Sewing machine

A sewing machine and needle technology, applied in the field of sewing machines, can solve the problems of difficulty in adjusting the tension of the first thread adjusting element, shortening the length, etc., and achieve the effects of preventing thread jumping and easy thread changing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, preferred embodiments of the sewing machine of the present invention will be described in detail with reference to the accompanying drawings.

[0034]

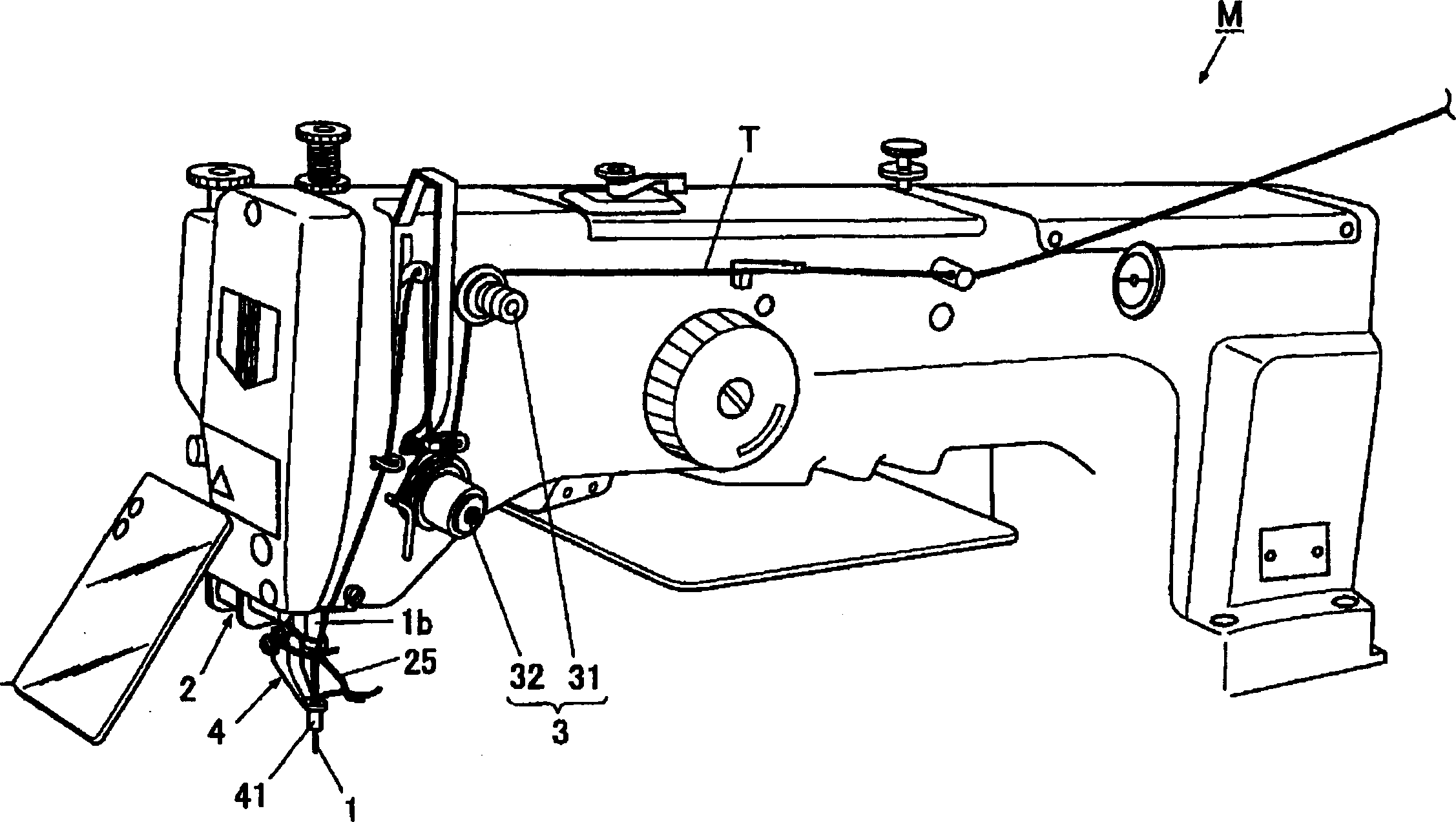

[0035] like Figure 1 to Figure 11 As shown, the sewing machine M has: a sewing machine motor 10 (refer to Figure 11 ) and is arranged on the needle bar 1b that moves up and down by the driving of the sewing machine motor 10, and the thread cutting device 8 that cuts the thread after the sewing of a predetermined cycle is completed (refer to Figure 11 ), and after the thread is cut by the thread cutting device 8, the thread sweeping device 2 that traverses between the needle 1 and the object to be sewn on the needle plate, and draws out the thread from the object to be sewn, and as a pair Insert through the needle hole 1a of the needle 1 (refer to image 3 ) to apply tension to the thread, as a thread tension application mechanism thread adjusting element 3, and when the needle 1 is drawn out from the sewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com