Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about "Hem-stitch machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

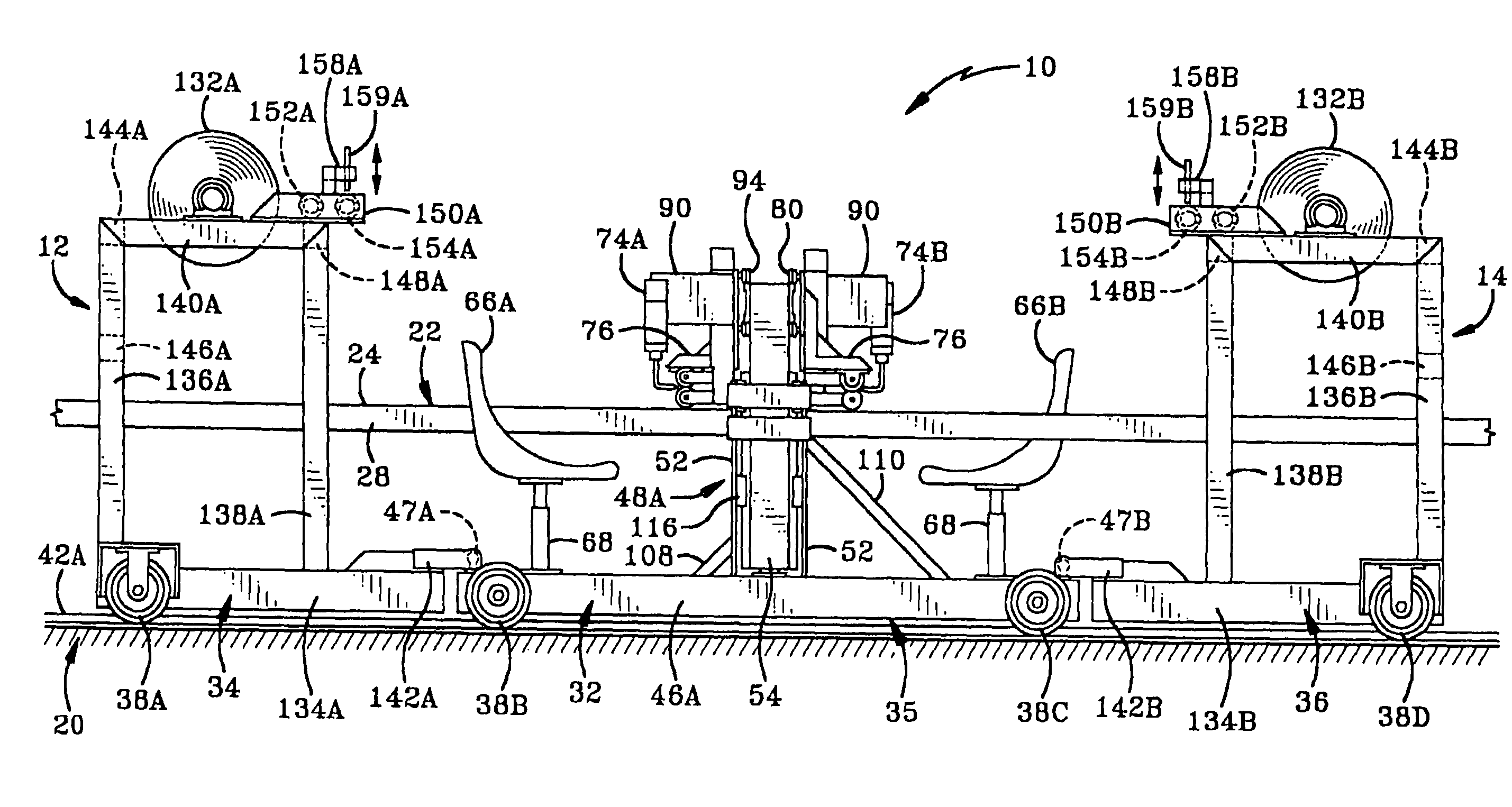

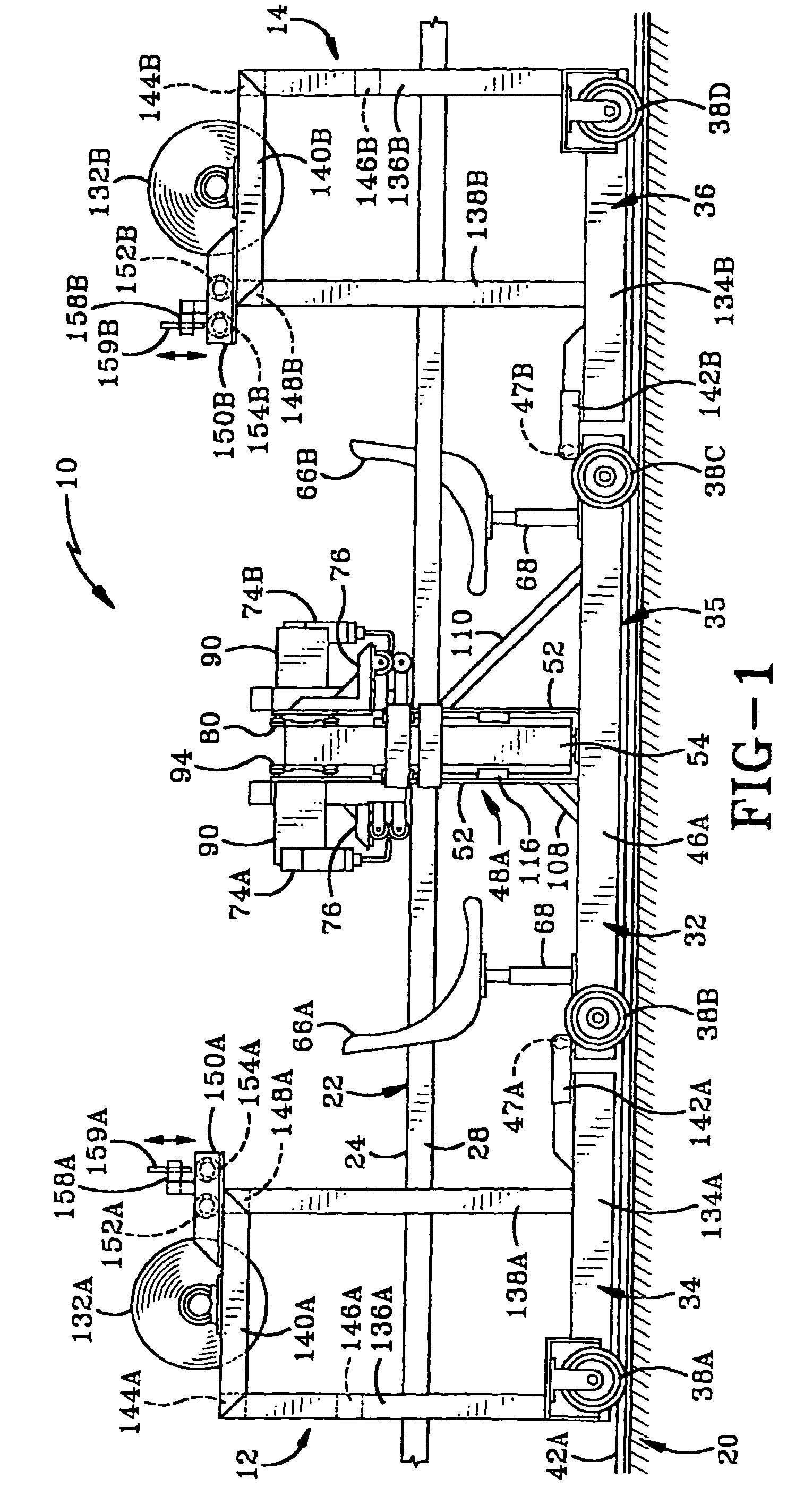

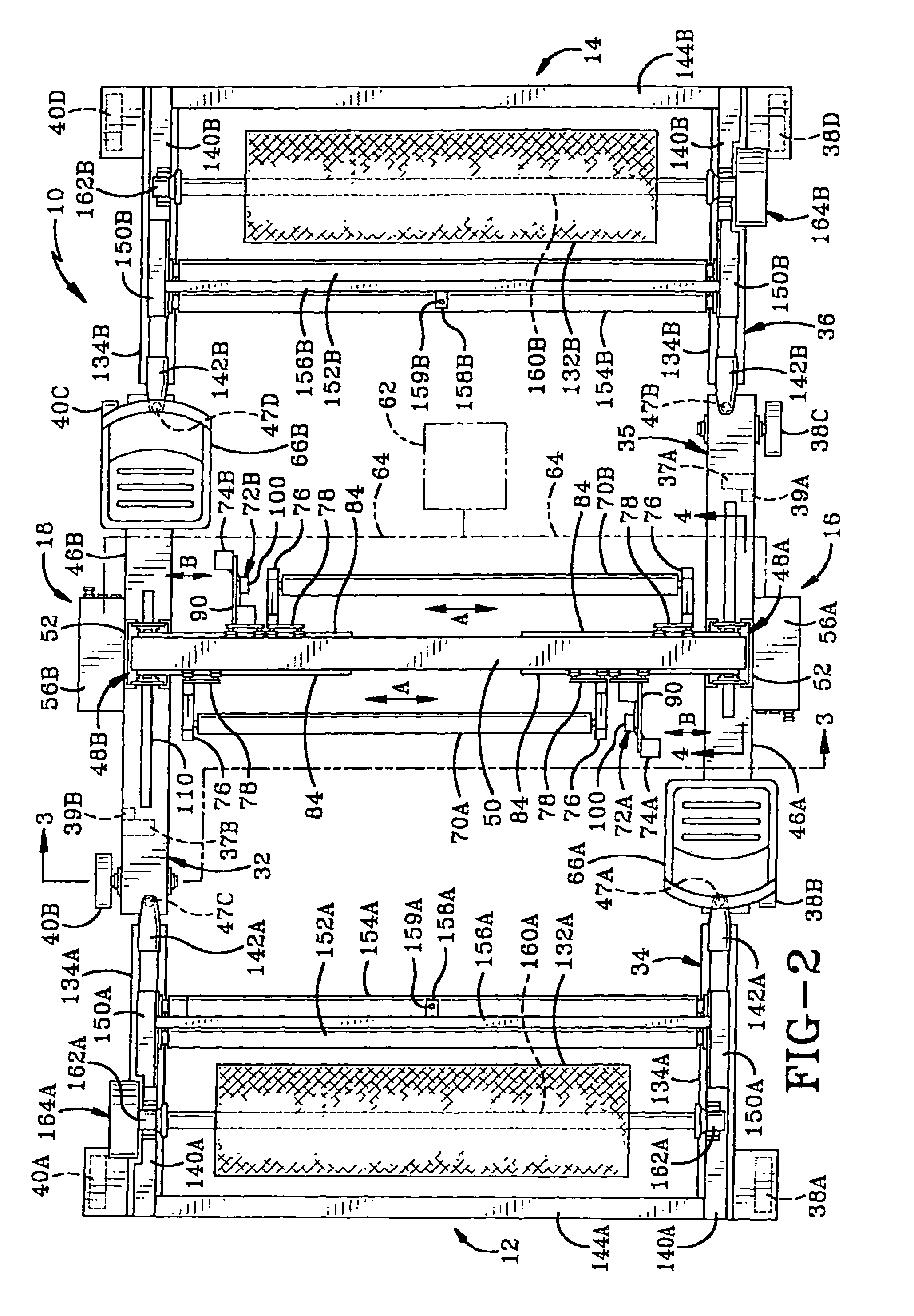

Bi-directional seaming machine

Owner:MILLER WELDMASTER CORP

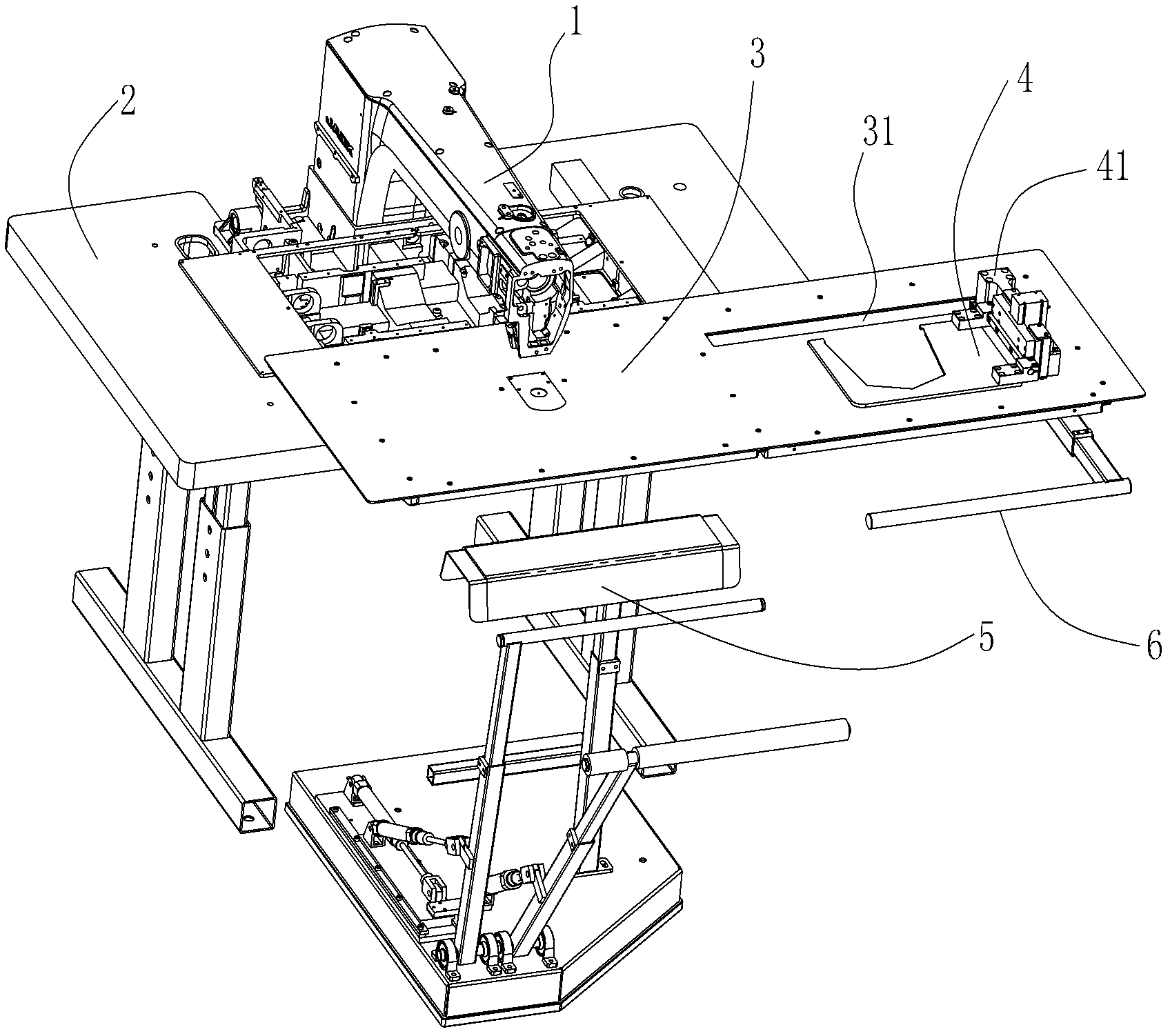

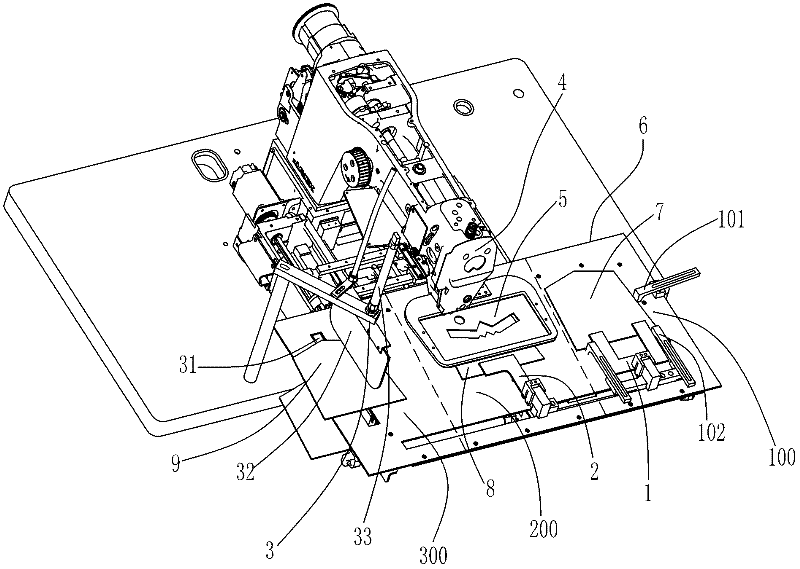

Automatic feed pocket patching machine

ActiveCN102409487ASimple structurePractical structureWork-feeding meansHem-stitch machinesManufacturing cost reductionComputer module

Owner:JACK SEWING MASCH CO LTD

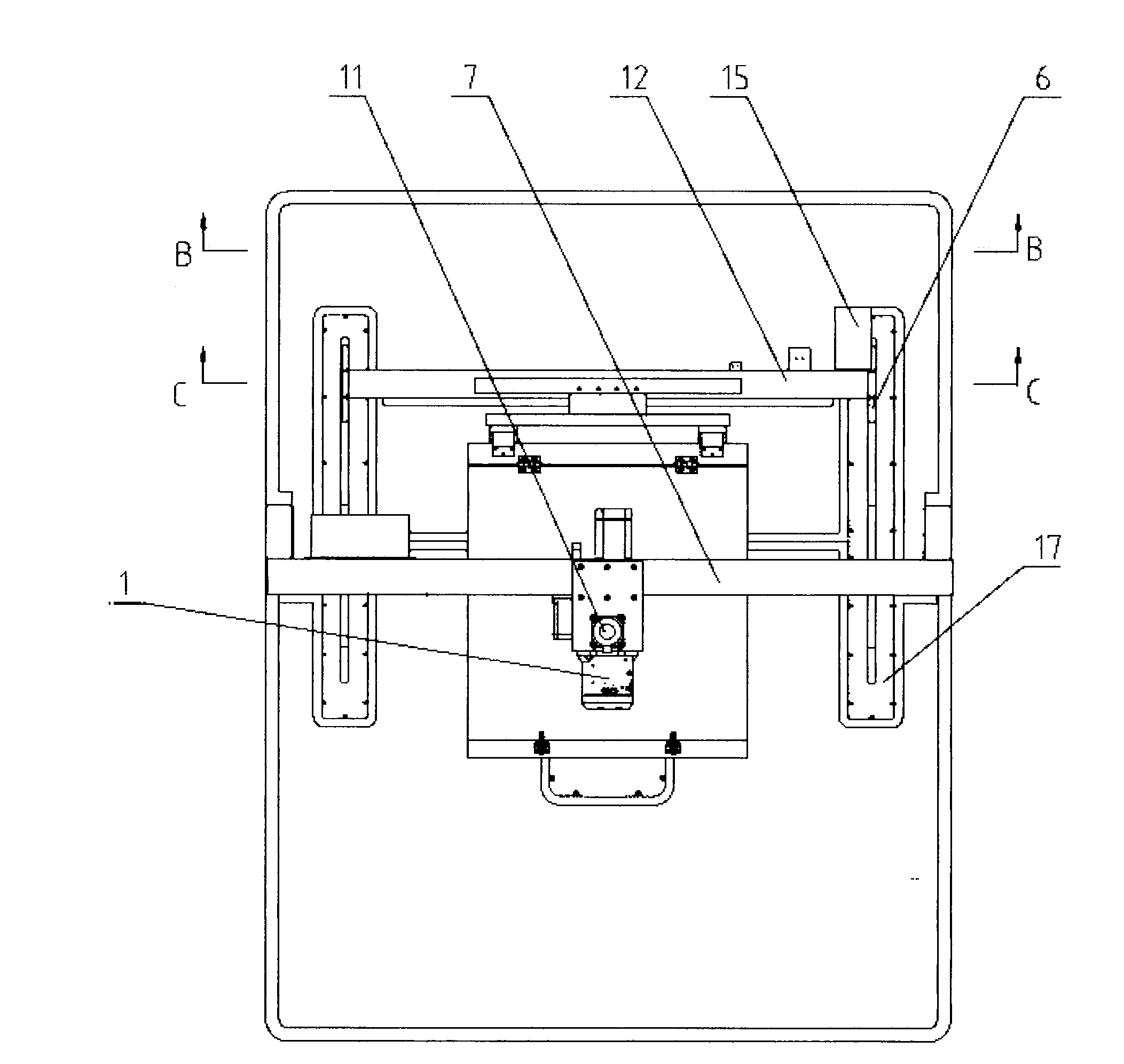

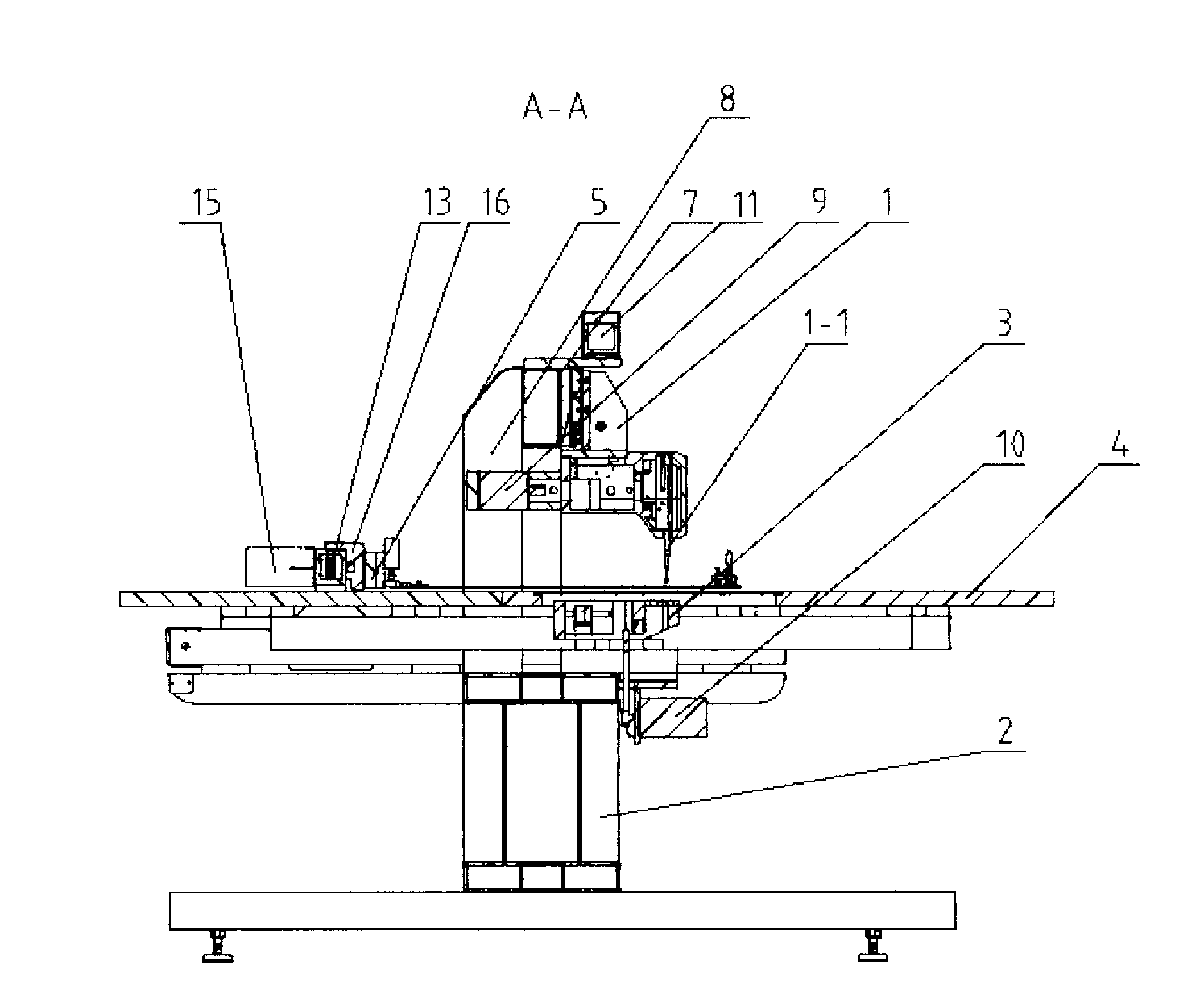

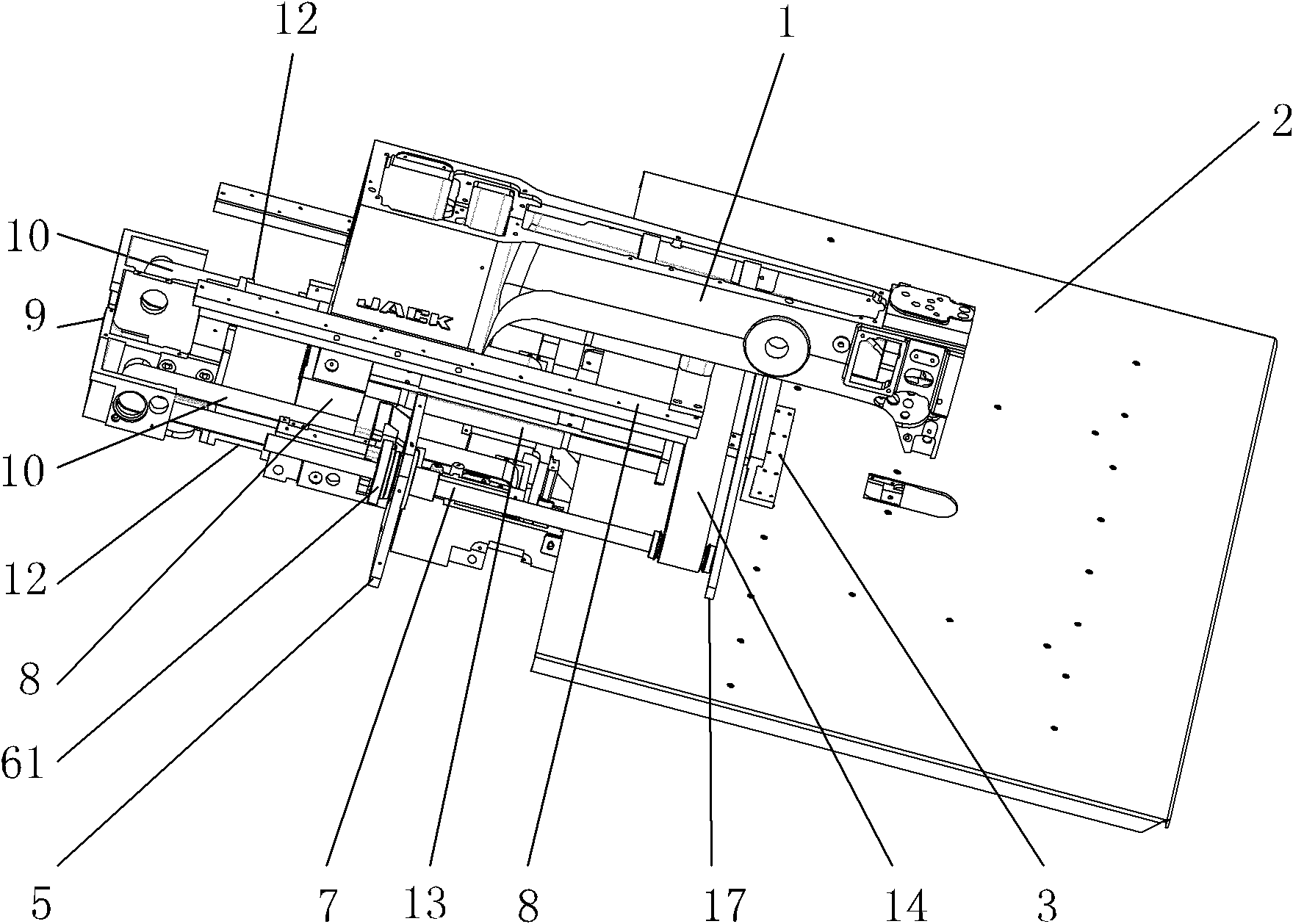

Machine head and machine base split type pattern sewing machine

InactiveCN101696534ASimple structureEasy to operateSewing-machine casingsWork-feeding meansBall screwElectric machinery

The invention relates to a machine head and machine base split type pattern sewing machine belonging to the technical field of sewing machines. The machine head and machine base split type pattern sewing machine comprises an X-direction feed device, a Y-direction feed device, a machine head, a machine base and a stand, wherein the X-direction feed device and the Y-direction feed device are driven by respectively independent motors; the Y-direction feed device drives the X-direction feed device to move along a Y direction; the X-direction feed device is provided with a double-ball screw, and the synchronous feed of the double-ball screw is realized through a synchronous belt so that the machine base and the machine head which are arranged on the X-direction feed device can synchronously move. The invention has simple structure and easy operation and can move along an X direction and the Y direction and achieve the purposes of sewing patterns with large areas and enhancing the work efficiency; in addition; the pattern sewing machine can more stably work through the double-ball screw arranged on the X-direction feed device.

Owner:JACK SEWING MASCH CO LTD

Industrial sewing machine

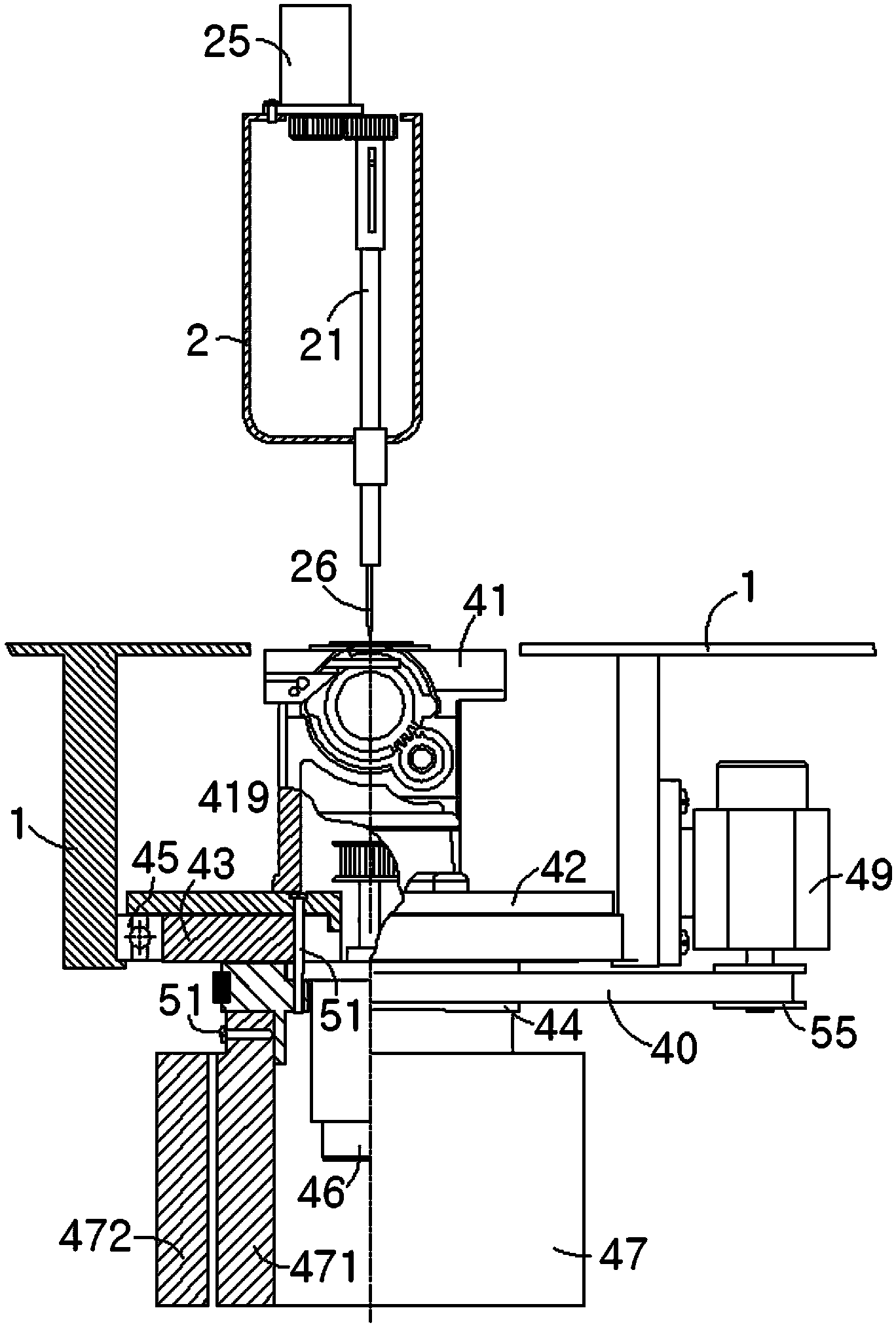

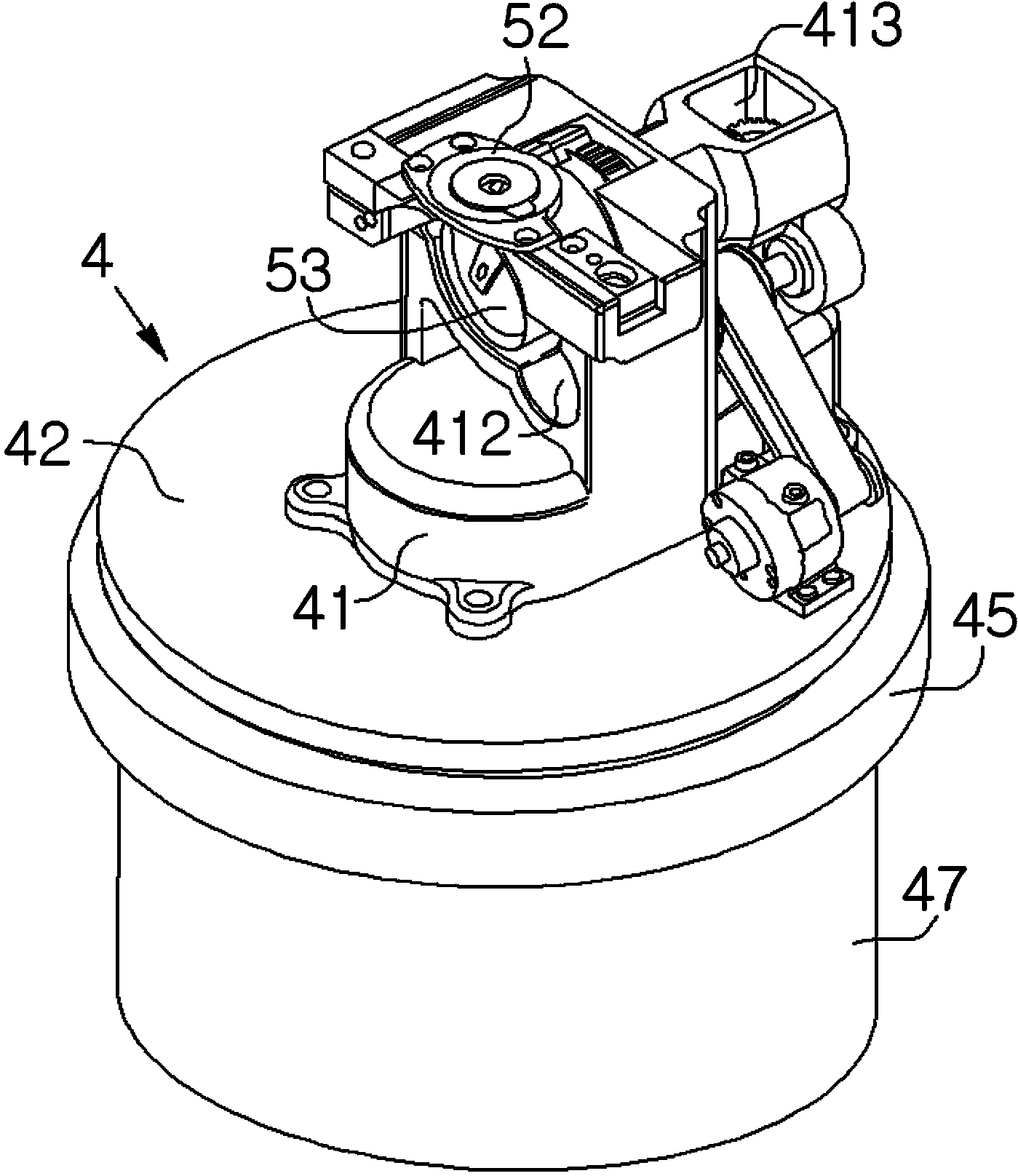

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

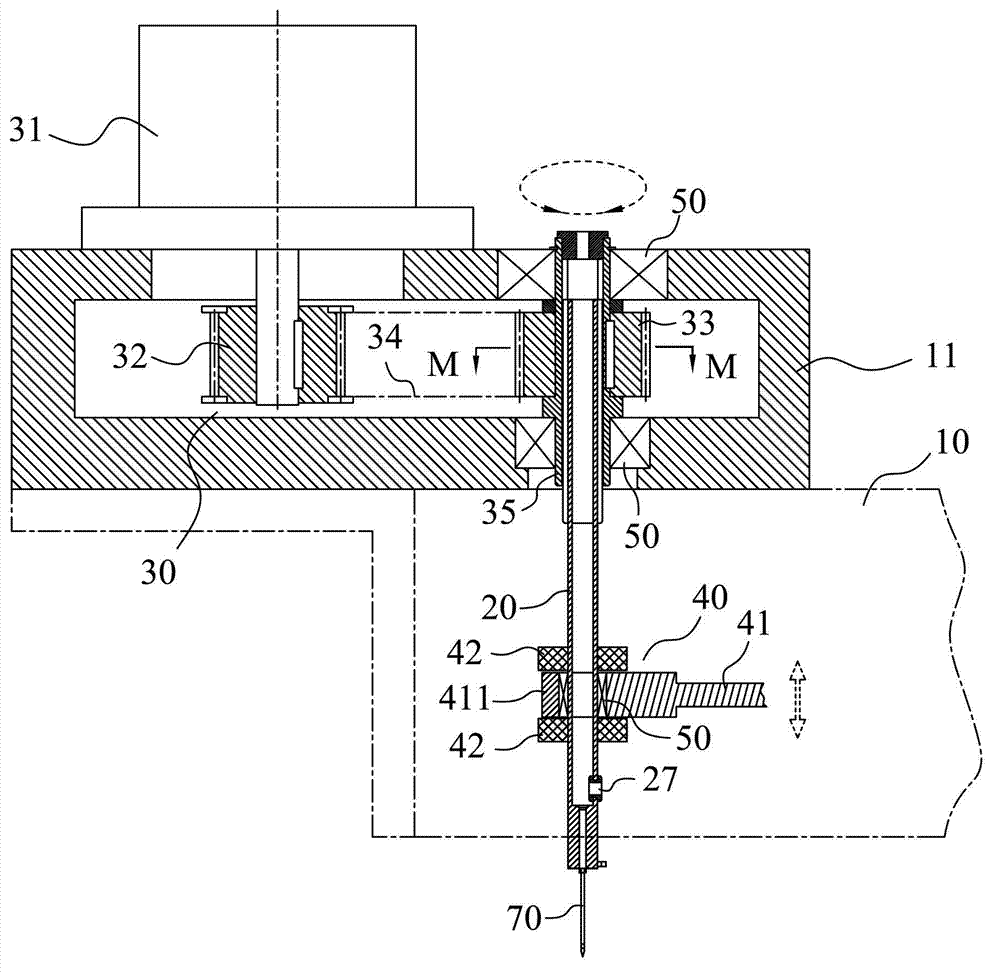

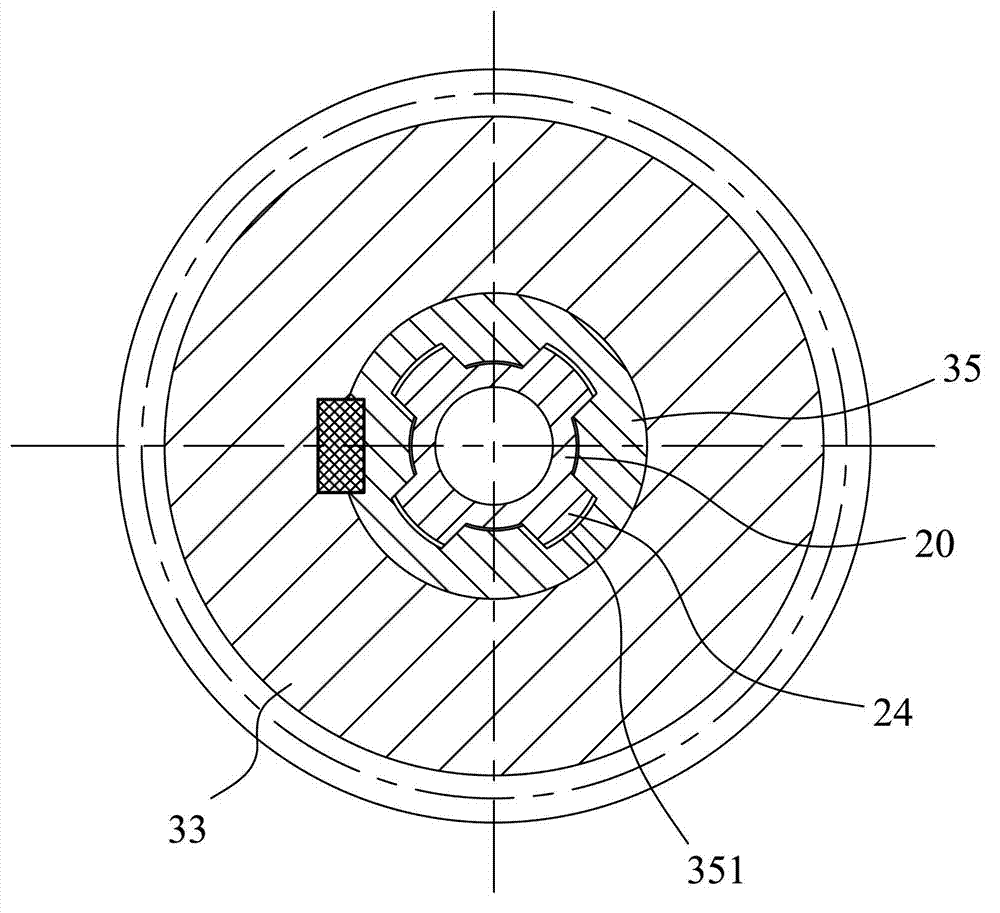

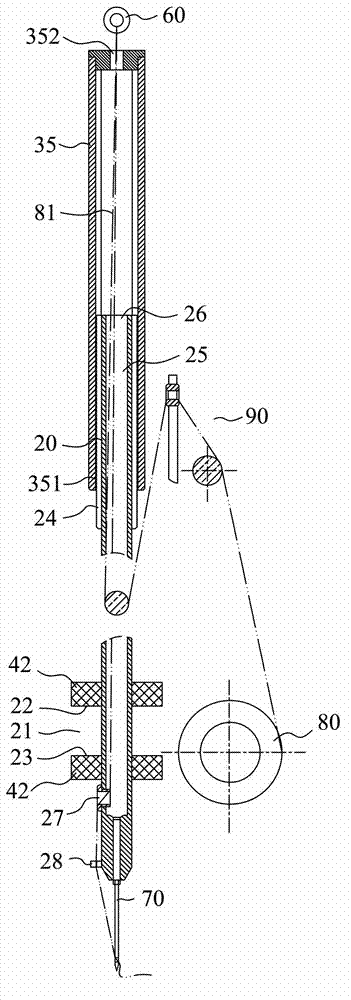

Needle-bar-rotating pattern sewing machine

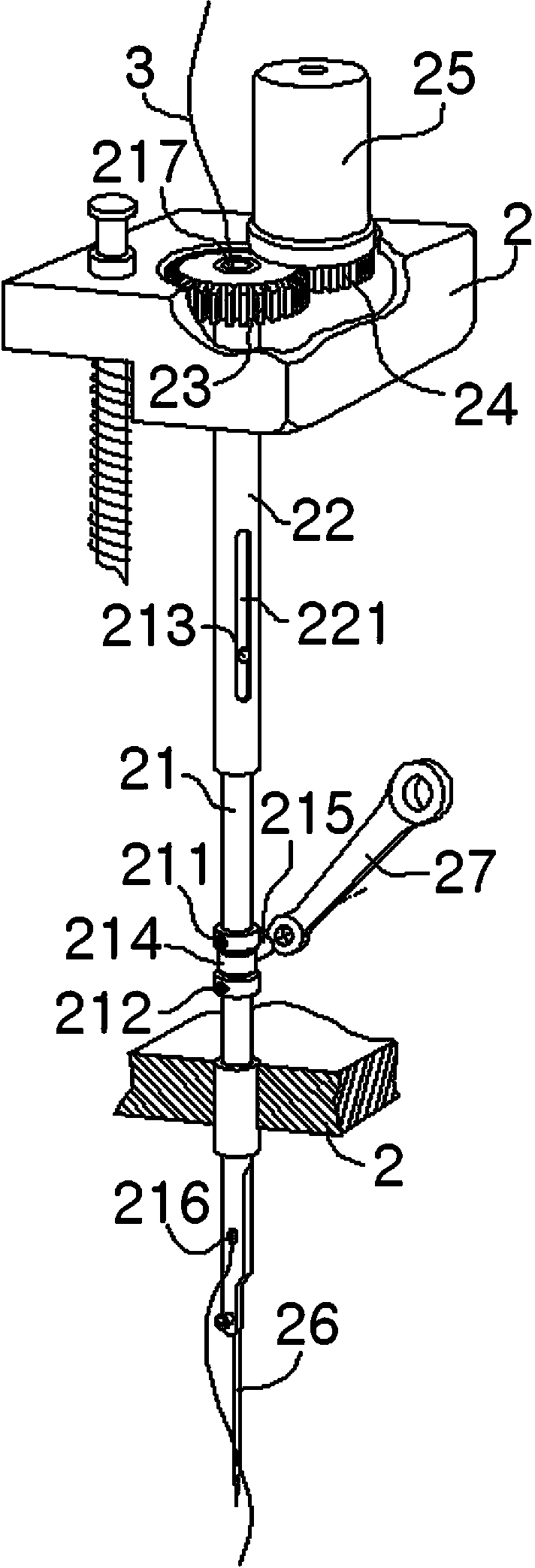

InactiveCN102776722AGuaranteed aestheticsThere will be no twisting phenomenonHem-stitch machinesNeedle barsYarnElectric machinery

The invention disclosed a needle-bar-rotating pattern sewing machine, which comprises a needle bar, a needle bar rotating mechanism and a needle bar up-and-down movement mechanism, wherein the needle bar rotating mechanism comprises a needle bar sheath; the needle bar moves up and down relative to the needle bar sheath; an axial thread inlet is arranged at the top of an axial thread hole formed in the hollow part of the needle bar; and a thread outlet is arranged at the lower end of the axial thread hole. As the needle bar up and down motion mechanism drives the needle bar into up-and-down movement to conduct stitching action, the needle bar rotating mechanism drives the needle bar to rotate; through regulating sewing stitches and directions, the changes of patterns and design directions are adaptive, and stitch esthetic appearance is ensured; and as the yarn passes through the axial thread hole of the needle bar, the phenomenon of twisted threads does not occur during the process of rotation of the needle bar. Therefore, the needle-bar-rotating pattern sewing machine provided by the invention has the beneficial effect that by replacing the way of large-volume machine head rotation with thin and small-volume needle bar rotation, stitches can be formed along the tangential direction of designs and patterns in sewing, the rotation inertia is reduced, the vibration is reduced, the rotation speed is improved, and the motor power is greatly reduced.

Owner:颜新宁

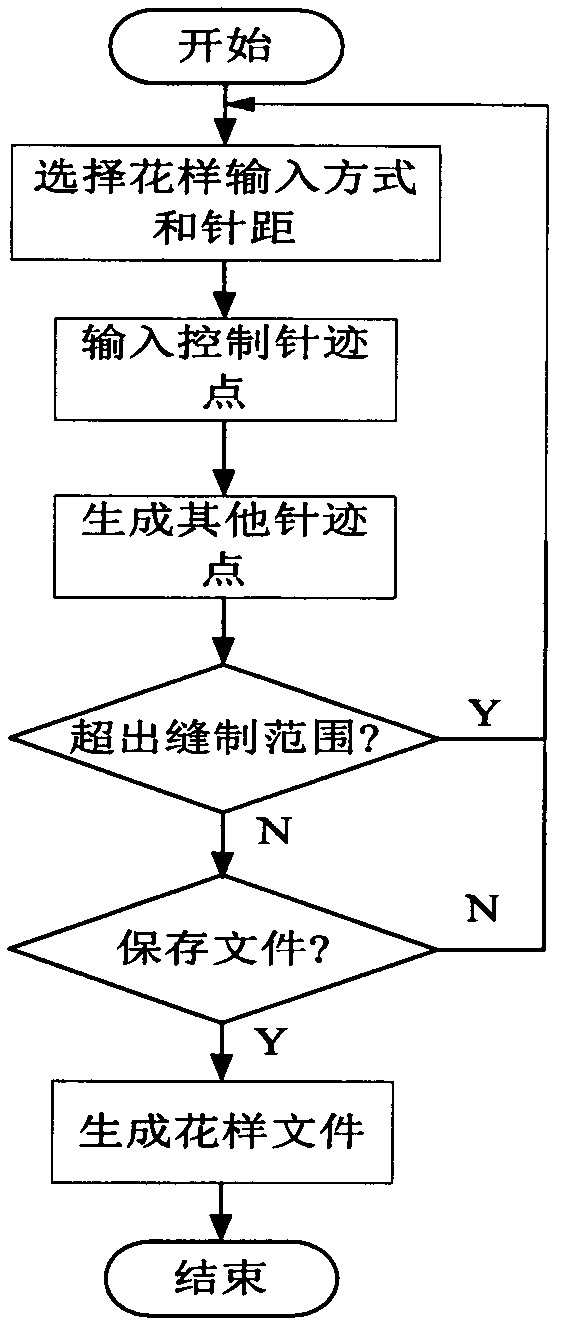

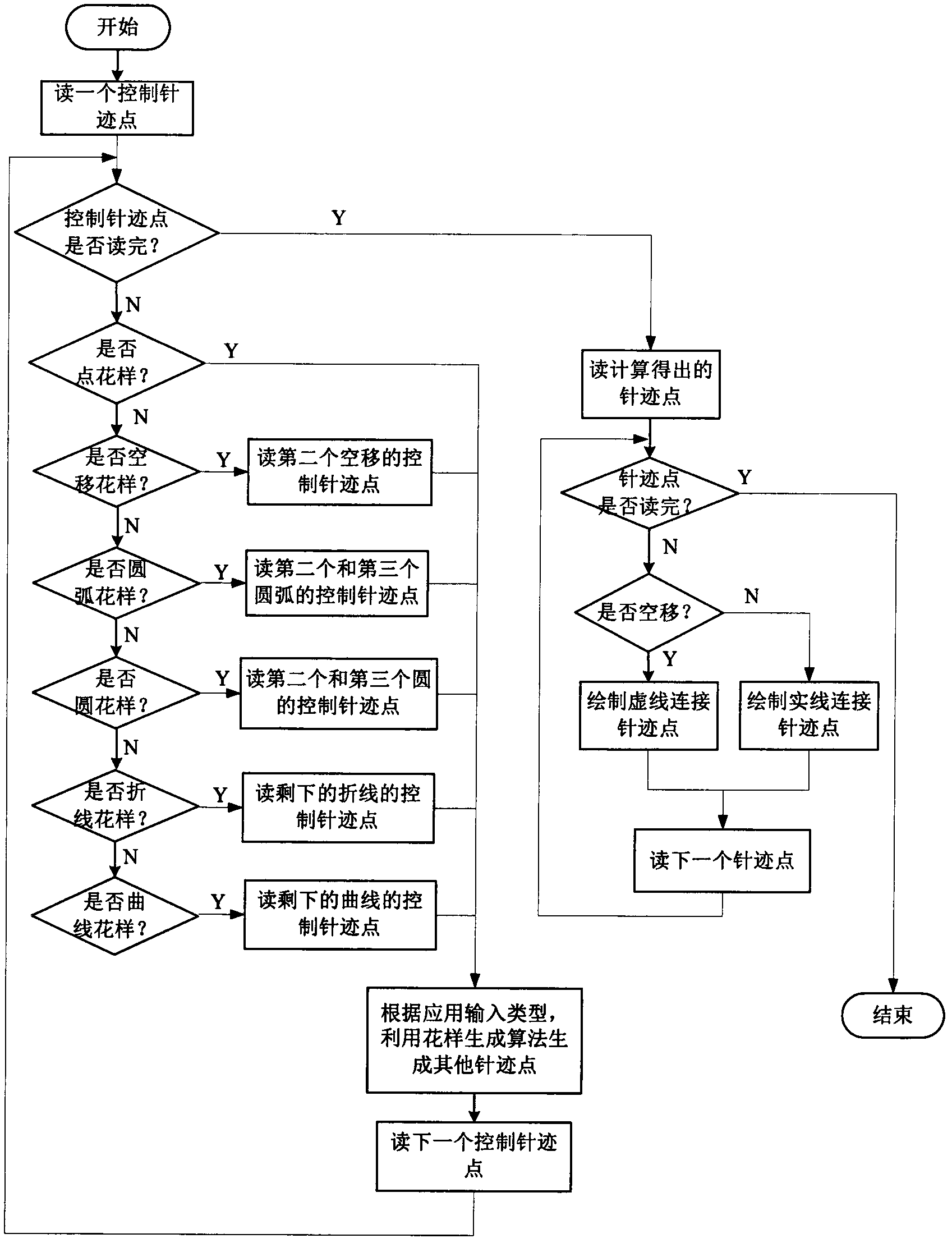

Pattern editing and pattern generating method for electronic pattern machine

InactiveCN102634933APattern editing is simple and convenientFriendly editing interfaceProgramme-controlled sewing machinesHem-stitch machinesPattern recognitionMachine control

The invention provides a pattern editing and pattern generating method for an electronic pattern machine. A pattern design is an important performance index of an electronic pattern machine control system. The pattern editing and pattern generating method disclosed by the invention provides a generation method of various pattern designs. The generation method comprises spatial migration, straight line, circle, circular arc, curve and polygon; on the basis, the generation method for pattern designs such as homodromous multiple sewing, converse multiple sewing, assistant sewing, front and back backstitch and overlapping sewing is realized, and the generation method for the complex pattern designs comprising various patterns is realized. The pattern generating method is integrated into pattern edition, and the pattern is automatically generated in the pattern edition. The pattern editing and pattern generating method has the technical effect that the abundant pattern design is applied, and the pattern can be simply and conveniently edited. A friendly editing interface is provided to support the dynamic edition and secondary edition of the pattern. The pattern editing and pattern generating method has the advantages of high operation efficiency and good pattern generating effect.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Novel quilting embroidery machine

InactiveCN101319440AShorten the lengthImprove rigidityHem-stitch machinesMattress sewingElectric machineryAutomotive engineering

The invention discloses a novel quilting embroidery machine, consisting of a machine frame, as well as a charging system, a discharging system and two sets of rolling systems which are arranged on the machine frame. A servo motor realizes the front and rear rolling and synchronous rotation in a Y direction through a synchronous cog belt; a machine head component and a shuttle box component are also arranged on the machine frame; the machine head component is arranged on a connecting plate; a linear guide rail is arranged on the connecting plate; the shuttle box component is arranged on a shuttle box component connecting plate, and a shuttle box component linear guide rail is arranged on the connecting plate; a driving component is also arranged on the machine frame; the driving component comprises the servo motor, a lead screw and a driving-connecting block; the driving-connecting block is connected with the machine head component connecting plate and the shuttle box component connecting plate; the driving component realizes the movement of the machine in an X direction. The servo motor and a transmission box connected with the servo motor are also arranged on the machine frame; the transmission box connects the machine head component connecting plate with the shuttle box component connecting plate into a whole; the transmission box drives a needle bar of the machine head component to move up and down and also drives the shuttle box component to rotate. The machine is applicable to quilting embroidery machines.

Owner:陈桢铭

Bent two-needle sewing machine

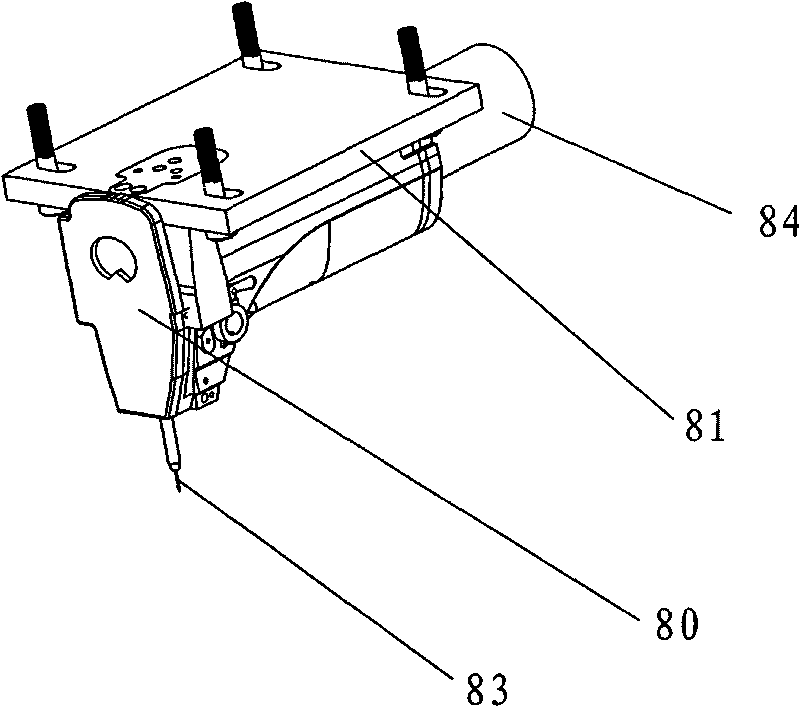

InactiveCN101525814AHigh precisionEasy to replaceSewing-machine casingsPressersEngineeringSewing machine

The invention provides a bent two-needle sewing machine, belongs to the mechanical technical field, and solves the technical problems that the existing bent two-needle sewing machine can not be conveniently installed and maintained, and can not manufacture different three-dimensional stripes. The bent two-needle sewing machine comprises a sewing machine head, a bottom board, a needle clamp and two needles fixedly connected on the needle clamp, wherein, the sewing machine head is fixedly connected on the bottom board; the needle clamp is connected with the sewing machine head; and a detachable mechanism is arranged between the needle clamp and the sewing machine head. The bent two-needle sewing machine has the advantages of high positioning precision of needles, convenient disassembly, assembly, replacement and maintenance, etc.

Owner:新通宇缝纫机股份有限公司

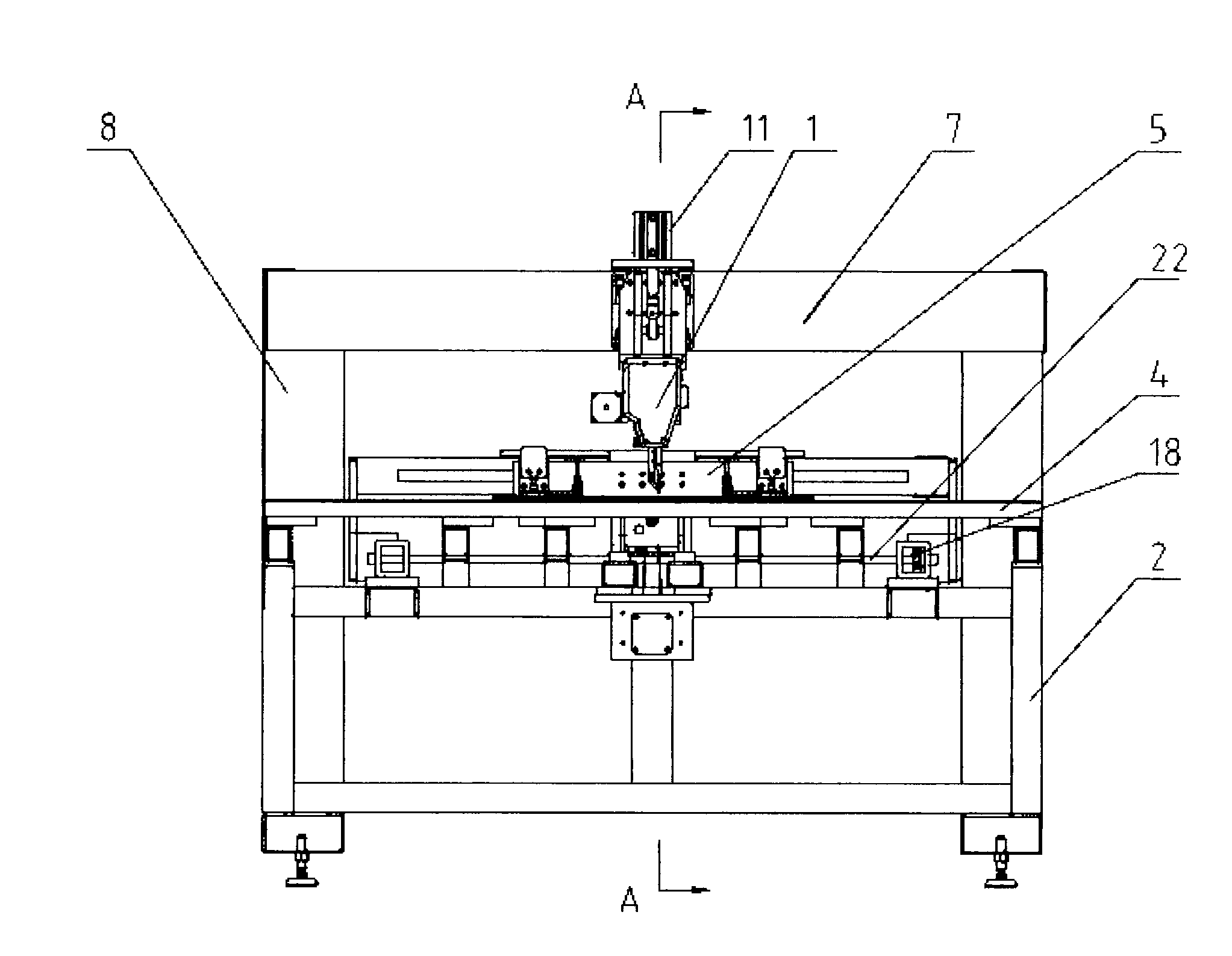

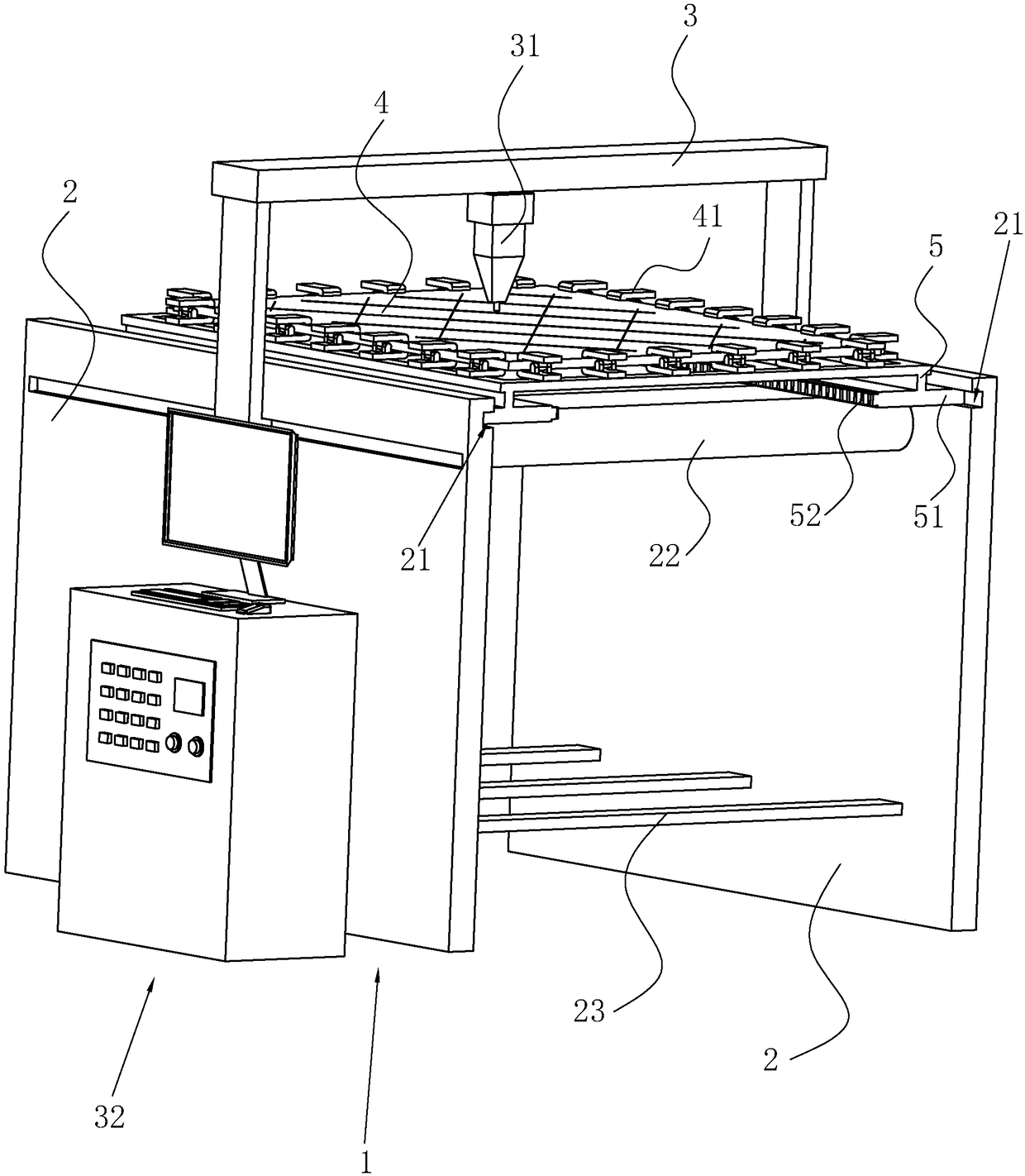

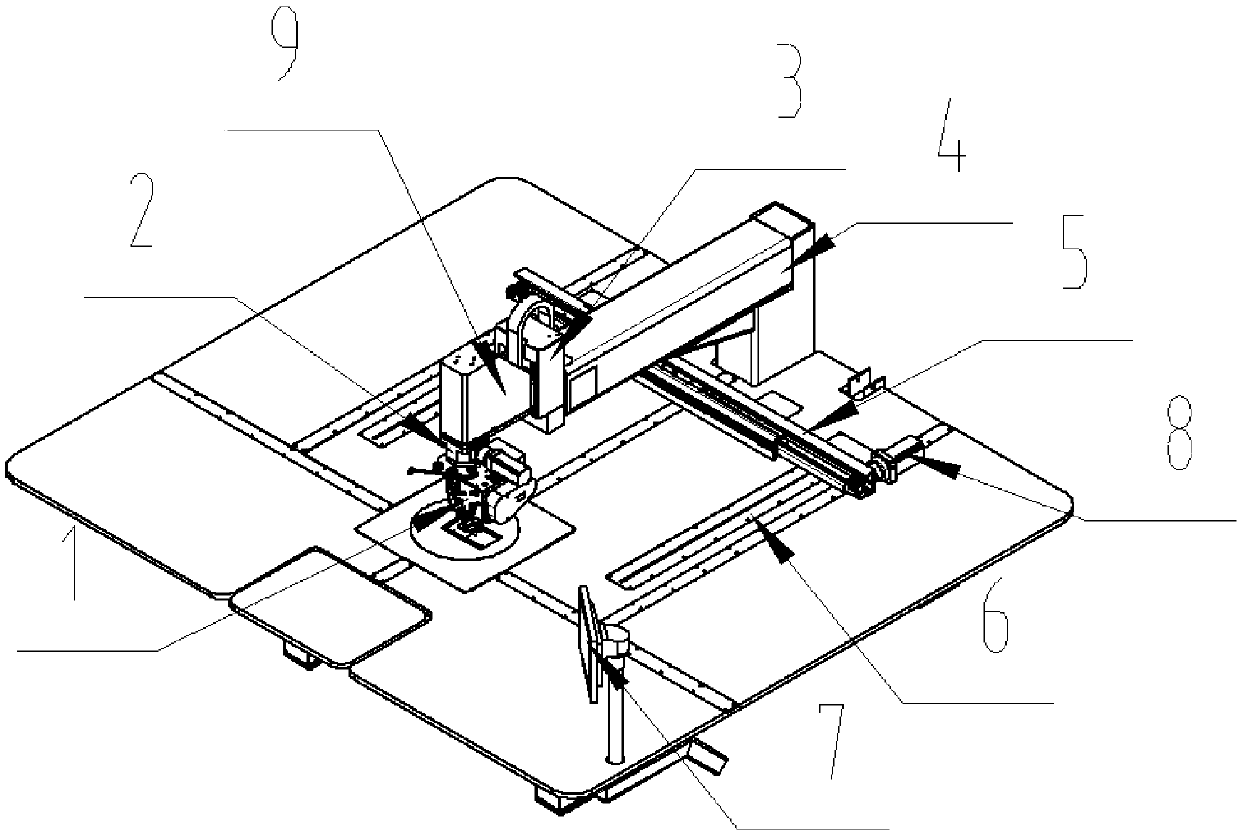

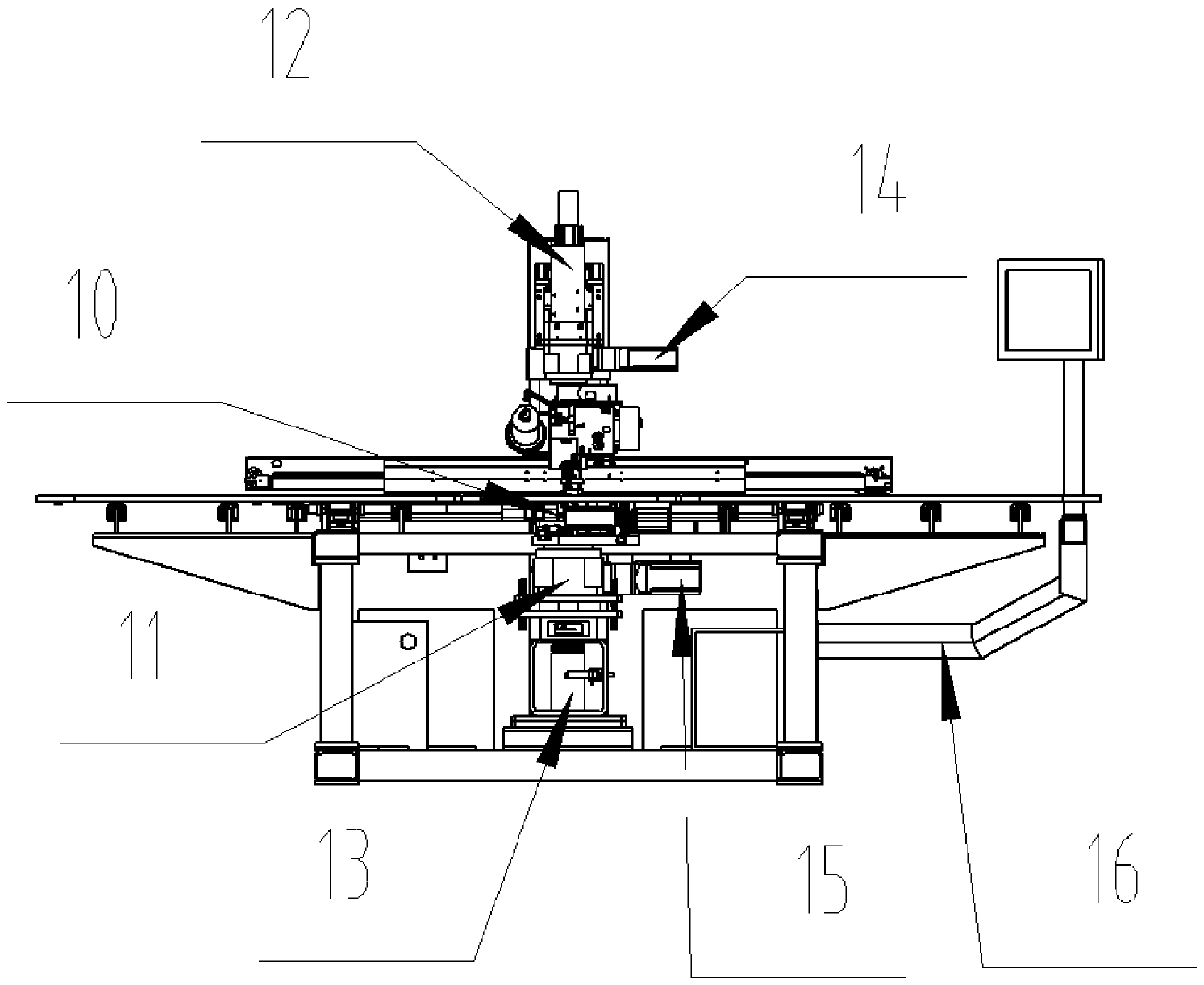

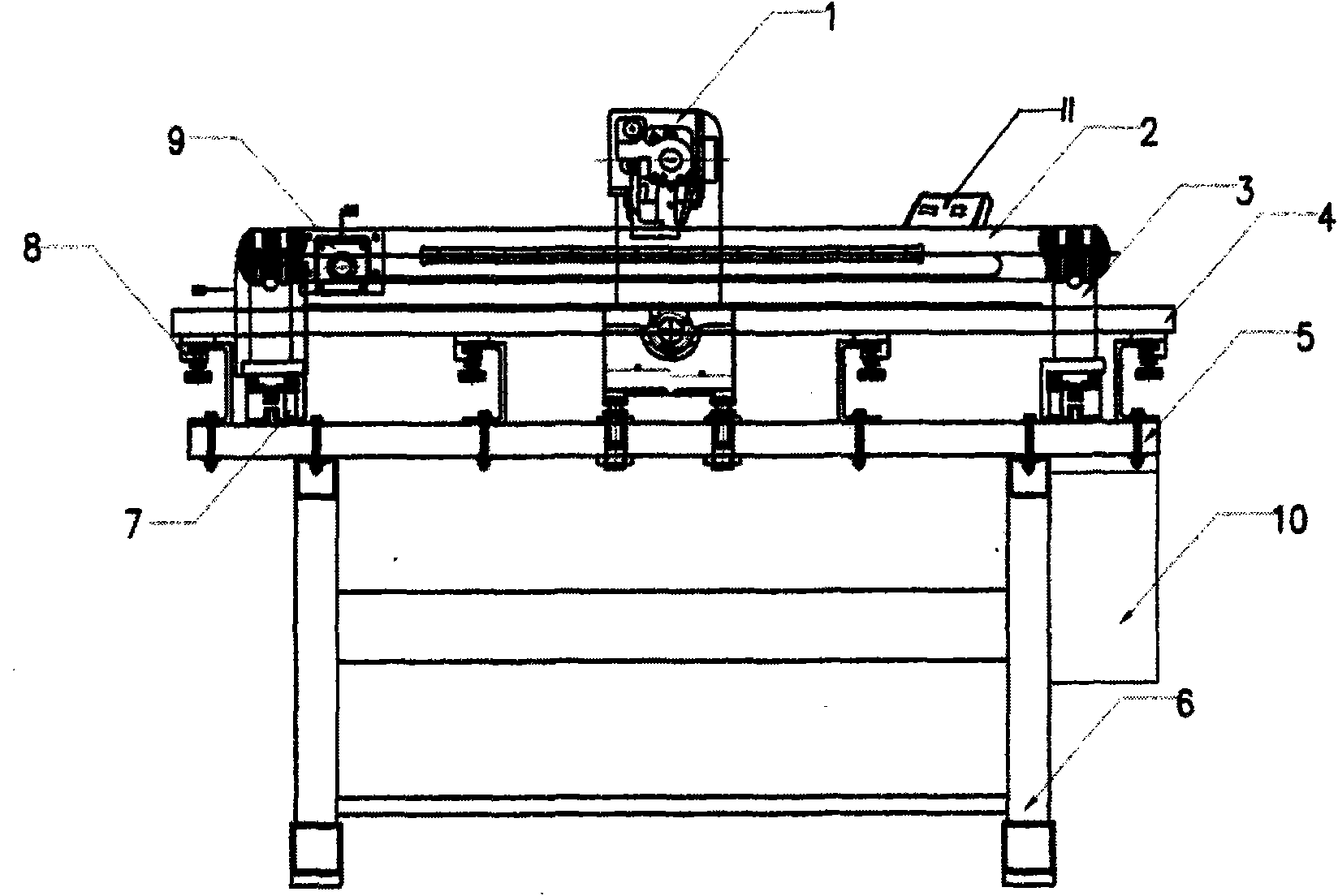

Gantry type large-width pattern sewing machine

InactiveCN102797117AInhibition rigidityAvoid shaking during sewingSewing-machine control devicesPressersEngineeringLateral movement

The invention discloses a gantry type large-width pattern sewing machine and belongs to the technical field of sewing machines. The gantry type large-width pattern sewing machine comprises a machine head, a rack, a rotating shuttle structure, a transverse motion module, a longitudinal motion module, a table plate arranged on the rack, and a pressing frame component positioned above the table plate, wherein the transverse motion module is longitudinally and movably arranged on the longitudinal motion module through a connecting plate; the pressing frame component is transversely and movably arranged on the transverse motion module; the longitudinal motion module is fixed on the rack; a rotating shuttle hole of the rotating shuttle structure is aligned with a needle of the machine head; and the gantry type large-width pattern sewing machine also comprises a cross beam, wherein upright columns are respectively fixed on two sides of the rack in the transverse movement direction of the pressing frame component; the cross beam is fixed on the two upright columns; and the machine head is arranged in the middle of the cross beam through a lifting device. According to the gantry type large-width pattern sewing machine, the size and travel of a pressing frame can be allowed to be greatly improved, so that the sewing area of a pattern machine is enlarged, and the phenomenon that the machine head is low in rigidity and shakes in the sewing process can be avoided.

Owner:SUZHOU AUTOMAZIONE AUTOMATIC SEWING EQUIP

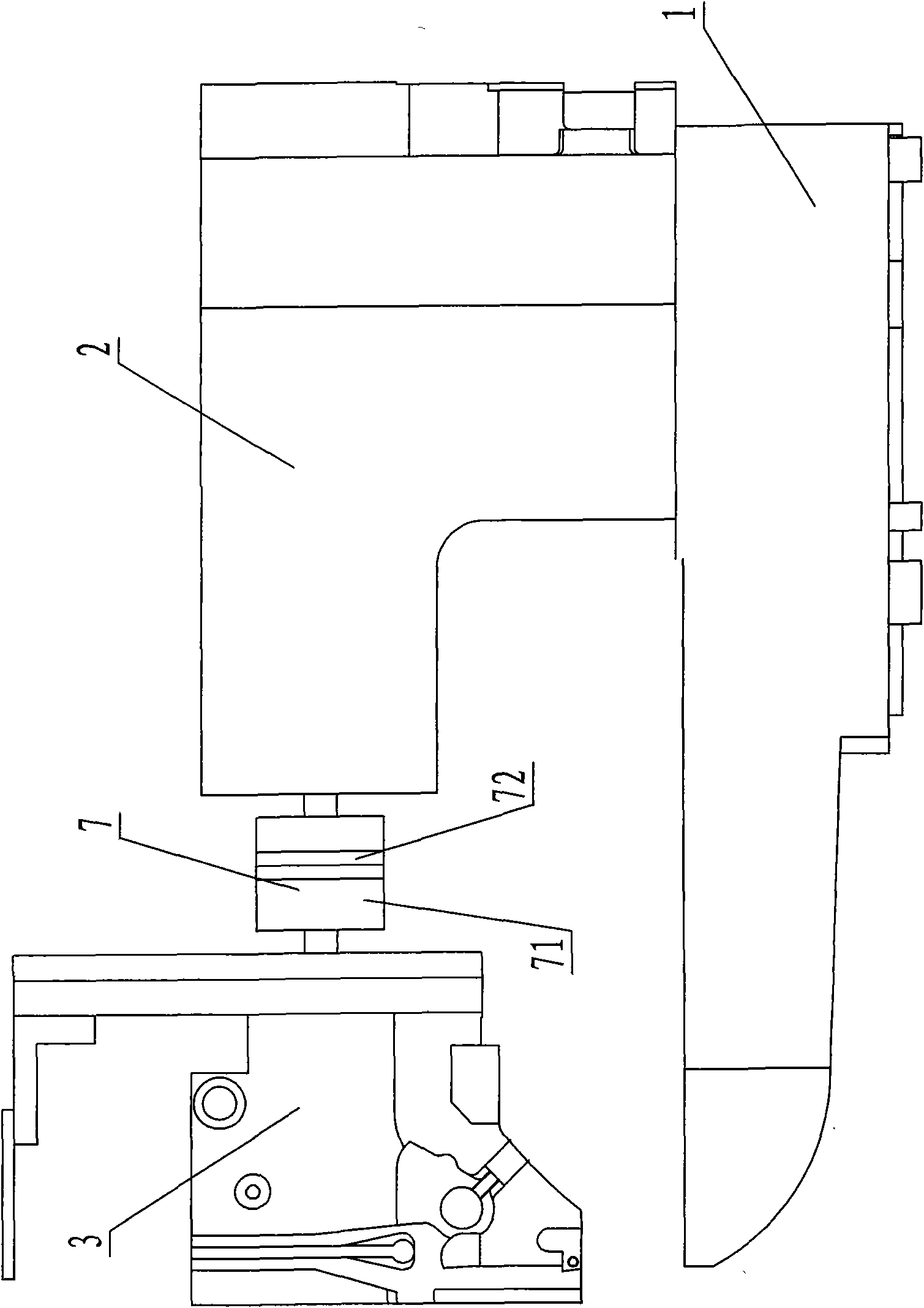

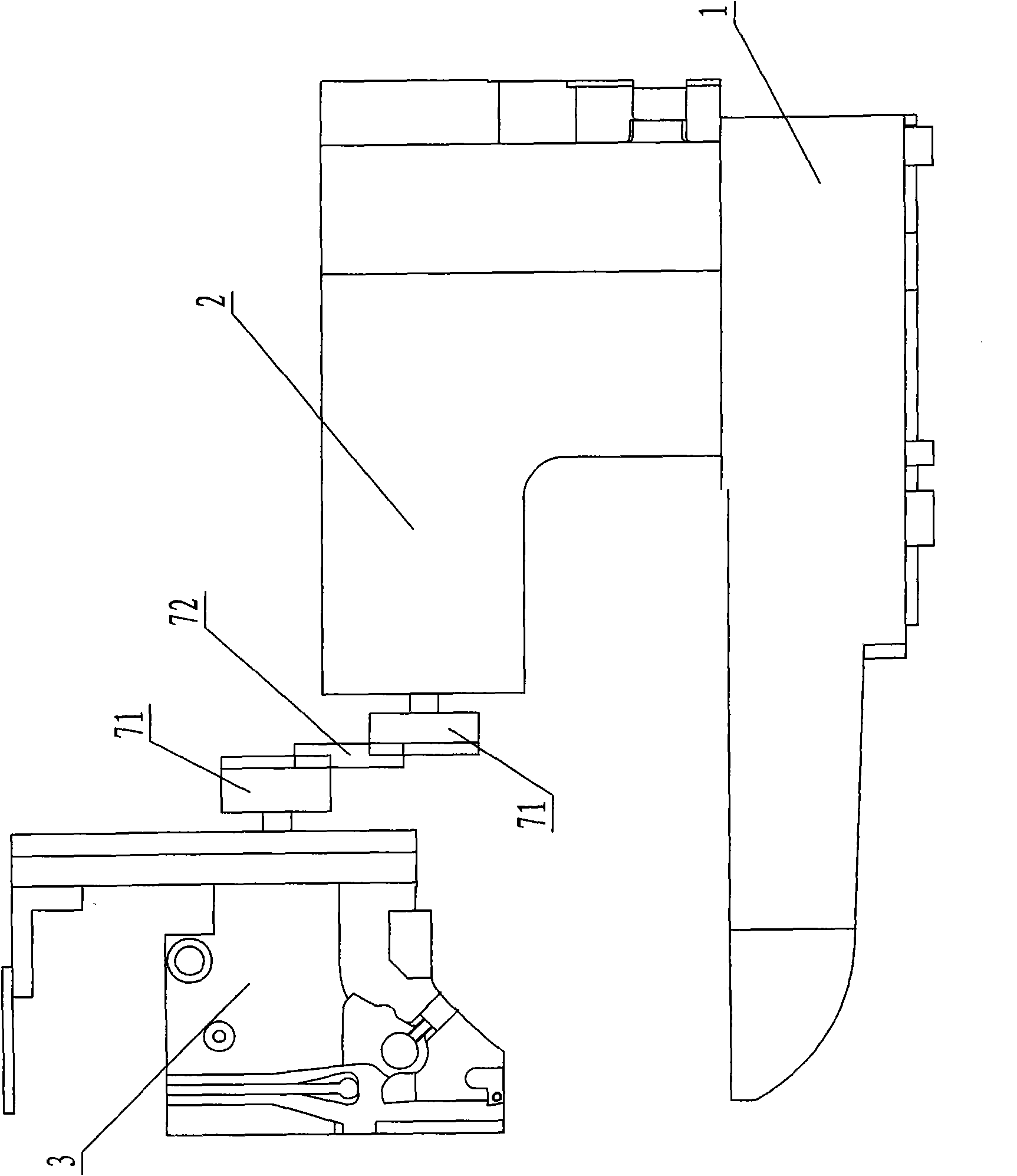

Electro-pattern sewing machine

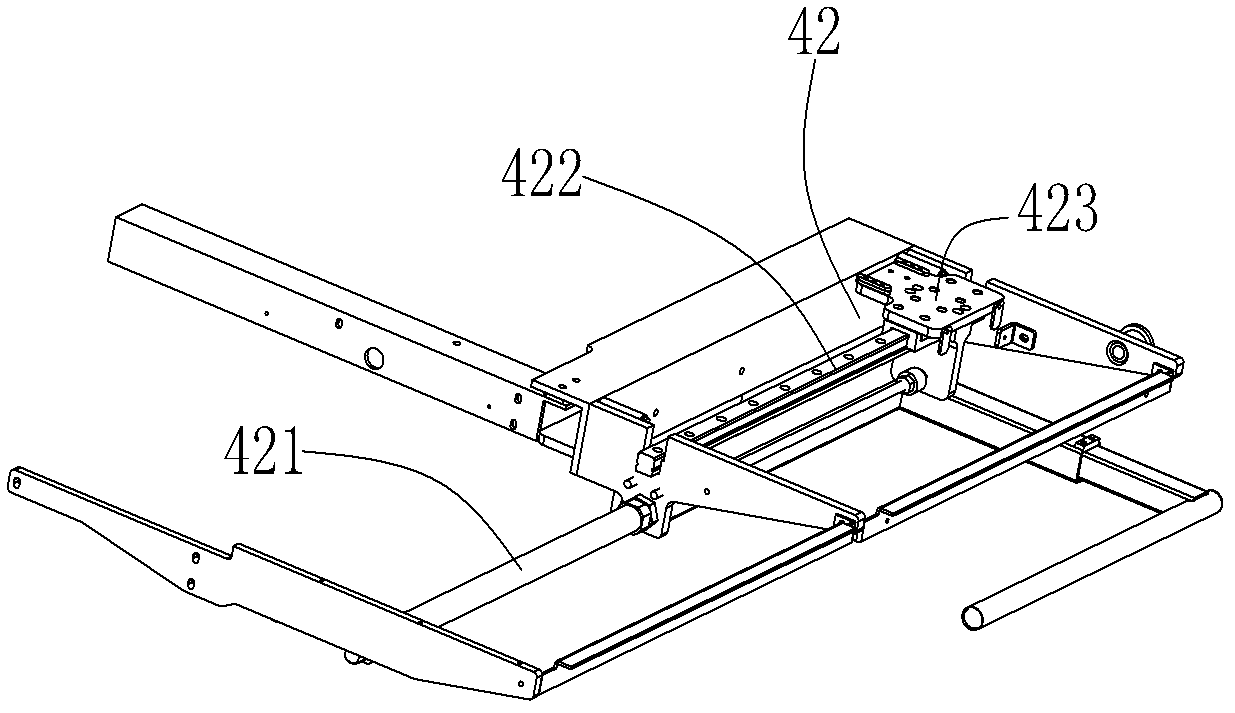

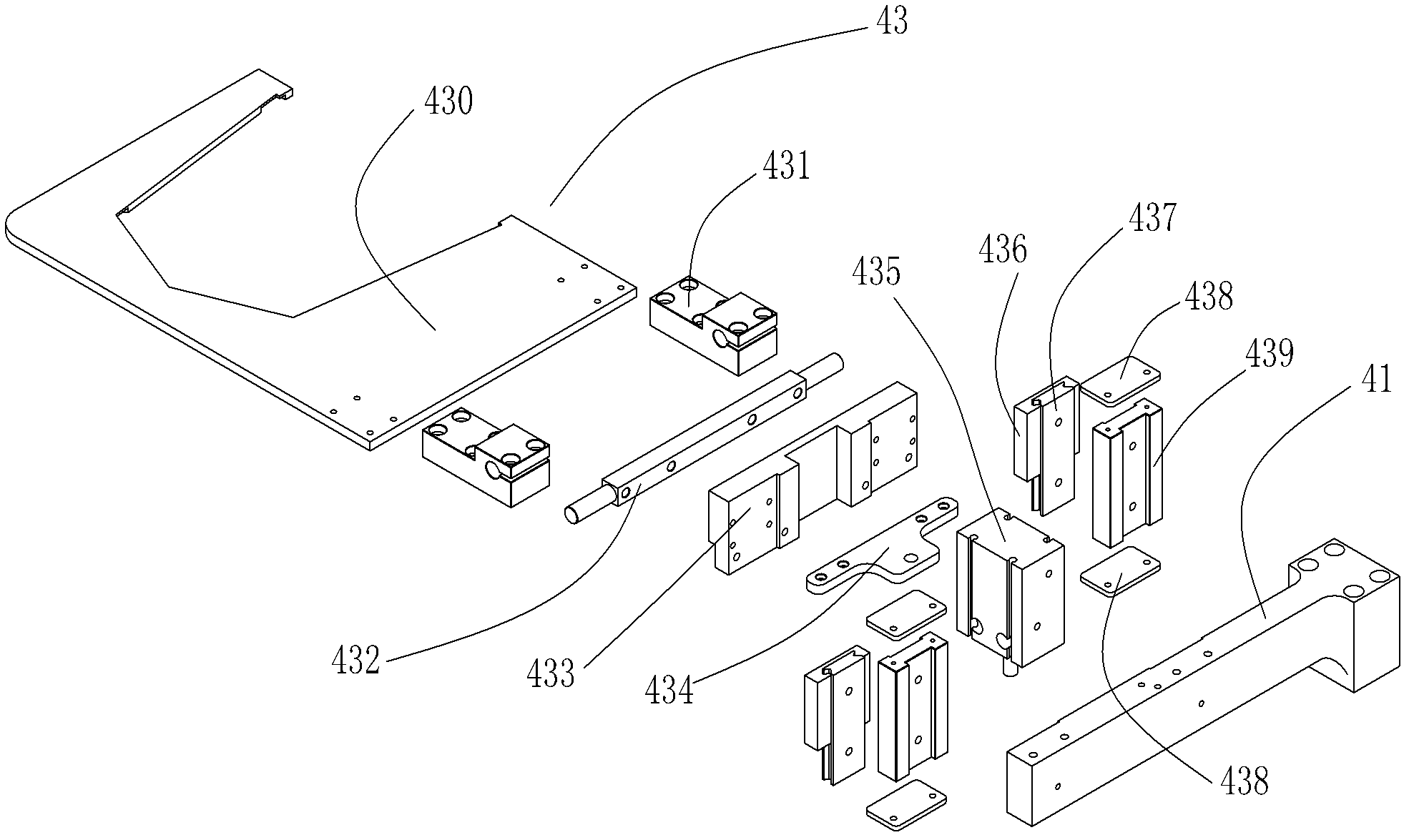

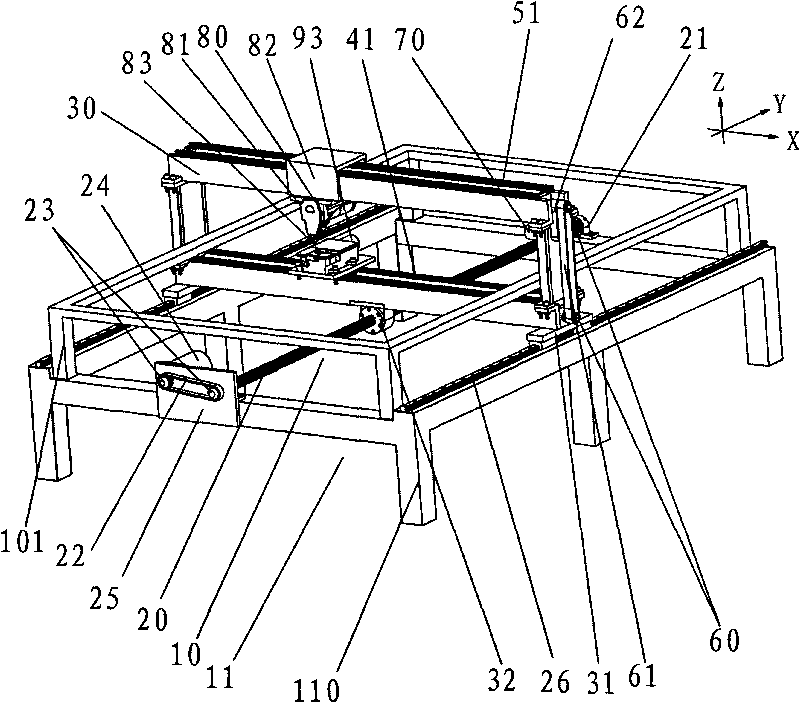

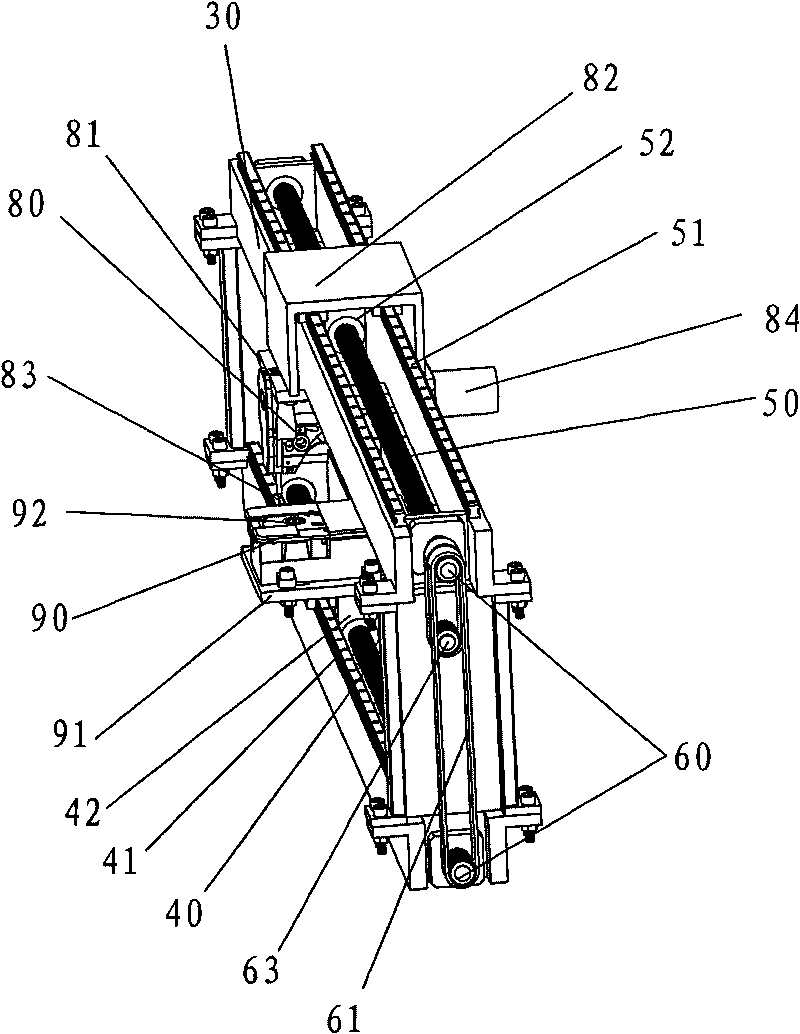

ActiveCN102409488AExtend the feeding distanceReduce deliveryWork-feeding meansHem-stitch machinesNeedle sizeTransmission belt

The invention belongs to the technical field of sewing machines and relates to an electro-pattern sewing machine. The electro-pattern sewing machine comprises a rack, a machine head, a feeding mechanism and a controller, wherein longitudinal slideways located at the rear side of the needle size are fixed on both sides of the machine head, a front cross beam is hung on the front ends of the longitudinal slideways, the front cross beam is internally provided with a transmission device, a feeding seat is fixed on the transverse movement part of the transmission device, the front end of a spline shaft is connected with the transmission device, the middle of the spline shaft is sleeved in a longitudinal guide hole of a mounting plate, a bull gear is sleeved on the spline shaft, a pinion which is in meshing transmission with the bull gear is driven by a driving motor, a lengthened cushion block is fixed between the bottom plate of the machine head and a rear cross beam, synchronous belt pulleys are fixed on the bottom plate of the machine head and both sides of the rear cross beam respectively, synchronous belts are sleeved on the synchronous belt pulleys, the front end of a transmission arm which is arranged longitudinally is fixed on the front cross beam and the rear end of the transmission arm is clamped on the transmission belts which are arranged longitudinally. The electro-pattern sewing machine has the following advantages: the machine is suitable for multistation feeding.

Owner:JACK SEWING MASCH CO LTD

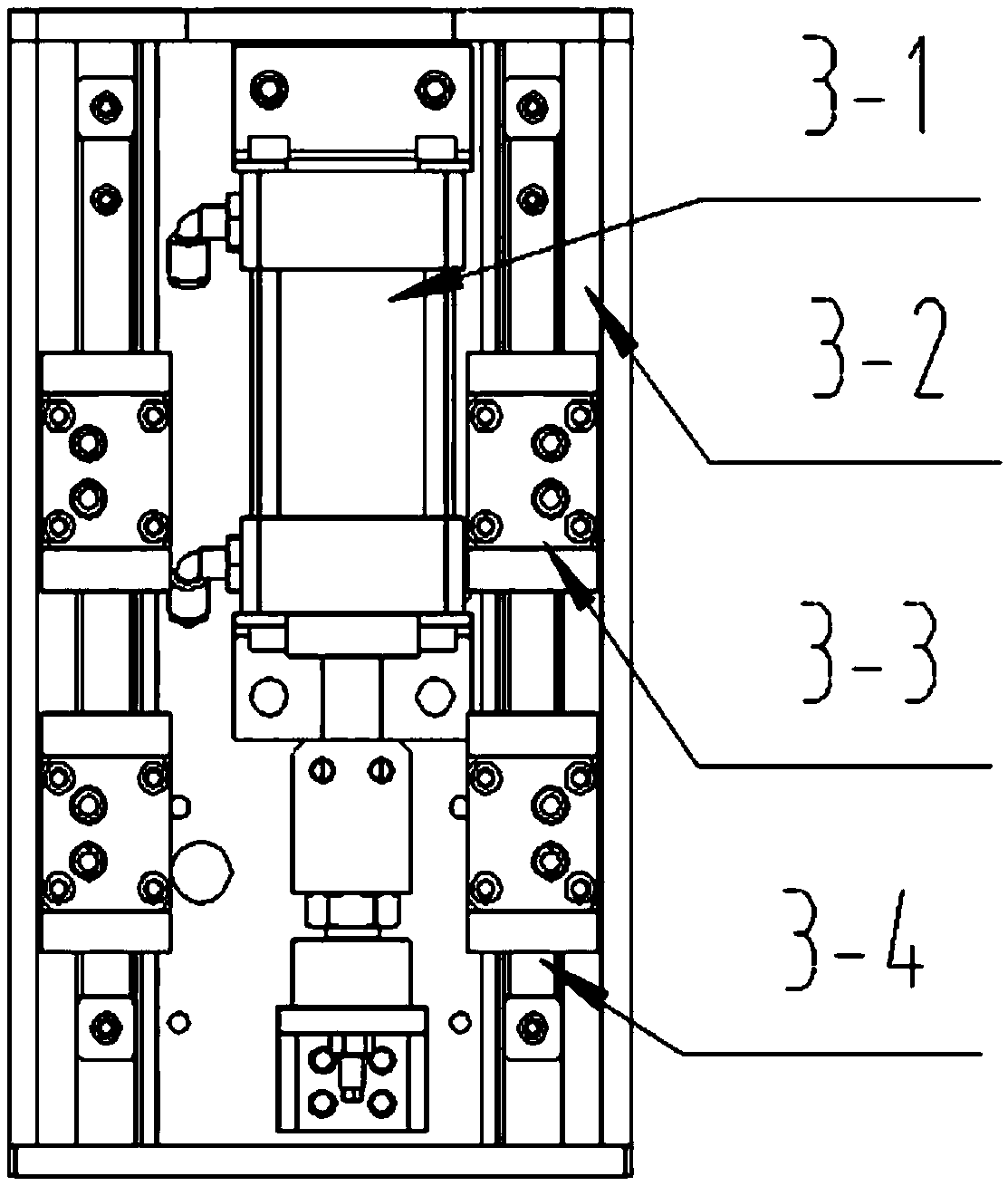

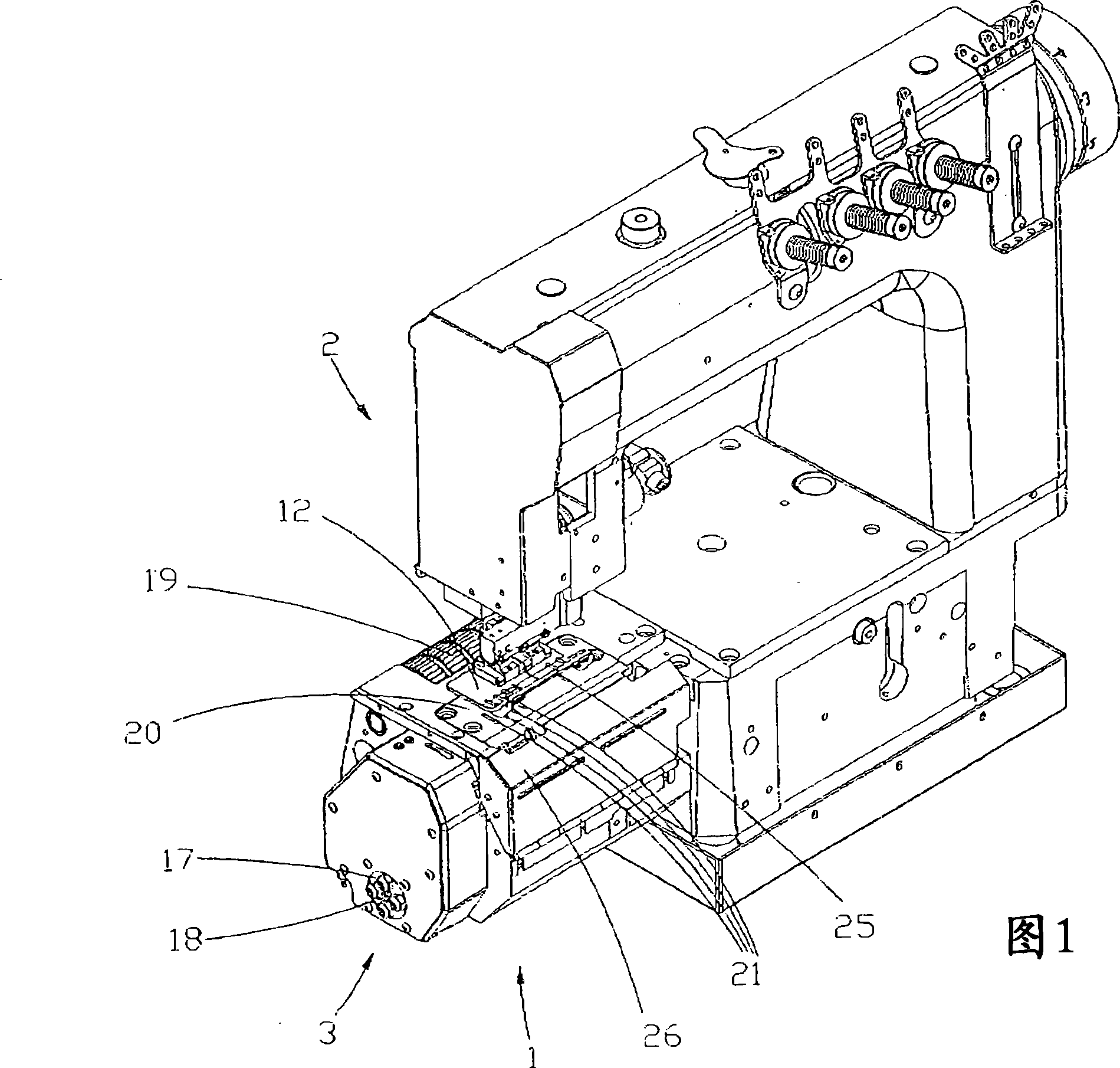

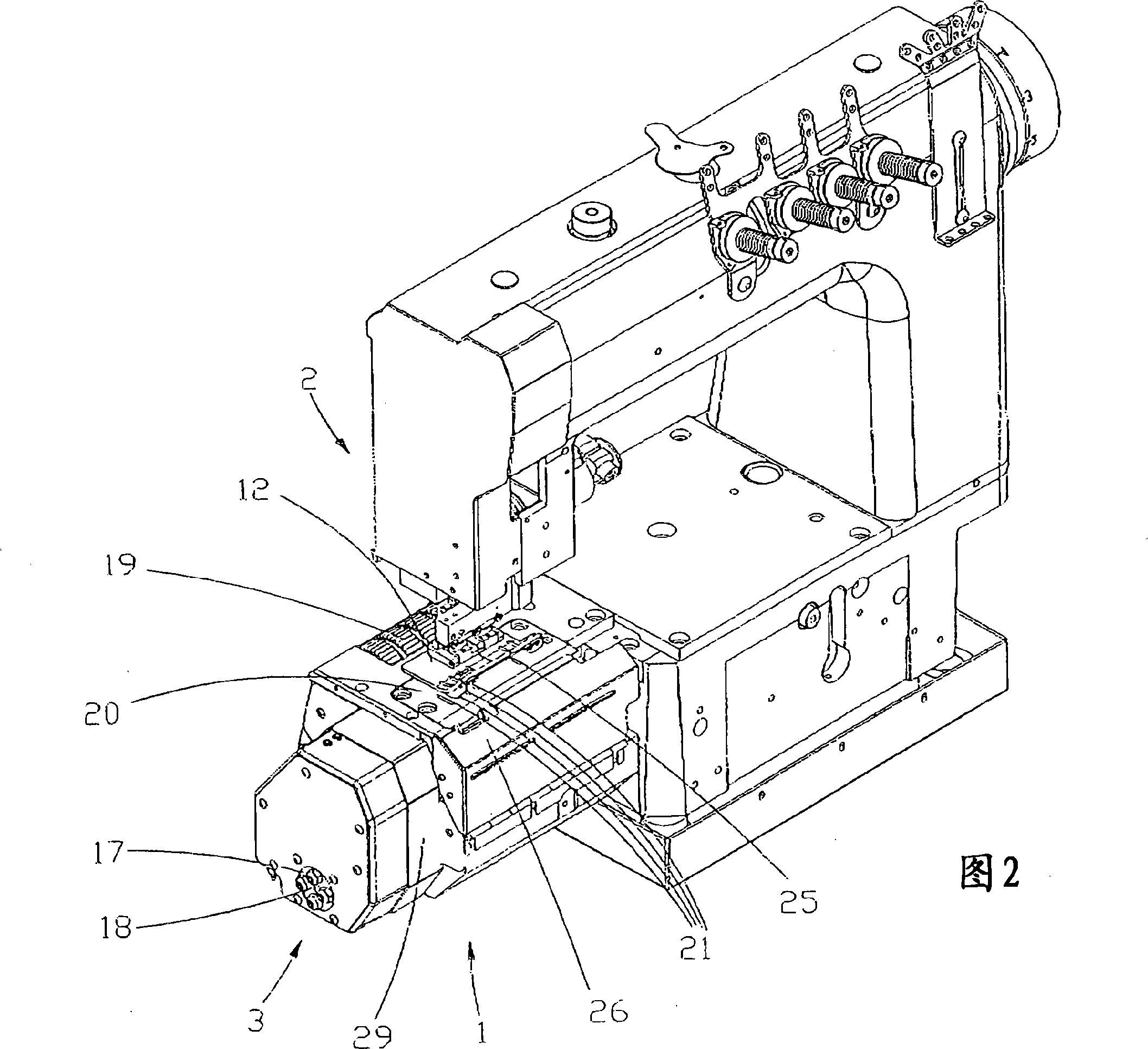

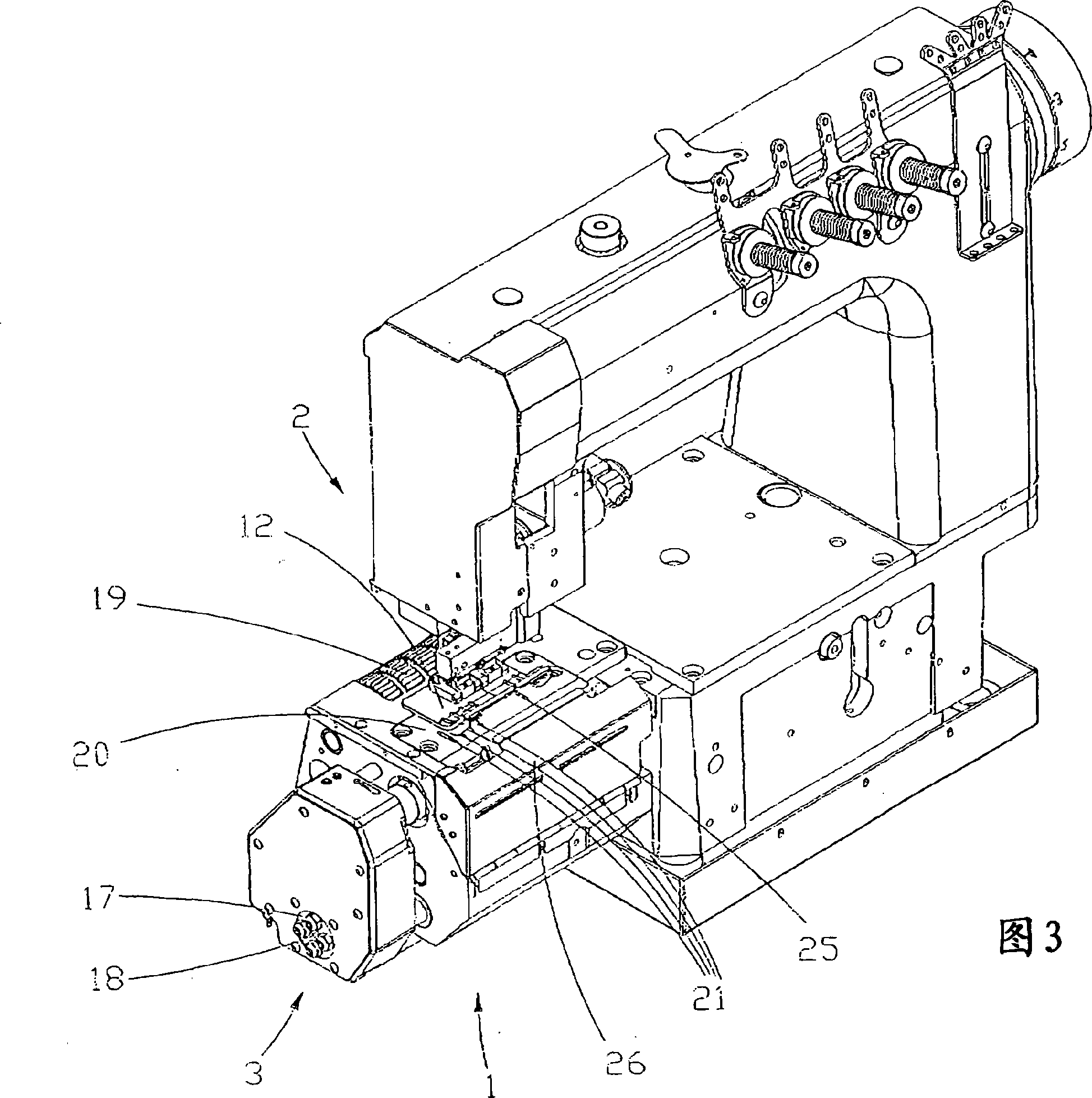

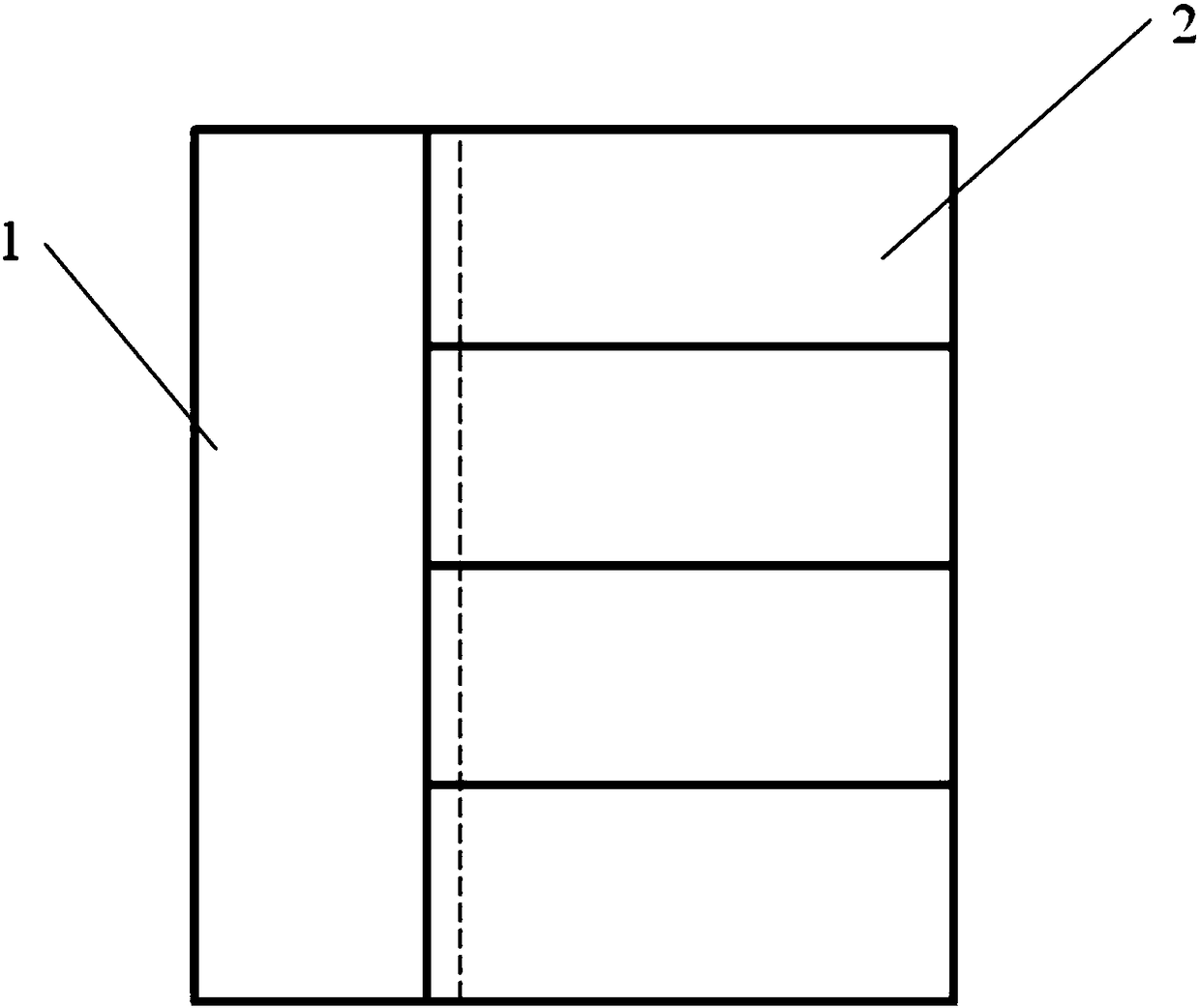

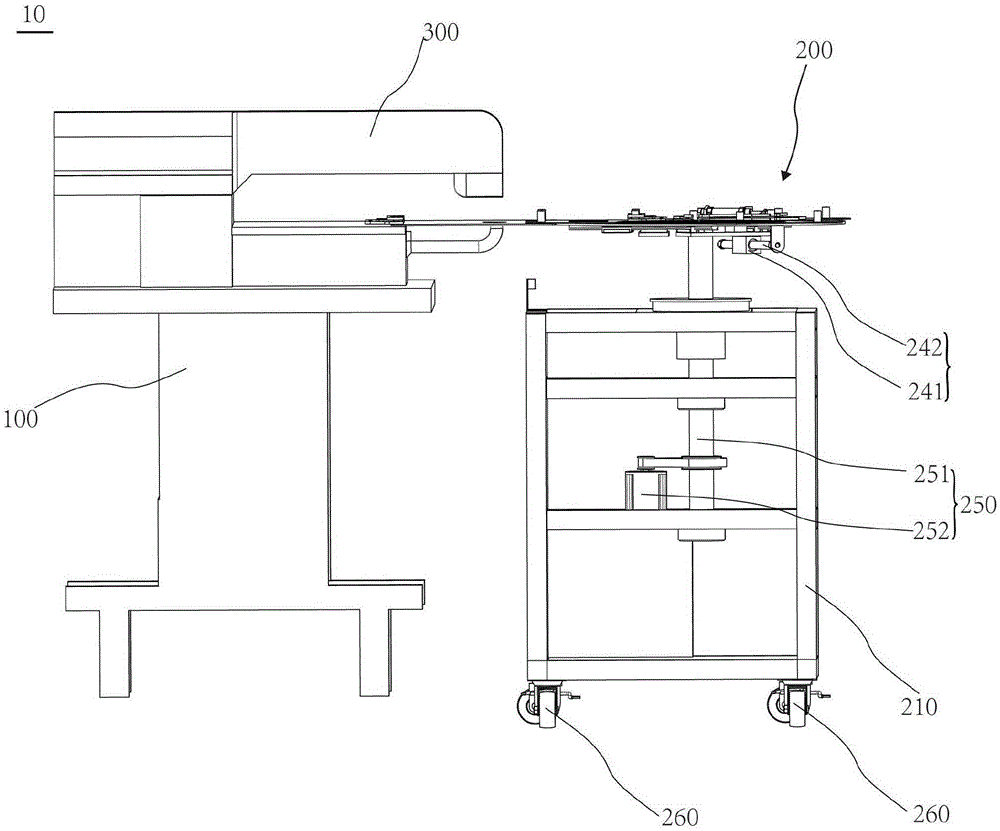

Split electronic pattern sewing machine

ActiveCN101581011AMeet sewing requirementsReduce labor intensitySewing-machine control devicesPressersIndustrial engineeringClutch

The invention discloses a split electronic pattern sewing machine, which comprises a machine seat, a machined body fixed on the machine seat, a machine head, an upper feeding bow and a lower feeding carriage, wherein a lifting device is arranged between the machine body and the machine head; the machine head is arranged on the lifting device and can move up and down; a closed type clutch for realizing the transmission connection between the machine body and the machine head is arranged between the machine body and the machine head; the lifting device is also connected with a compressing device which can synchronously lift with the machine head as well as compress sewn materials; after compressing the sewn materials, the compressing device synchronously moves with the upper feeding bow and the lower feeding carriage for feeding; and a frame needle arranged on the machine head sews patterns on the sewn materials. In the split electronic pattern sewing machine, the separation of the machine head and the machine body of the prior integrated electronic pattern sewing machine is realized and the lifting device is used to raise the machine head to ensure enough layer space of the machine head, so the requirements for sewing patterns on less than 90 millimeter extra-thick materials are met, the influences of human factors on product quality during manual operation are overcome, cost is saved, efficiency is improved, and labor intensity is reduced.

Owner:CHANGZHOU INDAL SEWING MACHINE

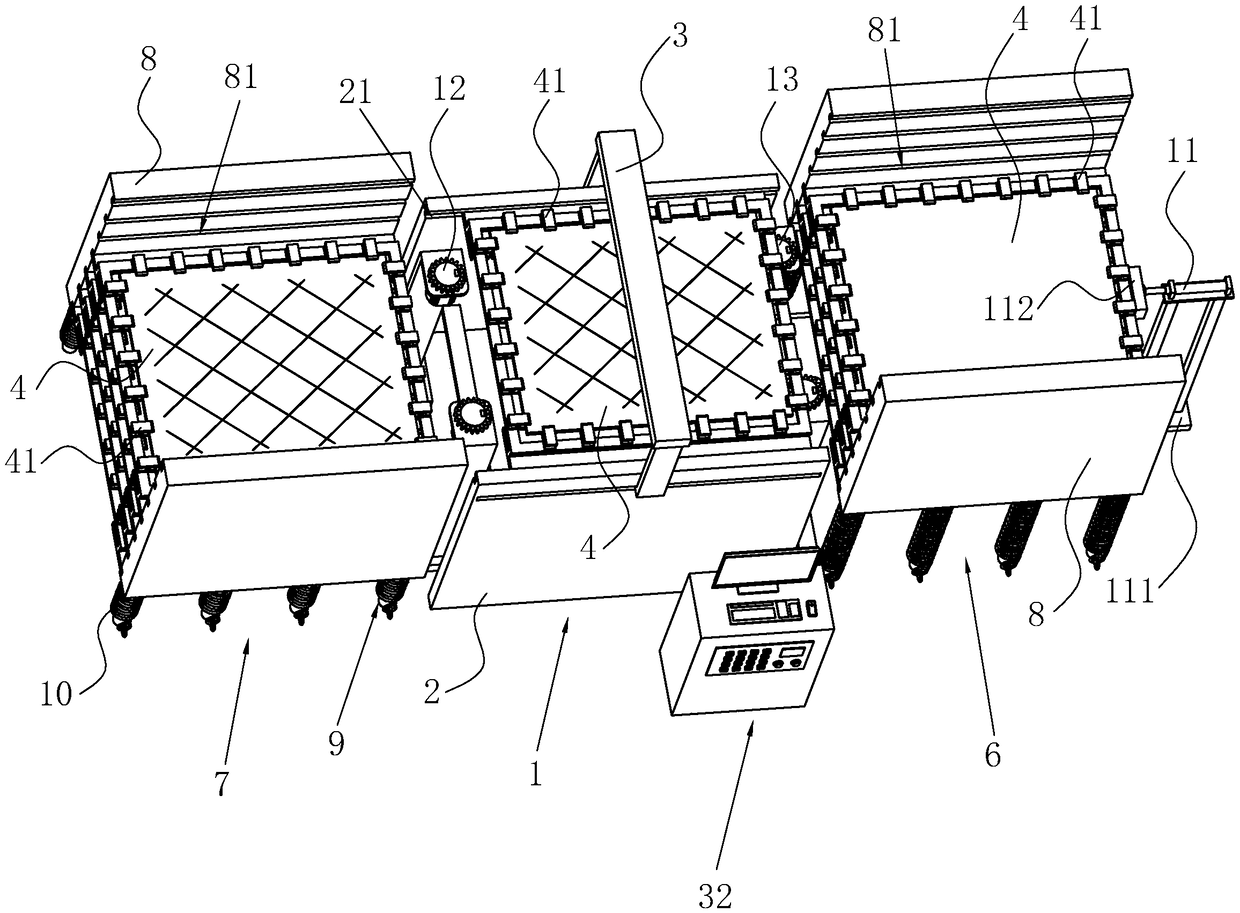

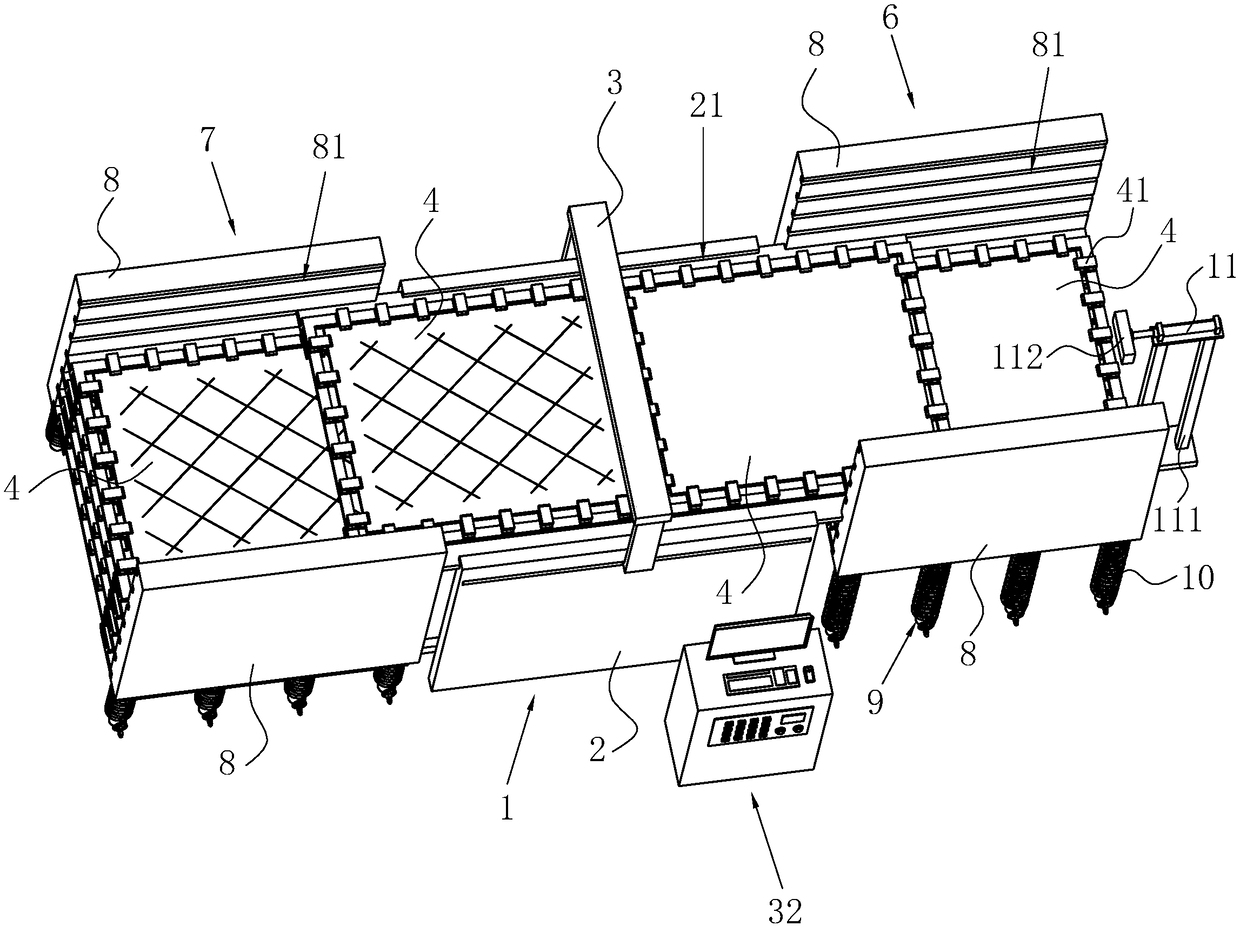

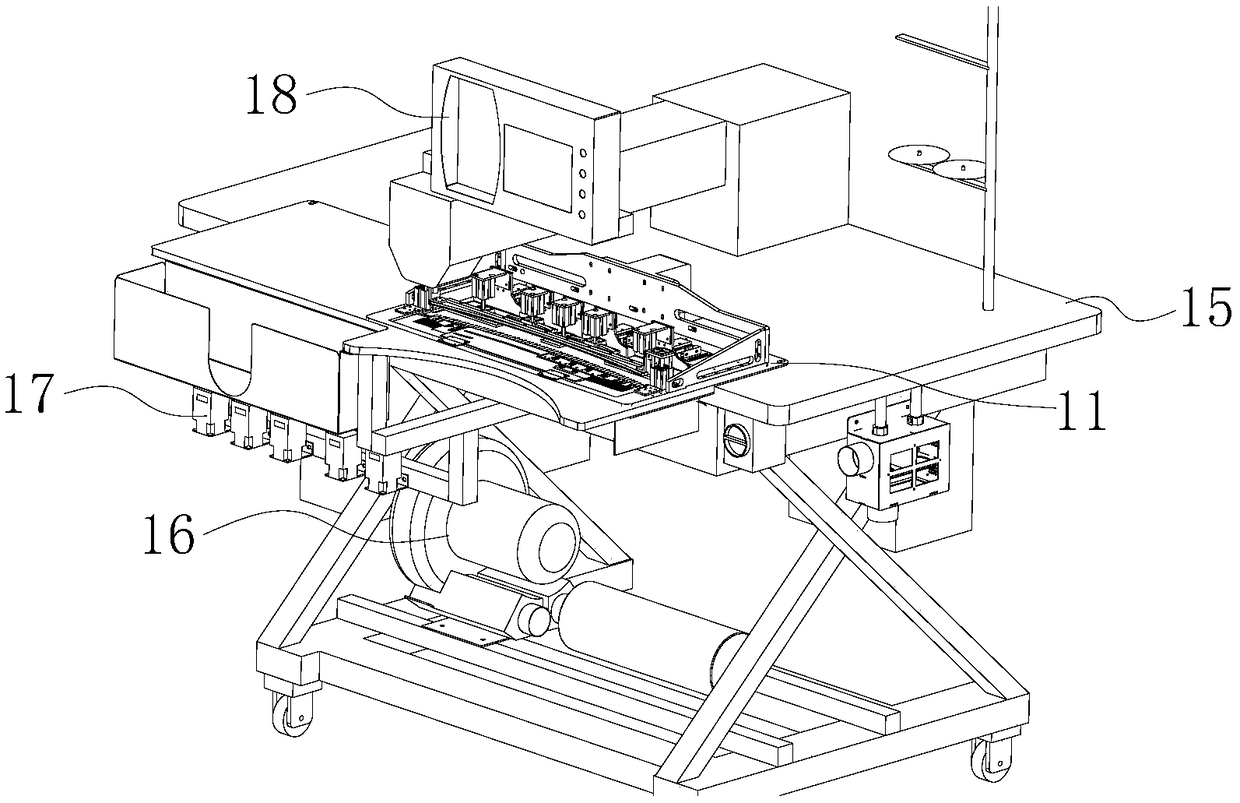

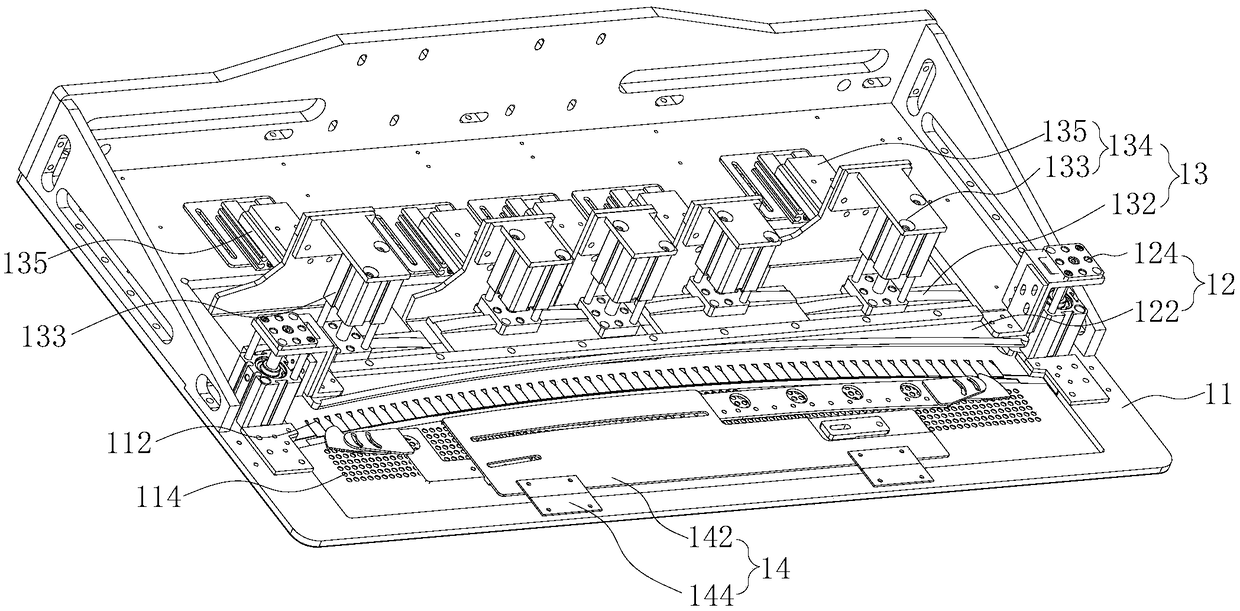

Intelligent numerical-control computerized quilting machine

ActiveCN108978053AAchieve replacementGuaranteed quilting efficiencySewing-machine control devicesHem-stitch machinesNumerical controlEngineering

The invention relates to an intelligent numerical-control computerized quilting machine, relating to the technical field of weaving equipment. The machine comprises a workbench, on which stretched cloth racks are arranged. A transverse rack located above the stretched cloth racks are slidably installed on the workbench. Additionally, a machine head sliding along the length direction is arranged atthe lower end of the transverse rack. The workbench comprises two support racks which are symmetrically arranged along the length direction. Multiple support rollers, vertical to the two support racks, are installed between the two support racks in a locating and rotary manner and arrayed along the length directions of the support racks. One end of the workbench is equipped with a feeding table used for stacking the stretched cloth racks to be quilted. The other end of the workbench is equipped with a material receiving table used for bearing quilted stretched cloth racks. The material receiving table and the feeding table are the same in structure and used in conjunction. One side, away from the workbench, of the feeding table is equipped with a material pushing device. A material pulling device is installed between the material receiving table and the workbench. One side of the workbench is equipped with a computer console. Additionally, the material pushing device and the materialpulling device are both in communication connection with the computer console. During application, the stretched cloth racks are quickly replaced by the intelligent numerical-control computerized quilting machine.

Owner:吉奥璐纺织品(南通)有限公司

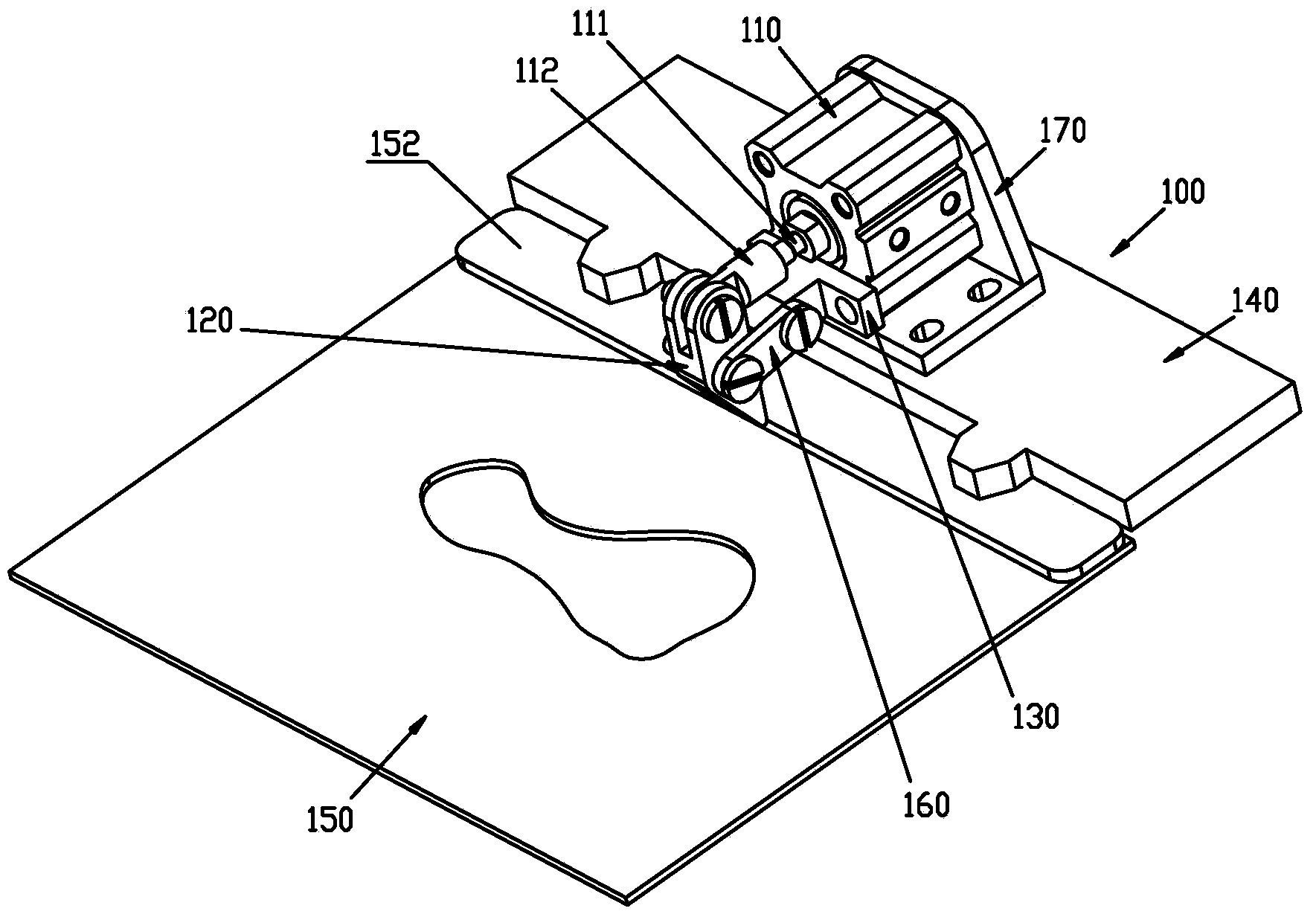

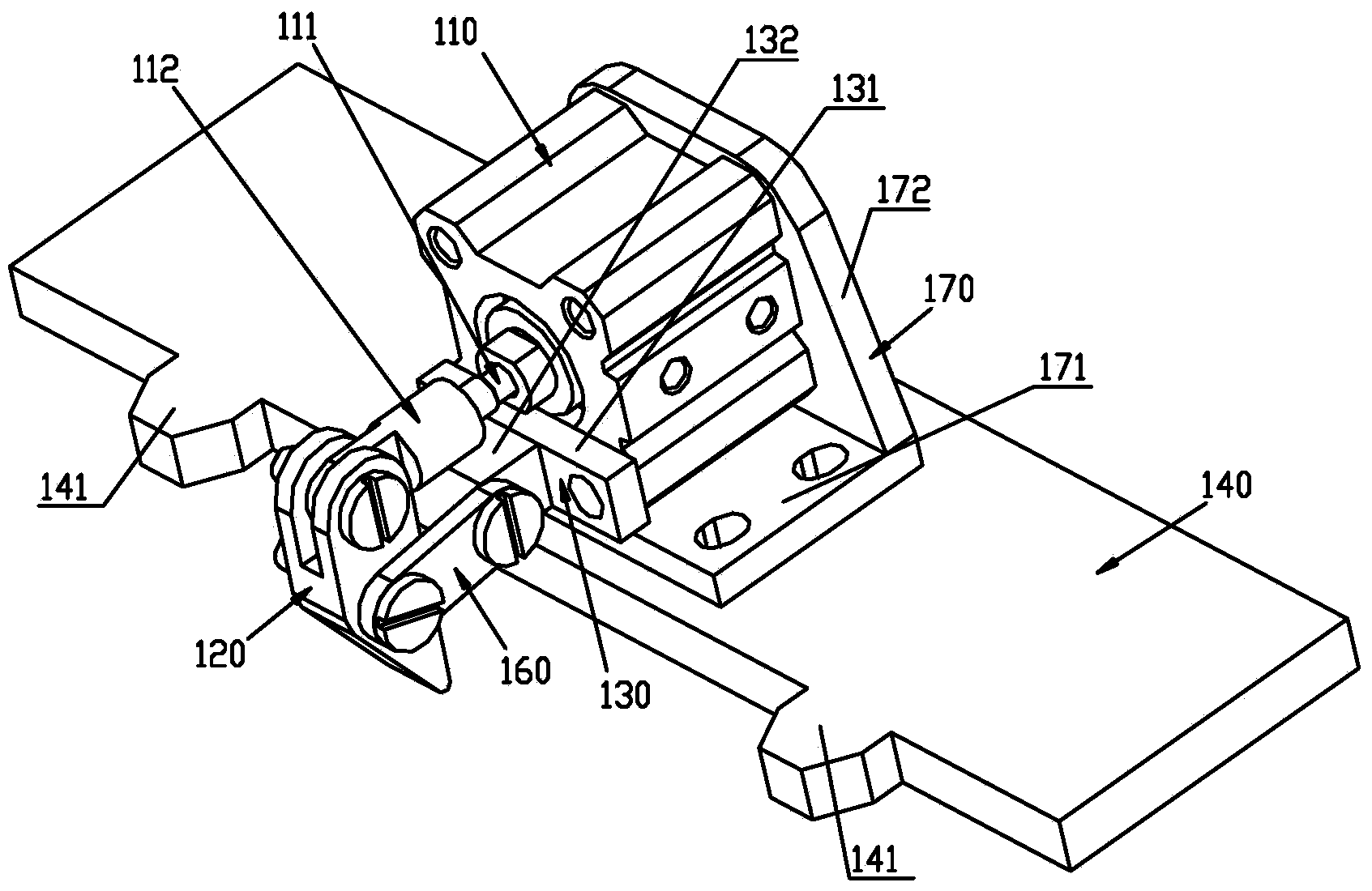

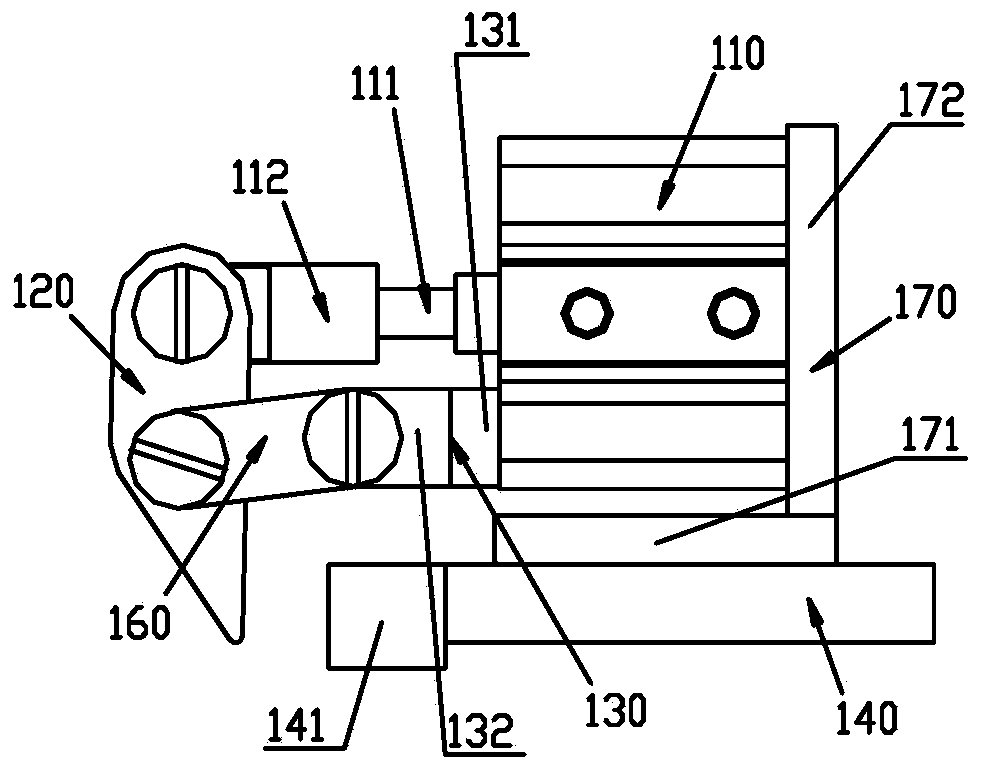

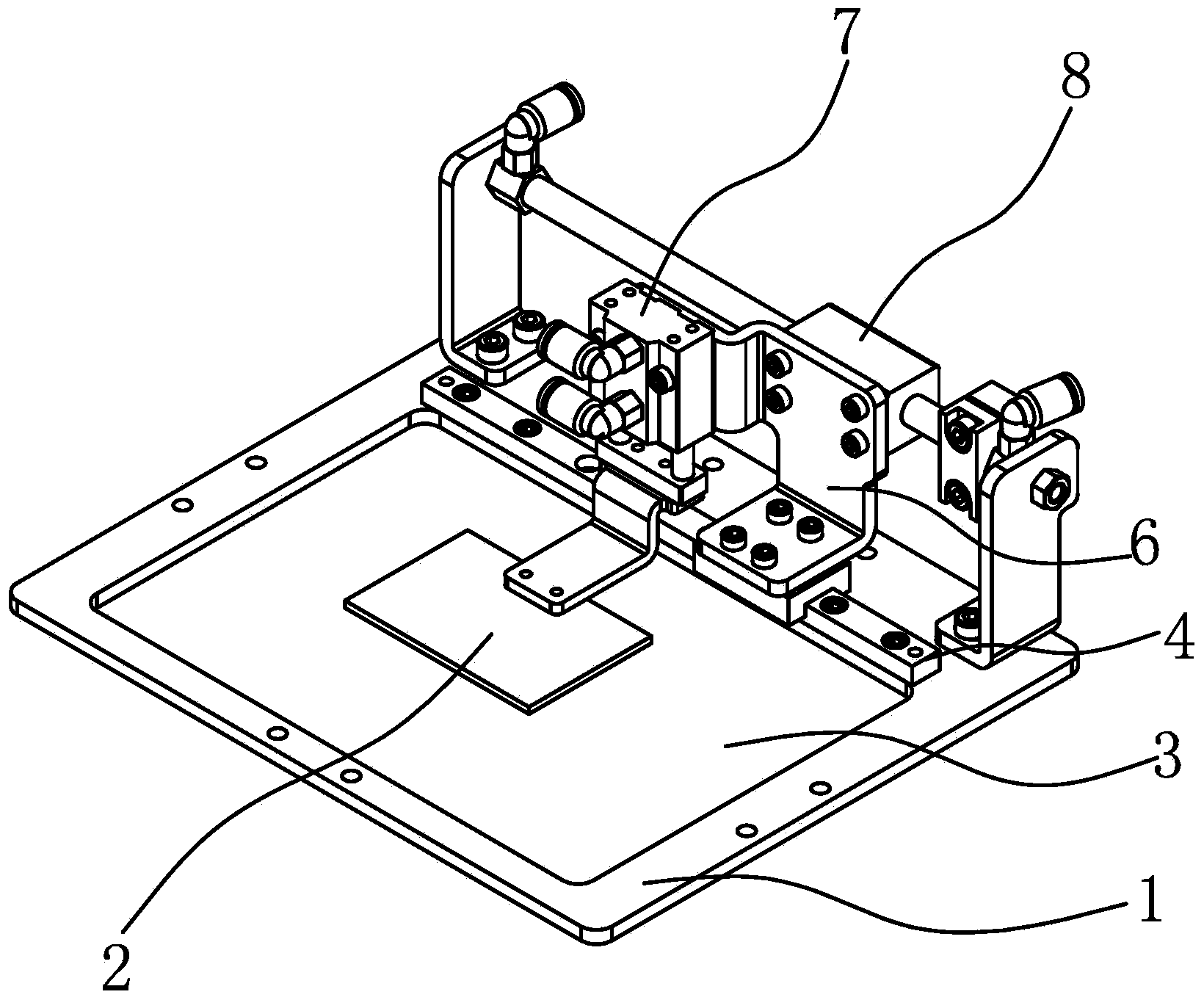

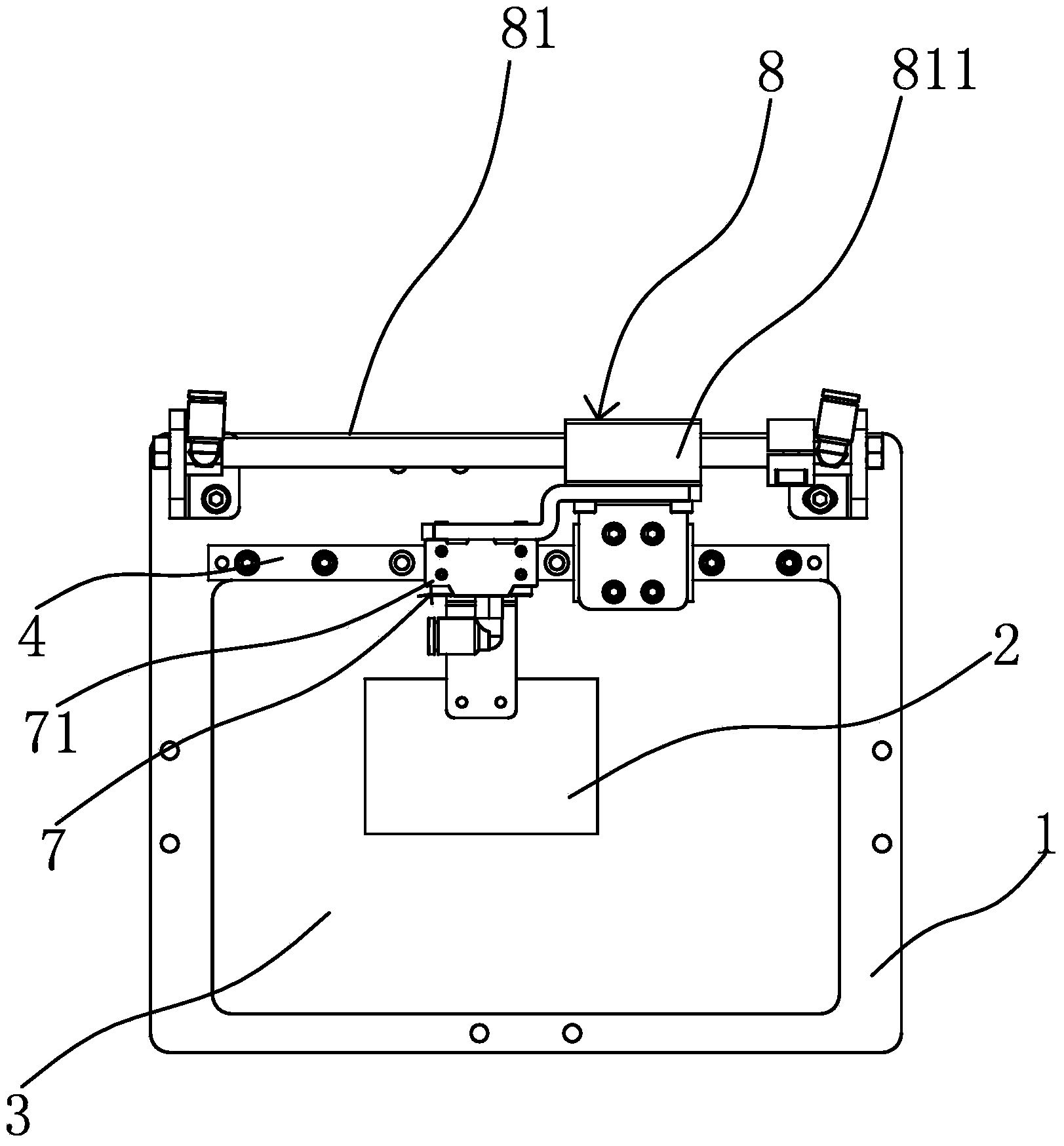

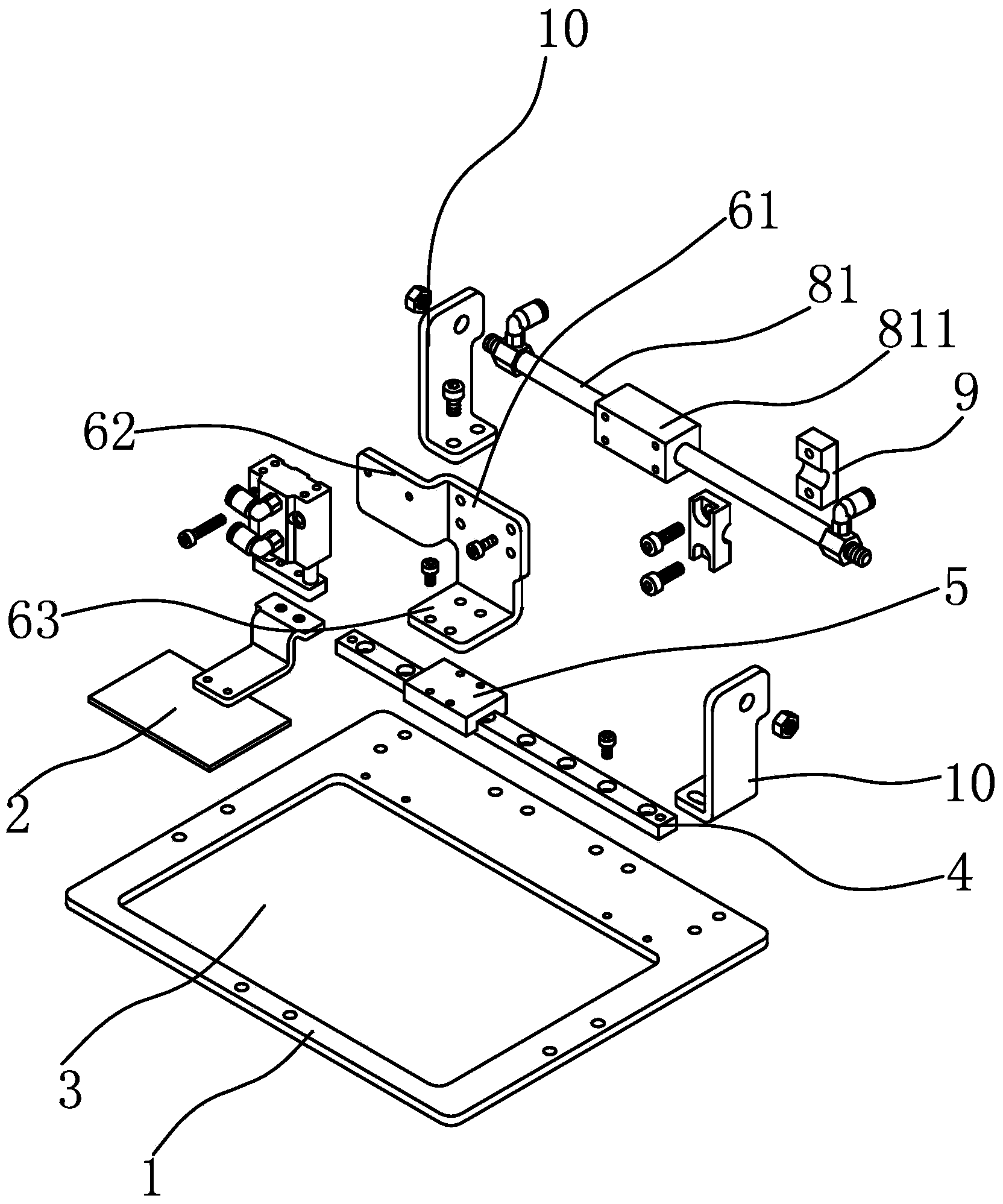

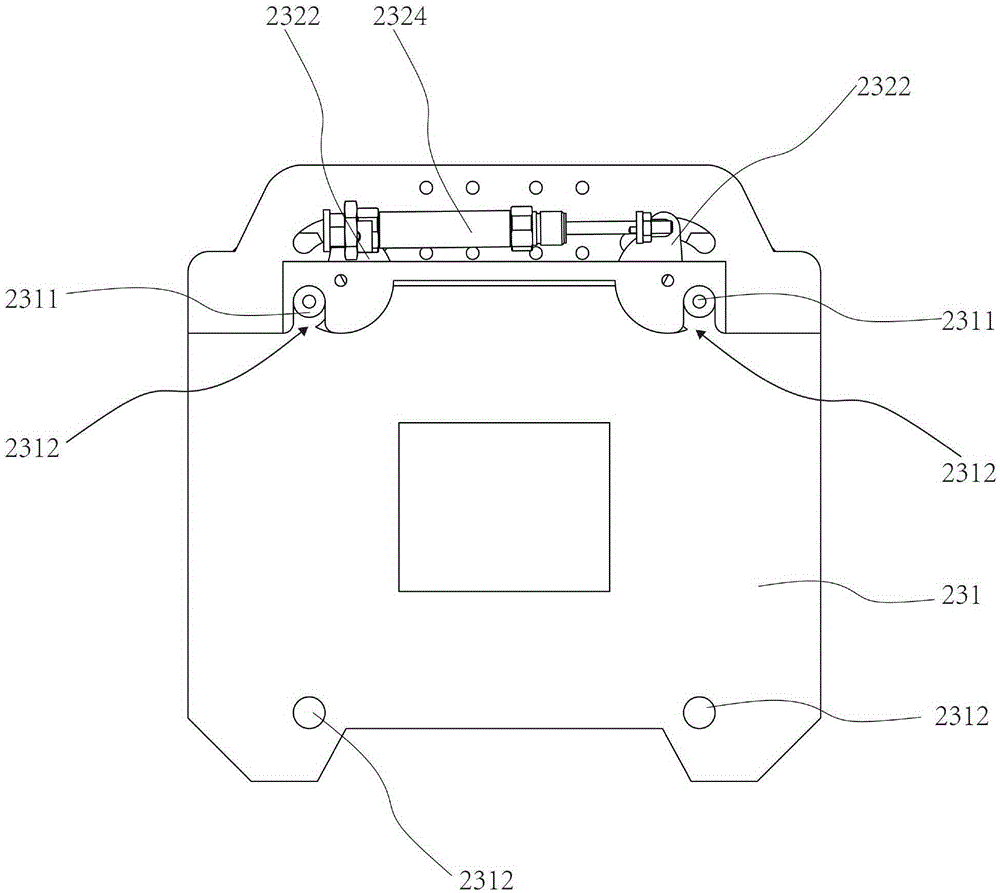

Pattern sewing machine template device

InactiveCN104389114AEasy to assemble and disassembleQuick assembly and disassemblyWork-feeding meansHem-stitch machinesComputer engineeringSewing machine

The invention provides a pattern sewing machine template device. The pattern sewing machine template device comprises a linear driver, a finger fastening piece, a bracket, a clamping seat and a template, wherein the rear end of the template and the front end of the clamping seat are mutually positioned in a manner of matching a positioning groove with a positioning lug boss; the rear end of the template is provided with a lug boss protruding out of the top surface of the template; the linear driver is fixed on the clamping seat; a retractable shaft of the linear driver is movably connected with the upper end of the finger fastening piece; the middle part of the finger fastening piece is movably connected with the bracket and the lower end of the finger fastening piece extends to the upper side of the template; the bracket is fixedly mounted relative to the clamping seat; when the retractable shaft of the linear driver is at a stretching-out state, the lower end of the finger fastening piece swings backwards and tightly presses the lug boss. According to the pattern sewing machine template device, the template is clamped and loosened by the stretching-out and retraction of the retractable shaft of the linear driver so that the template is convenient and rapid to detach and the working efficiency of a pattern sewing machine is improved; the whole structure is simple so that the configuration cost is also low.

Owner:BULLMER ELECTROMECHANICAL TECH

Decorating sewing machine

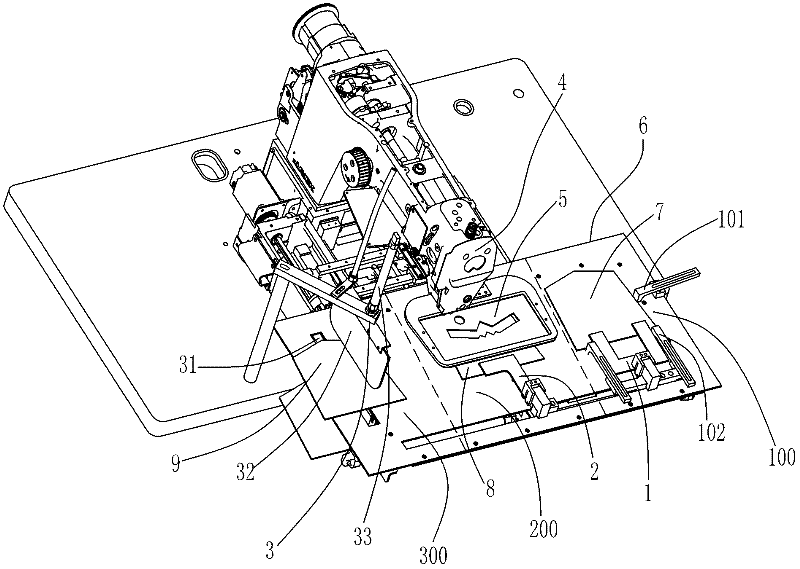

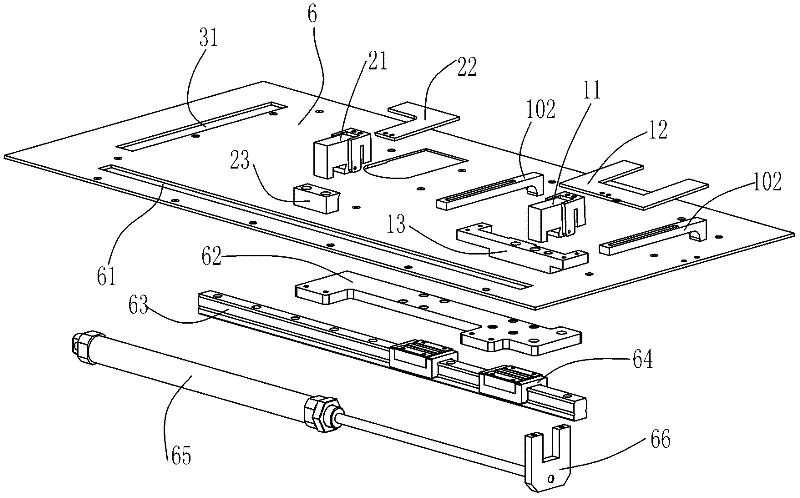

ActiveCN102358995AGuaranteed positioning accuracyIncrease productivitySewing-machine elementsHem-stitch machinesSewing machineEngineering

The invention discloses a decorating sewing machine, which comprises a machine head and a machine plate positioned below the machine head, wherein a template mechanism is arranged below the machine head; a feeding position, a sewing position and a discharging position are formed in sequence along the longitudinal direction of the machine plate; the template mechanism is positioned at the sewing position; a first feeding mechanism is arranged corresponding to the feeding position; a second feeding mechanism is arranged corresponding to the sewing position; a discharging mechanism is arranged corresponding to the discharging position; the first feeding mechanism and the second feeding mechanism can move synchronously along the longitudinal direction; and when the first feeding mechanism moves from the feeding position to the sewing position, the second feeding mechanism just moves from the sewing position to the discharging position. In the invention, the machine plate is provided with three positions, i.e., the feeding position, the sewing position and the discharging position in sequence along the longitudinal direction, and two feeding mechanism and a discharging mechanism are arranged, so that sewing and feeding can be performed simultaneously, two feeding actions are completed simultaneously, the production efficiency is increased, and the positioning accuracy of a pocket at the sewing position can be ensured.

Owner:JACK SEWING MASCH CO LTD

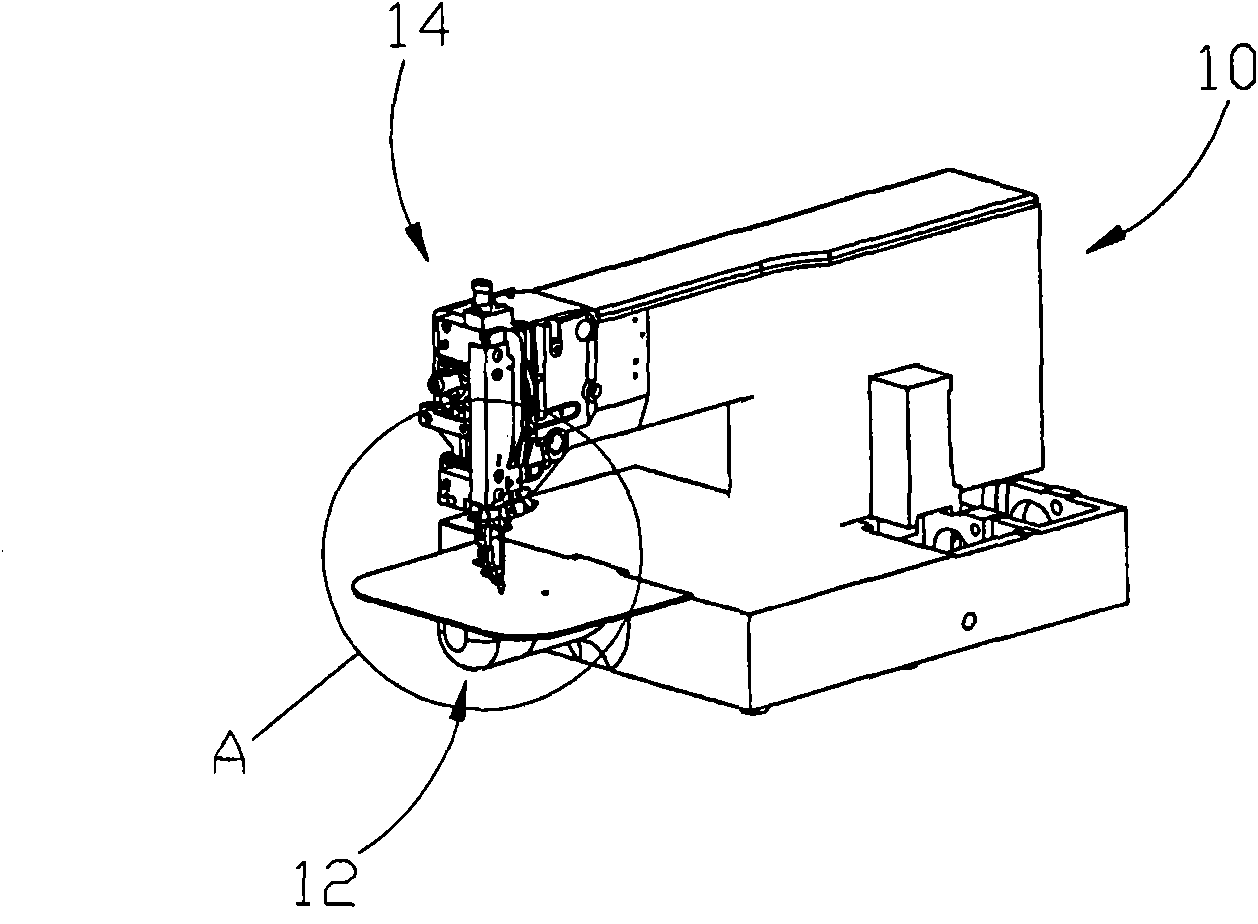

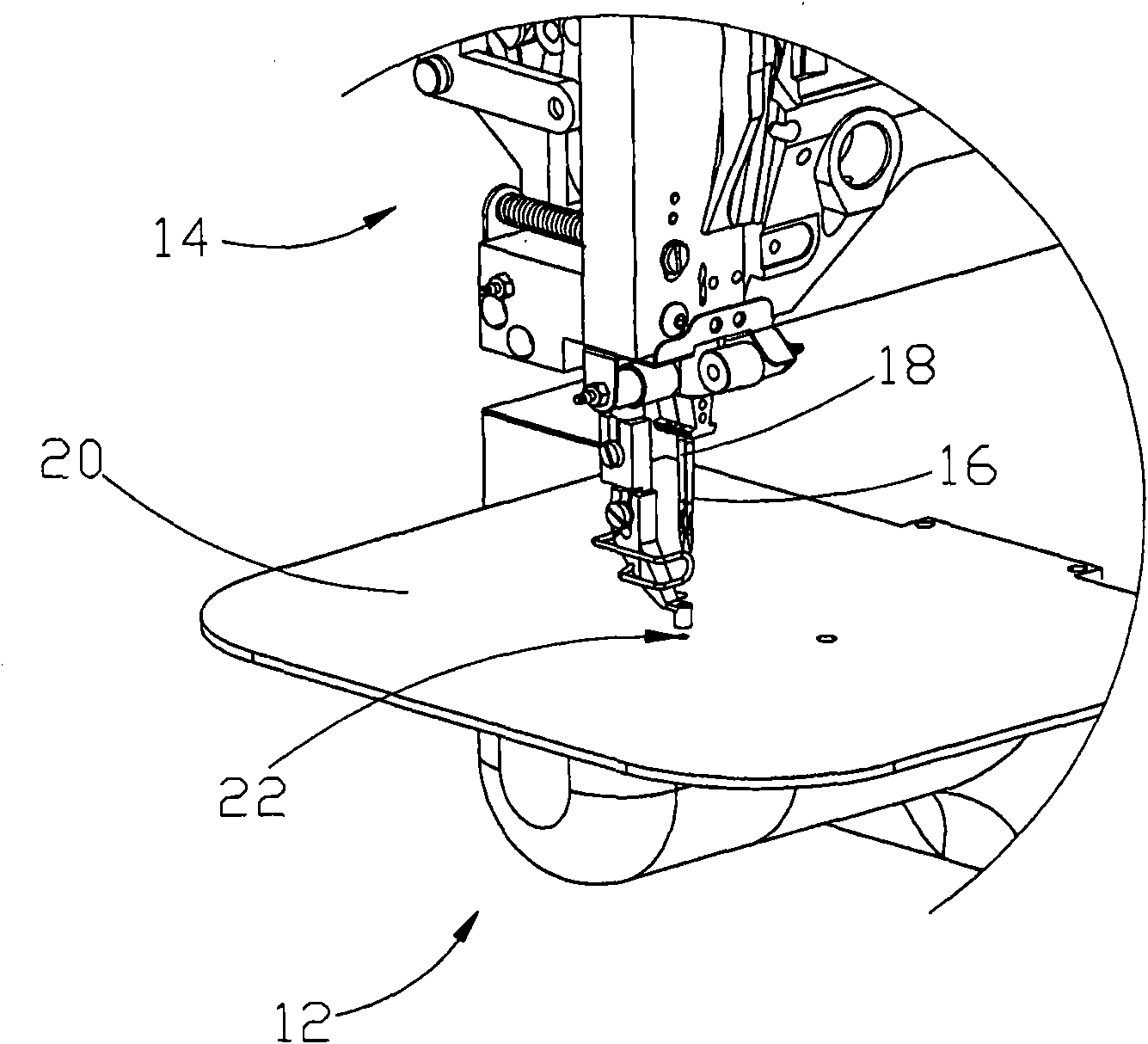

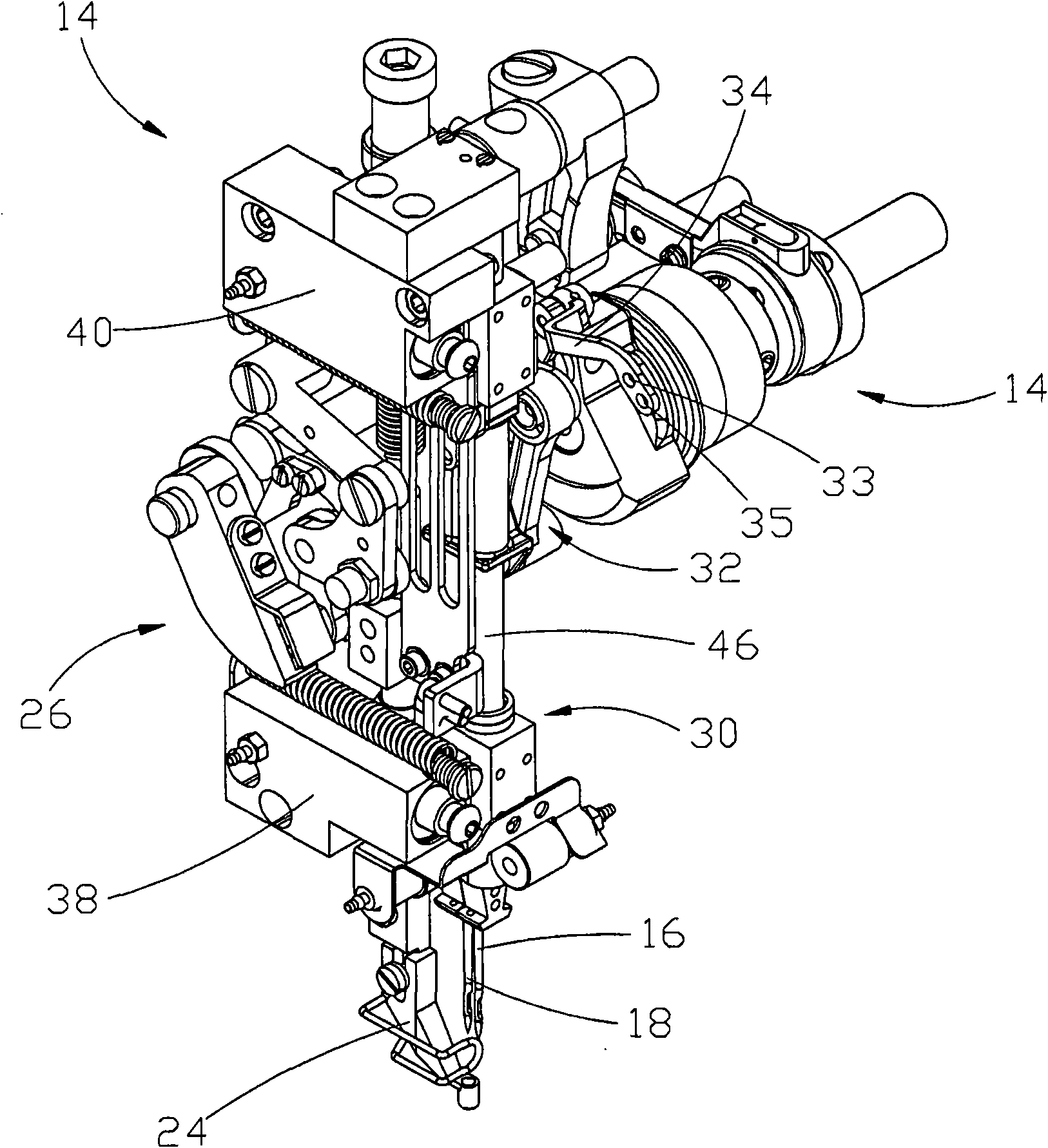

Sewing machine

ActiveCN101619522ASimple structureAvoid leavingProgramme-controlled sewing machinesLeather sewingReciprocating motionEngineering

Sewing machine (10) comprising a base (12) with a crochet and a head (14) that comprises a needle support (30), a fabric pressure foot (24) and its adjusting means (26), motor means (28) to make a needle sew together with the crochet, and lever means (32) to turn the rotary motion of the driving means into a vertical reciprocating motion. The needle support (30) in turn comprises at least two needle bars (46, 48) that are moved vertically by said lever means (32), and a connecting element (50) to couple the lever means (32) with at lead a needle bar (46, 48). Each needle bar (46, 48) is coupled with a needle (16, 18) through a respective thread and actuated selectively in the crochet in order to allow the sewing.

Owner:VI BE MAC

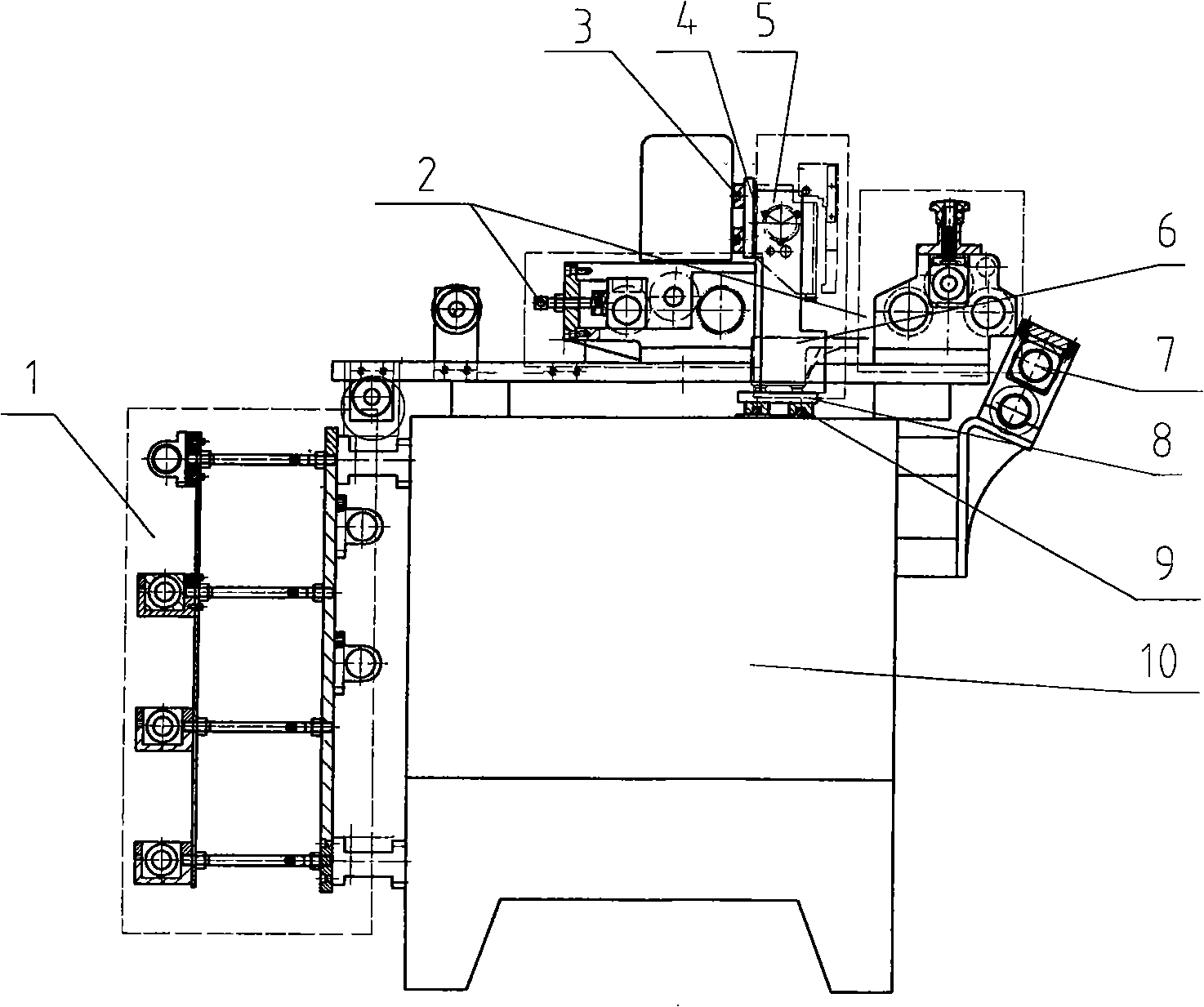

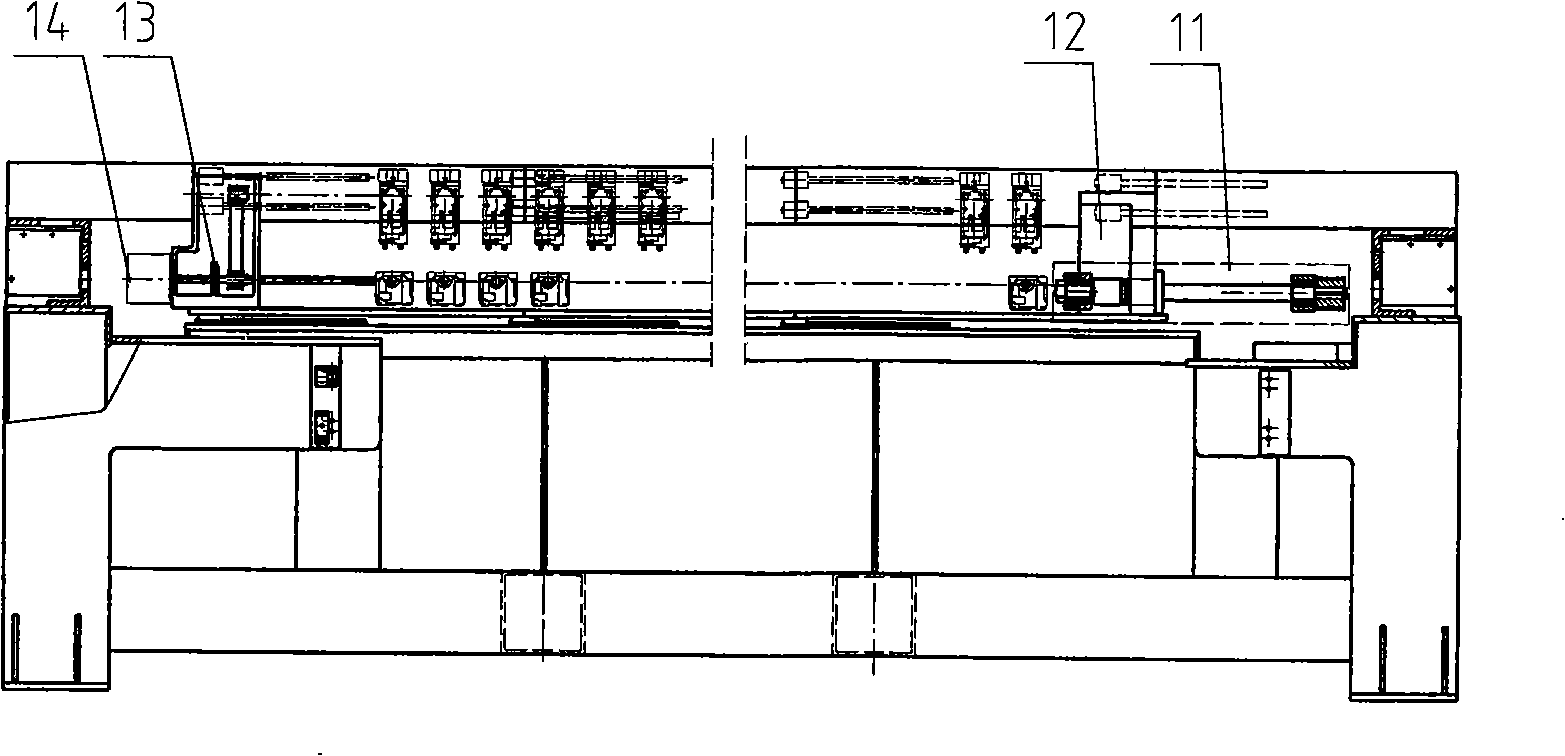

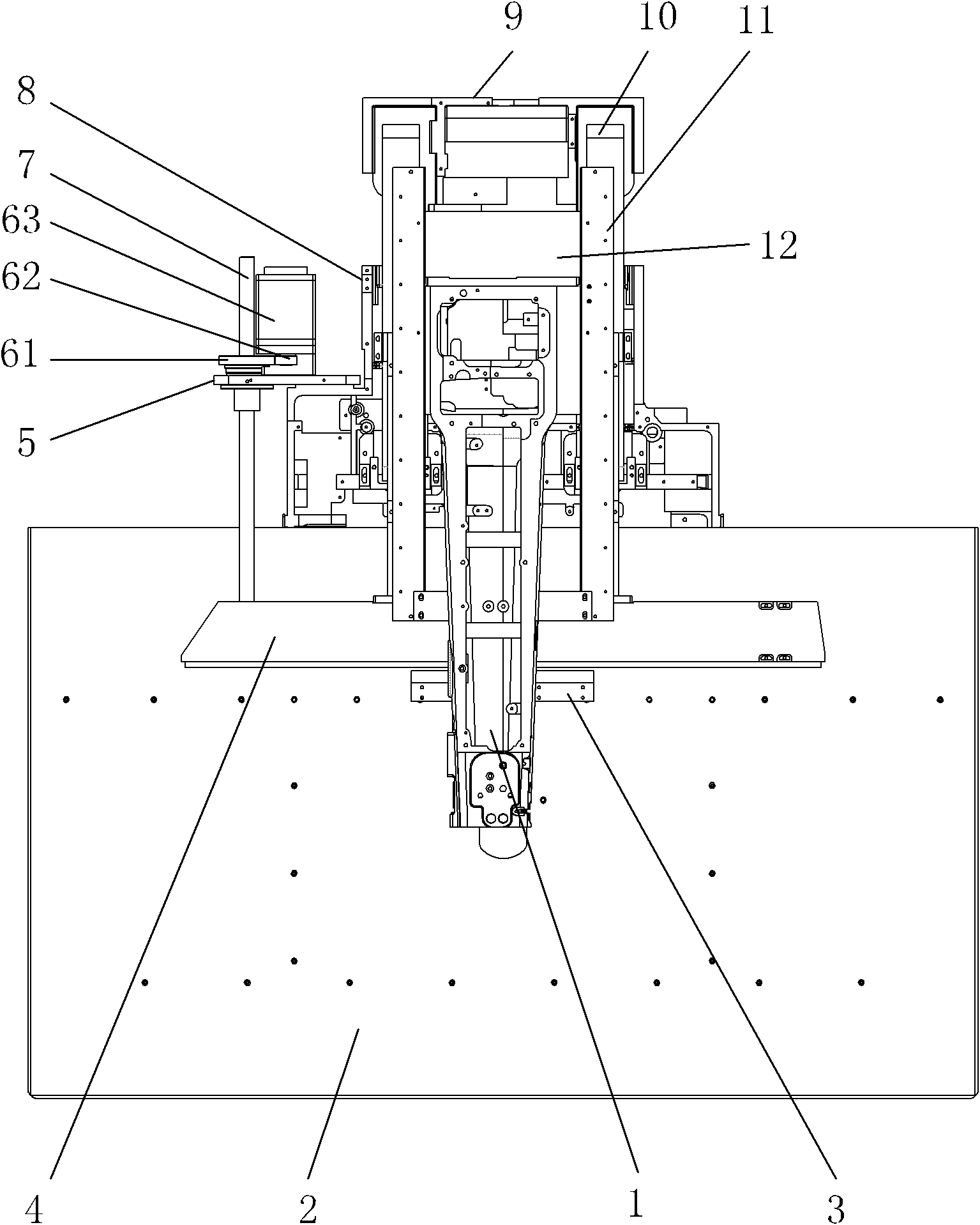

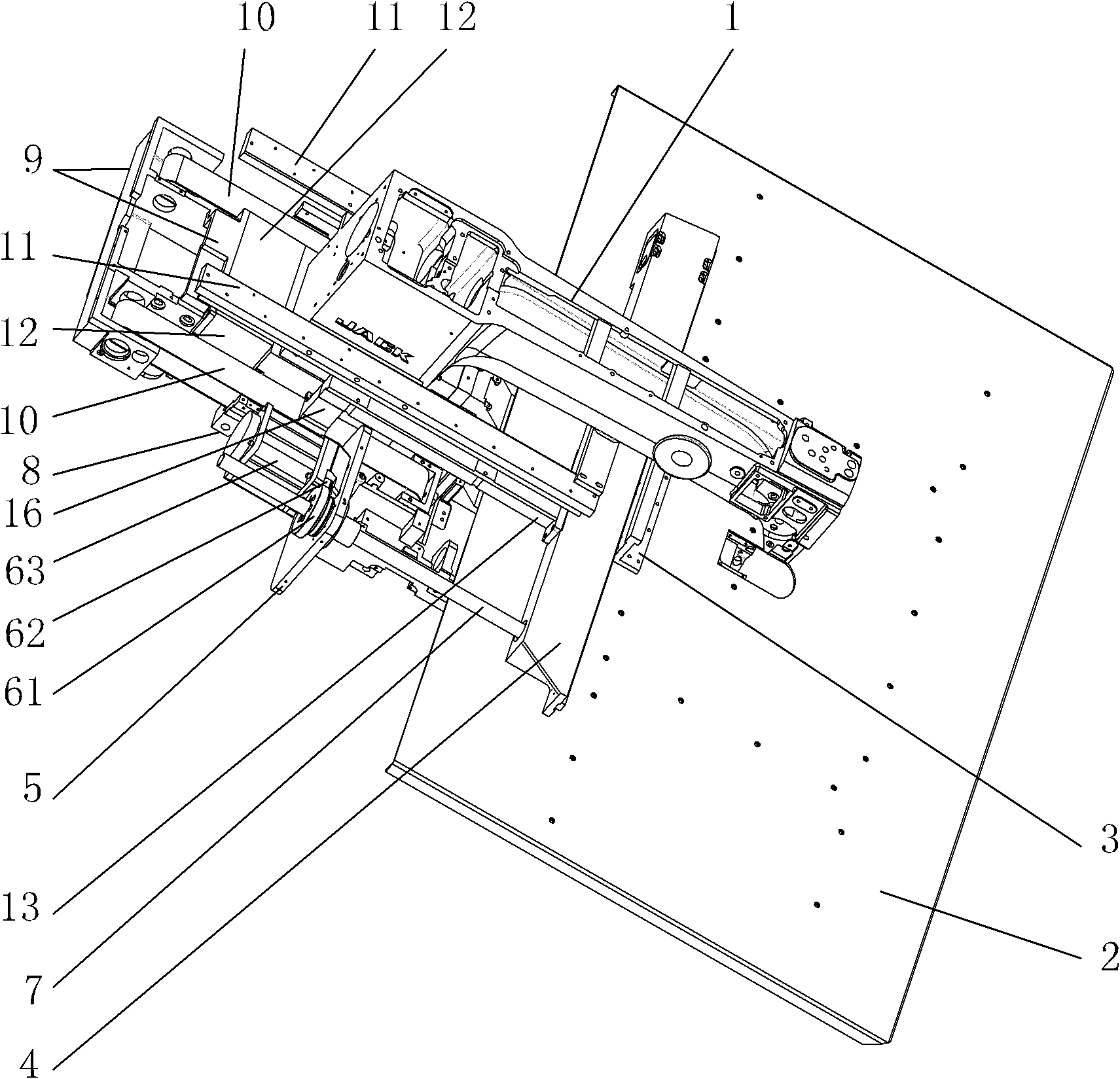

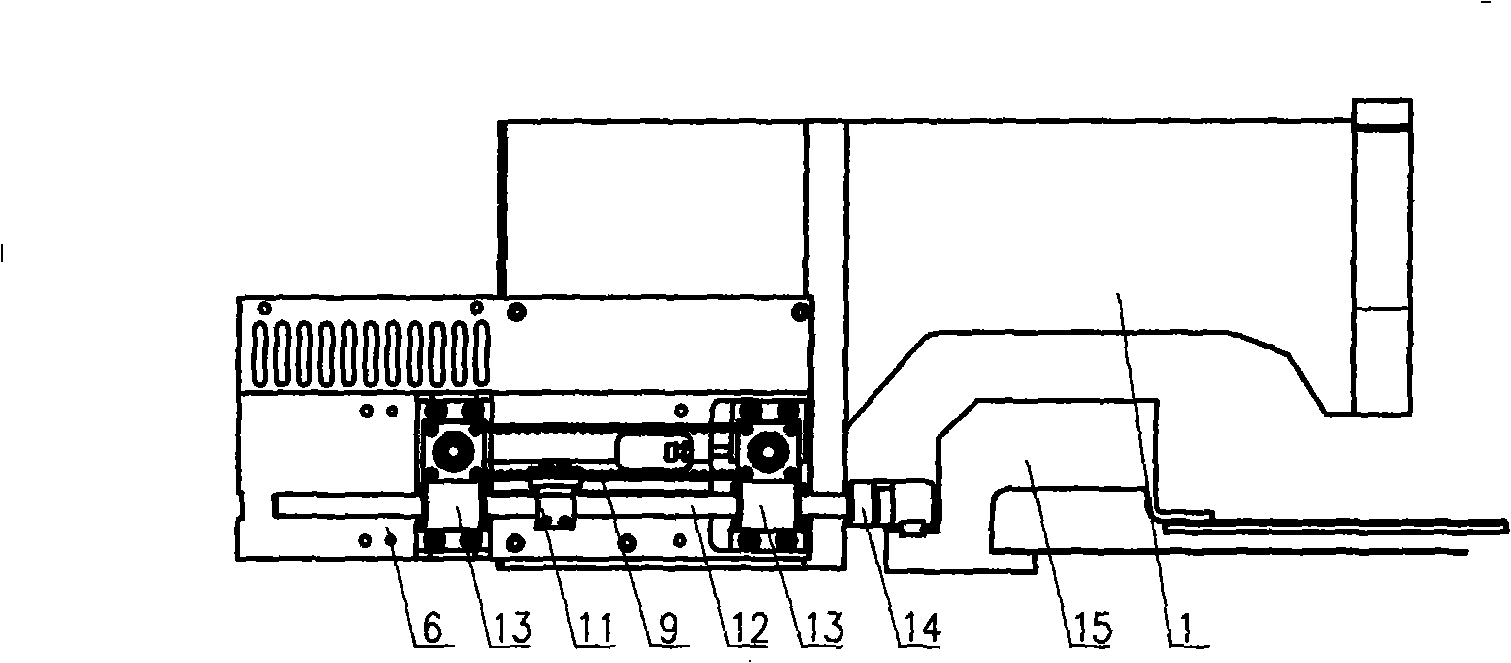

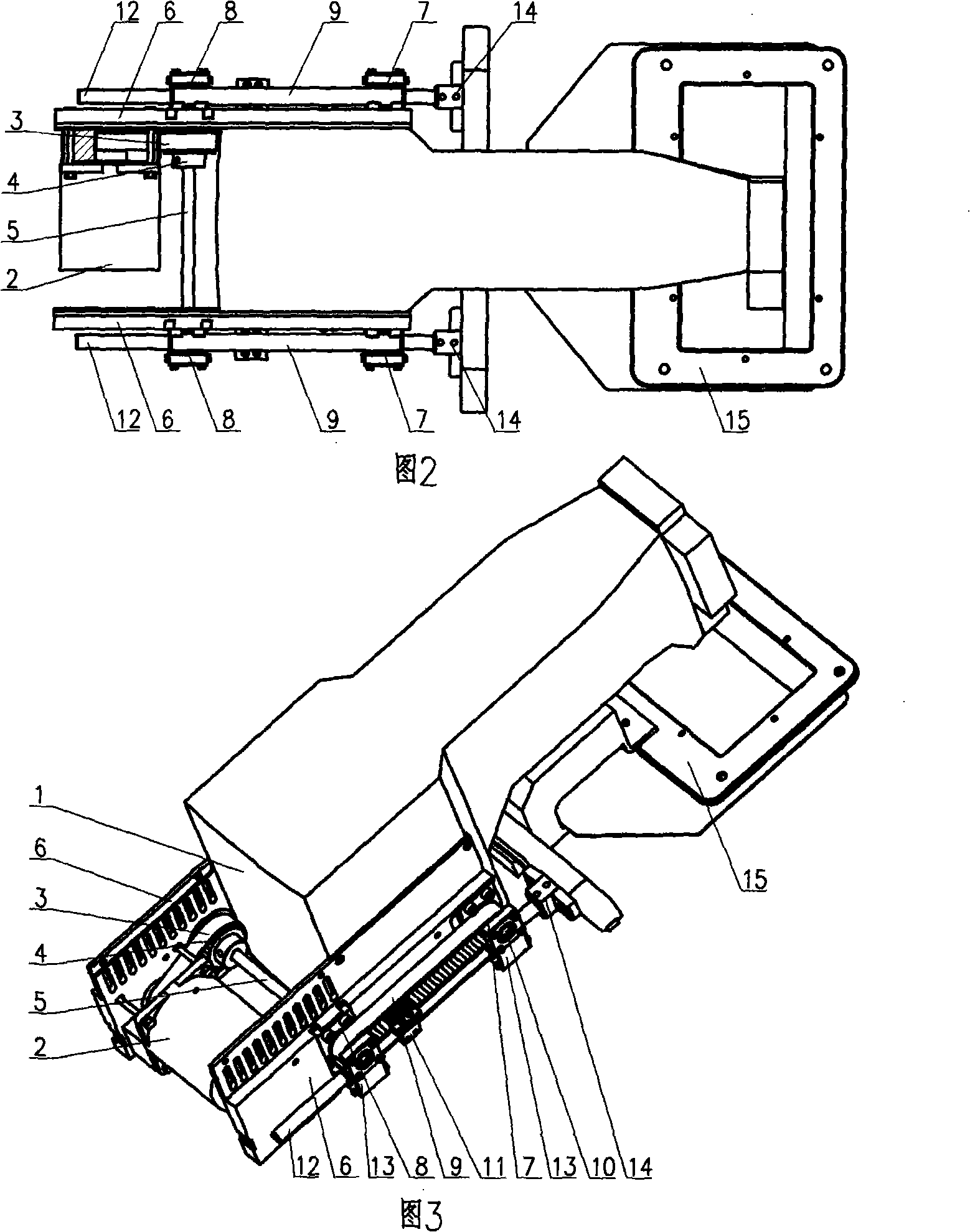

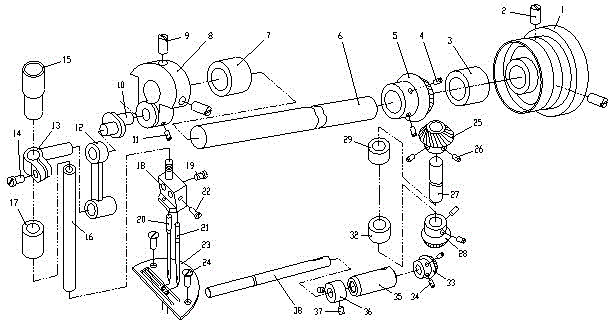

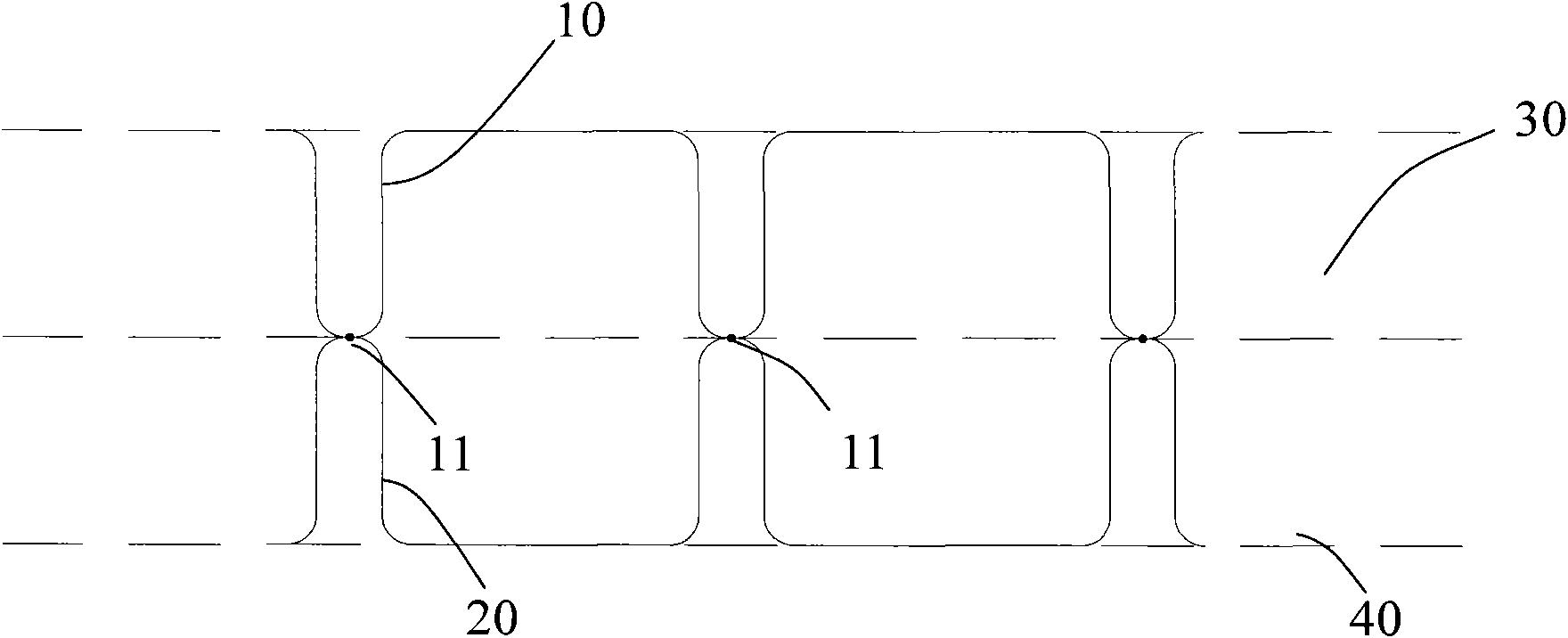

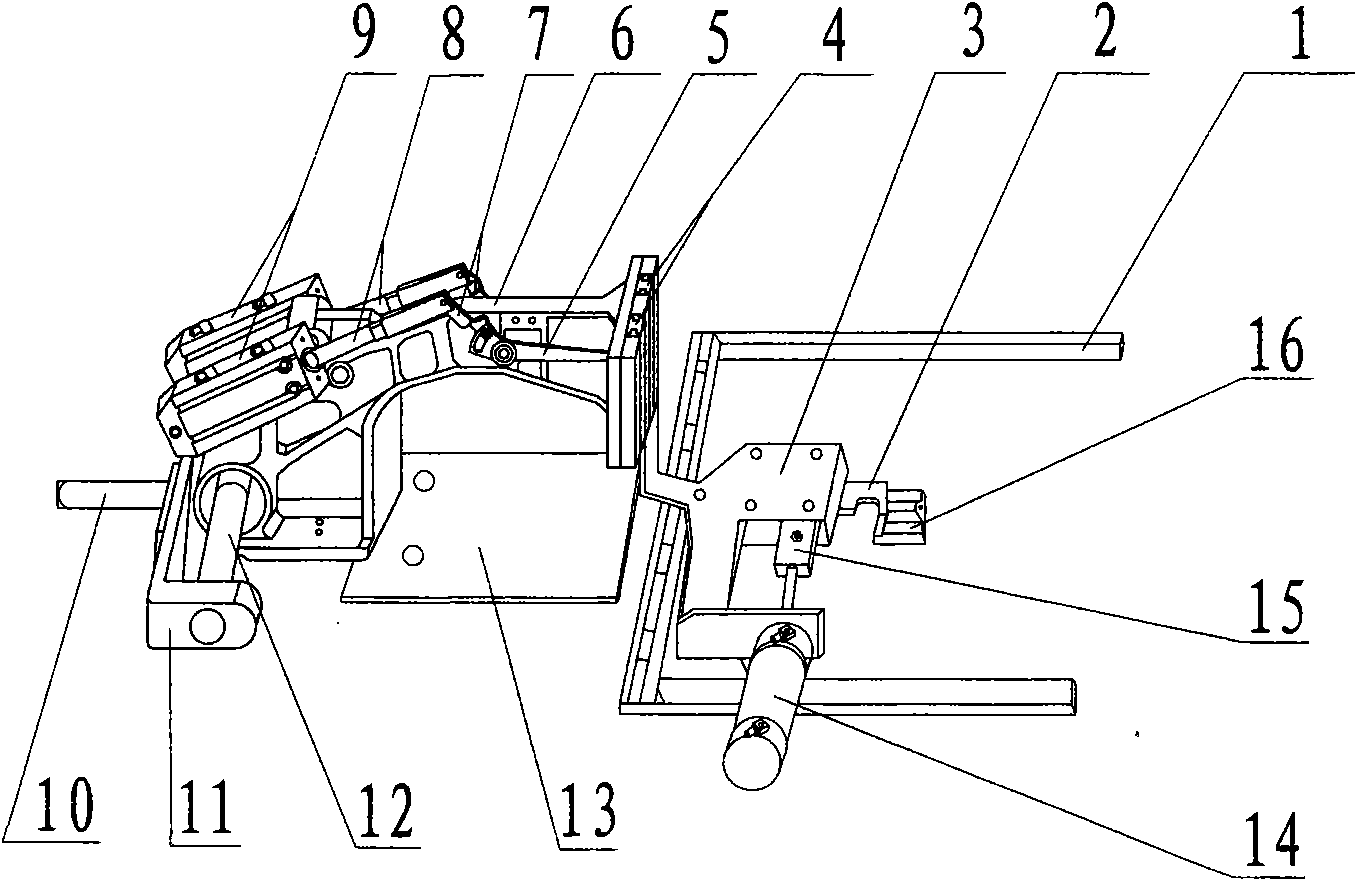

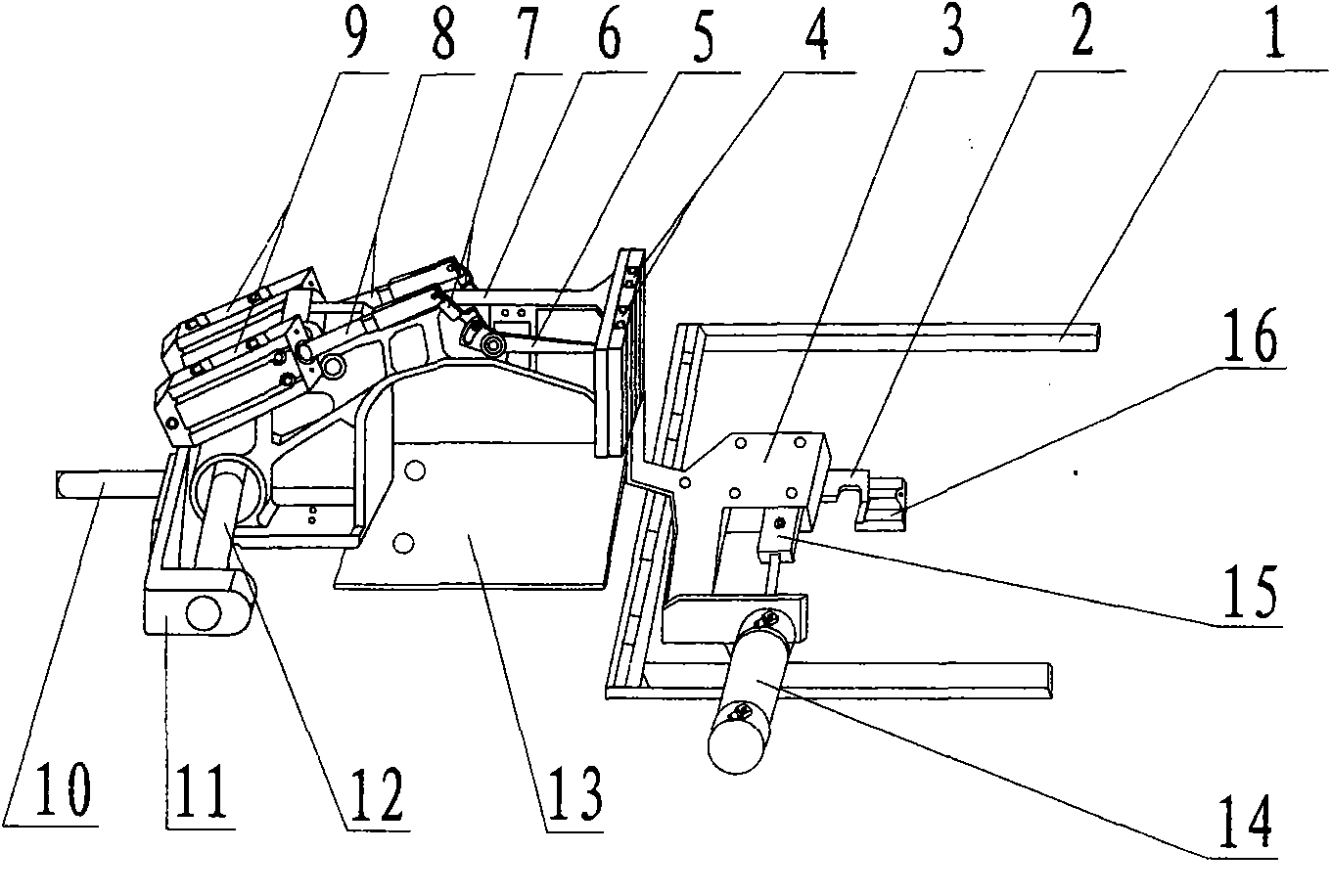

Longitudinal feeding structure of electronic pattern sewing machine

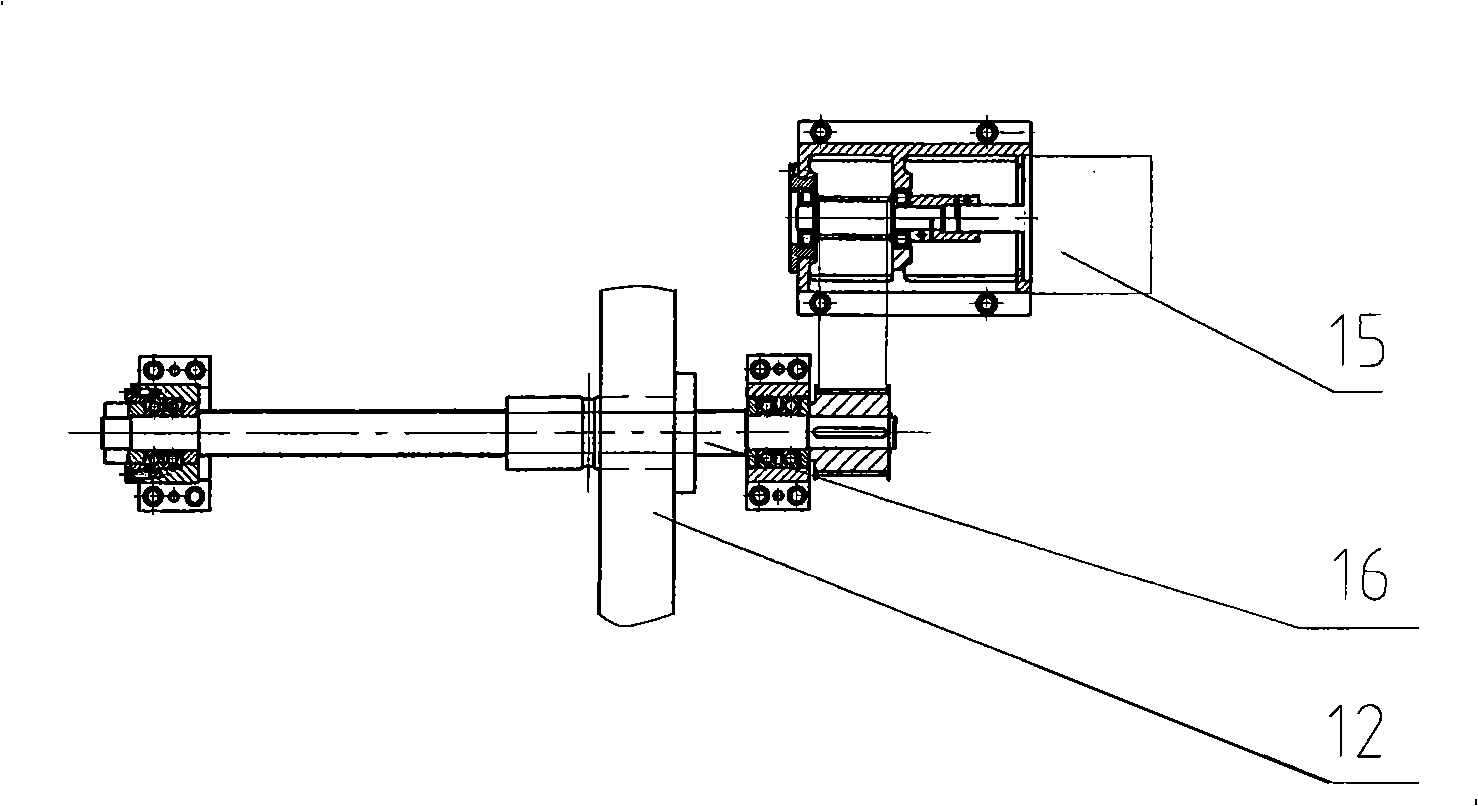

The invention belongs to the sewing machine technology, in particular to the design of a vertical feed mechanism of an electronic pattern machine that a holding apparatus can be driven to move stably, which comprises a nose1, a motor 2, a synchronous motor drive belt 3, a synchronous pulley 4, a synchronous pulley shaft 5, a fixation apparatus 6, a feed drive synchronous pulley 7, a feed driven synchronous pulley 8, a feed synchronous belt 9, a feed driven synchronous belt shaft 10, a feed shaft and a synchronous belt clamping component 11, a feed shaft 12, a feed shaft fixation seat 13, a connection component 14 and a holding apparatus 15, and characterized in that the vertical feed power of the holding apparatus 13 of the electric pattern machine is provided from the motor 1 through twice transmission of the synchronous belt and can be controlled through the program. The vertical feed of the holding apparatus 15 is achieved through the pushing of the feed shaft 12 in fractional packed on the fixation seat 13 of feed shaft on both sides of the nose. The power of the feed shaft 12 is provided through the feed synchronous belt 9. The feed shaft 12 and the feed synchronous belt 9 are linked together through the feed shaft and the synchronous clamping component 11. The power of the motor 2 is connected through a synchronous structure, thus the vertical feed of the electric pattern machine is achieved.

Owner:JACK SEWING MASCH CO LTD

Special side-sliding pressing pin for pattern machine

InactiveCN104328606AEasy to moveImprove the pressing effectPressersHem-stitch machinesMechanical engineeringSewing needle

The invention provides a special side-sliding pressing pin for a pattern machine, belongs to the technical field of sewing devices, and solves the technical problems of poor material pressing effect, poor convenience and the like of an existing special side-sliding pressing pin. The special side-sliding pressing pin comprises a material pressing frame and a material pressing template, wherein an operation through hole capable of extending into the material pressing template and a sewing needle is formed in the middle of the material pressing frame; a sliding rail is fixedly arranged at one side of the material pressing frame along the length direction of the side edge; the sliding rail is connected with a connection plate in a sliding manner; a lifting mechanism capable of driving the material pressing template to move up and down is fixedly arranged on the connection plate; the material pressing template is connected with the lifting mechanism; the bottom surface of the material pressing template can be level to the bottom surface of the material pressing frame; the special side-sliding pressing pin also comprises a driving piece which can drive the connection plate to move on the sliding rail along the length direction of the sliding rail. The driving piece in the pressing pin can drive the material pressing template to move on the sliding rail, so that the position of the material pressing template in a sewing area can be changed, the condition that the whole sewing can be finished once during sewing can be ensured, and further the sewing efficiency and the sewing effect can be improved.

Owner:ZHEJIANG ZOJE SEWING MACHINE +2

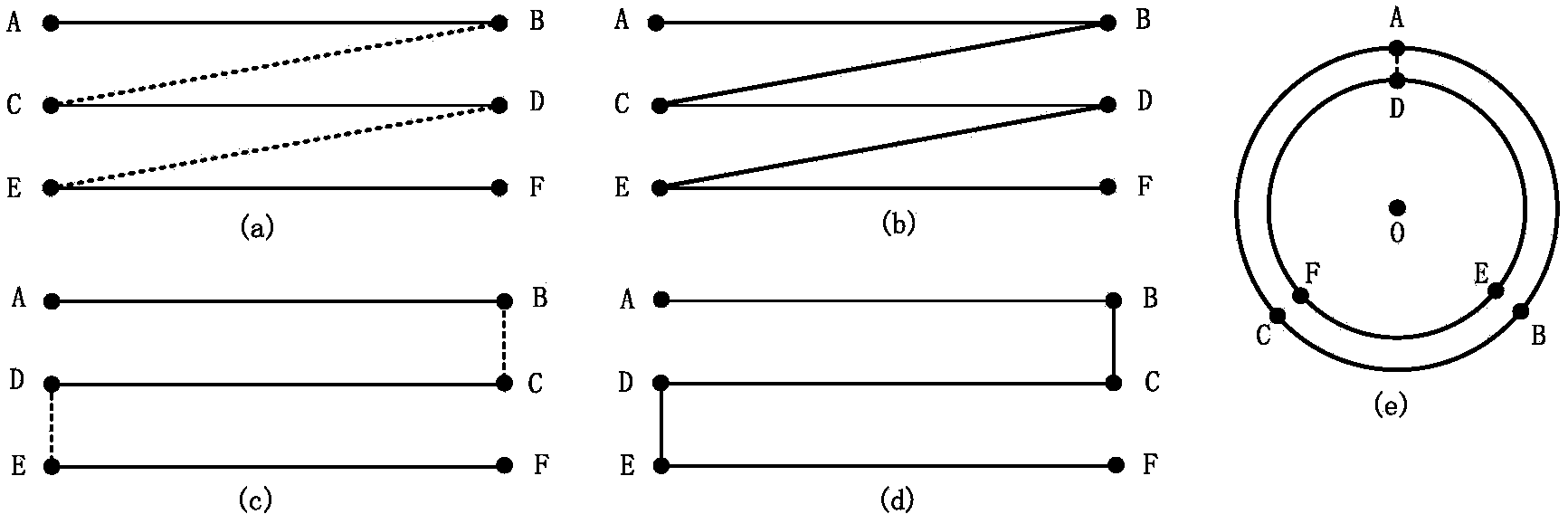

Method for controlling electronic pattern machine to perform multiple sewing

ActiveCN103668793AImprove general performanceSolve the problem of multiple seams in polygonsProgramme-controlled sewing machinesHem-stitch machinesNumerical controlGraphics

The invention discloses a method for controlling an electronic pattern machine to perform multiple sewing. The method includes the steps that first, key point data in pattern data are established, then, multiple sewing key point data are generated by the key point data, uniform discretization is performed on every segment of basic geometric figure by the multiple sewing key point data, and relative coordinates of pattern points obtained after every segment is subjected to uniform discretization are combined in sequence to generate pattern data; finally, a multiple sewing pattern data file is established by the multiple sewing key point data, the pattern data and a header file, the obtained pattern data file is stored into an electronic control system of the electronic pattern machine, and the electronic control system of the electronic pattern machine controls an X-axis stepping motor and a Y-axis steeping motor to be matched with a spindle servo motor to operate and sew designed patterns according to the pattern data file. The method is high in universality, all types of polygonal multiple sewing problems can be solved, and the method can be used for CNC machine tool cutter feeding path planning.

Owner:中国船舶重工集团公司第七〇五研究所

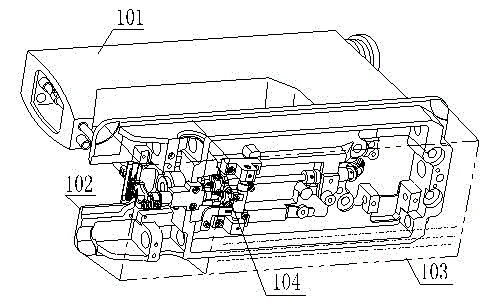

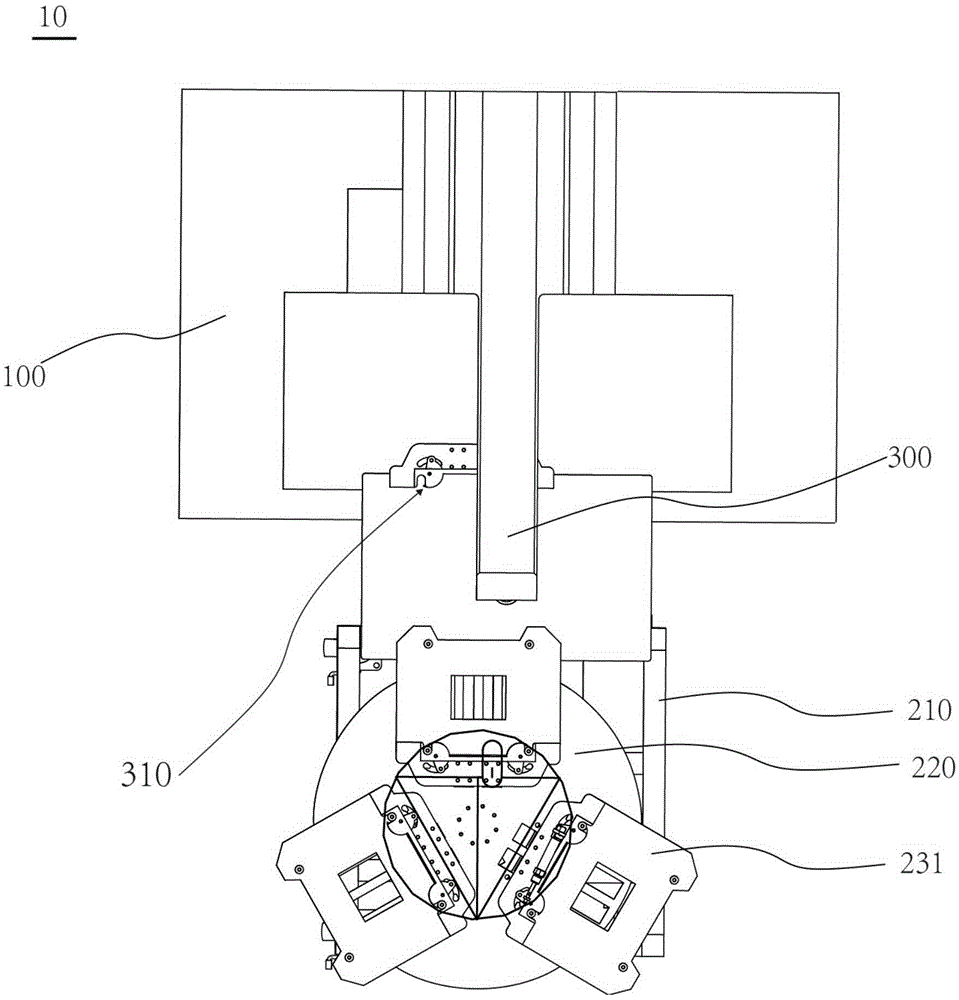

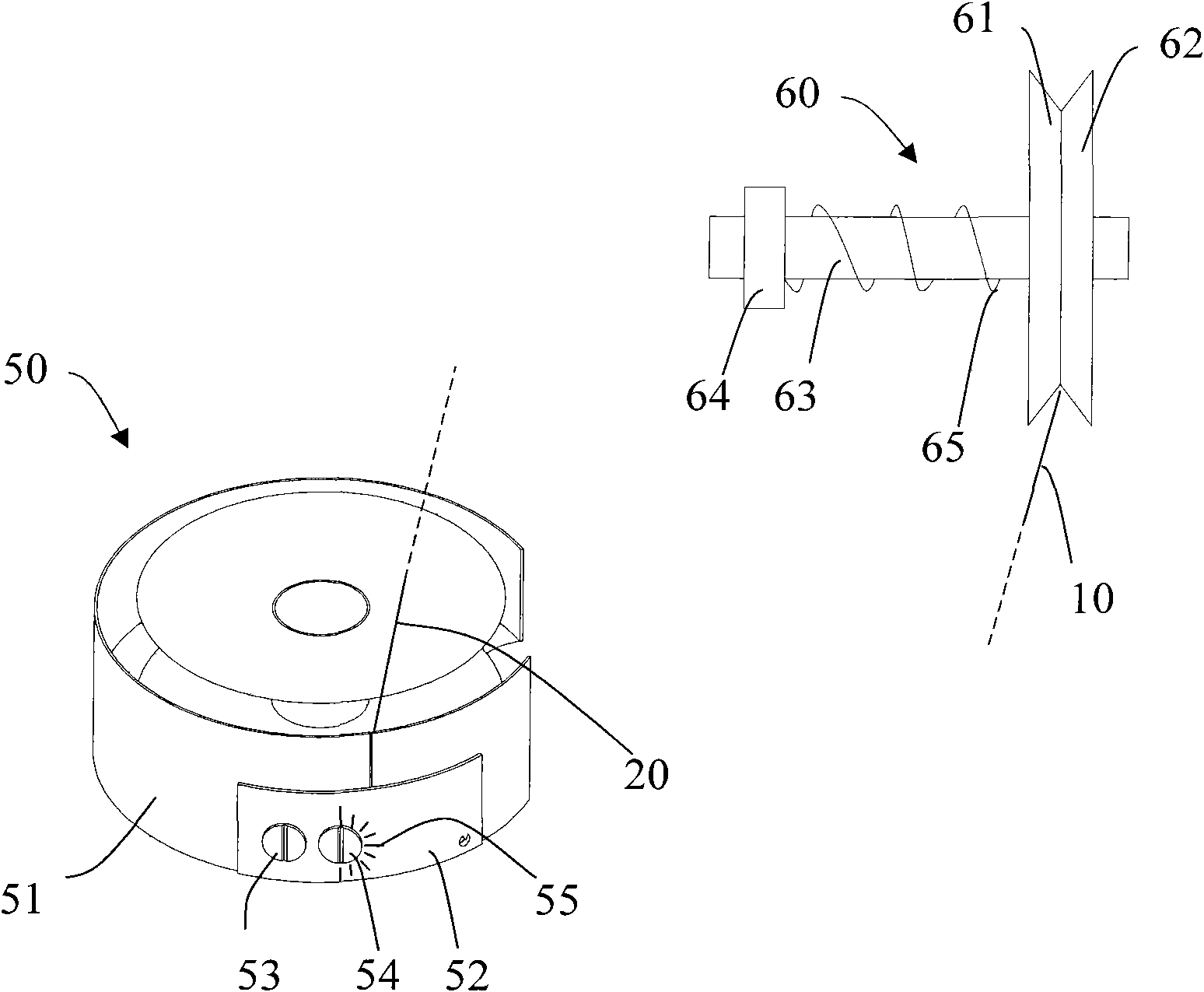

Full-automatic sewing machine with arbitrarily rotatable machine head

PendingCN111118746AGuaranteed to be consistent and beautifulVariety of sewing contoursHem-stitch machinesLoop takersRotary stageElectric machinery

The present invention discloses a full-automatic sewing machine with an arbitrarily rotatable machine head. The machine mainly comprises the rotating machine head, an upper rotating table, a pneumaticlifting slide table, a machine frame, an X-direction driver, a Y-direction driver, an operation box, a tabouret driving motor, a machine head support, a rotating shuttle, a lower rotating table, an upper current collecting slip ring, a lower current collecting slip ring, an upper rotating table motor, a lower rotating table motor and an operation box support arm, wherein the pneumatic slide tablecomprises an air cylinder, a profile base, a sliding block and a sliding rail; and the upper rotating table is mounted on the machine head support through an inlaid nut and four M6 inner hexagon screws and then is mounted on the sliding block of the pneumatic slide table through eight M6 inner hexagon screws. The machine overcomes the defect in solving the stitch consistency problem in the priorart; the current collecting slip rings are added, so that the function of arbitrary rotation in the full-angle range can be realized, the reciprocating rotation in the fixed rotation range is avoided,and the efficiency is improved; and the machine head can be lifted, so that the machine is suitable for thin and thick material sewing.

Owner:上工富怡智能制造(天津)有限公司

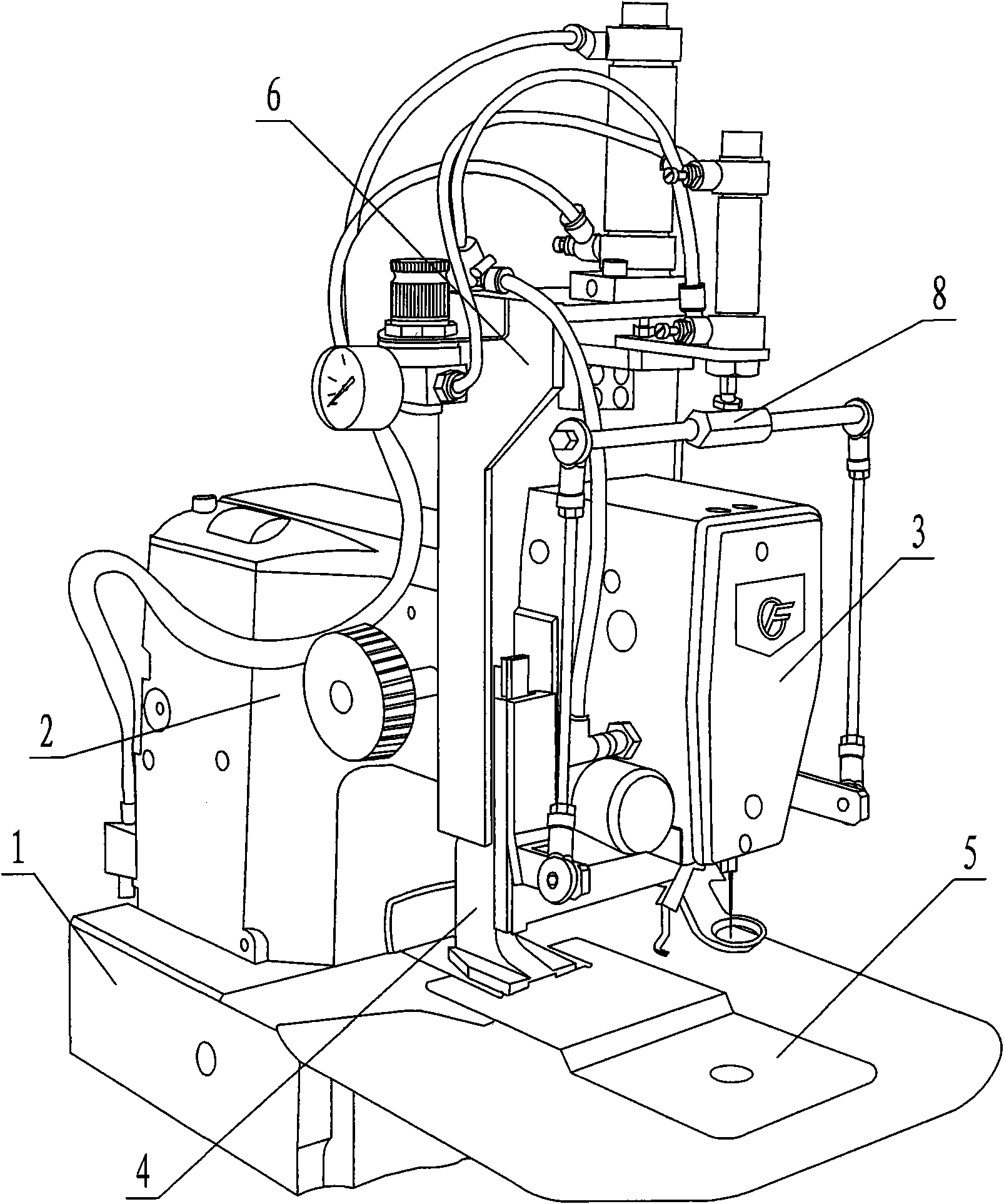

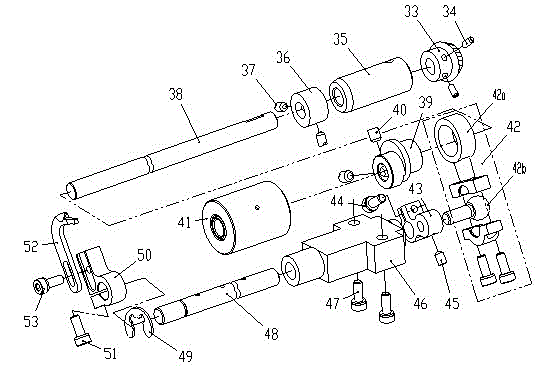

Bead edge stitch sewing machine

ActiveCN102877222AImprove sewing effectReduce vibrationLubrication/cooling devicesHem-stitch machinesGear wheelEngineering

The invention discloses a bead edge stitch sewing machine which comprises a head and a bottom plate. The head is arranged on the bottom plate; a cloth pricking mechanism is arranged in the head; the cloth pricking mechanism is connected with an upper shaft; the power drive of the upper shaft is implemented by a belt pulley; the upper shaft drives a lower shaft by two pairs of bevel gears and a vertical shaft; the lower shaft is connected with a thread expansion ring mechanism capable of ensuring stitches to be reliably formed; the thread expansion ring mechanism is arranged below the bottom plate; the lower shaft is fixedly connected with a thread shifting cam; the phase relation of the thread shifting cam and a sewing needle can be regulated; the thread shifting cam is connected with a thread shifting shaft by a thread shifting crank; the thread shifting shaft is connected with a thread shifting plate; the lower shaft is fixedly connected with a thread pushing cam; the phase relation of the thread pushing cam and the thread shifting cam can be regulated; the thread pushing cam is fixedly connected with a sliding block shaft by a thread pushing crank; a sliding block is movably arranged on the sliding block shaft; the sliding block can rotate relative to the sliding block shaft; the sliding block is in sliding fit with a groove part of a thread pushing rod; and the thread pushing rod is connected with a thread pushing plate. According to the invention, the perfect sewing effect can be achieved.

Owner:ZHEJIANG MAQI SEWING MACHINE

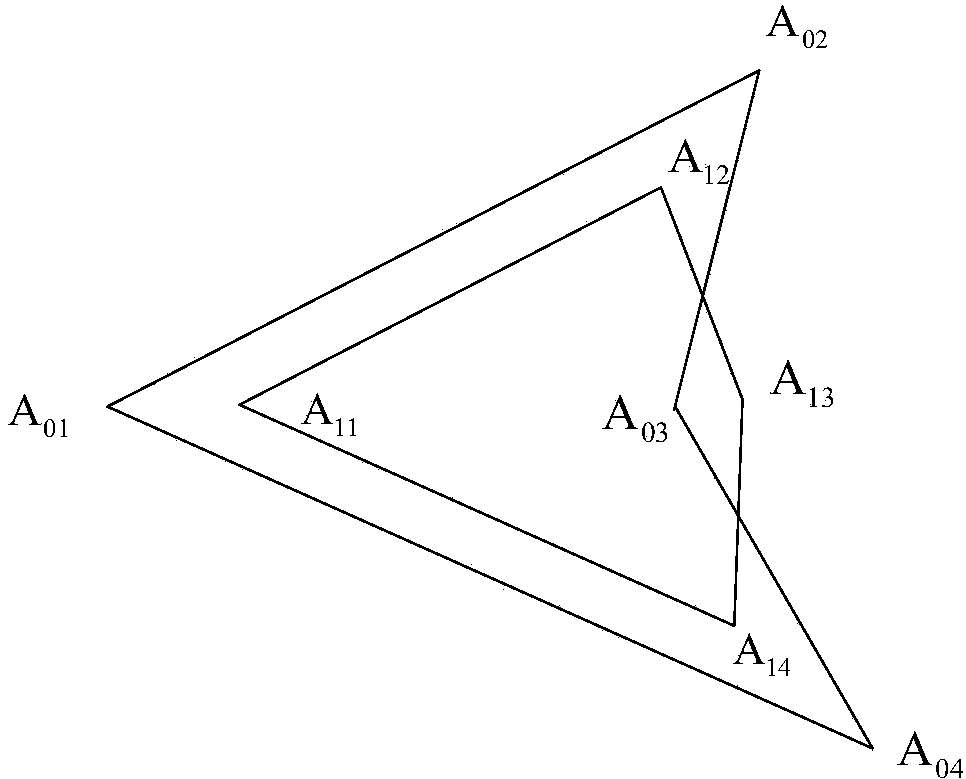

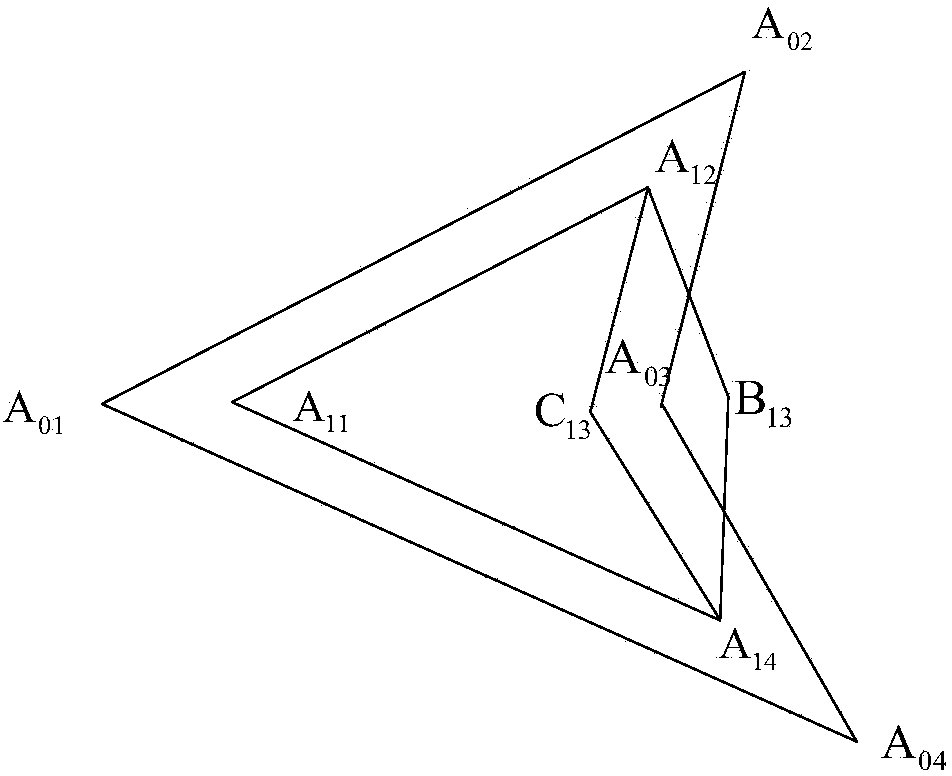

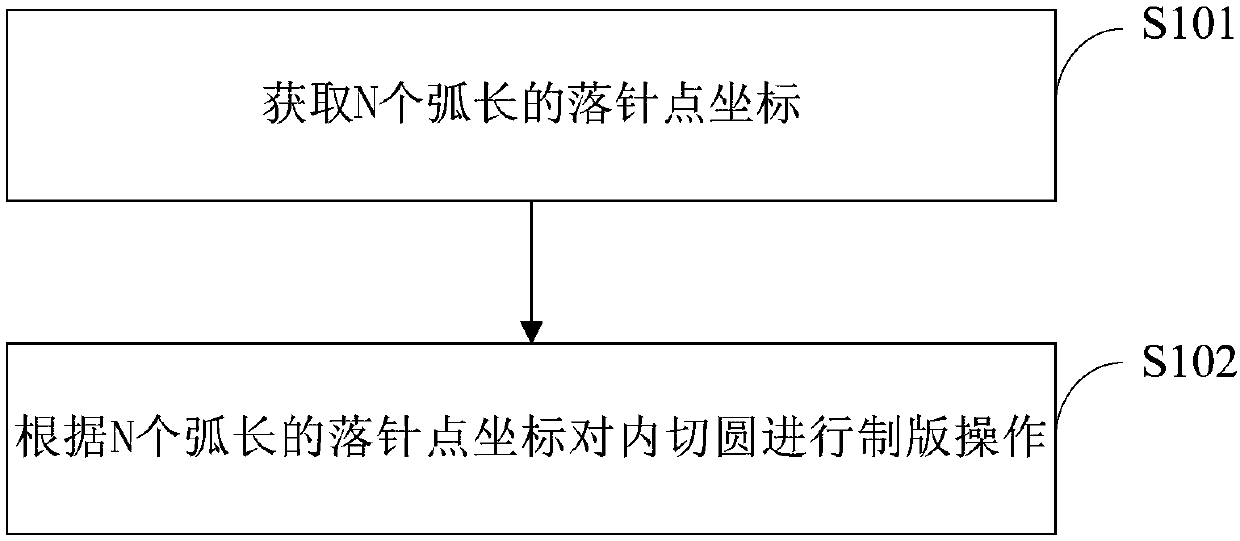

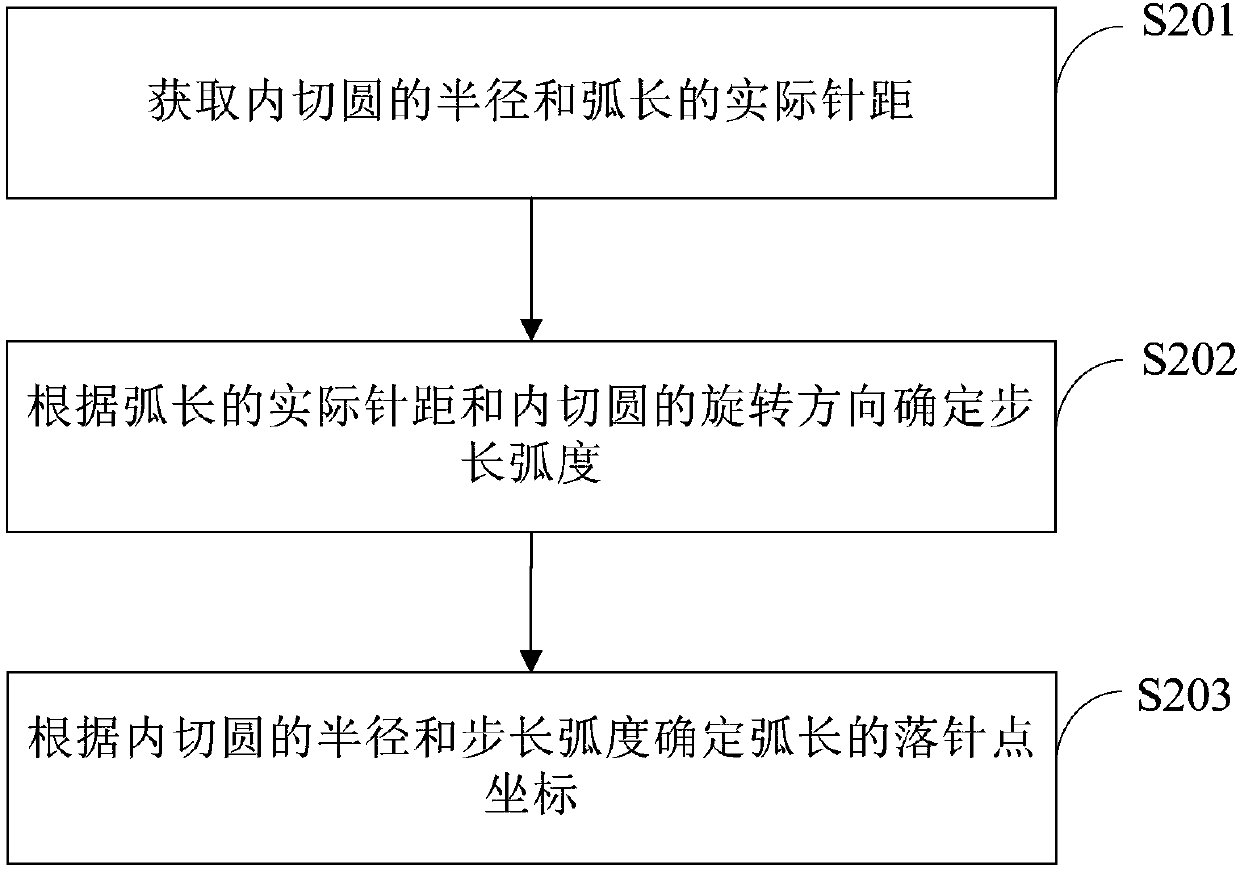

Pattern making method and device of sewing machine, readable storage medium and sewing machine

ActiveCN107904794AImprove processing efficiencyIncrease overlapProgramme-controlled sewing machinesHem-stitch machinesGraphicsEngineering

The invention provides a pattern making method and device of a sewing machine, a readable storage medium and the sewing machine which are applied to an inscribed circle set in a pattern, and the inscribed circle is divided into N arc lengths. The plate making method of the sewing machine includes the steps of obtaining the coordinates of the stitching points of the N arc lengths and conducting pattern making operation according to the coordinates of the stitching points of the N arc lengths, wherein N is an integer greater than or equal to 2. The pattern making method and device of the sewingmachine, the readable storage medium and the sewing machine increase the overlapping rate of the stitching points of the pattern and the inscribed circle at an inscribed point.

Owner:BEIJING DAHAO TECH +1

Special type pattern machine for sewing in large area

InactiveCN102337641ASimple structureOperational securityProgramme-controlled sewing machinesHem-stitch machinesDisplay deviceEngineering

The invention discloses a special type pattern machine for sewing in a large area. The special type pattern machine comprises a machine head, a guide rail, a sliding support, a frame, a Y-direction guide rail, a bedplate fixing frame, an X-direction driving motor, an electric cabinet, a digital display and the like. A core part of a control system is a digital signal processor (DSP) master chip, namely a central processing module and a field programmable gate array (FDGA); the control system comprises a controller, a driver, a motor and electromagnets; the controller controls the movement of a servomotor for a spindle and a step motor for a cloth feeding mechanism, and completes other auxiliary functions by means of the electromagnets; in the cloth feeding mechanism, X-direction and Y-direction step motors drive shafts L2 and L1 to make the X and Y displace, the X-direction step motor drives the shaft L2 and a width module through an arc gear, and the Y-direction step motor drives a length module through a gear to brake the shaft L1; and a touch screen technology is adopted, a built-in liquid crystal display panel sets an upper limit and a lower limit in midway limitation, and electronic static discharge (ESD) control is installed. The special type pattern machine has high production efficiency, wide sewing range and diversified sewing patterns.

Owner:麻佰林

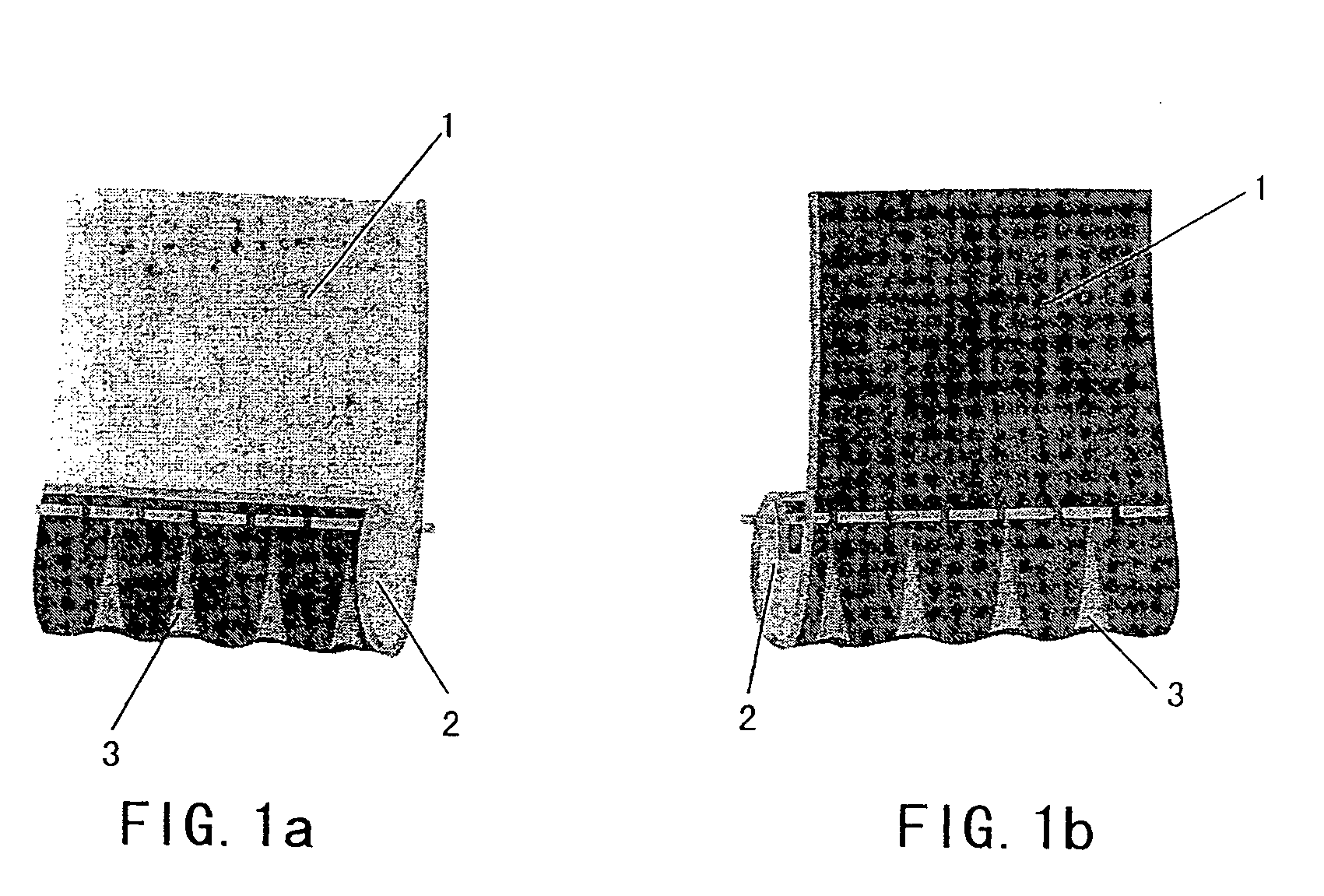

Multifunction sewing machine designed to sew fabrics using different layouts and types of stitches

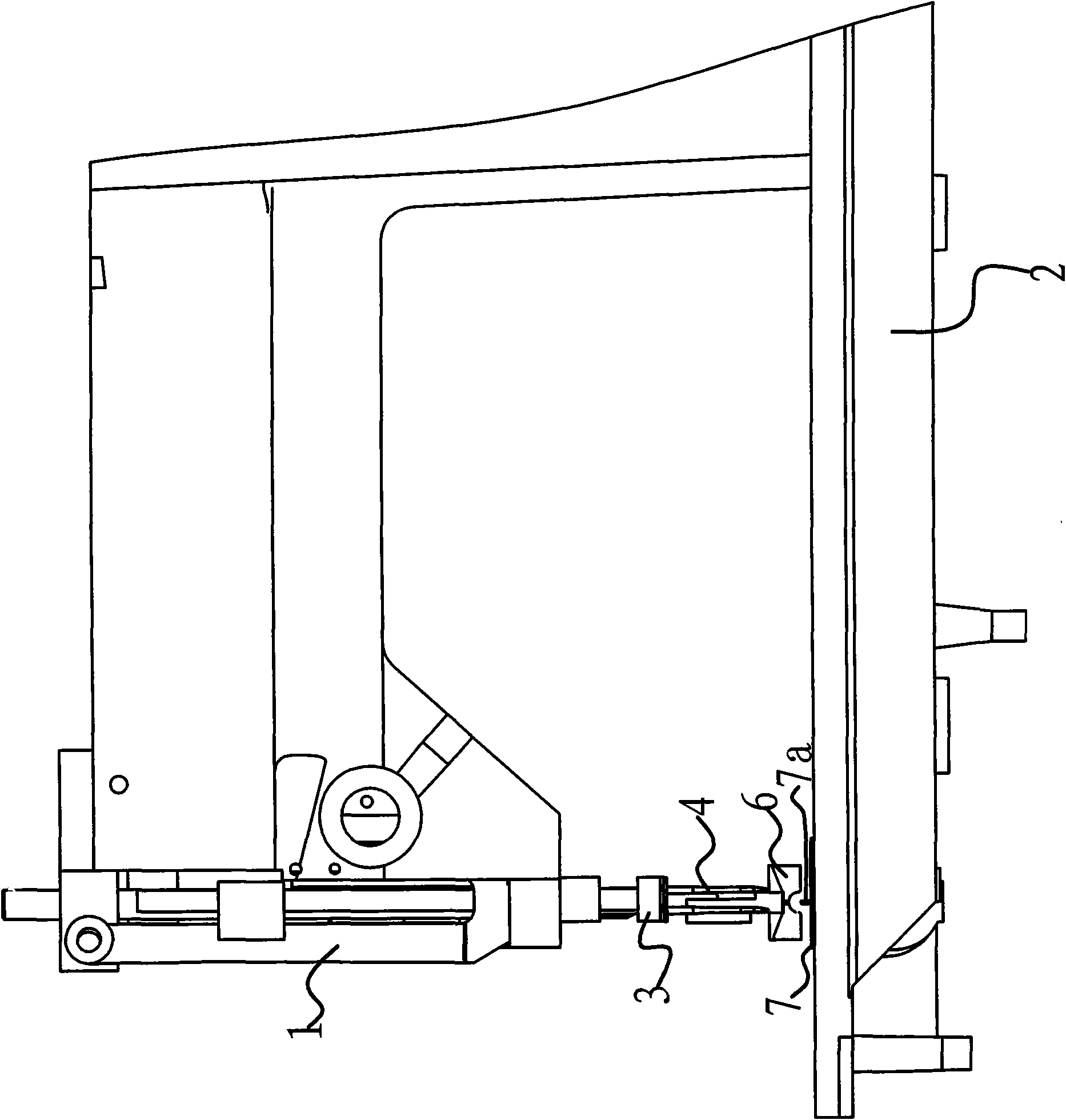

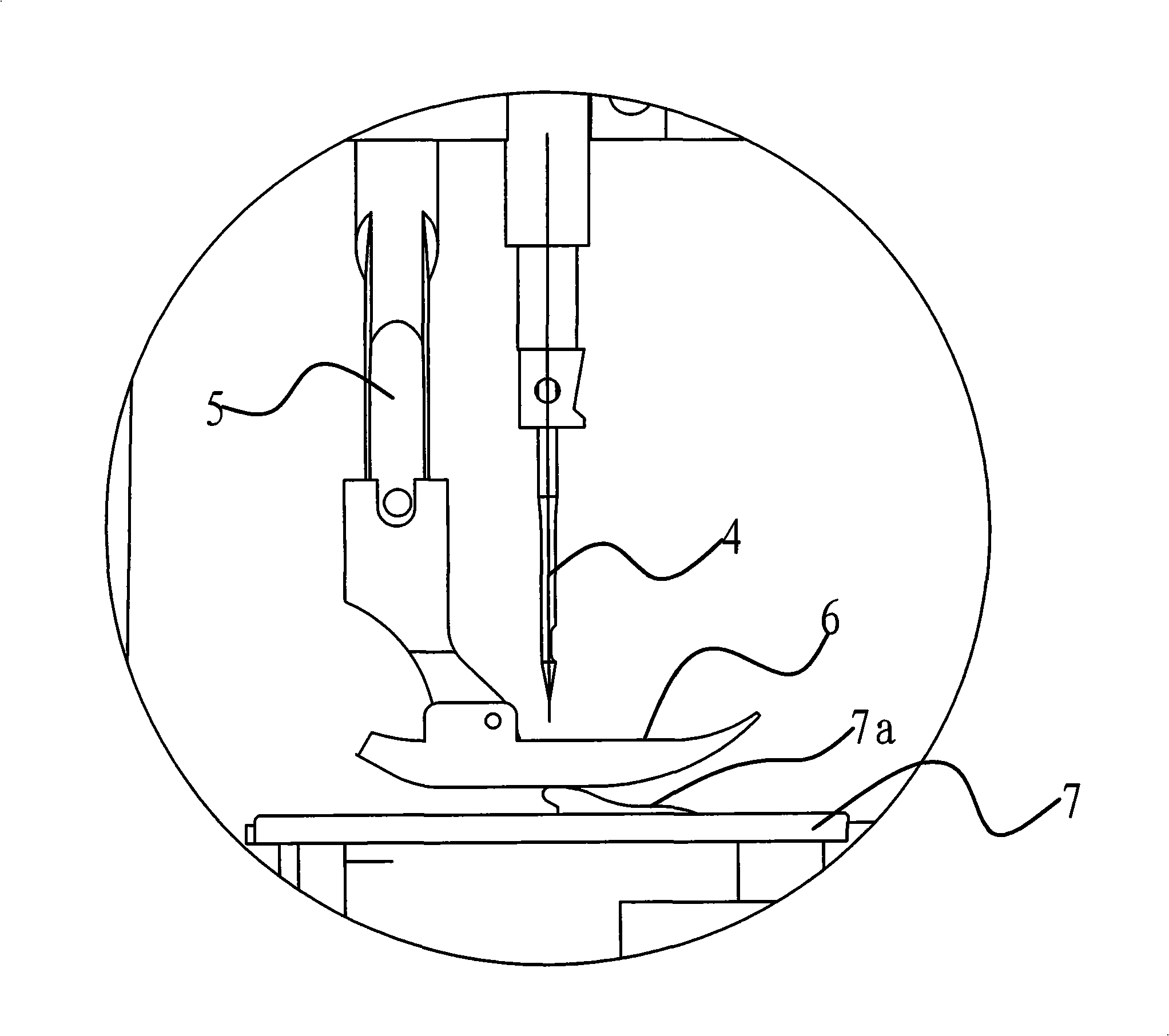

ActiveCN101058924AAdjustable distanceLow costSewing-machine casingsWork-feeding meansEngineeringSewing machine

The invention concerns a sewing machine, preferably of the industrial type, with a base (1) designed to mechanically sew together two pieces of fabric by using different types of stitches thanks to the layout of means (5, 6, 7, 27) driven and adjusted according to the machine operator's requirements. In particular these means (5, 6, 7, 27) can be positioned at desired distances one from the other to ensure the proper positioning of the stitches in the desired zones.

Owner:VI BE MAC

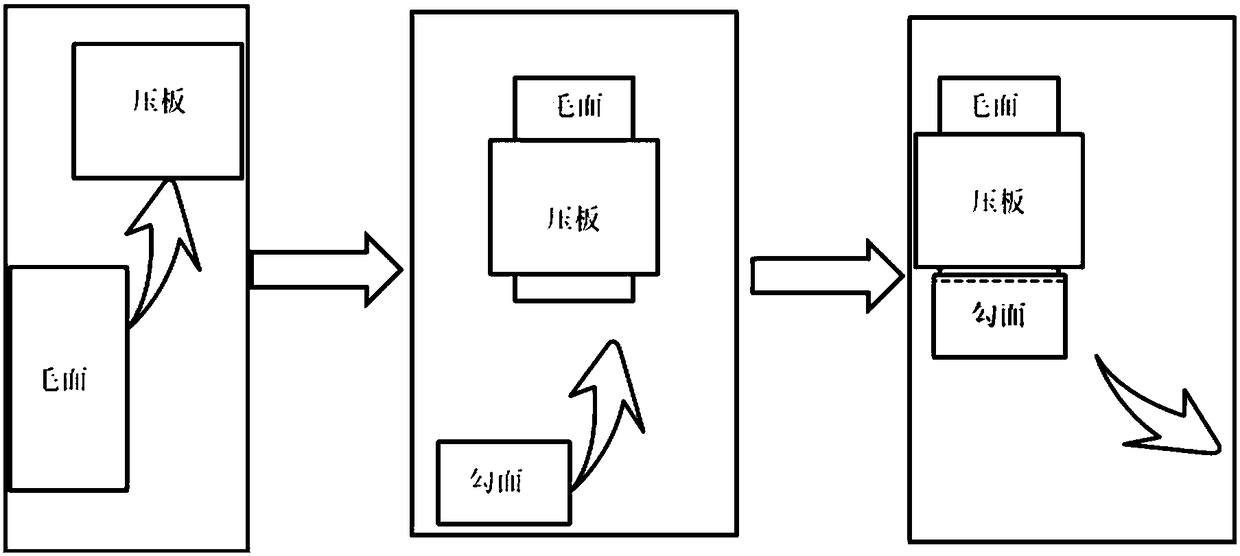

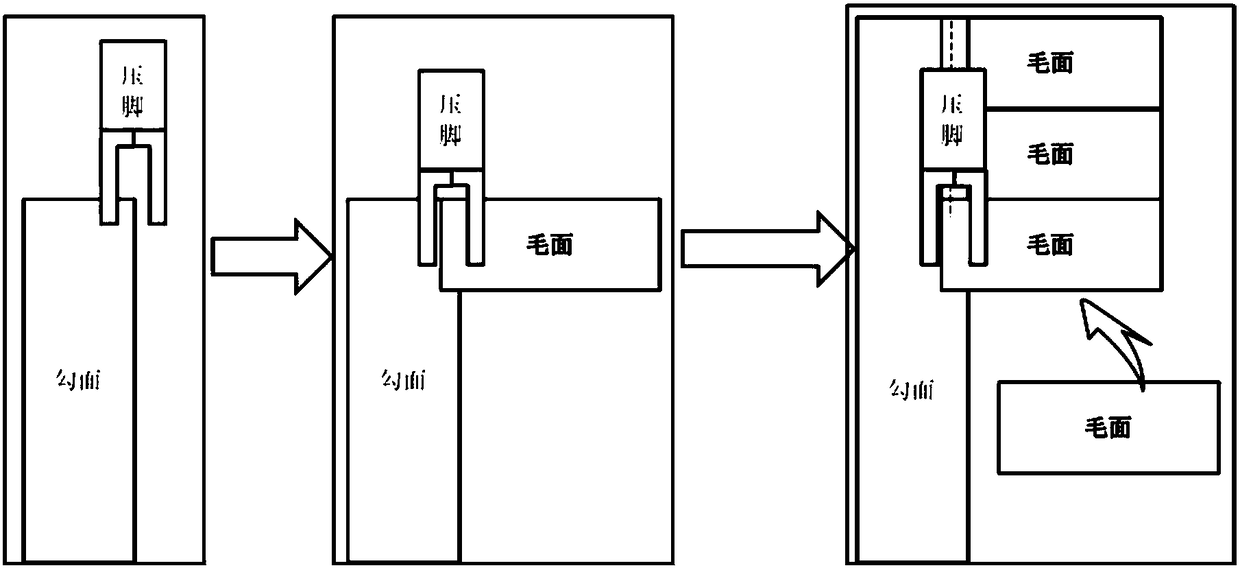

Processing method of hook and loop fastener

InactiveCN108158139AReduce labor intensityEase of batch processingHem-stitch machinesHaberdasheryEngineeringFastener

The invention discloses a processing method of a hook and loop fastener. The method includes the following steps that S1, a hook fabric is laid flat on a sewing device and stretched into the lower portion of a presser foot from one side of the presser foot of the sewing device, and the brim line of the hook fabric is aligned with a central line of the presser foot; S2, a loop fabric is stretched into the portion between the presser foot and the hook fabric from the other side of the presser foot and partially overlapped with the hook fabric; S3, the loop fabric is in sewing connection with thehook fabric through the sewing device; S4, the hook fabric is trimmed till the length of the hook fabric is equal to the width of the loop fabric. Compared with the prior art, the method has the advantages that the production efficiency is high, the processing quality is great, and the production cost is low.

Owner:FUJIAN PUTIAN KAYUHUA SHOES MANUFACTORY CO LTD

Sewing positioning device and automatic sewing equipment

PendingCN108893876AGuaranteed uniformityGuaranteed aestheticsWork-feeding meansPressersEngineeringMechanical engineering

The invention relates to a sewing positioning device and automatic sewing equipment. The sewing positioning device comprises a working table with a working table surface, a cloth pressing mechanism, acloth pulling mechanism and a clamping mechanism, wherein the cloth pressing mechanism comprises a cloth pressing block and a lifting driving part, the cloth pressing block is used for pressing a fabric on the working table surface, and the lifting driving part is connected with the cloth pressing block to drive the cloth pressing block to rise or fall relative to the working table surface; the cloth pulling mechanism comprises a cloth pulling block and a cloth pulling driving component, the cloth pulling block is located on one side of cloth pressing block, and the cloth pulling driving component is connected with the cloth pulling block to drive the cloth pulling block to tighten the fabric away from the press block; and the clamping mechanism is arranged on one side of the cloth pressing block away from the cloth pulling block to press the fabric when the cloth pulling block tightens the fabric. The sewing positioning device can cooperate with sewing mechanisms such as a pattern machine to ensure that the fabric will not be misplaced in the sewing process, so that the product yield is improved, and the production efficiency is greatly improved compared with the traditional manual method.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Machine sewing system and machine sewing method

InactiveCN105401350AAvoid waitingReduce waiting timeHem-stitch machinesEngineeringMechanical engineering

The invention discloses a machine sewing system and a machine sewing method thereof. The machine sewing system comprises a machine table, a feeding device, a machine sewing device and a control device. The feeding device comprises a plurality of loading components, a turntable and a rotation driving component. The plurality of loading components are arranged on the same surface of the turntable and are used for placing fabric cutting pieces. The rotation driving component is arranged on the machine table and is used for driving turntable to rotate relative to the machine table so as to drive the loading components on the turntable to rotate. The machine sewing device is arranged on the machine table. When the loading components rotates to reach the machine sewing device, the fabric cutting pieces are delivered to the machine sewing station of the machine sewing device by means of the loading components. The machine sewing device is used for conducting the machine sewing operation on the fabric cutting pieces. The control device is electrically connected with the loading components, the rotation driving component and the machine sewing device. The machine sewing system saves the time.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Method for patterning and coloring surface of cloth

The invention discloses a method for patterning and coloring the surface of cloth. In the method, the tightness of lower threads and upper threads is adjusted through a bobbin case and a thread adjusting spring on an adjusting sewing machine so as to raise the knots of the lower threads and the upper threads from the surface of the cloth to form patterns and colors on the surface of the cloth. The knots of the lower threads and the upper threads are used for sewing the cloth originally. In the method, the knots are raised from the surface of the cloth to product patterns and colors, so the cloth is patterned without adopting other equipment besides the conventional equipment.

Owner:SHANGHAI CONCH APPL

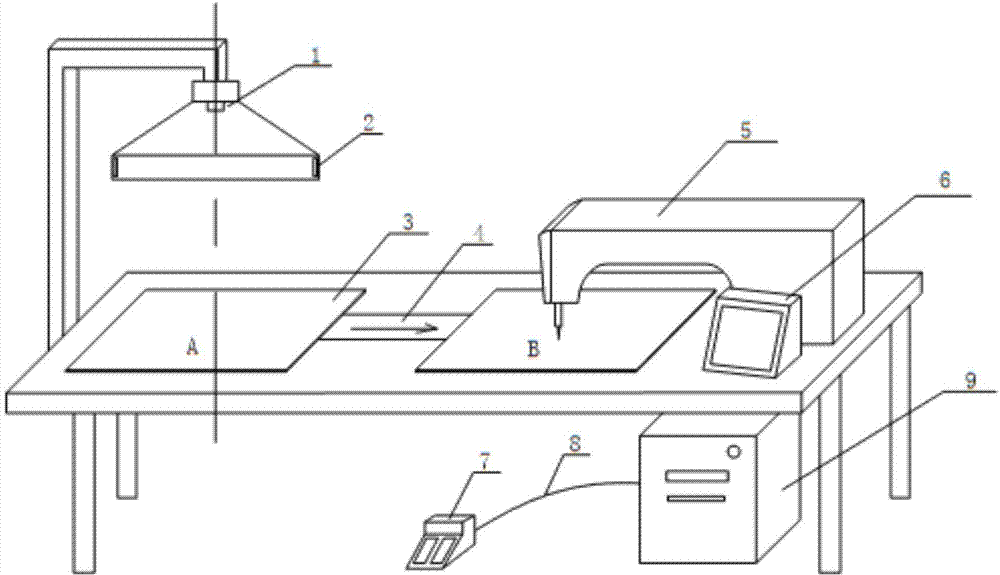

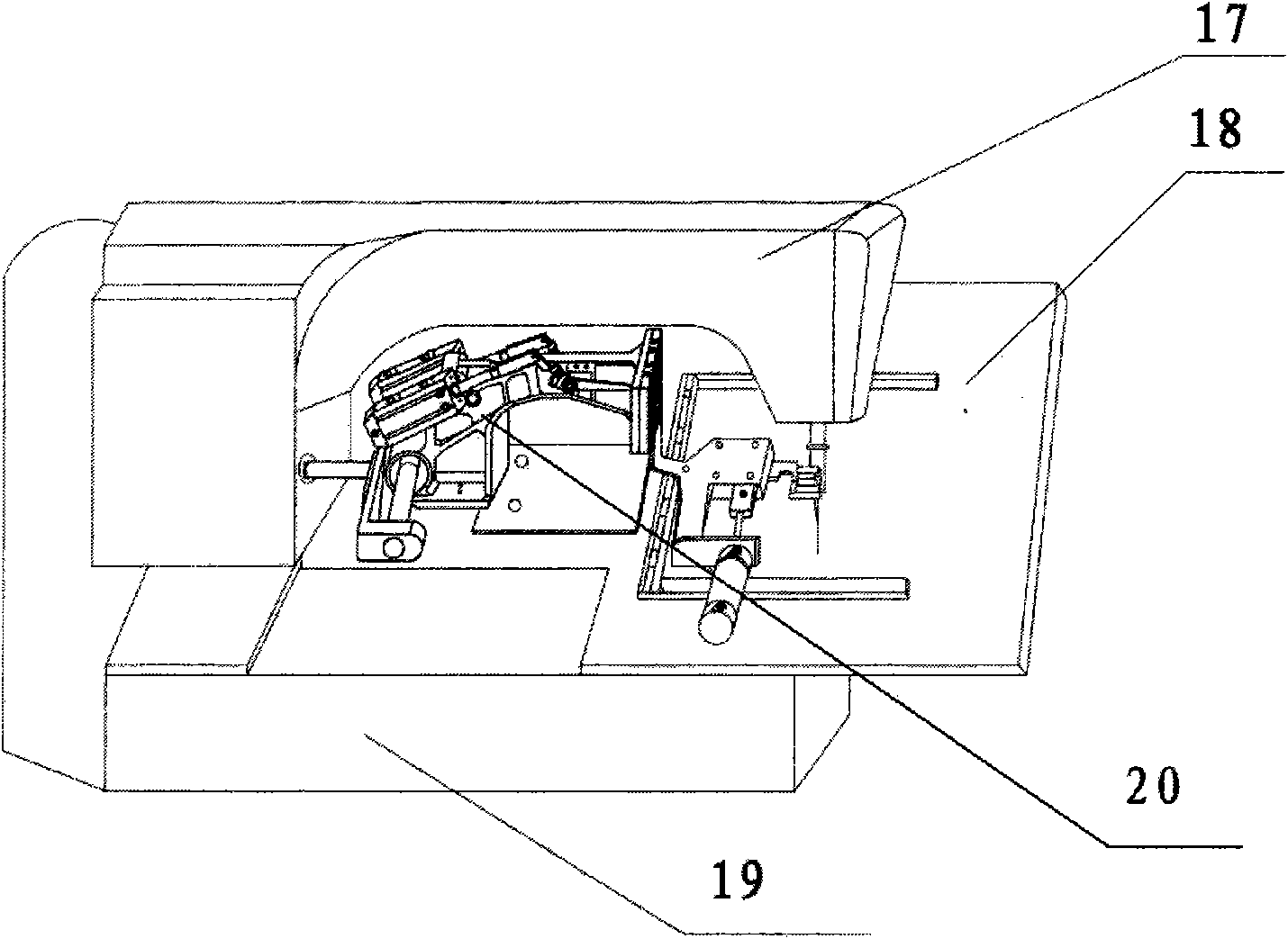

Computerized pattern forming machine based on visual control

ActiveCN104711785AFlexible and automatic adjustmentGuaranteed stitching qualityProgramme-controlled sewing machinesSewing-machine control devicesImaging processingData file

The invention discloses a computerized pattern forming machine based on visual control and relates to the field of industrial sewing machines. The computerized pattern forming machine comprises a machine tool main body (5), an operation panel (6), a pedal controller (7) and a control case (9) and also comprises a visual identification device, wherein the operation panel (6) can be used for inputting control parameters of sewing processing; the pedal controller (7) is used for starting the processing or stopping the processing; the control case (9) is used for image processing and system control; the visual identification device is used for taking photos for to-be-sewn cut pieces; the control case (9) is electrically connected with the operation panel (6), the machine tool main body (5) and the visual identification device so as to carry out image processing on images shot by the visual identification device and control the machine tool main body to carry out sewing by combining with the control parameters of sewing processing. The computerized pattern forming machine disclosed by the invention has the advantages that data files of the sewing paths corresponding to all the cut pieces can be generated, and the sewing can be automatically carried out according to the sewing paths, so that the problems that plates need to be manufactured and the sewing quality can not meet the requirement in the prior art can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel intelligent pneumatic automatic structure pattern machine

InactiveCN102337640AVersatileMovement is fast and smoothProgramme-controlled sewing machinesPressersDrive shaftGear wheel

The invention discloses a novel intelligent pneumatic automatic structure pattern machine, which is composed of a feeding frame, a sliding block, a presser foot lever piece, a presser foot arm, a presser foot connecting rod, a Y transmission shaft, an X-shaft bracket, a rolling-over cylinder, a rolling-over presser foot and the like. A servo motor controls an automatic line catcher mechanism flow to form a whole by a computer system control device; the automatic line catcher mechanism drives a connecting rod to brake a linkage movement lever; the linkage movement lever brakes a front-and-back sliding crank connected with the line catcher; the servo motor is connected with a main shaft by a coupler in which a helical gear is arranged; the presser foot is an X and Y-shaft bidirectional moving rolling-over presser foot structure; the X and Y-shaft bidirectional moving rolling-over presser foot structure brakes a cylinder sliding block guide rail moving kinematic pair by the computer system control device; the cylinder sliding block guide rail moving kinematic pair drives the presser foot connecting rod to transmit by the cylinder; and the presser foot connecting rod transmits to brake a rolling-over transmission gear. The novel intelligent pneumatic automatic structure pattern machine slides in a sliding rail mode and has few faults, and the function of the rolling-over presser foot is diversified.

Owner:麻佰林

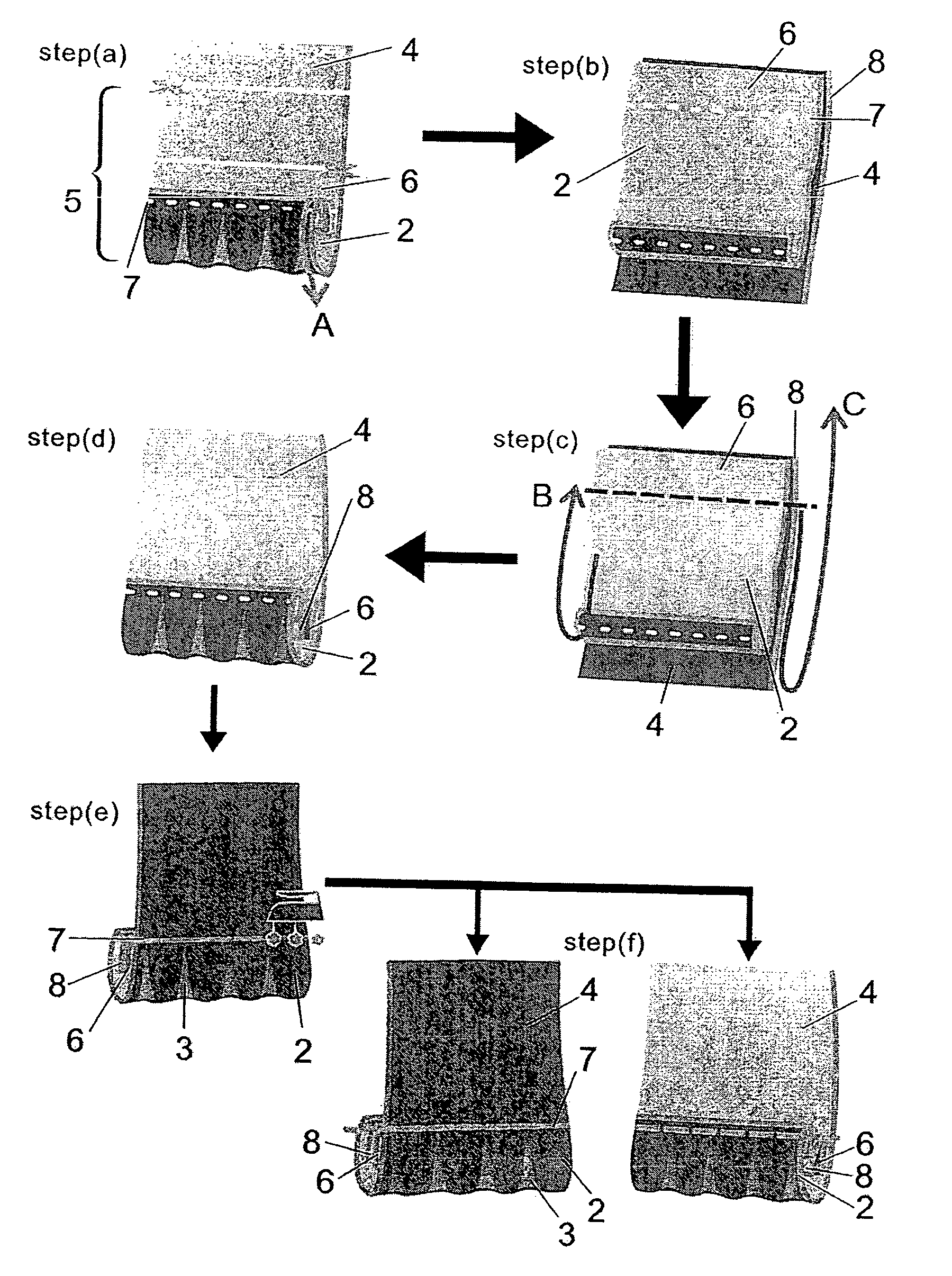

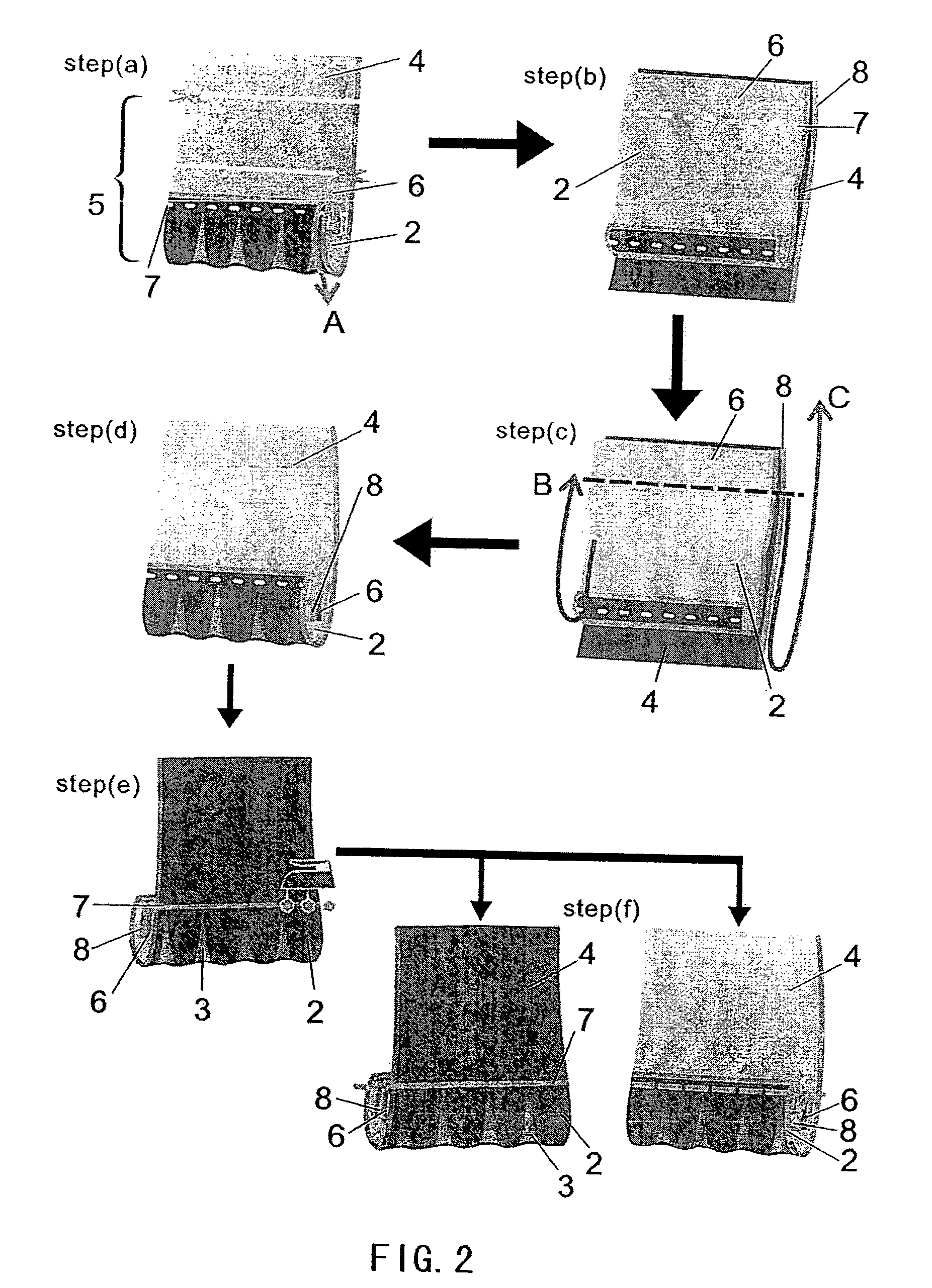

Hidden seam rehemming method for jeans

A hidden seam rehemming method for jeans, comprising steps as follows: (a) cutting down a part with desired length including the hem from the jean to be shortened, and cutting down the hem with a first seam allowance from the cut-down part; (b) taking out threads from the hem and unfolding the hem such that three rows of needle holes in the hem appear; (c) sewing the unfolded hem with a remaining part of the jean along the upmost row of needle holes in such way that the outside surface of the unfolded hem contacts the outside surface of the remaining part; (d). folding the first seam allowance of the hem and a second allowance of the remaining part toward the inside surface of the jean; (e). pressing the first and the second seam allowances with nail or iron such that the seam allowances lie against the inside surface of the jean; (f). folding the hem along original fold marks thereof such that the three rows of needle holes are superposed again and sewing it from the outside surface along the joint seam between the hem and the remaining part.

Owner:LEE KAM MING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com