Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about "Thread-laying mechanisms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

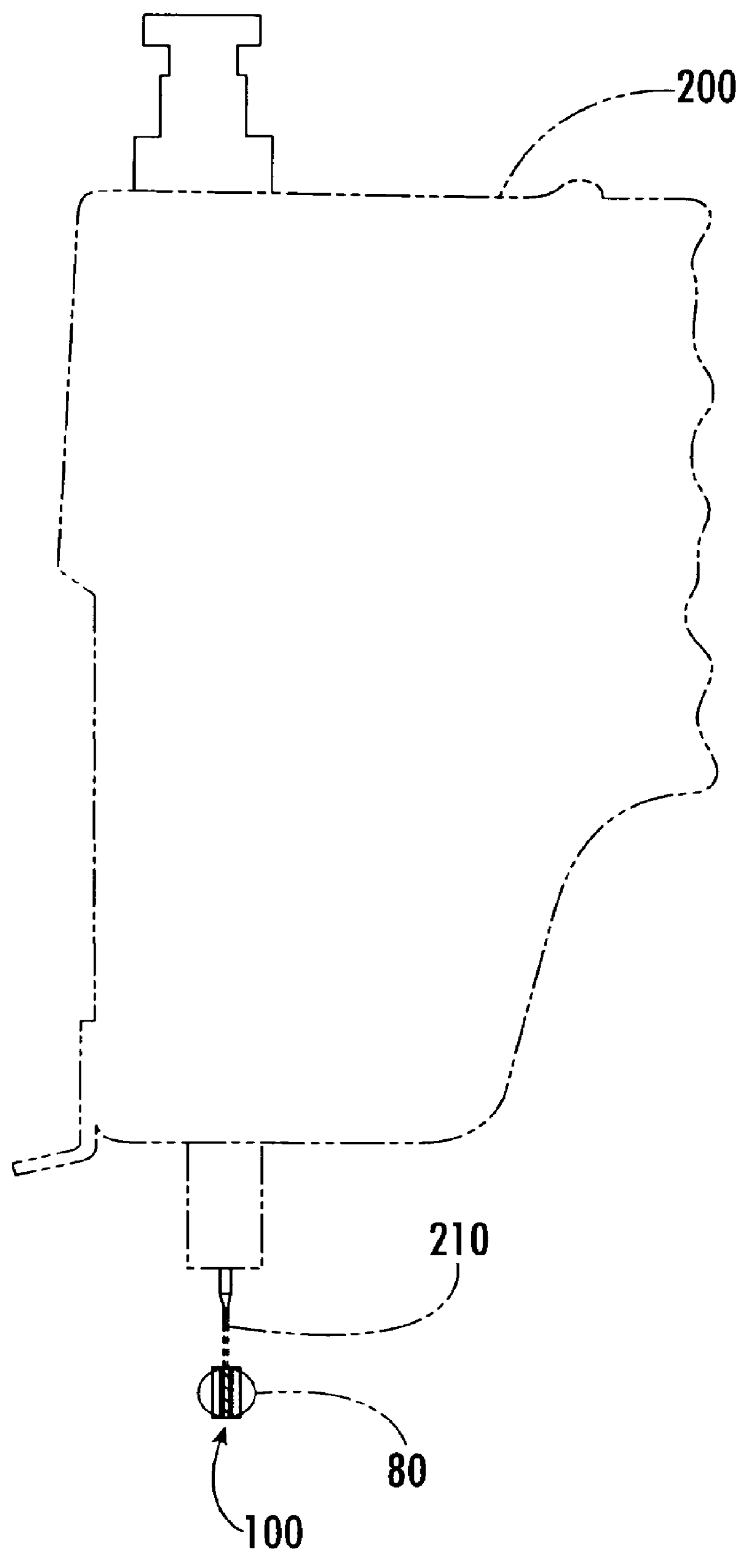

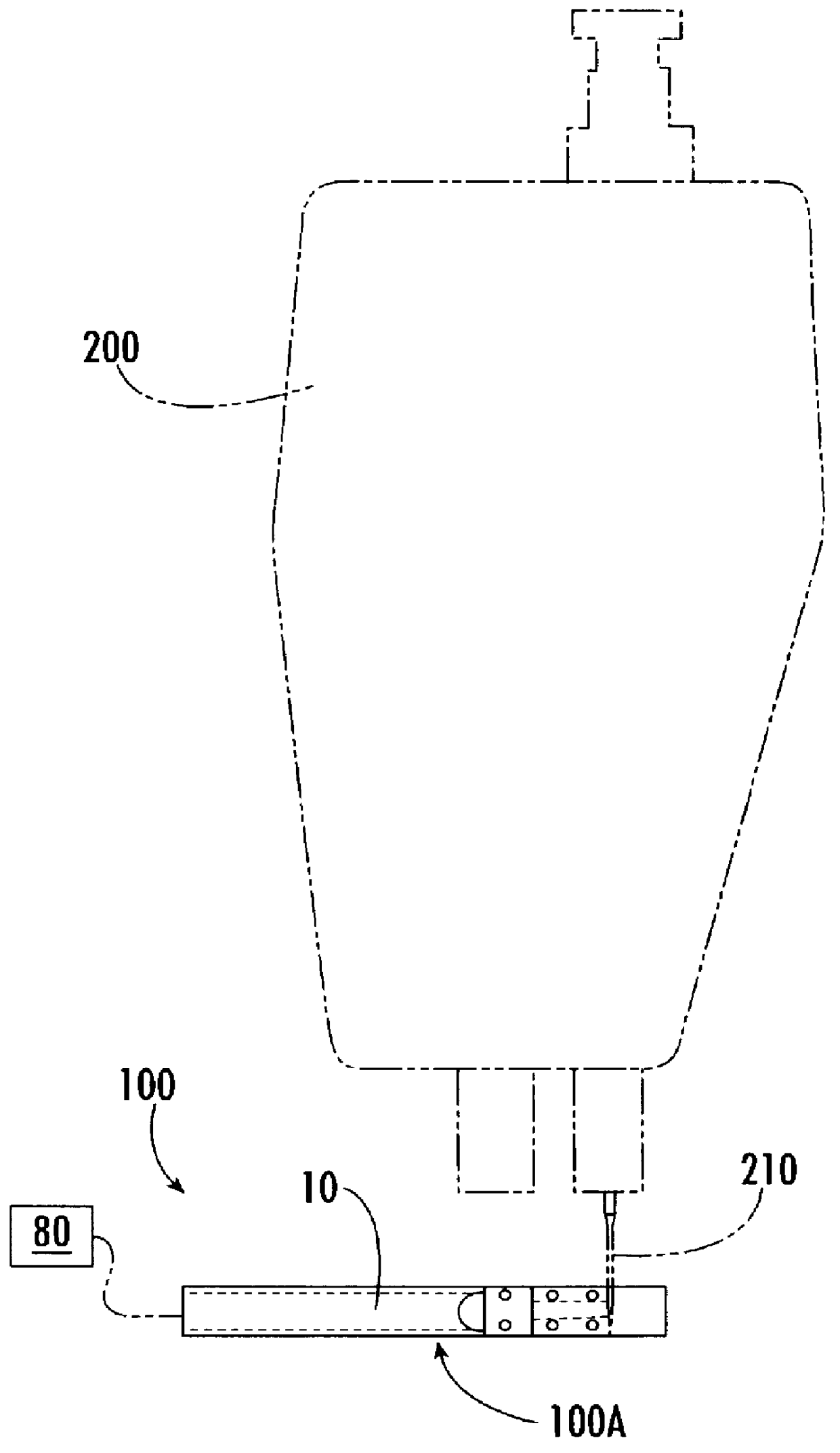

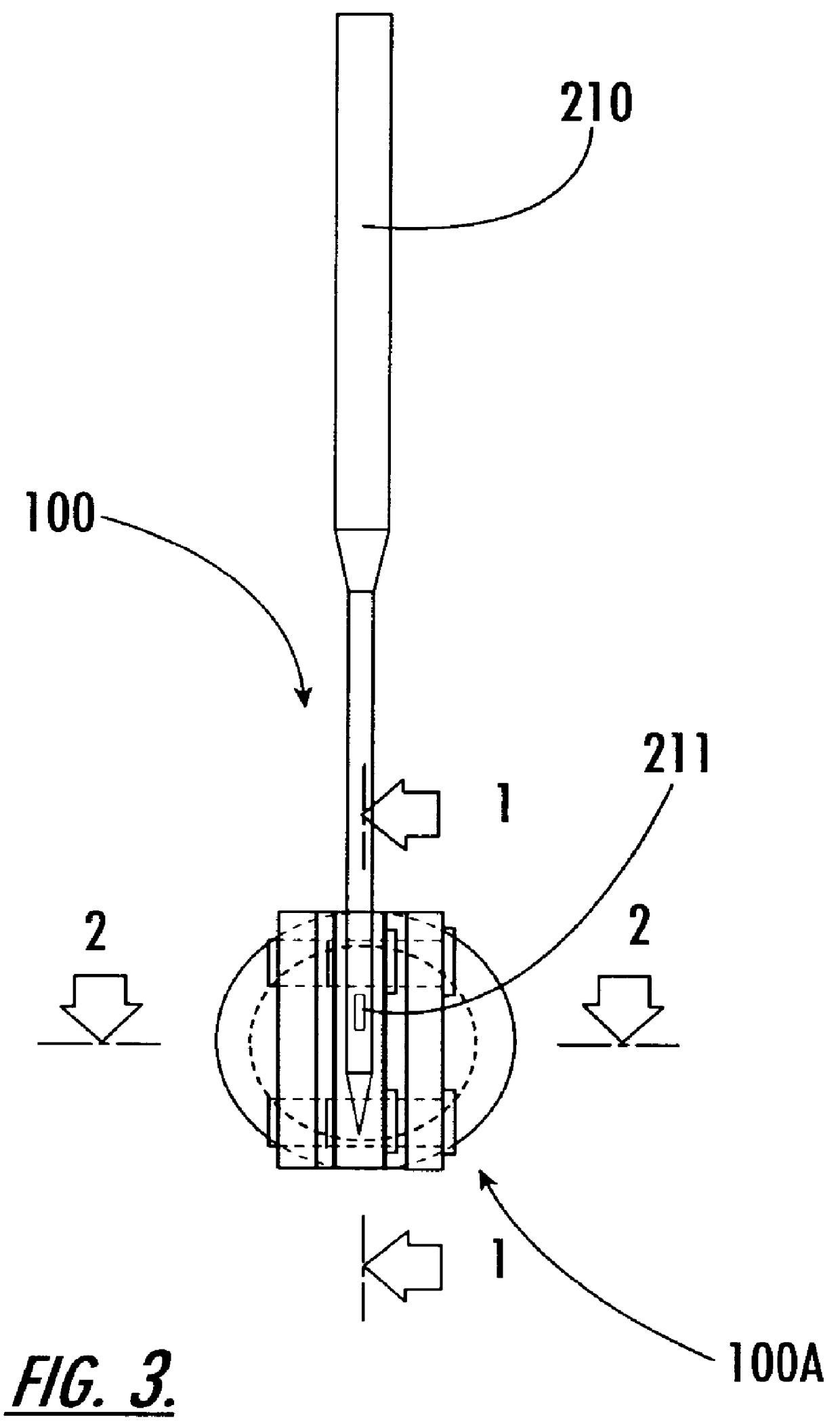

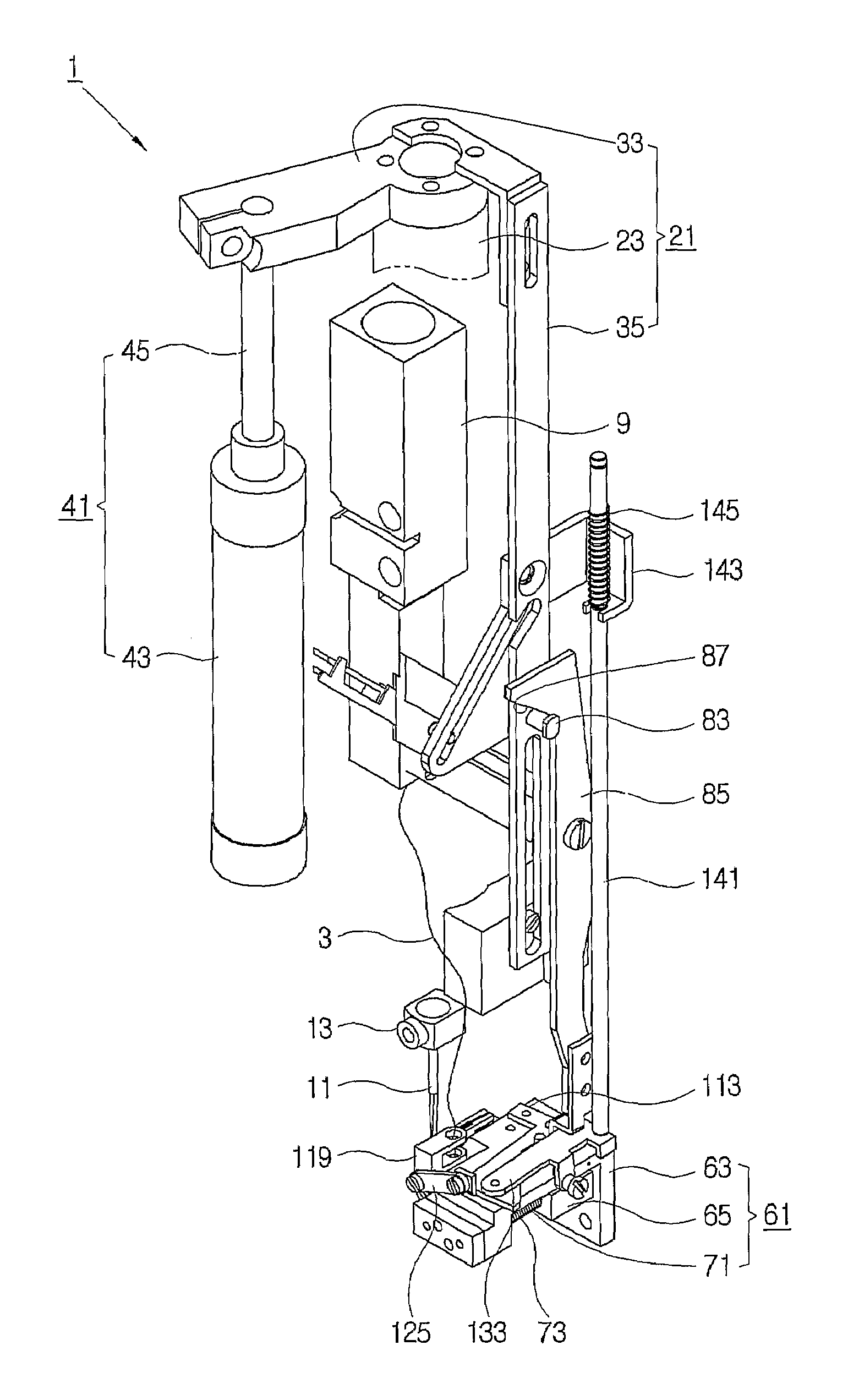

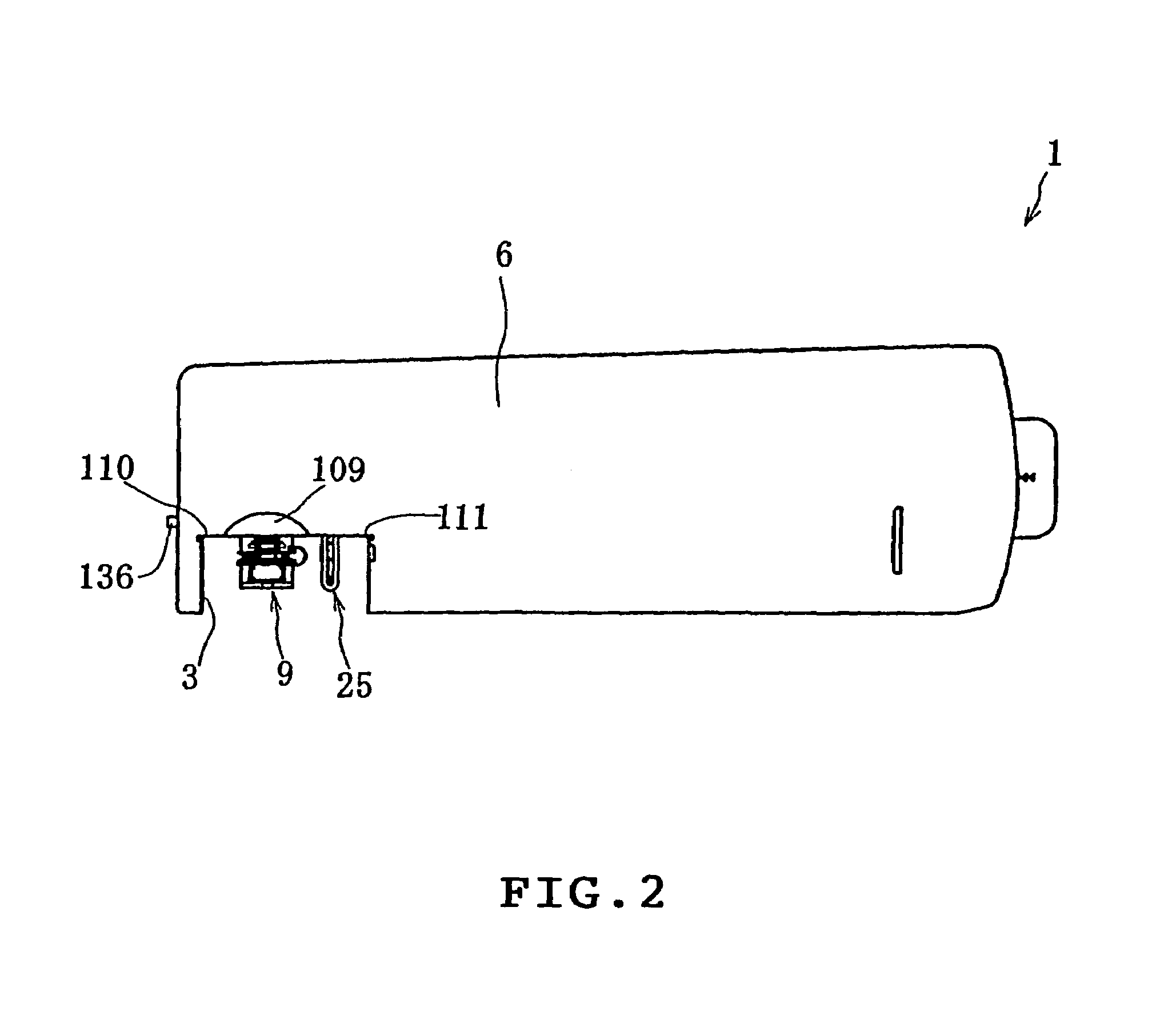

Threading device of sewing machine

InactiveUS20080257241A1Easily and visually recognizeReduce stepsFilament handlingLightening equipmentEngineeringScrew thread

A threading device of a sewing machine includes a thread inserting base formed with a thread path hole having a thread inserting port opened toward an outer side of a sewing machine frame, and further formed with an air path hole which joins the thread path hole in the vicinity of the thread inserting port, an air supply device coupled to the air path hole to supply compressed air, and illuminating means provided on the sewing machine frame to irradiate a joining portion of the thread path hole and the air path hole. The thread inserting base includes a transparent member through which at least the joining portion of the thread path hole and the air path hole can be visually recognized.

Owner:JUKI CORP

Thread drawing device of sewing machine

InactiveCN101158089AImprove sewing qualityImprove work efficiencyNeedle severing devicesThread-break detectorsEngineeringComputer control

The invention provides a wire grip of a sewing machine, pertaining to the sewing machine field, which solves the problem that: an ordinary computer controlled flat bed sewing machine tends to cause a nest-shaped stitch. The wire grip of the sewing machine is positioned on a machine head of the sewing machine and between a small wire clamping nut and a wire clamping device; the wire grip consists of a wire drawing head arranged on the machine head and a drive device that can ensure the wire drawing head to slide to and fro along the level direction, and the wire drawing head is provided with a through hole for passing a sewing wire. The wire grip of the sewing machine has the advantages that the nest shaped stitch does not be produced during the sewing process, so the stitch is beautiful; moreover, the wire grip has the advantages of simple whole structure, convenient operation and using, low manufacturing cost, and good working stability.

Owner:JACK SEWING MASCH CO LTD

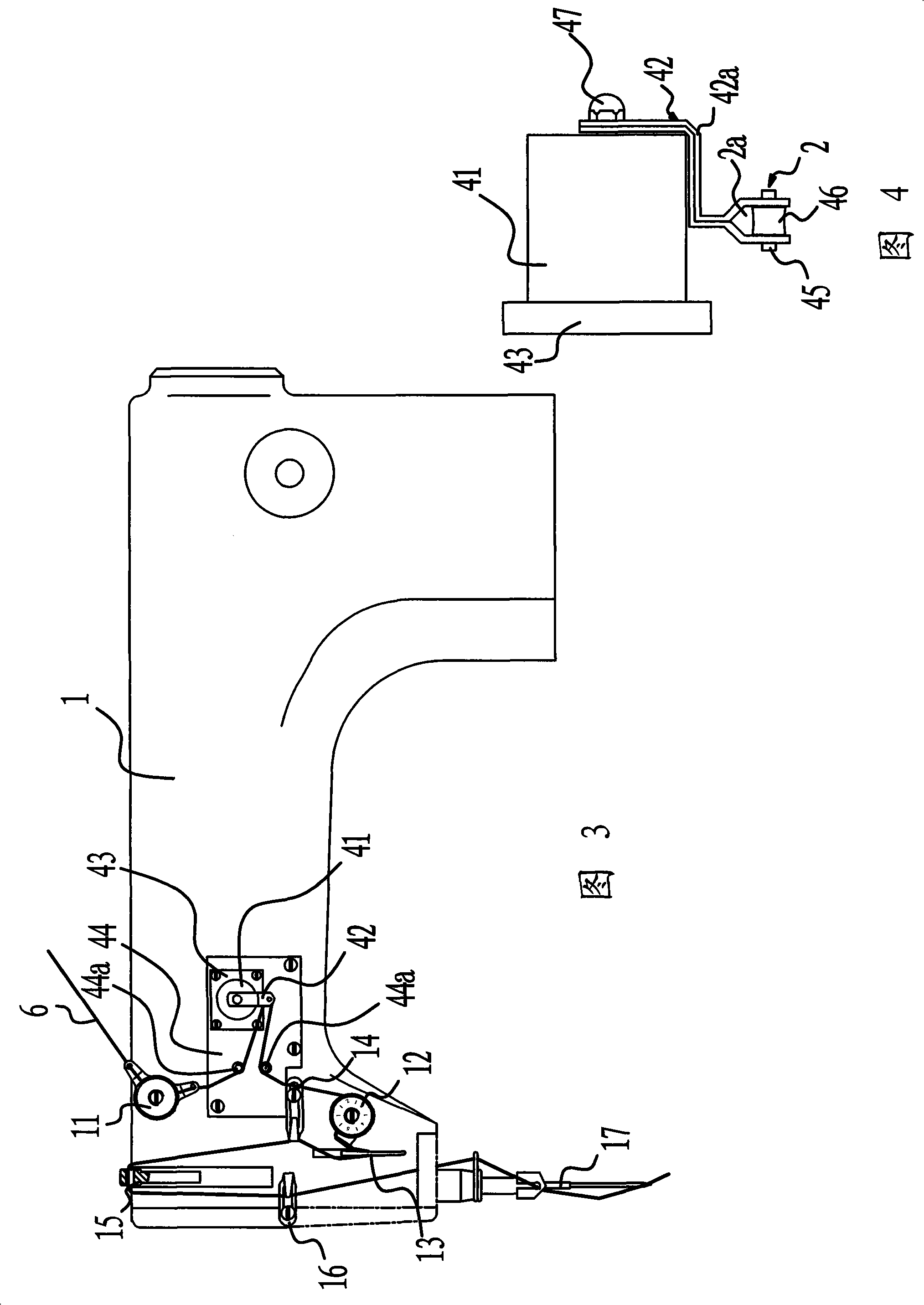

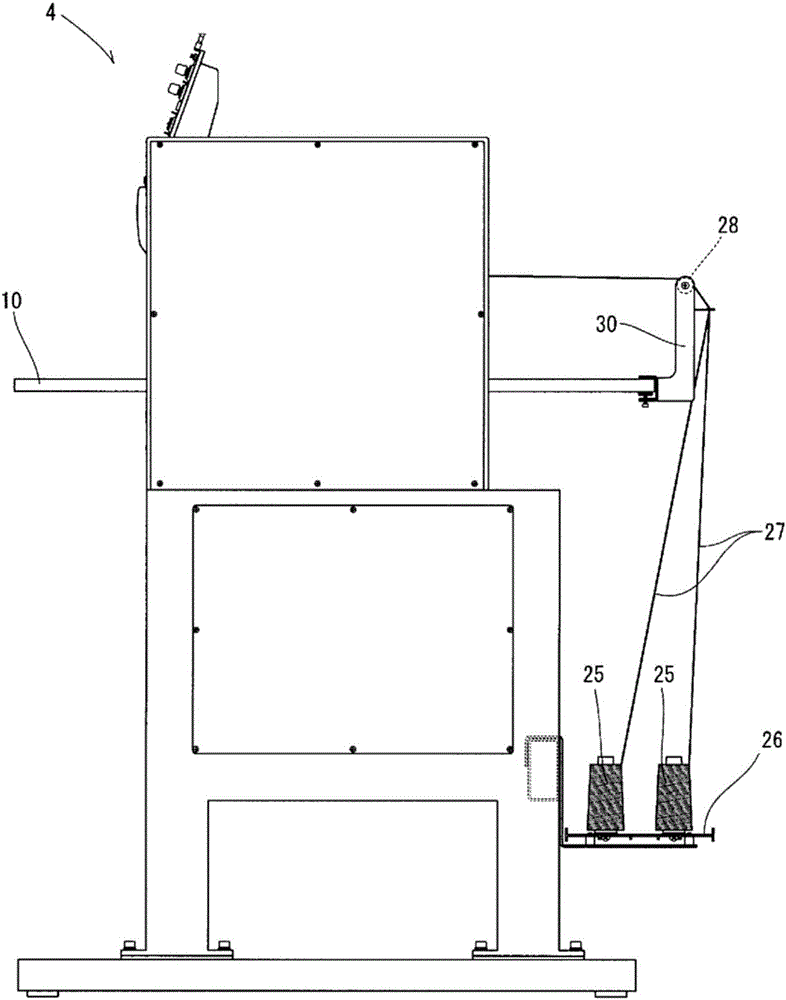

Full-automatic pocket patching machine

ActiveCN104746243ASo as not to damageSolve the contradiction between supply and demandWork-feeding meansPressersEngineeringFully automated

The invention discloses a full-automatic pocket patching machine and accordingly the working efficiency is high, the degree of automation is high, and sewn finished products comprise double sides and multiple colors. The full-automatic pocket patching machine comprises a base station (1) and a material folding mechanism (2), a feeding mechanism (3), a sewing mechanism (4) and a controller (5) which are arranged on the base station (1); the sewing mechanism (4) comprises a sewing table, a head, at least two working needles, a plurality of pressing feet, an automatic needle replacement module and a pressing foot lifting mechanism; the working needles are arranged on the head; the pressing feet are matched with the working needles respectively; the pressing foot lifting mechanism is matched with the pressing feet; the sewing table is provided with at least two spindles which are matched with the working needles respectively. The full-automatic pocket patching machine is applied to the technical field of automatic sewing equipment.

Owner:深圳市达益信智能设备有限公司

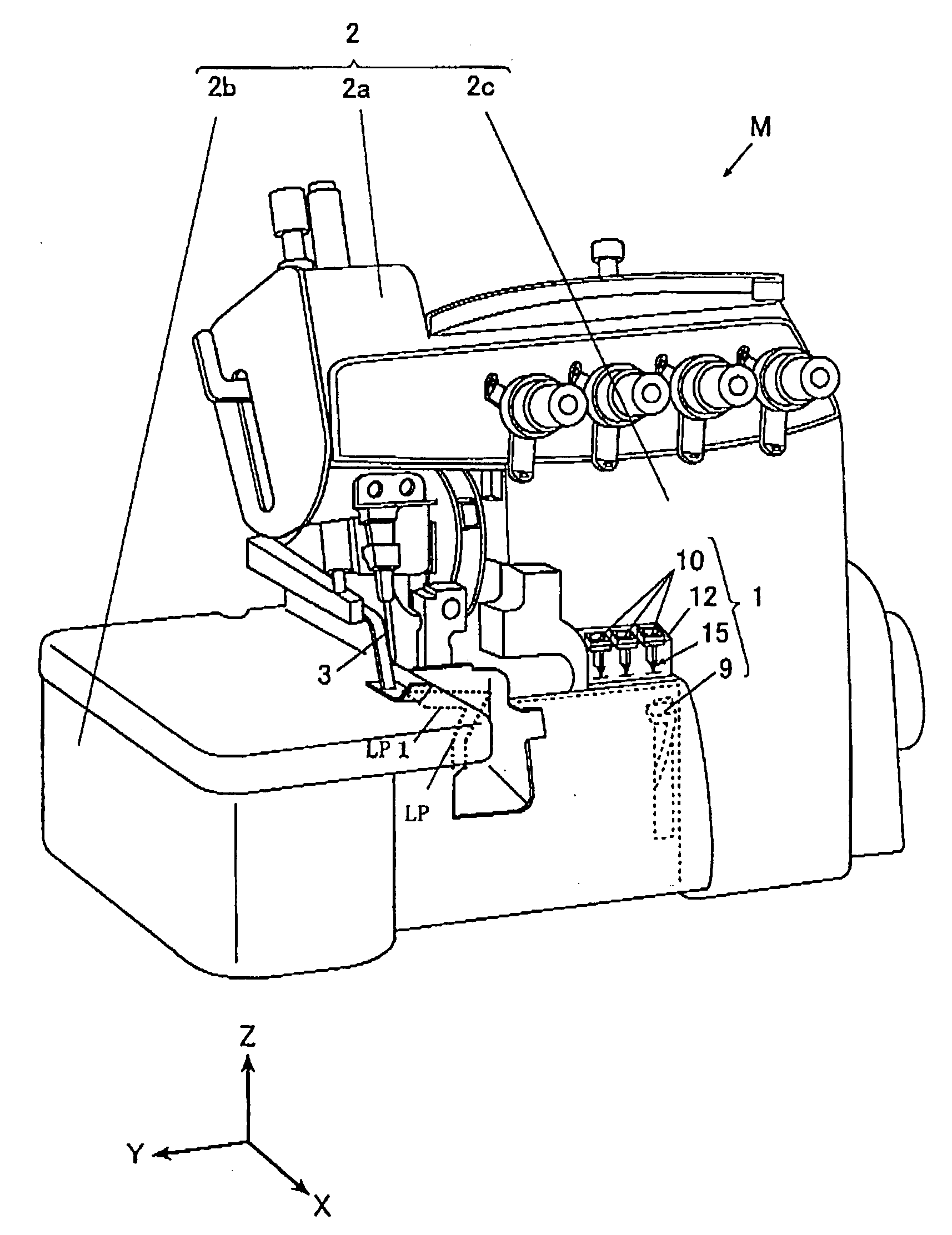

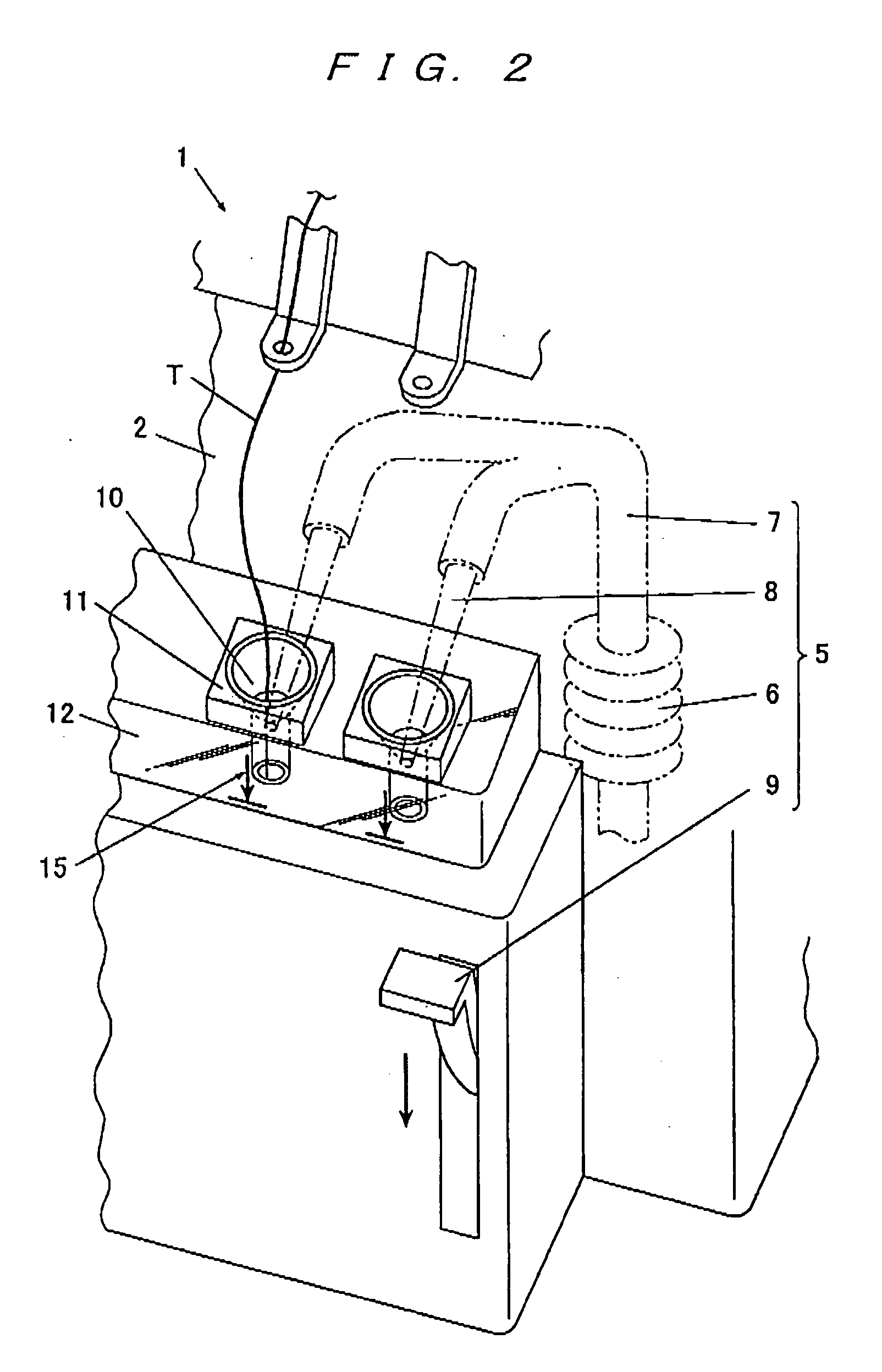

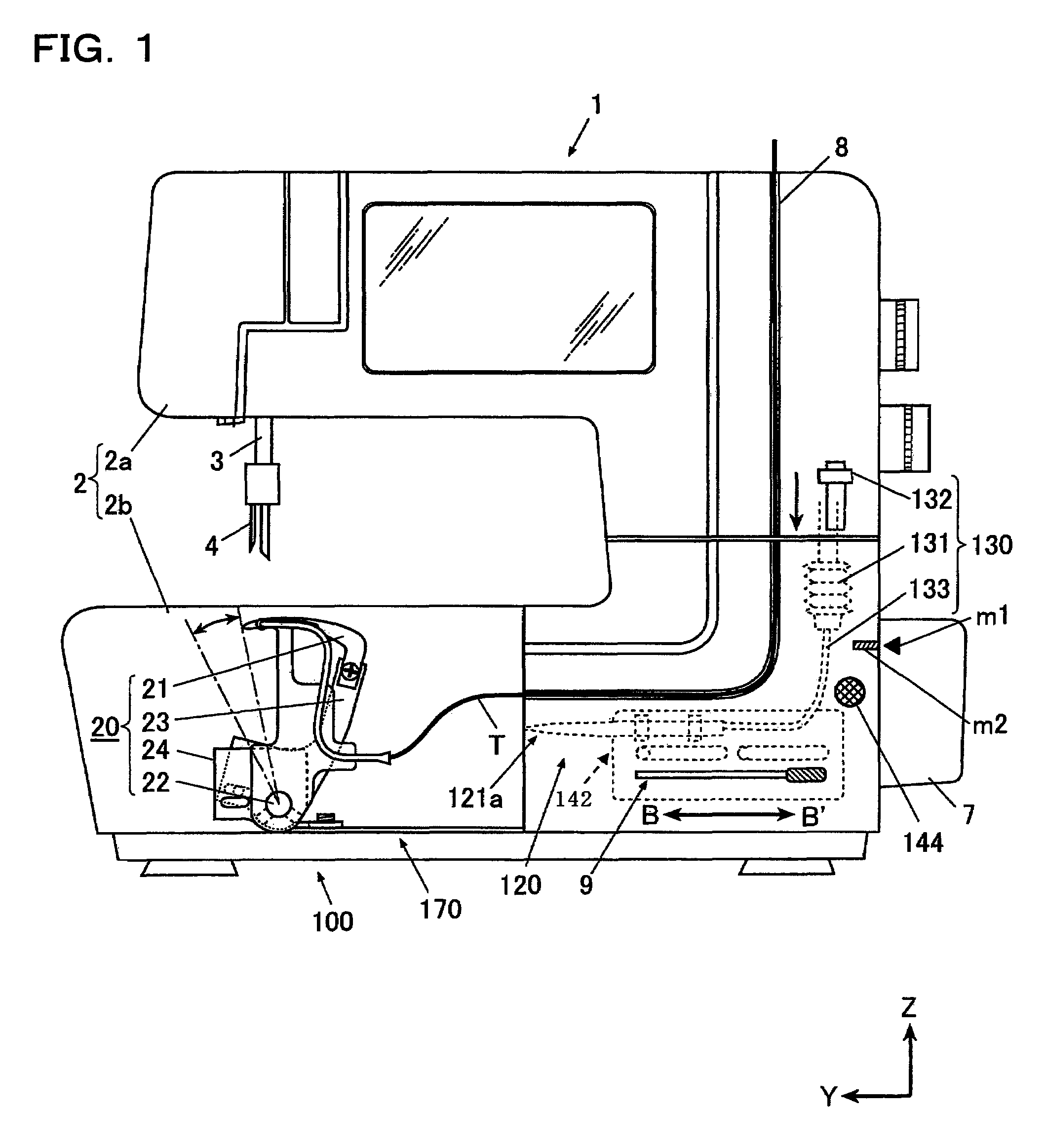

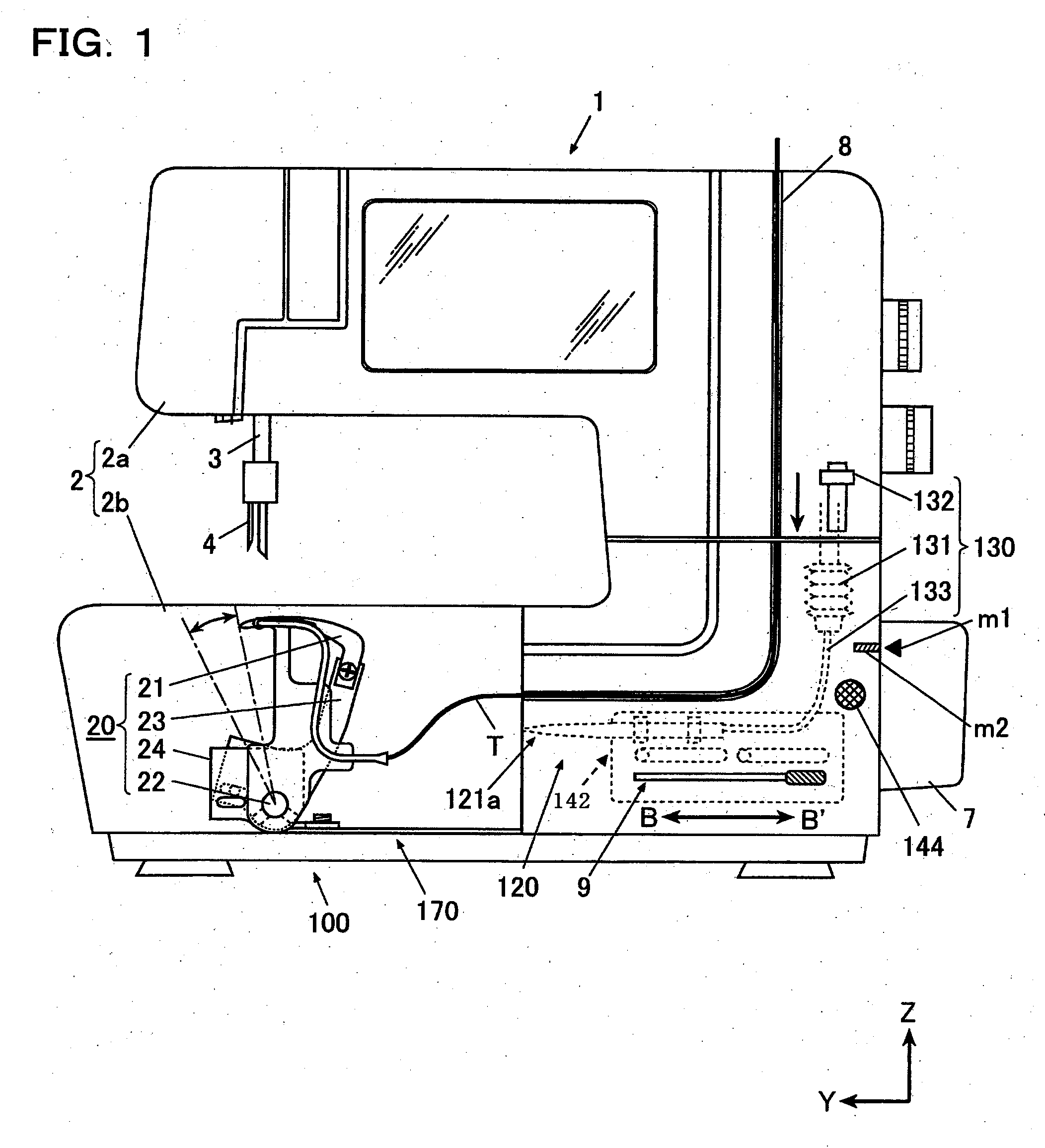

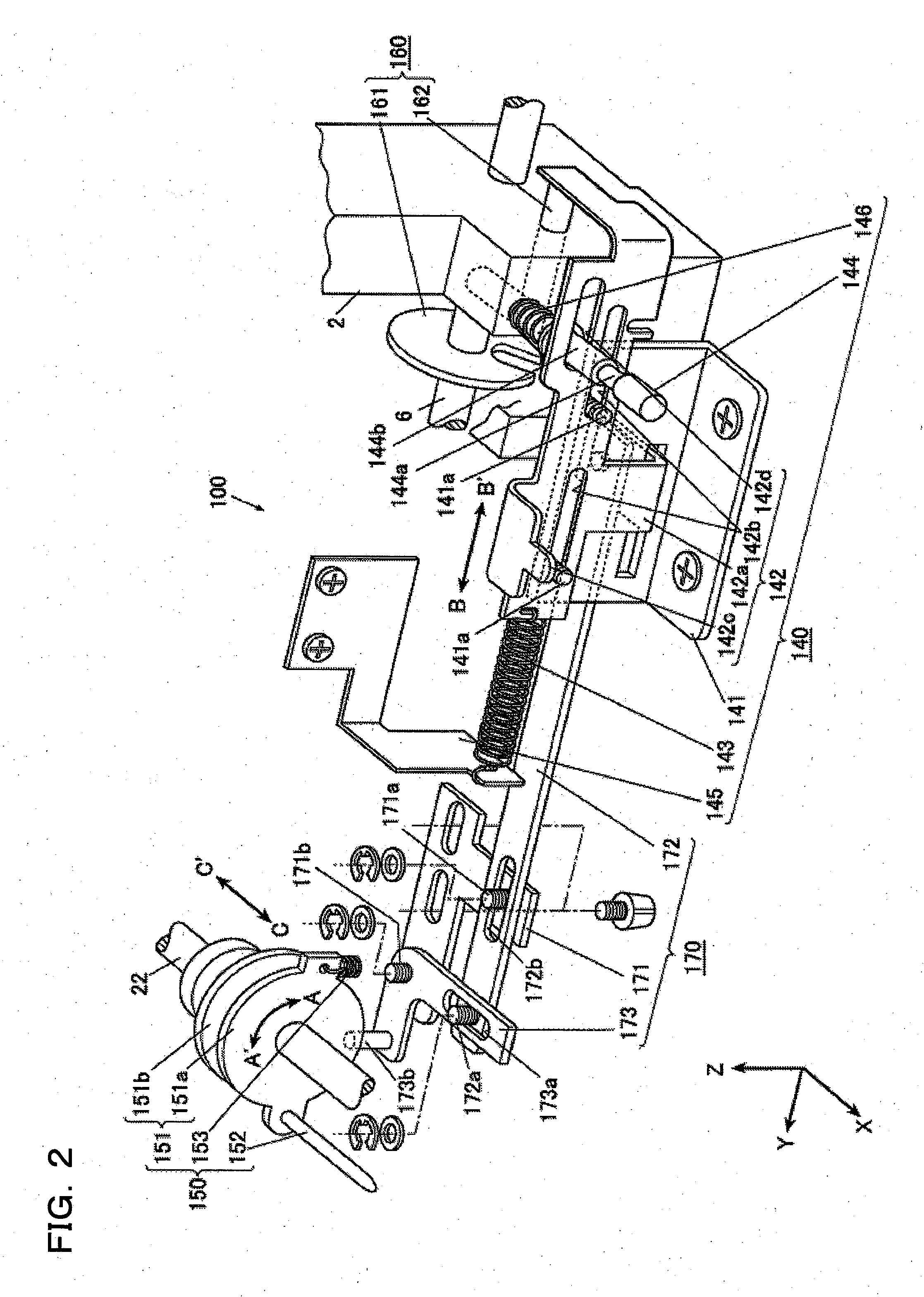

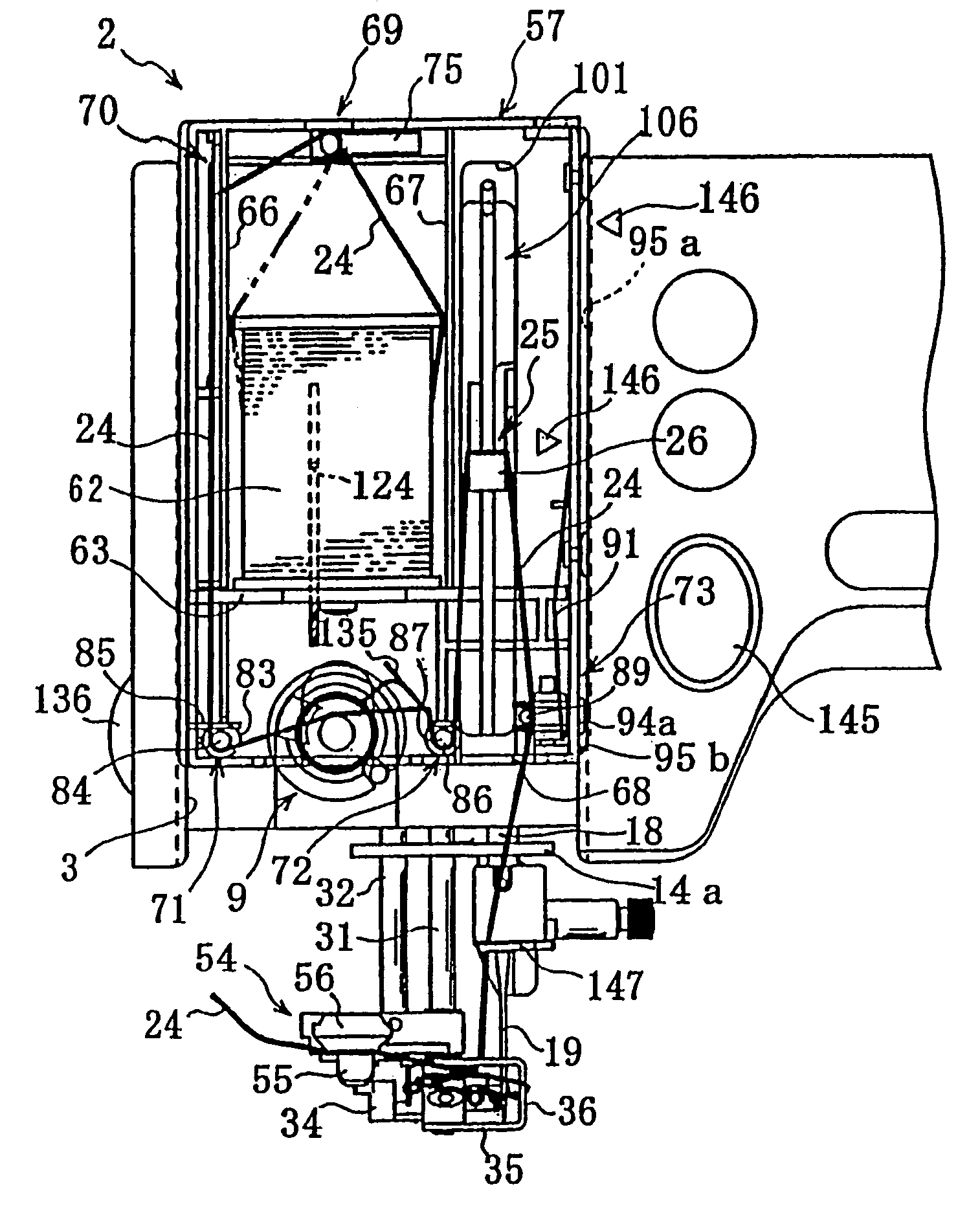

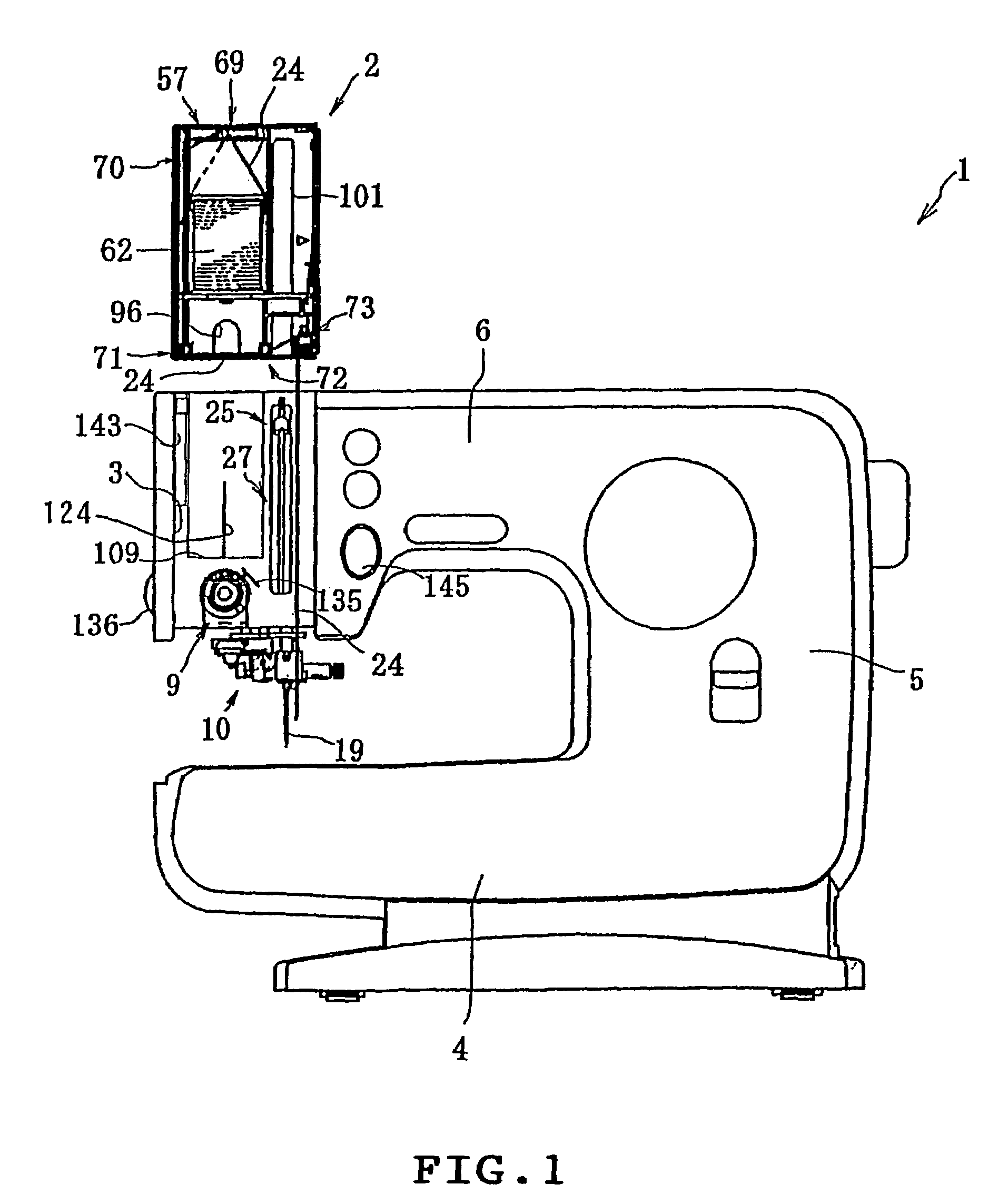

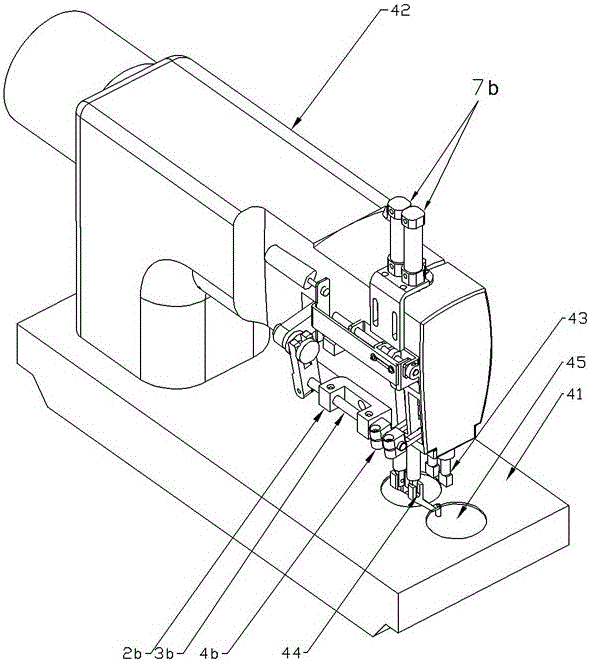

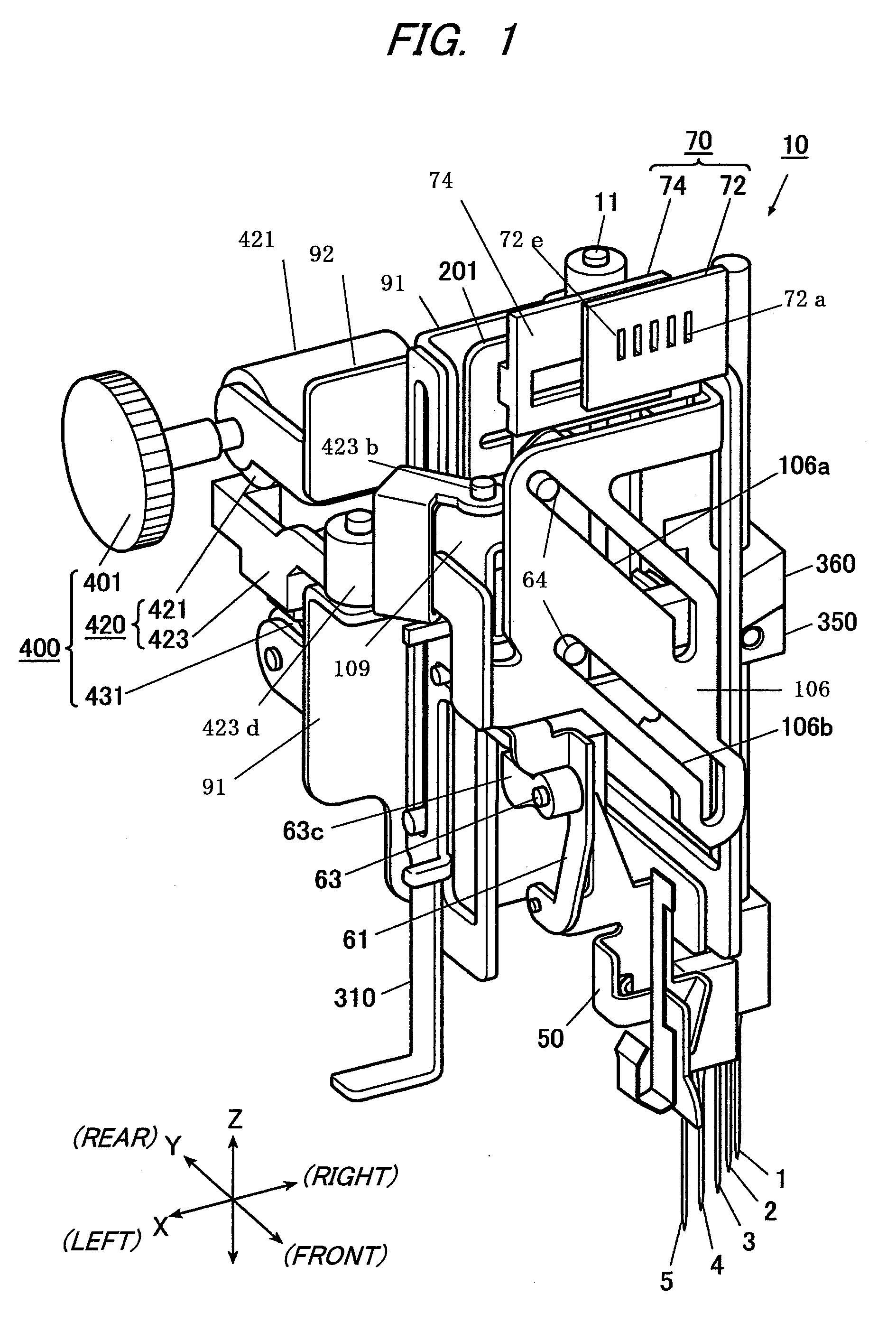

Sewing machine

A sewing machine includes a looper formed with a thread hole, a looper shaft holding the looper, and a thread pipe fixed to the looper shaft. The thread pipe includes a thread inserting port at one end and a thread discharging port at the other end. The sewing machine further includes a nozzle from which air is sprayed toward the thread inserting port, a switching mechanism operable to disconnect the looper from the looper shaft when the looper is at a front position, and a moving member which moves the looper to a rear position when the looper is disconnected from the looper shaft by the switching mechanism. When the looper is disconnected from the looper shaft and is moved to the rear position, the thread discharging port matches the thread hole, and the thread inserting port becomes close to the nozzle.

Owner:JUKI CORP

Sewing machine

InactiveUS20080134950A1Easy to optimizeSewing-machine control devicesFilament handlingThreaded pipeEngineering

A sewing machine includes a looper formed with a thread hole, a looper shaft holding the looper, and a thread pipe fixed to the looper shaft. The thread pipe includes a thread inserting port at one end and a thread discharging port at the other end. The sewing machine further includes a nozzle from which air is sprayed toward the thread inserting port, a switching mechanism operable to disconnect the looper from the looper shaft when the looper is at a front position, and a moving member which moves the looper to a rear position when the looper is disconnected from the looper shaft by the switching mechanism. When the looper is disconnected from the looper shaft and is moved to the rear position, the thread discharging port matches the thread hole, and the thread inserting port becomes close to the nozzle.

Owner:JUKI CORP

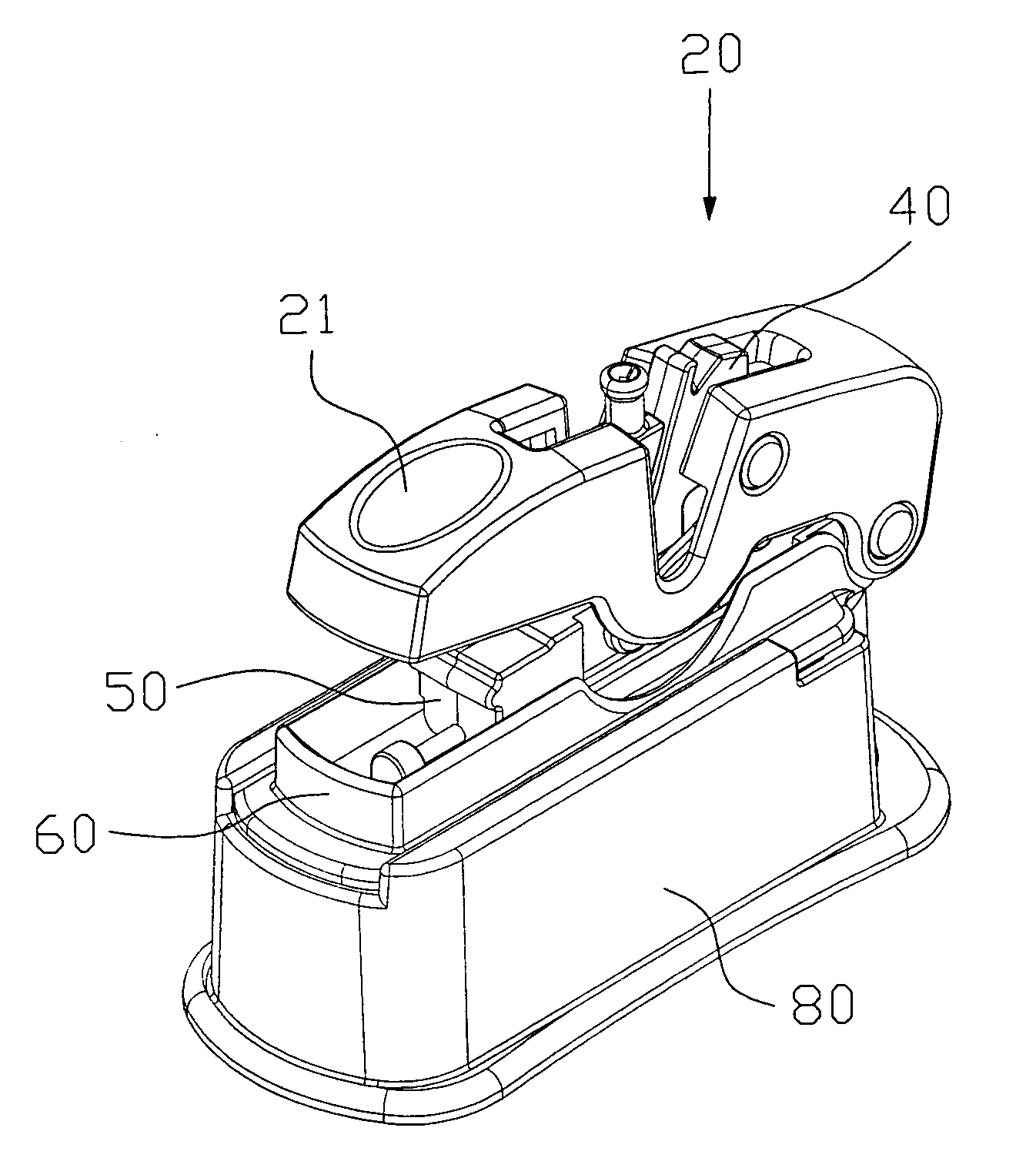

Threading apparatus for sewing machine

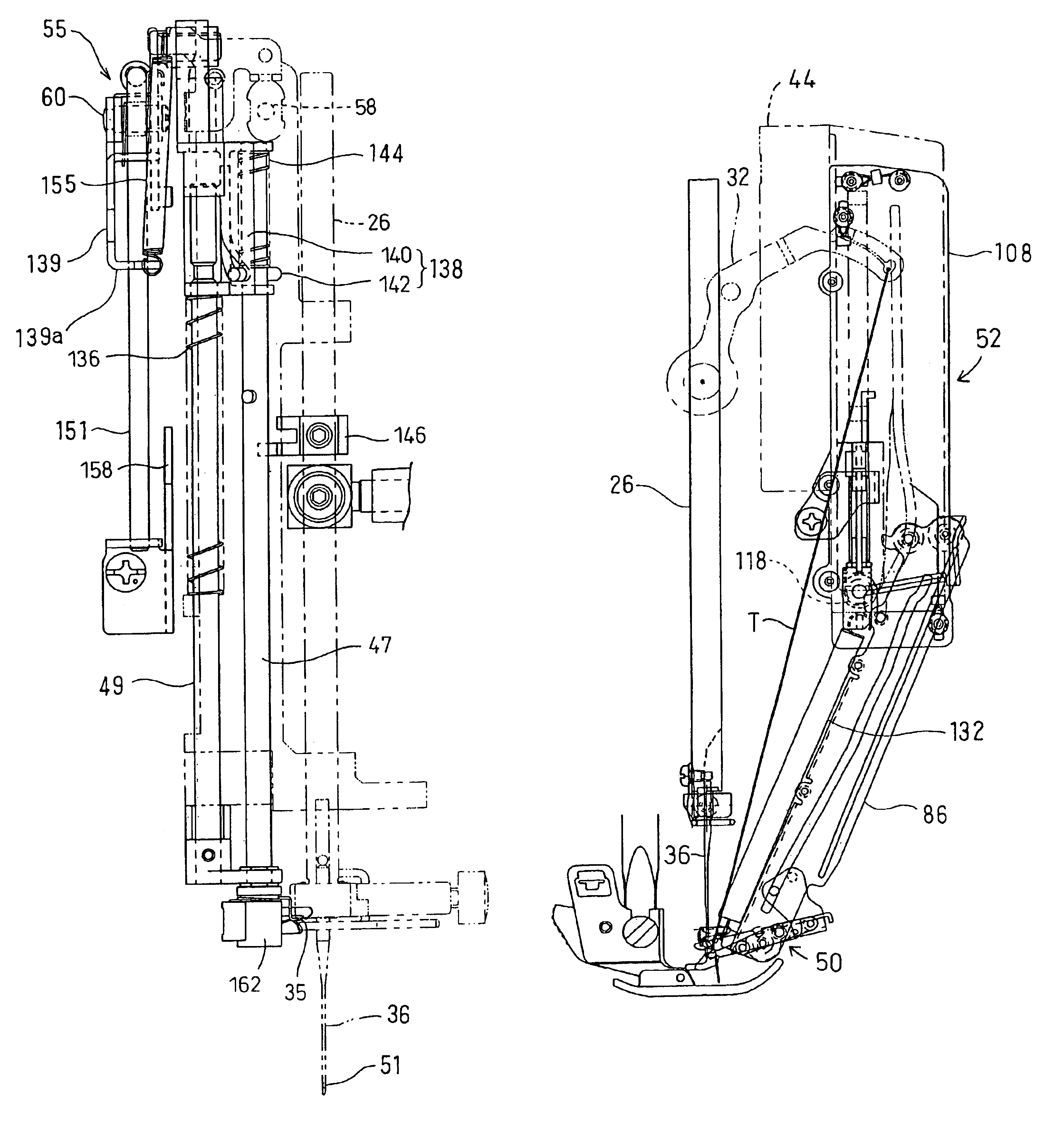

InactiveUS6959656B2Reliably be passed through needle eyeReduce movement speedThread-laying mechanismsNeedle-threading devicesEngineeringSewing needle

A sewing machine includes a sewing needle having an eye, a threading hook passed through the eye of the needle, a traveling mechanism for traveling the threading hook so that the threading hook is advanced through the eye of the needle and retreated through the eye of the needle, a thread holding member for holding the thread, a moving mechanism for moving the thread holding member between a first position where the thread holding member is close to the threading hook having been advanced through the eye of the needle and a second position where the thread holding member is away from the threading hook having been advanced through the eye of the needle, and a speed reducing mechanism for reducing a moving speed of the thread holding member while the thread holding member is holding the thread and being moved near the threading hook having been advanced through the eye of the needle.

Owner:BROTHER KOGYO KK

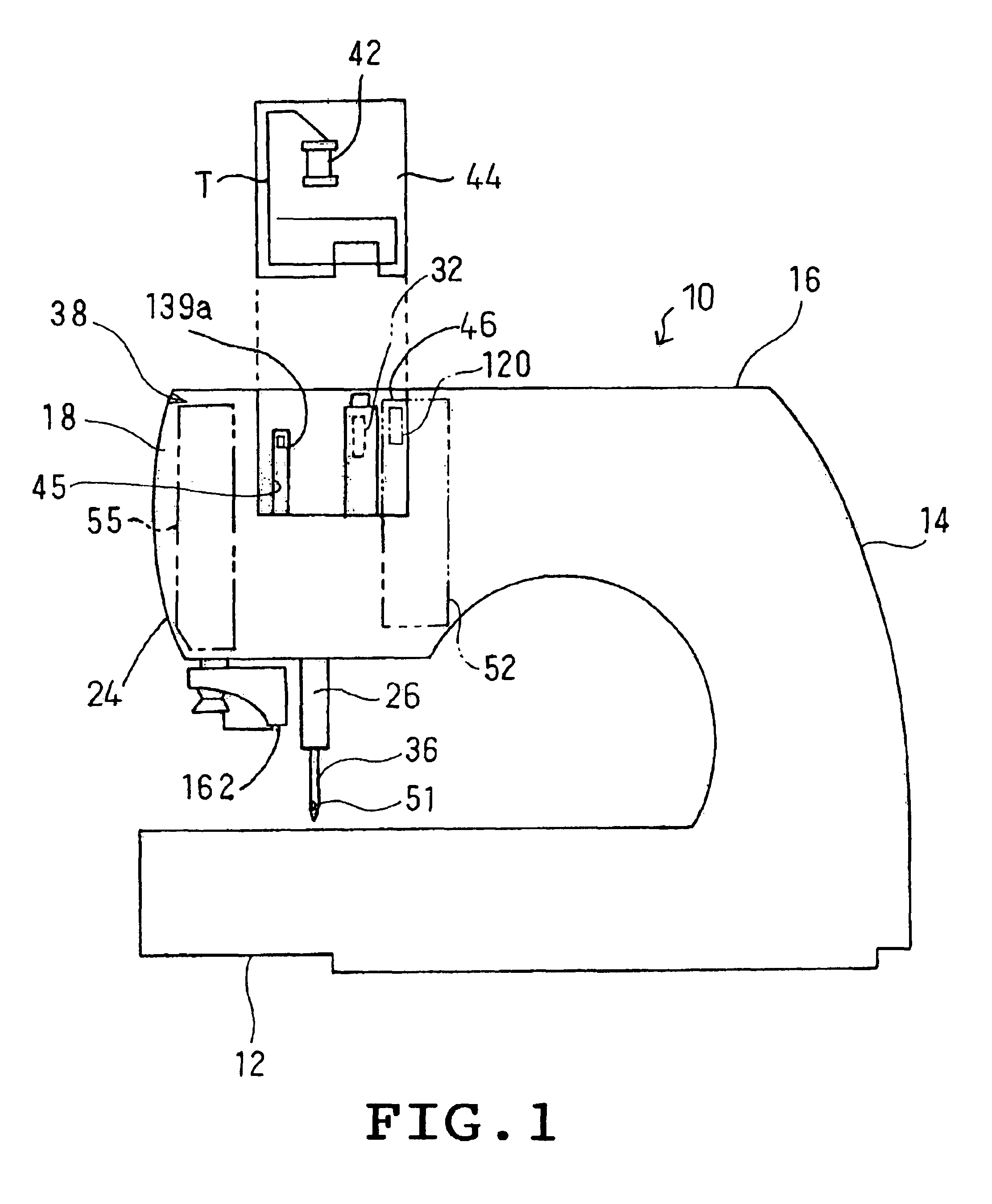

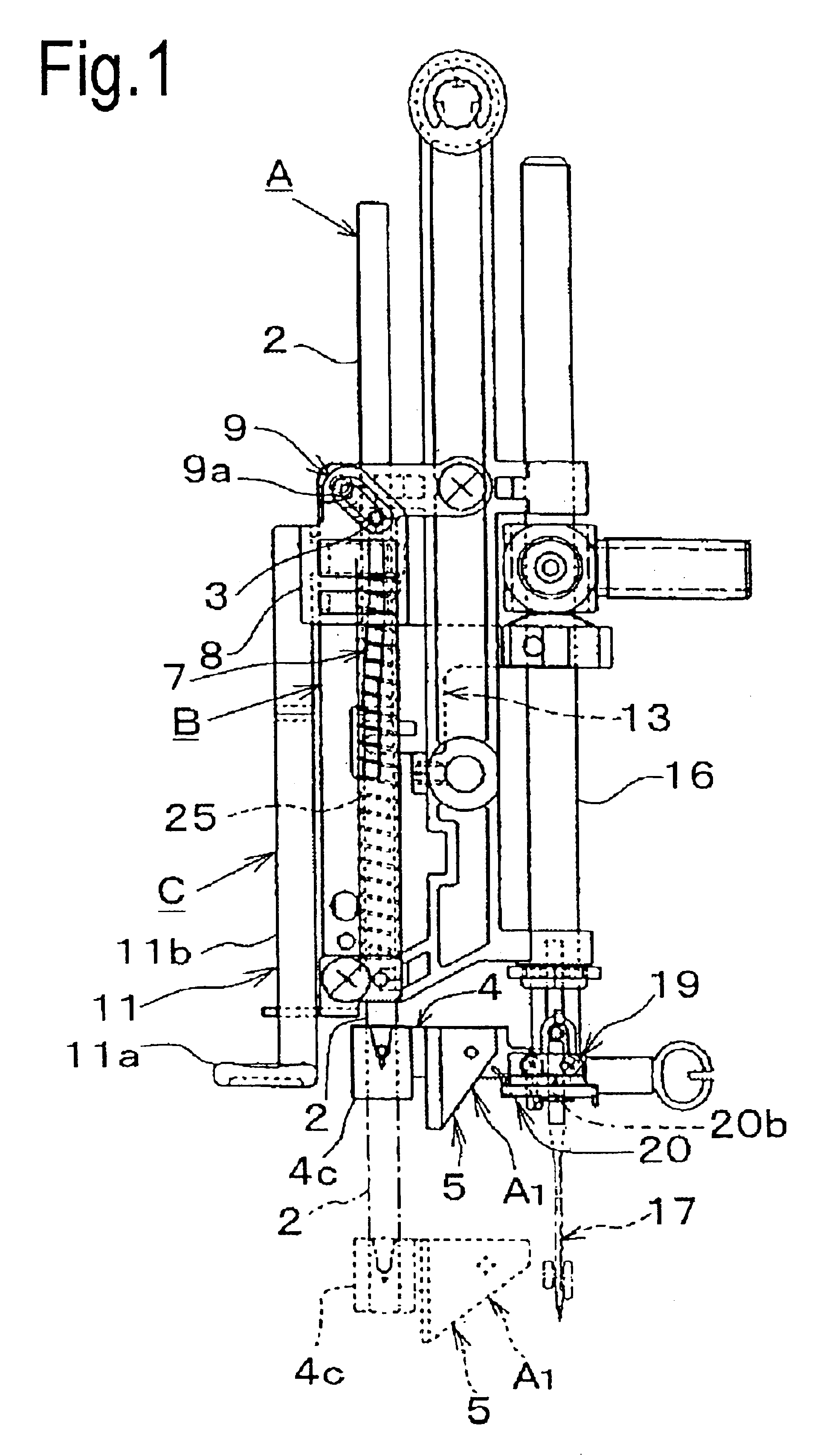

Threading device of sewing machine

ActiveUS6918344B2Easy to operateSimple structureThread-laying mechanismsNeedle-threading devicesBiomedical engineeringSewing machine

A threading device of sewing machine is disclosed, wherein the upper thread extended from a thread supply mounted on a sewing machine body may be easily and smoothly guided into engagement with a thread holder simultaneously when the threading device is operated to pass the upper thread through the eye of needle attached to the lower end of needle bar, the thread holder being arranged between the thread supply and the needle. The threading device comprises a vertically movable needle bar 16 having a needle attached to the lower end thereof, the needle having a needle eye, a needle bar support 1 for supporting the needle bar 16 such that the same may be vertically movable, a thread holder 20 mounted to the lower end of the needle bar 16, a threading member A1 having a thread engaging portion 5 and a threading hook 4b, a threading shaft 2 for having the threading member A1 secured to the lower end thereof, an operating section C for vertically moving and axially rotating the threading shaft 2 to pass the upper thread n through the needle eye 17a, the threading member A1 being so formed as to provide the thread engaging portion 5 for guiding the upper thread to the needle eye 17a, the needle holder 20 being formed with a groove 20b for holding the upper thread n, the groove 20b having an opening 20a at which the upper thread n is guided into the groove 20b from the rear side of the thread holder 20 while the thread engaging portion 5 is moved down with the upper thread n which is to be passed through the needle eye 17a.

Owner:JANOME CORP

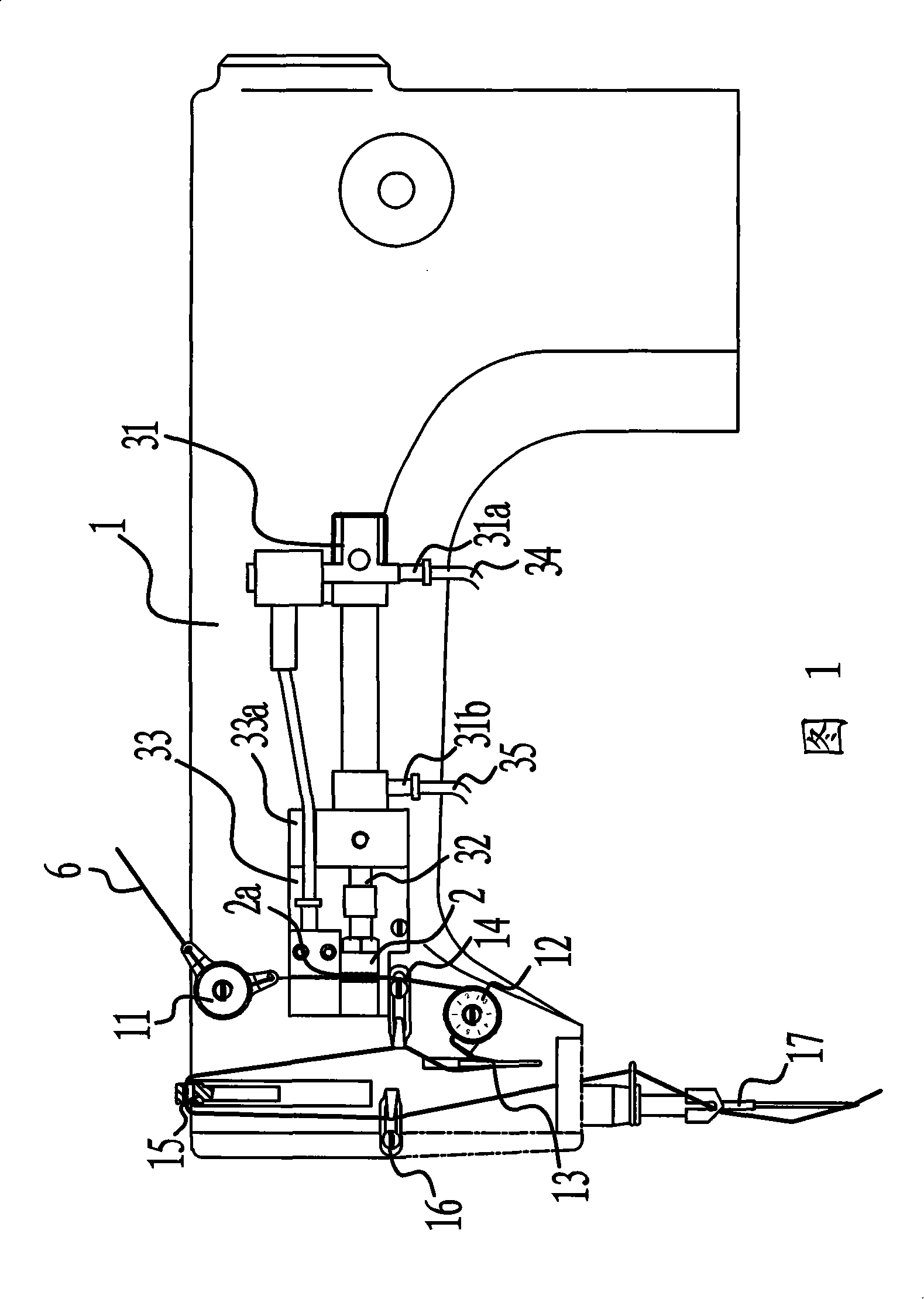

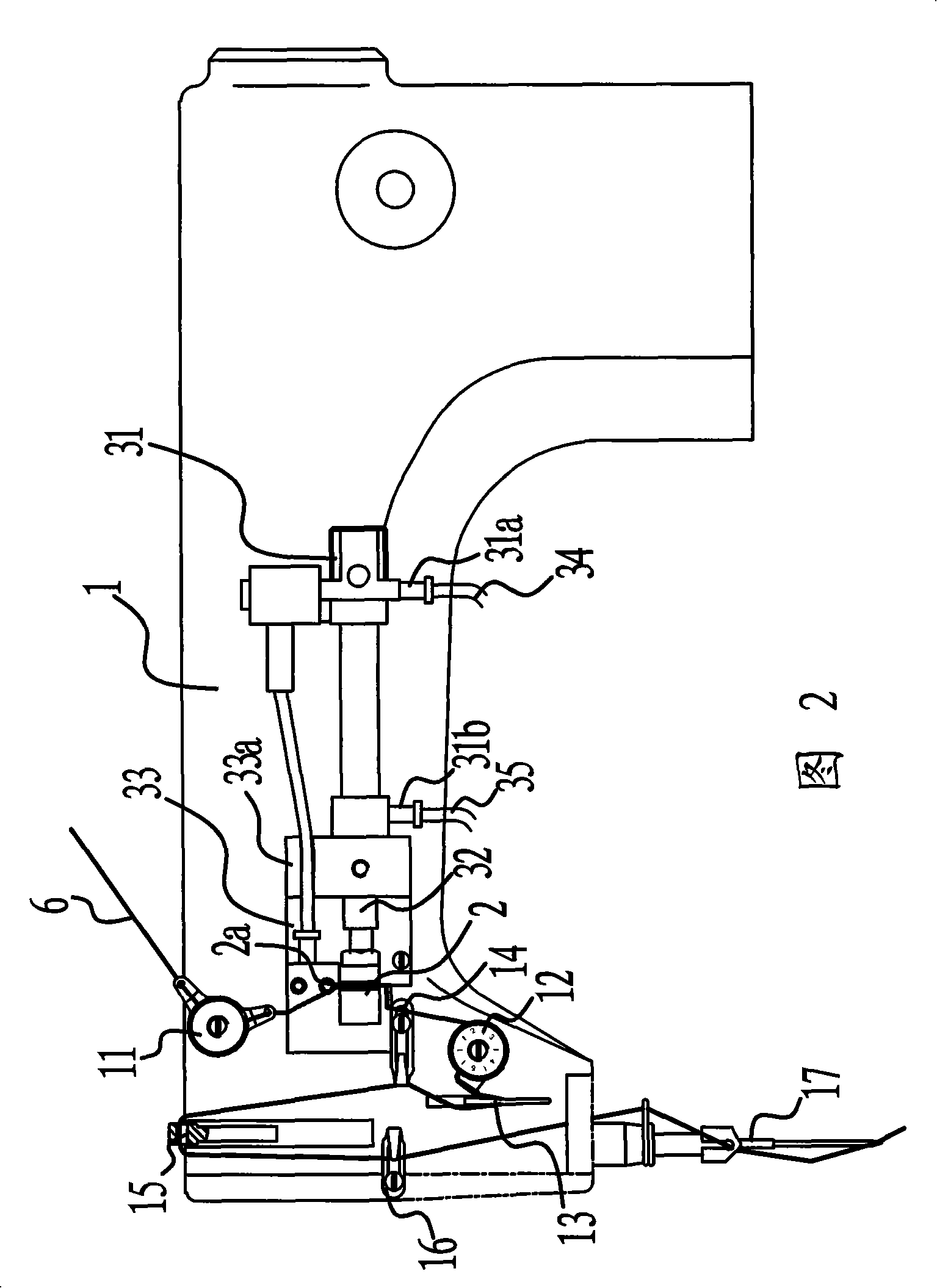

Thread tensioner for a sewing machine

InactiveCN1600932AEasy to controlAdjustable preloadSewing-machine control devicesThread-laying mechanismsEngineeringSewing machine

The thread tensioner (9) for a sewing machine has a supporting plate (12) equipped with a first thread tensioning device (18) and a second thread tensioning device (17) on the supporting plate, and the tension load to the thread (10) is overcome. For the purpose, a release lever (31) is connected with the supporting plate (12), and works to abut on a release pin (30) of the thread tensioning devices (17, 18). The thread tensioner works in a manner that the release lever (31) abuts on the first thread tightening device (18) first and then the second thread tensioning device (17) with the progress of the pivotably moving processes by separate releasing steps by using a solenoid (36).

Owner:DURKOPP ADLER AG

Rotating thread-moving device of sewing machine

InactiveCN101319437AEasy to removeImprove sewing qualityWorkpiece carriersNeedle severing devicesEngineeringSewing needle

This invention is related to a thread wiping device of sewing machine. This invention includes a fixing component that allows a needle rod to pass through a sewing needle and is combined at the lower part of a sewing head of the sewing machine; a fastening component combined at the fixing component; a power generating mechanism combined at the fastening component so as to generate the driving force; a power transmission mechanism connecting the power generating mechanism and transmitting the power; and a thread wiping hook that convolutes in a set angle along the driving of the power transmission mechanism. According to this invention, the thread wiping hook is enable to convolute in the set angle after the fastening component connecting with the thread wiping hook to rotate about the needed angle by using the needed rod as the center, therefore, the broken thread can be easily extracted from the sewing material in any direction so that the sewing quality is improved.

Owner:MOBASE SUNSTAR CO LTD

Sewing machine

InactiveUS20080308027A1Made evenlyEasy to carryThread-laying mechanismsNeedle-threading devicesThreaded pipeScrew thread

A lower end of a thread guide lever, which is rockably attached to a lower looper and supports a thread pipe, and an air ejecting unit, which faces a thread inserting hole of the thread pipe and ejects air toward the thread inserting hole, are coupled via a coupling member so that they are interlocked with each other. The coupling member is moved such that a discharging port of an air nozzle is positioned at an ejecting position close to the thread inserting hole when a thread discharging hole is positioned at a threading position which is coincident with a thread hole of a lower looper, and such that the air nozzle is moved to a standby position when the thread discharging hole is moved to a retreating position.

Owner:JUKI CORP

Threading apparatus for sewing machine

InactiveUS6067920AEffective guidanceReduce the impact of collisionThread-laying mechanismsNeedle-threading devicesYarnEngineering

The present invention provides an air suction device for a threading apparatus that creates an air flow to be directed toward a needle eye in order to guide a yarn through the eye. The air suction device is comprised of: (a) an air device externally provided for generating reduced pressure; (b) an air suction pipe connected to the external air device; and (c) an air path leading to a front portion of the air suction pipe. The air path is comprised of a pair of leaf springs to horizontally hold a needle, and upper and lower elastic members which run parallel between the pair of leaf springs. To effectively direct air into the needle eye, an air-tight environment is provided around the needle eye: (1) air entry above and beneath the needle eye is prevented by the body of the needle; (2) air entry from both sides of the needle is prevented by the pair of leaf springs that hold the needle; and (3) air inflow behind the needle is prevented by rear-positioned elastic members which tightly fit the needle.

Owner:STEP Y K

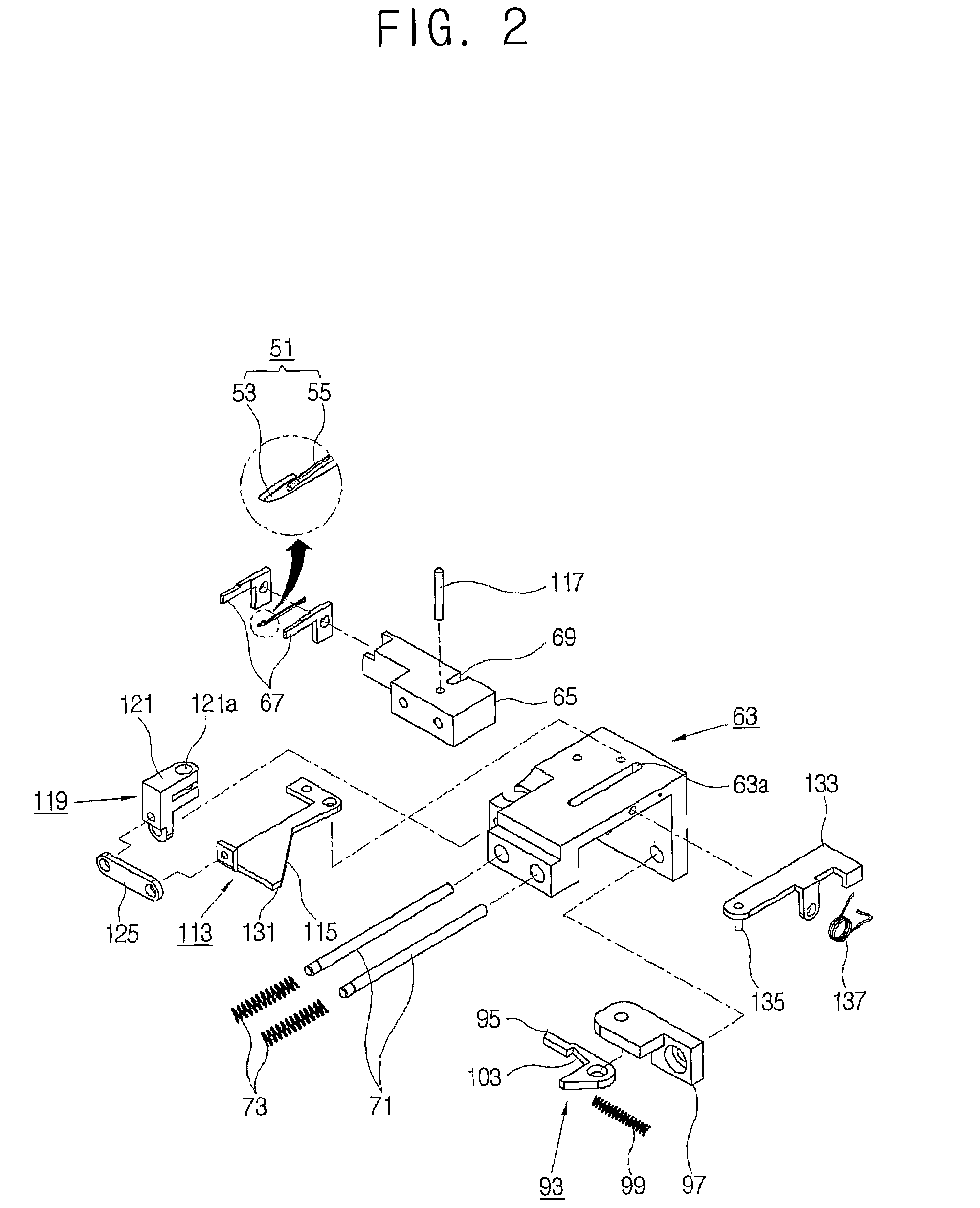

Needle threader for sewing machine

ActiveUS20090183663A1Smoothly be moved verticallyReliable retentionThread-laying mechanismsNeedle-threading devicesEngineeringSewing machine

A needle threader for a sewing machine includes a threading mechanism including a threading hook mounted on a lower end of a threading shaft and a thread guide member. The threading hook and the thread guide member are movable among a thread guide preparation position where the threading hook and the thread guide member are located near a height position of a needle clamp, a threading operation position where a threading operation is carried out with the threading hook being level with an eye of a needle, and a retreat position which is located above the thread guide preparation position and to which the threading hook and the thread guide member are retreated. A vertical moving mechanism moves the threading shaft vertically so that the threading mechanism is moved between the thread guide preparation position and the threading operation position.

Owner:BROTHER KOGYO KK

Sewing machine

A sewing machine includes a head on which a needle bar for fixing a needle is mounted, a thread cutting blade mounted in the head so as to be capable of cutting an end of a thread which is threaded so as to be passed through an eye of the needle, and a holder mounted in the head so as to be capable of holding the thread end after the thread end has been cut by the thread cutting blade. The thread cutting blade is positioned so that a first amount of thread from the eye of the needle mounted in the head to the thread end held by the holder equals a second amount of thread by which the thread end is drawn to an underside of a cloth in a stitch formed immediately after start of a sewing operation.

Owner:BROTHER KOGYO KK

Threading device of sewing machine

InactiveUS20090064914A1Avoid breakingAvoid collisionThread-laying mechanismsNeedle-threading devicesEngineeringMotion transfer

A threading device of a sewing machine is provided. The threading device includes a threading hook which moves forward to enter an eye of a needle to catch a needle thread, and moves rearward with the needle thread being caught to insert the needle thread through the eye, a threading shaft which holds the threading hook, an operating member which is operated to move the threading shaft, a threading operation mechanism which transmits the movement of the threading shaft to the threading hook to move the threading hook back and forth, and a restricting device which makes the threading operation mechanism inoperable when the spreader mechanism is attached to the sewing machine main body, and makes the threading operation mechanism operable when the spreader mechanism is detached from the sewing machine main body.

Owner:JUKI CORP

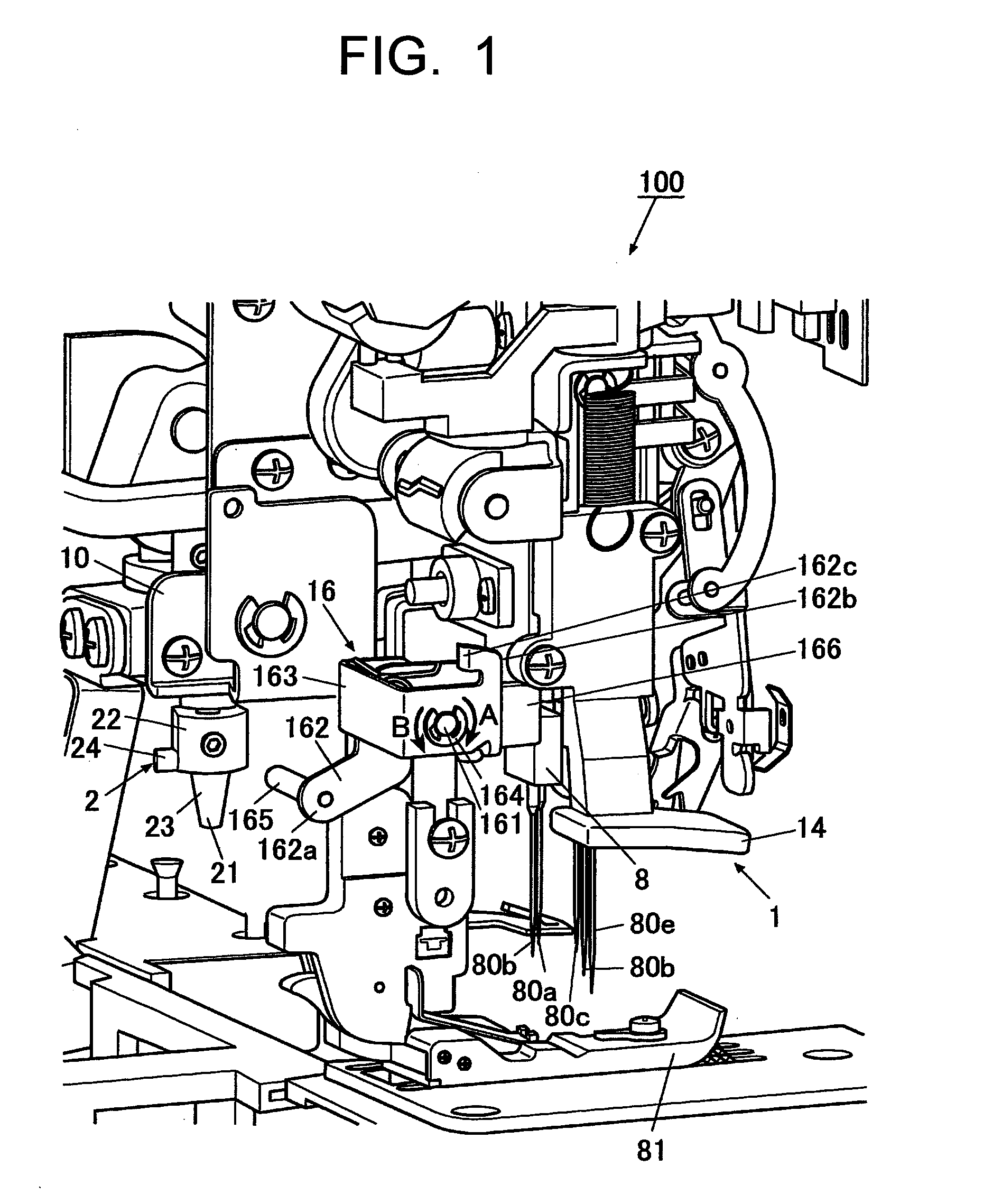

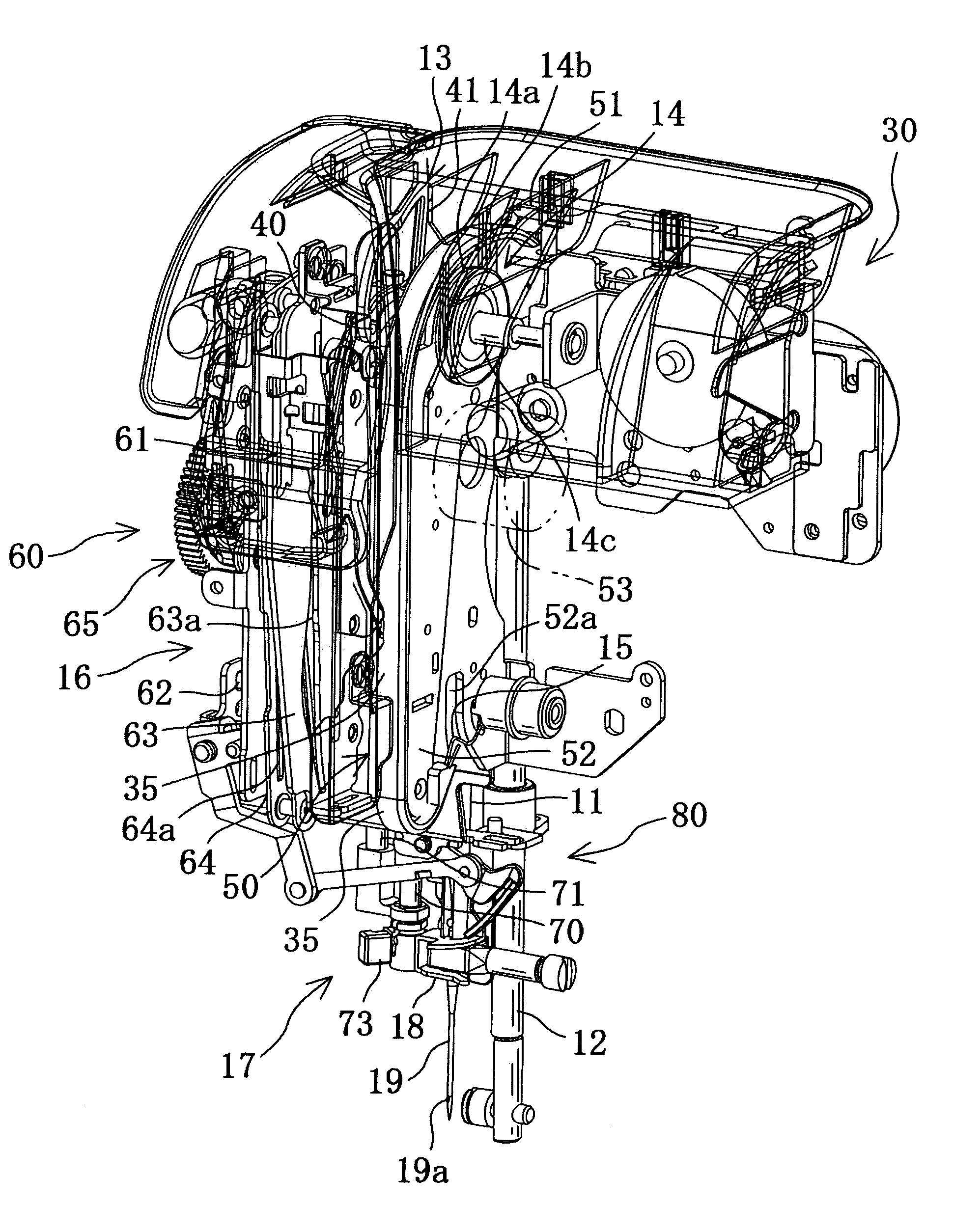

Gas carrying threading device of sewing machine

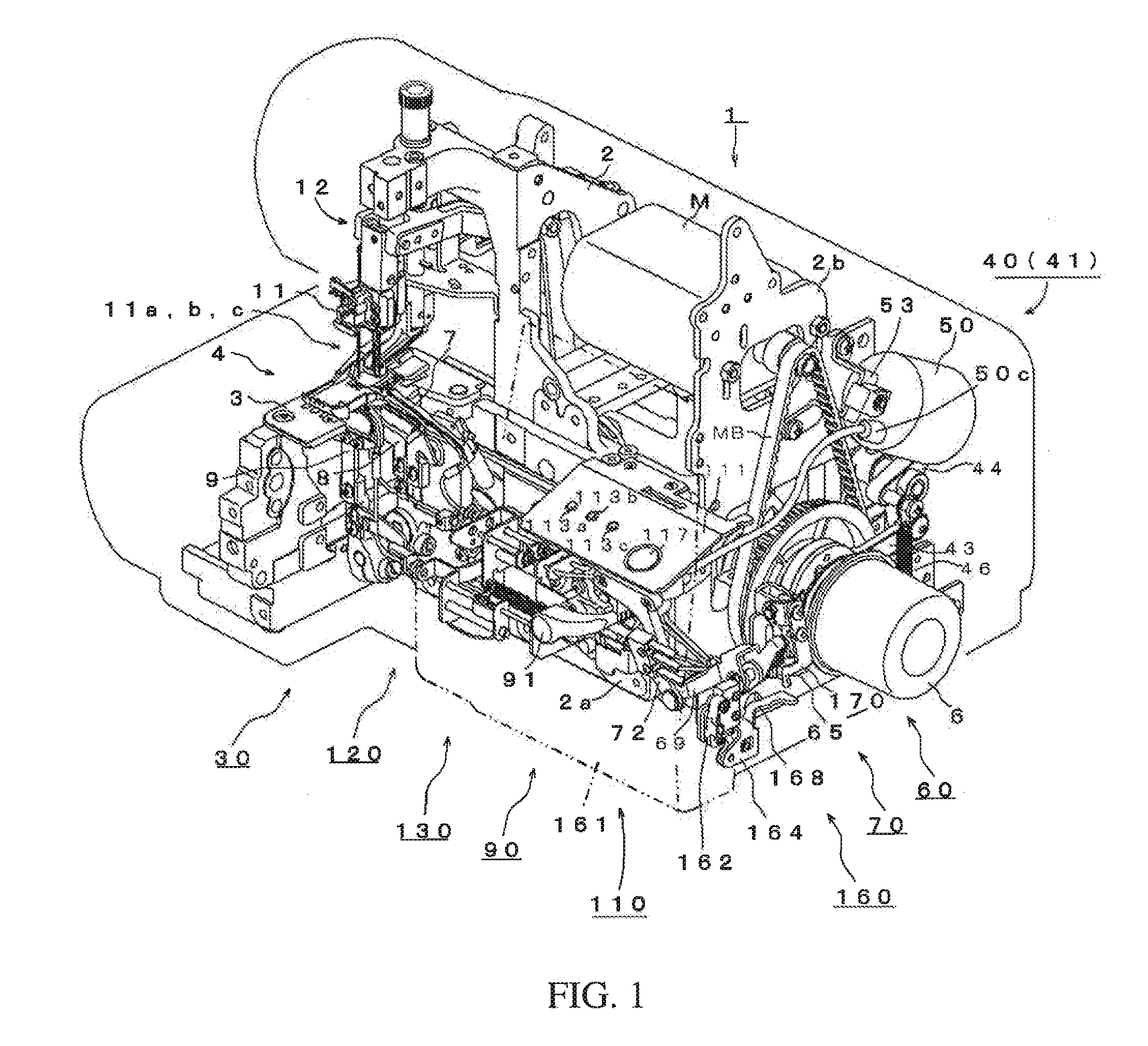

ActiveUS20140190383A1Simple structureQuality improvementSewing-machine control devicesThread-laying mechanismsElectric power transmissionDrive shaft

When performing the threading to the looper by one-touch operation, the abnormal changeover to the stitch forming state of the looper threading / stitch forming changeover mechanism during the gas supply operation of the gas supply pump is prohibited. The device comprises: a clutch (60) for transmitting the power from the sewing machine motor (M) to the drive shaft (5) that drives the stitch forming device (30) including the looper (7, 8, 9) at the time of the stitch formation or to the gas supply pump (41) at the time of the looper threading respectively; a looper threading / stitch forming changeover mechanism (90) for changing over the clutch so that the transmission of the power to the stitch forming device is interrupted and the power is transmitted to the gas supply pump at the time of the looper threading and the power is transmitted to the stitch forming device and the transmission of the power to the gas supply pump is interrupted at the time of the stitch formation; and a changeover prohibition mechanism (160) for prohibiting the abnormal changeover to the stitch forming state of the looper threading / stitch forming changeover mechanism during the gas supply operation of the gas supply pump.

Owner:SUZUKI MFG CO LTD

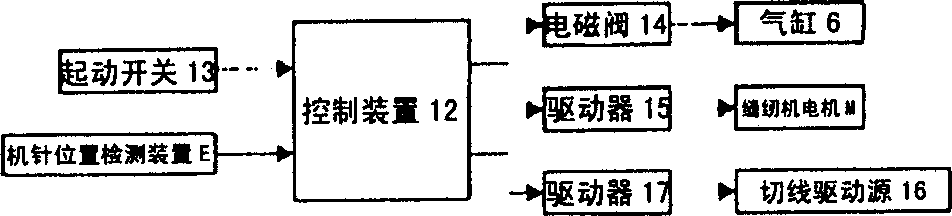

Sewing machine

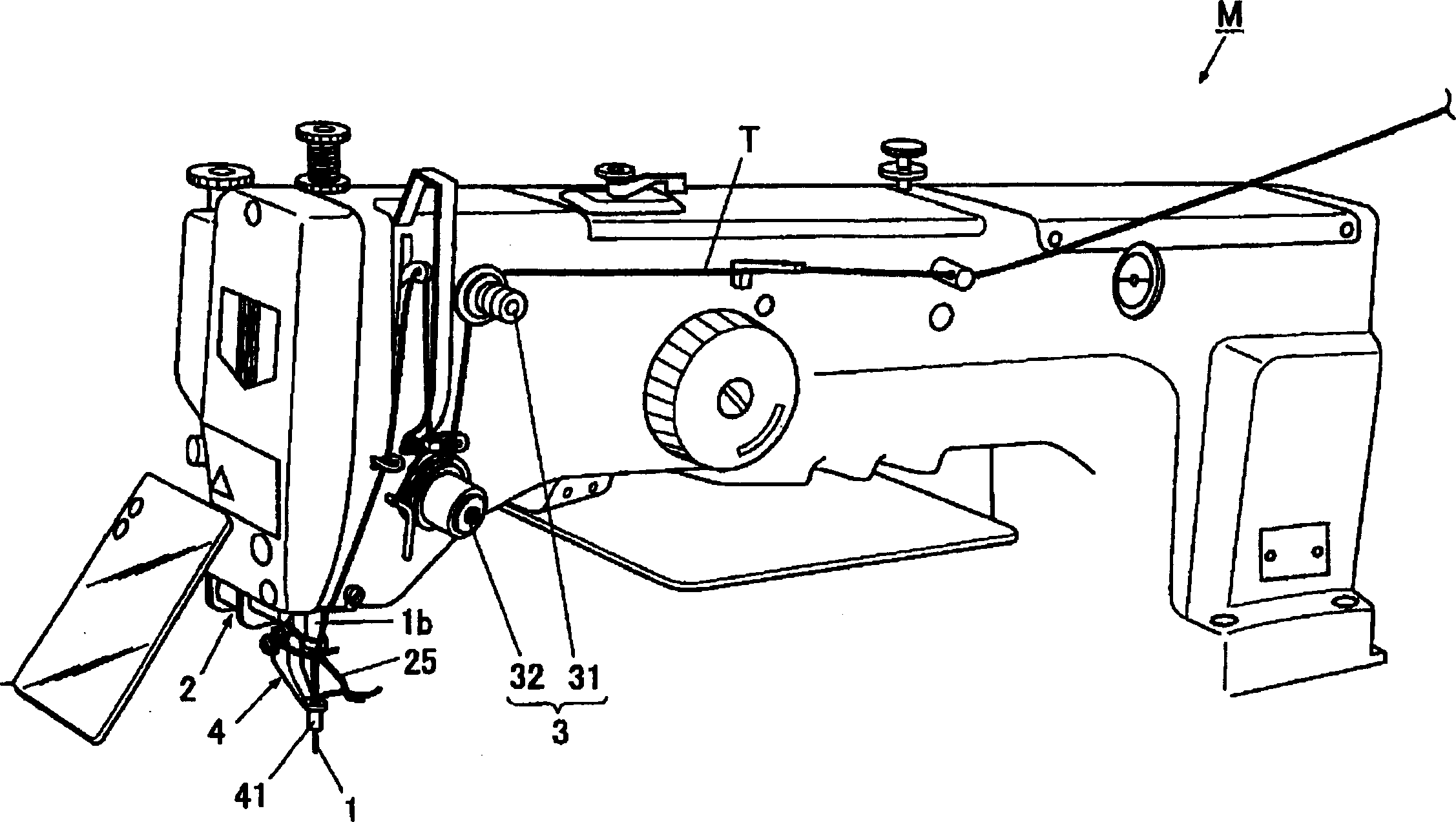

InactiveCN1800478ADoes not affect aestheticsEasy to change lineProgramme-controlled sewing machinesNeedle severing devicesWire tensionEngineering

A sewing machine (M) comprising: a needle (1) through which a thread (T) is passed through a needle hole formed at a front end and which sews an object to be sewn placed on a needle plate by moving up and down, And the thread cutting device that cuts the thread (T) after the specified amount of sewing is completed, and the thread (T) is cut across the needle (1) and the object to be sewn after the thread (T) is cut by the thread cutting device. ) a thread wiper (2) drawn out from the object to be sewn, and a tension applying mechanism (3) that applies tension to the thread (T) inserted in the needle hole, and a thread tension control mechanism; wherein; the thread The tension control mechanism controls the action of the thread tension applying mechanism (3), so that when the thread (T) is pulled out from the sewing object by the thread wiper (2), tension is applied to the thread, and the thread (T) ) is pulled out from the object to be sewn to release the tension applied to the thread. In this sewing machine, the length of the thread coming out from the needle hole of the machine needle after the thread is cut can be optimized.

Owner:JUKI CORP

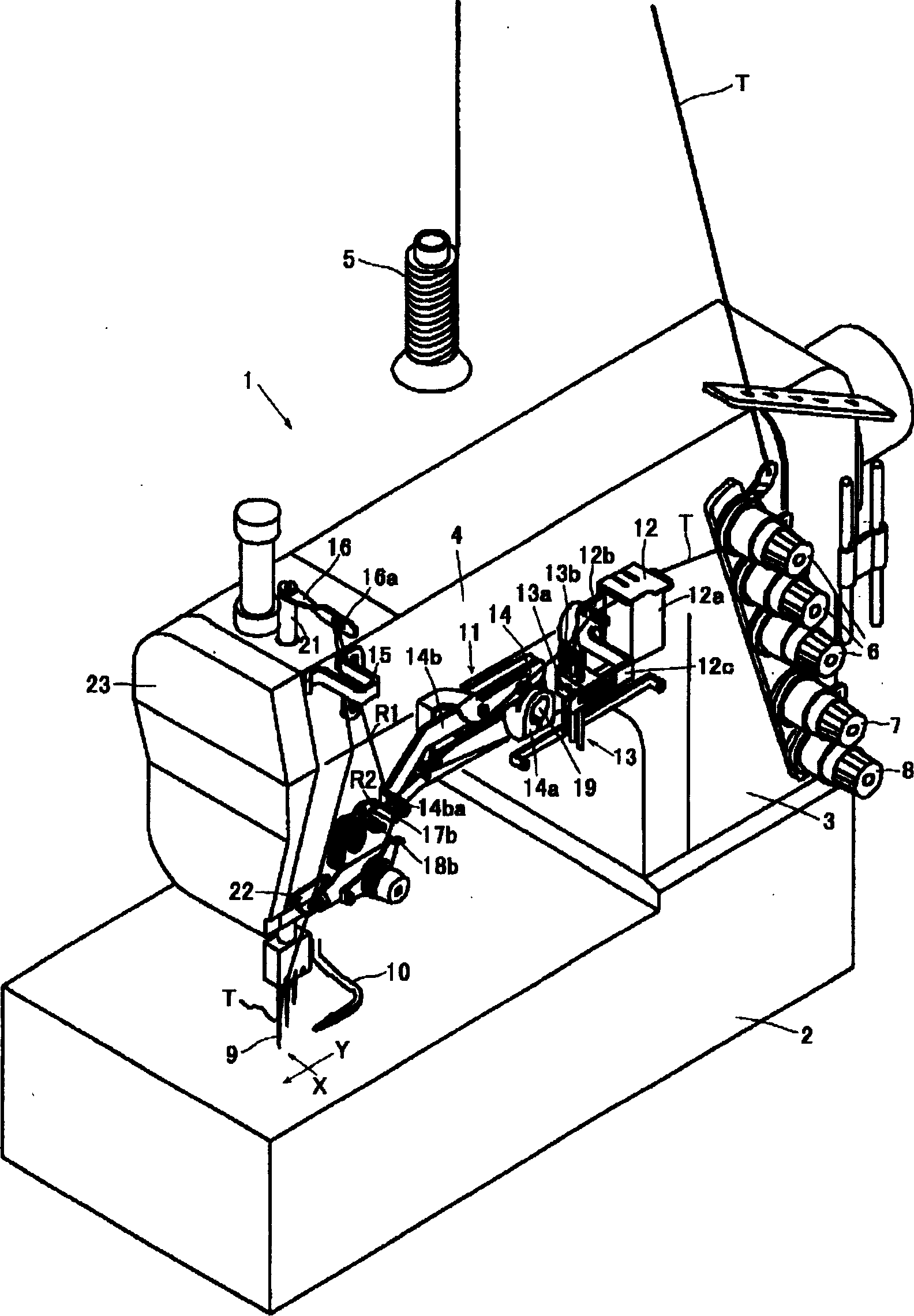

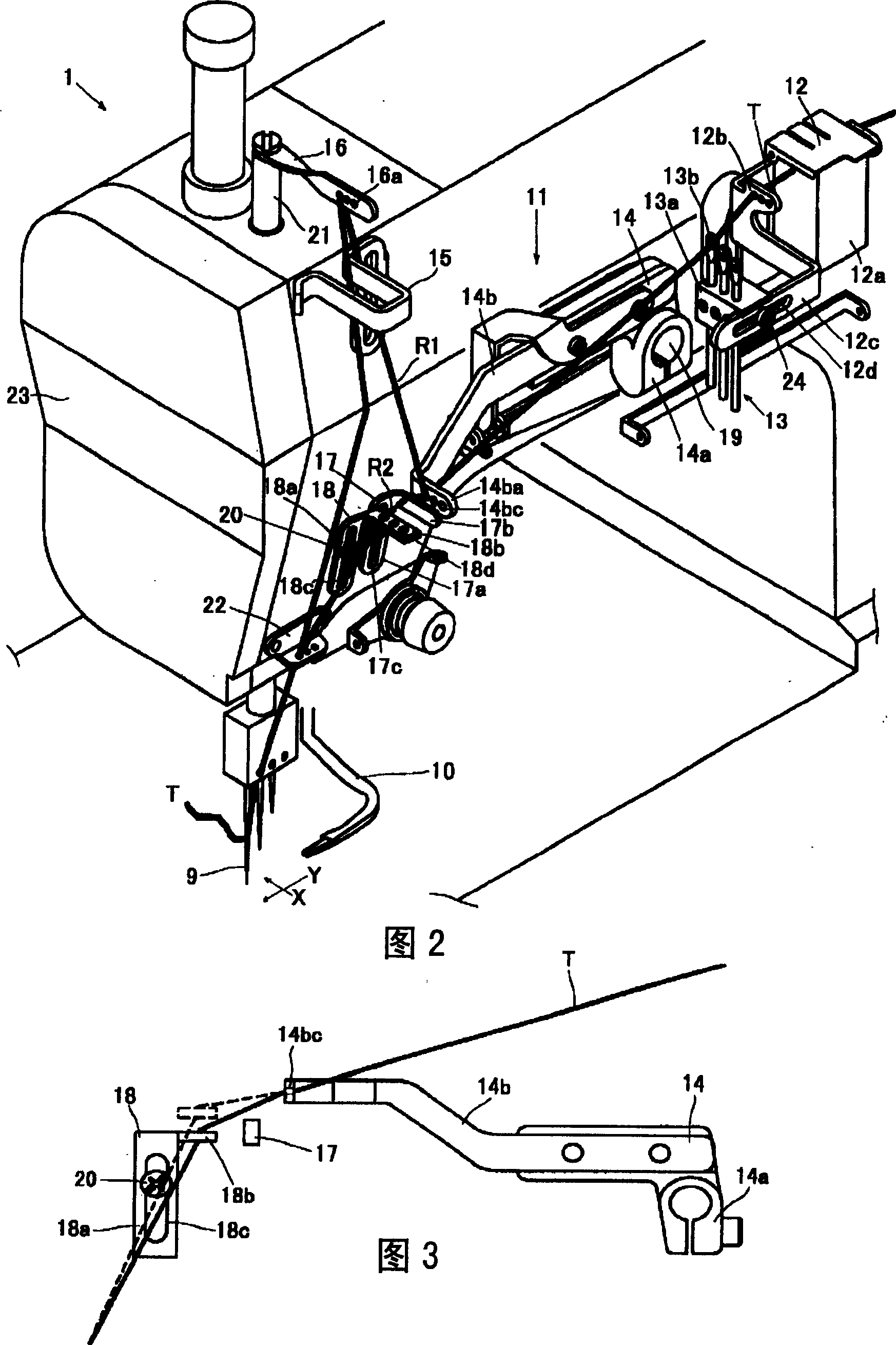

Take-up device for sewing machine

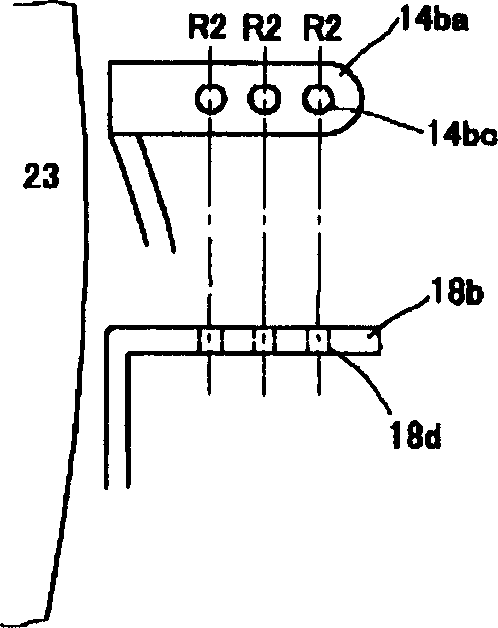

Provided is a thread feeding device of a sewing machine capable of selecting optimum thread-reeling-out control. In the thread feeding device of the sewing machine capable of selecting a first thread path R1 reaching a needle 9 through a swinging thread take-up lever 14 and a needle-bar take-up lever 16 from a bobbin 5 and a second thread path R2 reaching the needle 9 through the swinging take-up lever 14 from the bobbin 5, there is provided a swinging take-up lever thread receiver 17 arranged at the position separated from a thread-reeling hole 14bc of the swinging take-up lever 14 to the needle side, and a needle thread T selecting the second thread path is disposed can be engaged with the receiver 14.

Owner:JUKI CORP

Needle threading machine

InactiveUS7444949B2Work lessImprove productivitySewing needlesThread-laying mechanismsProduction rateReciprocating motion

Disclosed is a needle threading machine of putting a thread through an eye of a needle provided in a sewing machine, the needle treading machine comprising a thread supplying unit supplying the thread along a predetermined thread guiding path; a thread catcher comprising a hook to hook the thread, and a hook supporter extended from the hook and supporting the hook; a thread catcher driver driving the thread catcher to reciprocate allowing the hook to be inserted in and return from the eye of the needle; and a thread guiding unit hooking the thread supplied from the thread supplying unit on the hook passed through the eye of the needle. Thus, the present invention provides a needle threading machine, in which a thread is stably hooked on a hook, thereby reducing a defective needle threading work and enhancing productivity.

Owner:INBRO

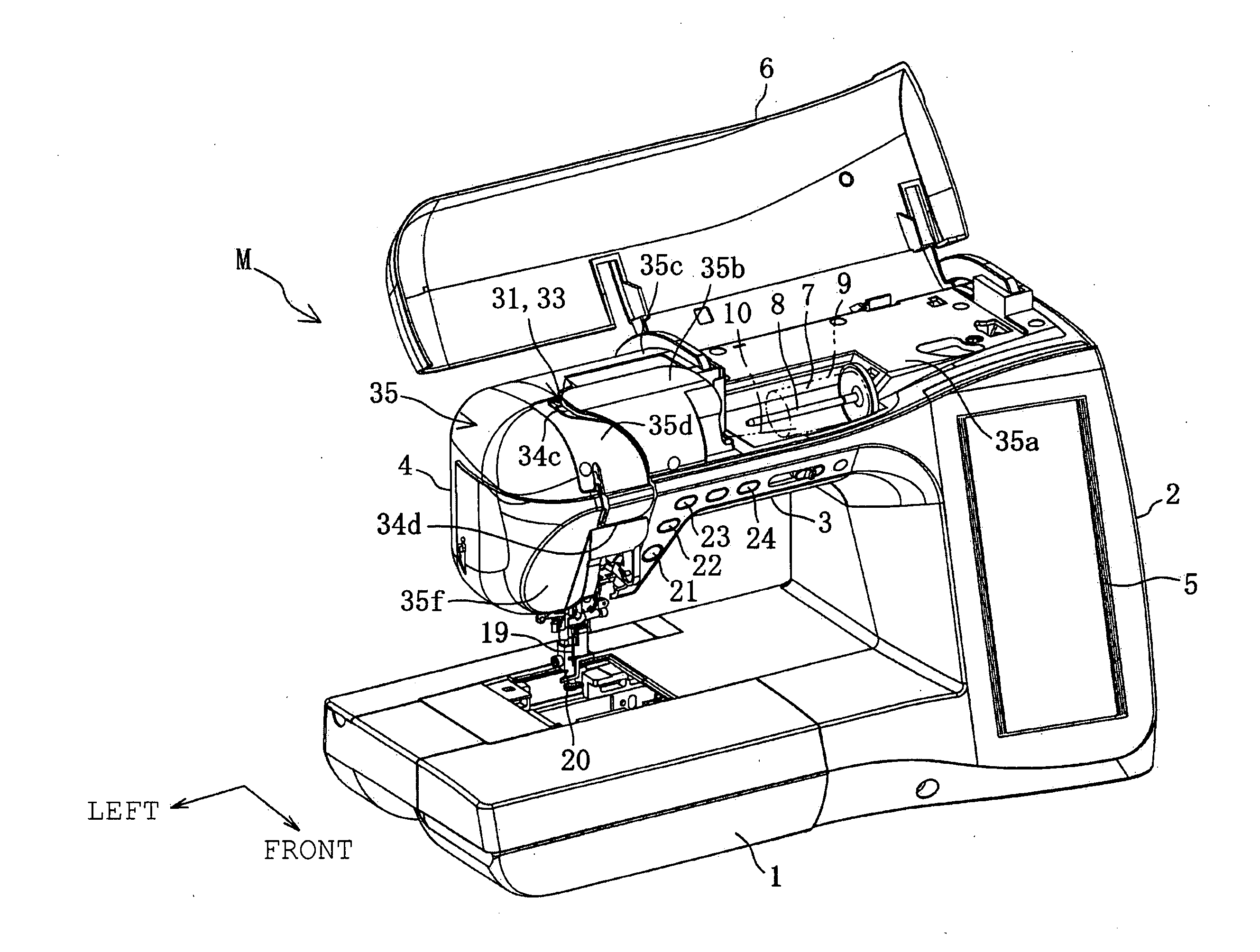

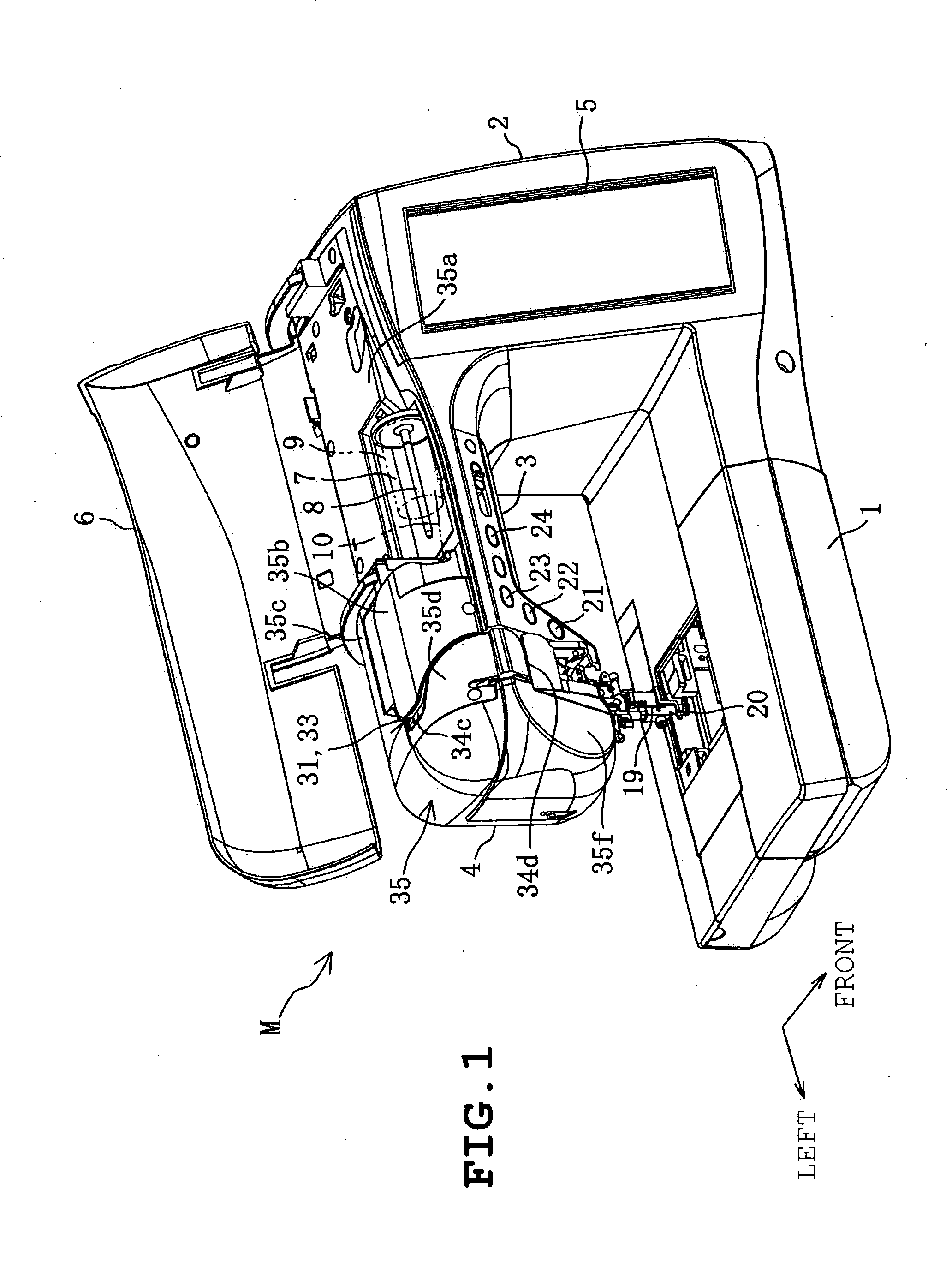

Sewing machine

InactiveUS6981459B2Operation efficiency can be improvedSimple engagementSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine includes a thread take-up lever and a thread tension regulator each disposed along a predetermined needle thread passage from a thread bobbin to a needle, an arm having a front face, and a movable controller disposed in the front of the arm so as to be movable at least within a predetermined range. The movable controller does not protrude out of the front face of the arm when moved in the predetermined range. The needle thread is engaged with at least one of the thread take-up lever and the thread tension regulator when the movable controller is moved within the predetermined range while the needle thread has been drawn from the thread bobbin near to the needle substantially along the predetermined needle thread passage.

Owner:BROTHER KOGYO KK

Embroidery machine able to sew cord material

In the present invention, an embroidery machine has a needle bar case (5) provided with a plurality of needle bars (3). When a main shaft (6) is rotated by a main shaft motor (first drive source) (60), the needle bars (3) are lift-driven and a known sewing operation is carried out. Lifting bars (15) are supported in the needle bar case (5) so as to respectively correspond to the needle bars (3), and each lifting bar (15) is lift-driven by a motor (second drive source) (16). As a substitute for a known fabric pressing body (18), at the lower end of the lifting bars (15) a cord guiding body (20) is attached that guides a cord material (27) above an object-of-sewing material. By changing the lifting stroke of the lifting bars (15), cord sewing or loop sewing of the cord material (27) is selectively carried out. Due to this configuration, it becomes possible to selectively carry out cord sewing and loop sewing of the cord material using a simple configuration.

Owner:TISM CO LTD

Automatic bag sticking machine

ActiveCN104746243BSo as not to damageSolve the contradiction between supply and demandWork-feeding meansPressersEngineeringAutomation

Owner:深圳市达益信智能设备有限公司

Sewing machine

InactiveCN1350083ALow costEasy to operateNeedle severing devicesThread-break detectorsEngineeringSewing needle

A sewing machine, where is disposed a securing pin 5 on the front surface HF of a sewing machine H so as to be able to project therefrom and, before a sewing needle 1 is moved to its bottom dead point after a thread is cut, the securing pin 5 is projected to thereby secure an upper thread T provided on a thread take-up 4. Also, even in case where the operation of the sewing machine is started, the projecting state of the securing pin 5 is held. That is, when the thread take-up 4 is moved down once and, after then, the thread take-up 4 is moved up; and, when the upward moving thread take-up 4 reaches its top dead point, the securing pin 5 is retreated. The sewing machine can draw out an end of an upper thread to the rear side of cloth, limiting the amount of the upper thread drawn out at a first stitch by means of a simple construction, and to prevent the upper thread from being pulled out when the cloth is taken out by limiting the amount of the upper thread drawn out when a sewing needle stops at an upper dead point after the thread is cut off.

Owner:JUKI CORP

Detachable threader

InactiveUS20100206206A1Rapid threading operationSmooth and efficientThread-laying mechanismsNeedle-threading devicesInterior spacePropeller

The present invention provides a detachable threader, which permits an upper holder block to be connected separately with a brake and a base; and the brake is linked with a propeller; a threading sheet is fixed on the propeller; with the orientation pin and restoring spring on the base, the upper holder block can be controlled in a manner to make the threading sheet move freely in the threading groove of the needle stand; additionally, a V-shaped groove is arranged at the bottom of the adapting hole; after the needle is inserted into the adapting hole, it can align automatically the needle hole with the threading groove; moreover, the base is linked with the detachable pedestal, wherein the inner space with an oblique surface is used to accommodate the needle and stitch.

Owner:CHANG PI CHAO

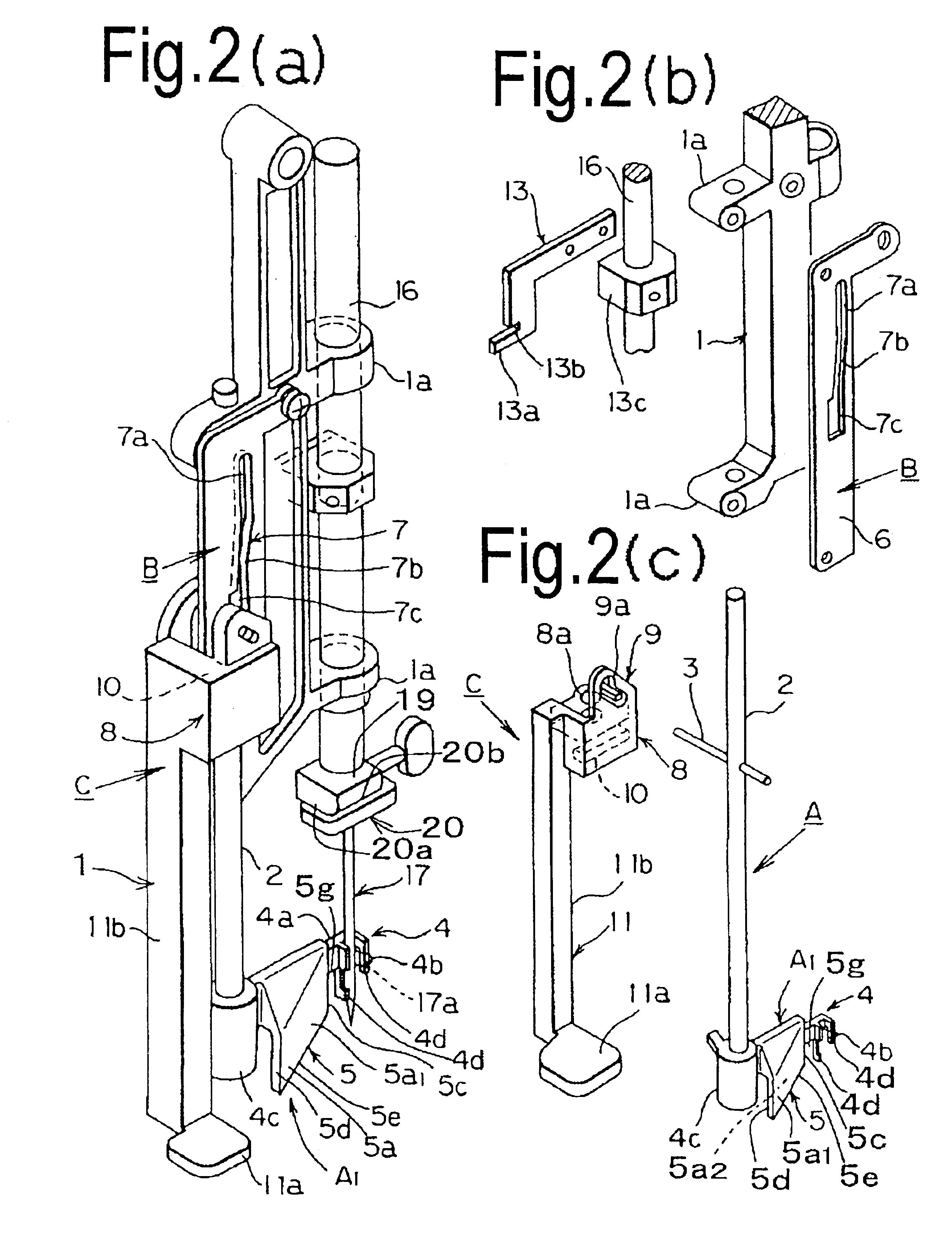

Sewing machine with automatic needle threader

ActiveUS7143706B2Automatically performAvoid interferenceProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing needle

A sewing machine includes a needle bar holding a sewing needle having an eye hole, a needle threading mechanism including a threading hook passing a needle thread through the eye hole of the sewing needle, a presser bar with a presser foot attached to its lower end, a vertically moving mechanism vertically moving the presser bar, a drive mechanism driving the vertically moving mechanism, a threading operation unit operating the needle threading mechanism, and a drive mechanism controlling unit controlling the drive mechanism vertically moving the presser bar to a position where interference between the presser foot and threading hook is avoided when the needle threading operation unit is operated.

Owner:BROTHER KOGYO KK

Sewing machine

InactiveUS7370592B2Heavy weightSmoothly paid outWork-feeding meansSewing-machine control devicesIncrease sizeEngineering

Sewing machine includes a tension detection section (26) for detecting tension acting on a sewn material (A) paid out from a rotary holder member, and a drive section for driving the rotary holder member, and the driving operation of the drive section (14) is controlled on the basis of the detection by the tension detection section. Once the tension acting on the sewn material has increased, the rotary holder member is driven to rotate by the drive section, so that the sewn material can be paid out smoothly from the rotary holder member. The sewing machine is particularly useful in a case where the rotary holder member is constructed into an increased size so that an increased amount of the sewn material can be wound thereon.

Owner:TOKAI IND SEWING MACH CO LTD

Threading device of sewing machine

InactiveUS7918171B2Avoid collisionThread-laying mechanismsNeedle-threading devicesEngineeringMotion transfer

A threading device of a sewing machine is provided. The threading device includes a threading hook which moves forward to enter an eye of a needle to catch a needle thread, and moves rearward with the needle thread being caught to insert the needle thread through the eye, a threading shaft which holds the threading hook, an operating member which is operated to move the threading shaft, a threading operation mechanism which transmits the movement of the threading shaft to the threading hook to move the threading hook back and forth, and a restricting device which makes the threading operation mechanism inoperable when the spreader mechanism is attached to the sewing machine main body, and makes the threading operation mechanism operable when the spreader mechanism is detached from the sewing machine main body.

Owner:JUKI CORP

Sewing machine with automatic threading mechanism

InactiveUS20060011117A1Hook reliableLess installation spaceThread-laying mechanismsNeedle-threading devicesEngineeringSewing machine

A sewing machine includes a plurality of thread hooking sections including a thread take-up lever and a thread tension regulator, and a thread guide thread hook mechanism having a thread hook member which is moveable nearly parallel to the vertical surface from a stand-by position to a thread hooking position. The sewing machine is configured to hook the extent of the needle thread from a thread transferring member moved to the vicinity of the eye to the thread take-up lever to hook it onto the needle bar thread guide.

Owner:BROTHER KOGYO KK

Threading device of sewing machine

InactiveUS20090013912A1Easy to confirmThread-laying mechanismsNeedle-threading devicesBiomedical engineeringSewing machine

A threading device of a sewing machine having a plurality of needles is provided. The threading device is configured to insert a thread through an eye of any one of the needles. The threading device includes a threading hook which moves forward to enter the eye of one of the needles and moves backward to catch and insert the thread through the eye, a threading mechanism which moves the threading hook to insert the thread, a selecting portion operable to select, among the plurality of needles, a needle through which the thread is to be inserted, a positioning mechanism which moves the threading hook to a position corresponding to the needle selected by operating the selecting portion, and a selected needle indicating device which distinguishably indicates the needle with respect to which the threading hook has been positioned by operating the selecting portion.

Owner:JUKI CORP

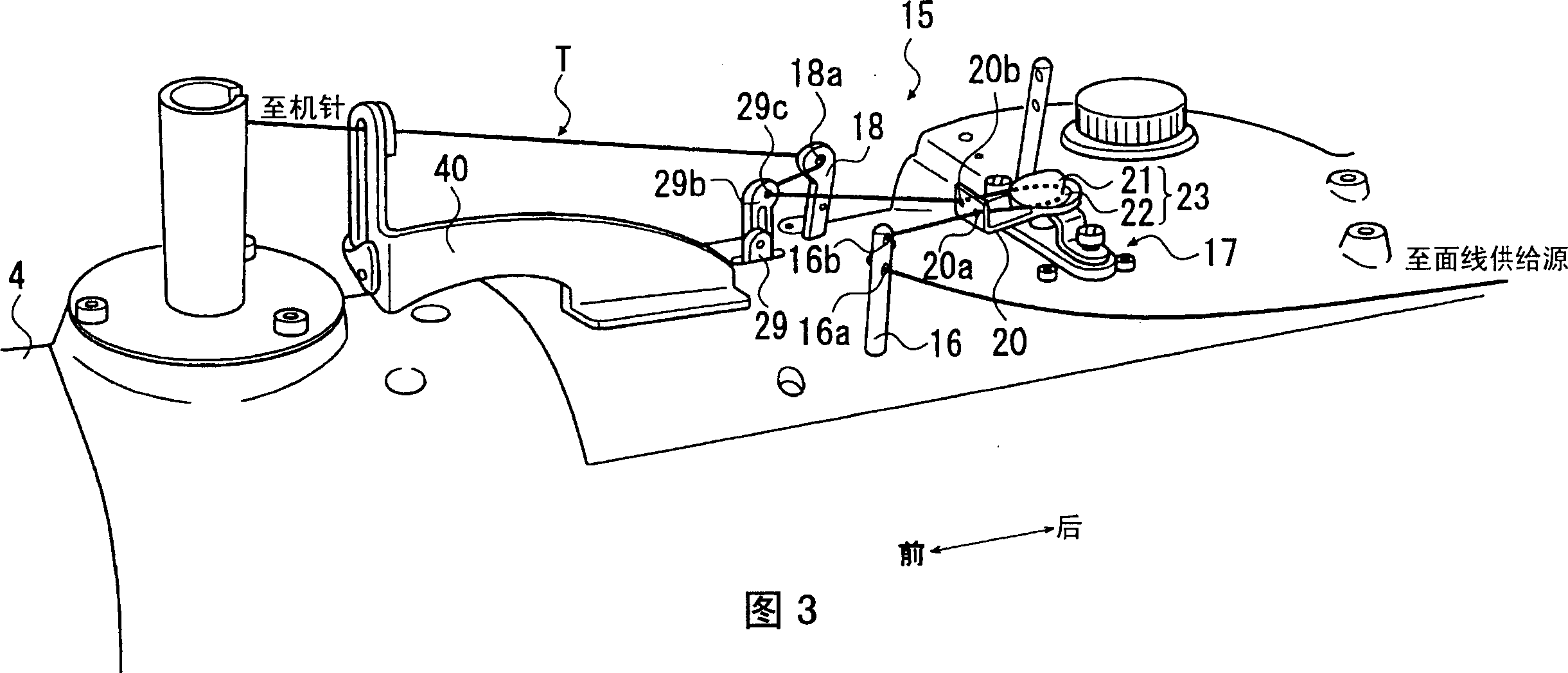

Sewing machines

InactiveCN1439759APrevent offlinePrevent getting involvedProgramme-controlled sewing machinesNeedle severing devicesEngineeringSewing machine

This sewing machine 1 includes a thread tension device 17 for applying pressing force to the needle thread, a needle thread handling member 29 for handling the needle thread guided from the thread tension device 17, air cylinders 26, 27 for moving the needle thread handling member 29 from the foremost position P10 through the middle position P30 to the last position P20, a needle thread cutting knife 14 for cutting the needle thread, and a control device 50 for controlling the air cylinders 26, 27. The needle thread is guided from the needle thread handling member 29 to a needle thread take-up lever 18 to finally reach a thread passing hole 6a of a needle 6. Immediately before the start of sewing, the needle thread handling member 29 is moved from the foremost position P10 to the last position P20. After the end of sewing, the needle thread handling member 29 is moved from the last position P20 to the middle position P30. After that, the pressing force to the needle thread is increased by the thread tension device. Subsequently, the needle thread handling member 29 is moved from the middle position P30 to the foremost position P10.

Owner:JUKI CORP

Needle threading machine

InactiveUS7337734B2Reduce harmIncreased durabilityThread-laying mechanismsNeedle-threading devicesReciprocating motionEngineering

The present invention relates to a needle threading machine of putting a thread through an eye of a needle provided in a sewing machine, the needle threading machine comprising a thread catcher comprising a hook to hook the thread, and a hook supporter extended from the hook and supporting the hook; a thread catcher driver driving the thread catcher to reciprocate allowing the hook to be inserted in and return from the eye of the needle; and a thread transporting unit transporting the thread caught in the hook away from the hook after the hook is returned from the eye of the needle. Thus, the present invention provides a needle threading machine capable of not only reducing damage on a thread but also increasing the durability of a thread catcher.

Owner:INBRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com