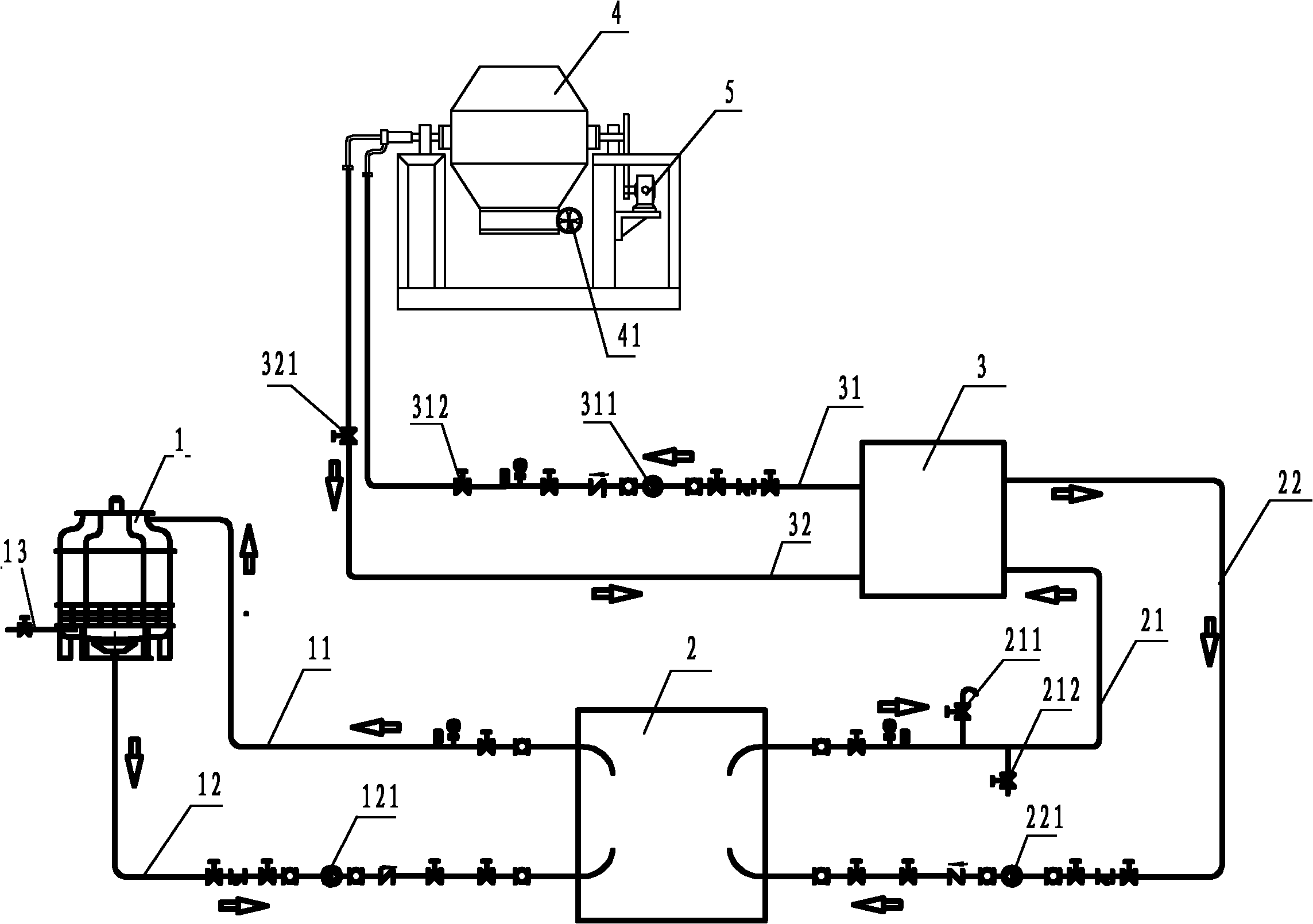

Dynamic crystallization technological method and device for stannous chloride solution

A technology of stannous chloride and crystallization device, applied in the directions of stannous chloride, tin halide, etc., can solve the problems of low crystallization temperature, high product hardness, low production efficiency, etc. The effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: put 1200 liters of tin protochloride concentrated solution under the condition of 40~60 ℃ into the rotary crystallizer, feed the coolant into the jacket of the rotary crystallizer, start the rotary crystallizer, and control the crystallization process during the whole crystallization process. The temperature difference between the stannous chloride concentrate and the coolant is 5-10°C, and the rotating speed of the rotary crystallizer is 2 r / min. After 20 hours, the crystallization temperature reaches 10°C. After the crystallization is completed, the material is discharged, dried and packaged to obtain 1.925 tons of product , The crystallization rate was 79.4%.

Embodiment 2

[0025] Embodiment 2: put 1220 liters of tin protochloride concentrated solution under the condition of 40~60 ℃ into the rotary crystallizer, feed the coolant into the jacket of the rotary crystallizer, start the rotary crystallizer, and control the crystallization process during the whole crystallization process. The temperature difference between the stannous chloride concentrate and the coolant is 5-10°C, and the rotation speed of the rotary crystallizer is 3 r / min. After 21 hours, the crystallization temperature reaches 8°C. After the crystallization is completed, the material is discharged, dried and packaged to obtain 2.05 tons of the product , The crystallization rate was 79.6%.

Embodiment 3

[0026] Embodiment 3: Put 1190 liters of tin protochloride concentrated solution under the condition of 40~60 ℃ into the rotary crystallizer, feed the coolant into the jacket of the rotary crystallizer, start the rotary crystallizer, and control the crystallization process during the whole crystallization process. The temperature difference between the stannous chloride concentrate and the coolant is 5-10°C, and the rotation speed of the rotary crystallizer is 4 r / min. After 19.5 hours, the crystallization temperature reaches 9°C. After the crystallization is completed, the material is discharged, dried and packaged to obtain 2.125 tons of the product , The crystallization rate is 78.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com