Ring sewing machine

A sewing machine and circular sewing technology, which is applied to sewing machine components, needle holders for sewing machines, and ferrule mechanisms for sewing machines, etc., can solve problems such as difficulty in completing threading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

[0075] In addition, the present invention is not limited to the above-mentioned embodiment. For example Picture 9 As shown, the following tension applying device 60 can also be used, which can adjust the fixed position of at least one pulley 61a of the two pulleys 61a and 61b along the moving direction of the base 62. Specifically, on the base 62, a groove 62a is formed along the moving direction of the base 62. A guide pin 63 is erected on the bottom surface of the pulley 61a on one side. The guide pin 63 is formed to be inserted into the groove 62a, and a threaded groove is formed on the surface. A fastening member such as a nut 64 is fitted into the guide pin 63 from the back side of the base 62, and after adjusting the position of the guide pin 63 in the groove 62a, the position of the pulley 61a can be fixed by tightening with the nut 64. The mounting of the base 62 with respect to the cover 45 is to insert a guide pin 65 standing on the base 62 with a threaded groove formed...

Deformed example 2

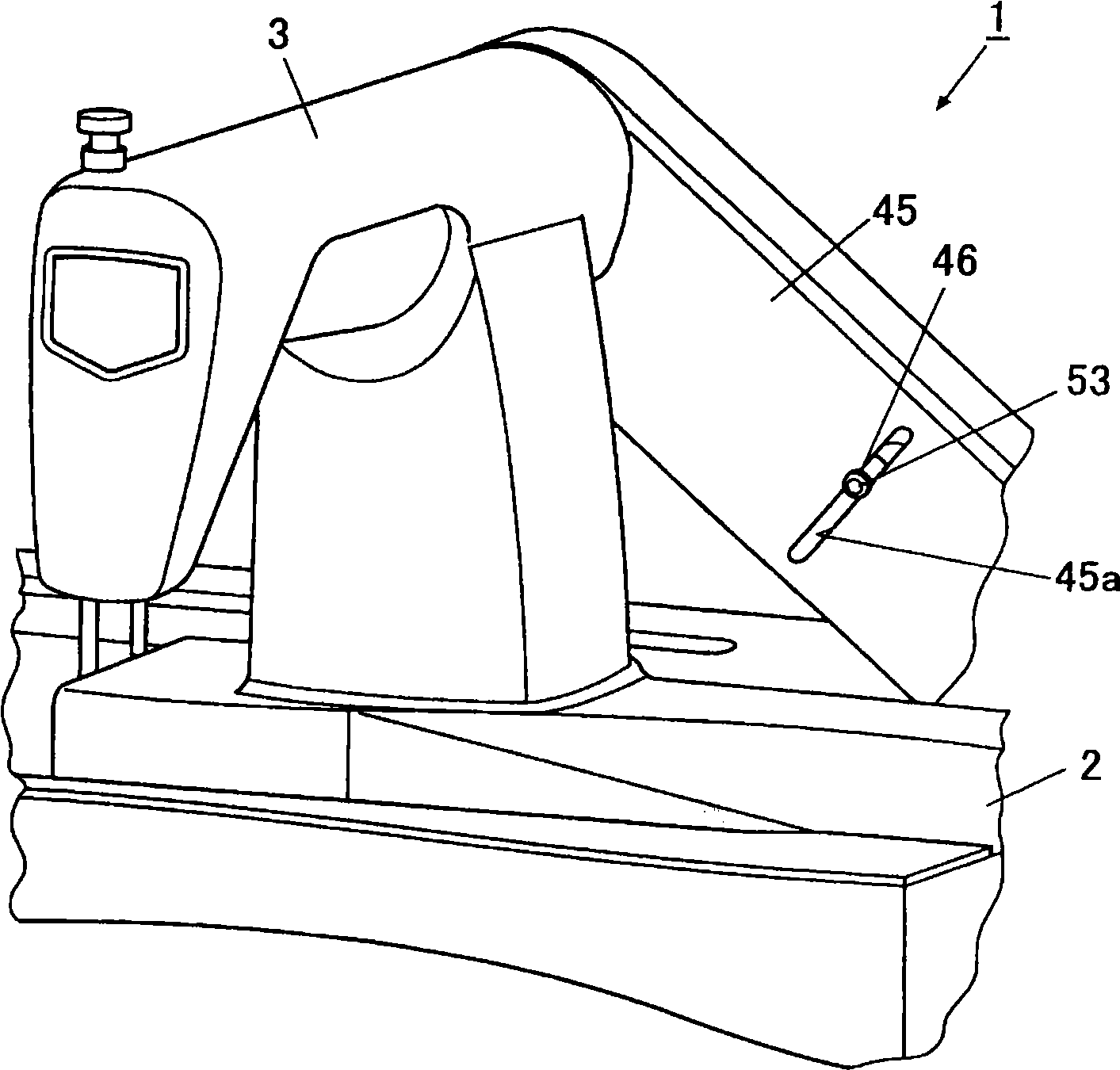

[0080] In addition, such as Picture 11 As shown, it is also possible to provide a stopper 70 at the initial position of the tension applying device 50 in the sewable state, which abuts against the aforementioned base 52 in the moving direction of the tension applying device 50. Specifically, in the state before the phases of the needle 17 and the looper 24 are shifted (the state where the pulley applies appropriate tension to the timing belt), a stopper 70 is provided on the outer cover 45, which is on the base The initial position of 52 abuts the base 52. The stopper 70 only needs to be present on the movement path of the base 52 that can move along the adjustment groove 45a, and it may be formed in any manner.

[0081] By adopting the above structure, after the base 52 is moved to move the looper 24 away from the needle 17 and the thread is threaded, when returning to the original sewable state, the user only needs to move the base 52 to abut the stopper 70 The location can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com