Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

374results about How to "Meet market needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

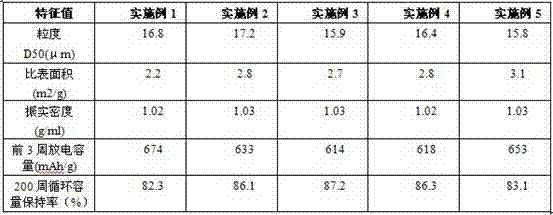

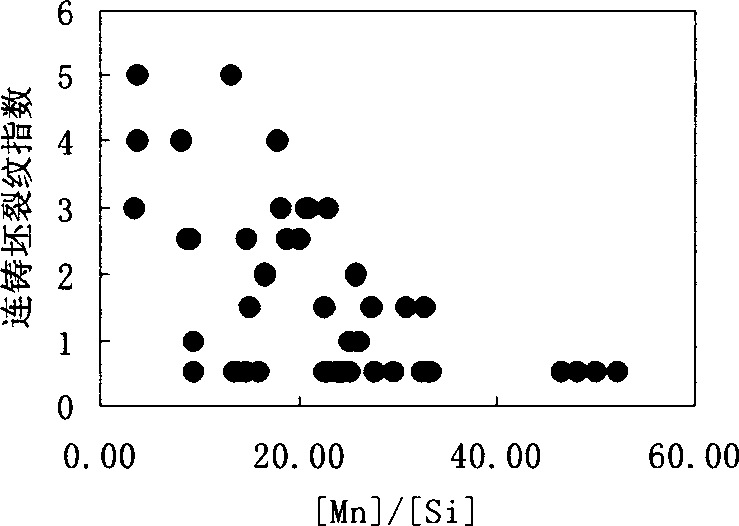

Silicon-carbon composite material for lithium ion battery and preparation method thereof

ActiveCN102891297AImprove cycle performanceIncrease capacityCell electrodesCarbon compositesCarboxymethyl cellulose

The invention discloses a silicon-carbon composite material for a lithium ion battery and a preparation method for the silicon-carbon composite material, and belongs to the field of lithium ion batteries. The silicon-carbon composite material is characterized in that carboxymethylcellulose sodium is used as a bonding agent, a liquid phase coating technology is used for silicon-carbon compounding, and a spray drying technology is used for drying granulation to prepare the silicon-carbon composite material with uniform granularity and excellent performance for the lithium ion battery. The silicon-carbon composite material and the preparation method thereof have the advantages that 1, the composite material for the lithium ion battery is prepared through a silicon-carbon compounding technology, and the capacity of the composite material is higher than that of the conventional graphite cathode material, reaches over 500mAh / g, and can meet requirements on the growing of the market of lithium ion batteries; 2, carboxymethylcellulose is used as a bonding agent which can be effectively coated and bonded on the silicon-carbon material to prevent efflorescence caused by silicon during charging and discharging, so that the cycling performance of the silicon-carbon composite material is effectively improved; and 3, the liquid phase coating and spray drying granulation technologies are adopted, so that the silicon-carbon material can be uniformly coated and bonded, has uniform granules, and is small in specific area, and the cycling performance of the silicon-carbon composite material is further improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

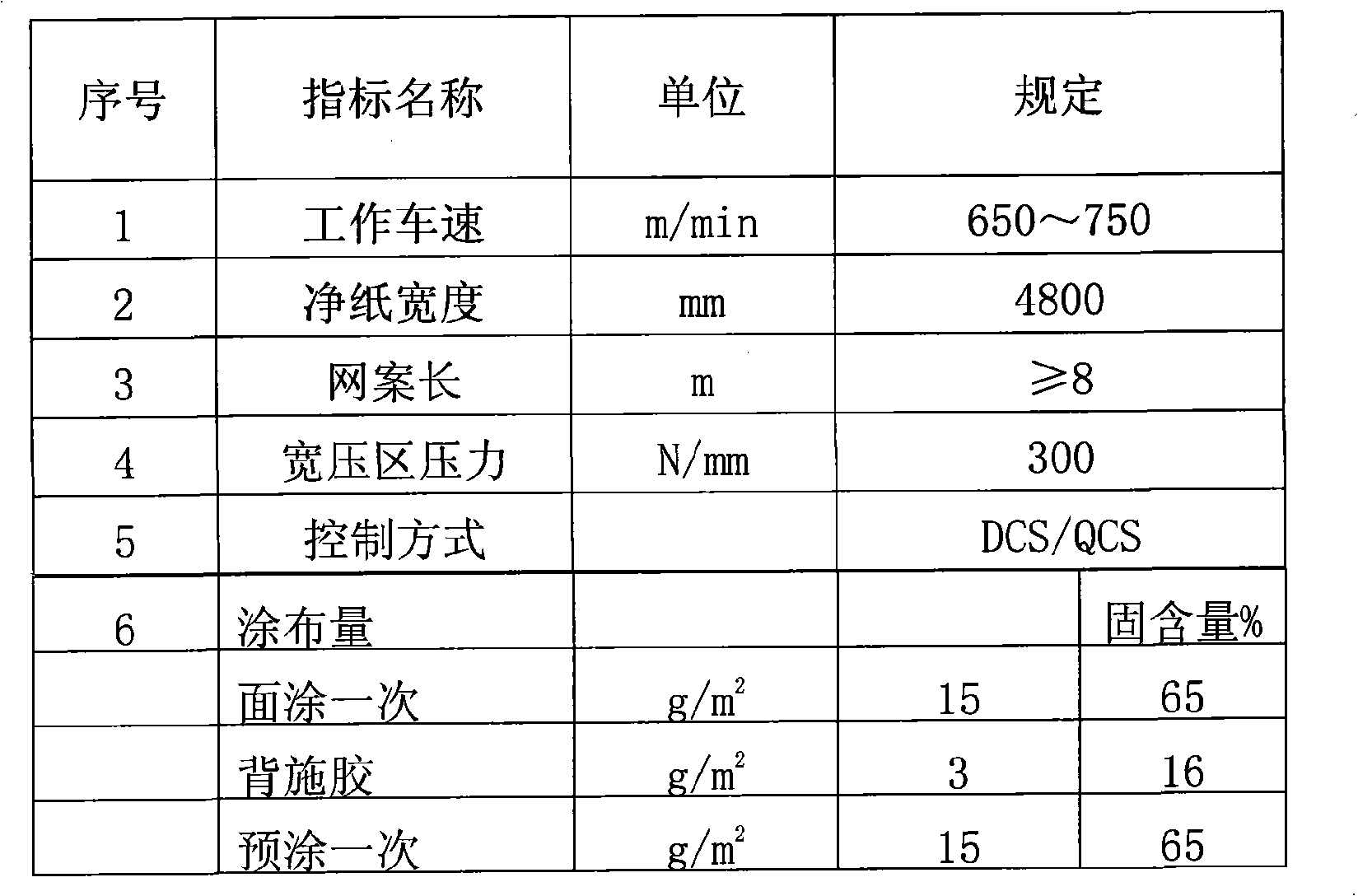

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

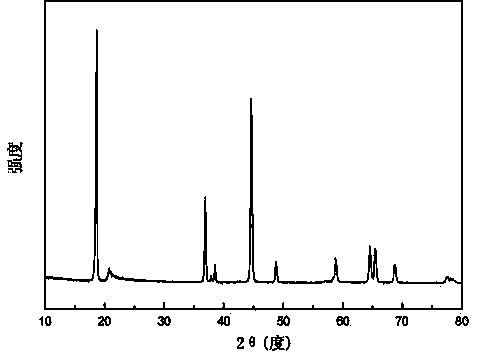

Preparation method of spherical high-capacity lithium-rich positive electrode material

ActiveCN103956479AEffective control of granularityIncrease energy densityCell electrodesSecondary cellsManganese oxideMaterials science

The invention discloses a preparation method of a spherical high-capacity lithium-rich positive electrode material. A sintering process is improved through regulating a coprecipitation reaction mode. The preparation method comprises the following steps: 1, preparing a nickel-cobalt-manganese sulfate solution; 2, performing a coprecipitation reaction on the nickel-cobalt-manganese sulfate solution and a mixed solution of a carbon carbonate solution and ammonia water at a pH value of 7-9 to obtain a solid-liquid mixture of a precursor; 3, filtering, separating, washing and drying to obtain a carbonate precursor; 4, performing gradient temperature rise on the carbonate precursor in a tubular furnace and keeping the temperature, cooling, crushing and sieving to obtain a nickel-cobalt-manganese oxide; and 5, mixing the nickel-cobalt-manganese oxide with lithium carbonate powder, and performing multi-section ventilation roasting in the tubular furnace to obtain the target object. The preparation method has the advantages that the sintering process is improved through regulating the coprecipitation reaction mode, the granularity of the precursor is effectively controlled, and the high-capacity lithium-rich lithium ion positive electrode material with a layered crystal structure, which is high in energy density, good in rate capability, low in cost, good in safety and long in service life, is prepared, and the market demand is met.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

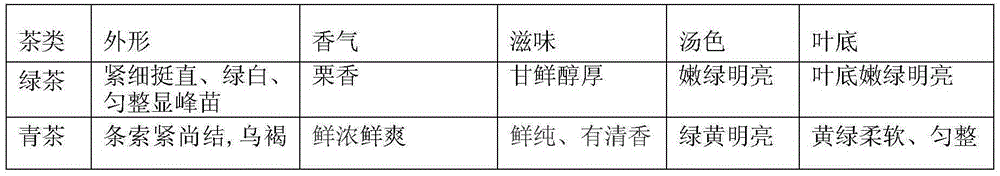

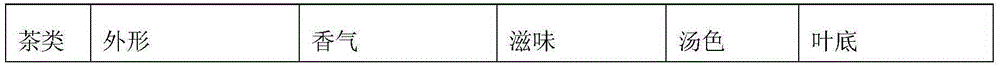

Method for processing multiple kinds of tea with spring tea

InactiveCN105360369AImprove qualityMeet market needsPre-extraction tea treatmentClimate change adaptationChemistryEpigallo-catechin gallate

The invention provides a method for processing multiple kinds of tea with spring tea, and belongs to the technical field of processing of tea leaves. The method comprises the following steps of at the early stage of the spring tea, picking tea leaves for making various high-end famous white tea, green tea, yellow tea and black tea; at the final stage of the spring tea that tea raw materials are old, producing oolong tea with tea leaves with one bud and 3-4 leaves and banjhi leaves. In this manner, regulation of a picking period is facilitated, the picking and making period of tea leaves is correspondingly prolonged, the quality of finished tea products in one batch is improved, and the added value is increased. In addition, multiple kinds of the tea are developed, a tea machine can be mutually and crisscross used and repeatedly utilized, idle time of machinery is shortened, the service time of the machinery is prolonged, the comprehensive utilization rate of the whole tea machine is fully exerted, the depreciable cost is reduced, and the utilization rate of factory buildings and the utilization rate of mechanical equipment are increased.

Owner:GUANGXI POLYTECHNIC

Additive for electrolytic copper foil and production process of electrolytic copper foil for 7-mu. m double-light lithium ion battery

The invention relates to an additive for an electrolytic copper foil. The additive is aqueous solution containing a brightening agent DPS and industrial gelatin, wherein the concentration of the DPS in the additive is 5-15g / L, and the concentration of the industrial gelatin is 1-4g / L. The invention further discloses a production process for preparing the electrolytic copper foil for a 7-mu. m double-light lithium ion battery by adopting the additive. The cost of the additive is lower, the performance index of the produced electrolytic copper foil meets a specified requirement, and the electrolytic copper foil can be taken as a copper foil special for a lithium battery.

Owner:LINGBAO WASON COPPER FOIL

Method and device for forming sliced meat, and machine for puncturing meat string

A method for slicing meat includes such steps as loading meat block in a charging hopper with longitudinal and transverse slots, and pushing the meat block while sequentially cutting it by transverse cutting blades, longitudinal cutting blades and horizontal cutting-off blades. A machine for slicing meat and make a string of meat slices is composed of a machine frame, a charging hopper with a meat pushing mechanism, a transverse and a longitudinal cutting blade modules, whose blades can be reciprocating to pass through the slots of charging hopper, a horizontal cutting blade module whose blades can be reciprocating to cut off the meat slices, an eccentric shaft connected with all blades, and a motor.

Owner:武跃峰

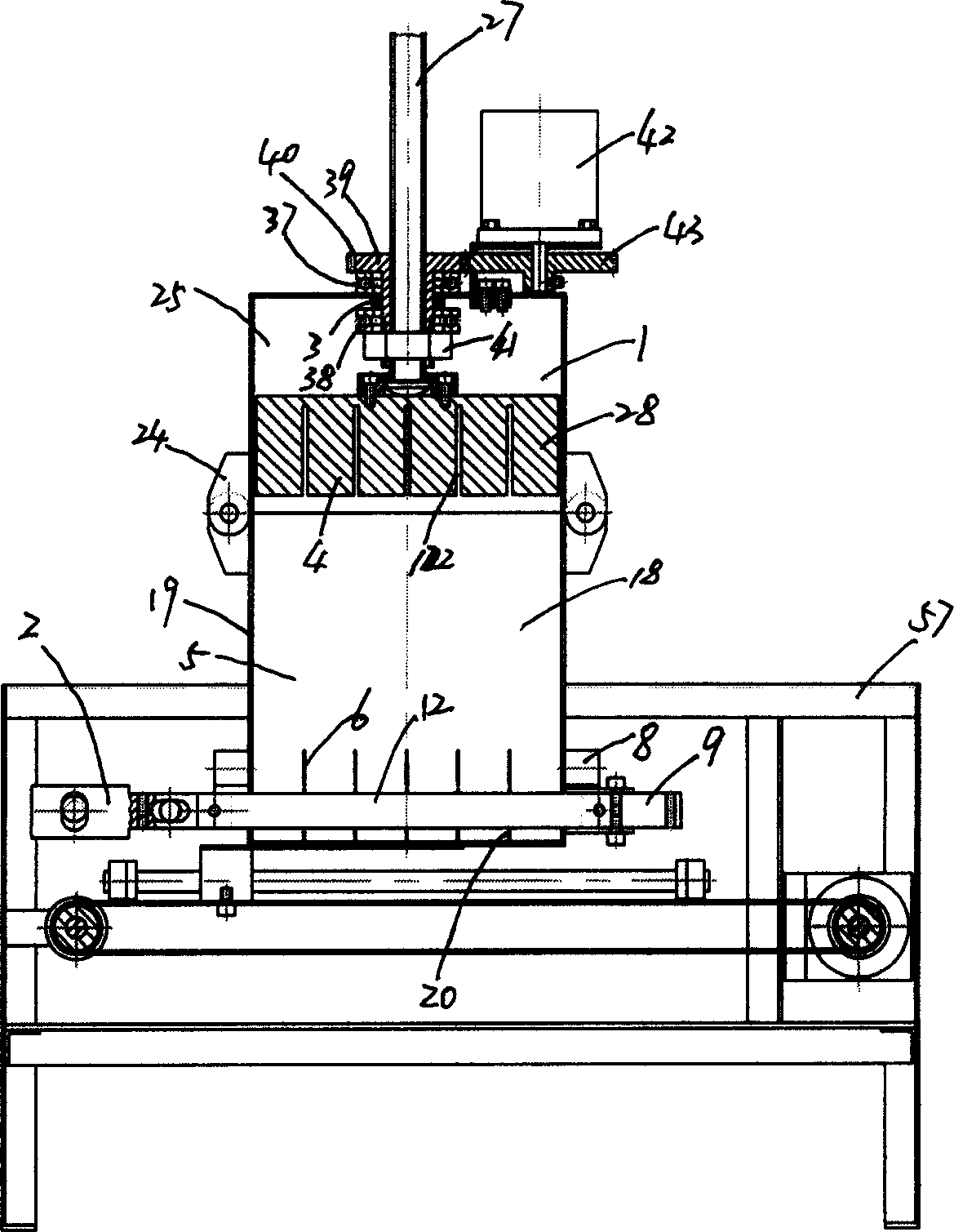

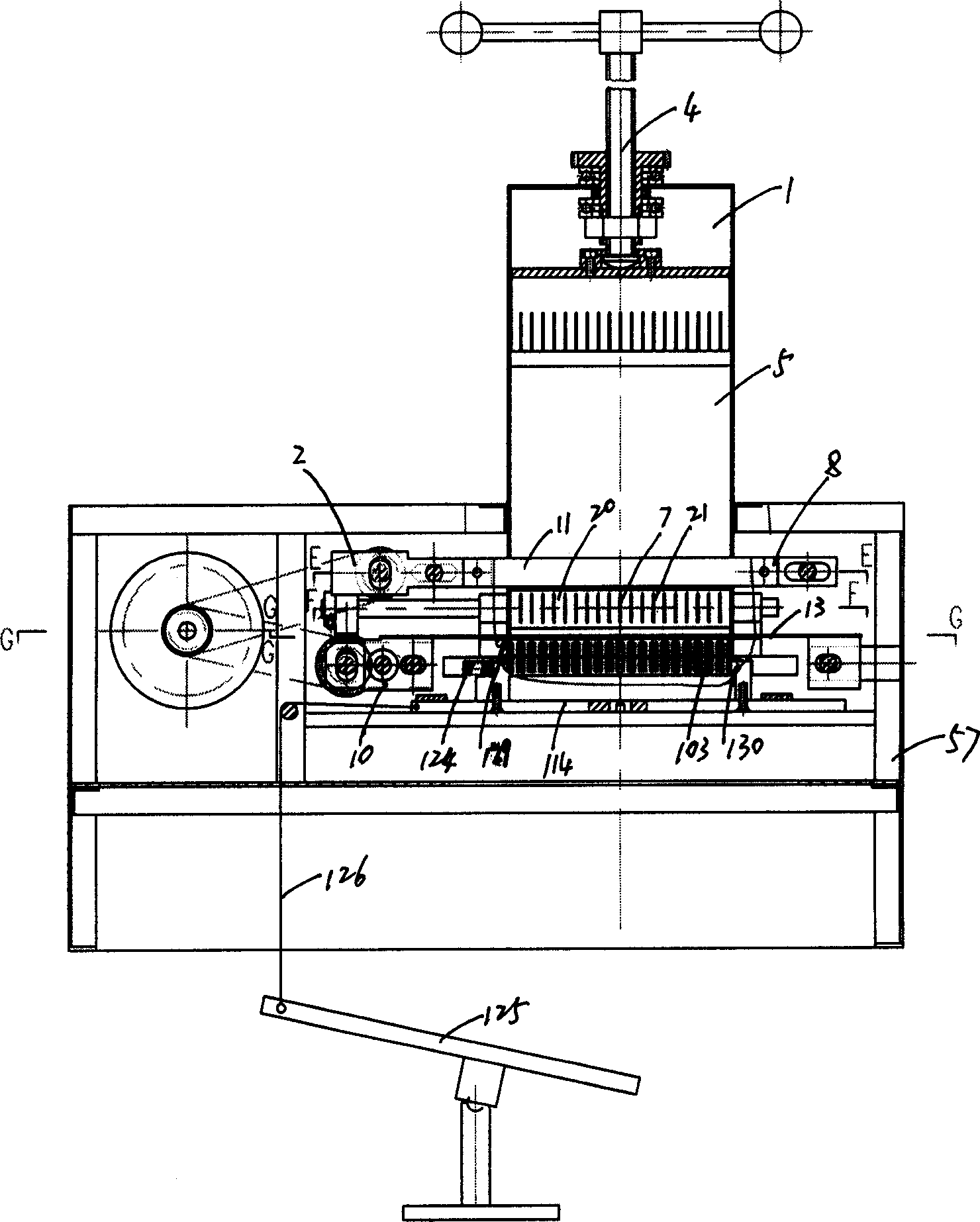

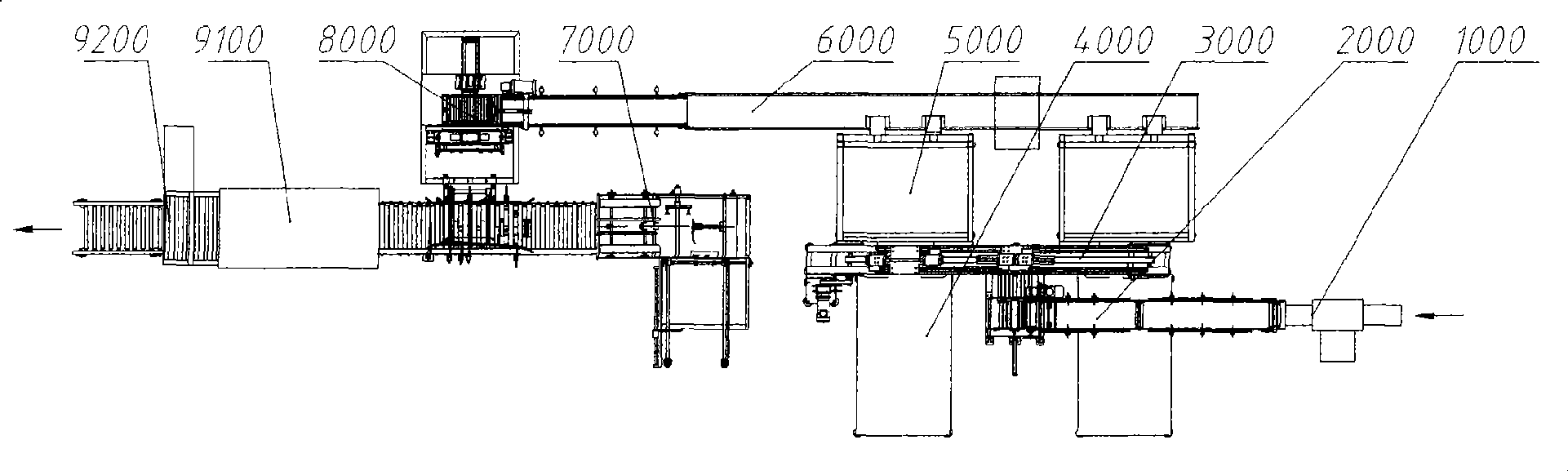

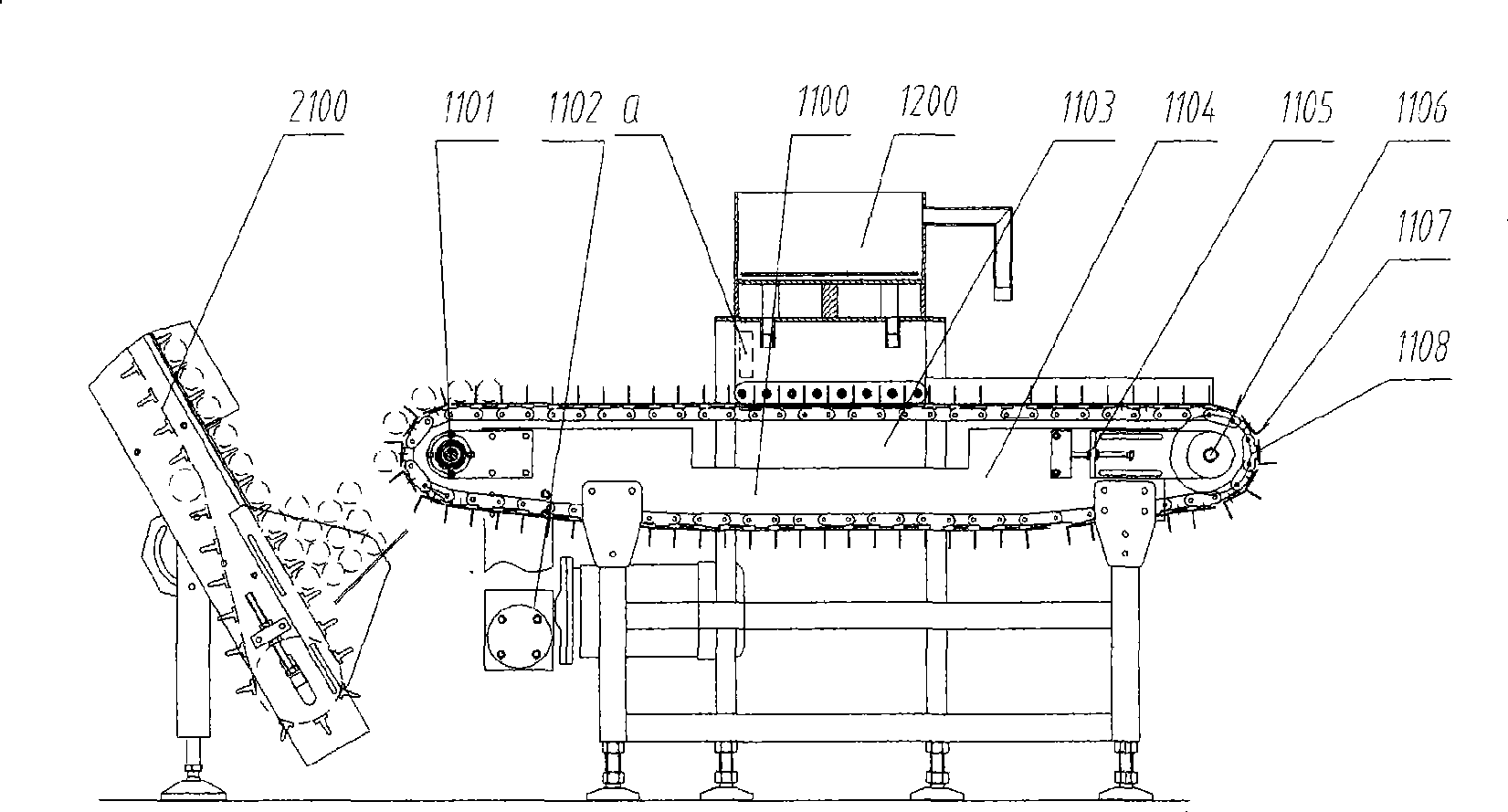

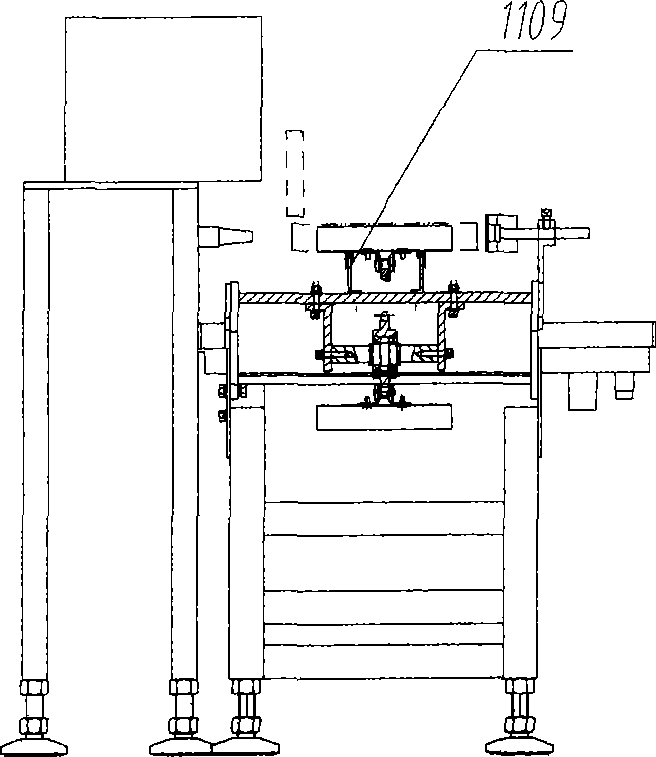

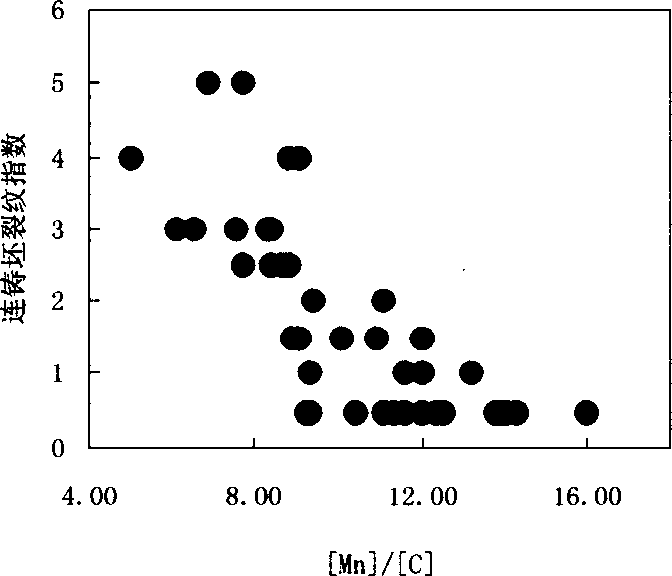

Civil explosive middle package and boxing production line

ActiveCN101373127AMeet the function of interchange productionImprove vacuuming effectAmmunition storageWaxProduction line

A package and boxing up production line of a medium package of domestic explosive comprises a single explosive cartridge wax spraying unit (1000), an automatic code card unit (2000), a cassette delivery unit (3000), a long push package unit (4000), an medium package sealing unit (5000), an medium delivery device (6000), an unpacking bottom-sealing unit (7000), a side-push type boxing up unit (8000) and a cover-folding box-sealing bunching unit (9000). The invention improves the unreasonable part of the prior production line, improves the production, overcomes factors influencing the production stability, adopts the device principle to decompose the full automatic medium explosive package production line into a plurality of devices, combines the devices with independent functions and mutually related to form an efficient packaging and boxing up production line of the medium package of domestic explosive with high automation.

Owner:WUHAN RENTIAN PACKAGING TECH

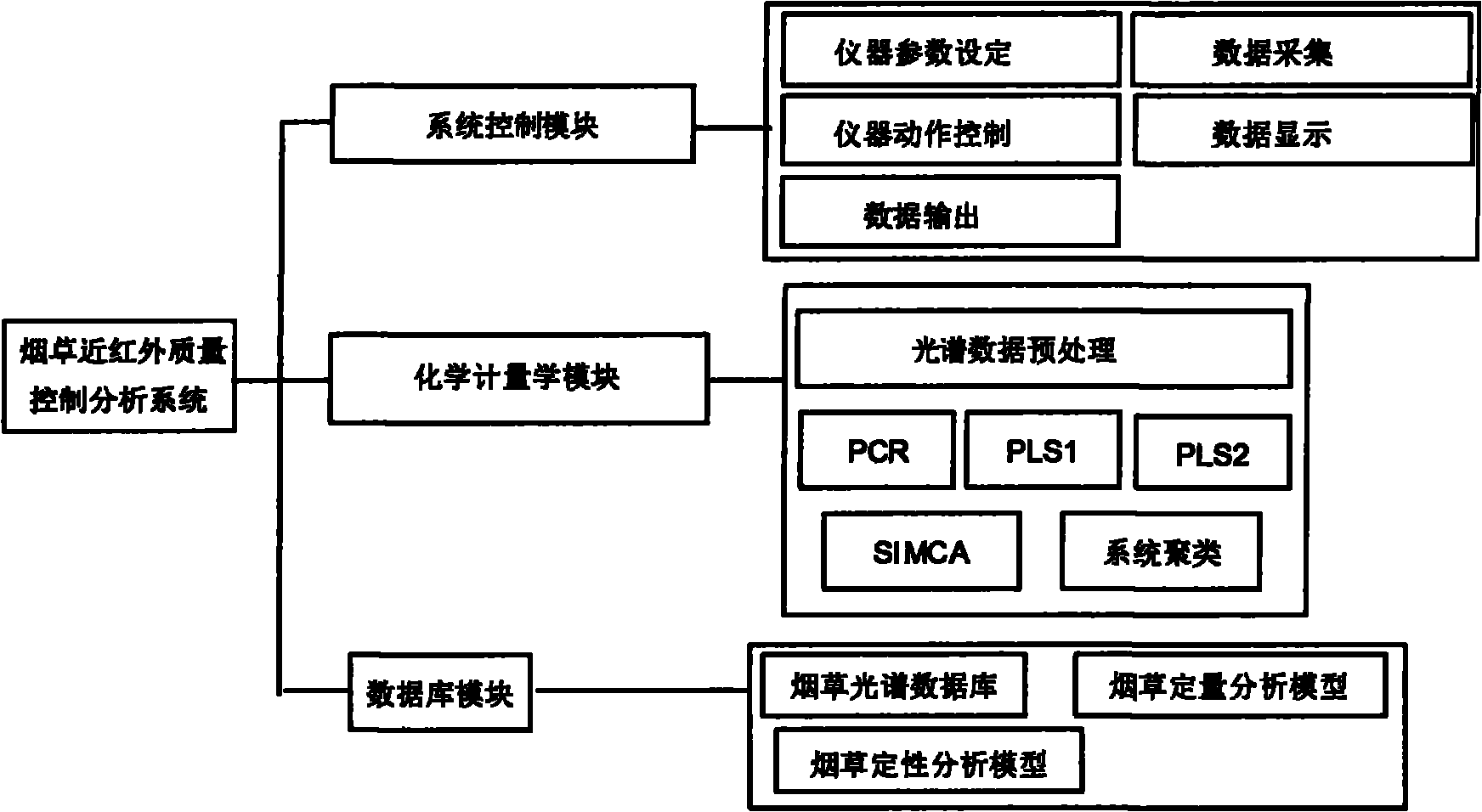

Near infrared quality control analysis method and system of tobacco

InactiveCN101995388AAchieve consistencyRealize evaluationColor/spectral properties measurementsQuality controlEngineering

The invention discloses a near infrared quality control analysis method of tobacco. The method comprises the following steps of: collecting representative tobacco samples and grinding into powder; opening a tobacco sample acquisition instrument and preheating; setting parameters of the instrument; scanning the representative tobacco samples one by one; selecting an unknown sample, grinding into powder and forming a scanner spectrogram; opening a chemometric module of an analysis system, selecting an algorithm, preprocessing spectral data and establishing a correction model: setting a wavelength range of between 700 and 1,100nm, standardizing a spectrum value and chemical value, saving the established model and starting to correct the model; and predicting the sample and starting to calculate after selecting the unknown sample so as to obtain a quantitative and qualitative sample analysis result. Through the method and the system, the quality parameter of the tobacco can be quickly measured, and the quality of the tobacco can be quickly measured, controlled and analyzed on site. The method and the system are also suitable for quality monitoring of medicaments, milk, milk powder and the like, raw material comparison, analysis of product consistency and the like.

Owner:BEIJING KAIYUAN SHENGSHI SCI & TECH DEV

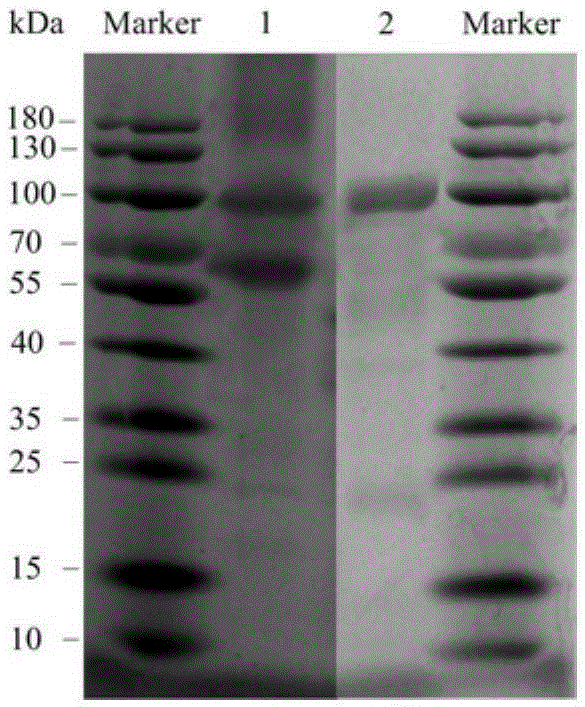

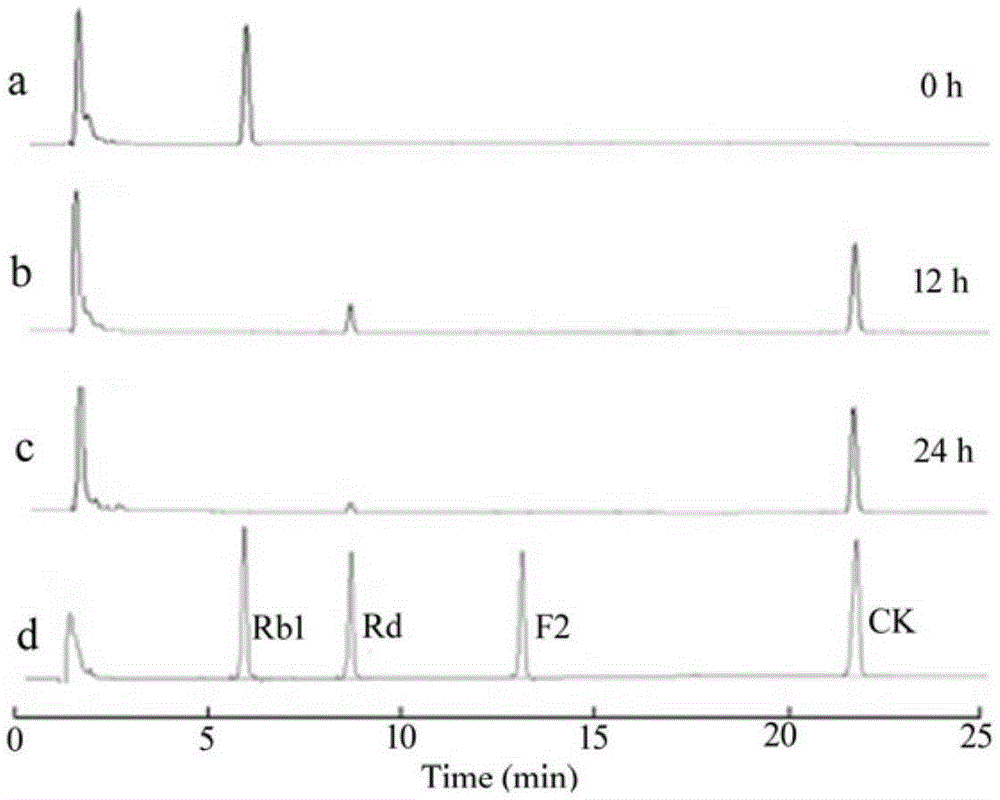

Method for preparing rare ginsenoside CK from transformed ginsenoside Rb1 and use thereof

ActiveCN105296587AImprove conversion rateRich in enzyme productionMicroorganism based processesFermentationBiotechnologyBifidobacterium

The invention discloses a method for preparing rare ginsenoside CK from transformed ginsenoside Rb1 and a use thereof. Ginsenoside Rb1 is transformed into rare ginsenoside CK by beta-glucosidase produced by bifidobacteria and a conversion rate is in a range of 62-68%. The transformed rare ginsenoside CK has very polarity, can be easily absorbed by the human body, and can enter into liver by blood circulation so that metabolism is finished and unique pharmacological effects are obtained. Bifidobacteria are edible probiotics and can produce glycosidase with high catalysis activity, selectivity and stability. The beta-glucosidase produced by bifidobacteria can transform ginsenoside Rb1 into rare ginsenoside CK, and has the advantages of high conversion rate, less side effect, safety, reliability, no pollution and industrial production easiness. The method has a low cost, simple processes and a short conversion period. Beta-glucosidase produced by bifidobacteria has an important application value in preparation of rare ginsenoside CK and the method utilizes the application value.

Owner:HUNAN INSTITUTE OF ENGINEERING

Method for processing multiple types of tea by adopting autumn Lingyun Baimao tea

InactiveCN105341204AChange the status quo of poor qualityImprove qualityPre-extraction tea treatmentClimate change adaptationBlack teaGreen tea

The invention provides a method for processing multiple types of tea by adopting autumn Lingyun Baimao tea, belonging to the technical field of tea processing. According to the method, different-grade materials of the Lingyun Baimao tea are adopted to process black tea, yellow tea, white tea, dark green tea and green tea in autumn; modification is performed on the basis of traditional black tea, yellow tea, white tea, dark green tea and green tea processing technologies, by controlling specific operation requirements of various processes, polyphenols and polysaccharides and aromatic substances such as ethers and alcohols of autumn tea are sufficiently converted and released, then aroma and taste are improved, and thus the tea quality is greatly improved; the current situation that only a single tea variety is produced in autumn is changed, tea products of multiple types are made, the qualities of aroma, taste and tea soup of the various tea products are better, so as to meet the needs of market, and the comprehensive utilization benefits of tea resources are increased.

Owner:GUANGXI POLYTECHNIC

Manufacturing method of cold-rolled SUS304 two-sided bright-annealed (BA) surface stainless steel

Provided is a manufacturing method of cold-rolled SUS304 two-sided bright-annealed (BA) surface stainless steel. The manufacturing method comprises the steps that a black rust hot roll is subjected toannealing and acid pickling; a multi-roller rolling machine carries out rough rolling, specifically, the reduction rate of rough rolling is controlled to be 10%-30%; a plurality of grinding racks areadopted to grind the upper surface and the lower surface of a rough-rolled steel plate; the multi-roller rolling machine carries out finish rolling, specifically, the steel plate is rolled to have the needed thickness; bright annealing is carried out under the whole hydrogen protective atmosphere, specifically, the annealing temperature is 1020-1140 DEG C; and after annealing under the whole hydrogen protective atmosphere is completed, modulation treatment is carried out through a leveling roller, the plate shape is adjusted, and surface glossiness of the product is improved. According to themanufacturing method, the process is reasonable, fine surface quality of the SUS304 BA product is ensured through range control of shot blasting process parameters, the ratio of abrasive belts of thegrinding process and surface control over the rollers of the rolling machine; it is ensured that the obverse side and the reverse side of the steel plate have the coincident resolution by carrying out rough grinding and finish rolling on the both sides; scratch defects of the reverse side are controlled through selection or protection of a plate shape roll of the rolling machine; and as for the prepared two-sided BA surface stainless steel, the obverse side and the reverse side have less defects and the coincident glossiness, and the two-sided BA surface stainless steel has broad applicationprospects.

Owner:NINGBO BAOXIN STAINLESS STEEL

Concentrated feed for over-sized fattening pigs and preparation method thereof

InactiveCN104489370AUniform growthReduce drug residuesAnimal feeding stuffBiotechnologyAnimal science

The invention relates to concentrated feed for over-sized fattening pigs and a preparation method thereof, belonging to the technical field of pig feed. The feed is prepared from the following raw materials in parts by weight: bean pulp, corn DDGS (distillers dried grains with soluble), soybean oil, mountain flour, calcium hydrogen phosphate, salt, organic selenium, 50% vitamin E, choline, 35% vitamin C, 75% glycine betaine, 98.5% lysine, threonine, an antioxidant, a mildew preventive, a composite enzyme preparation, a feed microecological preparation, phytase, a sweetening agent, a vitamin premix, a trace element premix and middlings bran. The later-stage physiological development characteristics of the over-sized fattening pigs are combined, the composite enzyme preparation and the microecological preparation are used for regulating the intestinal health of the pigs, no antibiotics are utilized, the normal feeding mode is changed, and after the concentrated feed is used for feeding the over-sized fattening pigs with weight of 125kg for 90-100 days before marketing, drug residues in meat are remarkably reduced, and the meat is relatively safe and excellent.

Owner:TONGWEI

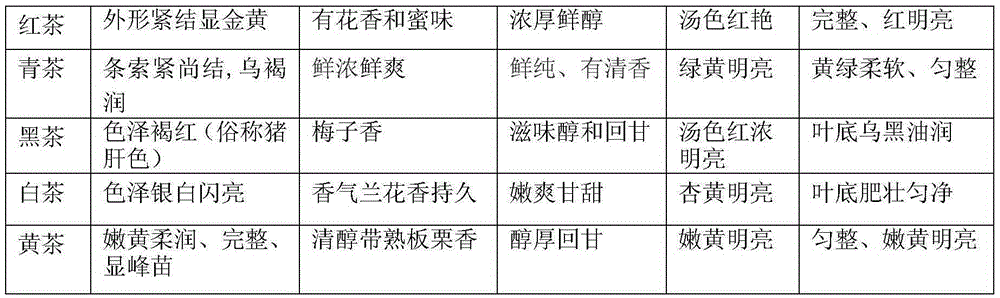

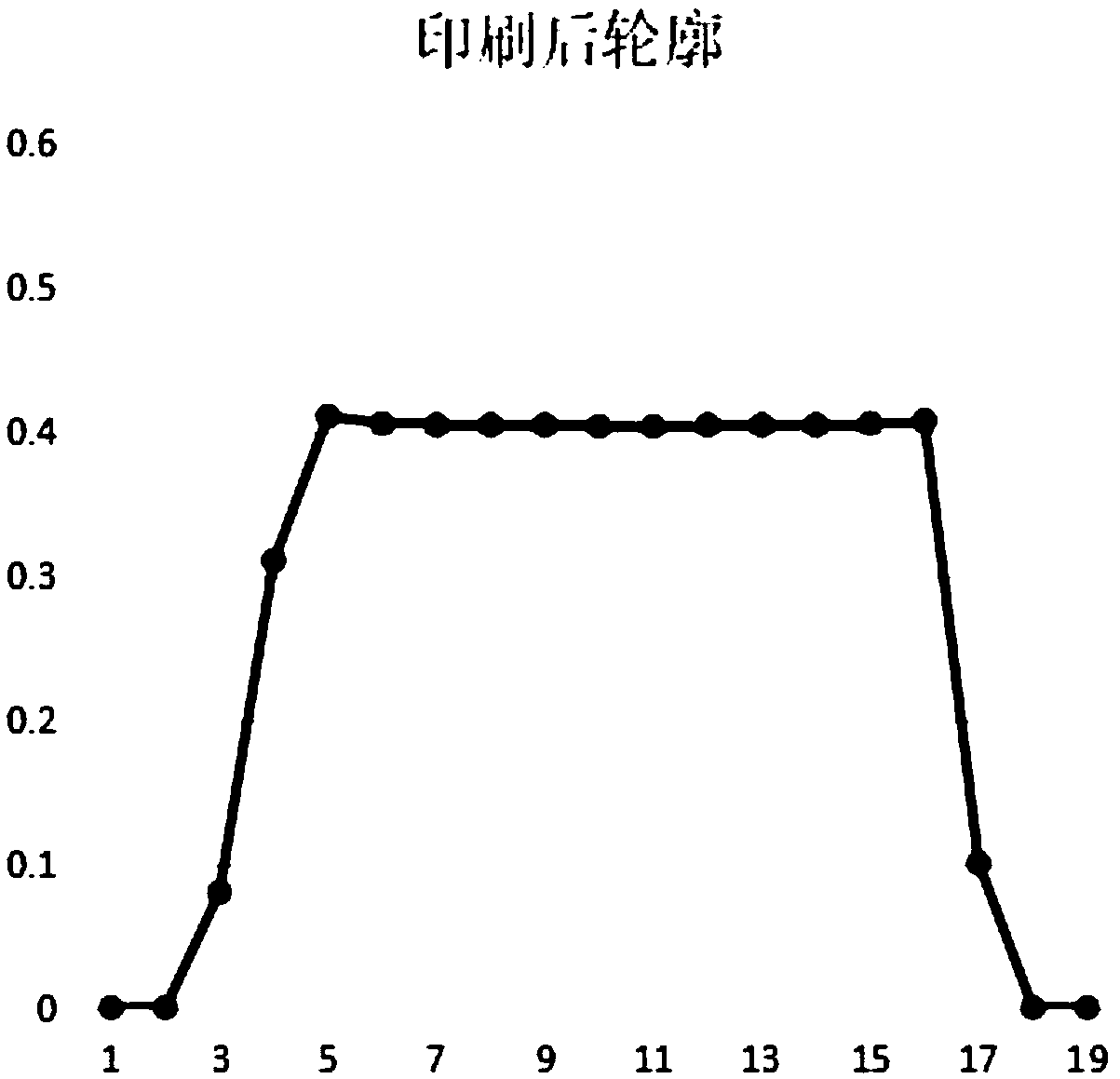

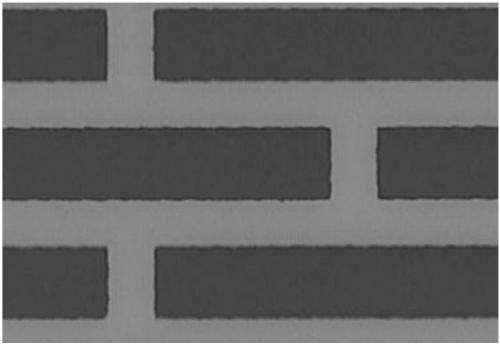

Nickel paste for multilayer ceramic capacitor based on gravure coating printing and application of nickel paste

ActiveCN109616321AQuality improvementImprove rheologyFixed capacitor dielectricStacked capacitorsConductive pasteOrganic solvent

The invention discloses nickel paste for a multilayer ceramic capacitor based on gravure coating printing and an application of the nickel paste; the nickel paste for the multilayer ceramic capacitorbased on gravure coating printing is characterized by comprising the following raw materials in parts by mass: 40-50 parts of nickel powder, 5-12 parts of ceramic powder, 0.1-2 parts of dispersing agent, 0.1-5 parts of plasticizer and 22.1-43 parts of glue, wherein the glue comprises the following substances of an organic solvent, resin and a thixotropic agent at the mass ratio of 80-98:2-4:0.1-0.2. The nickel paste has high rheological property and thixotropy, the requirements of the market are met, high-quality conductive paste can be obtained, and the pattern is good after being printed, and the nickel paste is free of burrs and the like; and after sintering, the continuity is high, and the yield is high, so that the production efficiency is improved, and the production cost is lowered.

Owner:大连海外华昇电子科技有限公司

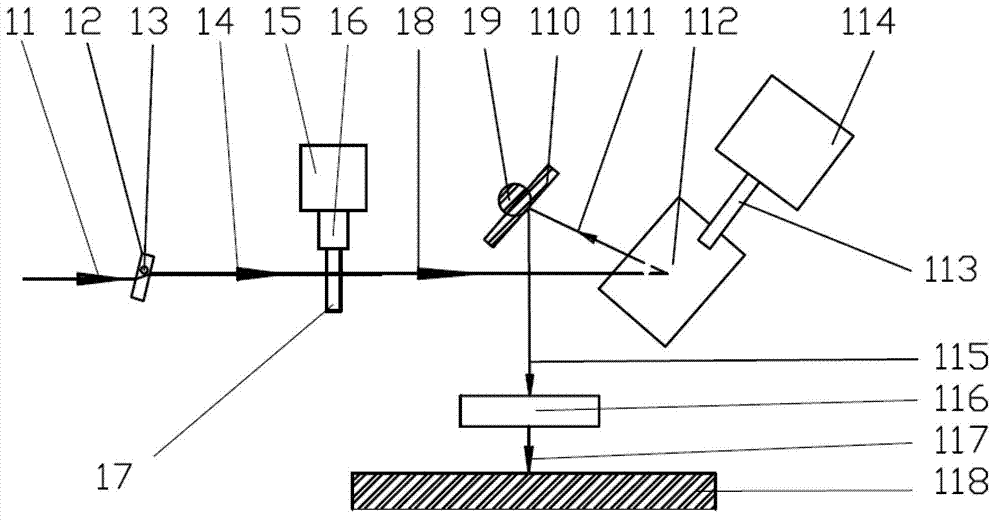

Large-size high-speed micropore drilling system

ActiveCN103203552AQuick switchImprove drilling efficiencyLaser beam welding apparatusFine structureLight beam

The invention relates to a large-size high-speed micropore drilling system which comprises a light beam space modulation module and a galvanometer scanning flat field focusing module. Particularly, the light beam space modulation module, particularly a plurality of transparent flat optical elements are combined with the galvanometer scanning flat field focusing module, the light beam space modulation module is used for modulating the space trace of a laser light beam, the galvanometer scanning flat field focusing module is used for focusing laser and rapidly switching laser spots at different machining positions, and the two modules are in division and cooperation. By the aid of the scheme, large-size micropore drilling can be realized, laser drilling efficiency and drilling quality are greatly improved, the large-size high-speed micropore drilling system is quite suitable for drilling straight holes, laser light beam filling and scanning shapes and sizes can be dynamically controlled, micropore drilling pore diameters can be dynamically changed, and fine structures can be flexibly machined.

Owner:张立国

Planting method for dendrobium officinale

InactiveCN104663396ASignificant progressHigh transplant survival rateBiocideAnimal repellantsMicrochiropteraPeat

The invention discloses a planting method for dendrobium officinale. The method comprises the following steps: crushing raw materials such as peat soil, peanut shells, pine wood bran, pine barks and a small amount of bat manure to obtain a substrate, performing high-temperature treatment, sterilizing and sowing dendrobium seeds, and transplanting the dendrobium to a greenhouse after a year; controlling proper temperature and moisture, wherein a spraying manner is adopted, the watering frequency is once every three days in January to March, once every two days in March to June, once every 5 to 6 days in June to September and once every three days in September to December; keeping the temperature in the greenhouse be 18 to 22 DEG C in the daytime and 15 to 20 DEG C at night; preventing the soft rot and the black spots of dendrobium officinale, and preventing and controlling snails, sarcoptes mites, phenacaspis dendrobii kuwana and red spider mites. According to the planting method for dendrobium officinale, the substrate with high adaptability to dendrobium officinale is adopted, and high dendrobium officinale transplantation survival rate, high growth speed, high yield and high active ingredient content are achieved.

Owner:CHONGQING MAIXIU AGRI DEV

Fast breeding system for flame nandina

InactiveCN101044841AHigh rooting rateIncrease root rateHorticulture methodsPlant tissue culturePurineMicrobiology

A fast reproduction system of flame nandina features that a controllable tissue culture technology is created, the culture medium for the efficient reproduction and strong plantlet culture is proportionally prepared from improved WP+6-benzylamino purine or improved WP+6-benzylamino purine, indolebutyric acid and granular white sugar, and the optimal rooting culture medium is proportionally from improved 1 / 2 WP and indolebutyric acid (or granular white sugar).

Owner:SHANGHAI ACAD OF AGRI SCI

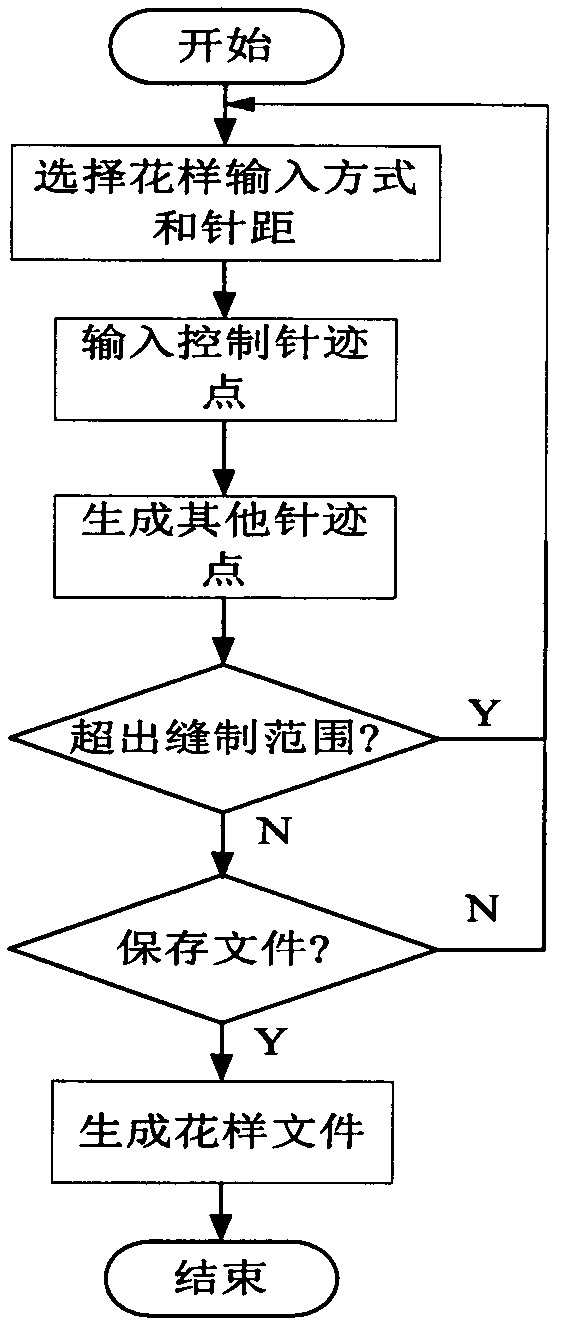

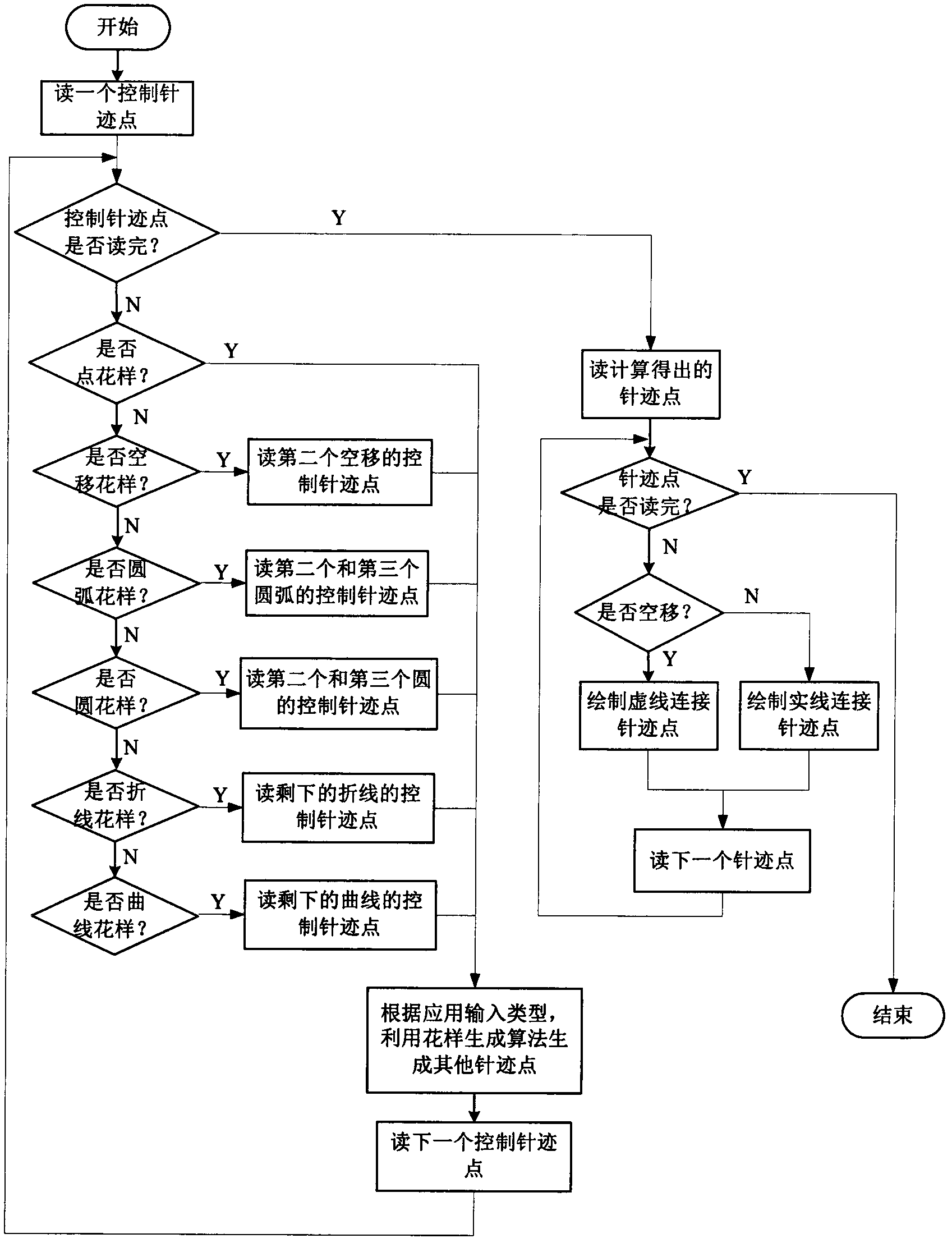

Pattern editing and pattern generating method for electronic pattern machine

InactiveCN102634933APattern editing is simple and convenientFriendly editing interfaceProgramme-controlled sewing machinesHem-stitch machinesPattern recognitionMachine control

The invention provides a pattern editing and pattern generating method for an electronic pattern machine. A pattern design is an important performance index of an electronic pattern machine control system. The pattern editing and pattern generating method disclosed by the invention provides a generation method of various pattern designs. The generation method comprises spatial migration, straight line, circle, circular arc, curve and polygon; on the basis, the generation method for pattern designs such as homodromous multiple sewing, converse multiple sewing, assistant sewing, front and back backstitch and overlapping sewing is realized, and the generation method for the complex pattern designs comprising various patterns is realized. The pattern generating method is integrated into pattern edition, and the pattern is automatically generated in the pattern edition. The pattern editing and pattern generating method has the technical effect that the abundant pattern design is applied, and the pattern can be simply and conveniently edited. A friendly editing interface is provided to support the dynamic edition and secondary edition of the pattern. The pattern editing and pattern generating method has the advantages of high operation efficiency and good pattern generating effect.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

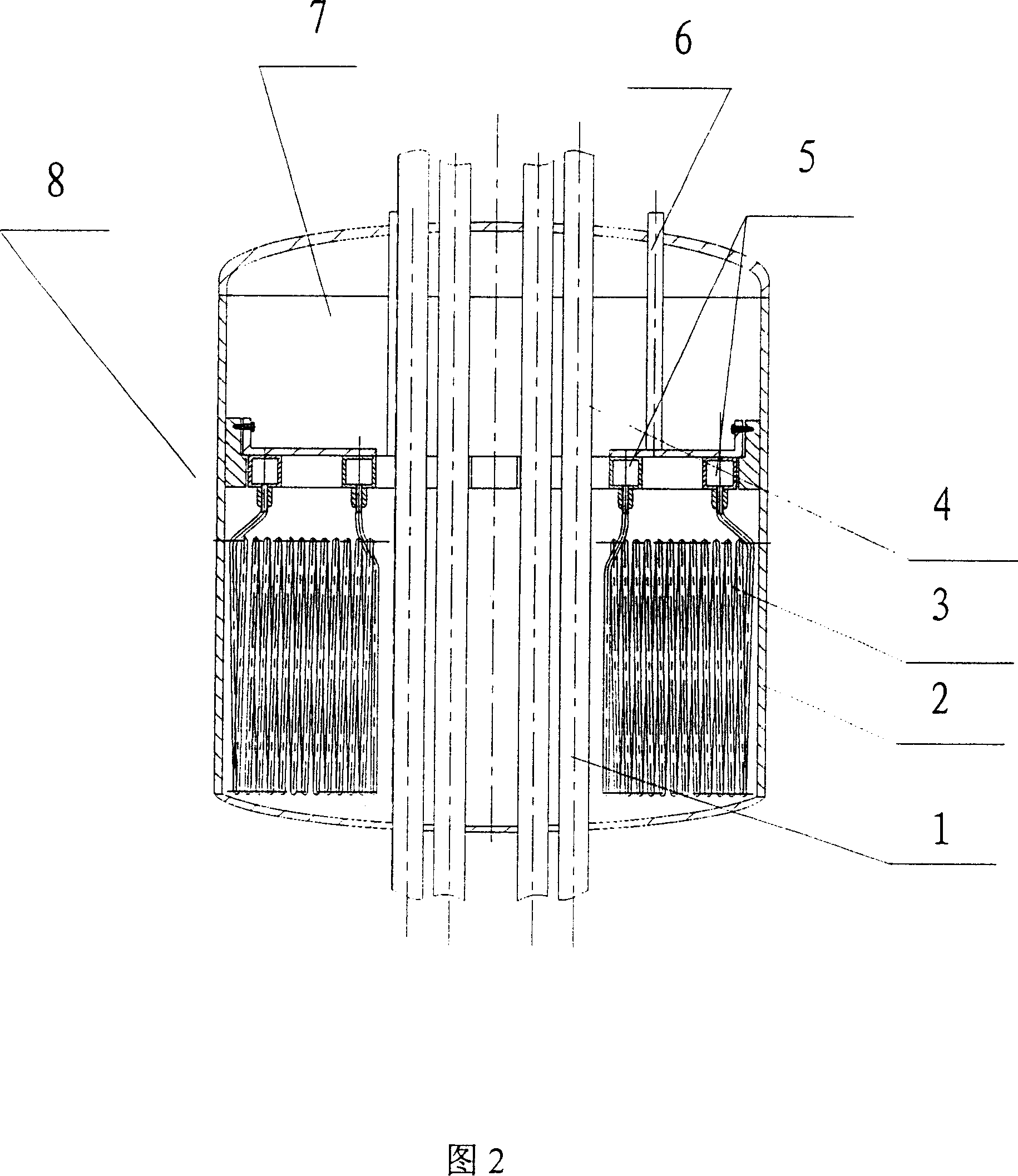

Water boiler solution nuclear reactor having inherent security

ActiveCN1992095AIncrease production capacityMeet market needsNuclear energy generationHomogenous reactorsNuclear reactorNuclear fuel cycle

The invention discloses a water-boiler solution-type reactor with fixed security, the concentrated UO2(NO3)2 solution or UO2SO4 solution is as the nuclear fuel, the flat in-core structure is adopted, the ratio of in-core solution height to in-core diameter is 0.3-0.8, when the ratio of volume to power is maintained at 2.0-2.5kW / L, the volume of the in-core solution can achieve 50-200L, the power of heap is bigger than 100kW.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for separating and extracting sweet tea tannins

InactiveCN101190276ASimple separation processEasy to operateSugar derivativesMetabolism disorderChlorobenzeneUltrafiltration

The invention relates to the separation and extraction methods of a sweet tea polyphenols. The invention uses integration of ultrafiltration with resin adsorption separation technique. Only ethanol is used as organic solvent during producing process and the separation technique of sweet tea polyphenols is optimized; the simple operation helps realize industrialized production; besides, the production process accords with environment protection requirement and the products accord with food and drug raw material requirements. The invention uses Guangxi sweet tea as raw materials to produce sweet tea polyphenols containing over 50% and 90%. Hyaluronidase inhibition in vitro experiment, in vivo experiments of mice passive dermato-allergic reaction and the delayed cutaneous hypersensitivity caused by dinitro-chlorobenzene confirm the invention has significant anti-anaphylaxis activity.

Owner:GUANGXI UNIV

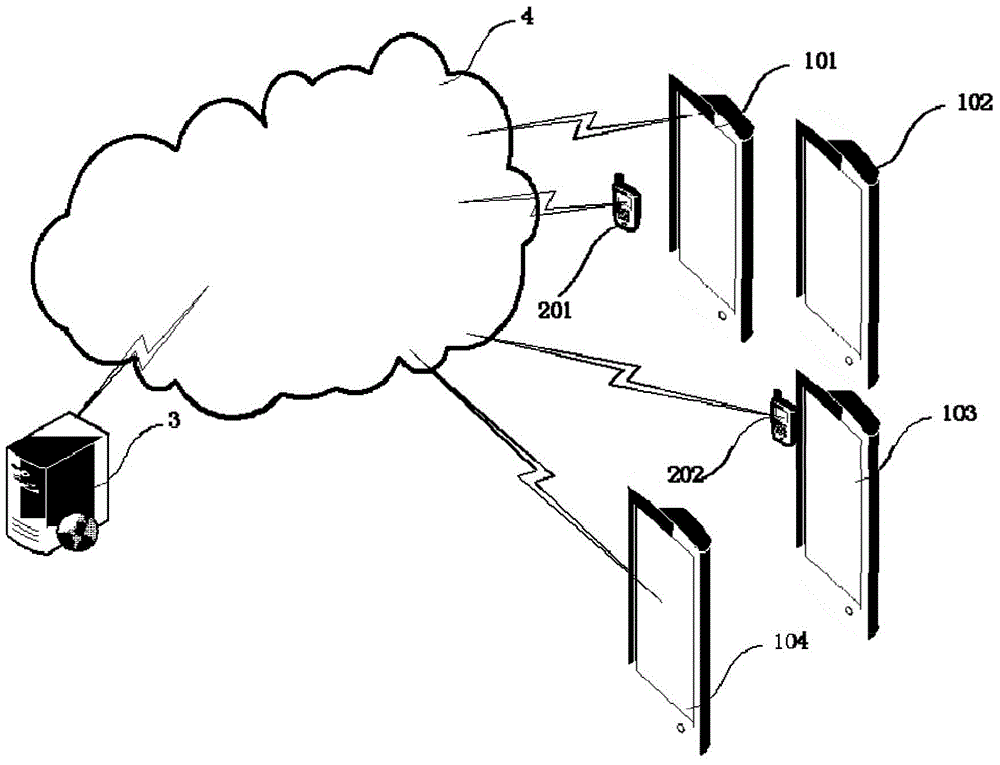

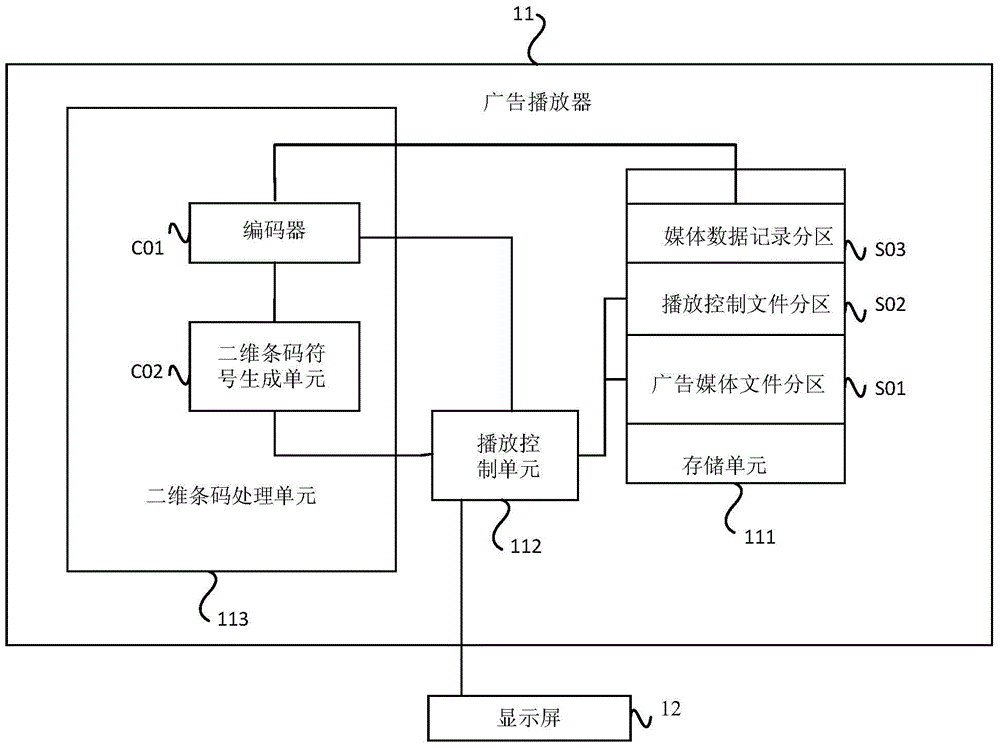

Internet advertisement system and advertisement information processing method

The present invention provides an internet advertisement system and an advertisement information processing method. Two-dimensional bar codes displayed on an advertisement play device is scanned and decoded based on an intelligent terminal, an access request is sent to a jump database based on the encoded internet link information in the two-dimensional bar codes, when the access request is received, a page address corresponding to the internet link information is found out from the jump database, and the response configured to indicate the intelligent terminal to jump to the page address is returned back to the intelligent terminal. Therefore the accurate collection is realized, and the value brought by the advertisement mode of an advertisement screen channel can be obtained through data analysis aiming at the consumption behavior or information obtaining behavior generated by the advertisement played by various advertisement screens. It is obtained whether the advertisement content played by the advertisement screens accords with the market requirement or not through further analysis of products consumed by users or the deeply understood product information.

Owner:北京图音数码科技有限公司

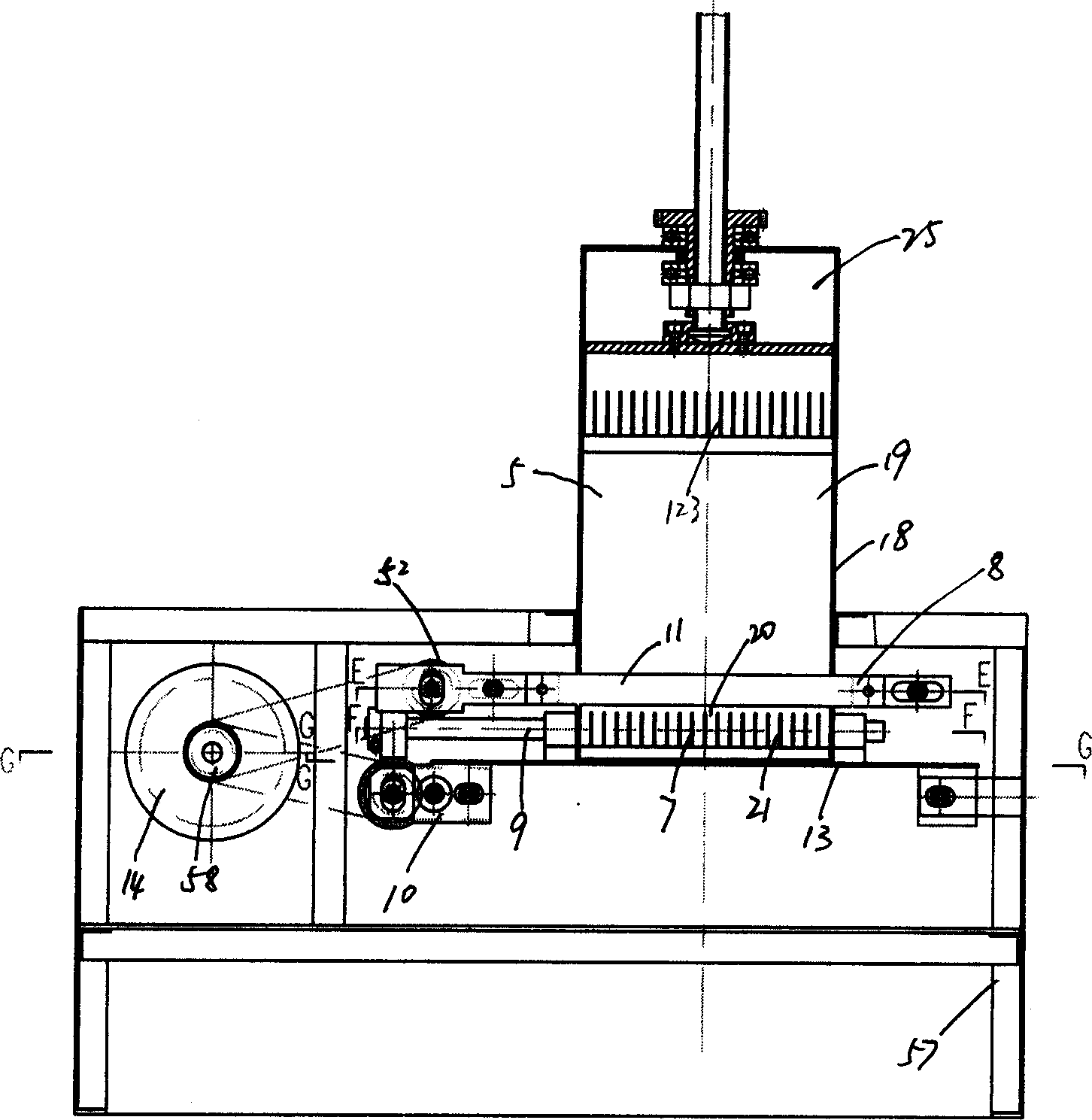

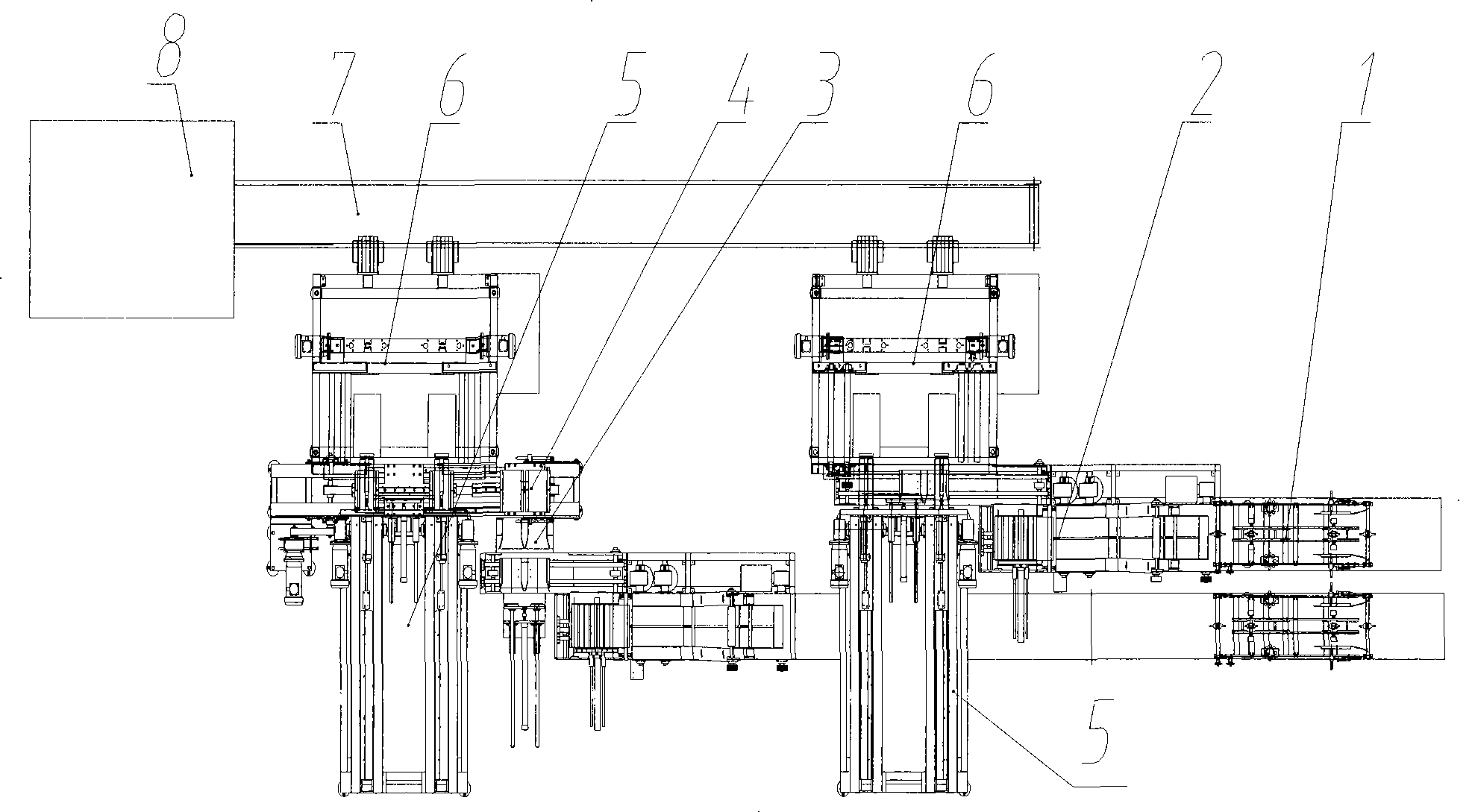

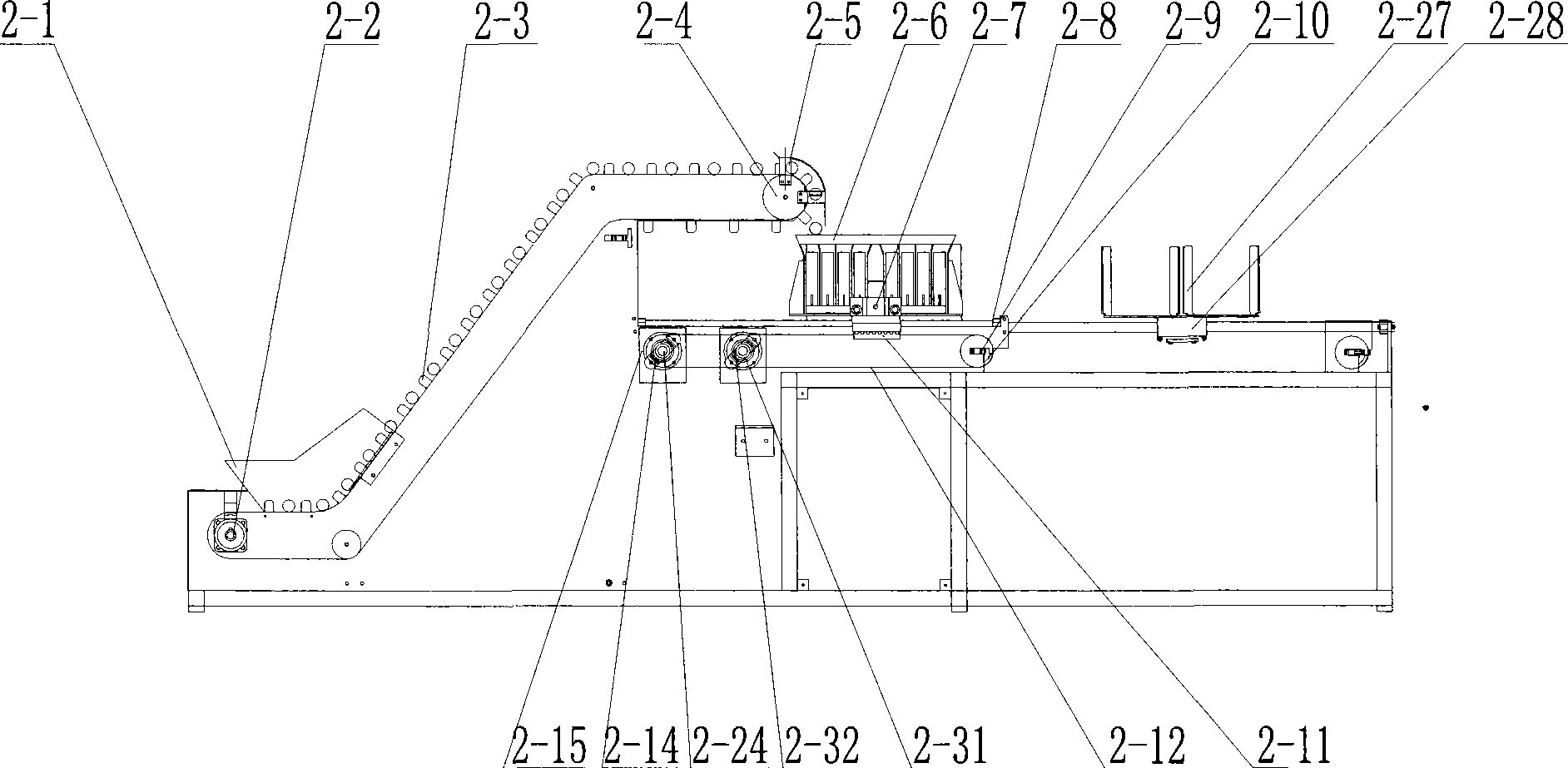

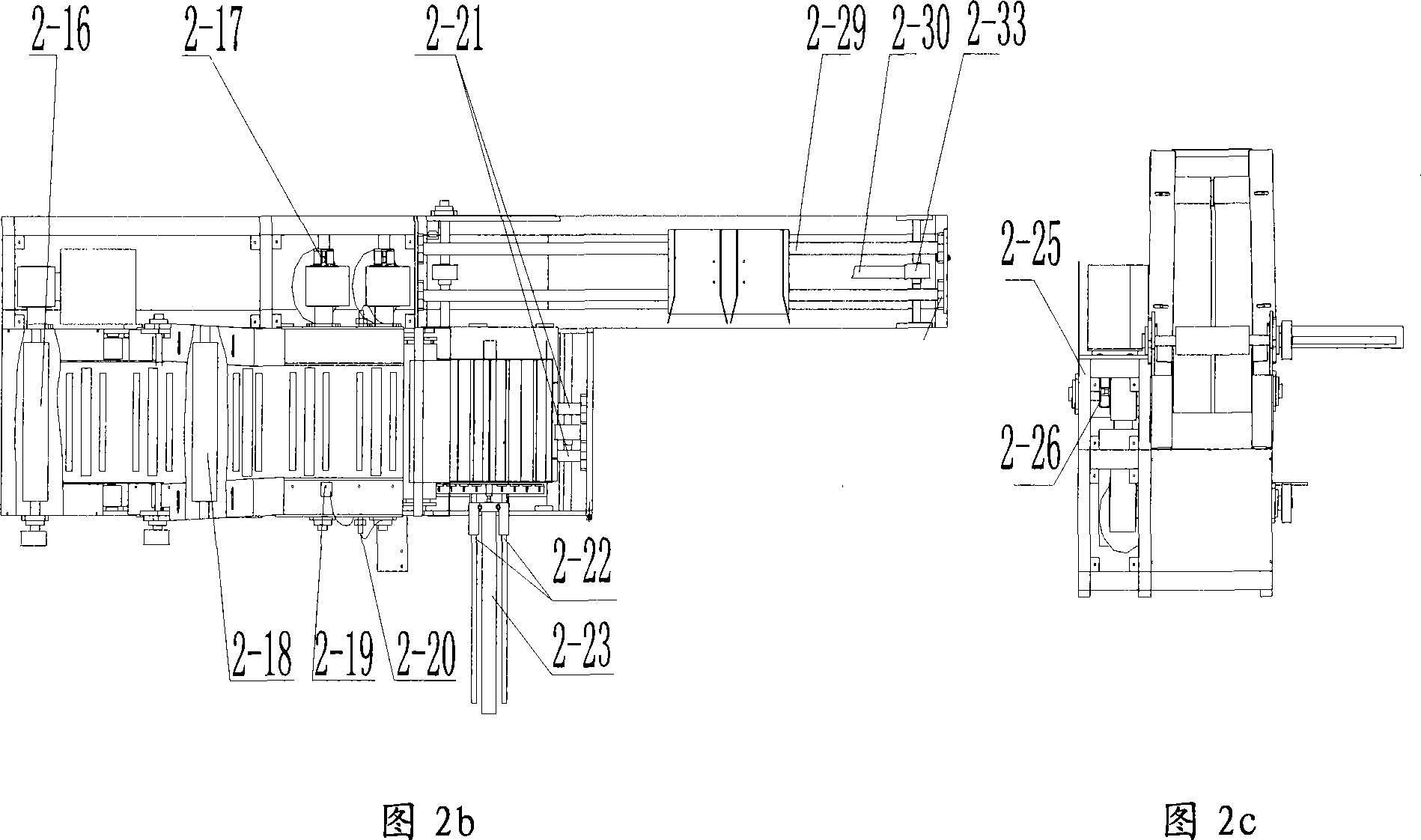

Civilian explosion automatic medium packaging box assembly line

ActiveCN101368809AIncrease productivityImprove performanceAmmunition storageProduction lineMulti site

The invention relates to a civilian explosive automatic package boxing production line, which is composed of an automatic package production machine, an automatic boxing machine and an electric control system; the components of the automatic package production machine are respectively fixed on a machine rack; the devices of the automatic boxing machine are arranged on the same main rack; the electric control system controls the operation of the entire automatic boxing machine and the automatic package production machine; and the automatic package production machine is connected with the automatic boxing machine through a chain conveyer of the automatic package production machine. The invention is significantly characterized by high production efficiency, as well as stable and reliable performances, wherein, the maximum production capacity of the production line reaches 4.5 tons / hour, while the maximum production capacity of the similar domestic products is around 2 tons / hour; the production line adopts the sophisticated reliable film roll forming seal technology and the boxing technology to achieve safe, stable and reliable performances of the entire production line; moreover, the production line adopts a multi-site design to reduce costs.

Owner:WUHAN RENTIAN PACKAGING TECH

Sludge treatment system and method in cement kiln

InactiveCN102976575ALarge amount of disposalRelieve pressureSludge treatment by de-watering/drying/thickeningDispersed particle separationLimit valueCement kiln

The invention discloses a sludge treatment system in a cement kiln, which is characterized by comprising a sludge drying device, a sludge incineration device, a sludge drying waste gas treatment device, a waste water treatment device, a first delivery mechanism for delivering dried sludge to the sludge incineration device, a second delivery mechanism for delivering sludge drying waste gas to the sludge drying waste gas treatment device, and a third delivery mechanism for delivering waste water generated by the sludge drying waste gas treatment device to the waste water treatment device, wherein the sludge drying device is connected with the sludge incineration device through the first delivery mechanism; the sludge drying device is connected with the sludge drying waste gas treatment device through the second delivery mechanism; and the sludge drying waste gas treatment device is connected with the waste water treatment device through the third delivery mechanism. The overall system achieves zero discharge of waste residue and waste water, and the waste gas discharge is lower than the limit value in the national discharge standard, thereby achieving the goal of converting sludge into resources and harmless substances.

Owner:广州市越堡水泥有限公司

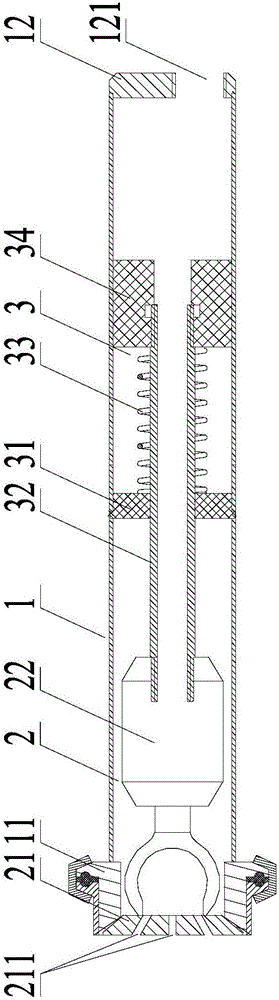

Pressure retractable cleaning device

ActiveCN106424044AThere is no risk of powder accumulationAvoid the disadvantages of manually installing cleaning devicesHollow article cleaningEngineeringHigh pressure water

The invention provides a pressure retractable cleaning device, which comprises a pipe cavity assembly, and a cleaning assembly and a retractable assembly arranged in the pipe cavity assembly in a sleeving way. The cleaning assembly is of a cavity structure; one end of the cleaning assembly is tightly matched with the pipe cavity assembly; cleaning medium outlets are formed in the end part; the other end of the cleaning assembly is fixedly connected with the retractable assembly in a sleeving way; and the retractable assembly is a retractable moving part with a pore passage inside. According to the pressure telescopic cleaning device provided by the invention, a cleaning ball block board fits to an inner wall of a cavity body to be cleaned, so that the defect that the cleaning device is manually installed before a cleaning program every time is avoided; in addition, during cleaning, high-pressure water or compressed gas can be adopted as power and is automatically retracted into the cleaning device after finishing cleaning, so that the defect that an existing retractable cleaning device requires an external air cylinder as a drive device is avoided; and the pressure retractable cleaning device provided by the invention is reasonable in structural design, low in production cost, convenient to assemble and disassemble, and good in cleaning effect, has no need for self-cleaning, can meet the market demand, and has a wider application prospect.

Owner:翰林航宇(天津)实业有限公司

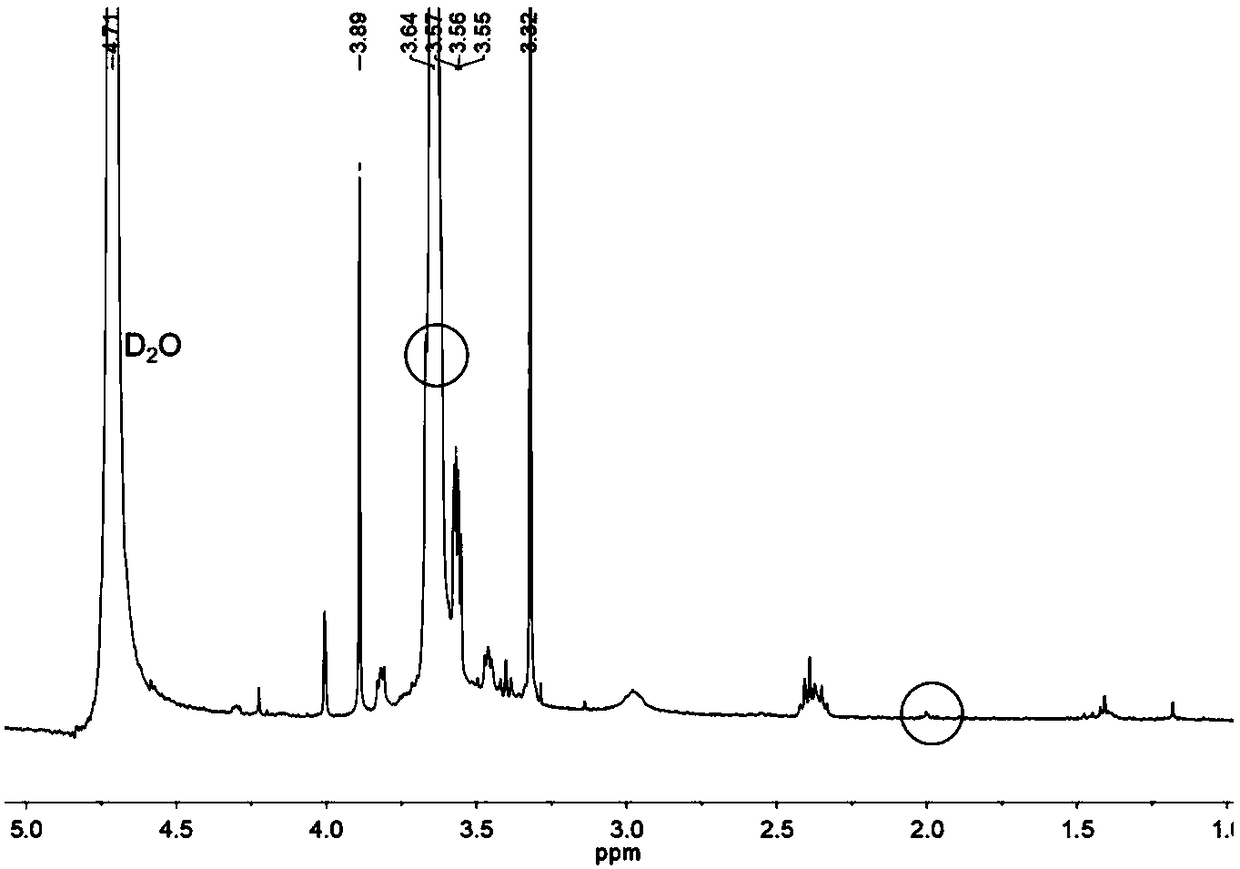

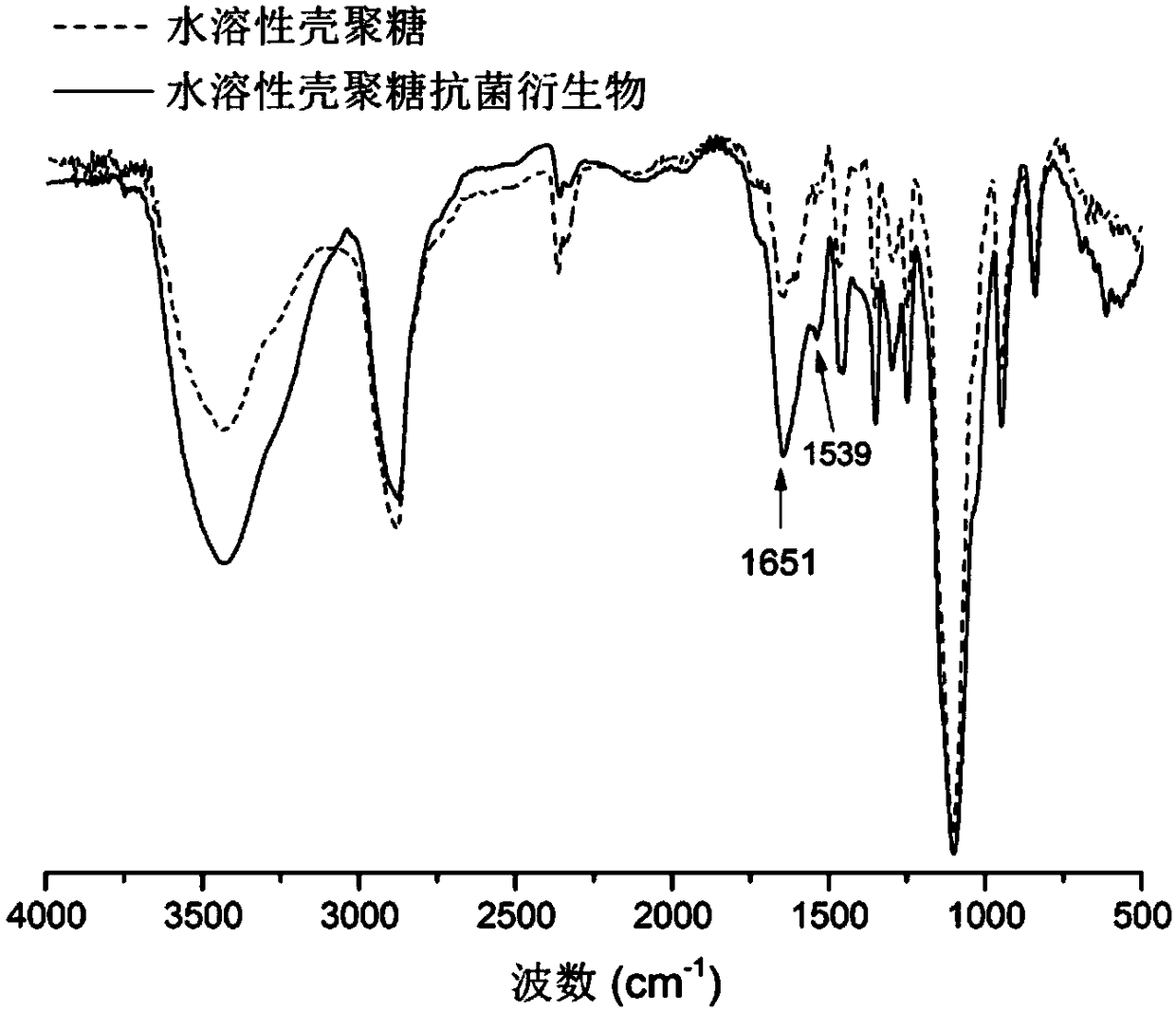

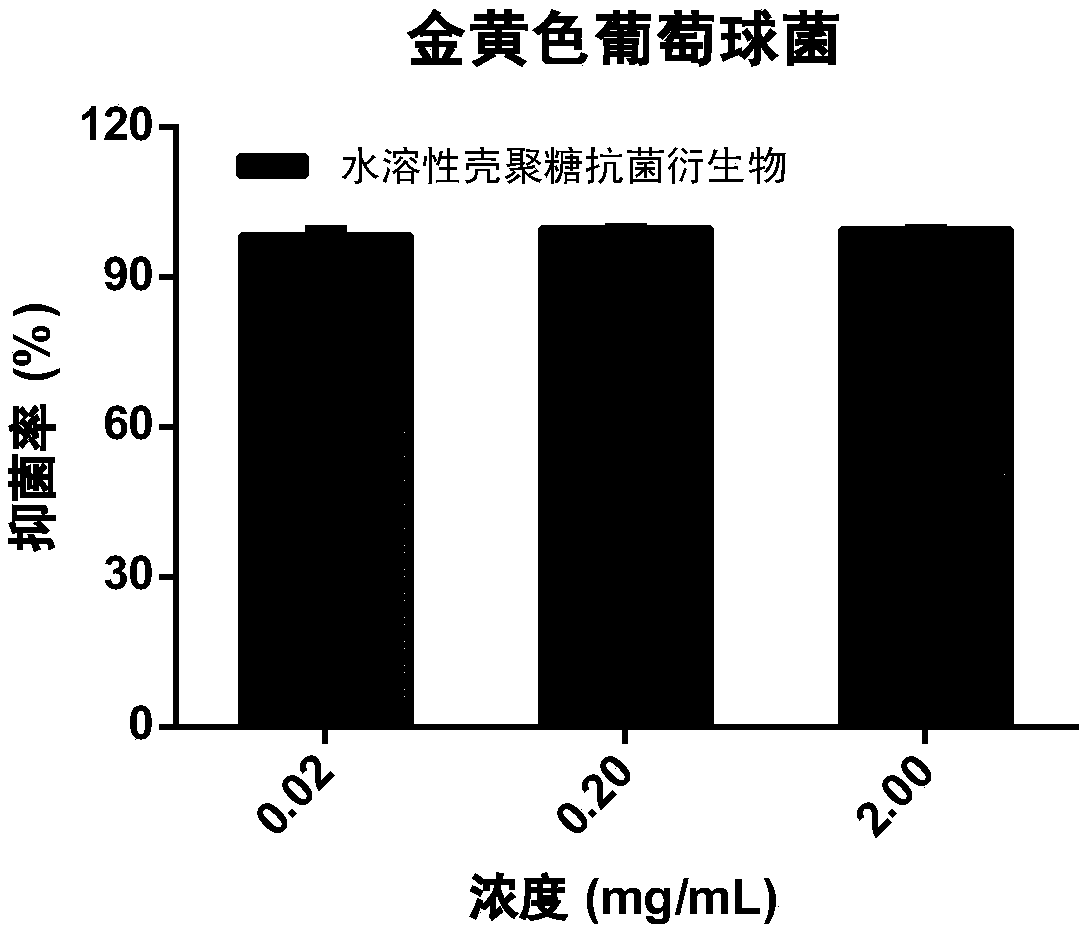

Water-soluble chitosan antibacterial derivative and preparation method thereof

ActiveCN109485747ABalanced antimicrobial propertiesBalance securityBiocideFungicidesSolubilityThiourea

The invention discloses a water-soluble chitosan antibacterial derivative and a preparation method thereof. The water-soluble chitosan antibacterial derivative comprises a chitosan framework and a bifunctional group for modifying amino on the chitosan framework, wherein the bifunctional group comprises guanidino and carbonyl methoxy polyethylene glycol. The side chain of chitosan is modified withguanidino and short-chain polyethylene glycol, and the chitosan achieves good antibacterial property and higher biological safety. According to the preparation method, firstly, the chitosan reacts with the carbonyl methoxy polyethylene glycol, water solubility of the chitosan is sufficiently improved, and biological safety is greatly improved; secondly, the chitosan reacts with thiourea trioxide,participation of the amino in subsequent reaction is effectively avoided if the guanidino is grafted in the first step, rich positive charge of the guanidino is effectively retained, and the positivecharge density of the water-soluble chitosan antibacterial derivative is ensured, so that the antibacterial effect of the water-soluble chitosan antibacterial derivative is better.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Method for digesting tobacco concrete from tobacco ribs

InactiveCN103416840ASolve the shortageDoes not contain does not exceed the standardTobacco treatmentEssential-oils/perfumesUltrafiltrationDesalination

The invention relates to a method for digesting tobacco concrete from tobacco ribs. The method for digesting the tobacco concrete from the tobacco ribs is characterized by comprising the first step of preprocessing and digesting the tobacco ribs, the second step of removing suspended solids and soluble macromolecule organic matter impurities, the third step of ultrafiltration, separation and purification, the fourth step of nanofiltration, desalination and dehydration, the fifth step of electrodialysis desalination and the sixth step of concentration. According to the method, deionized water serves as a reagent, an organic reagent is not used, cost is greatly reduced, the effect on the quality of the concrete from the organic reagent impurities is eradicated, and the safety of the concrete is improved.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

Method for raising lithium manganate production capacity and compacted density of positive electrode in lithium manganate battery

InactiveCN102364724AIncrease production capacityClose contactCell electrodesPorosityLithium carbonate

A method for raising the lithium manganate production capacity and the compacted density of a positive electrode in a lithium manganate battery. The technological steps contain: adding an organic binder hydroxypropyl-cellulose into a mixture of manganese dioxide and lithium carbonate, uniformly mixing, compacting into a lithium manganate lump, sintering, crushing the sintered lithium manganate lump, and sieving to obtain a lithium manganate product; compacting the lithium manganate product into a pole piece by a routine method, and making the lithium manganate pole piece into a 053048 aluminium shell effect battery by a routine method. By the steps of compacting the mixture into a lump and then sintering, the proportion of the sintered stockpile is raised by 31% than that of a mixture which dose not undergo compacting and sintering steps, the quality of the lithium manganate product is improved, and the porosity is reduced, thus raising the bulk energy density of the battery.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Integral wooden door made of wood fiber composite materials

ActiveCN102555003ASimple process conditionsSimple manufacturing processWood working apparatusFlat articlesEnvironmental resistanceWood fibre

The invention discloses an integral wooden door made of wood fiber composite materials. In the integral wooden door, a traditional wooden door manufacturing process mode is broken through, the wood fiber composite materials which are mainly made of waste wood leftover materials or slash materials are molded at one step by the aid of mould pressing technology, the integral wooden door is successfully manufactured by the aid of optimized hot pressing process, the thickness of the integral wooden door ranges from 30mm to 60mm, and the density of the integral wooden door ranges from 0.65g / cm3 to 1.05g / cm3. Compared with an existing merchant wooden door, the integral wooden door is simple in manufacture, high in efficiency and low in cost, is environment-friendly, and has extremely wide application prospect and economic prospect.

Owner:浙江新木材料科技有限公司

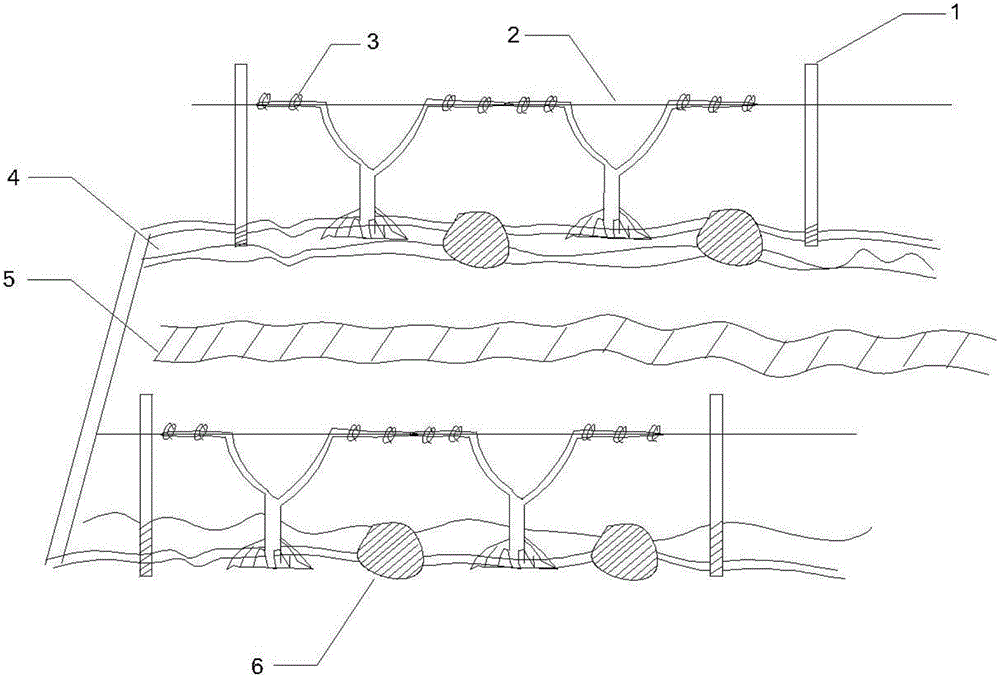

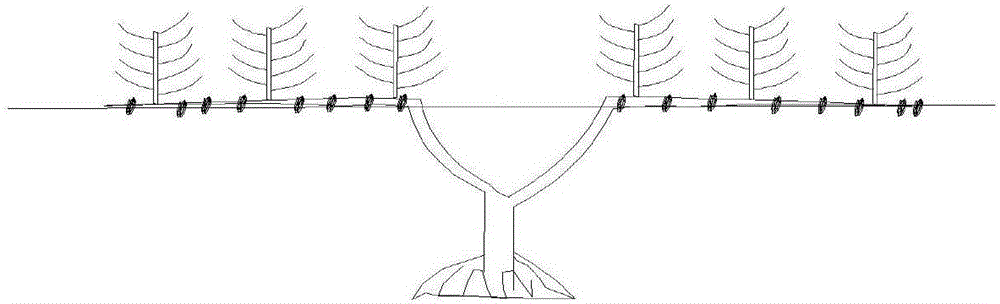

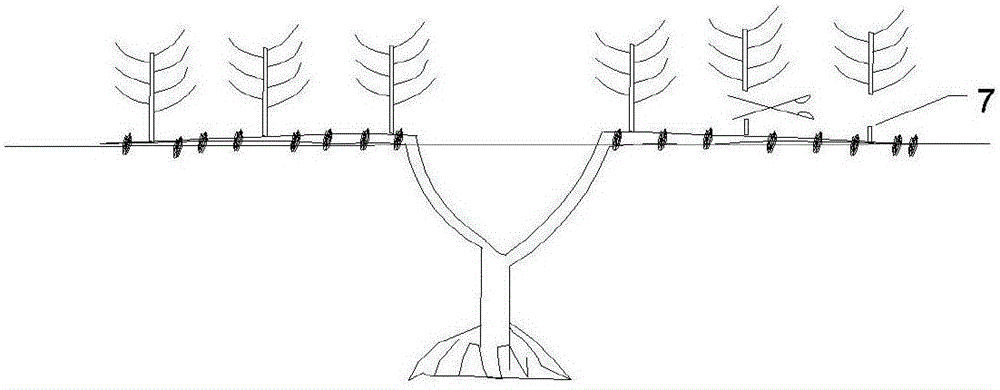

A method of cultivating greenhouse mulberries by using horizontal straight line fist growing

InactiveCN106105951AShort training periodIncrease productionClimate change adaptationGreenhouse cultivationFertilizerFist

The invention provides a method of cultivating greenhouse mulberries by using horizontal straight line fist growing. The method comprises the steps of greenhouse building, disinfection, field planting, water and fertilizer management, greenhouse covering management, trimming, bud picking and pinching, harvesting and management, and disease and pest control. Vertical upward concrete pillars are arranged in field planting rows at intervals; the concrete pillars in the same field planting row are in one straight line and are bound and connected via an iron wire strip; the field planting rows are covered with mulching film. Compared with the prior art, the method has the advantages of short culture period, high yield and high benefit. The method can shift the time of coming into the market of mulberries to an earlier time of March, enables mulberries to mature 2-3 months earlier than those cultivated in the open, enables the yield per mu to reach 2000 kg, meets the requirement of the fresh fruit market and enables the price to be increased severalfold.

Owner:张媛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com