Method for producing amorphous alloy base material of round billet

A technology of amorphous alloy and production method, applied in the production field of amorphous alloy base material round billet, can solve the problems of less external sales, irregular shape of base material, poor quality stability, etc. The effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment.

[0033] The production process of this embodiment: intermediate frequency furnace smelting——tapping steel to ladle, refining with bottom blowing argon and cooling——adding molten steel to tundish—tundish nozzle (separation ring)—mold—guiding roller table— Billet drawing machine-cutting machine-transverse cooling bed-roller table-cutting + hydraulic pressure breaking-roller table-casting billet collection.

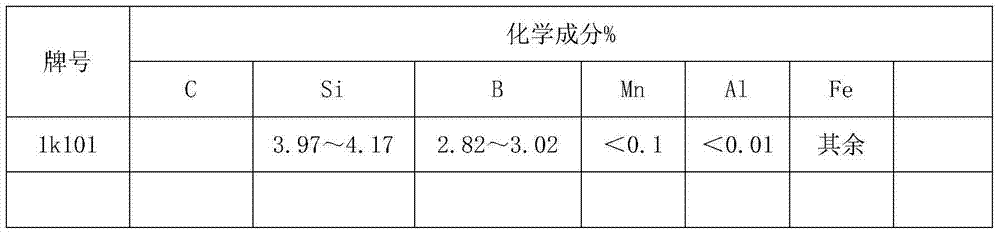

[0034] The composition ratio of the amorphous alloy base material:

[0035]

[0036] The invention adopts the intermediate frequency furnace for smelting: the intermediate frequency furnace is used for smelting under the protection environment of argon gas.

[0037] The smelting operation process is as follows:

[0038] 1. The first furnace of the new furnace is not allowed to smelt this steel type.

[0039] 2. Material ratio: industrial pure iron 78.50%, boron iron 17.25%, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com