Dicumyl peroxide production method

A technology of dicumyl peroxide and its production method, which is applied to the preparation of peroxide compounds, chemical instruments and methods, and the preparation of organic compounds. Eliminate the problems of low yield of granular crystals, and achieve the effects of perfect crystal growth, reduced occlusion and coalescence, and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The production method of dicumyl peroxide of the present invention.

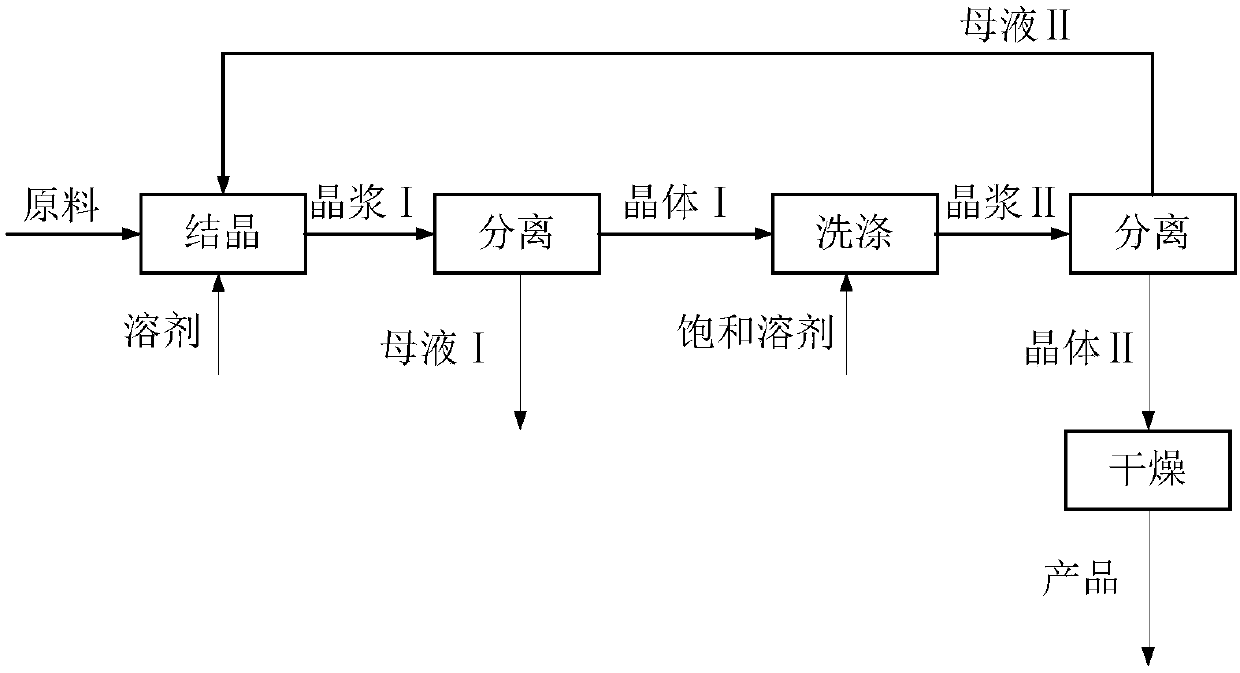

[0024] Such as figure 1 Described, the 90% raw material that contains dicumyl peroxide concentration is carried out cooling crystallization in the crystallizer with crystallization solvent (95% ethanol), adds crystal seed when being down to saturation temperature, and seed crystal amount is diisopropyl peroxide 10% of the amount of benzene raw material, the purity of the seed crystals is 99.5%, the particle size is 710 μm, the heat transfer temperature difference is controlled to be 3°C, and the crystallization end point temperature is 2°C to obtain crystal slurry I containing dicumyl peroxide crystals; I carry out solid-liquid separation to obtain dicumyl peroxide crystals I and crystallization mother liquor I, and the crystallization mother liquor I is discharged from the crystallization device for solvent recovery; the dicumyl peroxide crystals I are sent into the beating tank, and saturated crysta...

Embodiment 2

[0026] The production method of dicumyl peroxide of the present invention.

[0027] Such asfigure 1 As described above, according to the operation method of Example 1, the crystallization process is continuous crystallization, only adding seed crystals during the start-up stage, the crystallization temperature is 5°C, the temperature difference of heat transfer is controlled to be 5°C, and the particle size of dicumyl peroxide crystal I The fine powder of ≤425μm accounts for 15%. The operating temperature of beating and washing is 7°C. Crystal I loses 15% of its mass due to beating and washing. Part of the crystallization mother liquor II is returned to the beating tank as washing liquid, and the rest is returned to the crystallizer to continue crystallization. The dicumyl peroxide product is finally obtained. The product is a granular crystal, regular in shape, transparent, free of occlusion and agglomeration, with a purity of 99.9%. The crystal particle size distribution is u...

Embodiment 3

[0029] The production method of dicumyl peroxide of the present invention.

[0030] Such as figure 1 As described above, according to the operation method of Example 1, the crystallization solvent is absolute ethanol, the crystallization process is continuous crystallization, only adding seed crystals during the start-up stage, the crystallization temperature is 0°C, the heat transfer temperature difference is controlled to be 2°C, diisoperoxide The fine powder with a particle size of ≤425μm accounts for 10% of the propylbenzene crystal I. The operating temperature for beating and washing is 3°C. The crystal I loses 10% of its mass due to beating and washing. Part of the crystallization mother liquor II is returned to the beating tank as washing liquid, and the rest is returned to the beating tank. Continue to crystallize in the crystallizer, and finally obtain the product of dicumyl peroxide. The product is a granular crystal, regular in shape, transparent, free of occlusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com