Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308 results about "Continuous crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing small-grain SAPO-11 molecular sieve

ActiveCN101205076ALower synthesis costThe process steps are simpleMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveDistilled water

The invention relates to a method for preparing a molecular sieve with small crystal of SAPO-11, which does not use any other organics additives except template. The method prepares the molecular sieve with small crystal of SAPO-11 which has a size ranging from 300mm to 800mm and has an AEL structure comprising water, phosphorus source, aluminum source, template, and silica source. The preparation method includes the following steps: (1) the preparation of colloid slurry: according to the total material mole ration of P2O5: (0.5 to 1.5)AL2O3: (0.4 to 2.0) R: (0 to 1.0)SiO2:(17 to 60) H2O, the water, the phosphorus source, the aluminum source, the template and the silica source are added under the condition of temperature of 5 to 80 DEG C, fast mixing and the PH value controlled between 3.5 to 7.0, wherein, R is the template; (2) the aging of slurry: the reaction mixture acquired from step (1) is gel static aged under the temperature of 80 to 190 DEG C for 0.5 to 24 hours then is cooled to the room temperature; (3) the crystallization of the slurry: under the stirring condition, 0 to 200 percent of distilled water of the total mixture is put into the aging solution, then the solution is heated up to 100 to 220 DEG C for continuous crystallization for 4 to 72 hours to get the product by filtering, washing and drying after the crystallization.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

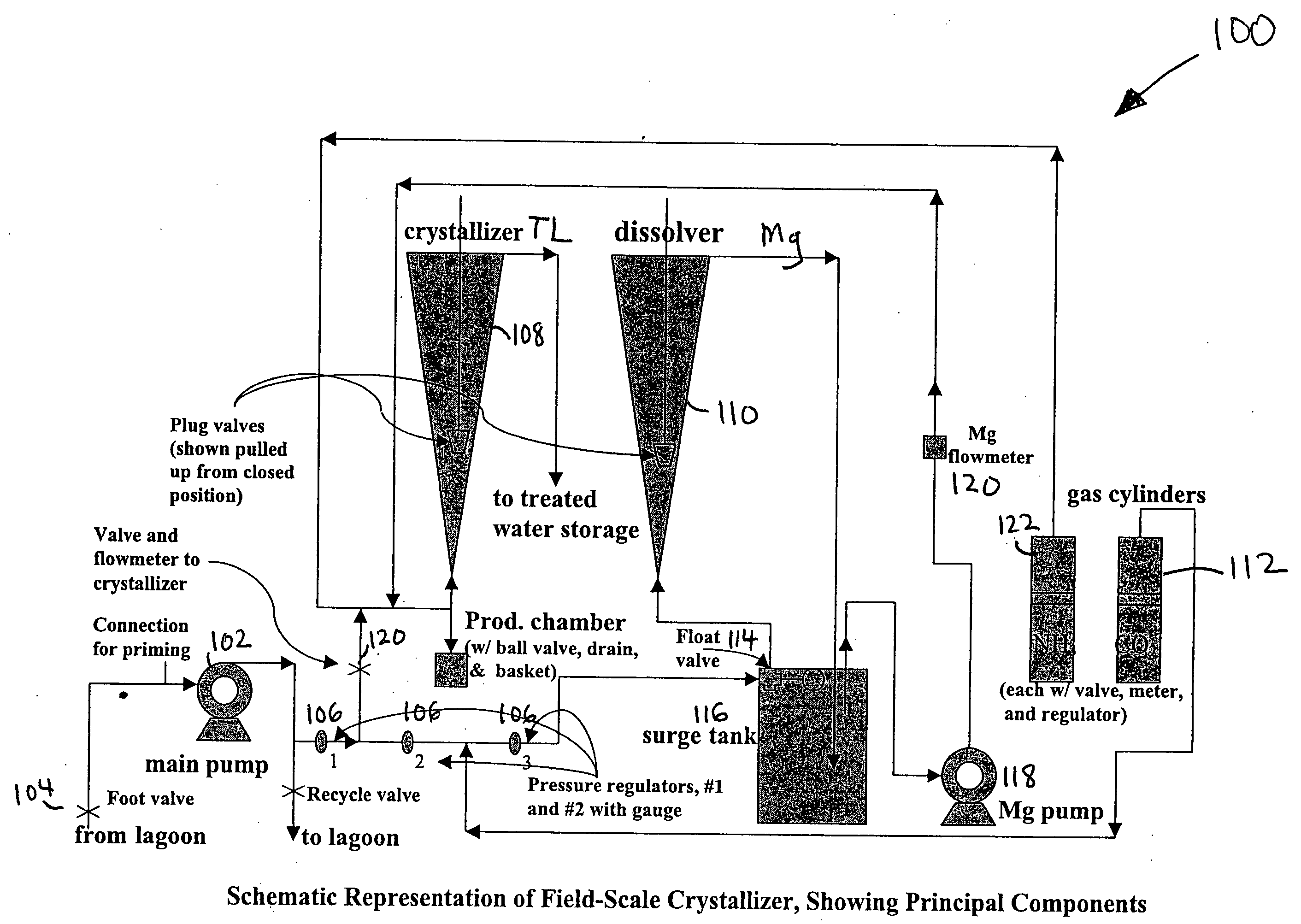

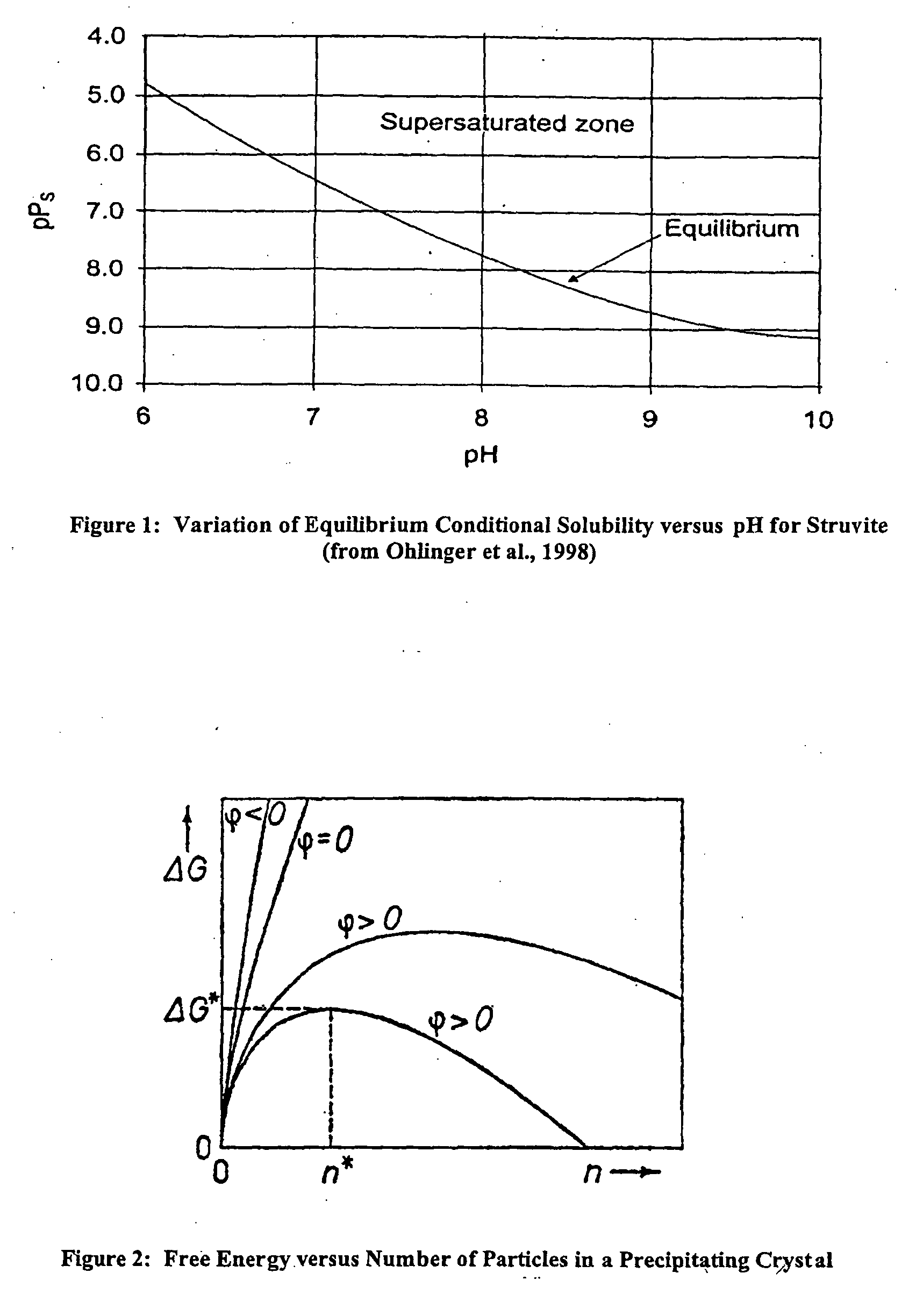

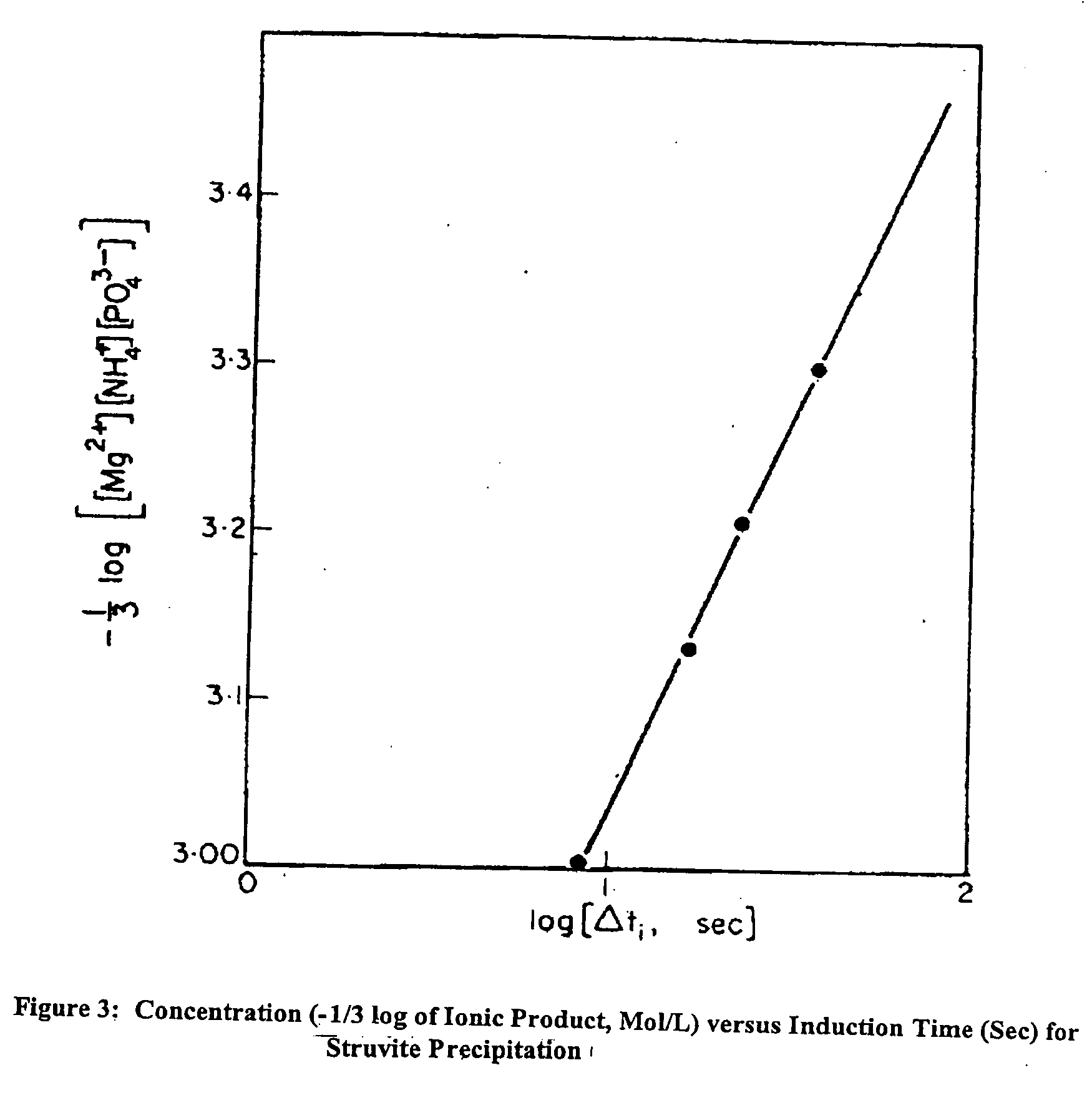

Apparatus and method for removing phosphorus from waste lagoon effluent

ActiveUS20050051495A1Reduce phosphorus contentWide particle size distributionWaste water treatment from animal husbandrySolid sorbent liquid separationFluidized bedStruvite Crystals

An apparatus and method for removing phosphorus from a wastewater effluent stream from a hog waste lagoon. The wastewater effluent is introduced to the bottom of an inverted cone-shaped continuous crystallizer including a fluidized bed of struvite therein. An effective amount of ammonia is introduced to the wastewater effluent at the bottom of the crystallizer to elevate the pH of wastewater effluent a predetermined amount. An effective amount of magnesium is also introduced to the wastewater effluent at the bottom of the crystallizer. The composition adjusted wastewater effluent is then continuously passed upwardly through the fluidized bed of struvite to reduce the total phosphorus content of the wastewater effluent a predetermined amount of up to about 80% or more. The treated wastewater effluent stream is removed from the top of the crystallizer, and struvite crystals that grow large enough to sink from the bottom of the crystallizer are periodically removed from a collection chamber therebeneath.

Owner:NORTH CAROLINA STATE UNIV

Method and device for recycling ammonium chloride from glycine mother liquor

The invention relates to a method and a device for recycling ammonium chloride from glycine mother liquor. The method is specially implemented as follows: after carrying out 2nd effect evaporation and concentration on glycine mother liquor containing ammonium chloride, carrying out continuous separation by crystallization on the obtained object so as to obtain ammonium chloride. The method comprises the following specific steps of: carrying out preliminary vacuum evaporation and concentration on glycine mother liquor by using an I-effect evaporator; feeding the obtained object into the I-effect evaporator to carrying out further evaporation and concentration on the obtain object; feeding the obtained object into a flash vessel, and carrying out flash vaporization and concentration on the obtained object in a vacuum state, so that the concentration of the obtained flash vaporization and concentration liquor reaches 45 + / -3%; feeding the flash vaporization and concentration liquor into a continuous crystallizer and carrying out circulating heat exchange and cooling crystallization; carrying out thickening and centrifugal separation on the obtained product so as to obtain an ammonium chloride product. In the whole process, the steam application amount is small, and the evaporation speed is rapid, so that the method and device disclosed by the invention have the characteristics of high efficiency and energy conservation, and are suitable for being widely used in workshops.

Owner:HUBEI XINGFA CHEM GRP CO LTD

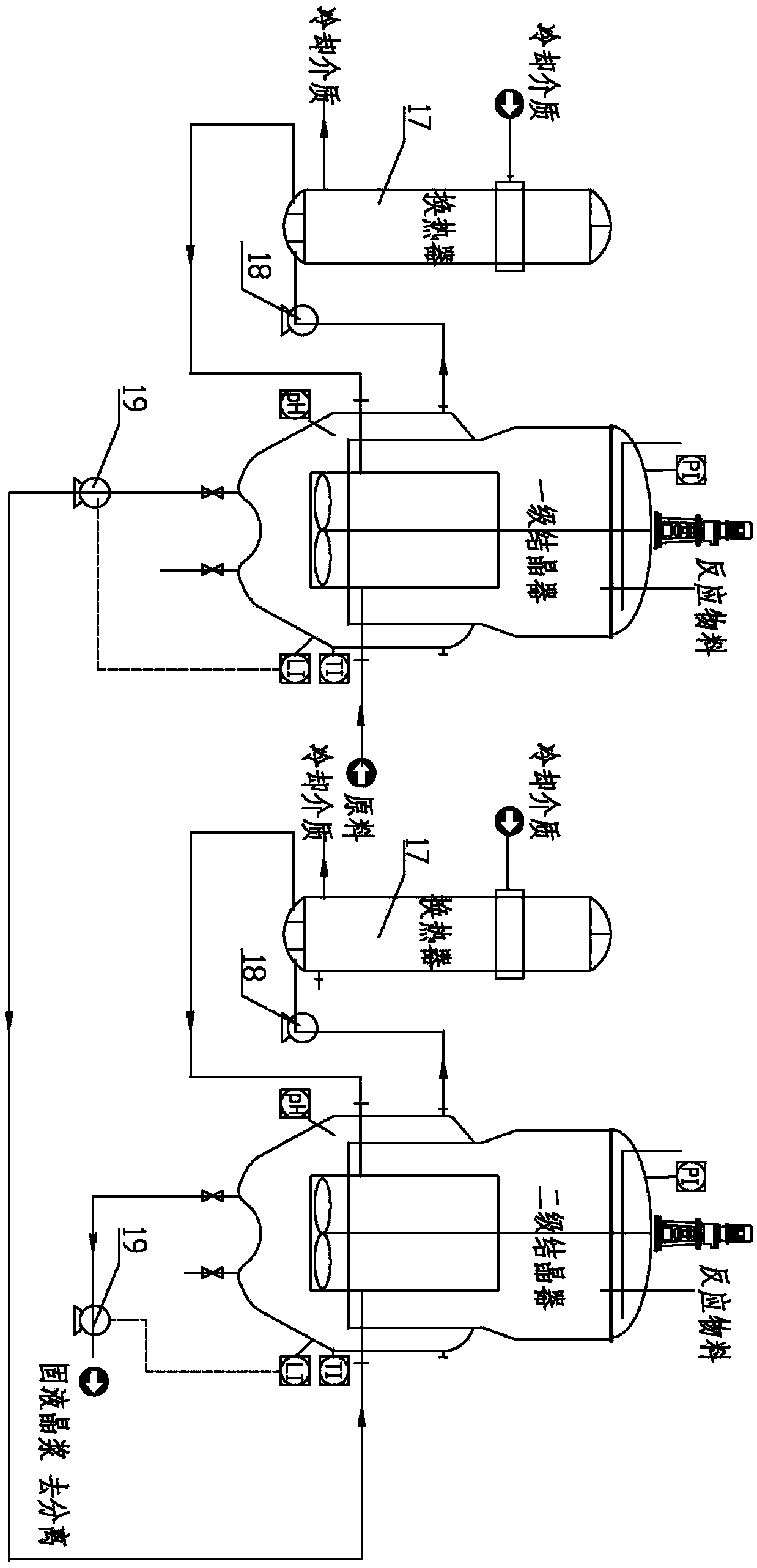

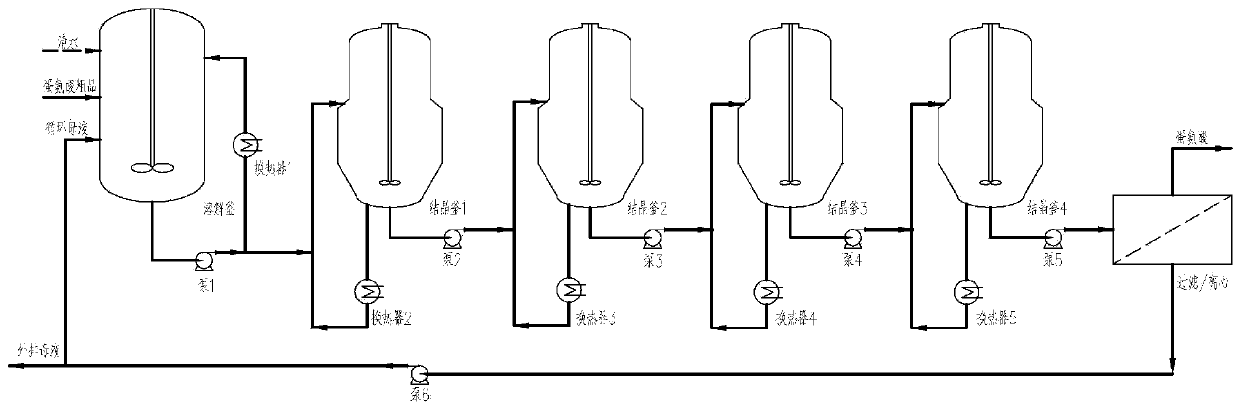

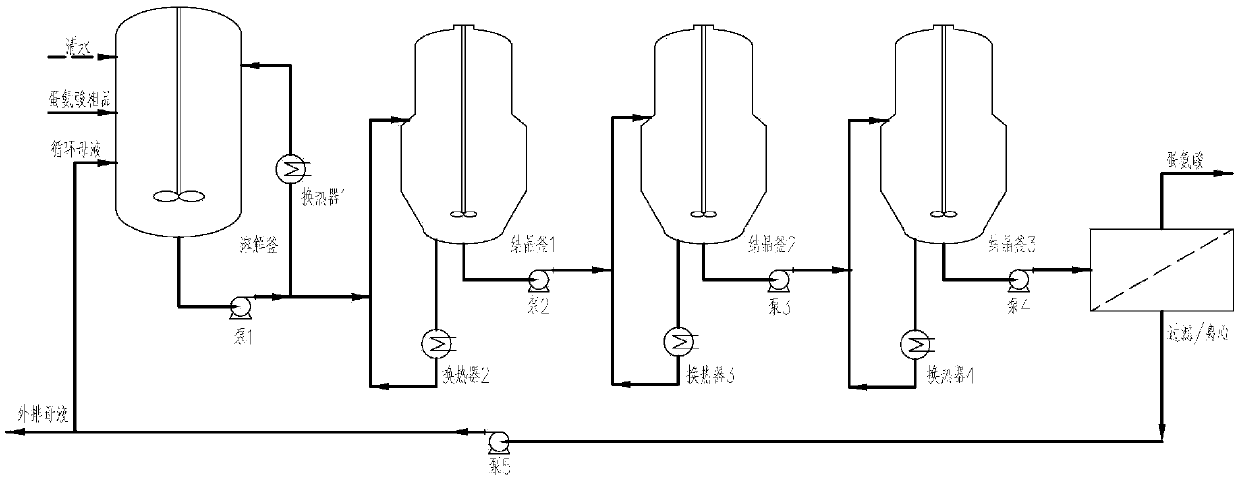

Continuous crystallization process for monopotassium phosphate

InactiveCN103159194AReduce manufacturing costEasy to operatePhosphorus compoundsSmall footprintMonopotassium phosphate

The invention discloses a continuous crystallization process for monopotassium phosphate. The continuous crystallization process comprises the following specific steps of: introducing a feed liquid to be crystallized into a first-stage continuous flash crystallizer so as to be separated into a primary clear liquid, primary crystal mush and secondary steam; discharging the primary crystal mush from the first-stage continuous flash crystallizer and feeding the primary crystal mush into a second-stage continuous cooling crystallizer, wherein the second-stage continuous cooling crystallizer is composed of an Oslo crystallizer and an external cooler; separating the primary crystal mush into secondary crystal mush and a secondary clear liquid in the Oslo crystallizer; discharging the secondary crystal mush from the Oslo crystallizer, feeding the secondary crystal mush into a thickener and separating the secondary crystal mush into triple clear liquid and triple crystal mush; discharging the triple crystal mush from the thickener, feeding the triple crystal mush into a centrifugal machine, and separating the triple crystal mush into solid monopotassium phosphate and a centrifugal liquid; and discharging the solid monopotassium phosphate from the centrifugal machine. The continuous crystallization process is stable in operation, low in energy consumption and low in labor intensity; and by using the continuous crystallization process, the operation stability and the product quality are greatly improved, the on-site operation environment is improved, and the production cost of the monopotassium phosphate is reduced. A mating device for the process is small in floor area and high in capacity.

Owner:HEBEI NUODA CHEM EQUIP

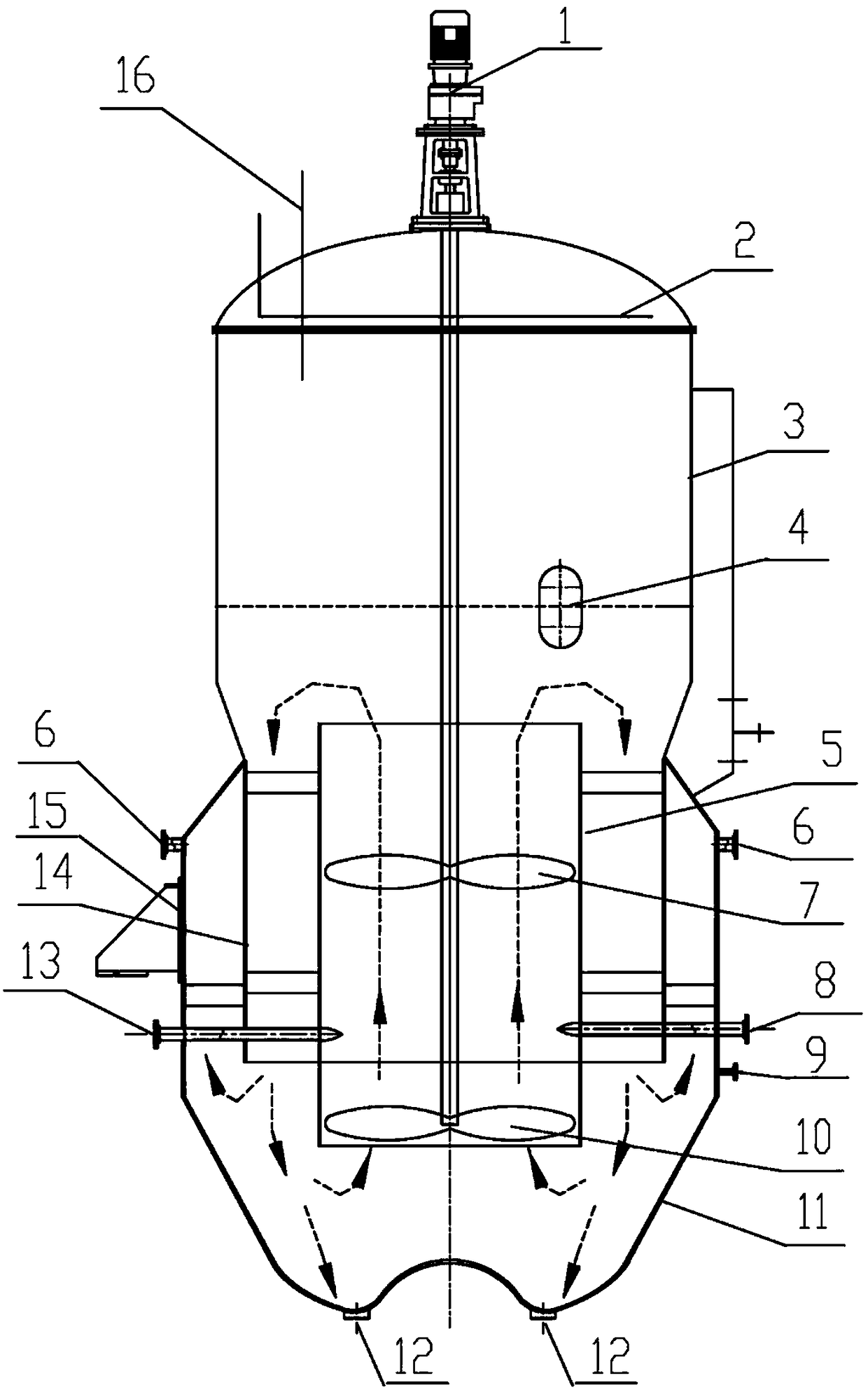

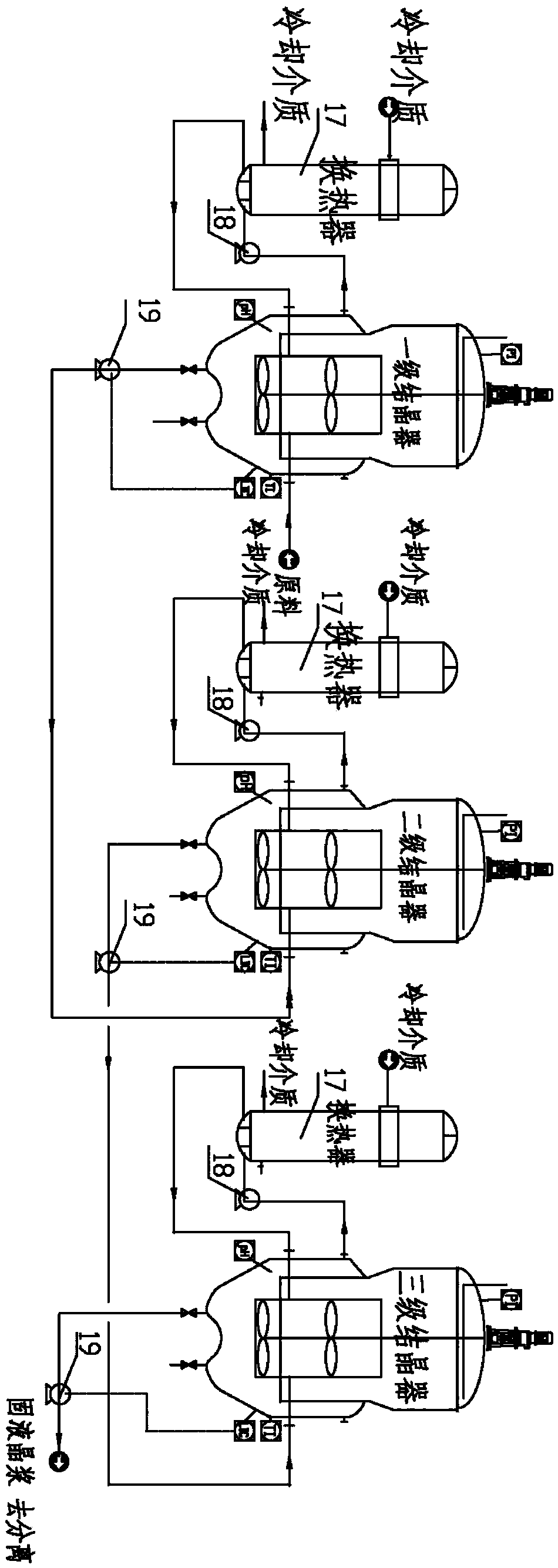

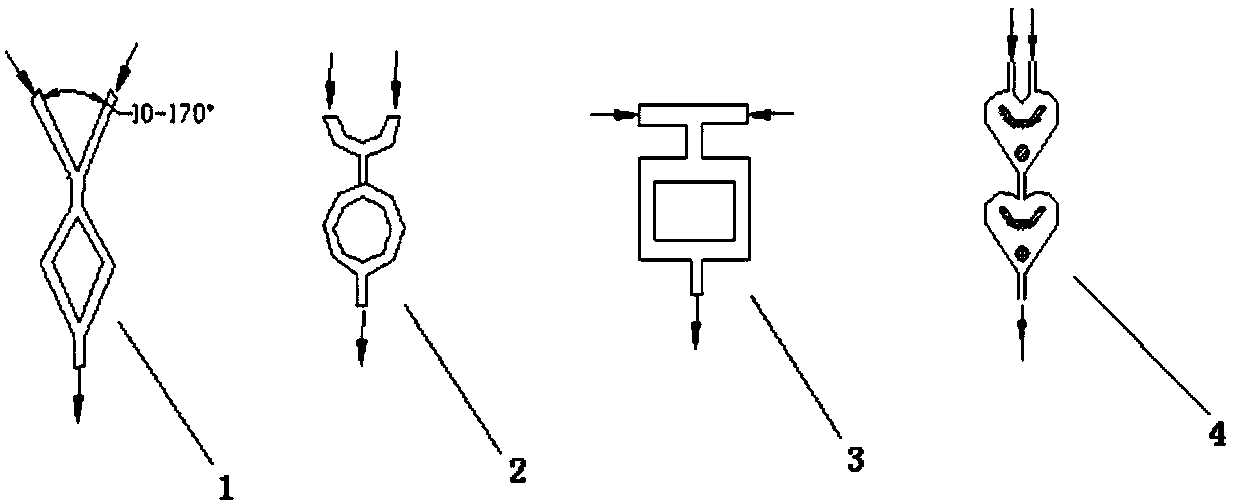

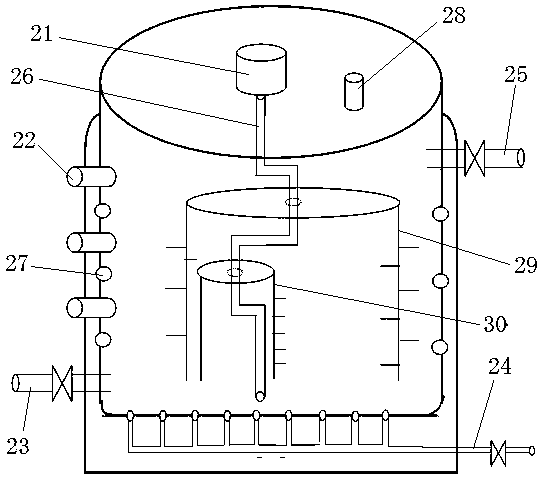

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

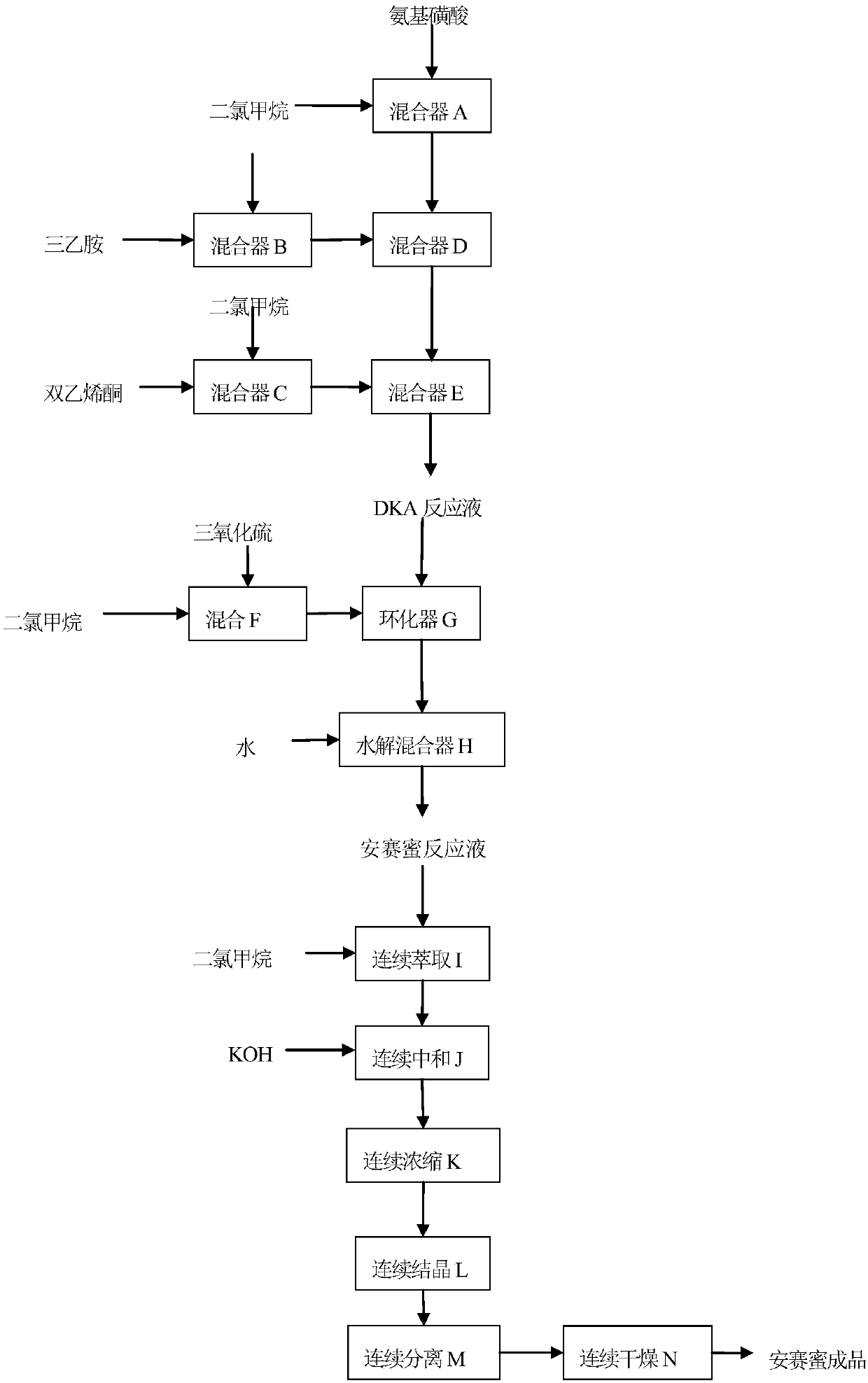

Method for continuously producing acesulfame potassium

The invention belongs to the field of chemical production, and provides a method for continuously producing acesulfame potassium, which comprises the following steps: continuously mixing and dissolving sulfamic acid and dichloromethane, continuously neutralizing with a triethylamine solution, introducing the neutralized reaction solution and ketene dimer into a continuous reactor, and carrying outaddition acylation reaction to obtain a DKA reaction solution; sulfur trioxide and solvent micro-mixing: S03, enabling dichloromethane to enter a micro-mixer, so as to prepare a cyclizing agent; cyclization and hydrolysis: continuously feeding the DKA reaction solution and a cyclizing agent into a cyclization microreactor to generate a cyclization reaction solution, and continuously feeding the cyclization reaction solution into a hydrolysis microreactor to obtain an acesulfamic acid reaction solution; enabling the acesulfame acid reaction liquid and dichloromethane to enter continuous extraction equipment, enabling an extracted organic phase and a potassium hydroxide aqueous solution to enter a continuous neutralization reactor to obtain acesulfame acid potassium reaction liquid, and subjecting the acesulfame acid potassium reaction liquid to continuous concentration, continuous crystallization, continuous separation and continuous drying to obtain the acesulfame acid potassium finished product. The process has the characteristics of simple process, low cost, good product quality, continuous whole process and the like.

Owner:NANTONG ACETIC ACID CHEM +1

Method for producing food-grade potassium chloride through multistage flash evaporation, cooling and continuous crystallization

ActiveCN103588225AReduce energy consumptionUniform particle sizeAlkali metal halide purificationPotassiumSlurry

The invention discloses a method for producing food-grade potassium chloride through multistage flash evaporation, cooling and continuous crystallization. The method comprises the following steps: 1) putting potassium chloride into a solution, heating to 100-110 DEG C to form a potassium chloride saturated solution I, 2) sequentially adding alkali and a purifier into the potassium chloride saturated solution I for heat preservation sedimentation, 3) filtering supernate obtained in Step 2), neutralizing with hydrochloric acid to be neutral, 4) pumping a potassium chloride saturated solution II to a single-effect flash evaporation crystallizer for flash evaporation, cooling and concentration, 5) conveying potassium chloride slurry I to a double-effect flash evaporation crystallizer for flash evaporation, cooling and the concentration with a forced circulation pump, 6) conveying potassium chloride slurry II to a triple-effect flash evaporation crystallizer for flash evaporation, cooling and concentration with another forced circulation pump, 7) separating potassium chloride slurry III with a centrifuge to form a potassium chloride wet product and a potassium chloride mother solution I, and 8) drying and packaging the potassium chloride wet product to form food-grade potassium chloride.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

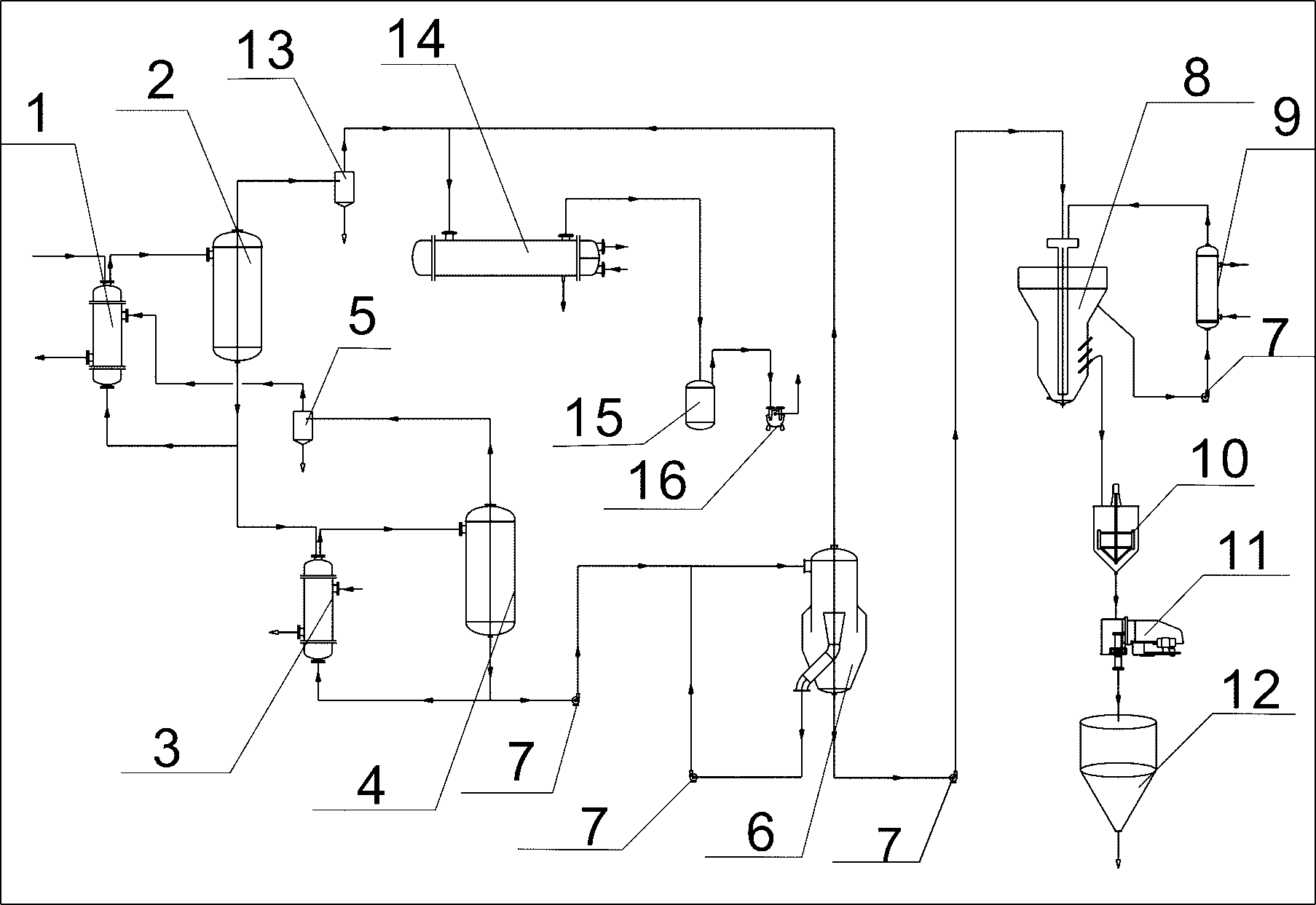

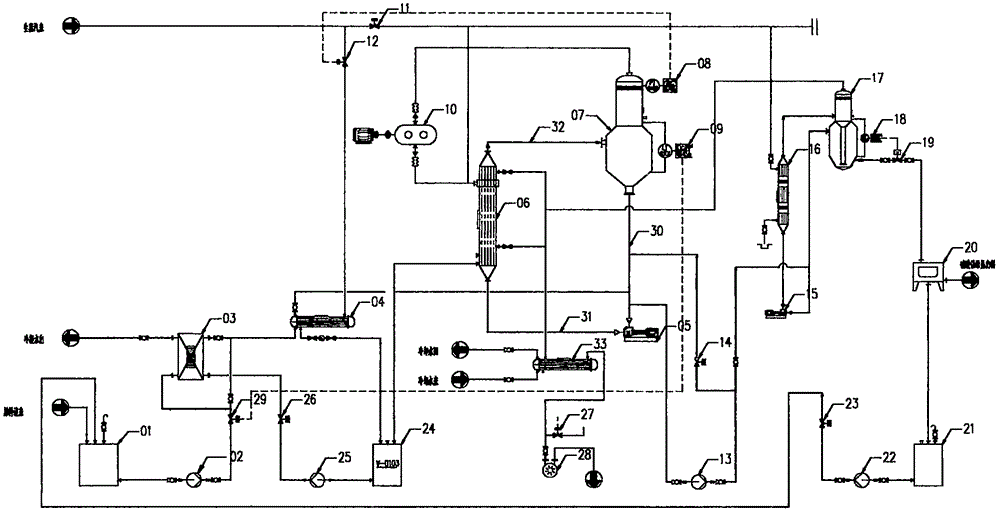

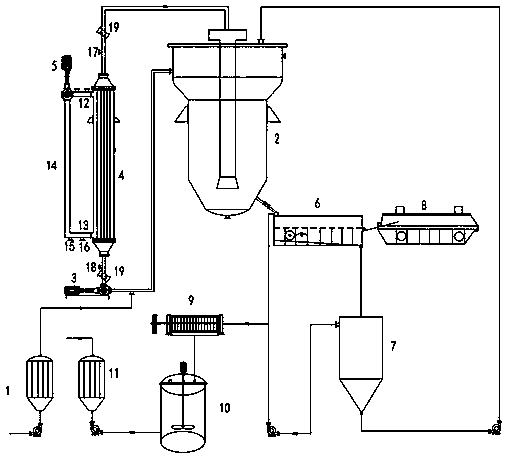

Device system for efficient cobalt sulfate concentration and continuous crystallization

ActiveCN106115804AGuaranteed cooling temperatureReduce dosageVacuum condensationEvaporation with vapour compressionEvaporationStock solution

The invention relates to a device system for efficient cobalt sulfate concentration and continuous crystallization. The device system provided by the invention comprises an evaporation heater (06), an evaporation separator (07), an OSLO vacuum crystallizer (17), a fine grain eliminating heater (16), a steam compressor (10), a condensate water preheater (03), a steam preheater (04), a centrifugal machine (20) and a pump. A stock solution enters the evaporation heater through the preheater, and the heater is connected with the separator and the circulating pump; the separator is connected with the OSLO vacuum crystallizer; a material liquid drop device is arranged in the middle of the OSLO vacuum crystallizer, a flash chamber is arranged at the top of a pipe, a circulating liquid outlet is formed in the side part, a secondary steam outlet is formed in the top of the flash chamber and is connected with a condenser and a fine grain eliminator, the crystallizer is connected with the centrifugal machine, and the centrifugal machine is connected with a mother liquid tank and a stock solution buffer tank to realize overall material liquid circulation. The system has the characteristics of energy conservation, continuity, automation and high efficiency, and obtained products are large in grain size and high in quality.

Owner:湖州惠鹏达节能环保科技有限公司

Long-chain binary acid continuous crystallization method

InactiveCN104418721AImprove industrial automationImprove product qualitySolution crystallizationCarboxylic compound separation/purificationChemistryContinuous crystallization

The invention provides a long-chain binary acid continuous crystallization method and an application thereof. The continuous crystallization method comprises the step that multi-stage crystallization, preferably three-stage crystallization, is sequentially carried out on an organic solution containing a binary acid. Compared with a batch crystallization device, the crystallization method disclosed by the invention is high in industrial automatic degree, and stable in product quality on the premise that the same product quality is obtained; meanwhile, the operating personnel are greatly reduced; and the investment cost is reduced by over 50% (on the product scale of 10,000t / year) in comparison with a batch crystallization device, and therefore, the high-quality long-chain binary acid crystal can be efficiently obtained through the continuous crystallization equipment; the equipment investment is reduced; the fluctuation in production is reduced; and the long-chain binary acid continuous crystallization method is an ideal long-chain binary acid crystallization method, and can be suitable for large-scale industrial production.

Owner:CATHAY R&D CENT CO LTD

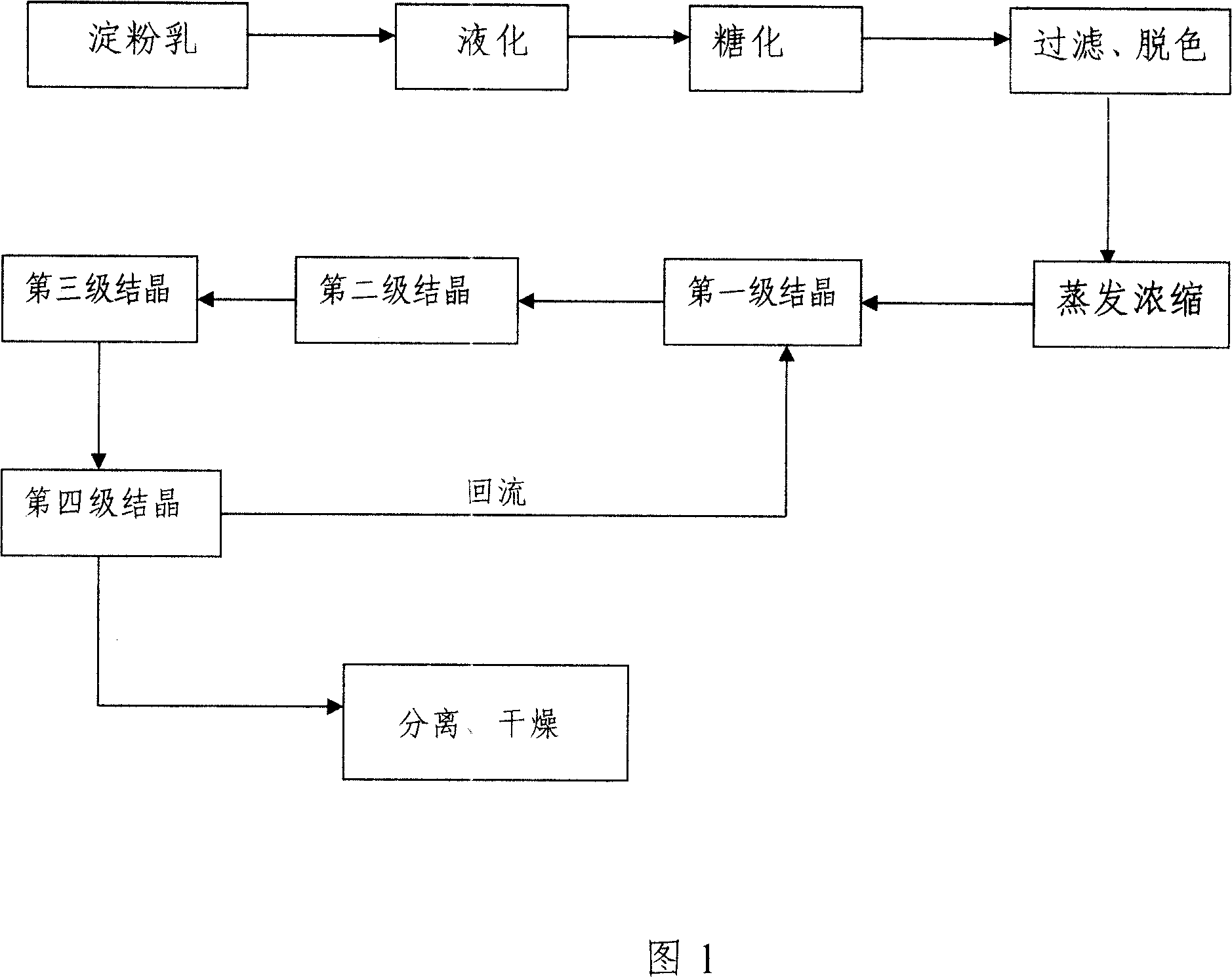

Horizontal continuous crystallization method adopting return current technique

InactiveCN101109021AIncrease the amount of seedHigh yieldGlucose productionGlucose productionReturn current

The invention provides a horizontal continuous crystallization applied with returning technology, which belongs to an improvement of a crystallized glucose production method. The invention adopts a plurality of horizontal crystallization pots in series to carry out continuous crystallization process. The following is the introduction of the process. Firstly starch milk is liquefied, saccharified, filtered and bleached, evaporated and concentrated to get sugar solution. Secondly the sugar solution is sent into a first horizontal pot and continuously sent to the next horizontal pot for crystallization to get crystal slurry. Most of the crystal slurry flows out from the discharging outlet of the last crystallization pot while the small part of the slurry returns into the first horizontal crystallization pot from the discharging outlet of the last one. As the seed of the first crystallization, the small part of the slurry then mixes with the sugar solution in the first horizontal crystallization pot. Changing the traditional way of simple adding crystal seed, the technical scheme uses part of crystal slurry returning into the first horizontal crystallization pot as the seed and increases the crystal seed in the horizontal crystallization pot, thereby improves the crystallized glucose output rate and quality.

Owner:SHANDONG XIWANG SUGAR

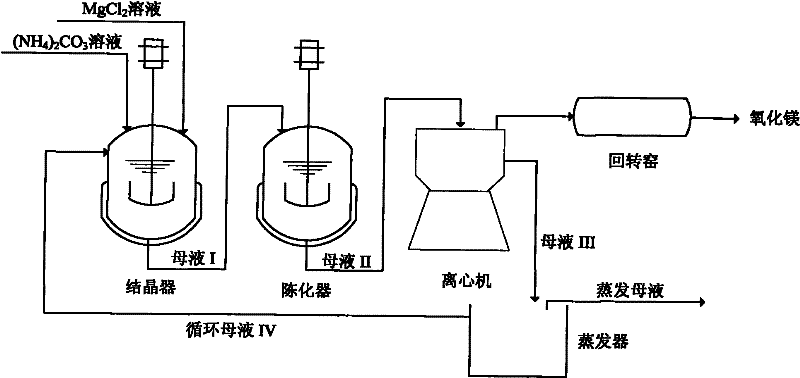

Method for preparing trihydrated magnesium carbonate by using continuous crystallization process

InactiveCN102190320ASimple reaction conditionsImprove the environmentMagnesium carbonatesSolution crystallizationHigh concentrationLithium

The invention belongs to the technical field of salt chemical industrial production, concretely, the invention relates to a method for preparing trihydrated magnesium carbonate by a using continuous crystallization process. The technical schemes of the present invention comprises: selecting high concentration magnesium chloride or high ratio of magnesium to lithium brine, ammonium carbonate as raw materials, adding into a continuous crystallizer for crystallizing, adding a crude product of trihydrated magnesium carbonate obtained by crystaling into an aging device for aging, obtaining a trihydrated magnesium carbonate crystal with good form and high purity for condition for providing conditions to produce high purity magnesium oxide. According to the method of the present invention, continuous crystallization in a process of producing trihydrated magnesium carbonate can be realized, the stability and automation degree of the crystallization in the process of producing trihydrated magnesium carbonate can be effectively raised, and the quality of products is increased as well as the production cost is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Separation and purification system of organic synthesis feed liquid and separation and purification method thereof

InactiveCN104174181AFull recoveryTake advantage ofGeneral water supply conservationMultistage water/sewage treatmentChemical industryPurification methods

The invention aims at the field of chemical industry and relates to a separation and purification system of organic synthesis feed liquid and a separation and purification method of the organic synthesis feed liquid. The separation and purification system comprises a crystallization system and a solid-liquid separation system which are sequentially arranged from front to back, wherein the crystallization system comprises a mixed suspension-mixed product-removal (MSMPR) crystallizer and a draft-tube-baffled (DTB) crystallizer which are connected with each other in series; the separation and purification system also comprises a liquid processing system used for processing waste liquid produced by the solid-liquid separation system; the liquid processing system comprises a desalting device and a membrane concentration device which are sequentially arranged from front to back. By virtue of the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof, the organic synthesis feed liquid is separated and purified by using a continuous crystallization technology, an electrodialysis technology and a membrane separation and concentration technology; the produced waste liquid is fully recycled and used, so that the separation and purification efficiency is improved, the purity and the yield of products are improved and the discharge of the waste liquid is reduced; the separation and purification system of the organic synthesis feed liquid and the separation and purification method thereof are strong in production industrialization and low in costs, and are especially suitable for producing iminodiacetonitrile.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for extracting branched chain amino acid from fermentation liquid by virtue of double-membrane continuous crystallization method

ActiveCN105294468AReduce labor intensityReduce maintenance costsOrganic compound preparationAmino-carboxyl compound preparationFiltration membraneIon exchange

The invention relates to a method for extracting branched chain amino acid from fermentation liquid by virtue of a double-membrane continuous crystallization method. According to the method, thalluses, most protein and pigments in the fermentation liquid are filtered in a cross flow manner by virtue of a double-membrane (micro-filtration membrane and nanofiltration membrane) separation system, then operation steps including sol deproteinization, activated carbon decoloration, vacuum concentration and crystallization, alkali dissolution, deproteinization decoloration, low-temperature iso-electric continuous crystallization and the like are carried out so as to obtain branched chain amino acid crystals with the purity not less than 98.5%, and the yield is not less than 80%; the thalluses are filtered by virtue of the micro-filtration membrane, and methods including centrifugation, filter press filter pressing and the like adopted in conventional fermentation liquid treatment are changed, so that the thalluses are thoroughly removed, and filtrate is clear and transparent; soluble protein in the fermentation liquid is further removed by virtue of sol, and a low-temperature iso-electric continuous crystallization manner is adopted, so that the product quality is improved; a traditional ion exchange process is omitted, so that the production of a lot of high ammonia-nitrogen wastewater is avoided, and the clean production of branched chain amino acid is realized.

Owner:天津达善生物科技有限公司

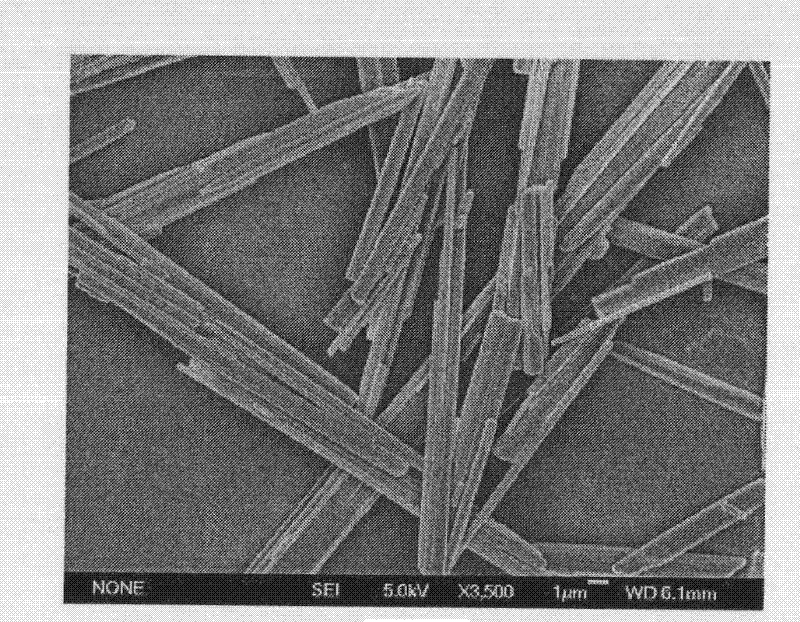

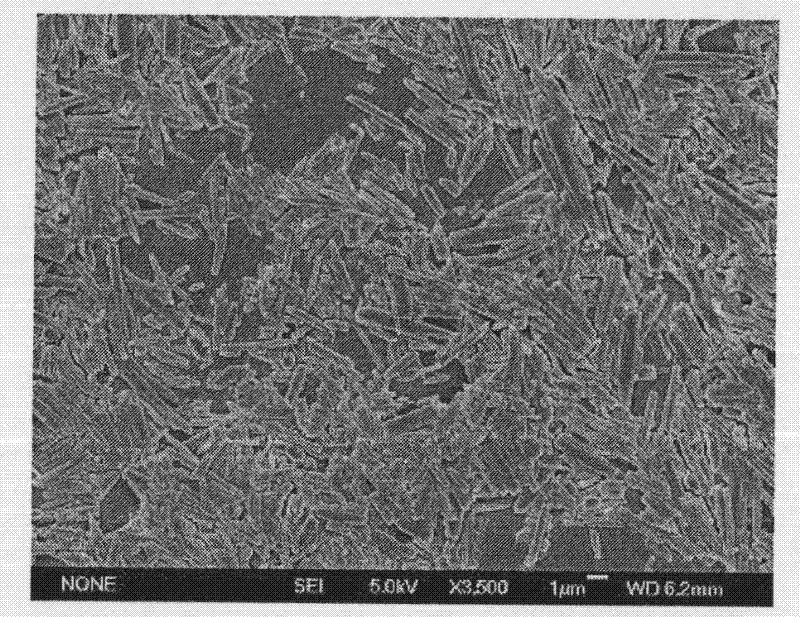

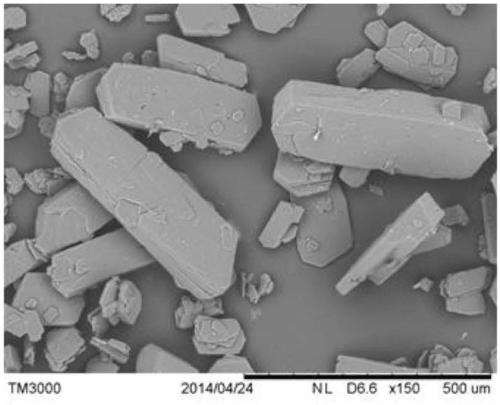

Multistage continuous crystallization method of short rod-like methionine crystals

ActiveCN109608372ASmall particle sizeControl granularityOrganic compound preparationOrganic chemistry methodsSlurryMethionine biosynthesis

The invention provides a multistage continuous crystallization method of short rod-like methionine crystals. The method includes: connecting a plurality of crystallizers in series; under the action ofa circulating device, dissolving a methionine raw material at 80-130DEG C; letting the dissolved feed solution enter a first stage crystallization kettle, and controlling the kettle temperature at 60-80DEG C; enabling the slurry to enter a second stage crystallization kettle, and controlling the kettle temperature at 40-60DEG C; enabling the slurry to enter a third stage crystallization kettle, and controlling the kettle temperature at 25-40DEG C; letting the slurry enter a fourth stage crystallization kettle, and controlling the kettle temperature at 15-25DEG C; letting the final slurry flowout of the crystallization kettle and enter a solid-liquid separation system, discharging the separated solid out of the system, and returning part of the mother liquor into a dissolution kettle forfurther circulation, with the circulation volume being 20-60% of the mother liquor volume. The stage number of the crystallization kettles is supposed to be optimized according to the actual situation, and the general ideal situation is 2-4 stages. The prepared methionine crystals have short rod-like crystal habit, the crystal size is uniform, the bulk density is high, the fluidity is good, the quality is stable, the operation is simple, and the production efficiency is high, therefore the method is suitable for large-scale industrial production.

Owner:TIANJIN UNIV +1

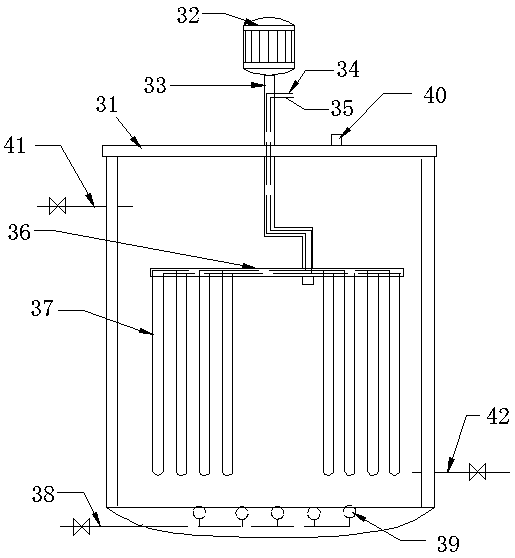

Continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as process thereof

ActiveCN107837557ARealize continuous productionHigh degree of automationCobalt sulfatesSolution crystallizationWater insolubleLotion

The invention discloses a continuous crystallization system of cobalt sulfate with coarse grain and low water insoluble matters as well as a process thereof. The continuous crystallization system comprises a filtering machine set, a cooling crystallization set, a discharging set, and connecting pipelines. The continuous crystallization process is as follows: a cooling crystallizer is full of a stock solution or mother liquor, a crystallization circulating pump is opened, cobalt sulphate concentrate which is precisely filtered and a crystallizer supernatant are mixed and enter an external cooler in order to form a supersaturated solution, and the solution enters a crystallizer through a crystallizer guide shell and grows on an original crystal nucleus; cobalt sulfate from an Oslo cooling crystallizer aging zone is discharged and enters a grader, and air drying of cobalt sulfate of coarse grain is directly carried out in order to obtain a qualified cobalt sulfate product; the grader fines enter a thickener, and underflow of the thickener returns the crystallizer and is used as a crystal seed; a part of the thickener overflow returns and is used as a washing lotion for grading, and apart of the thickener overflow is filtered by a filter press and a precision filter and enters an evaporative concentration process. The process has the advantages of good continuity, large proportionof products with coarse grain, low content of water insoluble matters, high crystallization rate, and the like.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

Method for producing calcium hydrogen citrate

ActiveCN103058853AFully crystallizedHigh purityCarboxylic acid salt preparationCarboxylic compound separation/purificationHydrogenSulfate

The invention relates to a method for producing calcium hydrogen citrate. The method mainly comprises the steps of: shortening reaction time from citric acid to the calcium hydrogen citrate; then providing a supersaturated solution of the calcium hydrogen citrate through a multistage neutralization reaction to realize continuous crystallization of the calcium hydrogen citrate; and prolonging the crystallization time of the calcium hydrogen citrate to realize full crystallization of the calcium hydrogen citrate. The method for producing the calcium hydrogen citrate reduces influence from silicate impurities and the like caused by purity defect of limestone powder to the quality of the calcium hydrogen citrate and the quality of a calcium sulfate by-product, removes most oxalic acid and realizes a method for preparing high-quality calcium hydrogen citrate from low-quality limestone powder. By adopting the method disclosed by the invention to prepare the calcium hydrogen citrate, the returning rate of the mother solution is dropped by about 50%, the obtained calcium hydrogen citrate crystal particles are big and uniform, and the purity of the calcium hydrogen citrate is far higher than that of the traditional calcium hydrogen citrate.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Process and equipment for synthesis of sub-micron 4A zeolite with continuous crystallization

InactiveCN101428816AEasy to control the crystallization processThe method of synthesizing zeolite is simple and easyAluminosilicate zeolite type-ASodium aluminateSODIUM SILICATE SOLN

A process for synthesizing submicron 4A zeolite by a continuous crystallization method comprises steps as follows: a sodium silicate solution with a certain concentration and a sodium aluminate solution with a certain concentration rapidly react and gel in a linear high-shear emulsifying machine; the gelled product is heated for crystallization in a controllable temperature tubular flowing crystallization reactor; then the crystallized product is washed and filtrated by a continuous filtering apparatus; and finally submicron 4A zeolite is obtained after drying. The invention has the advantages of simple and easy process method for synthesizing zeolite, small device, high preparation efficiency, continuous operation, and average grain diameter of synthesized submicron 4A zeolite smaller than 1 micron.

Owner:CHINA RES INST OF DAILY CHEM IND

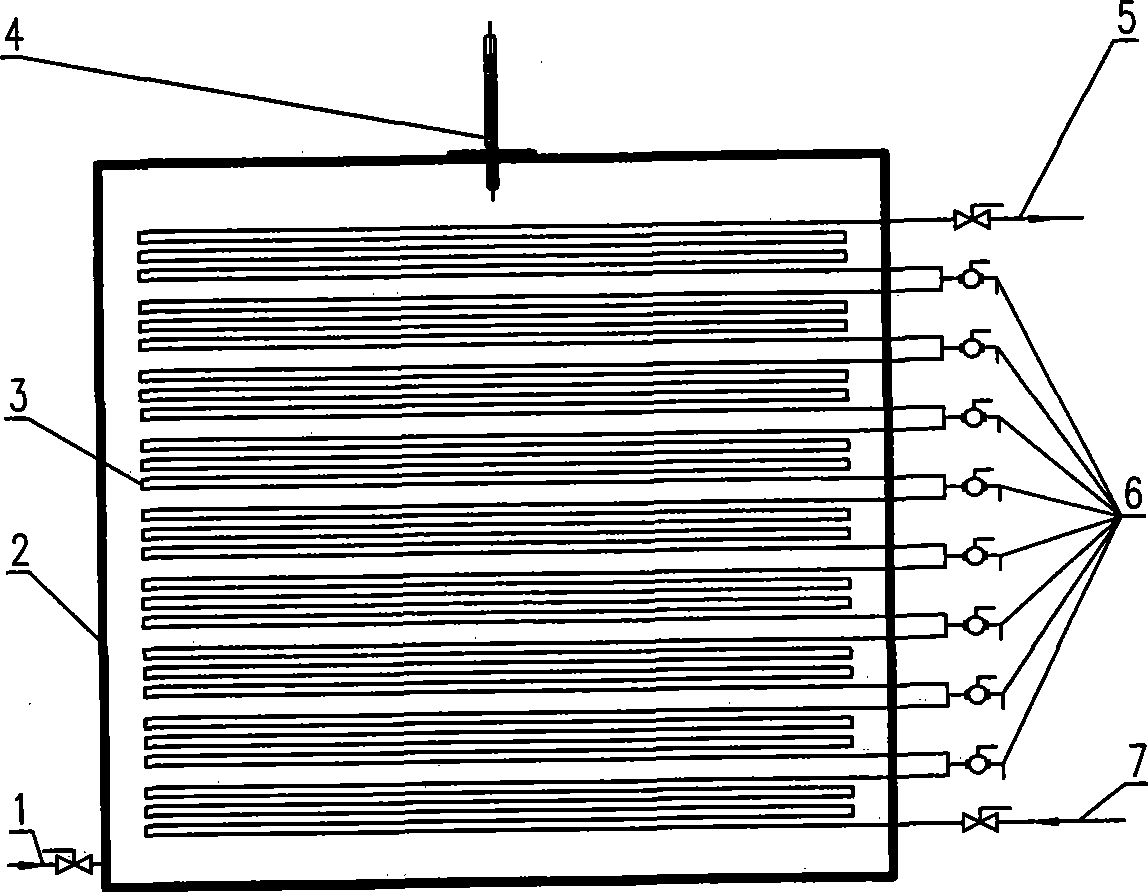

Method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining

ActiveCN107746746ALess destructiveDestructiveFatty-oils/fats refiningFatty-oils/fats separationOil and greaseVegetable oil

A method and equipment for improving quality of vegetable oil through continuous crystallization, crystal growing, and dewaxing refining are disclosed. Oil and grease dewaxing is performed through eight-stage staged cooling crystallization, six-stage constant-temperature crystal growing, and two-stage low-temperature filtration. Special crystallization and crystal growing devices are adopted, interferences of transmission on crystallization and crystal growing processes are effectively solved as a whole, the heat conduction efficiency is higher, crystal damage caused by a transmission device and relative movement in an oil and grease system is less, energy consumption is lower, crystal dispersibility is significantly improved, and aggregation effects of wax, esters and high-melting-point fat are better. The method and the equipment can further improve dewaxing, winterization and dewaxing effects in crystallization and crystal growing processes of wax-containing vegetable oil, prolong oil product refrigeration time to 60 h or above, improve flavor and quality of oil and make oil palatability good. The method and the equipment are suitable for corn oil, sunflower seed oil, soybean oil, rice bran oil, and the like, and are particularly suitable for corn oil, sunflower seed oil, and the like.

Owner:SHANDONG XIWANG FOOD

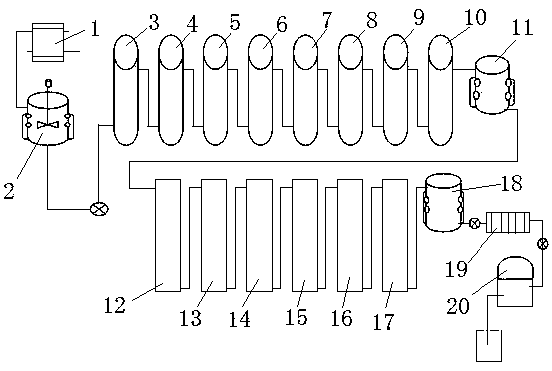

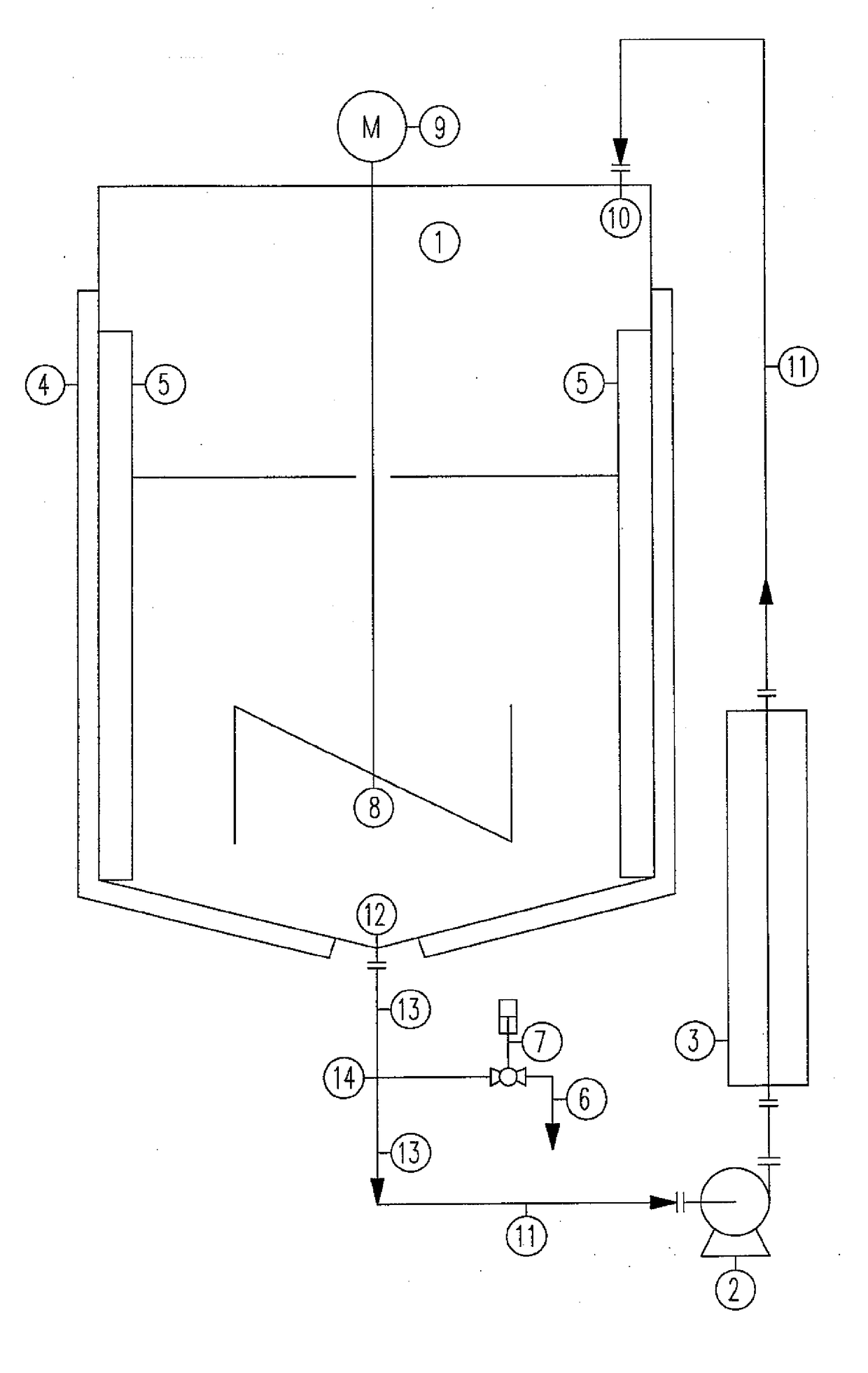

Continuous crystallization method of tetraacetylethylenediamine

ActiveCN102580347AContinuous crystallization achievedIncrease productivitySolution crystallizationCyclic processTetraacetylethylenediamine

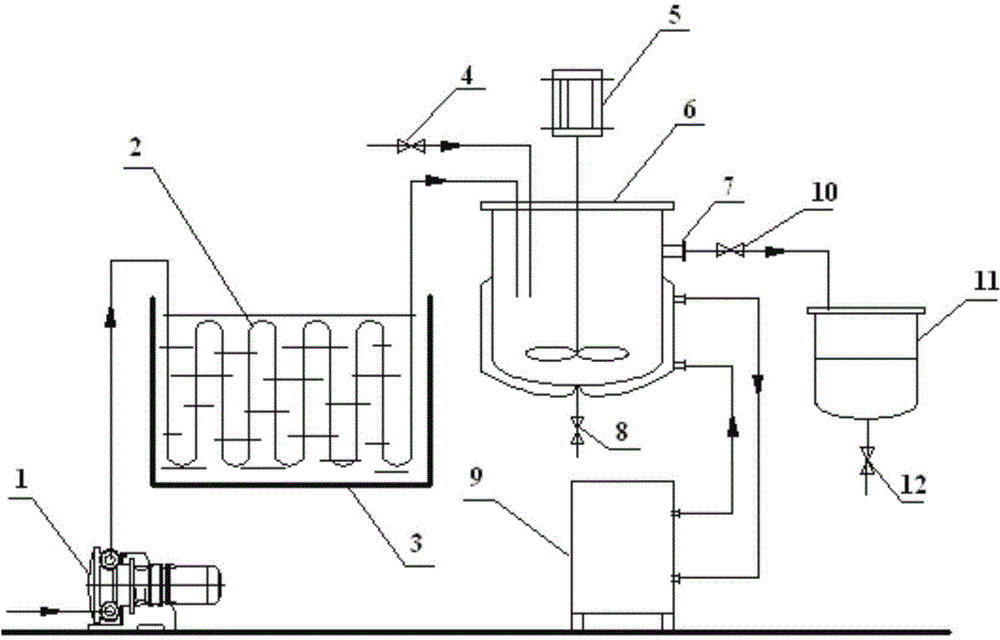

The invention discloses a continuous crystallization method of tetraacetylethylenediamine. The method is characterized by comprising the following steps that: (a) after the synthesis reaction of tetraacetylethylenediamine is finished, reaction material enters a crystallization pre-cooling kettle, and the temperature of the material is kept at 100-140 DEGE C; (b) the material in the crystallization pre-cooling kettle is conveyed by a crystallization feed pump, mixed with the outer circulation material of a continuous crystallizer and then conveyed by an outer circulation pump 2 of a crystallizer, and enters a continuous crystallizer 1 through a heat exchanger 3; (c) the material in the crystallizer passes through an outer circulation material outlet 2.8 and the outer circulation pump 2 and the heat exchanger 3 to enter the crystallizer from the an outer circulation material inlet 2.9 to finish the outer circulation process; and (d) the material discharged from the crystallization system is conveyed into a centrifugal separation device by a crystallization discharge pump 4 from a crystal mush outlet 2.11, and the obtained solid is washed and dried to obtain the crystal of tetraacetylethylenediamine. Through the method disclosed by the invention, the high-purity pure white tetraacetylethylenediamine product can be directly obtained, continuous crystallization is realized, and the production efficiency and product quality are obviously improved.

Owner:ZHEJIANG JINKE CHEM

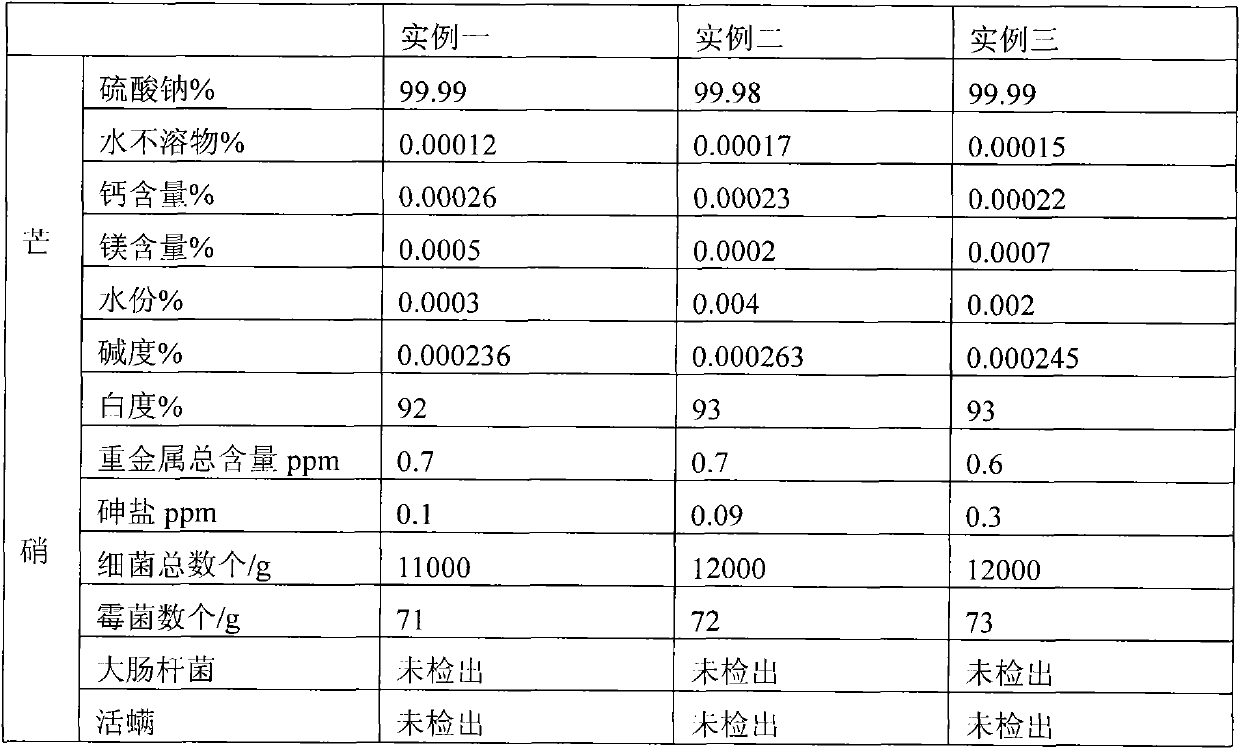

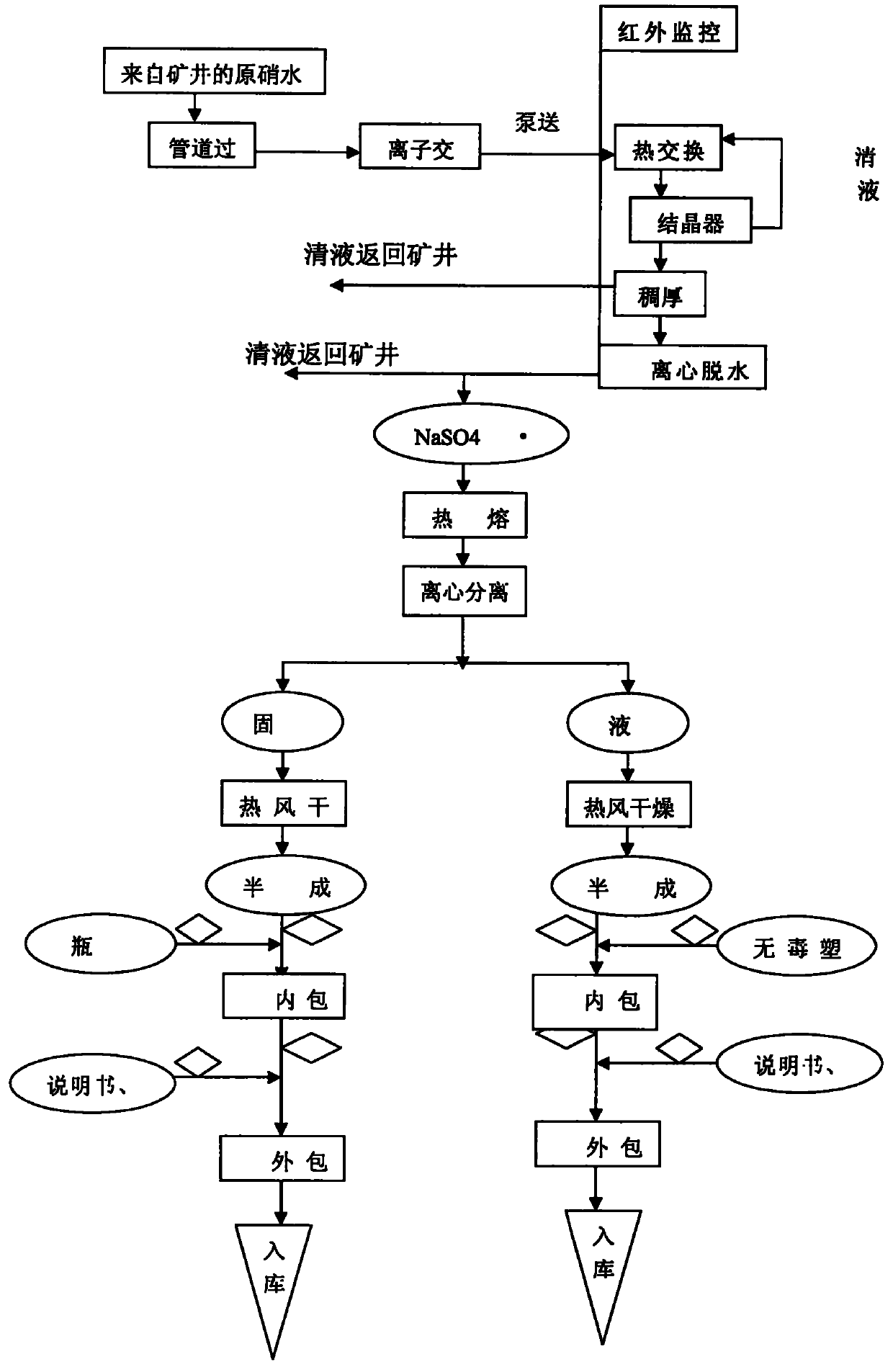

Technique for manufacturing anhydrous medicinal mirabilite

ActiveCN101948123AMonitor drynessMonitor cleanlinessAlkali metal sulfite/sulfate purificationIon exchangeEngineering

The invention relates to a technique for manufacturing anhydrous medicinal mirabilite. The method comprises the following steps: under the monitoring of an on-line infrared computer automatic monitoring system and the regulation and control of a porous plate liquid balance flowmeter, when the indoor air cleanliness of a production shop achieves a certain index, removing mechanical impurities from original nitrate solution (transported underground) with a certain concentration through a pipeline filter, purifying by ion exchange to obtain fine nitrate solution with low content of metallic ion impurities, inputting the fine nitrate solution into a continuous crystallization system, carrying out continuous solid-liquid separation on the crystallized crystal slurry through a strap type centrifugal machine to obtain medicinal mirabilite crystals, melting the medicinal mirabilite crystals in a steam heating or electric heating mode, carrying out solid-liquid separation, respectively drying solid and liquid with hot air to obtain the anhydrous medicinal mirabilite, and finally, carrying out aseptic packaging by using an automatic packaging system. On the premise of ensuring high product purity and conformity to GMP requirements, the invention has more ideal unit productivity.

Owner:四川省川眉药业有限公司

Method for preparing spherical Bayer stones

InactiveCN102432051AUniform particle sizeUniform particle distributionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateSodium bicarbonate

The invention relates to a method for preparing spherical Bayer stones. The method comprises steps that: (1) an aqueous solution of sodium bicarbonate and a sodium aluminate solution are respectively added into a continuous crystallization reactor; a reaction is carried out under a temperature of 40-60 DEG C, and an average residence time is 45-90min; when the reaction reaches a steady state, a Bayer stone solid suspension solution is obtained, wherein the adding speed of the aqueous solution of sodium bicarbonate is 4.26-8.7mL / min; the adding speed of the sodium aluminate solution is 1.1-2.9mL / min; and the molar ratio of sodium bicarbonate to sodium oxide in aluminate is 0.90:1-2.59:1; (2) the suspension solution obtained in the step (1) is subject to solid-liquid separation; a solid phase and a liquid phase are collected; the solid phase is washed and dried, such that a Bayer stone product is obtained; (3) carbon dioxide gas is delivered to the liquid phase obtained in the step (2),such that a sodium bicarbonate solution is obtained; the produced sodium bicarbonate solution is used in the step (1), and the steps (1)-(3) are repeated. The method provided by the invention is advantaged in that: with the method, the prepared Bayer stones have regular spherical shapes and uniform particle distribution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Perovskite light emitting diode based on ultraviolet thermal annealing process and a preparation method thereof

ActiveCN109256475AIncrease brightnessImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsHole transport layer

The invention discloses a perovskite light emitting diode based on an ultraviolet thermal annealing process and a preparation method thereof. The preparation method comprises the following steps: cleaning and drying the substrate, and arranging an anode layer on the substrate; And then carrying out ultraviolet ozone treatment; And then preparing a hole transport layer on the anode layer of the substrate; spin-coating The mixed solution of perovskite material doped with UV curing agent on the hole transport layer, then annealed and irradiated with UV light to obtain the cross-linked perovskitefilm luminescent layer. And preparing an electron transport layer and a cathode layer by vapor deposition on the light emitting layer; Finally performing encapsulation. perovskite material is doped with an ultraviolet curing agent and the ultraviolet light is irradiate to prepare a luminescent layer, the generated perovskite thin film is dense, continuous, good in crystallinity and strong in water-oxygen corrosion resistance, so that the brightness and efficiency of the perovskite light-emitting diode are improved, and the stability of the device is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for producing nano crystalline stone materials

InactiveCN101182108ADiffuse diffuse reflection effect is goodReduce production processGlass productionMetallurgyNucleation

A nano-crystal stone material production method comprises steps as follows. Firstly, glass melt is melted. Used raw materials comprises following components and the weight percent of all components is that: 50-70 percent of SiO2, 4-10 percent of CaO, 5-10 percent of MgO, 5-8 percent of Al2O3, 2-8 percent of Na2O, 0-8 percent of K2O, 1-4 percent of ZnO, 1-2.5 percent of B2O3, 1-2 percent of P2O5 and 0-1 percent of Sb2O3. Glass substrate is pressed. Then, the nucleation, the crystallization and the annealing treatment are implemented. Compared with the prior art, the invention has the beneficial effect that because a product is formed through the one-step forming, the continuous crystallization and the annealing, the production procedures are reduced and the cost and the energy consumption are greatly lowered. The invention also has the advantages of short production cycle, low firing temperature and good product performance.

Owner:SHANTOU SPECIAL ECONOMIC ZONE GUOFEN INDAL

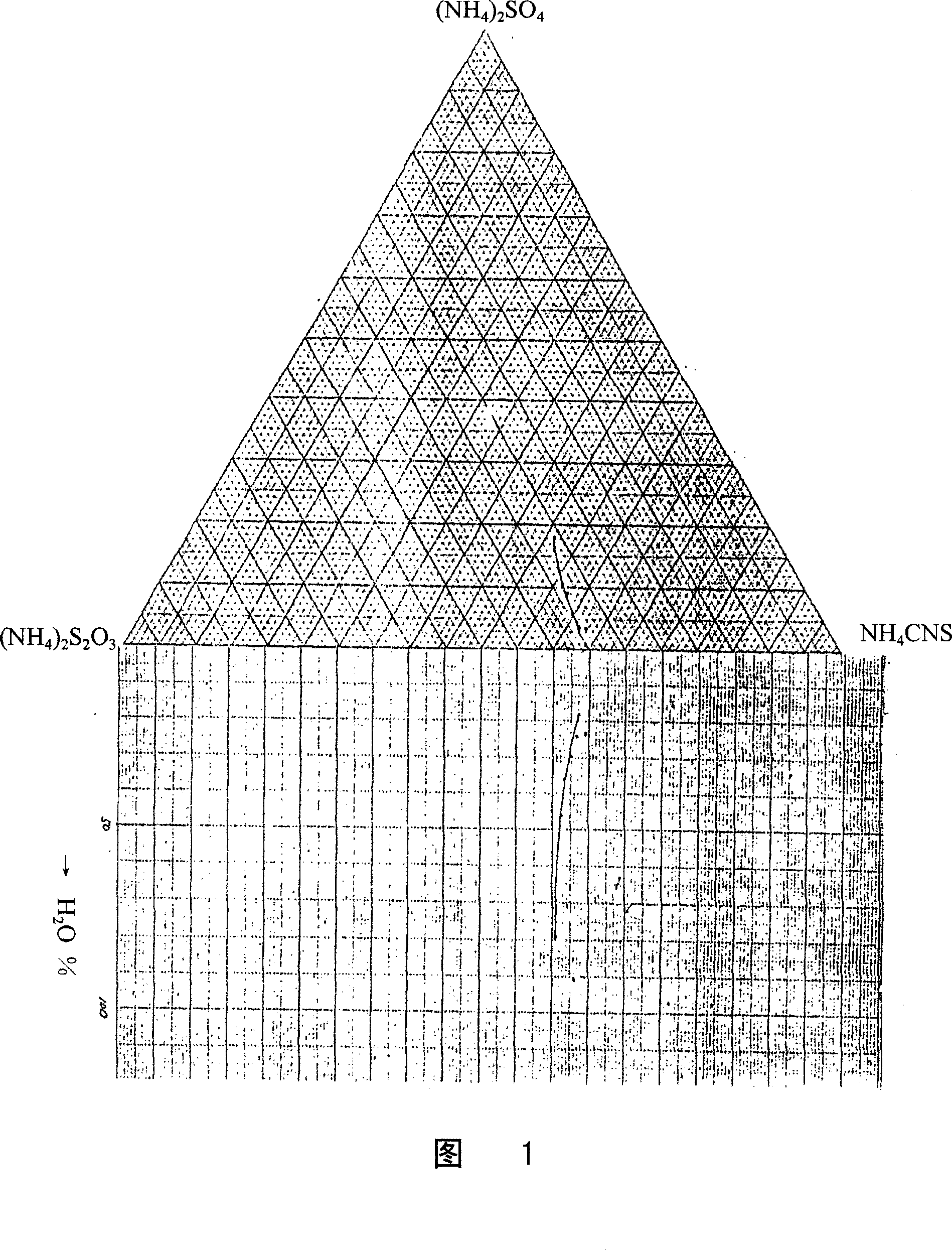

Reclamation of ammonium sulfocyanate and ammonium thiosulfate from coke oven gas ammonia liquid phase catalysis waste water

InactiveCN101143744ASatisfied with recyclingImprove utilization factorThiosulfates/dithionites/polythionitesThiocyanic acidSolution phaseChemistry

The invention uses the principle of a water solution phase diagram of a multi-component system to reclaim the NH4 CNS and the (NH4)2S2O3 from the ammonia water liquid phase catalytic waste water of the coke oven gas respectively. The content of the reclaimed NH4 CNS can reach greater than or equal to 95 percent, and the dried content of the NH4 CNS can reach greater than or equal to 98 percent. The content of the reclaimed (NH4)2S2O3 can reach greater than or equal to 93 percent, and the dried content of the (NH4)2S2O3 can reach greater than or equal to 97 percent. The NH4 CNS can be continuously evaporated during the reclamation process of the invention; the liquid and solid separation is processed in at a continuous normal temperature; the continuous crystallization, the high equipment coefficient and the increasing treatment content accord with the requirements of big plants. The invention successfully solves the environmental pollution of the desulphurization and decyanation waste water of the coke oven gas, and reclaims the main components in the waste water. The invention is characterized in an improved and simplified process, a practical and reliable technology and a low cost etc.

Owner:苏州市浒关焦炉煤气三废治理厂

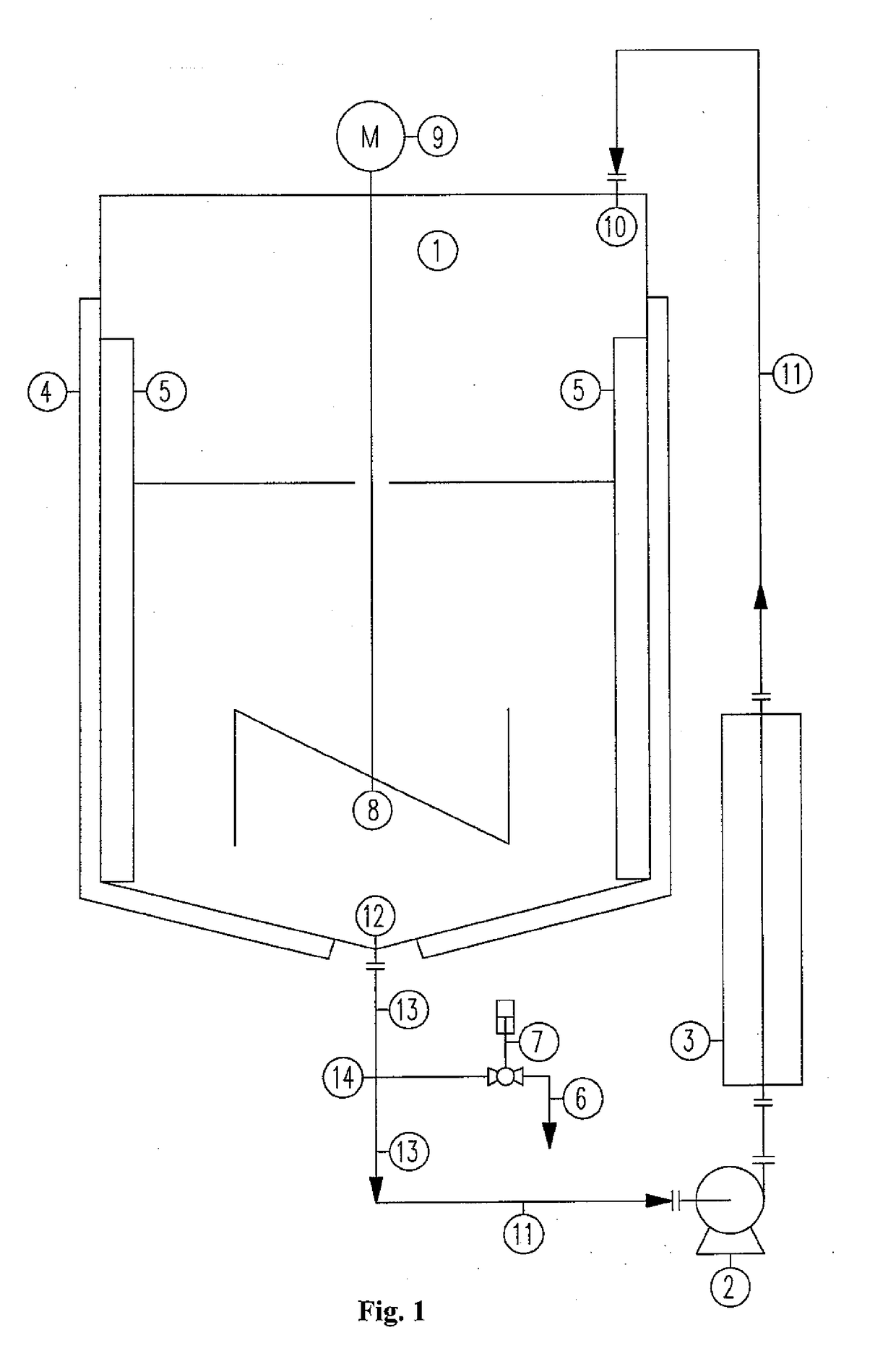

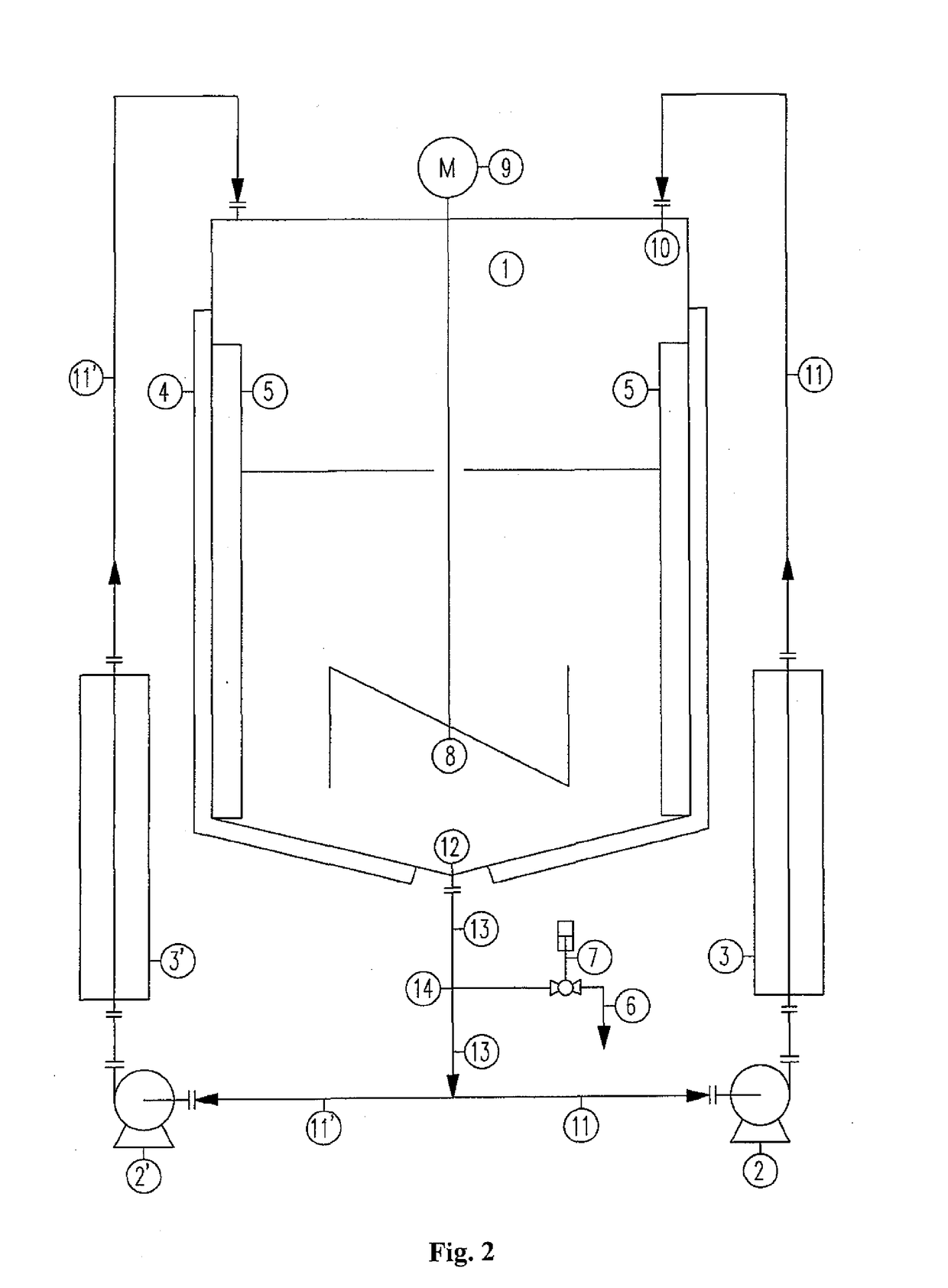

Discontinuous crystallization unit for the production of ball-shaped crystals

InactiveUS20170128854A1Easy to controlPolycrystalline material growthFrom normal temperature solutionsCooling curveCirculator pump

Owner:ERUCA TECH SRO

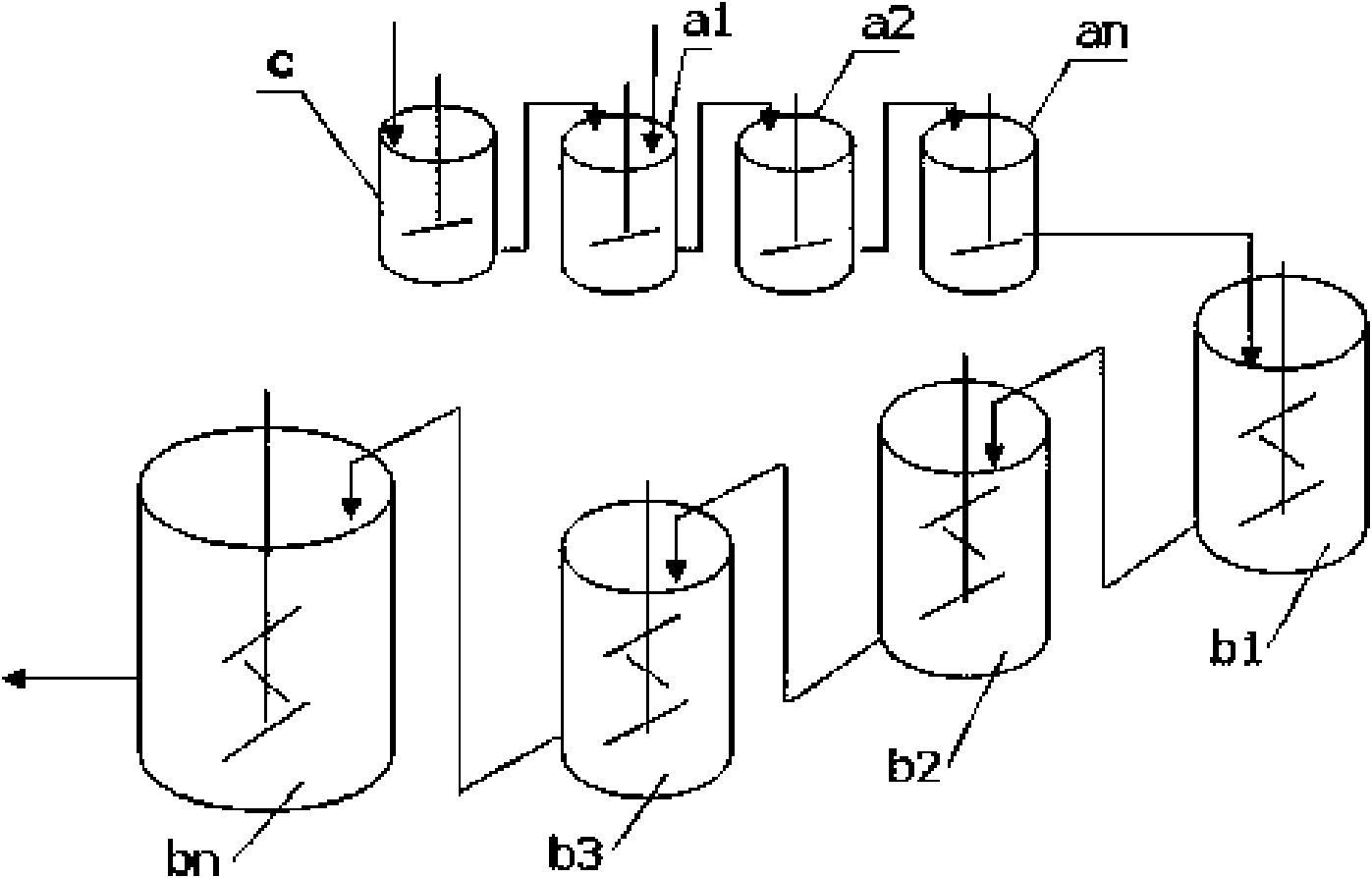

Method for preparing 4A zeolite by continuous crystallization

ActiveCN101654257AReduce manual control pointsReduce labor intensityAluminosilicate zeolite type-ATwo temperatureSodium silicate

The invention discloses a method for preparing 4A zeolite by continuous crystallization. A sodium metaaluminate solution and sodium silicate are used as raw materials to prepare the 4A zeolite, groovetype devices connected in series are divided into two groups to carry out continuous crystallization at two temperatures, and the continuous crystallization is divided into two processes of precrystallization and growing crystallization; a guiding agent is added in the phase of the precrystallization at lower temperature to induce a crystal nucleus so that a crystal initially grows; the temperature rises in the phase of the growing crystallization, the 4A crystal fully grows till the crystallization is perfect, and the process of continuous crystallization is finally finished. The method caneffectively lower a manual control point to carry out centralized control, reduce the labor intensity and improve the production efficiency; and because the temperature gradually rises, thereby effectively inhibiting a mixed crystal and ensuring stable quality of products.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

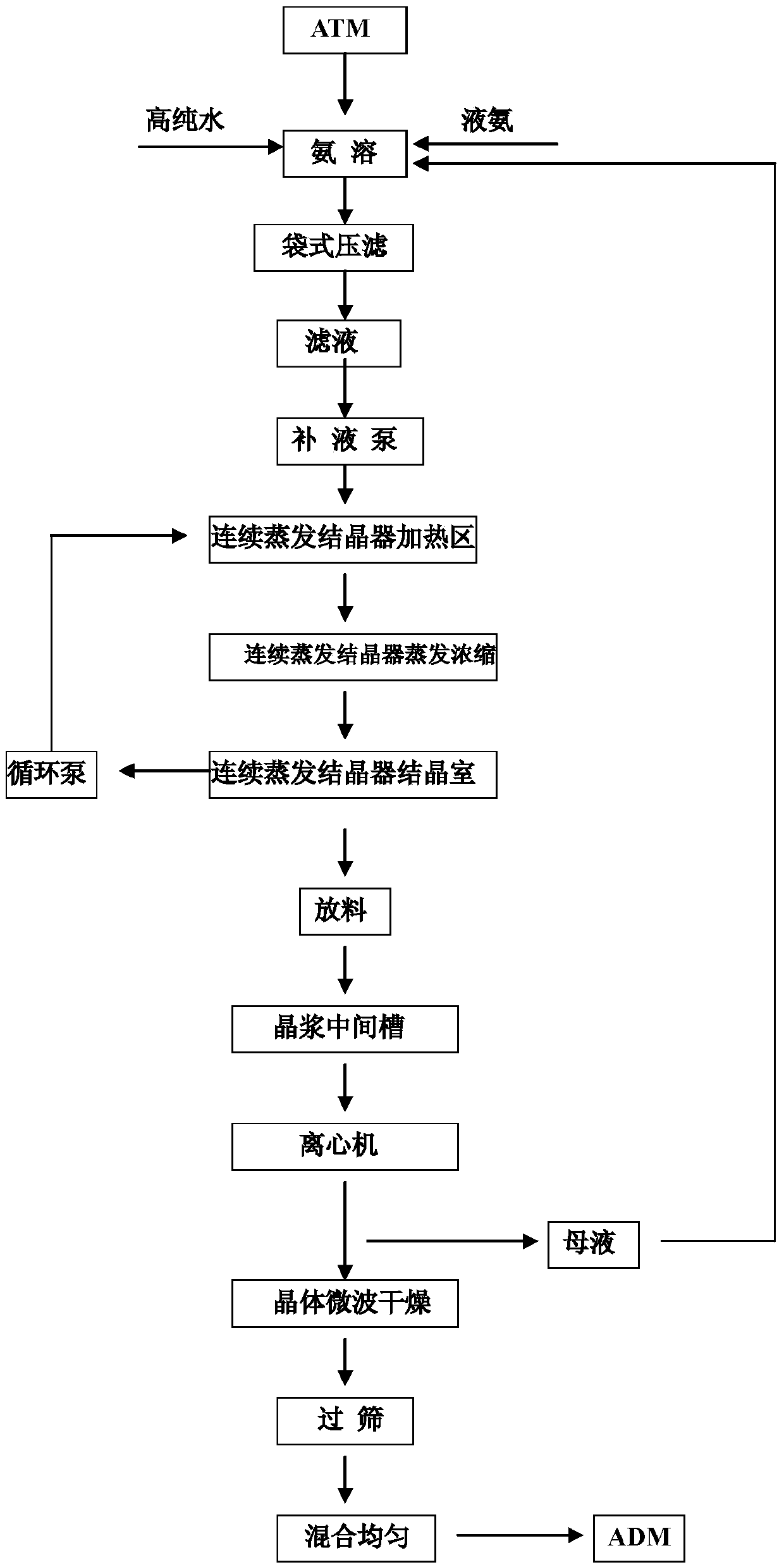

Ammonium dimolybdate automatic continuous crystallization production process

ActiveCN105502501AImprove performanceWide variety of sourcesMolybdeum compoundsFiltrationEvaporation

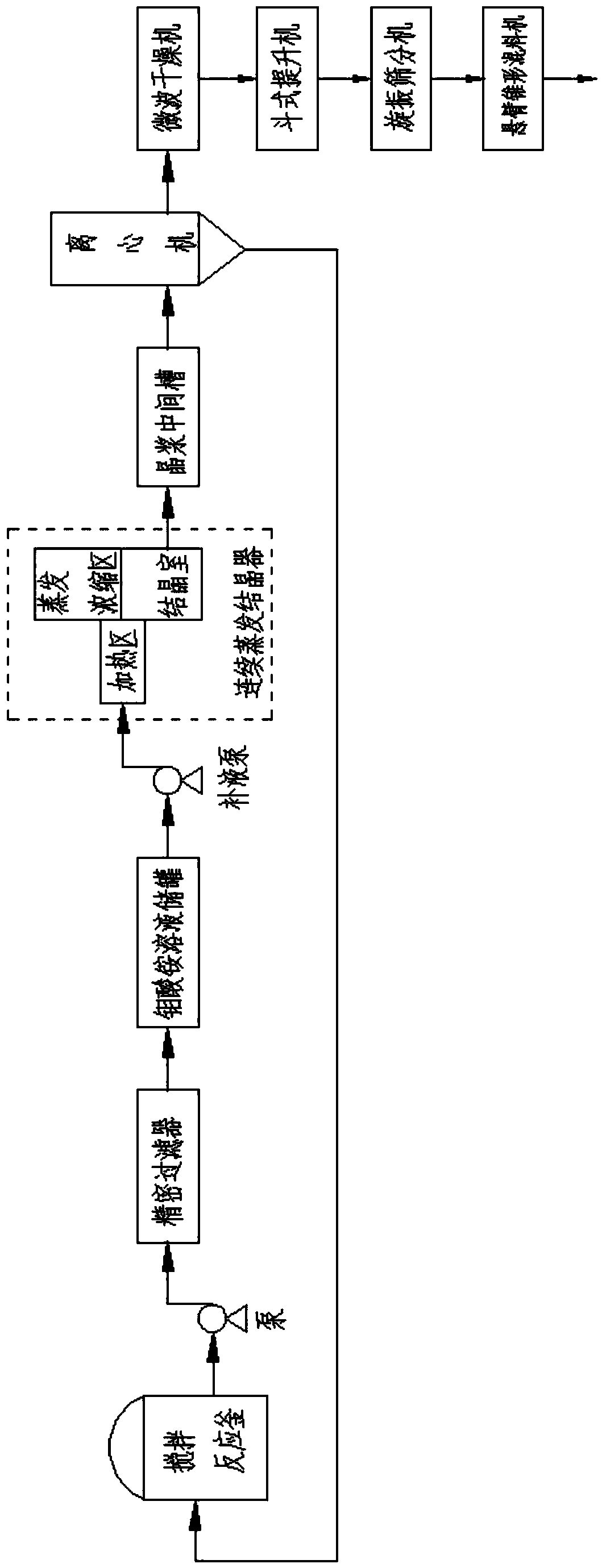

An ammonium dimolybdate automatic continuous crystallization production process comprises the following steps: solution density, a pH value and temperature in an ammonia dissolution process in a stirring reaction still are adjusted; an ammonia dissolution solution is pumped into a precision filter for filtration, then the filtered ammonia dissolution solution enters a continuous evaporating crystallizer with a constant feed liquid feeding amount in a circulating manner, and the heating, the evaporation and the crystallization of the solution are carried out in three independent working areas, namely, a heating area, an evaporation concentration area and a crystallization chamber separately, wherein the three areas work simultaneously; crystal slurry density is controlled, after crystallization, a crystal slurry enters a crystal slurry intermediate tank so as to enter a centrifuger for solid-liquid separation, after separation, an ammonium dimolybdate crystal drops in a microwave dryer to be dried, then the product (the dried ammonium dimolybdate crystal) is conveyed to a sieving machine to be subjected to sieving through a bucket elevator, and then the sieved ammonium dimolybdate crystal enters a cantilever tapered mixer to be mixed. The production process has the advantages that not only is the ammonium dimolybdate automatic continuous crystallization production realized, but also the single crystal, large particle size and high loose ratio ammonium dimolybdate is obtained through selection of a domestic crystallizer and control of a crystallization condition.

Owner:JINZHOU TIANQIAO REFRACTORY METAL

Continuous crystallization process for preparing nitroguanidine through nitric acid method

InactiveCN104860849AEmission reductionNo importOrganic chemistryOrganic compound preparationNitroguanidineFiltration

The invention relates to a continuous crystallization process for preparing nitroguanidine through a nitric acid method. The process is applied to continuous crystallization for preparing single-compound explosive nitroguanidine and belongs to the technical field of preparation processes of explosives and powder. According to the process disclosed by the invention, the nitroguanidine is dissolved in a nitric acid solution, the synthetic process is optimized by virtue of a micro-tube reactor, the requirement of the reaction system on the nitric acid concentration is reduced, and the product yield is improved. A continuous crystallizer and a filter are arranged behind the micro-tube reactor, the continuous crystallization and filtration process is established, the manual operation is reduced, and the production efficiency of the product is improved; and moreover, with the adoption of ultrasonic oscillating and washing, the washing frequency is reduced, and wastewater emission is reduced. The process disclosed by the invention has the advantages of simplicity, high continuity, high product yield, small wastewater emission amount and the like and is particularly suitable for continuous crystallization for preparing single-compound explosive nitroguanidine.

Owner:XIAN MODERN CHEM RES INST

Method for continuous crystallisation of vitamin C

ActiveCN101397286AAchieve continuous crystallizationRegular crystal formOrganic chemistryVitamin CCentrifugation

The invention discloses a vitamin-C continuous crystallization method, including the following steps: a vitamin-C aqueous solution after ion-exchange is pumped into a first-stage crystallizing device for crystallization by vacuum evaporation; then the vitamin-C evaporated concentrated solution generated in the first-stage crystallizing device is continuously guided into a second-stage crystallizing device for crystallization by vacuum cooling; after the liquid and solid are separated, the crystals are washed and processed by centrifugation and then are continuously discharged to obtain the crude vitamin-C crystals; the crude vitamin-C crystals are dissolved by purified water and then pumped into a third-stage crystallizing device through a filter pump so as to realize the continuous crystallization of refined vitamin-C; after the liquid and solid are separated, the crystals are washed and processed by centrifugation and then are continuously discharged to obtain the refined vitamin-C crystals. The method adopted by the invention can realize the continuous crystallization of vitamin-C and obtain the large, even and well-shaped grains, which not only can enhance the quality, but also can reduce the manufacturing cost.

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

Processes for the crystallization of 2,2,4,4-tetramethylcyclobutanediol

ActiveUS7989667B2High purityHigh yieldOrganic compound preparationOrganic chemistry methodsCrystallographySolvent

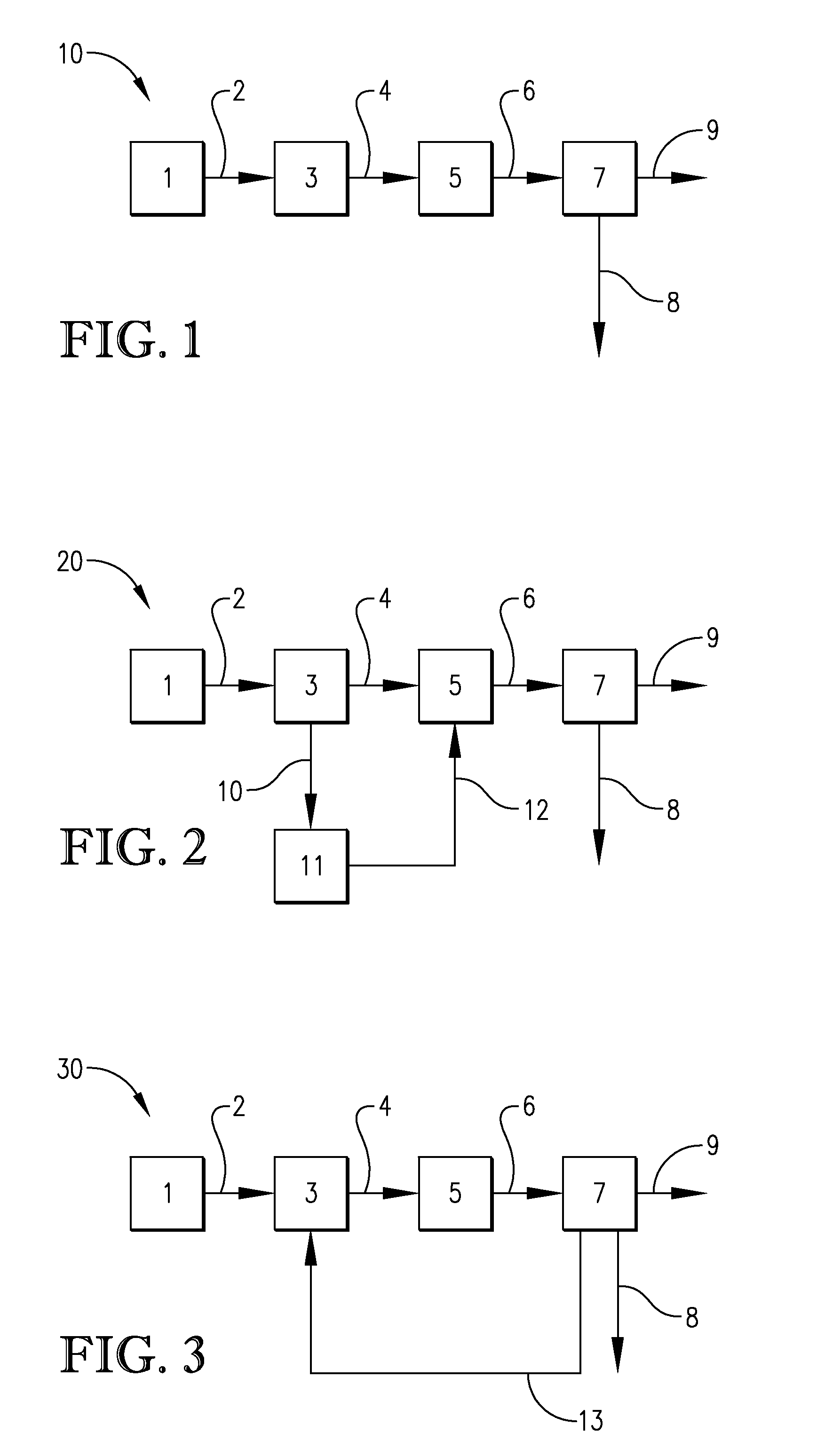

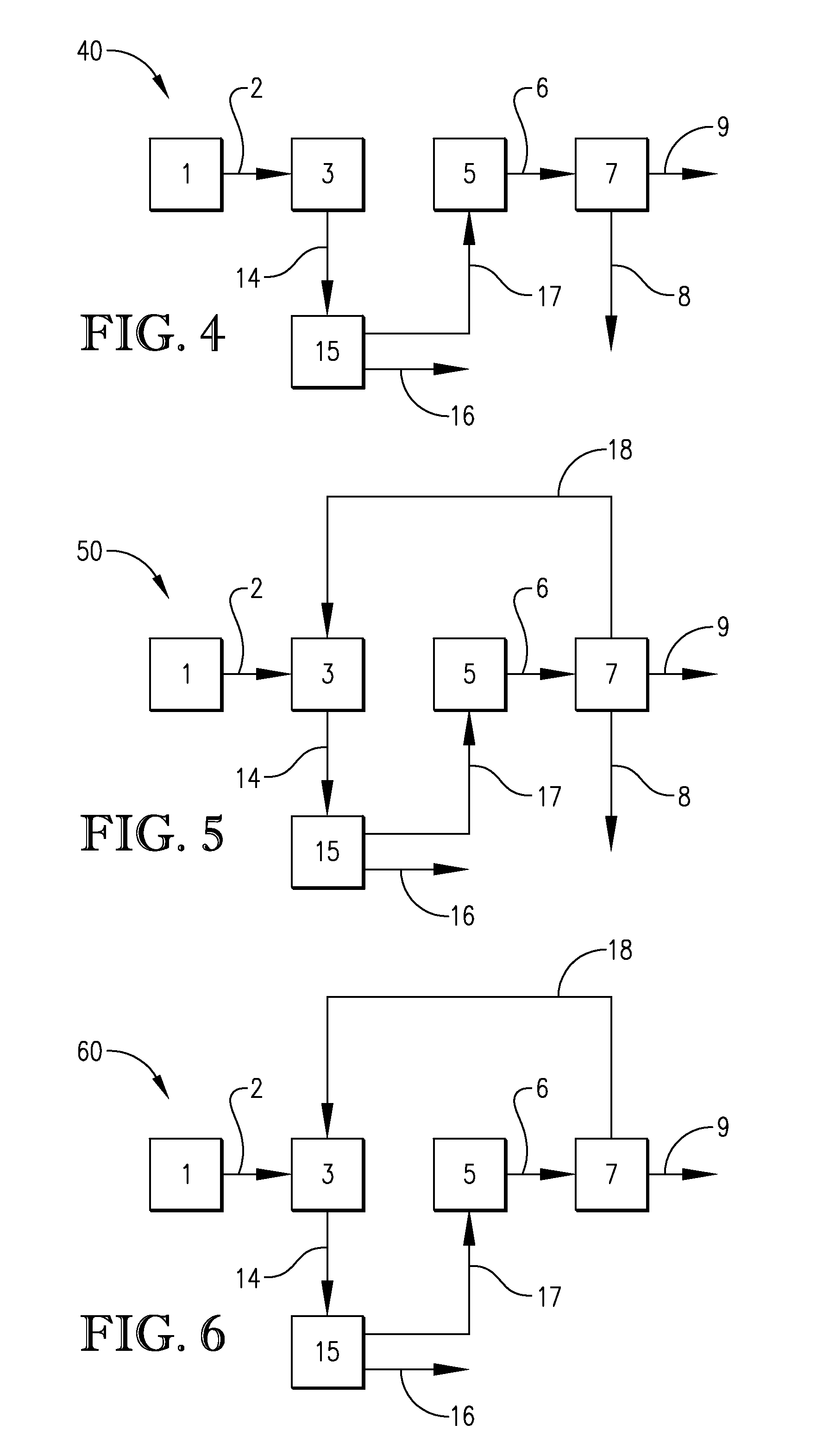

Disclosed is a novel process for the continuous crystallization of a mixture of cis-2,2,4,4-tetramethylcyclobutanediol and trans-2,2,4,4-tetramethylcyclobutanediol dissolved in a solvent.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com