Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Shape rule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

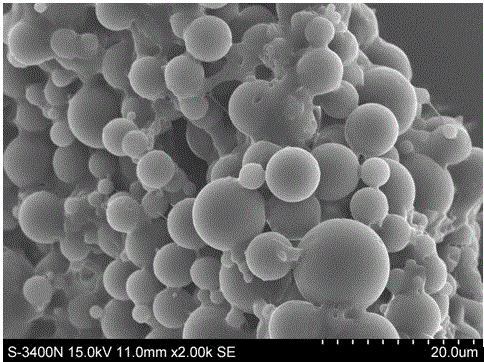

Aripiprazole sustained-release microspheres and preparation method thereof

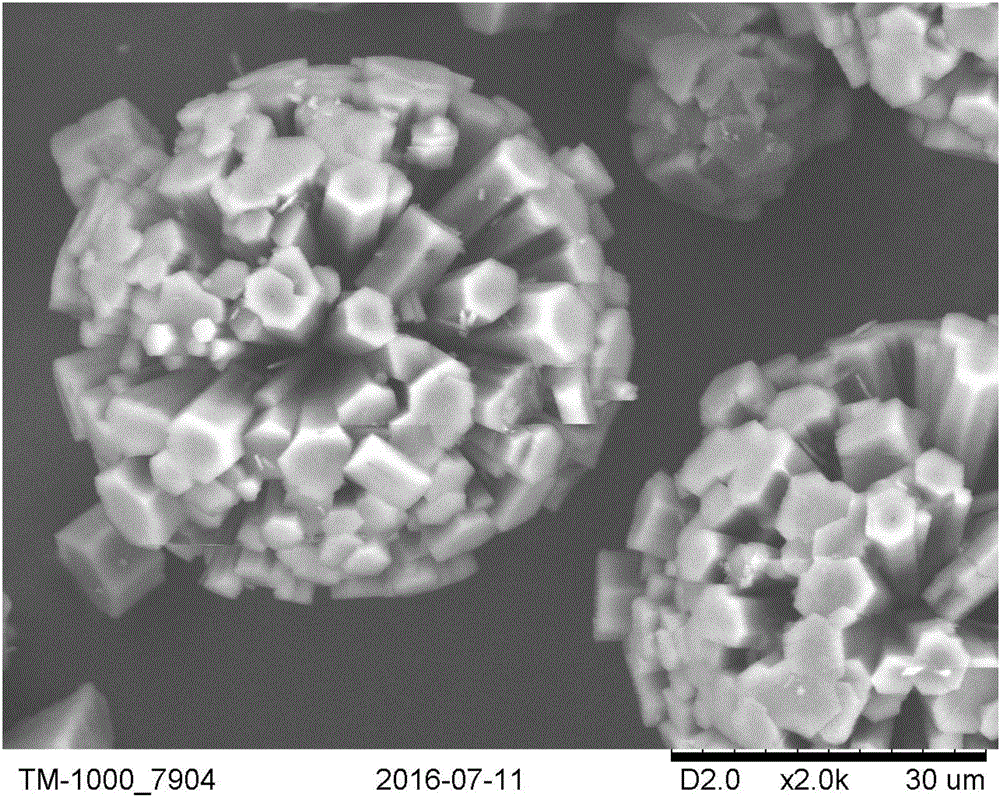

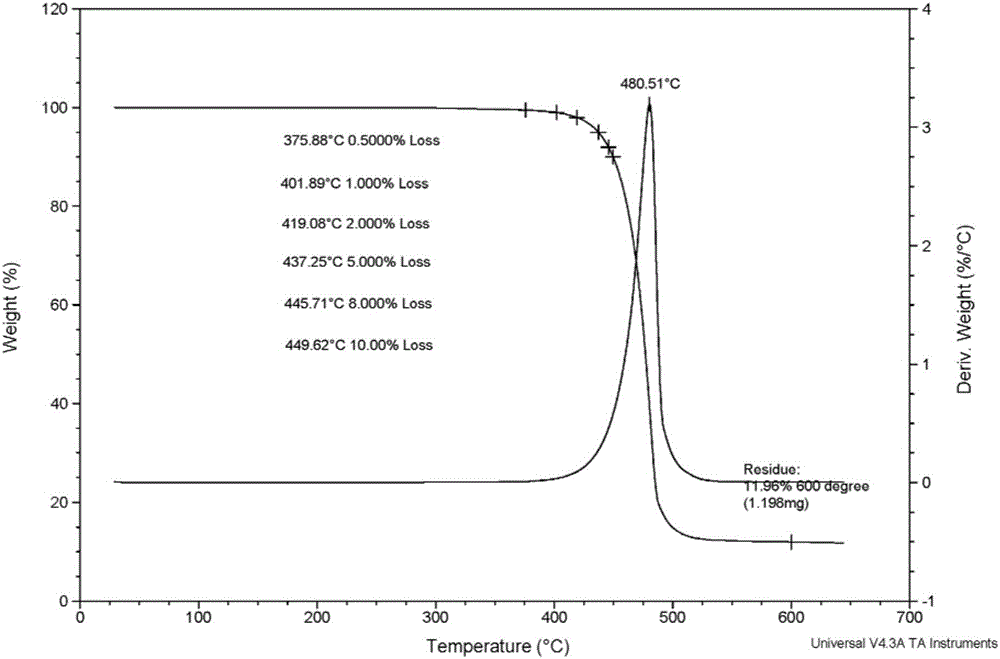

ActiveCN105310997AImprove complianceGood treatment effectOrganic active ingredientsNervous disorderAcetic acidMicrosphere

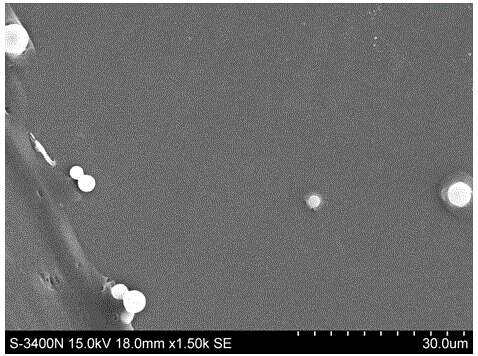

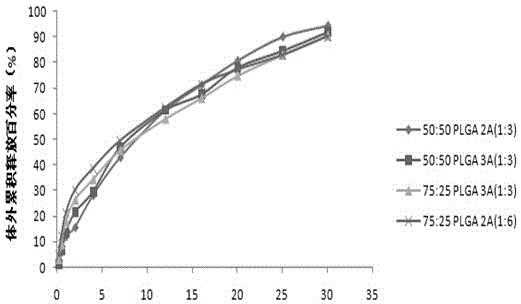

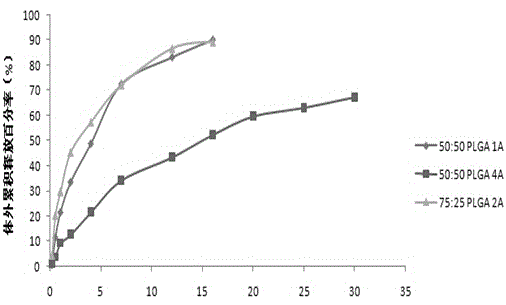

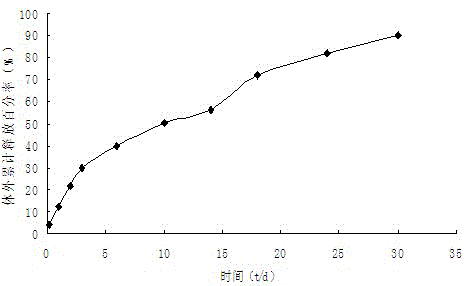

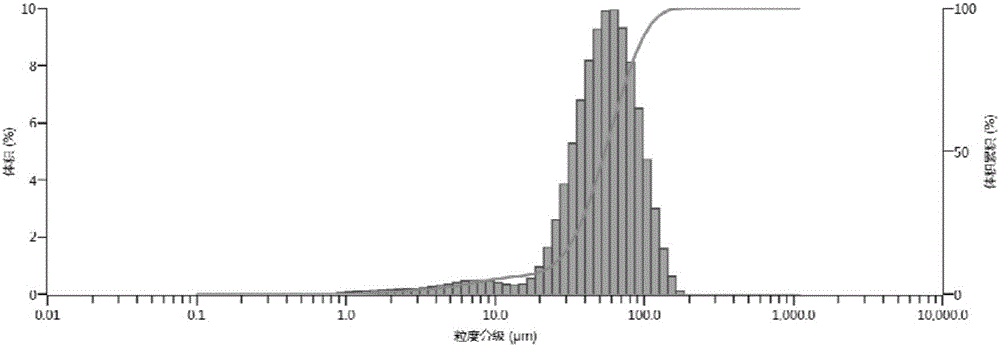

The invention relates to aripiprazole sustained-release microspheres and a preparation method thereof. The sustained-release microspheres include aripiprazole and a bio-degradable pharmaceutical high-molecular material PLGA, wherein the ratio of lactic acid to hydroxyacetic acid in the PLGA is 75:50-25:50. The PLGA is 25000-35000 Dolton in molecular weight. The addition weight ratio of the aripiprazole to the PLGA is 1:1-20. The aripiprazole accounts for 3.01-21.09% of total weight of the microsphere. The aripiprazole sustained-release microspheres have high drug embedding rate, is high in drug loading capacity, is smooth and round in surface and can release more than 90% of the drug in 30 days.

Owner:CHONGQING PHARMA RES INST

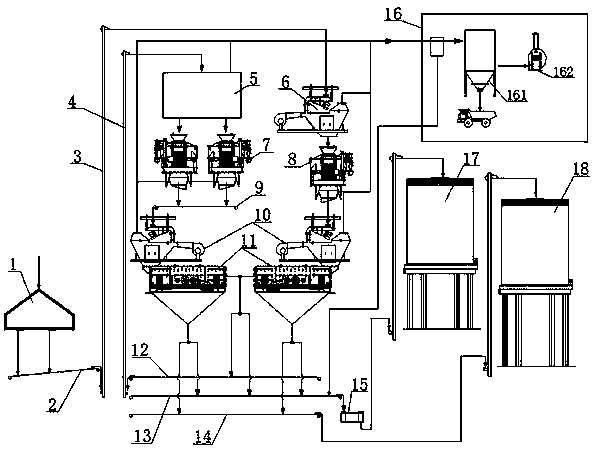

Machine-made sand production station and sand making method

The invention discloses a machine-made sand production station and a sand making method. The machine-made sand production station comprises a steel structure framework, a vibrator feeder, a powder removal machine, a sand-making machine, a shaper, a screening machine and dust removal equipment, and adopts a novel layout manner as follows: the sand-making machine is arranged on the top of the steelstructure framework, the screening machine with high vibration is arranged at the bottom, and the screening machine is separated from the structure framework, so that vibration of the steel structureis reduced, the weight of the steel structure of the station is reduced on premise of ensuring the safety, and investment of the production station is reduced. Two sand-making machines are used for simultaneously making sand, and a novel manner of matching the shaper and two screening machines is adopted, so that the sand making efficiency is improved, the grains of finished sand are full and round and more regular. The powder removal machines are arranged at a feeding hole and a discharging hole of the shaper, and a two-stage powder removal process is adopted, so that stone powder content ofthe finished sand can be effectively controlled, and the quality of the finished sand is improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

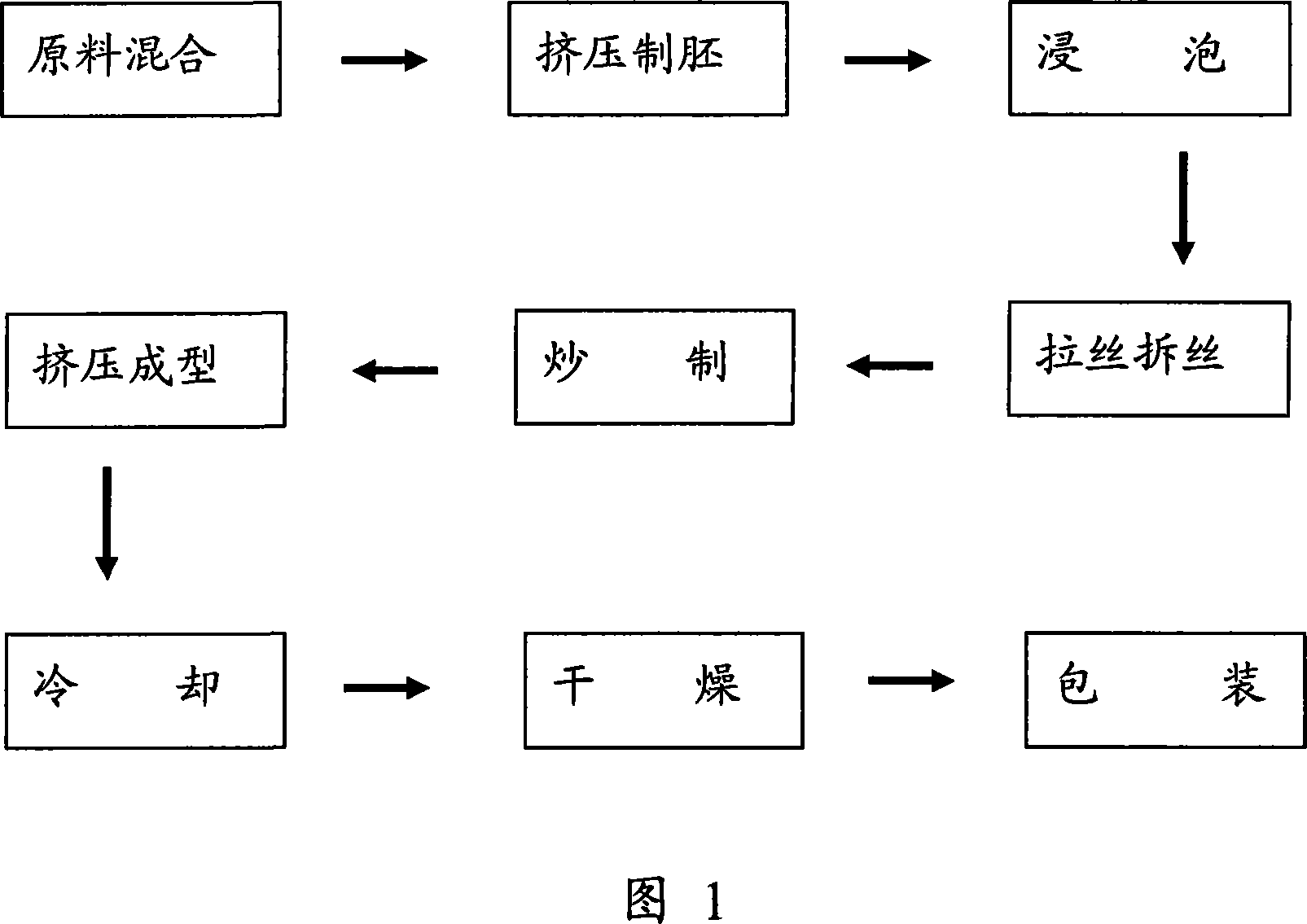

Soyabean protein meat and preparing technique thereof

ActiveCN101176538AFibrous feeling is obviousEvenly distributedCheese manufactureVegetable proteins working-upBiotechnologyPreservative

The invention discloses a soybean protein meat and a production process thereof. The raw materials are composed of 22%-50% of soybean protein powder, 1.3%-12% of glutinous rice flour, 1.73%-30% of starch, seasoning and preservative and water. A production process of soybean protein meat, comprising the following steps: mixing crushed soybean protein powder and gluten powder, adding water to stir evenly, and extruding to obtain embryo material; soaking embryo material in water, drawing and removing wire, adding seasoning , fried to taste; seasoning, starch and preservatives are added to the fried embryo material, stirred evenly and then extruded to obtain soybean protein meat. The soybean protein meat of the invention has good taste, regular appearance, uniform taste and high quality.

Owner:浙江小王子食品有限公司

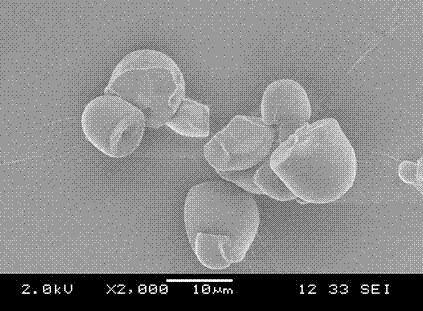

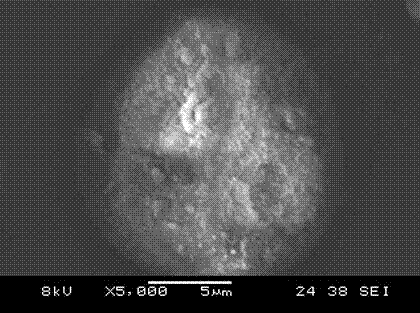

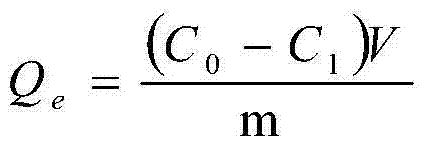

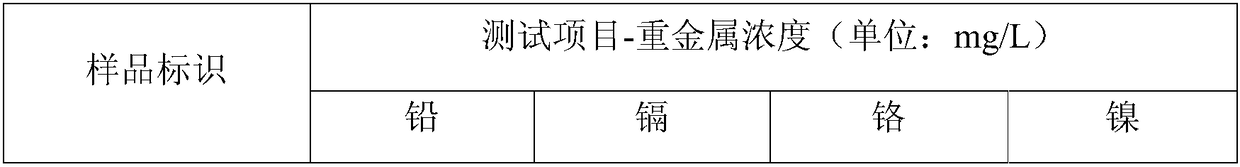

Preparation method of cross-linked type AM/AA (acrylamide/acrylic acid) grafted xanthogenic acid esterified cassava starch microsphere and adsorption of cross-linked type AM/AA grafted xanthogenic acid esterified cassava starch microsphere to Cu<2+>

ActiveCN104497324AShape ruleUniform particle sizeOther chemical processesAlkali metal oxides/hydroxidesIonHeavy metals

The invention discloses a preparation method of a cross-linked type AM / AA (acrylamide / acrylic acid) grafted xanthogenic acid esterified cassava starch microsphere and adsorption application of the cross-linked type AM / AAgrafted xanthogenic acid esterified cassava starch microsphere to Cu<2+>. The preparation method of the cross-linked type AM / AA grafted xanthogenic acid esterified cassava starch microsphere comprises the following steps: firstly preparing cross-linked AM / AA grafted xanthogenic acid esterified cassava starch, and then carrying out processing steps, namely emulsion dispersion, separation, washing, drying and the like by adopting a reversed-phase microemulsion method under the alkali condition while Span-80 is taken as an emulsifying agent, so that the cross-linked type AM / AA grafted xanthogenic acid esterified cassava starch microsphere with a regular shape, uniform granularity, good inner pore development and good adsorption property is obtained. A Cu<2+> adsorption performance test shows that the adsorption capacity of the cross-linked type AM / AA grafted xanthogenic acid esterified cassava starch microsphere reaches up to 20.18mg / g, and the Cu<2+> removal rate can reach up to 84.08%. The preparation method of the cross-linked type AM / AA grafted xanthogenic acid esterified cassava starch microsphere has the advantages that modified cassava starch is compounded in multiple steps in reverse-phased emulsion to prepare the starch microsphere, so that the prepared starch microsphere is in a good spatial reticular structure, the specific area is increased, and the Cu<2+> adsorption performance is excellent. Therefore, the starch microsphere has great application values in the aspects of industrial sewage purification, heavy metal adsorption and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

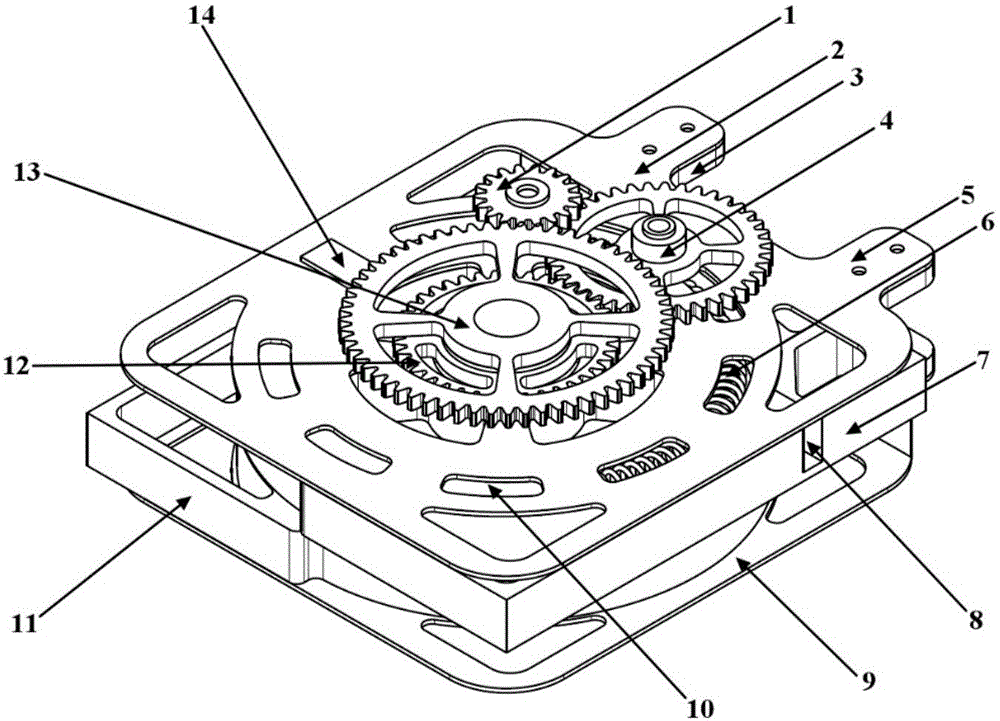

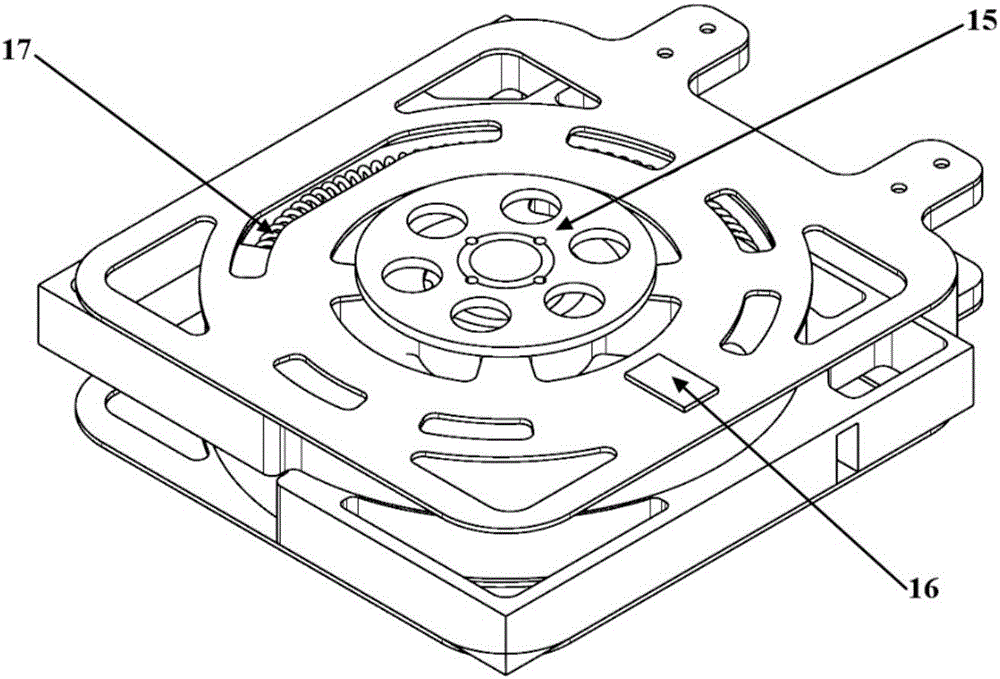

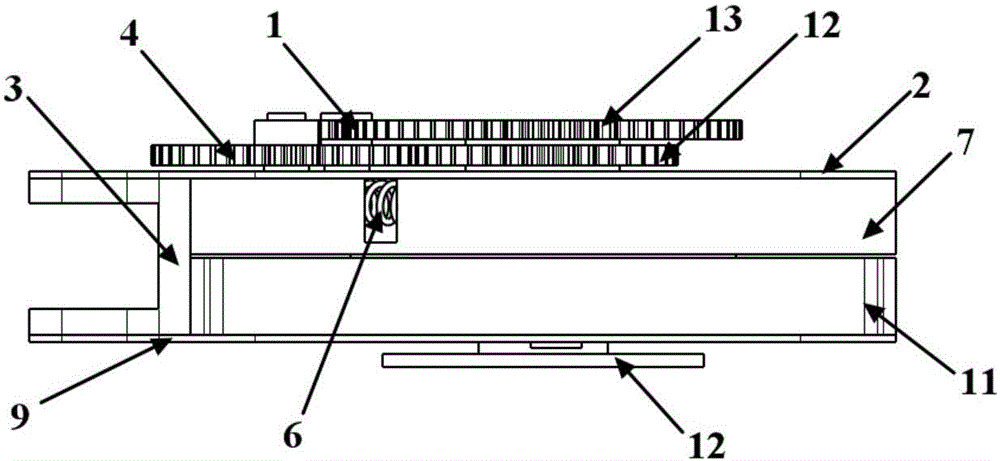

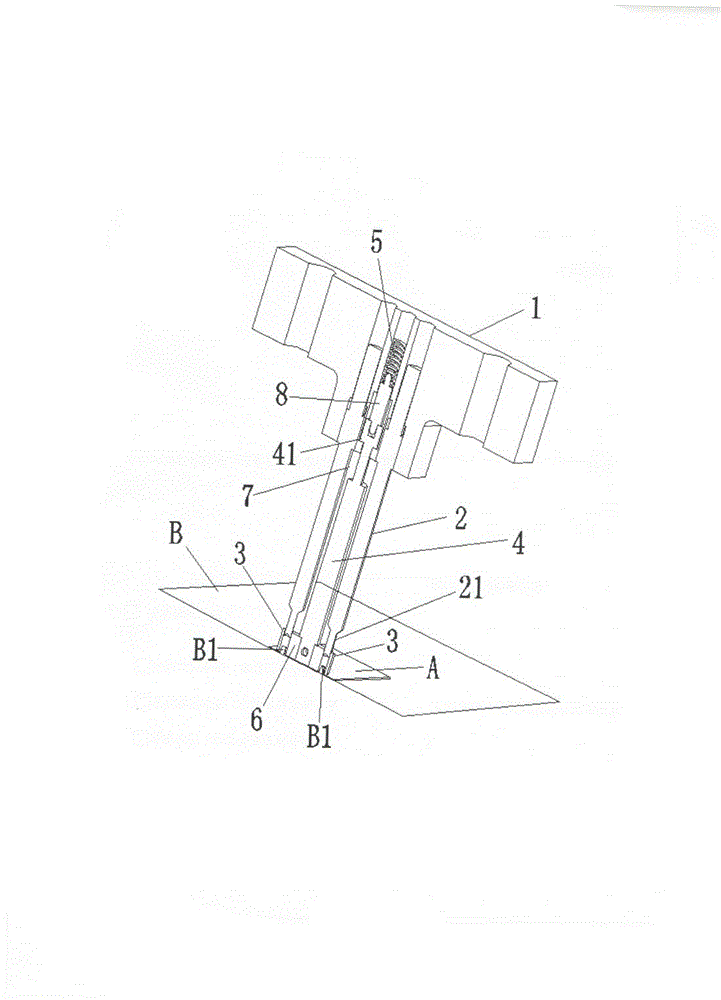

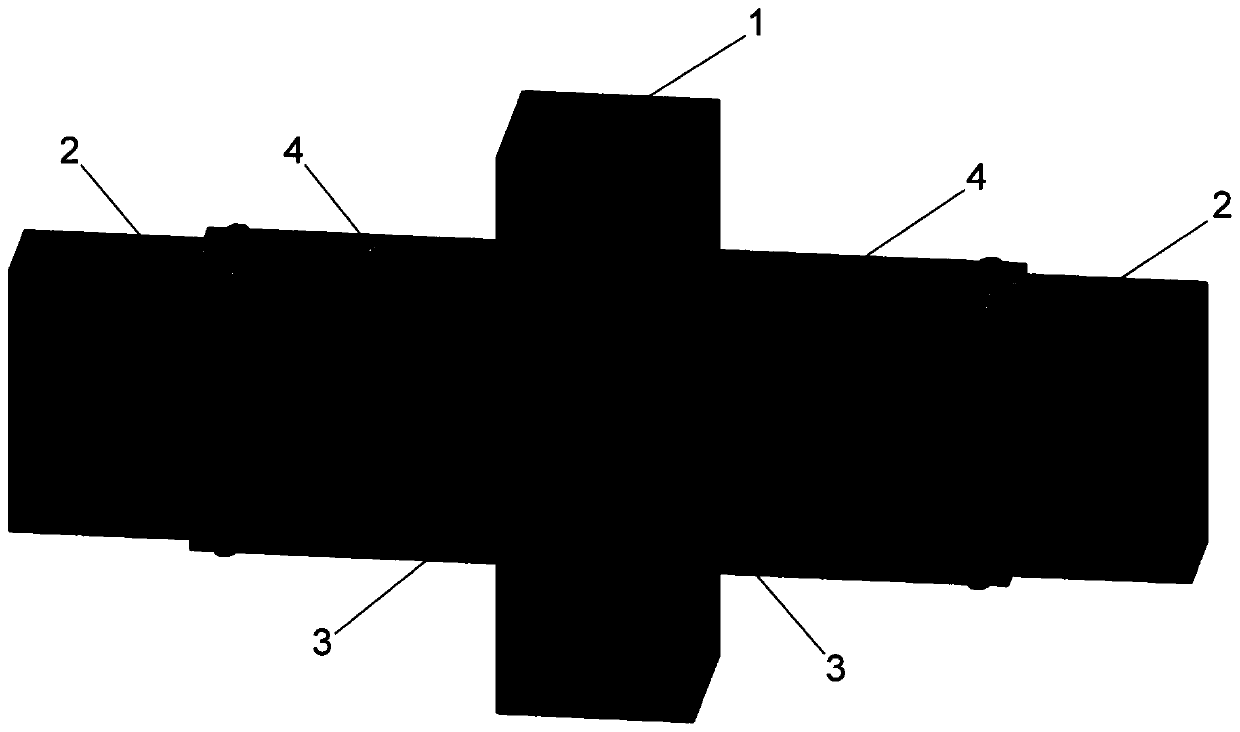

Wing synchronous unfolding system of catapult unmanned aerial vehicle folding wings and using method

ActiveCN106809374AIncrease success rateImprove reliabilityWing adjustmentsMarine engineeringFlight vehicle

The invention relates to a wing synchronous unfolding system of catapult unmanned aerial vehicle folding wings and a using method. The wing synchronous unfolding system comprises two wing extending units and a synchronous gear mechanism, and the wing extending units of left and right wings are enabled to rotate by 0-90 degrees around axis of a main gear through elastic resilience generated by compressing springs in the process of folding the wings to complete a folding and unfolding function of the wings; left and right cover plates are fixedly connected with a fuselage through retaining blocks with lugs; and by designing the synchronous gear mechanism, synchronous unfolding of the left and right wings is guaranteed. In order to reduce structural weight and improve flying efficiency, weight of each unit is reduced on the premise that structural strength is guaranteed. By the wing synchronous unfolding system, accurate positioning and reliable unfolding of the left and right wings of a folding wing unmanned aerial vehicle can be realized reliably, and catapult success rate of the unmanned aerial vehicle is increased, so that reliability of the whole unmanned aerial vehicle is improved substantially. The wing synchronous unfolding system has the advantages that the system is reasonable in design, easy to implement, low in cost and simple and quick in folding mode, and the wings after being folded are regular and attractive in appearance and convenient to carry.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Iloperidone sustained release microsphere and preparation method thereof

InactiveCN103599074AHigh encapsulation efficiencyHigh drug loadingOrganic active ingredientsNervous disorderMicrosphereGlycolic acid

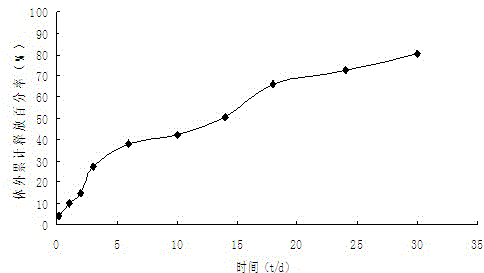

The invention relates to an iloperidone sustained release microsphere and a preparation method thereof. The sustained release microsphere mainly comprises iloperidone and a biodegradable pharmaceutical polymer material PLGA (poly lactic-co-glycolic acid), wherein the molar ratio of lactic acid of PLGA to glycolic acid is (75-50):(25-50), the dosing weight ratio of the iloperidone to the PLGA is 1:(1-10), and the iloperidone is 3.5-15.5% of the total weight of the microsphere. According to the prepared iloperidone sustained release microsphere, the medicine encapsulation efficiency is high, the drug loading capacity is high, and the surface of the microsphere is smooth and round. The sustained release microsphere is used for curing psychosis, can prolong the action time of the medicine, reduces the dosing times, and greatly improves the obedience of patients in taking medicine.

Owner:CHONGQING PHARMA RES INST

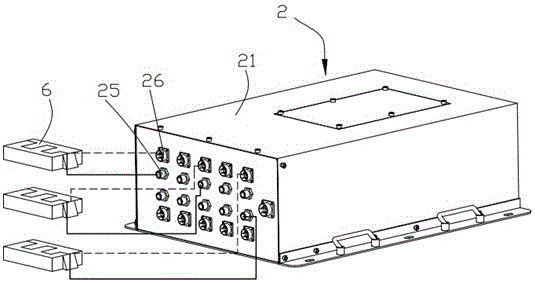

Fire alarm and protection device for passenger car lithium battery boxes and working method thereof

InactiveCN107433000ASimple structureShape ruleFire rescueFire alarm electric actuationFire detectionEngineering

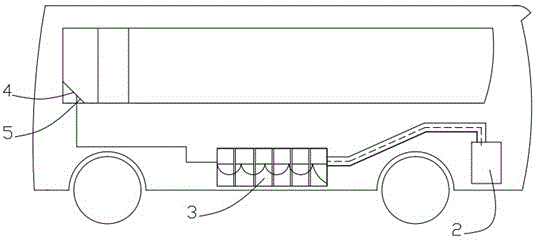

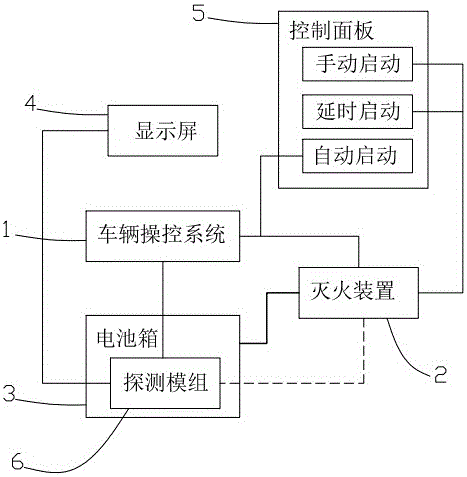

The invention provides a fire alarm and protection device for passenger car lithium battery boxes. The fire alarm and protection device for the passenger car lithium battery boxes comprises a vehicle control system, a fire extinguishing device, a plurality of battery boxes, a display screen and a control panel, the fire extinguishing device and the plurality of battery boxes are arranged on a passenger car chassis, the display screen and the control panel are arranged in a cab; the fire extinguishing device and the plurality of battery boxes are connected by fire extinguishing agent conveying pipelines, each battery box is provided with a detection module, the detection module and the display screen are connected by a power supply and control system harness, and the detection module and the fire extinguishing device are connected by a fire detection harness. Compared with the related technology, the detection module for sensing fire is used in the fire alarm and protection device for the passenger car lithium battery boxes, the detection module has own sensor, arrangement of a sampling pipe network is not needed, the fire alarm and protection device can be directly placed in the battery boxes, the fire alarm and protection device integrates special gas and smoke detection together, has the advantages of simple structure, small occupied space, and convenient installation. The invention also provides a working method for the fire alarm and protection device for the passenger car lithium battery boxes.

Owner:湖南鸿腾新能源技术有限公司

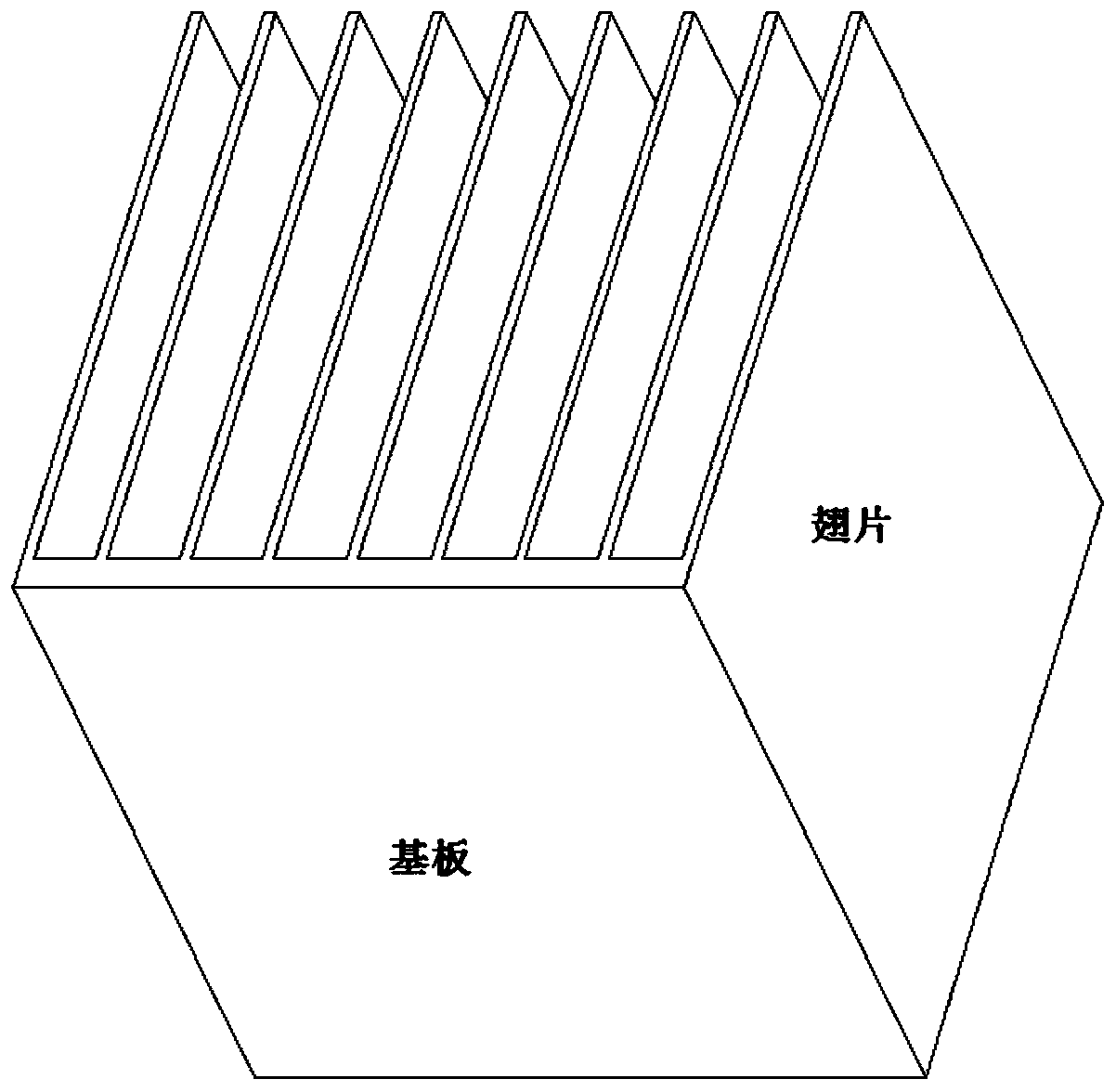

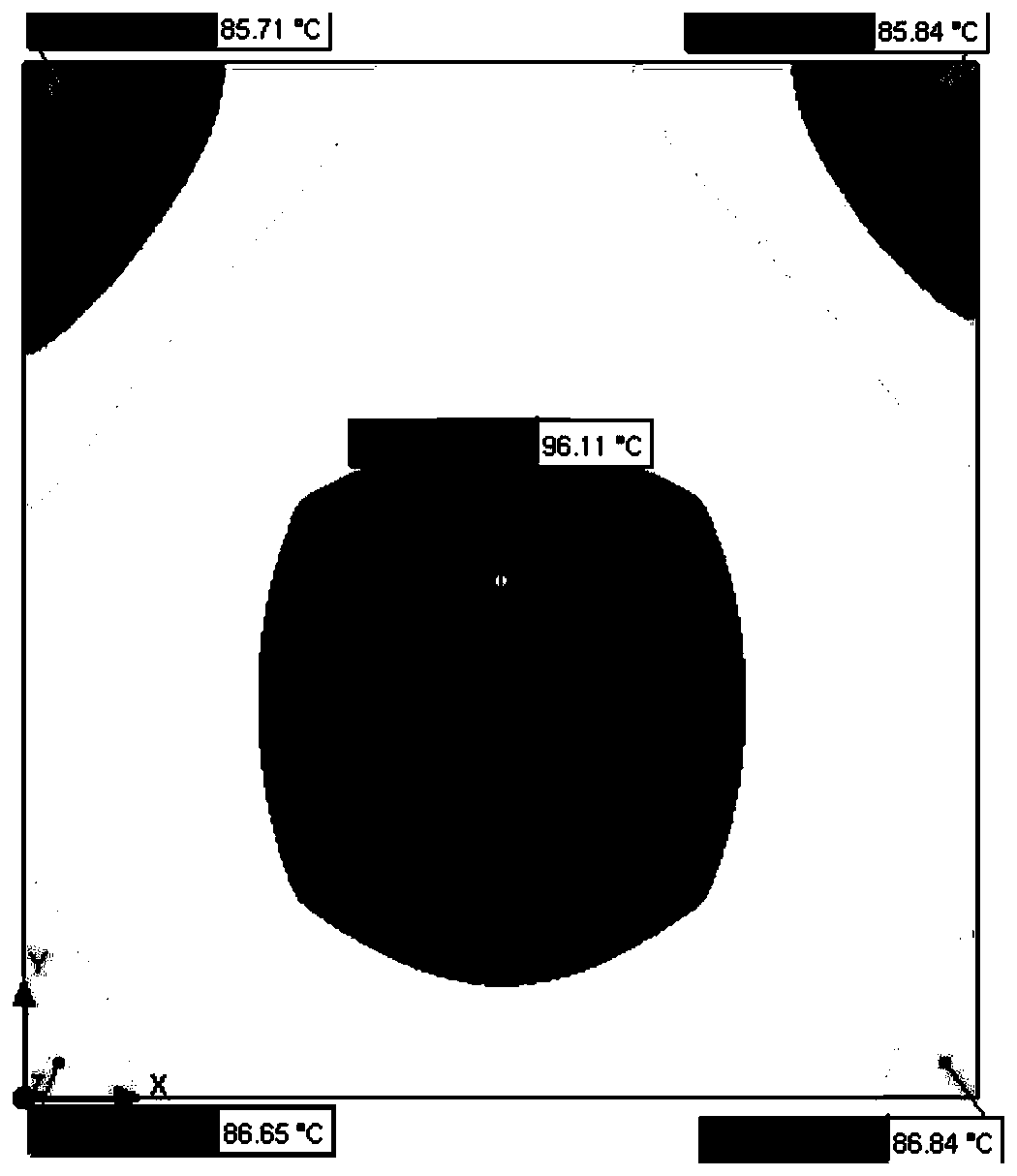

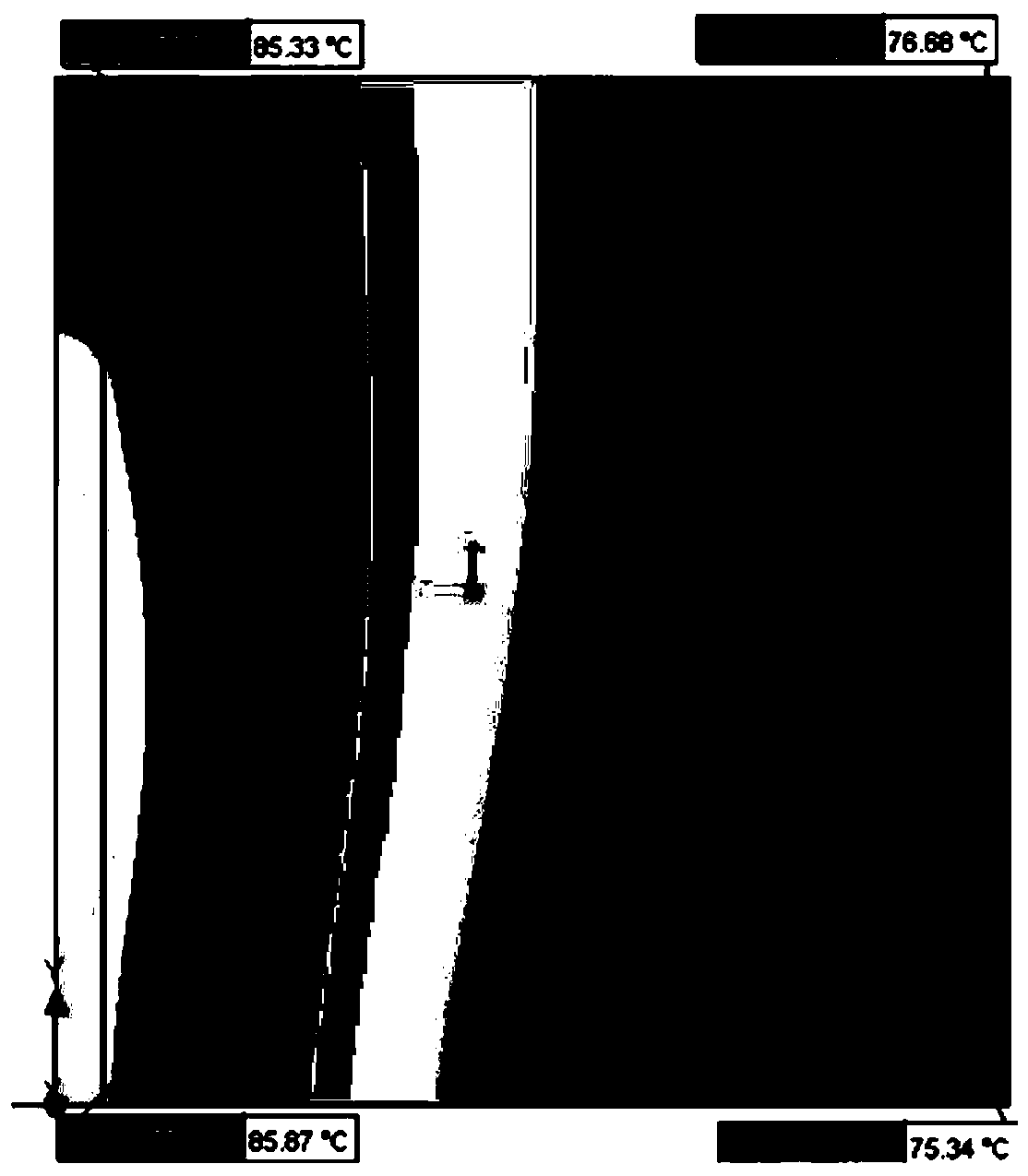

Multi-dimensional phase change radiator and manufacturing method thereof

PendingCN111031748AImprove cooling efficiencyImprove heat dissipation uniformityModifications using liquid coolingModifications by conduction heat transferPhysicsCommunications-electronics

Owner:上海合辰科新材料有限公司

One-dimensional temperature field modulation method

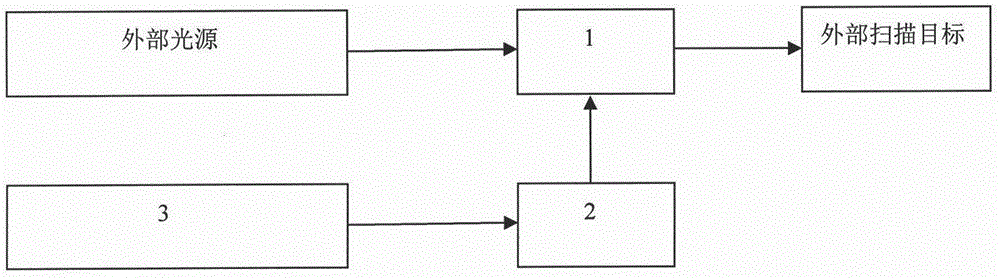

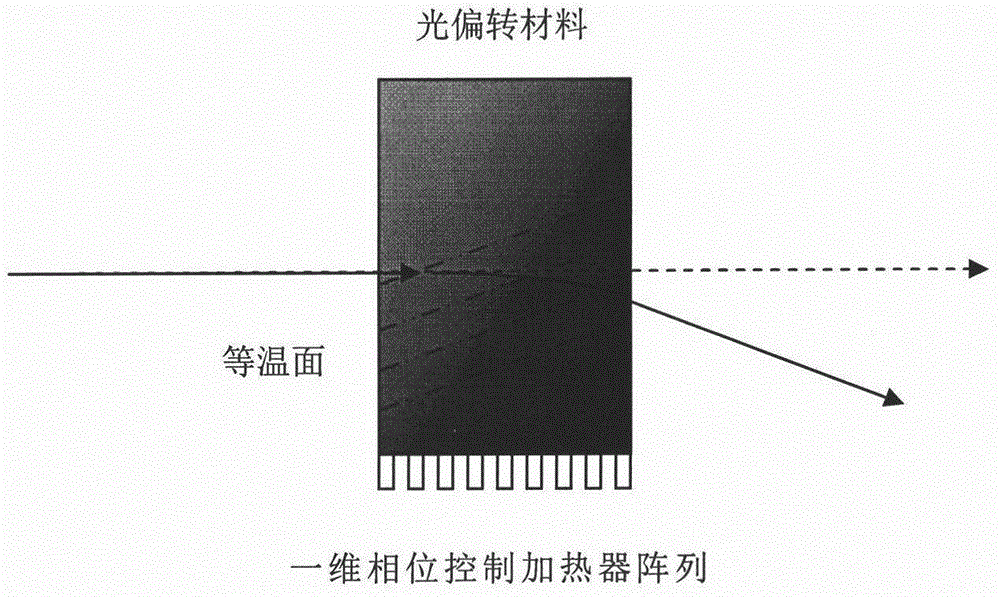

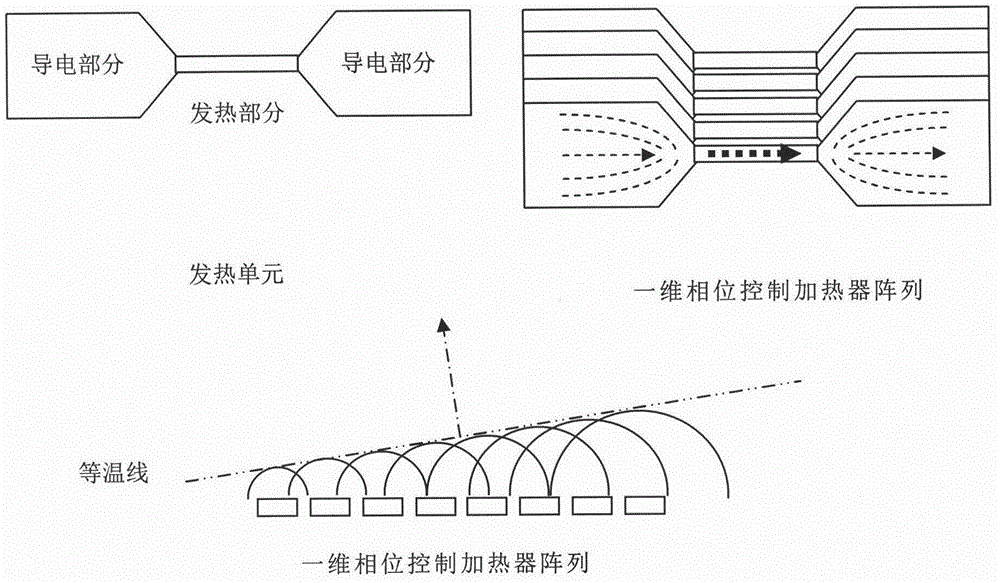

The invention relates to a one-dimensional temperature field modulation method, in particular to a method for carrying out one-dimensional temperature field modulation by adopting a one-dimensional phase control heater array. The modulation method comprises the following steps of: 1) calculating driving signal phase difference between two adjacent heating units in the one-dimensional phase control heater array; 2) inputting the driving signal phase difference obtained in the step 1) into a control circuit to produce a multichannel driving signal with specific phase difference between two adjacent signals; and 3) transmitting the multichannel driving signal obtained in the step 2) to a corresponding heating unit in the one-dimensional phase control heater array, so as to produce an inclined gradient temperature field in a light deflection material, and a solid-state optical scanning device realizes light beam deflection and scanning.

Owner:蚌埠正浩电子科技有限公司

Preparation method and application of large-particle-size spherical dialkylphosphinate

ActiveCN106632464ALarge particle sizeShape ruleGroup 5/15 element organic compoundsLarge particleSeed crystal

The invention discloses a preparation method and application of large-particle-size spherical dialkylphosphinate. Preparation methods and application of present dialkylphosphinate have many defects. The preparation method of the invention comprises the steps of 1) preparing dialkylphosphinic acid or / and dialkylphosphinate into a solution; 2) adding a compound, dissolved in an alcohol or / or aqueous solution and containing nitrogen or both nitrogen and phosphorus, as precipitation seed crystal into the solution of dialkylphosphinic acid or / and dialkylphosphinate, and adding suitable surfactant to provide improved dispersion to obtain mixed solution; 3) dropwise adding soluble metal salt solution into the above mixed solution, cooling after reacting, filtering, washing, and drying to obtain the large-particle-size spherical dialkylphosphinate. The large-particle-size spherical dialkylphosphinate of the invention can be added to a polymer material as a halogen-free flame retardant in order to improve polymer mobility, and the mixing effect is significant.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM +1

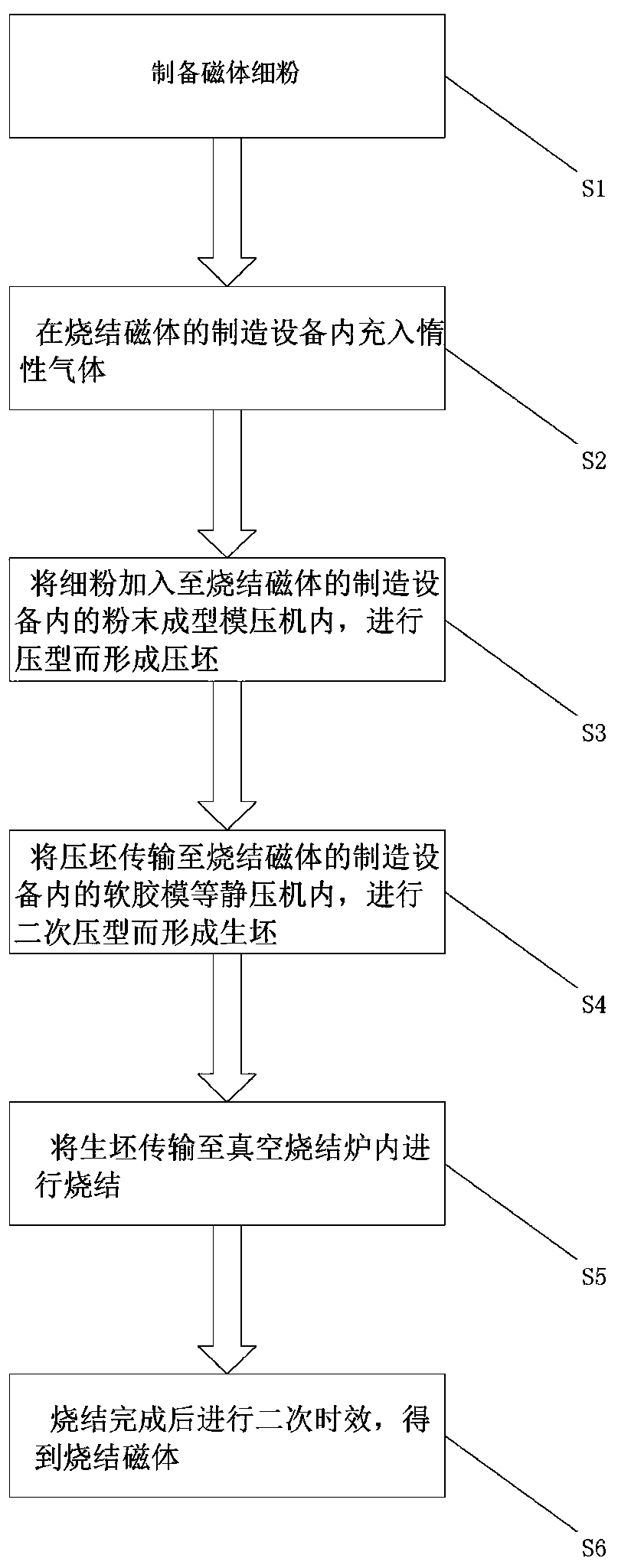

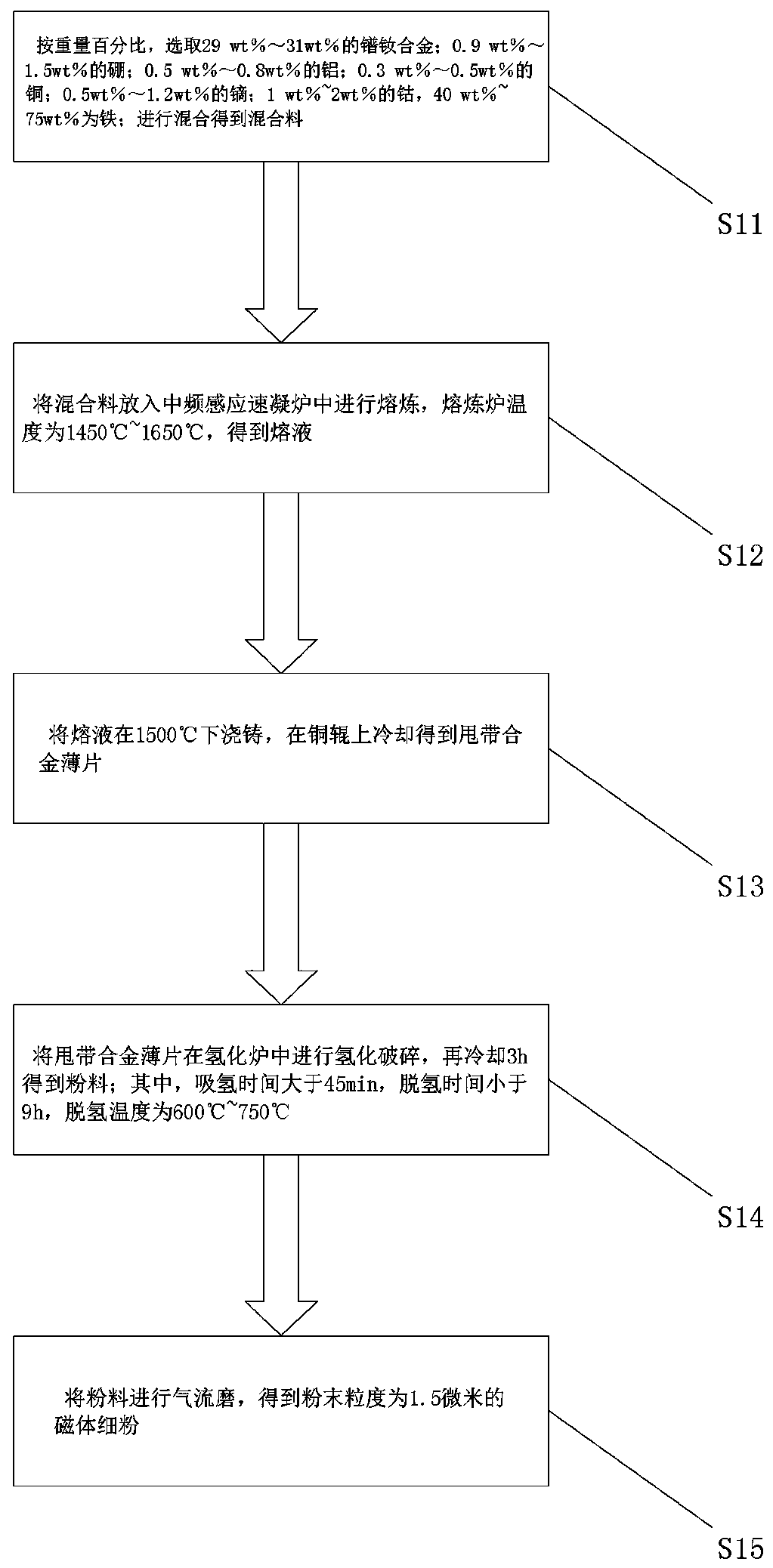

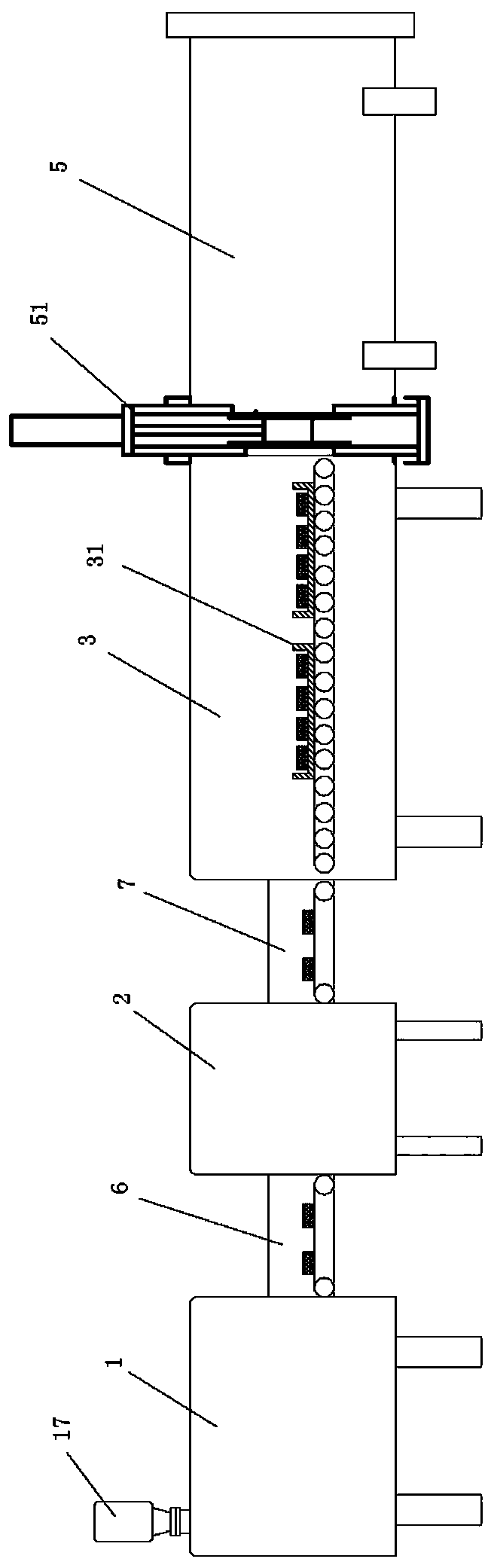

Method and equipment for manufacturing continuous sintered magnet

PendingCN110323022AAvoid crackingShape ruleInductances/transformers/magnets manufactureMagnetic materialsCompression moldingDouble-time

The invention relates to the technical field of magnet material production, and relates to a method and equipment for manufacturing a continuous sintered magnet; the preparation method comprises the following steps of firstly, preparing fine powder of the magnet; secondly, filling inert gas into the manufacturing equipment of the continuous sintering magnet; then adding the magnetic fine powder into a powder forming molding press in the manufacturing equipment of the continuous sintering magnet, and performing compression molding to form a pressed blank; then conveying the pressed blank to a soft rubber die isostatic pressing machine in the manufacturing equipment of the continuous sintering magnet, and carrying out secondary compression molding to form a green body; then conveying the green body into a vacuum sintering furnace for sintering; and finally, carrying out secondary aging after sintering is completed, so as to obtain the sintered magnet. According to the method, the inert gas is introduced into the manufacturing equipment of the continuous sintered magnet, under the protection of inert gas, the fine powder of the magnet is subjected to double-time compression, so that after compression molding, the shape is regular, the density is uniform, the orientation degree is good, and then sintering is carried out to prepare the magnet, so that cracking and corner missing arenot formed easily on the magnet, and the percent of pass is ensured.

Owner:JIANGXI JLMAG RARE EARTH

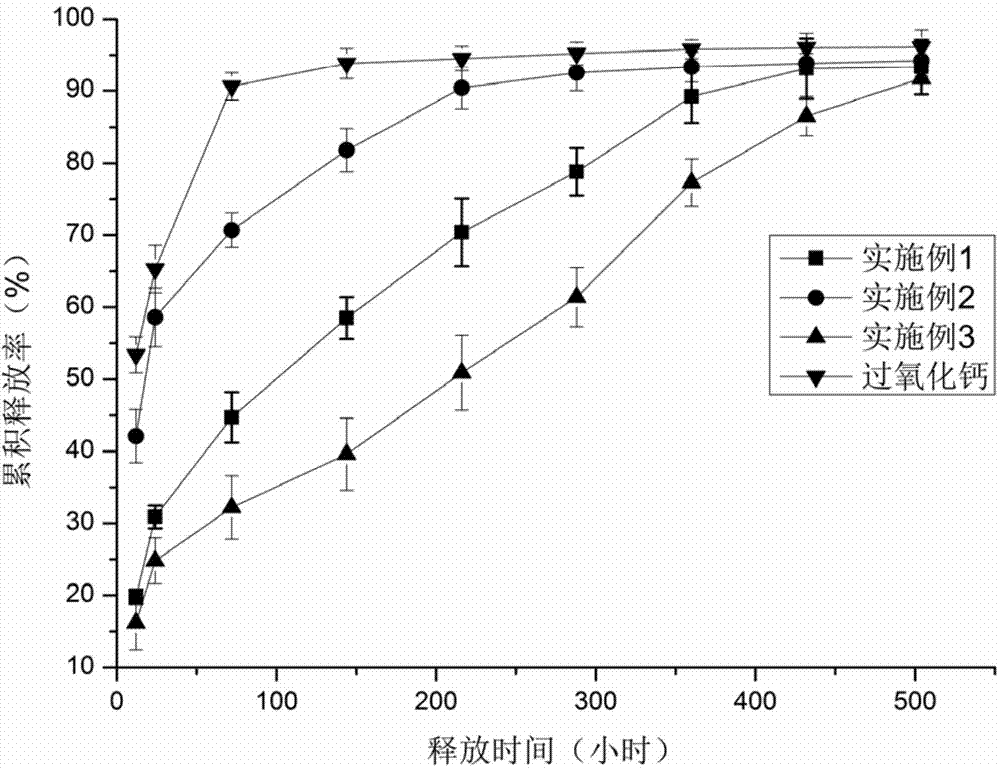

Calcium peroxide microcapsule and preparation method thereof

ActiveCN104840484AGood size controlShape ruleAntibacterial agentsPeroxide active ingredientsDrug release rateCellulose

The invention discloses a preparation method of a calcium peroxide microcapsule. The method comprises the following steps: 1, dissolving a polymer in dichloromethane to obtain a polymer solution, wherein the polymer is ethylcellulose or a polylactic acid and ethylcellulose mixture; 2, adding calcium peroxide to the polymer solution obtained in step 1, and stirring for dispersion; and 3, adding petroleum ether to a reaction system obtained in step 2 in a dropwise manner, and stirring for dispersion to obtain the calcium peroxide microcapsule. The calcium peroxide microcapsule prepared through the preparation method has the advantages of controllable dimension, regular profile, and controllable drug release rate, and a pulvis is convenient for oral local application; and the preparation method has the advantages of simplicity, feasibility, high preparation efficiency, and convenience for large scale application.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

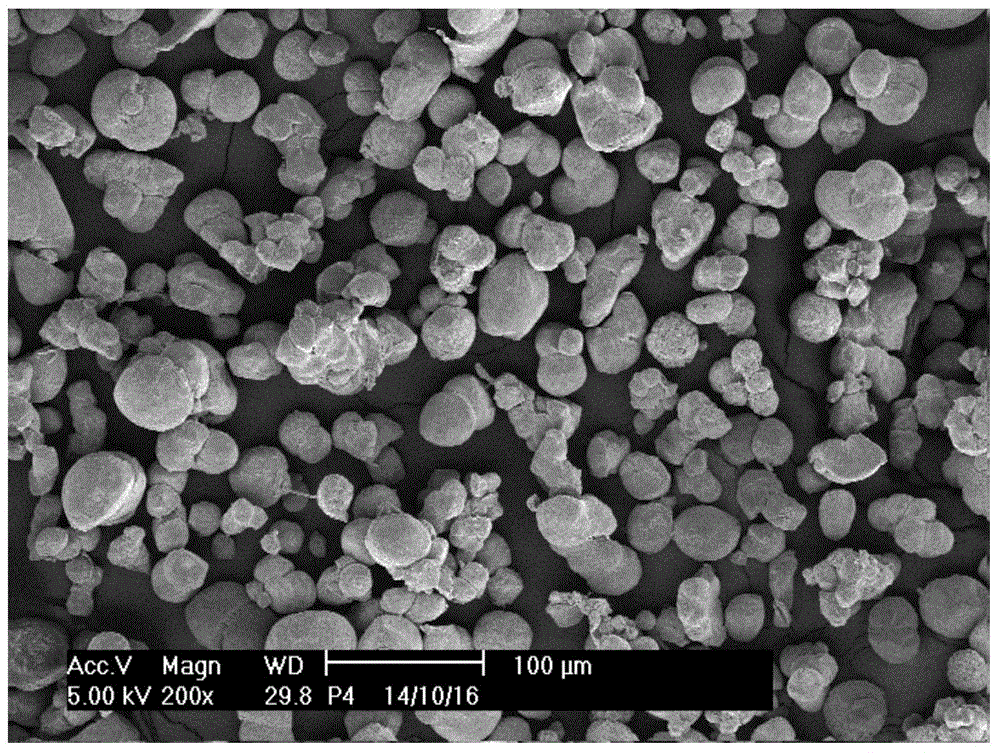

Polylactic resin powder for selective laser sintering and a preparation method thereof

The invention provides a preparation method of a polylactic resin powder for selective laser sintering. The preparation method includes the following steps: a) at a heating temperature, dissolving polylactic resin in an organic solvent composed of at least one of acetone, butanone, 2-pentanone, 3-pentanone, cyclopentanone, methyl isopropyl ketone, tetrahydrofuran and dioxane to obtain a polylactic resin solution; and b) decreasing the temperature of the polylactic resin solution to separate out a solid precipitate. In the method, a proper solvent is firstly selected, and then proper temperature increasing and decreasing methods are designed at certain temperature and under certain pressure, thereby preparing the polylactic resin powder raw material which is very suitable for the selective laser sintering in shape, characters and the like. The method is free of other additives and can be used for producing the polylactic resin powder, which is moderate in size, has a smooth surface, is good in dispersibility, is small in particle size distribution and has proper bulk density, for the selective laser sintering.

Owner:CHINA PETROLEUM & CHEM CORP +1

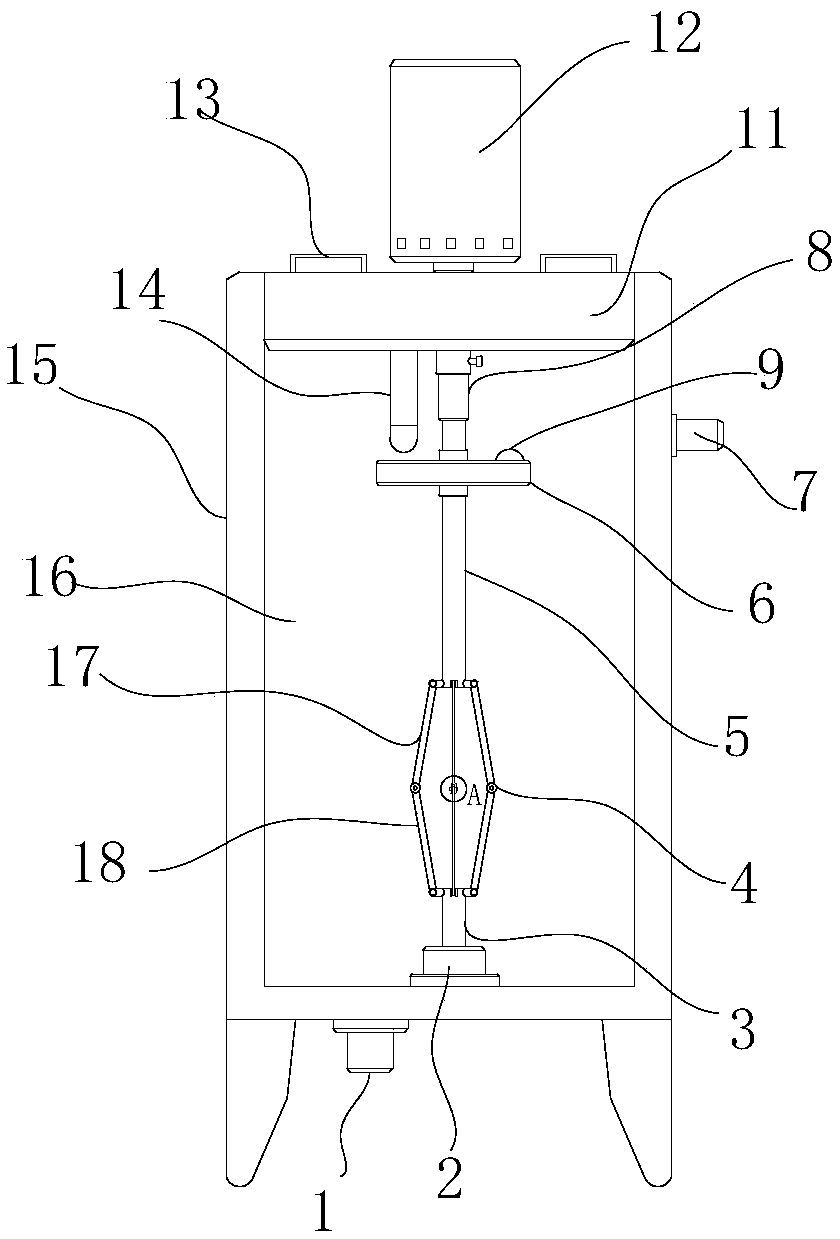

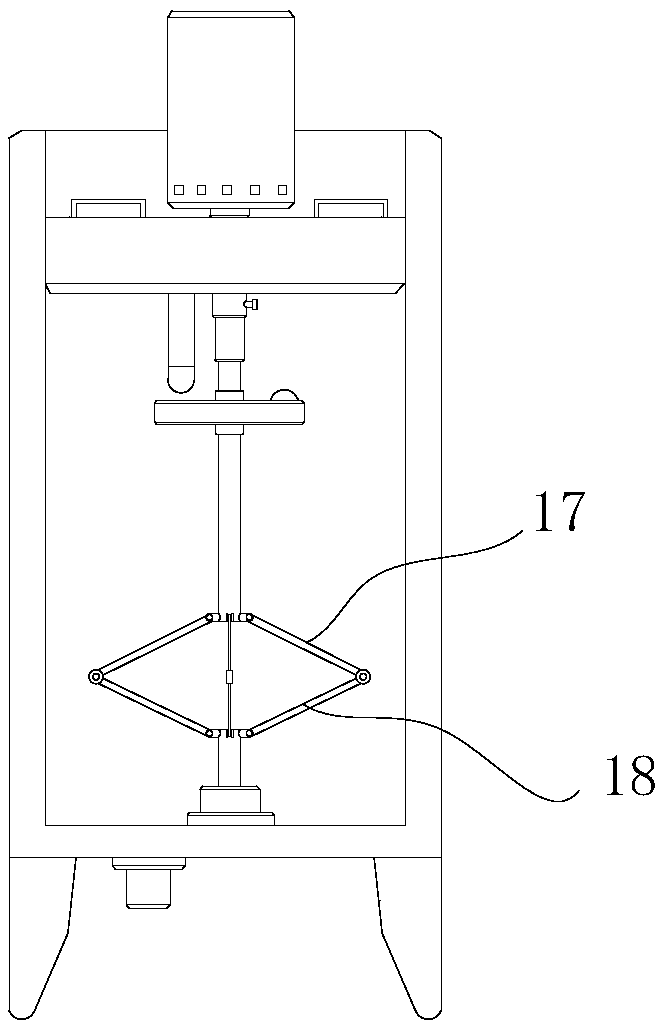

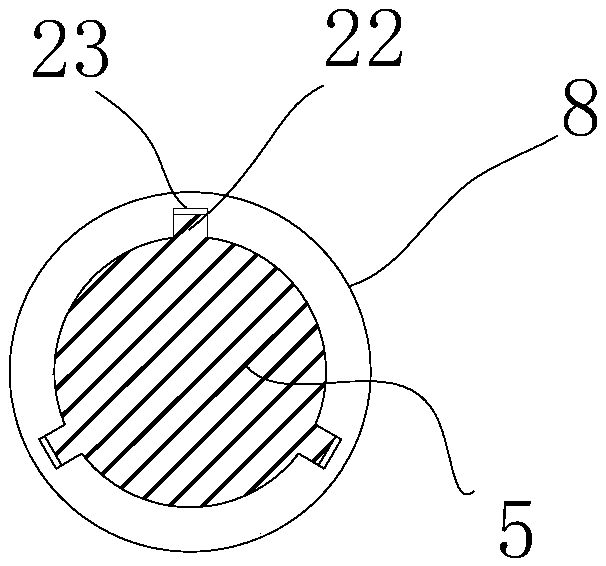

Concrete stirrer

ActiveCN108972886AAdjust the mixing widthDifferent mixing effectsCement mixing apparatusCouplingArchitectural engineering

The invention discloses a concrete stirrer. The concrete stirrer comprises a stirring shell, wherein the upper end face of the stirring shell is open; the inner wall of the opening end is provided with an internal thread; a rotating cover is arranged in the opening end in a threaded manner; the outer wall of the rotating cover is in threaded engagement with the internal thread of the opening end;a driving motor is arranged on the top of the rotating cover; a motor shaft of the driving motor is connected with a connecting rod through a coupler; a first rotating rod is arranged in the connecting rod in a telescopic manner; the top of the first rotating rod is arranged in the connecting rod in a telescopic manner; the bottom of the first rotating rod is provided with one or above first stirring blades around the first rotating rod. By adopting the concrete stirrer, the included angle between a first stirring blade and a second stirring blade can be adjusted by means of the height of therotating cover relative to the stirring shell in order to adjust the stirring width of the whole stirring blade, and lifting type opening-closing stirring can be realized during stirring, so that thestirring efficiency is improved greatly. When not being in use, the whole stirring rod is in a beeline form, so that the concrete stirrer is convenient to carry and clean.

Owner:天门市天安建材有限公司

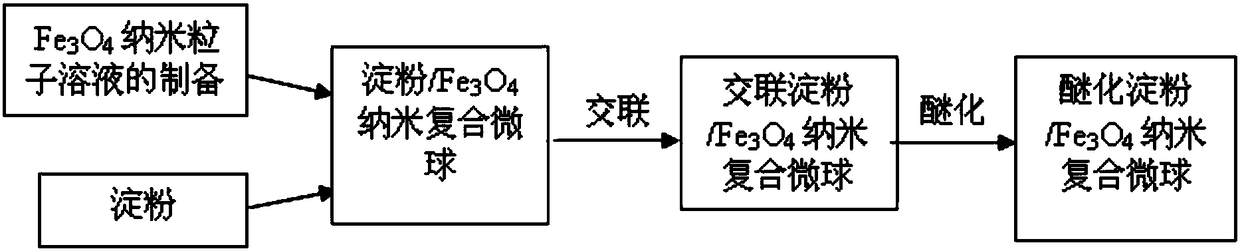

Modified starch water treatment agent and preparation and application methods thereof

ActiveCN108147518AReduce environmental pollutionBroad application prospectsWater contaminantsWater/sewage treatment by flocculation/precipitationIonChemistry

The invention discloses a modified starch water treatment agent and preparation and application methods thereof. The preparation method of the modified starch water treatment agent comprises (1) adding water into Fe3O4 nanoparticle solution, performing ultrasonic treatment, adding in starch, performing ultrasonic treatment, adding NaCl solution, performing ultrasonic treatment, and through reaction, obtaining starch / Fe3O4 nano composite microspheres; (2) mixing the starch / Fe3O4 nano composite microspheres, NaOH solution and epoxypropane for reaction to obtain cross-linked starch / Fe3O4 nano composite microspheres; (3) mixing and uniformly stirring the cross-linked starch / Fe3O4 nano composite microspheres, deionized water and epoxypropane, adding in perchloric acid for reaction to obtain themodified starch water treatment agent. The modified starch water treatment agent can be applied to treating heavy metal wastewater and is high in absorbing effects on hazardous heavy metal in industrial wastewater, and meanwhile, treated residues are easy to decompose by microorganisms to be free from toxicity and harm to the environment, thereby being a highly environment-friendly absorbing material.

Owner:湖南省塑料研究所有限公司

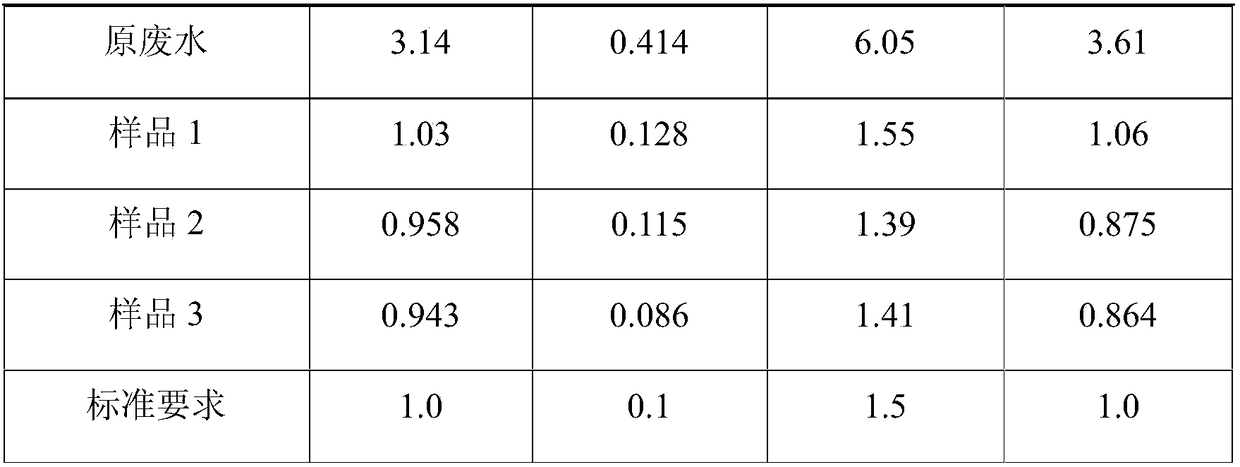

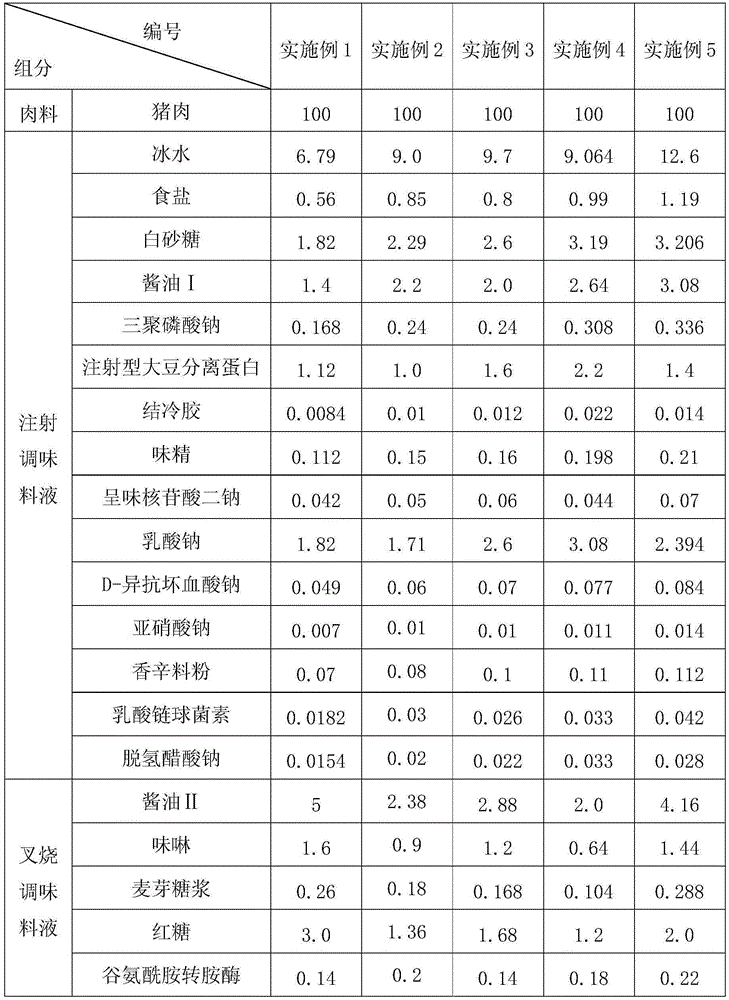

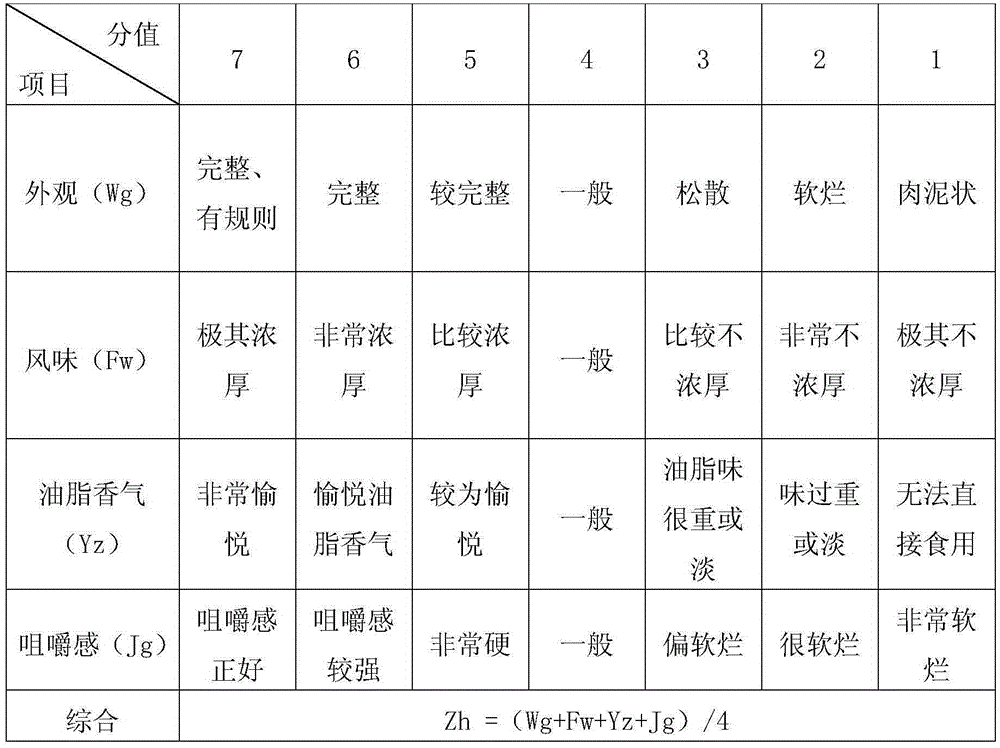

Japanese barbecued pork capable of being stored at room temperature and preparing method thereof

The invention discloses Japanese barbecued pork capable of being stored at room temperature and a preparing method thereof. The Japanese barbecued pork is prepared from, by weight, 100 parts of meat, 12-25 parts of injection seasoner liquid and 3.5-10 parts of barbecued pork seasoner liquid. The preparing method mainly comprises the steps of seasoner liquid preparation, meat preparation, pickling, sausage filling, curing, slicing, packaging, detection and sterilization. By optimizing the formula and the preparing method, the prepared Japanese barbecued pork has the advantages of being regular in shape, uniform and good in taste, high in fiber sense, high in chewiness, suitable for being stored at room temperature and long in storage life and has broad market prospects and great market benefits.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Carbon fiber-graphene filled flexible high thermal conductive insulating flame retardant plastic for LED and preparation method of plastic

InactiveCN106589856AHigh phosphorus contentImprove flame retardant performanceHeat-exchange elementsPolytetramethylene terephthalatePolymer science

The invention discloses a carbon fiber-graphene filled flexible high thermal conductive insulating flame retardant plastic for an LED and a preparation method of the plastic. The plastic is characterized by taking magnesium oxide, boron nitride, PBT, EVA, glass fiber, 107 glue, dibutyltin dilaurate, tetraethyl orthosilicate, melamine cyanurate, zinc borate, aluminum hypophosphite, bamboo charcoal, nano SiO2, butyltin chloride dihydroxide, graphene oxide, carbon fiber, aluminum oxide, 1-butyl-3-methylimidazolium hexafluorophosphate and the like as raw material. According to the plastic, H550 surface treated silicone rubber is prepared, butyltin chloride dihydroxide serves as a catalyst, and reinforcing and toughening treatment is conducted on polybutylene terephthalate (PBT) with nano SiO2; a composite flame retardant is prepared from aluminum hypophosphite and melamine cyanurate; the carbon fiber-graphene filled flexible high thermal conductive insulating flame retardant plastic for the LED is obtained.

Owner:铜陵市铜峰光电科技有限公司

Integzal type oxidation catalyst of sulfur dioxide possessing regular channels and its preparing method

InactiveCN1431046AHigh strengthIncrease production capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberFiber

An integral catalyst with regulator channels for oxidizing SO2 is prepared from vanadium oxide, alkali-metal compound, silicon oxide or the mixture of silicon oxide and silicon aluminium oxide as carrier, and glass fibres and / or asbestos fibres and / or meallic wool through mixing, moulding, demoulding, drying and calcining.

Owner:成都川大天华科技开发有限责任公司

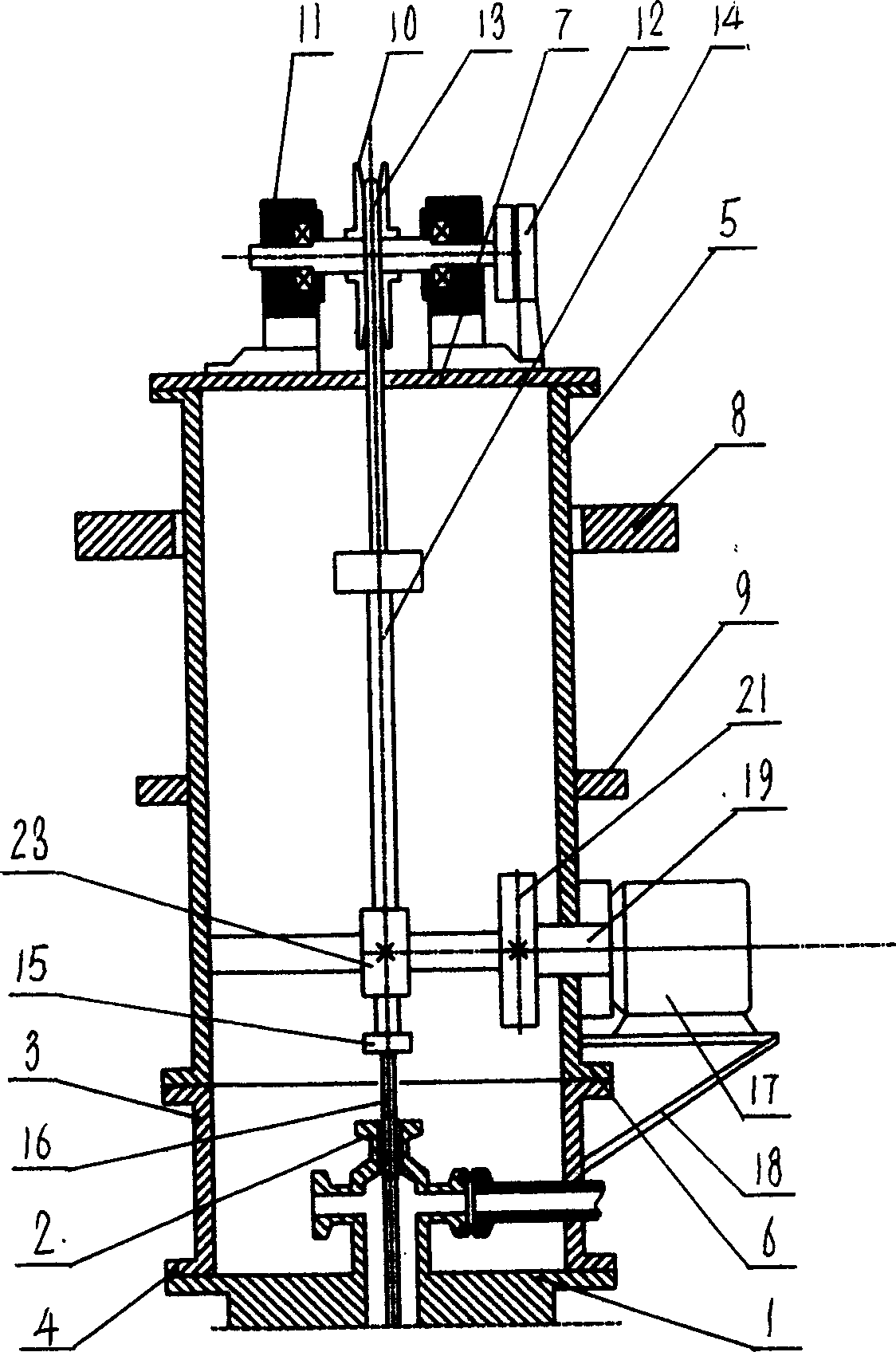

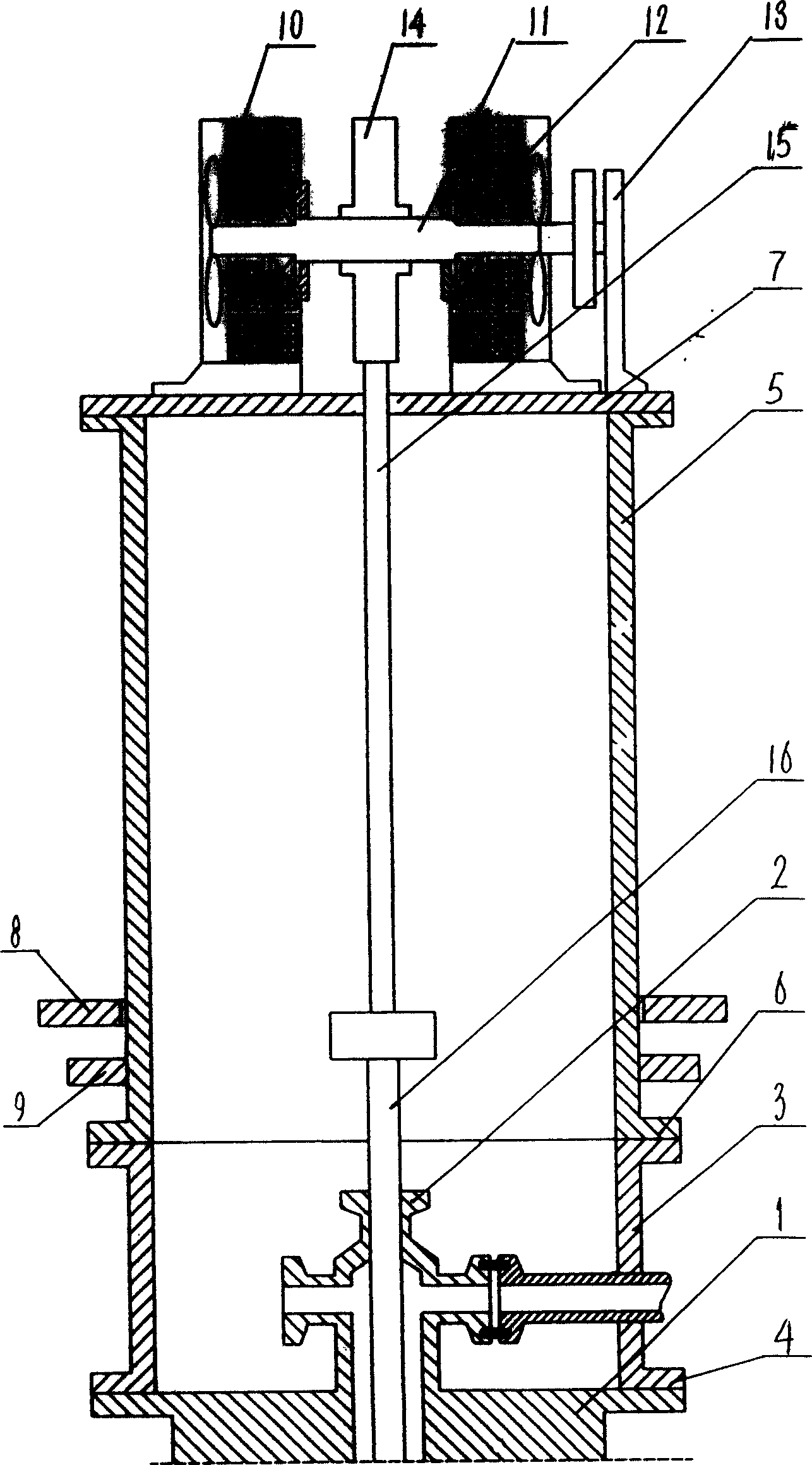

Vertical tube-gear rack type pumping unit

The vertical tube-gear rack type pumping unit consists of four-way assembly in the well head with oil well head in the center, pup joint in the well head connected to the four-way assembly, vertical tube on the pup joint, connected via flange to the pup joint and with cap in the top and annular balance weight around it, hoisting sheave installed on the vertical tube cap and capable of rotation in front and inverse directions, weight suspending rope with one end connected to the balance weight, gear rack connected to the other end of the weight suspending rope, pumping rod connected via the well head to the reciprocating pump in the well, and transmission mechanism to drive the gear rack to reciprocate up and down. The present invention has simple structure, regular outer appearance, short transmission line, less transmission parts, easy maintenance and long service life.

Owner:李华林

Hot-melting jig

Owner:镒生电线塑料(昆山)有限公司

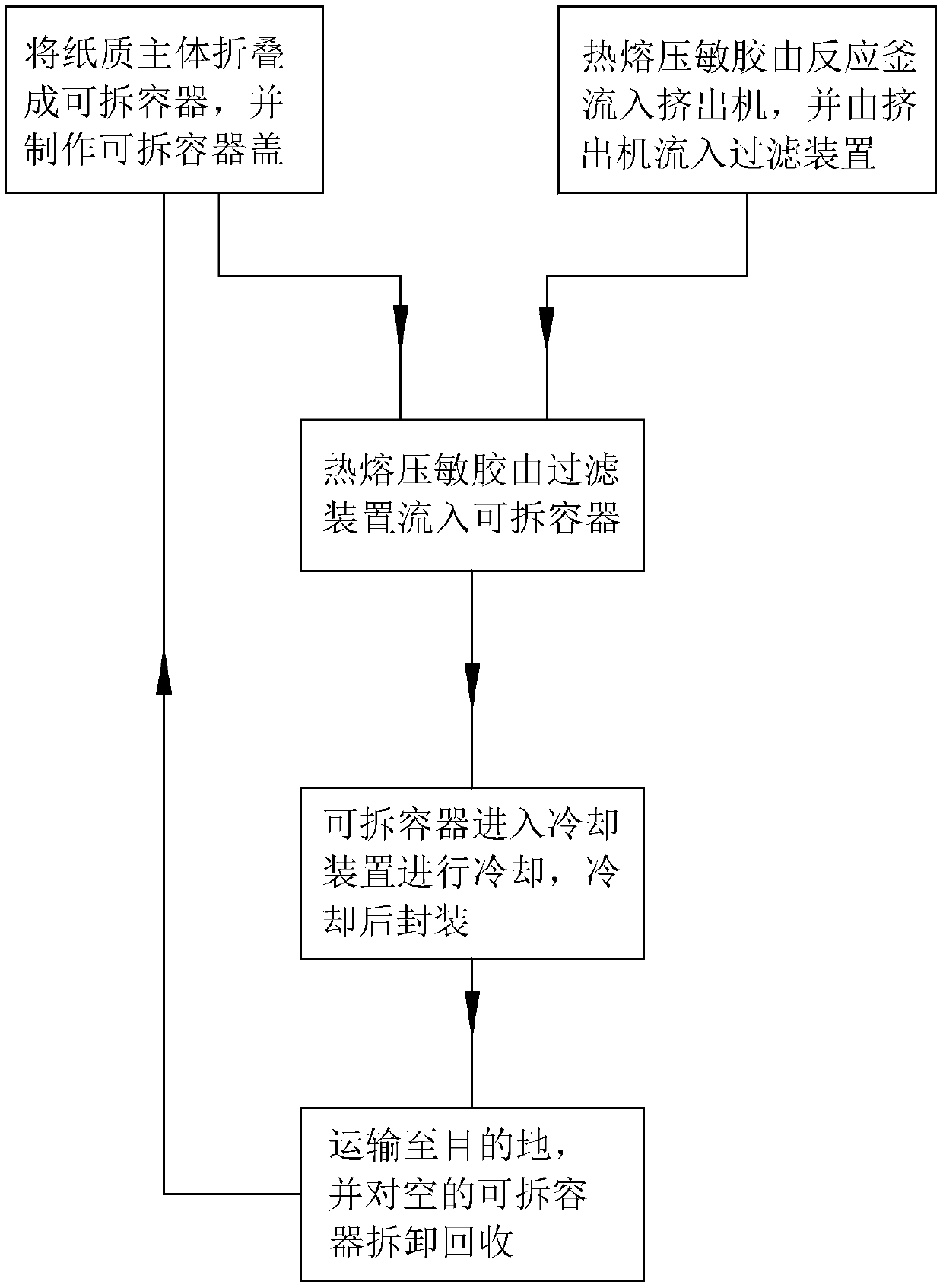

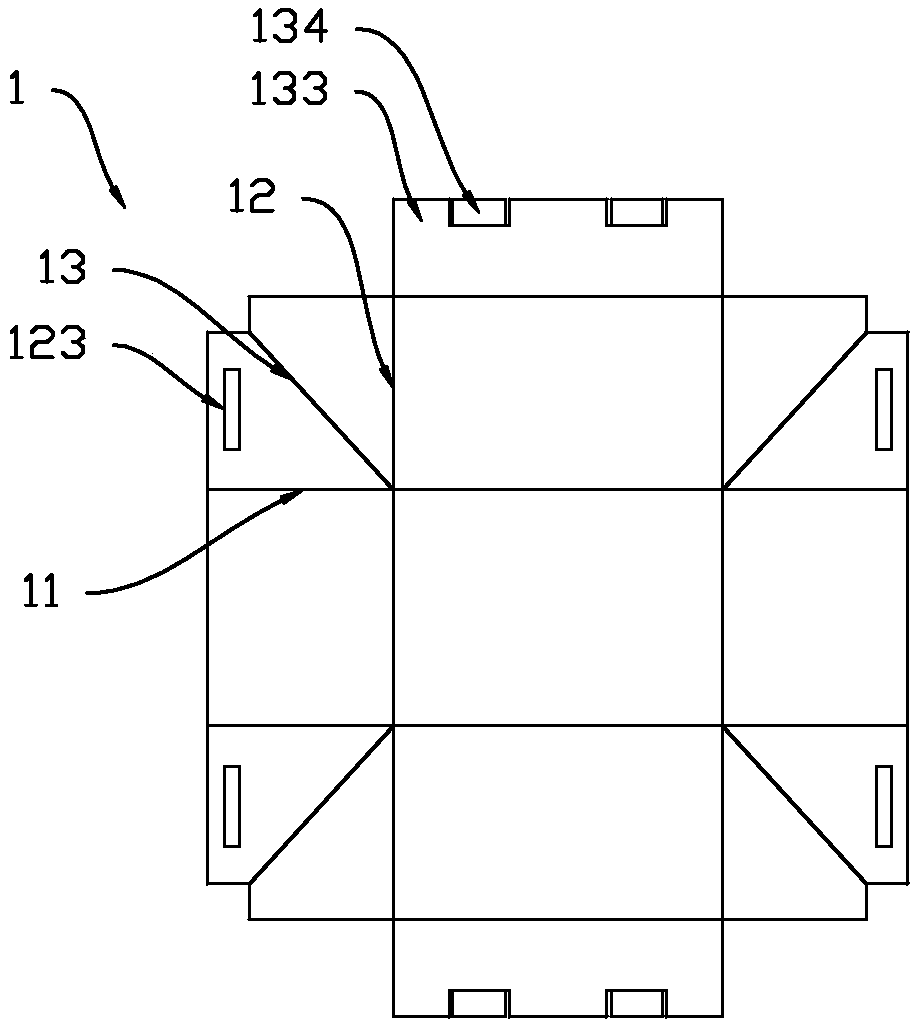

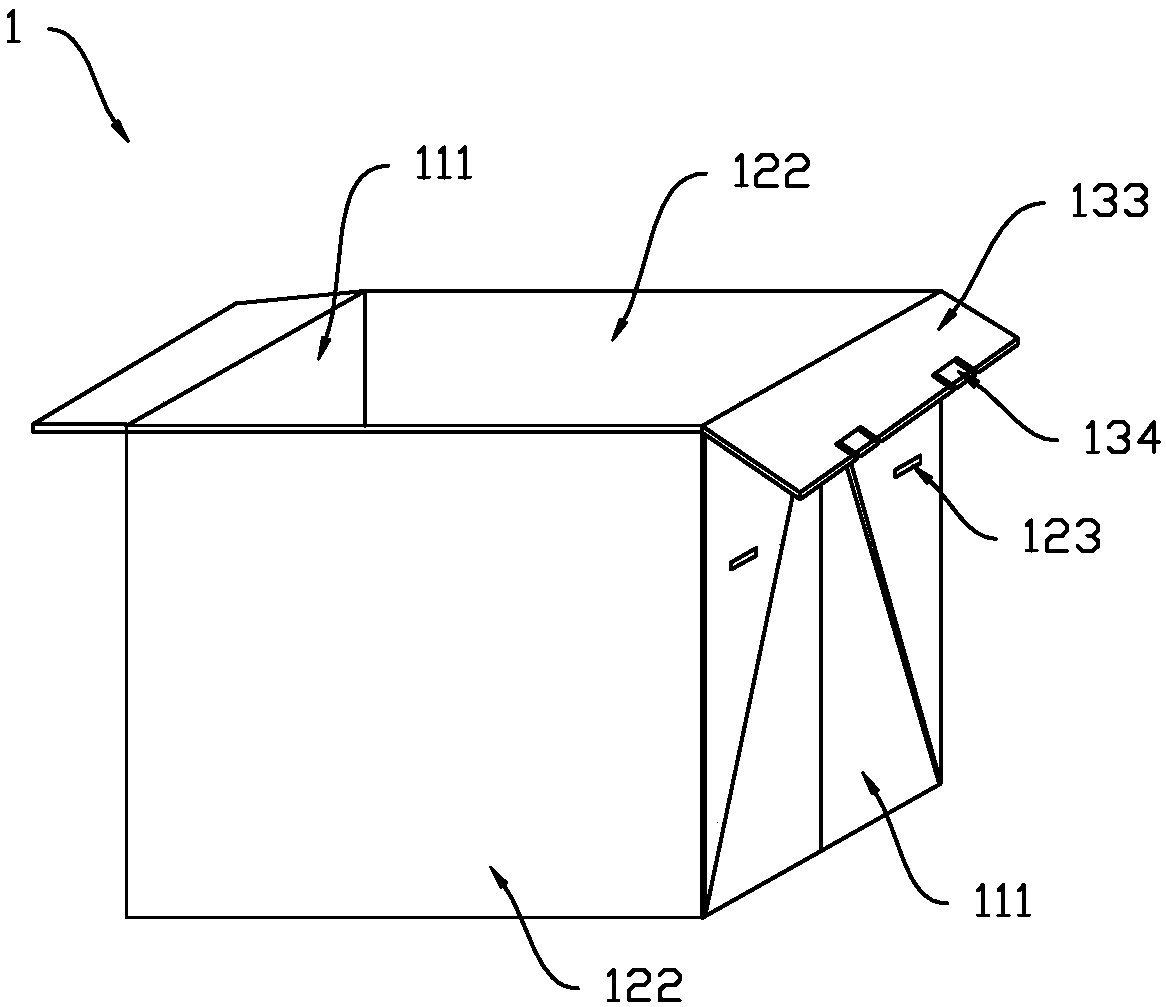

Packing method of hot-melt pressure-sensitive adhesive

Owner:旭川新材料(广东)股份有限公司

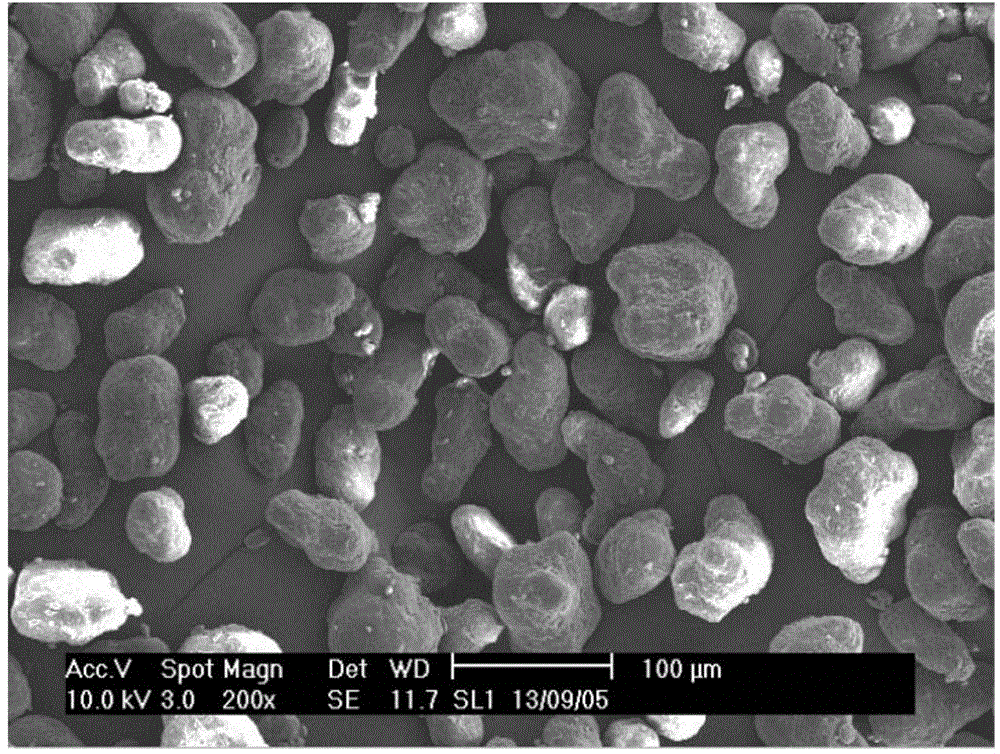

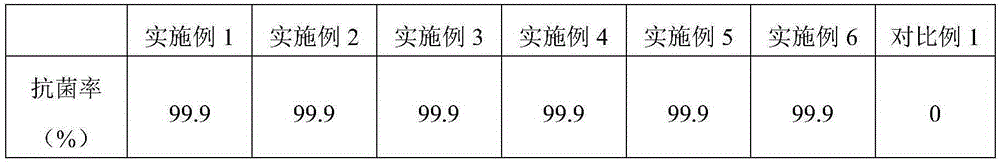

Antibacterial polypropylene resin powder used for selective laser sintering and preparation thereof

InactiveCN106565975AUniform particle size distributionGood fluidity of powderAlkaneSelective laser sintering

A preparing method of antibacterial polypropylene resin powder used for selective laser sintering is provided. The method includes a) dissolving polypropylene resin to an alkane organic solvent at a heating temperature to obtain a polypropylene resin solution, b) cooling the polypropylene resin solution prepared in the step a) to allow a solid precipitate to precipitate out, and c) adding auxiliary agents into a solid liquid mixture obtained in the step b), then fully mixing the mixture, and drying the mixture to obtain the power, wherein the auxiliary agents comprise an antibacterial agent, an antioxidant and a powder separating agent. The method is simple and easy to operate. A sintering raw material having excellent processing performance is provided for selective laser sintering, and a novel direction is provided for processing and application of functional polypropylene resin. The invention further provides the antibacterial polypropylene resin powder prepared by the method and a selective laser sintering method adopting the antibacterial polypropylene resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

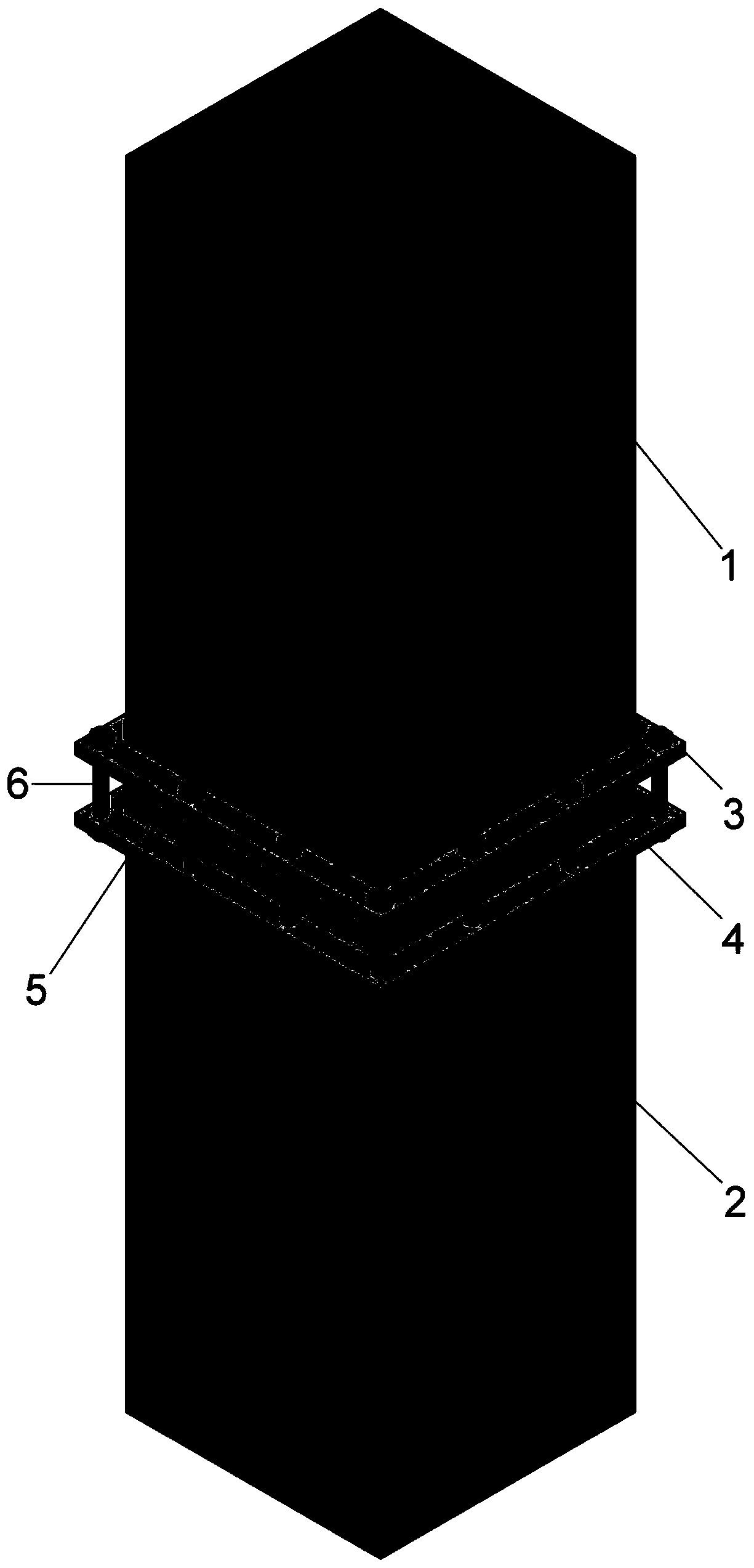

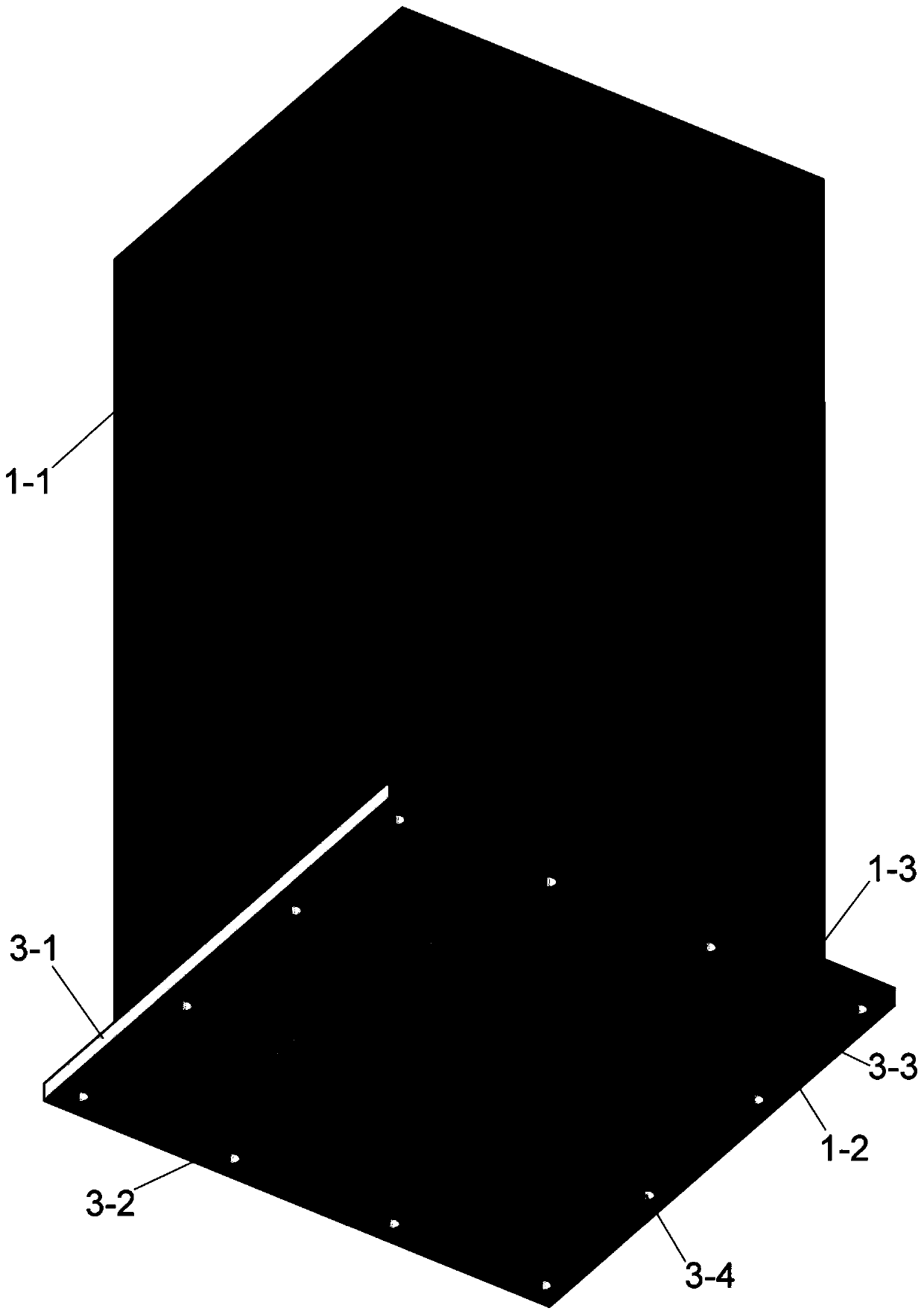

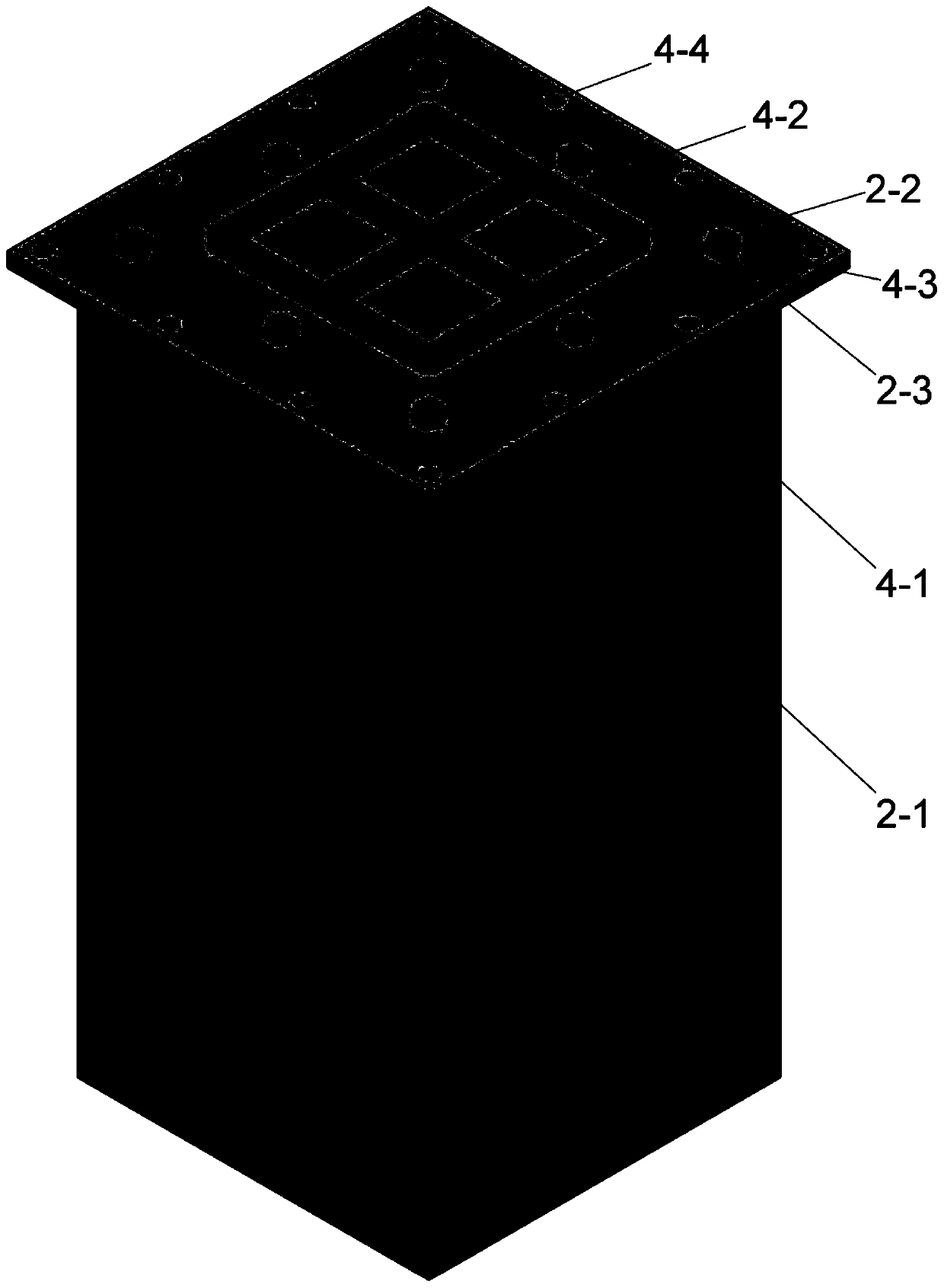

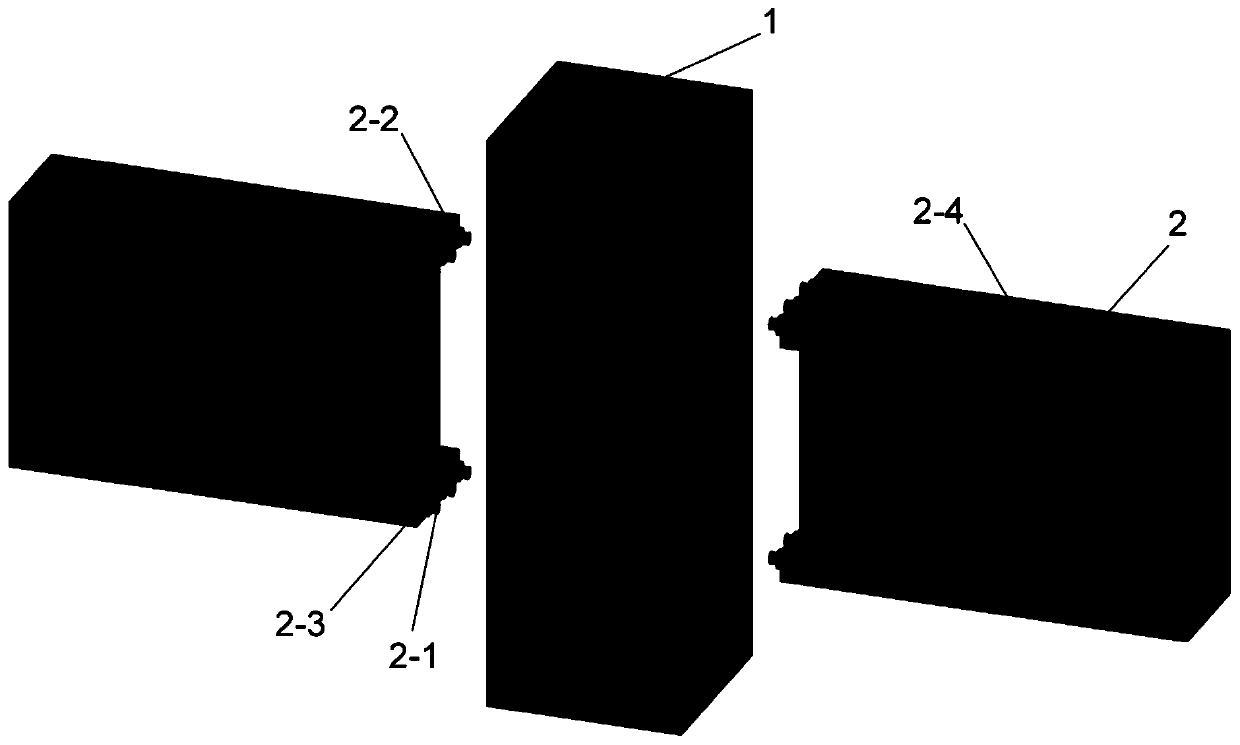

Steel plate interface bolt connecting structure and method for reinforced concrete column and column

InactiveCN110924525ASimple connection structureImprove performanceBuilding constructionsReinforced concrete columnEngineering

The invention discloses a steel plate interface bolt connecting structure and method for a reinforced concrete column and a column, and the connection of a prefabricated column and a column is realized by using a connecting bolt through an upper column steel plate assembly and a lower column steel plate which are fixed at the column bottom of an upper column and the column top of a lower column and an interlayer assembly clamped between the upper column steel plate assembly and the lower column steel plate. The prefabricated column is in a conventional regular shape, no rib is exposed, and nohole is reserved; the steel plate assemblies of the upper column and the lower column are each composed of an interface steel plate, a set of shear keys, a set of inner ring round holes and a set of outer ring round holes. The interlayer assembly is composed of a steel plate hoop and micro-expansion mortar filled in the steel plate hoop. The connecting method comprises the main steps: manufacturing the steel plate assemblies of the upper column and the lower column, and prefabricating the steel plate assemblies with the upper column and the lower column into a whole; placing the steel plate hoop in place and filling micro-expansion mortar in the steel plate hoop; connecting the upper column interface steel plate and the lower column interface steel plate through connecting bolts, and completing the connection of the upper column and the lower column. The invention provides the connecting structure with more simplified columns and excellent performances.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of composite diamond fretsaw

InactiveCN101838838BImprove control abilityImprove sharpnessElectrolytic coatingsFine working devicesDiamond wire sawAlloy

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

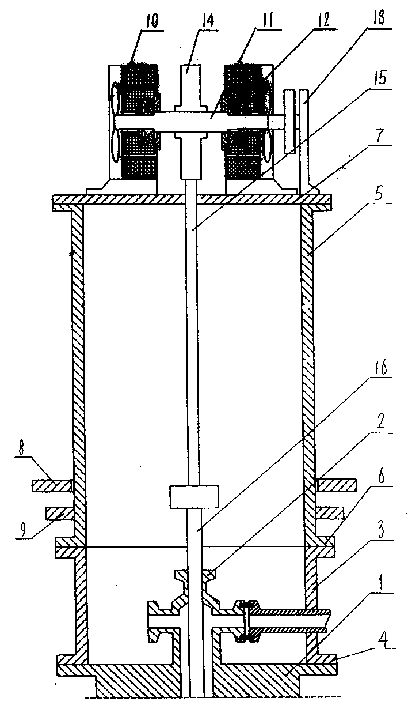

Split motor-drived vertical-pipe reciprocating chain pumping unit

The invention is a two-piece electric-machine drive vertical-tube type reciprocating-chain oil pumping unit, a beam-free one composed of wellhead large four-way, wellhead short section, vertical tube, electric machine, chain wheel and oil pumping rod. The large four-way is fixed at the wellhead and set with wellhead small four-way at the center; the well short section situated on the large four-way; the vertical tube situated on the short section, the top of the vertical tube set with a cap, and a ring balance weight slipping over the periphery of the vertical tube and able to slide upwards and downwards along the vertical tube; the electric machine is a two-piece permanent-magnet low-speed synchronous one, fixed on the cap and the output shaft supported on the right and left pieces by bearings; the chain wheel connected to the center of the output shaft by bond and able to rotate forwards and reversely under the electric machine drive; one end of the chain linked with the balance weight, and the other one linked with the upper end of the oil pumping rod round the chain wheel; the lower end of the oil pumping rod passing through the small four-way to link up with the underground reciprocating pump.

Owner:李华林

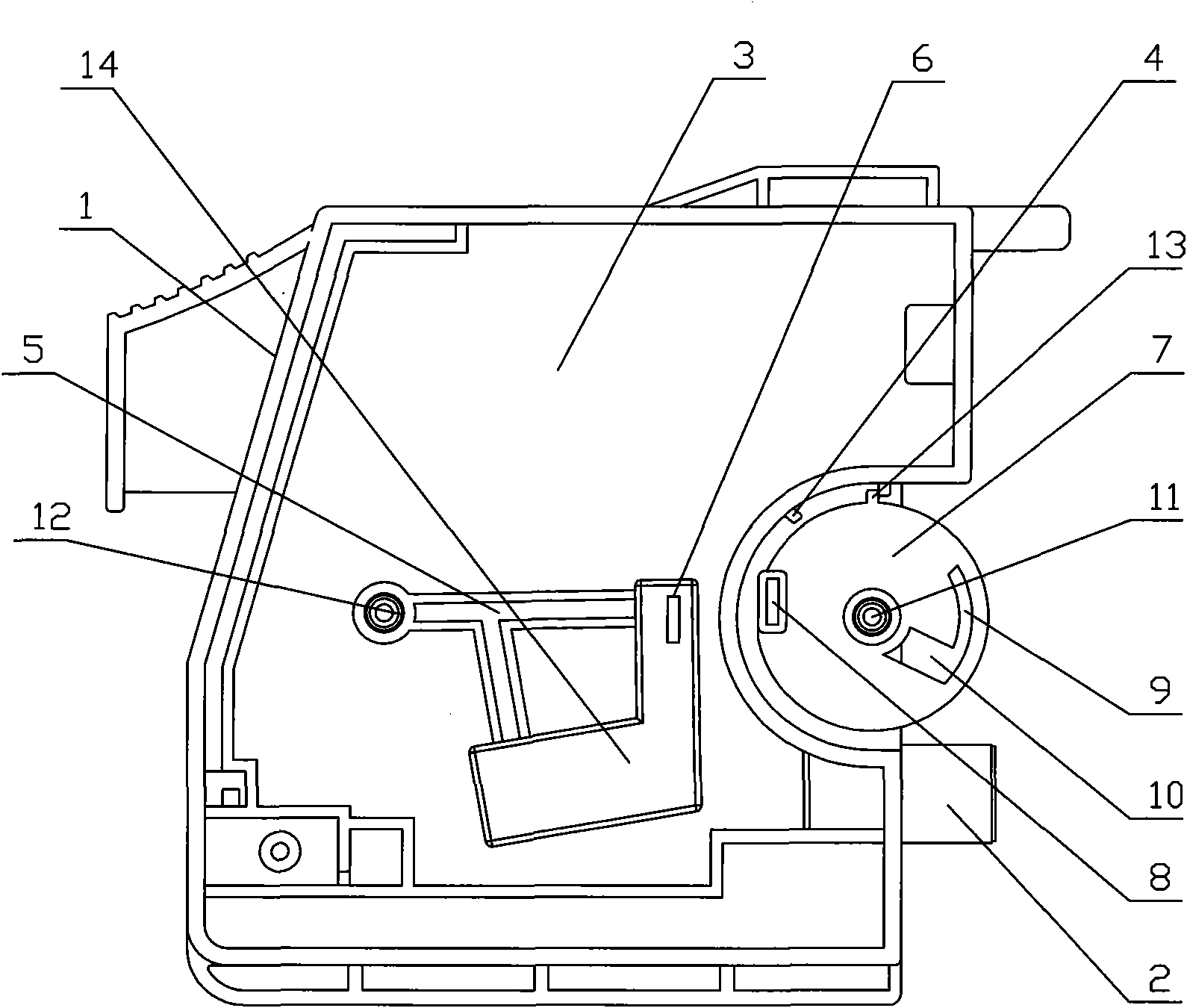

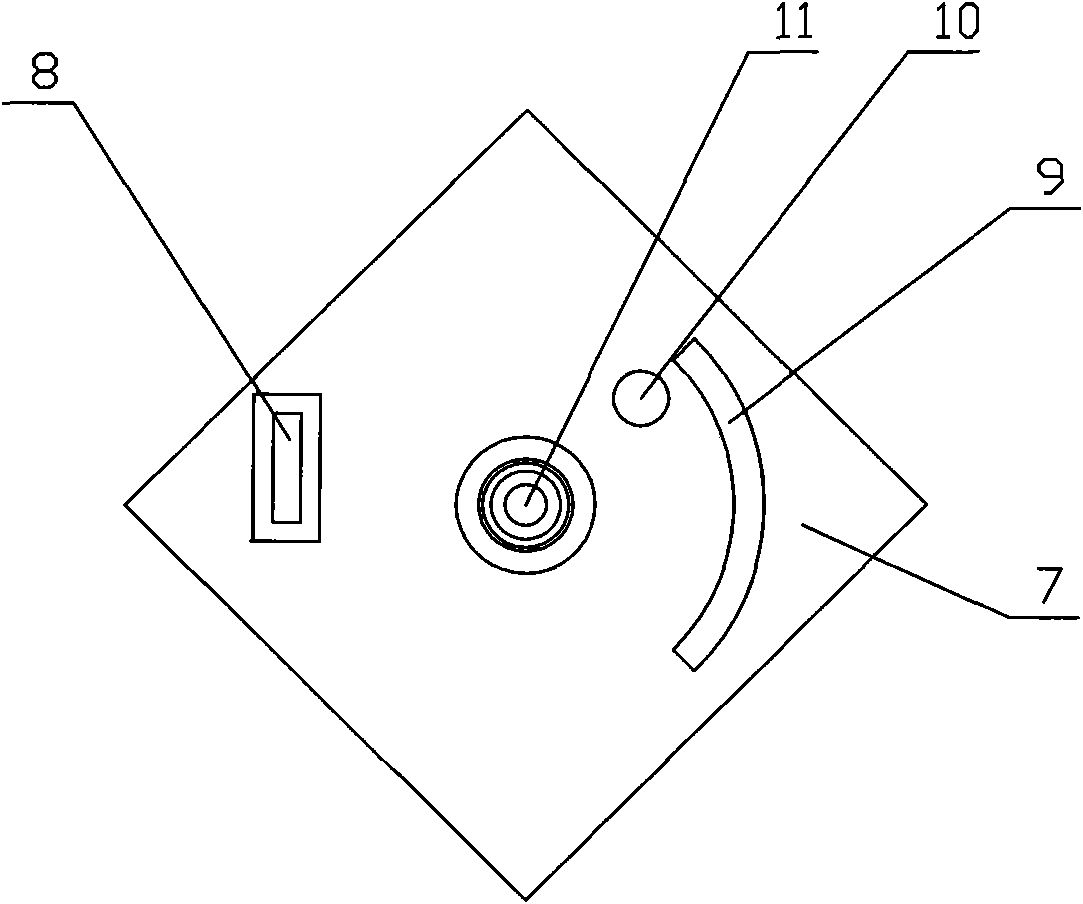

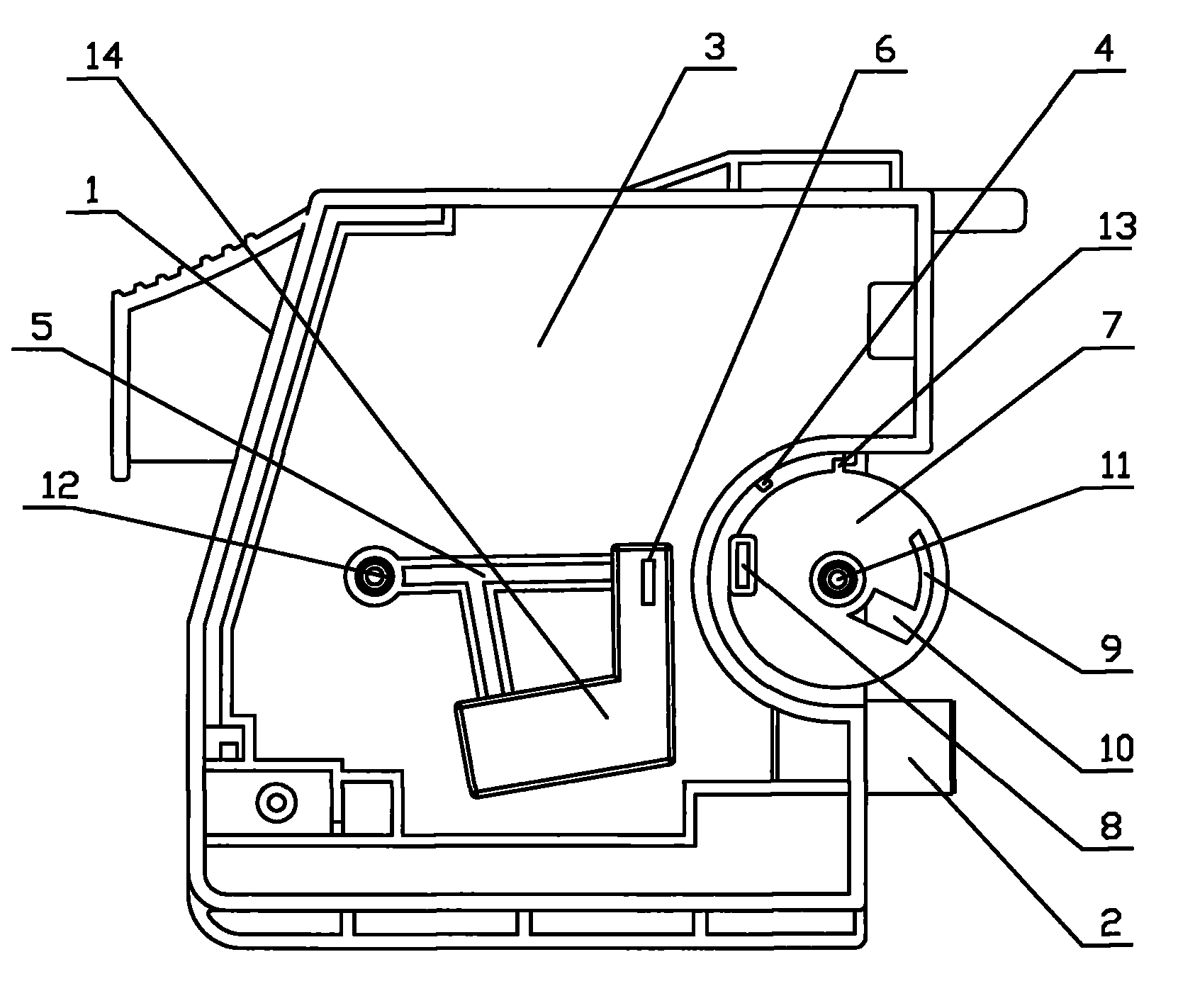

Ink box with steering wheel detection mechanism

The invention relates to an ink box with a steering wheel detection mechanism, which mainly comprises a box body and an ink outlet matched with a printer. The box body is internally provided with a containing cavity used for storing ink; a steering wheel which is adjacent to the containing cavity is arranged on the box body; the steering wheel is fixed on the ink box through a hinge fixing point and provided with a direction control part, an ink identification hole and an ink detection hole, wherein the direction control part is arranged at one side of the hinge fixing point and close to the containing cavity; the ink identification hole is arranged at the other side of the hinge fixing point, which is opposite to the direction control part; and the ink detection hole is arranged between the ink identification hole and the hinge fixing point and independent of the ink detection hole or crossed with the ink identification hole. The ink box with the steering wheel detection mechanism separates the containing cavity from the steering wheel, the ink identification hole and the ink detection hole are reasonably designed on the steering wheel, therefore, defects of the ink box are effectively avoided.

Owner:孙荣华

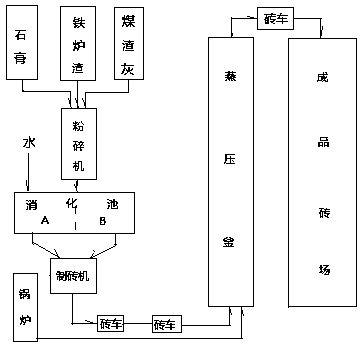

Stone coal slag autoclaved brick production method

The invention relates to a stone coal slag autoclaved brick production method. The stone coal slag autoclaved brick production method comprises limestone, stone coal, clay, vertical lime kiln, lime, alime warehouse, a stone coal clay slag, coal ash, a crusher, a digestion cell, water, a brick production machine, brick car, an autoclave, and a finished product brick yard. The stone coal slag autoclaved brick production method is characterized by comprising the steps of adding 10 to 20 percent of clay to be calcined when the lime is calcined, separating the lime from waste slag at an outlet ofthe lime kiln, wherein the waste slag comprises stone coal slag, clay slag and lime, since the slag comprises a given amount of silicate hydrogel substances and lime, the autoclaved brick is high in pressure resisting strength; by adding little coal ash into the digestion cell, adding 15 to 18 percent of water, mixing, naturally cooling the lime, digesting for 4 to 6 hours, producing the brick byvirtue of the brick production machine, placing the green brick onto the brick car, fully filling the autoclave, closing autoclave doors on two ends, introducing steam, autoclaving for 4 to 6 hours, then standing for 2 to 4 hours, jointly delivering the brick and the finished product brick car out of the autoclave, transporting to the finished product brick yard. The prepared autoclaved brick is smooth in surface, regular in appearance and high in strength, and has better performance than the clay brick.

Owner:杨朴

Eyedrop bottle

ActiveCN108785076AImprove effective space utilizationShape rulePharmaceutical containersMedical packagingEngineeringBottle

The invention discloses an eyedrop bottle, which comprises an outer bottle body, a corrugated silica gel inner liner is inserted into the outer bottle body, the upper end of the silica gel inner lineris connected with the extrusion part of the inner liner, the outer bottle body is internally and rotatbly mounted with a spiral driving sleeve sleeved on the external of the silica gel inner liner, the inner wall of the spiral driving sleeve is formed with driving inner threads; the outer wall of the extrusion part of the inner liner is formed with a driven bump matching with the driving inner threads, the upper part of the inner wall of the spiral driving sleeve is formed with ratchets; the upper end of the outer bottle body is connected with a button part, the upper part of the outer wall of the button part is formed with a guide bump, the upper end of the outer bottle body is formed with an inclined guide groove slidably matching with the guide bump, and the bottom end of the button part is formed with a ratchet part which coordinates with the ratchets to drive the rotation of the spiral driving sleeve. The eyedrop bottle has the advantages that the effective space utilization ratio is high, and the button part used for manual operation is only partially exposed to the top of the outer bottle body, making the overall shape of the packaging bottle more regular and beautiful.

Owner:SHENZHEN PEOPLES HOSPITAL

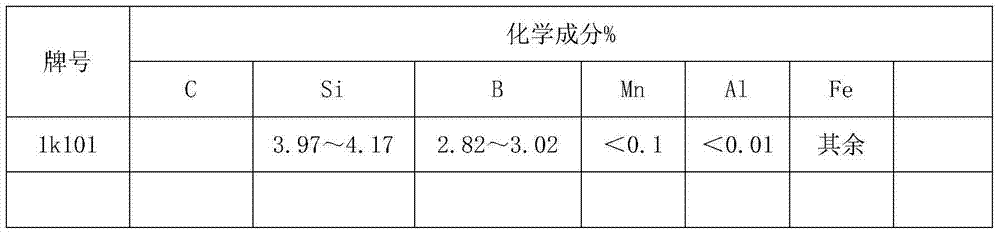

Method for producing amorphous alloy base material of round billet

The invention discloses a method for producing an amorphous alloy base material of a round billet. A high-capacity and medium-frequency furnace is utilized to smelt, and a horizontal continuous casting process is adopted to draw, so that a base material billet is regular in shape, and fewer in impurities by craft adjustment, and the produced base material is stable in quality and high in production efficiency.

Owner:JINAN JIGANG IRON ALLOY FACTORY

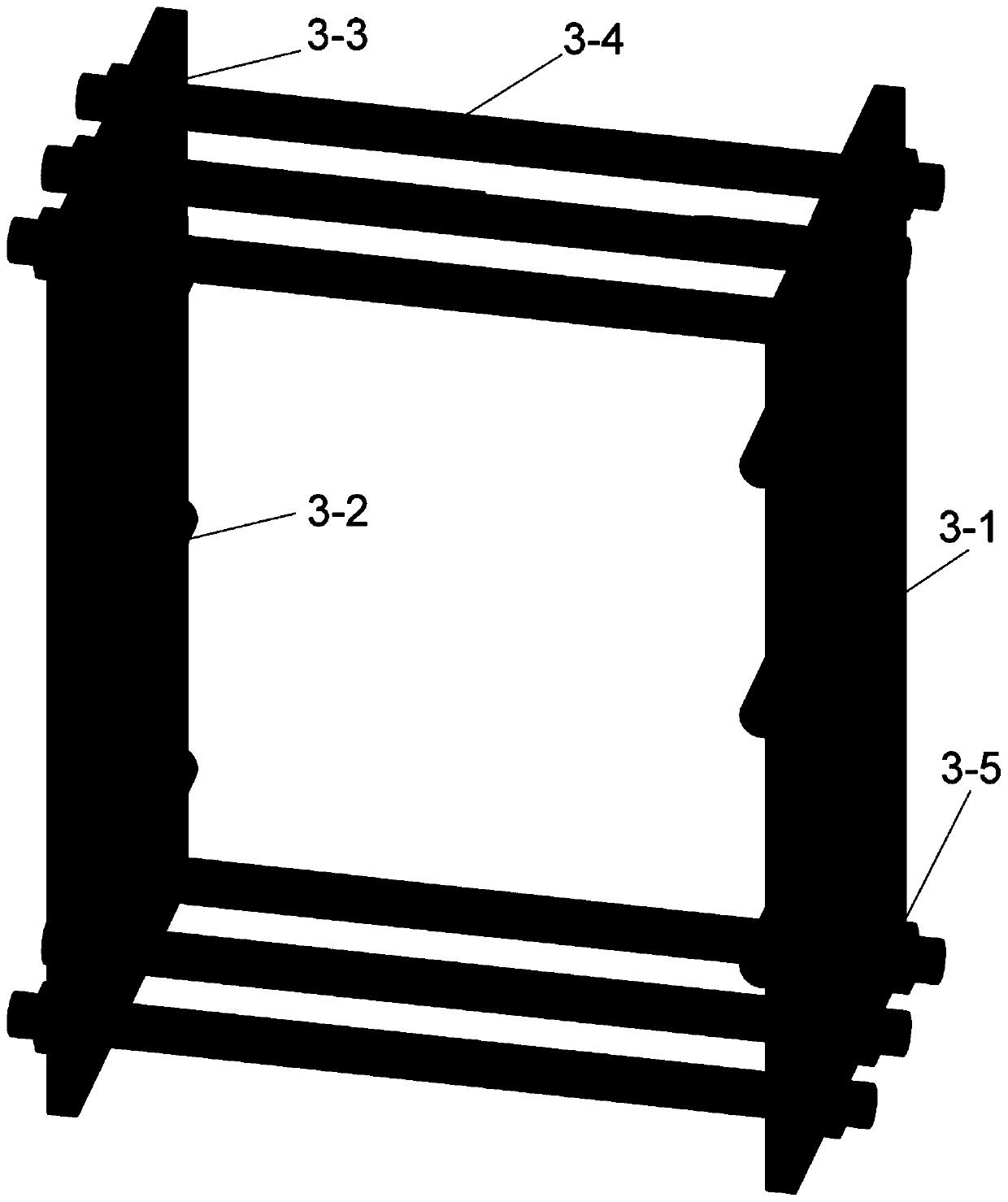

Steel plate interface connecting structure and method for reinforced concrete beam and column

The invention discloses a steel plate interface connecting structure and method for a reinforced concrete beam and column. The connection of a prefabricated column and a prefabricated beam is achievedthrough an auxiliary interface steel sleeve and a steel beam shoe. The interface steel sleeve is formed into a whole by connecting two interface steel plates, two groups of shear keys and two groupsof anchor tie bars, and the interface steel sleeve is embedded on the column; the steel beam shoe is a steel sleeve with openings in the two ends, wherein the steel sleeve is defined by two side plates, a bottom plate and a top plate. After assembly, the prefabricated beam is sleeved with the steel beam shoe. The interface steel sleeve and the steel beam shoe are connected through welding. Duringconnection, the interface steel sleeve and the column are prefabricated into the whole, then the bottom plate and the two side plates of the steel beam shoe are welded to the interface steel plate toform a notch, and the notch and the column are connected into the whole; the beam is seated in the notch of the steel beam shoe, and then the top plate of the steel beam shoe is welded to the interface steel plate and the side plates to form an enclosure; plug welding holes are welded, screws are screwed into the screw holes, and then the assembling connection is completed. The connecting structure provided by the invention has the advantages that the beam and the column are simplified, and the performance is excellent.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com