Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

877results about "Loop takers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for improved apparel fit

ActiveUS7092782B2Accurate methodIncreasing retail inventoryBuying/selling/leasing transactionsSpecial data processing applicationsEngineeringType selection

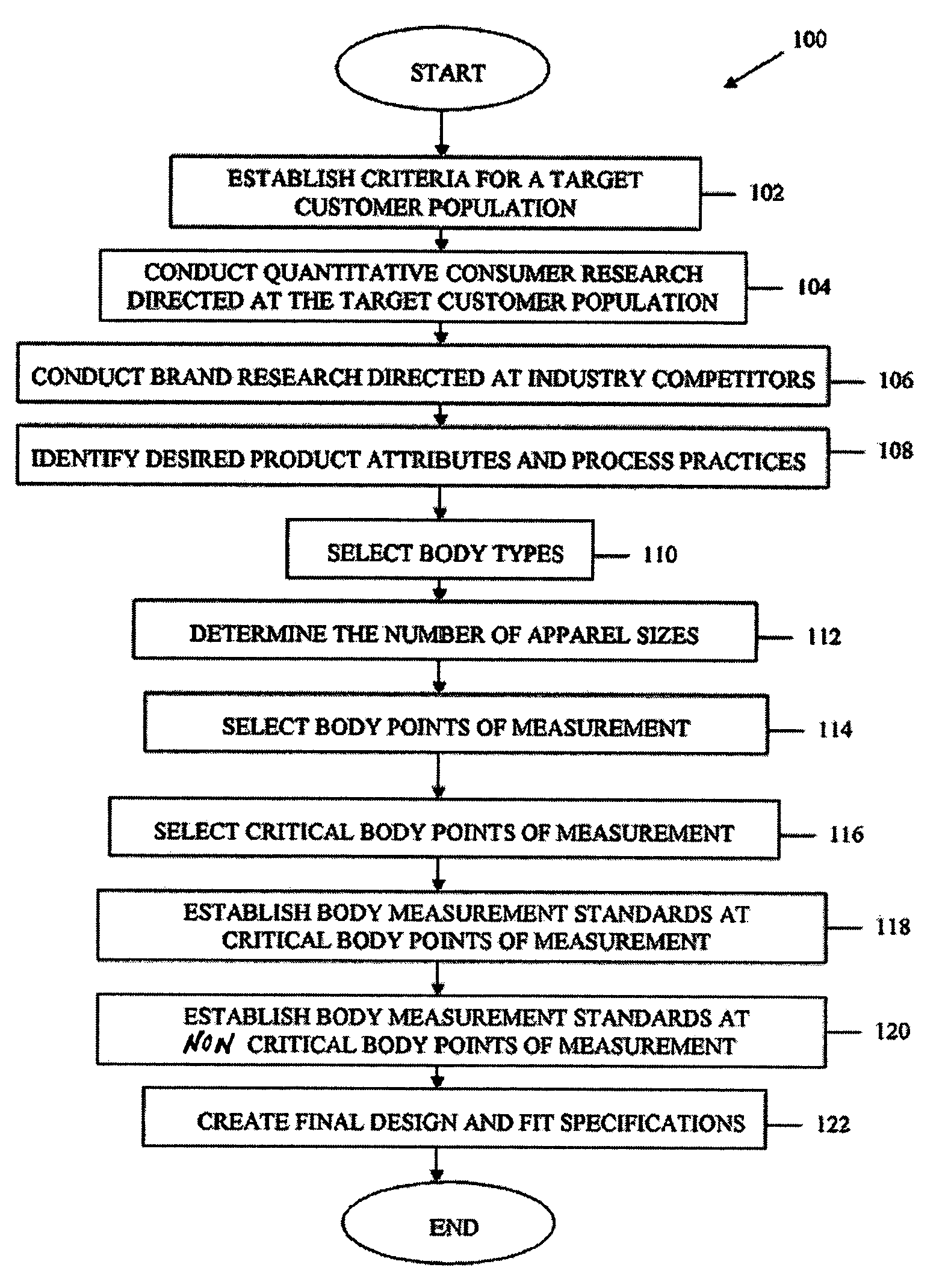

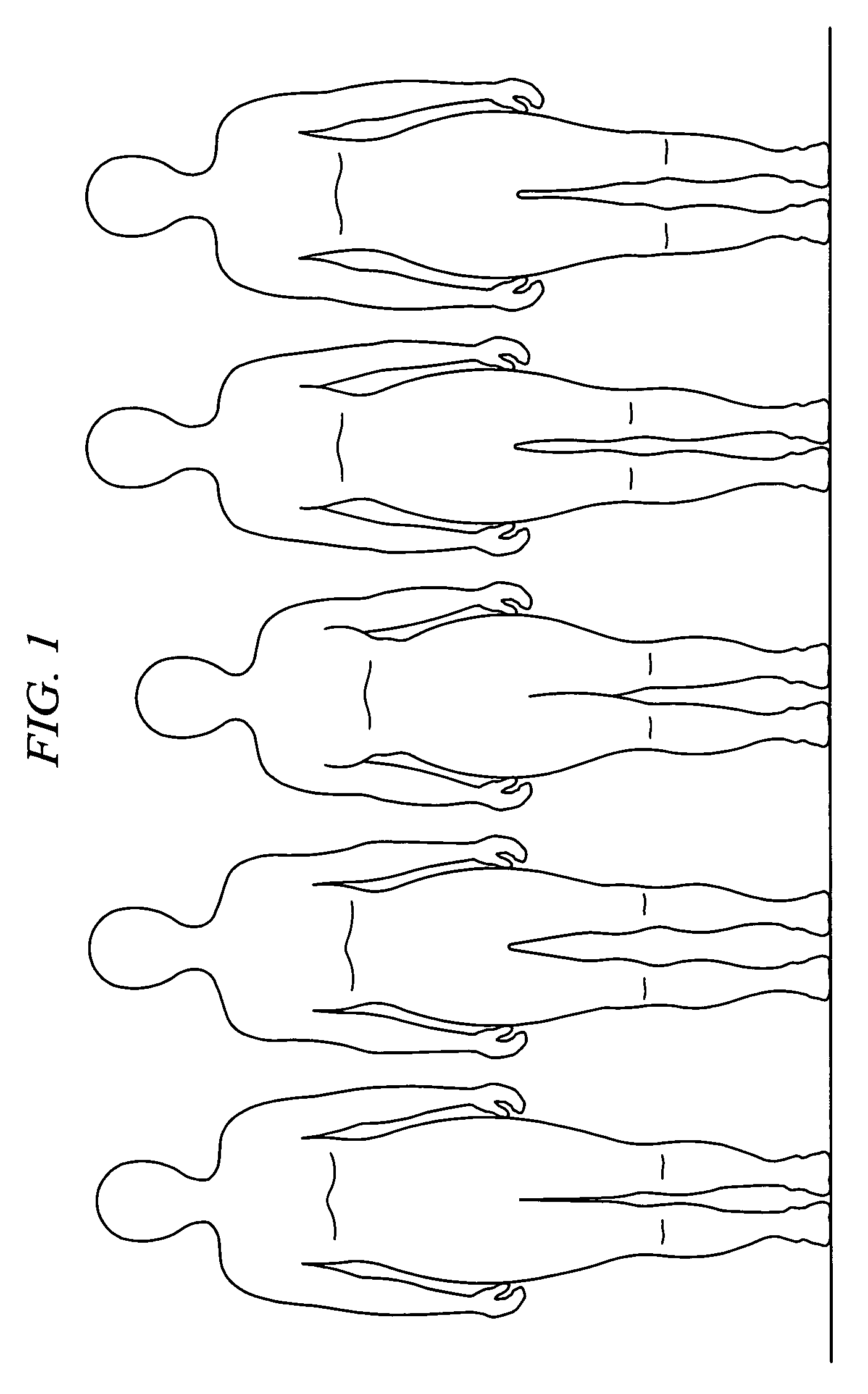

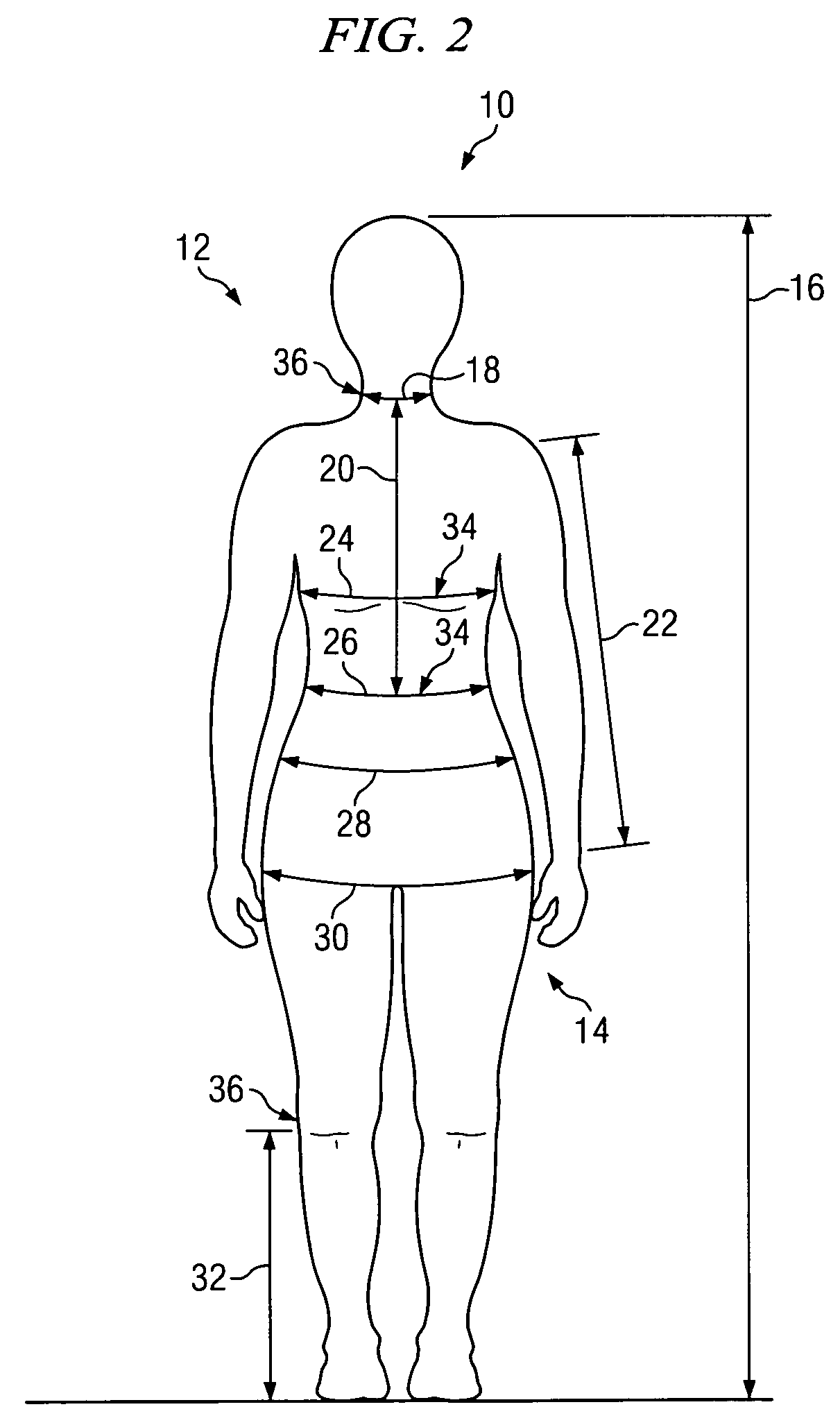

Systems and methods for providing garments with improved and customized fits to one or more target consumer groups fit are described in the present invention. One method provides for a garment fit to a target consumer group comprising the steps of determining common body types for the target consumer group, establishing customized body measurement standards for each body type, selecting at least one real fit model for each body type, creating a sample garment in a range of sizes using grading rules, checking each sample garment on a fit model selected for each size and body type, preparing a block for each sample garment size and body type, and using the block to provide a garment fit for a target consumer group. Additional aspects are also disclosed.

Owner:ADVANTAGE PLATFORM SERVICES INC

Gate apparatus for tufting loop and cut pile stitches

InactiveUS7222576B2Efficiently employedTufting apparatusLoop takersEngineeringMechanical engineering

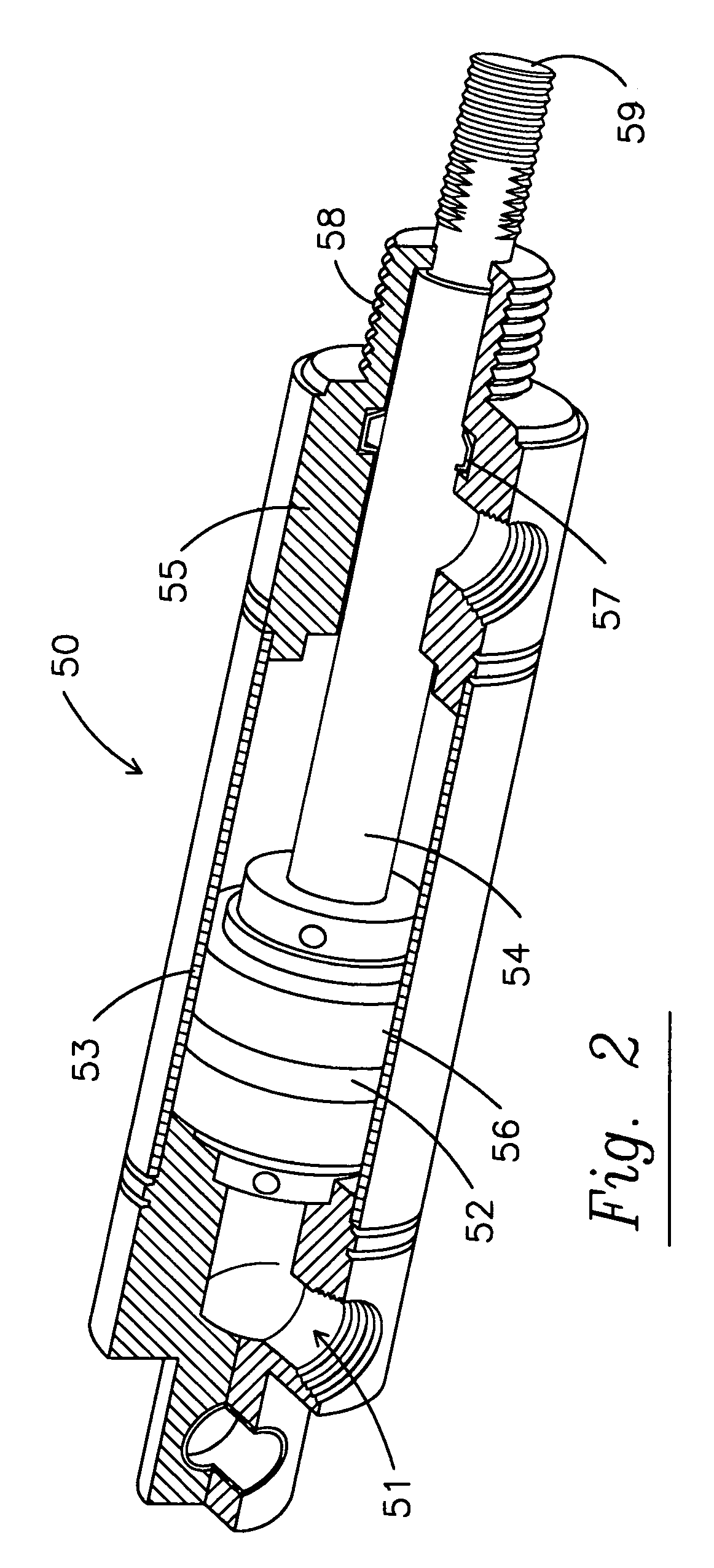

A gated looper apparatus has an array of individually mounted pressurizable air cylinders with piston rods acting against biased slider bars in communication with looper gates. Baising elements are mounted external of pneumatic cylinders about slider bars with protective ferules to provide greater responsiveness and ease of maintenance.

Owner:TUFTCO

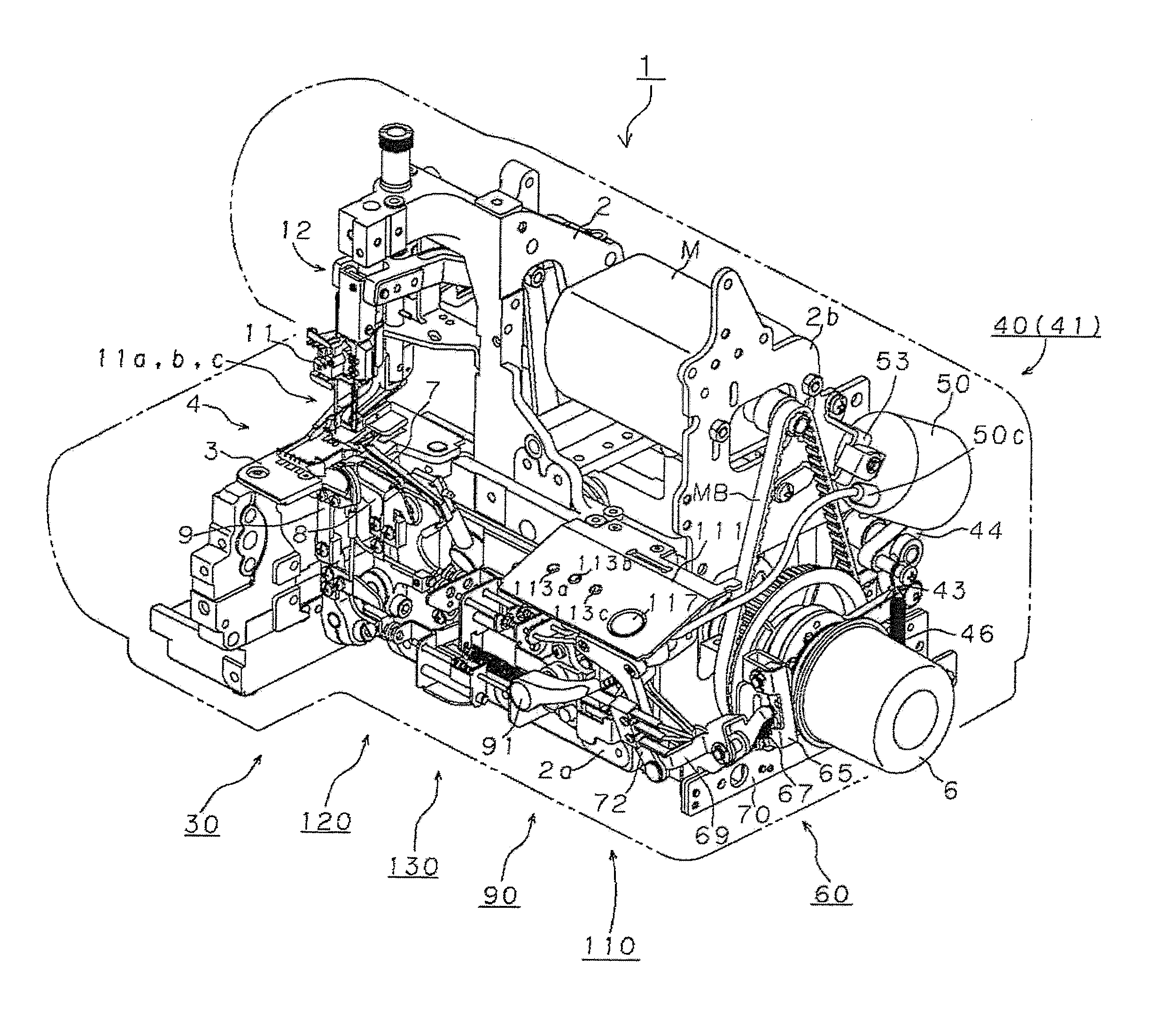

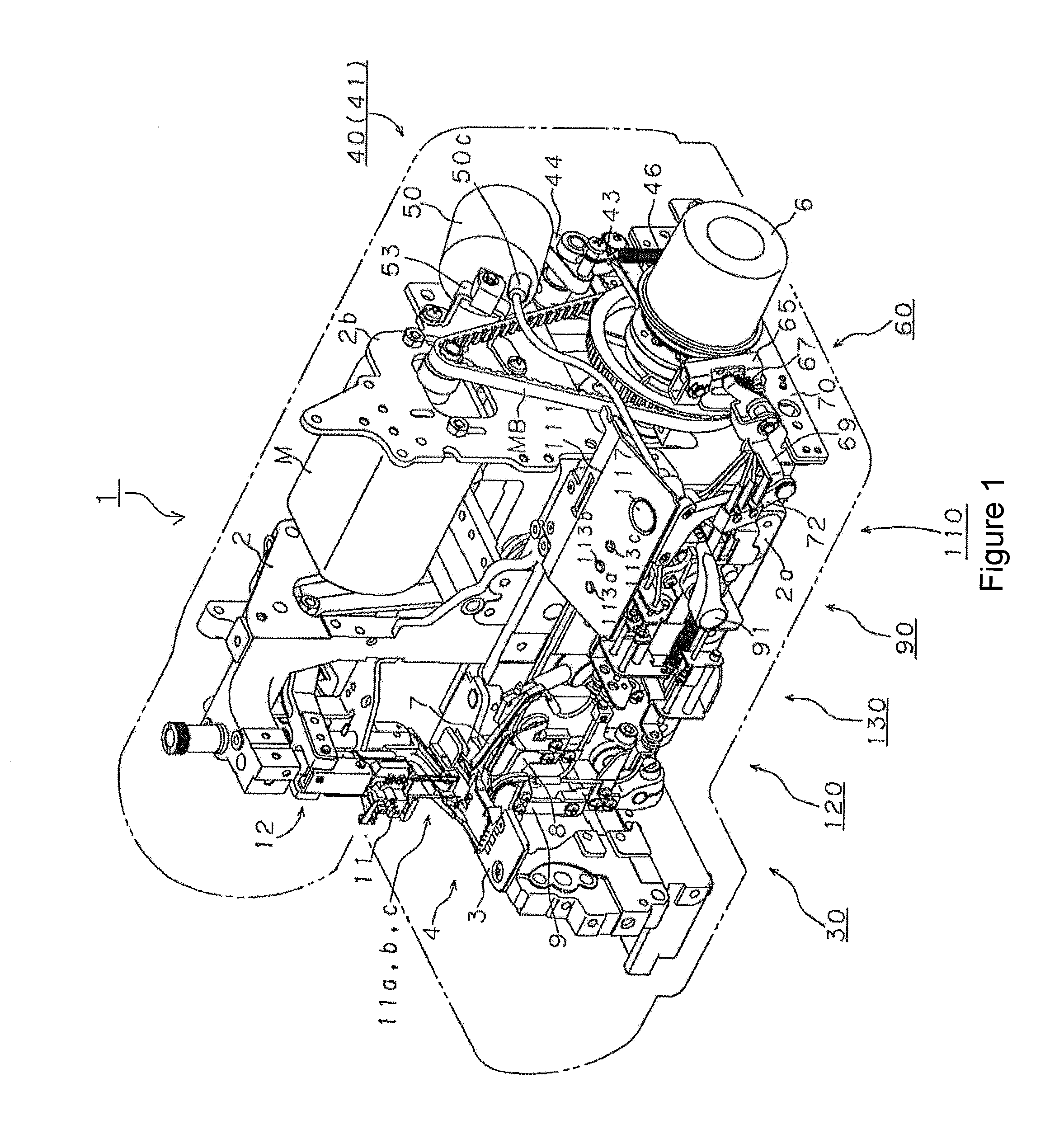

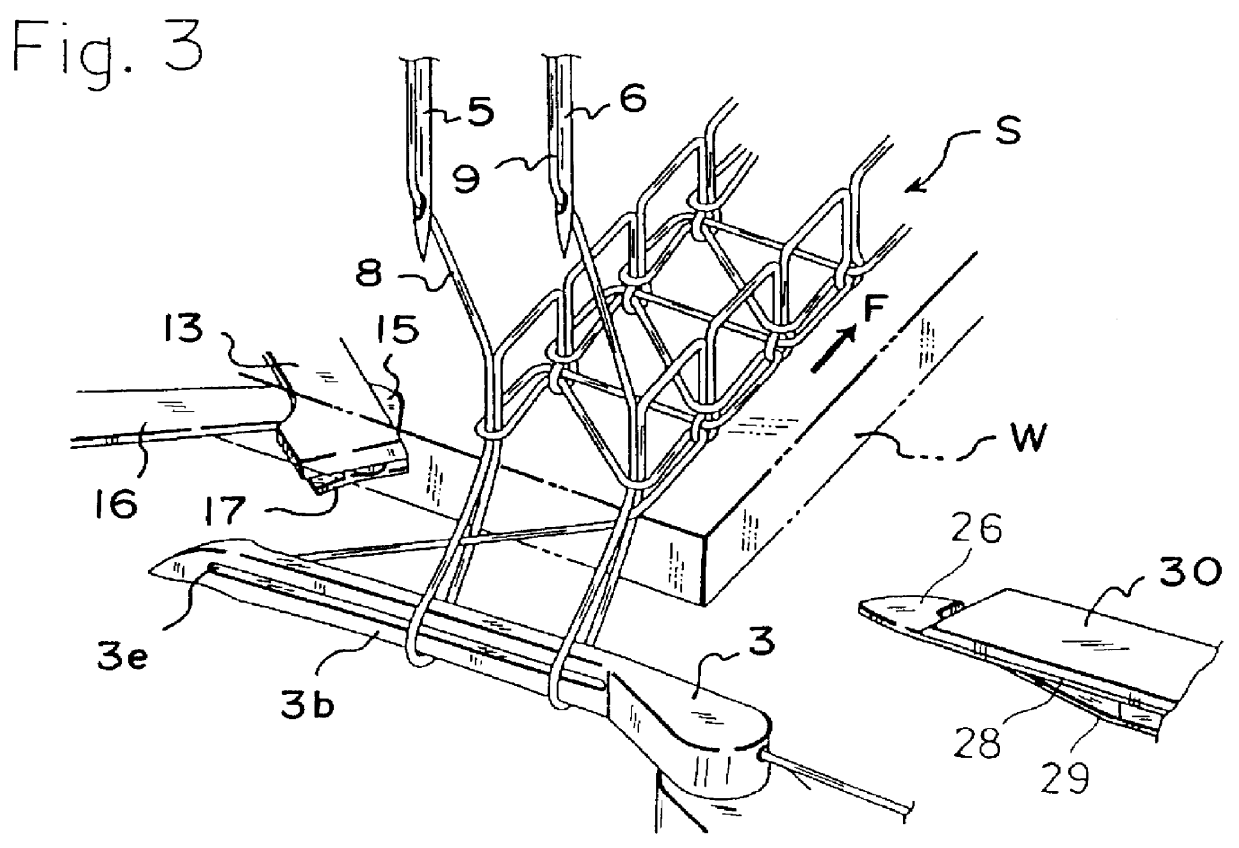

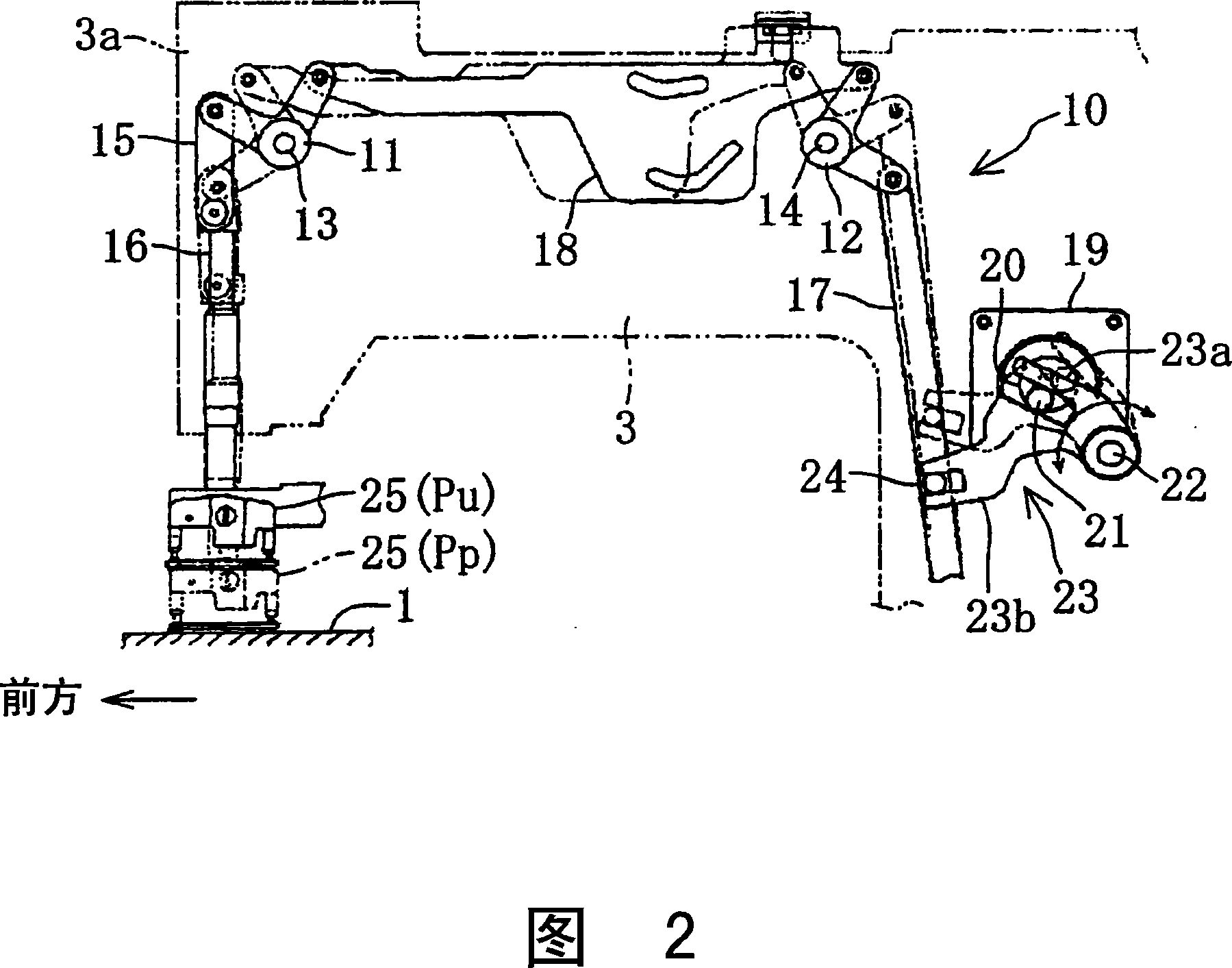

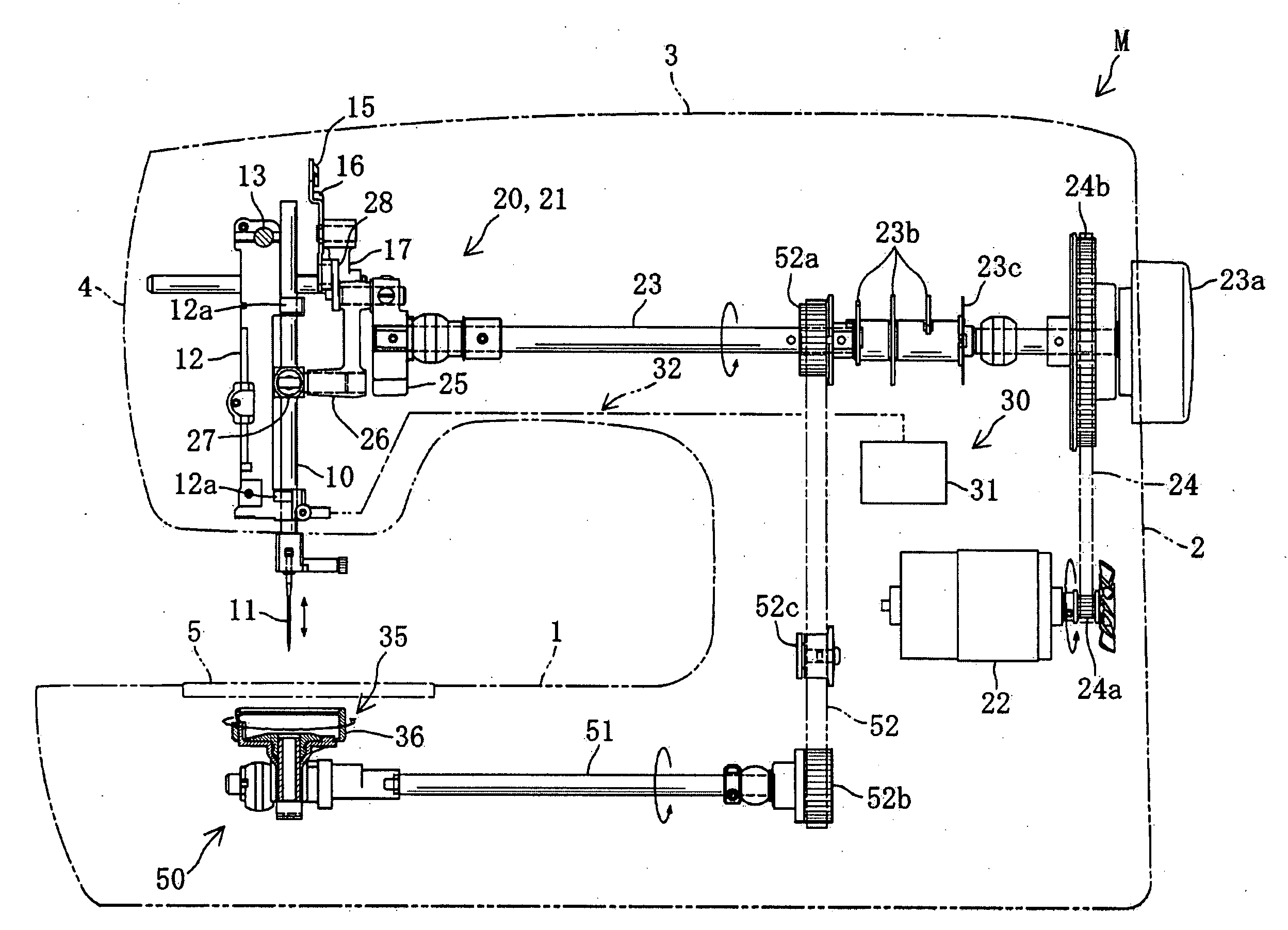

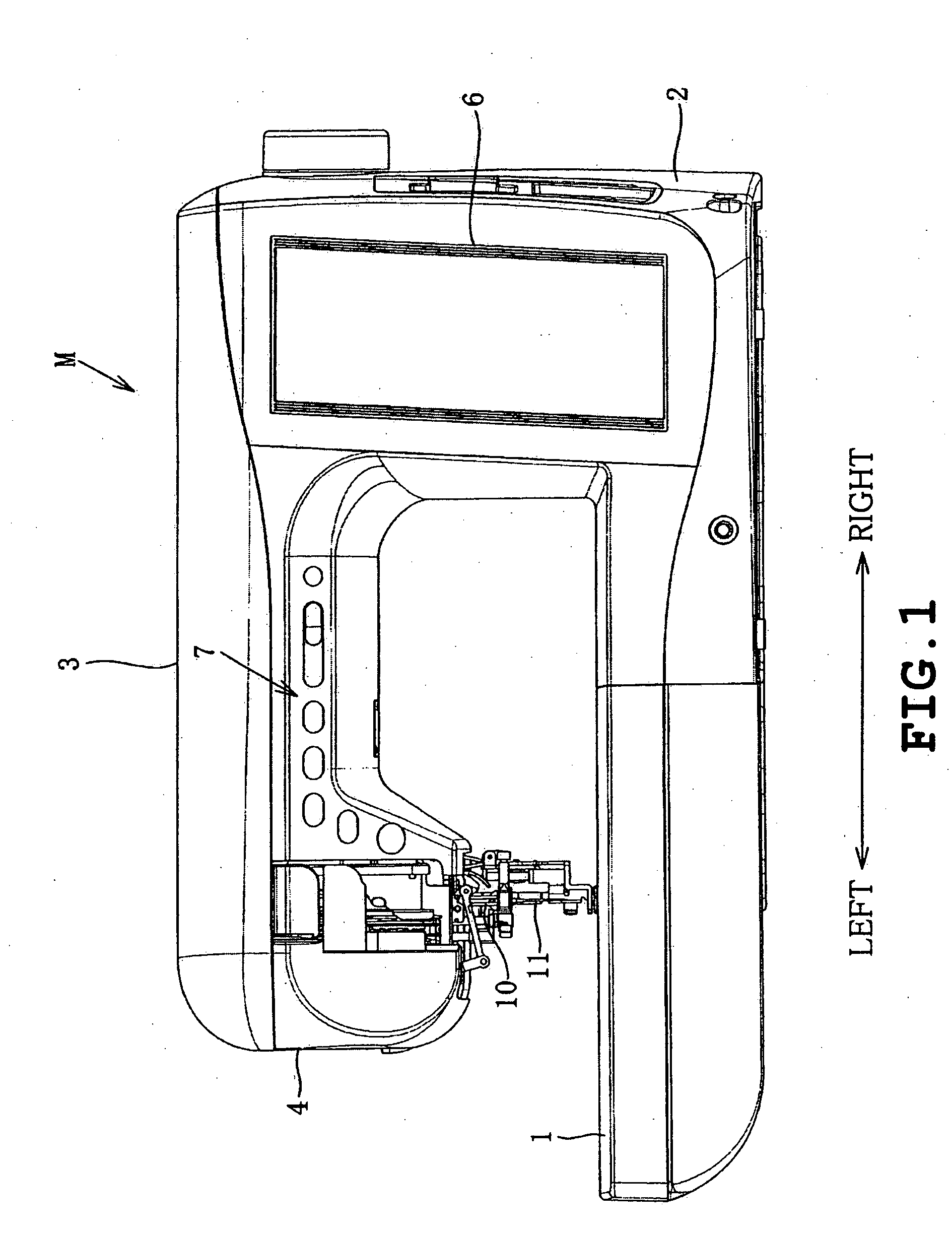

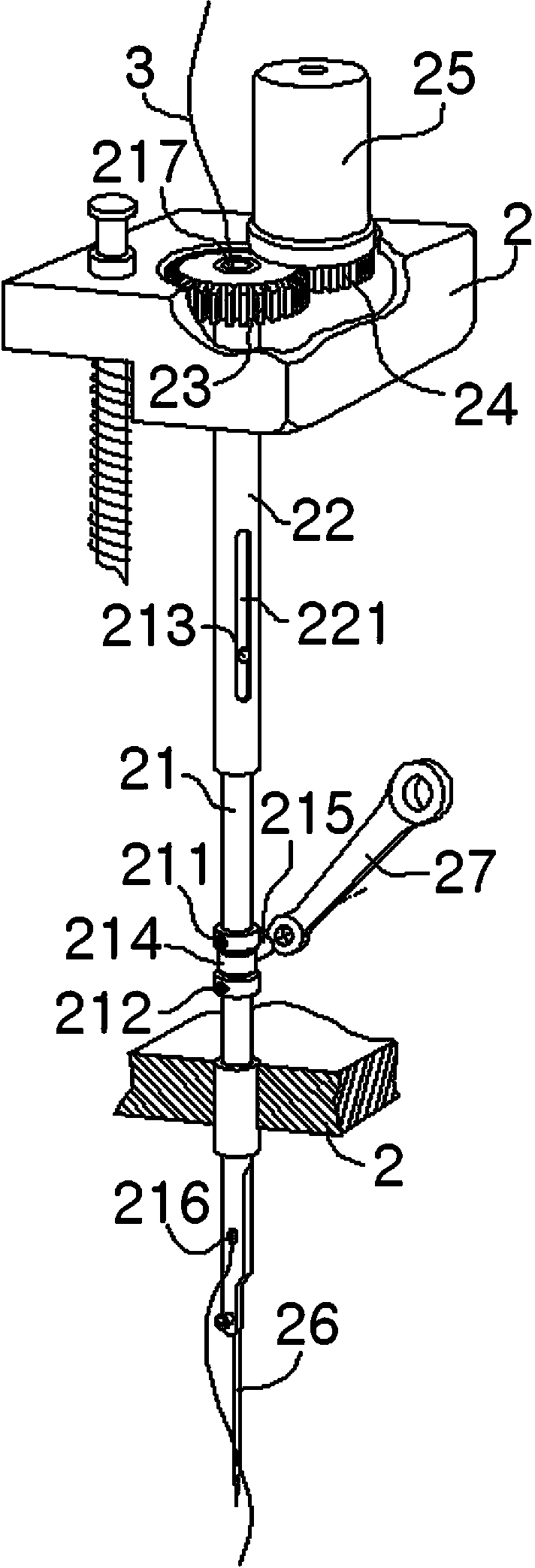

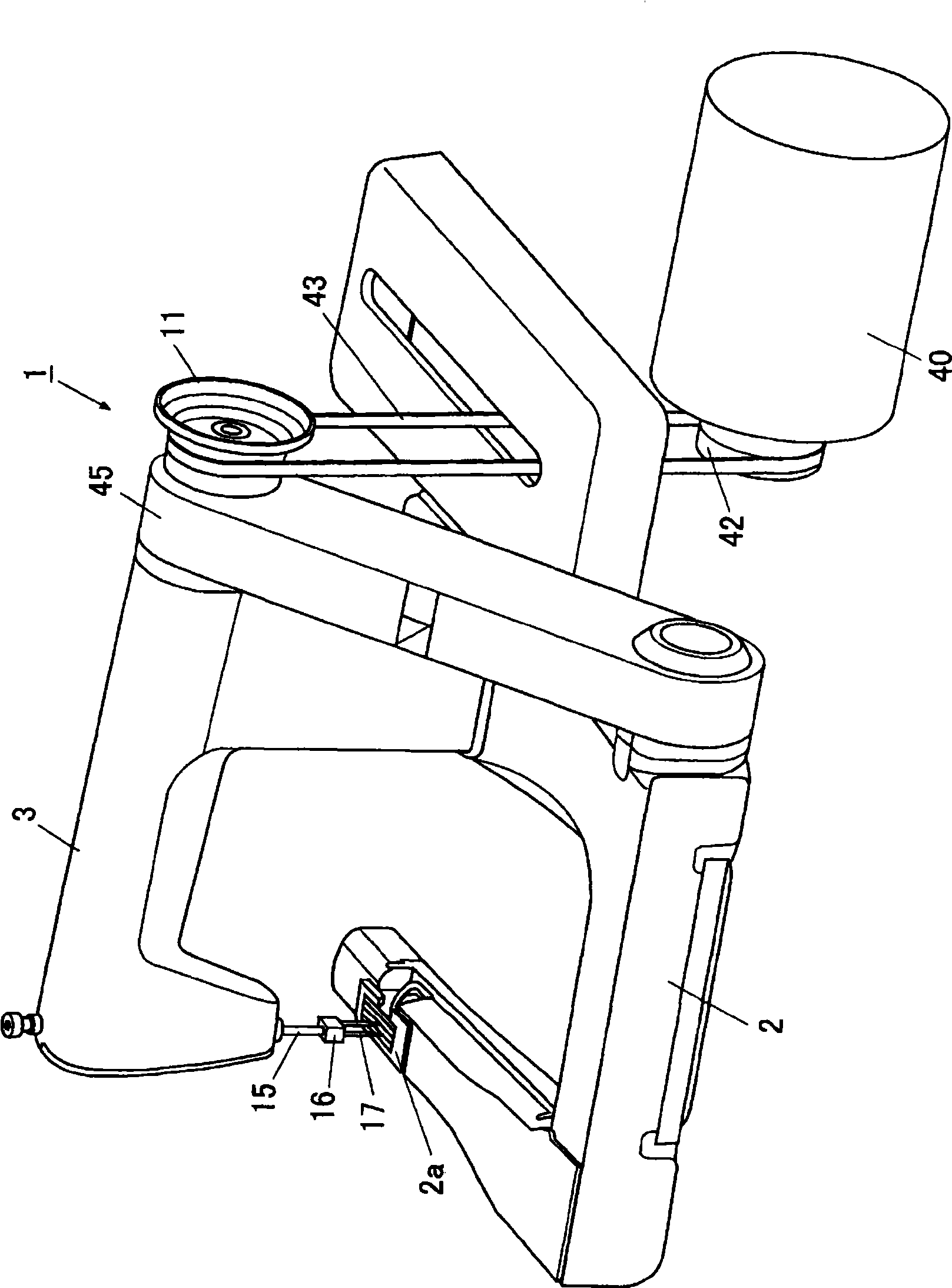

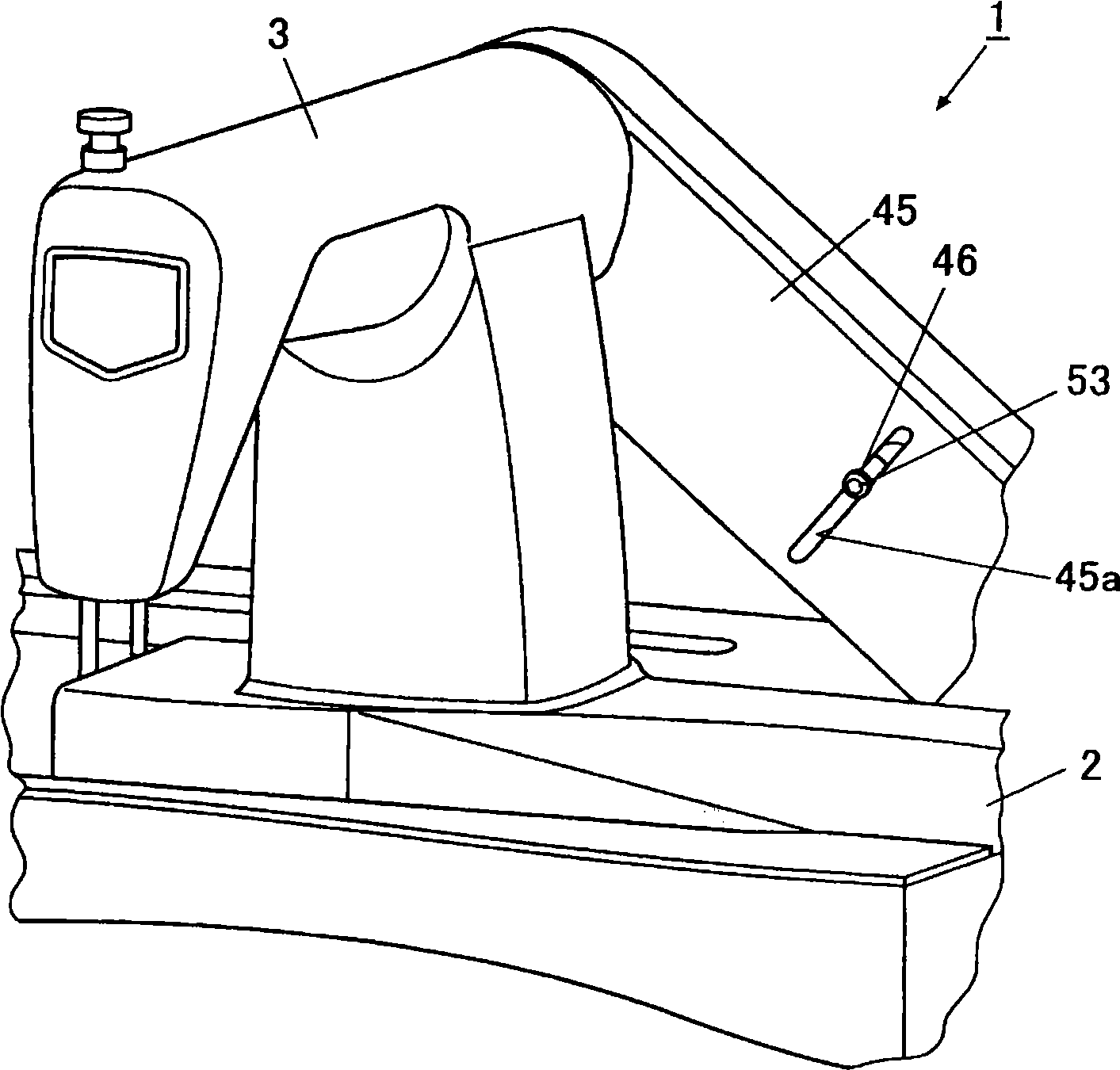

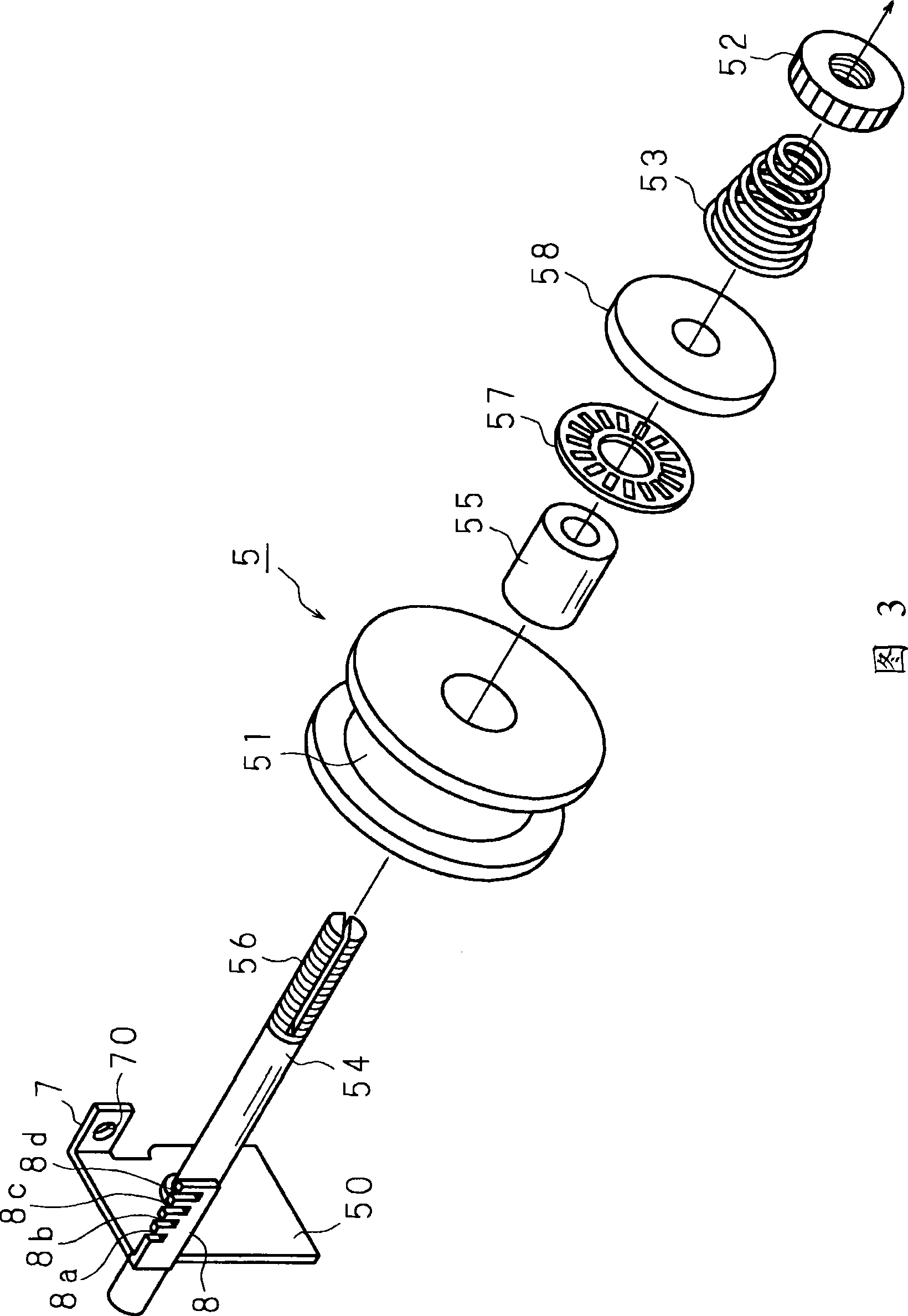

Gas Carrying Threading Device of Sewing Machine

ActiveUS20120210922A1Easy to handleEasy to operateThread-break detectorsNeedle-threading devicesTransmitted powerDrive shaft

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

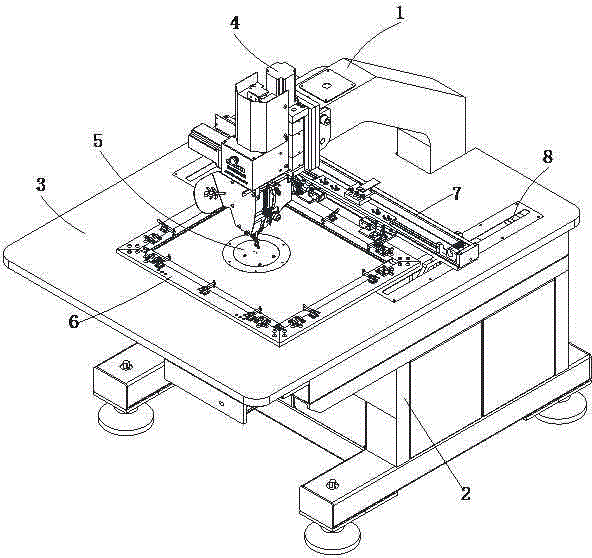

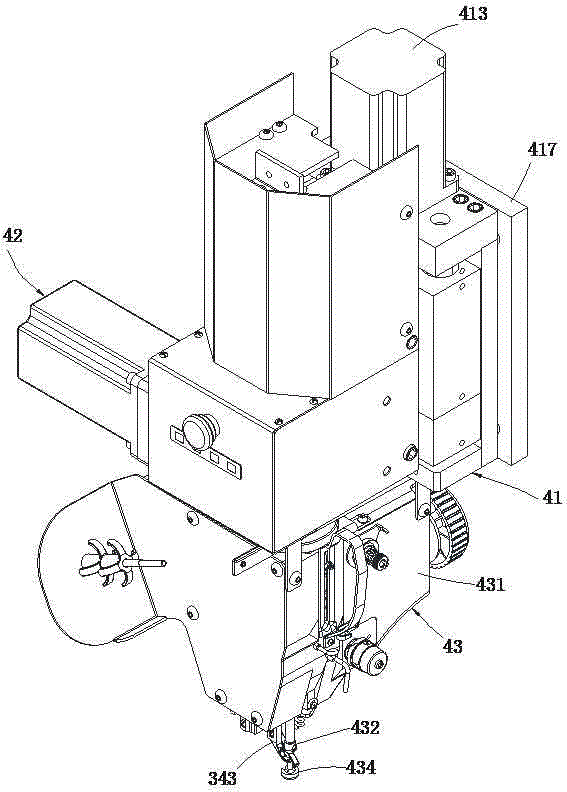

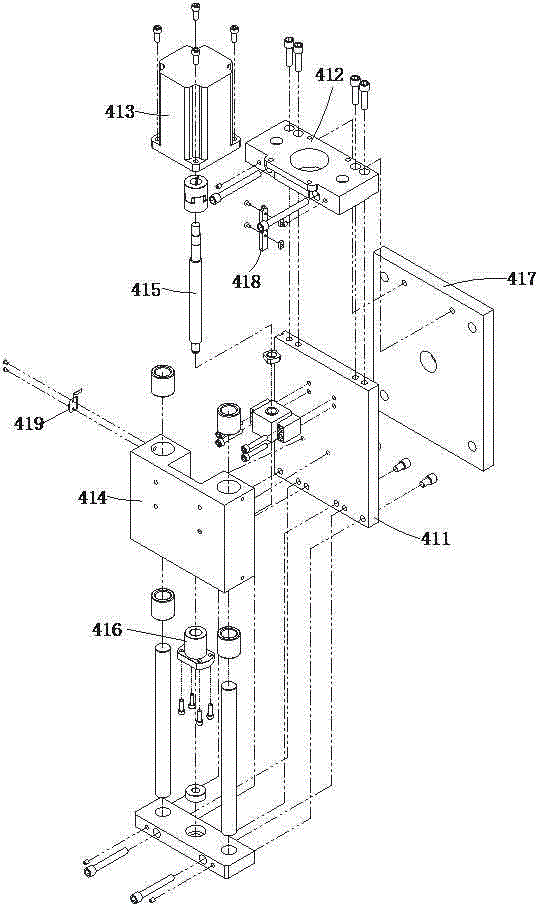

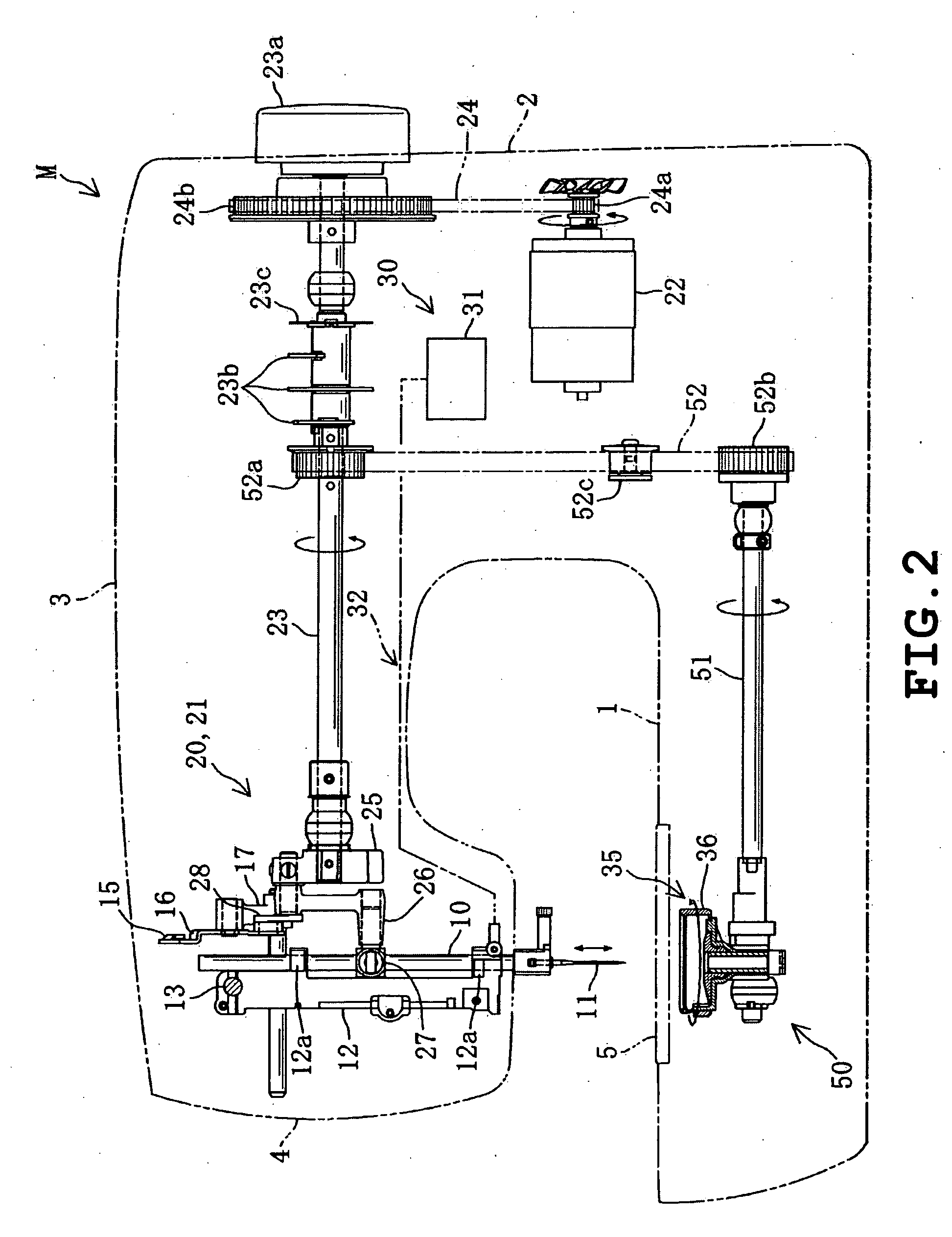

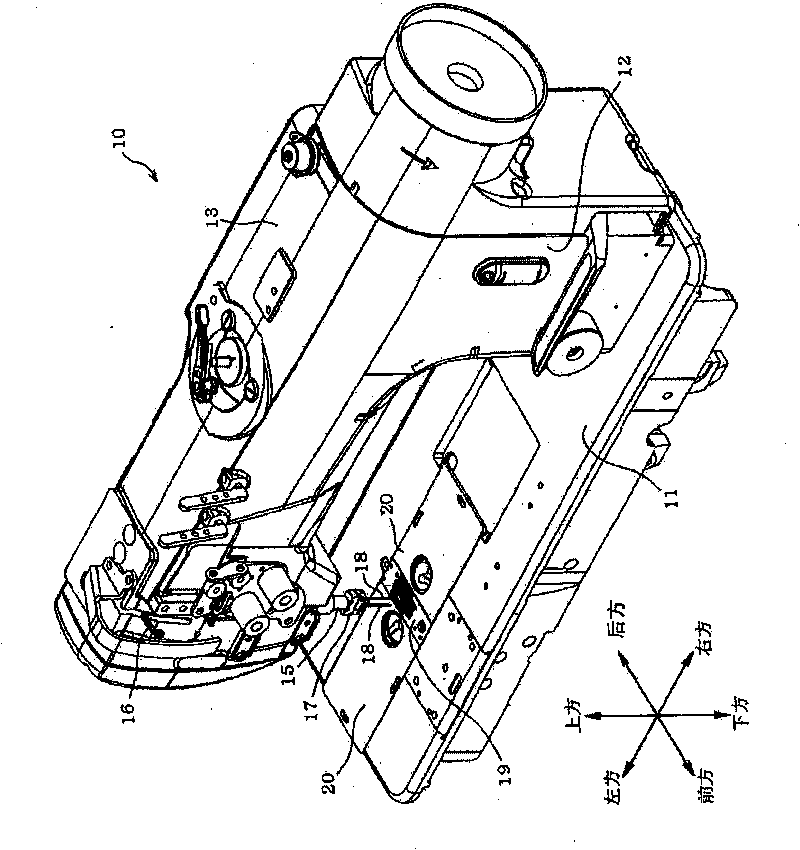

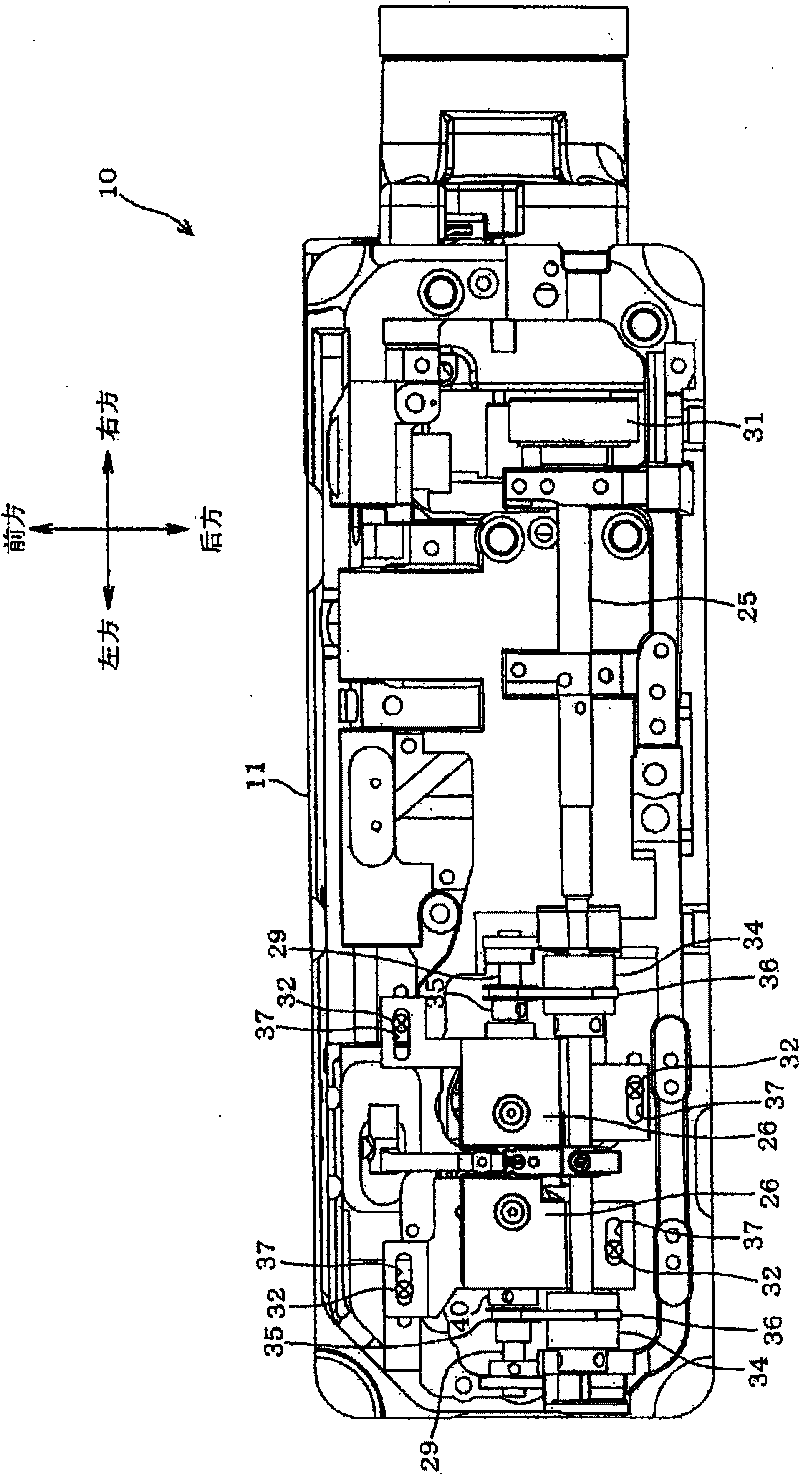

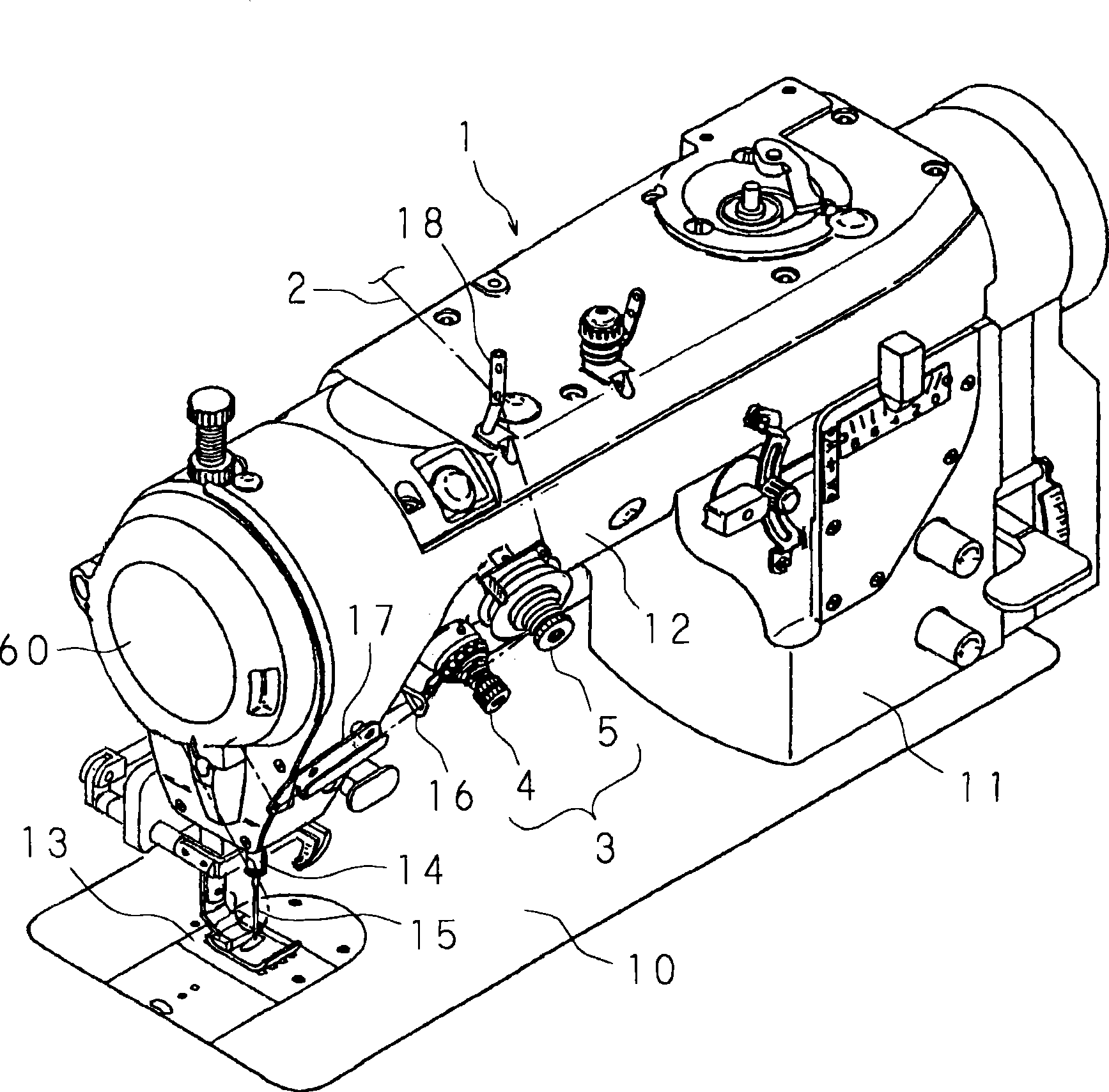

Outrigger rotating type independently-driven automatic sewing equipment

ActiveCN103981638AMeet processing needsPowerfulPressersNeedle barsFailure rateAutomatic test equipment

The invention relates to outrigger rotating type independently-driven automatic sewing equipment. The equipment comprises an upper machine head and a lower machine head which are independently driven respectively, wherein the upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, the machine head rotating assembly is fixedly arranged on the machine head lifting assembly, the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly, and the upper machine head can rise / fall and can also adaptively rotate synchronously with the lower machine head; the lower machine head comprises a bottom line rotating assembly and a bottom shuttling system, the bottom shuttling system is arranged at the upper part of the bottom line rotating assembly, and the bottom line rotating assembly drives the bottom shuttling system to rotate in 360 degrees in any direction; each of the upper and lower machine heads is further provided with a servo-control system, and the servo-control systems control the steering of a bottom line rotating shaft and control the bottom line rotating shaft and machine head rotating shafts to correspond to each other and be in the same rotating speed. The equipment has the advantages that various machining needs can be met, the scope of application is greatly enlarged, and the function is powerful; the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

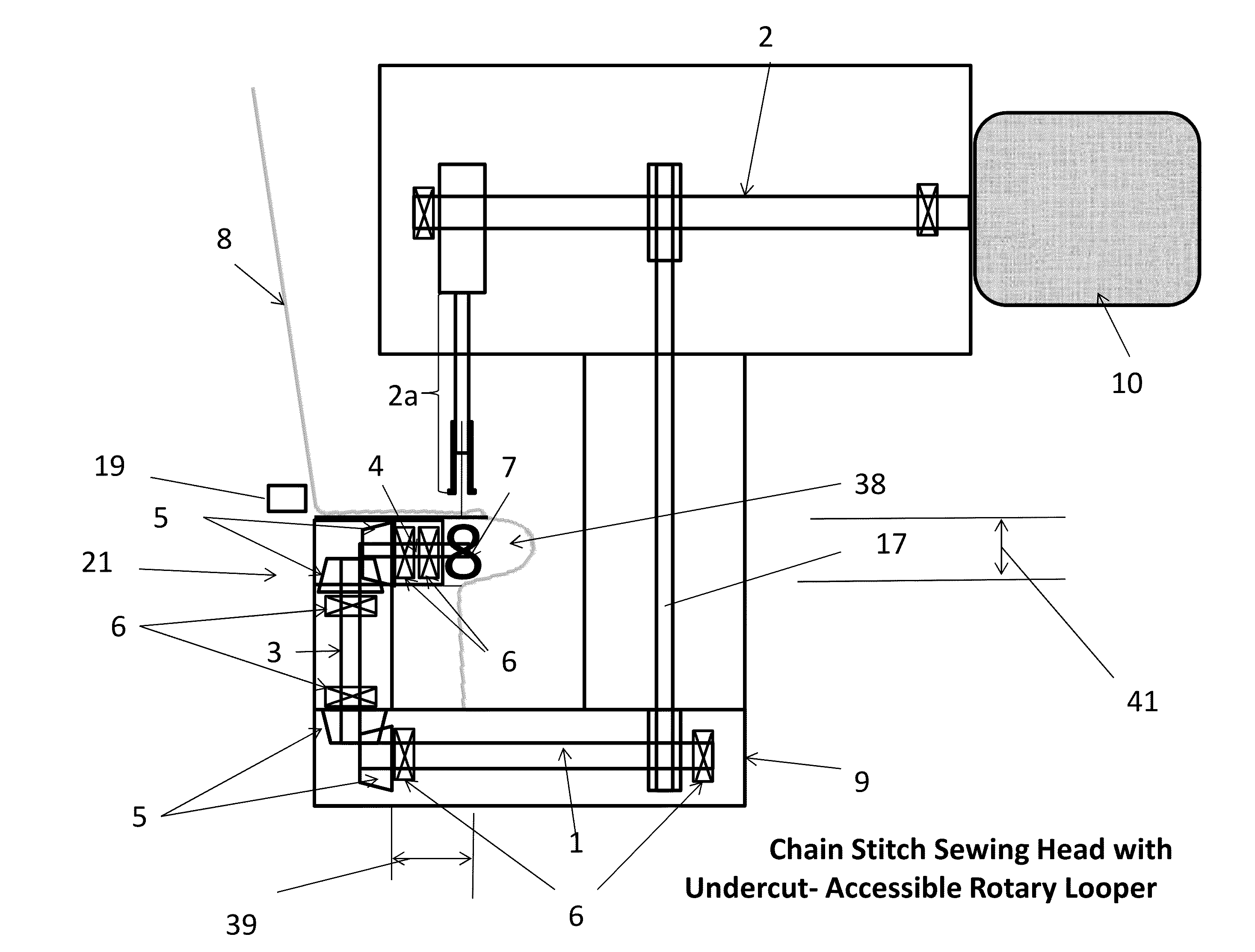

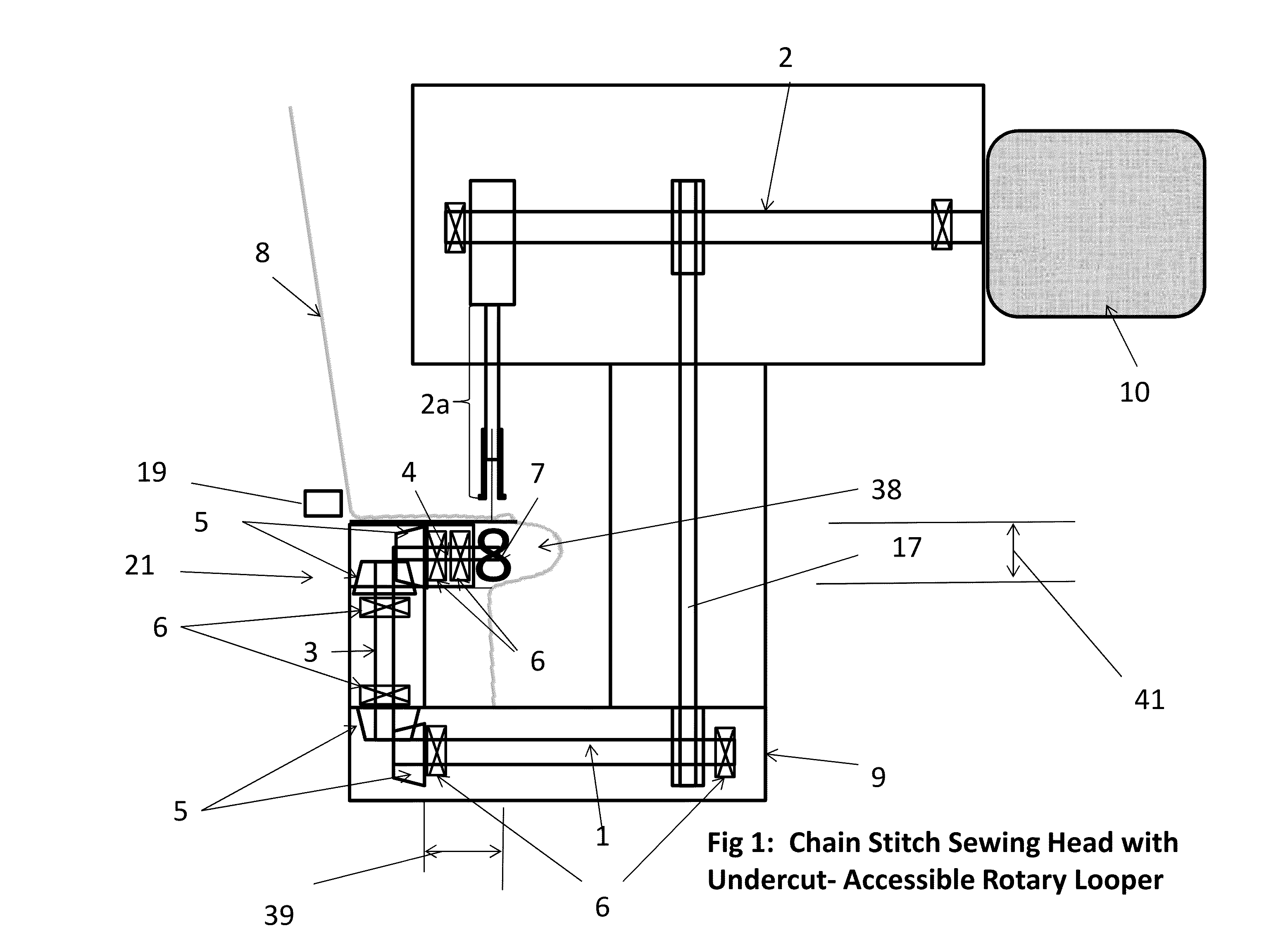

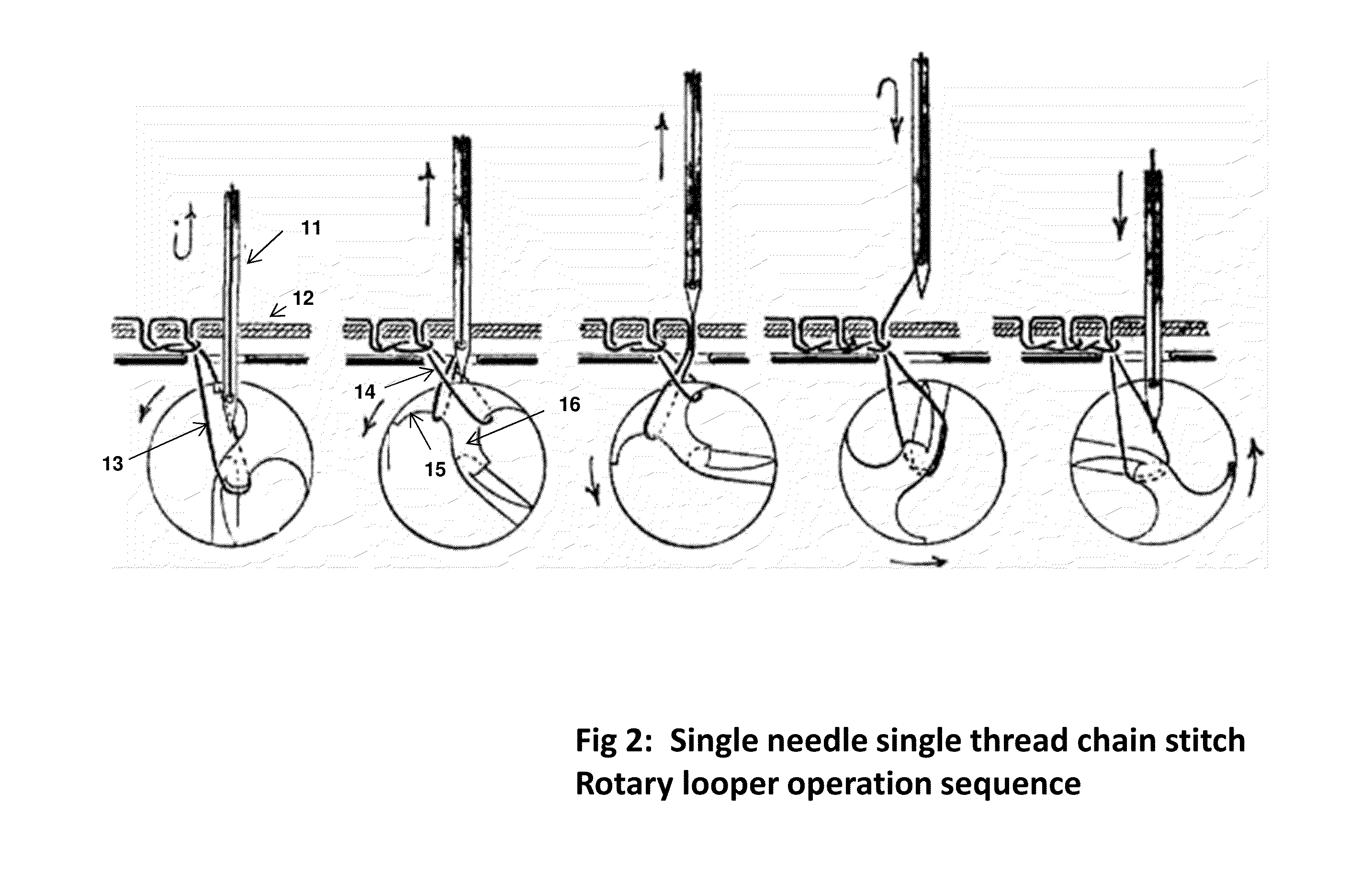

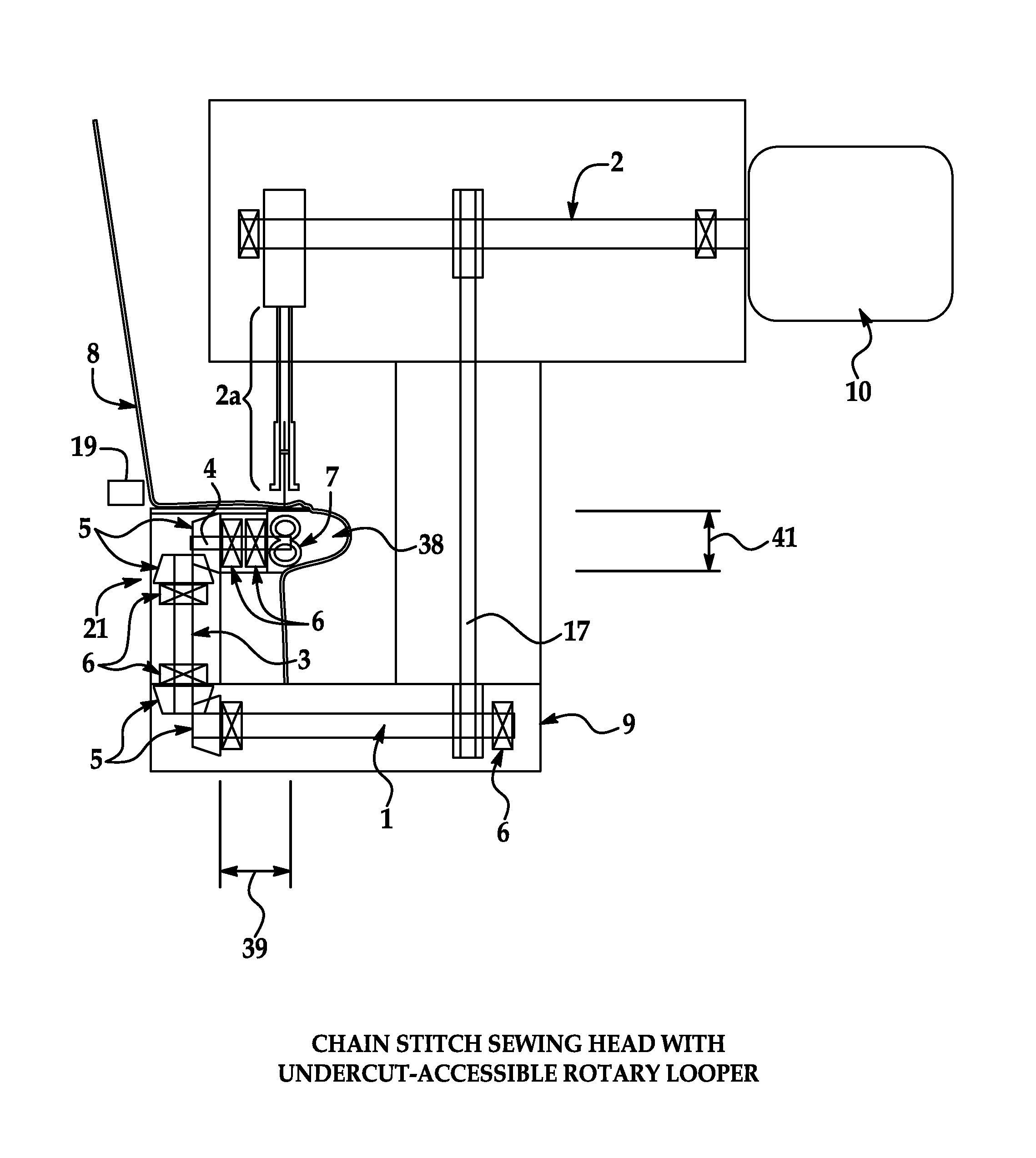

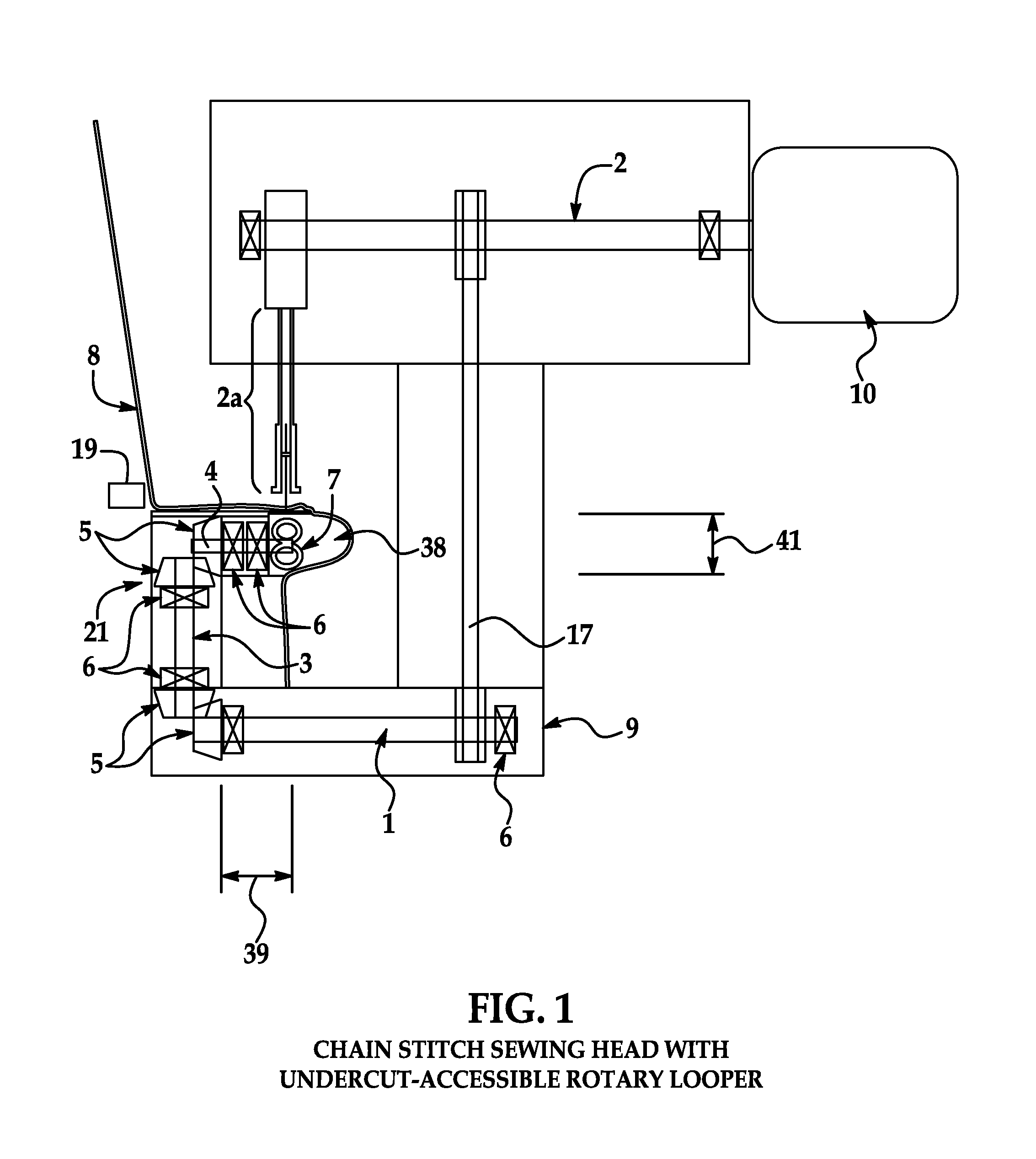

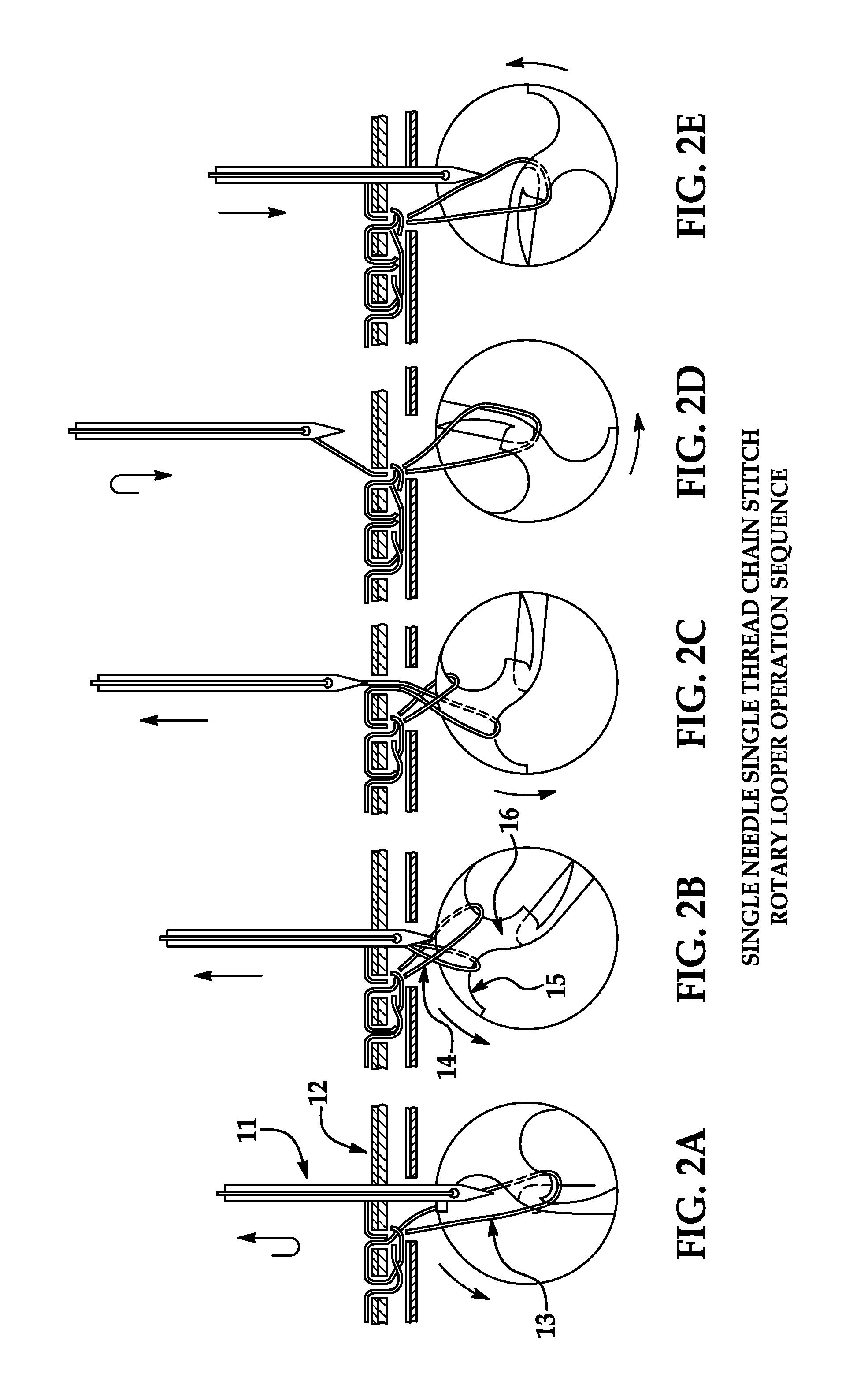

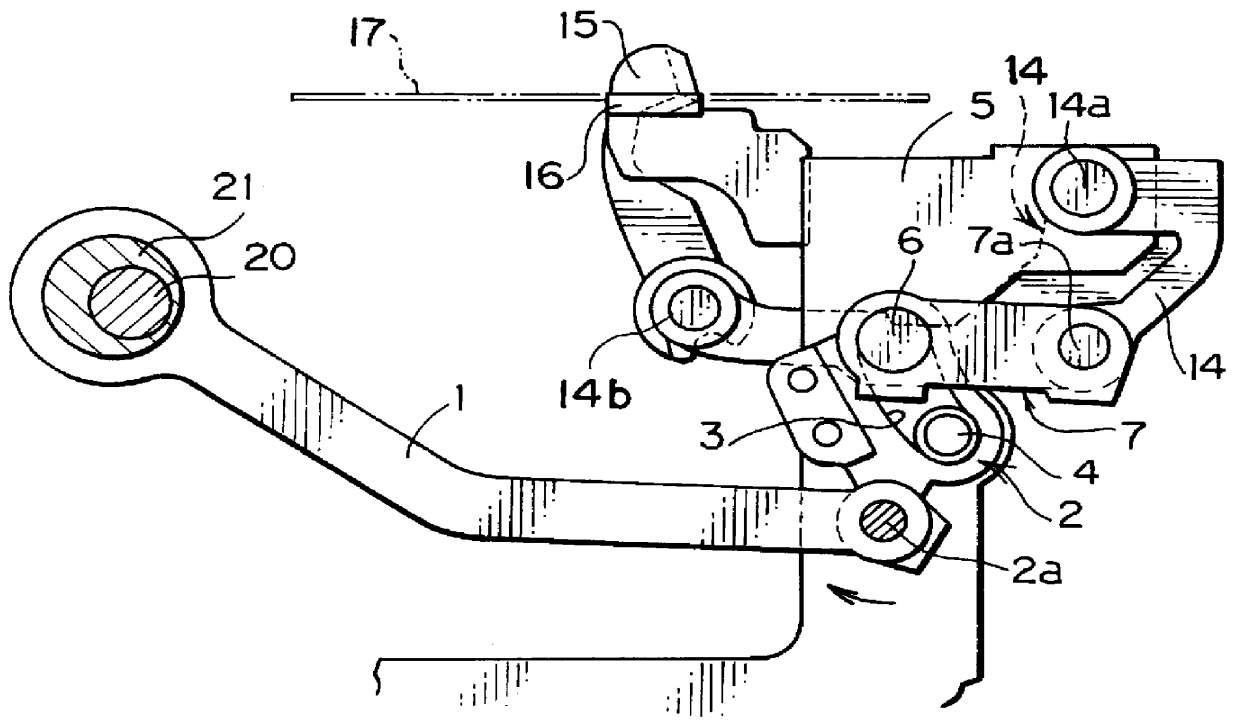

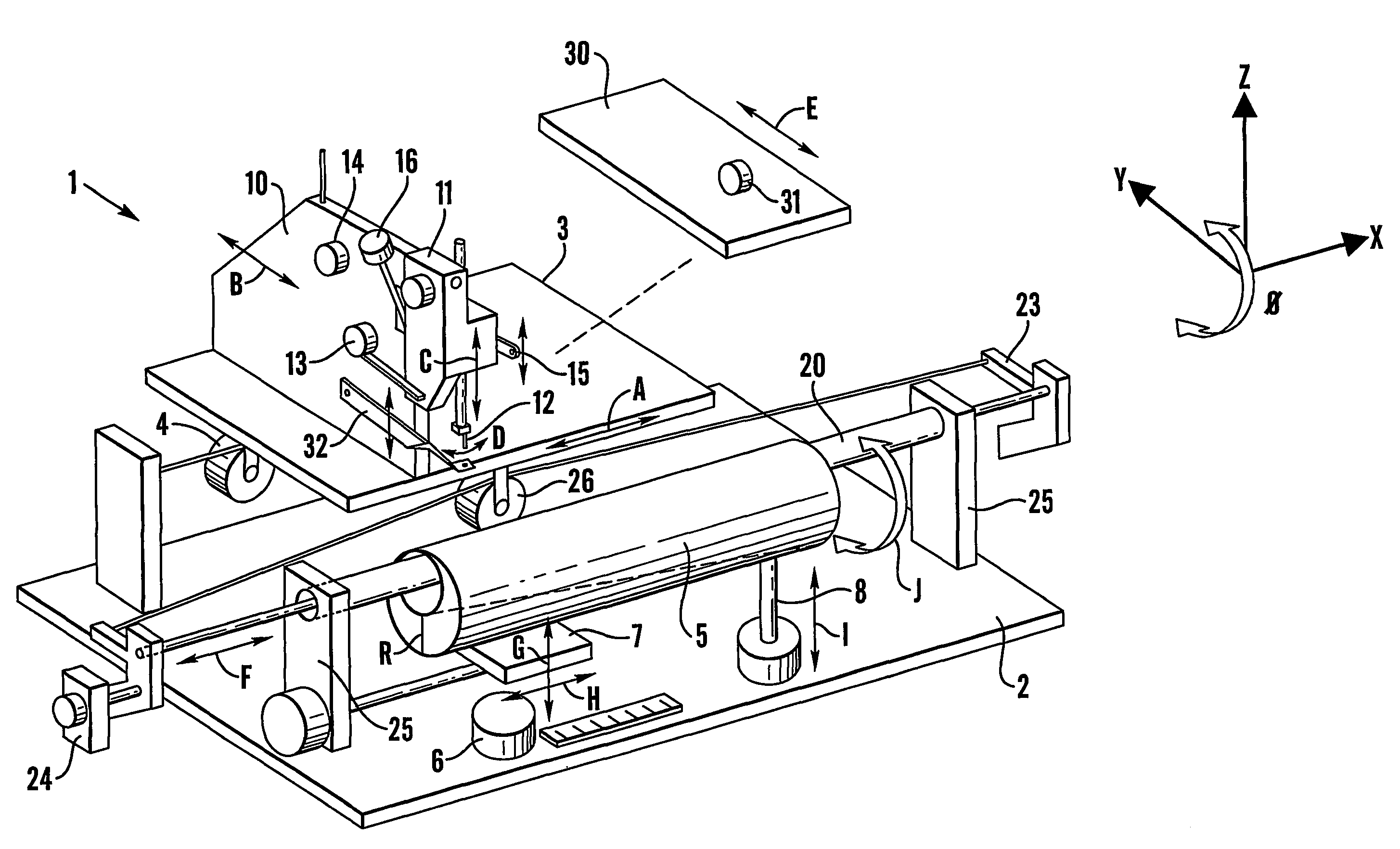

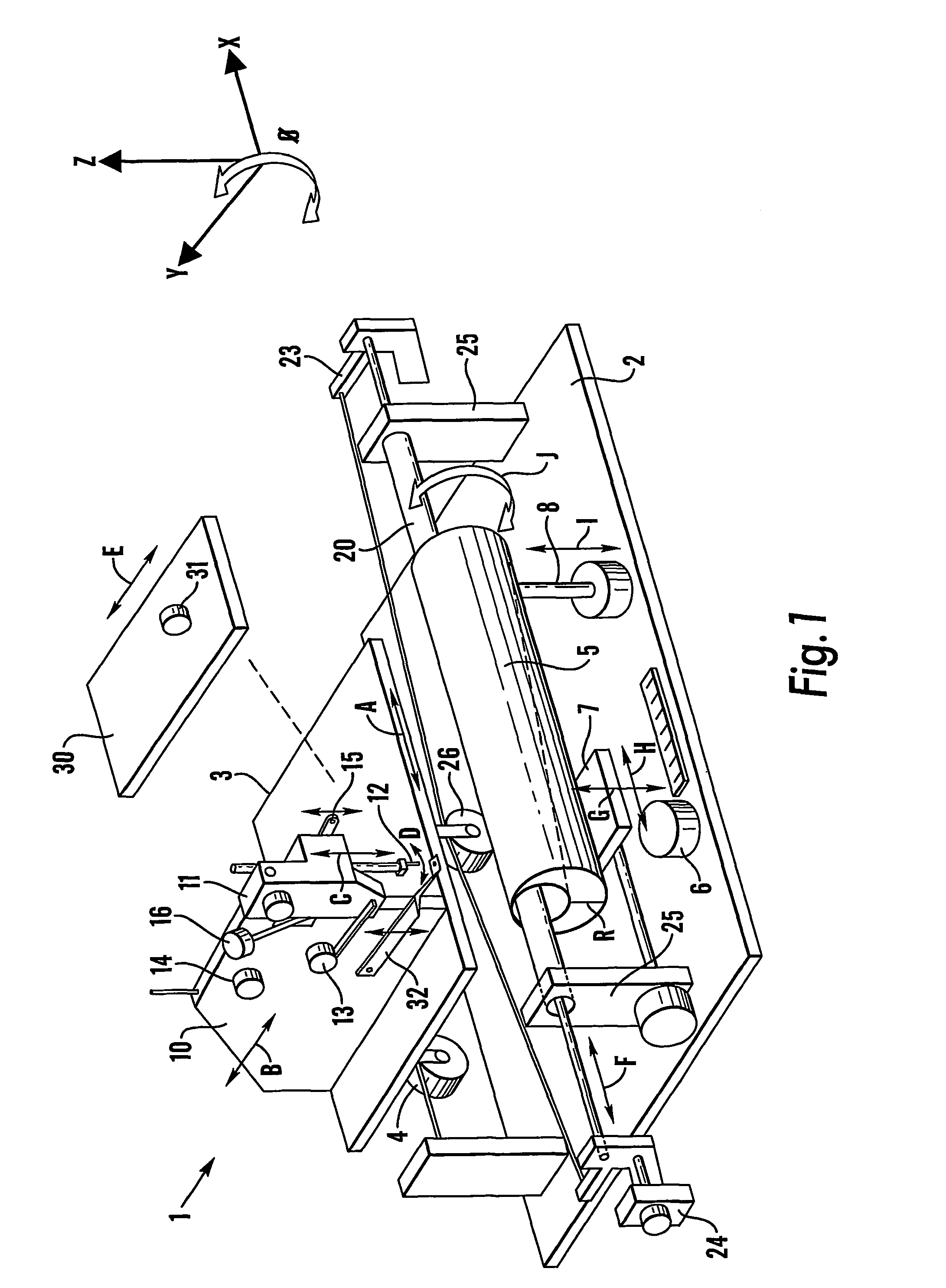

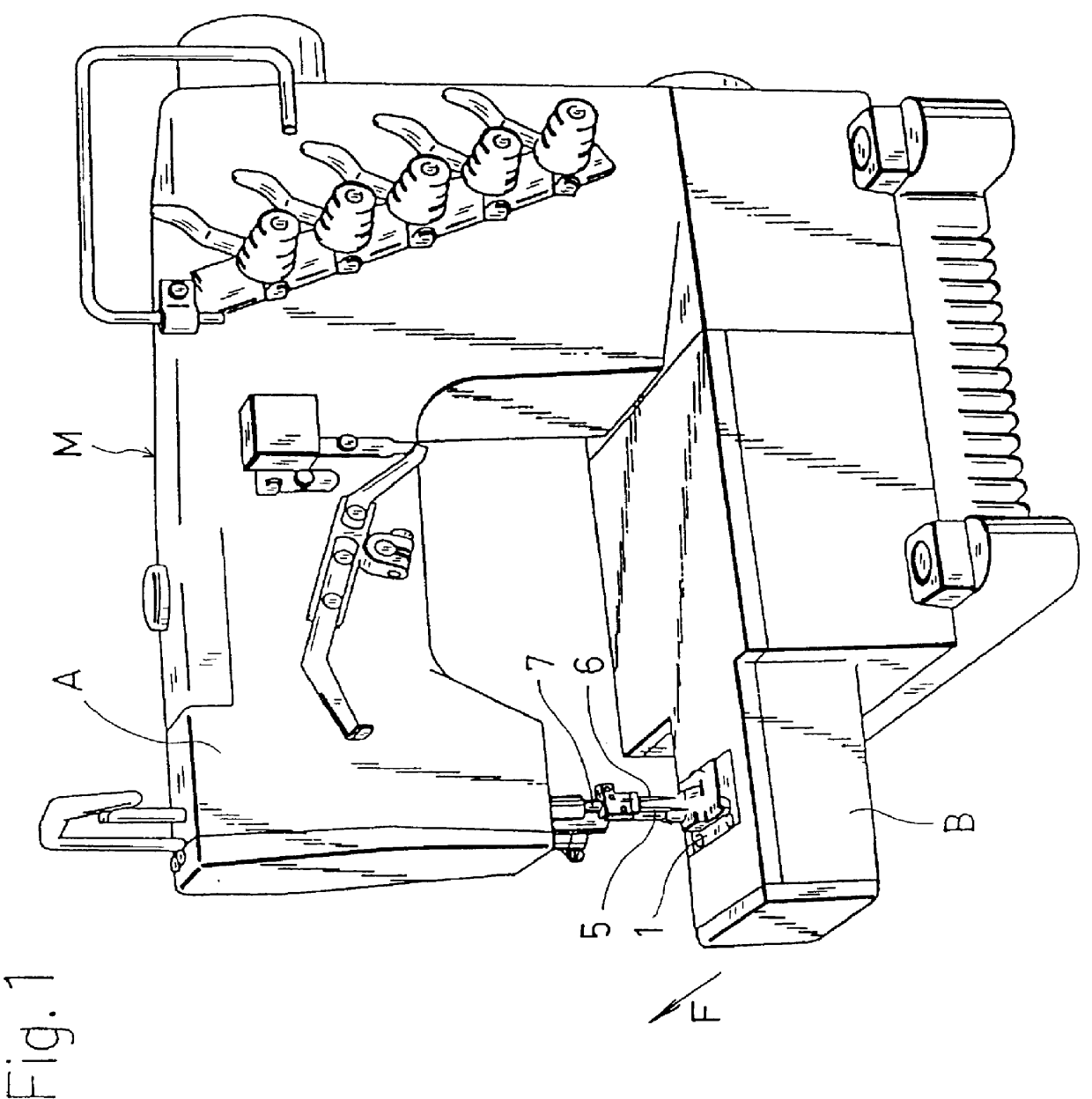

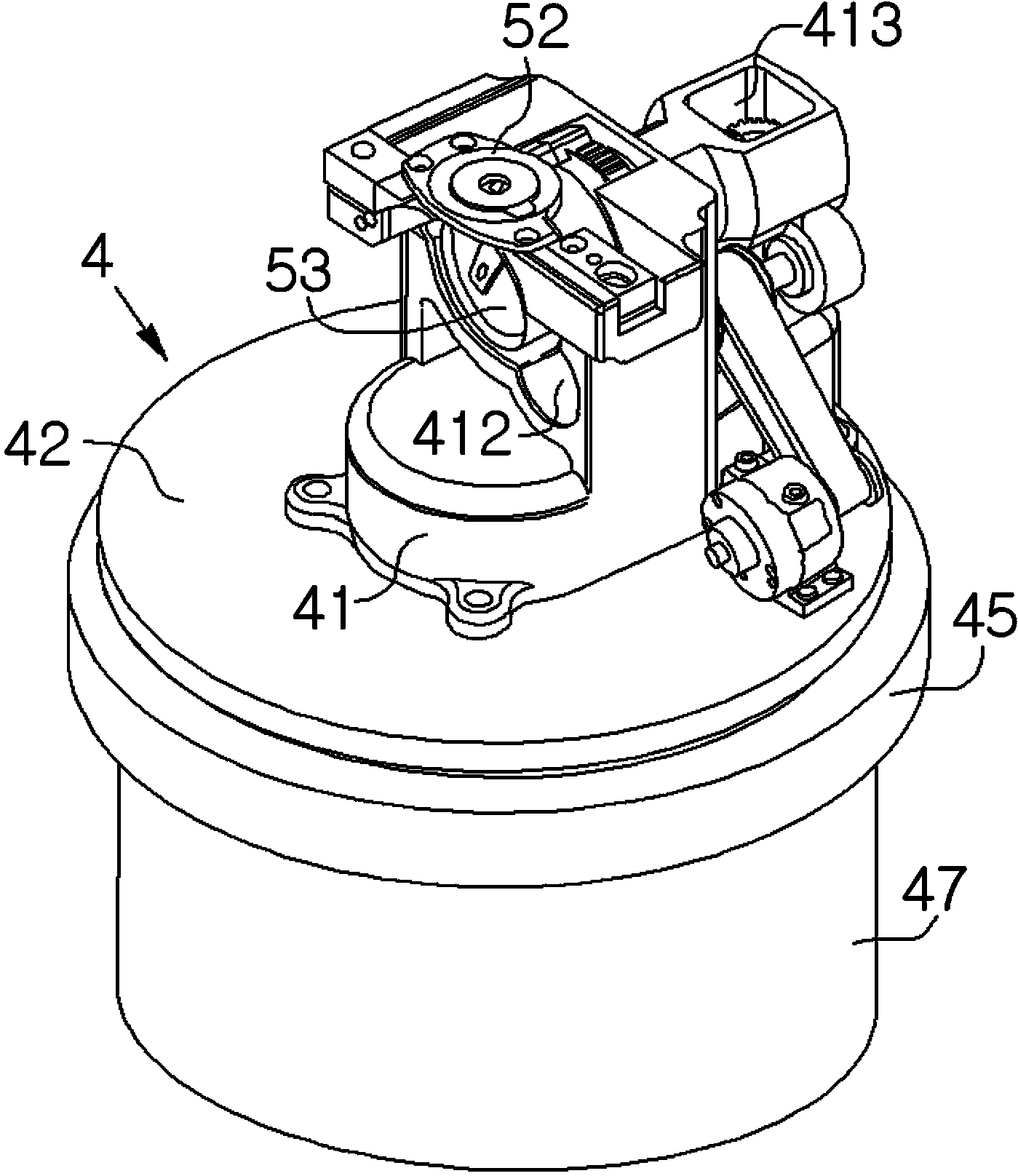

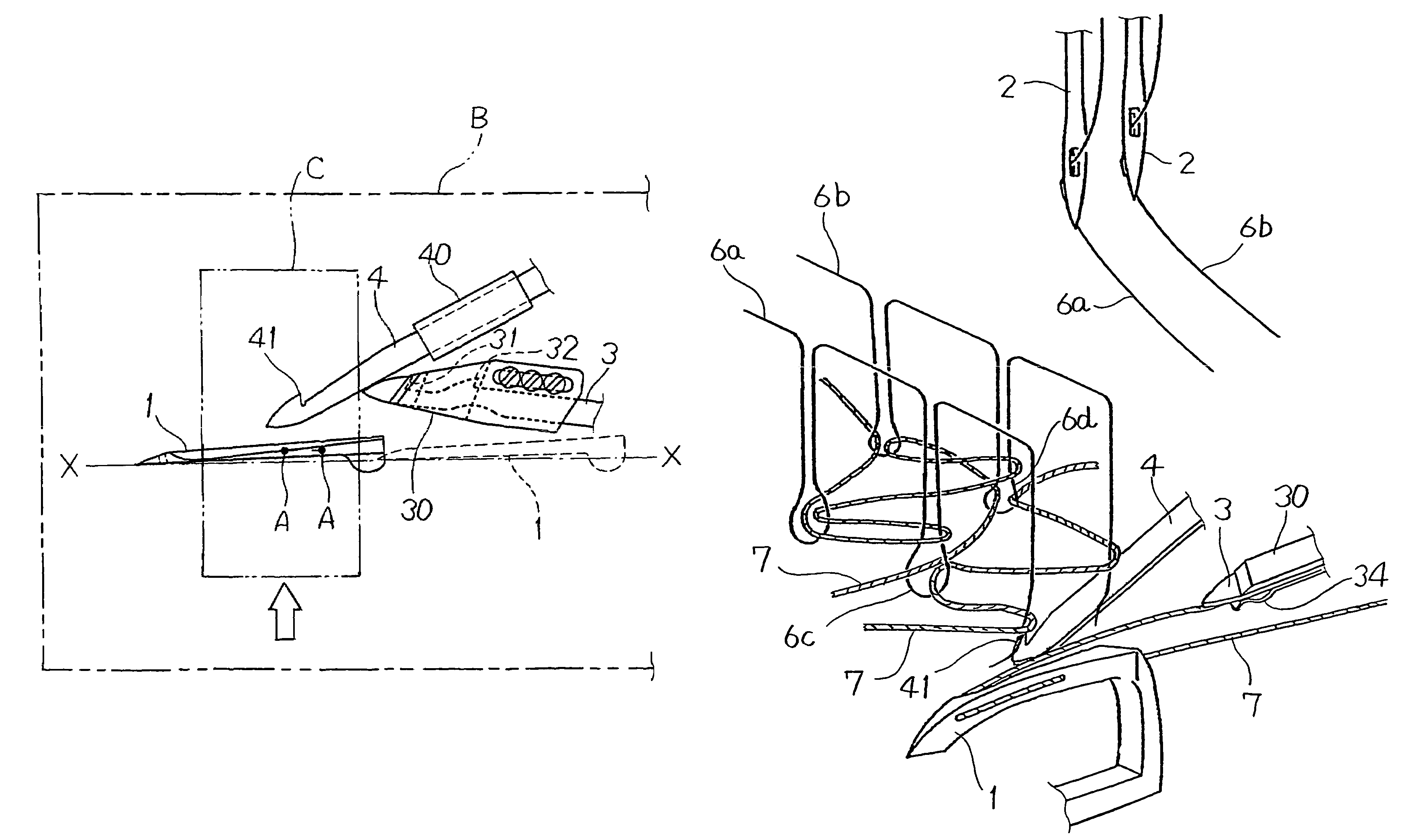

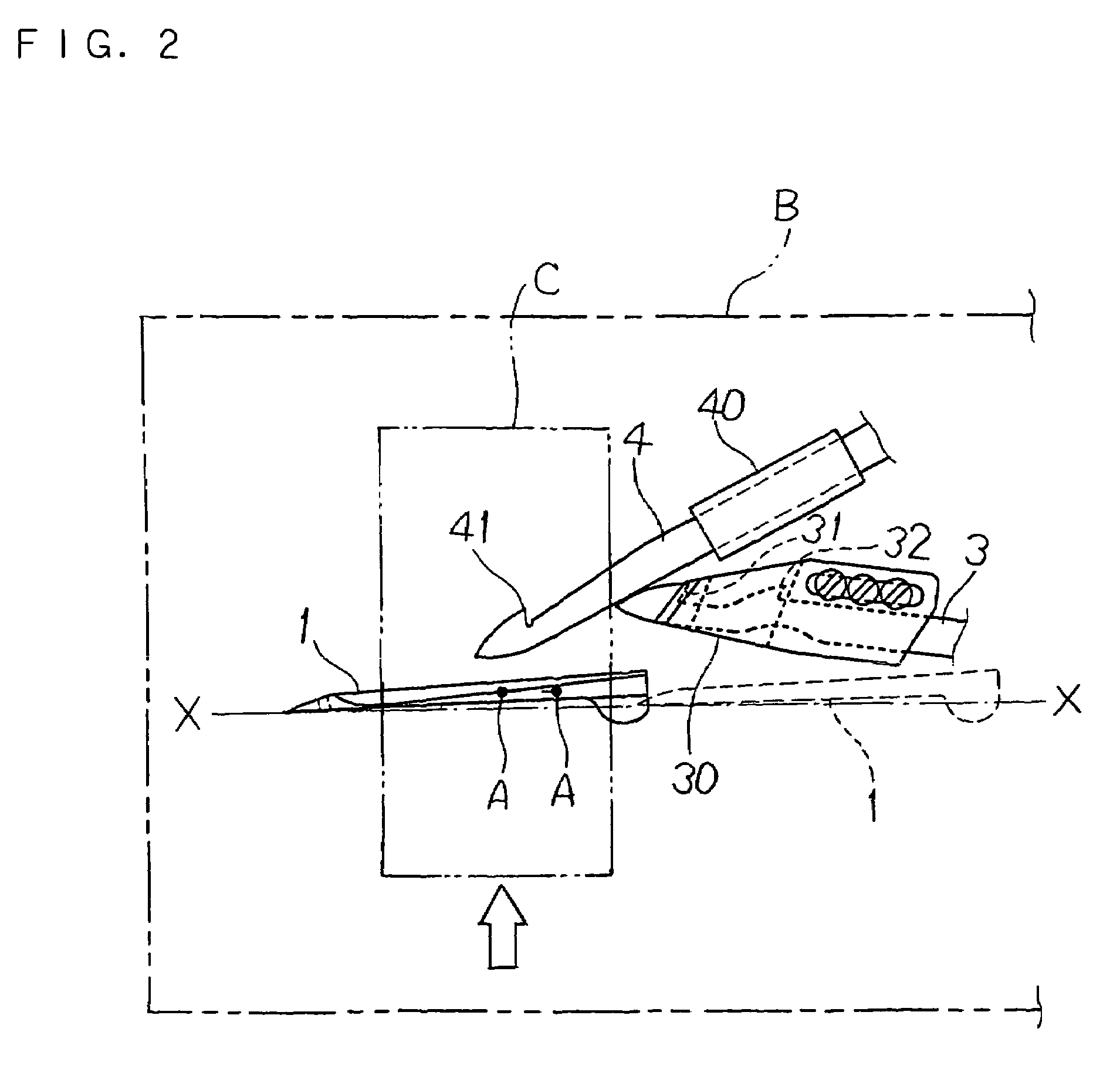

Apparatus for stitching vehicle interior components

An apparatus for stitching an interior component is disclosed herein. The component having an outer skin layer and the apparatus is a single needle chain stitch machine with a rotary looper and wherein a needle of the apparatus descends through the interior component and a hook of the rotary looper engages a thread loop formed during retraction of the needle after it has descended through the interior component; and wherein the apparatus further includes a mechanism for moving the interior component relative to the needle and looper to establish a stitch length.

Owner:INTEVA PRODUCTS LLC

Apparatus for stitching vehicle interior components

An apparatus for stitching an interior component is disclosed herein. The component having an outer skin layer and the apparatus is a single needle chain stitch machine with a rotary looper and wherein a needle of the apparatus descends through the interior component and a hook of the rotary looper engages a thread loop formed during retraction of the needle after it has descended through the interior component; and wherein the apparatus further includes a mechanism for moving the interior component relative to the needle and looper to establish a stitch length.

Owner:INTEVA PRODUCTS LLC

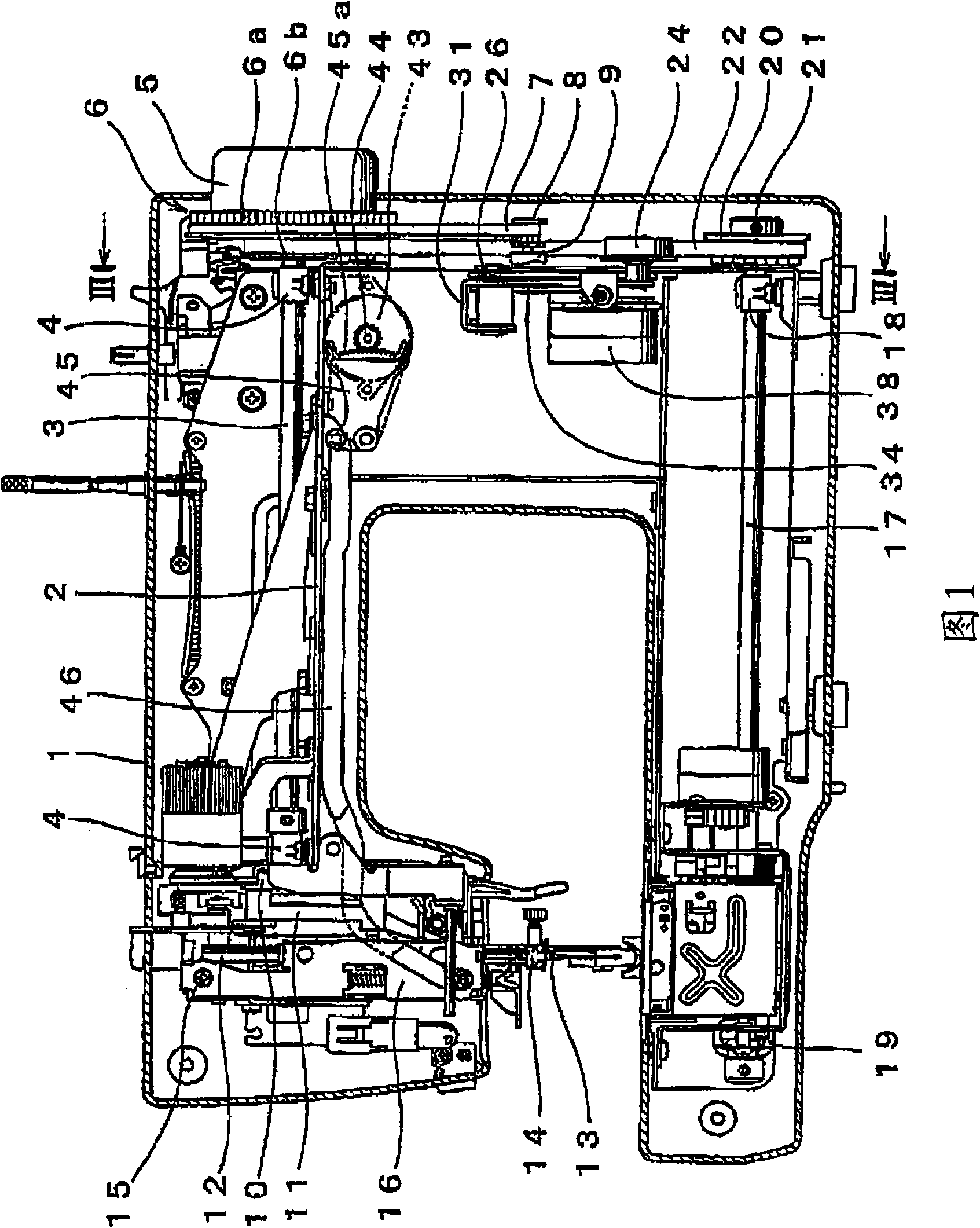

Overlock sewing machine with movable cutter

InactiveUS6101960AEasy to operateSimple structureWorkpiece carriersLoop takersDrive shaftReciprocating motion

An overlock sewing machine has a movable cutter which is activated in association with rotation of a main drive shaft to cooperate with a fixed cutter provided in the same plane with an upper surface of a needle plate, to thereby cut a work while the work is being stitched. A link mechanism includes a drive link having one end rotatably connected to a mount and the other end is connected to the movable cutter and a swingable link having an arcuate guide groove extending between one end and a center axis thereof around which the swingable link is swingingly moved. The drive link has a point between opposite ends thereof operatively connected to the arcuate guide groove of the swingable link. An operating device includes an operating shaft which is operatively connected to the point of the drive shaft so that the point of the drive link may be substantially moved along the arcuate guide groove of the swingable link between said one end and center axis thereof by manipulation of an operating knob. The drive link having the point thereof moved to one end of the swingable link will be swingingly reciprocated to activate the movable cutter, and having the point thereof moved to the central axis of the swingable link will move the movable cutter to an inoperative position below the needle plate where the movable cutter is held at standstill.

Owner:JANOME CORP

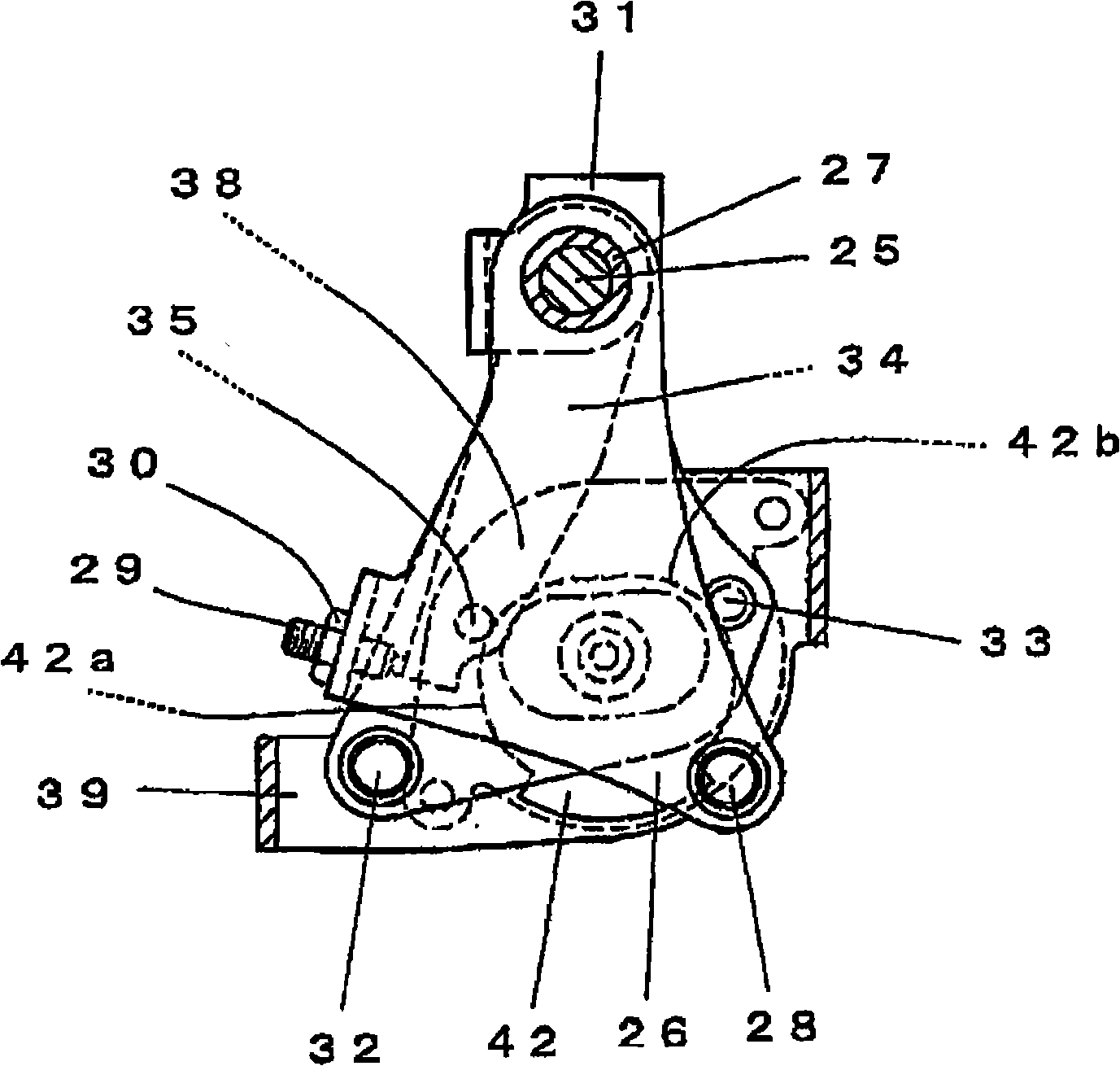

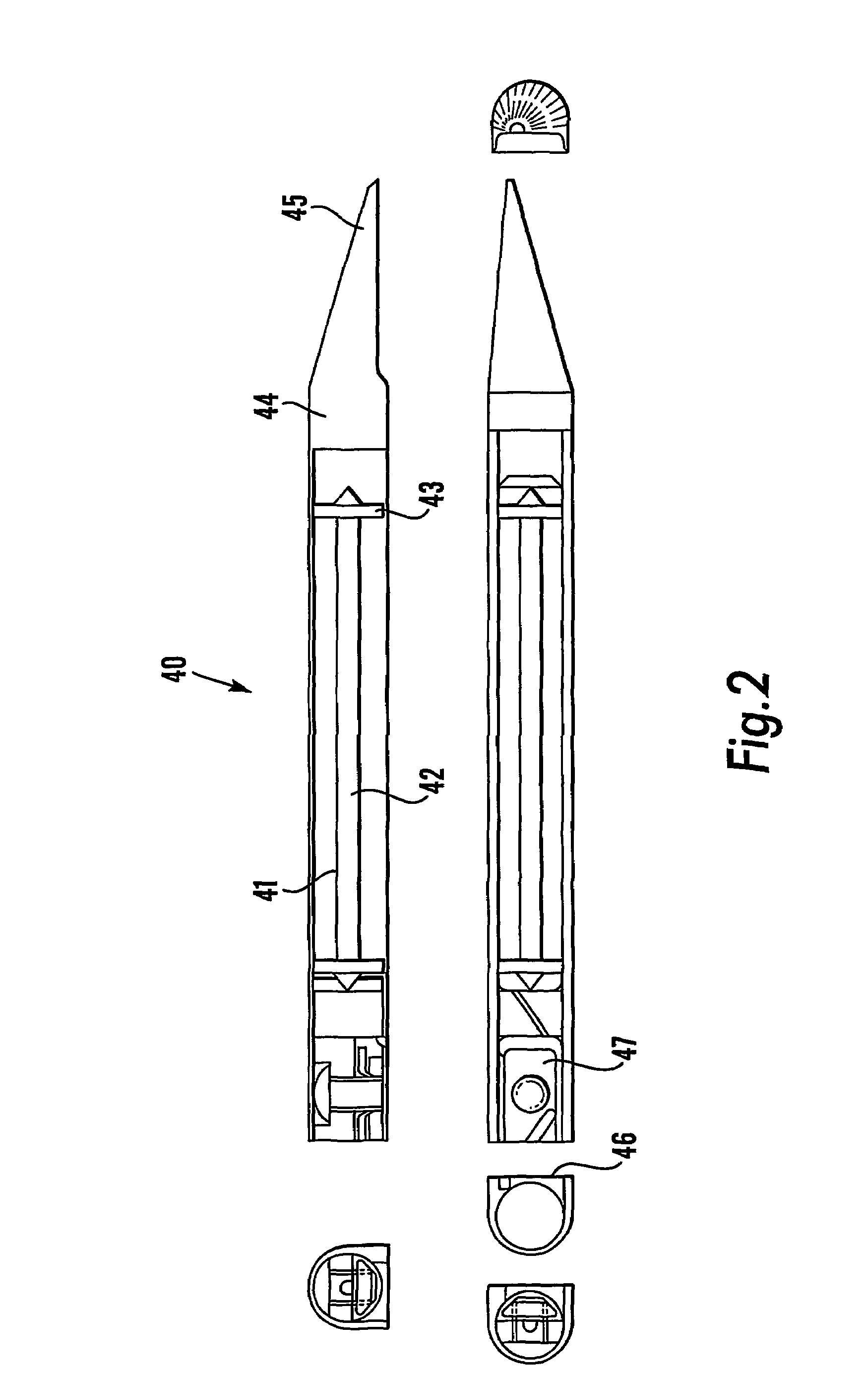

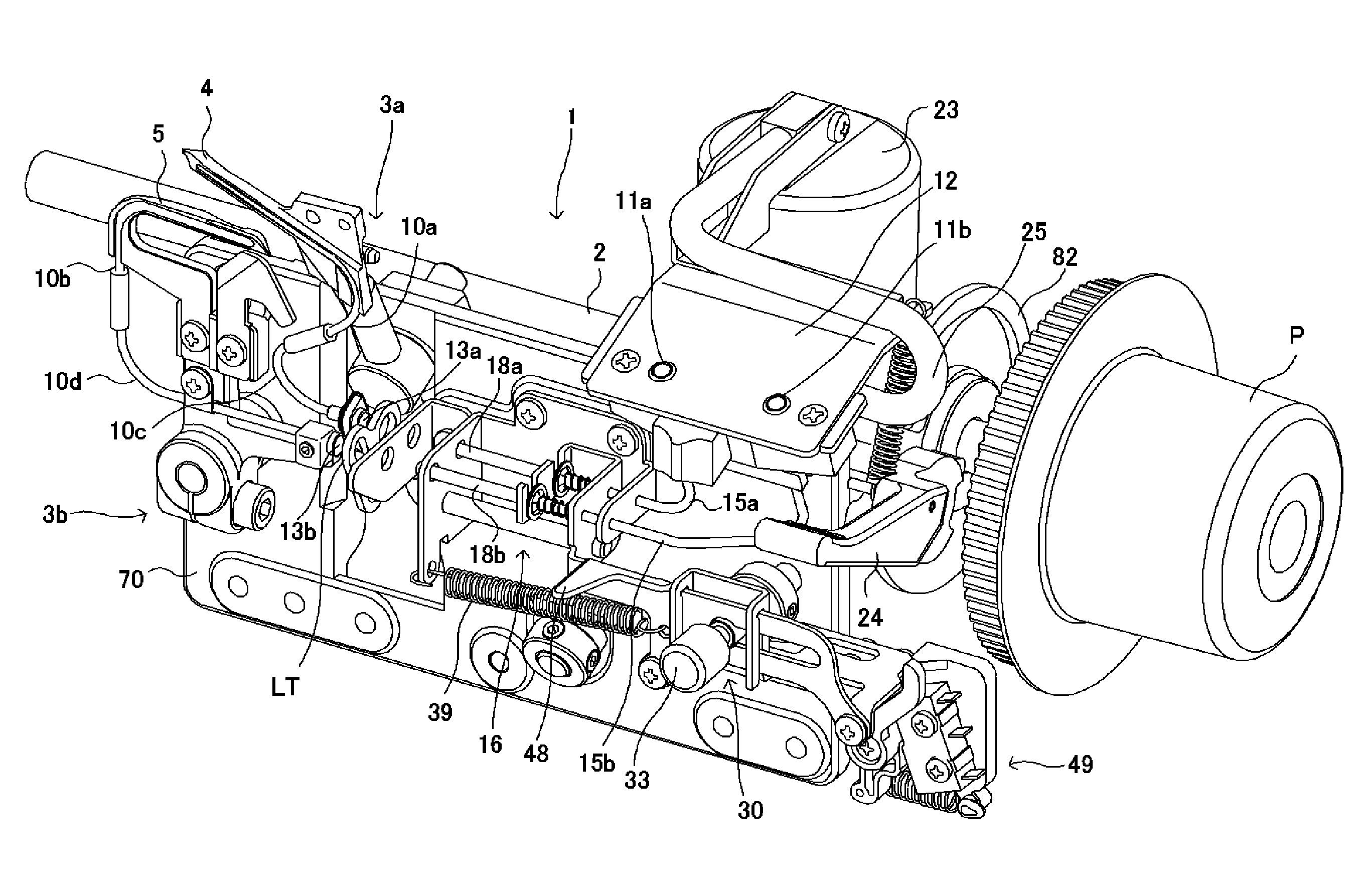

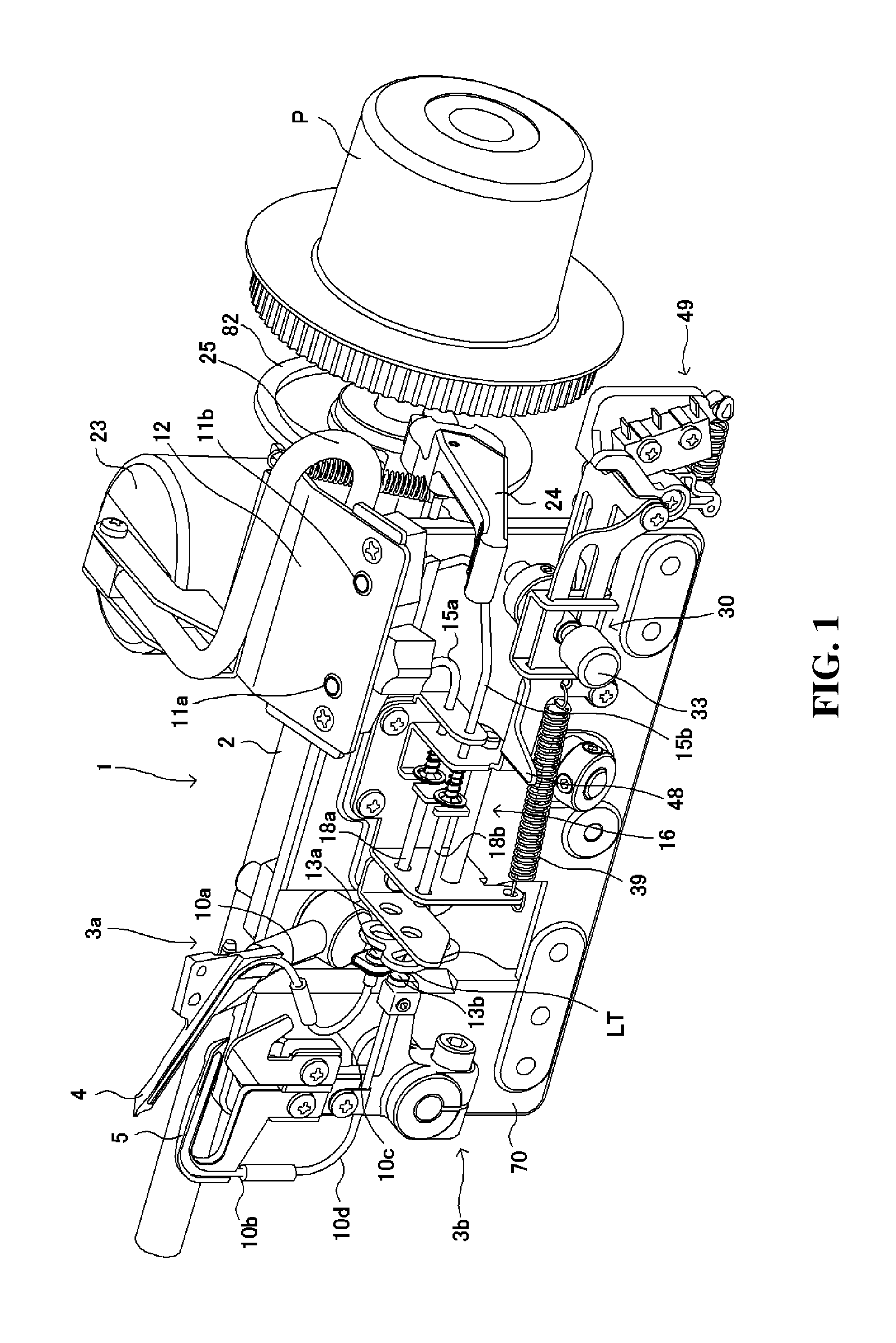

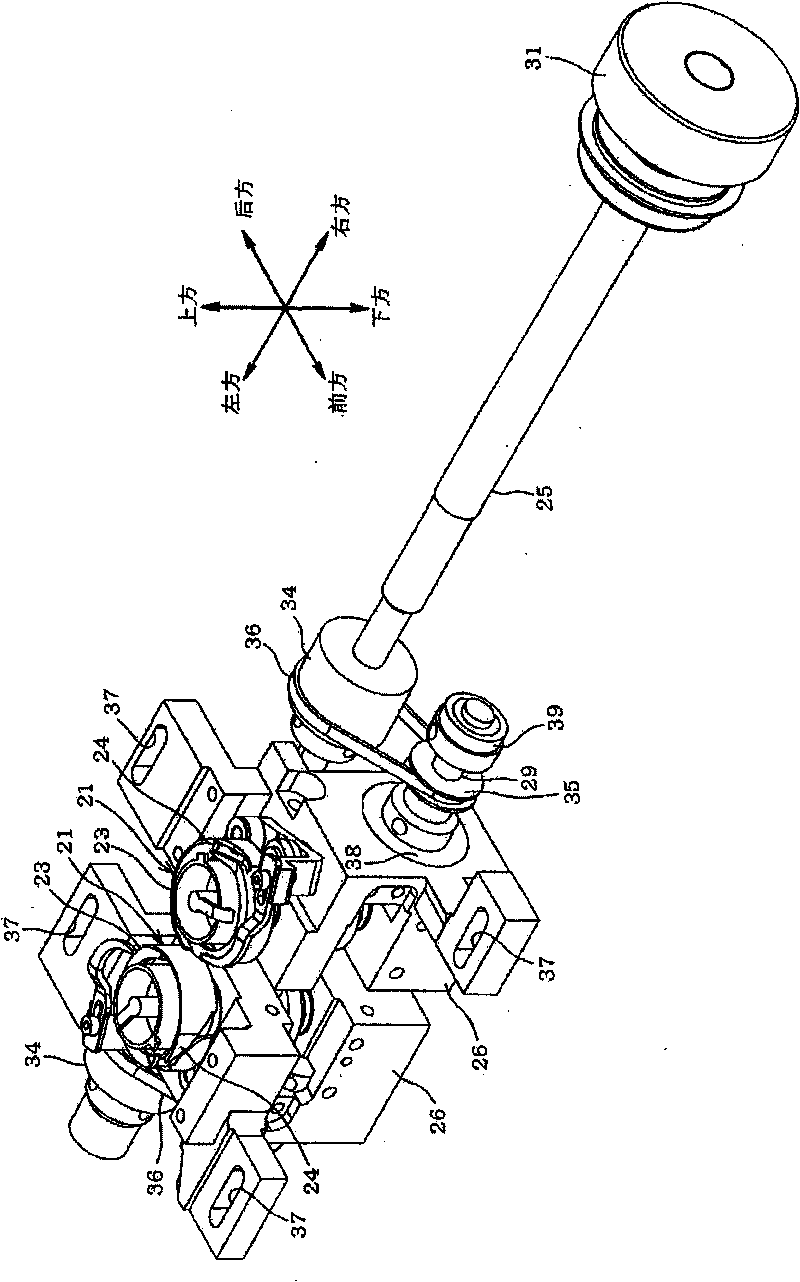

Apparatus for adjusting timing of needle and looptaker of sewing machine

An apparatus for adjusting a timing of a needle and a looptaker of a sewing machine provided at a zigzag sewing machine having an upper shaft for driving a needle bar, a lower shaft for driving a looptaker, a machine frame, and a timing belt for connecting and synchronizing the shafts includes a cam member including a first cam surface and a second cam surface, a first arm member and a second arm member supported by the machine frame and a first pulley and a second pulley mounted to the first arm member and the second arm member respectively and always contacting the timing belt, the first pulley following the first cam surface and the second pulley following the second cam surface.

Owner:SINGER SOURCING LTD LLC

Method for manufacturing stent-grafts

A sewing machine is provided which is capable of sewing reinforcing wire to tubular grafts in order to form stent grafts. A bobbin (which may be seated in a shuttle) carries a bottom thread through the bore of the tubular graft and forms a stitch in combination with a top thread carried on a needle which pierces the graft wall.

Owner:ANSON MEDICAL LTD

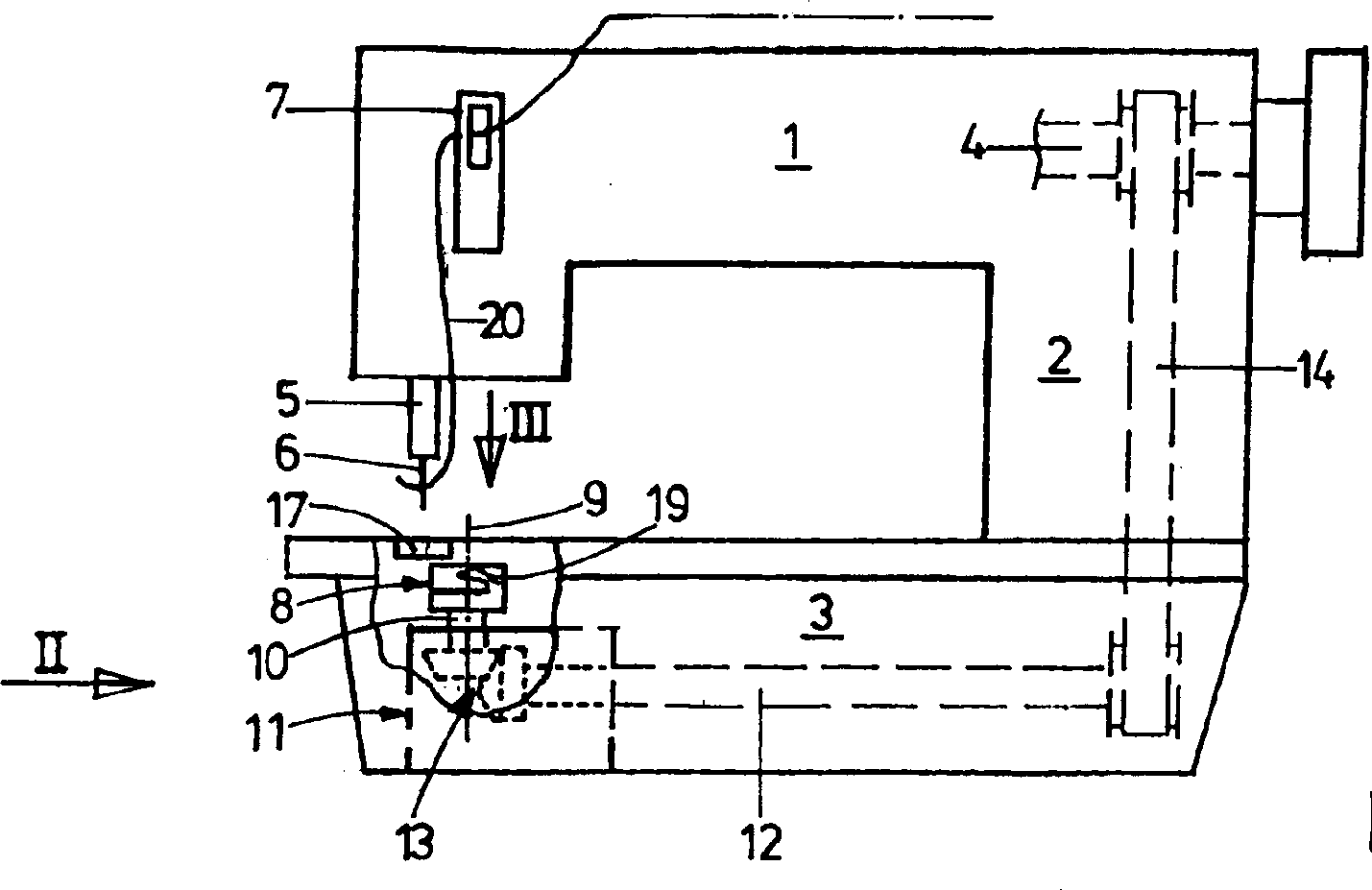

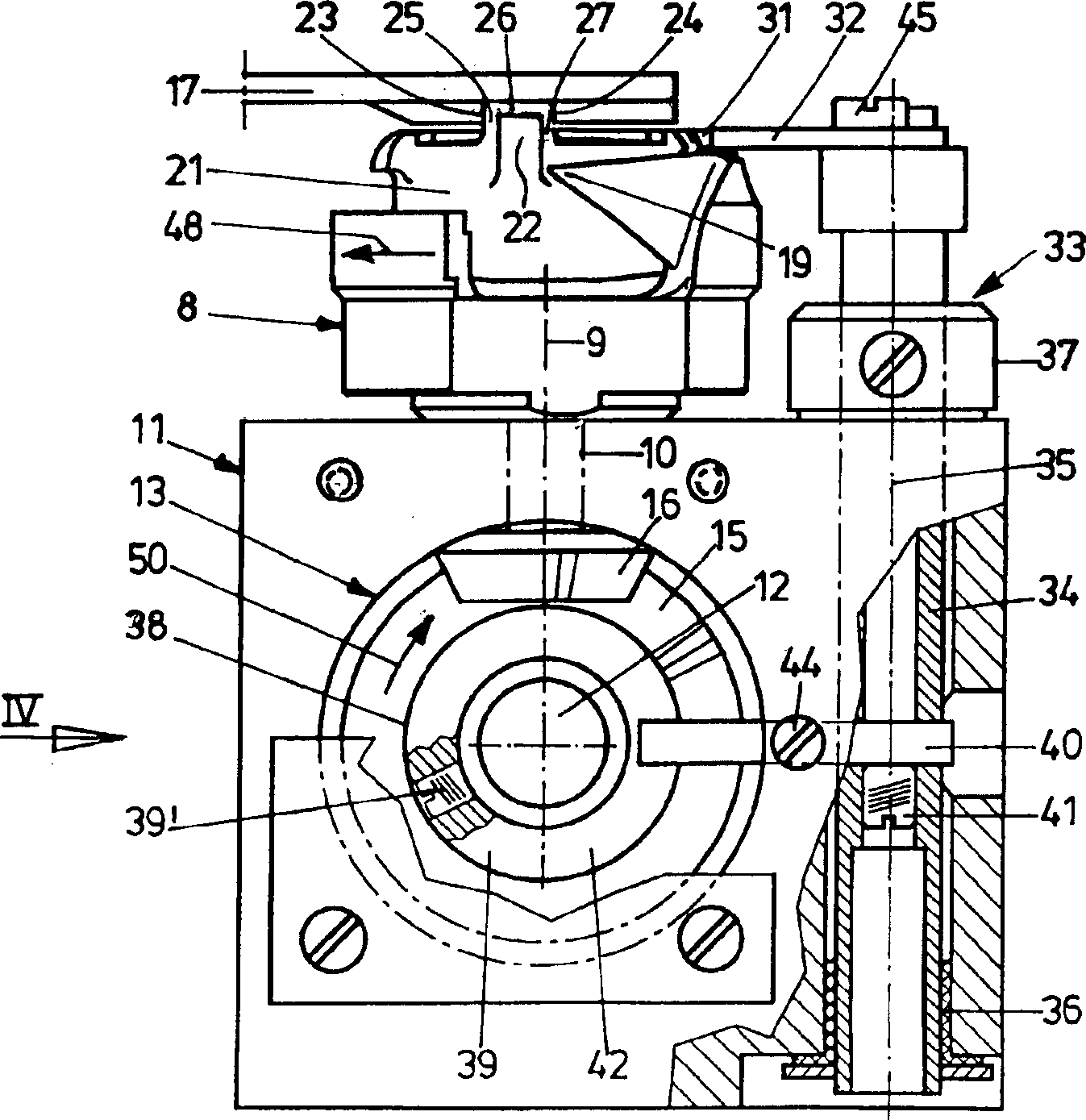

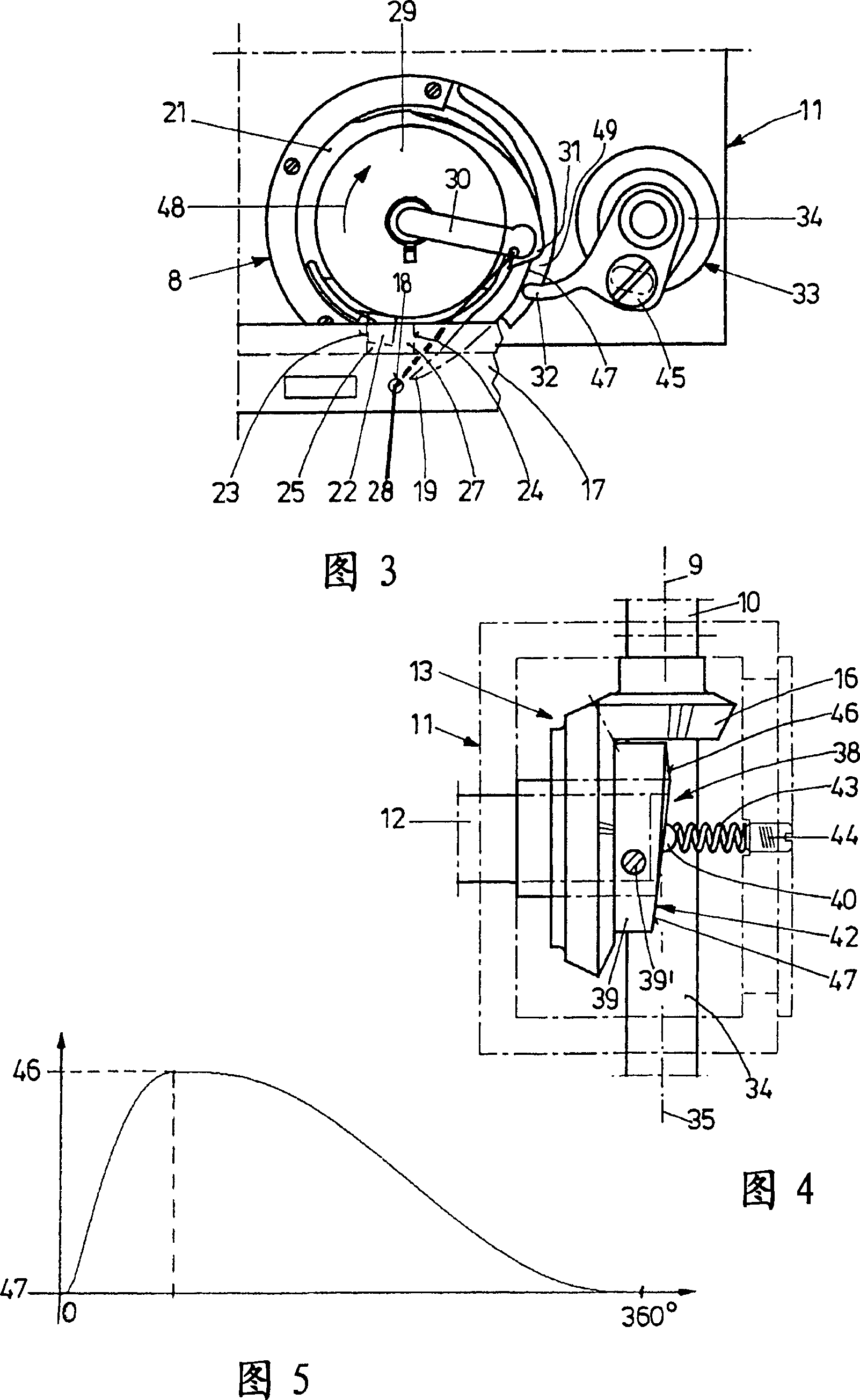

Sewing machine

The sewing machine has a looper (8) which is powered to rotate around a vertical axis, incorporating a bobbin capsule (21) with lifter cams (31). A capsule lifter (33) has a lifter lever (32) to make contact with the cams, and a feeler lever (40). The feeler lever lies against a cam disk surface (42) of an axial cam disk (39), fitted to a transmission shaft with its power taken from the looper drive shaft (10).

Owner:DURKOPP ADLER GMBH

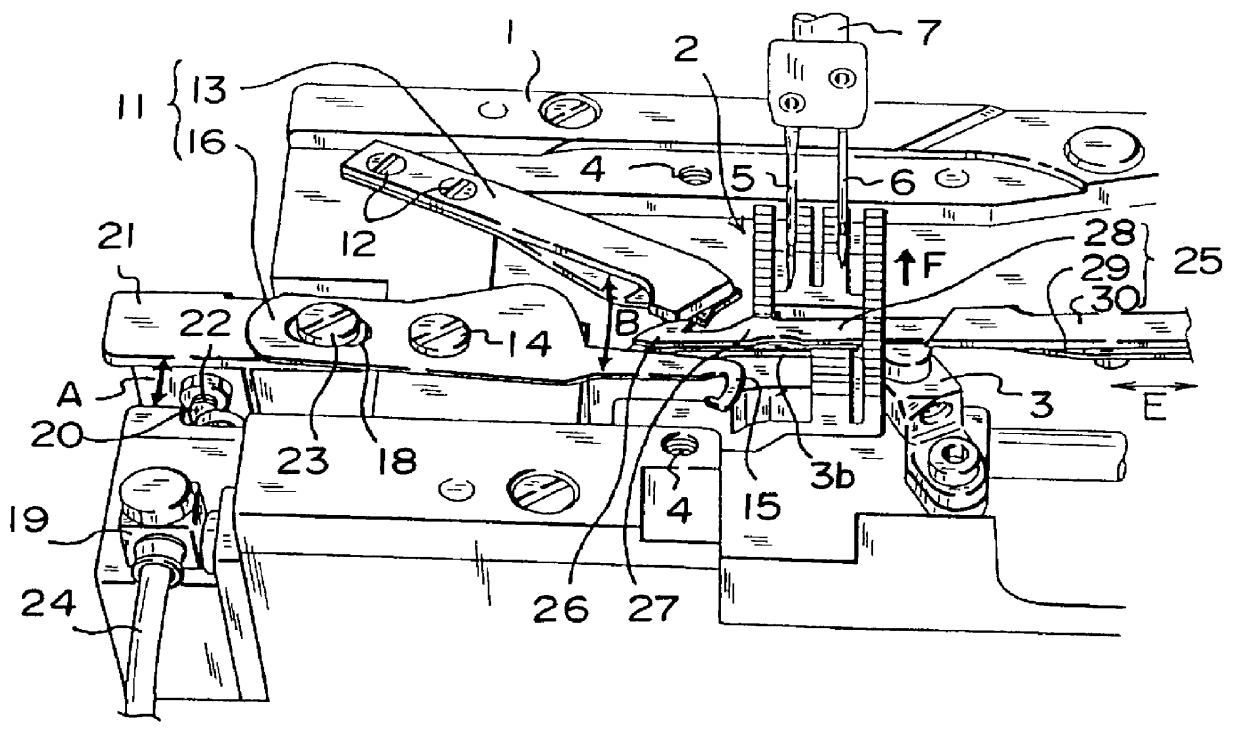

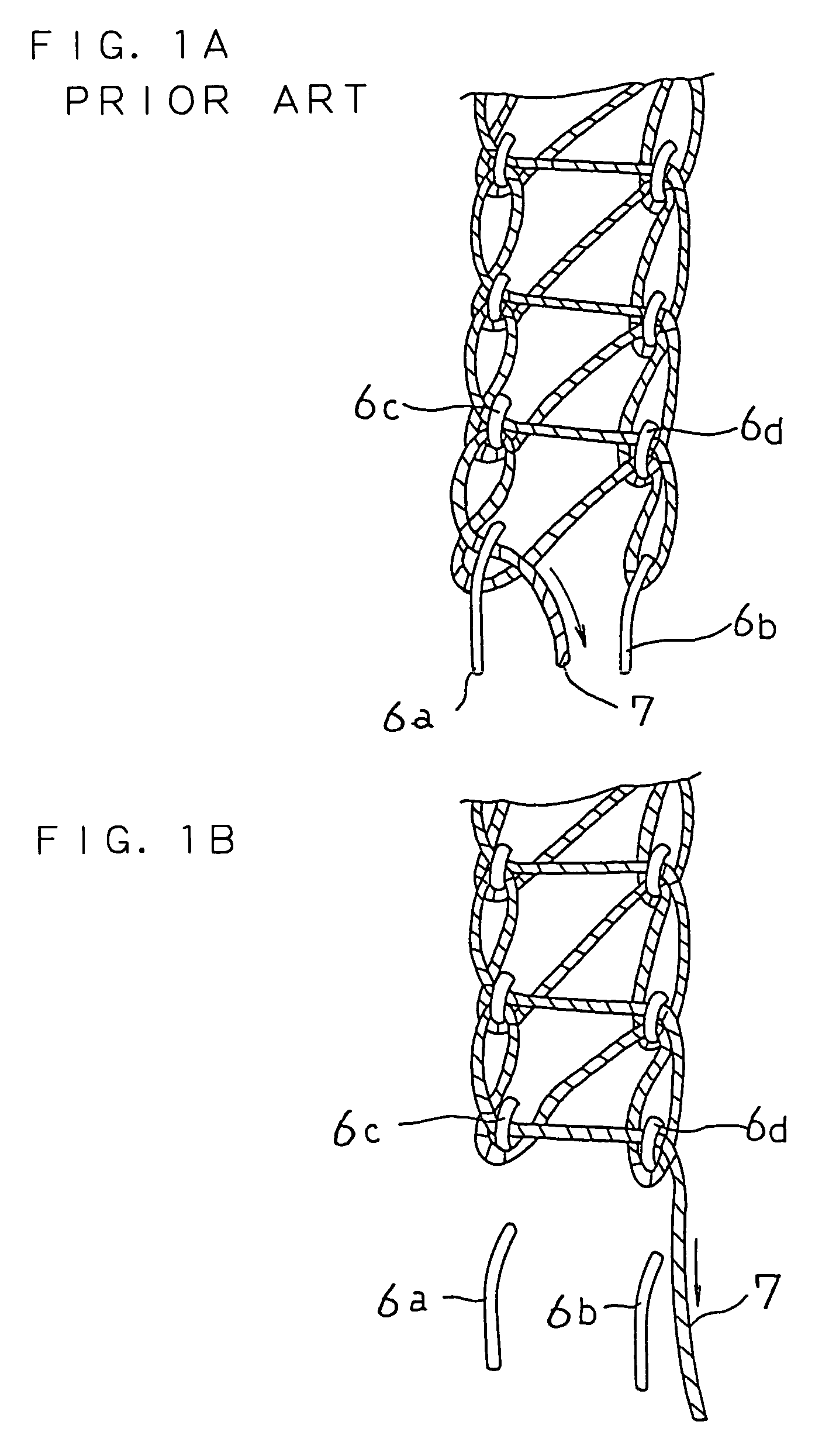

Method and apparatus for preventing a seam from raveling in double chain stitch sewing machine

InactiveUS6119613APreventing a seam from ravelingNeedle severing devicesLoop holdersEngineeringDouble chain

A method and apparatus for preventing a seam from raveling in a double chain stitch sewing machine according to the present invention are applied to sewing of cloth by a double chain stitch sewing machine. Near the sewing end point for forming a double chain stitch by collaboration of a plurality of needles and a looper, the looper thread consecutive to the looper from the cloth is hooked and engaged on the hook at the left side of the needles. After driving the sewing machine for a half stitch or one stitch in this state, the looper thread hooked on the hook is cut off. Simultaneously with this cutting or before or after the cutting, the needle thread loop consecutive to the needles from the sewing end of the cloth through the looper is cut off between the looper and the cloth. Further, capturing the cut looper thread consecutive to the looper from the cloth, the end of the cut looper thread is pulled out from the final needle thread loop at the end of sewing. Therefore, raveling of thread from the sewing end point is prevented, and the length of the thread end consecutive to the sewing end point is short, so that sewn products of good appearance may be obtained.

Owner:PEGASUS SEWING MACHINE MFG

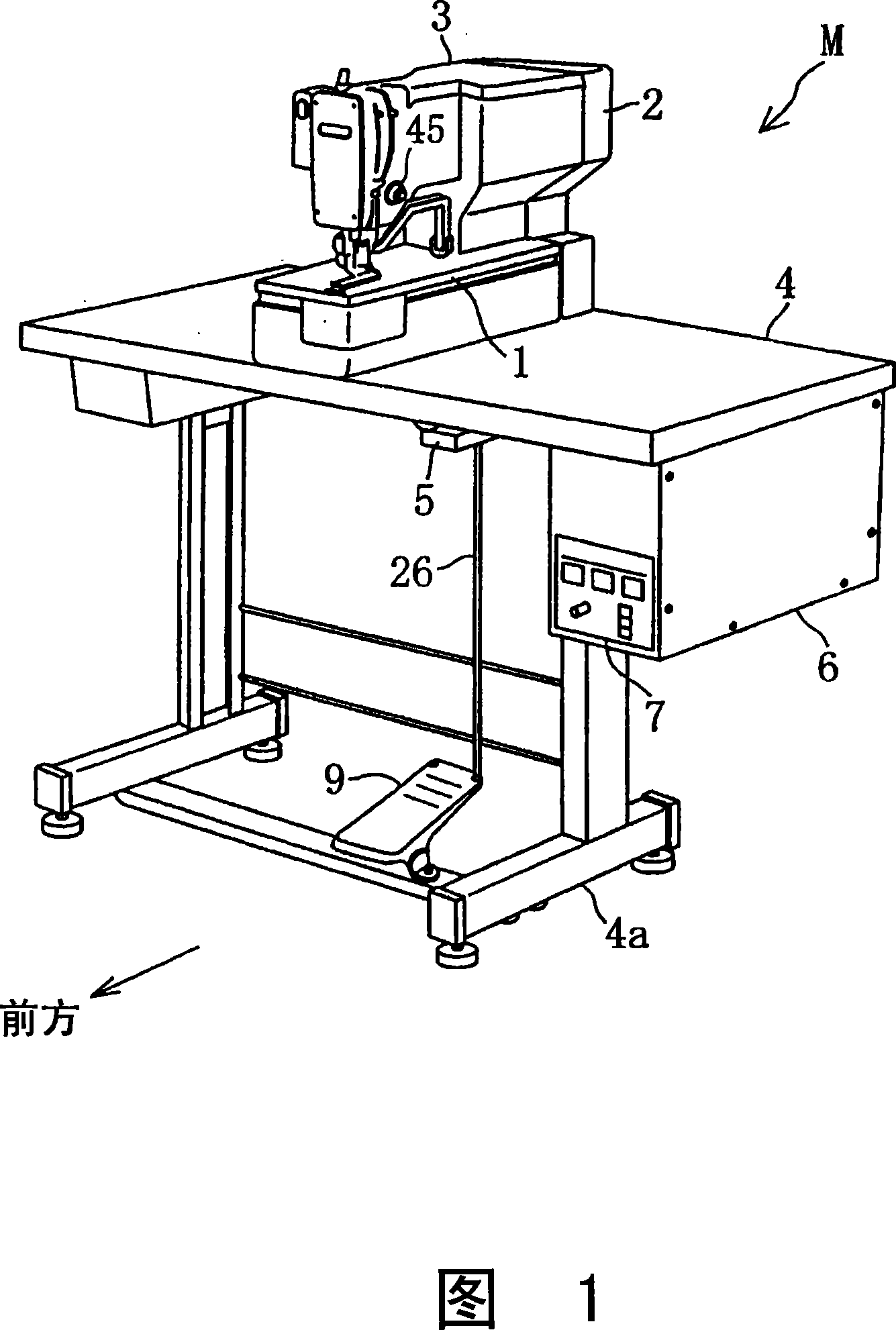

Thread adjusting device for sewing machine

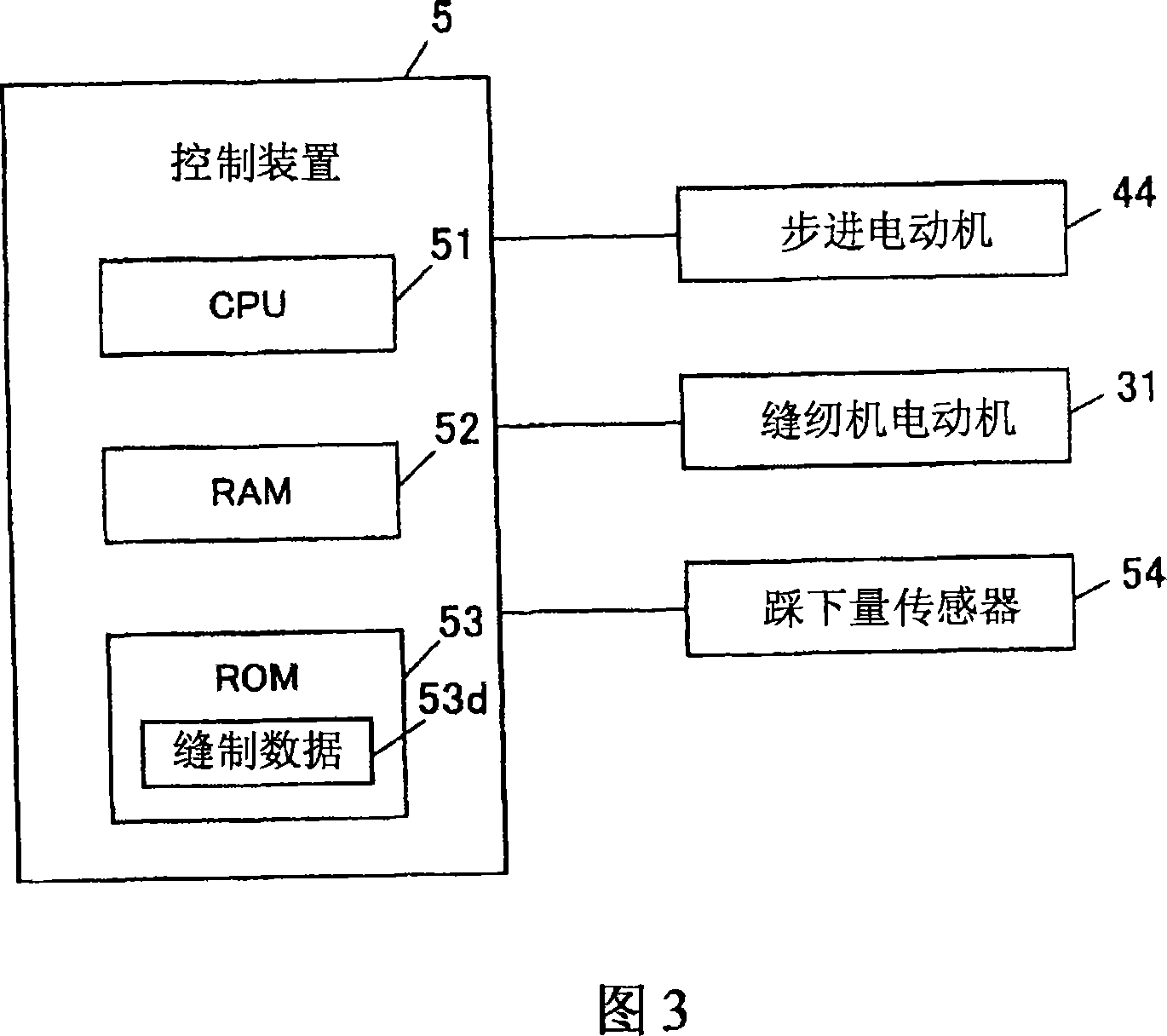

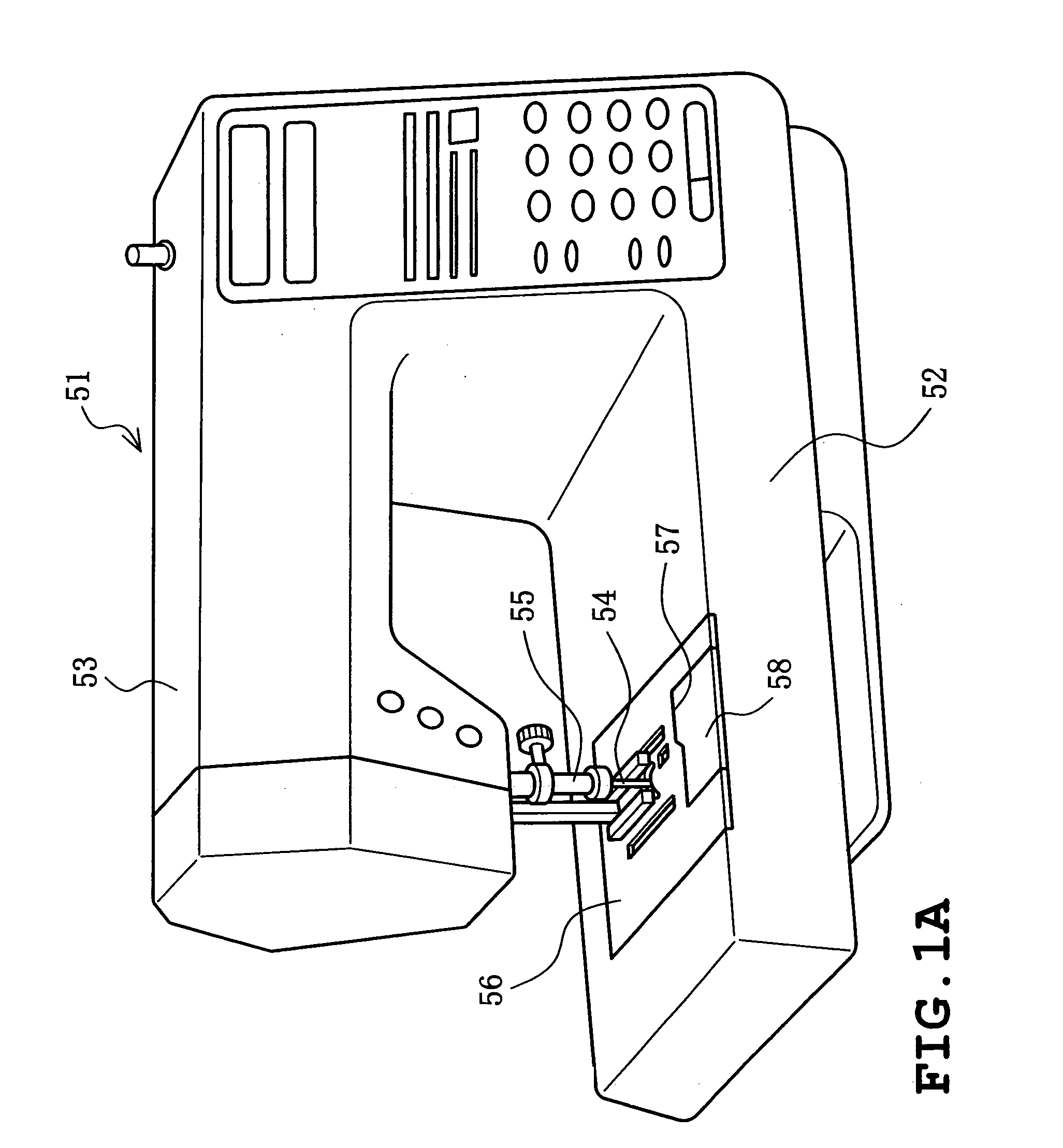

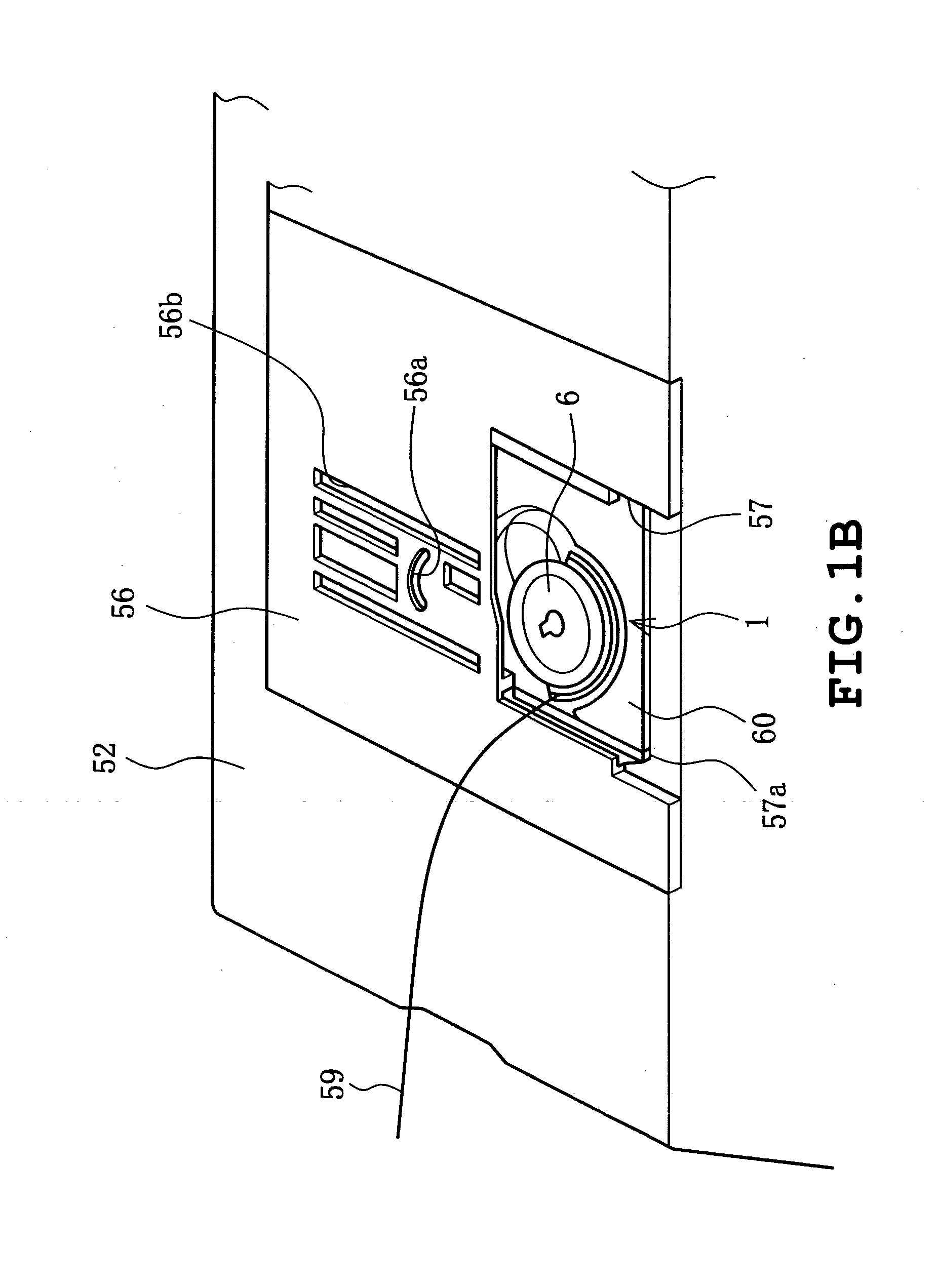

InactiveCN101122071ASuppress feverEliminate operational interruptionsProgramme-controlled sewing machinesSewing-machine control devicesEngineeringStops device

A thread tension guide apparatus for a sewing machine is provided to inhibit the heat emission of a tension discharge actuator, thereby enhancing the efficiency of the sewing work. The thread tension guide apparatus comprises a tension releasing device. In the tension releasing device, an output shaft protruded by the operation of a tension releasing solenoid separates a pair of thread control dishes and releases the tension of the upper thread. In the thread control dish, the tension releasing device drives to the tension release state and thereafter the tension release state is maintained by a tension maintaining device. At the state that the tension releasing state is continuously maintained by the tension releasing device, a stop device stops the operation of the tension releasing solenoid. The tension maintaining device comprises a tension releasing actuator for switching a combination member. A control box(6) is installed at the lower right end of a sewing machine table(4).

Owner:BROTHER KOGYO KK

Sewing machine

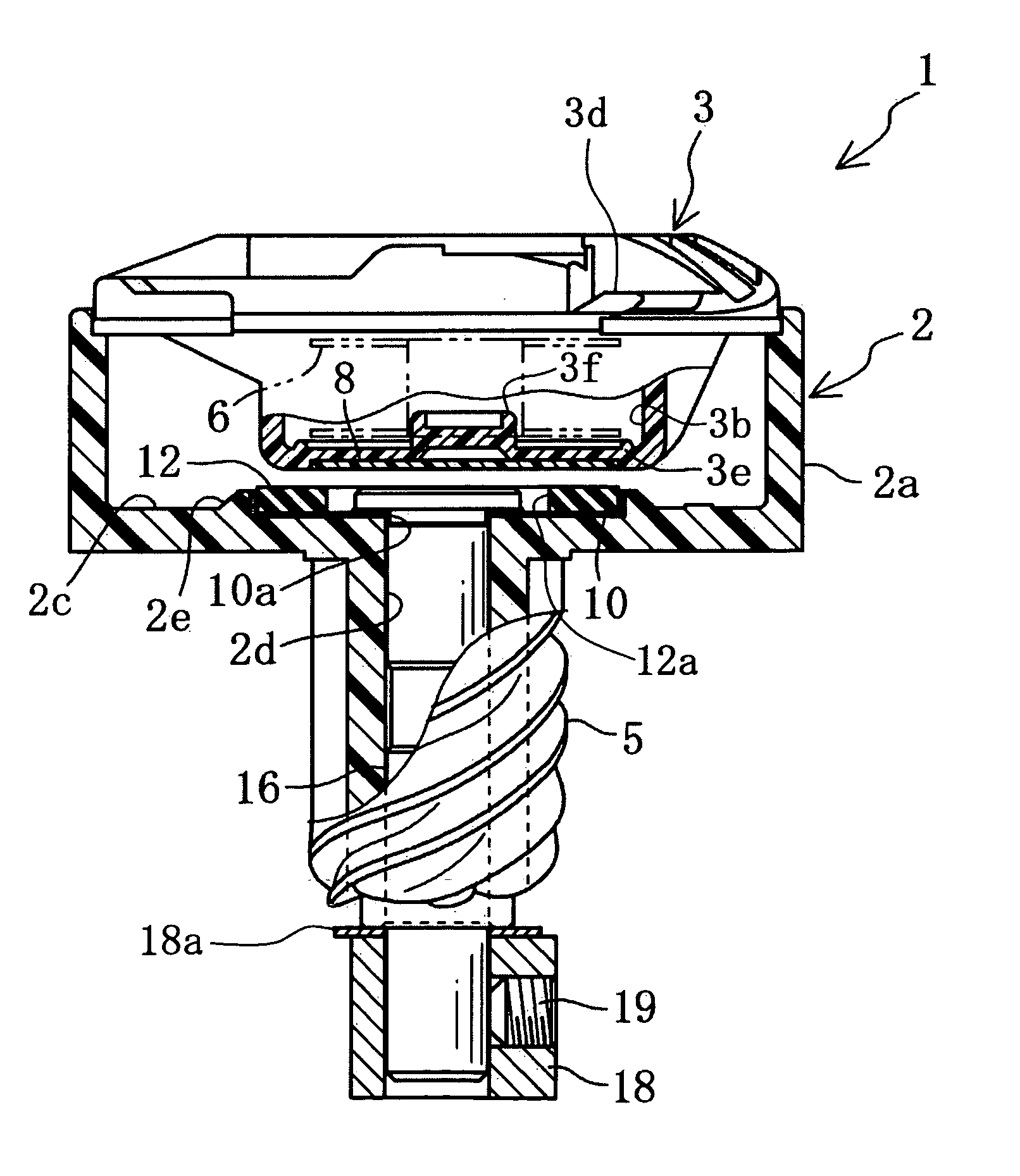

ActiveUS20080216722A1Reliably prevent stitch skippingAccurate synchronizationSewing-machine control devicesNeedle barsGear wheelEngineering

A sewing machine includes a rotating hook, a lower shaft rotating the rotating hook in synchronization with vertical movement of the needlebar, a lower shaft gear including a helical gear and slidably mounted on the lower shaft, a hook gear including a helical gear capable of mesh engagement with the lower shaft gear and mounted on the rotating hook, a drive force transmission mechanism supporting the lower shaft so that the lower shaft is axially moveable and transmits rotation of the lower shaft to the lower shaft gear, a cam mechanism axially moving the lower shaft gear to adjust at least one of a left encounter timing for seizure of the needle thread loop by the hook beak when the needle occupies a left needle location and a right encounter timing for seizure of the needle thread loop by the hook beak when the needle occupies a right needle location.

Owner:BROTHER KOGYO KK

Industrial sewing machine

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

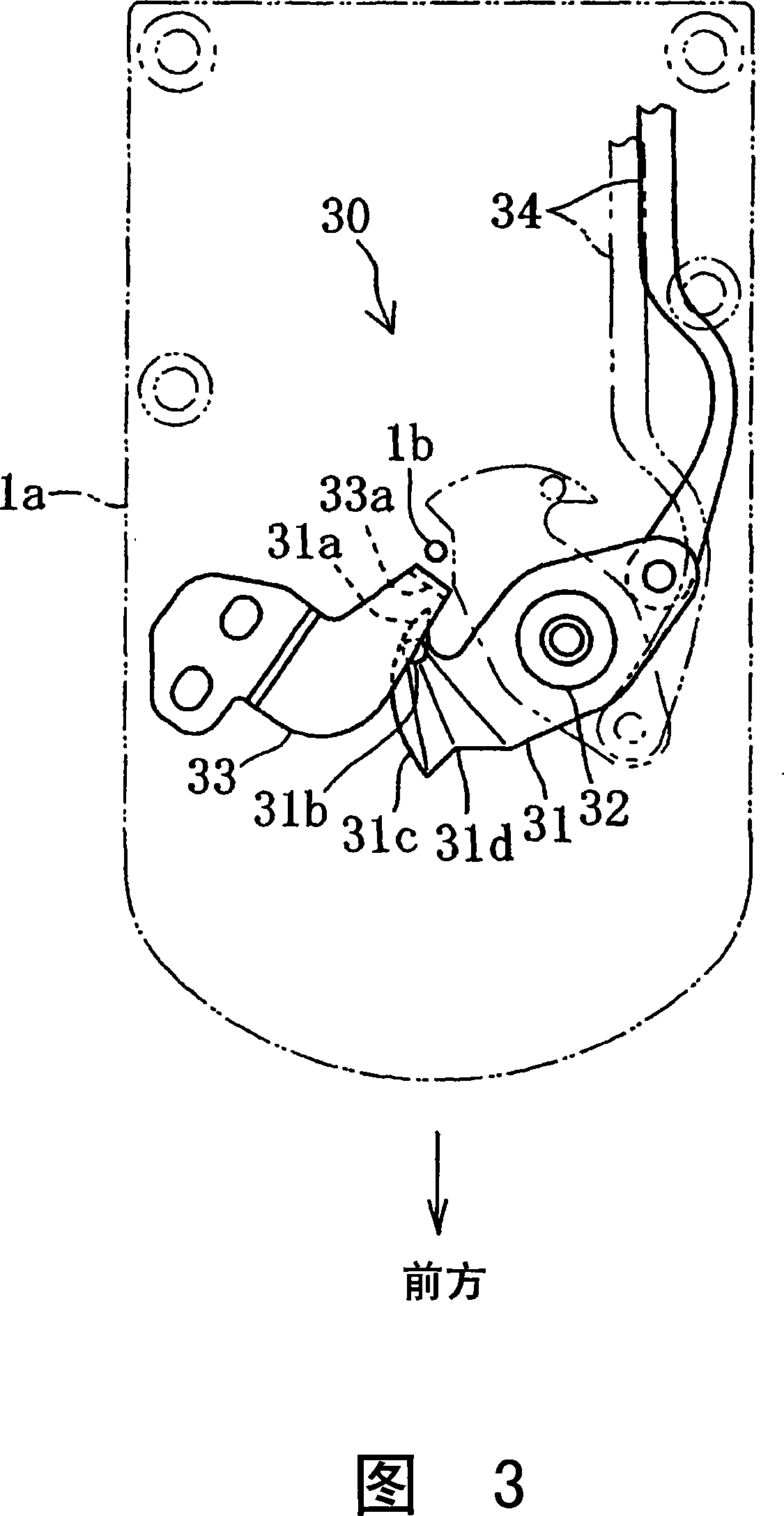

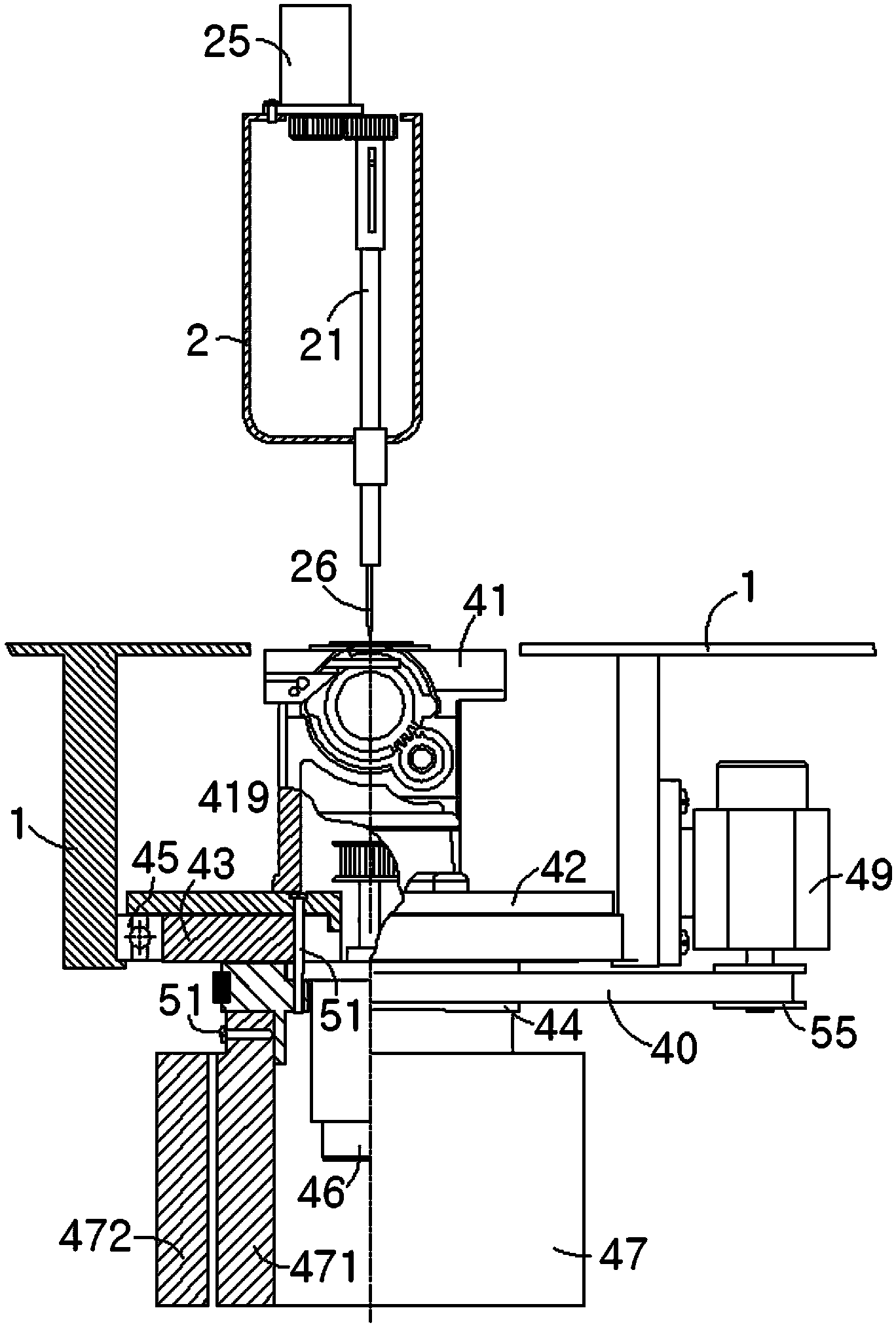

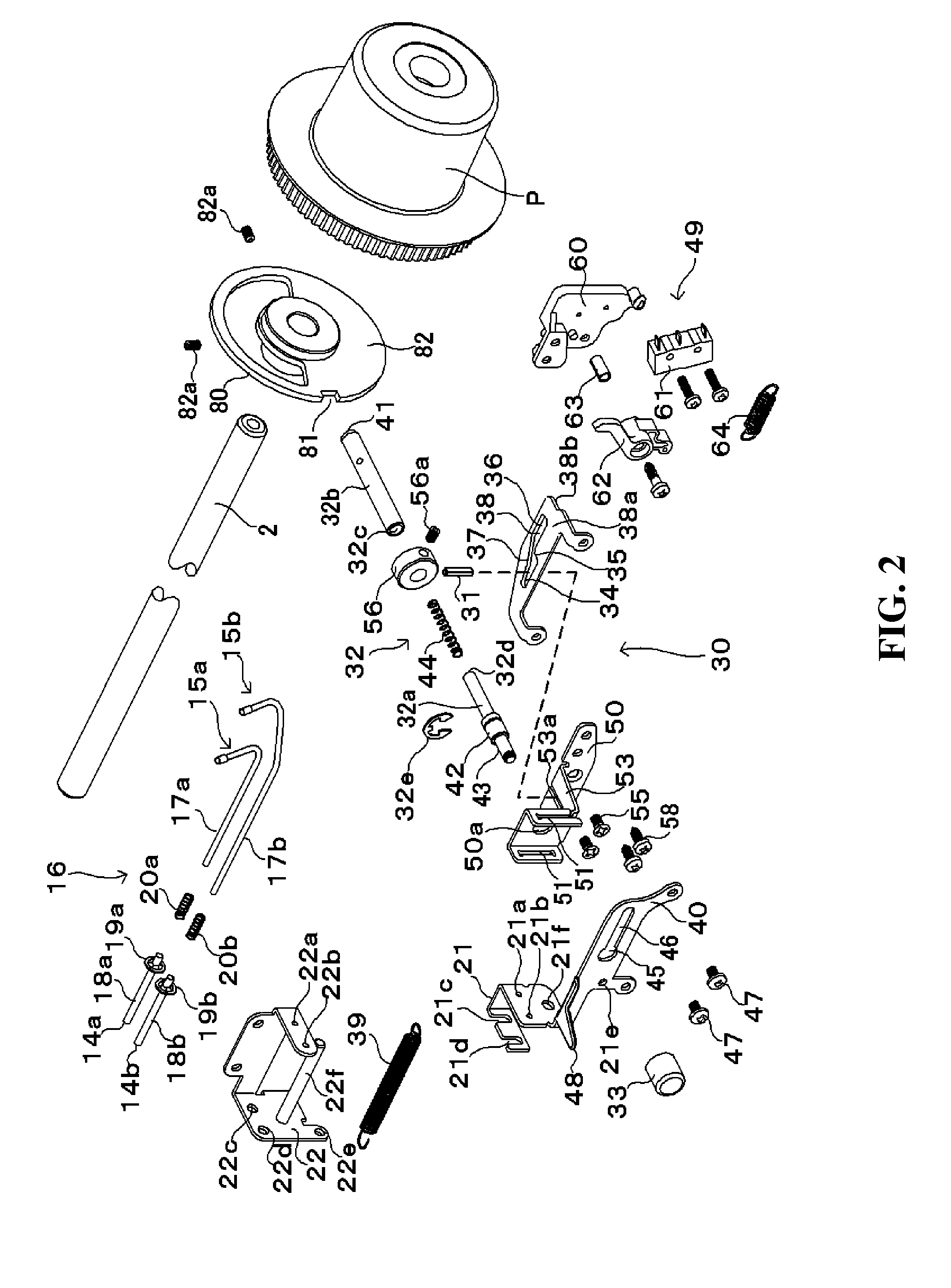

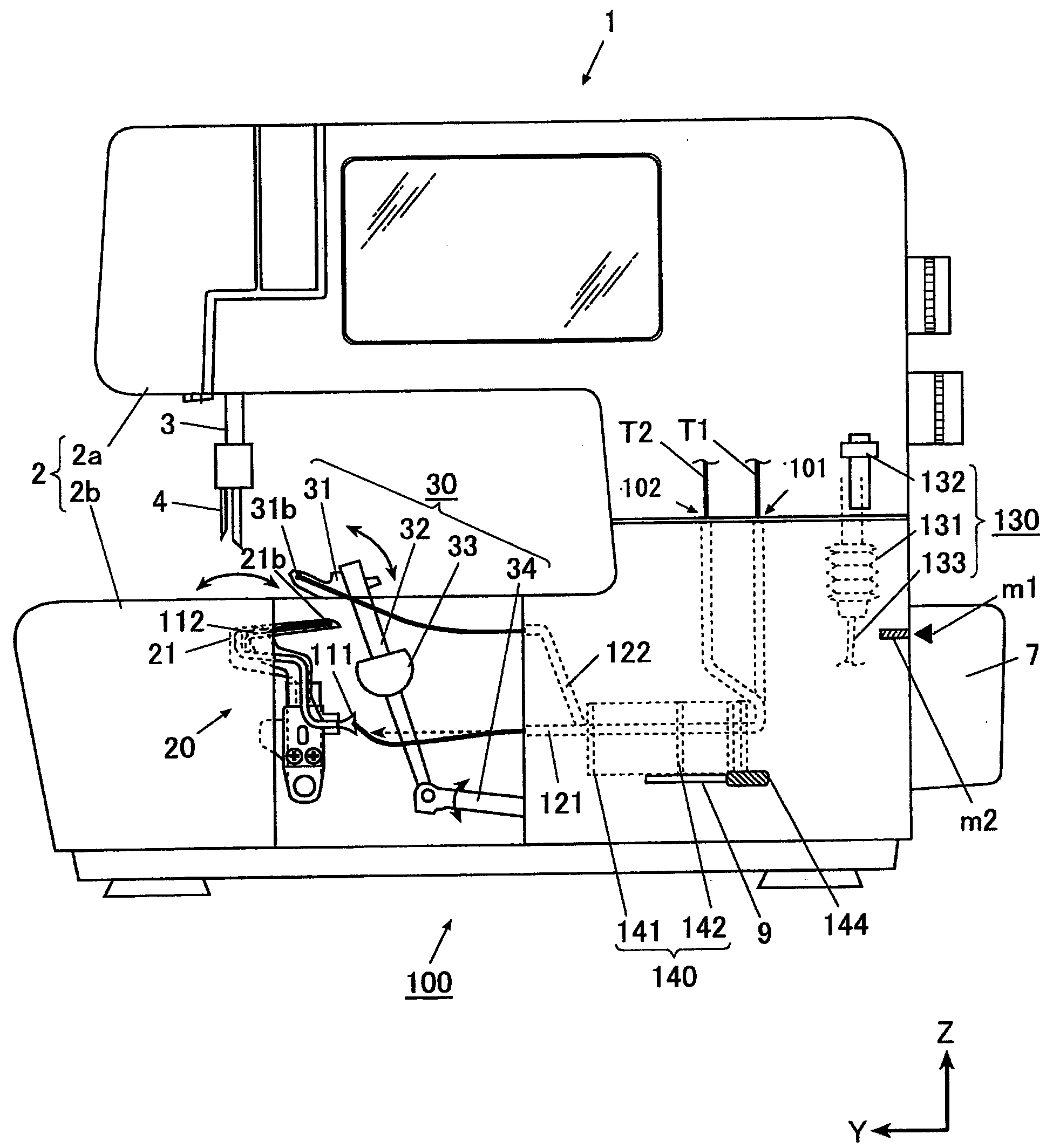

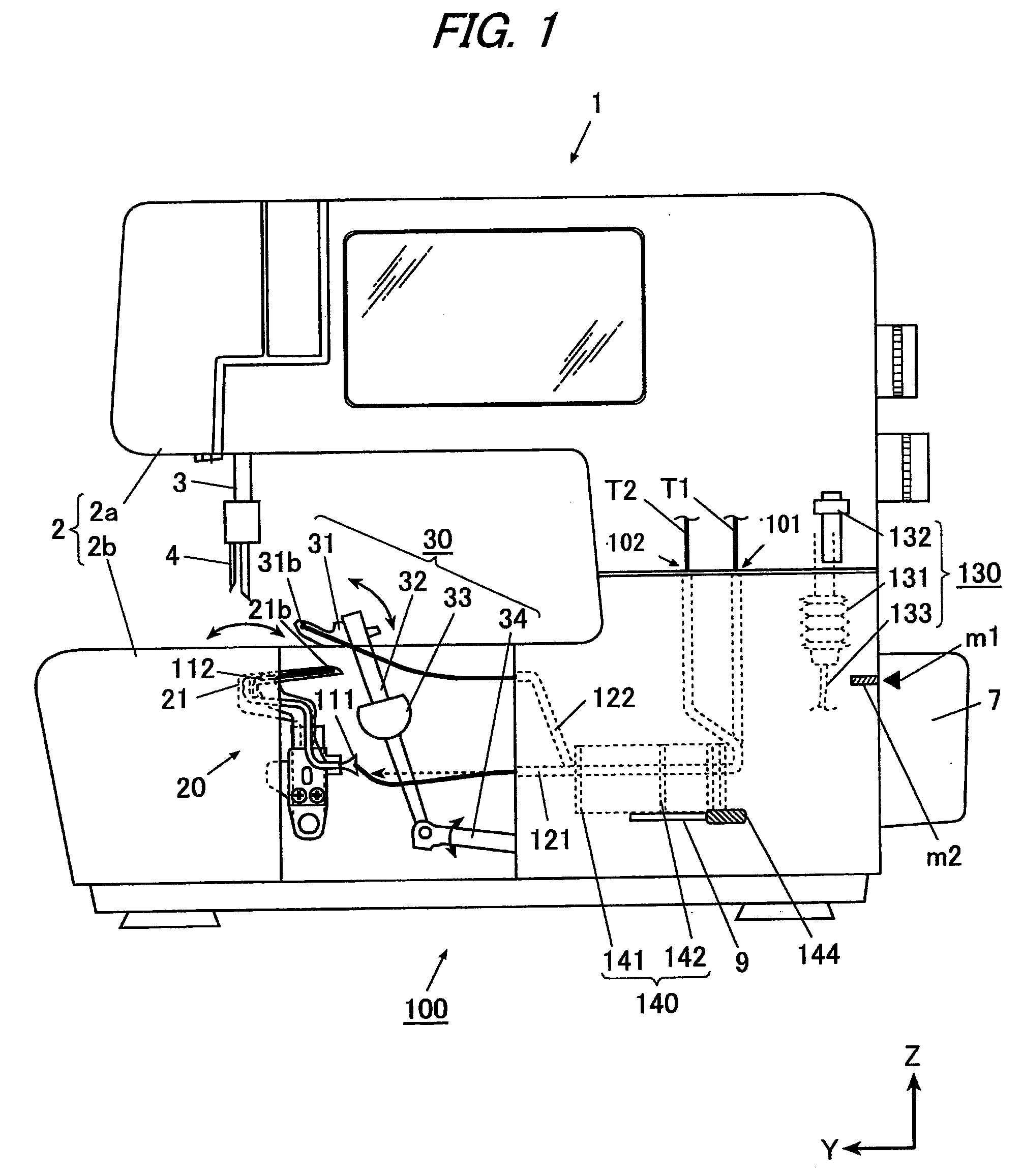

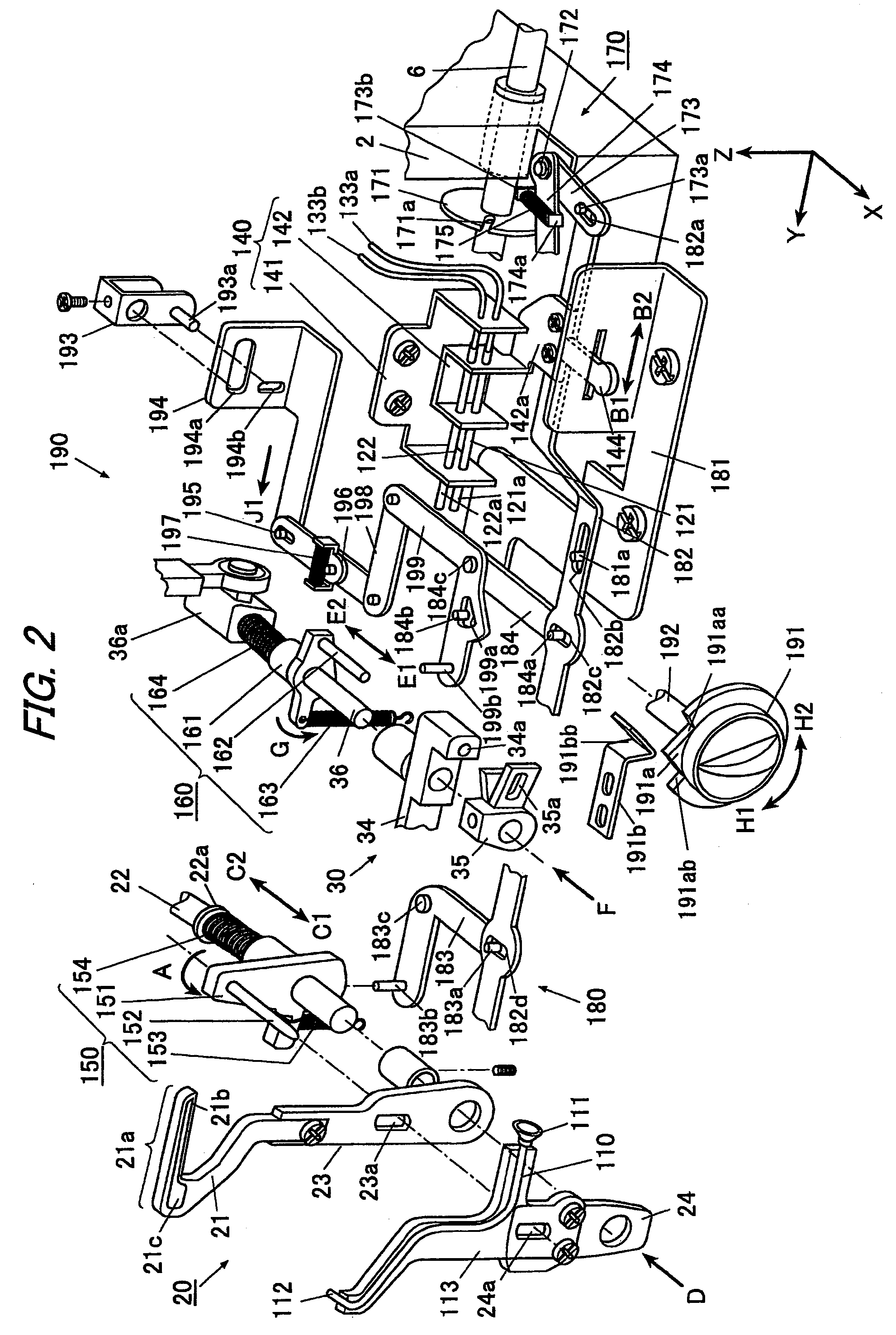

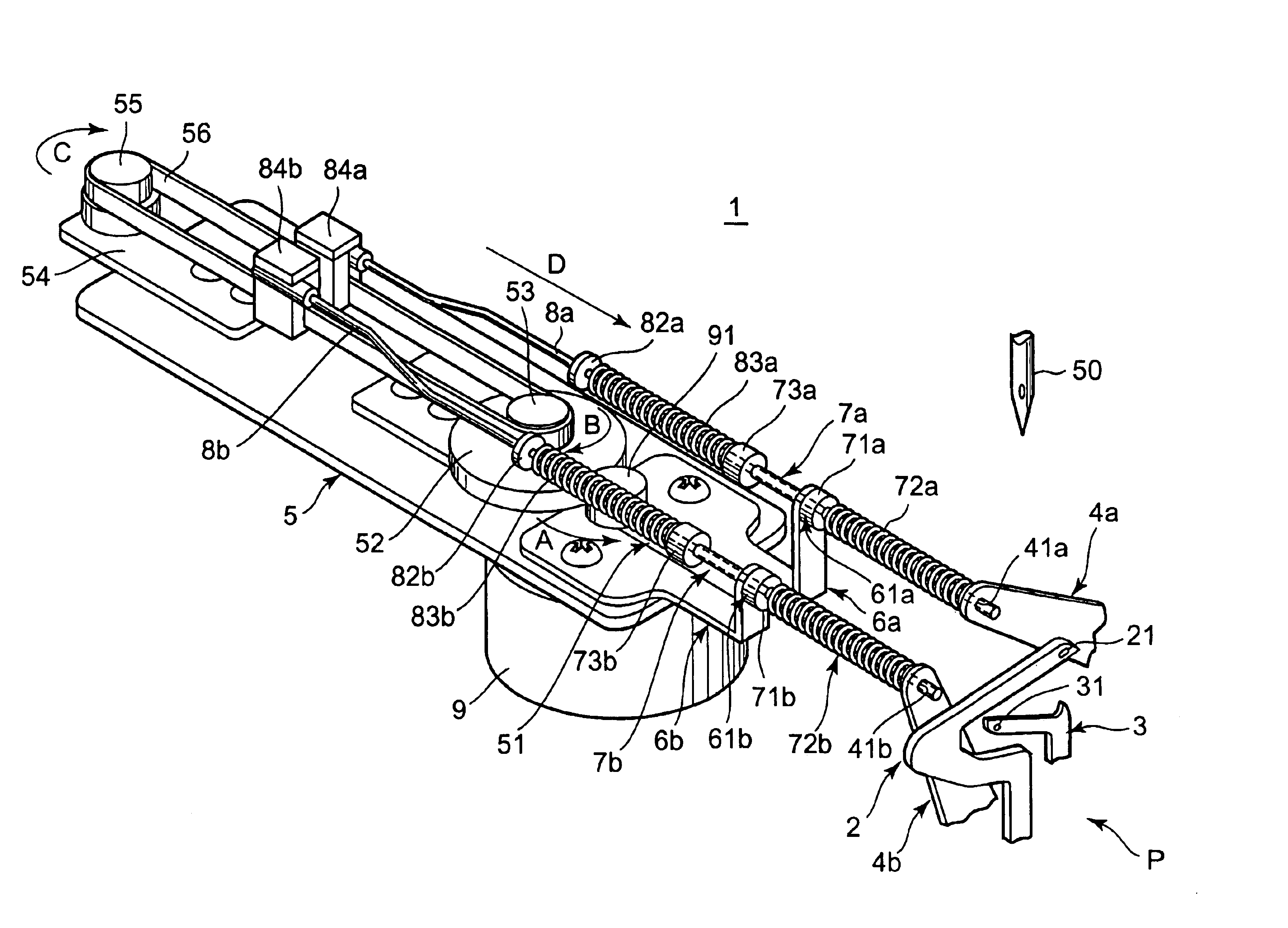

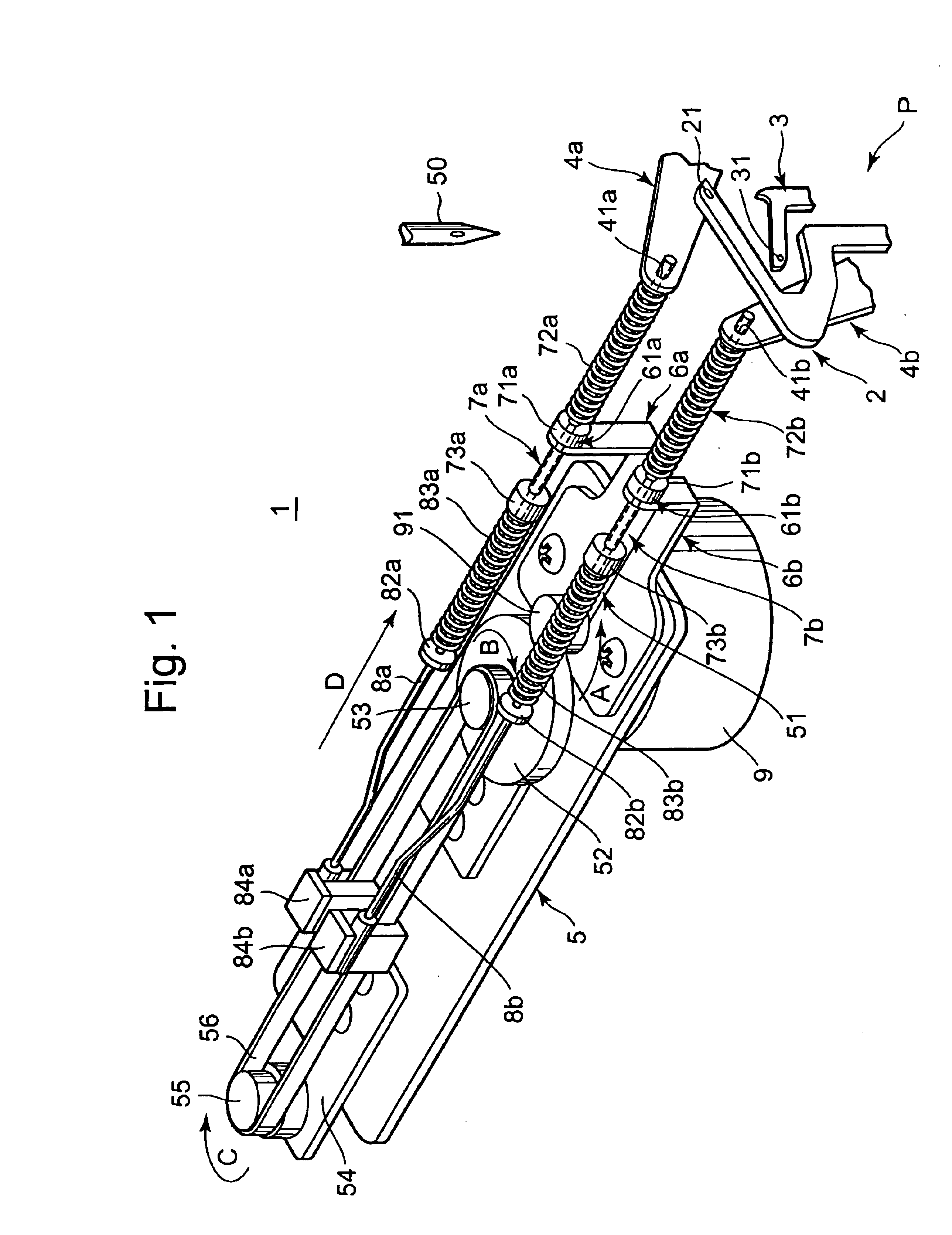

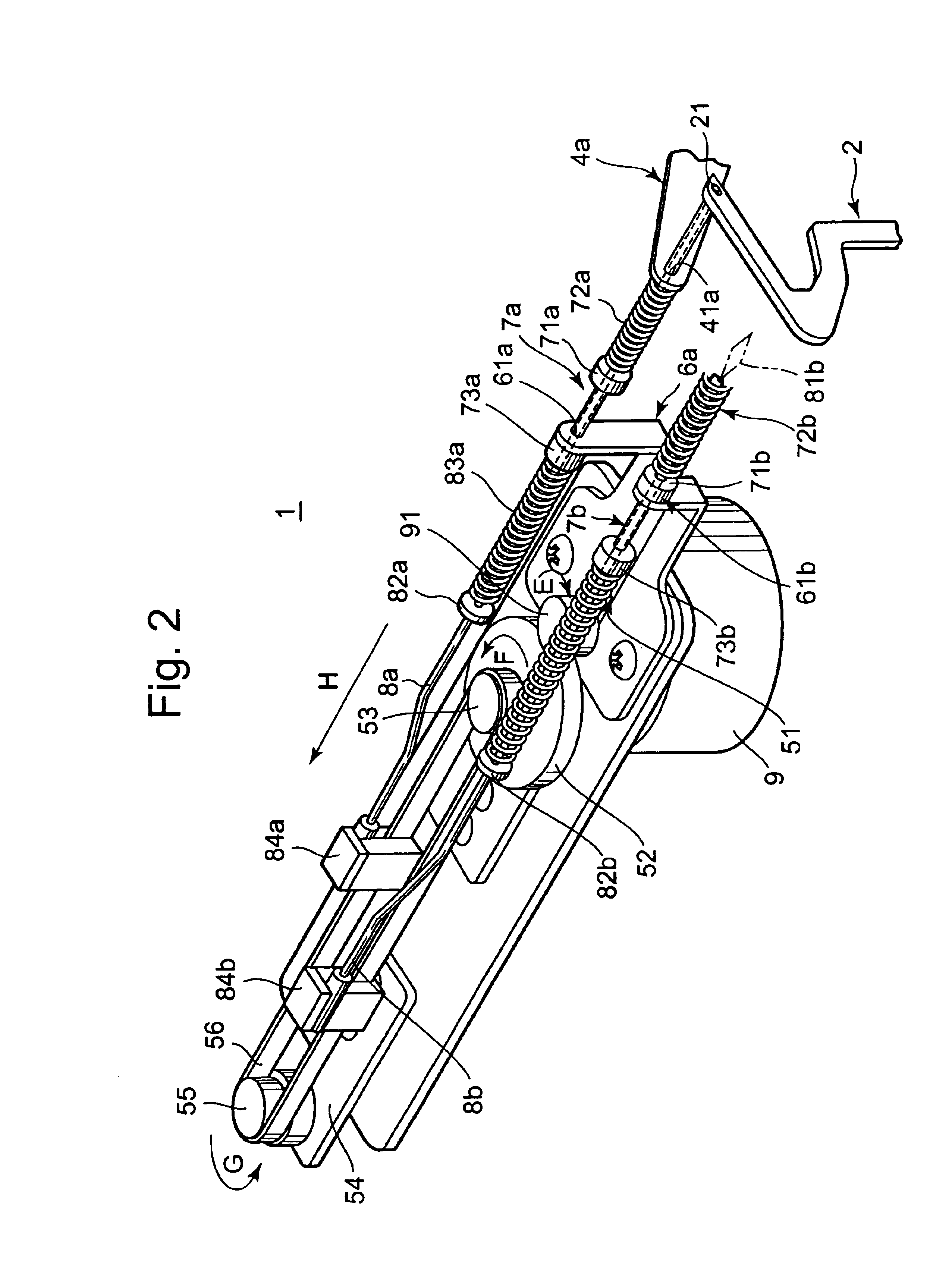

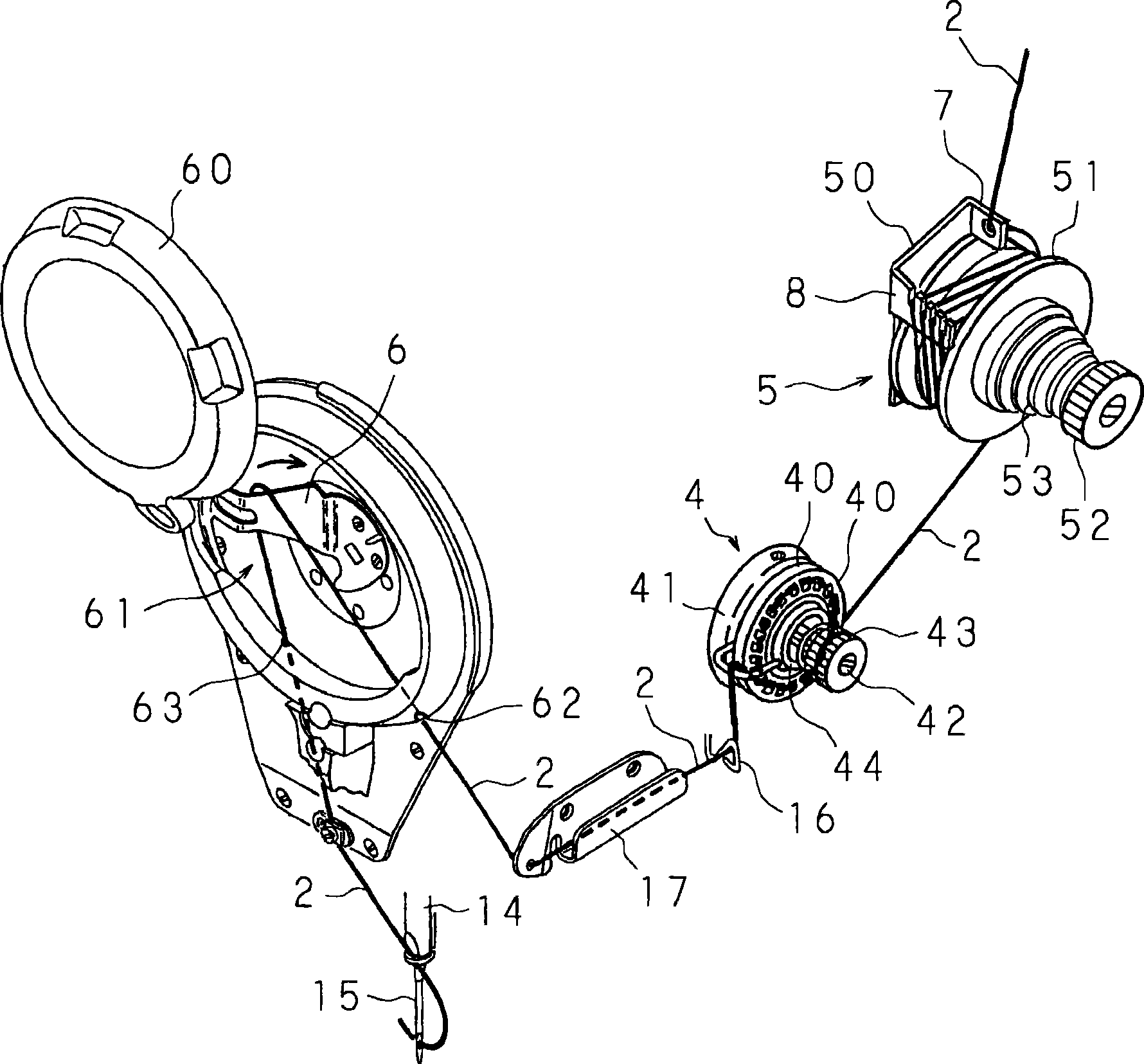

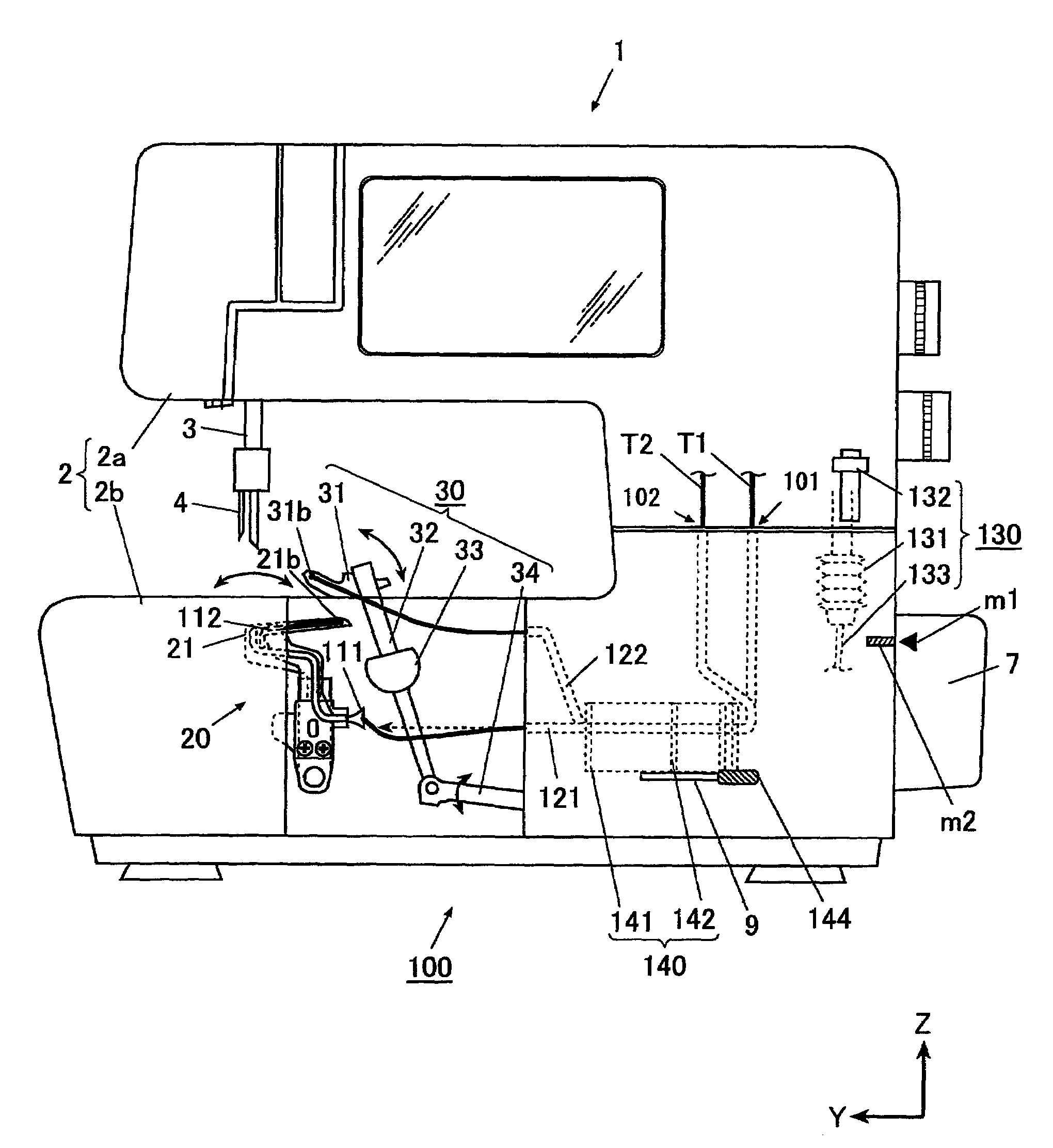

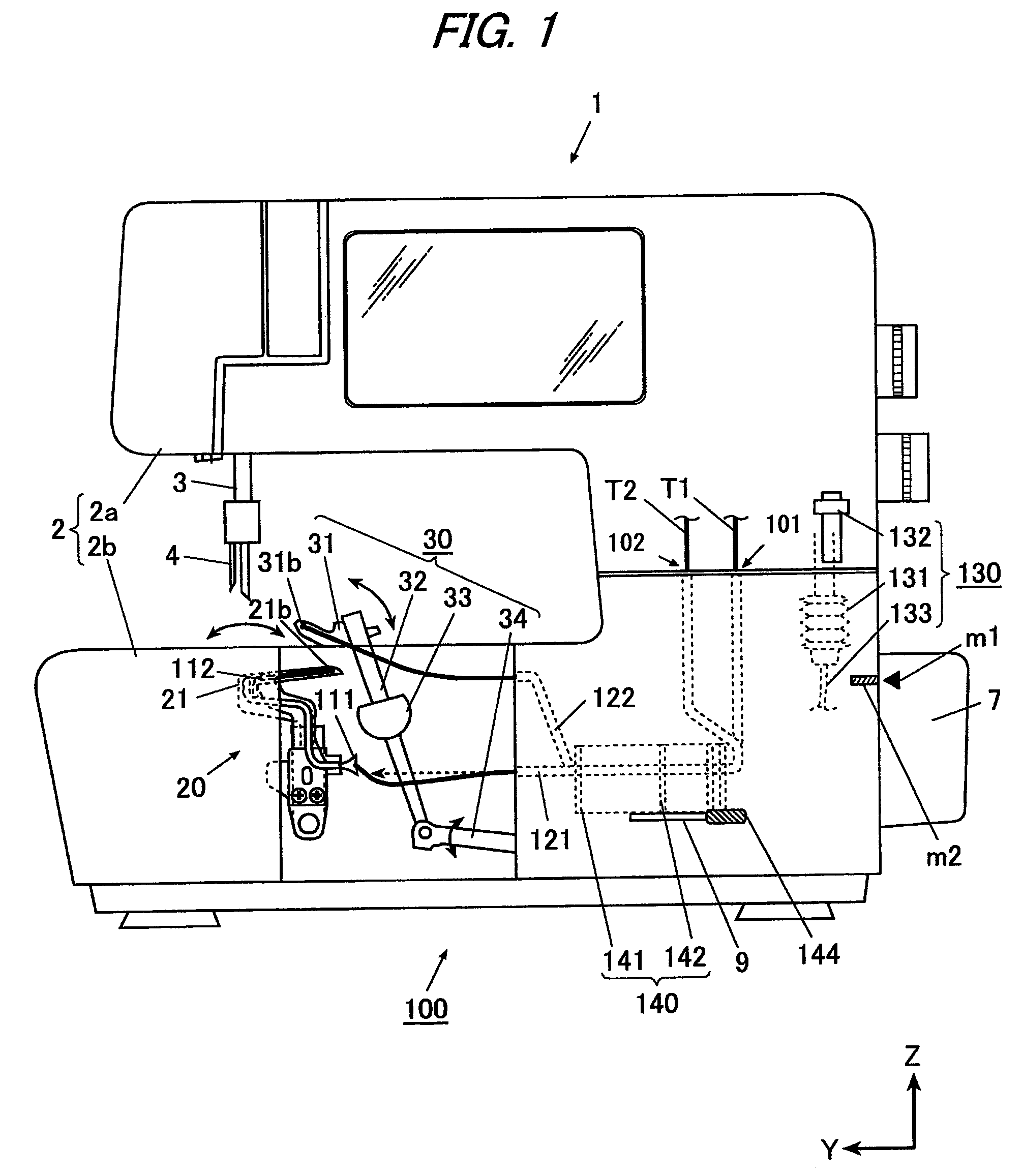

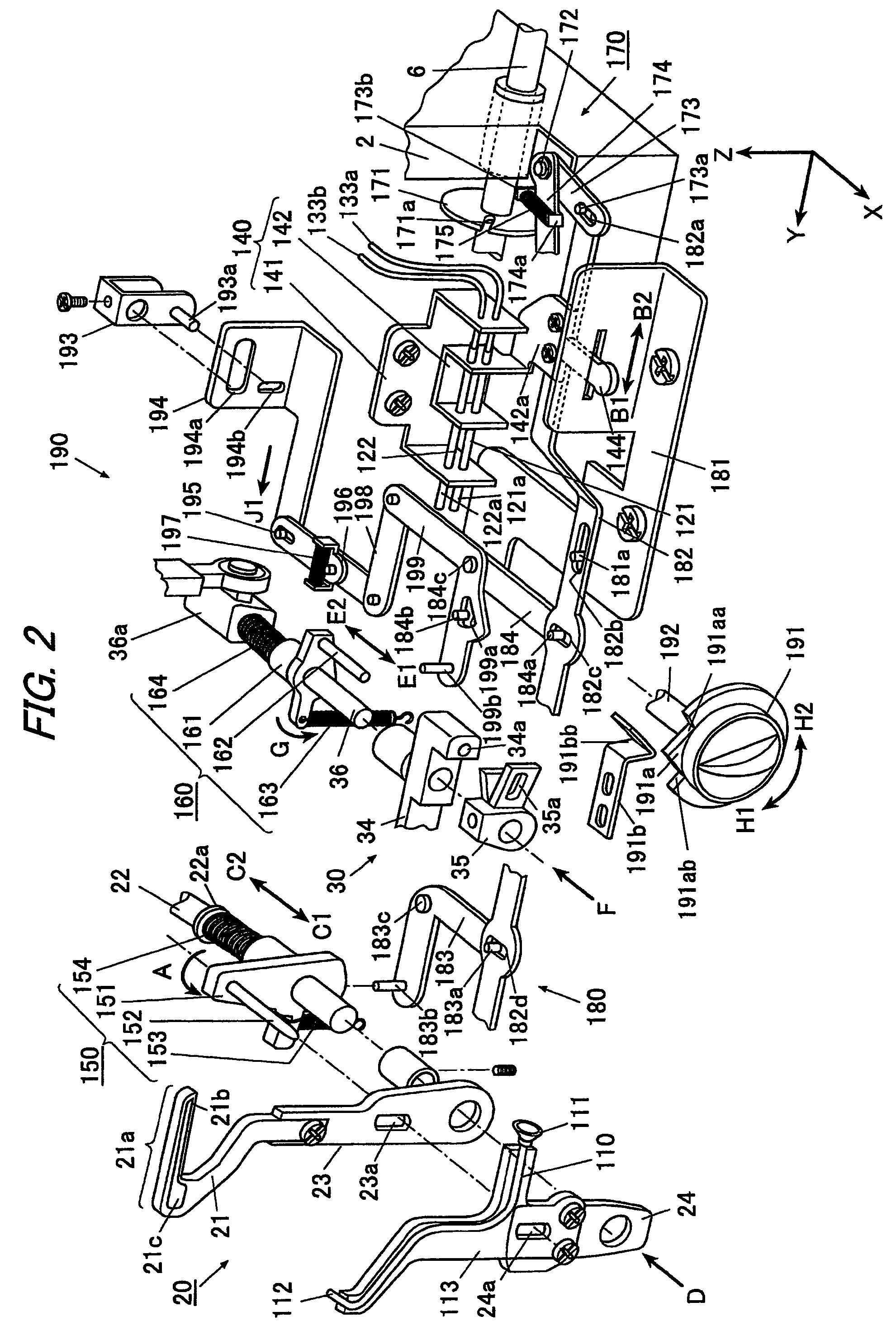

Gas carrying threading device of sewing machine

A threading to a looper is performed with one-touch operation. A looper threading / sewing changeover mechanism 30 including a push button 33 for a pressing operation of a push button shaft 32 that a control pin 31 is protruded and provided, a control groove cam 38 which includes a first control groove cam portion 34—a fourth control groove cam portion 37 which receive the control pin, a connecting movement plate 40 which supports a thread guide portion and which is elastically repelled toward a threading state that a thread guide outlet of the thread guide portion contacts to a looper thread inlet of the looper by a first spring 39, and a connecting positioning plate 82 which rotates together with a main shaft 2 integrally and has a peripheral surface 80 that a tip portion 41 of the push button shaft contacts and has a notch portion 81 that the tip portion of the push button shaft is fitted is provided.

Owner:SUZUKI MFG CO LTD

Sewing machine

A sewing machine includes an upper looper formed with a thread hole, an upper looper shaft which oscillates the upper looper between an upper position and a lower position, switching means operable to switch a coupled state and a decoupled state between the upper looper and the upper looper shaft, moving means for moving the upper looper, which has been decoupled from the upper looper shaft by the switching means, to the lower position, a thread guiding pipe formed with a thread discharging port, and first operating means operable to decouple the upper looper and the upper looper shaft via the switching means, and to move the thread discharging port of the thread guiding pipe to a position at which the thread discharging port is aligned with the thread hole of the upper looper in the lower position.

Owner:JUKI CORP

Sewing machine

ActiveCN101100793AImprove sewing qualityImprove sewing efficiencySewing-machine control devicesNeedle barsRing deviceTime transfer

The present invention is to improve sewing efficiency through omitting the regulating work of the installation position of a kettle (or a beating ring device) generated through the thickness of the matter to sewing or the rotation delay of sewing speed as well as a kettle (or a beating ring device). A sartorius comprises an upper axis, which keeps a needle of a sewing needle move up and down; a lower axis, driving a sewing catching unit which catches the upper thread of the sewing needle to swing with the lower thread; a drive source, applying rotary drive on the upper axis and the lower axis; an upper axis rotary part, rotating along with the upper axis; a lower axis rotary part, rotating along with the lower axis; a drive transferring part, which loop shaped frames set on the upper axis rotary part and the lower axis rotary part, at the same time transfers the rotary drive of a rotary part rotated by means of the drive source to another rotary part, the drive transferring part ensures the length rate of two frame parts connecting with the position between the upper axis and the lower axis rotary part to be alter automatically through outside force.

Owner:JUKI CORP

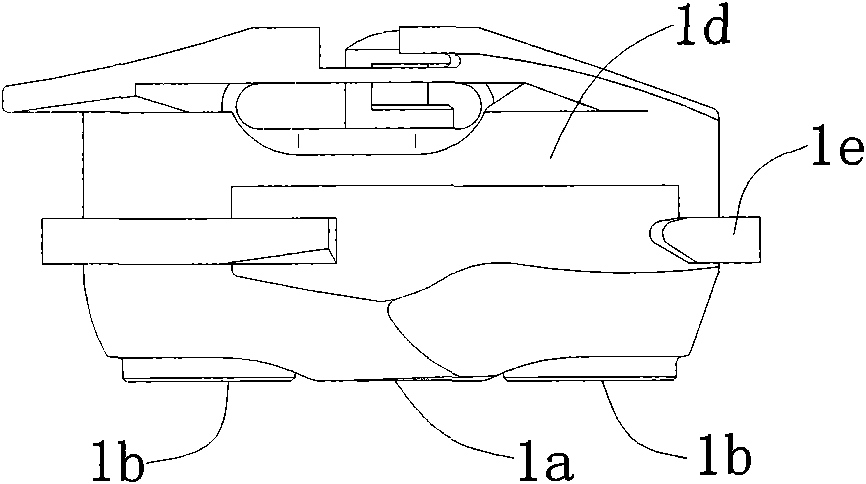

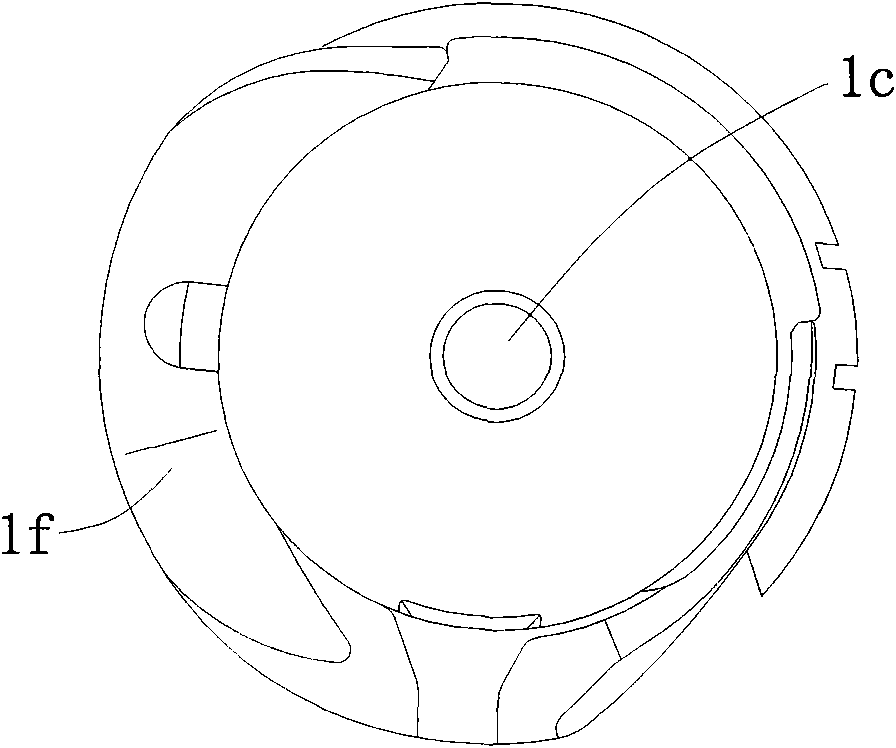

Horizontal rotary hook for sewing machine

Owner:BROTHER KOGYO KK

Seam ravel preventing apparatus and ravel preventing method

InactiveUS7497177B2Stable executionPreventing ravelingNeedle severing devicesLoop takersEngineeringScrew thread

A looper is brought into an advance state at the end of sewing, and a looper thread hanging hook arranged on the right rear side of a needle drop position is forced to advance and retreat to catch a looper thread running to the rear side of the looper and hold it on the rear side of the needle drop position. After performing sewing for one stitch in this state, the thread cutting hook arranged on the right side of the needle drop position is forced to advance and retreat to catch the looper thread running to the rear side of the looper with a first hold section and catch needle threads and the looper thread held by the looper thread hanging hook with a second hook section, and then these threads are collectively cut by bringing them into slide-contact with a thread cutting knife.

Owner:YAMATO SEWING MASCH MFG CO LTD

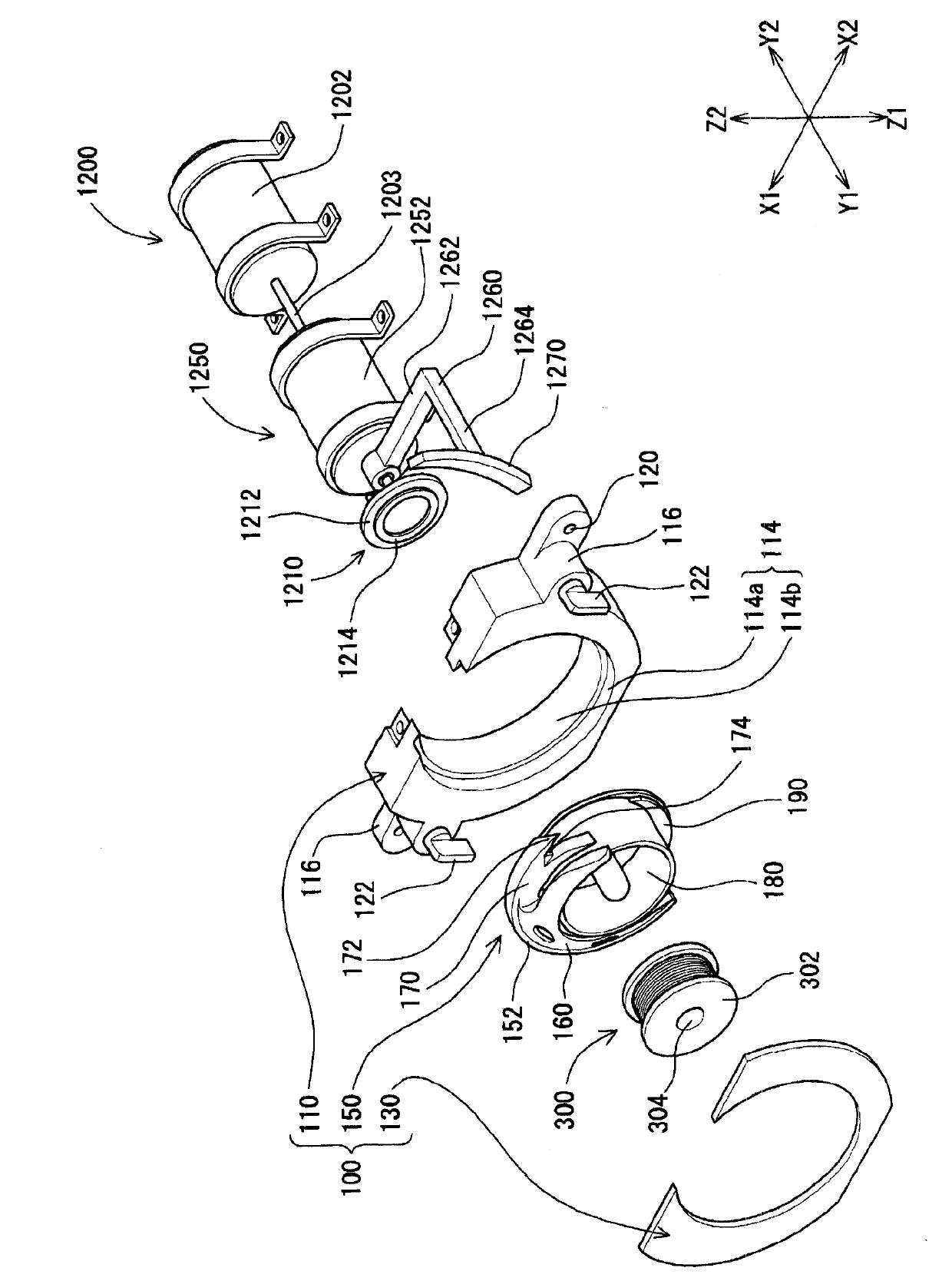

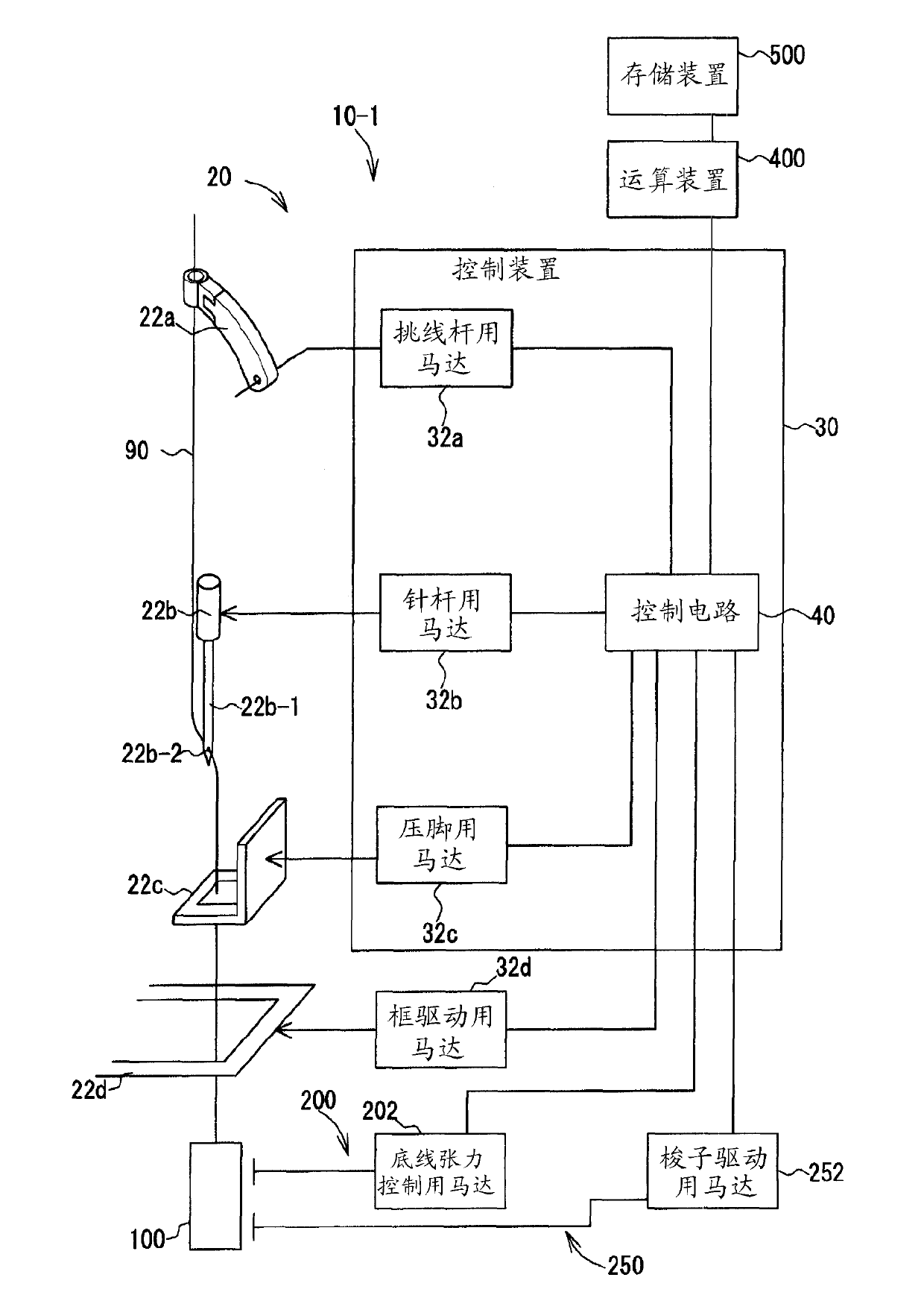

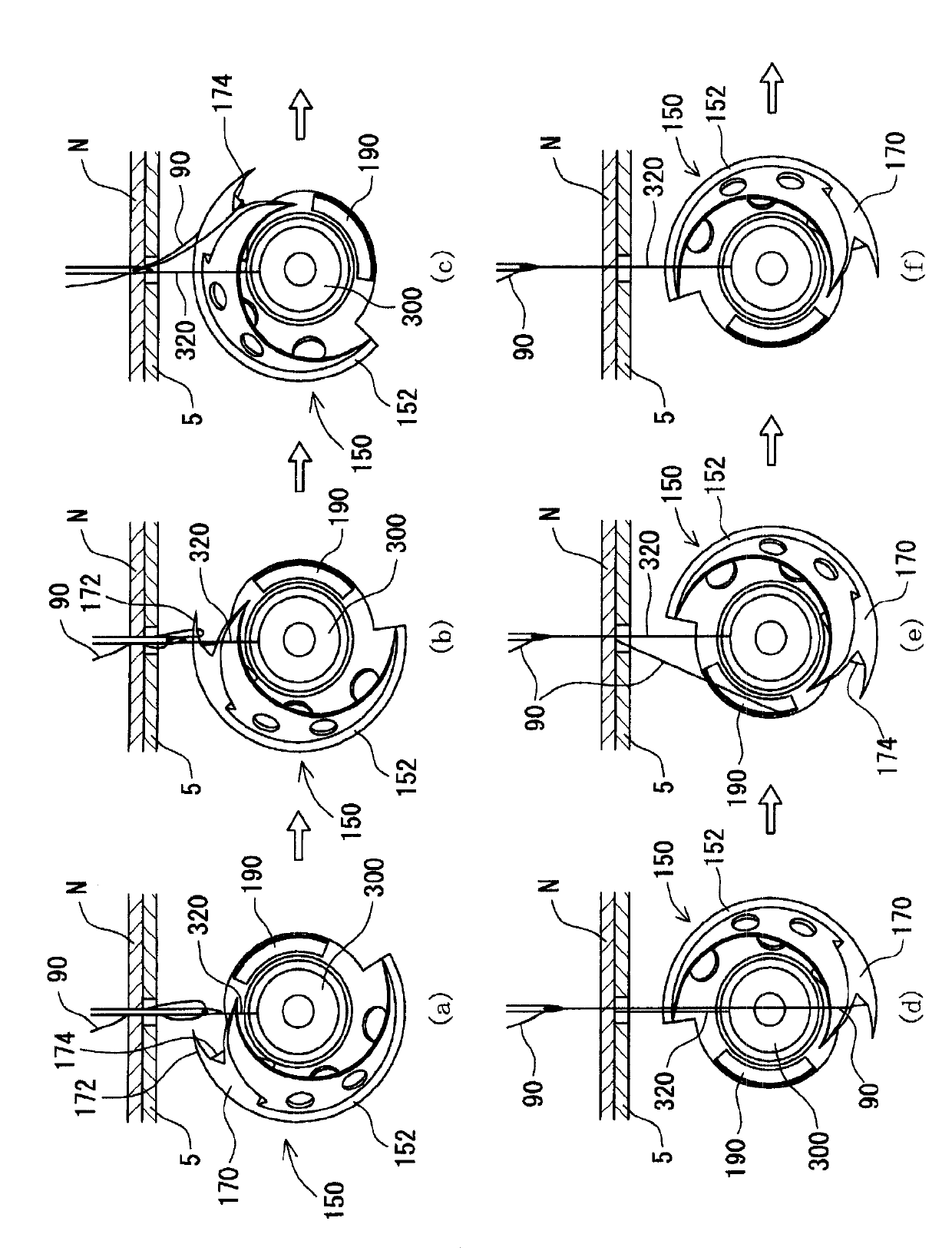

Lower-thread tension control device for sewing machine, and sewing machine

A lower-thread tension control device for a sewing machine, capable of finely and accurately controlling the tension of a lower thread without relying on frictional force. A lower-thread tension control device for a sewing machine comprises an outer shuttle (110), a middle-shuttle presser (130), a middle shuttle (150), a lower-thread tension control mechanism (200), a shuttle driving section (250), and a bobbin (300). A magnet section (190) is provided to the middle shuttle (150). A magnet section (270) is provided close to the magnet section (190), to an arm (260) provided to the rotating shaft of a shuttle driving motor (252) of the shuttle driving section (250). The middle shuttle (150) is rotated by rotating the magnet section (270) by means of the motor (252). Also, a magnet section (214) is provided to a rotating disc (210) which is provided to the rotating shaft of a lower-thread tension controlling motor (202) of the lower-thread tension control mechanism (200) so as to be close to the middle shuttle (150). A magnet section is provided to a portion of the bobbin (300), said portion being located on the rotating disc (210) side, and the bobbin (300) is rotated by the motor (202).

Owner:NSD

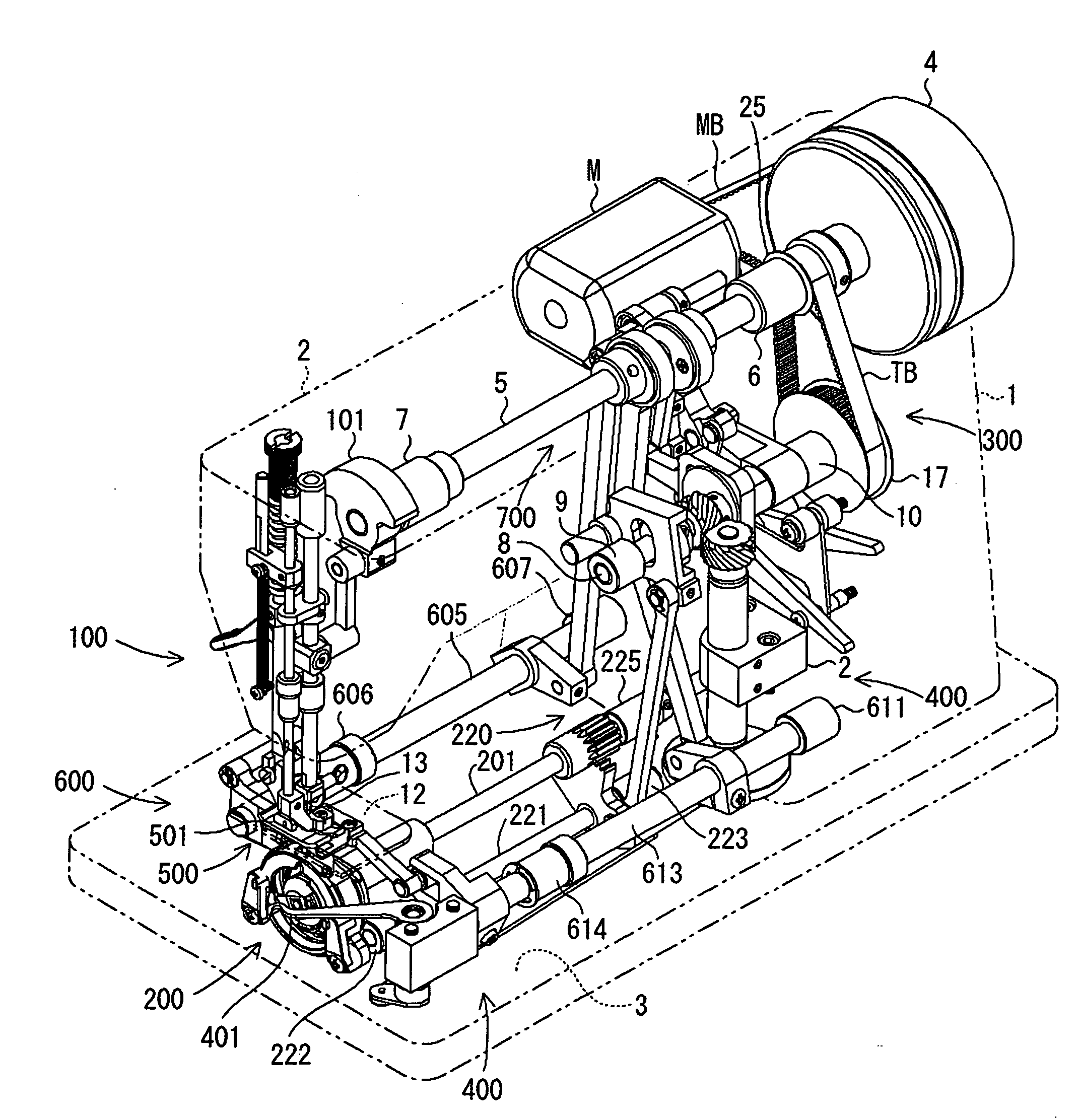

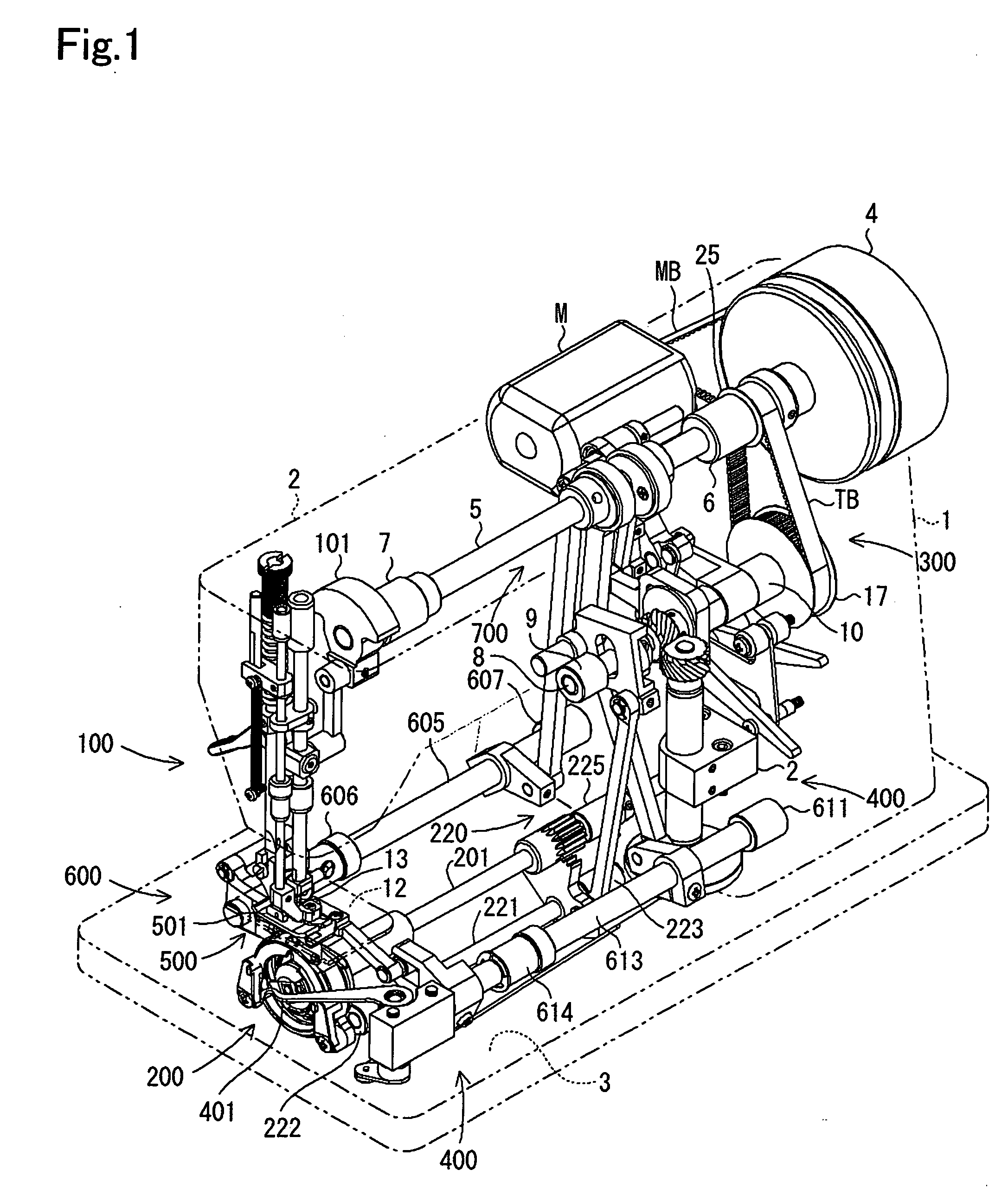

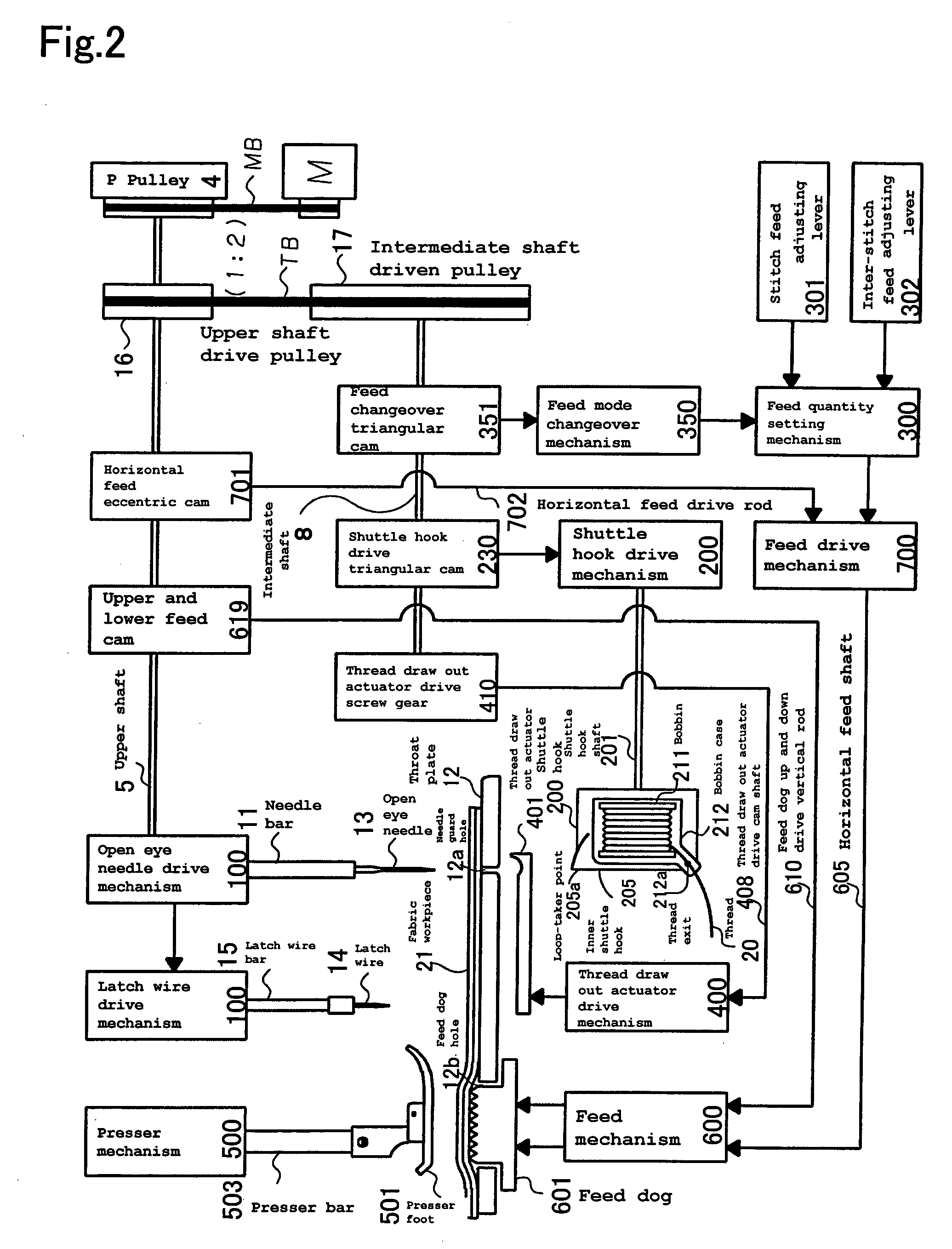

Method and Sewing Machine for Forming Single-Thread Locked Handstitches

ActiveUS20090007830A1Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

Looper threading apparatus for sewing machine

Owner:JUKI CORP

Sewing machine

ActiveCN1824872AAvoid unreasonable forceIncreased durabilityNeedle barsLoop takersEngineeringVertical motion

The sewing machine of the present invention has a needle bar crank linked to a main shaft, a vertical movement transmission mechanism linked to the needle bar crank, and a needle swing mechanism for swinging the needle bar. The up and down movement transmission mechanism includes: a ring-shaped member having a space defined by a ring-shaped inner peripheral surface, through which the needle bar passes; and a pair of upper and lower needle bar frame members, which are fixed on the outside of the needle bar, and Arranged on the upper and lower sides of the ring member. The ring member is journally connected to the needle bar crank. A clearance for swinging is ensured between the annular inner peripheral surface of the space of the annular member and the outer periphery of the needle bar. The needle bar can swing without being in contact with the annular inner peripheral surface within the swing gap.

Owner:BROTHER KOGYO KK

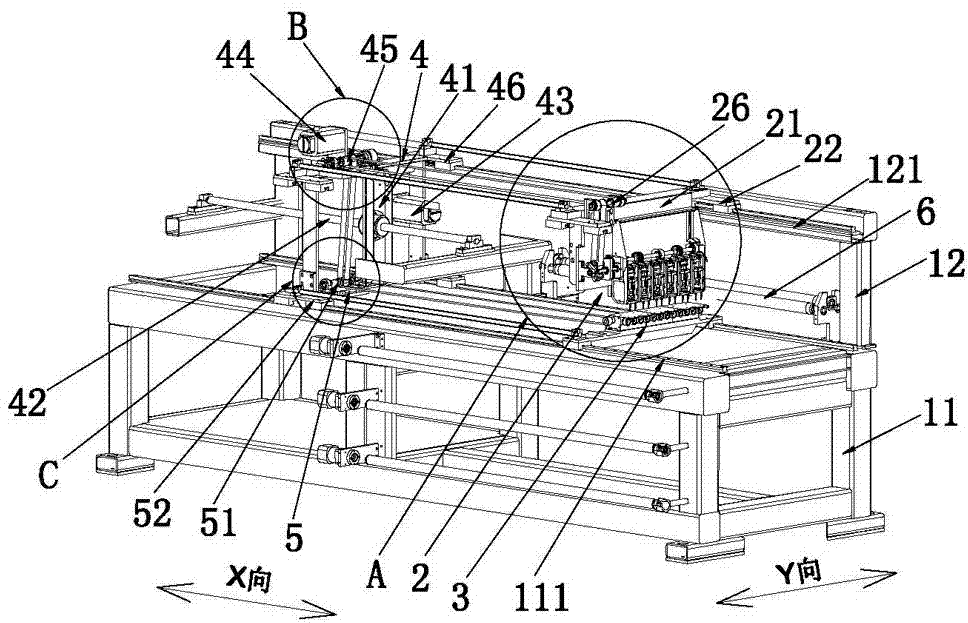

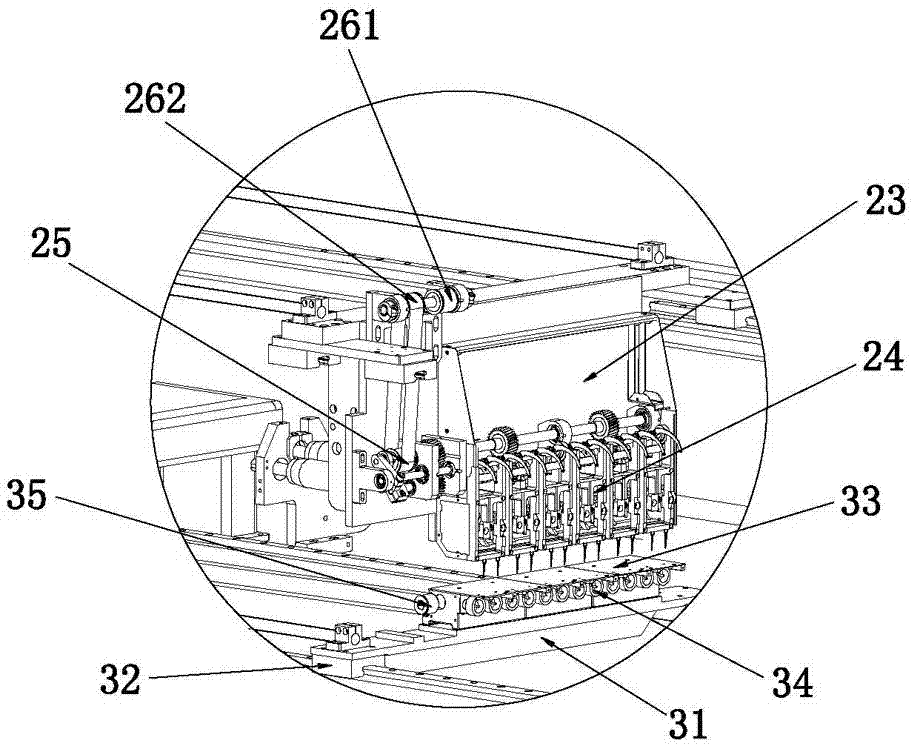

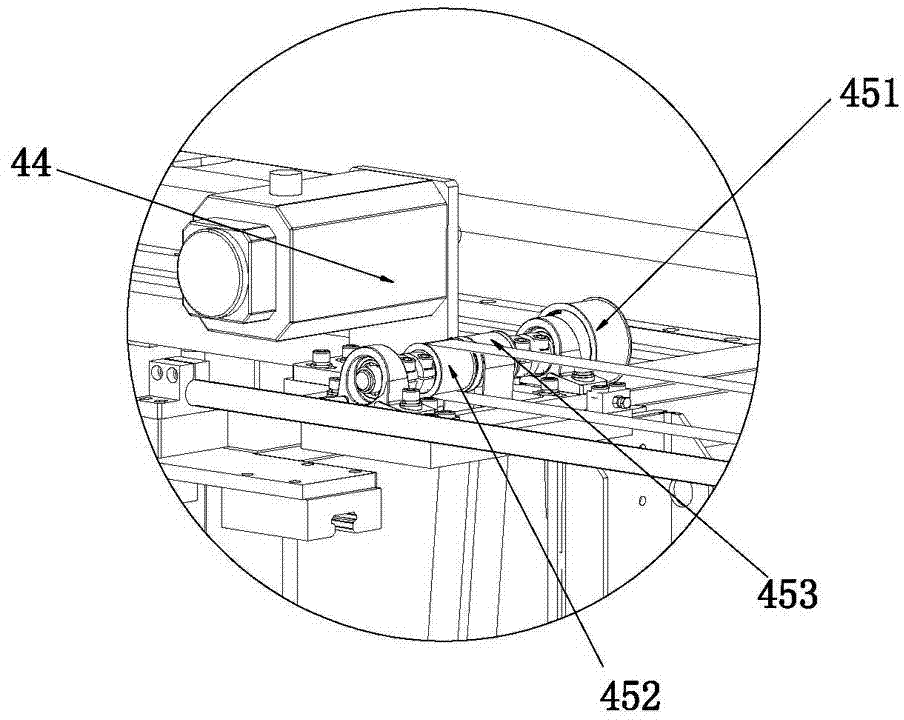

Numerical-control sewing and embroidering quilting machine provided with horizontal multi-needle machine head

InactiveCN104499188ANo mutual interferenceEasy offlineWork-feeding meansMattress sewingNumerical controlMechanical engineering

The invention belongs to the technical field of quilting machines, and particularly relates to a numerical-control sewing and embroidering quilting machine provided with a horizontal multi-needle machine head. The numerical-control sewing and embroidering quilting machine comprises a frame, wherein the frame comprises a rack and an upper frame which is arranged at the upper end of the rack; the frame is provided with the multi-needle machine head capable of moving longitudinally; a rotating shuttle mechanism is arranged under the multi-needle machine head; the frame is provided with a first driving mechanism for driving the multi-needle machine head and the rotating shuttle mechanism to move synchronously; the multi-needle machine head is connected with the upper frame in a sliding manner; the rotating shuttle mechanism is connected with the rack in the sliding manner; the frame is also provided with a second driving mechanism for driving a fabric to be fed horizontally. The multi-needle machine head of the numerical-control sewing and embroidering quilting machine is arranged in a direction vertical to the feeding direction of the fabric, so that two adjacent needles have no interference in sewing trace during sewing, no wired node is formed in a spliced point, and thus the node is unlikely to loosen, and the quality and the attractive appearance of the product are guaranteed; a plurality of sewing needles work simultaneously, so the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH +1

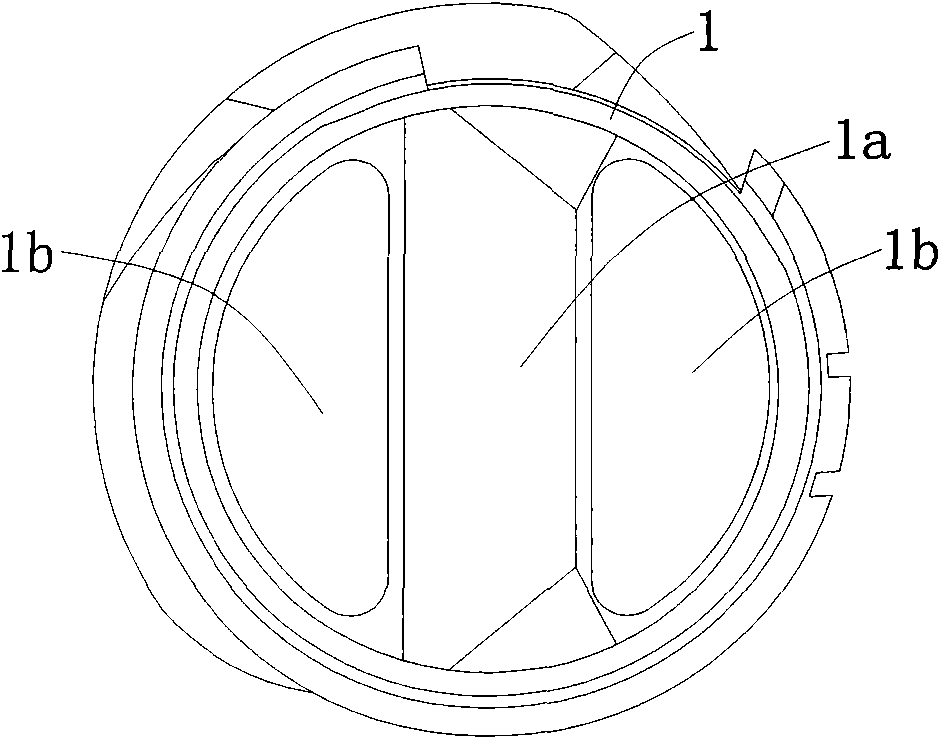

Process for manufacturing rotating shuttle inner shuttle bottom supporting structure

The invention discloses a process for manufacturing a rotating shuttle inner shuttle bottom supporting structure, which comprises the following steps of powder molding, sintering and blast sanding, wherein in the step of powder molding, iron-based alloy powder is prepared into a rotating shuttle inner shuttle blank by using a metallurgy powder molding method; a strip-shaped plate is prepared at the bottom of the rotating shuttle inner shuttle blank, and supporting plates are respectively arranged between one side of the strip-shaped plate and a side wall of the rotating shuttle inner shuttle blank and the other side of the strip-shaped plate and the side wall of the rotating shuttle inner shuttle blank respectively; the rotating shuttle inner shuttle blank is subjected to a step of punching molding after the steps of sintering and blast sanding; in the step of punching molding, the supporting plates at the bottom are punched and separated from the rotating shuttle inner shuttle in a punching mode. In the process for manufacturing the rotating shuttle inner shuttle bottom supporting structure, a rotating shuttle inner shuttle is manufactured by the powder metallurgy technology, and the supporting plate structure is prefabricated, so that a product does not deform during sintering and molding. Therefore, the sintered product has high hardness and strength and more uniform texture.

Owner:NINGBO YINZHOU YONGYAO SEWING MACHINERY

Shuttle driving device of sewing machine

InactiveCN101736536ASuppress noiseEasy to adjust the arrangement intervalLoop takersDrive shaftSewing machine

The present invention relates to shuttle driving device of a sewing machine, wherein the arrangement space of two shuttles is adjusted through moving a shuttle seat. A shuttle driving shaft of the shuttle seat and a lower shaft in a base are sustained to a transmission state in the moving range of the shuttle seat. The shuttle seat is a small component configured in the base. An operator can easily adjust the arrangement space through moving the shuttle seat. The shuttle seat moves at a state when the connection between the shuttle driving shaft and the lower shaft is sustained. An operator can adjust the arrangement space of two shuttles at a state that the rotation positions of shuttles are unchanged.

Owner:BROTHER KOGYO KK

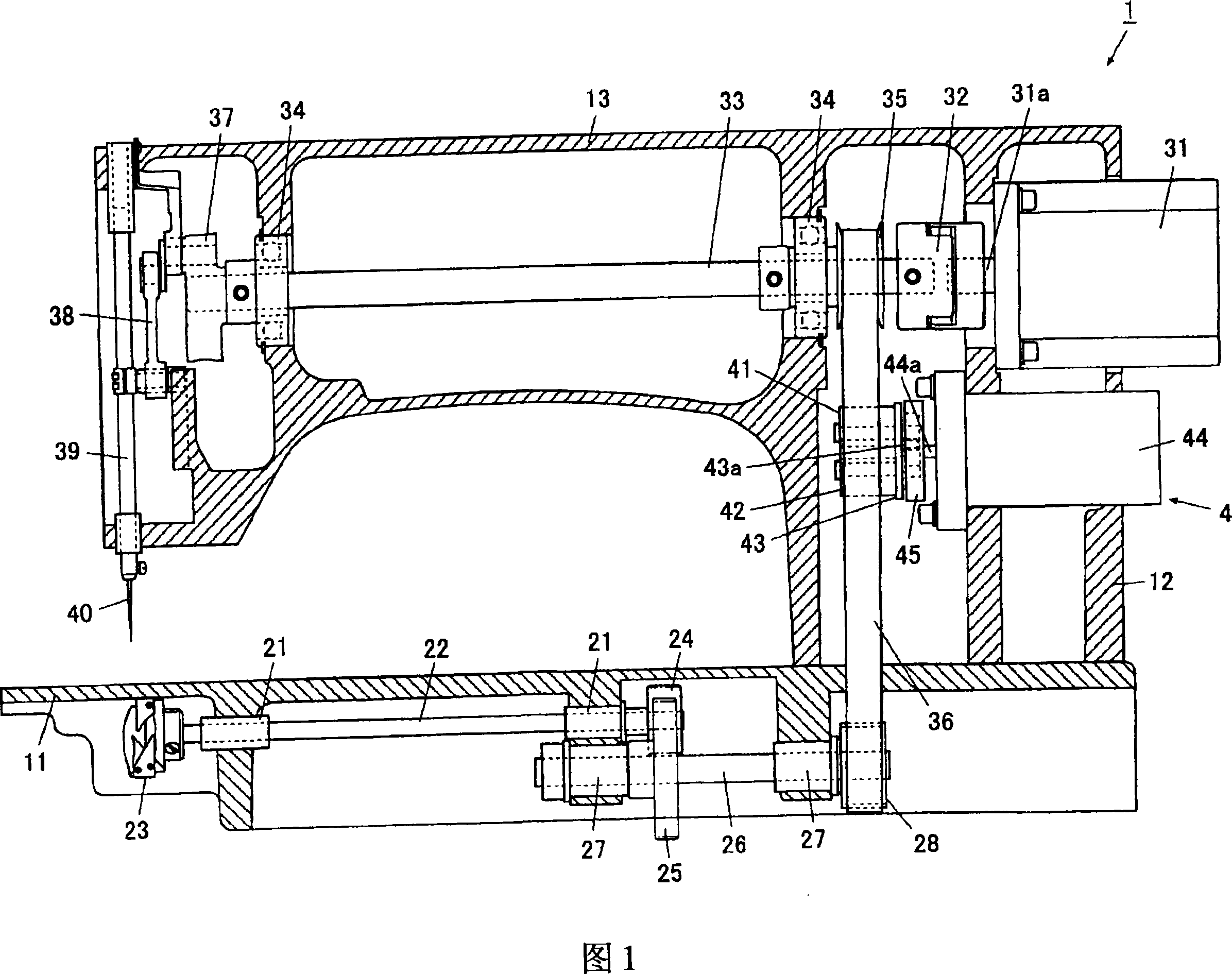

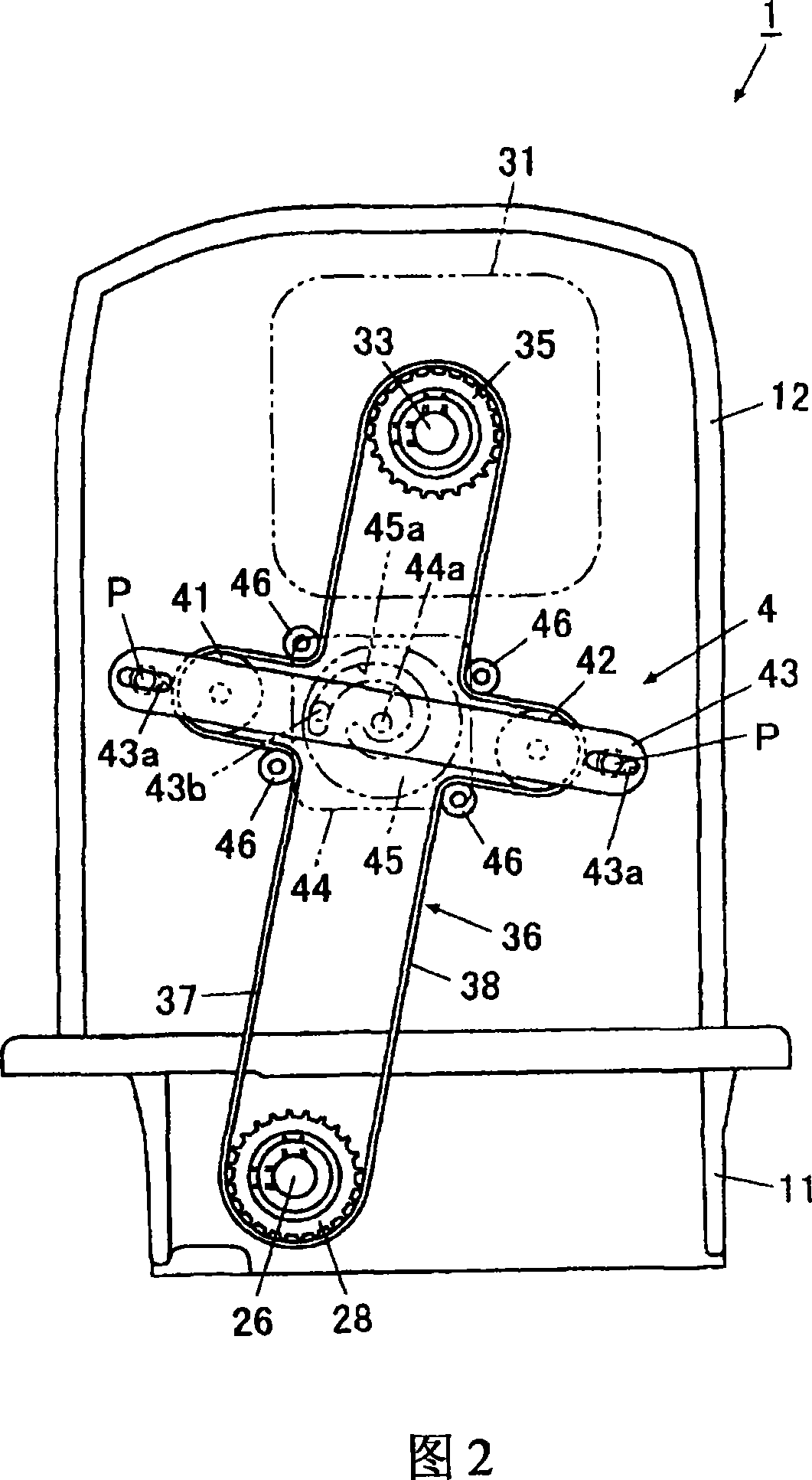

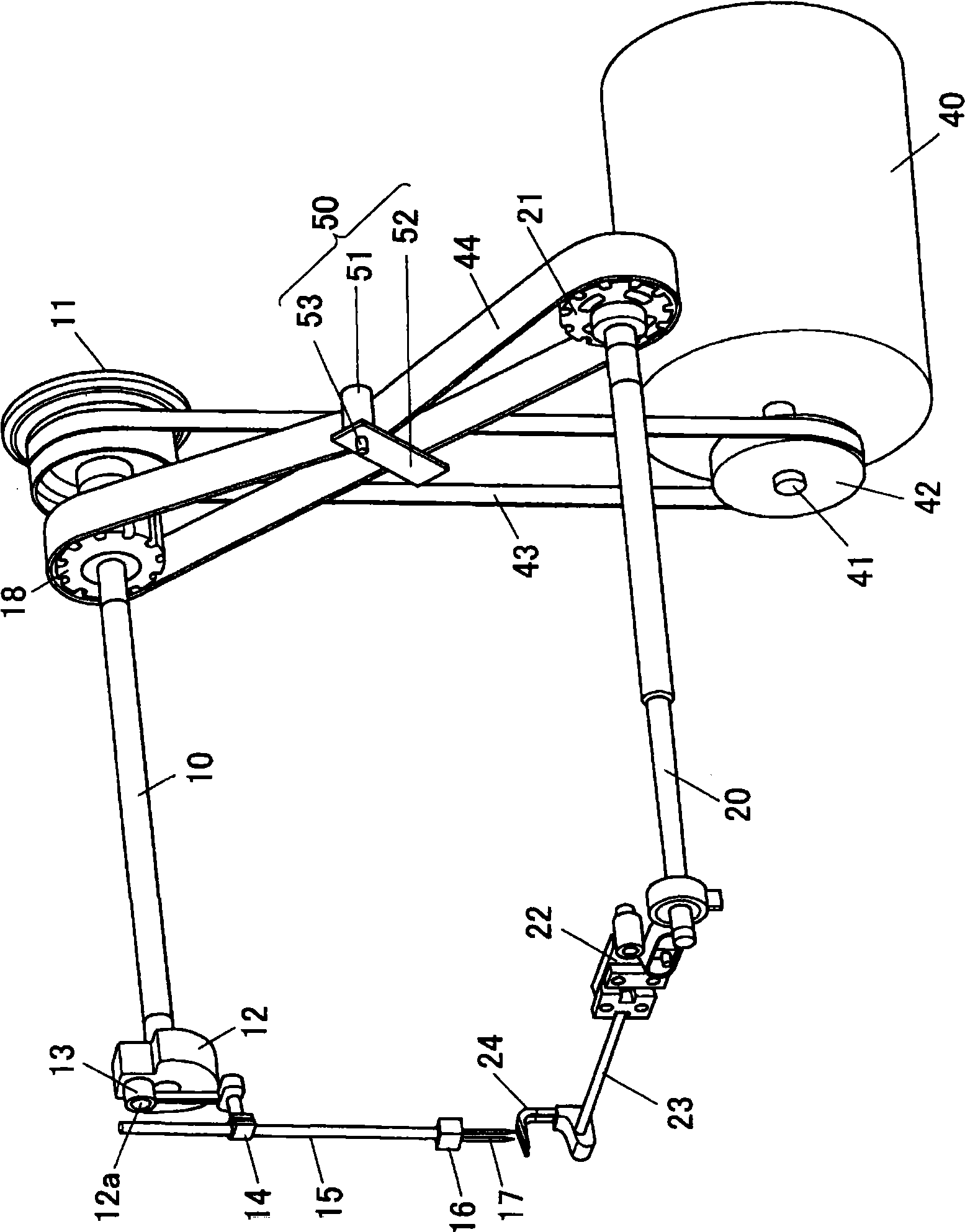

Ring sewing machine

InactiveCN101545182AImprove workabilityEliminate loosenessNeedle barsLoop takersEngineeringSewing machine

The invention provides a ring sewing machine which preventing loosening of looper, and enhancing workability of threading through looper in the mean time. The ring sewing machine comprises an upper shaft and a lower shaft which are disposed parallel to each other; a ring shaped synchronous belt, which is disposed between the upper shaft and the lower shaft and delivers rotation thereof to the lower shaft; a needle rod, which is connected to the upper shaft and swings cooperatively with the rotation of the upper shaft; and a looper shaft, which is connected to the lower shaft, and swings cooperatively with the rotation of the lower shaft. The ring sewing machine comprises a tension applying means including two belt wheels, which are arranged on external side of the synchronous belt with the synchronous belt clamped therein; and a substrate for supporting two belt wheels, which is capable of moving on the direction intersecting the line formed by connecting the upper shaft core and lower shaft core.

Owner:JUKI CORP

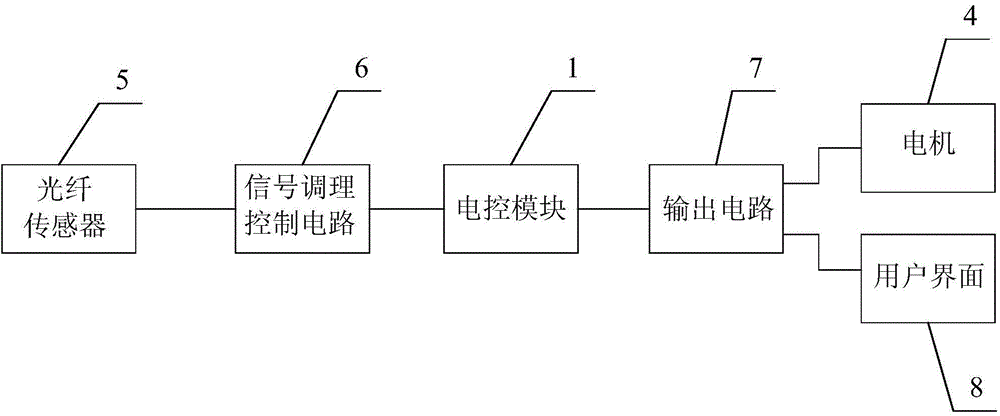

Bottom wire detection control system and method based on optical fiber sensor and applied to industrial sewing machine

ActiveCN104372538AImprove detection accuracyGuaranteed reliabilityBobbin-winding devicesLoop takersBobbinEngineering

The invention provides a bottom wire detection control system based on an optical fiber sensor and applied to an industrial sewing machine. The system comprises an electric control module, a rotating shuttle and a motor. The rotating shuttle comprises a shuttle case and a shuttle core. The shuttle core comprises a winding post and flanges arranged at the two ends of the winding post. A reflective sheet is fixed to the outer circumferential face of the winding post, and bottom wires are wound around the winding post. The optical fiber sensor is fixed to a shuttle support. The shuttle case is provided with an optical fiber emitter inlet and a gap, wherein the optical fiber emitter inlet and the gap are communicated with each other. The optical fiber sensor is connected with the electric control module through a signal conditioning control circuit. The electric control module is also connected with the motor through an output circuit. The bottom wire detection control system applied to the industrial sewing machine can judge whether the shuttle core is not installed in the shuttle case and whether the bottom wires on the shuttle core are enough according to optical signals of reflected light detected by the optical fiber sensor; meanwhile, the optical fiber sensor is adopted as a detection element, so that the system is high in sensitivity, higher and more reliable in detection performance and higher in anti-electromagnetic-interference capability.

Owner:BULLMER ELECTROMECHANICAL TECH

Thread adjusting device of sewing machine

InactiveCN101372796AStable tensionCircumference difference achievedSewing-machine control devicesTensioning devicesCotton materialSewing machine

This invention provides a thread adjusting device of sewing machine, which is capable of stably giving minute tension to the top thread provided to the needle through a balance, and is capable of sewing thin cloth, soft cloth with good quality but without generating stitch defect. The thread adjusting device comprises an auxiliary thread adjusting device for giving preparation tension to the top thread provided to a rotation resistance main thread adjusting device (4), including: a rotary cylinder (51) that winds and keeps several rings top threads in the peripheral width direction in a spaced way, an extruding spring (53) applying thrust to the rotary cylinder (51) and a regulating knob that adjusts the spring of the extruding spring (53). In addition, a guide groove is formed in a thread passage component (8) extending in the width direction of the rotation cylinder (41). The top thread (2) wound on the rotation cylinder (51) is hanged in the guide groove. The perimeter of the top thread (2) is gradually shortened from the thread supply source to the main thread adjusting device (4).

Owner:YAMATO SEWING MASCH MFG CO LTD

Sewing machine

A sewing machine includes an upper looper formed with a thread hole, an upper looper shaft which oscillates the upper looper between an upper position and a lower position, switching means operable to switch a coupled state and a decoupled state between the upper looper and the upper looper shaft, moving means for moving the upper looper, which has been decoupled from the upper looper shaft by the switching means, to the lower position, a thread guiding pipe formed with a thread discharging port, and first operating means operable to decouple the upper looper and the upper looper shaft via the switching means, and to move the thread discharging port of the thread guiding pipe to a position at which the thread discharging port is aligned with the thread hole of the upper looper in the lower position.

Owner:JUKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com