Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Regular crystal form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

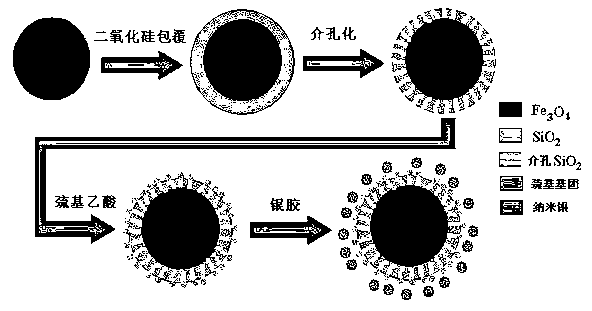

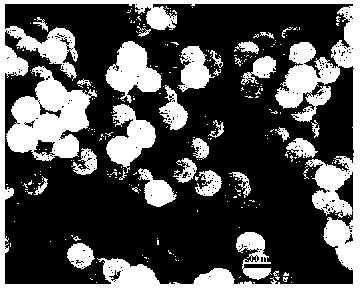

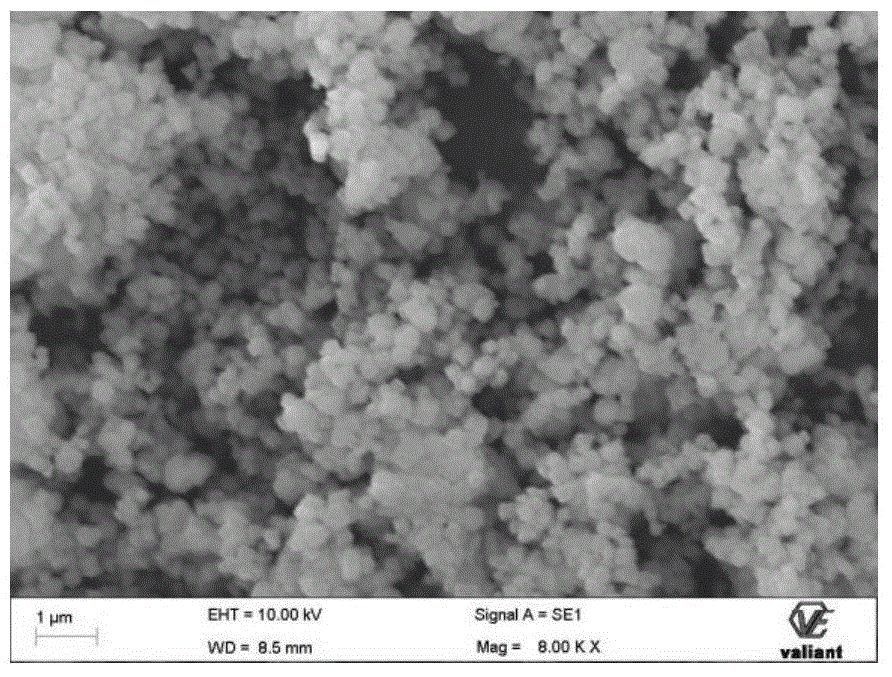

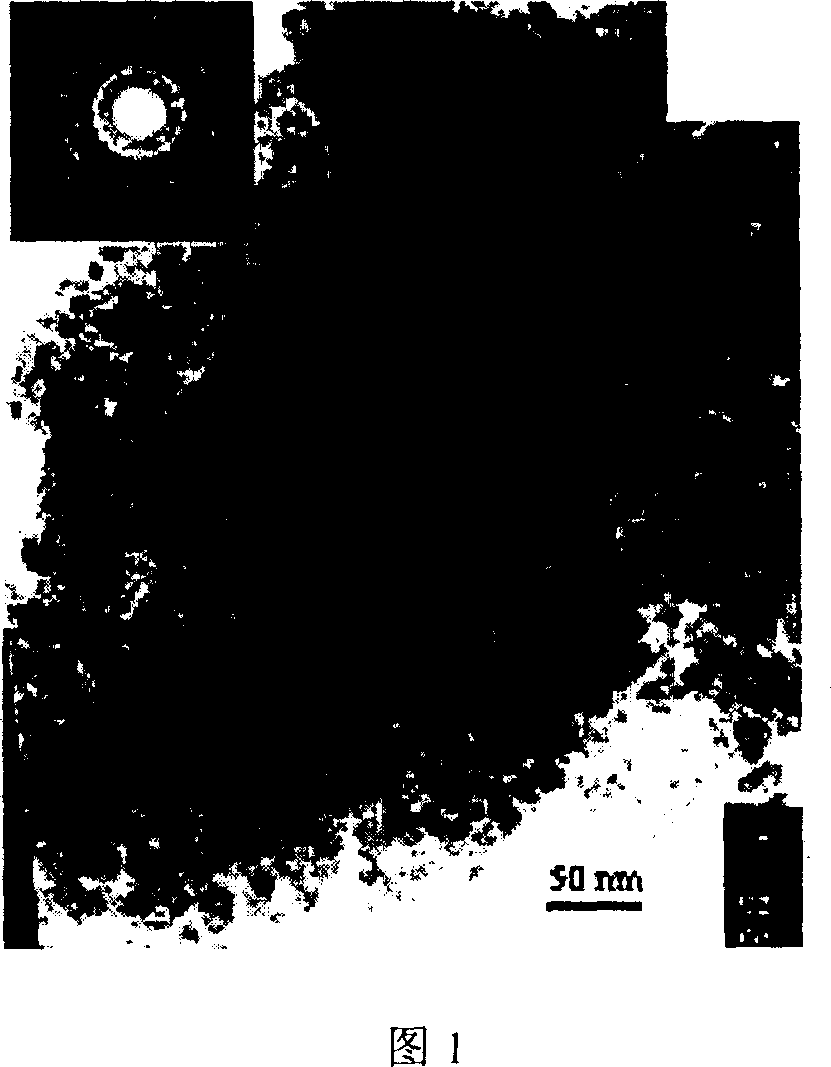

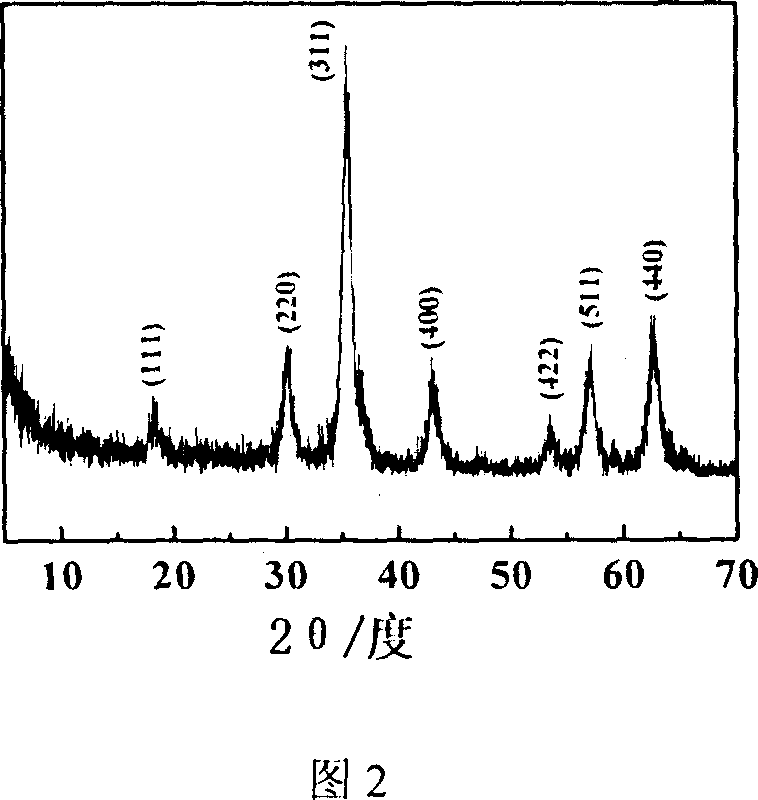

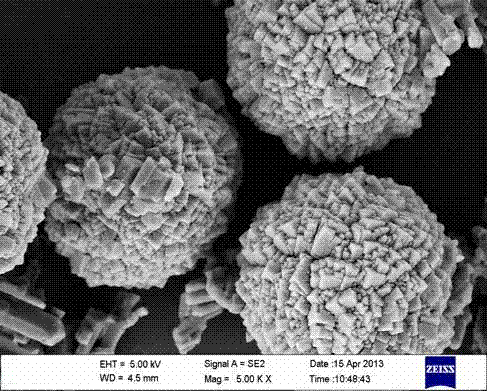

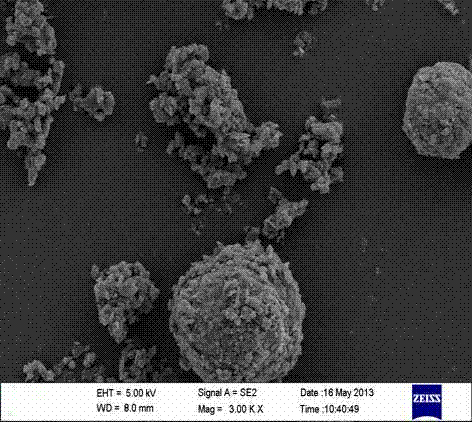

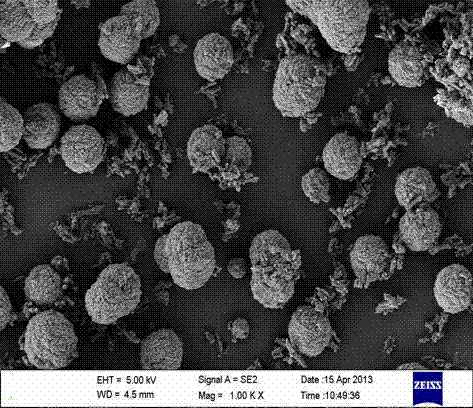

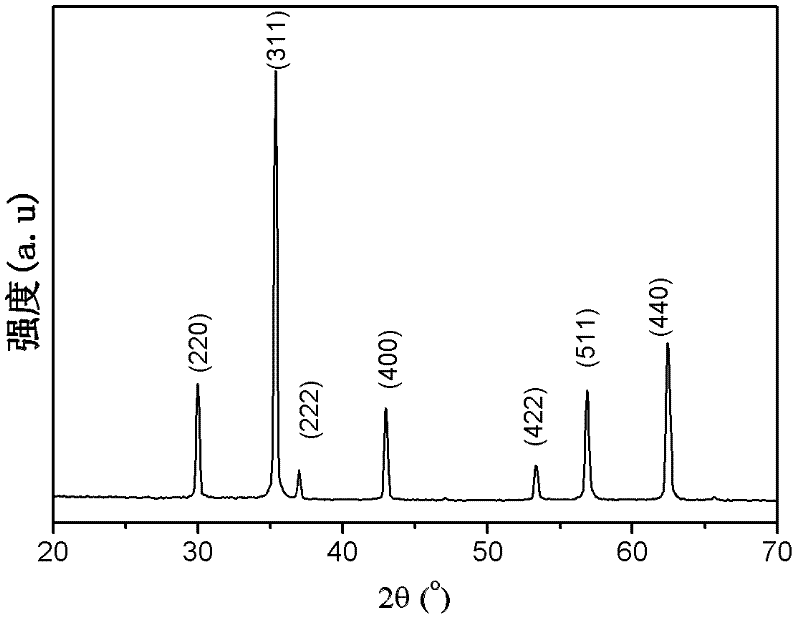

Preparation method of nanosilver and sulfydryl jointly modified magnetic microspheres

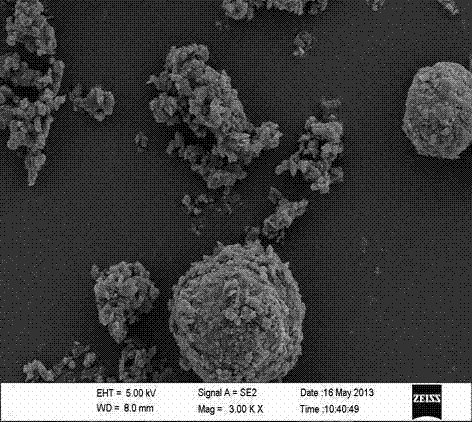

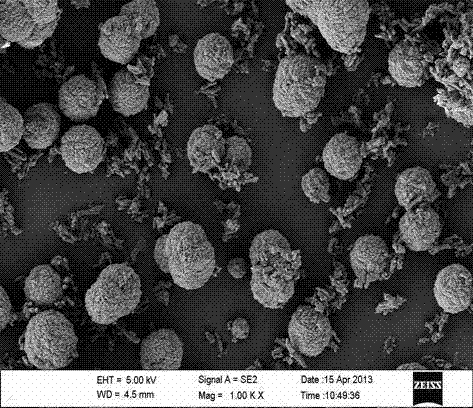

InactiveCN103223322AUniform particle size distributionReduce agglomeration effectMicroballoon preparationMicrocapsule preparationChemical reactionMagnetic bead

The invention belongs to the technical field of magnetic materials and in particular relates to a preparation method of nanosilver and sulfydryl jointly modified magnetic microspheres. The preparation method comprises the following steps of: 1) preparing Fe3O4 magnetic microspheres; 2) preparing SiO2 wrapped Fe3O4 magnetic microspheres; (3) preparing sulfydryl modified SiO2 wrapped Fe3O4 magnetic microspheres; and 4) preparing nanosilver and sulfydryl jointly modified SiO2 wrapped Fe3O4 magnetic microspheres. According to the method, nano Fe3O4 is wrapped by a silane coupling agent and the stability and the acid-base resistance are improved due to the safety and the stability of silica; and a functional sulfydryl group is introduced into the surface through chemical reaction, so that novel modified magnetic nanoparticles are obtained. Due to investment and development of biological technology industry, life science and diagnostic reagent industry, the development of biological magnetic bead products with the technological advantage and the cost performance advantage is greatly promoted.

Owner:LUOYANG NORMAL UNIV

Normal-temperature dechlorinating agent

ActiveCN103127903ARegular crystal formImprove dechlorination effectOther chemical processesDispersed particle separationCopper oxideImpurity

The invention discloses a normal-temperature dechlorinating agent. The normal-temperature dechlorinating agent is mainly prepared from 20-30 parts of ferrous sulfate, 20-40 parts of CaO and 10-25 parts of attapulgite clay in parts by weight and further comprises 15-25 parts of waste catalyst, wherein active components of the waste catalyst include copper oxide and zinc oxide. According to the normal-temperature dechlorinating agent, the ferrous sulfate has weak acidity and can react with calcium carbonate impurity in calcium oxide to enable the crystal form of the calcium oxide to be more regular, and meanwhile, ferrous ions are continuously oxidized into iron oxide to enable the crystal forms of the calcium oxide and the iron oxide to be mutually doped, so that the dechlorinating effect of the dechlorinating agent is improved; and according to a preparation method of dechlorinating agent disclosed by the invention, a roasting process is not needed, the energy consumption is reduced, devices used in the preparation process are decreased, the preparation step is simplified, and the preparation cost is lowered.

Owner:SHENYANG SANJUKAITE CATALYST

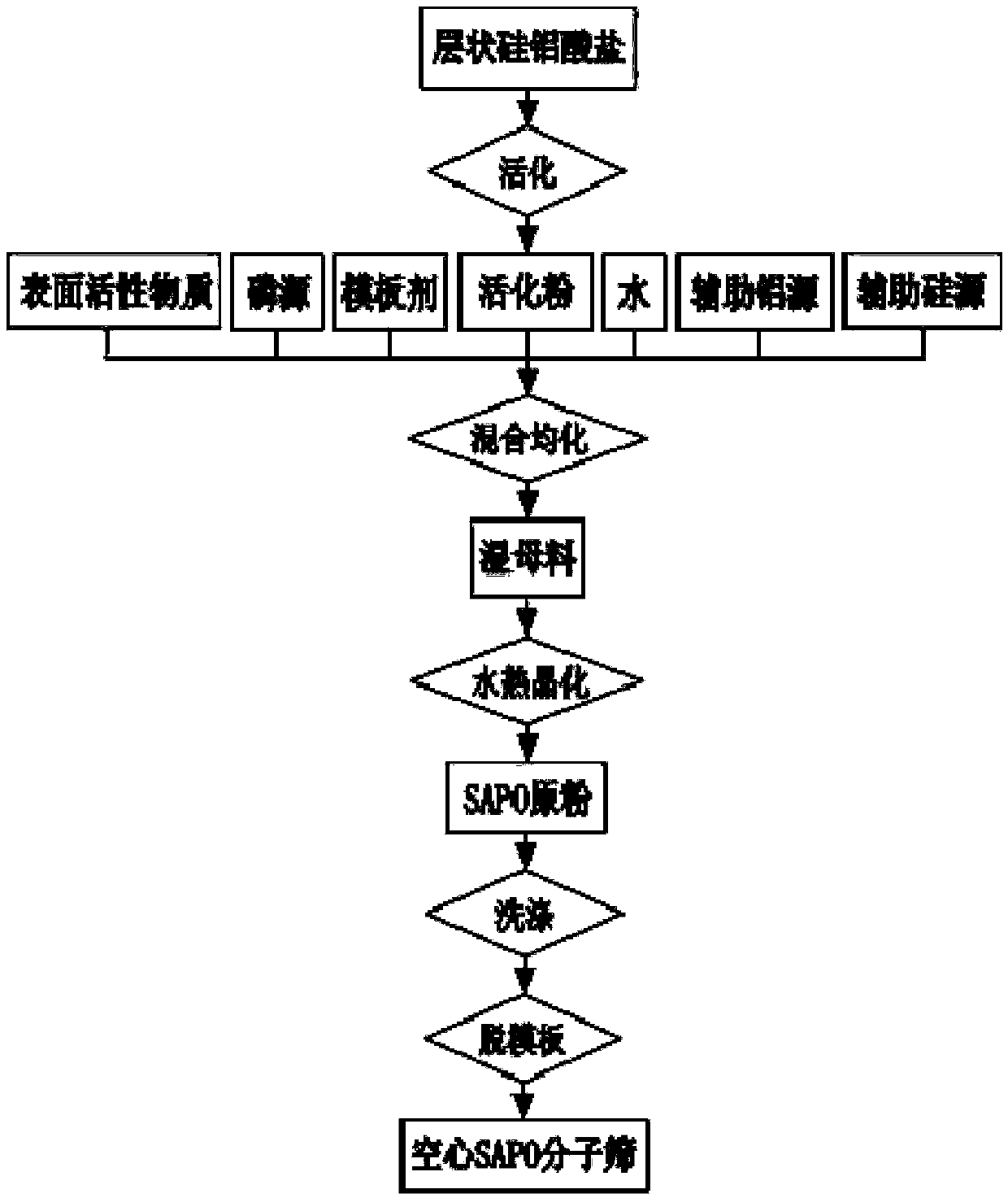

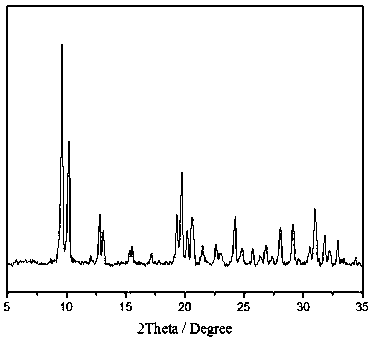

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964456ASuitable for acidityExtend your lifeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSingle crystal

The invention discloses an SAPO molecular sieve, which has hollow single crystals. The SAPO molecular sieve has optional pore structure, adjustable silicon content and distribution, controllable strength and density of acid site, and long service life of catalyst. The invention also discloses a preparation method of the SAPO molecular sieve. The method uses layered silicate as a raw material, which is subjected to activation, and mixed and homogenized with a phosphorus source, an auxiliary aluminum source and water to obtain a wet masterbatch; and the wet masterbatch is subjected to hydrothermal crystallization to obtain a raw powder of the hollow SAPO molecular sieve, wherein the molar ratio of Al and Si in the wet masterbatch is higher than 1. The method use easily available raw materials, has low cost and can be prepare the SAPO molecular sieve with hollow structure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

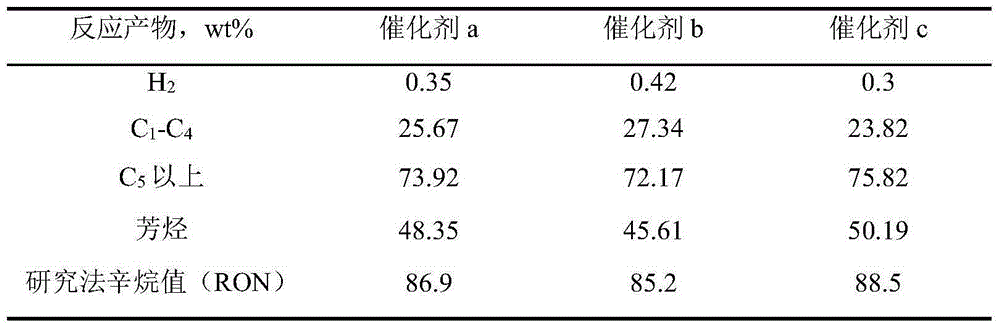

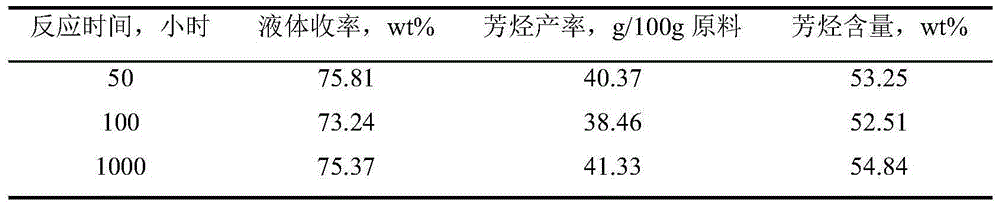

Catalyst for straight-run naphtha aromatization and preparation method thereof

InactiveCN106552663ARegular skeleton structureFast responseMolecular sieve catalystsHigher alkanesNaphtha

The invention discloses a catalyst for straight-run naphtha aromatization and a preparation method thereof. The catalyst for straight-run naphtha aromatization is prepared by modifying a nano ZSM-5 molecular sieve, preparing a carrier and preparing the catalyst. The catalyst is suitable for treating raw materials with high alkane content. And the catalyst has high catalytic activity and high arene selectivity. So the catalyst can be applied to more mild process conditions and can be applied to production of high-octane gasoline blending components and chemical raw materials like benzene, toluene, xylene, etc.

Owner:PETROCHINA CO LTD

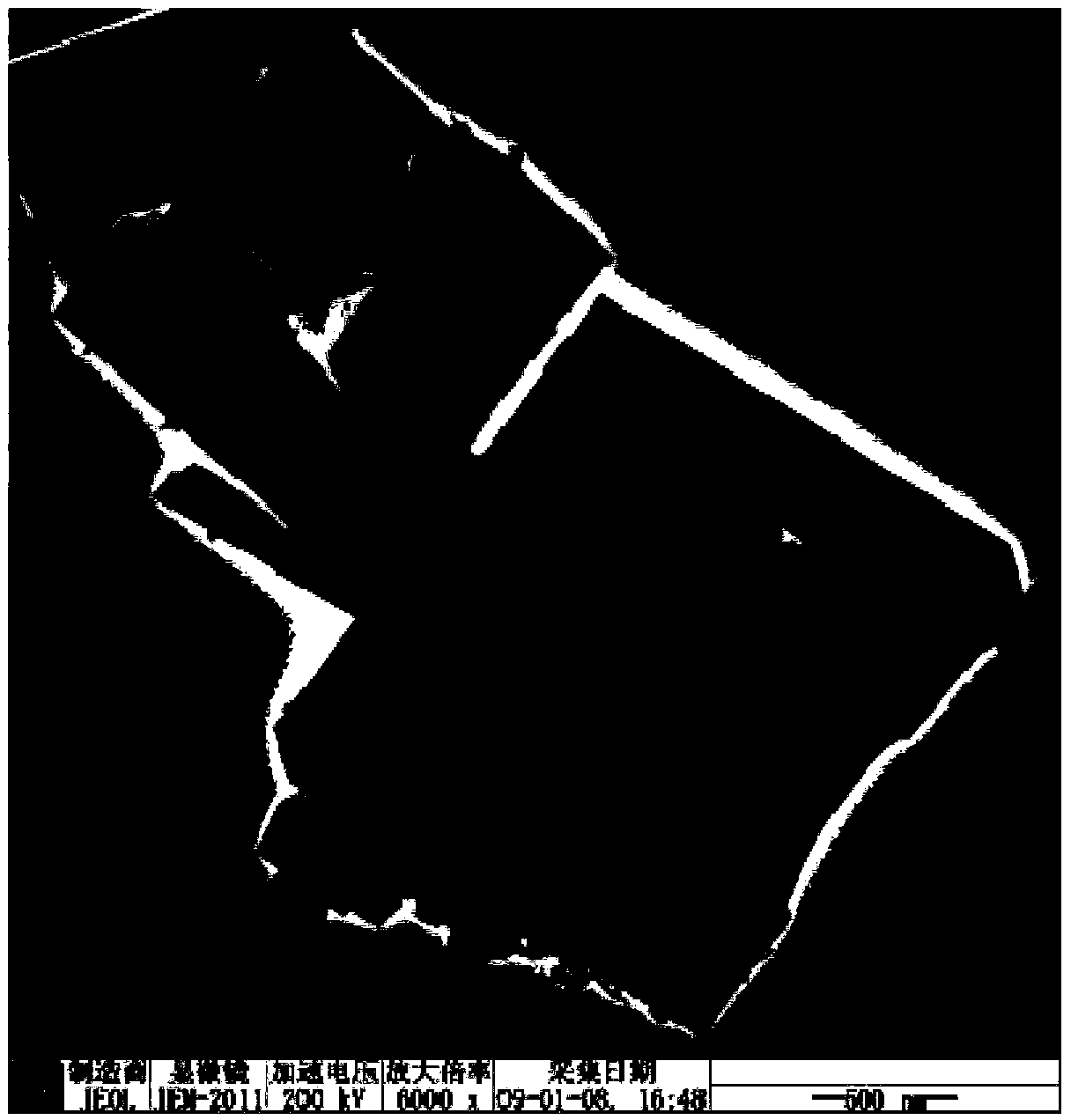

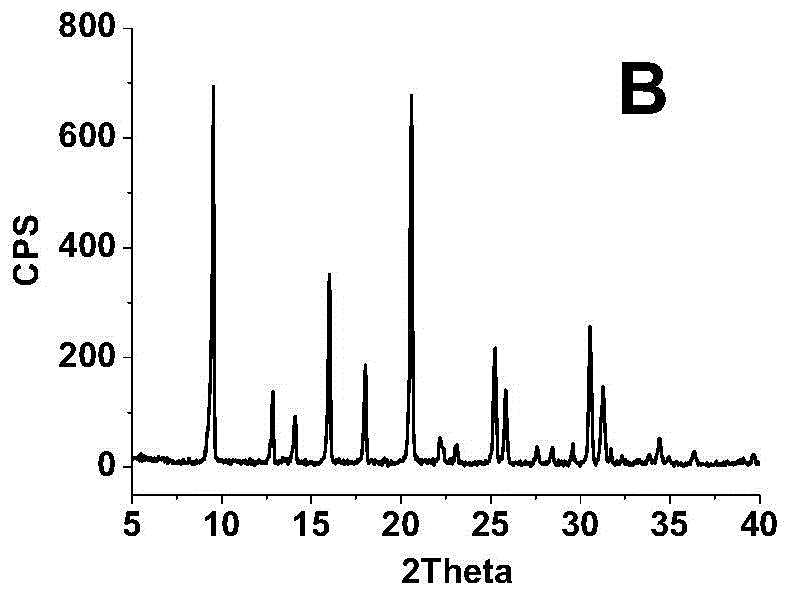

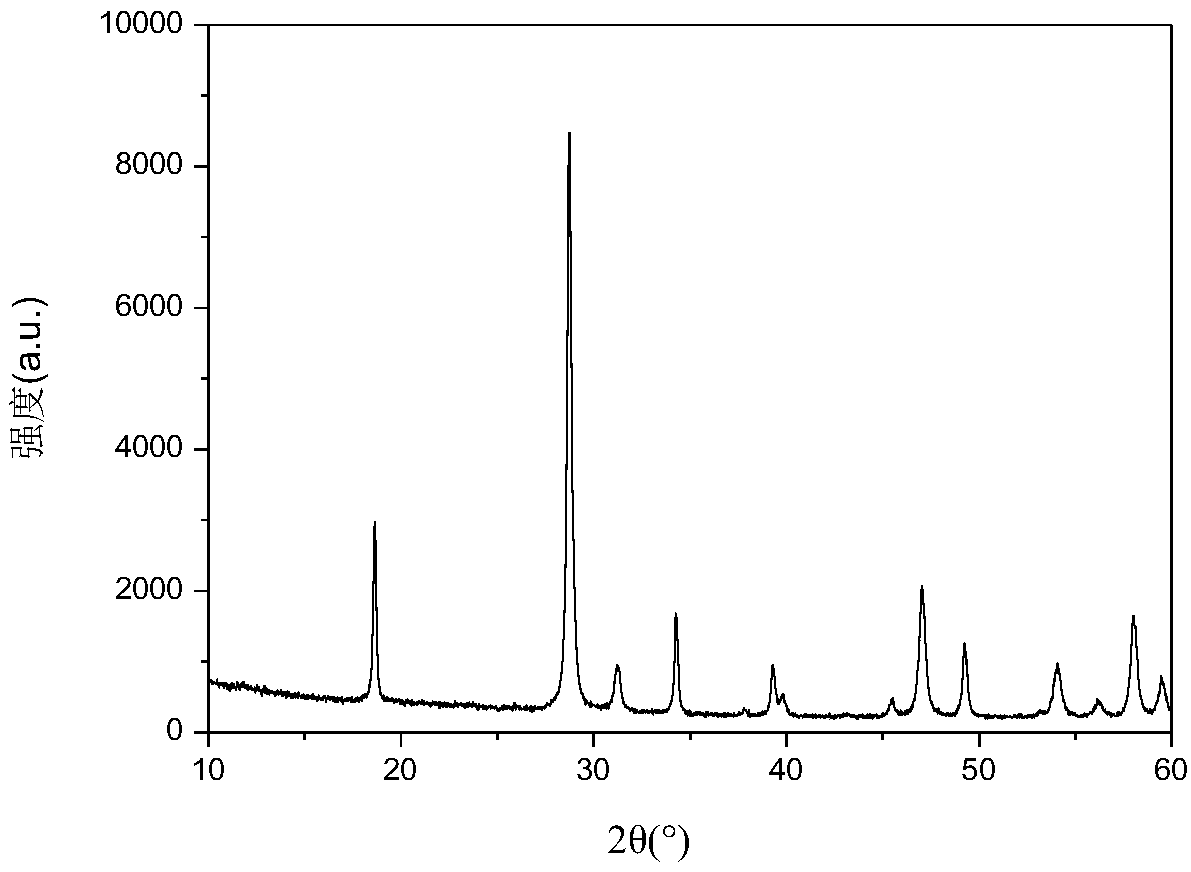

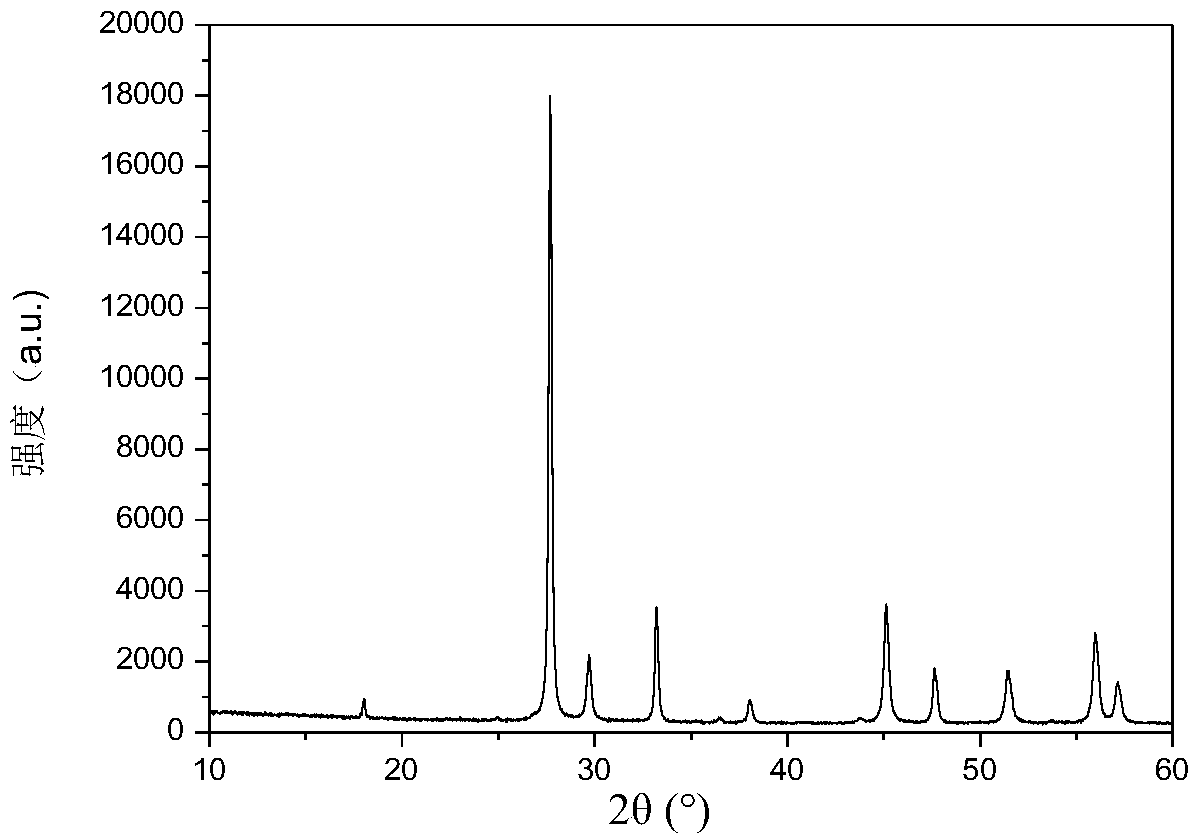

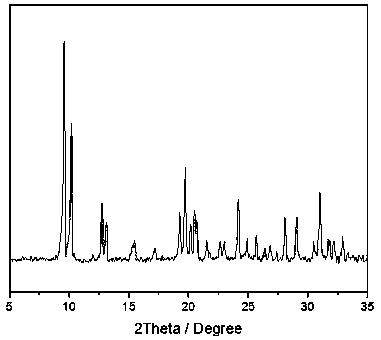

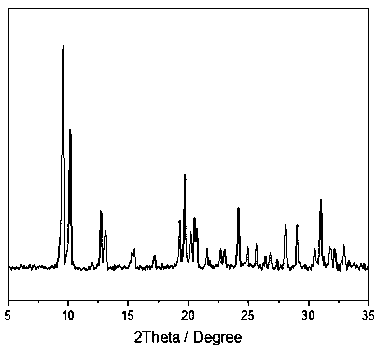

Preparation method of small-grain SAPO-34 molecular sieve

InactiveCN104556093AHigh crystallinityRegular crystal formMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesIonMolecular sieve

The invention relates to a preparation method of a small-grain SAPO-34 molecular sieve. The preparation method comprises the following steps: mixing an aluminum source and a phosphorus source with deionized water, stirring for 1-5 h, then adding a silicon source, an organic amine template agent R, an auxiliary template agent R' and an organic solvent A, continuously stirring for 1-5 h to obtain a gel, transferring the gel into a crystallization kettle, crystallizing for 12-108 h at the temperature of 160-220 DEG C to obtain a mixed liquor, filtering the mixed liquor to obtain a filter cake, washing the filter cake with deionized water, drying, and roasting to obtain an SAPO-34 molecular sieve. On the basis of using a conventional organic amine template agent, a small amount of auxiliary template agent R' and organic solvent A are added, and the cube-shaped SAPO-34 molecular sieve which is high in degree of crystallinity, regular in crystal form and 0.2 microns in grain size is successfully prepared through a hydrothermal crystallization method; moreover, the method is simple in procedures and easy to operate, the SAPO-34 molecular sieve has a great industrialization development prospect, and is expected to be used as a catalyst for preparing low-carbon olefinethrough methanol conversio and a catalyst for treating automobile exhaust.

Owner:VALIANT CO LTD

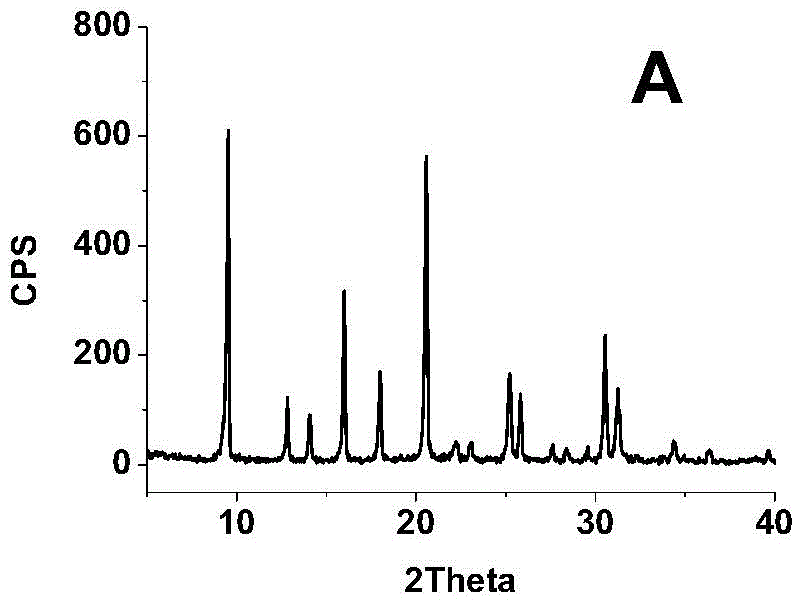

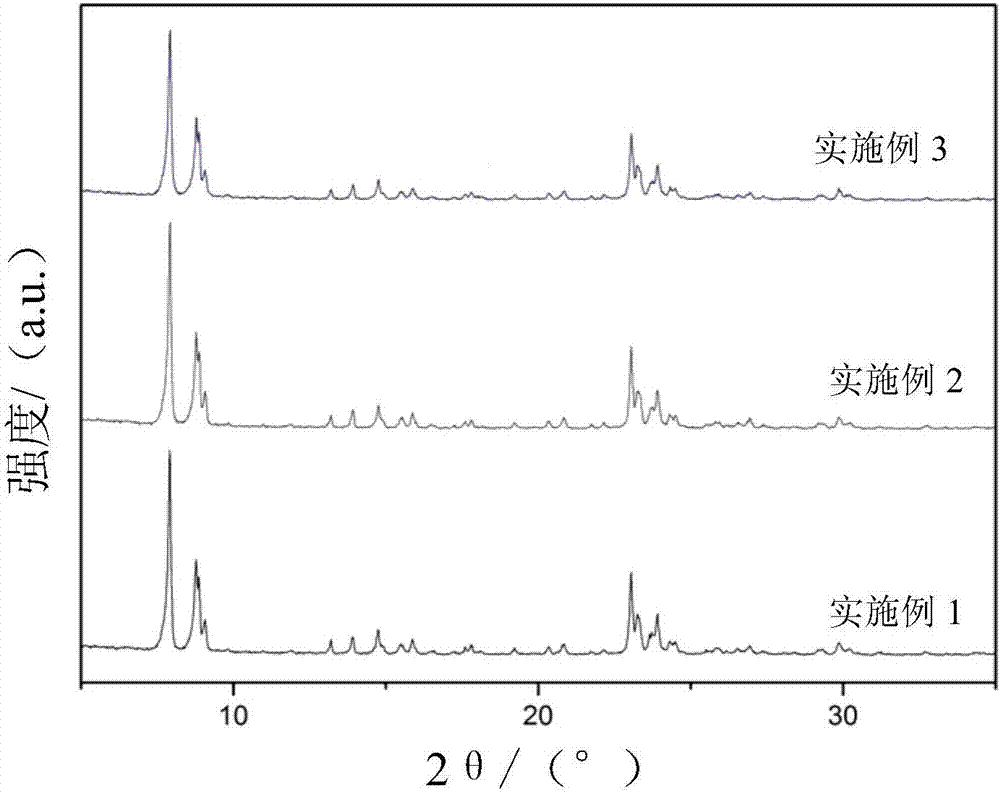

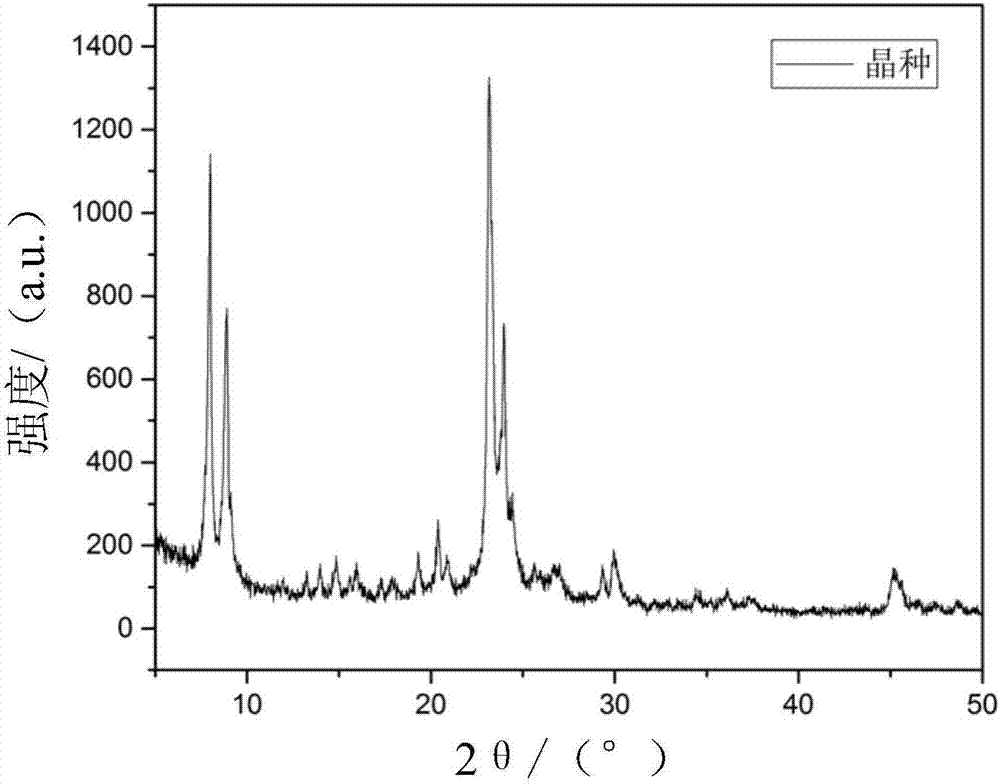

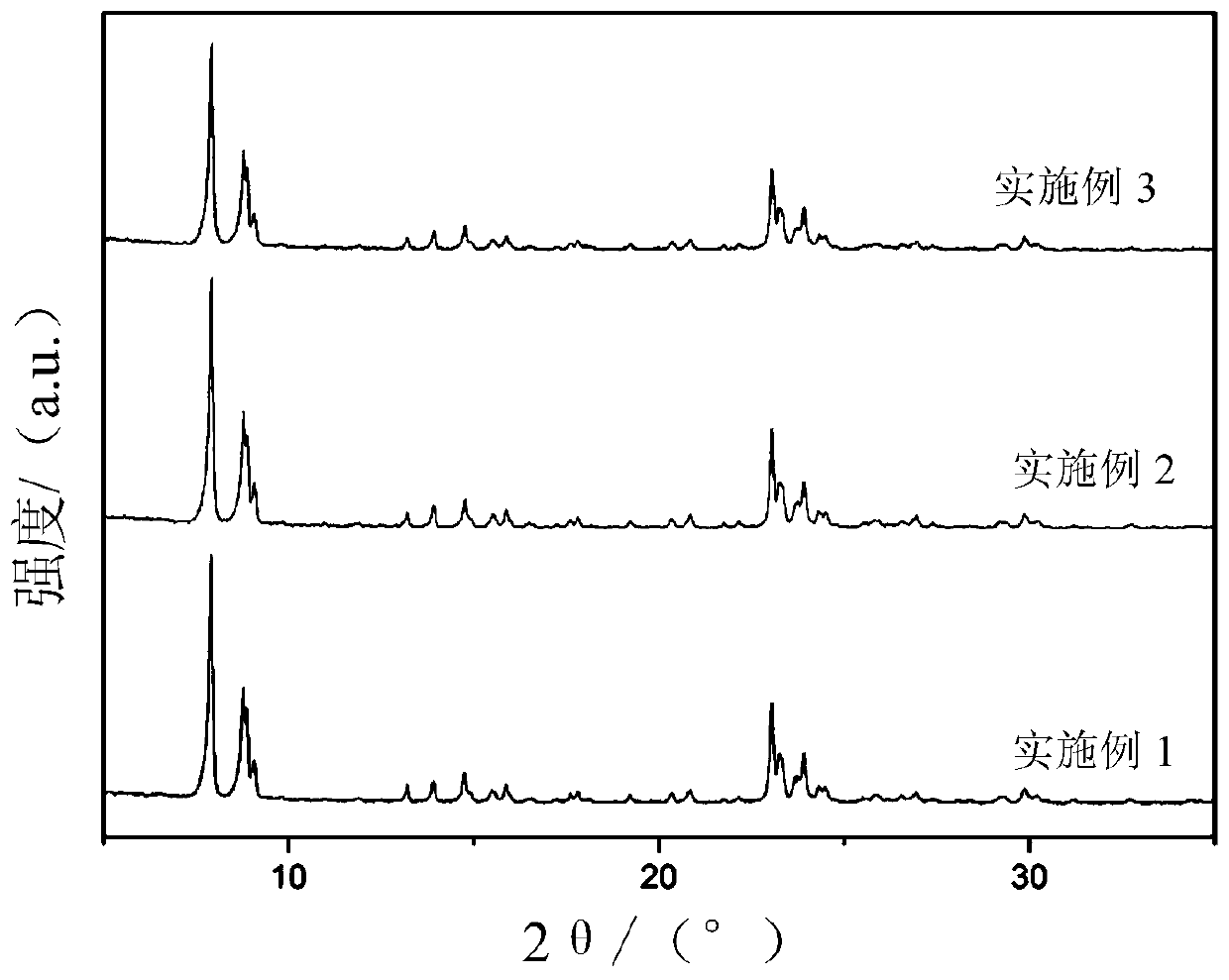

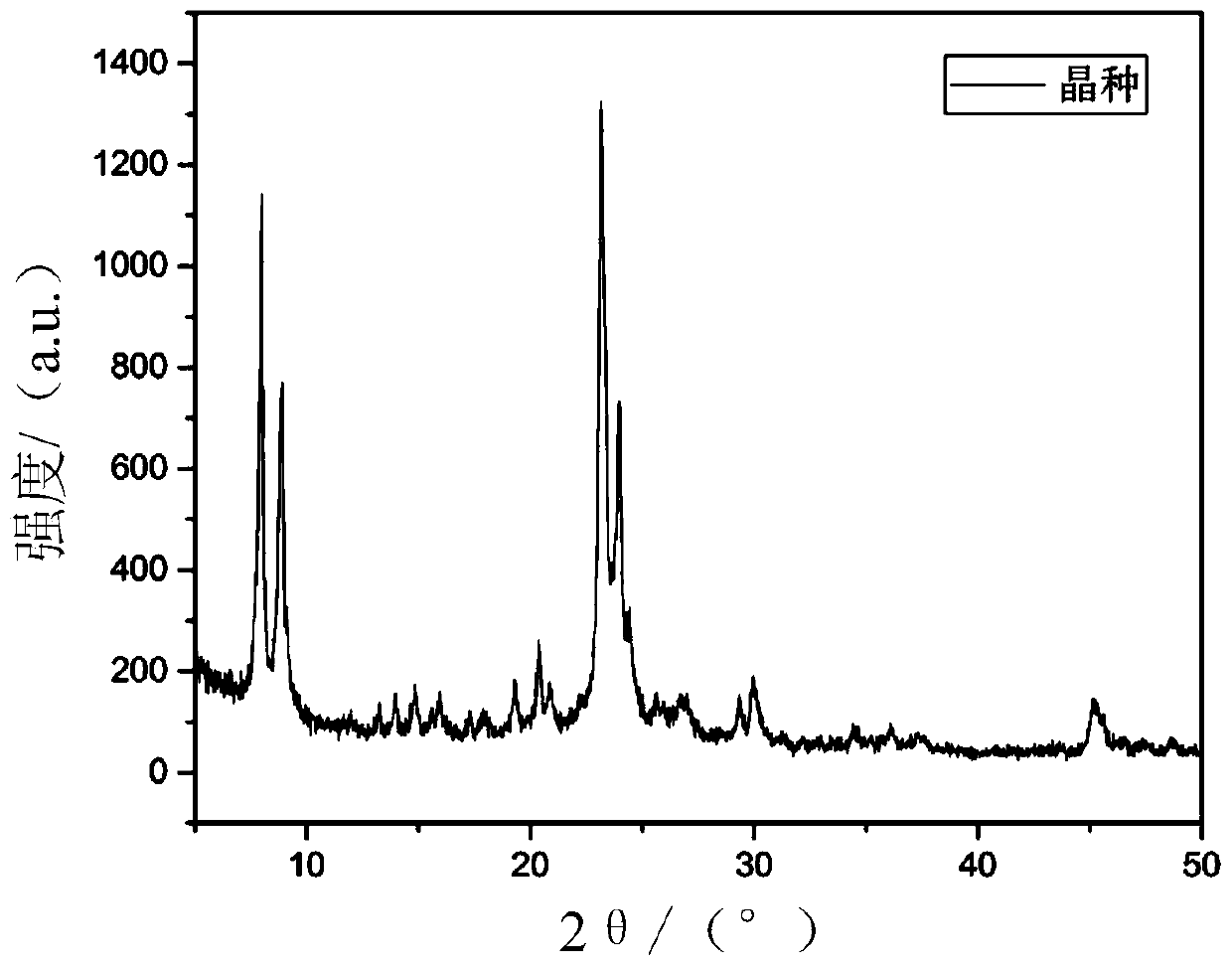

A ZSM-5 molecular sieve, a preparing method thereof and applications of the molecular sieve

ActiveCN106865566AWide range of regulationRegular crystal formPentasil aluminosilicate zeoliteThin layerHigh silica

A ZSM-5 molecular sieve, a preparing method thereof and applications of the molecular sieve are provided. The ZSM-5 molecular sieve is prepared through an amine-free system. A silica-alumina ratio of the ZSM-5 molecular sieve is 40-200. The ZSM-5 molecular sieve is prepared by adopting a nanometer thin-layer ZSM-5 molecular sieve having a high silica-alumina ratio as a crystal seed with the mole ratio of raw materials meeting a condition that the mole ratio of SiO2 to Al2O3 is 100:(0.04-2). Compared with molecular sieves synthesized under traditional template-free conditions, the ZSM-5 molecular sieve synthesized by the method is a molecular sieve having a high silica-alumina ratio (higher than 40). The silica-alumina ratio of the prepared flake ZSM-5 molecular sieve is adjustable in a large range (40-200).

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

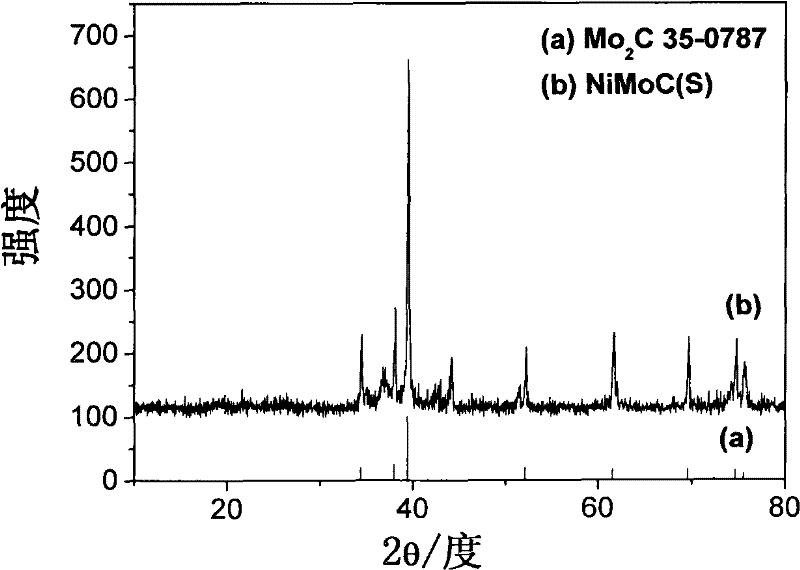

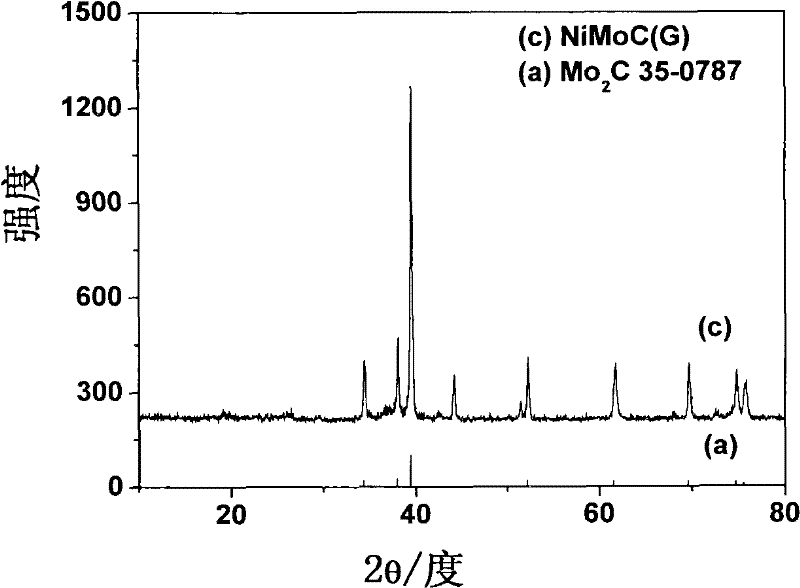

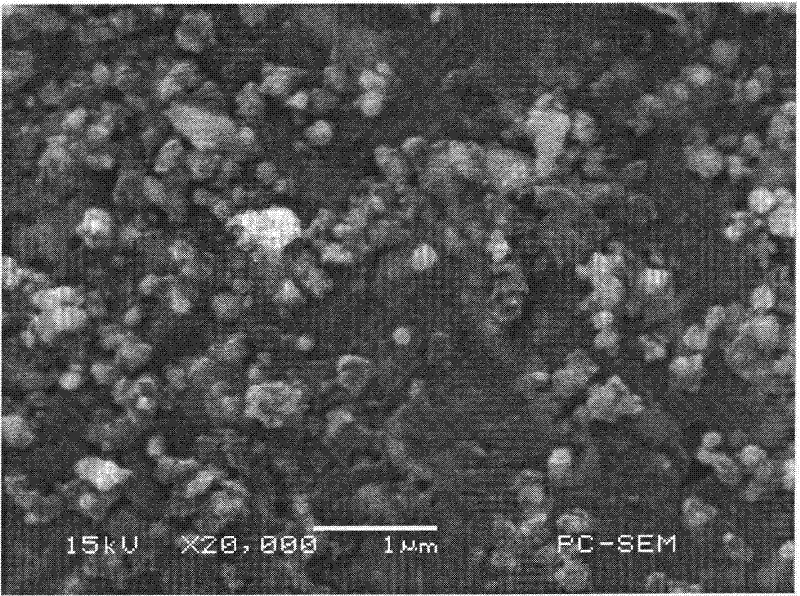

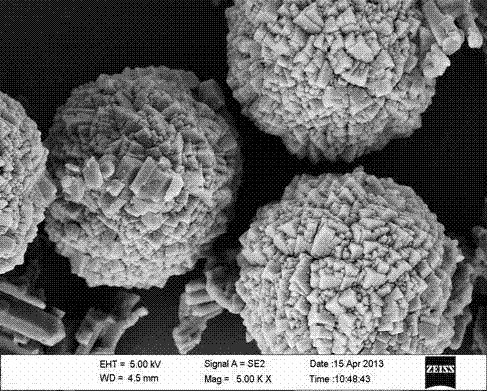

Application of nickel-molybdenum carbide in production of anode of microbial fuel cell

InactiveCN101752569ASimple preparation processReduce production processFinal product manufactureCell electrodesMicrobial fuel cellFuel cells

The invention discloses application of nickel-molybdenum carbide in the production of the anode of a microbial fuel cell. Compared with molybdenum carbide, due to the doped nickel, the crystal formation of the nickel-molybdenum carbide is more complete, the degree of crystallinity is improved, and the specific surface area is enlarged. When used as an anode catalyst, the nickel-molybdenum carbide can easily catalyze the oxidation of products produced in microbial fermentation, and can greatly improve the electric energy output of a microbial fuel cell. Compared with the conventional Pt catalyst, the nickel-molybdenum carbide has the advantages of low price and wide scope of sources. The microbial fuel cell assembled with the nickel-molybdenum carbide as the anode catalyst can operate stably for a long term, and has high power output.

Owner:SOUTH CHINA NORMAL UNIVERSITY

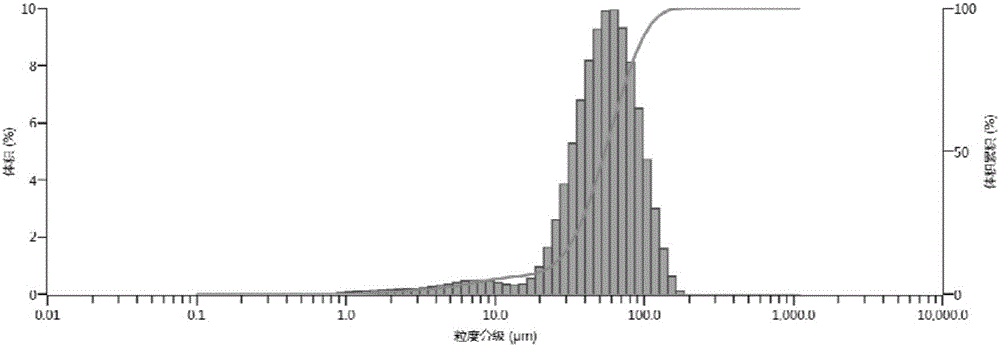

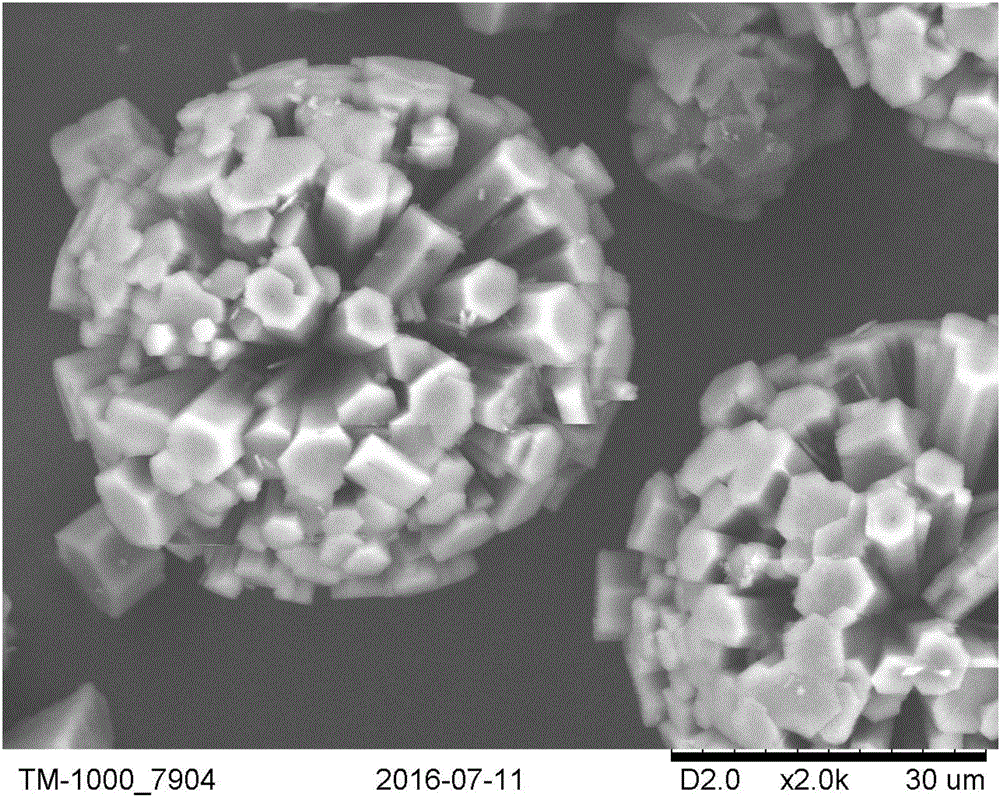

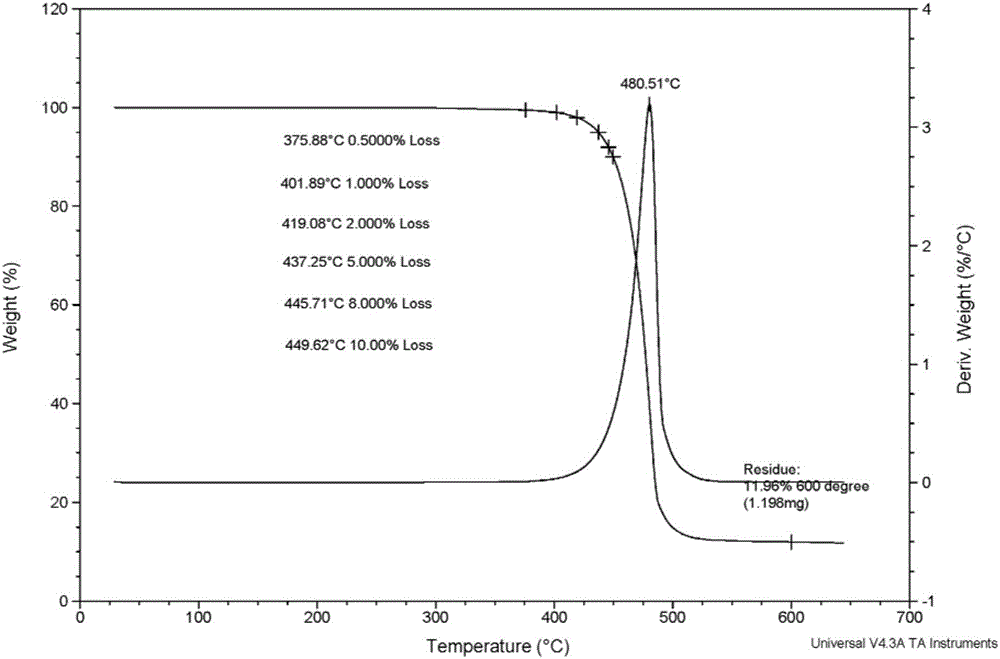

Preparation method of spherical aluminum hypophosphite

ActiveCN103613084ALarge particle sizeSmall particle sizePhosphorus compoundsAluminium sulfatePhosphoric acid

The invention discloses a preparation method of spherical aluminum hypophosphite. In the method disclosed by the invention, sodium hypophosphite reacts with aluminum sulfate; meanwhile, melamine cyanurate is added as a seed crystal in the earlier stage of reaction, and different dispersants are added to improve the dispersion effect. The spherical aluminum hypophosphite prepared by the method disclosed by the invention has the characteristics of small particle size, regular crystal form and the like, thus the drop of mechanical properties of plastics after the addition of a flame retardant is reduced. Meanwhile, by adopting the melamine cyanurate seed crystal as a synergist in the flame retardant, the flame retardance effect of aluminum hypophosphite after plastic addition is remarkably improved.

Owner:JINAN TAIXING FINE CHEM

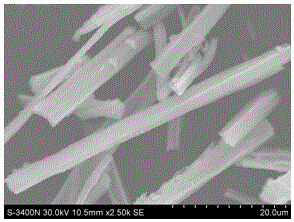

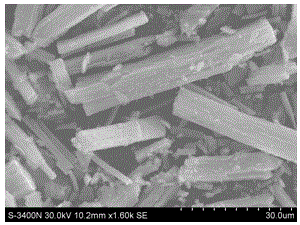

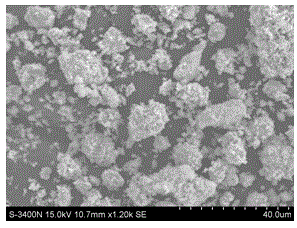

Method for preparing gypsum whisker by using phosphate tailings and raffinate phosphoric acid

InactiveCN104328481ASolve environmental problemsRegular crystal formPolycrystalline material growthFrom normal temperature solutionsChemical industryO-Phosphoric Acid

The invention discloses a method for preparing gypsum whisker by using phosphate tailings and raffinate phosphoric acid. A technical scheme adopted in the invention is characterized in that the method comprises the following steps: taking a certain amount tailing powder with a certain particle size, adding a certain amount of distilled water to prepare a tailing slurry with a certain solid content, gradually adding raffinate phosphoric acid, reacting under certain conditions, filtering after the reaction, gradually adding a certain concentration of sulfuric acid into the obtained filtrate, reacting for a certain time, filtering, washing the obtained filter cake, and drying the washed filter cake in a drying box to obtain the gypsum whisker. The gypsum whisker is prepared through a two-step technology by using the raffinate phosphoric acid, the phosphate tailings and other phosphorus chemical industry enterprise waste resources as raw materials, and the growth form of the crystals of the gypsum whisker is controlled in the formation process of the phosphate crystals, so compared with traditional gypsum whisker preparation technologies, the method has the advantages of production cost reduction, solving of the environmental protection problem of the phosphorous chemical enterprises to a certain extent, and full use of magnesium resources in the raffinate phosphoric acid and the tailings.

Owner:WENGFU (GRP) CO LTD

Preparation method for metal molybdate micro-nano structure powder

The invention discloses a preparation method for metal molybdate micro-nano structure powder. The method comprises the following steps that firstly, an amide compound and water are mixed so as to obtain a mixed solvent, and then soluble divalent metal salt is dissolved in the mixed solvent; then sodium molybdate or ammonium heptamolybdate is added under the stirring condition so as to obtain a reaction precursor, and finally the reaction precursor is transferred into a reaction kettle for hydrothermal reaction so as to obtain a precipitate; and the precipitate is washed and dried so as to obtain the metal molybdate micro-nano structure powder with a specific morphology structure, good crystallinity and high purity. The preparation method for the molybdate micro-nano structure powder has the advantages that the raw materials are cheap and easy to obtain, the preparation temperature is low (180 DEG C or below), synthesis equipment is simple, in addition, a surfactant is not required to control the morphology and the structure for a template agent or a microemulsion environment, a preparation process is simple, the cost is low, and large-scale production is easy to realize.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Preparation method and application of large-particle-size spherical dialkylphosphinate

ActiveCN106632464ALarge particle sizeShape ruleGroup 5/15 element organic compoundsLarge particleSeed crystal

The invention discloses a preparation method and application of large-particle-size spherical dialkylphosphinate. Preparation methods and application of present dialkylphosphinate have many defects. The preparation method of the invention comprises the steps of 1) preparing dialkylphosphinic acid or / and dialkylphosphinate into a solution; 2) adding a compound, dissolved in an alcohol or / or aqueous solution and containing nitrogen or both nitrogen and phosphorus, as precipitation seed crystal into the solution of dialkylphosphinic acid or / and dialkylphosphinate, and adding suitable surfactant to provide improved dispersion to obtain mixed solution; 3) dropwise adding soluble metal salt solution into the above mixed solution, cooling after reacting, filtering, washing, and drying to obtain the large-particle-size spherical dialkylphosphinate. The large-particle-size spherical dialkylphosphinate of the invention can be added to a polymer material as a halogen-free flame retardant in order to improve polymer mobility, and the mixing effect is significant.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM +1

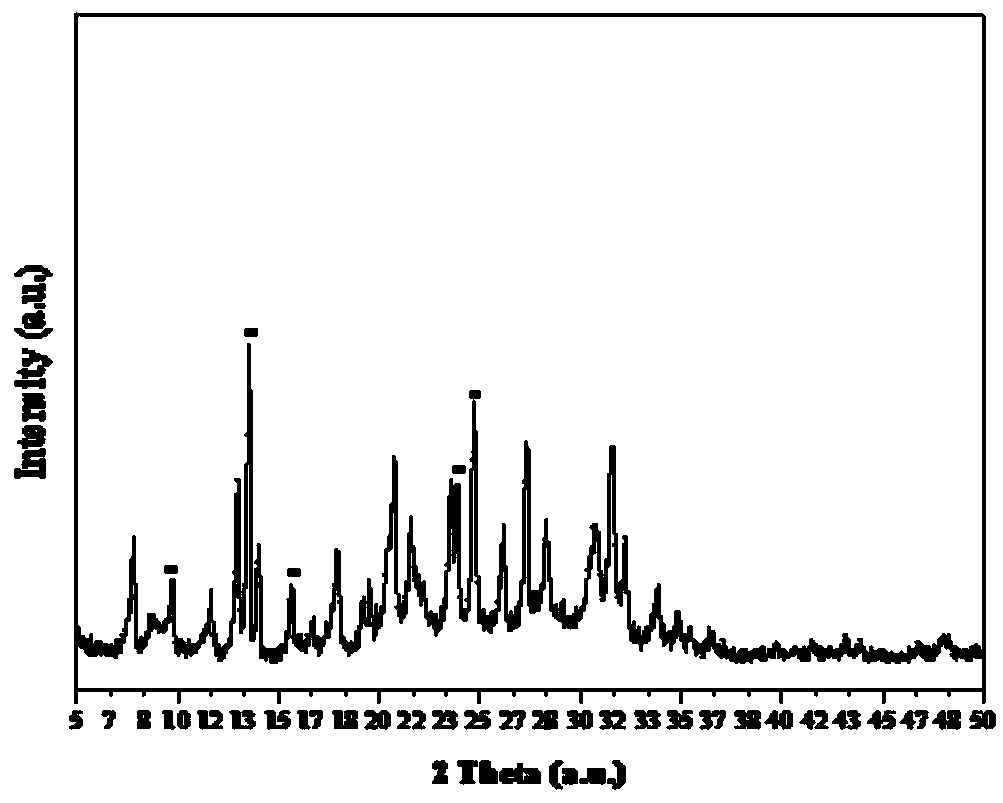

Method for synthesizing small-crystal-grain aluminum phosphate molecular sieves AlPO4-34

ActiveCN106672990ASmall sizeUniform particle size distributionMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesAluminium isopropoxideCrystallinity

The invention relates to a method for synthesizing small-crystal-grain aluminum phosphate molecular sieves AlPO4-34. According to the method, pseudo-boehmite or aluminum isopropoxide is used as an aluminum source, phosphoric acid serves as a phosphorus source, tetraethylammonium hydroxide and morpholine serve as template agents, and hydrofluoric acid serves as a fluorine source. The small-crystal-grain aluminum phosphate molecular sieves AlPO4-34, which are high in crystallinity and regular in crystal form, are synthesized by a pre-crystallization and seed crystal adding method on the basis of using the conventional raw materials and the mixed template agent. The grain size is small, and the average grain size is smaller than 1.5 microns and is only 0.05 to 1 micron after conditions are optimized. According to the method, the crystallinity is high, the morphology is regular, and the grain size distribution is uniform.

Owner:NANKAI UNIV

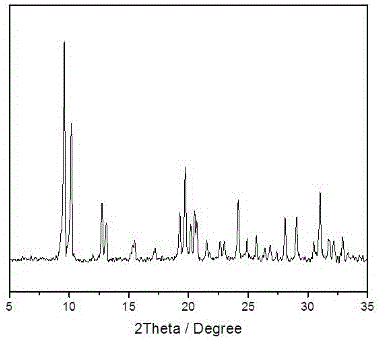

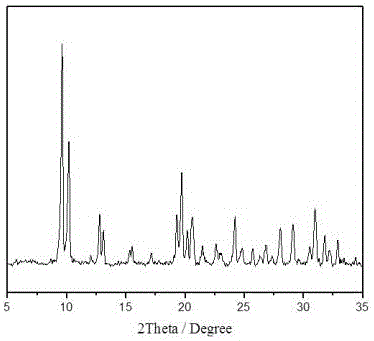

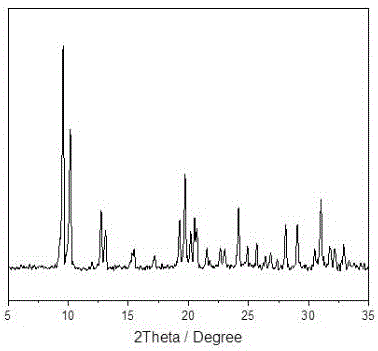

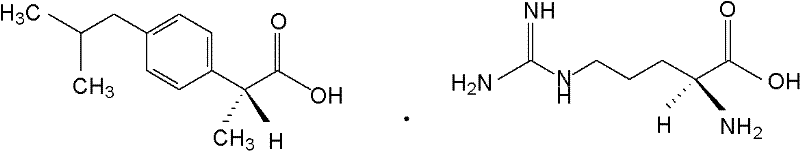

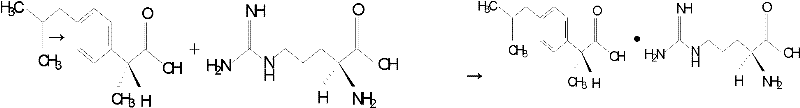

Preparation method of arginine dexibuprofen

ActiveCN102344360AHigh yieldHigh purityOrganic compound preparationMetabolism disorderArginineFiltration

The invention discloses a preparation method of an arginine dexibuprofen raw medicine. The method comprises the steps of: dissolving dexibuprofen in ethanol, heating the mixture to a temperature of 50DEG C-60DEG C, adding L-arginine in a dropwise manner slowly and continuously under stirring within 10min-20min, continuing stirring for reaction for 2h-3.5h with the temperature maintained at 50DEG C-60DEG C, leaving the mixture to stand for 25min-35min and cool to a temperature of 18DEG C-30DEG C, conducting pumping filtration so as to obtain crystals, then washing and drying the crystals, thus obtaining white crystals, i.e. arginine dexibuprofen. The preparation method of the invention has simple process, high yield, no refining step, shortened production period, and no need for any special equipment, thus being suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Preparation method for rod-like CuO-ZnO composite oxide catalyst

InactiveCN104607193AAdjustable copper-zinc molar ratioUniform sizeOrganic compound preparationHydroxy compound preparationPtru catalystPolyethylene glycol

The invention discloses a preparation method for a rod-like CuO-ZnO composite oxide catalyst. The method comprises the following steps: adding a glycine aqueous solution and a polyethylene glycol aqueous solution into a mixed aqueous solution of copper acetate and zinc acetate, wherein the additive amount of the glycine aqueous solution is ensured that the ratio of molar weight of glycine to total molar weight of copper acetate and zinc acetate is 1 to 1, and the additive amount of the polyethylene glycol aqueous solution is ensured that the ratio of mass of polyethylene glycol to total mass of copper acetate and zinc acetate is 1 to 1; putting an obtained mixed solution into a thermostat water bath at a temperature of 80-90 DEG C for 20-30 minutes, taking out, standing at a room temperature for 1-2 days, controlling the vacuum degree to be 0.08-0.098 MPa for vacuum suction filtration, drying obtained crystals at a controlled temperature of 40-50 DEG C for 12 hours, and calcining at a controlled temperature of 400 DEG C for 240 minutes to obtain the rod-like CuO-ZnO composite oxide catalyst with a good catalytic effect. Instruments and equipment used in the preparation method are simple, and the preparation method is simple to operate and easy for large-scale production.

Owner:SHANGHAI INST OF TECH

Preparation method of high infrared reflection titanate nano-powder

InactiveCN102030376AGood dispersionUniform sizeNanotechnologyChromium compoundsWater basedIr reflection

The invention discloses a preparation method of high infrared reflection titanate nano-powder, which belongs to the field of preparation of nano-materials. The general formula of the titanate nano-powder is MxTiOy, wherein M is nickel or chromium; and the titanate nano-powder is prepared according to the following steps: 1) mixing acrylic acid with water based on the ratio in parts by weight of (1-4): 1, thus obtaining an acrylic acid water solution A; 2) weighing soluble M saltand Ti (titanium) salt, adding the soluble M salt and Ti salt into the acrylic acid water solution A in the step 1), and dissolving, thus obtaining a homogeneous system B; 3) adding water solution of peroxy type initiator with the weight content of 2-10% into the homogeneous system B in the step 2) under stirring condition, thus obtaining a solution C; and 4) heating the solution C obtained in the step 3) at the temperature of 60-100 DEG C till the system is completely polymerized, then drying at the temperature of 80-250 DEG C until getting solids, cooling, grinding, and calcining for 2-5 hours at the temperature of 600-800 DEG C in an atmosphere. The prepared nano-power has good dispersivity, and the size of the prepared nano-power is uniform and is in the range of 20-80nm.

Owner:SHIJIAZHUANG TIEDAO UNIV

Production technology and application of calcium hydrophosphate

InactiveCN102992292AComplete crystal formRegular crystal formPhosphorus compoundsLuminescent compositionsSlurryDigestion

The invention relates to a production technology and application of calcium hydrophosphate. The production technology comprises the following steps of: by using an ammonium dibasic phosphate and a calcium chloride solution as raw materials, carrying out double liquid phases to obtain hydryoxyapetite by stirring at a certain temperature and flow rate, then dewatering through a belt filter to separate and washing a mother liquid till chloride ions reach 500PPM, thus obtaining hydryoxyapetite; adding a certain amount of deionized water to hydryoxyapetite, adjusting a slurry ratio to be in line with technological requirements, adding a certain amount of acid, carrying out high-temperature digestion after adjusting a pH value, observing the state of the slurry after raising the temperature to 90 DEG C, stopping heating when the slurry is expanded and solidified, and removing two crystal water after settling for 30 minutes, thereby obtaining calcium phosphate dibasic anhydrous; carrying out washing chlorine, dewatering, drying and sieving, thus obtaining the calcium hydrophosphate finished product. The production technology has the advantages that the synthetic technology is simple, raw materials are easily obtained, by-products can be recycled, and the environmental pollution is little.

Owner:LIAONING GOLDEN ANCHOR IND

Method for preparing nano calcium carbonate

InactiveCN107324368AModerate surface areaRegular crystal formCalcium/strontium/barium carbonatesCarbideSlurry

The present invention provides a kind of preparation method of nano-calcium carbonate, comprises the following steps: (1) take out and weigh the quicklime obtained after the limestone is calcined at high temperature, digest the quicklime, and refine it into Ca( OH)2 slurry; (2) Prepare Ca(OH)2 raw slurry for refrigeration, add crystal form control agent to react, then add dispersant, carbonize with CO2, (3) thicken the cooked slurry after carbonization, add Activated by composite activator, dehydrated, dried, pulverized and classified to obtain 50-100nm nano-active calcium carbonate. By adopting the preparation method and surface modification method of nano-calcium carbonate of the present invention, the prepared nano-calcium carbonate has moderate specific surface area, regular crystal form, and good surface modification effect, which can greatly improve the excellent dispersion performance and ink absorption of calendered film products. performance, with very good market value.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Preparation method of SAPO-56/SAPO-34 composite molecular sieve

InactiveCN108862315ADifferent crystal morphologyHigh crystallinityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesHexamethylenediaminePhosphoric acid

The invention discloses a preparation method of a SAPO-56 / SAPO-34 composite molecular sieve synthesized by N,N,N,N-tetramethyl-1,6-hexamethylenediamine and triethylamine. The preparation method comprises the steps that firstly, the N,N,N,N-tetramethyl-1,6-hexamethylenediamine and the triethylamine are fully stirred and uniformly mixed; then, the mixture is added into a water solution to obtain a mixed solution; an aluminum source and a silicon source are sequentially added into the mixed solution; the stirring is performed for a period of time until the dissolution is complete; then, phosphoric acid is dropwise added; after the stirring is performed for a period of time, uniformly mixed gel is obtained; the obtained mixture is transferred into a high-pressure reaction kettle; after the crystallization reaction, a solid-phase product is subjected to deionized water washing, filtering and drying; then, roasting is performed in a muffle furnace; the composite SAPO-56 / SAPO-34 molecular sieve is obtained. The synthesized SAPO-56 / SAPO-34 composite molecular sieve has the advantages that the crystal morphologies are different; the crystal form is regular; the solid phase yield is high; the foundation is laid for the further preparation and study of the composite molecular sieve.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

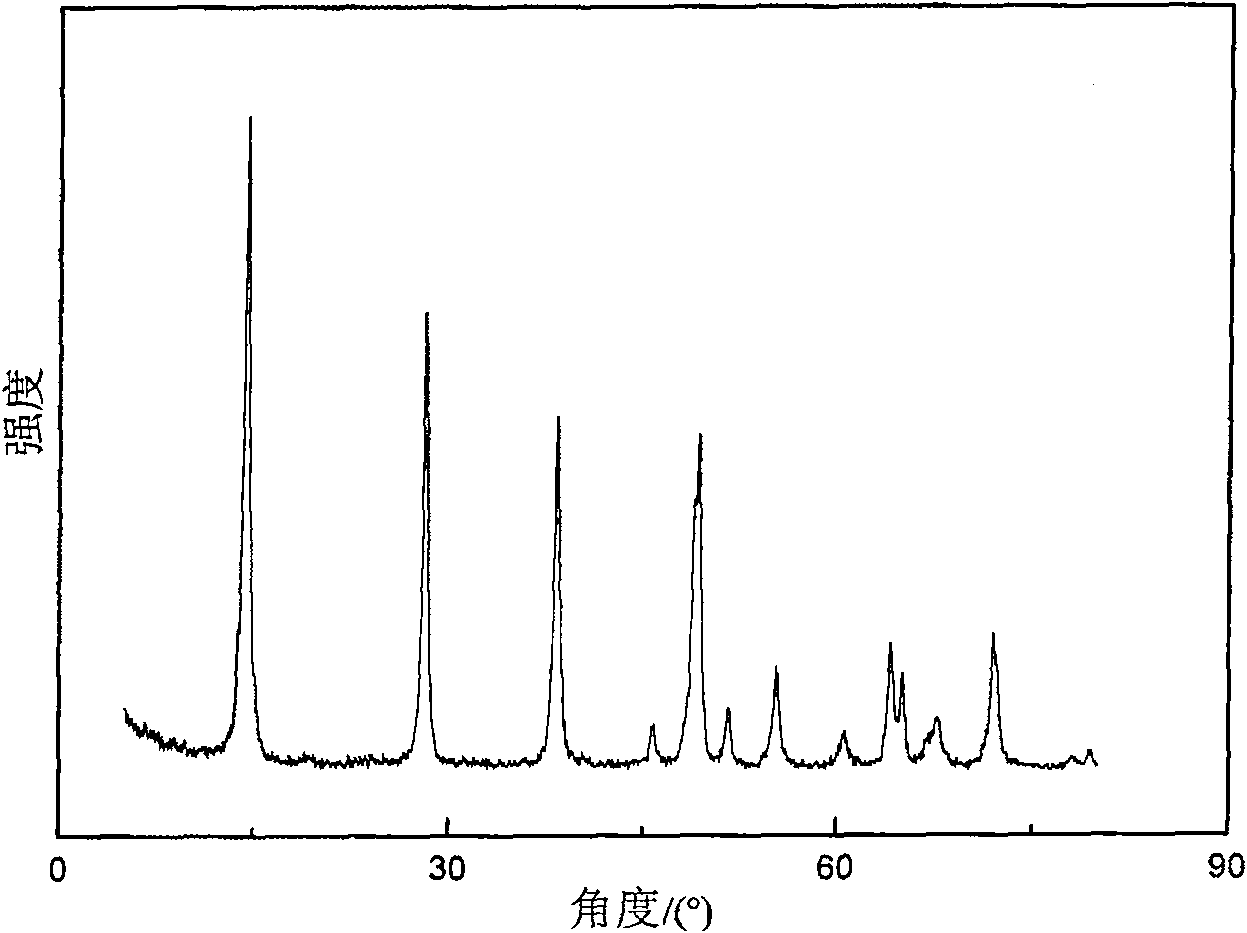

Prepn process of nanometer spinel type ferrite powder

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

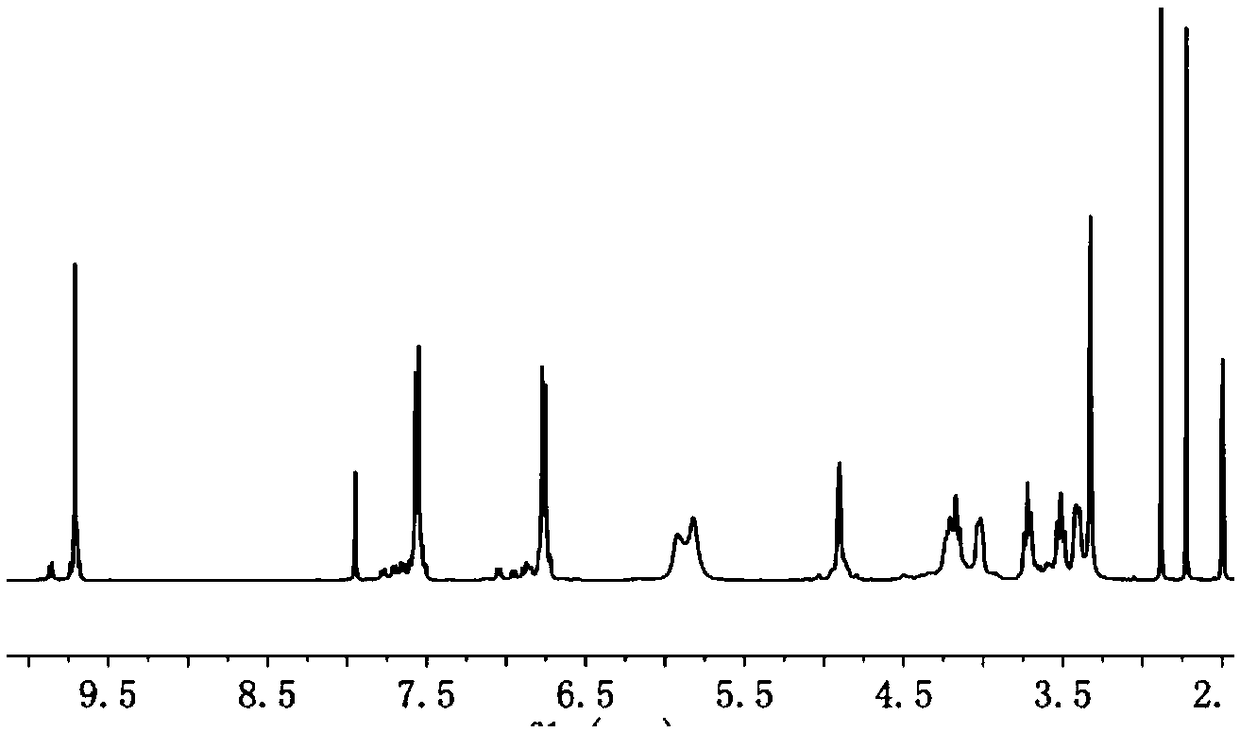

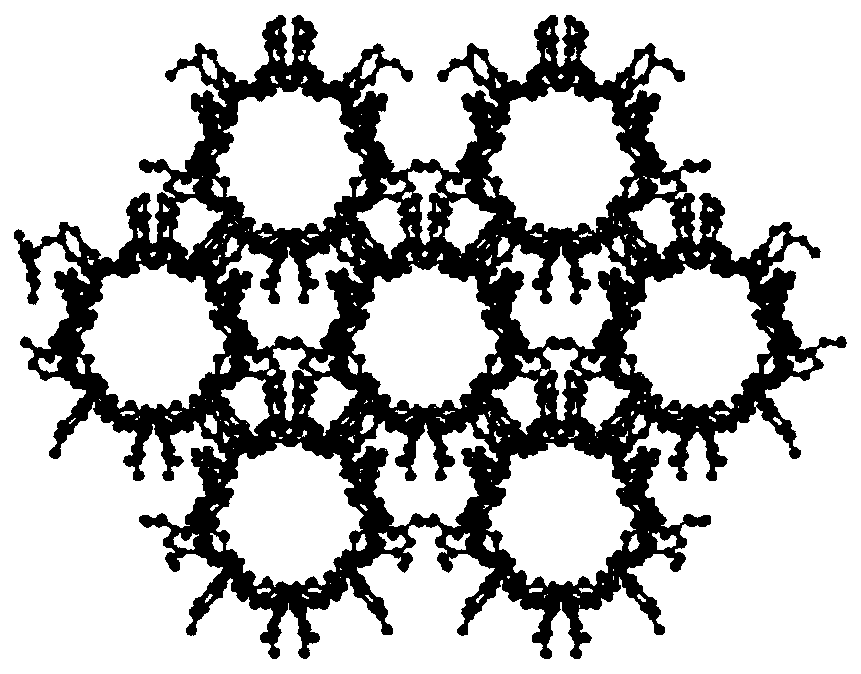

Preparation method of cyclodextrin constructed adsorbing material based on micropore structure

ActiveCN109158087APromote generationEasy to separate and purifyOther chemical processesAlkali metal oxides/hydroxidesDiffusion methodsSodium methoxide

The invention discloses a preparation method of a cyclodextrin constructed adsorbing material based on a micropore structure. According to the method, by substituting 6-hydroxy of cyclodextrin by p-hydroxy benzaldehyde, the cavity of the cyclodextrin is widened, and the adsorbing material with a larger pore structure is further obtained. The preparation method comprises the following reaction steps: dissolving triphenylphosphine into N,N-dimethylformamide under oxygen-free and anhydrous conditions, dropwise adding bromine to prepare a Vilsmeier-Haack reagent; dropping a DMF (Dimethyl Formamide) solution of the cyclodextrin into the solution, regulating the pH value of the solution to be 7-8 with sodium methoxide after reaction completion, and performing suction filtration to obtain a crudeproduct; dissolving the crude product into the DMF, dropping into distilled water, and performing suction filtration to obtain hexabromocyclodextrin; substituting bromine in the cyclodextrin by nucleophilicity of phenolic hydroxyl groups in the p-hydroxy benzaldehyde so as to obtain 6-p-methylsulfonylphenyl cyclodextrin, dropping the reaction solution into water to separate, and performing suction filtration, thereby obtaining the crude product. The per-[6-oxo-6-(4-benzoylphenyl)]-cyclodextrin with the micropore structure is prepared by utilizing a solution diffusion method.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method of spherical aluminum hypophosphite

ActiveCN103613084BLarge particle sizeSmall particle sizePhosphorus compoundsAluminium sulfatePhosphoric acid

The invention discloses a preparation method of spherical aluminum hypophosphite. In the method disclosed by the invention, sodium hypophosphite reacts with aluminum sulfate; meanwhile, melamine cyanurate is added as a seed crystal in the earlier stage of reaction, and different dispersants are added to improve the dispersion effect. The spherical aluminum hypophosphite prepared by the method disclosed by the invention has the characteristics of small particle size, regular crystal form and the like, thus the drop of mechanical properties of plastics after the addition of a flame retardant is reduced. Meanwhile, by adopting the melamine cyanurate seed crystal as a synergist in the flame retardant, the flame retardance effect of aluminum hypophosphite after plastic addition is remarkably improved.

Owner:JINAN TAIXING FINE CHEM

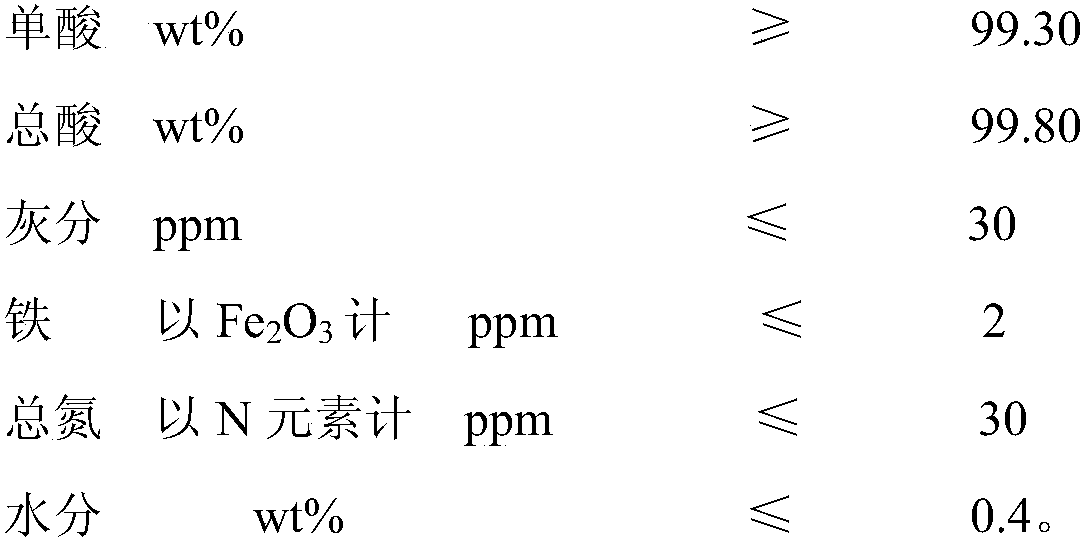

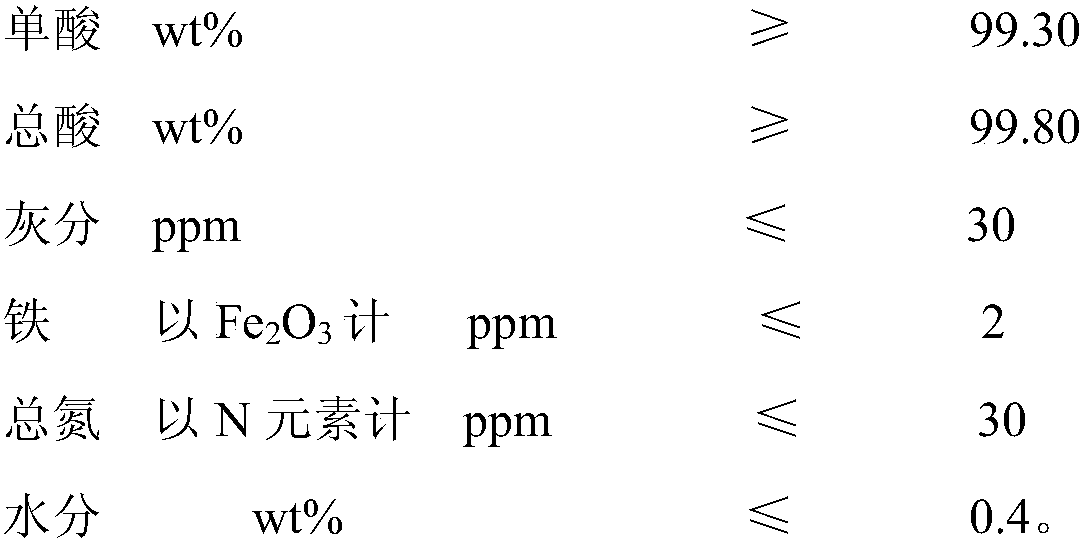

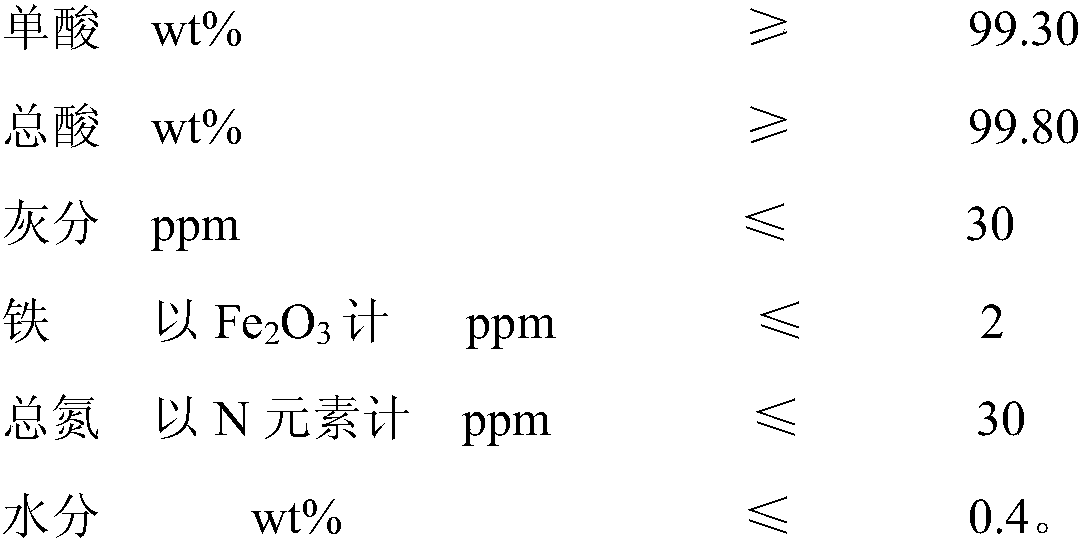

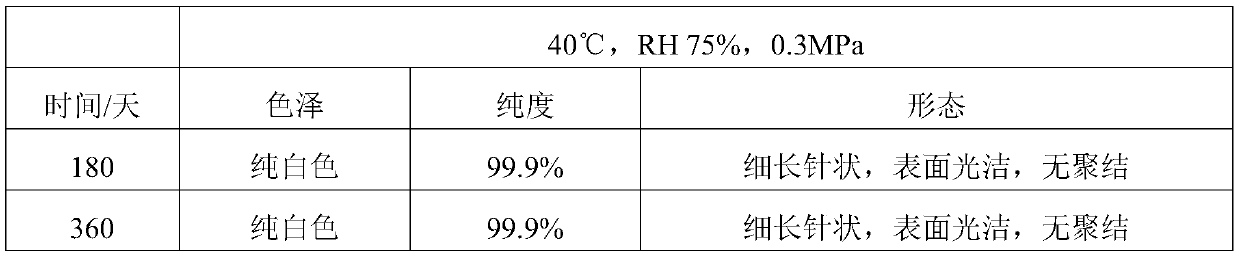

Refining and purifying method of dodecanedioic acid

InactiveCN108084015AHigh yieldHigh purityCarboxylic compound separation/purificationIon contentTotal nitrogen

The invention relates to a refining and purifying method of dodecanedioic acid. The method is characterized in that the moisture content of a crude dodecane material is controlled to be lower than orequal to 1.0 wt% and the content of an acetic acid solvent is higher than or equal to 95.0wt%; three-section gradient cooling is adopted in a crystallization process, and inducing seed crystals are added after second-section cooling to induce crystallization; crystallized filter cakes are firstly eluted with acetic acid, then eluted with water and subjected to centrifugal filtration; then, the filter cakes are washed with water at the environment temperature; the acetic acid solvent produced in the refining process is completely recovered with an azeotropic distillation method to be recycled;a washing solution and mother liquor produced in the refining process are completely recovered and recycled. The refining and purifying method of dodecanedioic acid has high product yield, lower refining cost and high purity. The refined and purified dodecanedioic acid has the total acid content of 99.90%, the monomer acid content of 99.45%, the total nitrogen of 6 ppm, the iron ion content of 0.5ppm, the ash content lower than or equal to 10 ppm, the moisture content lower than or equal to 0.10% and the comprehensive yield of purification of 98.64%. All quality technical indexes meet the user requirement.

Owner:ZIBO GUANGTONG CHEM

The synthetic method of small grain alpo4-34 aluminum phosphate molecular sieve

ActiveCN106672990BSmall sizeUniform particle size distributionMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesO-Phosphoric AcidMorpholine

The invention relates to a method for synthesizing small-crystal-grain aluminum phosphate molecular sieves AlPO4-34. According to the method, pseudo-boehmite or aluminum isopropoxide is used as an aluminum source, phosphoric acid serves as a phosphorus source, tetraethylammonium hydroxide and morpholine serve as template agents, and hydrofluoric acid serves as a fluorine source. The small-crystal-grain aluminum phosphate molecular sieves AlPO4-34, which are high in crystallinity and regular in crystal form, are synthesized by a pre-crystallization and seed crystal adding method on the basis of using the conventional raw materials and the mixed template agent. The grain size is small, and the average grain size is smaller than 1.5 microns and is only 0.05 to 1 micron after conditions are optimized. According to the method, the crystallinity is high, the morphology is regular, and the grain size distribution is uniform.

Owner:NANKAI UNIV

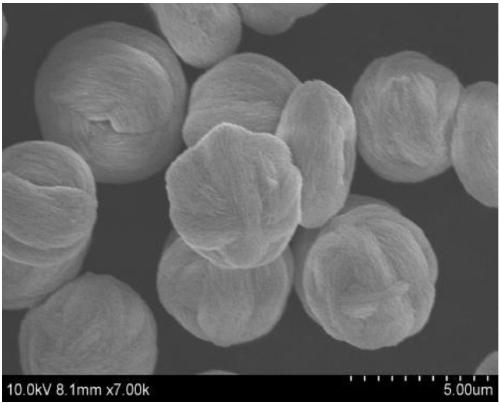

Method for preparing nano crystal boehmite

InactiveCN100569650CHigh crystallinityRegular crystal formNanostructure manufactureAluminium oxides/hydroxidesWater dispersibleReaction temperature

The invention discloses a preparation method of nano-crystal boehmite, which comprises the following steps: (1) hydrolysis reaction: mixing distilled water and aluminum isopropoxide in a molar ratio of 50-150:1, heating to 70-90 ℃, react for 1~2h, filter the reaction product, and dry in an oven at 80-90℃ for 8-12h; (2) hydrothermal reaction, put the dried product in step (1) into a high-pressure reactor, and use distilled water as the reaction medium , the filling degree of the reactor is 60%-80%, the reaction temperature is 150-200°C, the reaction time is 4-12h, and the nano-crystal boehmite is obtained. The nano crystal boehmite product prepared by the invention has high crystallinity, regular crystal form, uniform particle size, simple dispersion condition and good dispersibility. And it has good water dispersibility, its dispersion condition is simple, the particle size distribution is uniform, and there is no obvious agglomeration phenomenon.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of F-doped gamma-ferric oxide hollow microspheres with adjustable bandwidth

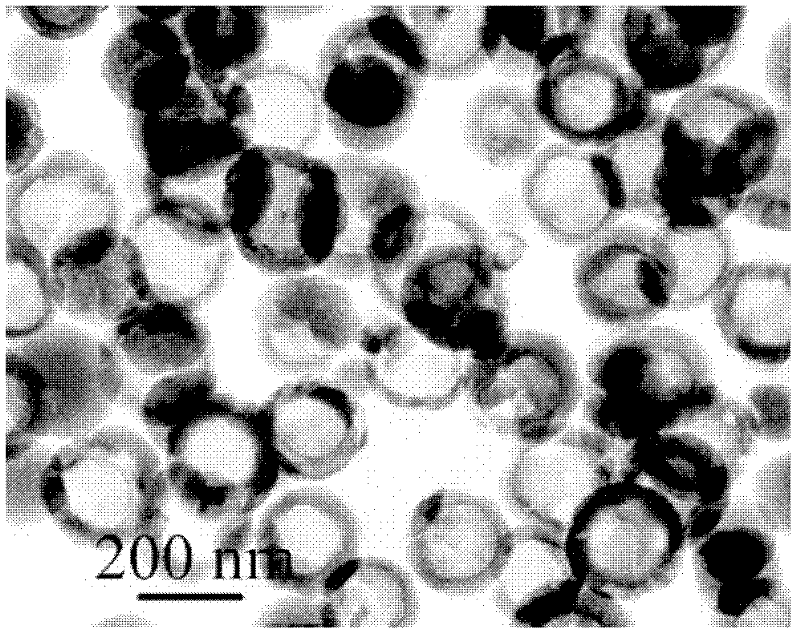

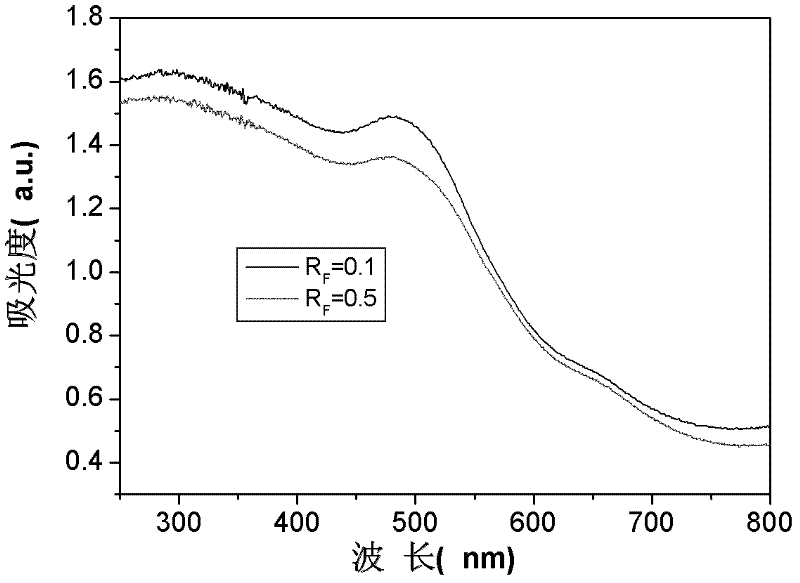

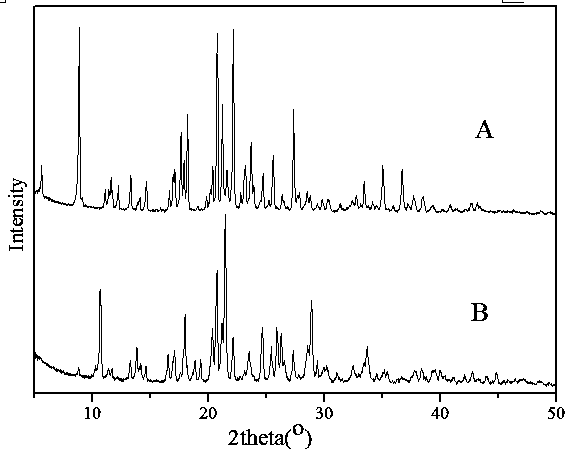

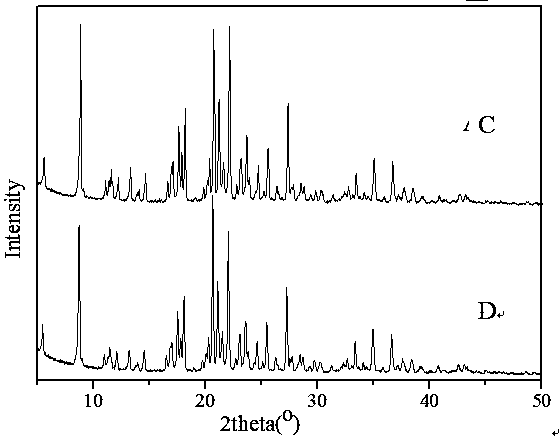

InactiveCN102502867ABandwidth adjustableGood dispersionMaterial nanotechnologyFerric oxidesEthylenediamineMicrosphere

The invention provides a preparation method of F-doped gamma-ferric oxide hollow microspheres with adjustable bandwidth. The preparation method comprises the steps of: (A) adding soluble ferric salt to 40 mL of ethylene glycol solution, and sufficiently stirring to form a first solution; (B) weighing a certain amount of fluoride salt, dissolving in the first solution, and sufficiently stirring to form a second solution, wherein 0<RF<=3 and RF is the atom number ratio of F to Fe; (C) adding ethylene diamine to the second solution to obtain a third solution; and (D) placing the third solution in a sealed reaction container, insulating heat for several hours to obtain precipitate, washing the precipitate, drying, and finally calcining at 250 DEG C to prepare the F-doped gamma-ferric oxide hollow microspheres, wherein the bandwidth of the F-doped gamma-ferric oxide hollow microspheres is adjusted by adjusting the RF value. The prepared F-doped gamma-ferric oxide hollow microspheres have the characteristics of good dispersivity, uniform size, regular crystal form and the like; and the raw materials are low in cost, and the preparation method is simple in process, can realize large-scale preparation and is suitable for scale production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Artemisinin separation and purification technology

The invention belongs to the technical field of separation and purification of artemisinin, and concretely relates to an artemisinin separation and purification technology. The separation and purification technology comprises the following steps: S1, Sweet Wormwood Herb extract is concentrated, and undergoes press filtration to obtain first crude artemisinin crystals and a first mother liquor, thefirst mother liquor is concentrated under a reduced pressure to obtain a first artemisinin extract; S2, the first artemisinin extract is added to an alcohol-water solution, stirring is performed fordissolving and dispersing, and then separation is carried out to obtain a first alcohol-water extract and a second artemisinin extract; S3, the second artemisinin extract undergoes processes in step S2 to obtain a second alcohol-water extract and a third artemisinin extract; S4, the first alcohol-water extract and the second alcohol-water extract are mixed, and the obtained mixture is cooled and crystallized, and then undergo press filtration to obtain second crude artemisinin crystals and a second mother liquor; and S5, the first crude artemisinin crystals and the second crude artemisinin crystals are mixed, and are dissolved in an alcohol solvent, the obtained solution is filtered, and the obtained filtrate is heated, and then undergoes reduced pressure concentration, cooling, press filtration and drying to obtain refined artemisinin. The product obtained by the separation and purification technology has the advantages of high recovery rate, high purity and high crystal form quality.

Owner:HUNAN HEALTHWARE BIOTECH LTD

A method for continuous crystallization of vitamin C

ActiveCN101397286BAchieve continuous crystallizationRegular crystal formOrganic chemistryVitamin K2Vitamin C

Owner:DSM JIANGSHAN PHARMACEUTICAL (JIANGSU) CO LTD

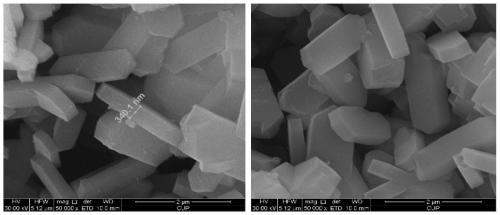

Preparation method of prothioconazole I-type crystal form

PendingCN110981822AFast preparationEasy to manufactureOrganic chemistry methodsSolvent evaporationPhysical chemistry

The invention relates to the field of compound crystal forms, in particular to a preparation method of a prothioconazole I-type crystal form. The preparation method comprises the following steps: dissolving a prothioconazole raw material in a solvent, filtering to obtain filtrate, standing the filtrate and separating out a solid phase, namely the prothioconazole I-type crystal form. According to the technical scheme, the prothioconazole I-type crystal form is prepared through a solvent evaporation method and a cooling method, the method is simple and easy to implement and low in cost, and theprepared product is high in yield and purity, good in stability without coalescence and suitable for being applied to industrial production.

Owner:HAILIR PESTICIDES & CHEM GRP

A kind of ZSM-5 molecular sieve and its preparation method and application

ActiveCN106865566BWide range of regulationRegular crystal formPentasil aluminosilicate zeoliteMolecular sieveEngineering

A ZSM-5 molecular sieve, a preparing method thereof and applications of the molecular sieve are provided. The ZSM-5 molecular sieve is prepared through an amine-free system. A silica-alumina ratio of the ZSM-5 molecular sieve is 40-200. The ZSM-5 molecular sieve is prepared by adopting a nanometer thin-layer ZSM-5 molecular sieve having a high silica-alumina ratio as a crystal seed with the mole ratio of raw materials meeting a condition that the mole ratio of SiO2 to Al2O3 is 100:(0.04-2). Compared with molecular sieves synthesized under traditional template-free conditions, the ZSM-5 molecular sieve synthesized by the method is a molecular sieve having a high silica-alumina ratio (higher than 40). The silica-alumina ratio of the prepared flake ZSM-5 molecular sieve is adjustable in a large range (40-200).

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

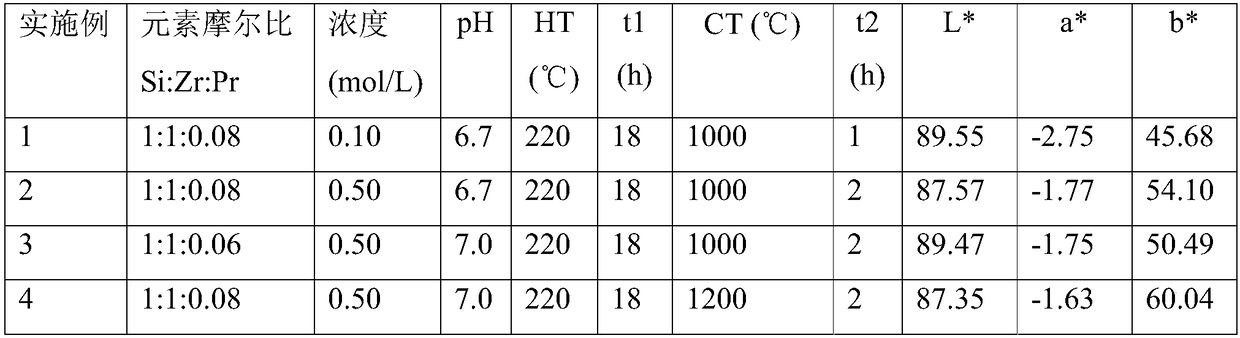

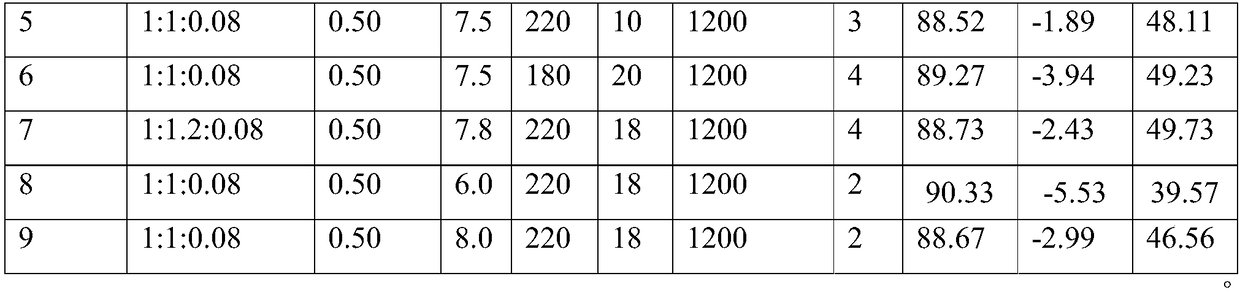

Nanometer praseodymium-zirconium yellow material and preparation method thereof

InactiveCN108862294ARaw materials are easy to obtainThe reaction conditions are mild and easy to controlPigmenting treatmentMaterial nanotechnologySodium nitrateHeat treated

The invention relates to a nanometer praseodymium-zirconium yellow material and a preparation method thereof. The method comprises the following steps of uniformly mixing praseodymium nitrate, a soluble silicon source water solution and a soluble zirconium source water solution to obtain a mixed solution; regulating the pH value of the obtained mixed solution to 6 to 8; performing hydrothermal reaction for 10 to 20 hours at 180 to 240 DEG C; then performing suction filtering and drying to obtain hydrothermal products; performing high-temperature treatment on the hydrothermal products at 800 to1200 DEG C for 1 to 4 hours; then performing grinding to obtain the nanometer praseodymium-zirconium yellow material. The nanometer praseodymium-zirconium yellow material obtained through preparationhas the advantages that the particle diameter is in a nanometer stage; the uniformity and stability are realized; the crystal form is regular; the color is fresh and bright; the application field iswide.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com