Method for preparing nano crystal boehmite

A technology of nanocrystals and boehmite, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of irregular powder shape, uneven particle size distribution, poor crystallinity of products, etc., and achieve uniform particle size , Regular crystal form, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

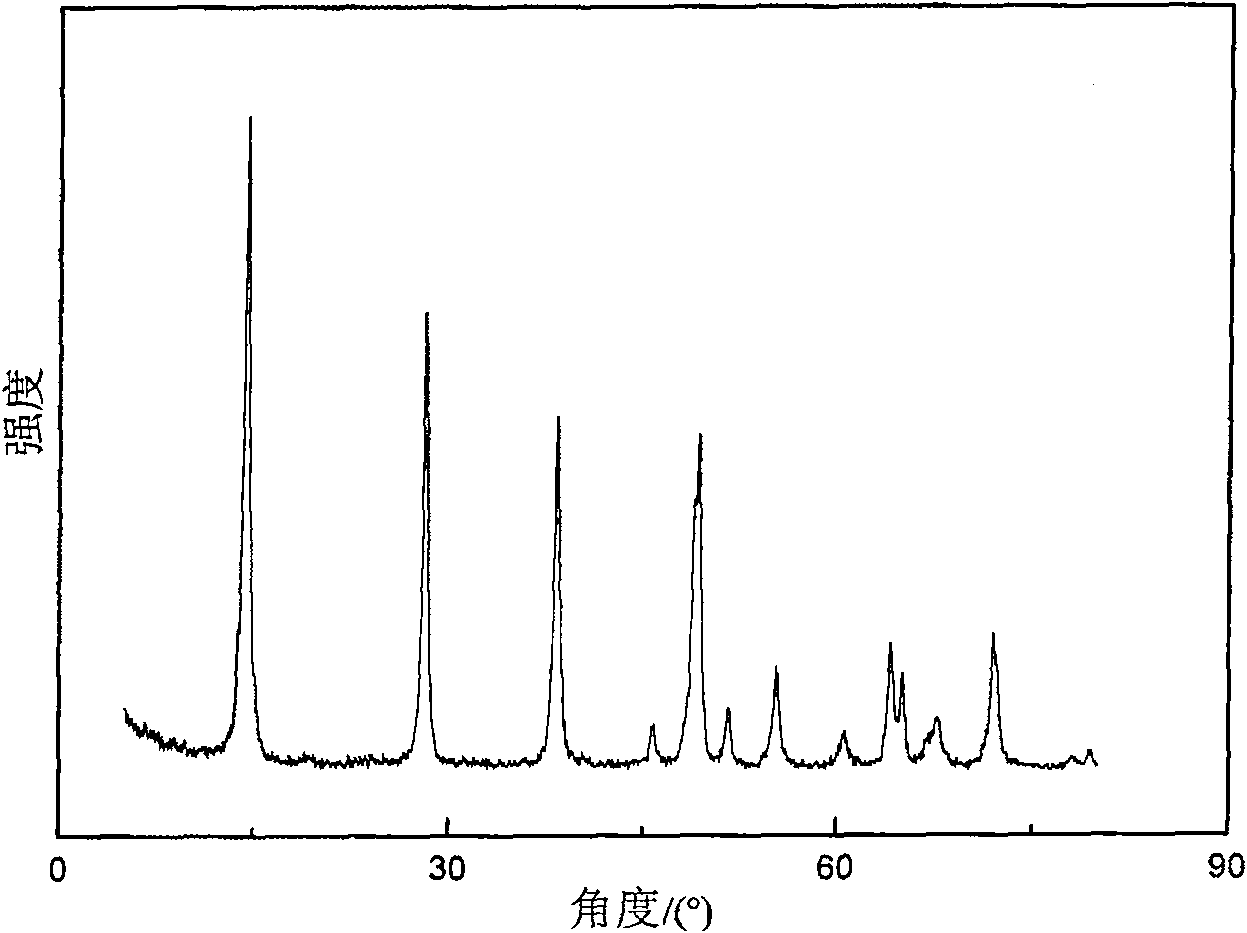

Image

Examples

Embodiment 1

[0024] (1) Hydrolysis reaction: 10g of aluminum isopropoxide, 80ml of distilled water, react at 70°C for 1h, filter, and dry at 90°C for 12h to obtain hydrated alumina.

[0025] (2) Hydrothermal reaction: Take 5 g of hydrated alumina prepared in step (1), 60 ml of distilled water, put them into a reaction kettle with a polytetrafluoroethylene lining, the filling degree of the reaction kettle is 60%, react at 150 ° C for 4 hours, filter and dry nanocrystalline boehmite.

[0026] (3) Dispersion: Take 1 g of nanocrystalline boehmite prepared in step (1), 100 ml of distilled water, disperse for one hour with a high-speed dispersion homogenizer, add dilute nitric acid until the pH value of the sol is 3-4, and obtain a homogeneous and stable sol .

[0027] Nanoparticles have small particle size, high surface energy, and a tendency to spontaneously agglomerate, and the existence of agglomeration will greatly affect the advantages of nanopowders. Therefore, the dispersion and stabili...

Embodiment 2

[0031] Others of this embodiment are the same as in Example 1, and the addition of distilled water is changed so that the mol ratio of water and aluminum isopropoxide is 50: 1; the hydrothermal reaction time of step (2) is extended to 12h, and nanocrystal boehmite is also produced .

Embodiment 3

[0033] (1) Hydrolysis reaction: 10g of aluminum isopropoxide, 80ml of distilled water, react at 70°C for 1h, filter, and dry at 90°C for 12h.

[0034] (2) Hydrothermal reaction: 5 g of hydrated alumina, 60 ml of distilled water, 60% filling degree of the reaction kettle, react at 200° C. for 4 h, filter and dry to obtain nanocrystalline boehmite.

[0035] (3) Dispersion: Boehmite 1g, distilled water 100ml, disperse in a high-speed dispersing homogenizer for one hour, add dilute nitric acid until the pH of the sol is 3-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com