Preparation method and application of large-particle-size spherical dialkylphosphinate

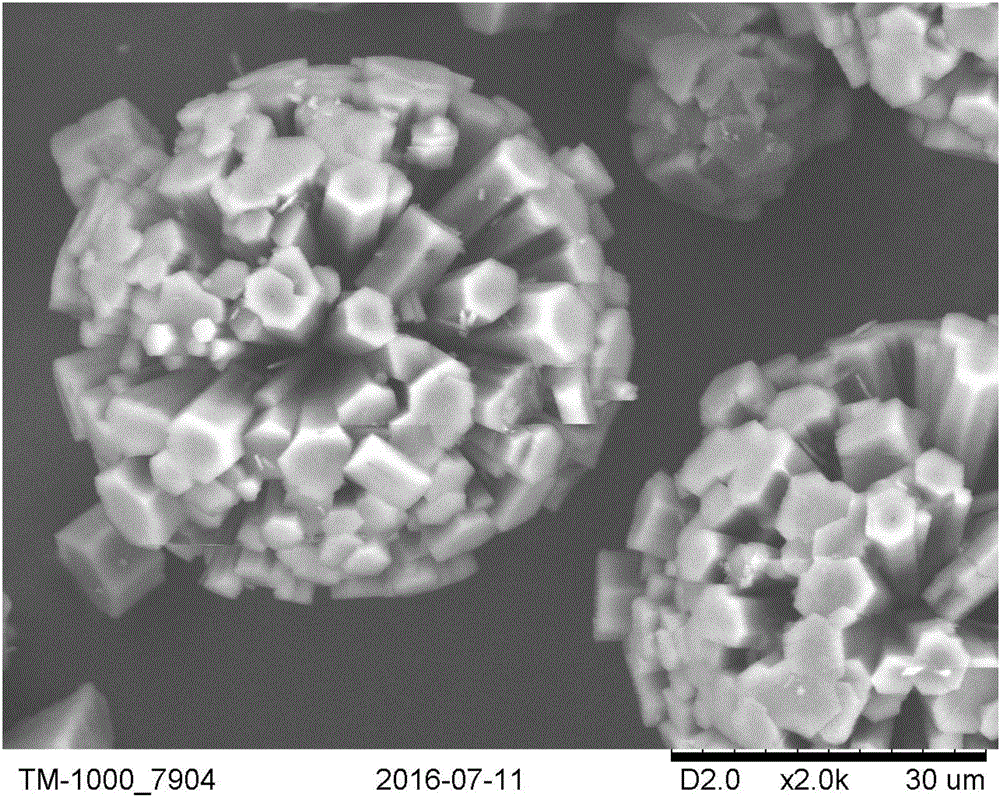

A technology of alkyl phosphinate and dialkyl phosphinic acid, which is applied in the field of preparation of large particle size spherical dialkyl phosphinate, to achieve the effect of improving equipment production capacity, simple filtration process, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 150 g of sodium diethylphosphinate and 600 mL of water into a 2000 mL four-necked flask equipped with a reflux condenser, an electric stirrer and a thermometer. With stirring, the solution was heated to 80°C.

[0042] 1.2 g of melamine polyphosphate was added to 50 g of 50% ethanol aqueous solution, and then 0.6 g of polyvinylpyrrolidone was added. With high speed stirring, the solution was heated to 50°C. After uniform dispersion, it was added to a four-necked flask to form a mixed solution.

[0043] The mixed solution was heated to 120°C under stirring and under pressure. Within 2.5 hours, 800 mL of a solution containing 115 g of aluminum sulfate octadecahydrate was added dropwise to the above mixed solution, and the mixture was reacted under pressure for 2 hours to obtain a white precipitate. Cool to room temperature, filter, wash, and dry to obtain a white powder product. The yield was 90.5%.

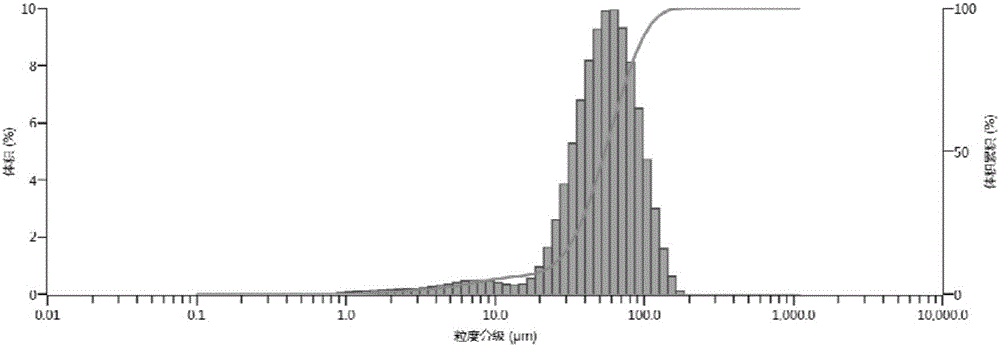

[0044] The product particle size (μm) distribution is: D(10): 2...

Embodiment 2

[0047] Add 150 g of sodium diethylphosphinate and 500 mL of water into a 2000 mL four-necked flask equipped with a reflux condenser, an electric stirrer and a thermometer. With stirring, the solution was heated to 90°C.

[0048] 1.0 g of melamine cyanurate was added to 50 g of 50% ethanol aqueous solution, and then 0.6 g of sodium dodecylbenzenesulfonate was added. With high speed stirring, the solution was heated to 50°C. After uniform dispersion, it was added to a four-necked flask to form a mixed solution.

[0049] Within 2.5 hours, 700 mL of a solution containing 115 g of aluminum sulfate octadecahydrate was added dropwise to the above mixed solution, and the mixture was incubated for 2 hours to obtain a white precipitate. Cool to room temperature, filter, wash, and dry to obtain a white powder product. The yield was 91.9%.

[0050] Product particle size (μm) distribution is: D(10):20; D(25):31; D(50):45; D(97):101;

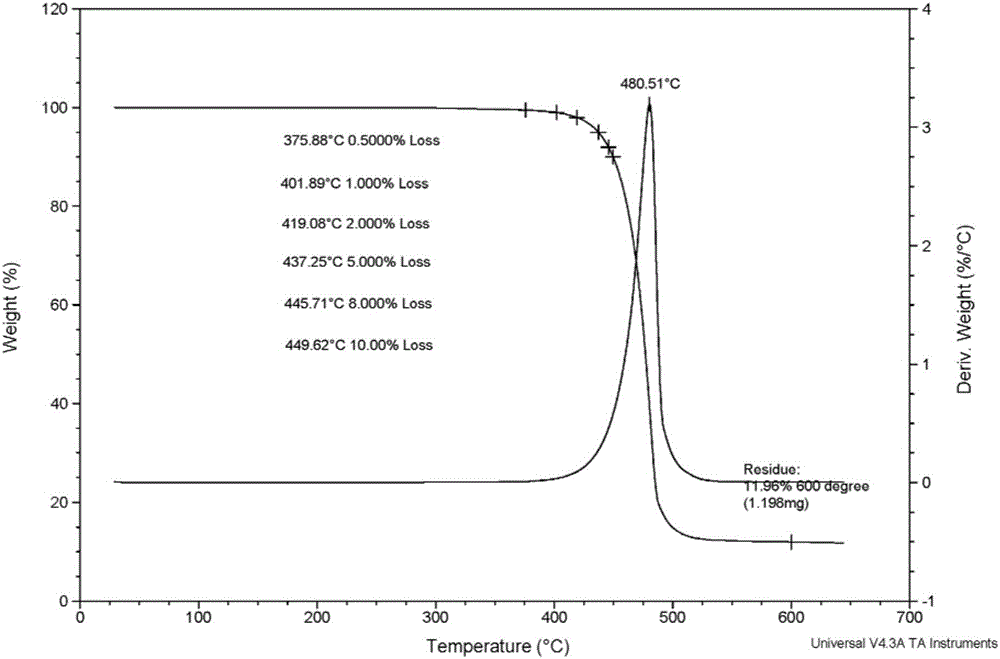

[0051] TGA: T1% = 380°C.

Embodiment 3

[0053] Add 150 g of sodium diethylphosphinate and 900 mL of water into a 2000 mL four-necked flask equipped with a reflux condenser, an electric stirrer and a thermometer. With stirring, the solution was heated to 80°C.

[0054] 0.8 g of melamine was added to 50 g of 50% methanol aqueous solution, and then 0.8 g of potassium dodecyl phosphate was added. With high speed stirring, the solution was heated to 50°C. After uniform dispersion, it was added to a four-necked flask to form a mixed solution.

[0055] Within 2.0 h, 900 mL of a solution containing 115 g of aluminum sulfate octadecahydrate was added dropwise to the above mixed solution, and kept for 2 h to obtain a white precipitate. Cool to room temperature, filter, wash, and dry to obtain a white powder product. The yield was 89.5%.

[0056] Product particle size (μm) distribution is: D(10): 15; D(25): 28; D(50): 35; D(97): 99;

[0057] TGA: T1% = 386°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com