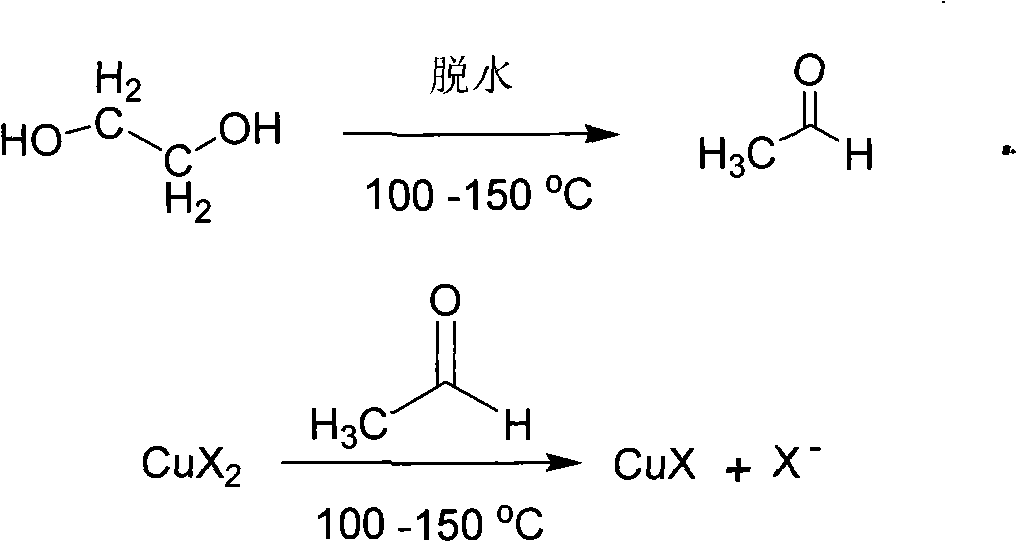

Method for preparing and purifying cuprous halide

The invention discloses a method for preparing and purifying cuprous halide. The method comprises the following steps of: placing copper halide in a reaction vessel, adding a glycol solvent into the vessel, and keeping the constant temperature of between 130 and 180 DEG C for 24 to 48 hours to produce white cuprous halide grains; and purifying the cuprous halide by a special purifying device; placing the cuprous halide serving as raw materials on the bottom of the purifying device; adding the glycol solvent and a small amount of corresponding alkali halate into the vessel to make the vessel achieve about 90 percent of the degree of filling, and sealing the opening of the vessel by a plug or a cover which is provided with a pore; heating the vessel, keeping the temperature of a lower clapboard on the bottom of the vessel at about 170 DEG C, and keeping the temperature of an upper clapboard on the top of the vessel at about 150 DEG C; and depositing the purified cuprous halide on the surfaces of the clapboards, and washing and drying the cuprous halide deposited on the surface of the upper clapboard to obtain analytically pure cuprous halide. The method has the characteristics of simple equipment and method for synthesis and purification, mild condition, and environmental protection; and the obtained cuprous halide has complete crystalline form, large grain size, high purity, and strong oxidation resistance.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

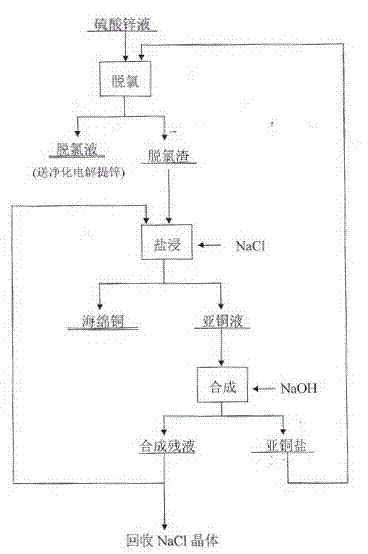

Method for circularly removing impurity chlorine in zinc sulfate solution by using cuprous salt

ActiveCN102732725AHigh active ingredientAvoid accumulationCopper chloridesProcess efficiency improvementSulfate zincSaline water

The invention relates to a method for circularly removing impurity chlorine in zinc sulfate solution by using cuprous salt. The method comprises the following steps of: reacting industrial cupric sulfate with electric furnace zinc powder in a chlorine-containing zinc sulfate solution to generate dechlorinating slag, i.e., cuprous chloride Cu2Cl2; leaching the dechlorinating slag by using industrial salt water, separating copper sponge to generate cuprous liquid Na2(CuCl3), and neutralizing by caustic soda liquid NaOH to synthesize original cuprous salt Cu2O.CuOH; and adding the cuprous salt into the chlorine-containing zinc sulfate solution to react so as to generate the dechlorinating slag, and repeatedly and circularly carrying out the steps. The method is characterized in that chlorinein the zinc sulfate solution is removed by using the active cuprous salt, so that the method is easy to operate and high in chlorine removing efficiency; the produced dechlorinating slag is leached by using the industrial salt, so that chlorine is enriched in the high-concentration industrial salt solution, comprehensive utilization is facilitated, and simultaneously, the impurity in the dechlorinating slag is removed, so that the accumulation of the impurity in the process of recycling can be avoided; and the leach liquor of the industrial salt can be neutralized and synthesized by the caustic soda liquid, and the product cuprous salt is high in active ingredients and less in impurity, so that effective removal of chlorine in the zinc sulfate solution is facilitated, and the dechlorinating efficiency of the zinc sulfate solution containing 1.0-20.0g / L of chlorine can reach 80-99%.

Owner:GREENNOVO ENVIRONMENTAL TECH CO LTD

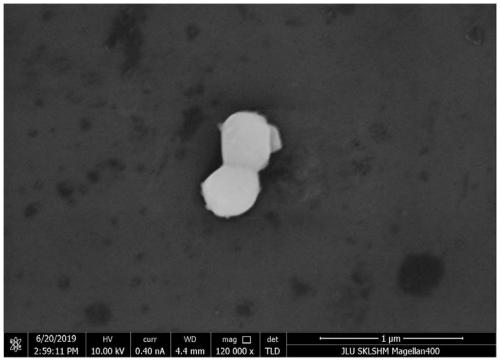

Hydroxyl copper chloride material and synthesizing method thereof

The invention discloses a hydroxyl copper chloride material and a synthesizing method, and belongs to the field of preparation of IB race hydroxyl chloride materials. The preparation method includes the steps that with copper chloride crystal particles and copper oxide powder being raw materials, firstly, the raw materials are mixed and then ground for two hours; then, at the temperature of 100-180 DEG C, sealed heating is conducted for 12 hours, and after reaction is ended, the raw materials are cooled to have room temperature, and then are ground for 30 minutes-1 hour; the processes of heating, cooling and grinding are repeated 3-4 times, so that hydroxyl copper chloride Cu(OH)Cl powder which is dark green is obtained. The prepared product is the compound Cu(OH)Cl composed of copper, hydroxyl and chlorine which are measured according to the proportion of 1:1:1, and is monoclinic system crystals, wherein the space group is P21 / a; the particle size of the crystals is 0.7-1.5 micrometers. The preparation method has the advantages of being simple and easy to implement and realizing a high crystallinity degree, a high yield of products, small losses, high purity and low costs for reactants.

Owner:JILIN UNIV

Method for treating copper-containing etching waste solution

ActiveCN109319823AAchieving zero emissionsReduce energy consumptionCopper chloridesCopper sulfatesAcid etchingChalcanthite

The invention discloses a method for treating a copper-containing etching waste solution. The method comprises the steps of mixing an acid etching waste solution, a first pH regulator, hydrogen peroxide and a first flocculating agent, and filtering to obtain a copper chloride solution; mixing an alkaline etching waste solution, a second pH regulator, magnesium chloride and a second flocculating agent, and filtering to obtain an ammoniacal copper solution; mixing a part of copper chloride solution, a part of ammoniacal copper solution and ammonium hydroxide, filter pressing, washing, and filterpressing to obtain a third filter cake and a first post-filtration solution; pulping the third filter cake to obtain a fourth post-mixed solution; mixing concentrated sulfuric acid and the fourth post-mixed solution, and cooling to obtain a chalcanthite crystal; filtering and dewatering the chalcanthite crystal to obtain a copper sulfate product; mixing and dewatering the other part of copper chloride solution, the other part of ammoniacal copper solution and ammonium hydroxide so as to obtain water-containing copper chloride hydroxides and a second post-filtration solution; drying the water-containing copper chloride hydroxides to obtain copper chloride hydroxides; and mixing the first post-filtration solution, the second post-filtration solution and an alkaline liquor to obtain the alkaline etching solution.

Owner:CHINA NERIN ENG

Method for producing copper chloride through waste etching liquid containing copper

The invention relates to a method for producing copper chloride through waste etching liquid containing copper. The method includes the following steps that 1, clean water is added in a neutralization kettle and heated, the acidic waste etching liquid and the alkaline waste etching liquid are added into the neutralization kettle for reaction, and the reacted liquid is subjected to centrifugation and rinsing to obtain copper chloride crystals; 2, the copper chloride crystals generated in the first step react with hydrochloric acid to obtain a copper chloride solution, and the solution is concentrated and crystallized to obtain a copper chloride dihydrate product; 3, the copper chloride dihydrate is dehydrated into anhydrous cupric chloride. The method has the advantages that the waste etching liquid containing copper is adopted to produce copper chloride, copper can be recovred and utilized better, and besides, pollution of the waste etching liquid containing copper to the environment is reduced; when the waste etching liquid containing copper is used for producing the copper chloride, impurities of the waste etching liquid containing copper do not need to be removed before the waste etching liquid is used, the purity of the prepared copper chloride is high, the production method is simple, and cost is low.

Owner:沈国强

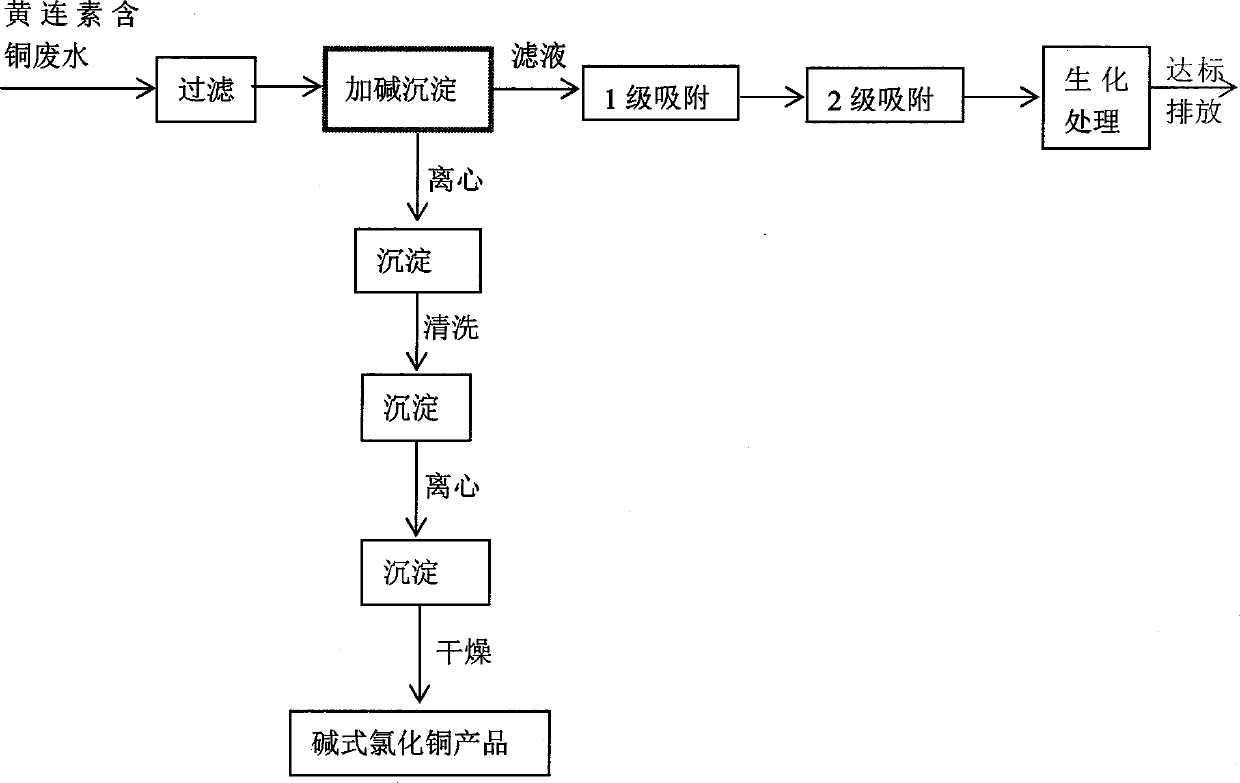

Process for producing basic copper chloride by using berberine copper-containing wastewater

InactiveCN103214021AAchieving processing powerImplement resourcesCopper chloridesBerberineHigh concentration

The invention relates to a process for producing basic copper chloride by using berberine copper-containing wastewater. The method comprises the steps that: berberine copper-containing wastewater is filtered by using a microporous membrane; 90-110g / L of a sodium hydroxide concentrated solution is added into the berberine copper-containing wastewater; a reaction is carried out under a temperature of 60-80 DEG C, a pH of 5-7, and a normal pressure, such that basic copper chloride precipitate is produced; after the reaction, the produced precipitate is first subjected to centrifugal separation; obtained solid is washed and subjected to washing and centrifugal separation; and the reaction product basic copper chloride is obtained after drying; centrifuged supernatant is subjected to two-level absorption, and is treated in a biochemical treatment device. According to the invention, basic copper chloride is prepared from berberine pharmaceutical wastewater containing high concentration of heavy metal copper, such that the treatment difficulty of the medicine pharmaceutical wastewater which is hard to degrade is reduced. The process provided by the invention is characterized in that: a copper ion removal rate in the berberine copper-containing wastewater is higher than 99.9%, such that high-concentration hard-to-degrade pharmaceutical wastewater is turned into organic wastewater which can be biodegraded. After biochemical treatment, the wastewater reaches a discharge standard. The process has the advantages of good treatment effect, convenient operation, and good application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com