Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about "Sewing stitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

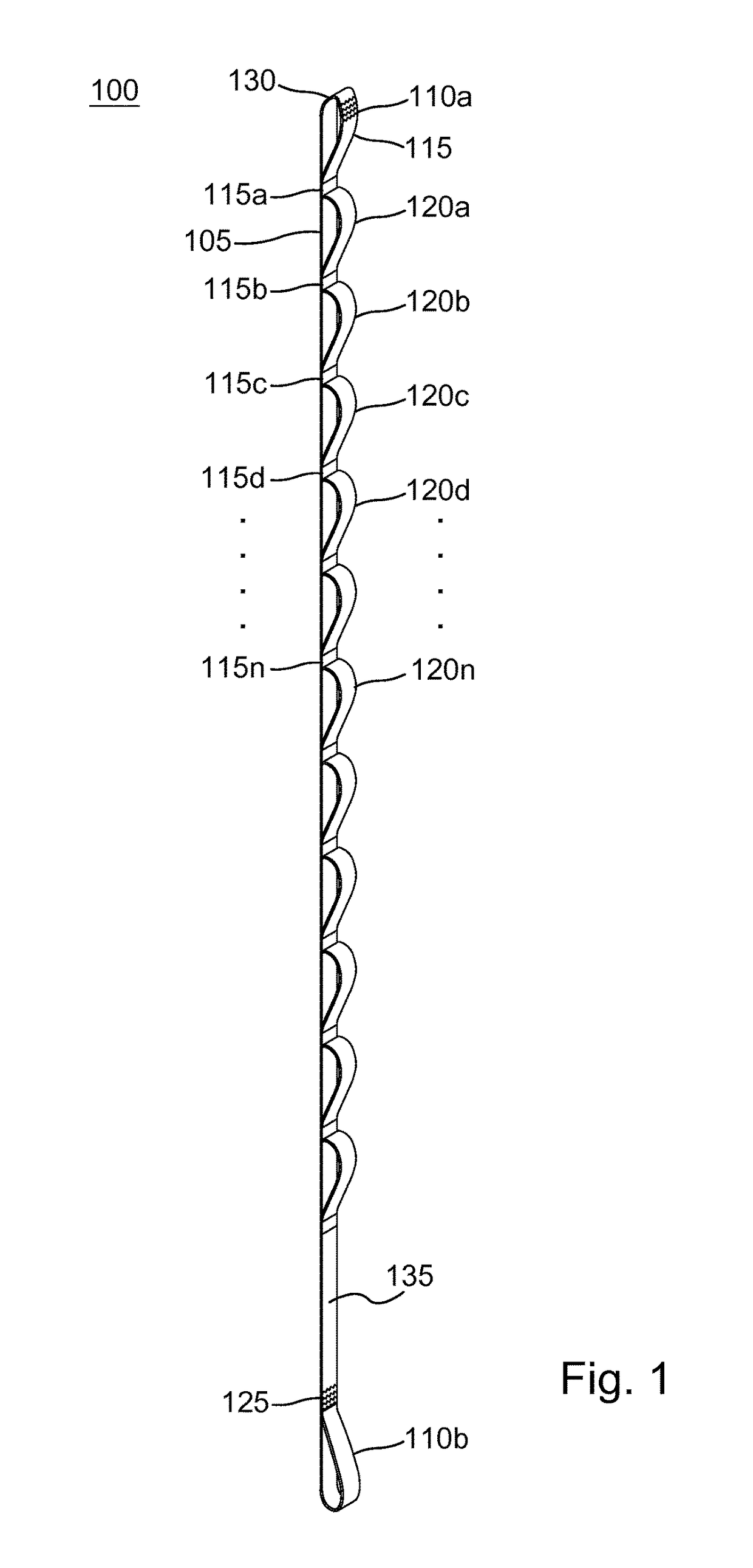

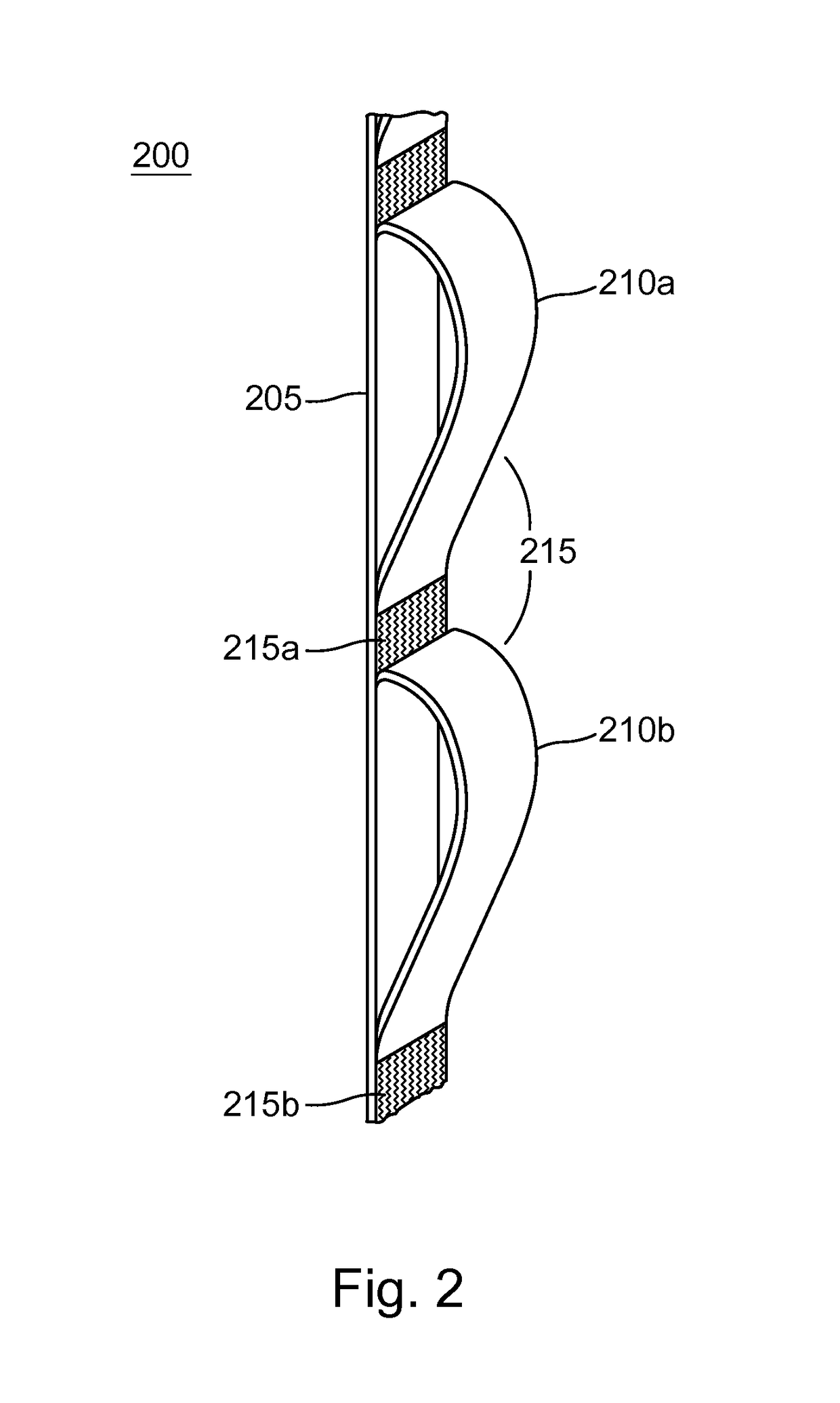

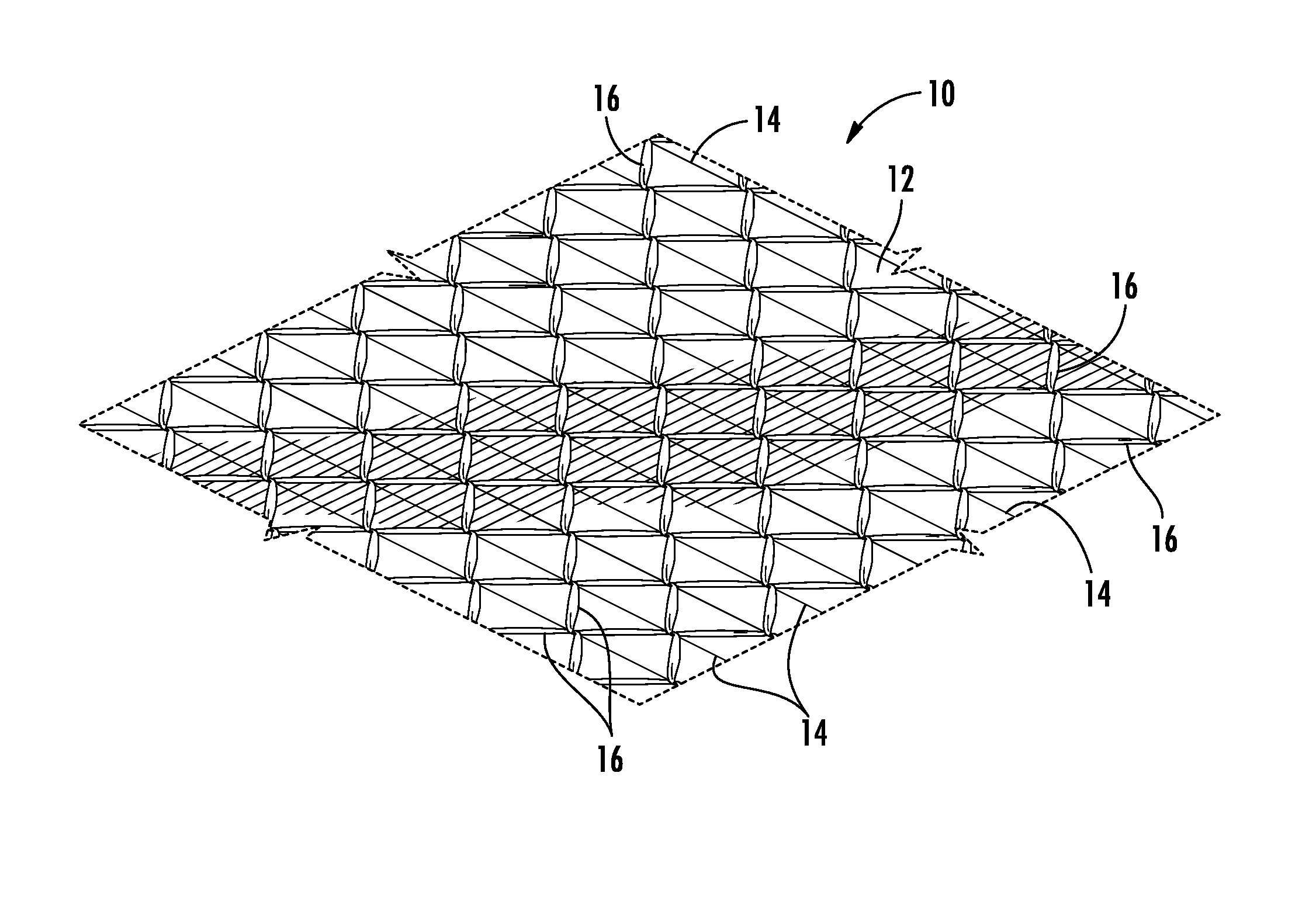

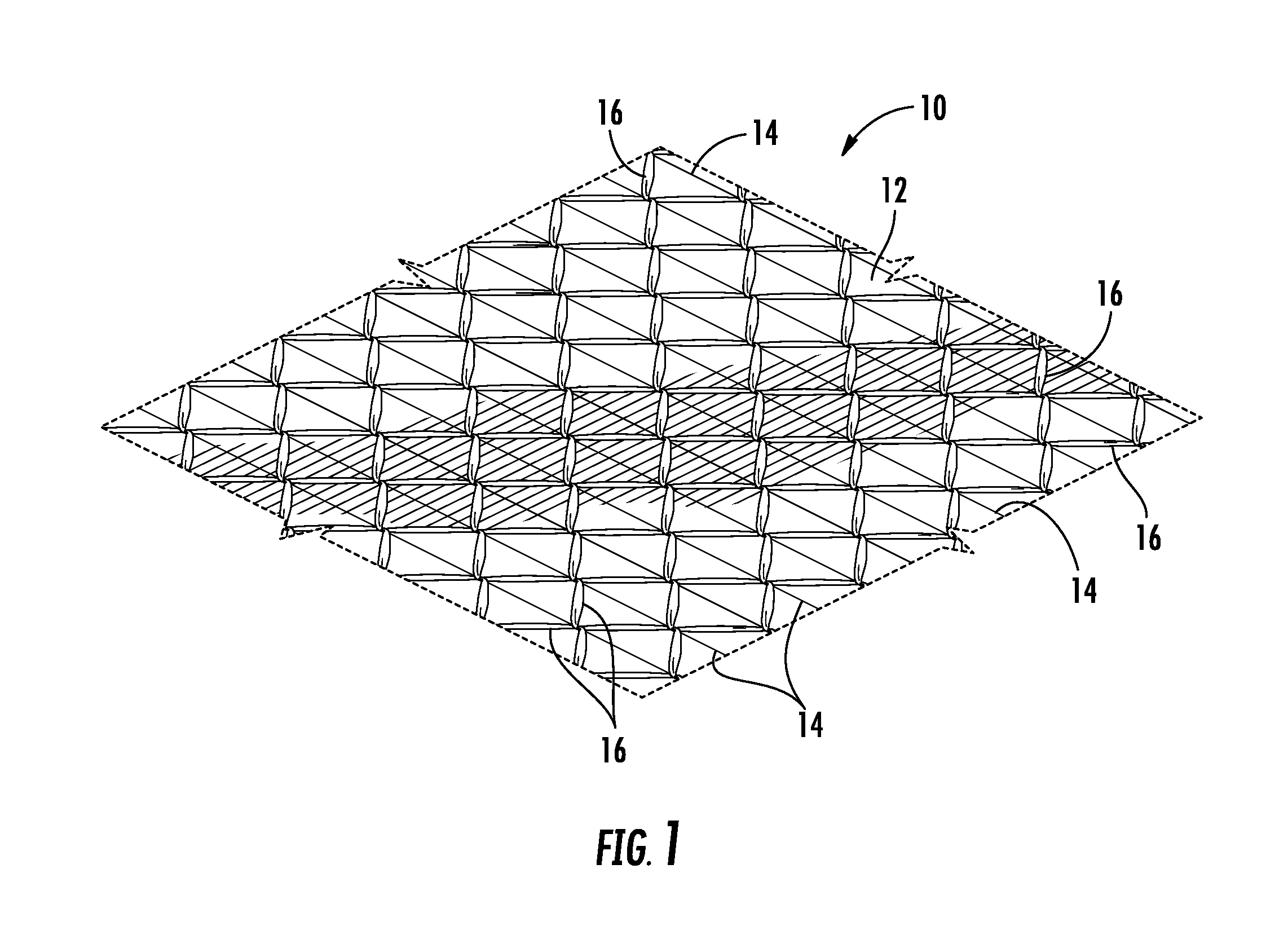

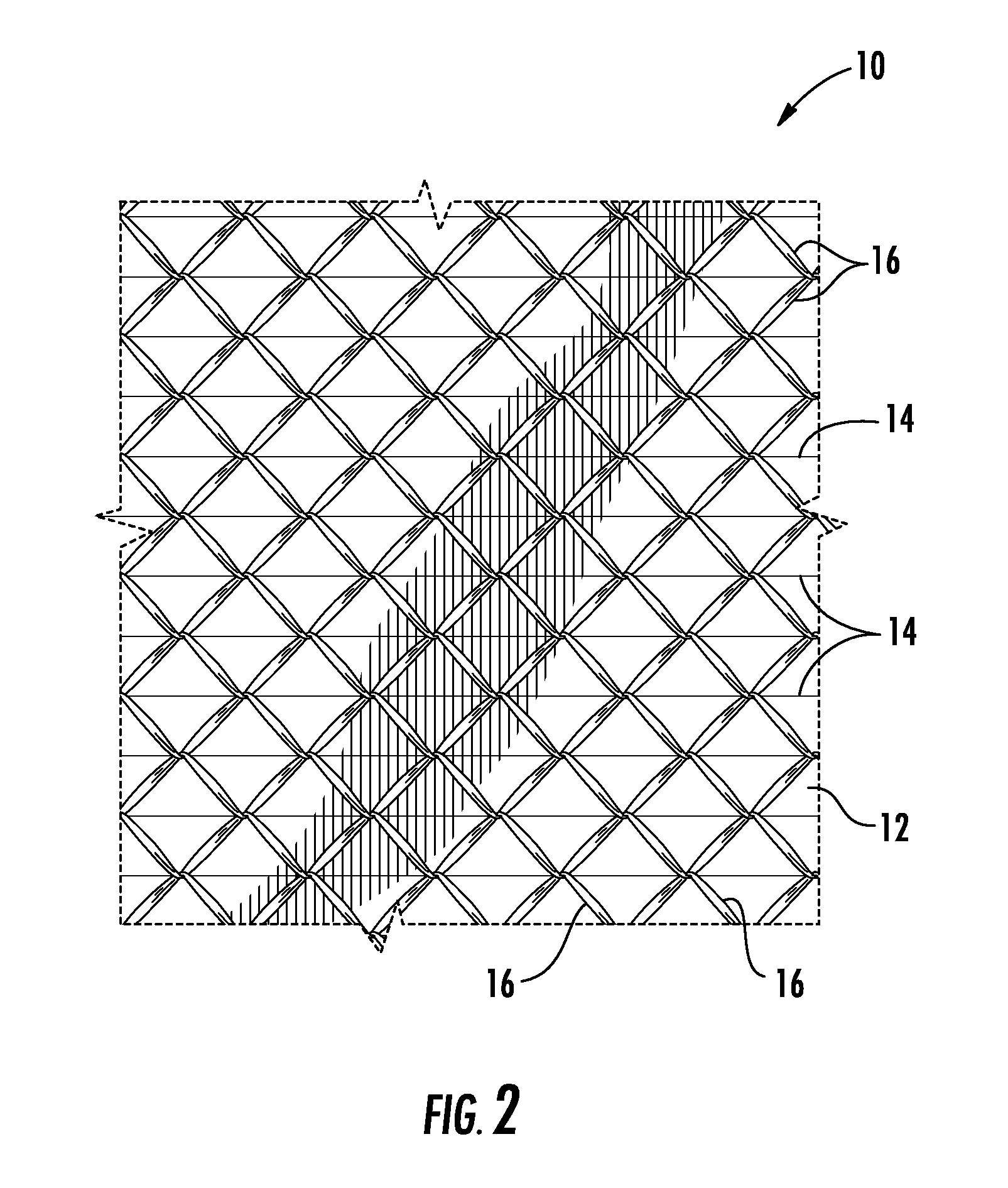

Using zigzags to create three-dimensional embroidered structures

InactiveUS7946236B2Good effectInternal osteosythesisLayered productsThree dimensional shapeEngineering

Owner:NUVASIVE

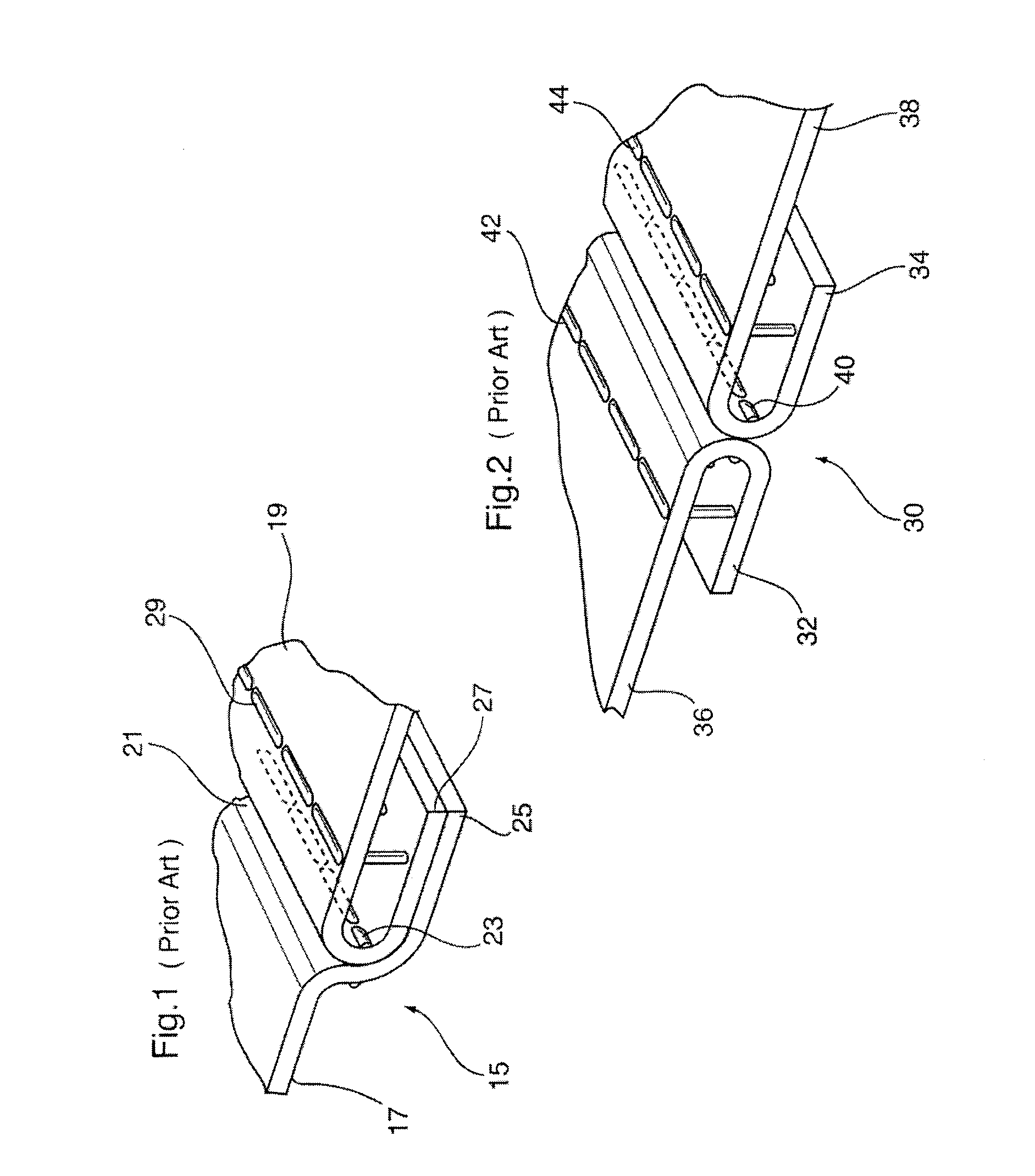

Method for stitching vehicle interior components and components formed from the method

A method of applying stitching to an interior component is provided herein. The method including the steps of: a) penetrating an outer skin layer, a substrate layer and an intermediary layer of the interior component with an awl to form a piercing therethrough; b) retracting the awl from the outer skin layer, the substrate layer and the intermediary layer; c) inserting a needle through the piercing through the substrate layer, the intermediary layer and the outer skin layer to grasp a thread positioned on the outer skin layer; d) pulling the thread through the outer skin layer, the intermediary layer and the substrate layer; e) looping the thread with a previous stitch passed through the outer skin layer, the intermediary layer and the substrate layer; f) advancing the interior component to another position; and g) repeating steps a-f until a predetermined amount of stitches are applied to the interior component.

Owner:INTEVA PRODUCTS LLC

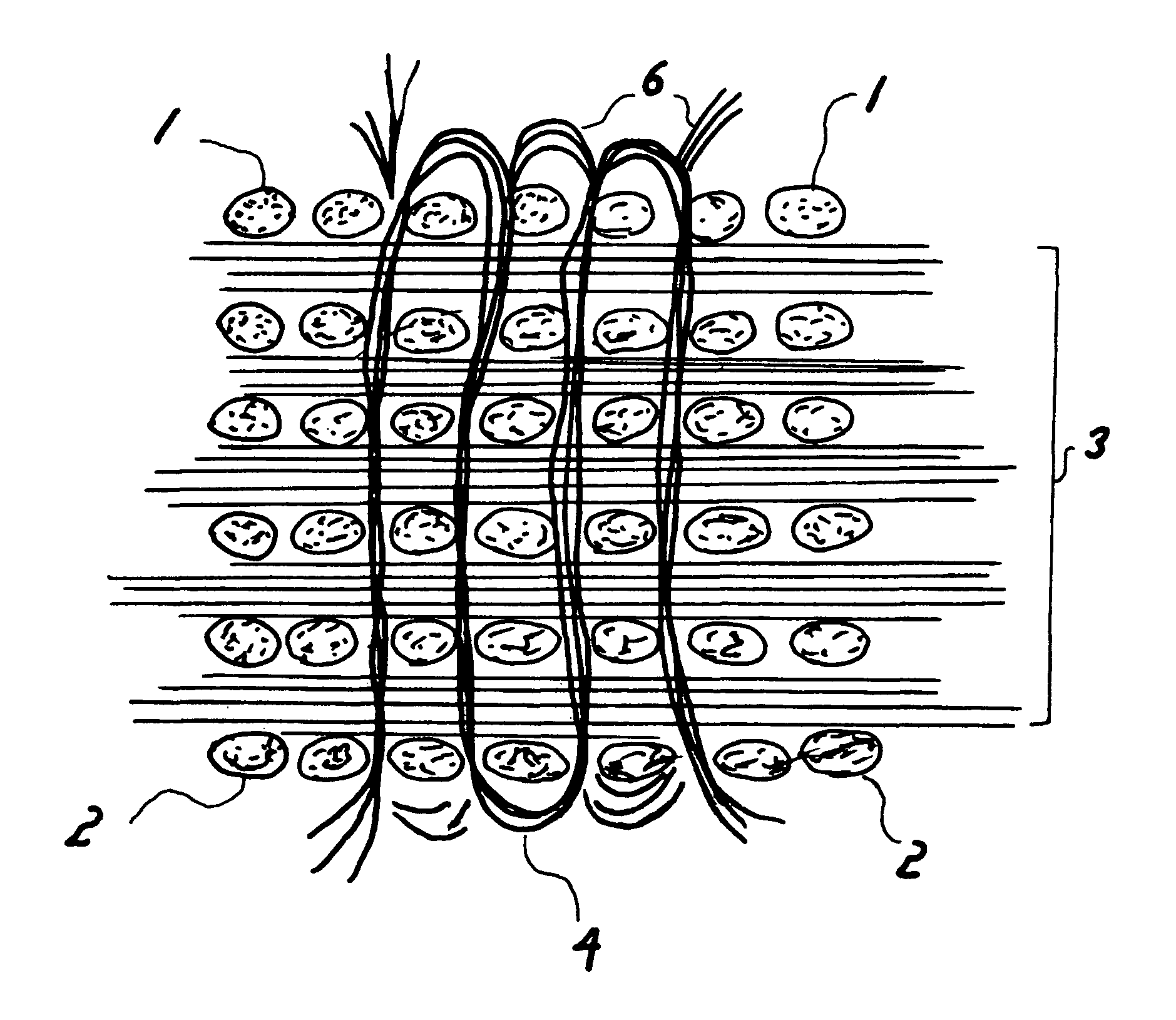

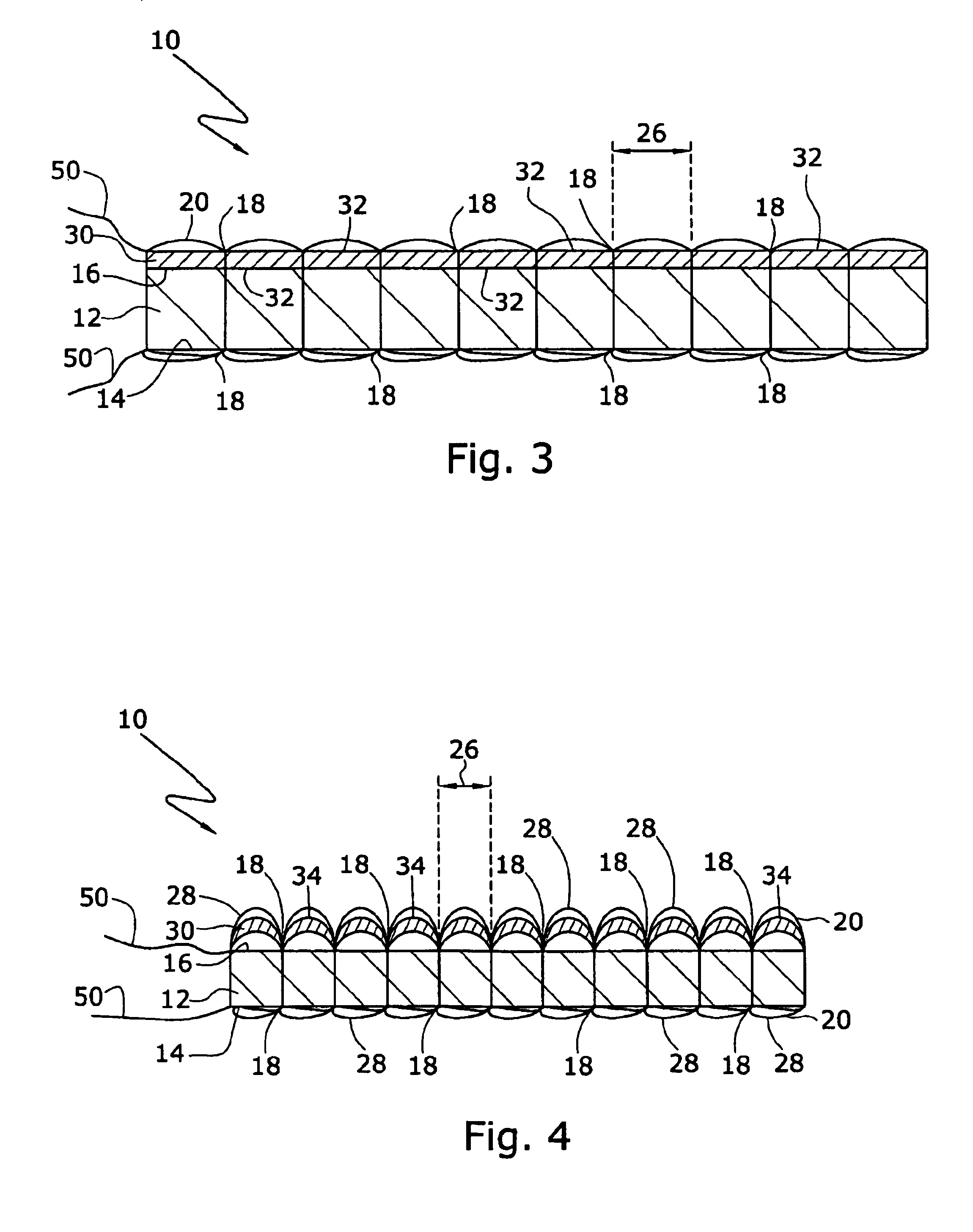

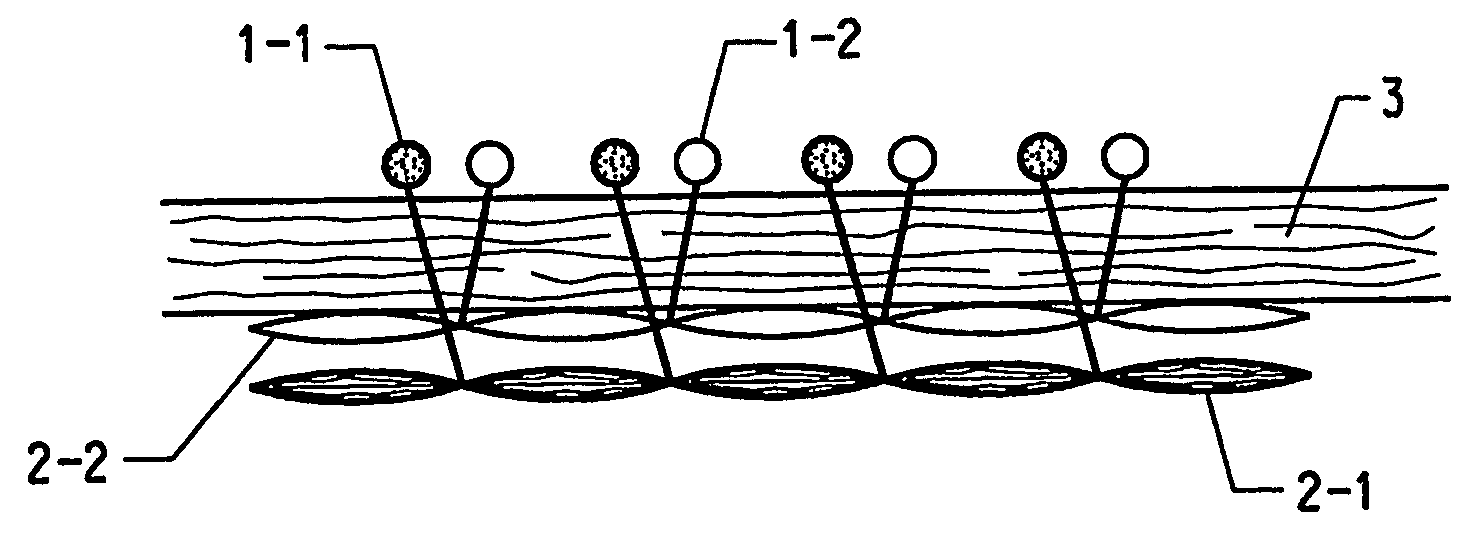

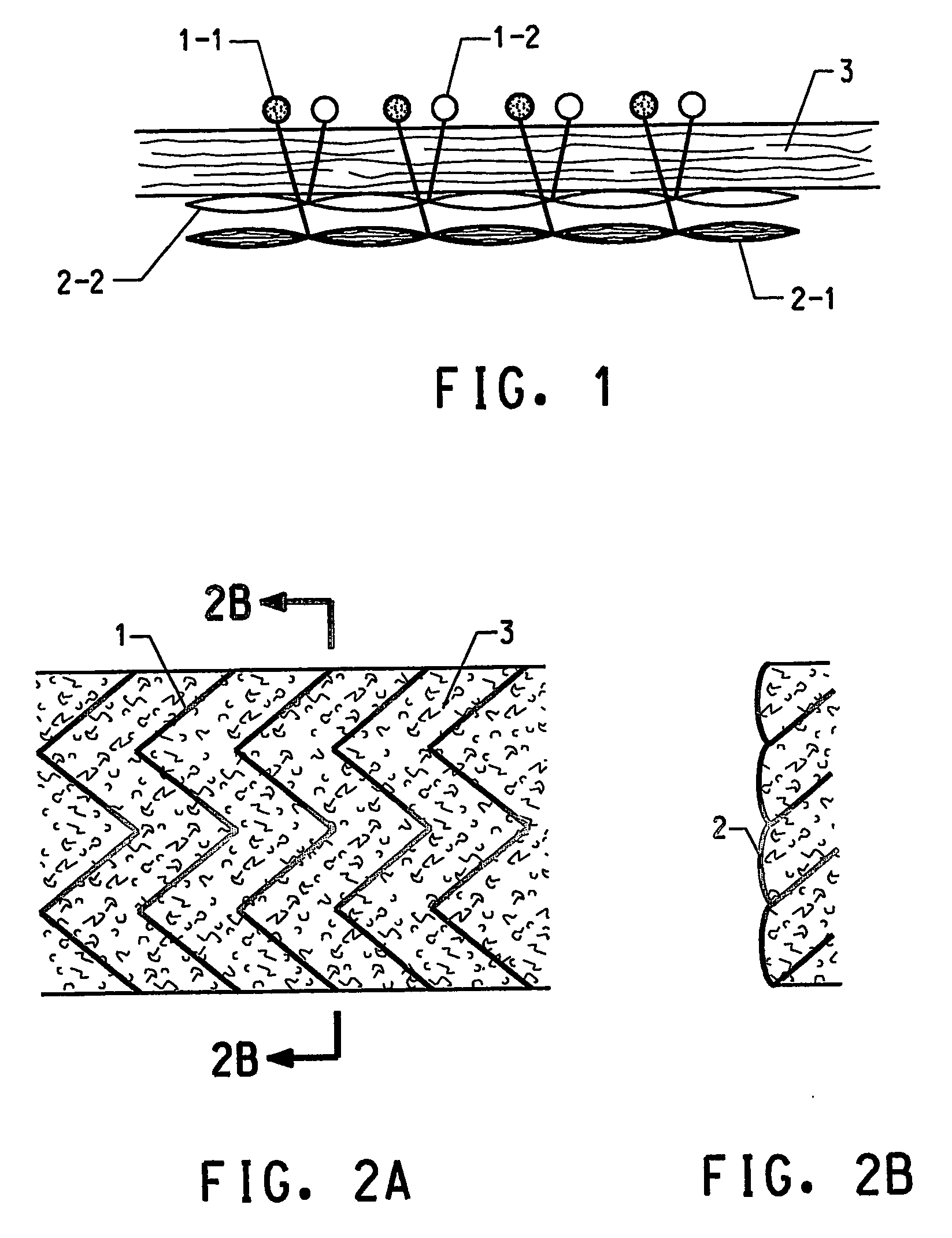

Inter/pre-cured layer/pre-cured embroidered composite laminate and method of producing same

InactiveUS8312827B1High strengthHigh peel strengthLeather sewingLayered productsMaterial typeFiber bundle

Methods of pre-cured (wet-out) composite lay up, are improved upon by embroidering, sewing, stitching, bundle-wrapping, tying, etc., substantially between layers and substantially normal, or in the “Z-direction” to the lay up with a wet or pre-cured fiber bundle or tow. The pre-cured tow is embroidered, etc. either in with a like, homogeneous wet to wet layering or a heterogeneous non-similar layering, between double or multiple layers. Heterogeneous examples include differing material types among layers, laying and embroidering in objects or voids, as well as wet-laminating / sewing in with an already-dry (set / cured) layer.

Owner:FREE JAMES J

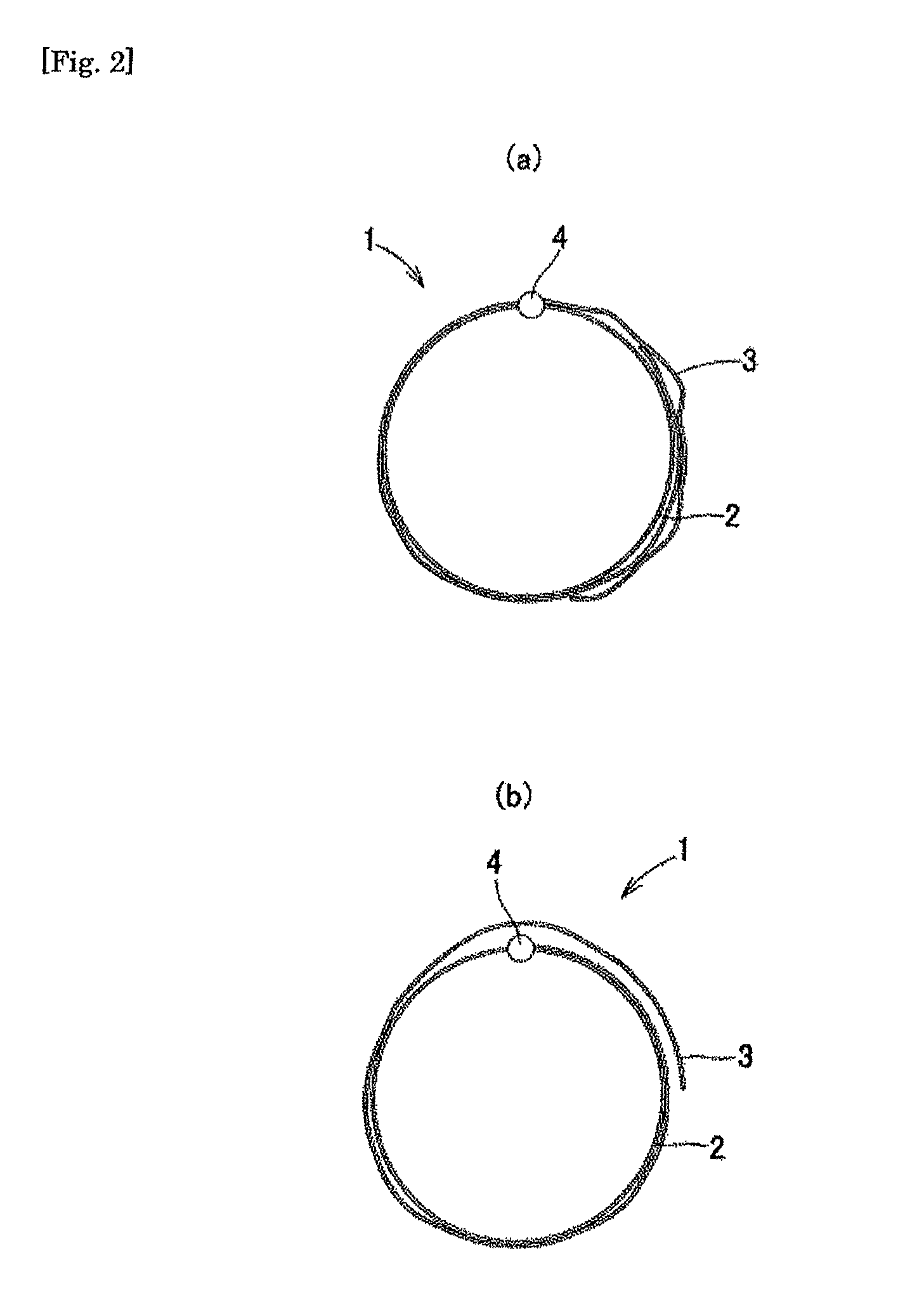

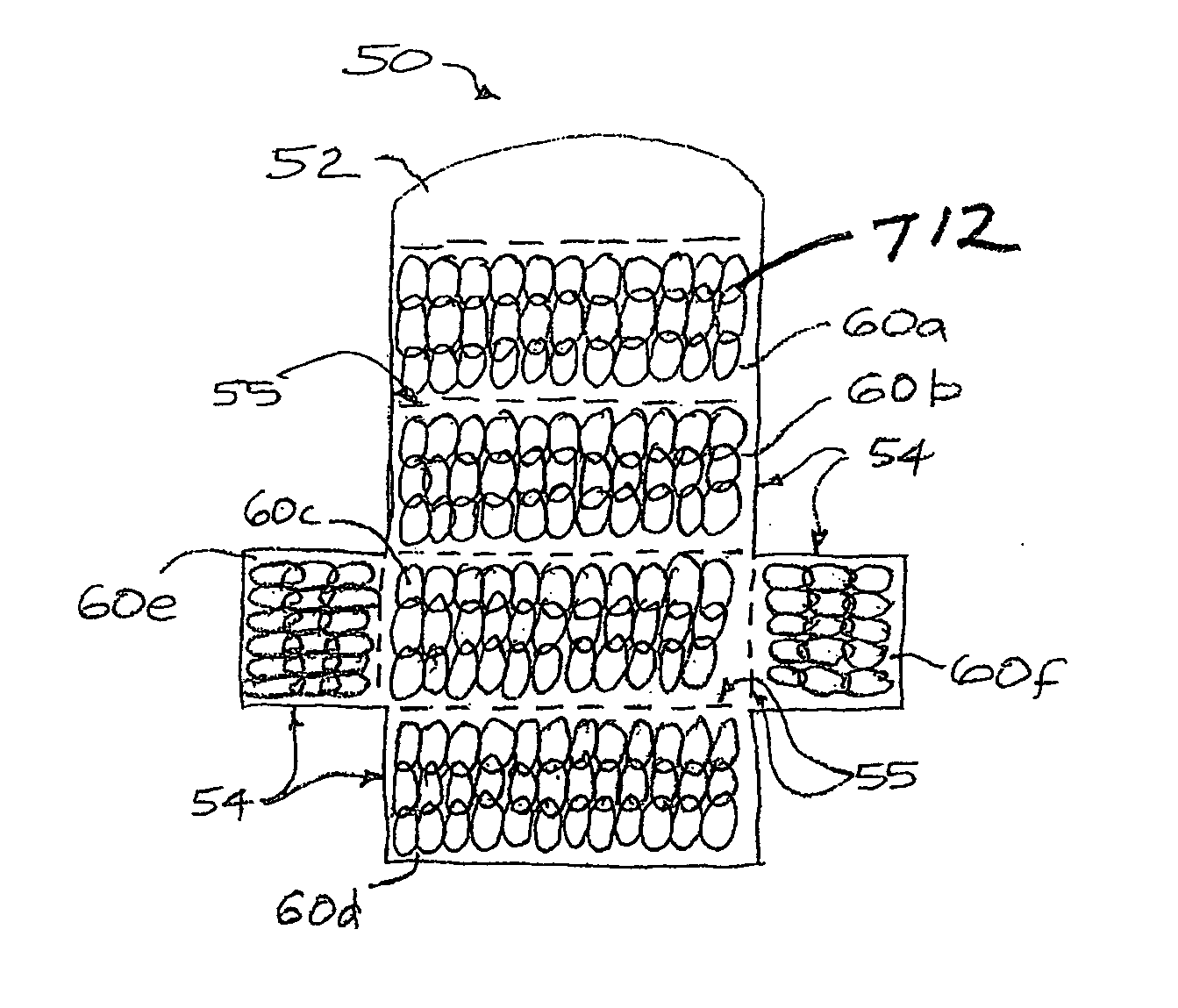

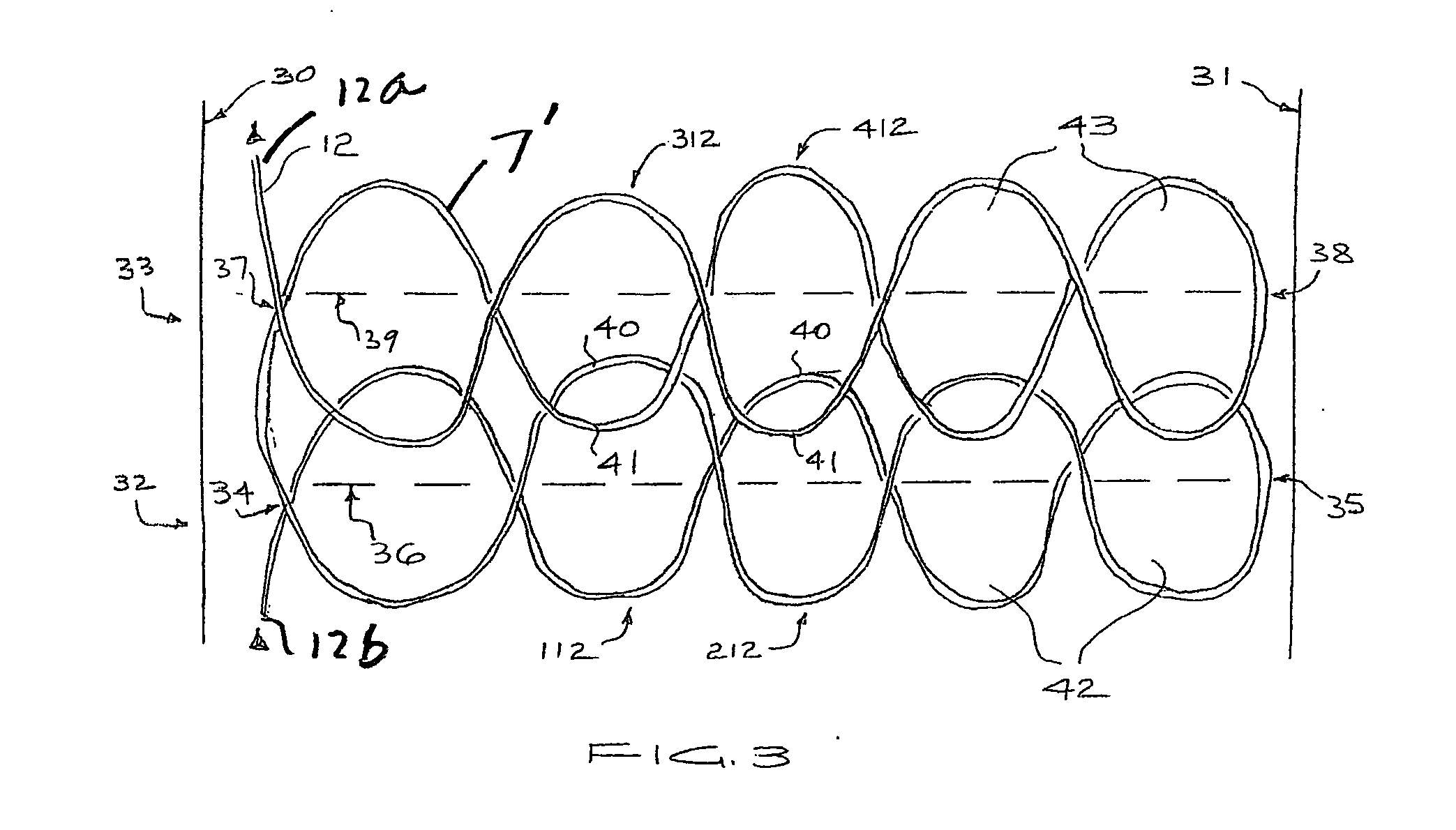

Medical device for body cavity and method of producing the same

InactiveUS20090326640A1Decreased blood flowFlow assuranceStentsLeather sewingMedical deviceDelivery system

A medical device for body cavity which has a main stent body and a sheet-shaped member having an opening and covering at least a part of the main stent body as described above. It is desirable that, when the main stent body is dilated from the first diameter in the compressed state to the second diameter, the above-described sheet-shaped member spreads so as to cover at least a part of the main stent body without restricting the movement of the main stent body toward the circumferential direction while the shape of the opening of the above-described sheet-shaped member is retained even after the dilation of the main stent body. The above-described medical device for body cavity is applied to a delivery system which has a first catheter for transporting the medical device for body cavity into the body. In this delivery system, the above-described medical device for body cavity is located at the front end of the first catheter as described above so as to allow indwelling thereof.

Owner:GIFU UNIVERSITY +1

Method for stitching vehicle interior components and components formed from the method

Owner:INTEVA PRODUCTS LLC

Sewn cover assembly and product foamed therewith

A sewn cover assembly of a type that is to undergo a foaming process involving injection and curing of a liquid foaming material therein. The cover assembly is formed by sewing together plural cover elements via two different sewing threads, using a sewing machine, so as to completely close and seal the needle holes formed therein against leakage of the liquid foaming material through the needle holes. Namely, one of the two threads used is large in thickness relative to another of them, thereby serving as a leakage preventive member in addition to being a sewing thread. A foamed product is also disclosed, which is formed by injecting and curing a liquid foaming material in such sewn cover assembly.

Owner:TACHI S CO LTD

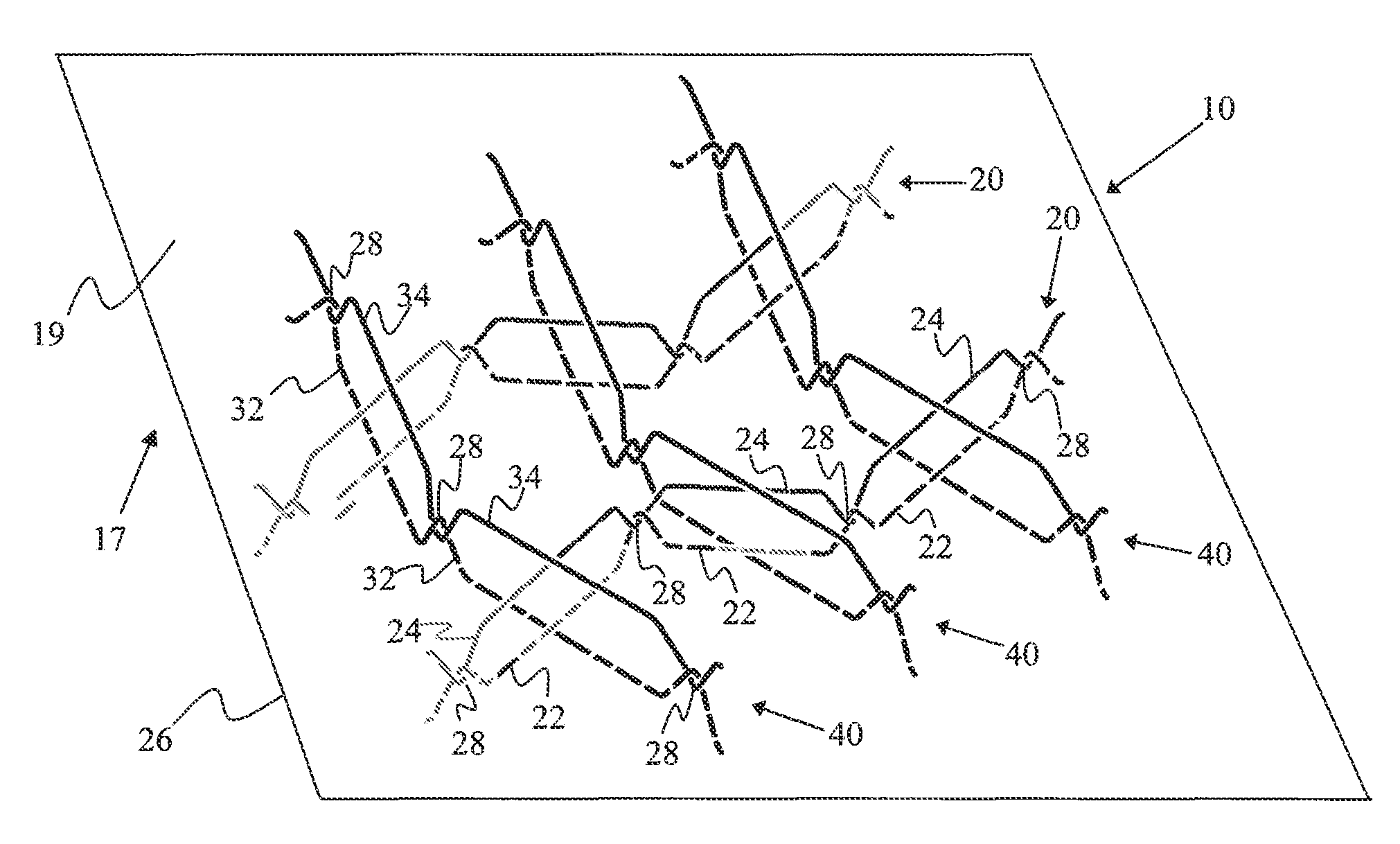

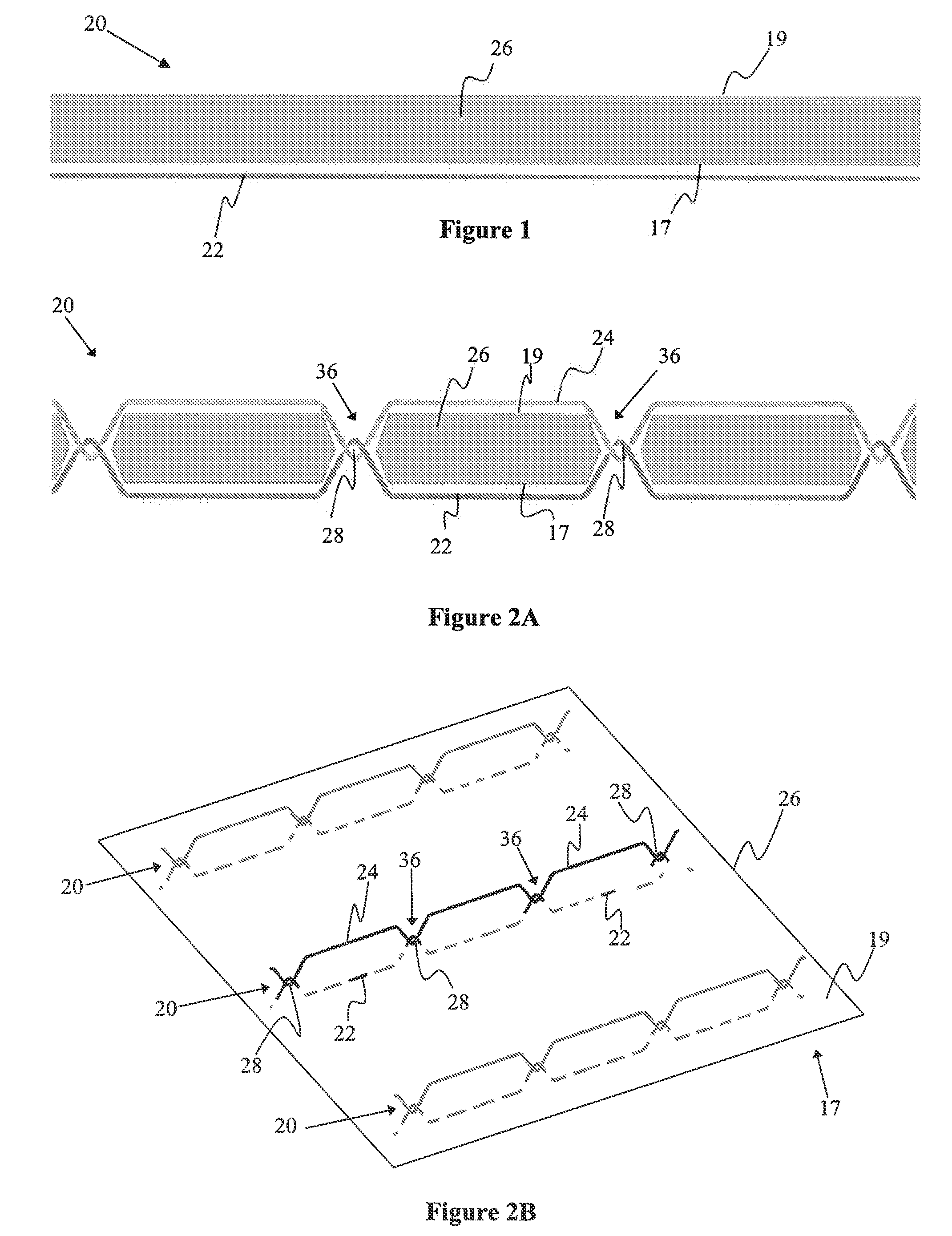

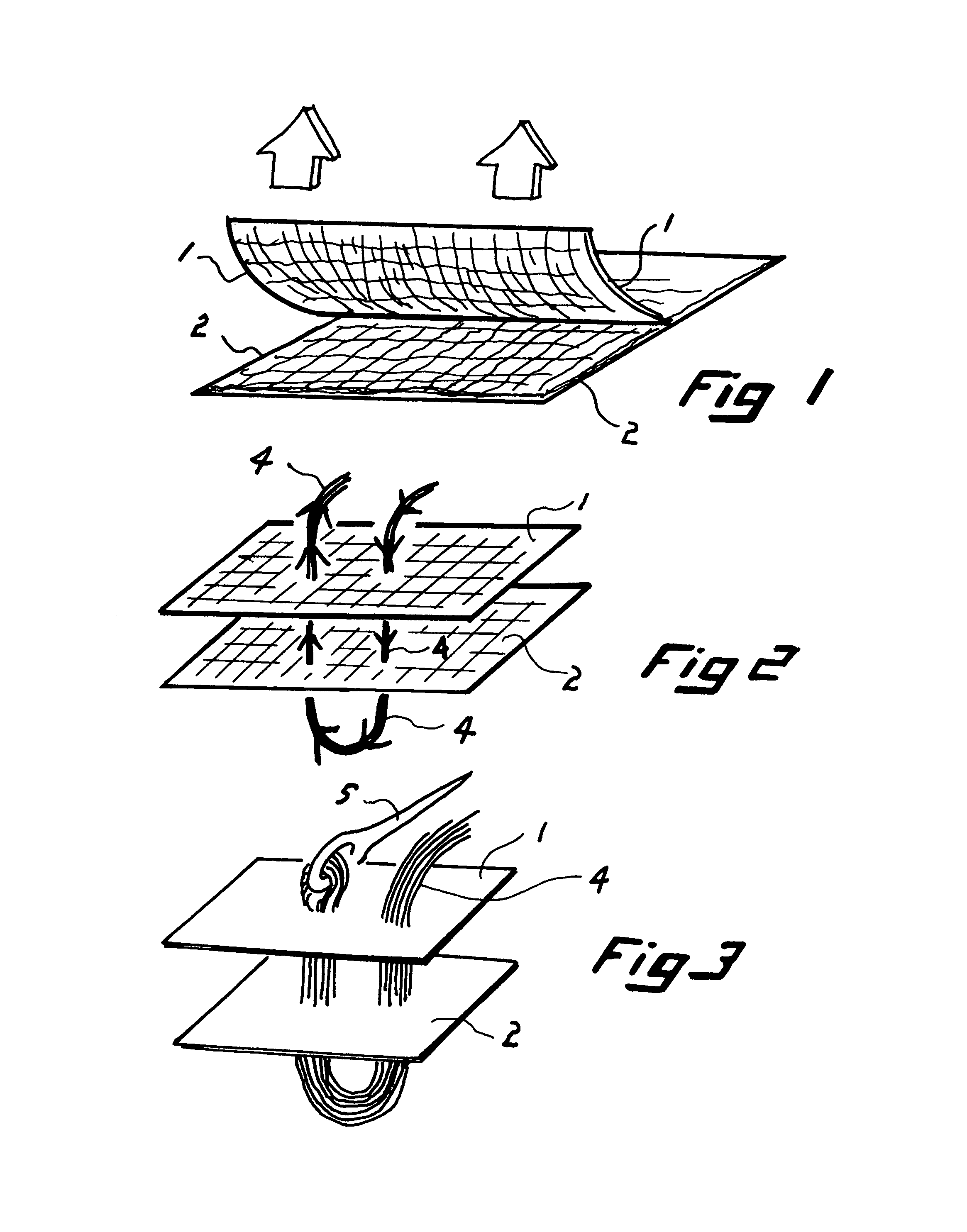

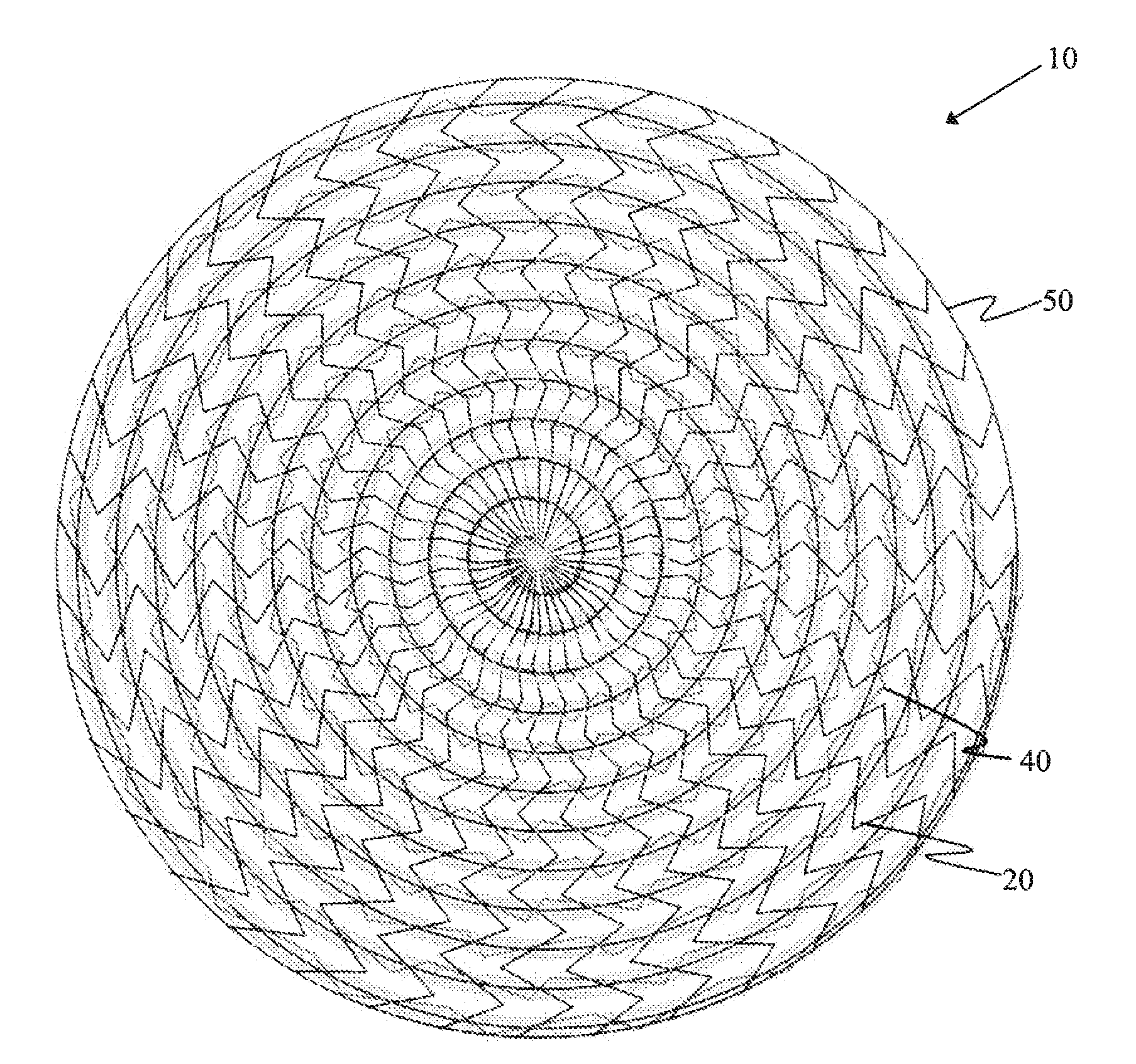

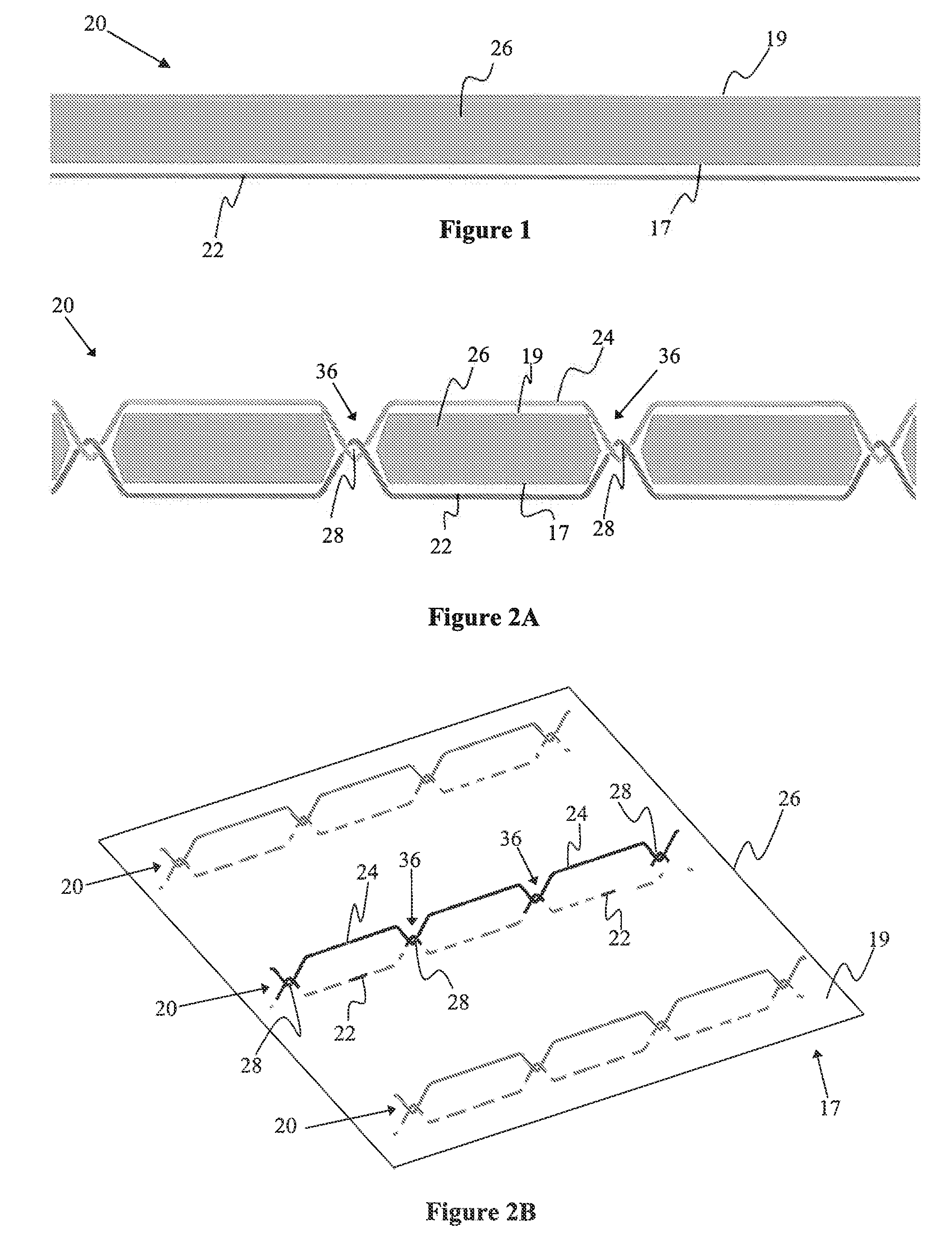

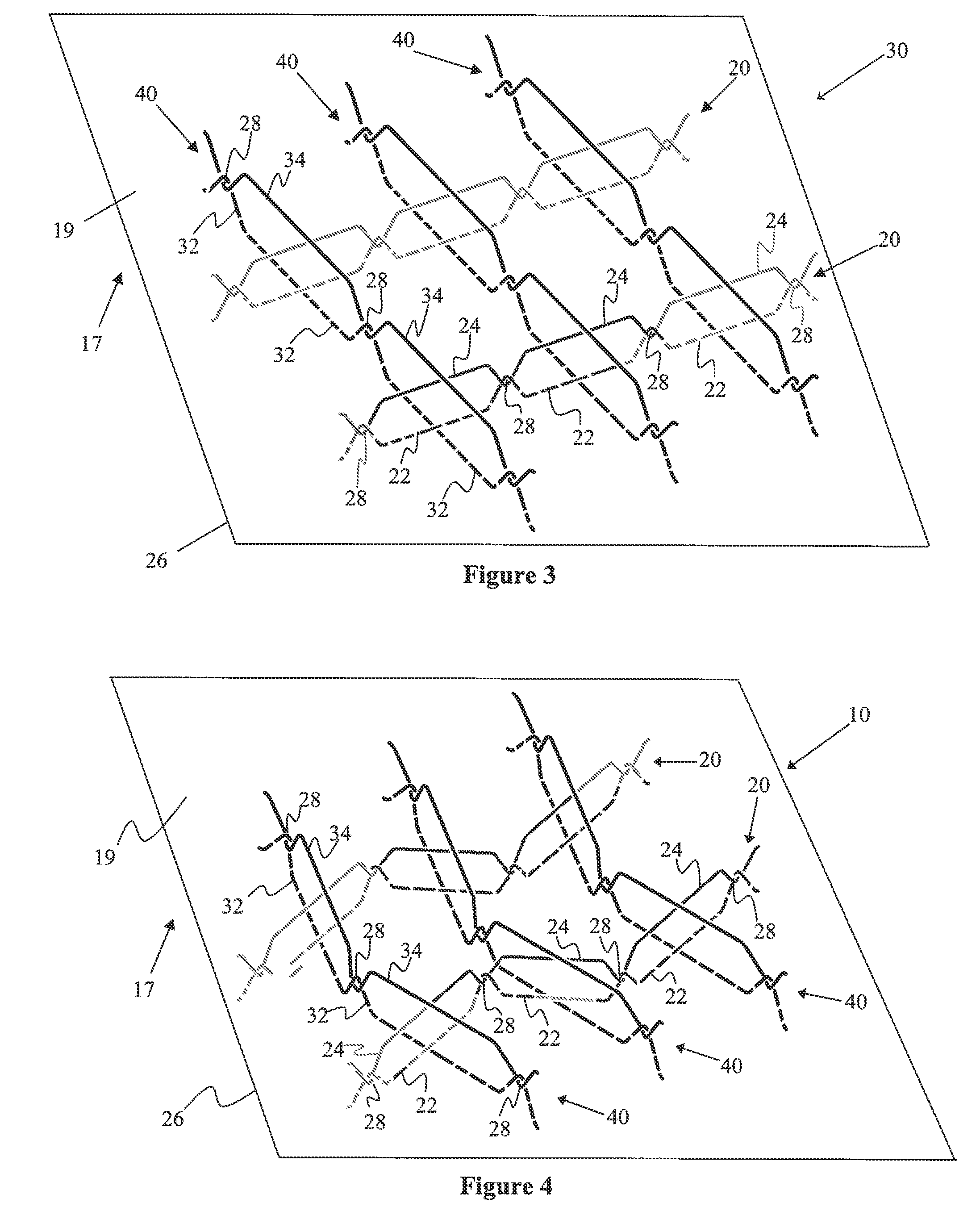

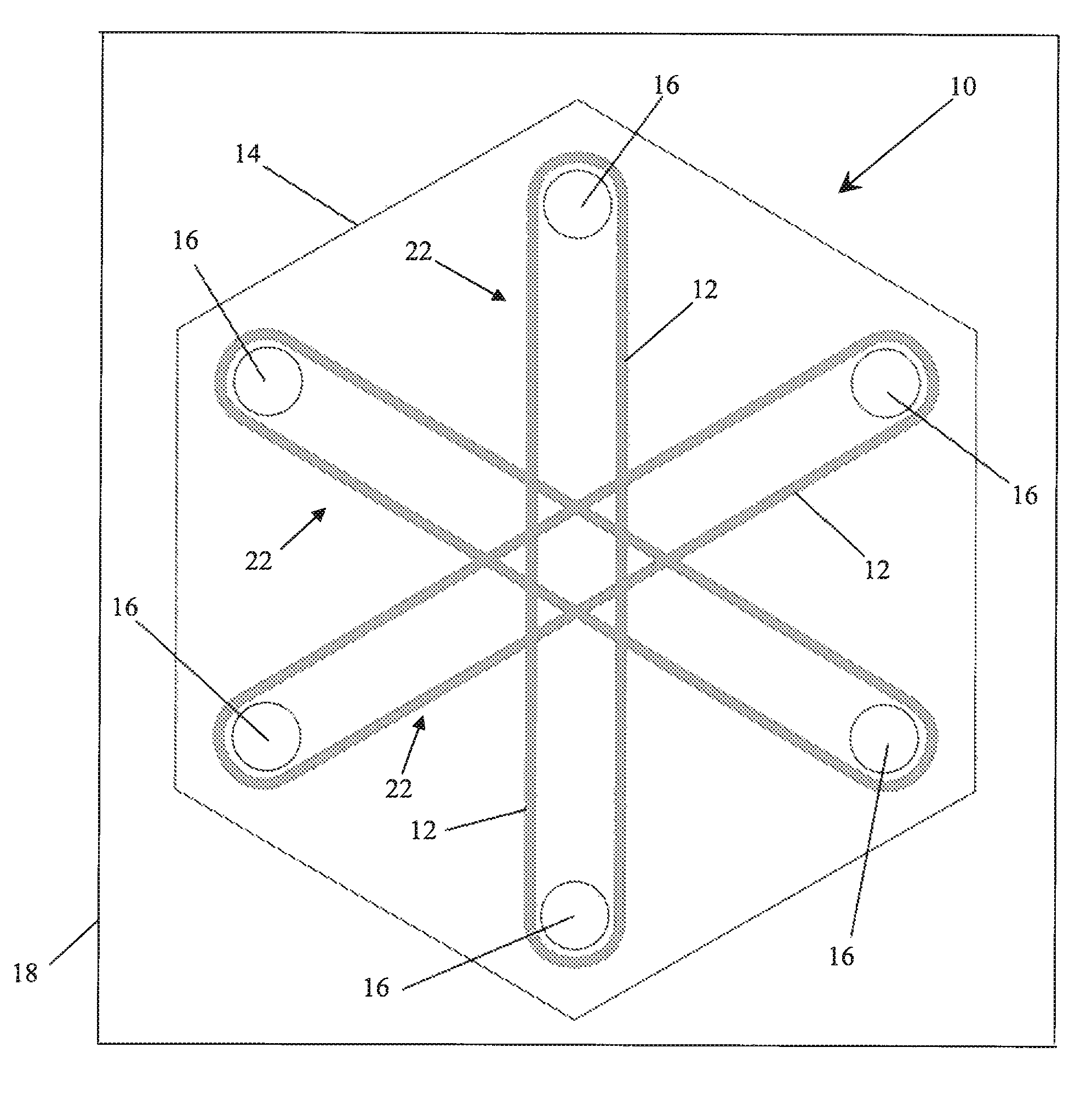

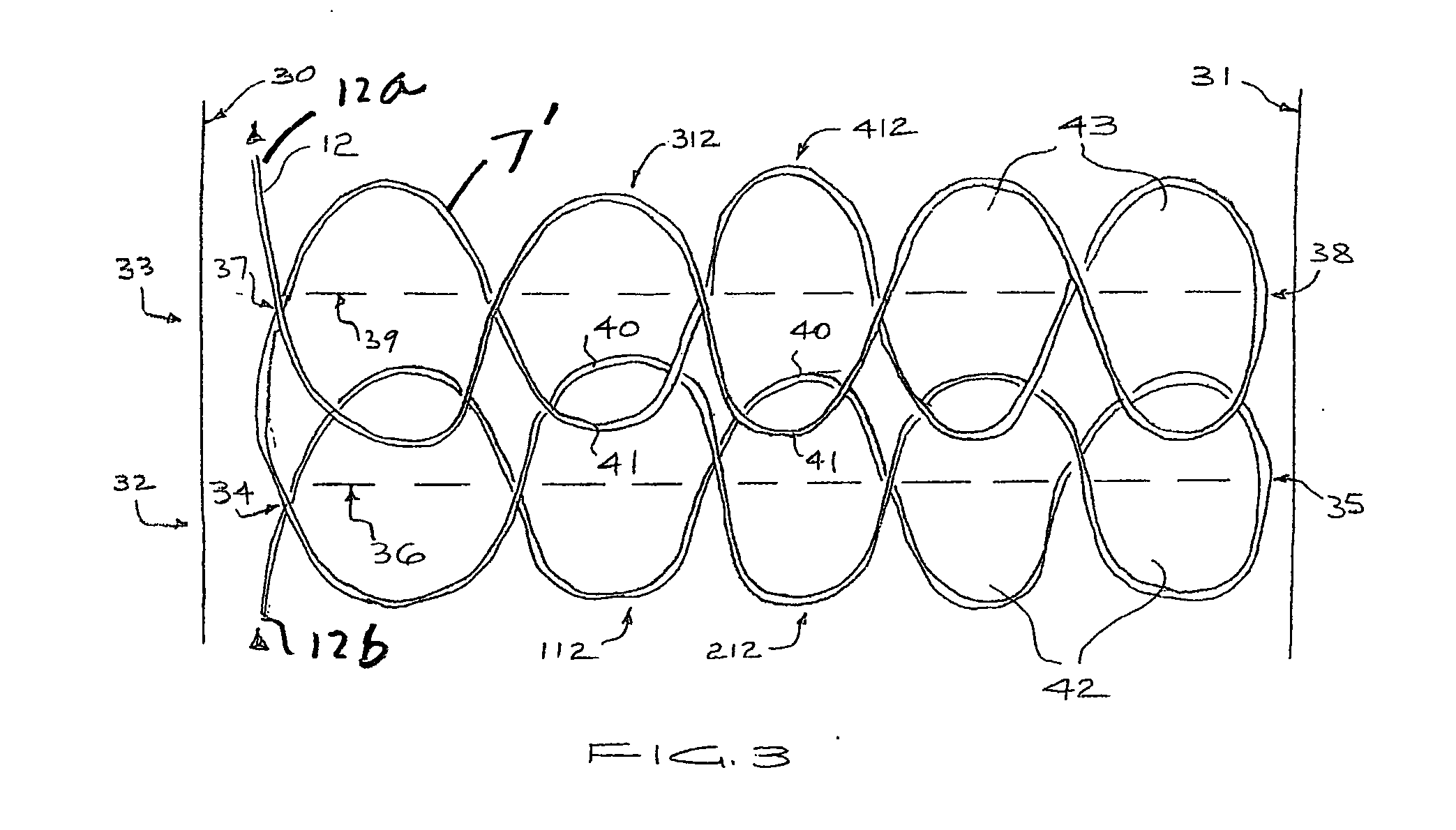

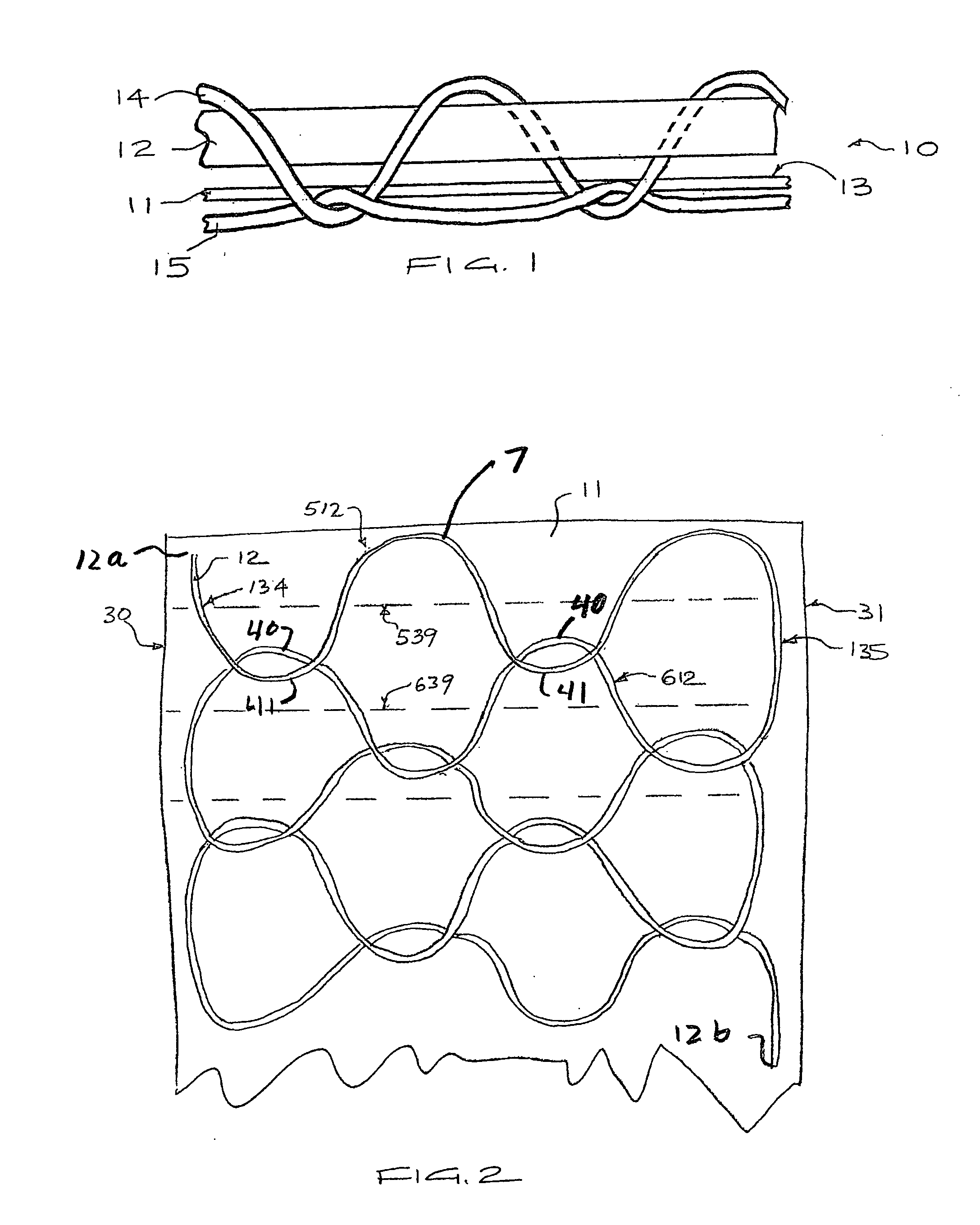

Using zigzags to create three-dimensional embroidered structures

InactiveUS20080178786A1Good effectInternal osteosythesisLayered productsEngineeringThree dimensional shape

Owner:NUVASIVE

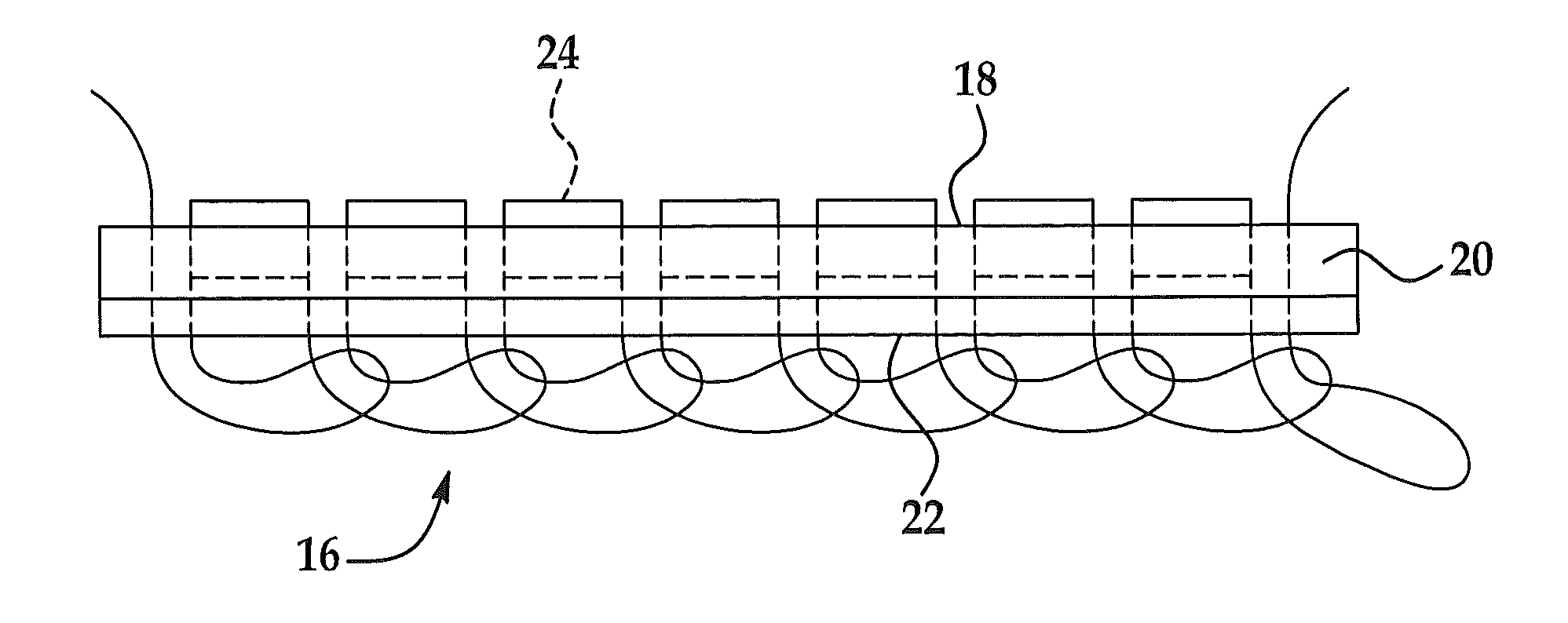

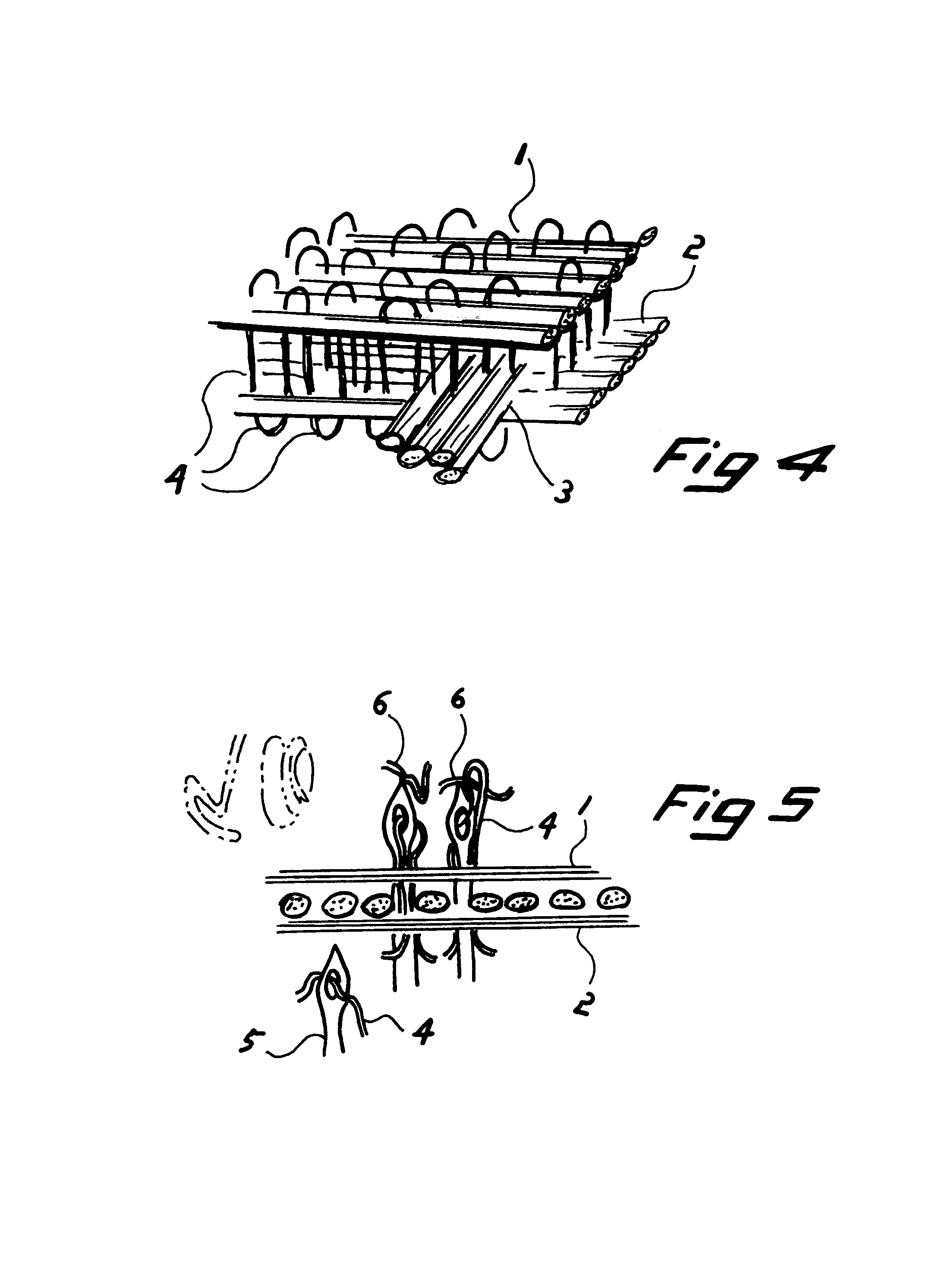

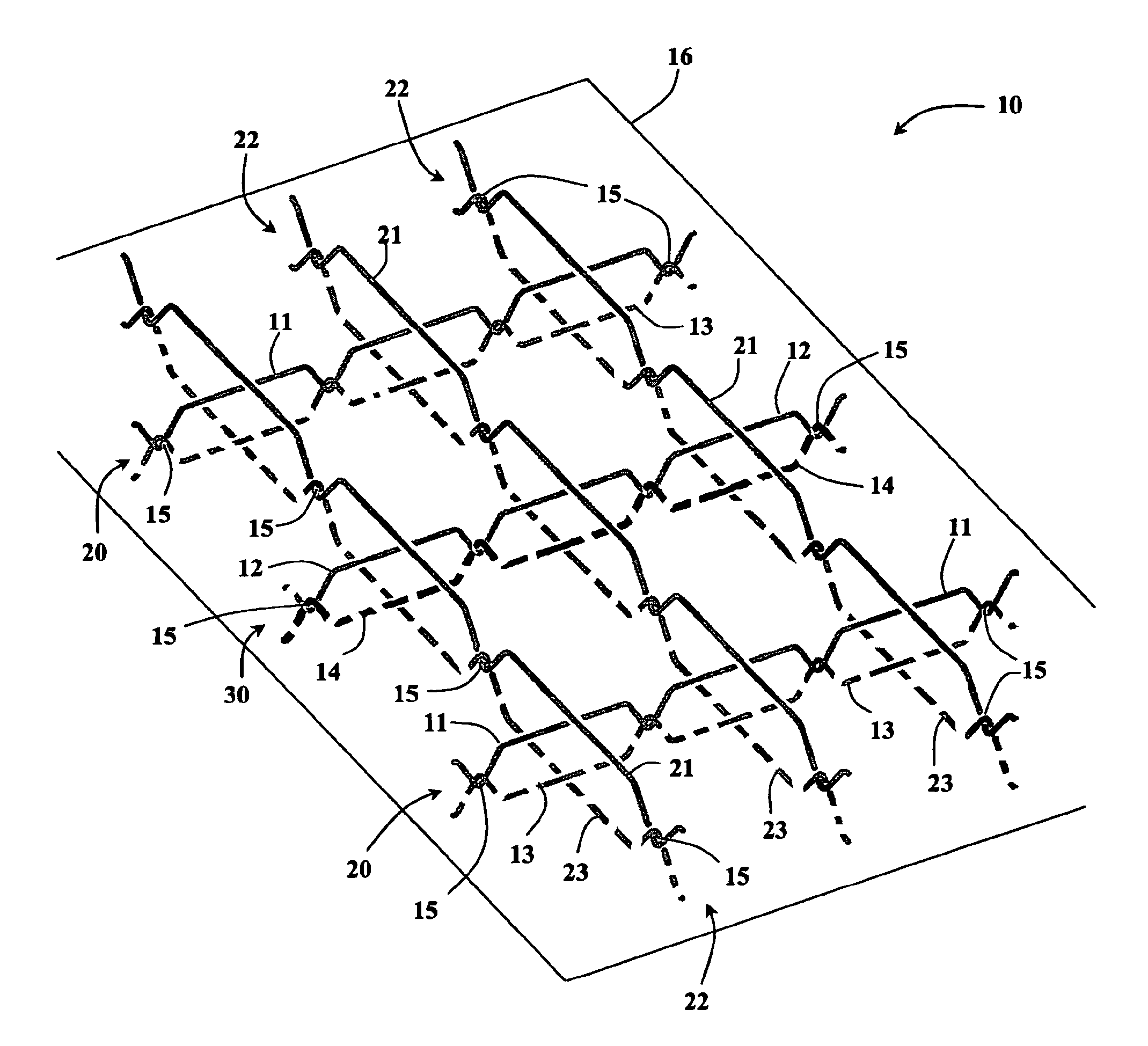

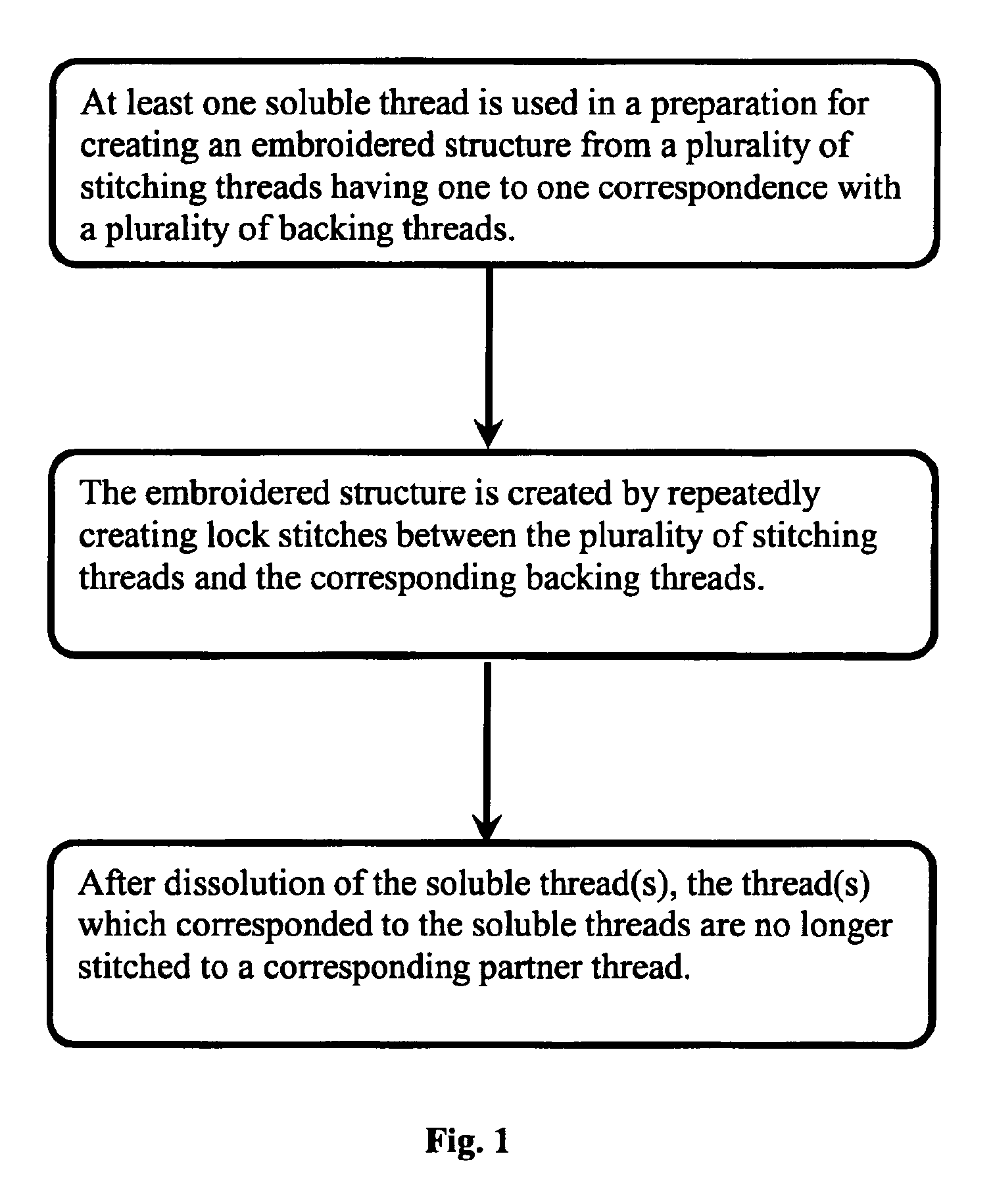

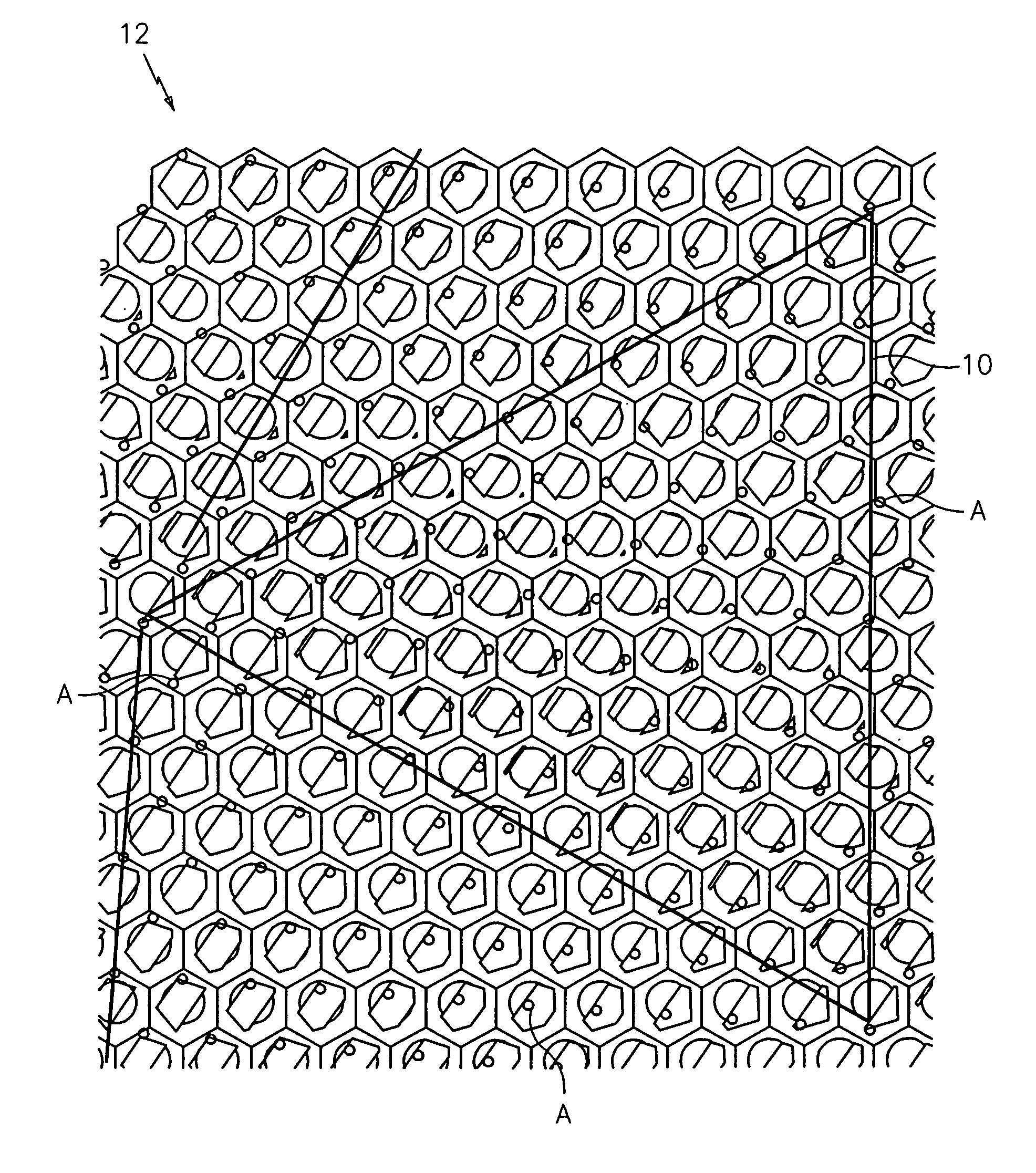

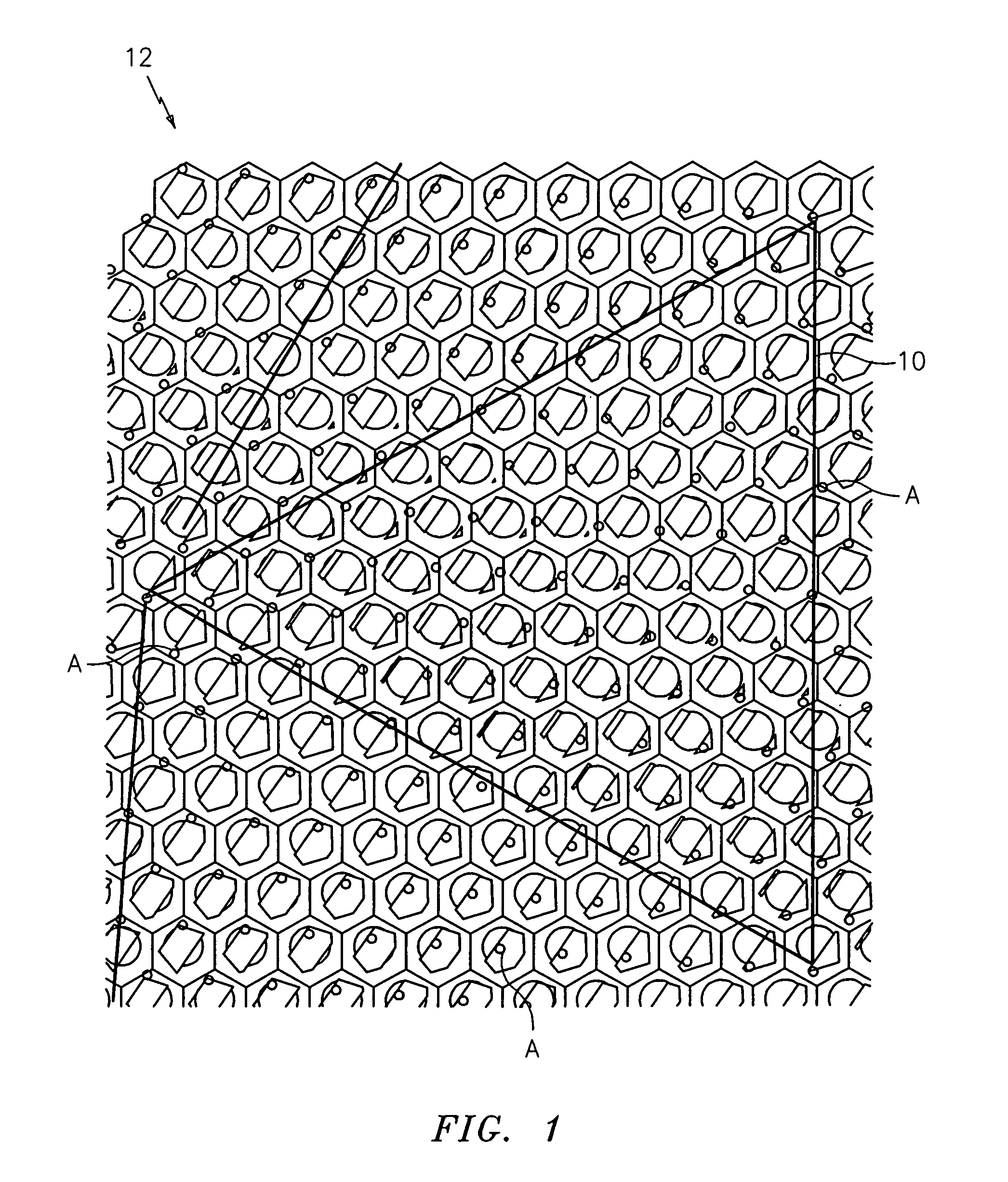

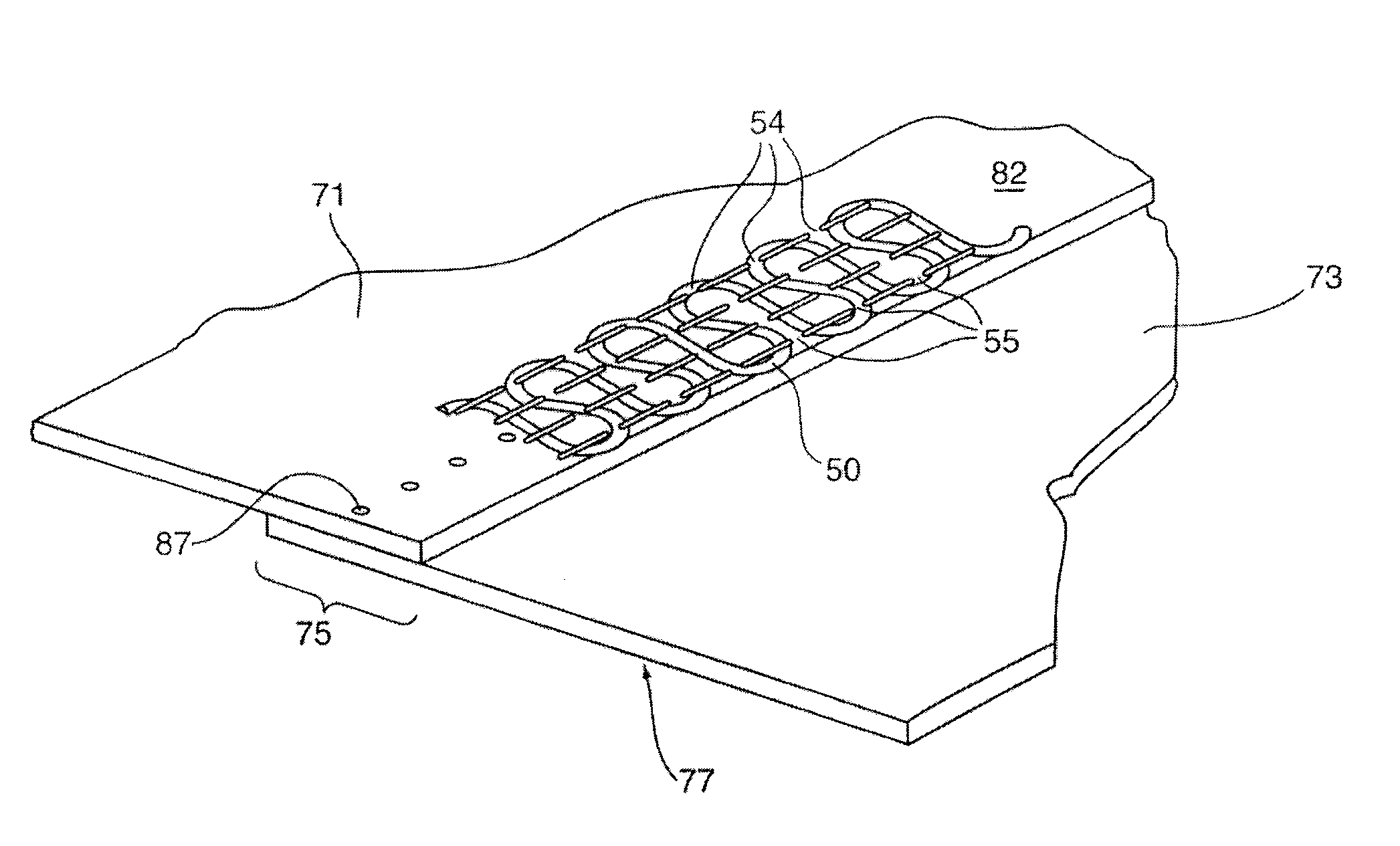

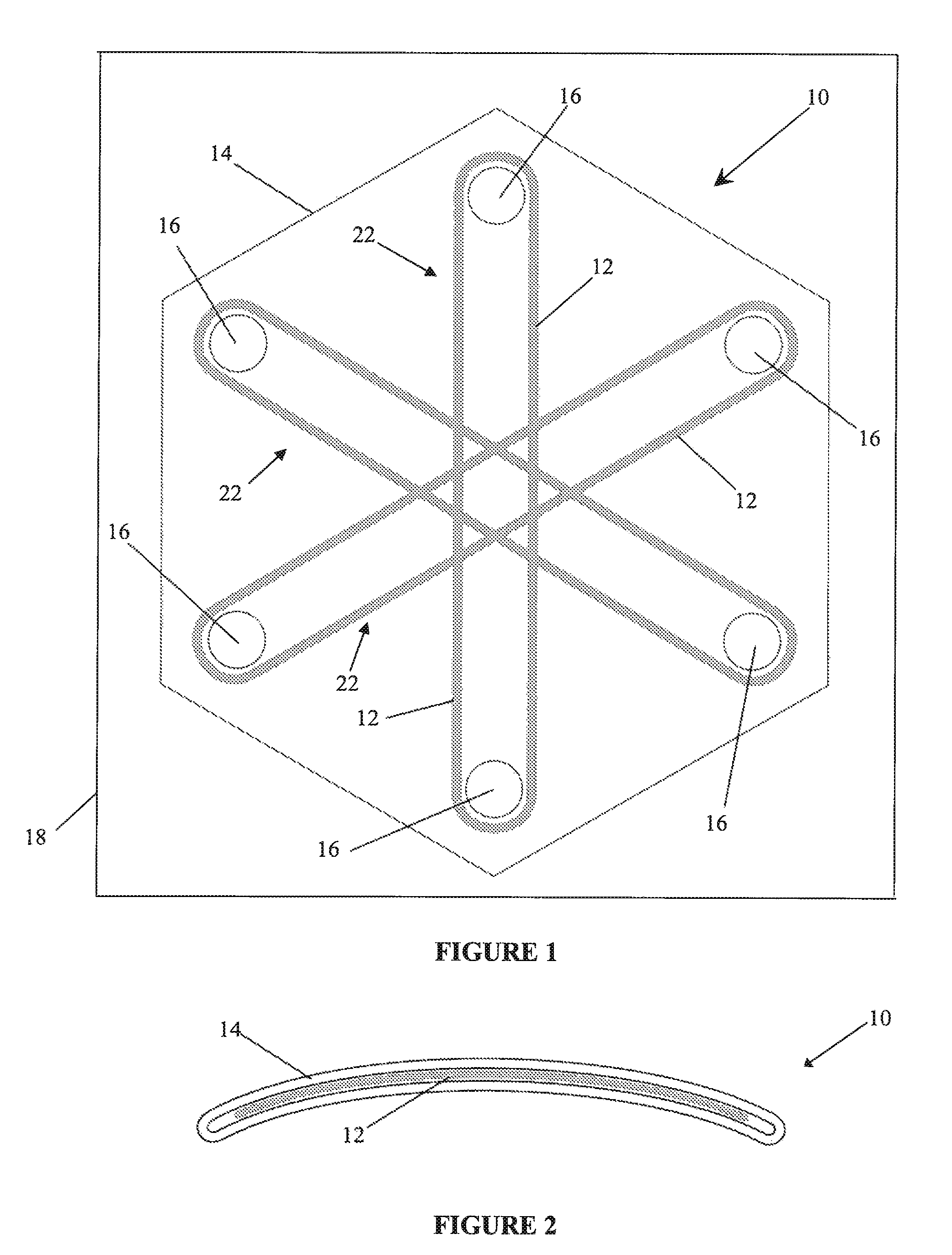

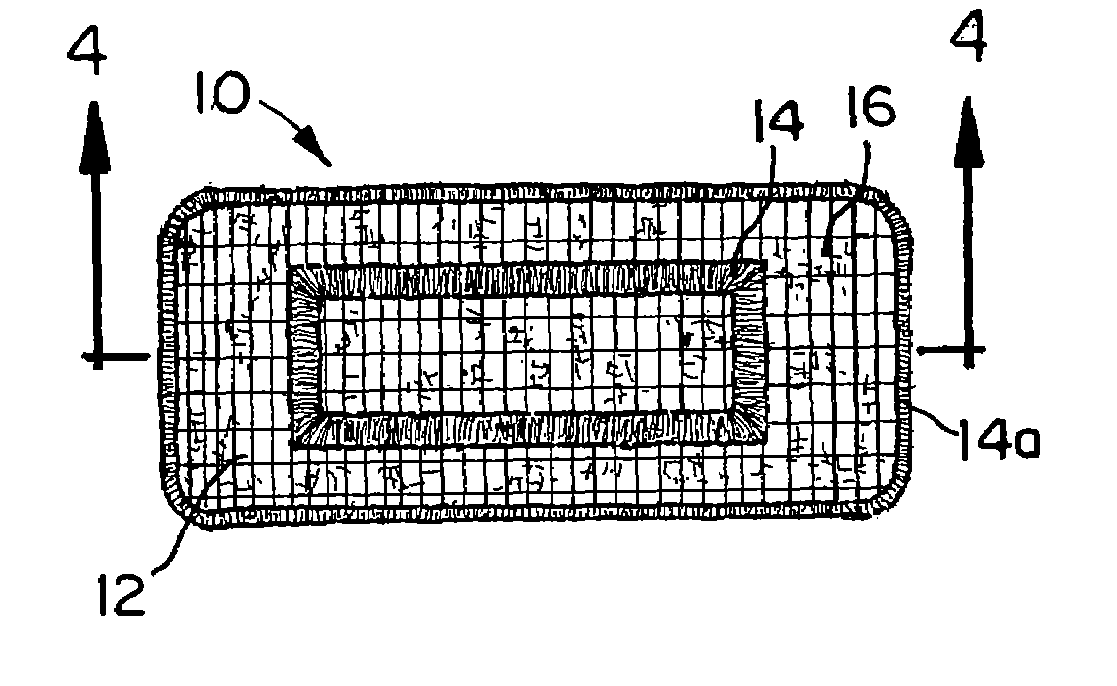

Embroidery using soluble thread

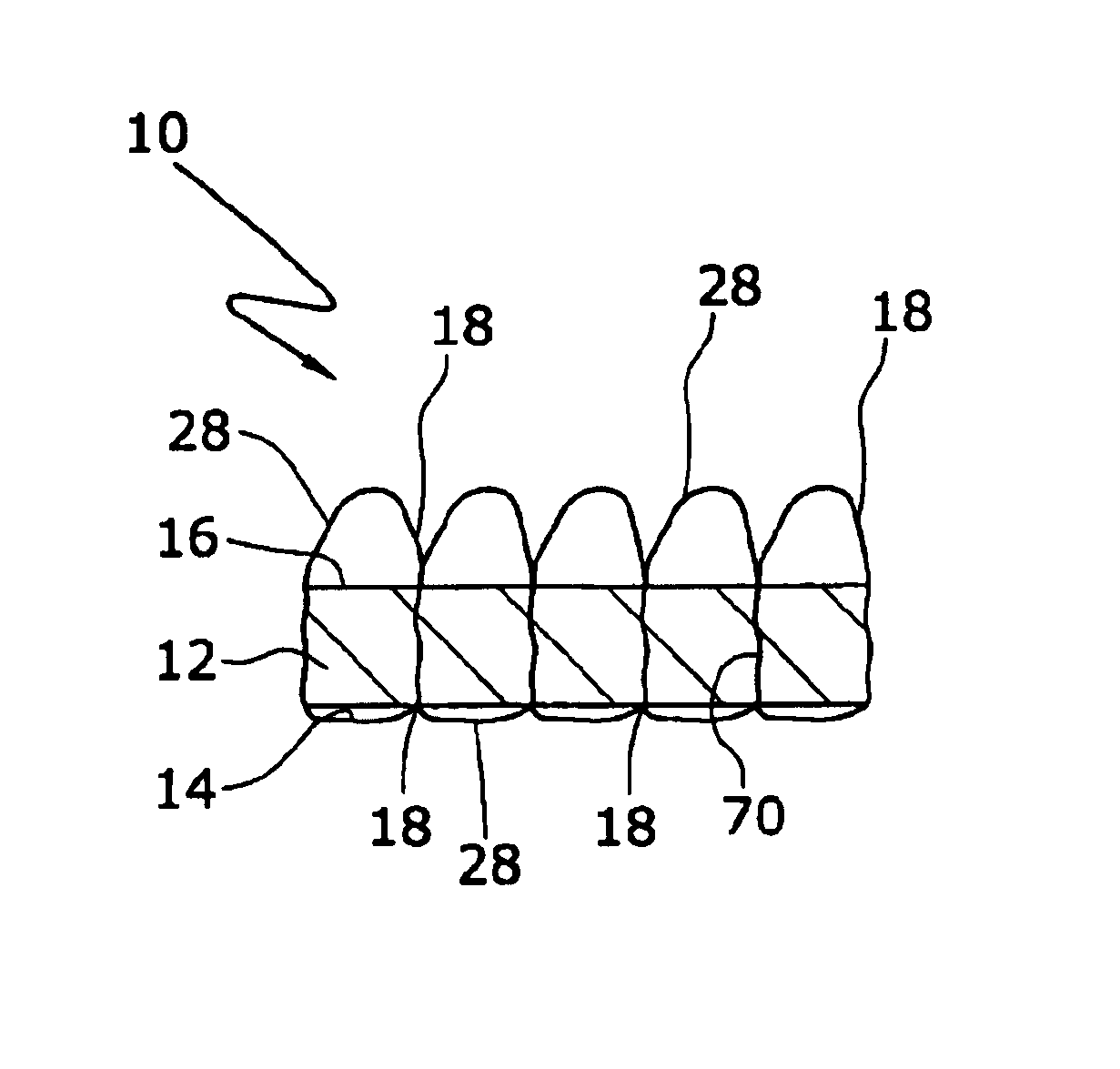

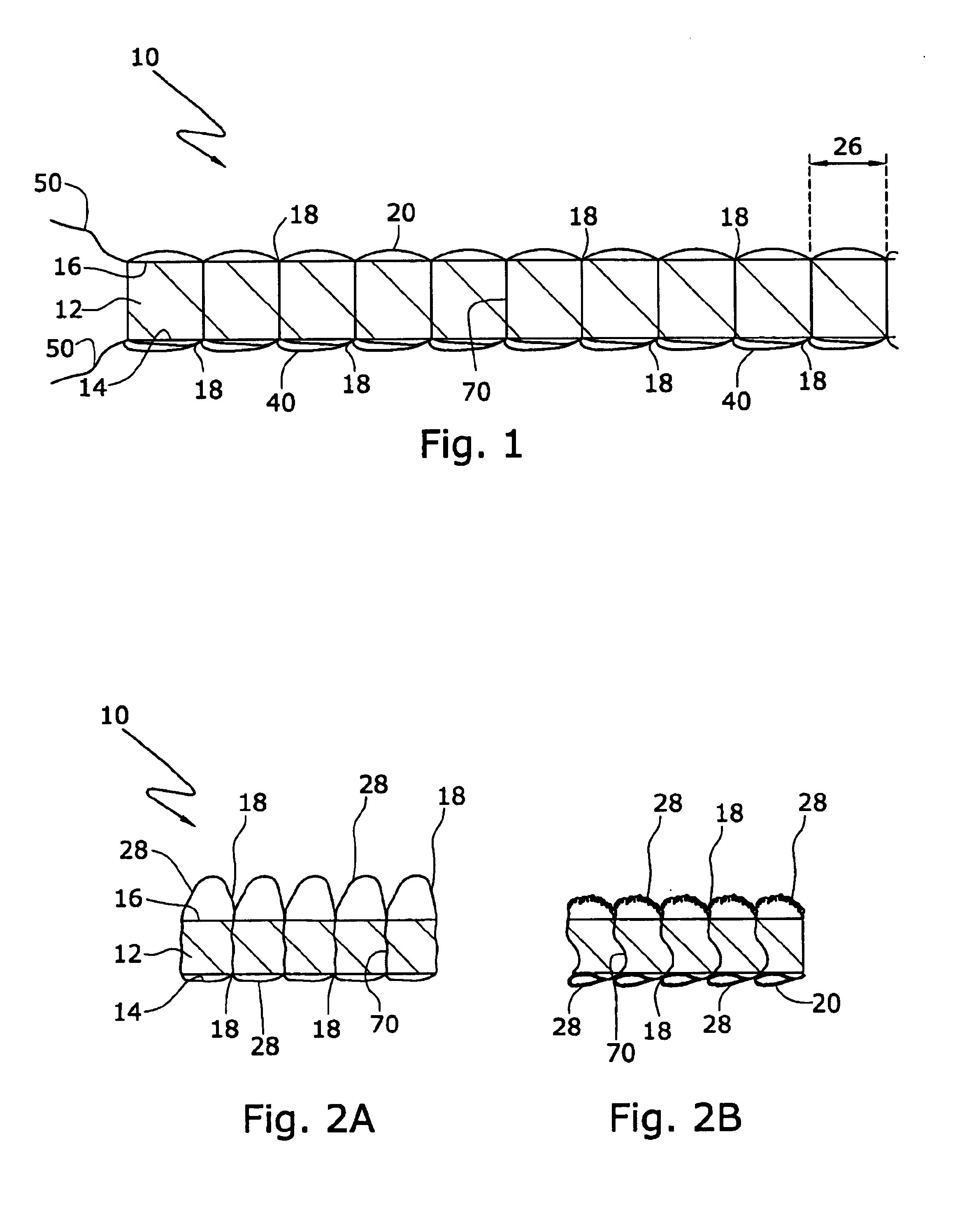

ActiveUS8074591B2Repeatable and inexpensive and conducive to mass productionEasy to manufactureLayered productsSewing stitchesMedical deviceBiomedical engineering

A manufacturing process and resultant medical devices and components thereof wherein one or more individual laces (12) is placed within an embroidered structure (10) using an automated process allowing for the manufacture of embroidered surgical implants containing laces to be mass produced repeatably and cost effectively.

Owner:NUVASIVE

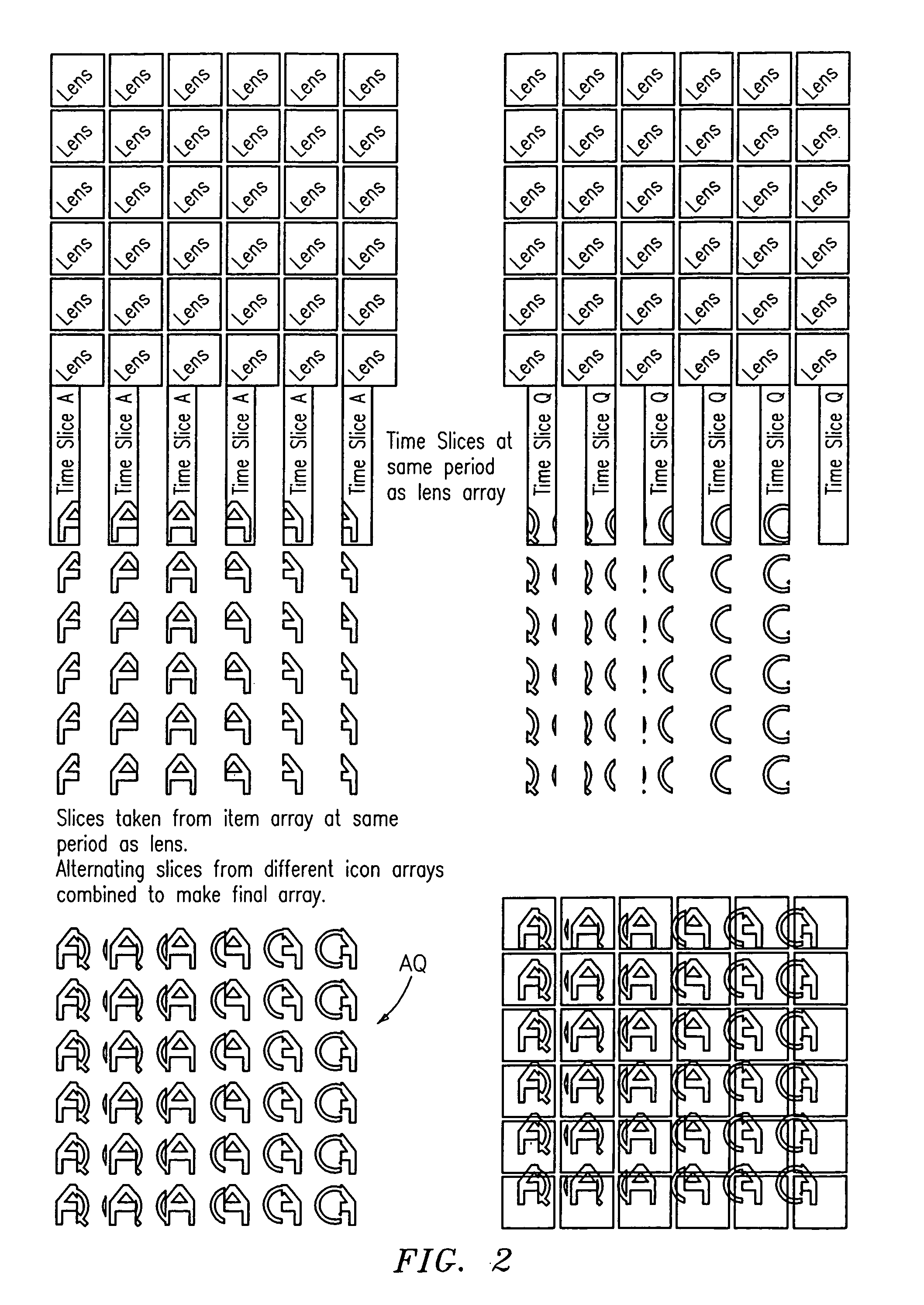

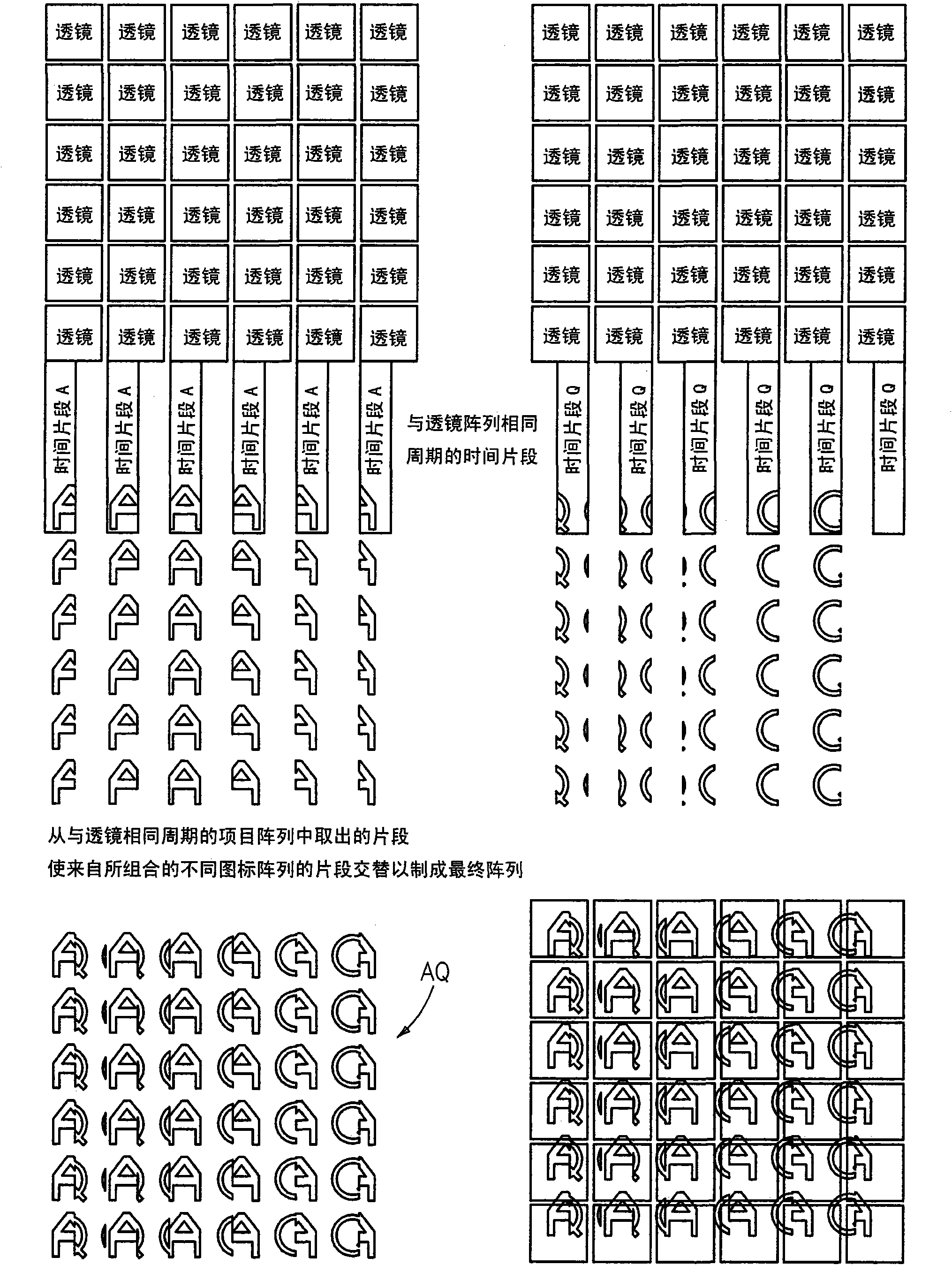

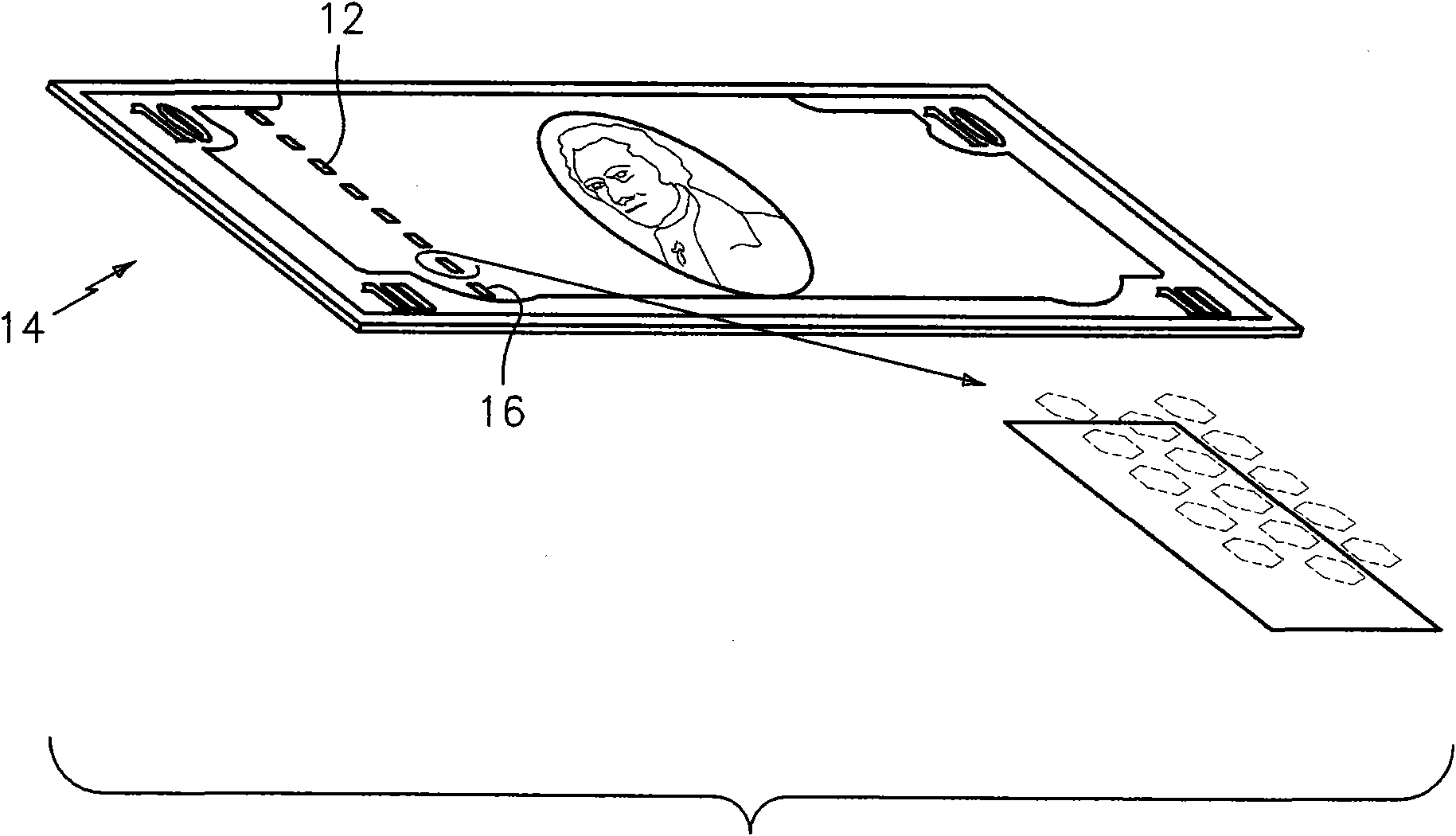

Micro-optic security device

ActiveUS8739711B2More resistant to counterfeitingOther printing matterLight effect designsComputer scienceIconoscope

Owner:CRANE SECURITY TECH

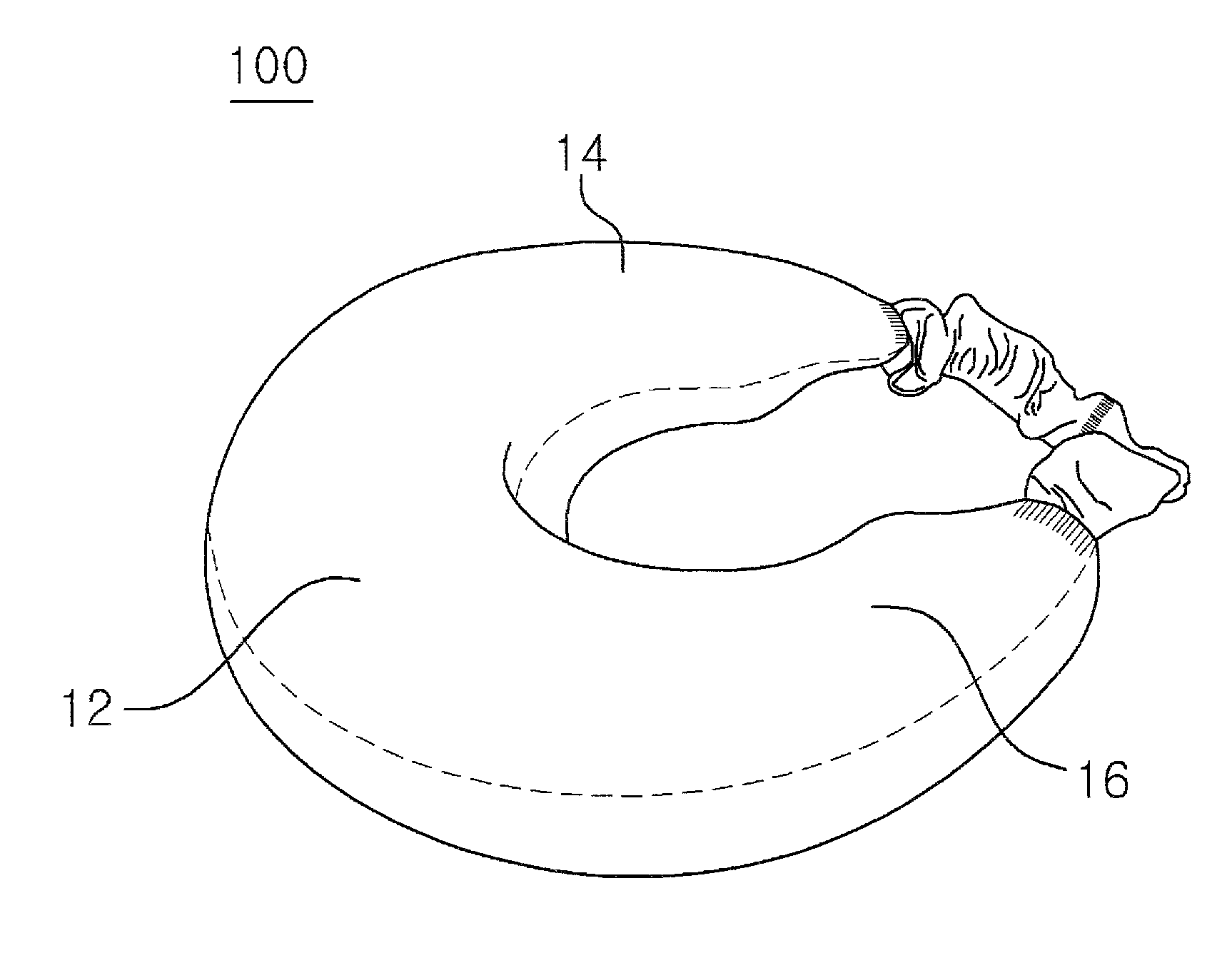

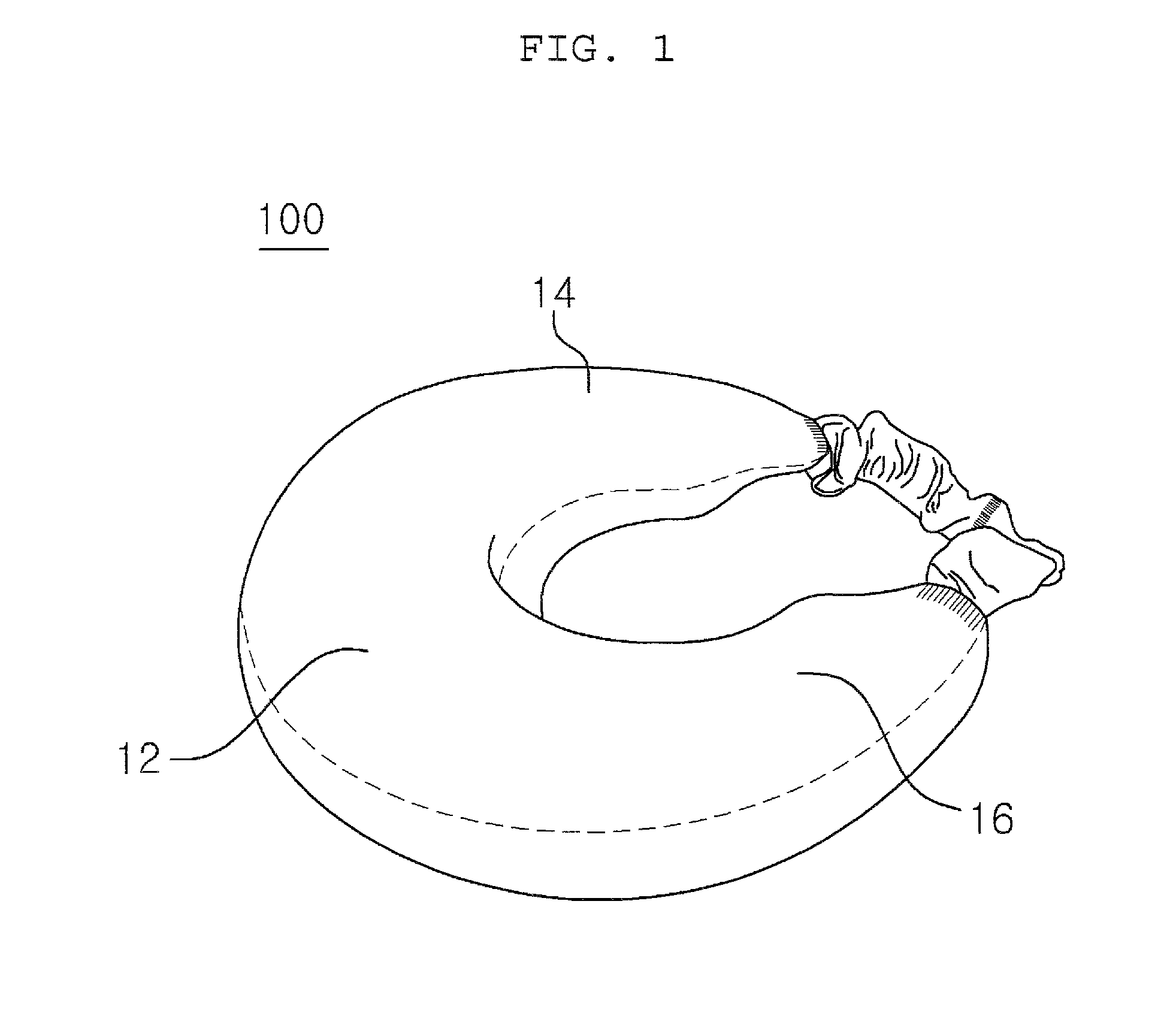

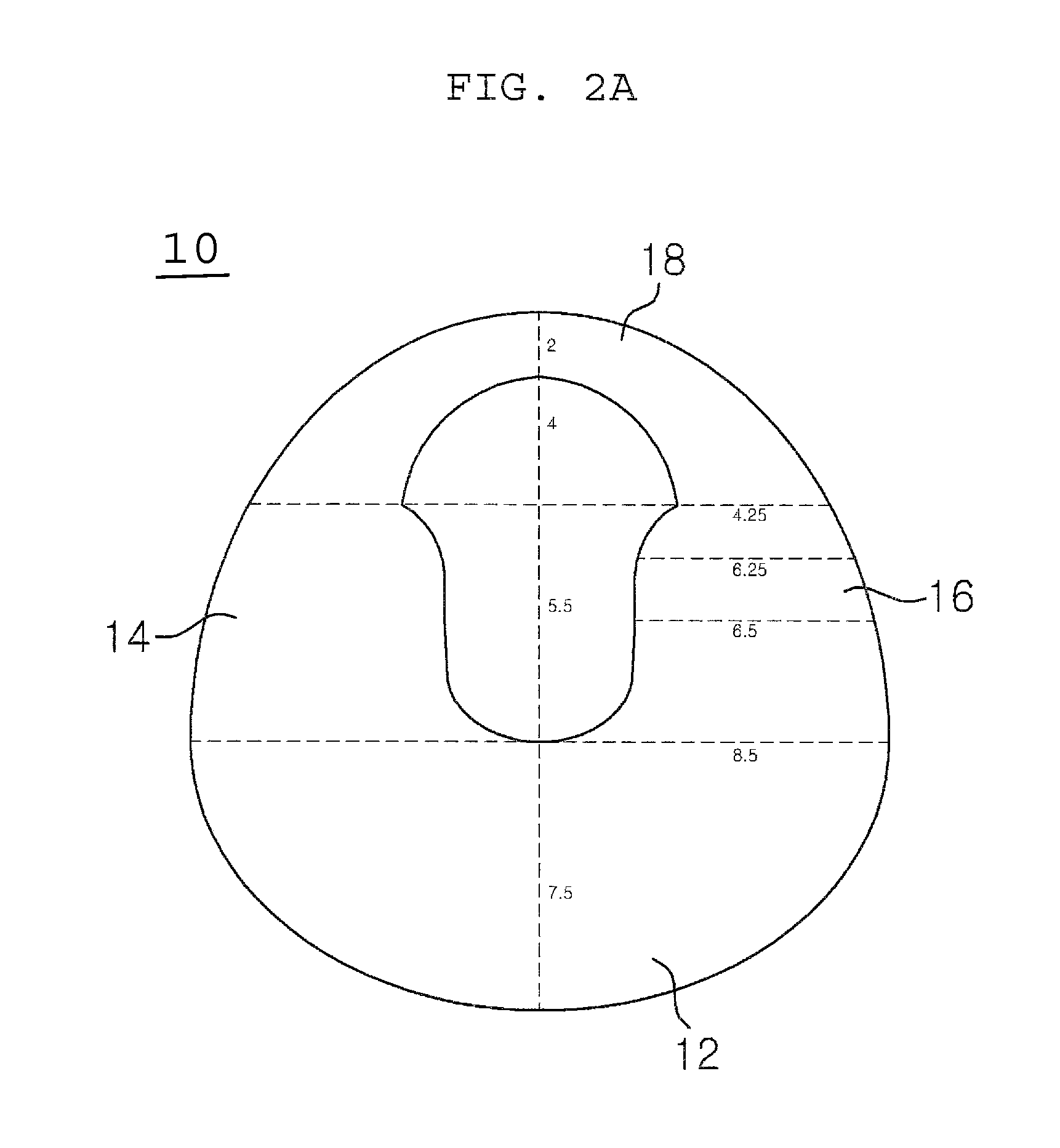

Neck pillow having a strap

InactiveUS20150059098A1Cure neck stiffnessRelieves pain in a person's neck or shoulderPillowsLeather sewingPhysical medicine and rehabilitation

The present invention relates to a neck pillow having a strap to support and comport the neck and the lower head of a user for providing support, comfort, safety, convenience and convenient carriage. The neck pillow includes first and second fabric layers, having a central portion, a left side portion, a right side portion, and a strap portion. The neck pillow further includes an elastic band placed between the strap portions. The central portion is constructed in a substantially hemispheric form and the left and right side portions extend and taper upwardly from the central portion. Additionally, the strap portion is configured to form a hemispheric shape and extends towards the left and right side portions.

Owner:JUNG HYOUNG SOOK

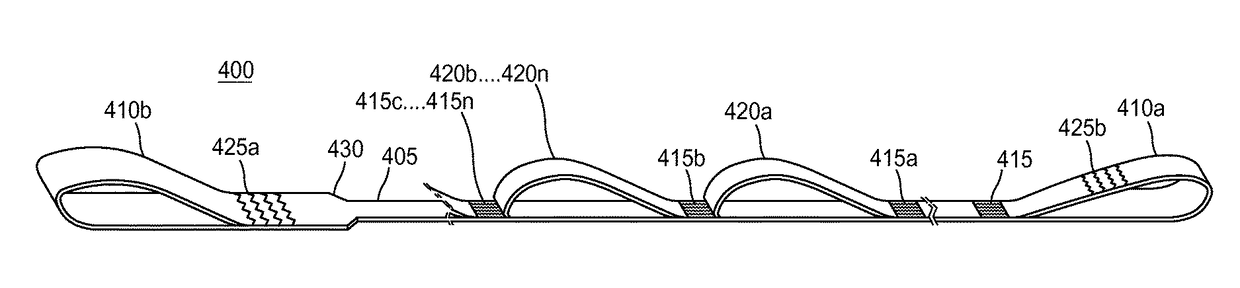

Single piece hammock strap with integral woven eyelets

Owner:KAMMOK HLDG

Flat seam construction for automotive upholstery

Owner:FAURECIA AUTOMOTIVE SEATING LLC

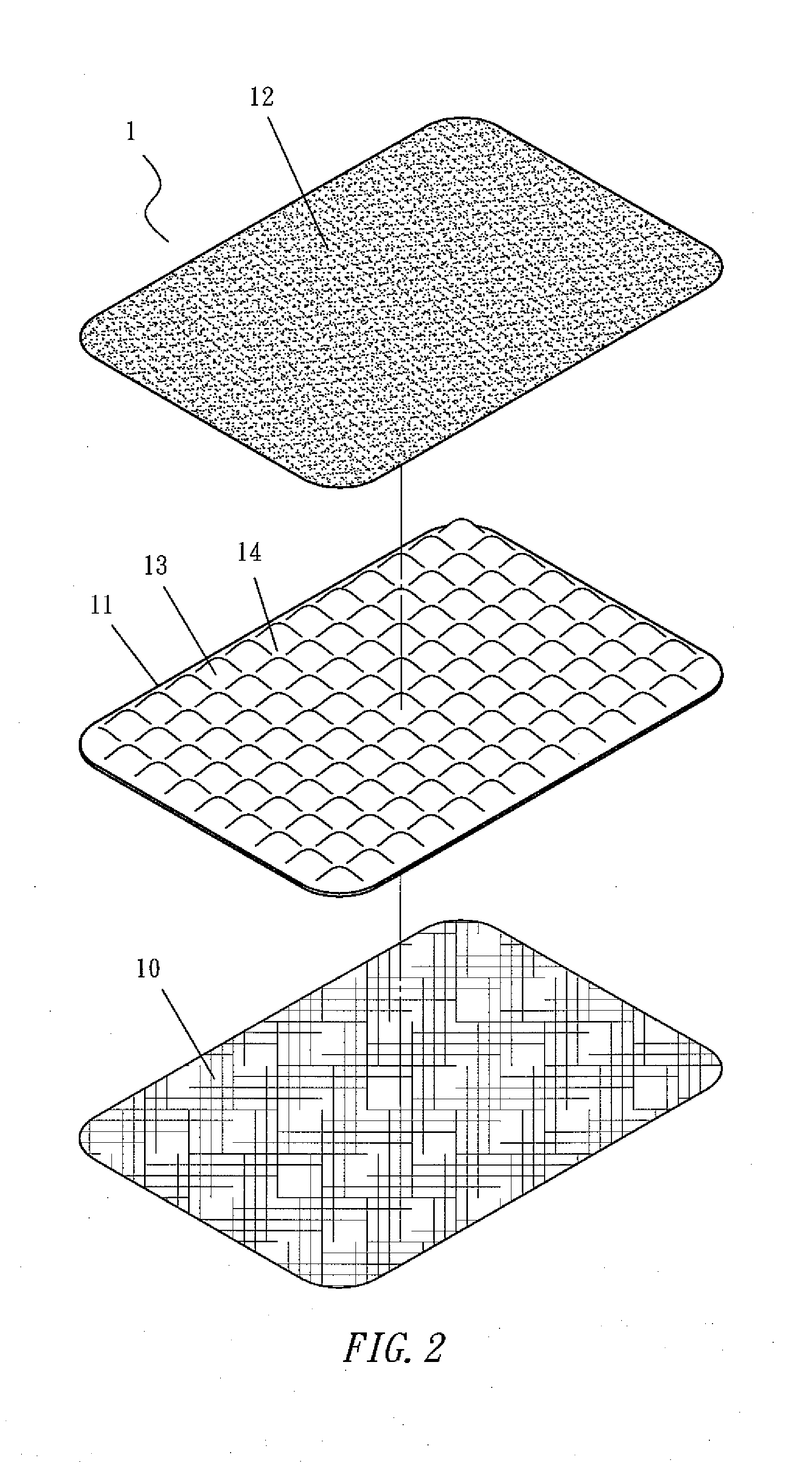

Ventilating Pad With Buffer And Elastic Support

A ventilating pad with buffer and elastic support is formed by connecting an underlying layer, a middle layer and a surface layer with one another, characterized in that the underlying layer is disposed under the middle layer, and the middle layer is disposed under the surface layer, and the middle layer comprises a plurality of elastic protrusions protruded from the top of the middle layer, and the surface layer is attached flatly with the middle layer and along the direction of the elastic protrusion of the middle layer, and a gap is formed between two adjacent elastic protrusions, such that a downwardly concave air passage is formed between the adjacent elastic protrusions, such that the application of the ventilating pad will not cause sweltering or discomfort.

Owner:WANG YU CHIEH

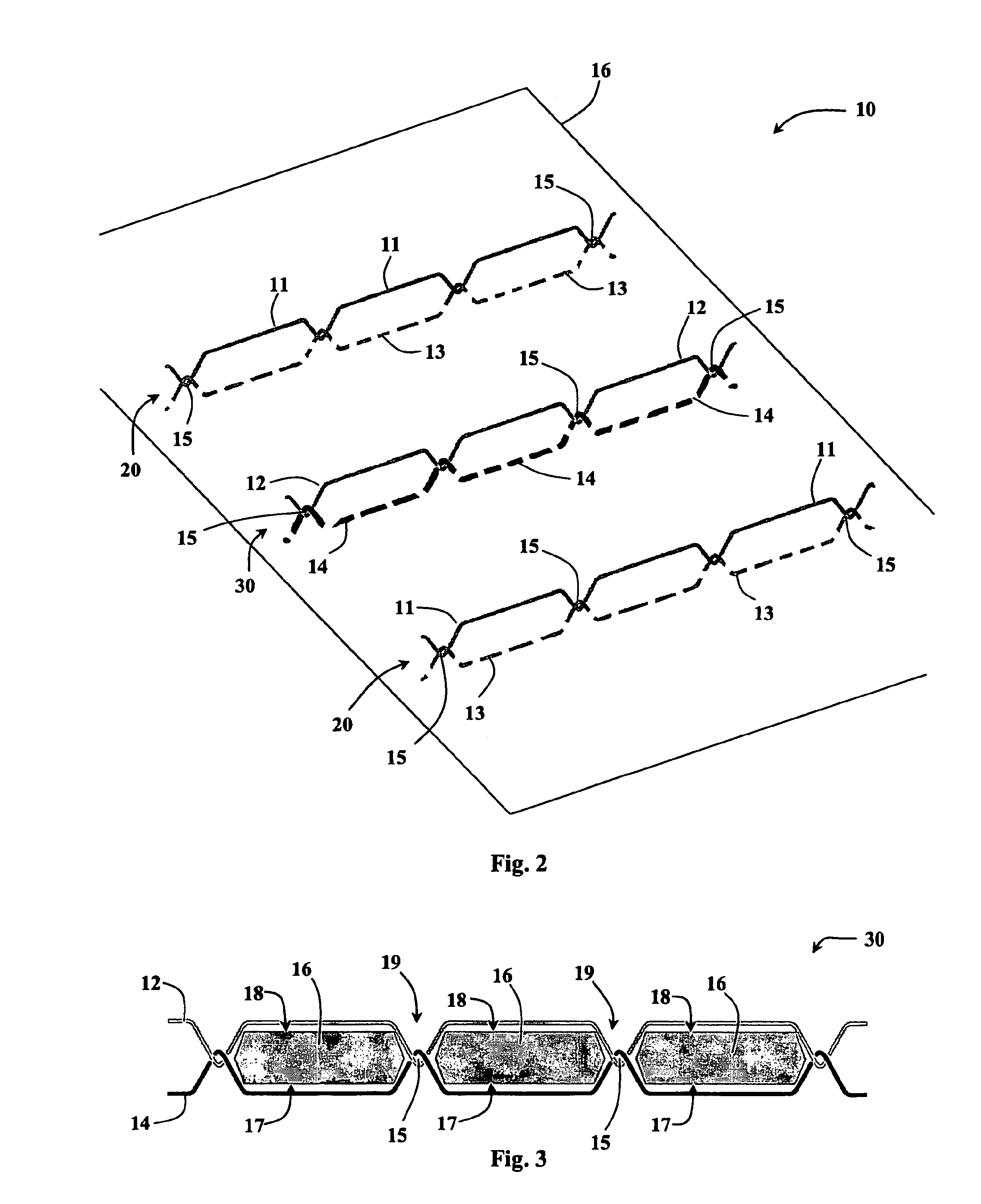

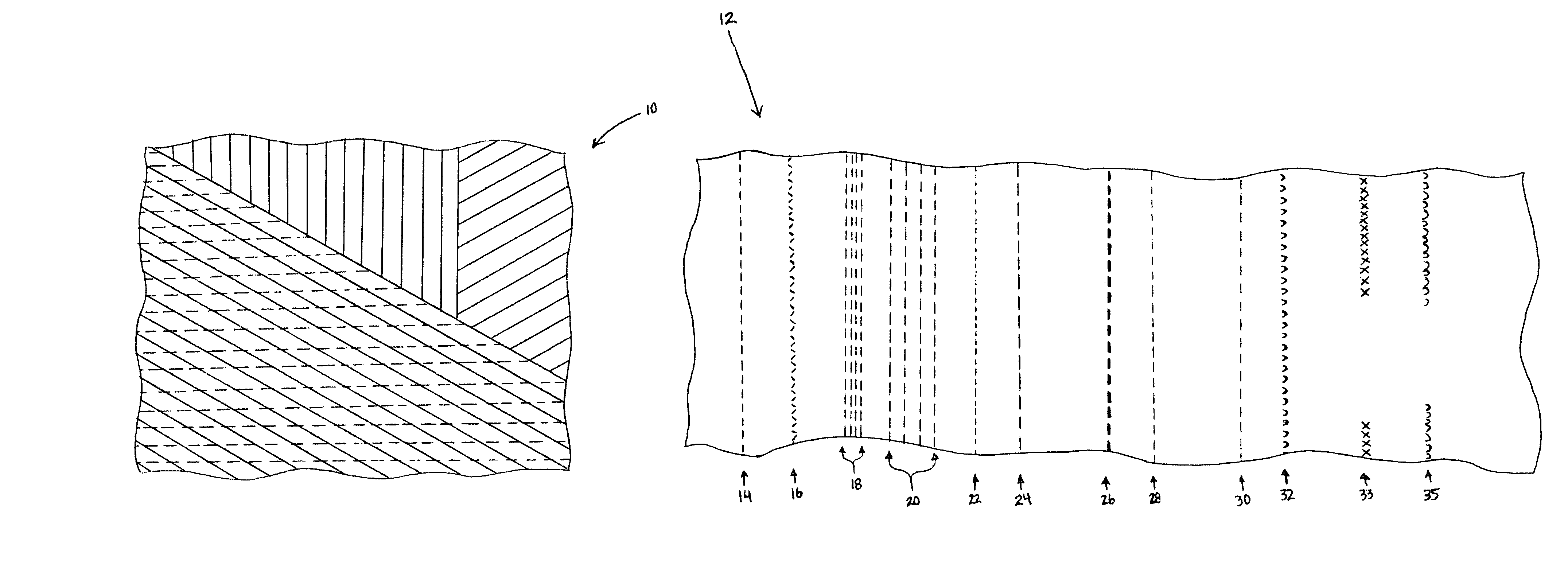

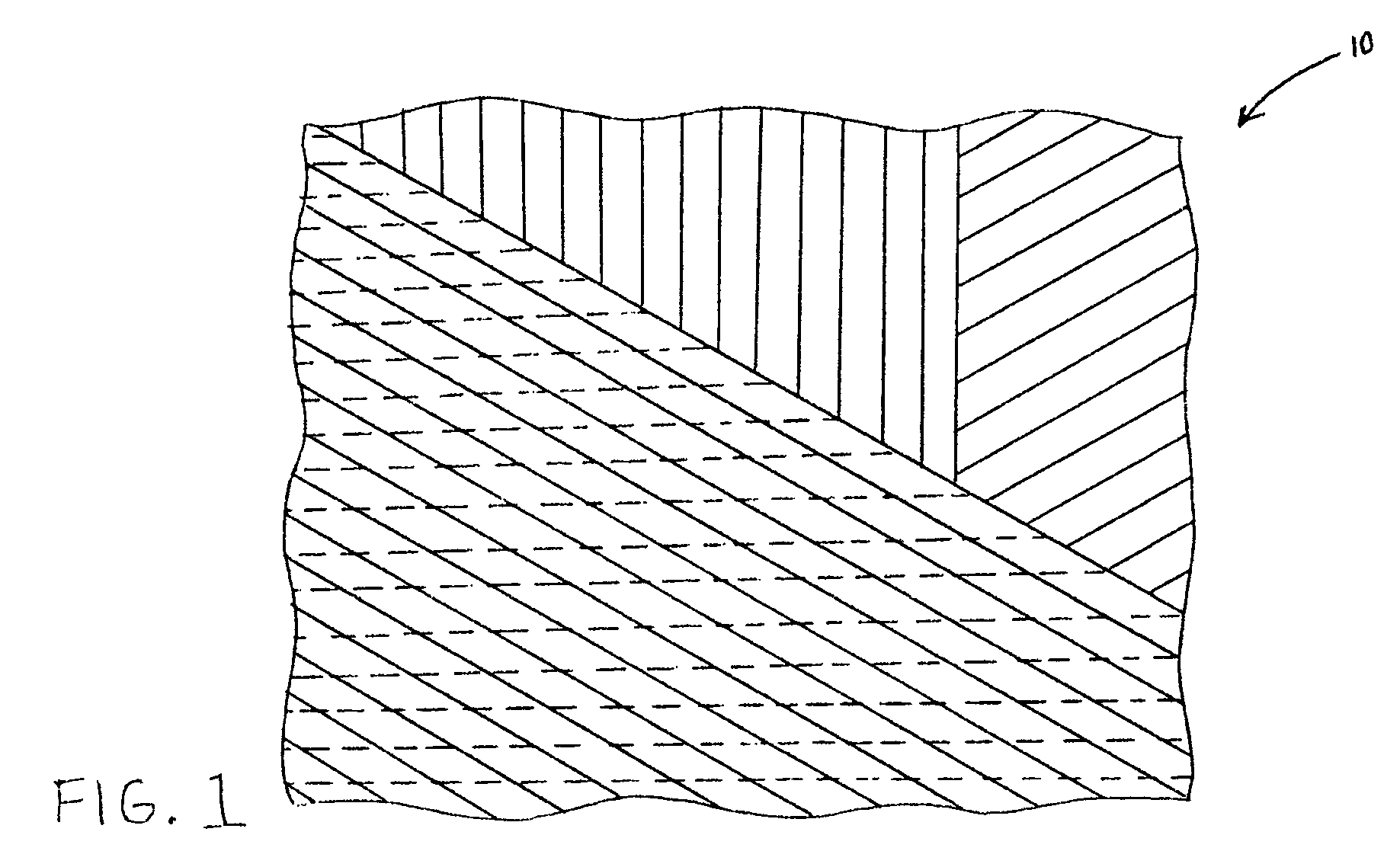

Stitch-bonded and gathered composites

InactiveUS6936327B2Good dimensional stabilityStretchabilityWarp knittingLaminationYarnMaterials science

Owner:J&J FLOORING GRP LLC

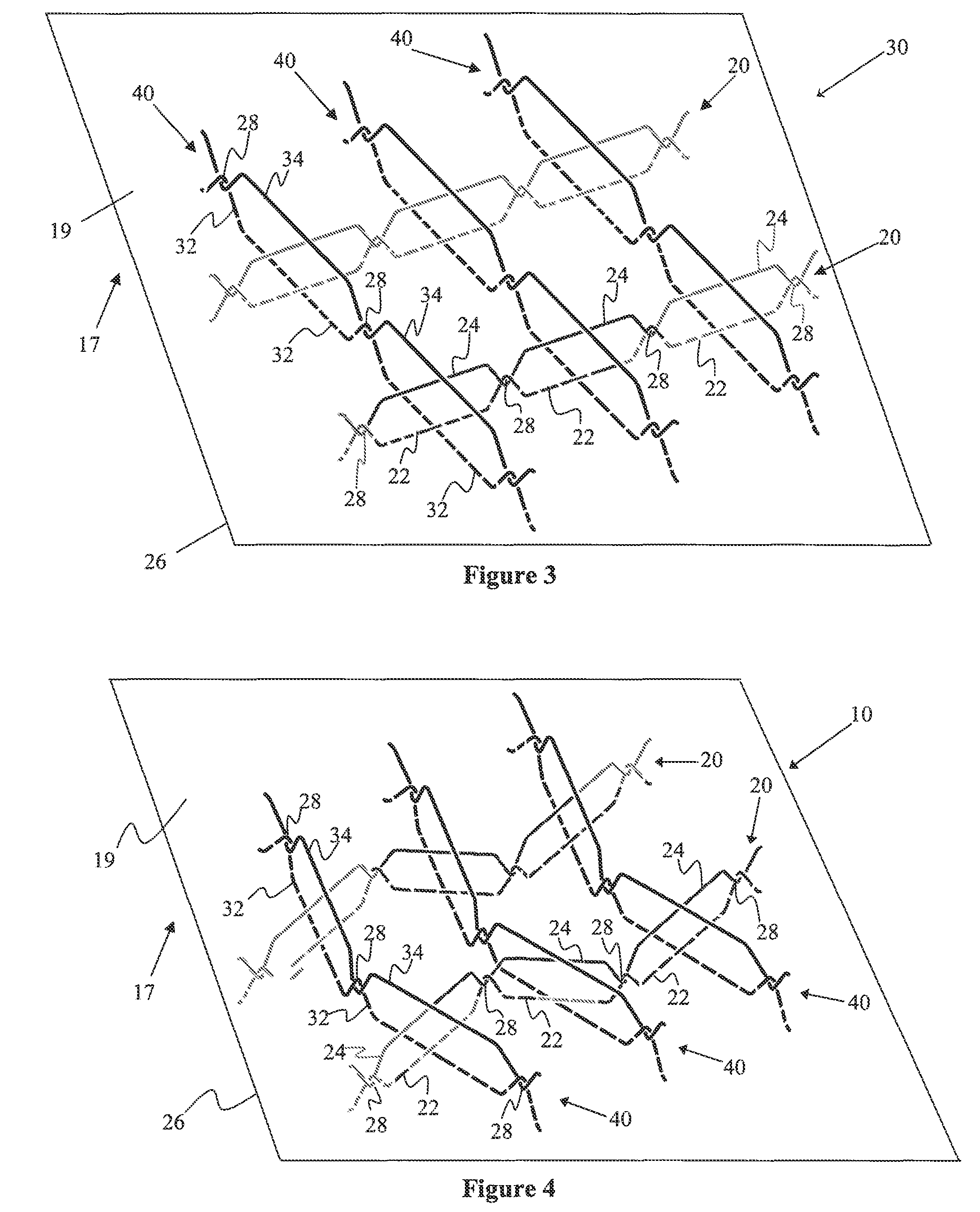

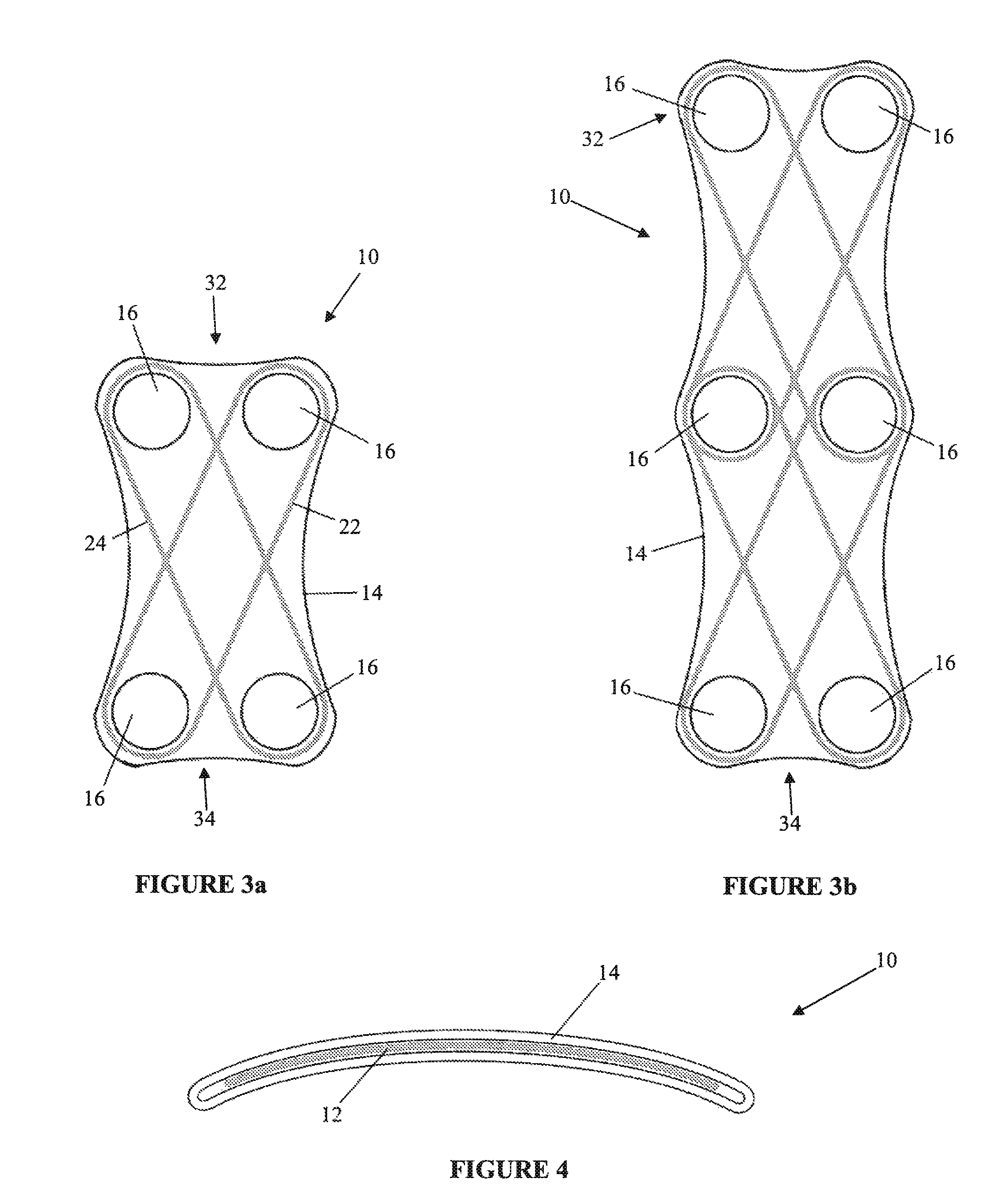

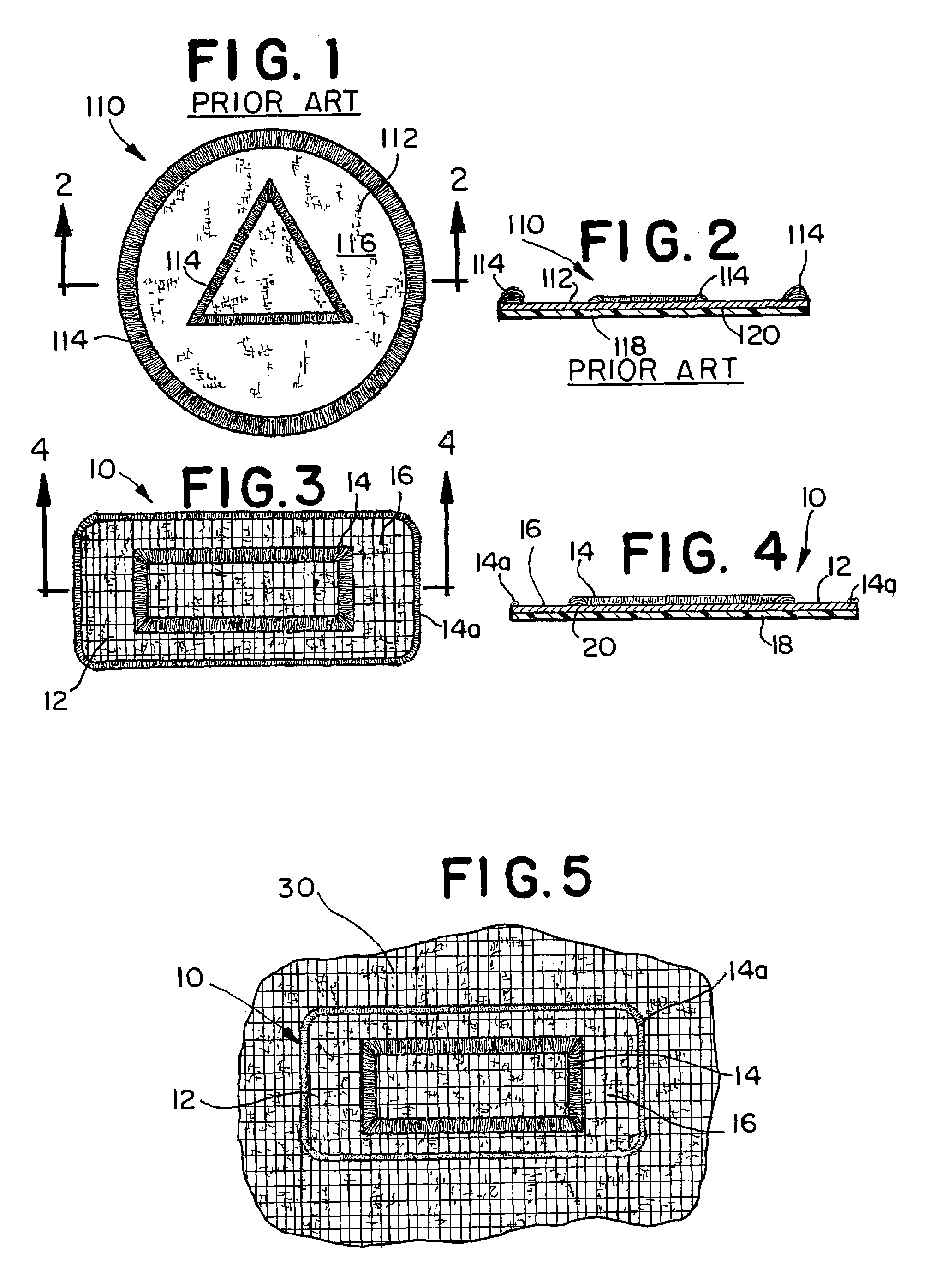

3-dimensional embroidery structures via tension shaping

InactiveUS7942104B2Cost effectiveInternal osteosythesisLayered productsThree dimensional shapeOrder structure

Owner:NUVASIVE

Security luggage bag

Owner:MRM HK

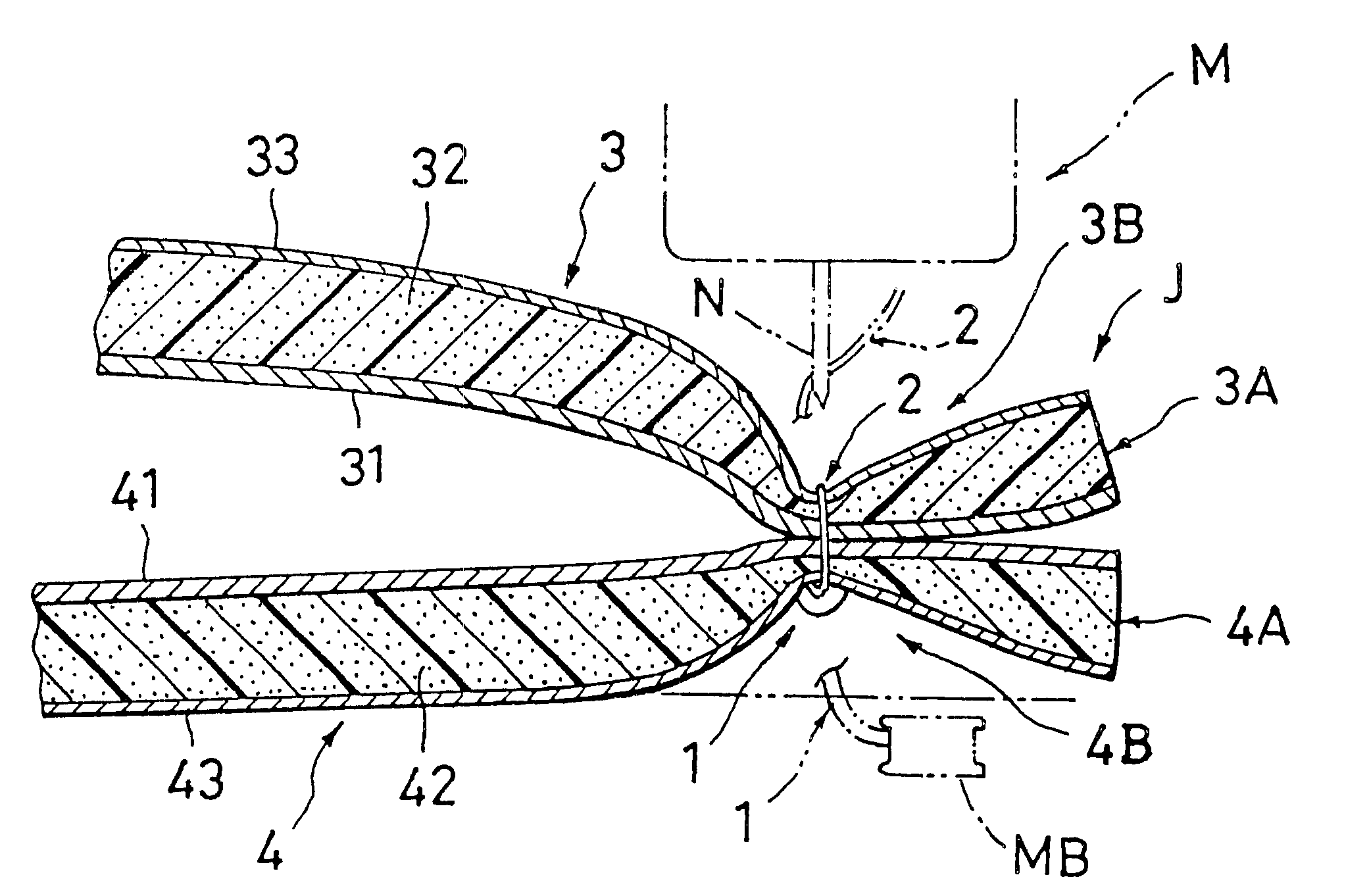

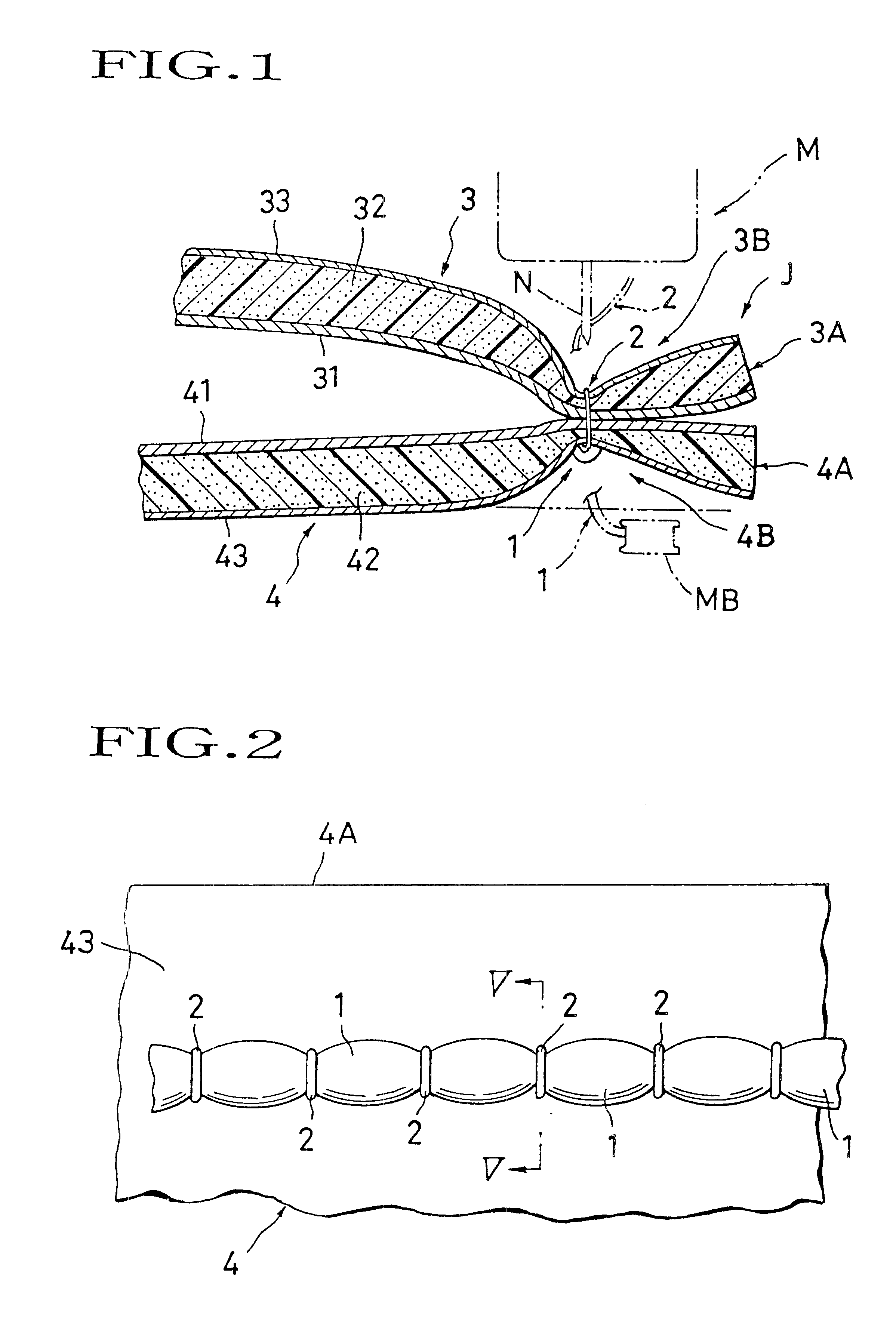

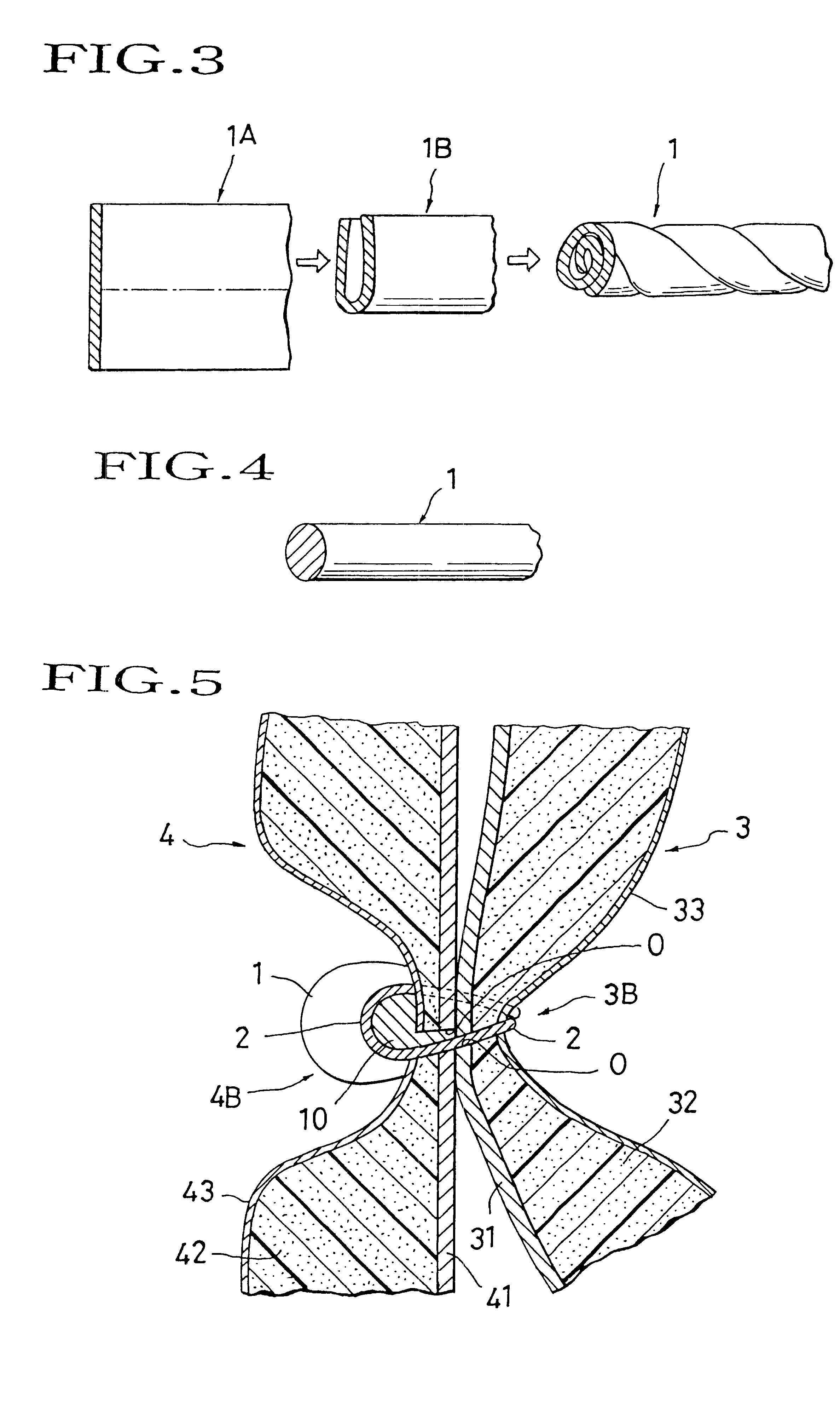

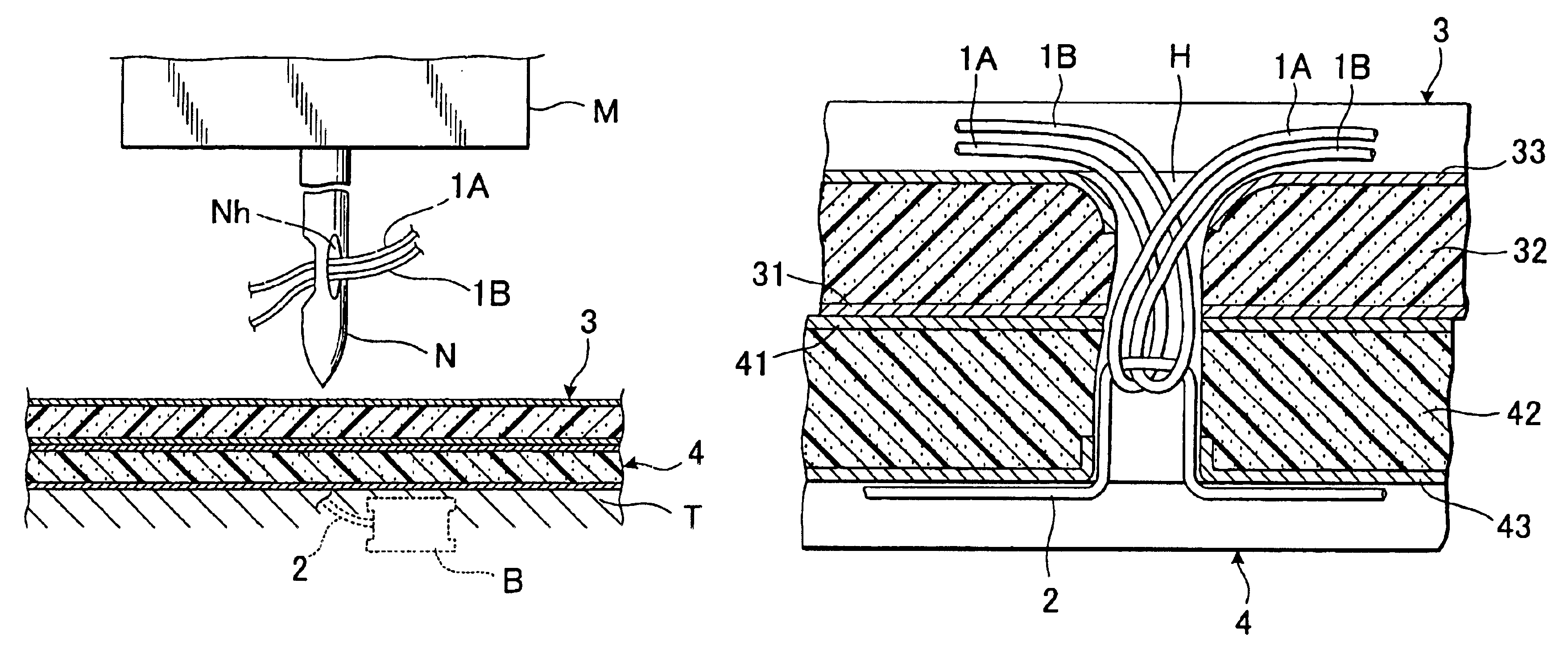

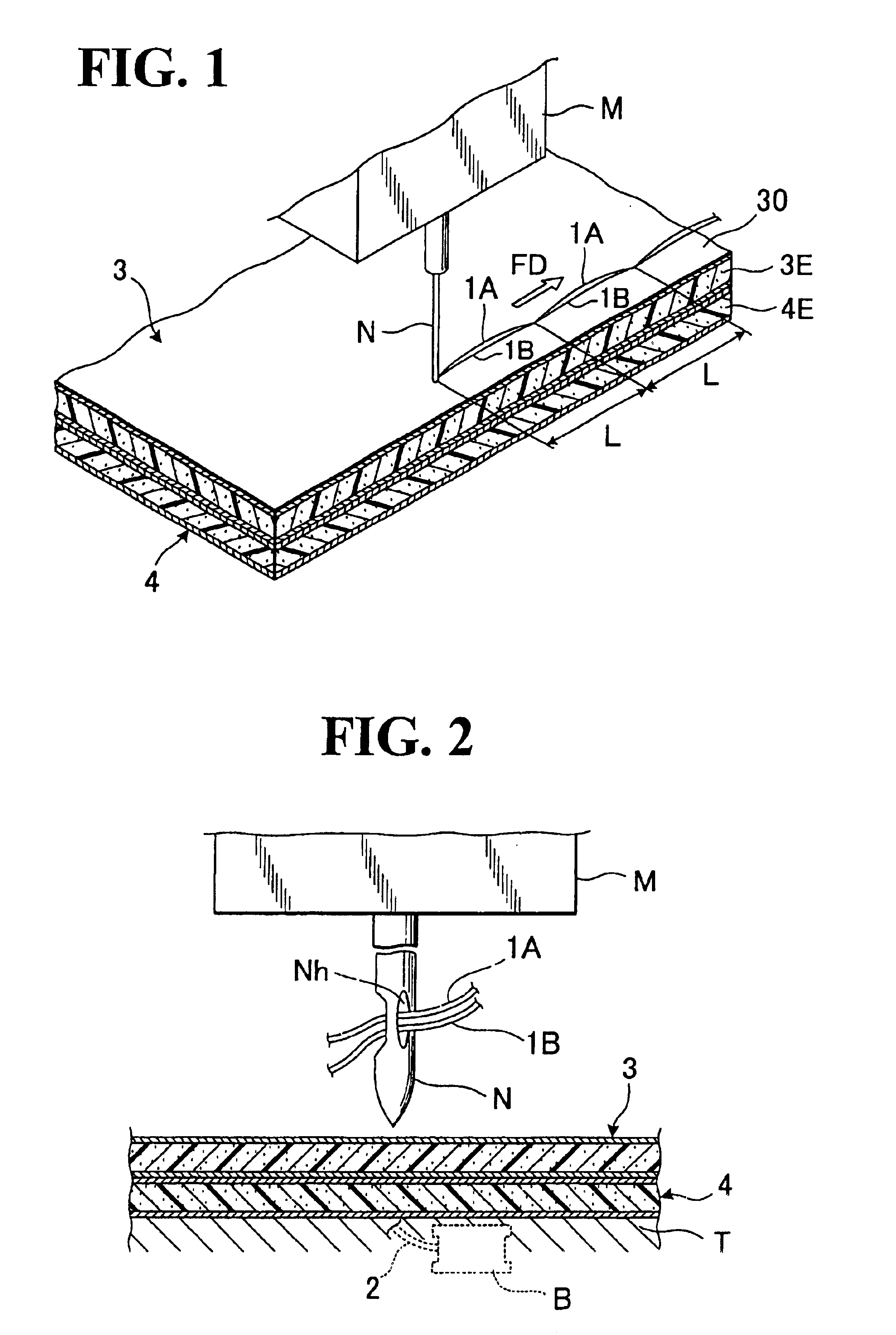

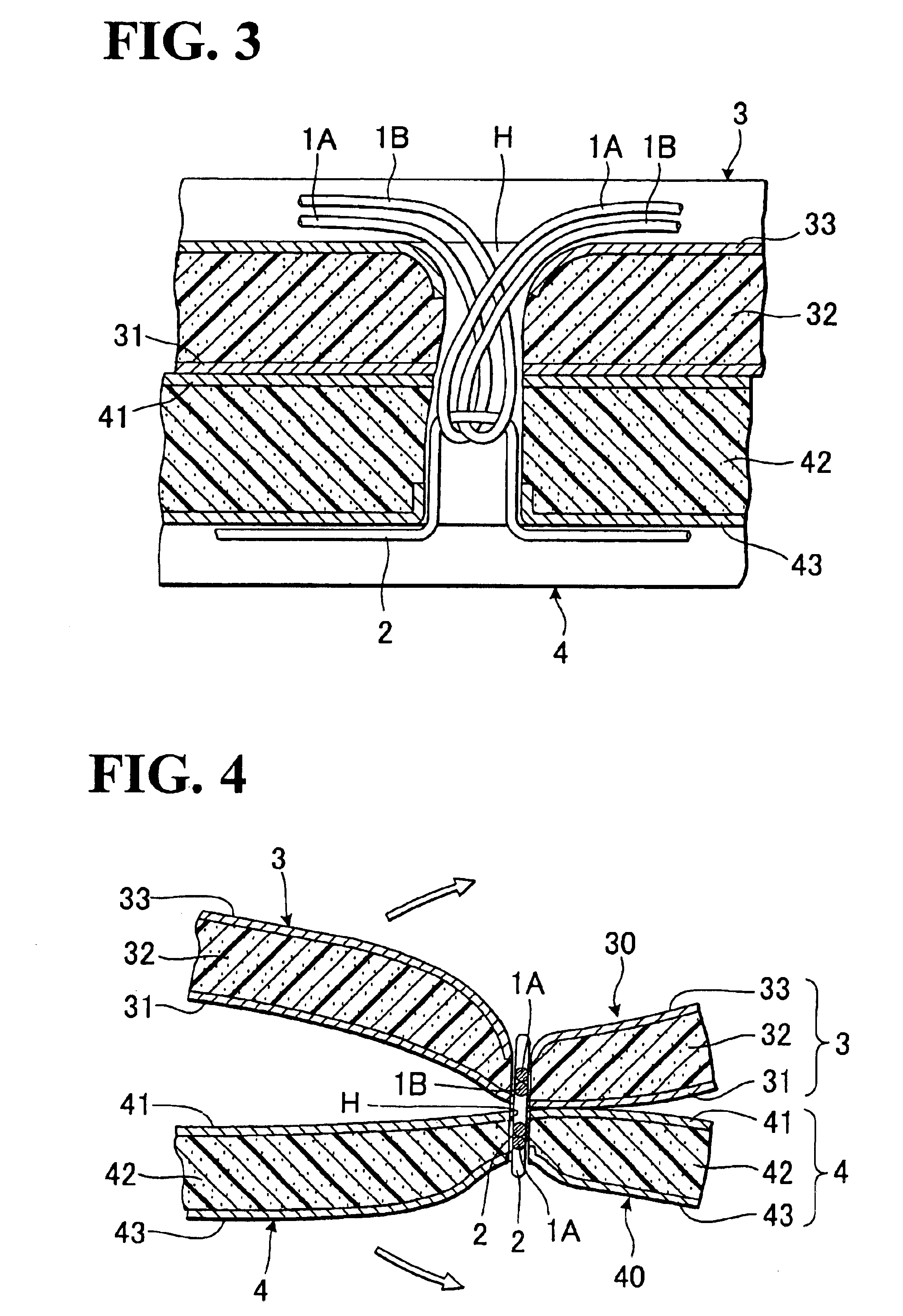

Method for sewing together covering elements adapted to undergo foaming process

A method for sewing together covering elements is provided, in which two first threads and a second thread are used in a sewing machine having sewing needle means. In operating the sewing machine, the covering elements are fed at a given feeding pitch, such that the two first threads are entwined about the second thread in each of needle holes formed by the sewing needle means in the covering elements. Those entwined three threads fill and close the needle hole, thereby preventing leakage of a liquid foaming agent at a foaming process for forming a foamed product integral with the covering elements. The sewing needle means may comprise one sewing needle, in which case, both two first threads are used in that one sewing needle, or alternatively may comprises two sewing needles, in which case, the two first sewing threads are respectively used in the two sewing needles.

Owner:TACHI S CO LTD

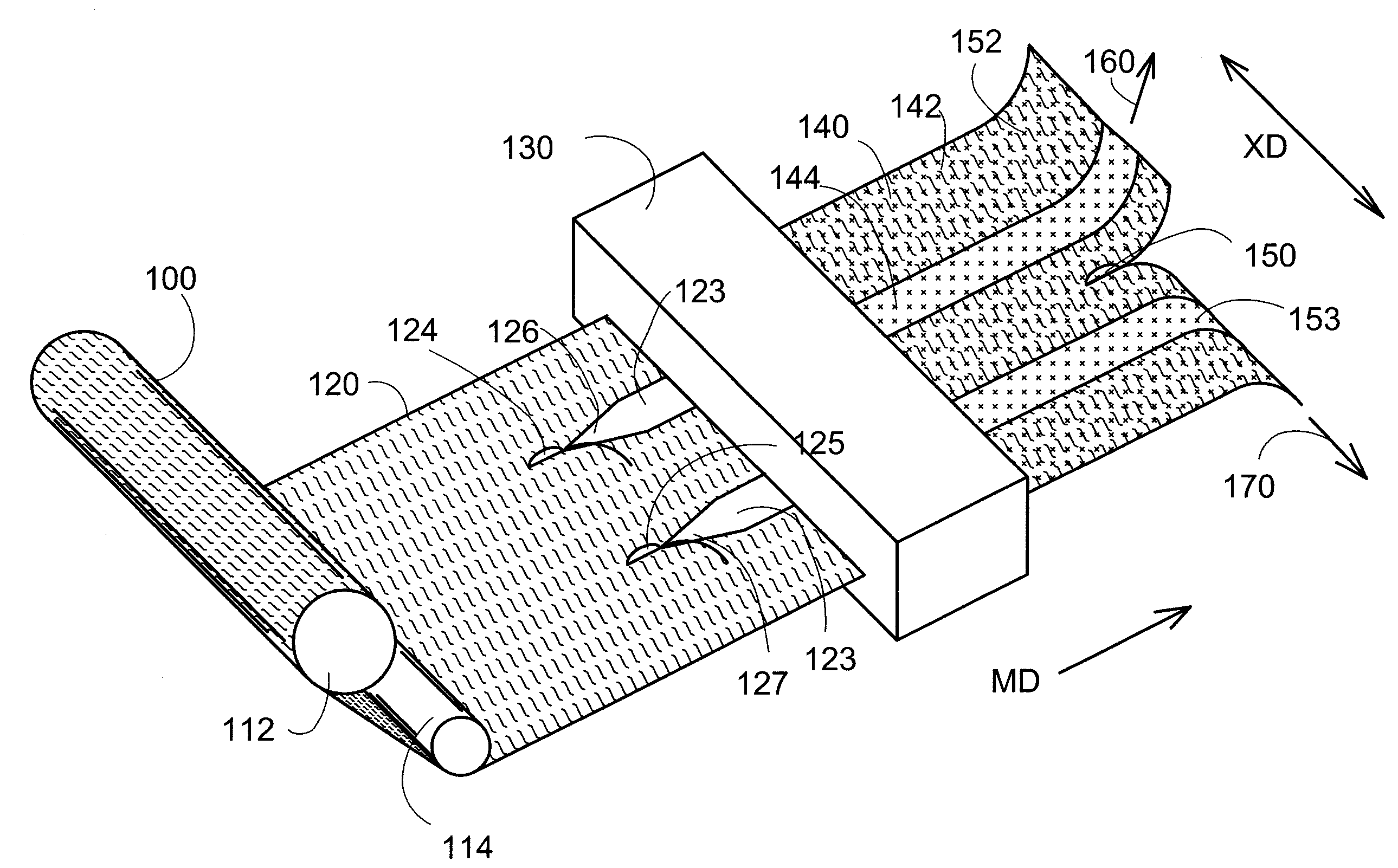

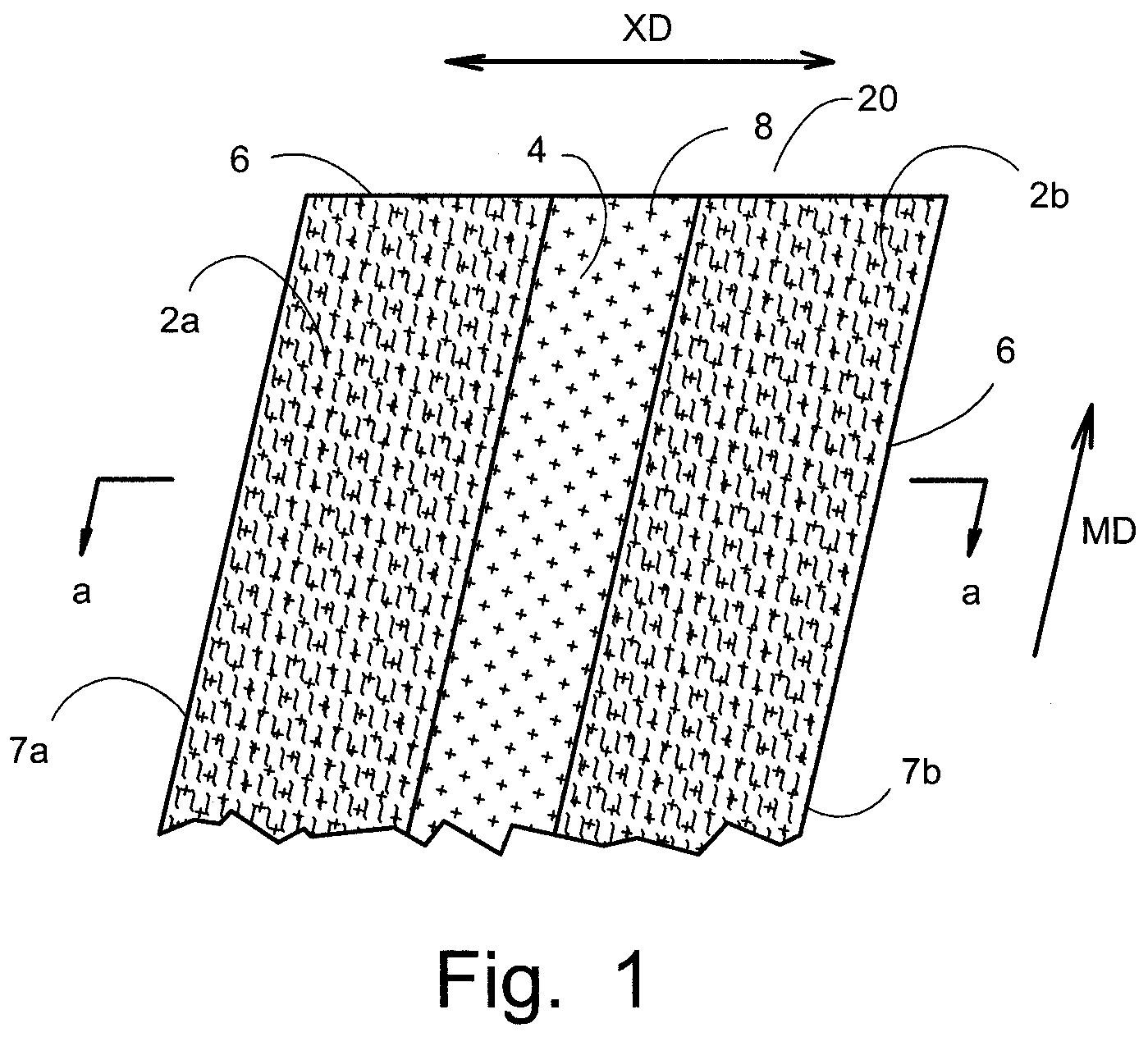

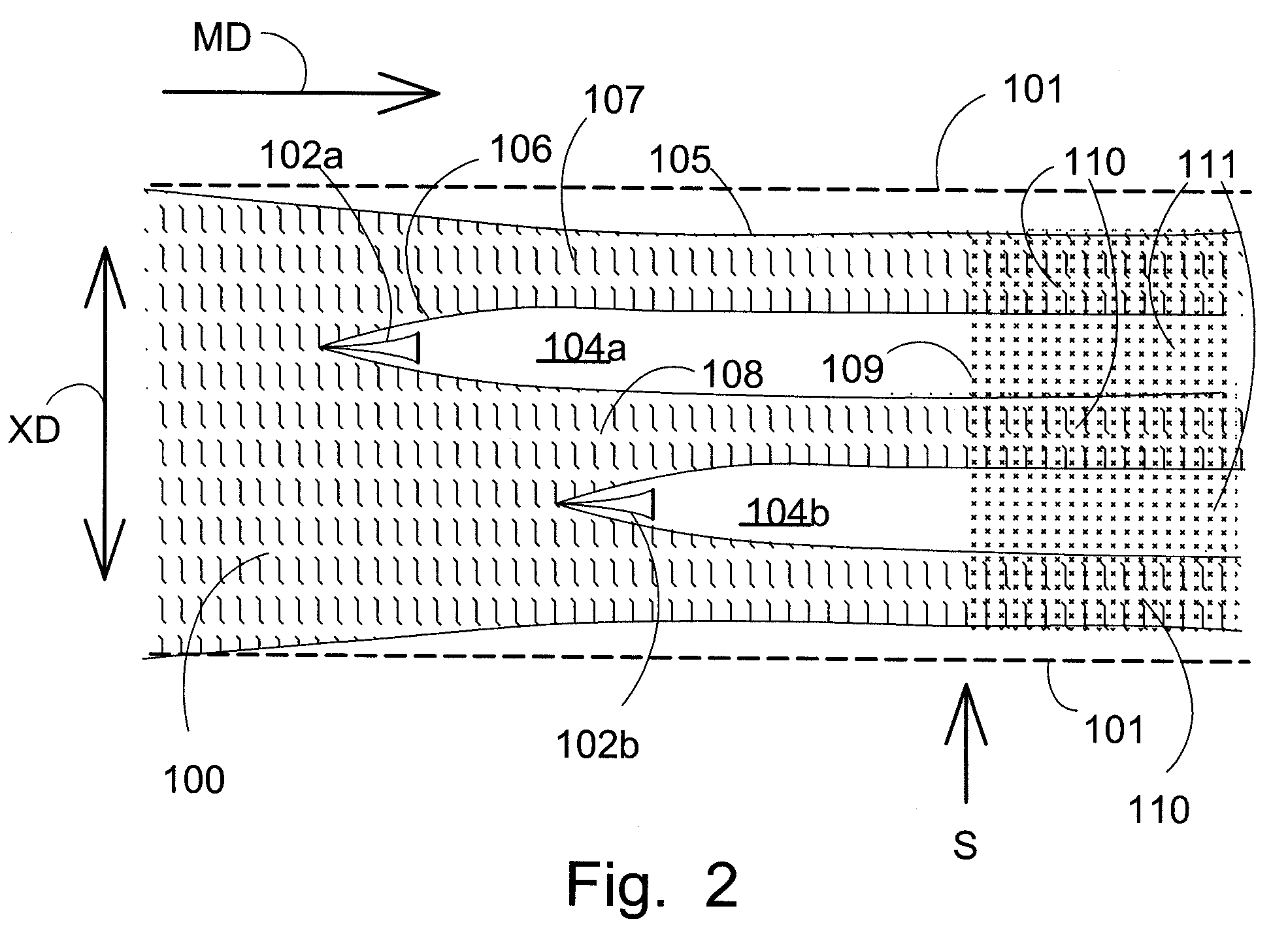

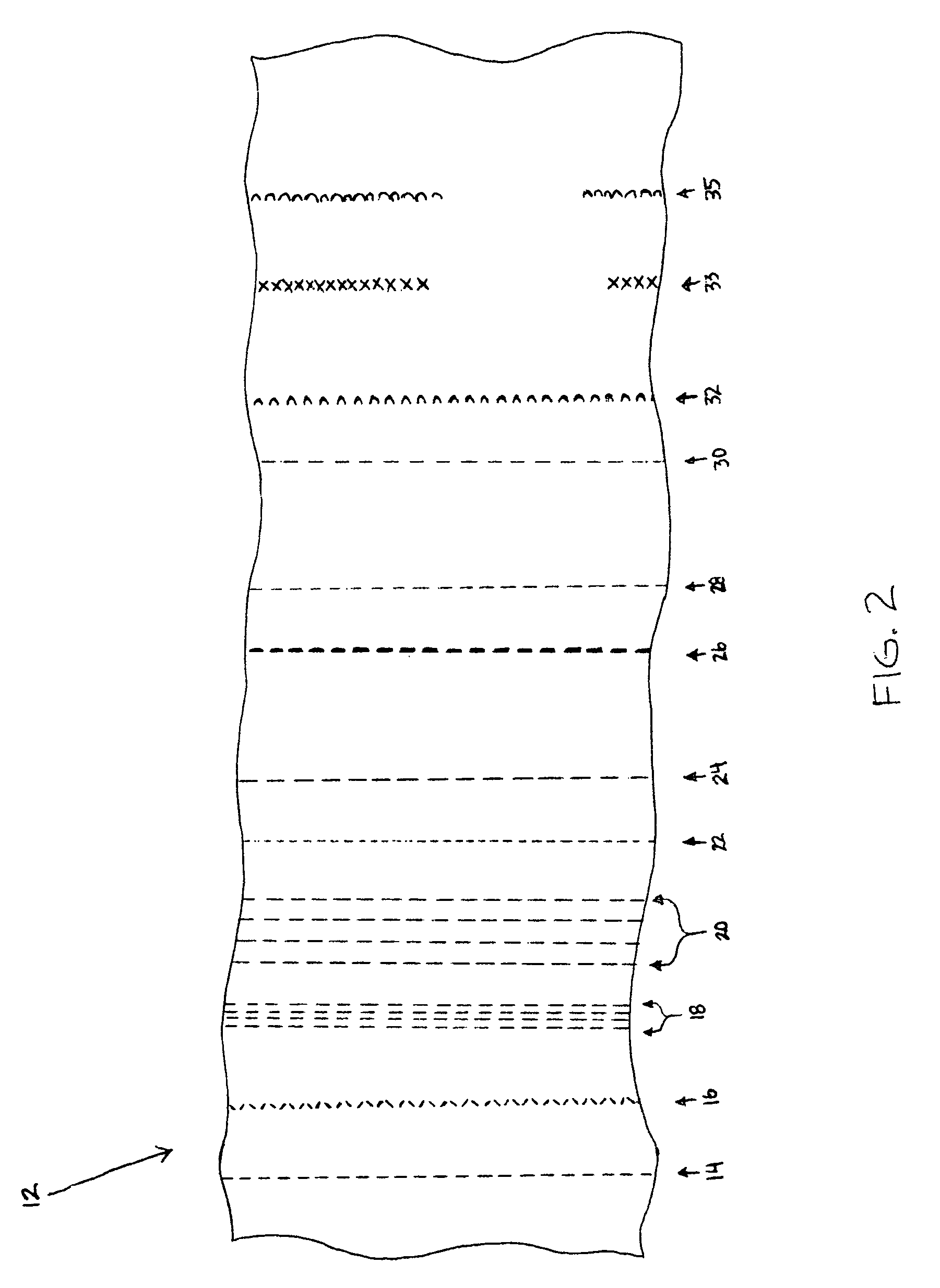

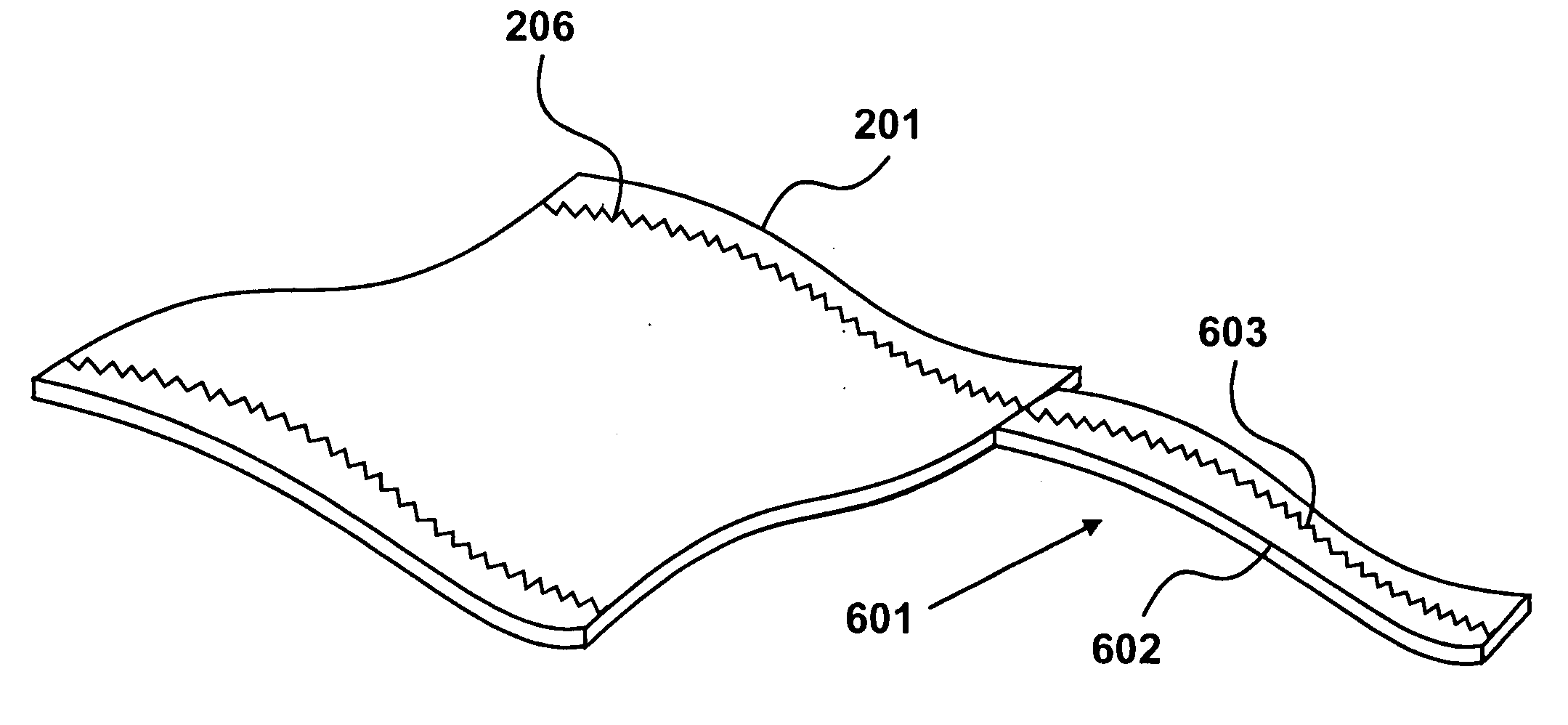

Stitchbonded fabric with a discontinuous substrate

A process makes stitchbonded fabric having a regionally segmented discontinuous base layer of webs of substrate material extending in the machine direction which webs are laterally separated by a region devoid of substrate material. The region devoid of substrate is formed prior to stitching by either (a) slitting the substrate and folding the material adjacent the slits outwardly in contact with substrate material outboard of the slit, or (b) slitting the substrate while applying tension in the machine direction that moves adjacent lips of the slit material away from each other. Once the discontinuous base layer is formed, threads are stitched through the laterally separated webs of substrate material and the intermediate region devoid of substrate material.

Owner:XYMID L L C

Stitchbonded fabric

The invention provides a stitchbonded nonwoven fabric comprising a nonwoven web, stitches of a first yarn, and stitches of a second yarn wherein the first yarn comprises polyester bicomponent fibers exhibiting latent crimp and comprising poly(ethylene terephthalate) and poly(trimethylene terephthalate). The invention further provides a process for making such stitch-bonded nonwoven fabric.

Owner:THE LYCRA CO LLC

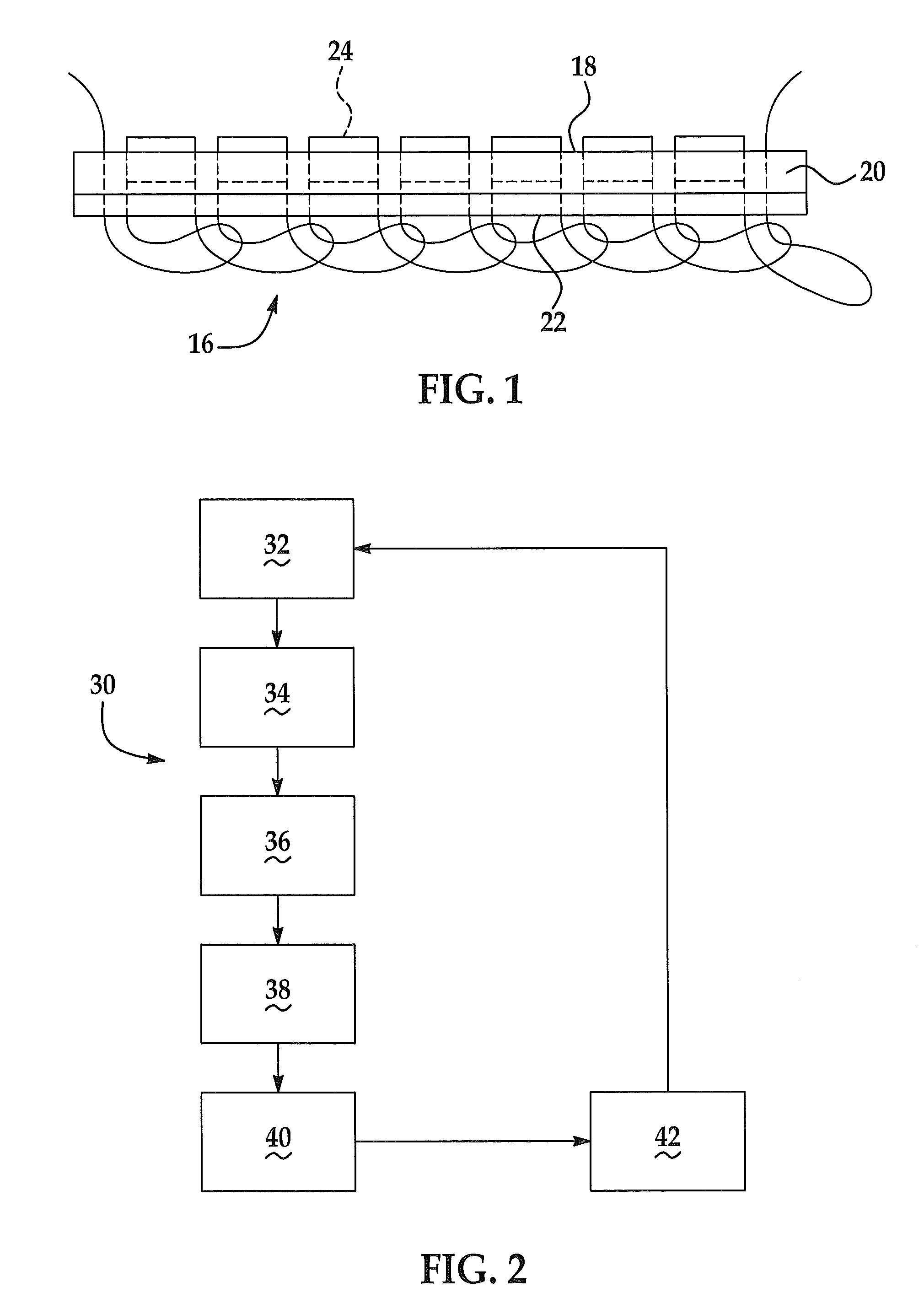

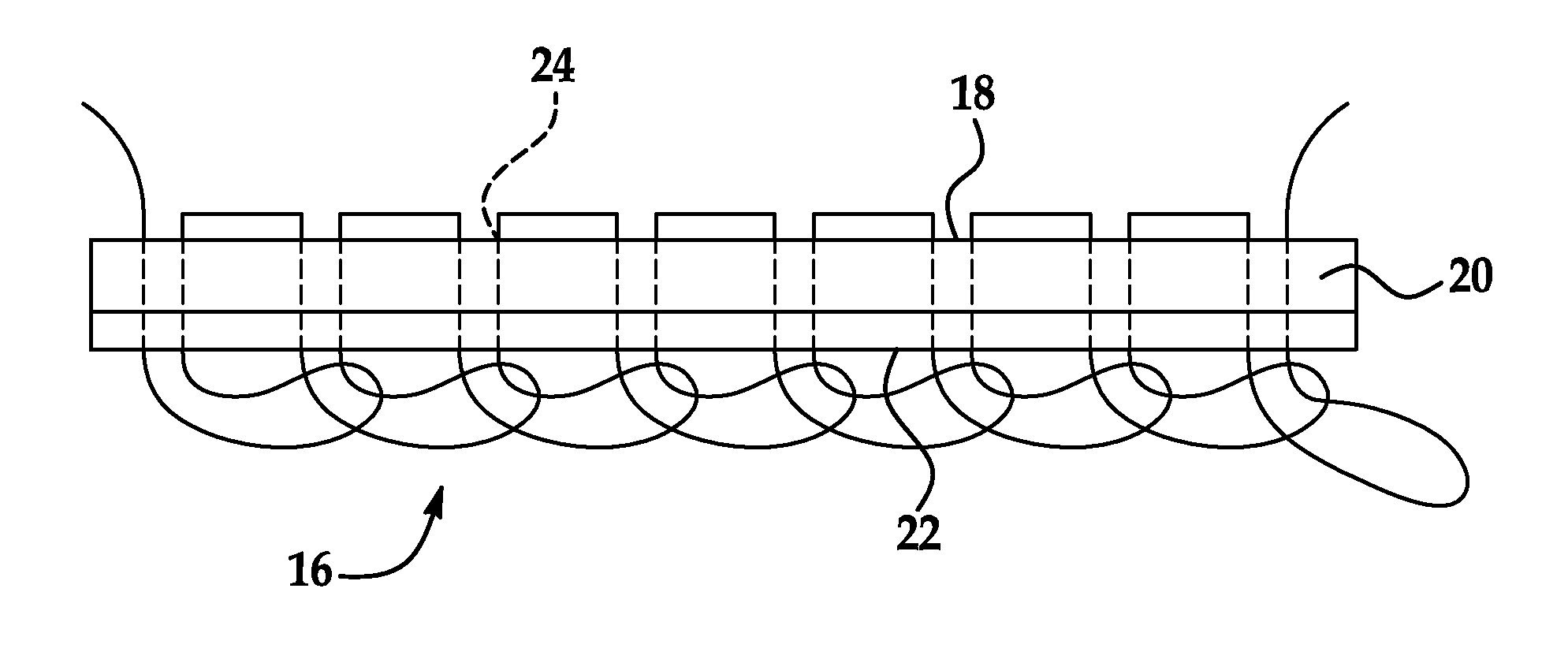

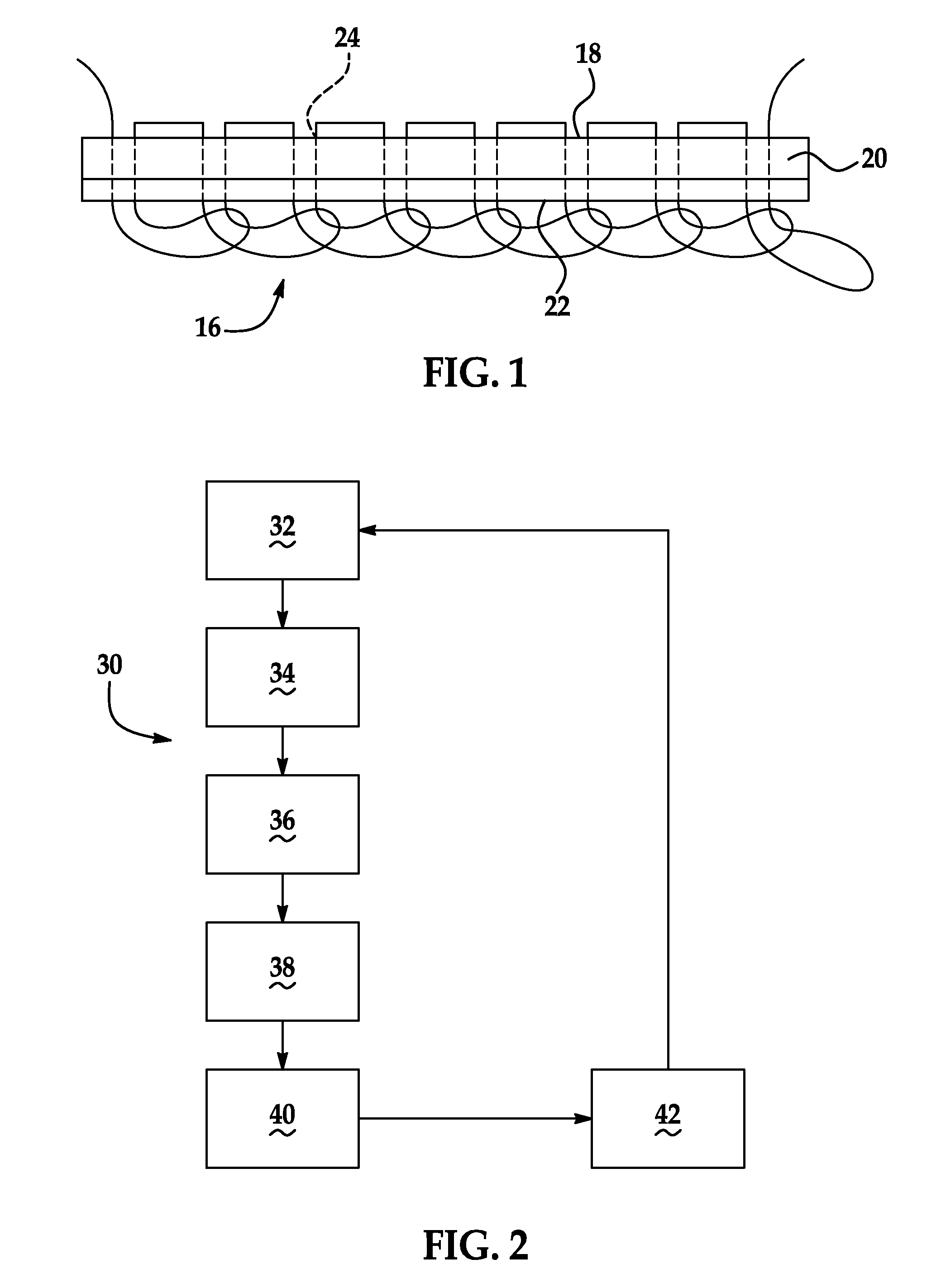

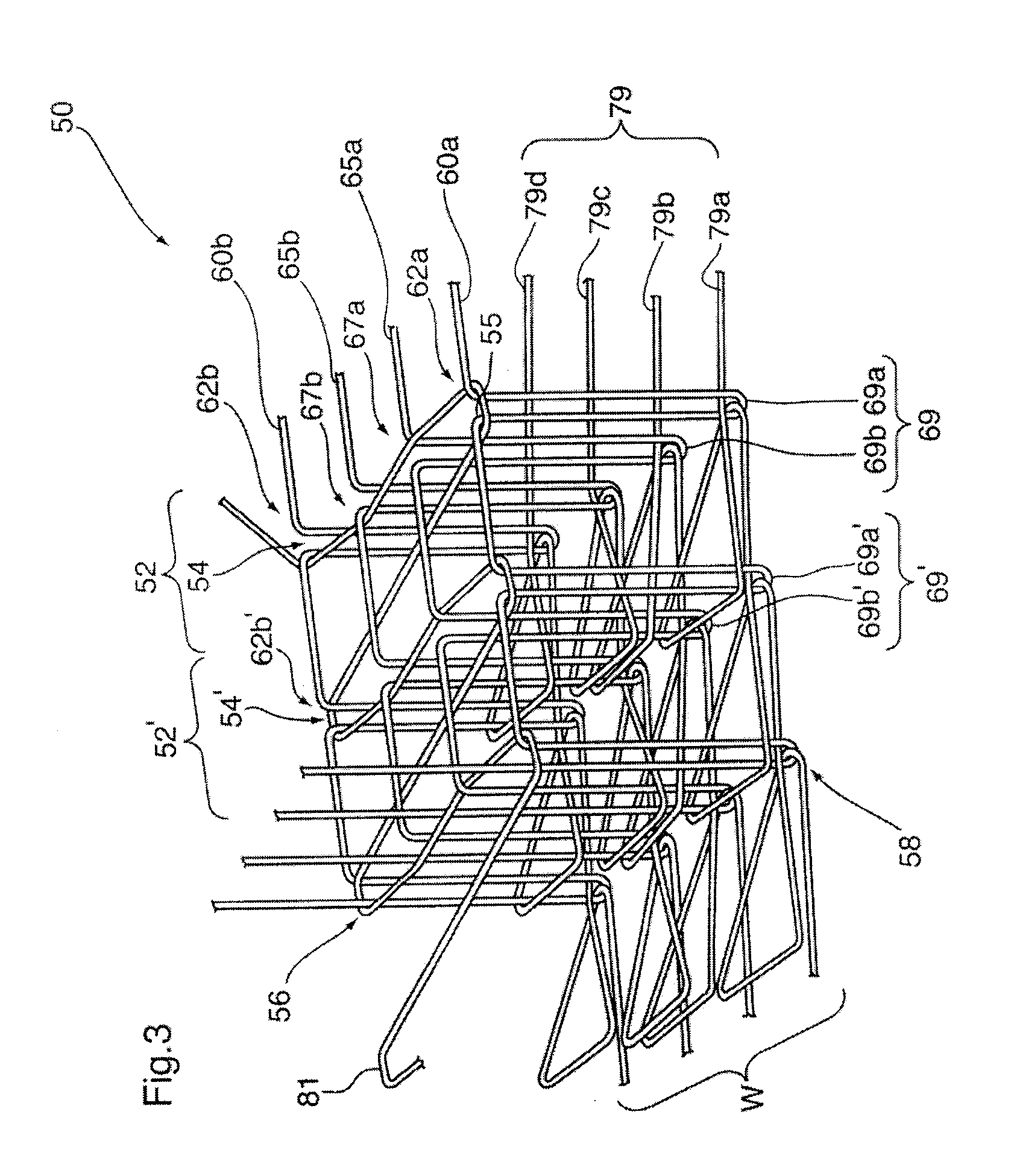

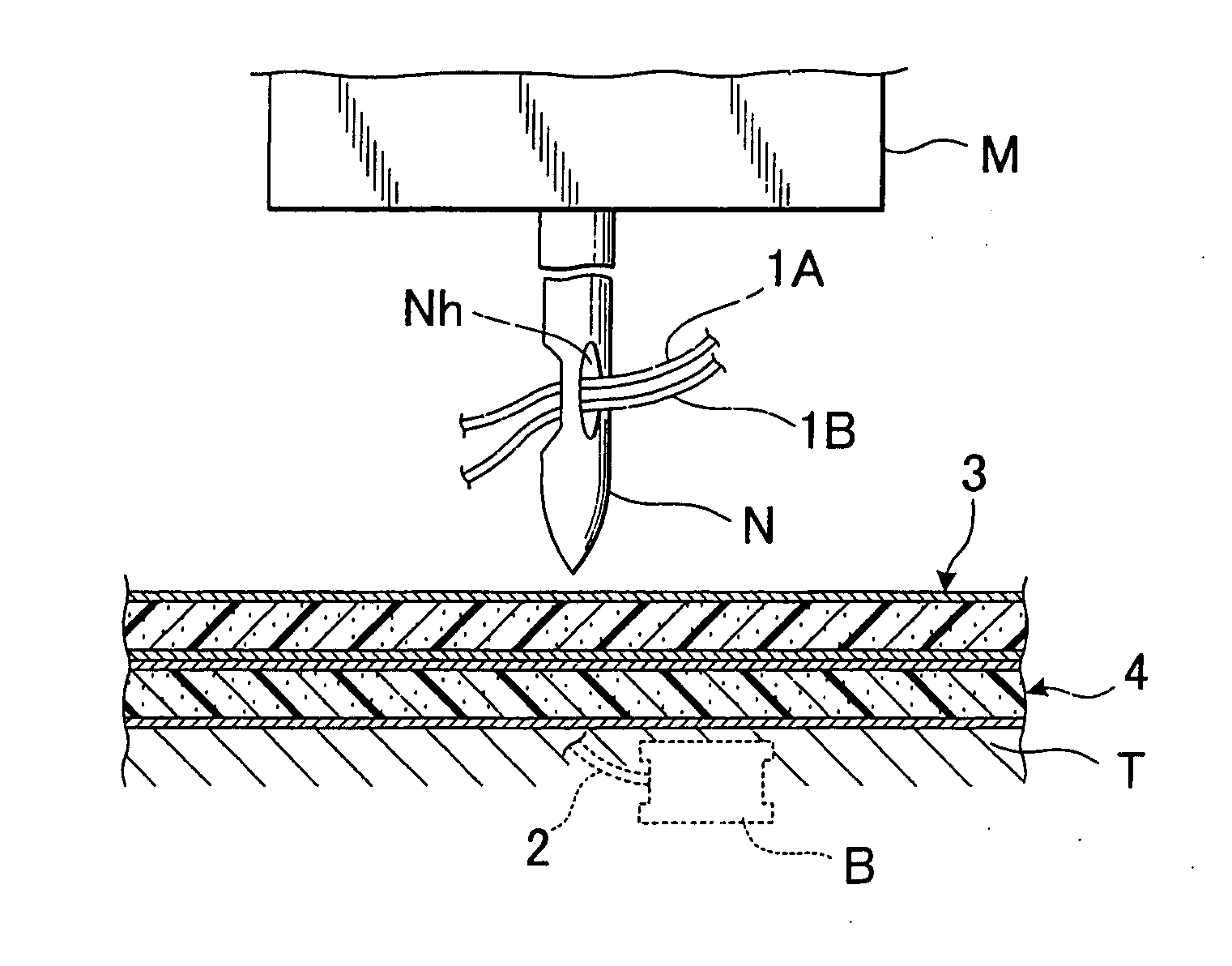

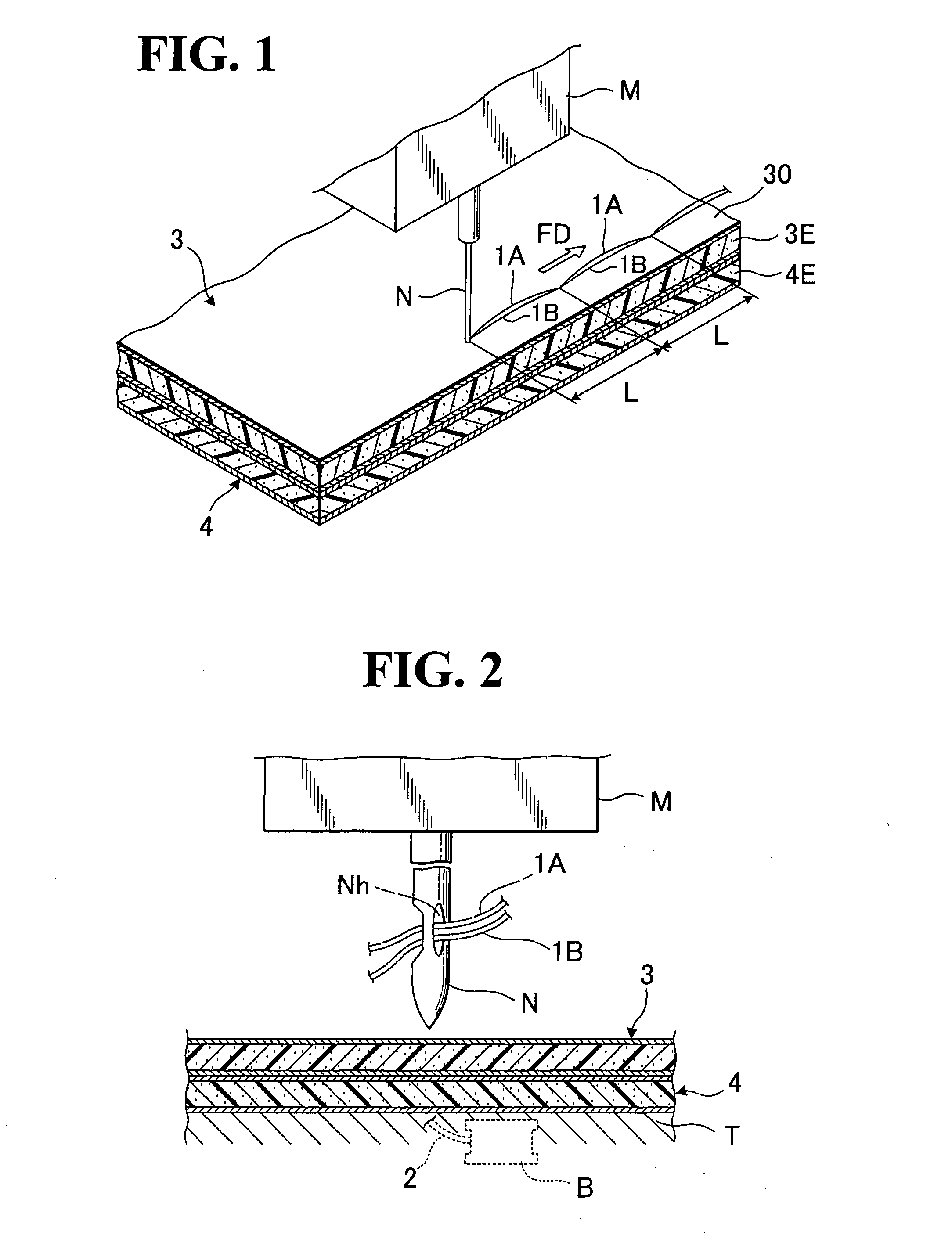

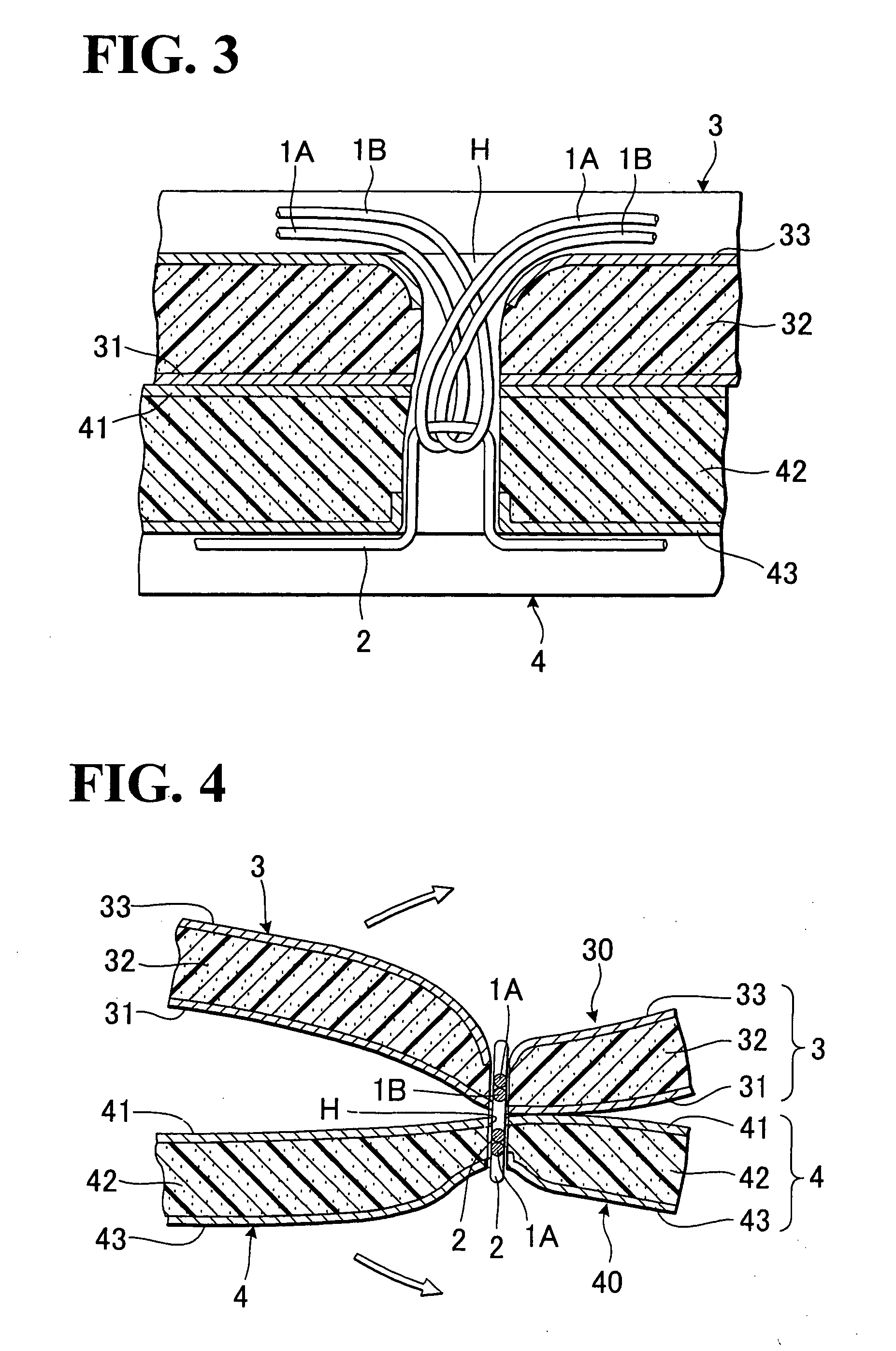

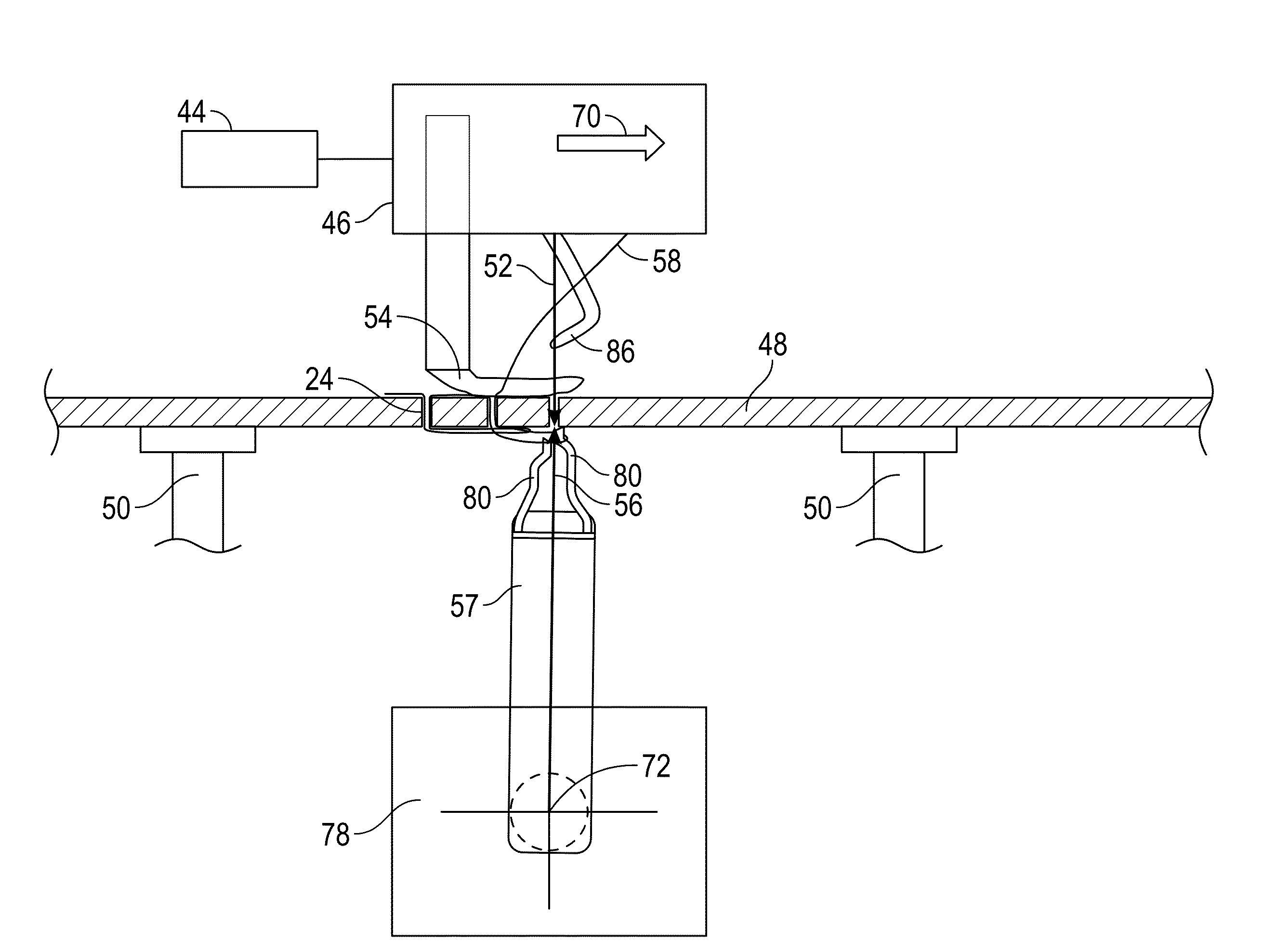

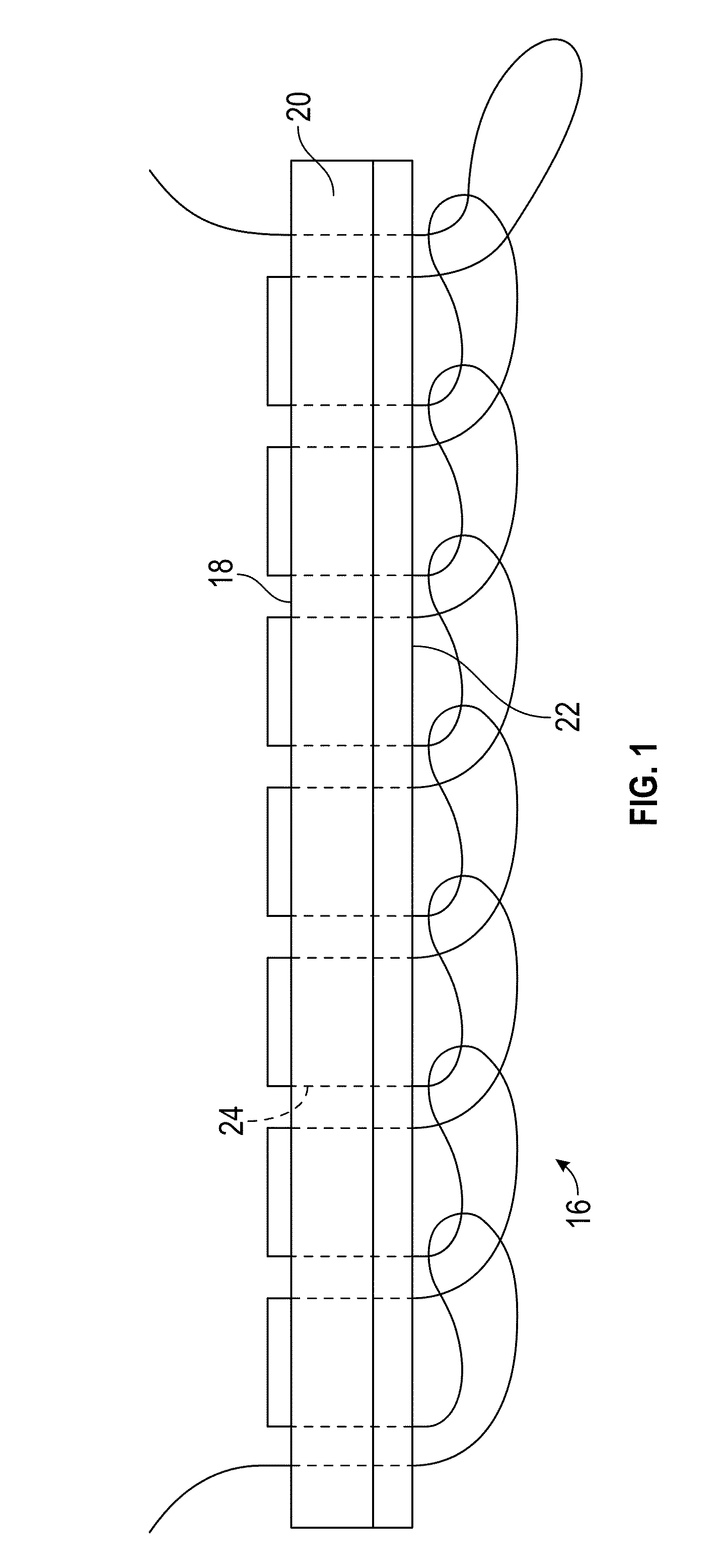

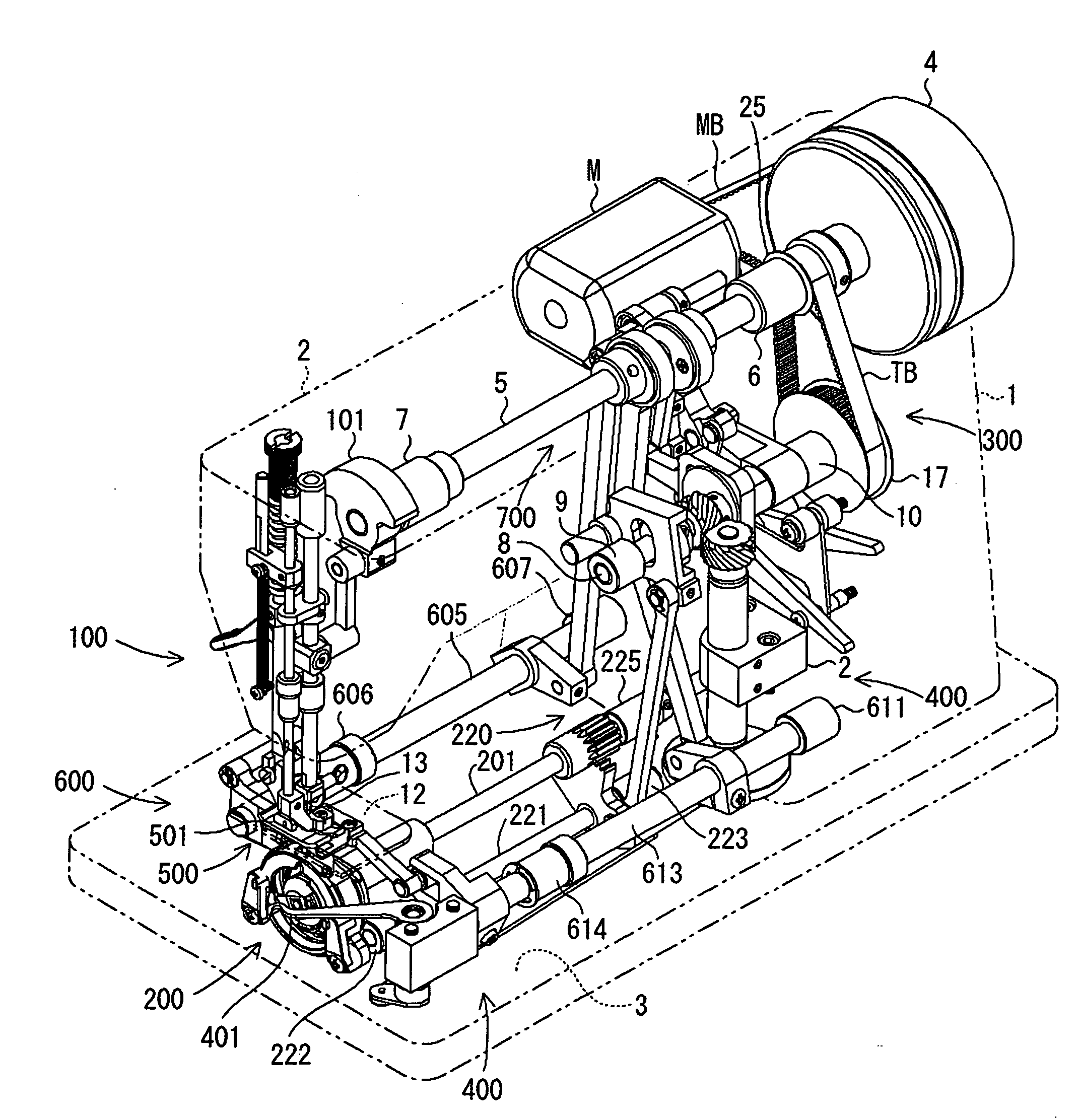

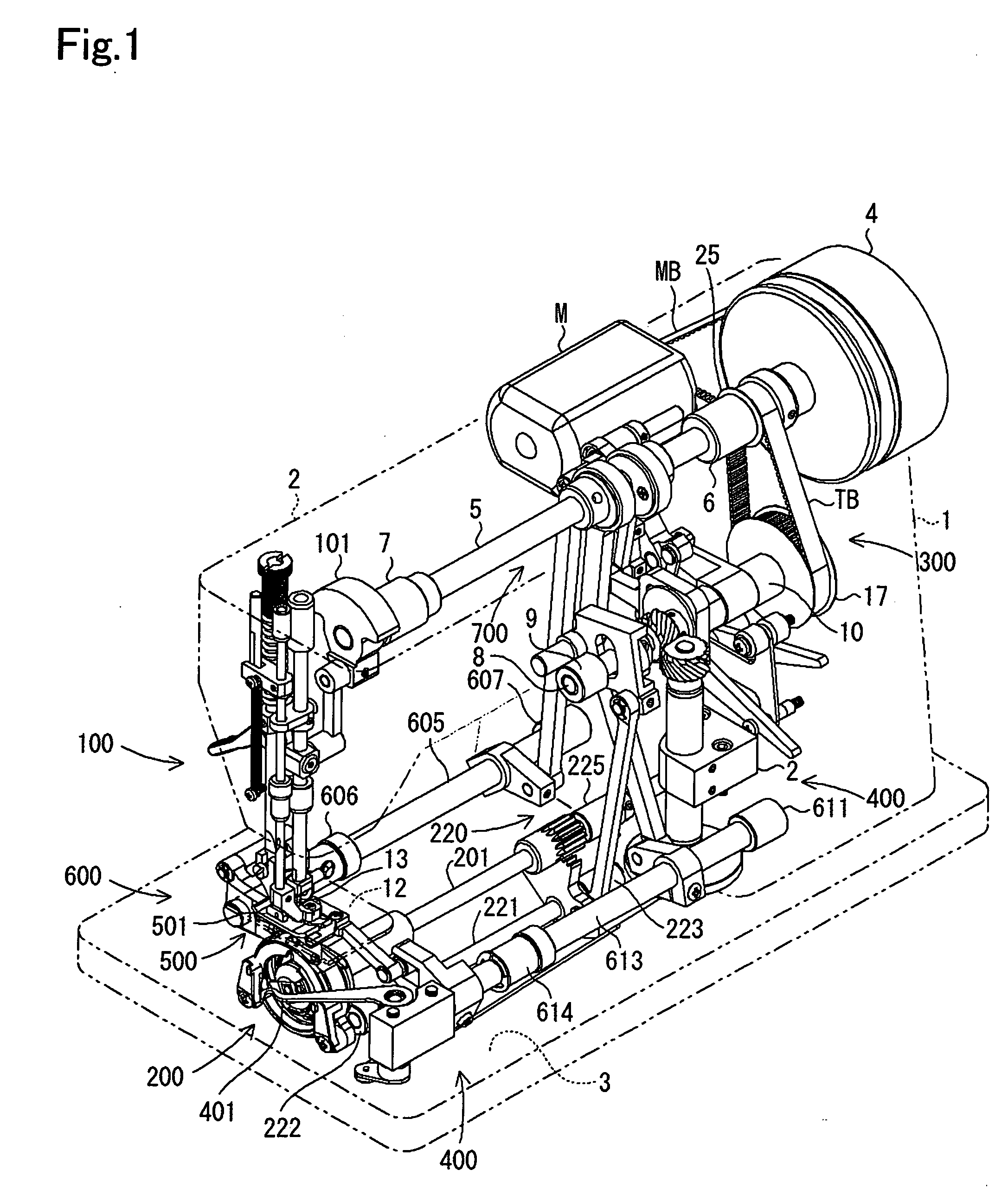

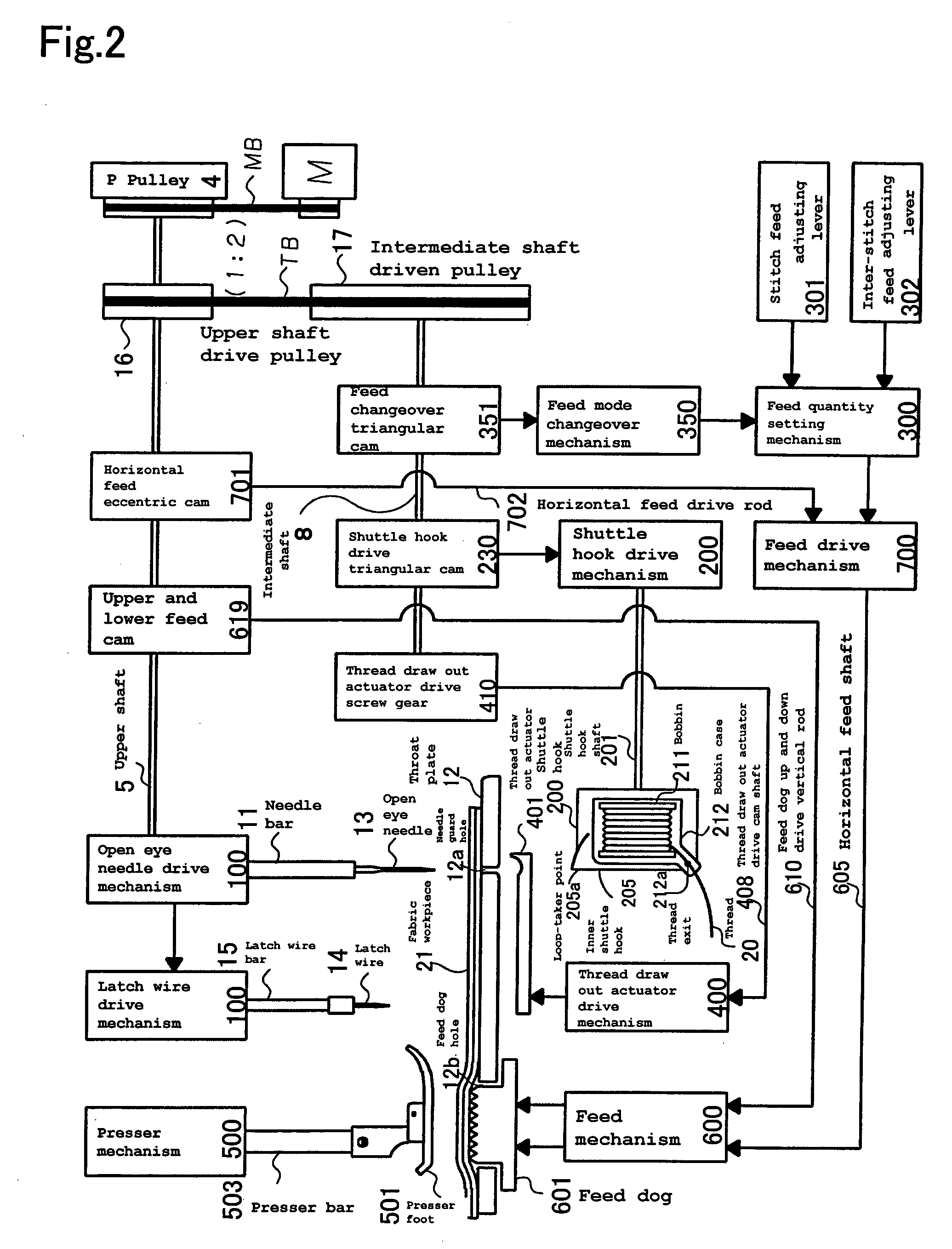

Apparatus and methods for stitching vehicle interior components and components formed from the methods

A method of applying stitching to an interior component is provided herein. The interior component having only a single layer of a substrate layer. The method including the steps of: a) penetrating substrate layer with an awl of a sewing head to form a piercing therethrough; b) retracting the awl from the substrate layer; c) inserting a needle of the same sewing head through the piercing through the substrate layer to grasp a thread positioned on a show surface of the outer skin layer; d) pulling the thread through the substrate layer; e) looping the thread with a previous stitch passed through the substrate layer; f) advancing the sewing head to another position with respect to the interior component, wherein a backside of the substrate layer is free of obstructions; and g) repeating steps a-f until a predetermined amount of stitches are applied to the interior component.

Owner:INTEVA PRODUCTS LLC

Method and Sewing Machine for Forming Single-Thread Locked Handstitches

ActiveUS20090007830A1Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

Sewing thread and sewn fabric product

InactiveUS20060180067A1Improve tensile propertiesImprove performanceLayered productsSewing stitchesFiberEngineering

A sewing thread containing 30% by weight or more of a poly(trimethylene terephthalate)-based staple fiber, and showing a breaking elongation of 30 to 100% and an instantaneous elastic recovery at a 5% elongation of 30 to 75%. This improved sewing thread has excellent suitability for sewing. With this sewing thread, sewn clothes which give no tight feeling and are highly comfortable to wear can be made.

Owner:SOLOTEX CORP

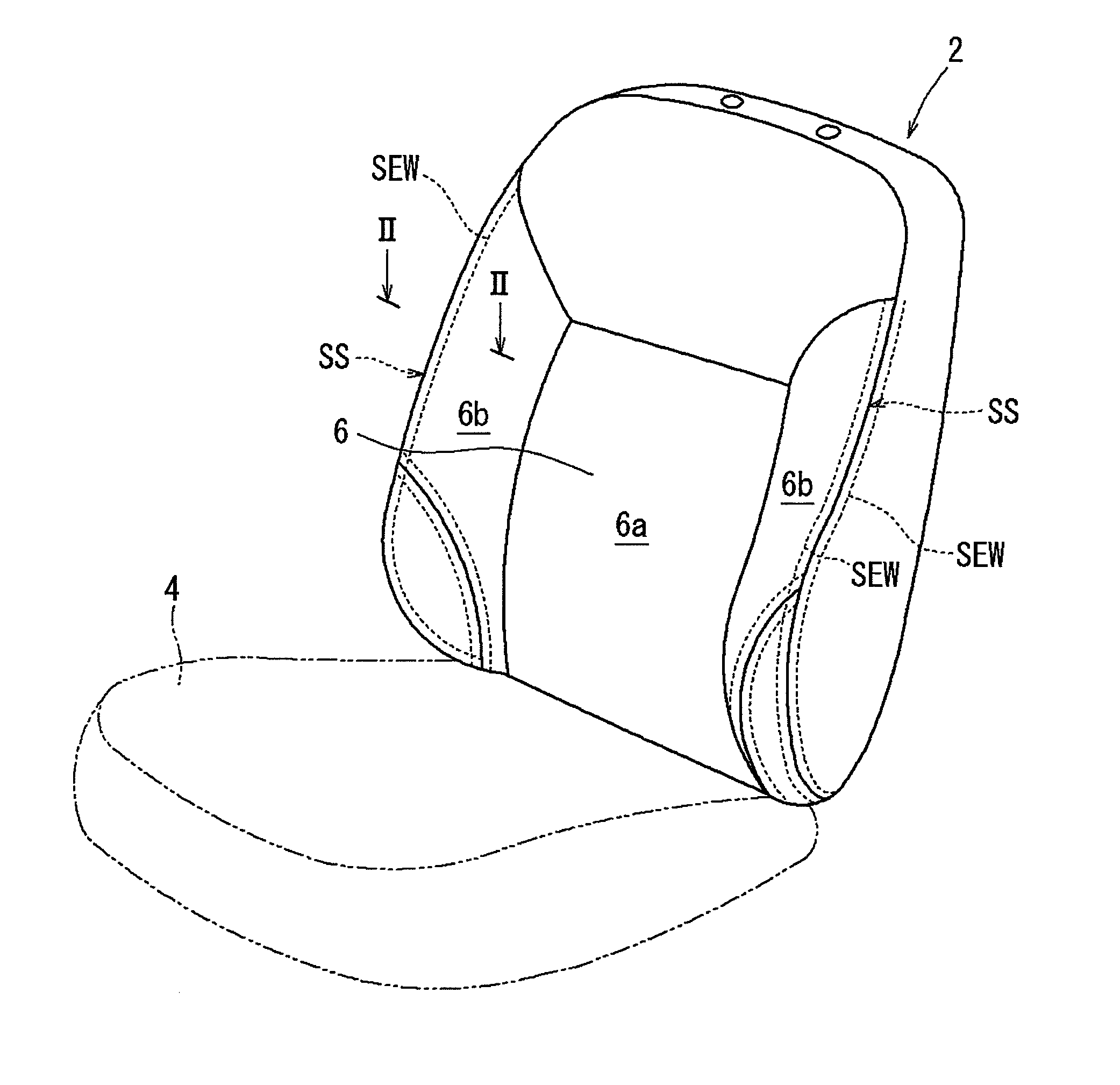

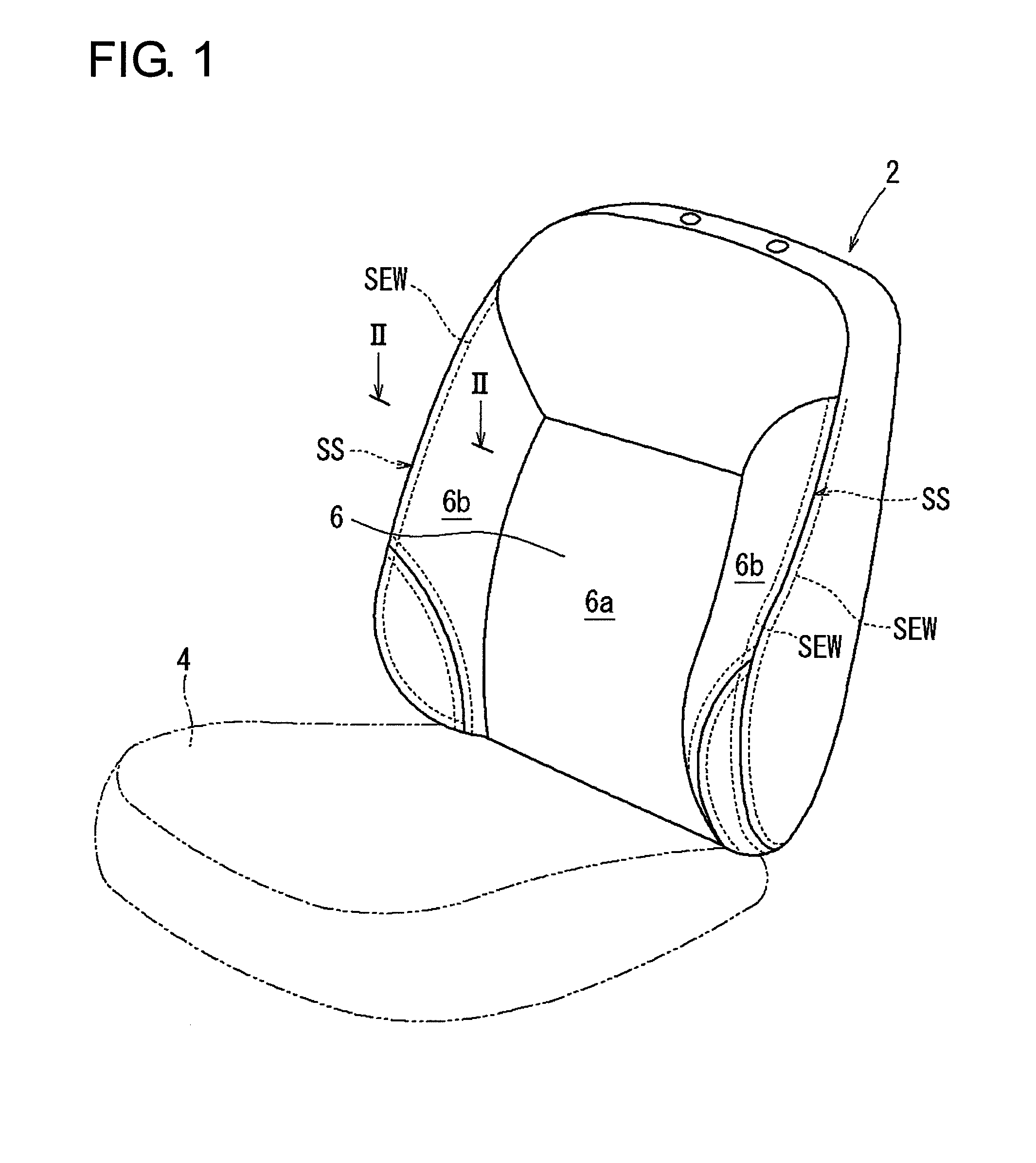

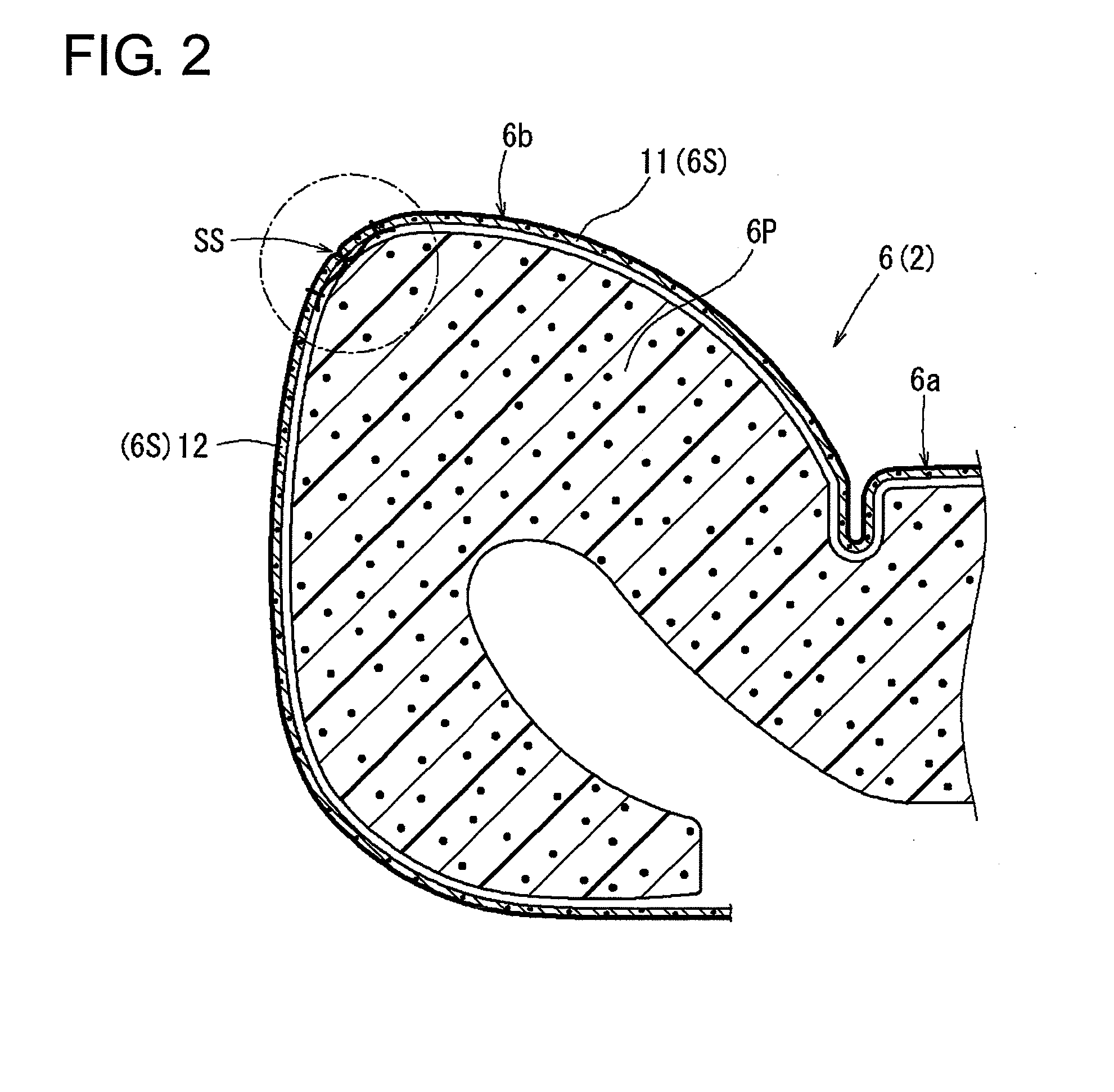

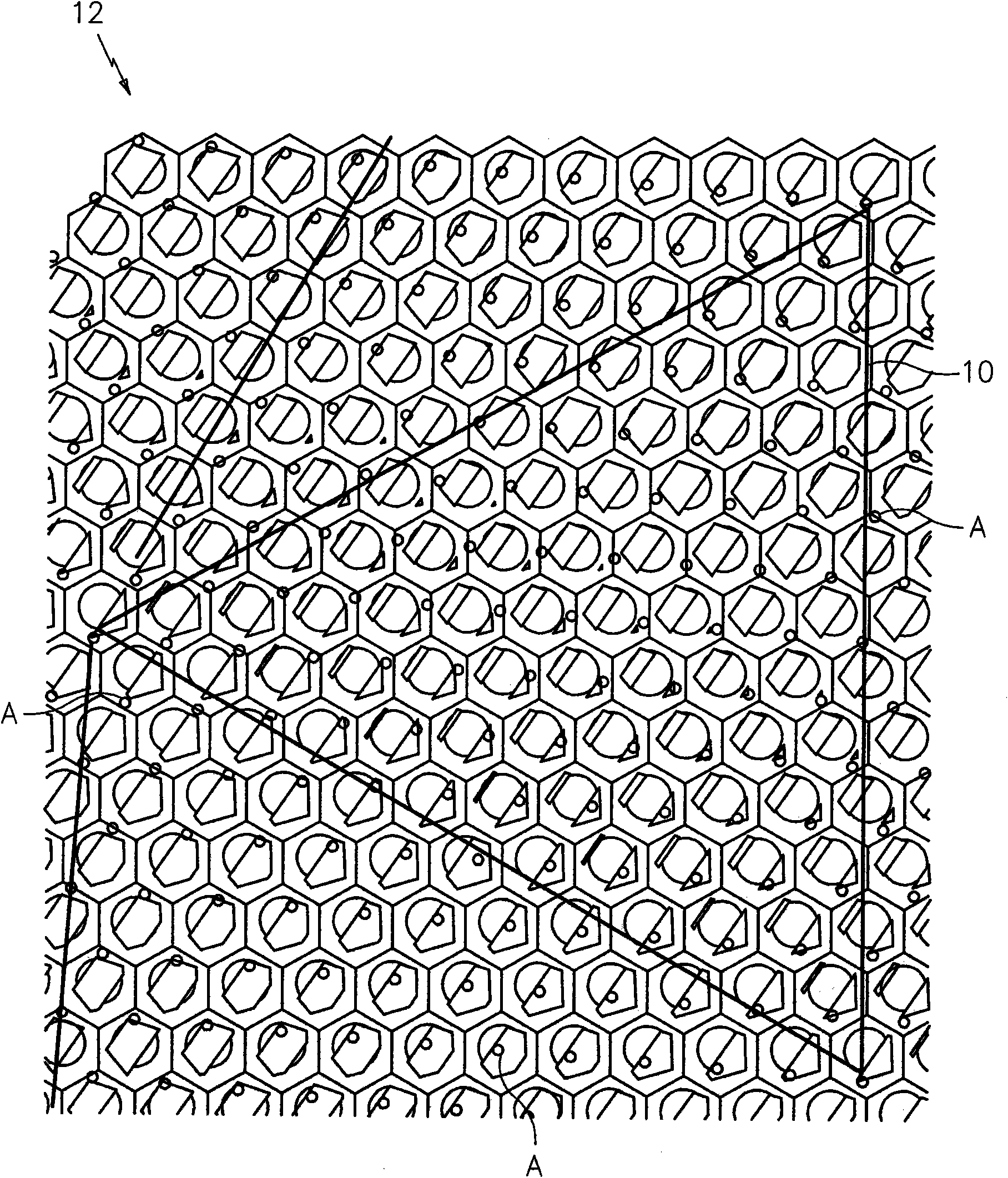

Sewing structure of facing sheet member for covering vehicle seat, method for producing the same, and air bag structure for vehicle seat

InactiveUS20100127487A1Reduce thicknessSimple structureUpholstery manufactureVehicle seatsFace sheetAirbag deployment

Owner:DUKE UNIV +1

Improved micro-optic security device

Owner:CRANE SECURITY TECH

Methods for improving conformability of non-crimp fabric and contoured composite components made using such methods

Methods for making a self-conforming non-crimp fabric involving tailoring at least a first parameter to anchor the fabric and at least a second parameter to provide conformability of the fabric, the first and second parameters selected from stitch type, stitch spacing, stitch density, stitch material, stitch weight, stitch tension, and combinations of the same.

Owner:GENERAL ELECTRIC CO

Embroidered emblem for securing to a first fabric

An embroidered emblem for securing to a first fabric is comprised of a fabric base having a front surface and a rear surface. The fabric base is made of the same or substantially the same material as the first fabric and has the same or substantially the same weave pattern and color as the first fabric. A design is embroidered into the fabric base, the design including a stitched border extending around the outer periphery of the front surface of the fabric base. The border is made utilizing a relatively small sized needle and a relatively thin, dull yarn which is the same or substantially the same color as the color of fabric base. In this manner, when the embroidered emblem is secured to the first fabric the border as well as the fabric base fades into the first fabric so as to be nearly invisible.

Owner:PENN EMBLEM

Security luggage bag

Owner:MRM HK

Electrical conductor element

InactiveUS20070056493A1Input/output for user-computer interactionEmergency casingsFiberElectrical conductor

A position sensor is shown for detecting the position of a mechanical interaction. The sensor includes a first conductive fabric layer having electrically conductive fibres incorporated therein to allow conduction in a first direction. The first conductive fabric layer has a first electrical conductor element a and a second electrical conductor element positioned at opposite ends of a first conductive path extending in a first direction. The first and second electrical conductor elements each comprise a length of electrically conductive thread machined to form a conductive track of stitches that extends in a second direction substantially perpendicular to the first direction. The first and second electrical conductor elements do not intersect.

Owner:PERATECH

Method for sewing together covering elements adapted to undergo foaming process

InactiveUS6845725B2Easy to operateSimple processSeat coveringsLeather sewingFoaming agentSewing needle

A method for sewing together covering elements is provided, in which two first threads and a second thread are used in a sewing machine having sewing needle means. In operating the sewing machine, the covering elements are fed at a given feeding pitch, such that the two first threads are entwined about the second thread in each of needle holes formed by the sewing needle means in the covering elements. Those entwined three threads fill and close the needle hole, thereby preventing leakage of a liquid foaming agent at a foaming process for forming a foamed product integral with the covering elements. The sewing needle means may comprise one sewing needle, in which case, both two first threads are used in that one sewing needle, or alternatively may comprises two sewing needles, in which case, the two first sewing threads are respectively used in the two sewing needles.

Owner:TACHI S CO LTD

Stitch bonded wipe

A disinfecting cleaning wipe of stitch-bonded construction. The wipe includes a stitching substrate of fibrous nonwoven material having a mass per unit area of not more than 30 grams per square meter. A first plurality of stitching yarns is disposed in stitched relation through the stitching substrate in a pattern of substantially parallel linear stitch lines extending in a first direction across the stitching substrate. At least a second plurality of stitching yarns is disposed in stitched relation through the stitching substrate in a repeating zigzag pattern to define a first group of surface yarn float segments extending diagonally between stitch positions at opposing linear stitch lines. A disinfecting solution at least partially saturates the cleaning wipe.

Owner:TIETEX INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com