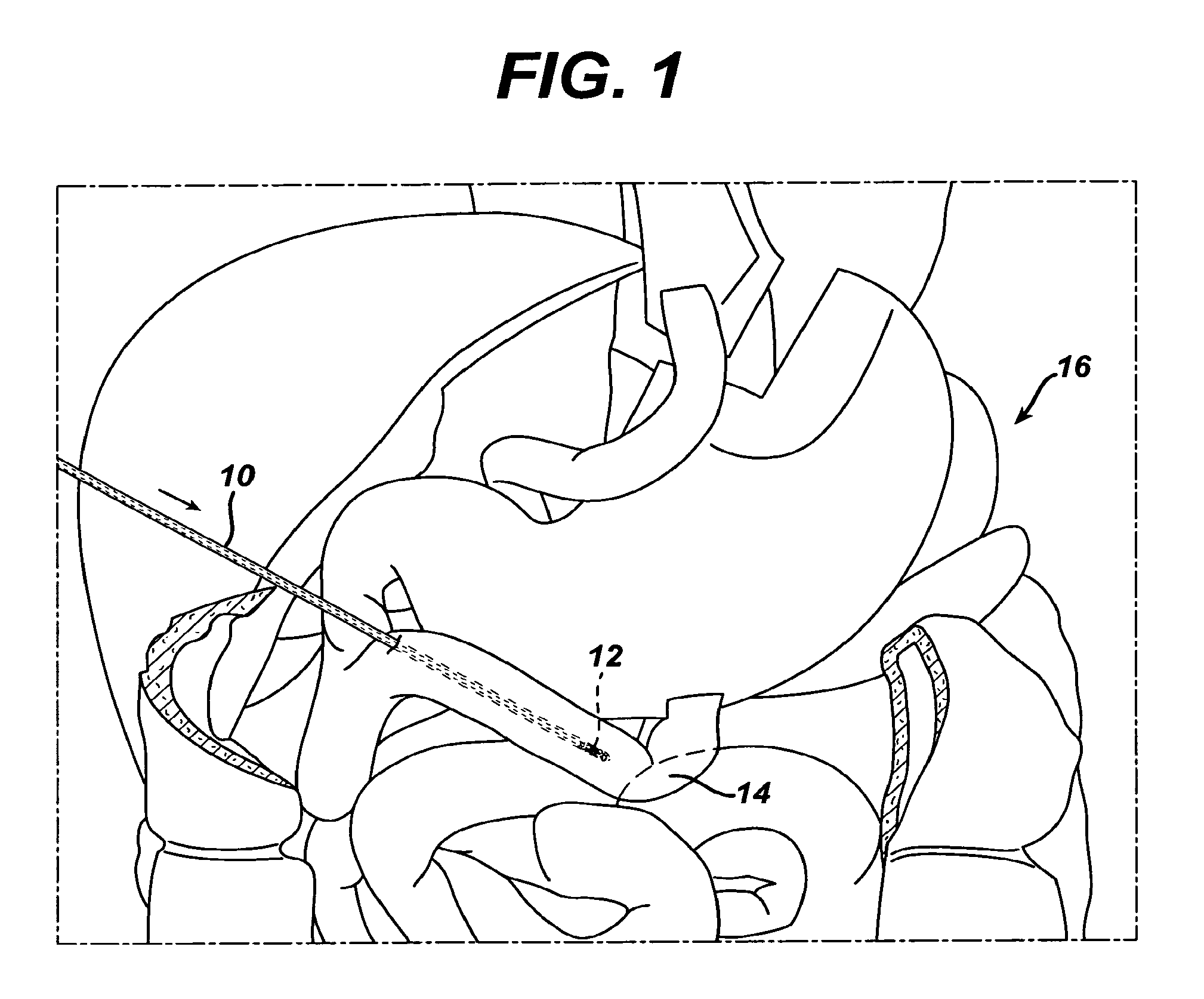

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1040 results about "Ring device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

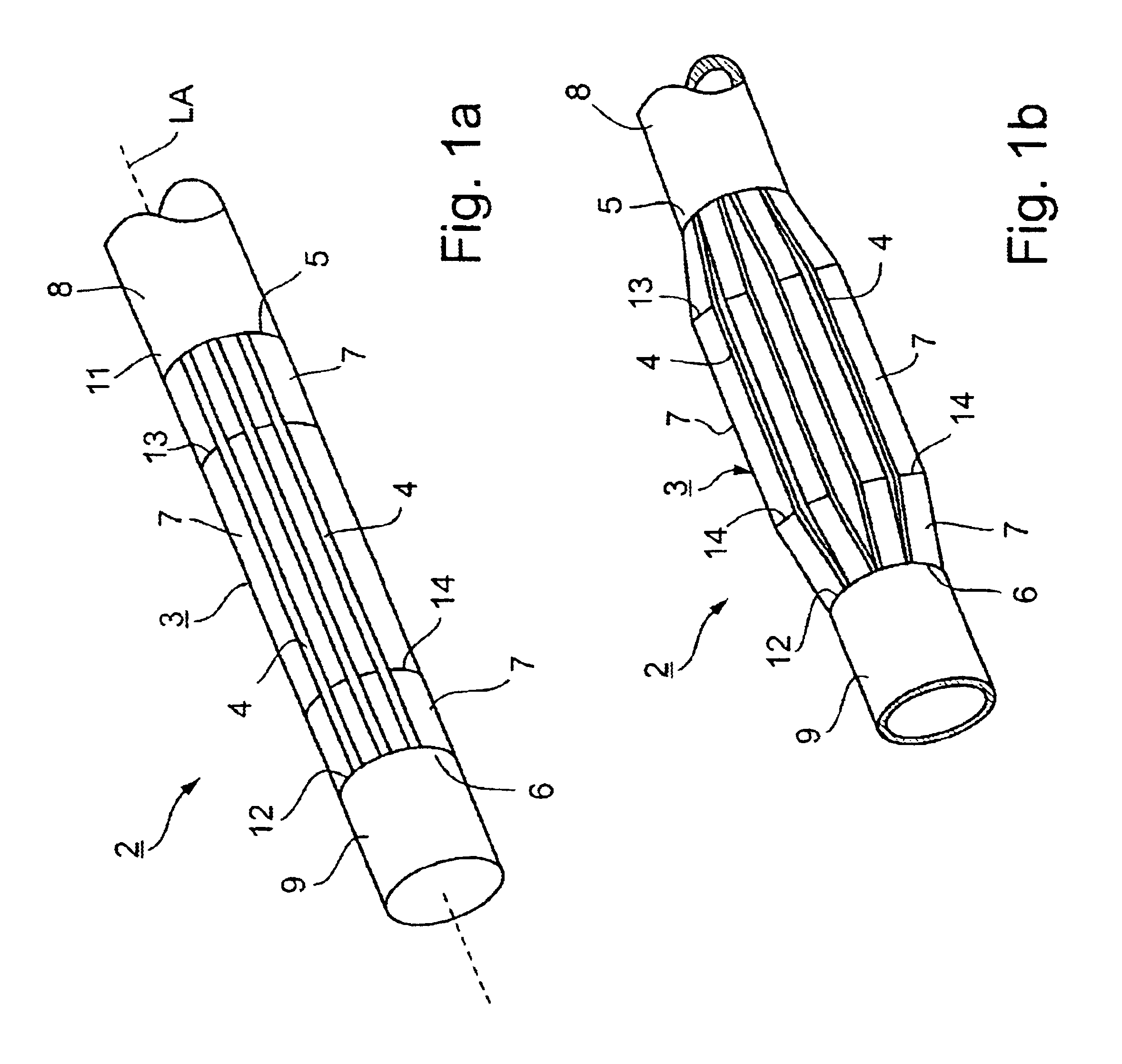

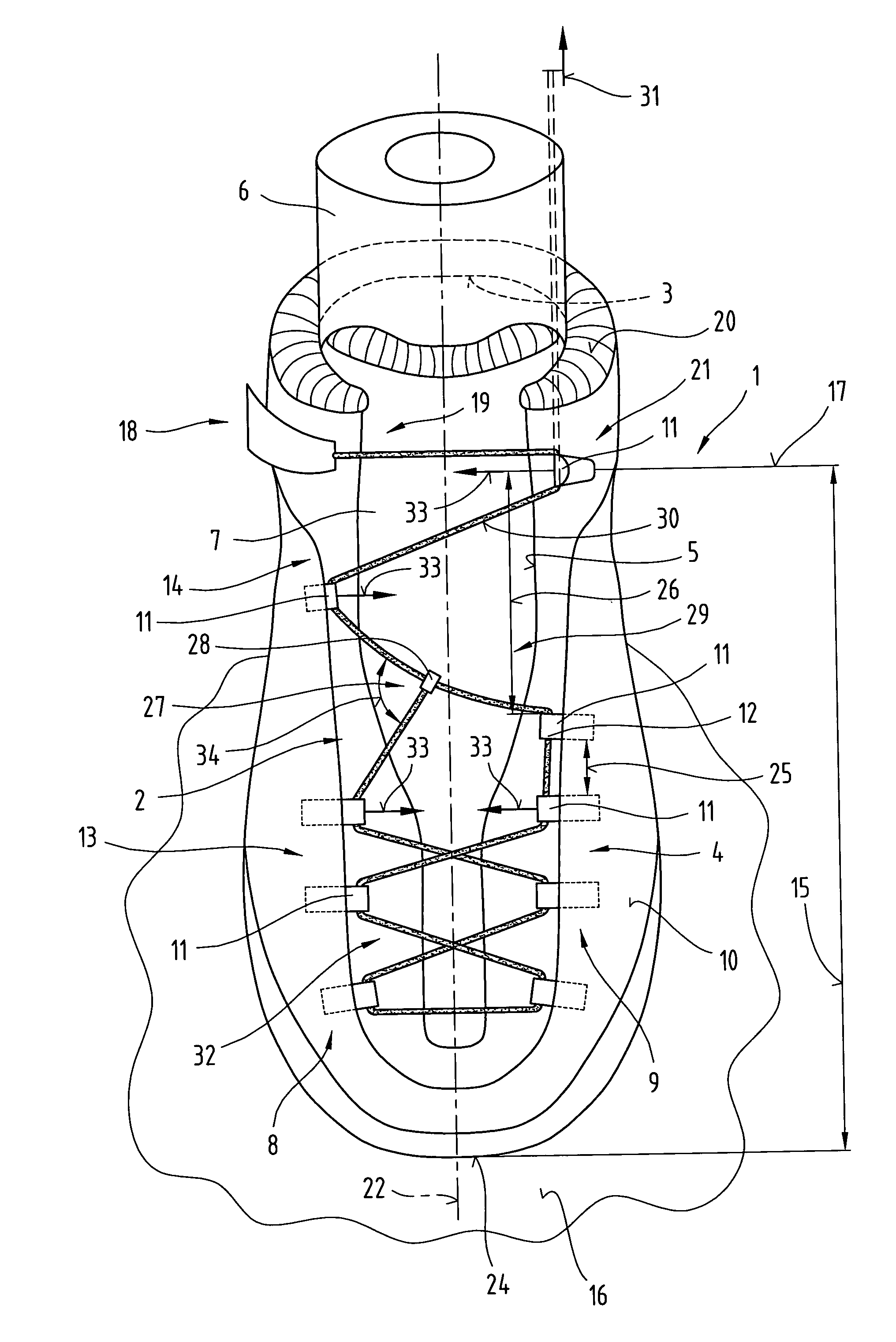

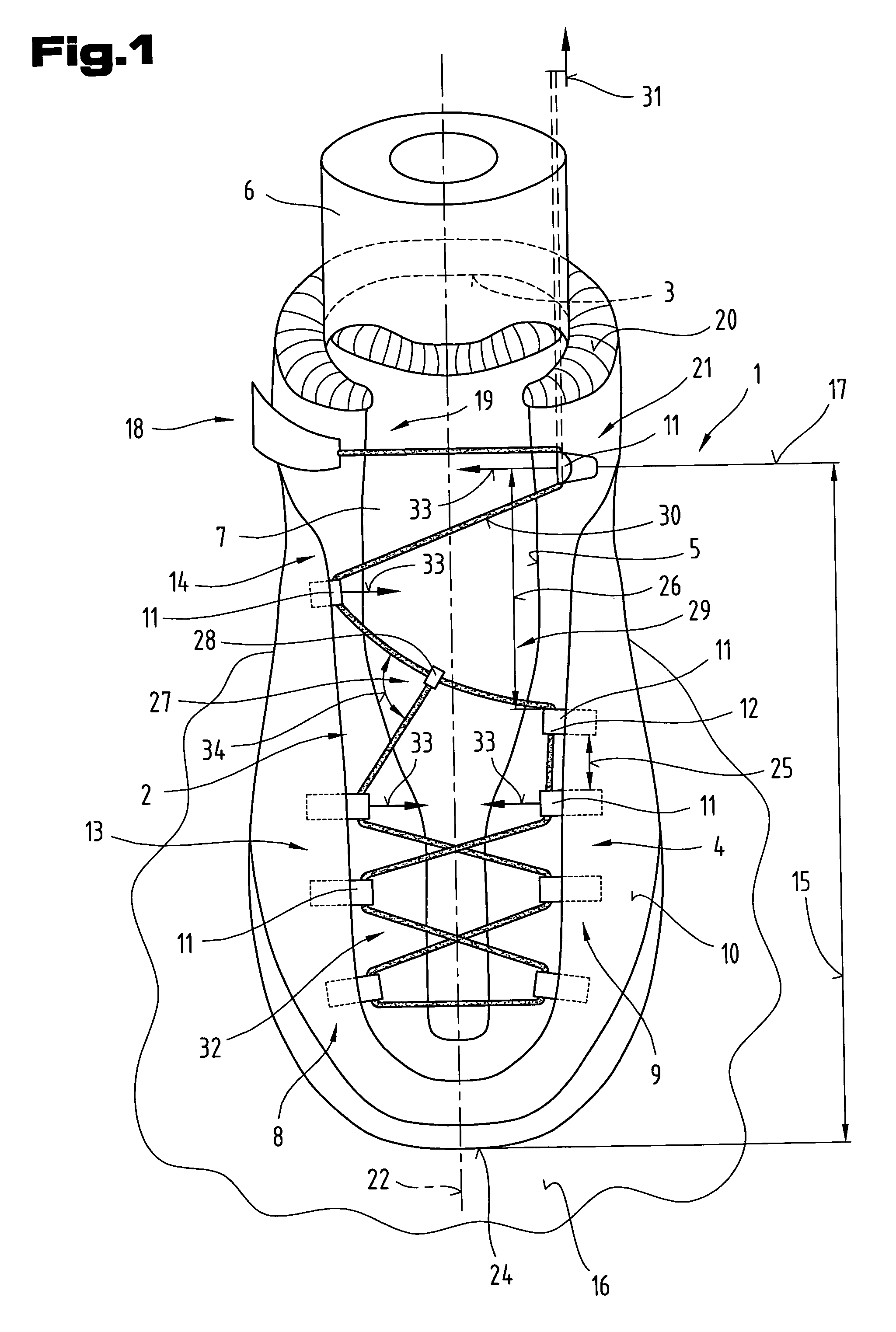

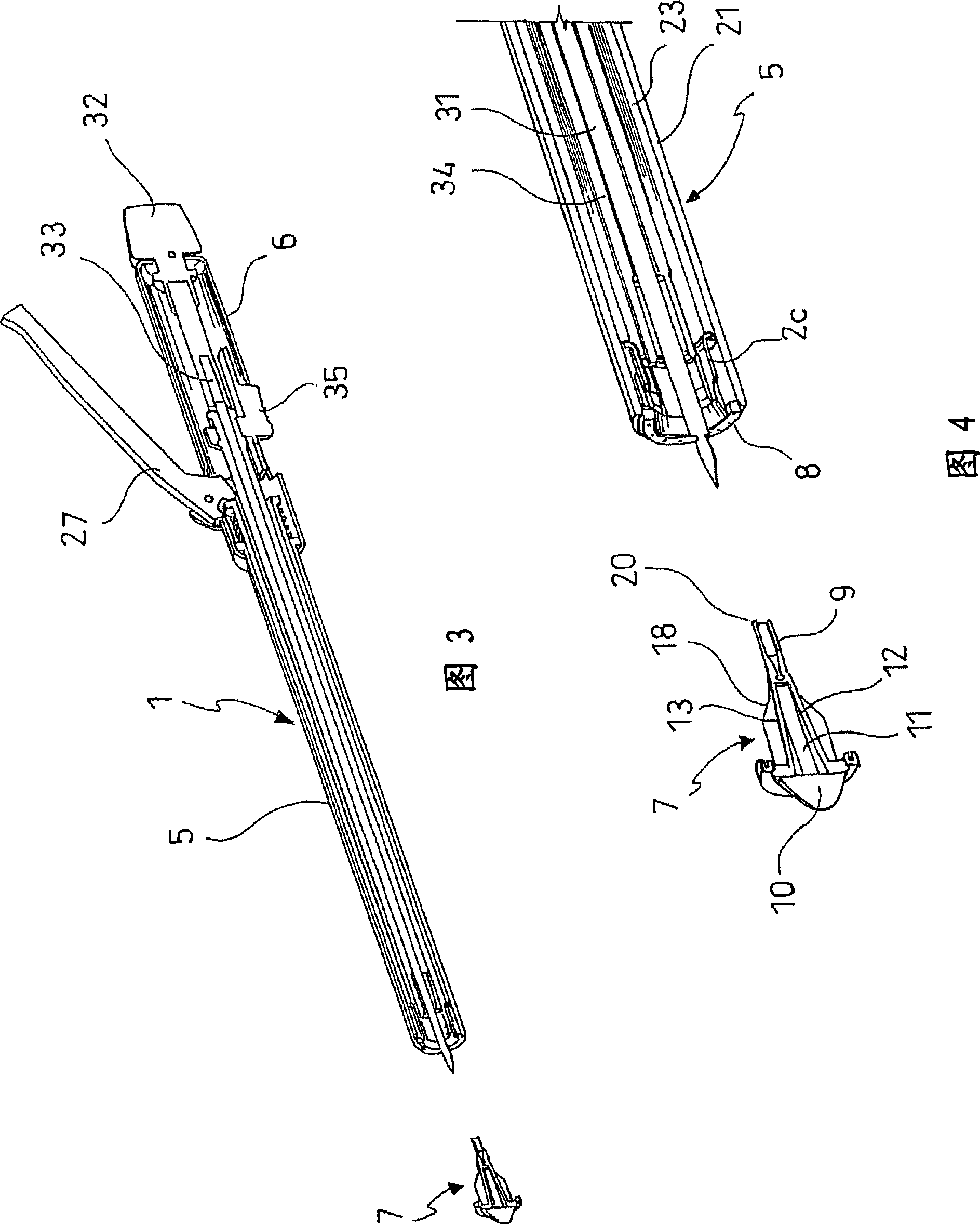

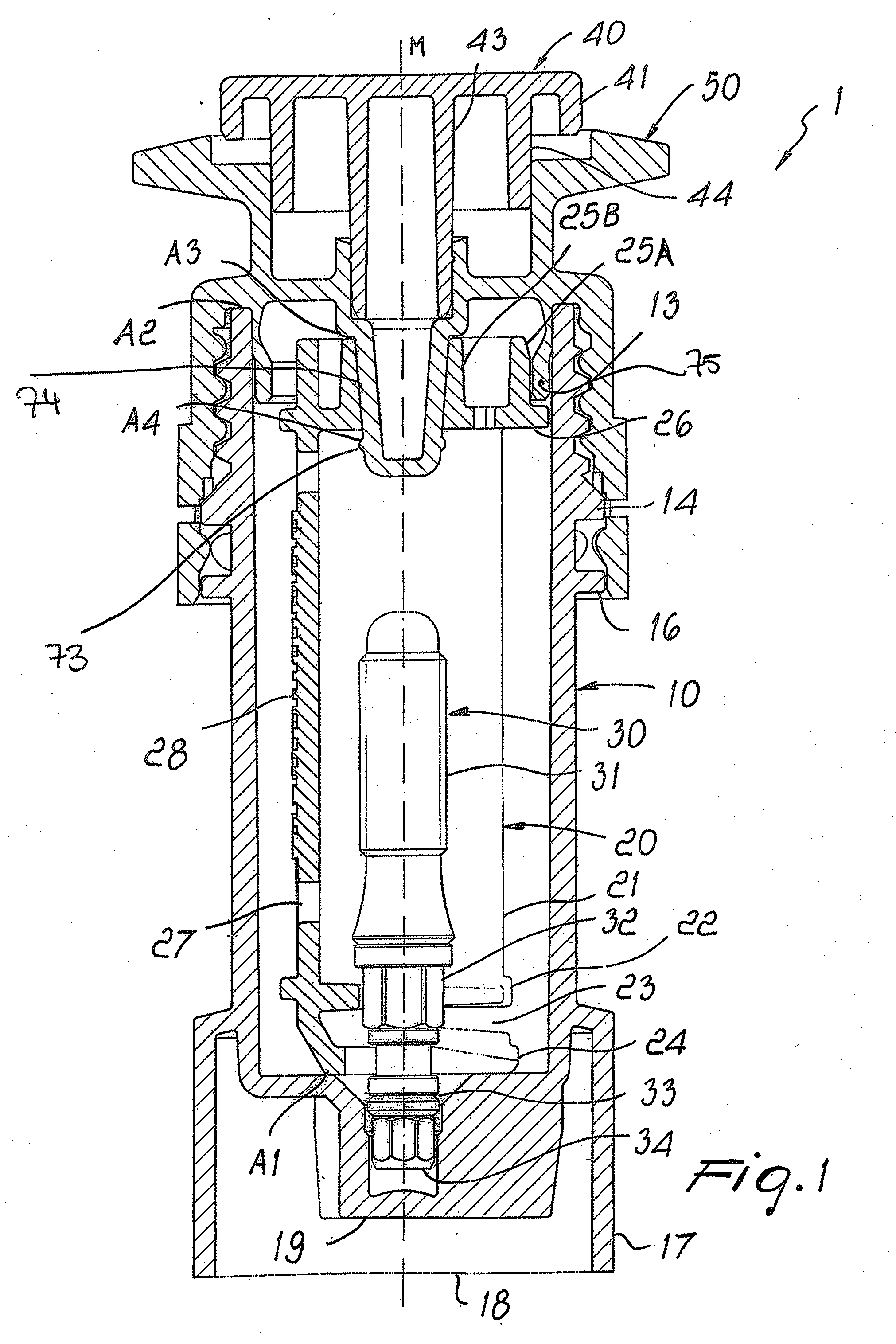

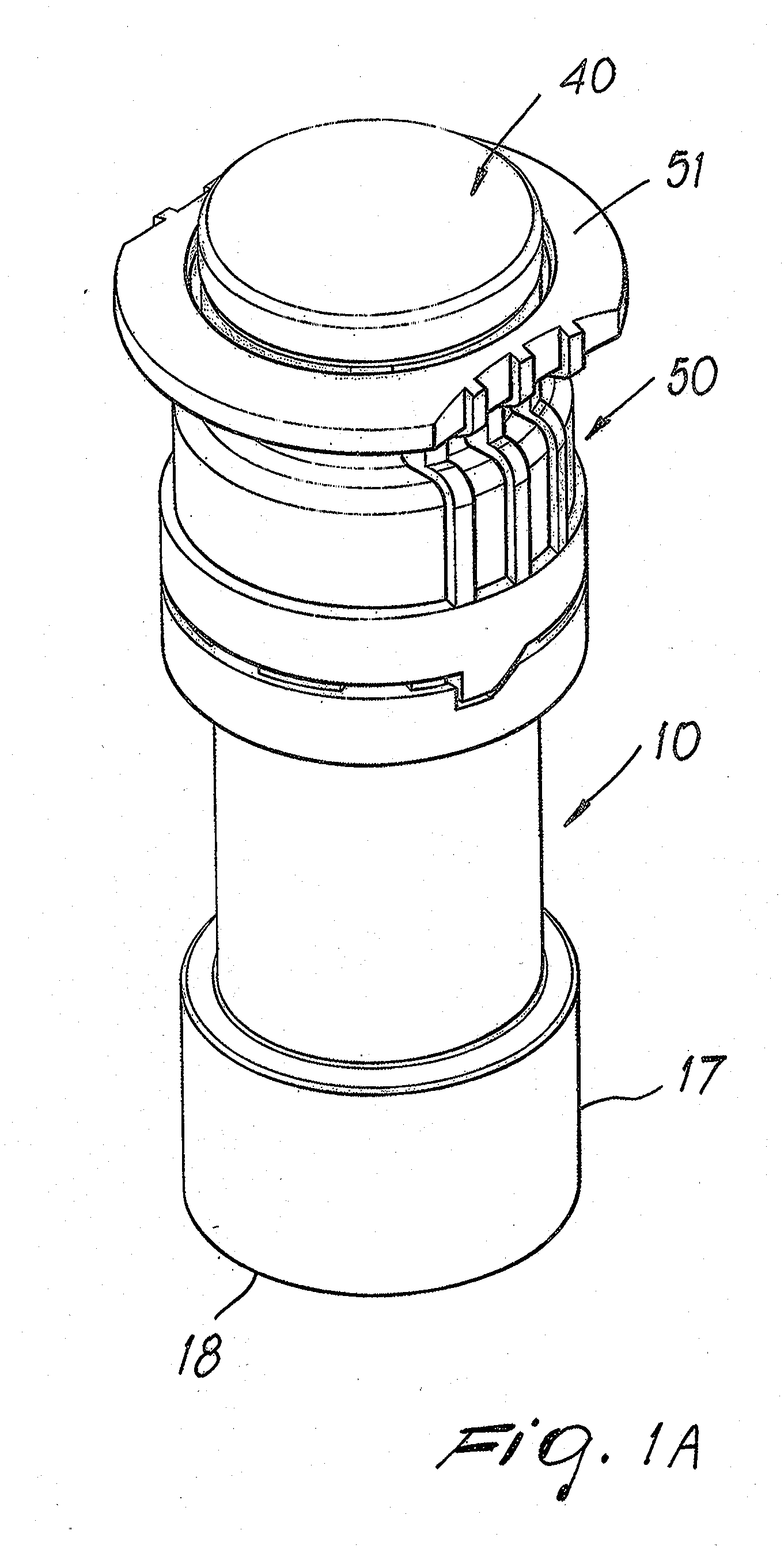

Expandable delivery appliance particularly for delivering intravascular devices

A delivery appliance for delivering an expandable annular device, particularly an expandable intravascular device, to a desired location in a lumen, includes an annular array of supporting strips extending from a proximal end of the annular array to a distal end of the annular array, to define an annular supporting surface for the expandable annular device. Each of the supporting strips is laterally deformable to radially expand or radially contract the annular array and the annular supporting surface defined thereby. A connecting stem passes through the annular array of supporting strips and has a distal end coupled to the supporting strips at the distal end of the annular array for axial movement therewith, and a proximal end passing through the proximal end of the annular array of supporting strips for axial movement with respect thereto. The proximal end of the connecting stem is axially movable in opposite directions to move the distal end of the annular array axially away from or towards, the proximal end of the annular array to radially contract or radially expand the annular supporting surface.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

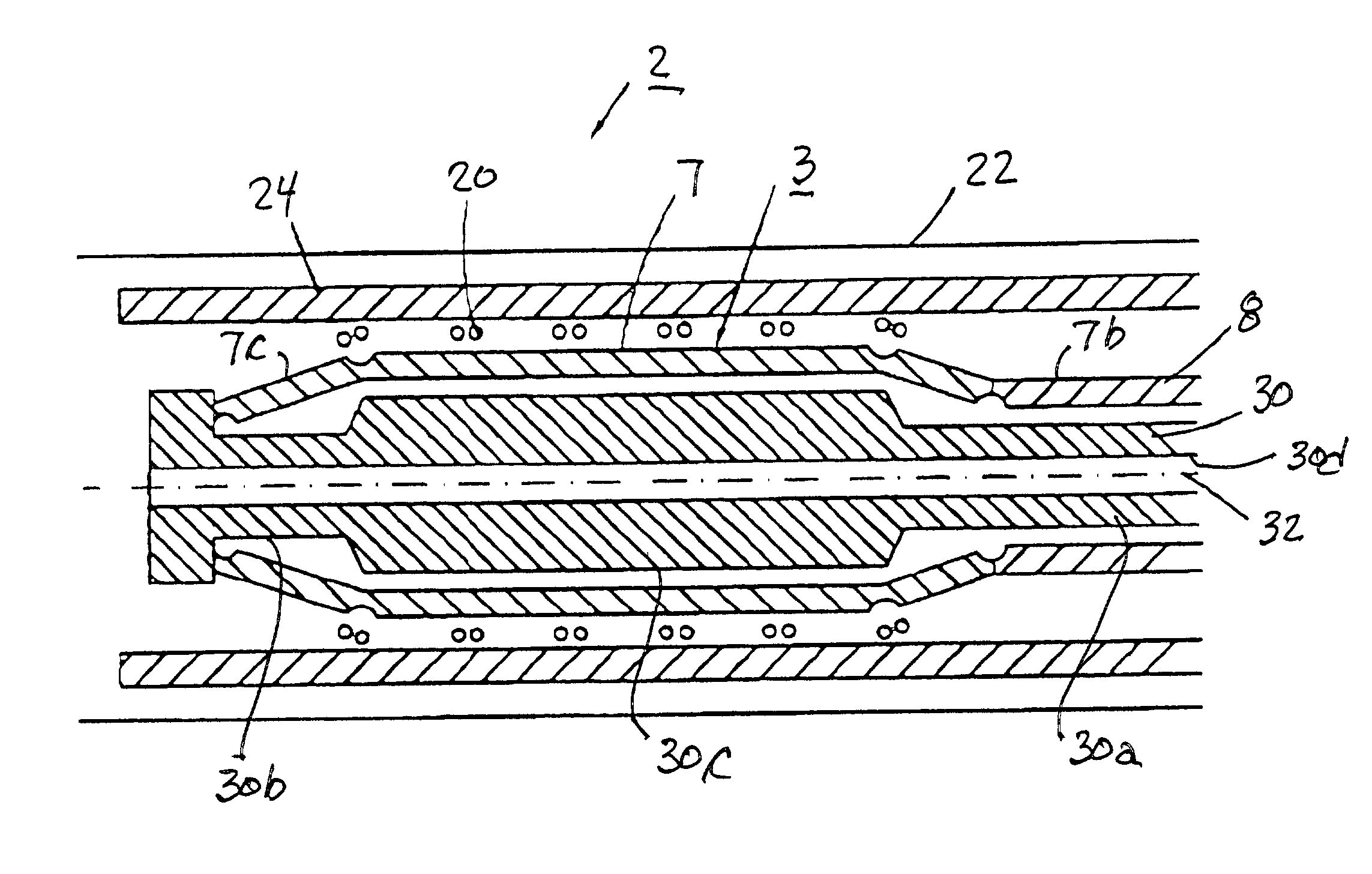

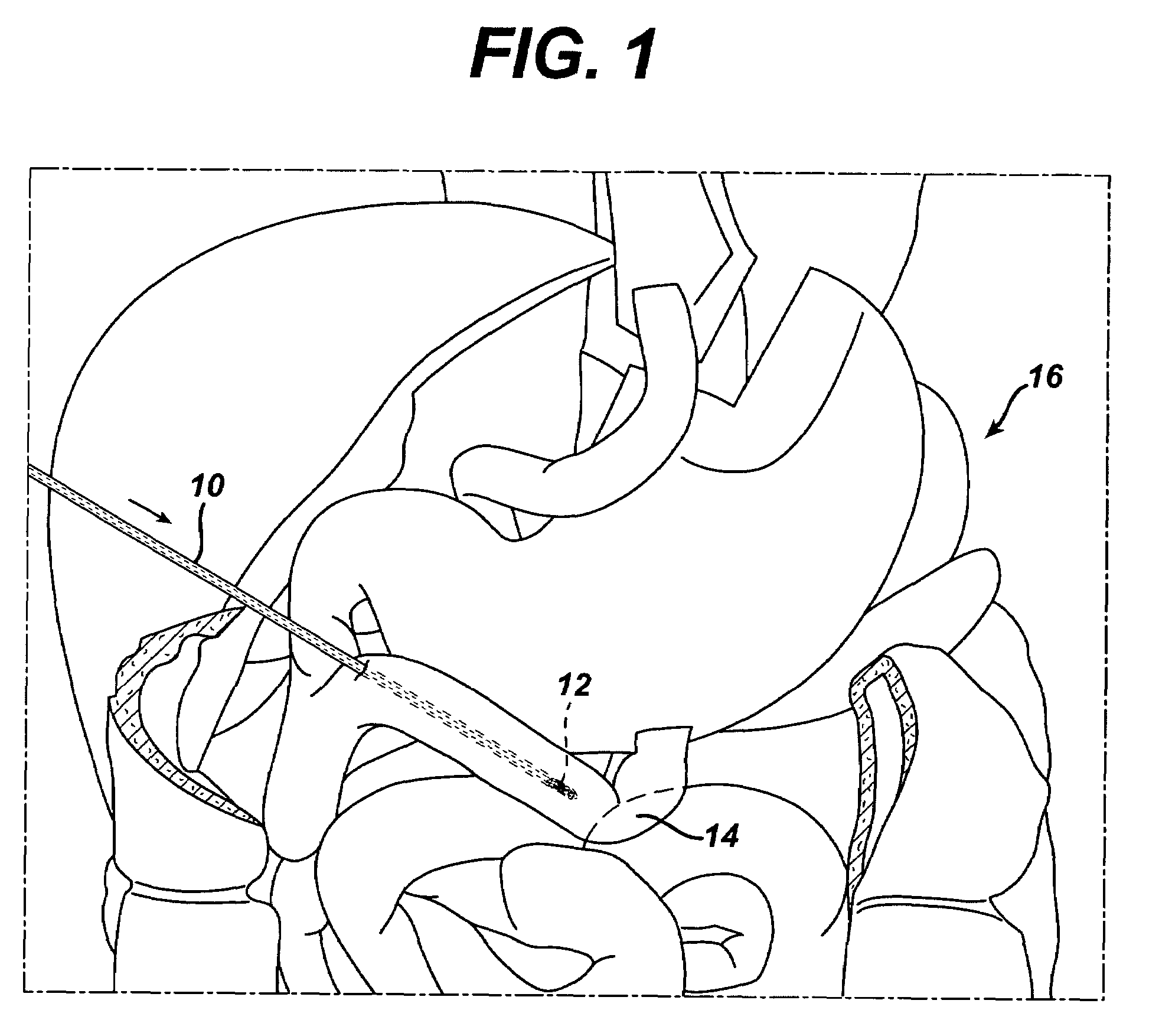

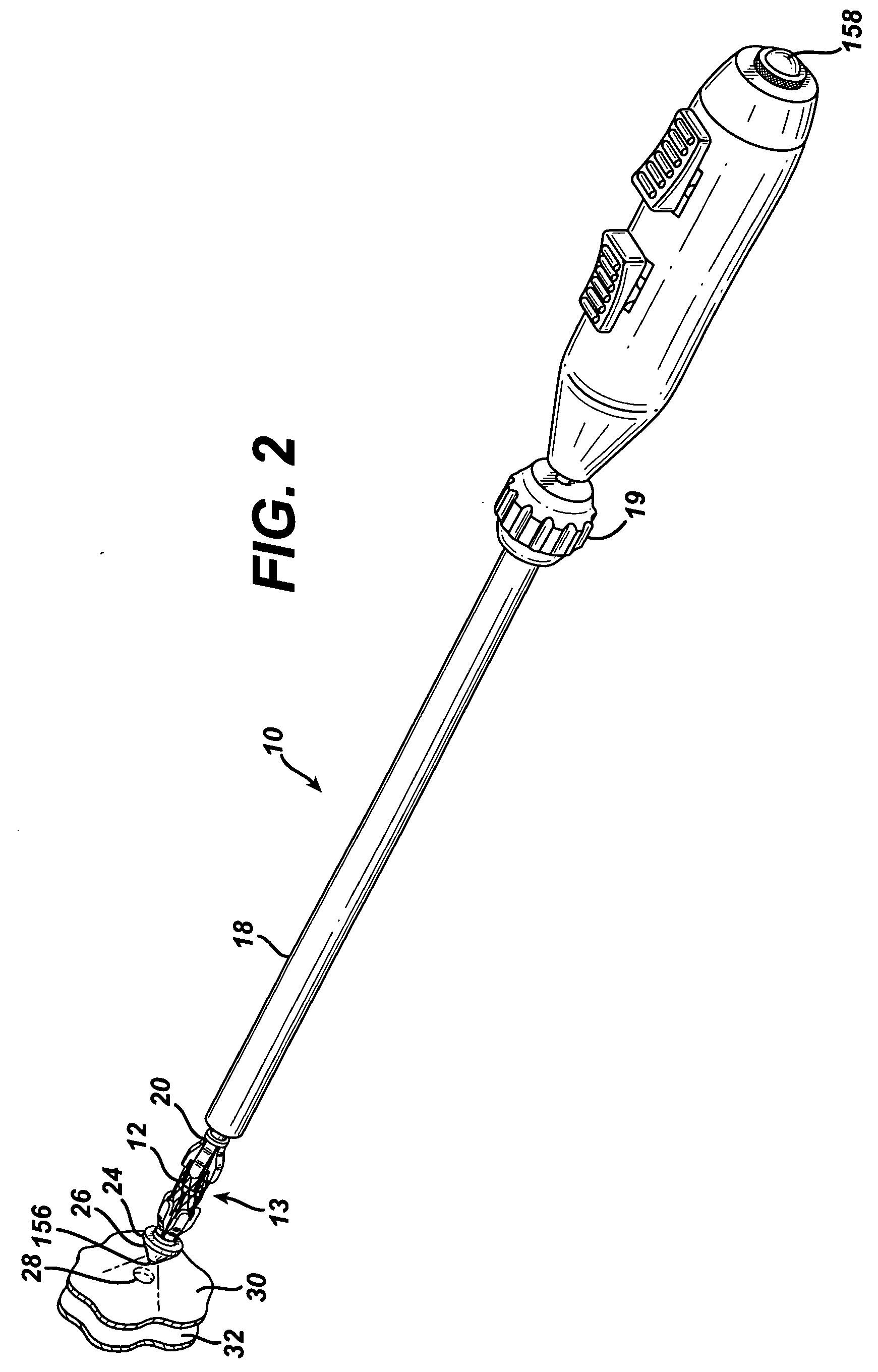

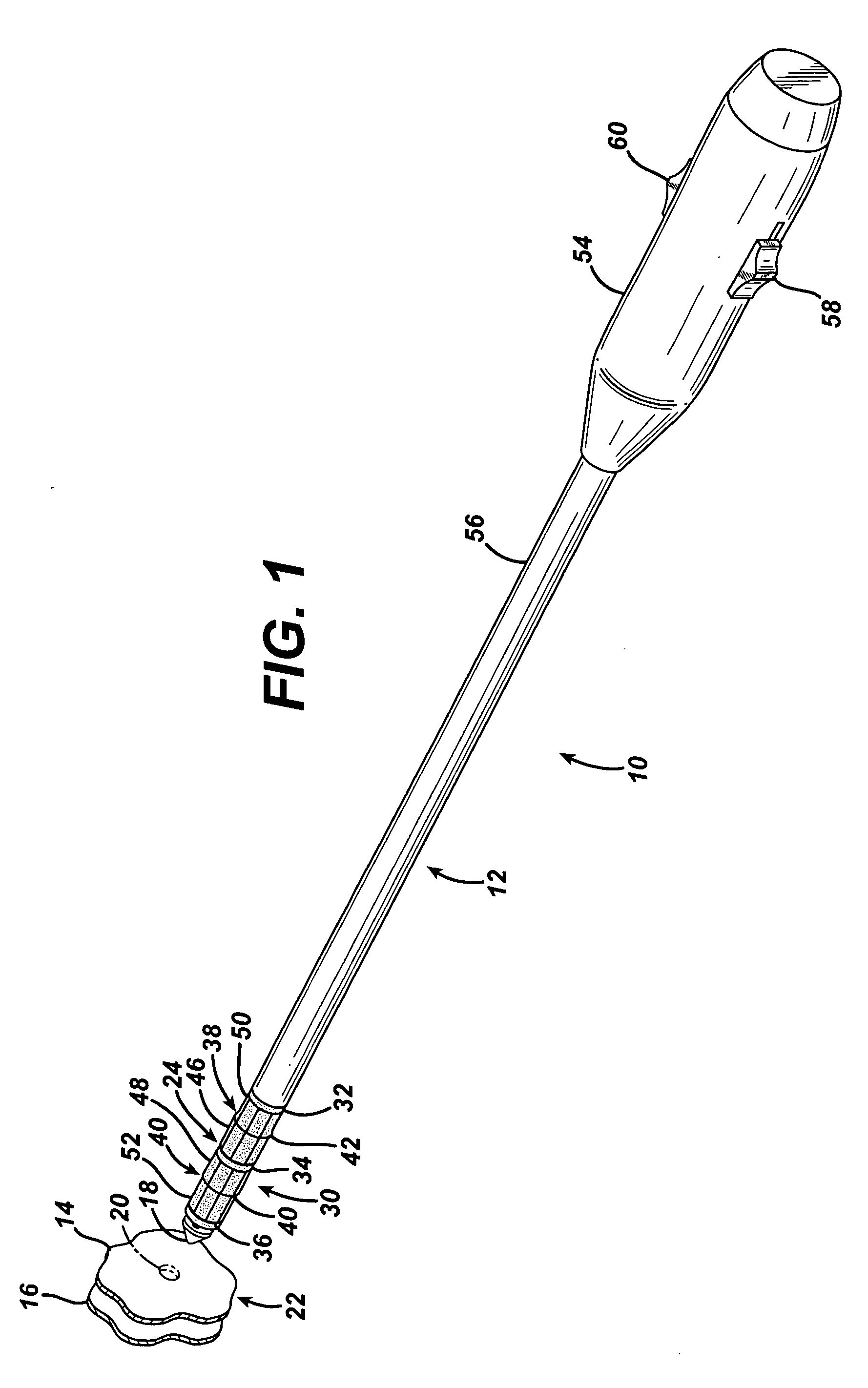

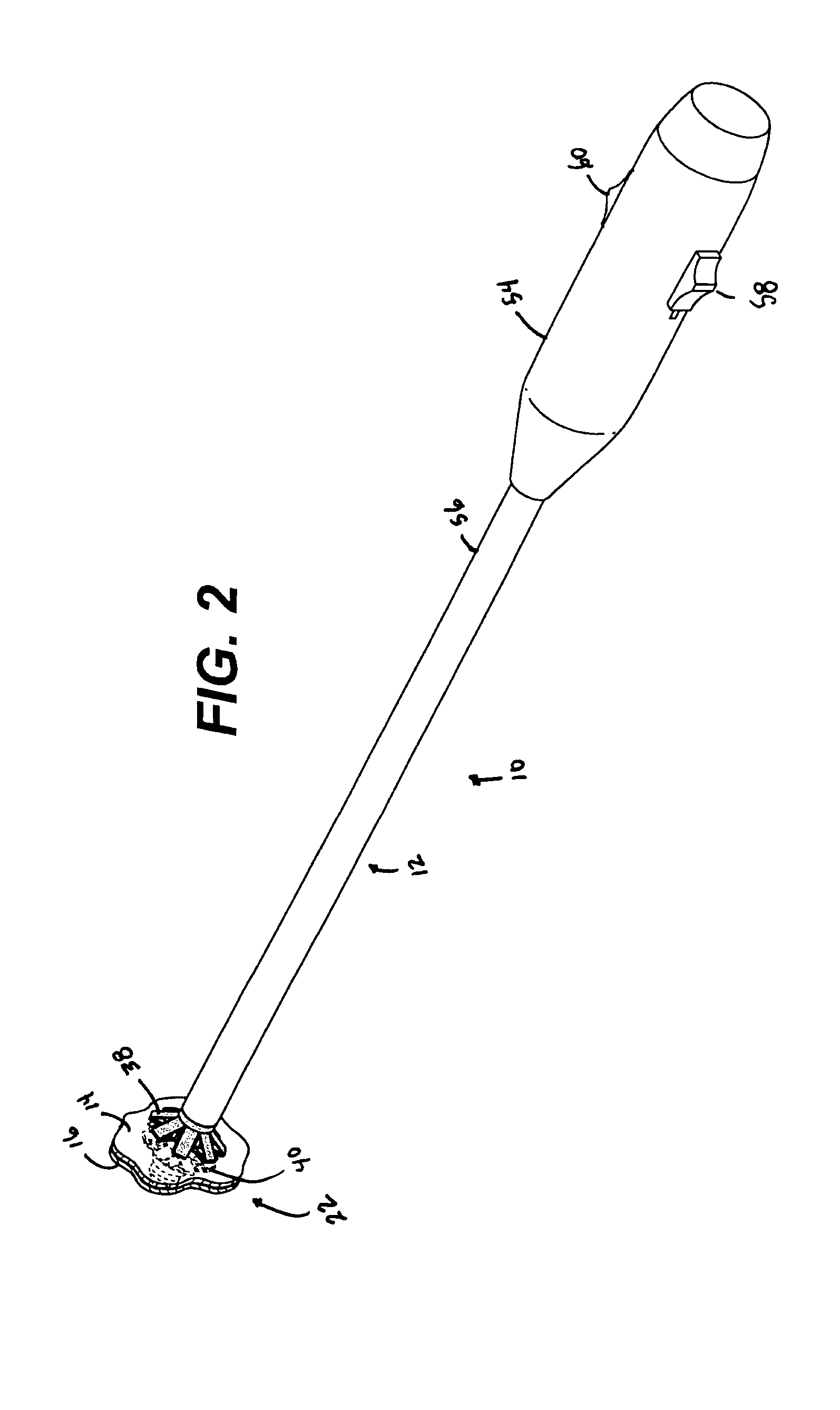

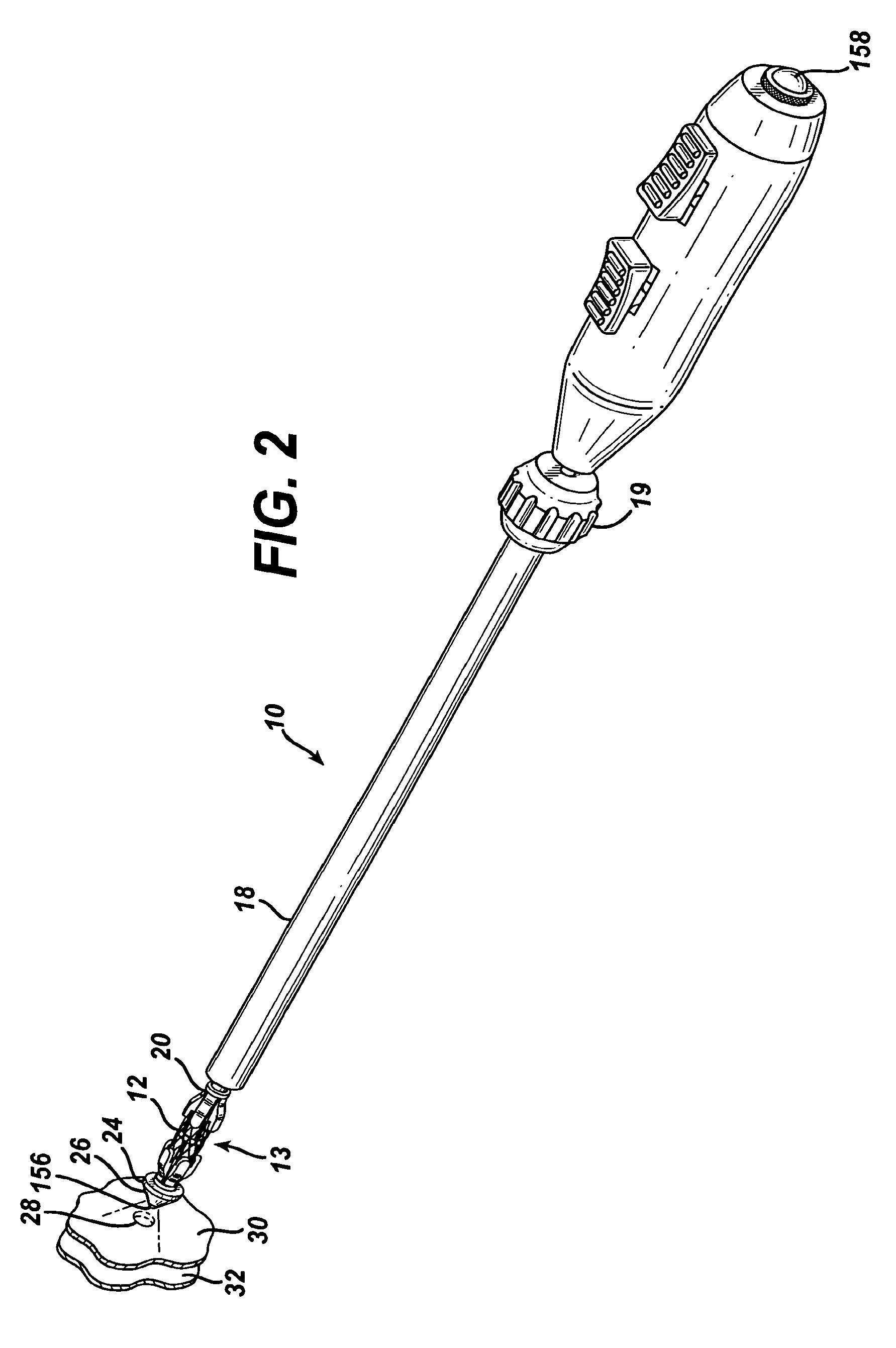

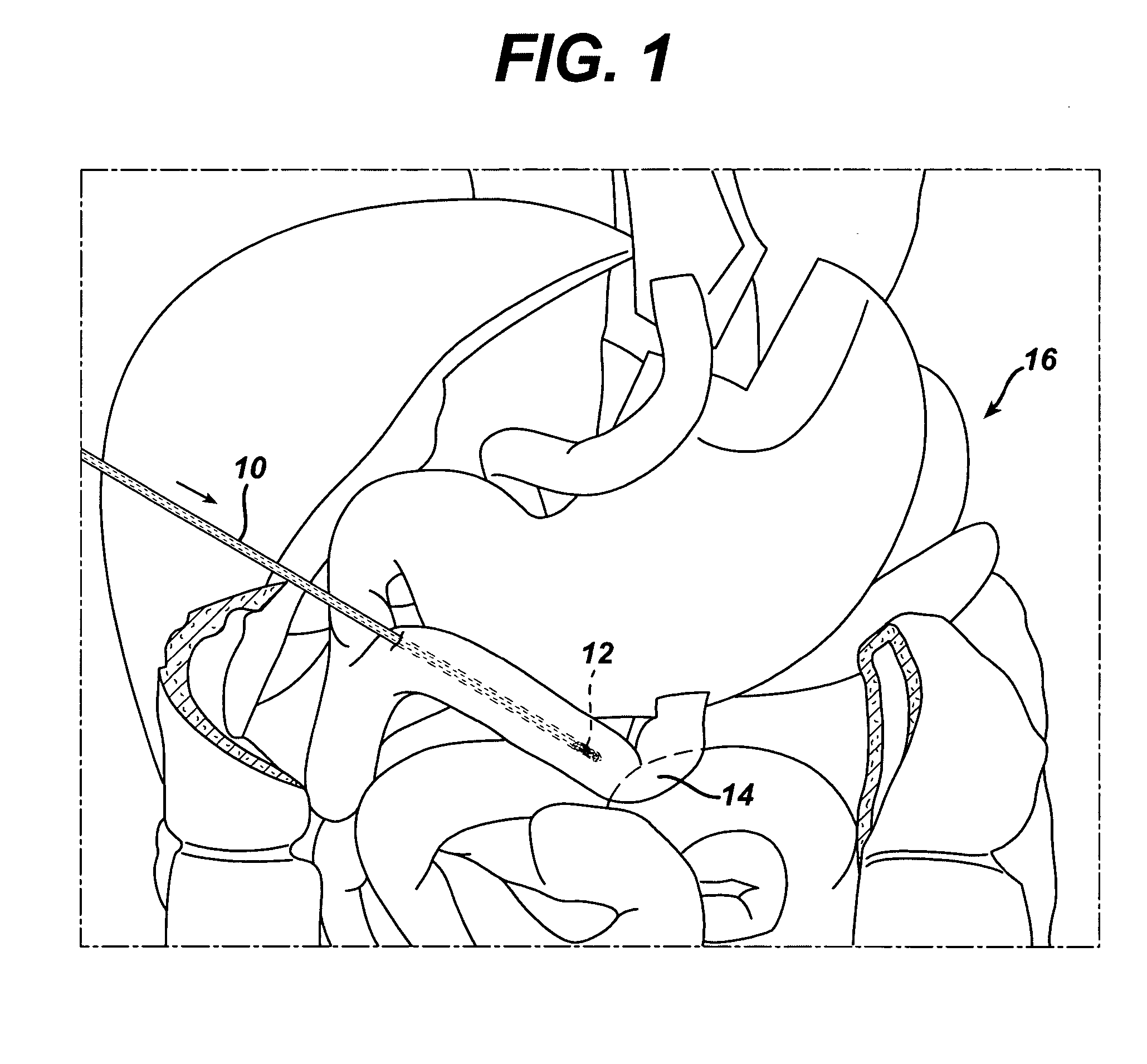

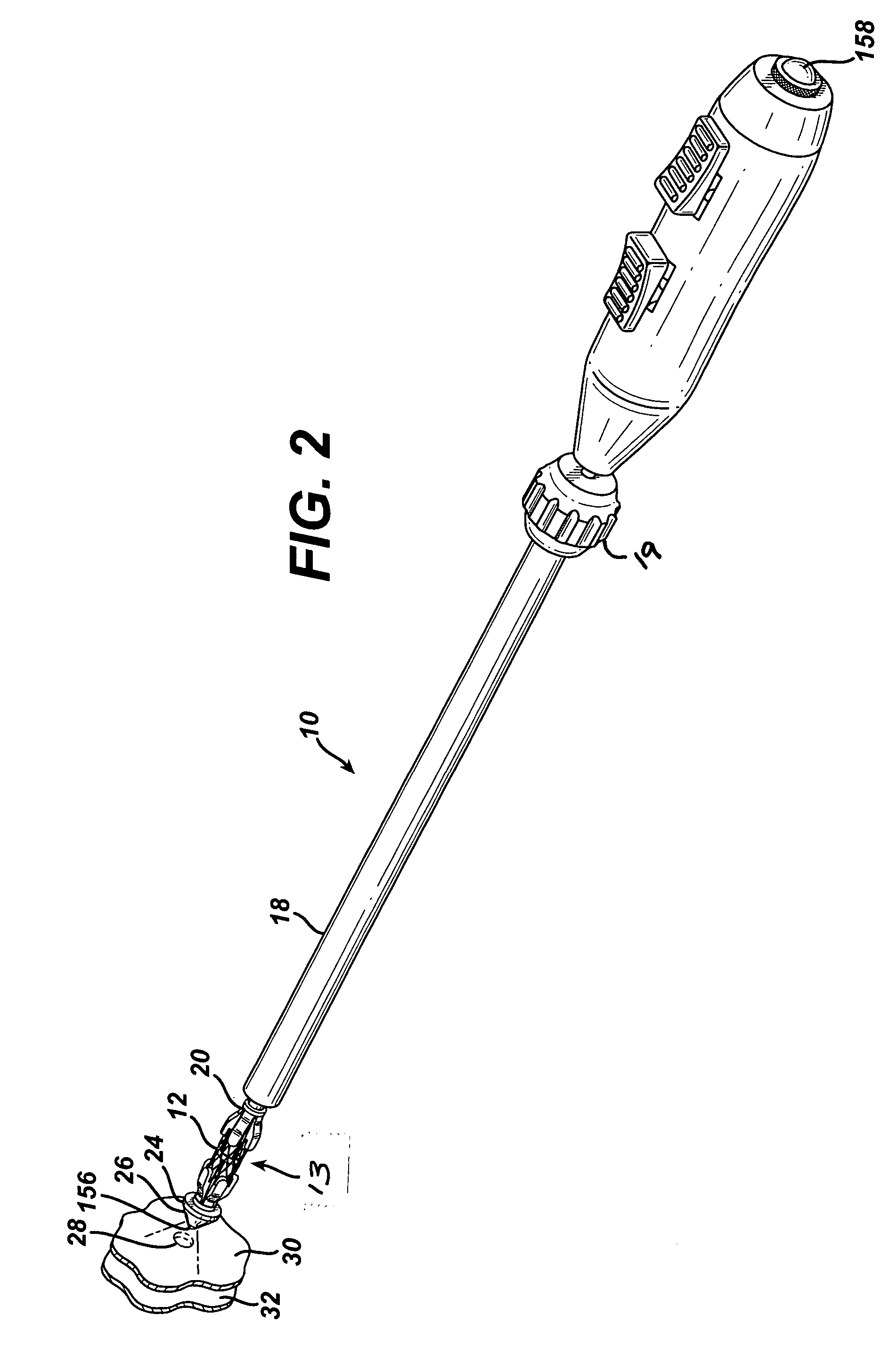

Single lumen anastomosis applier for self-deploying fastener

A surgical tool or applier facilitates laparoscopic or endoscopic implantation through a single bodily tissue lumen of an anastomotic ring device for forming a hollow rivet type of attachment between tissue lumens. In addition to forming a puncture between apposite tissue walls at the anastomosis site, the applier assists or wholly actuates the anastomotic ring device and is retracted to deploy the actuated ring device. Illumination incorporated into a distal portion of a cannula enables confirmation of deployment.

Owner:ETHICON ENDO SURGERY INC

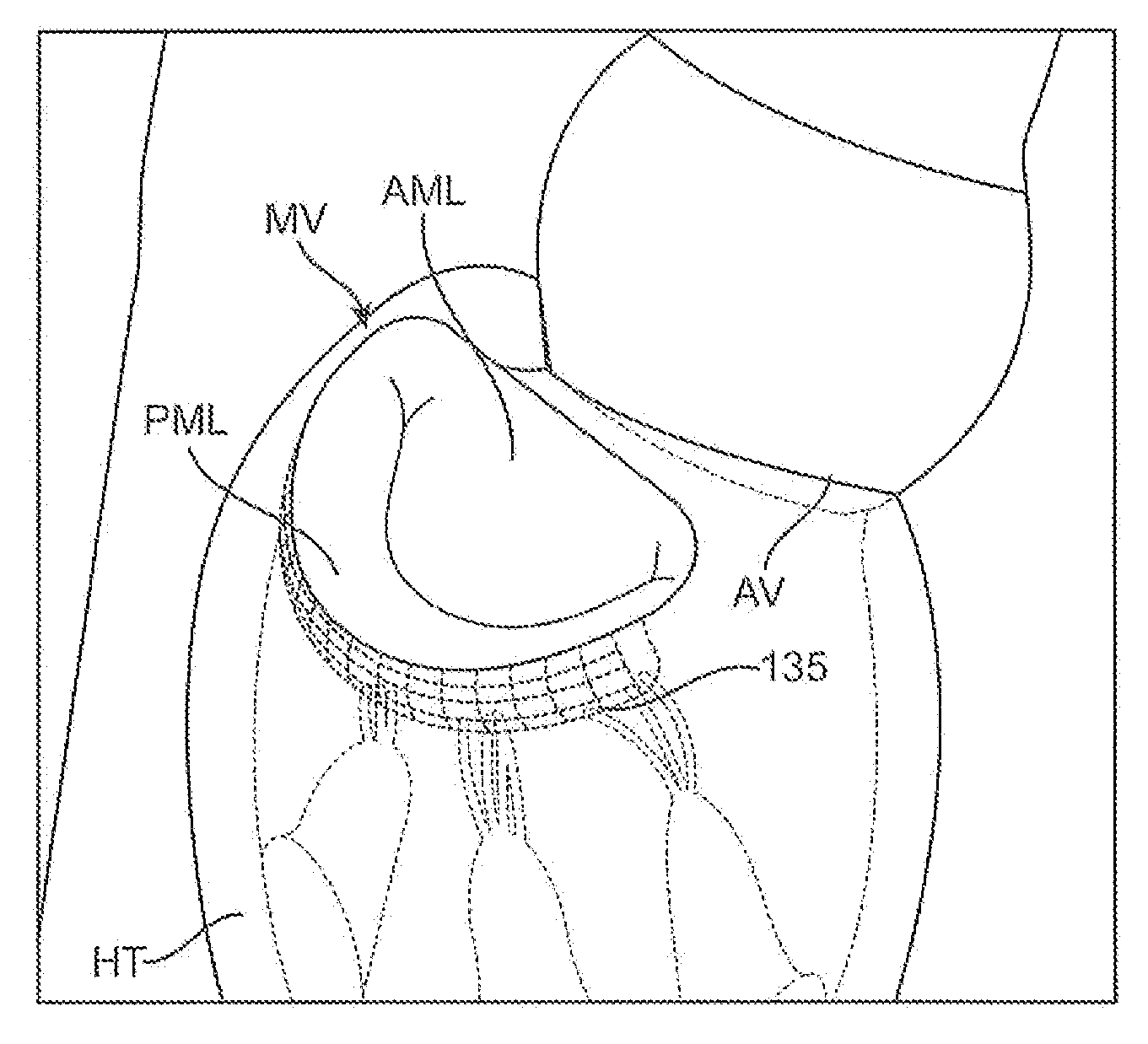

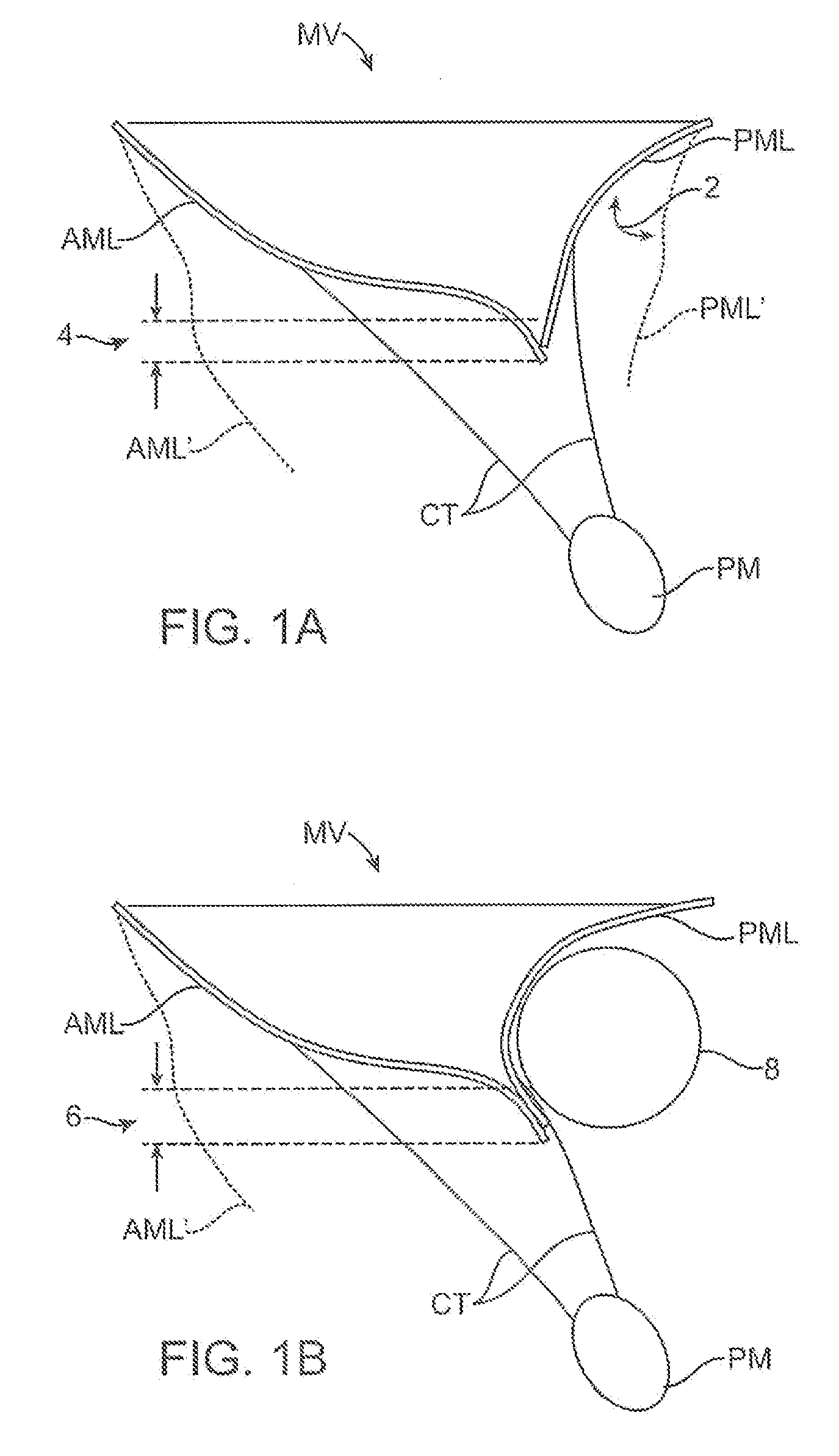

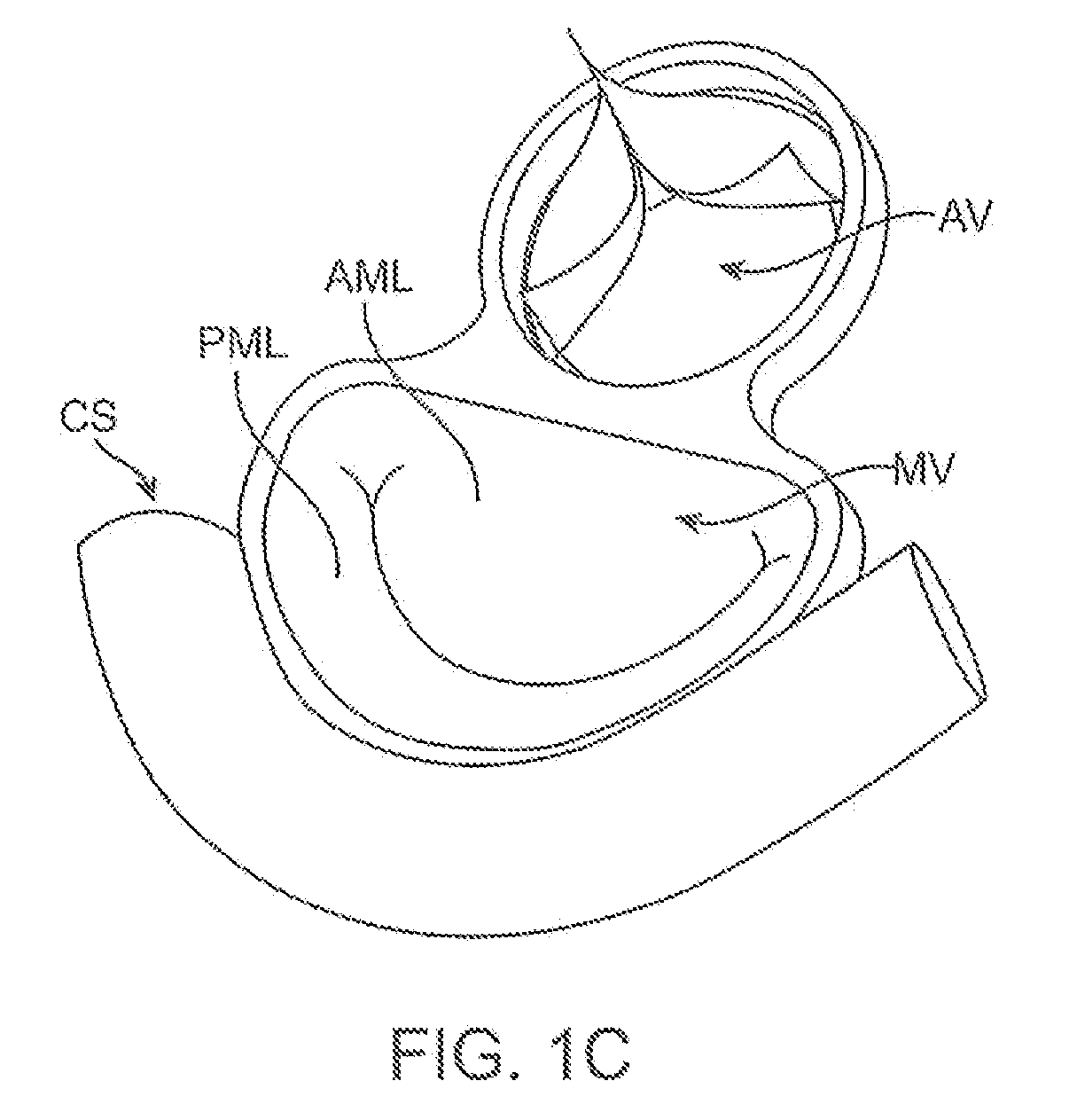

Methods and apparatus for mitral valve repair

InactiveUS20080039935A1Inhibiting and preventing prolapseSlide freelyAnnuloplasty ringsPosterior leafletSystole

Methods and apparatus for mitral valve repair are disclosed herein where the posterior mitral leaflet is supported or buttressed in a frozen or immobile position to facilitate the proper coaptation of the leaflets. An implantable apparatus may be advanced and positioned intravascularly beneath the posterior leaflet of the mitral valve. The apparatus may include one or more individual balloon members, each of which may be optionally configured with supporting integrated structures. A magnet chain catheter may be positioned within the coronary sinus and adjacent to the mitral valve to magnetically secure the apparatus in position beneath the posterior mitral leaflet. Alternatively, a split-ring device may be placed about the chordae tendineae supporting the mitral valve such that the ring slides along the chordae tendineae alternately against the mitral leaflet and towards the papillary muscles during systole and diastole.

Owner:BUCH WALLY +1

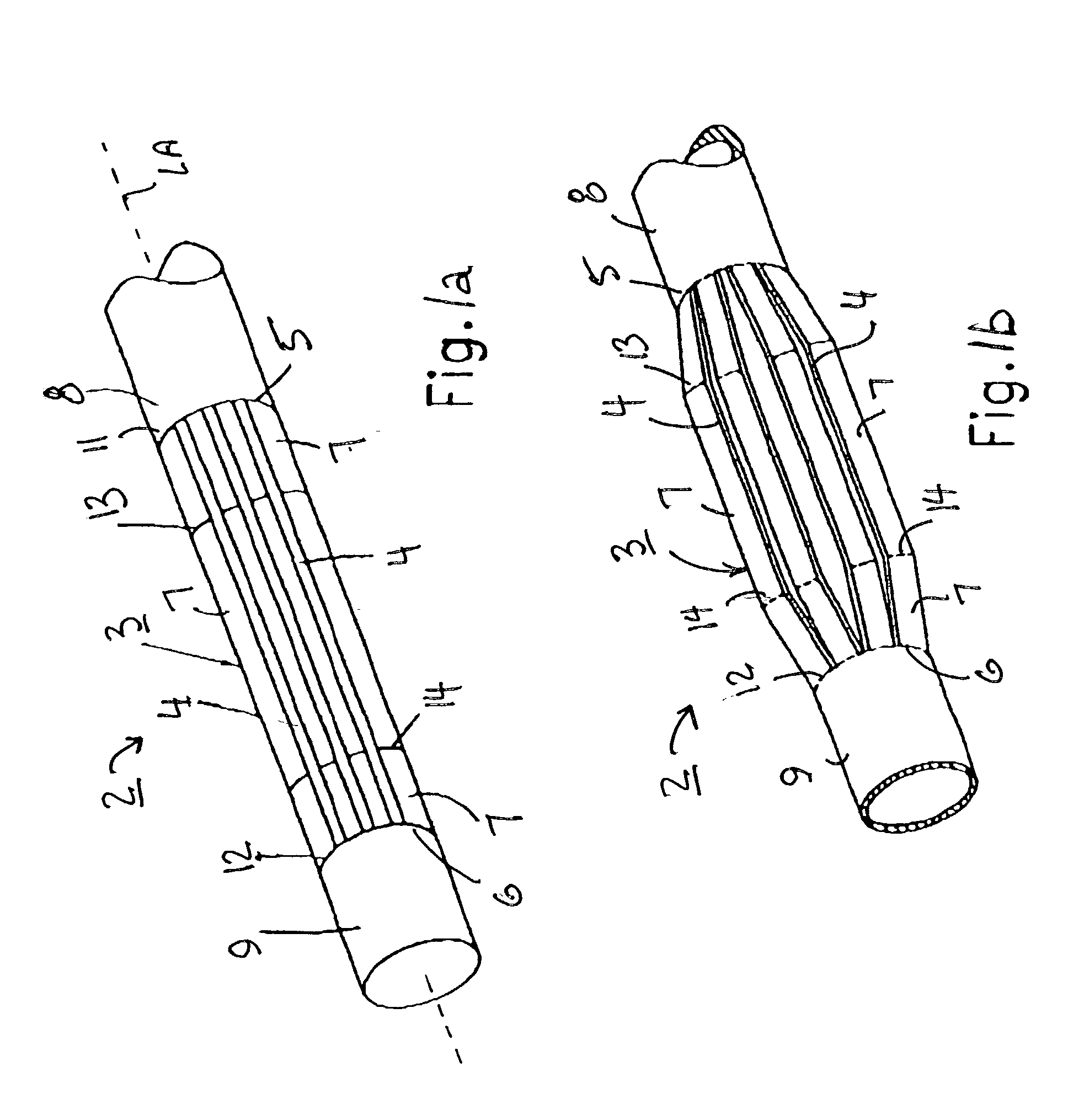

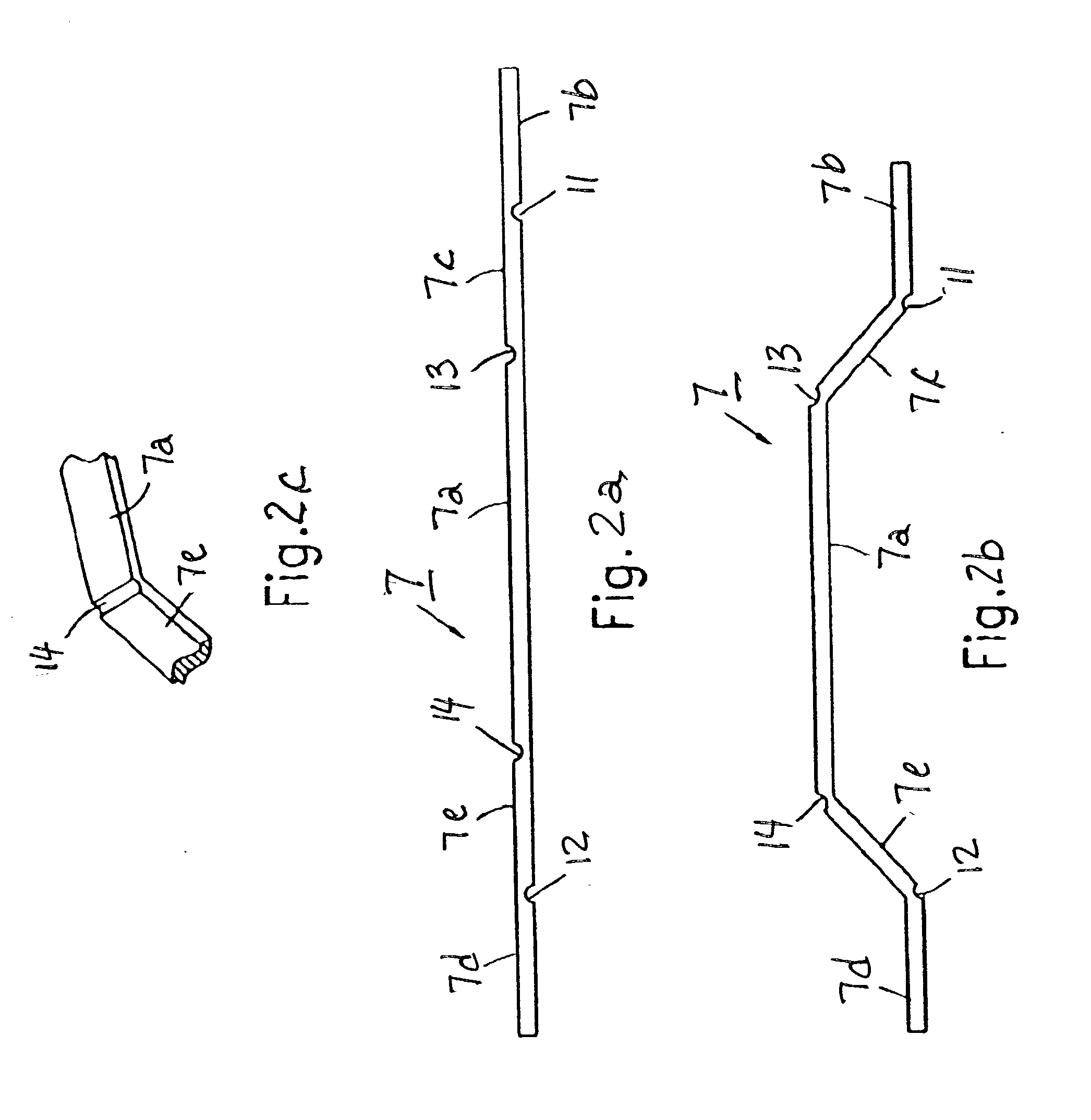

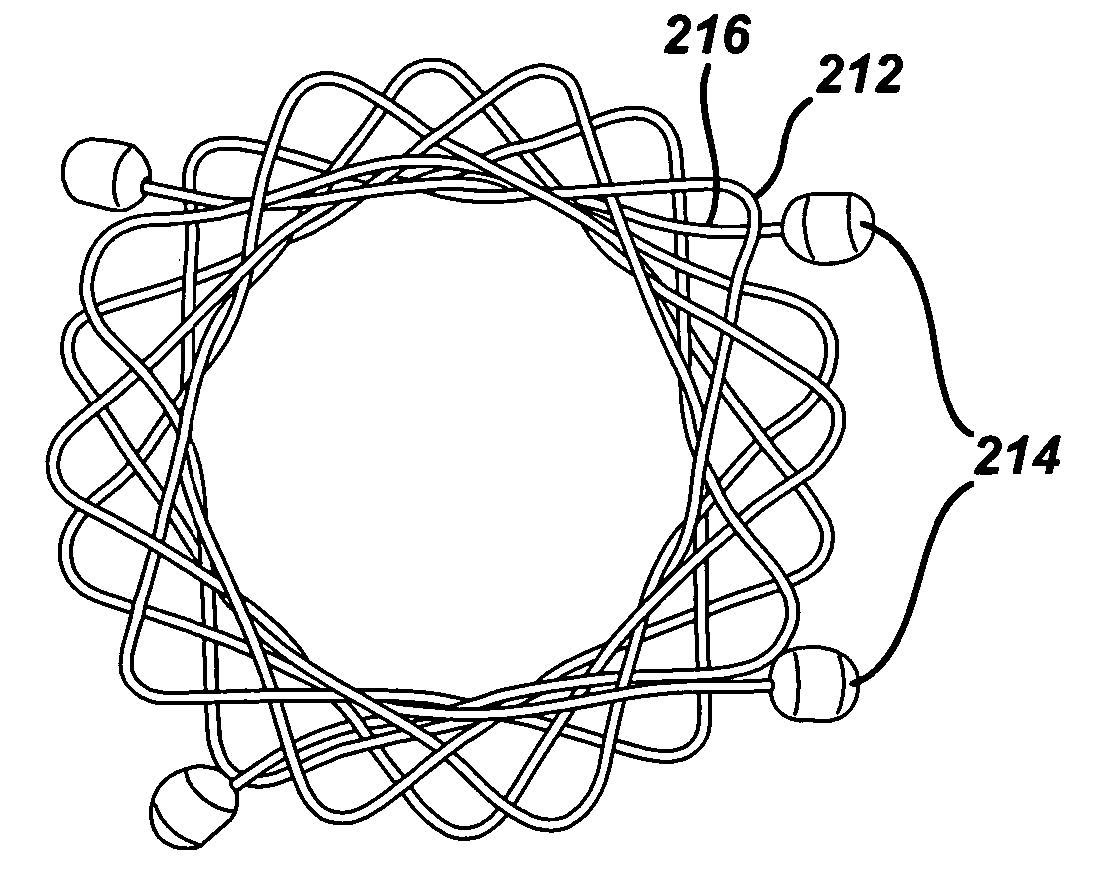

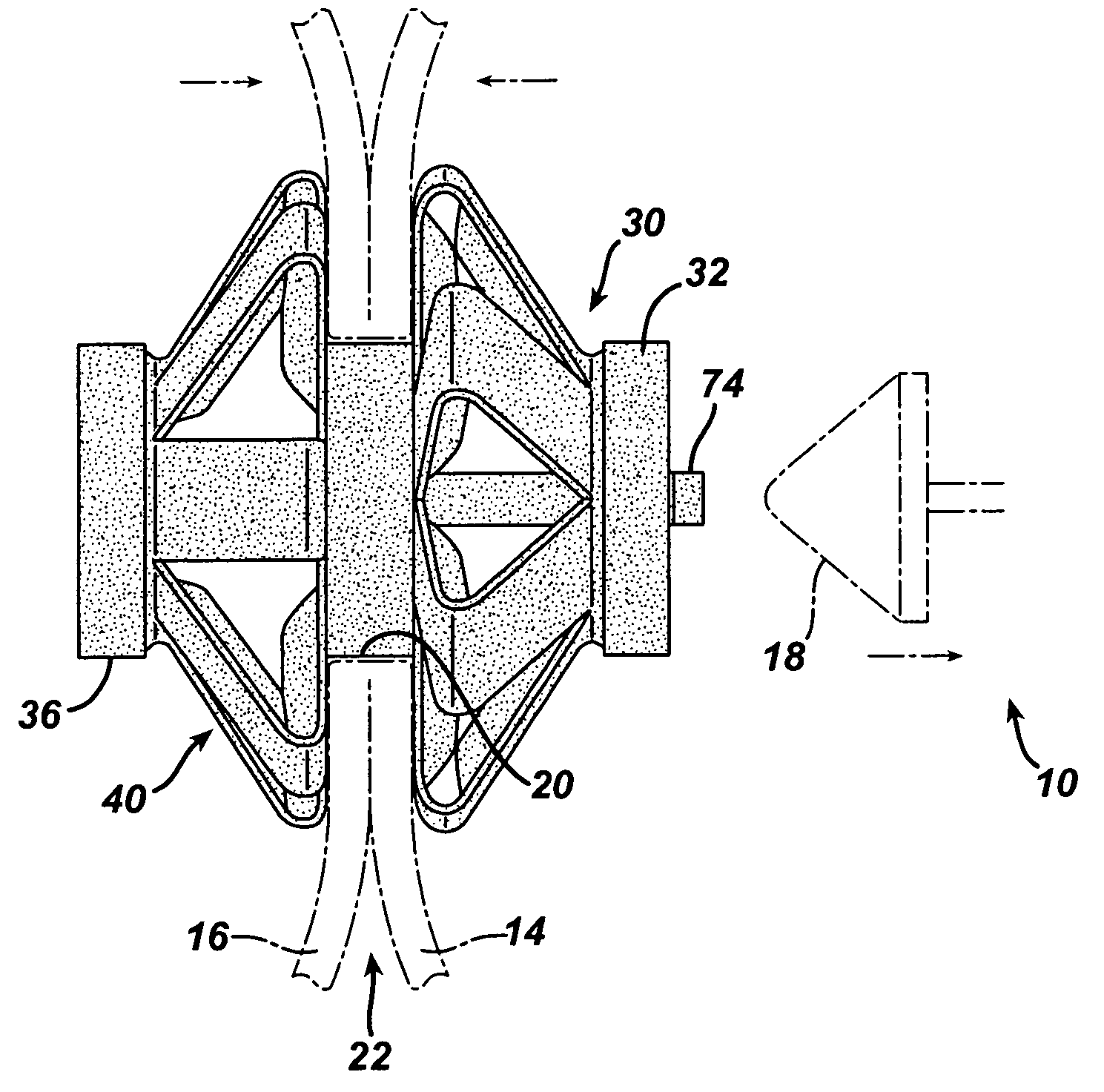

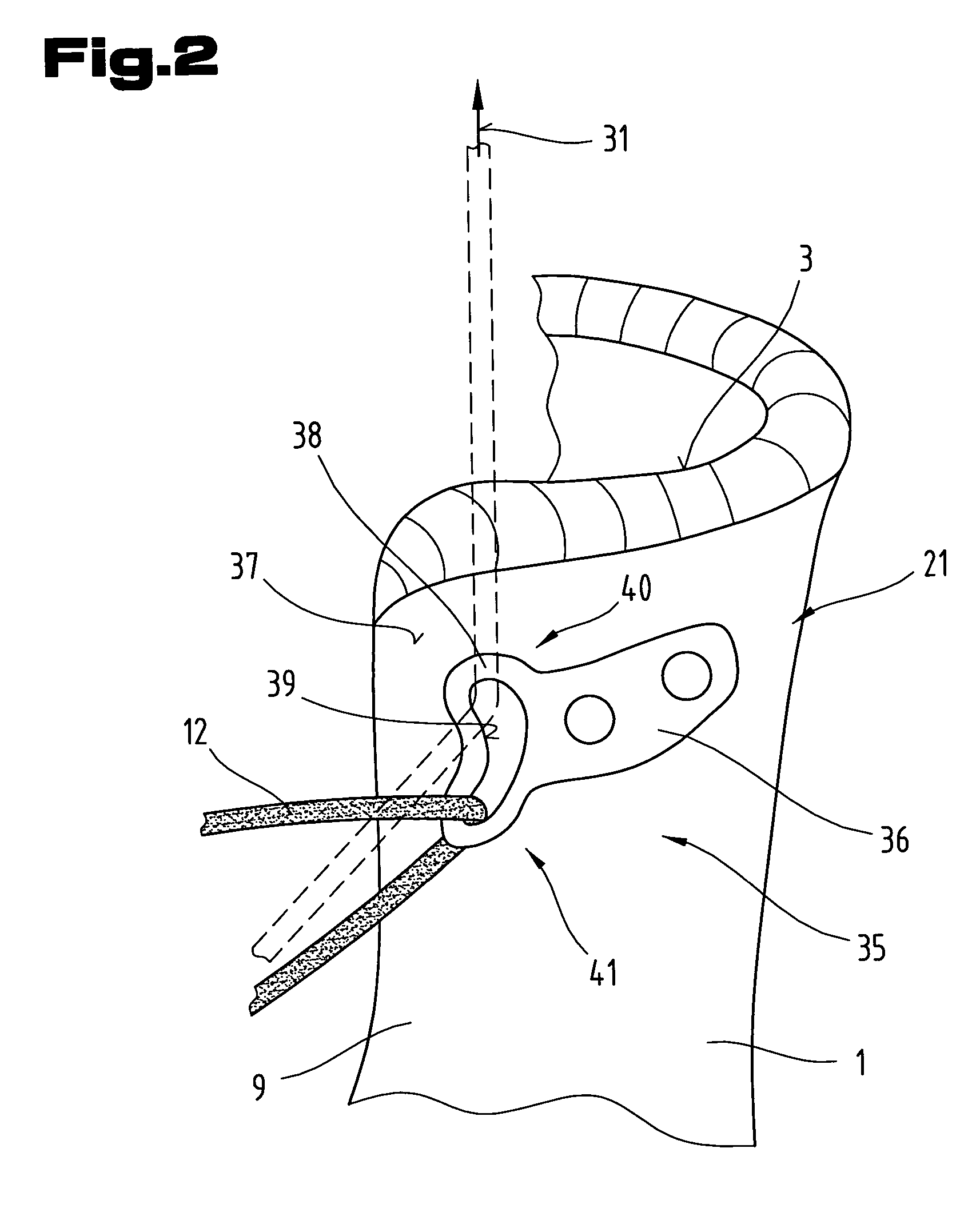

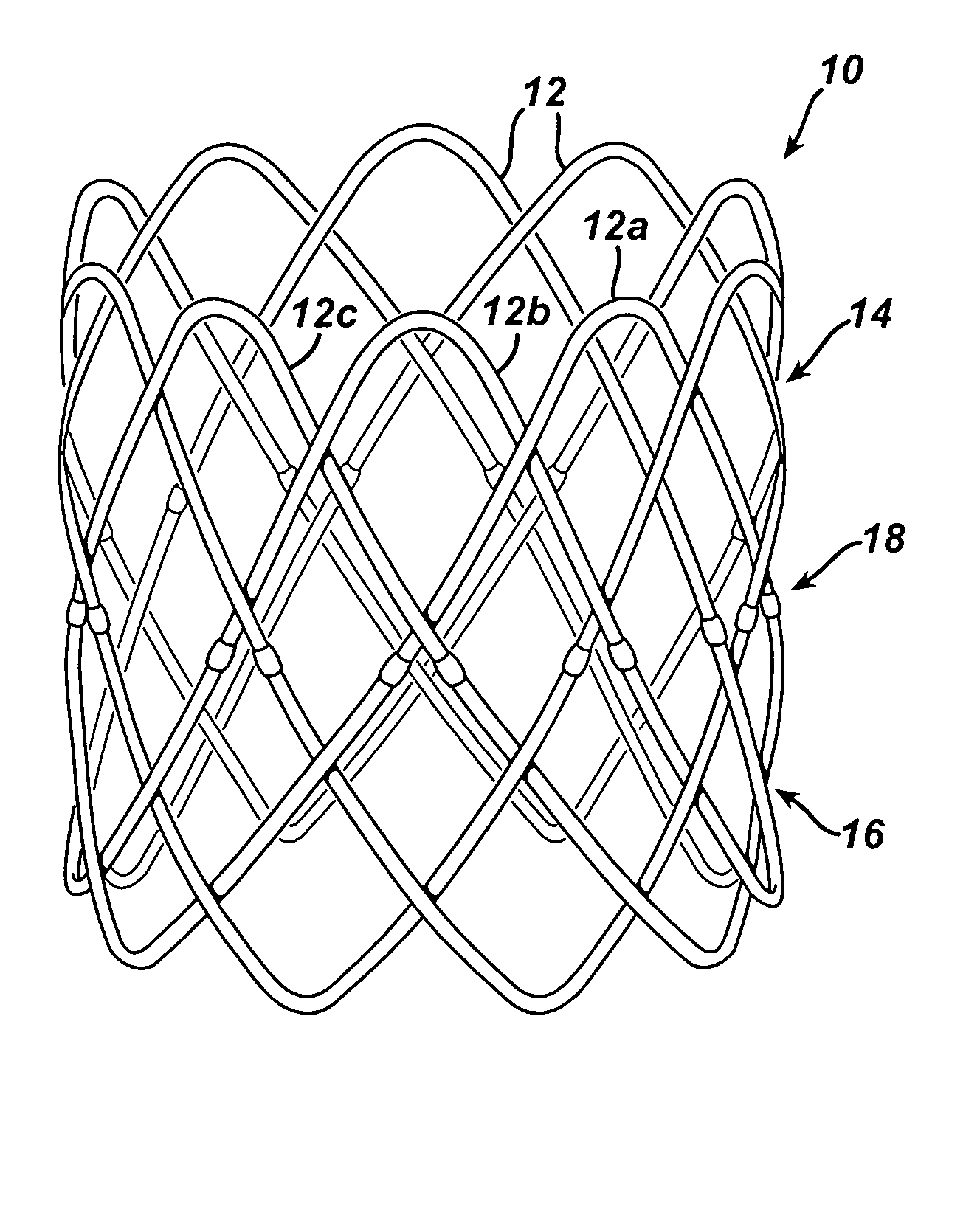

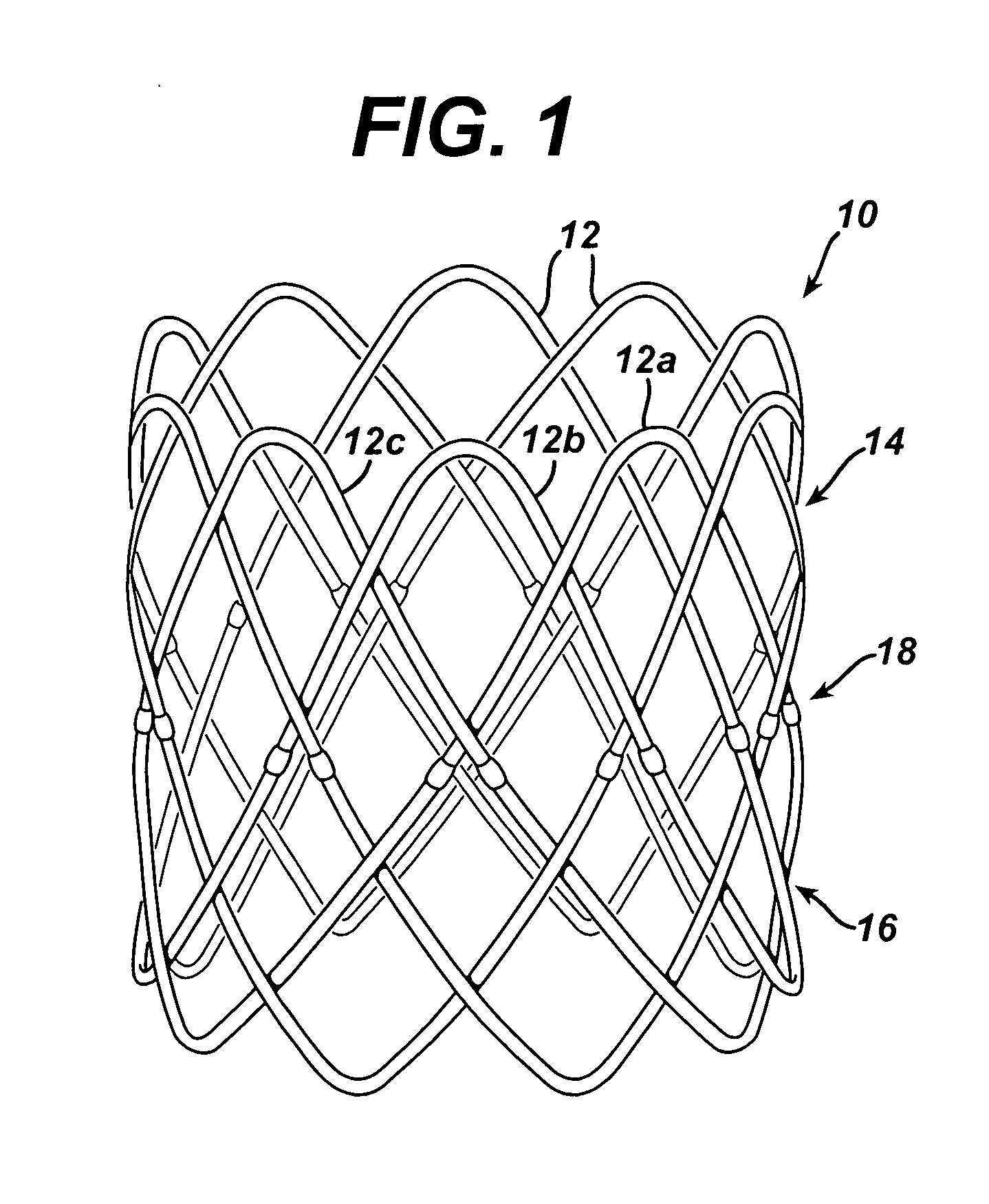

Anastomosis wire ring device

InactiveUS20050070934A1Reduce manufacturing costEasy to driveBlood vesselsSurgical veterinaryRing deviceMemory effect

An anastomotic ring device for forming a hollow rivet (ring) attachment between tissue lumens facilitates laparoscopic or endoscopic implantation by including features that facilitate actuation from a stressed, generally cylindrical shape. Economical manufacturer is achieved by weaving open ended strands into a generally cylindrical stent shape that is imparted with a Shape Memory Effect (SME) to actuate to a hollow rivet (ring) shape. Alternatively or in addition to SME inherent in the woven strands, an actuating force may be received from a helical spring element incorporated into the ring. Self-actuating ring devices are enhanced by forming woven strands into petals that diverge from opposing petals such that the strands encounter less friction when actuating. Each of these features alone or in combination enhance clinical use of anastomotic ring devices, such as a bariatric gastric bypass procedure.

Owner:ETHICON ENDO SURGERY INC

Single lumen access deployable ring for intralumenal anastomosis

Creating an anastomosis, or the surgical formation of a passage between two normally distinct vessels or lumens, is enhanced by an applier that introduces a ring device without the need for a separate anvil to form a hollow rivet shaped attachment. Moreover, the ring device may be advantageously formed in a cylindrical shape from molded polymer material or stamped from sheet metal with proximal and distal rings connected by proximal and distal arms that respectively form hinged, ring shaped so appose tissue walls. A center ring or portion sits in the attachment site. The applier causes actuating by moving the rings relative to one another. A latching mechanism locks the rings in the actuating state.

Owner:ETHICON ENDO SURGERY INC

Expandable delivery appliance particularly for delivering intravascular devices

A delivery appliance for delivering an expandable annular device, particularly an expandable intravascular device, to a desired location in a lumen, includes an annular array of supporting strips extending from a proximal end of the annular array to a distal end of the annular array, to define an annular supporting surface for the expandable annular device. Each of the supporting strips is laterally deformable to radially expand or radially contract the annular array and the annular supporting surface defined thereby. A connecting stem passes through the annular array of supporting strips and has a distal end coupled to the supporting strips at the distal end of the annular array for axial movement therewith, and a proximal end passing through the proximal end of the annular array of supporting strips for axial movement with respect thereto. The proximal end of the connecting stem is axially movable in opposite directions to move the distal end of the annular array axially away from or towards, the proximal end of the annular array to radially contract or radially expand the annular supporting surface.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

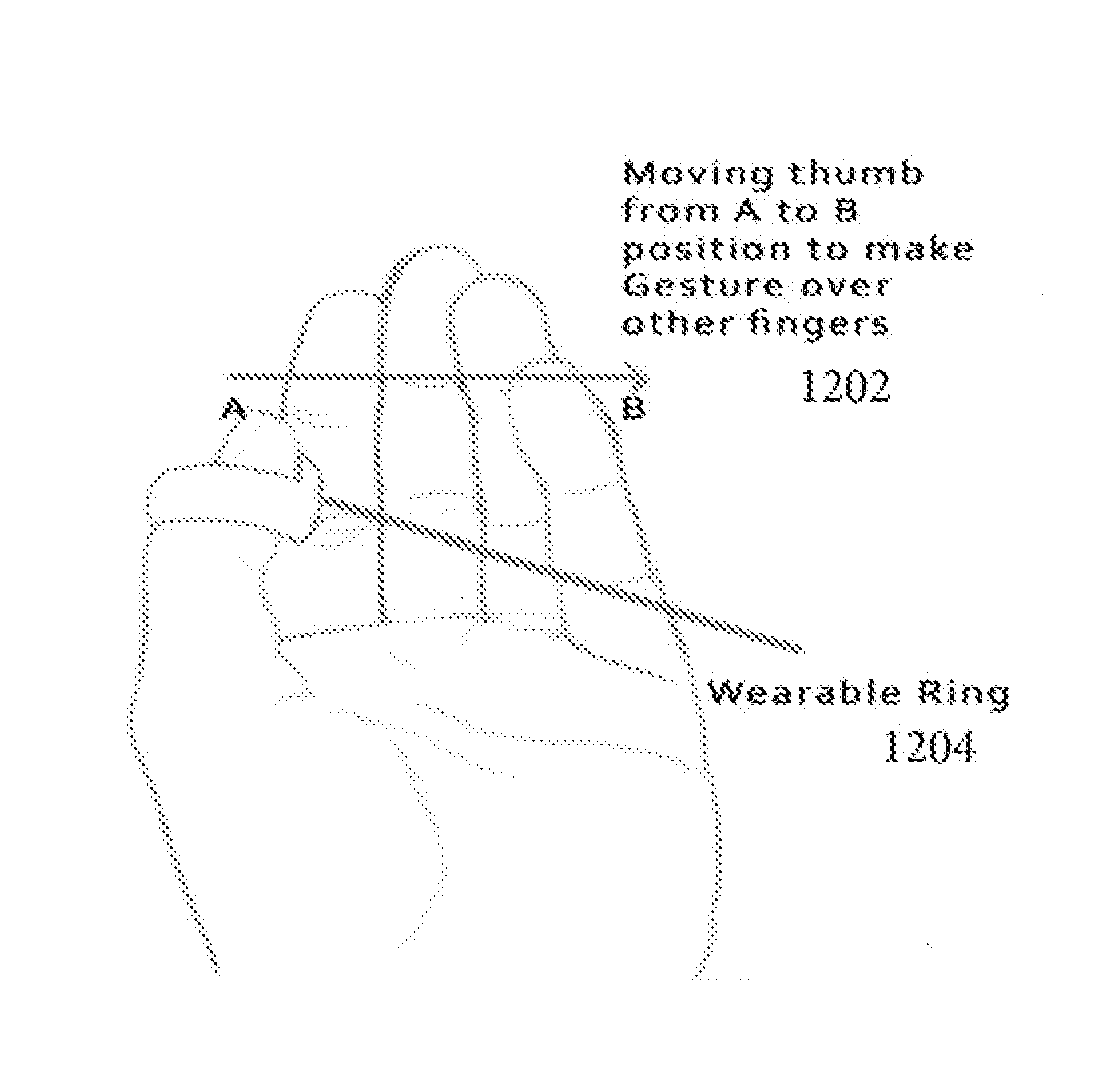

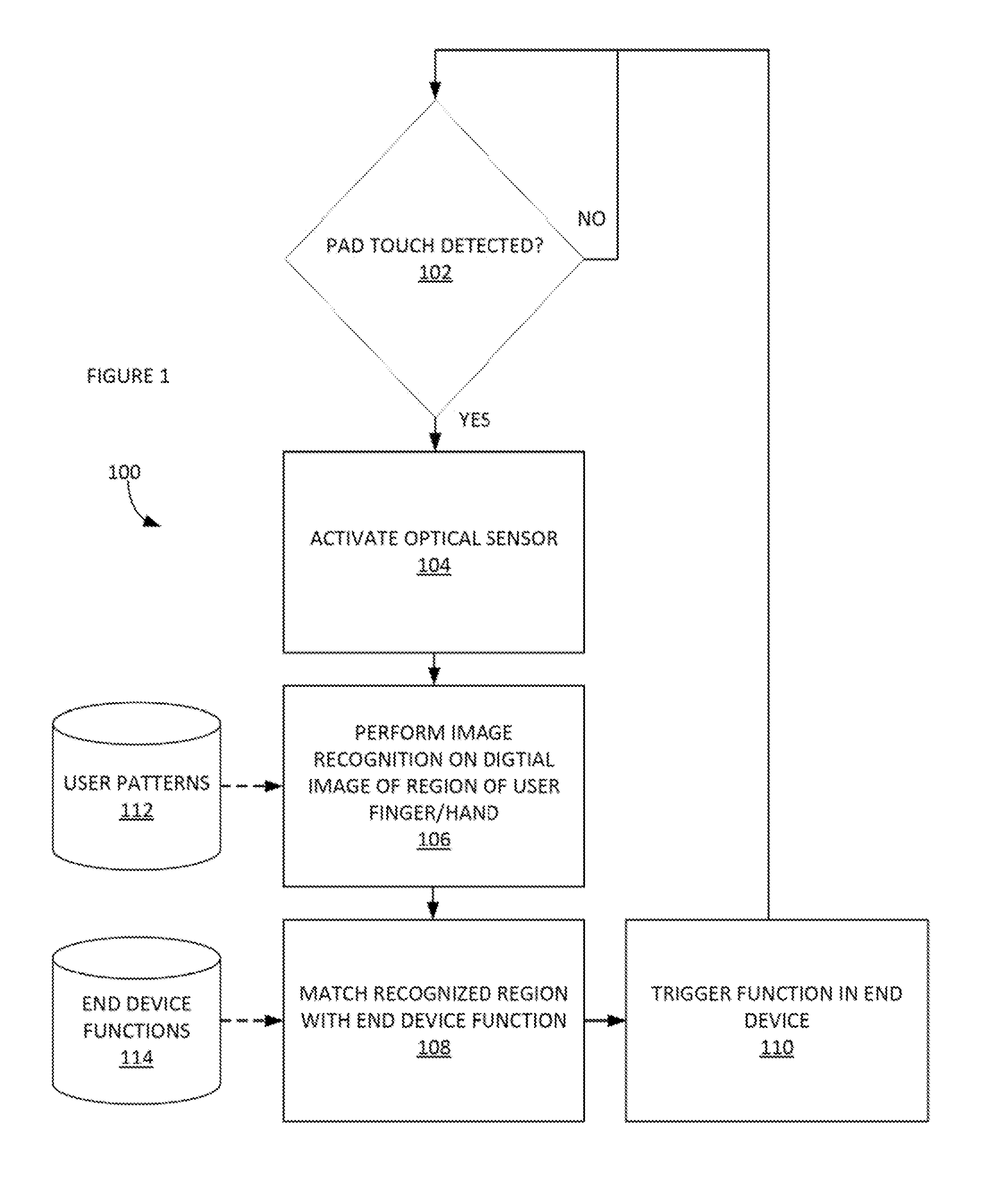

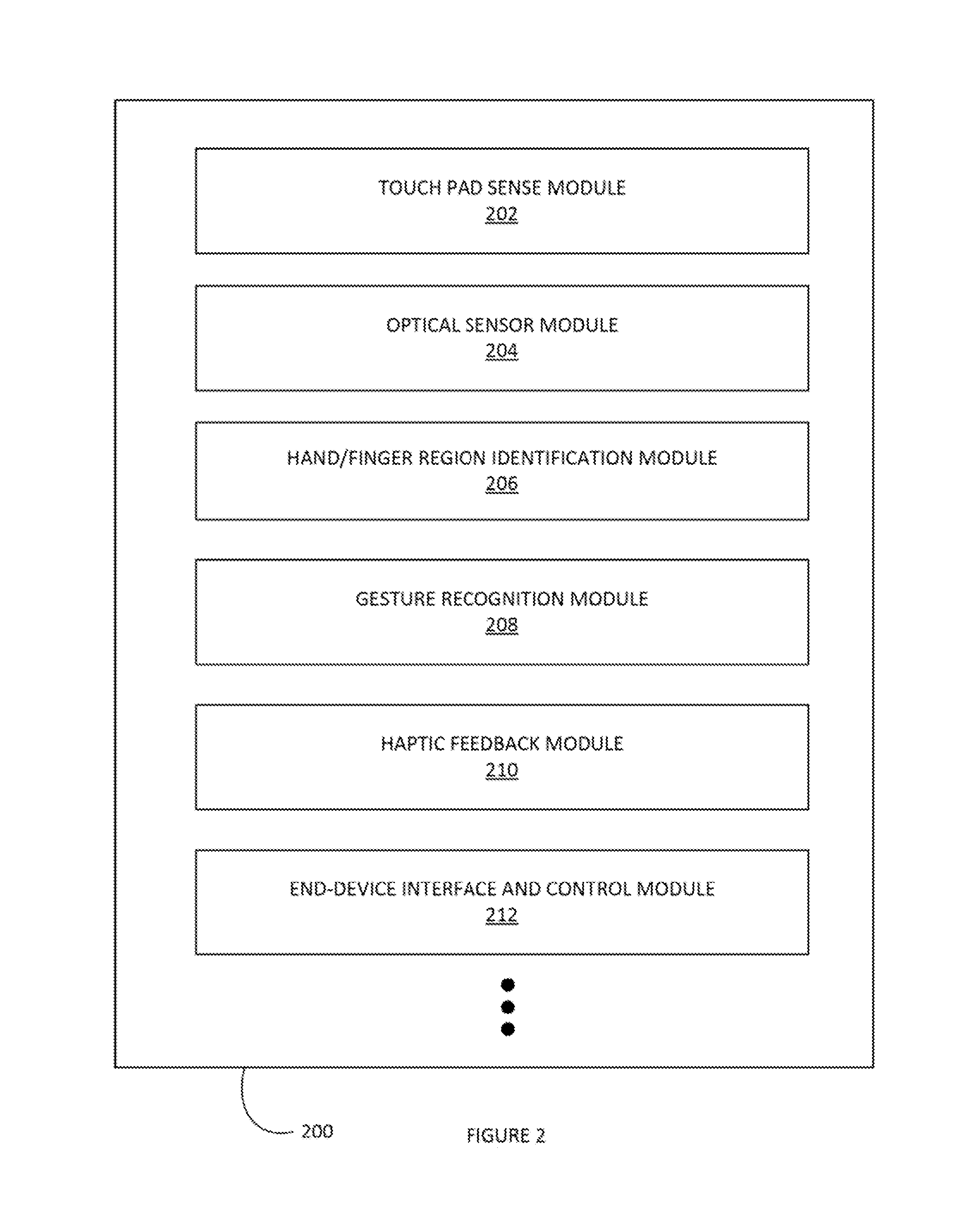

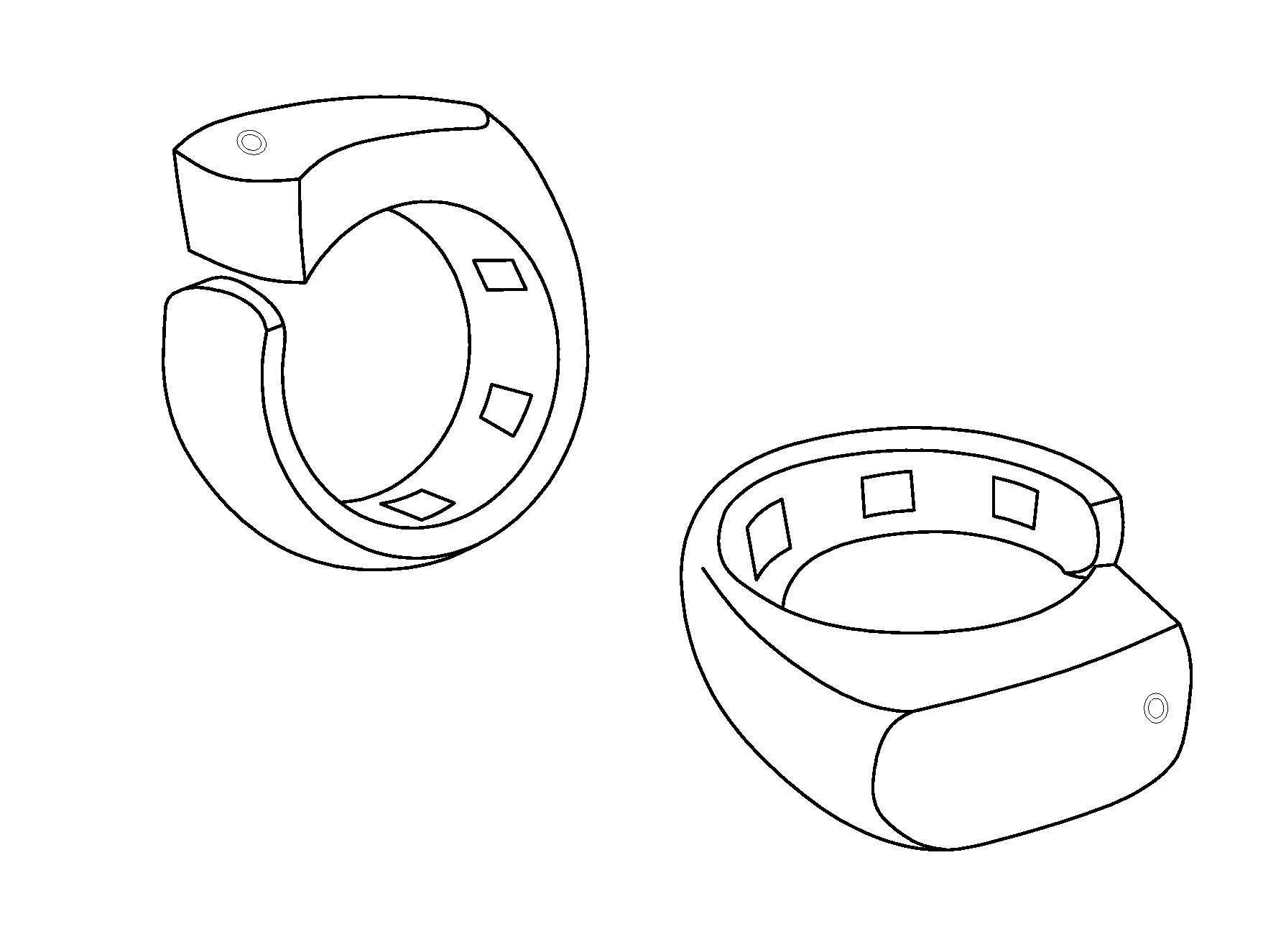

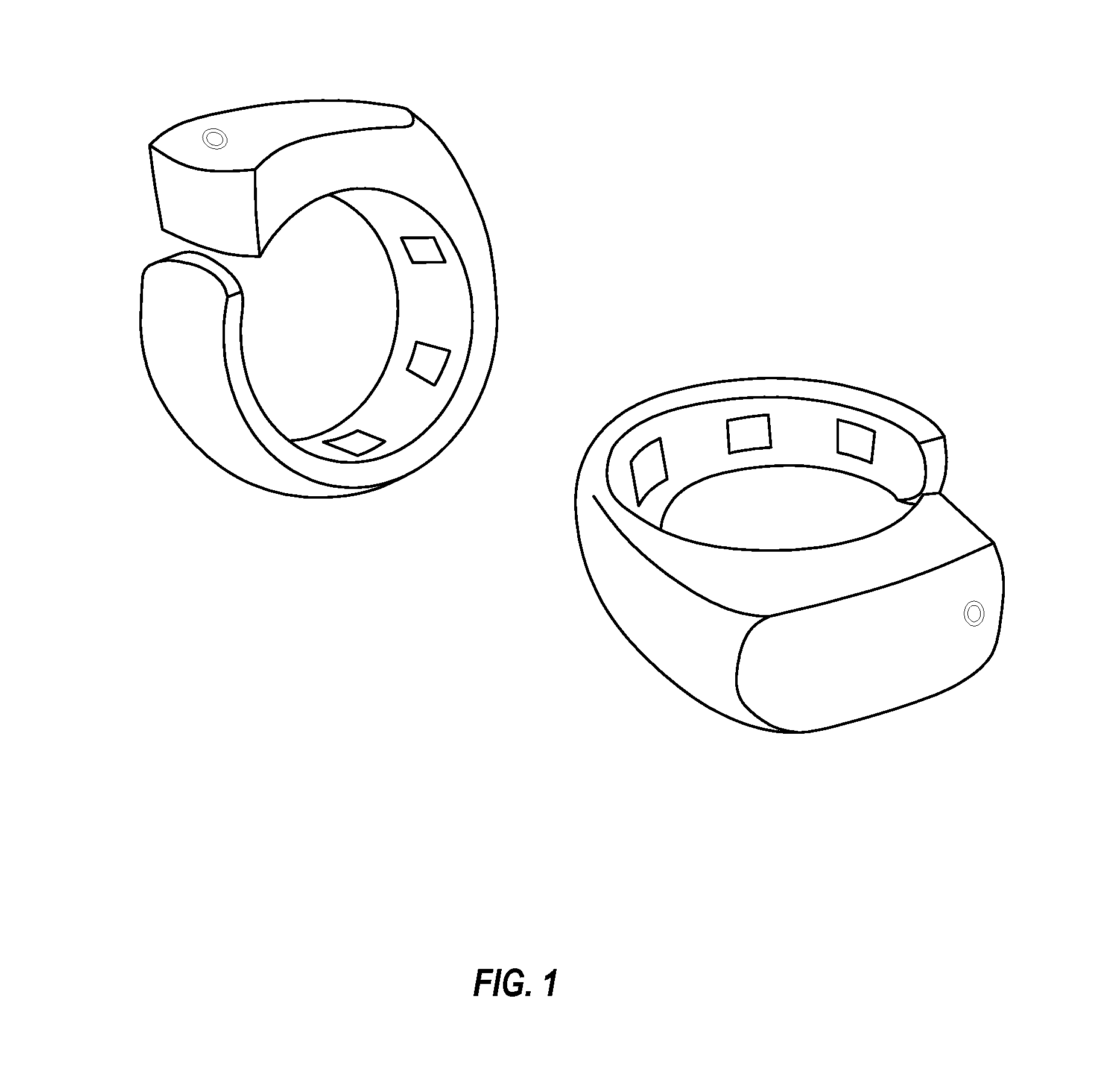

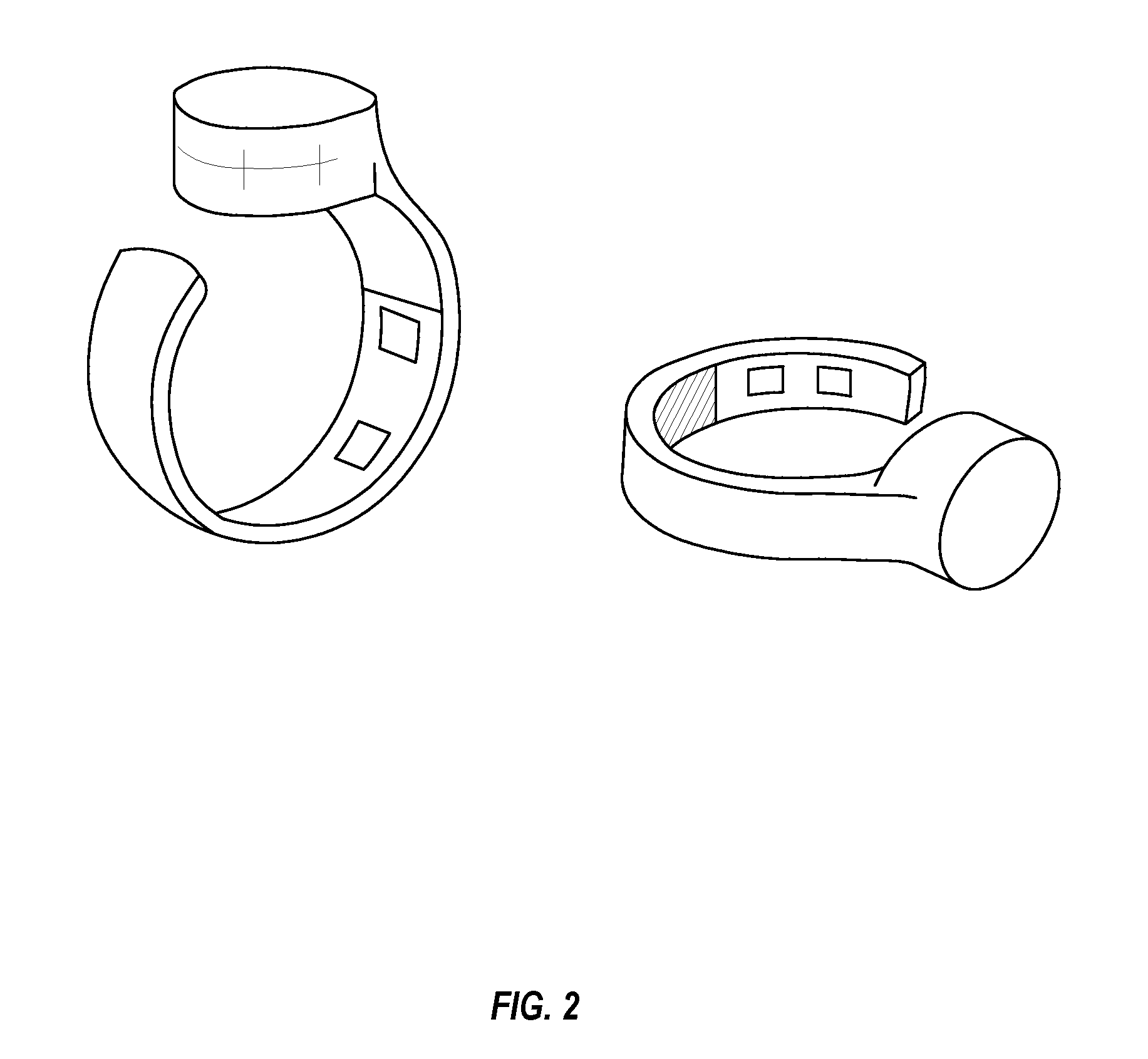

Method and system of a wearable ring device for management of another computing device

InactiveUS20150062086A1Input/output for user-computer interactionGraph readingRing deviceTerminal equipment

In one exemplary aspect, a method of a wearable ring device senses a touch event with a touch sensor in a wearable ring device. An optical sensor in the wearable ring device is activated. A digital image of a user hand region is obtained with the optical sensor. A list of end device functions is obtained. Each element of the list of end device functions is associated with a separate user hand region. The digital image of the user hand region obtained with the optical sensor is matched with an end device function. The end device function matched with the digital image of the user hand region obtained with the optical sensor is trigger.

Owner:FIN ROBOTICS

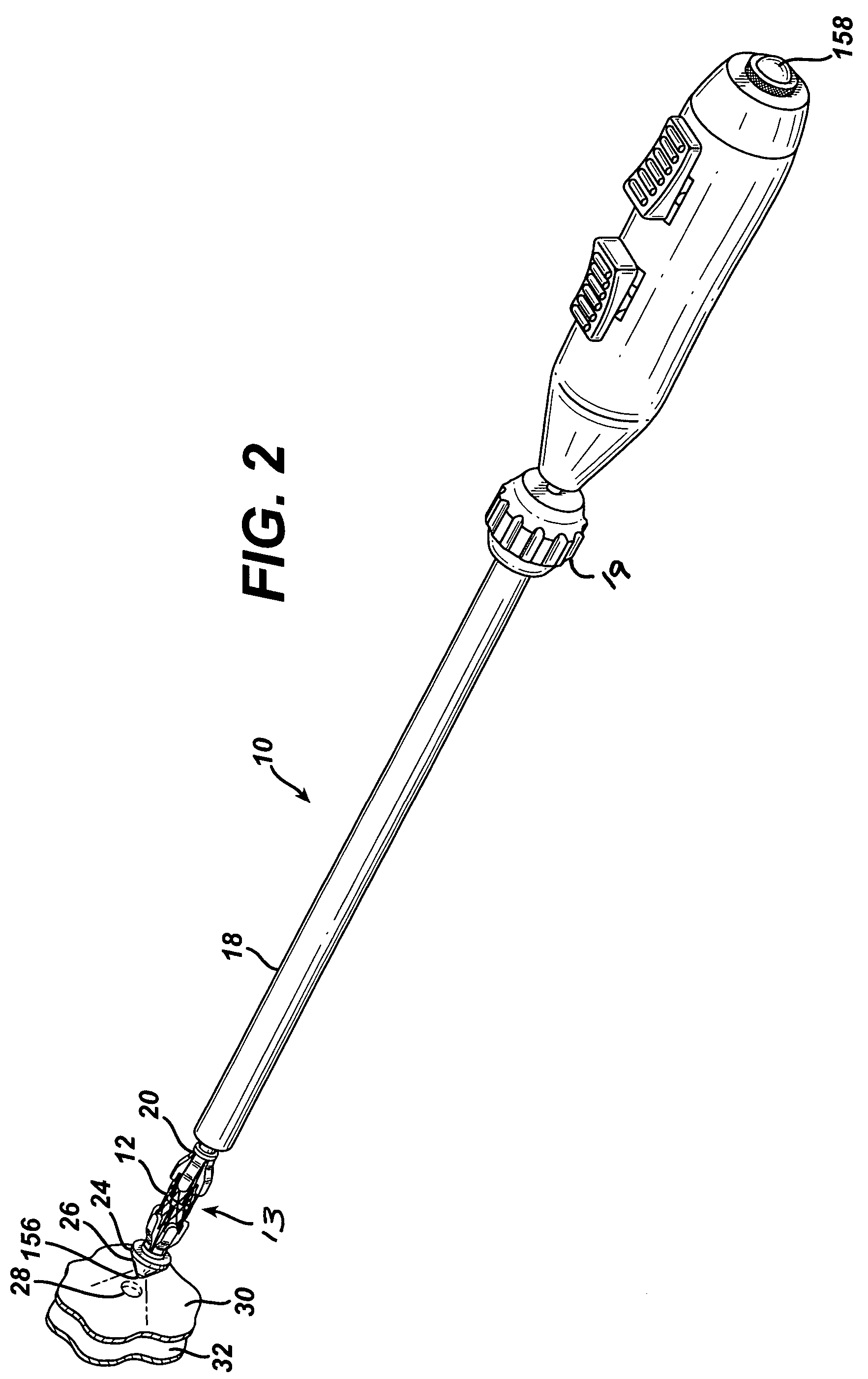

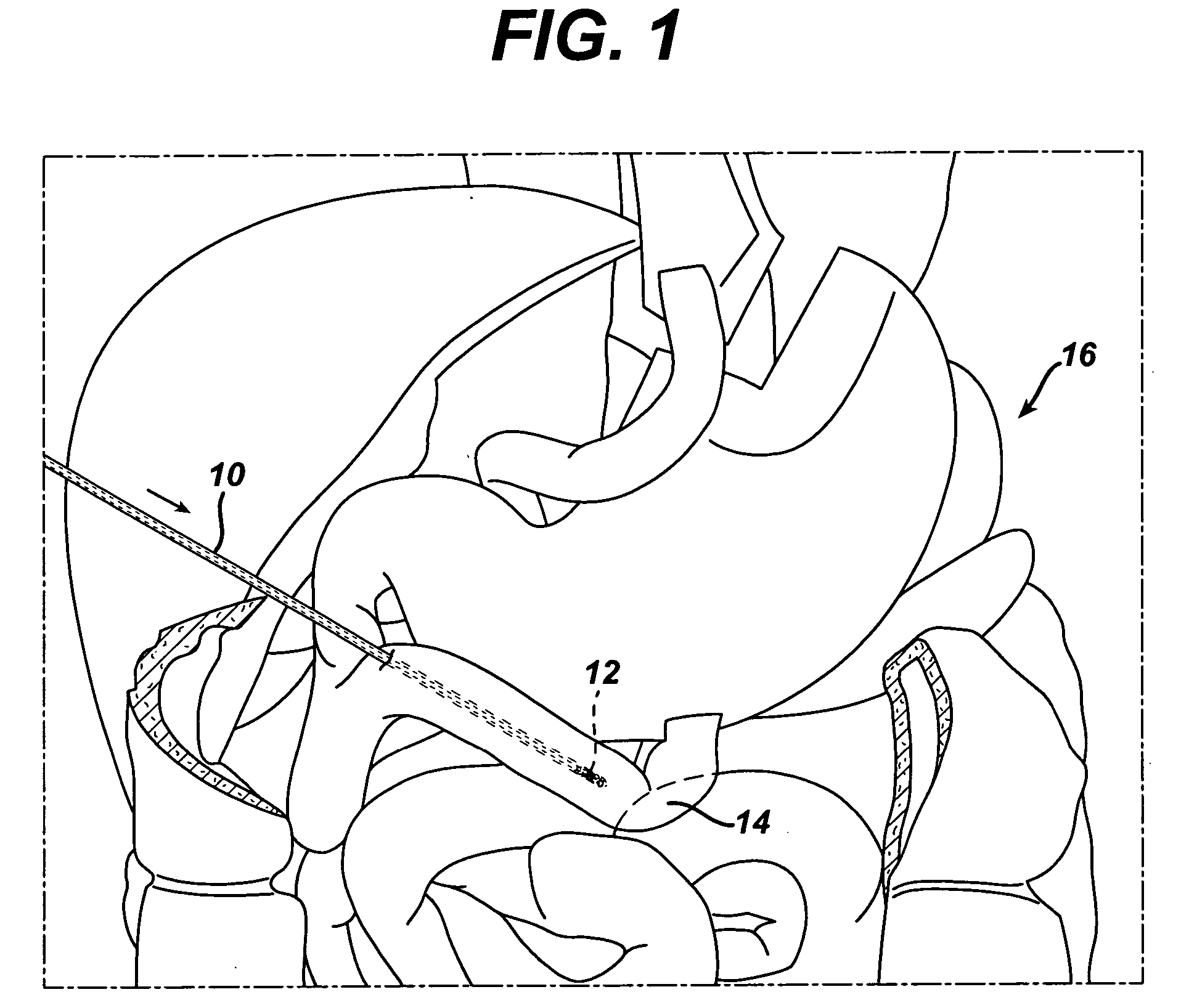

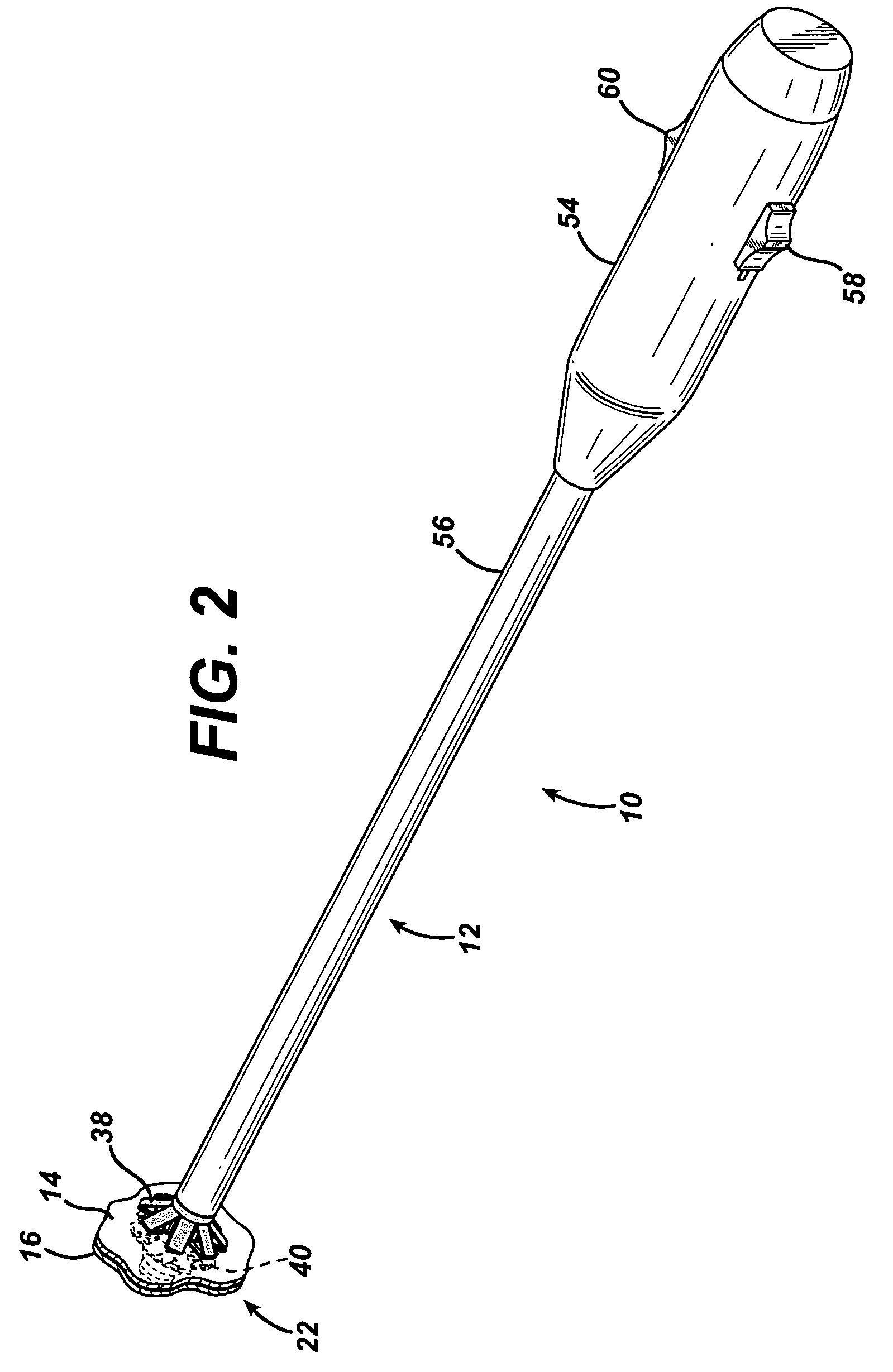

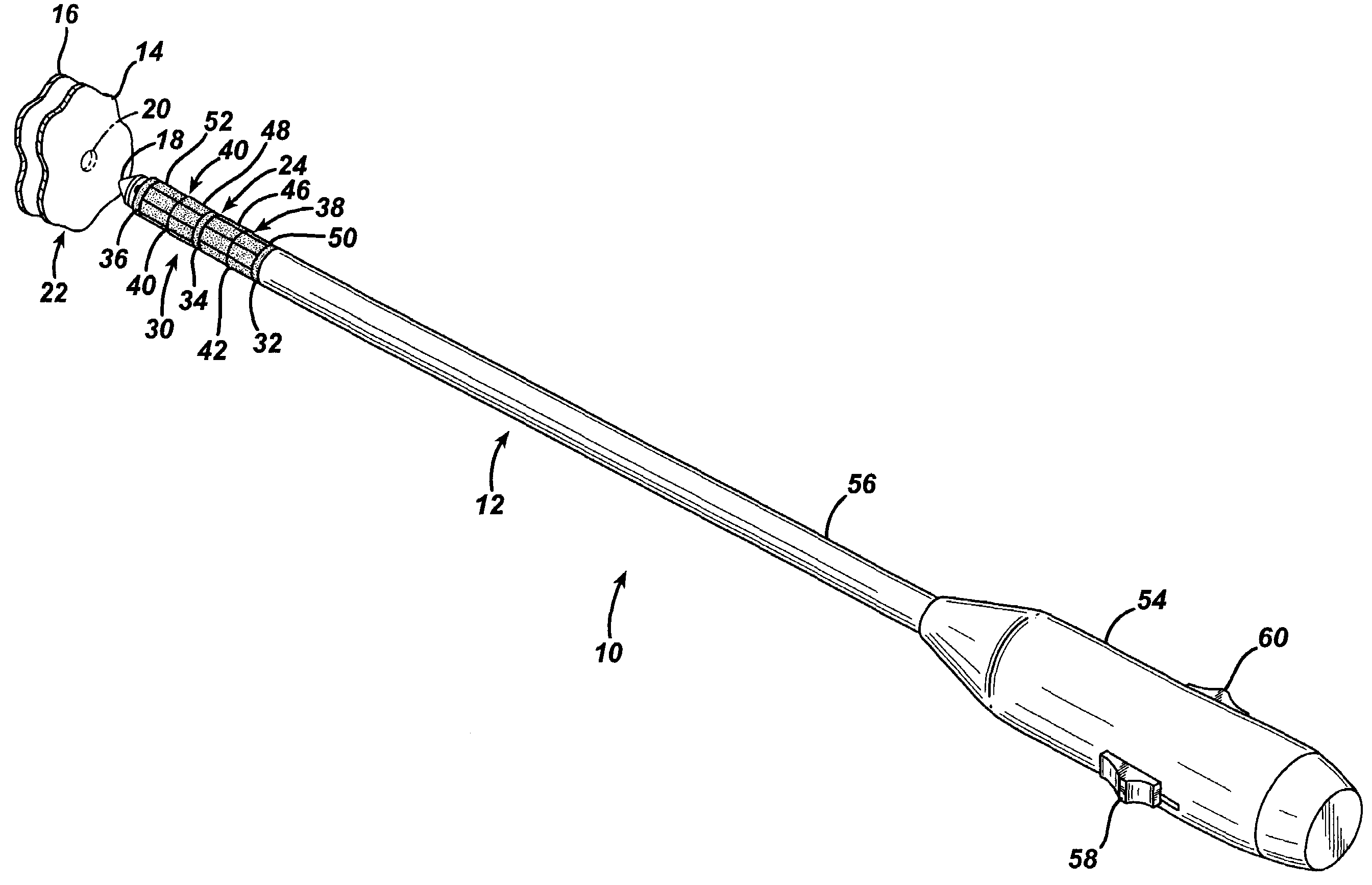

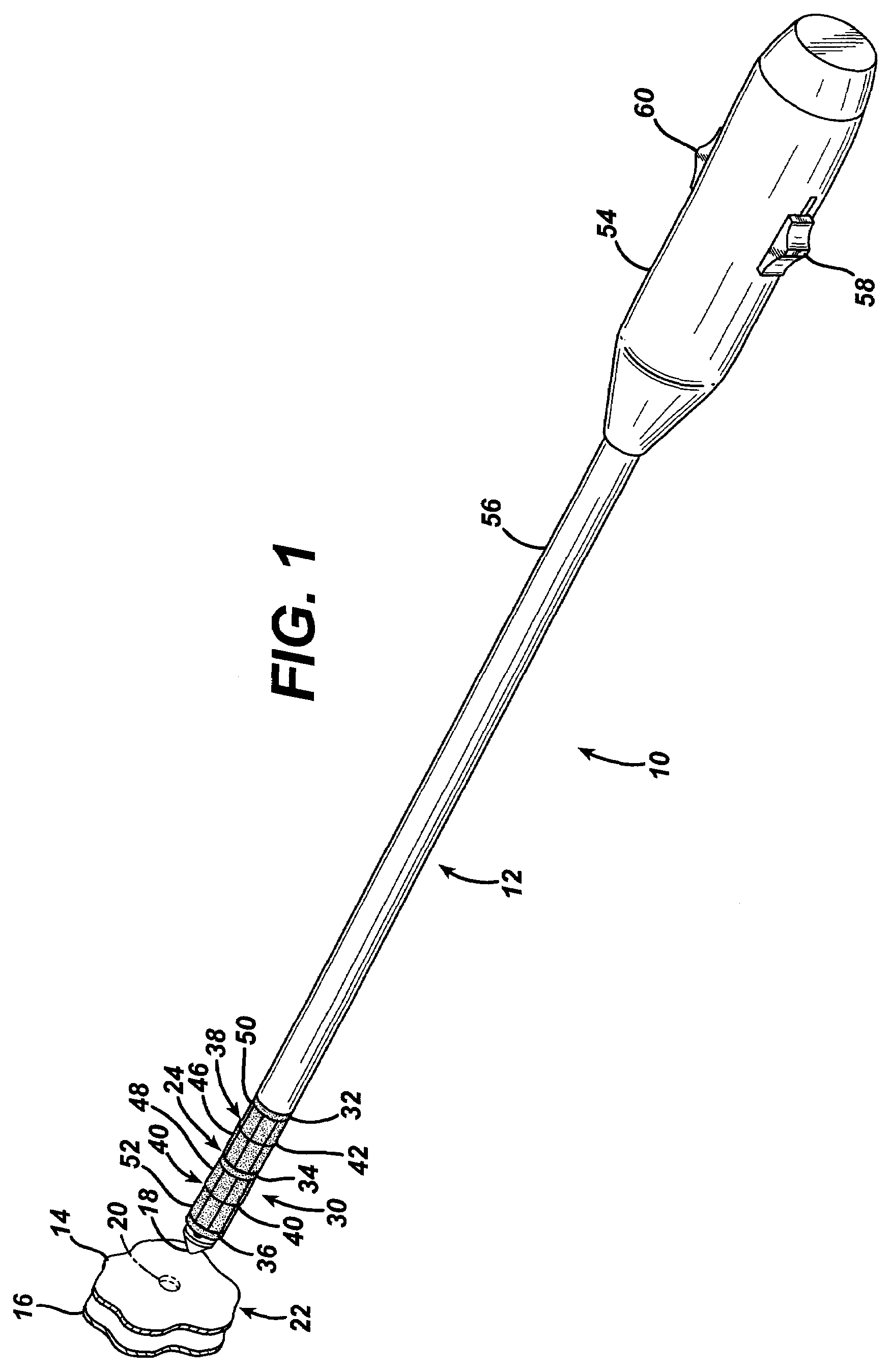

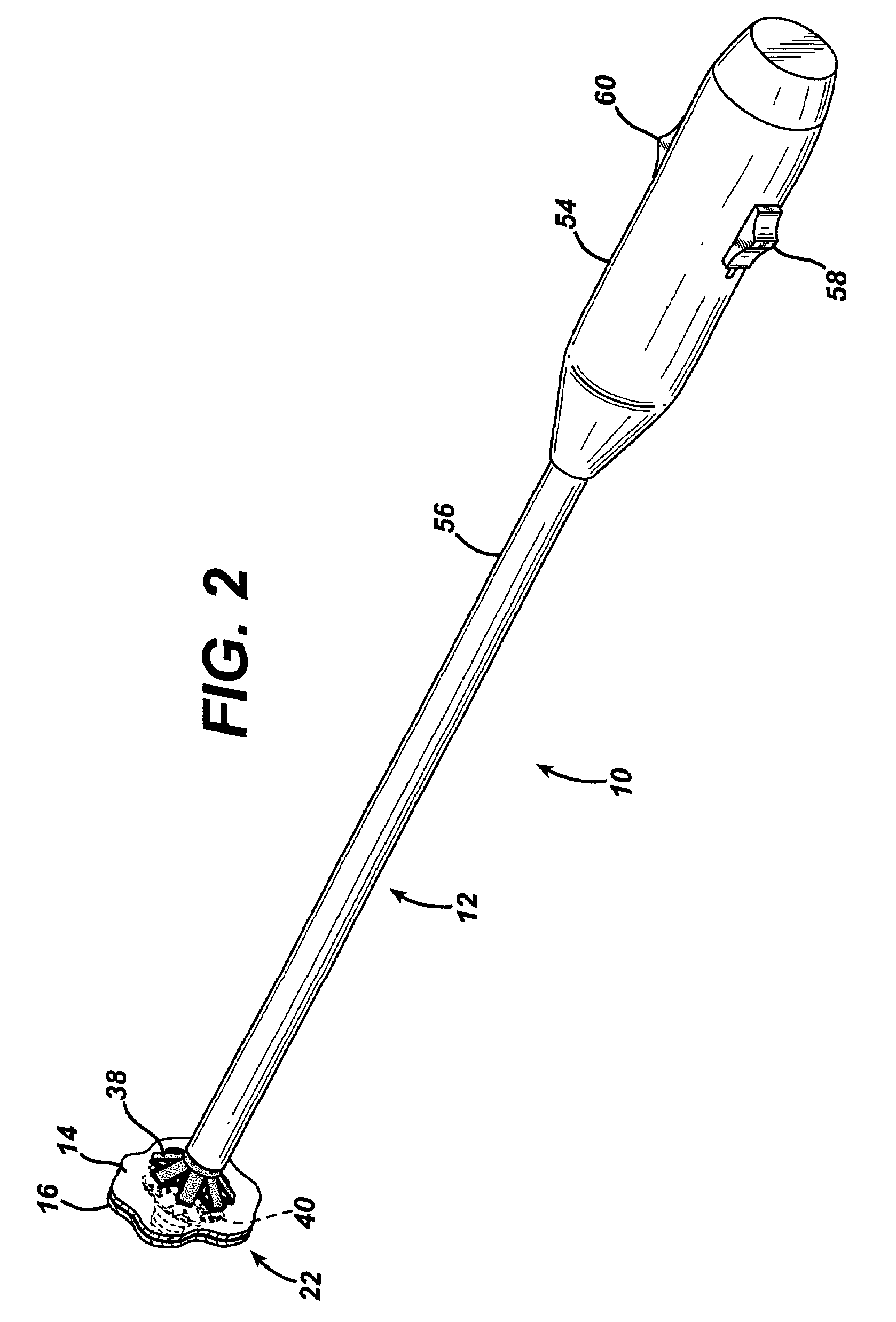

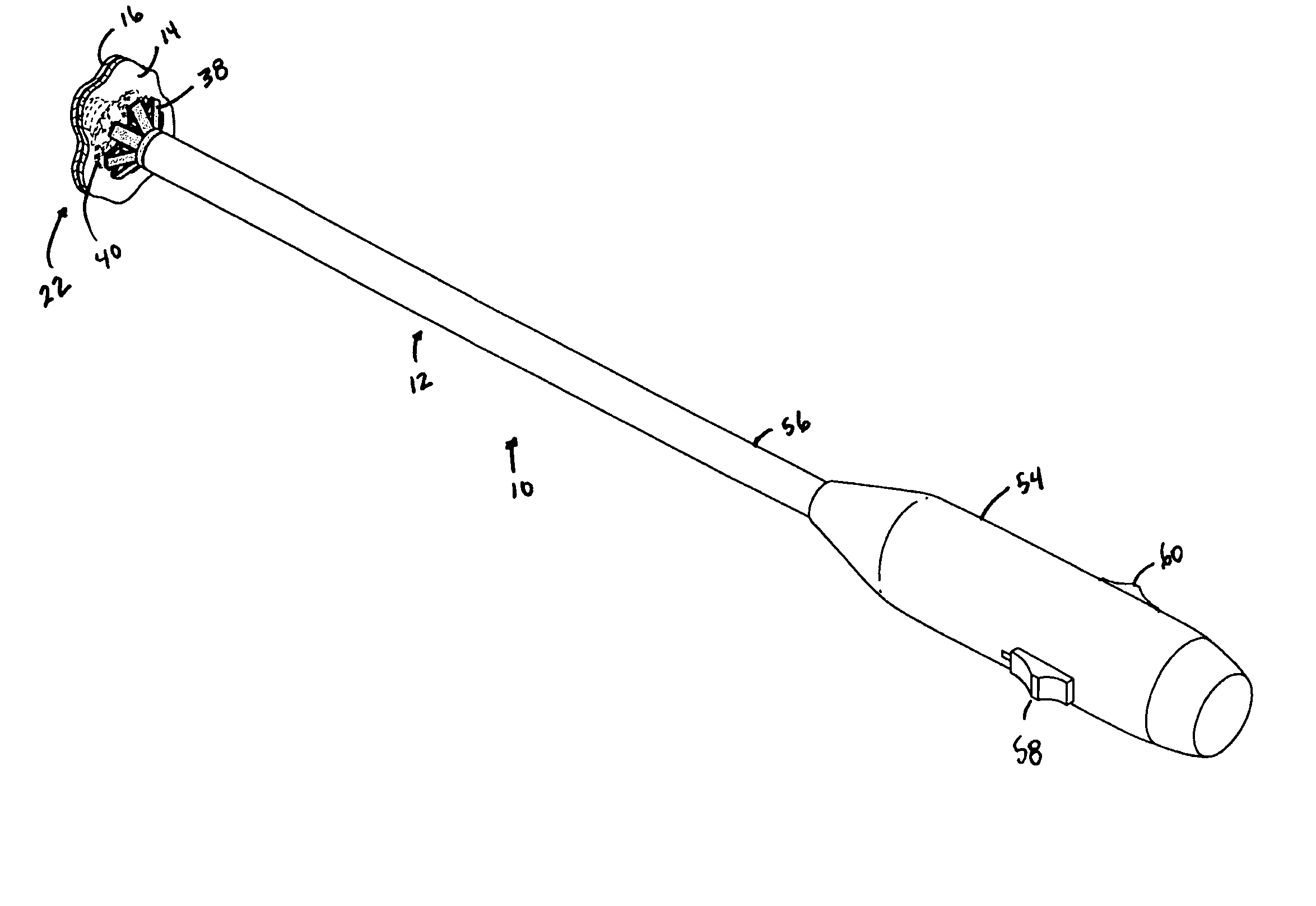

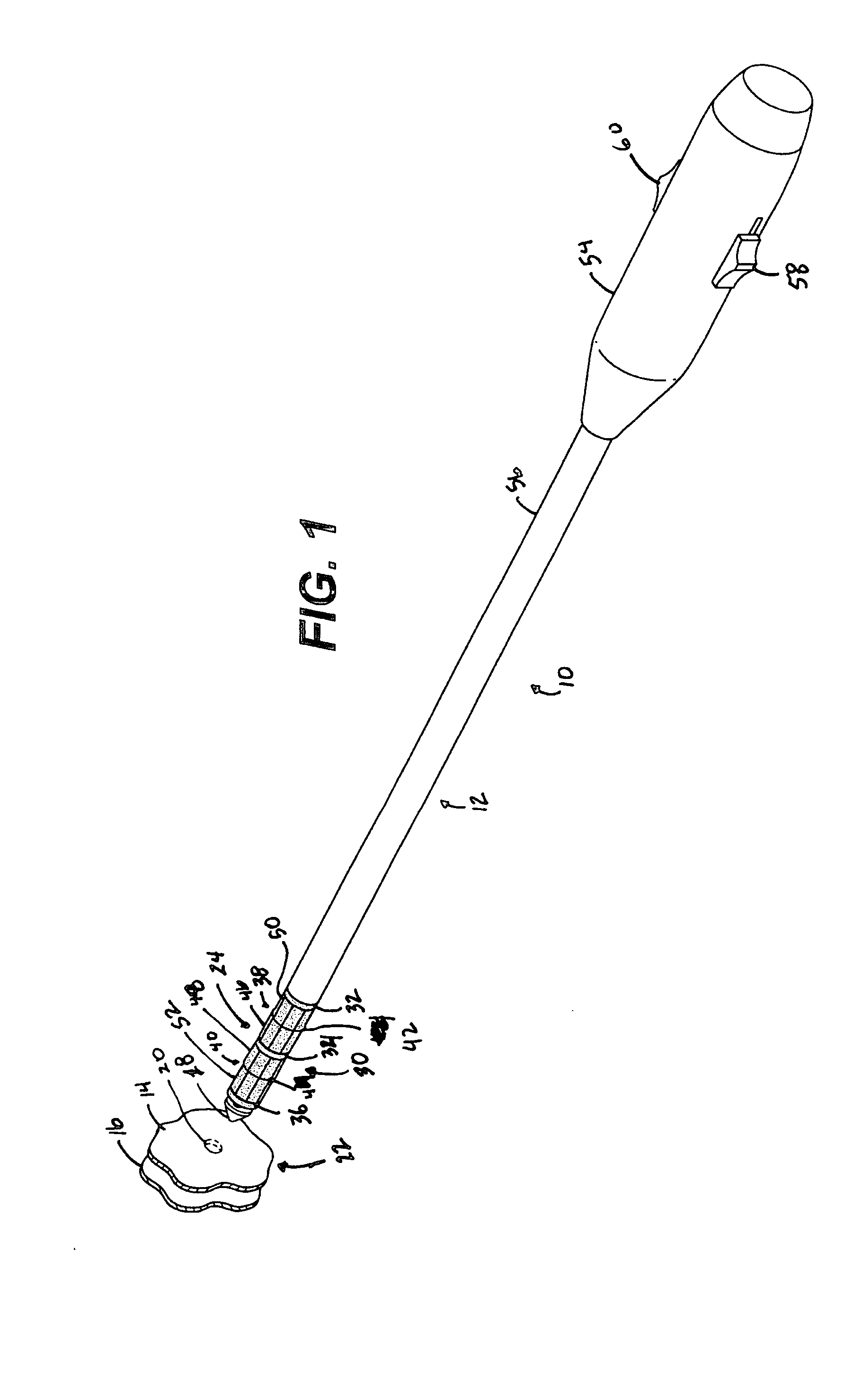

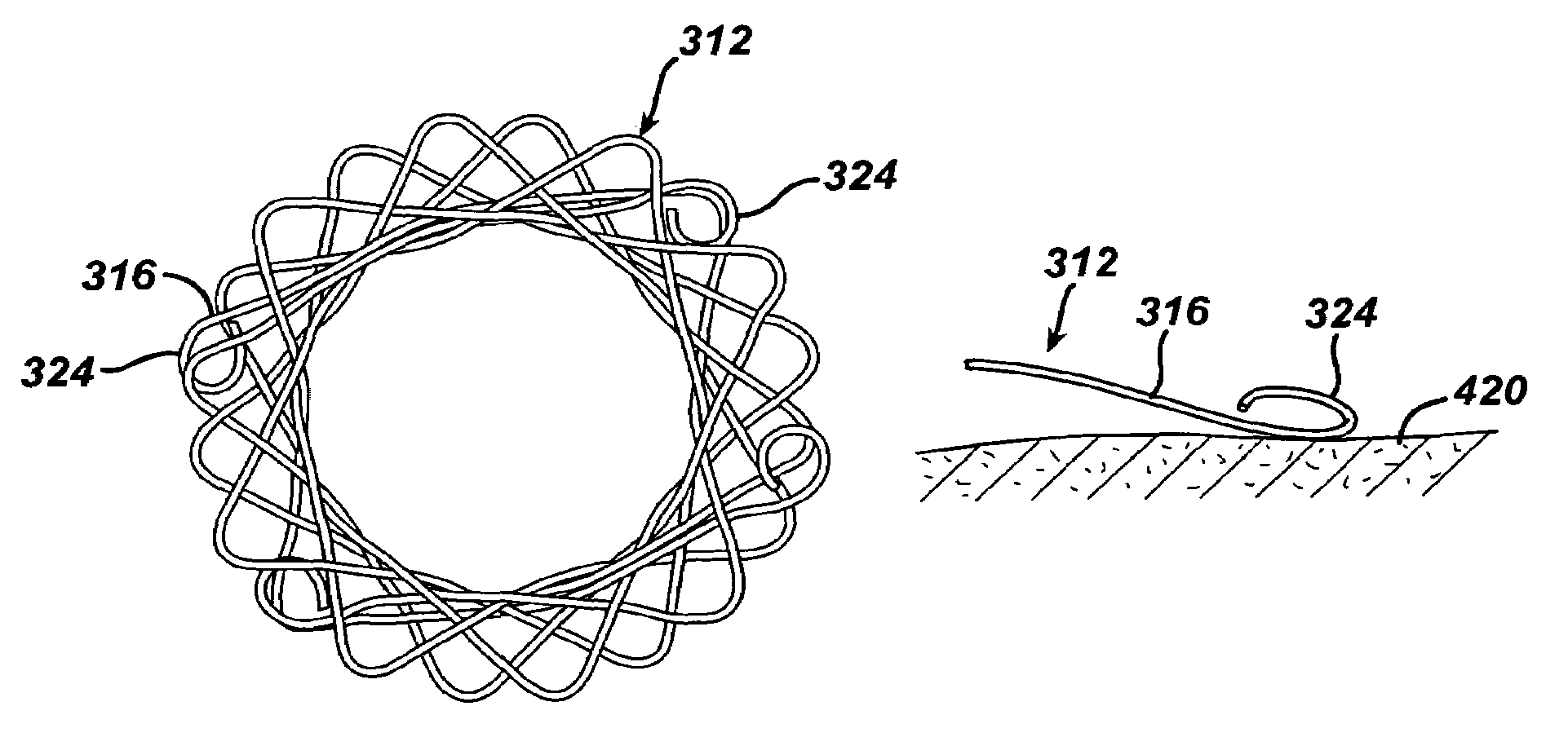

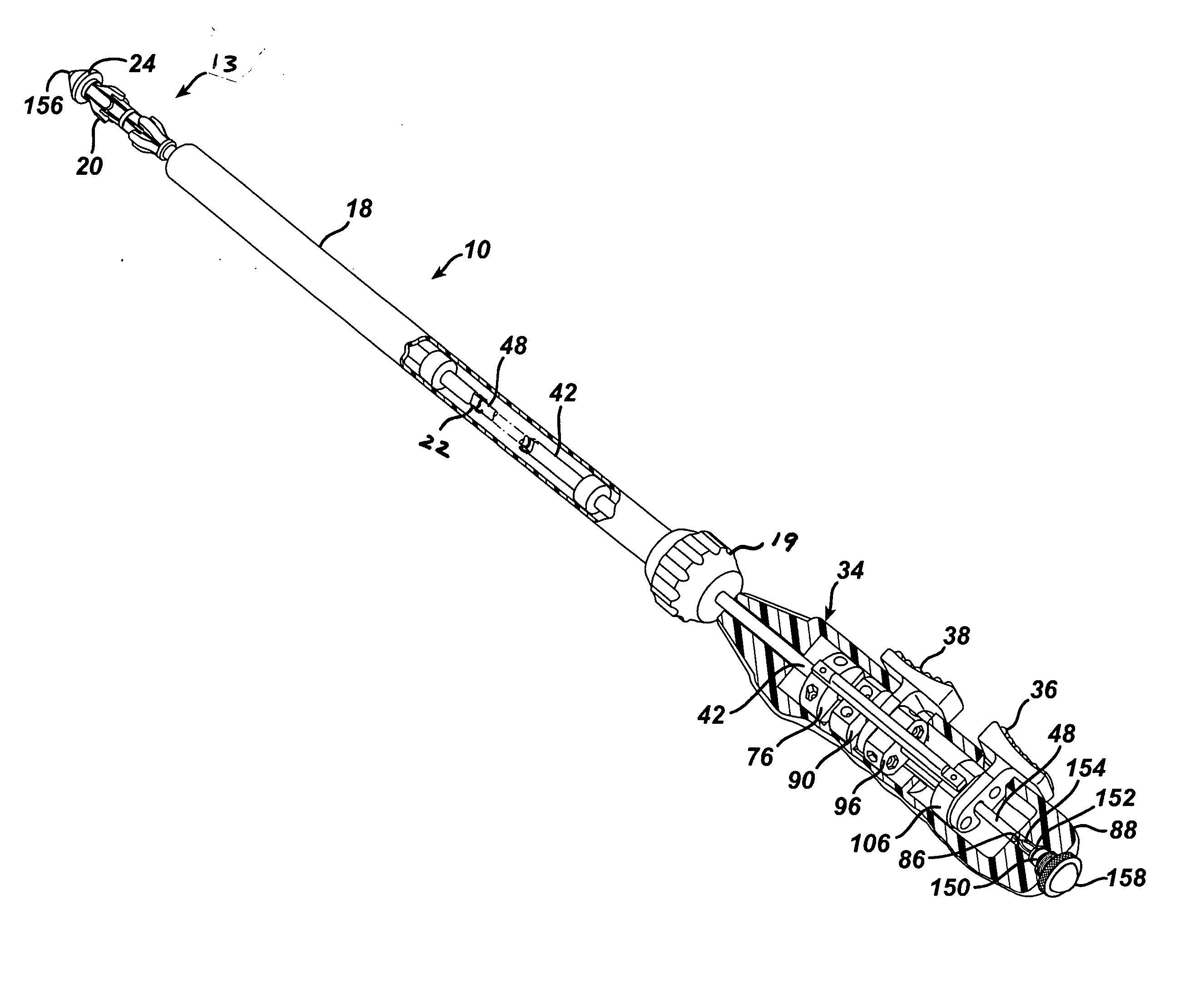

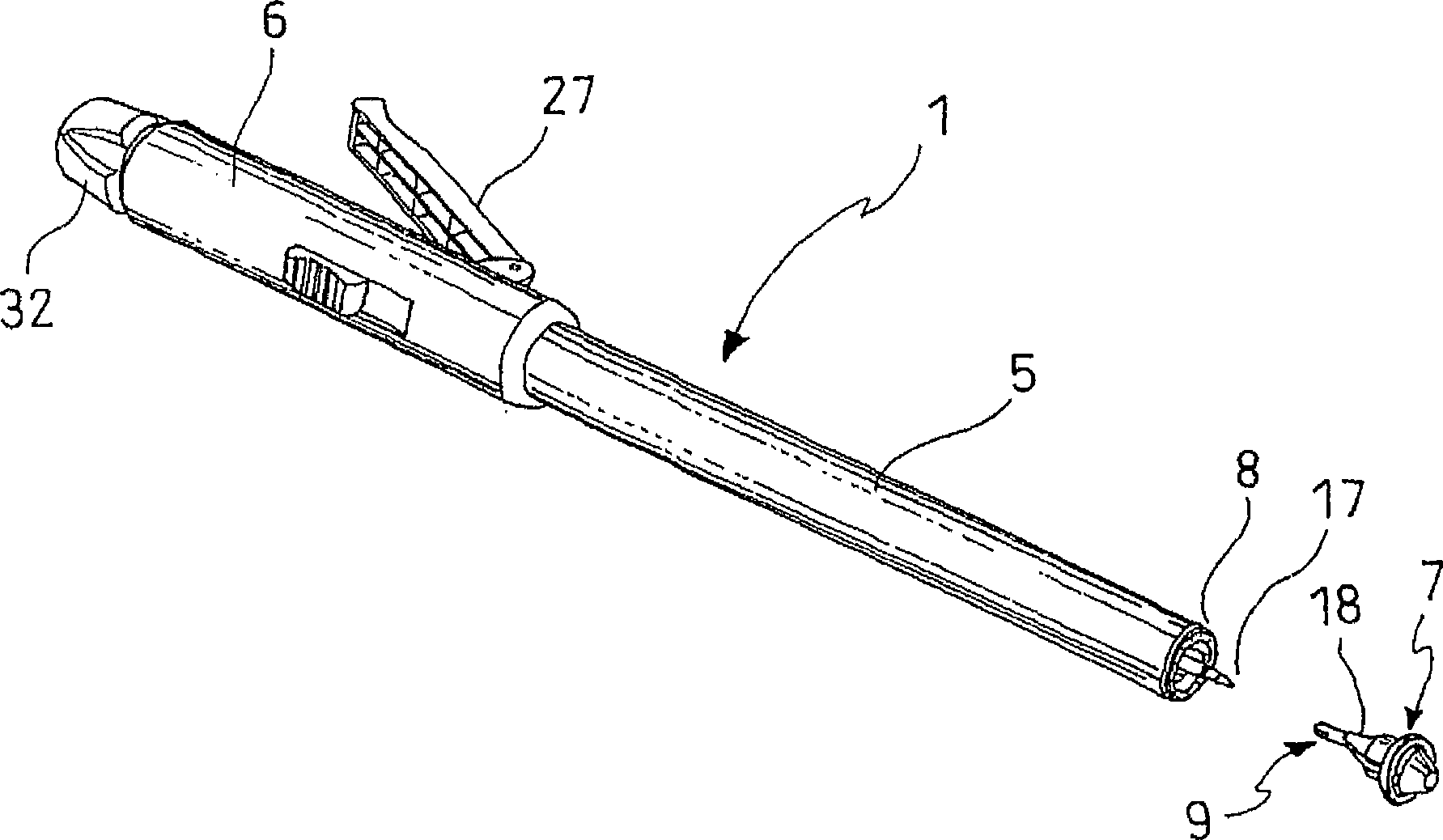

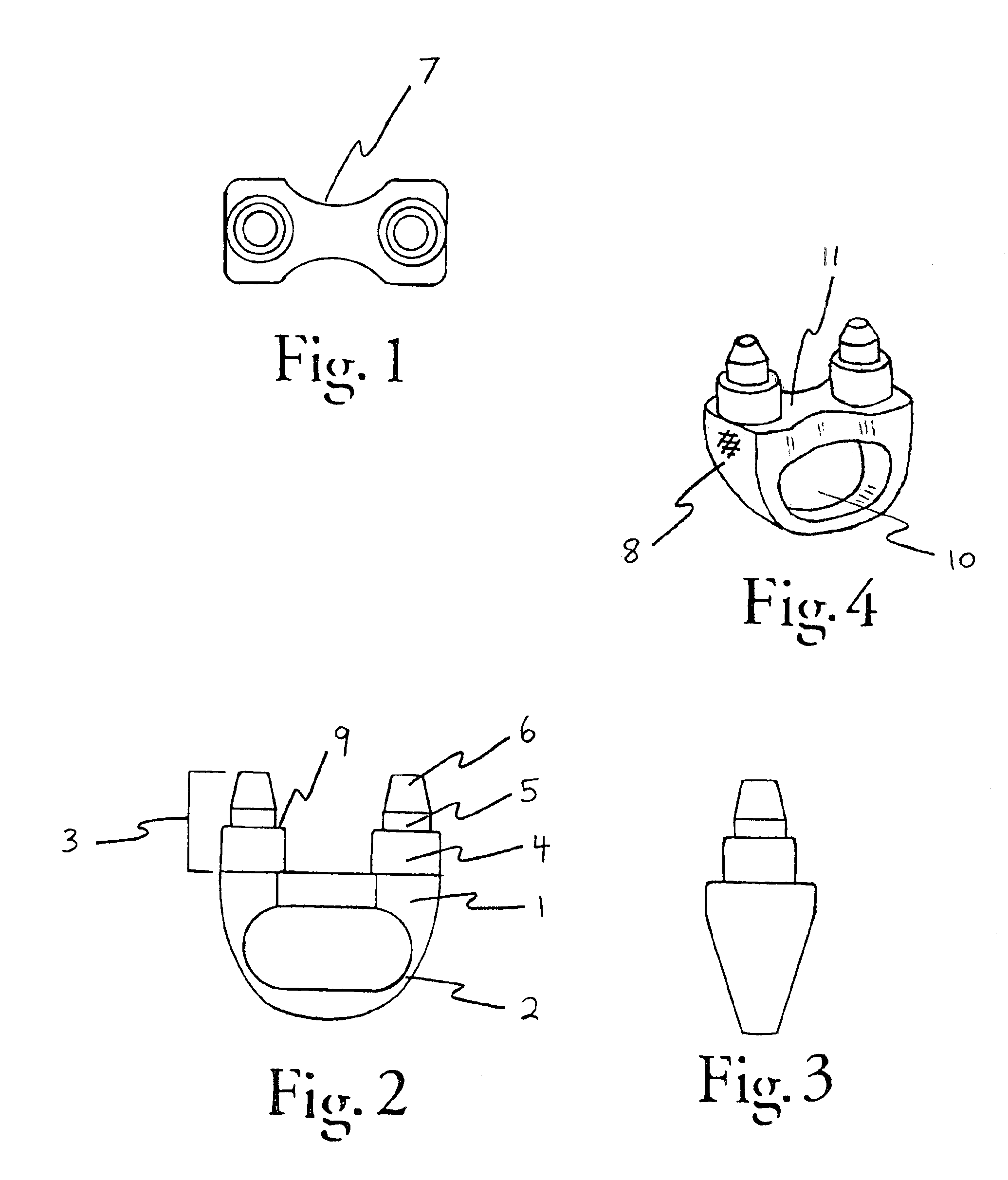

Applier for fastener for single lumen access anastomosis

ActiveUS7452363B2Easy to controlPrecise positioningSuture equipmentsDiagnostic markersRing deviceMedicine

Creating an anastomosis, or the surgical formation of a passage between two normally distinct vessels or lumens, is enhanced by an applier that introduces a ring device without the need for a separate anvil to form a hollow rivet shaped attachment. Moreover, the ring device may be advantageously formed in a cylindrical shape from molded polymer material or stamped from sheet metal with proximal and distal rings connected by proximal and distal arms that respectively form hinged, ring shaped so appose tissue walls. A center ring or portion sits in the attachment site. The applier causes actuating by moving the rings relative to one another. A latching mechanism locks the rings in the actuating state.

Owner:ETHICON ENDO SURGERY INC

Applier for fastener for single lumen access anastomosis

ActiveUS20050070926A1Easy to controlPrecise positioningSuture equipmentsDiagnostic markersRing deviceAttachment site

Creating an anastomosis, or the surgical formation of a passage between two normally distinct vessels or lumens, is enhanced by an applier that introduces a ring device without the need for a separate anvil to form a hollow rivet shaped attachment. Moreover, the ring device may be advantageously formed in a cylindrical shape from molded polymer material or stamped from sheet metal with proximal and distal rings connected by proximal and distal arms that respectively form hinged, ring shaped so appose tissue walls. A center ring or portion sits in the attachment site. The applier causes actuating by moving the rings relative to one another. A latching mechanism locks the rings in the actuating state.

Owner:ETHICON ENDO SURGERY INC

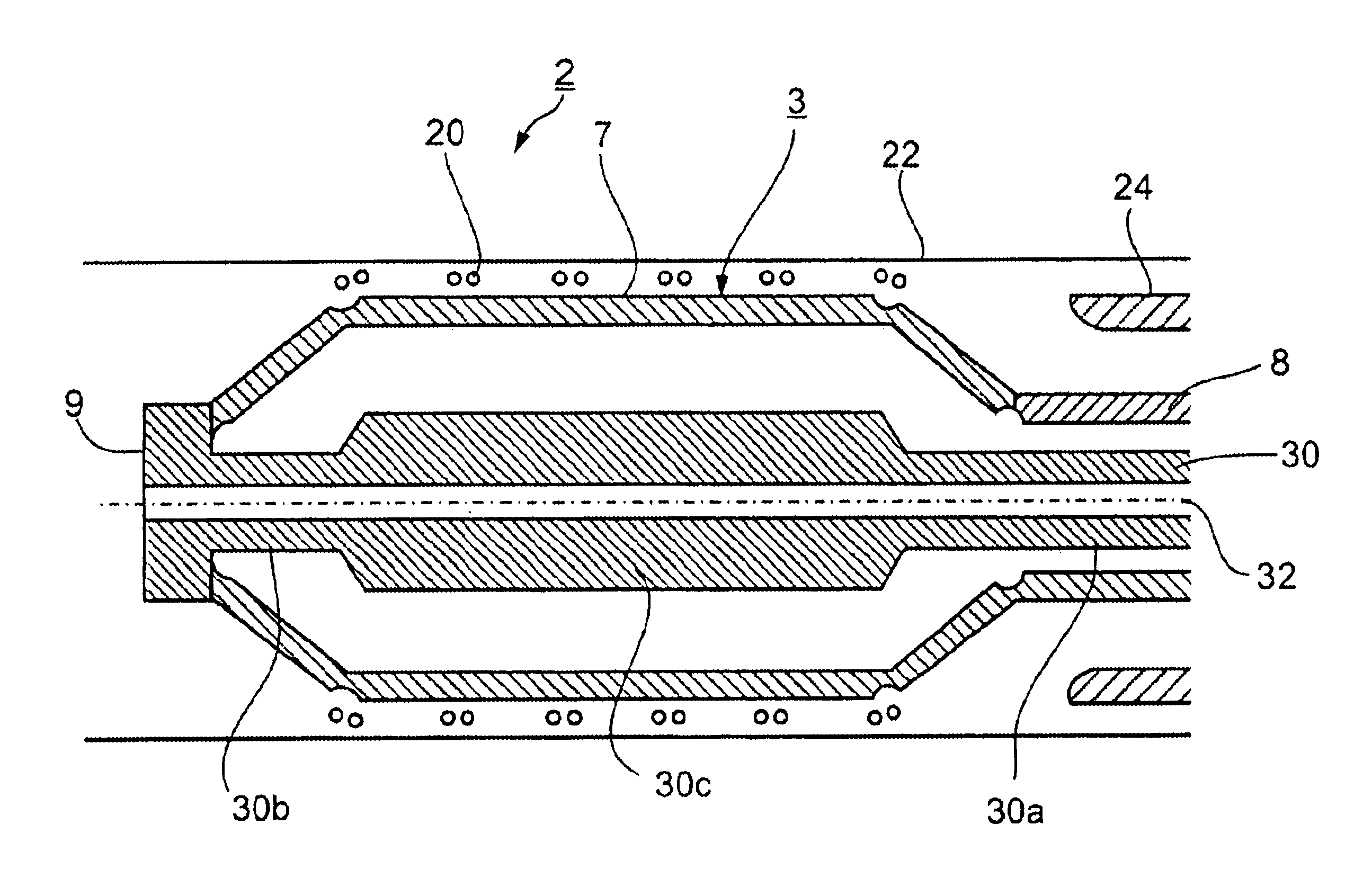

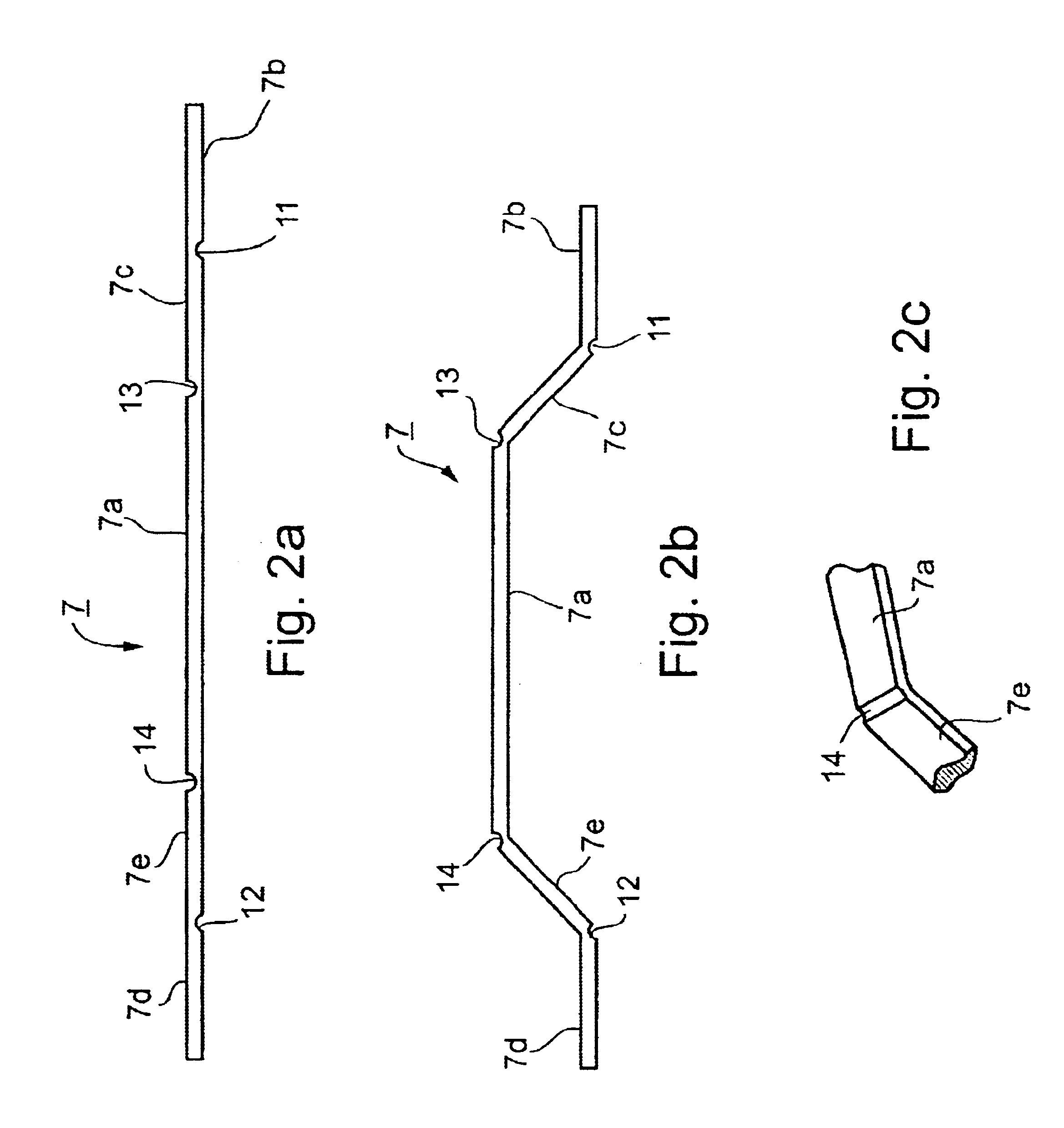

Lacing system for a shoe

InactiveUS7266911B2Result in bending elasticityEasy to insertLacing hooksInsolesRing deviceAnkle region

The invention relates to a lacing system (2) for a shoe (1), in particular for an inner shoe, with a cord-type or lace-type tensioning means (12) and looping means (11) for the tensioning means (12) arranged on oppositely lying wall regions (8, 9) of a shoe cut-out (5) extending from an entry opening (3) approximately to as far as an ankle region (4) and having at least one fixing means (18) for the tensioning means (12). In a first tensioning region (13) extending across the ankle region (4), the looping means (11) are arranged more or less opposite one another and in another tensioning region (14) extending in the direction towards the entry opening (3), the looping means (11) are arranged offset in height from one another on the oppositely lying wall regions (8, 9) and the tensioning means (12) in the first tensioning region (13) forms a tensioning loop (32) zigzaging over the shoe cut-out (5), from which a tensioning means cord (30) spanning the shoe cut-out (5) in a zigzag pattern between the looping means (11) forms the other tensioning region (14), and an end region (19) of the tensioning means cord (30) is joined to the shoe (1) by means of the fixing device (18) disposed in the region of the entry opening (3) in a clamped and / or releasable arrangement.

Owner:ATOMIC AUSTRIA

Anastomosis wire ring device

InactiveUS7608086B2Reduce manufacturing costEasy to driveBlood vesselsSurgical veterinaryRing deviceMemory effect

An anastomotic ring device for forming a hollow rivet (ring) attachment between tissue lumens facilitates laparoscopic or endoscopic implantation by including features that facilitate actuation from a stressed, generally cylindrical shape. Economical manufacturer is achieved by weaving open ended strands into a generally cylindrical stent shape that is imparted with a Shape Memory Effect (SME) to actuate to a hollow rivet (ring) shape. Alternatively or in addition to SME inherent in the woven strands, an actuating force may be received from a helical spring element incorporated into the ring. Self-actuating ring devices are enhanced by forming woven strands into petals that diverge from opposing petals such that the strands encounter less friction when actuating. Each of these features alone or in combination enhance clinical use of anastomotic ring devices, such as a bariatric gastric bypass procedure.

Owner:ETHICON ENDO SURGERY INC

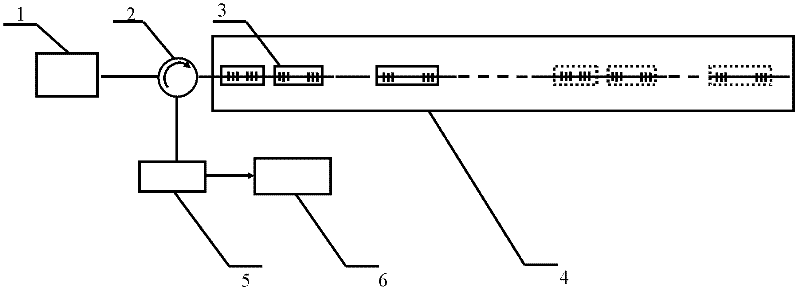

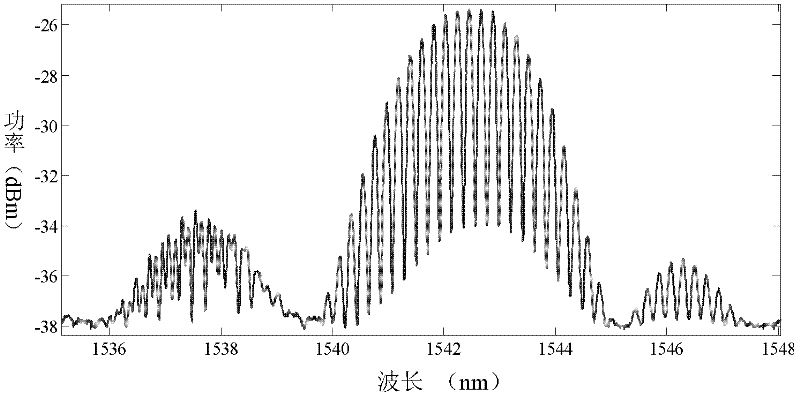

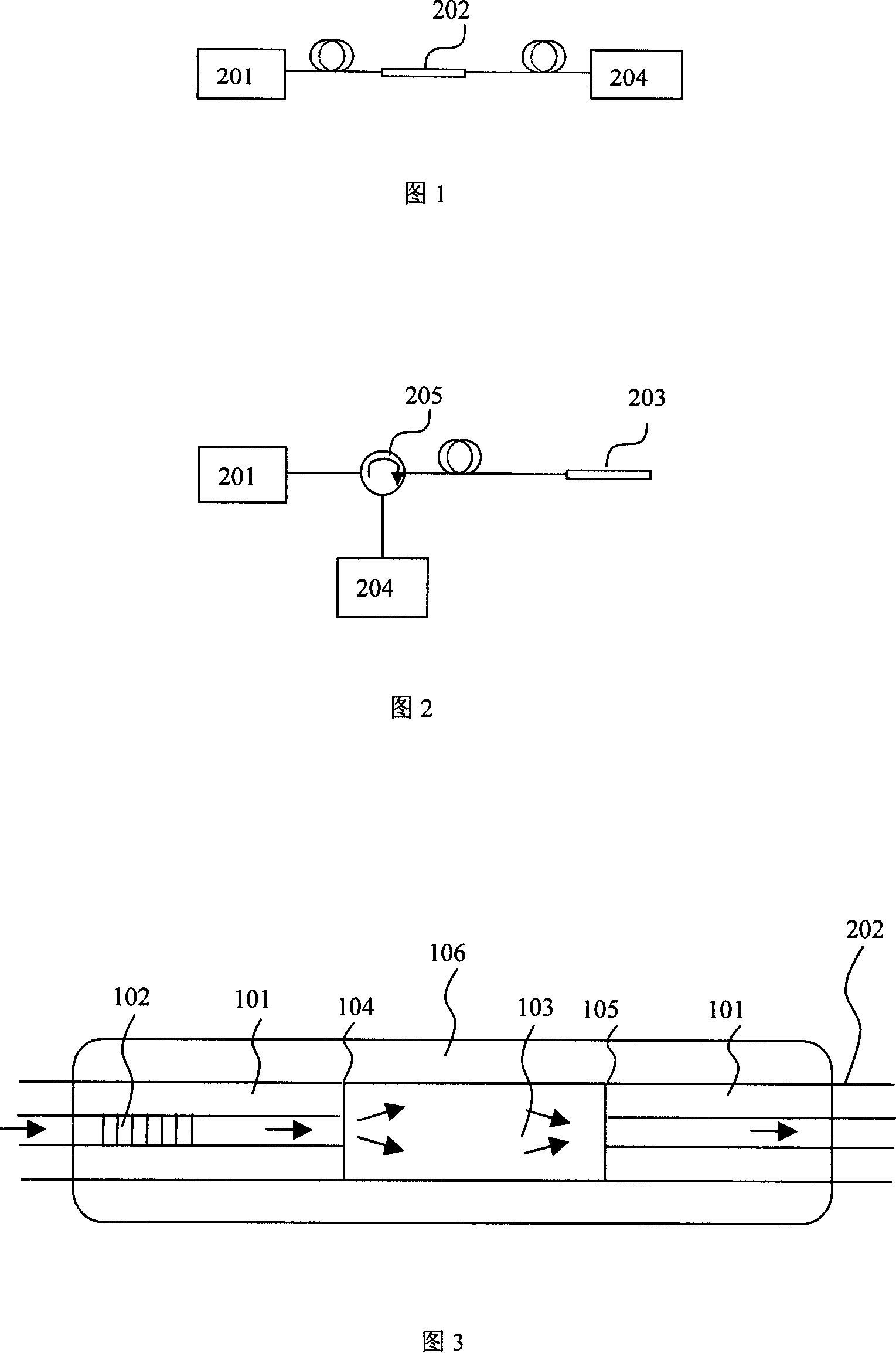

Micro-structure fiber optic Fabry-Perot cavity quasi based quasi-distributed sensor

ActiveCN102519499AIncrease multiplexing capacityEasy to prepareForce measurement by measuring optical property variationThermometers using physical/chemical changesMicro structureRing device

The invention relates to a micro-structure fiber optic Fabry-Perot cavity quasi based quasi-distributed sensor, which comprises a broadband light source (1), a fiber optic circular (2), a plurality of sensor units (3), a sensor-based optical fiber (4), an optical spectrum analyzer (5) and a data processor (6), wherein each sensor unit (3) is a micro-structure fiber optic Fabry-Perot cavity, and the sensor units are connected in series and are integrated on the sensor-based optical fiber (4); and three ports of the fiber optic ring device (2) are respectively connected with the broadband light source (1), the sensor-based optical fiber (4) integrating all sensor units, and the optical spectrum analyzer (5), and the optical spectrum analyzer (5) is connected with the data processor (6). The micro-structure fiber optic Fabry-Perot cavity quasi based quasi-distributed sensor has the advantages of large sensing capacity, simple structure, low cost, wide application prospect and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

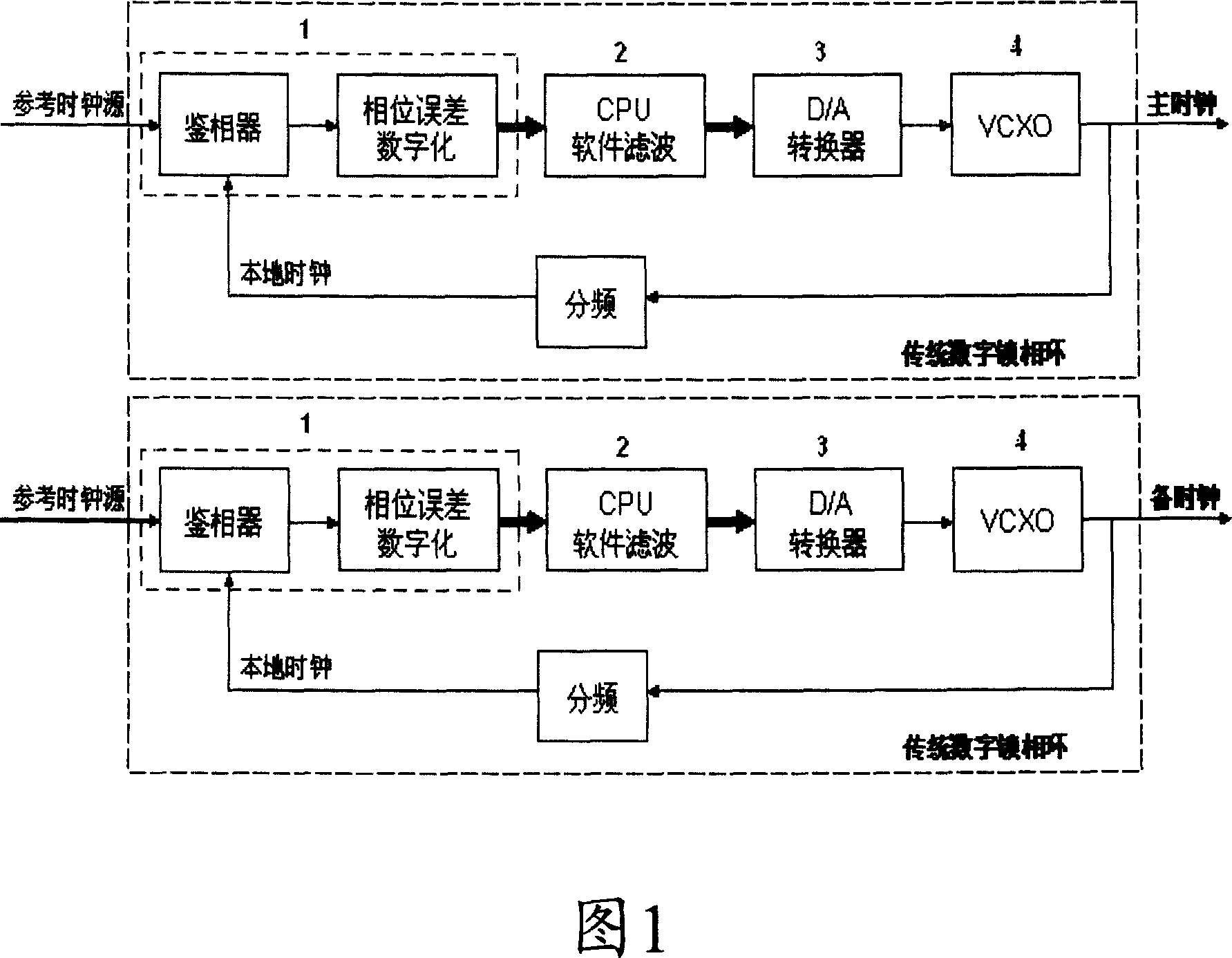

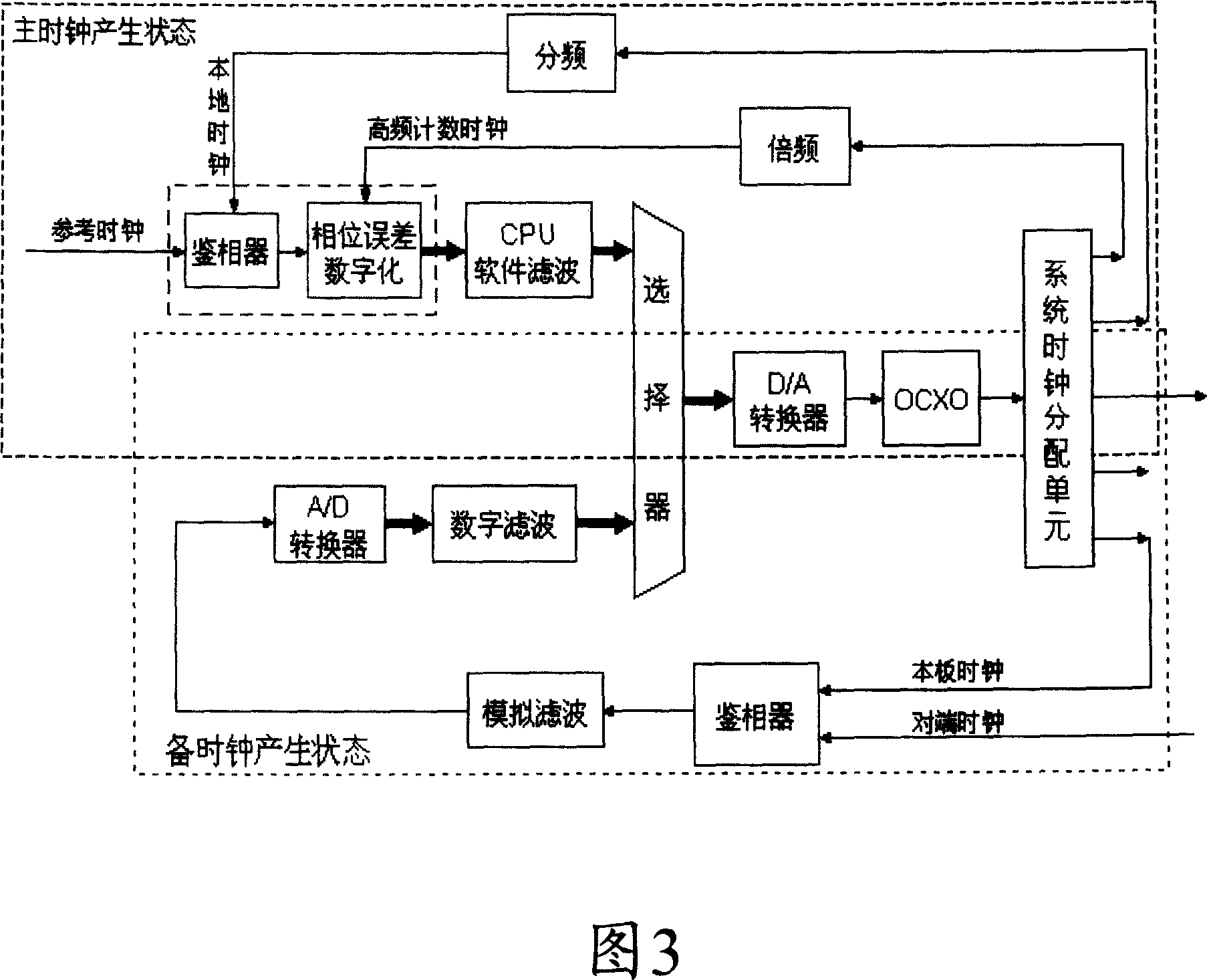

A digital phase lock loop device for smooth switching of clock phase and its method

InactiveCN101079630ASimple structureEasy to integratePulse automatic controlPhase differenceEngineering

The invention discloses a digital locked ring device to realize clock phase smooth conversion, which is characterized by the following: the reference source processes the selected reference clock according to master spare pattern; the time digital converses the reference clock and phase difference from local clock of frequency divider into the corresponding coded digital code to realize phase demodulation and phase difference digitalization to be transmitted to CPU filter and locked processing unit the proceed linear phase disposal, low-pass digital filter disposal, locked disposal, which outputs the digital phased error signal to the digifax converser as corresponding analog voltage-controlled value, in order to control the corresponding vibrating frequency output by voltage-controlled crystal oscillator; the frequency is processed by frequency divider to transmit the local clock with the same frequency as reference frequency to time digital converter. The invention realizes high-precision error control of main spare systems, which is convenient to integrate chip with high reliability and integration level.

Owner:ZTE CORP

Single lumen anastomosis applier for self-deploying fastener

A surgical tool or applier facilitates laparoscopic or endoscopic implantation through a single bodily tissue lumen of an anastomotic ring device for forming a hollow rivet type of attachment between tissue lumens. In addition to forming a puncture between apposite tissue walls at the anastomosis site, the applier assists or wholly actuates the anastomotic ring device and is retracted to deploy the actuated ring device. Illumination incorporated into a distal portion of a cannula enables confirmation of deployment.

Owner:ETHICON ENDO SURGERY INC

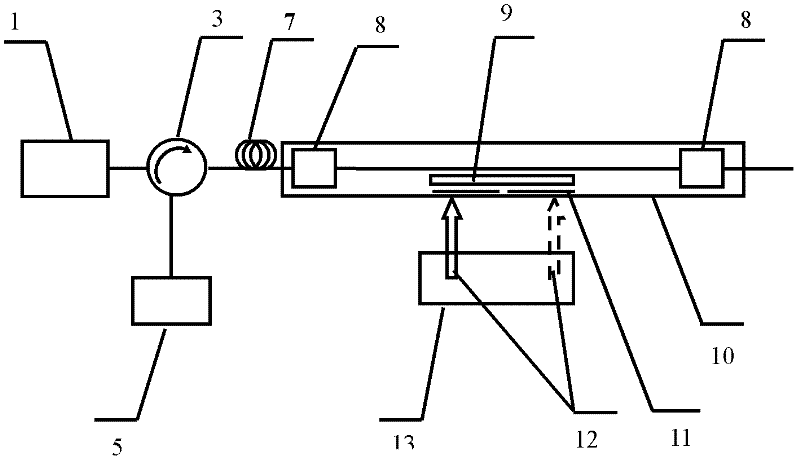

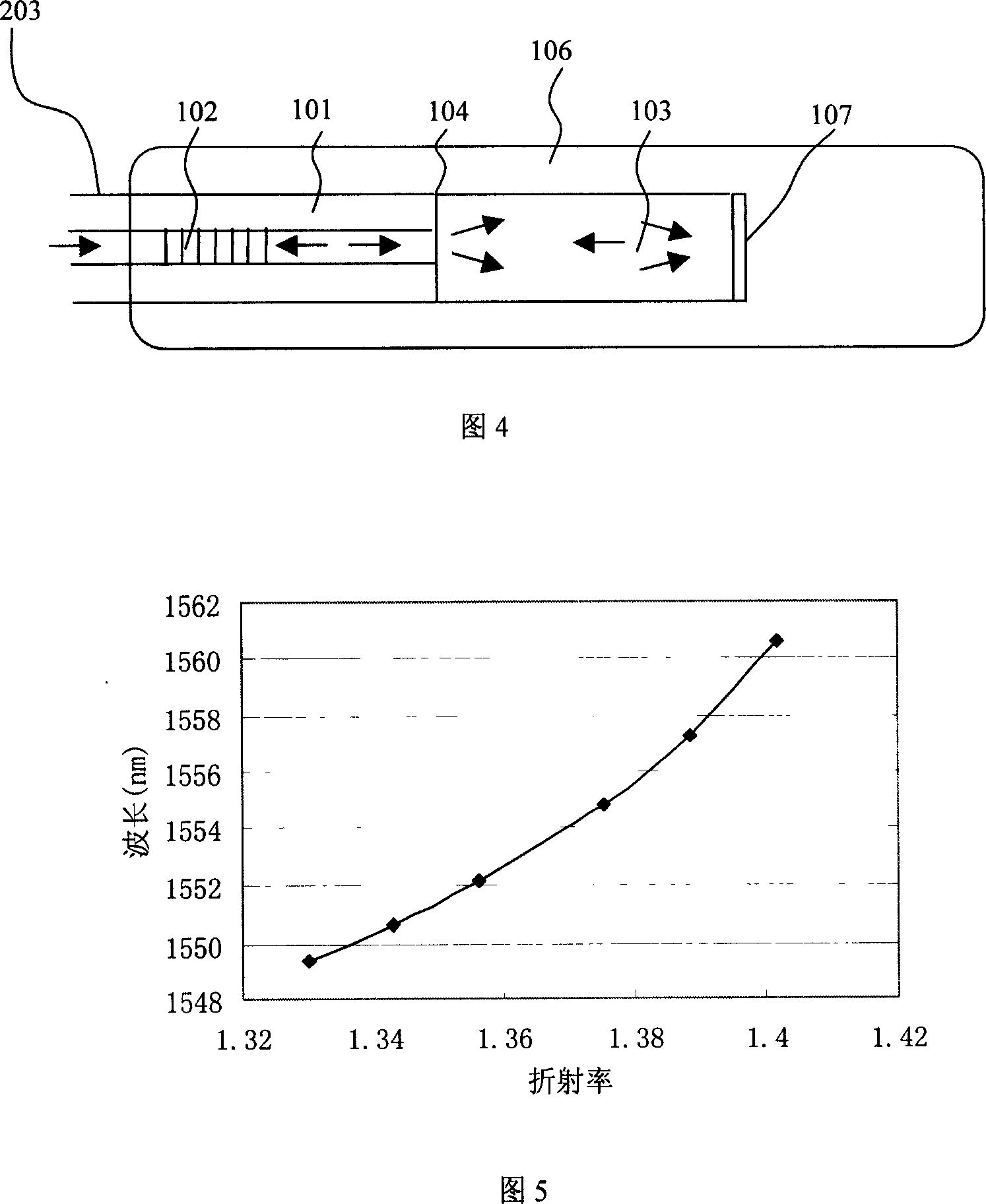

Fibre optic sensor for measuring temperature and refractive index of liquid contemporarily

InactiveCN1963400ASimple structureEasy to manufacturePhase-affecting property measurementsThermometers using physical/chemical changesGratingLiquid temperature

This invention discloses one fiber sensor to measure liquid temperature and reflection rate, wherein, the device comprises transparent and reflection types; the transparent device comprises wide band light source with out end connected to the sensor of temperature ad reflection rate with output end connected to the wave length modulation device; the transparent fiber temperature and reflection rate sensor comprises fiber Brag grating, single mode input fiber and fiber without fiber and output fiber; the reflection device comprises fiber ring device connected to wide band source, wave length demodulator and reflection temperature and reflection rate sensor.

Owner:CHINA NAT ACAD NANOTECH & ENG

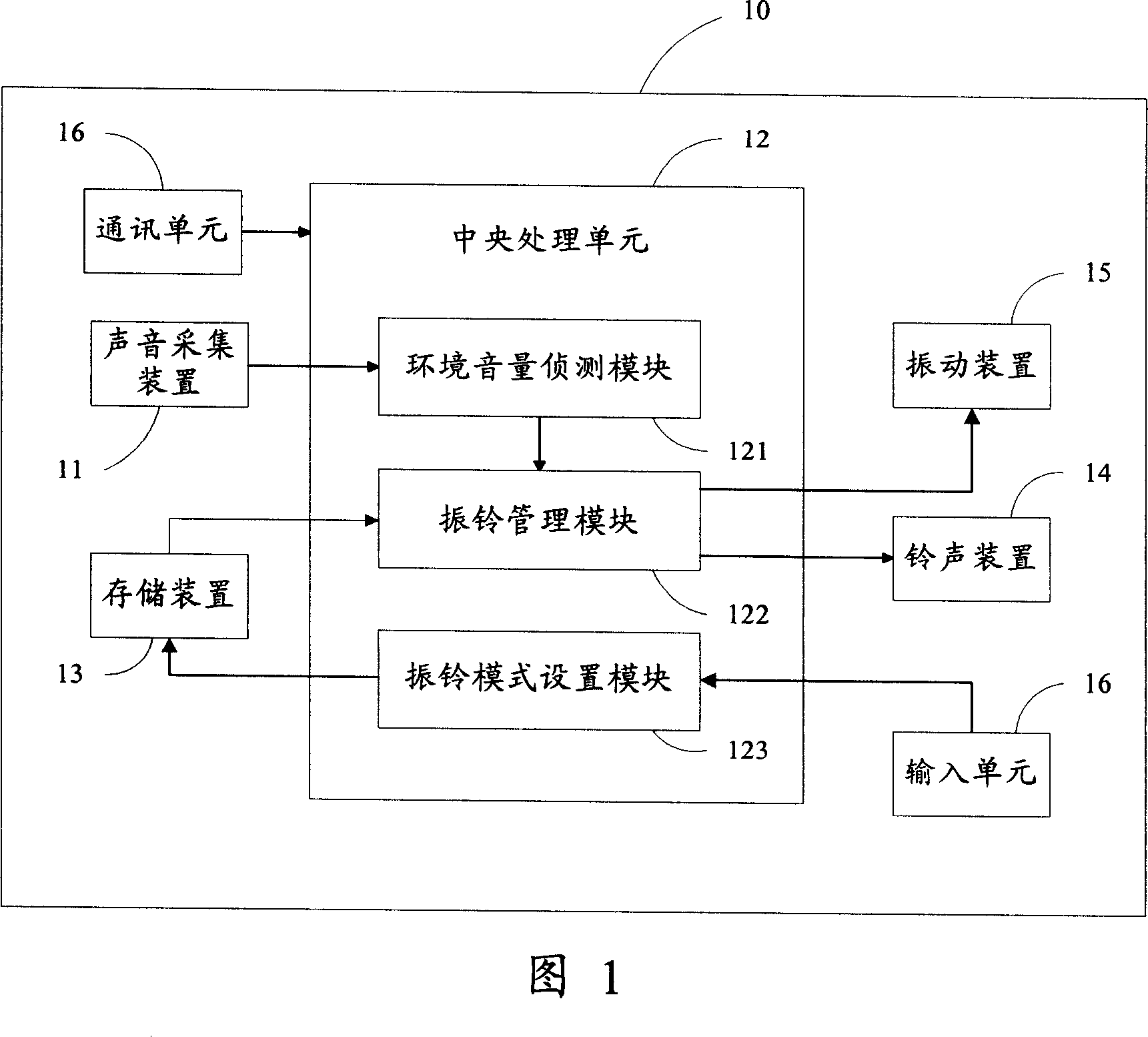

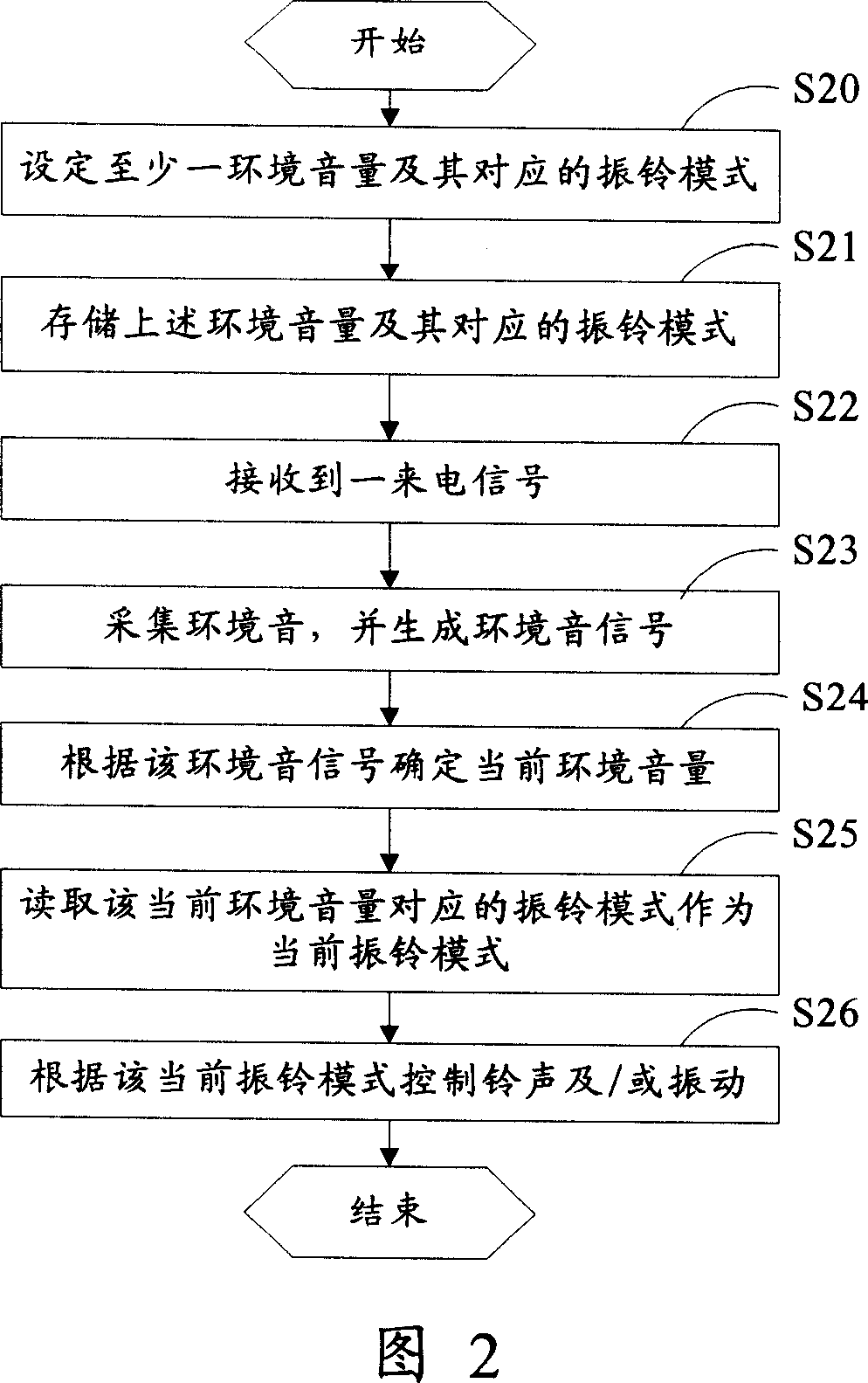

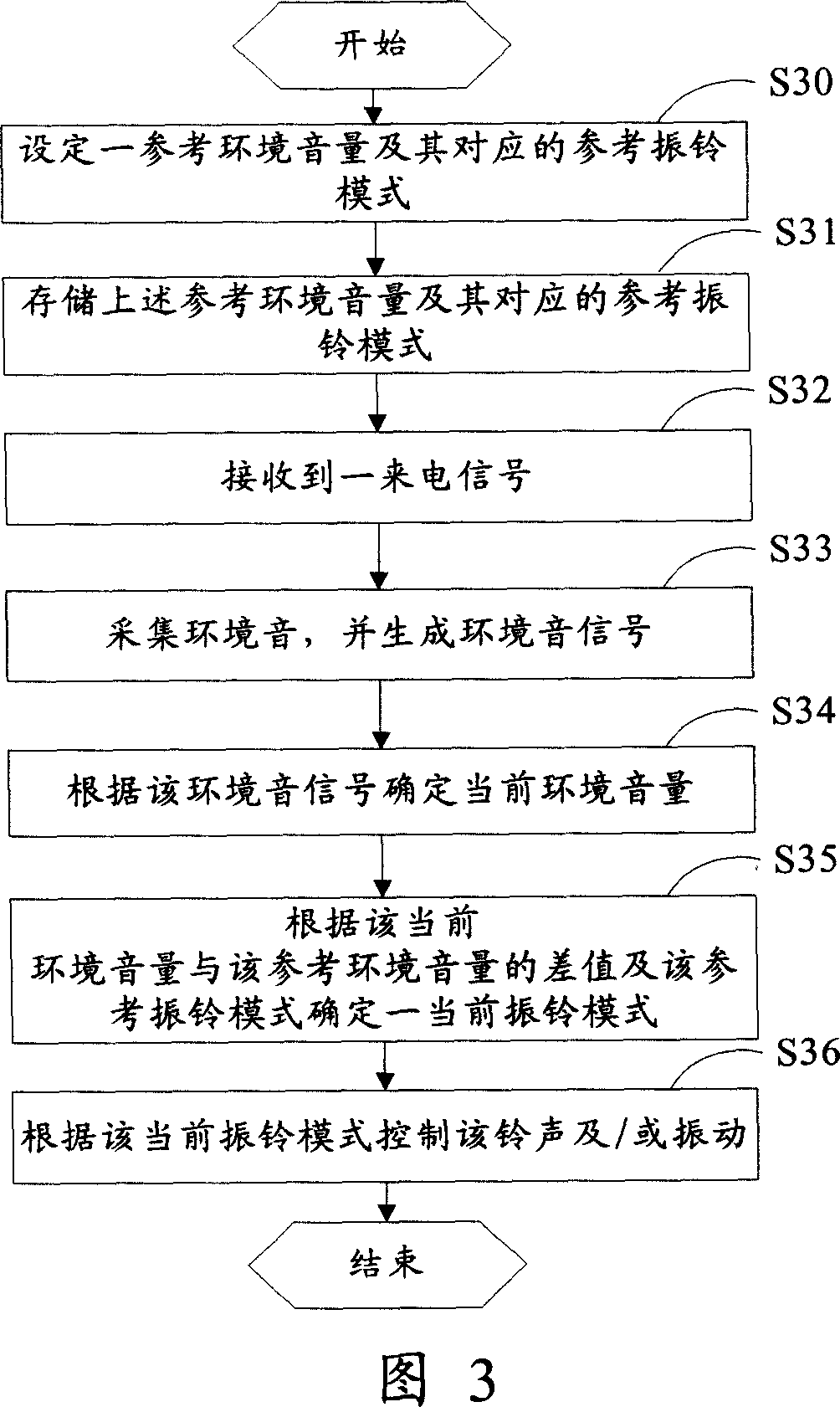

A mobile communication device and method for automatically adjusting the ring mode

The provided mobile communication device fit to automatic adjusting ringing mode comprises: a communication unit, a memory, a sound collection device, an input unit, a CPU included an environmental ring detection module and a ringing mode setting module and a rining management module, a vibration device, and a ring device. The relative method comprises: when receiving a calling signal, collecting environmental sound to form signal and determine current environmental volume; then, adjusting the ringing mode to operate the ring and / or vibration. This invention prevents others from disturbing as loud ringing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

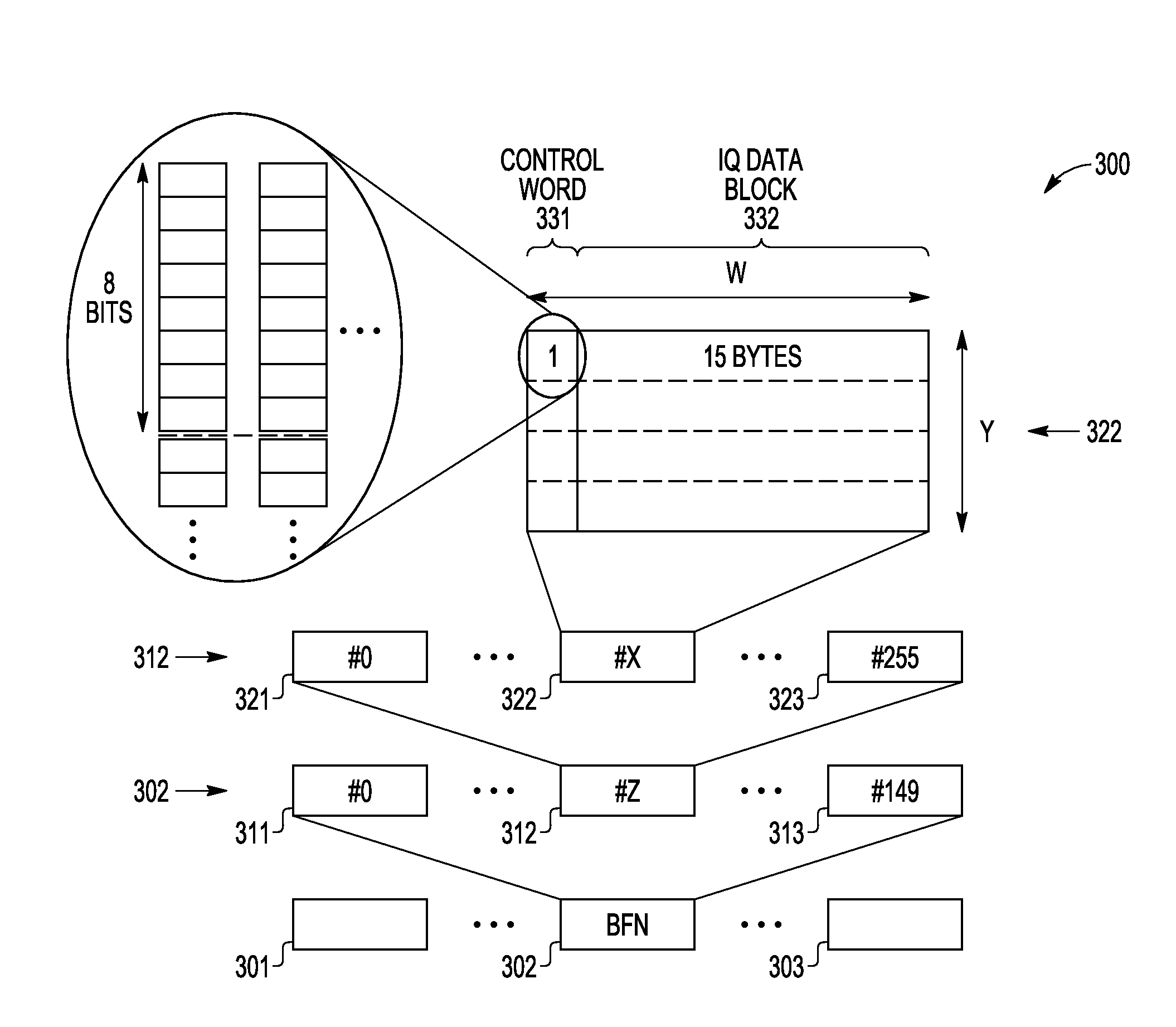

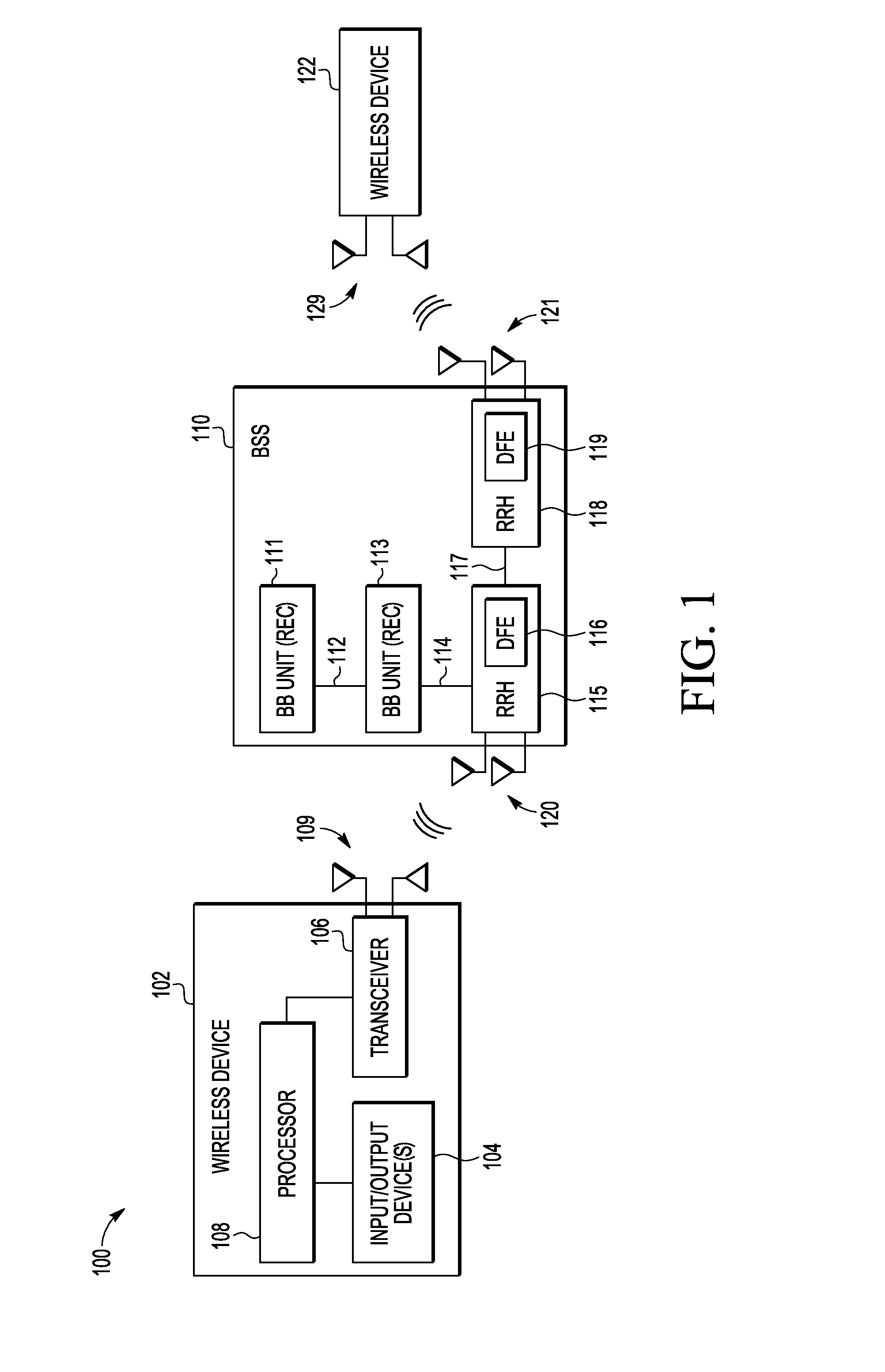

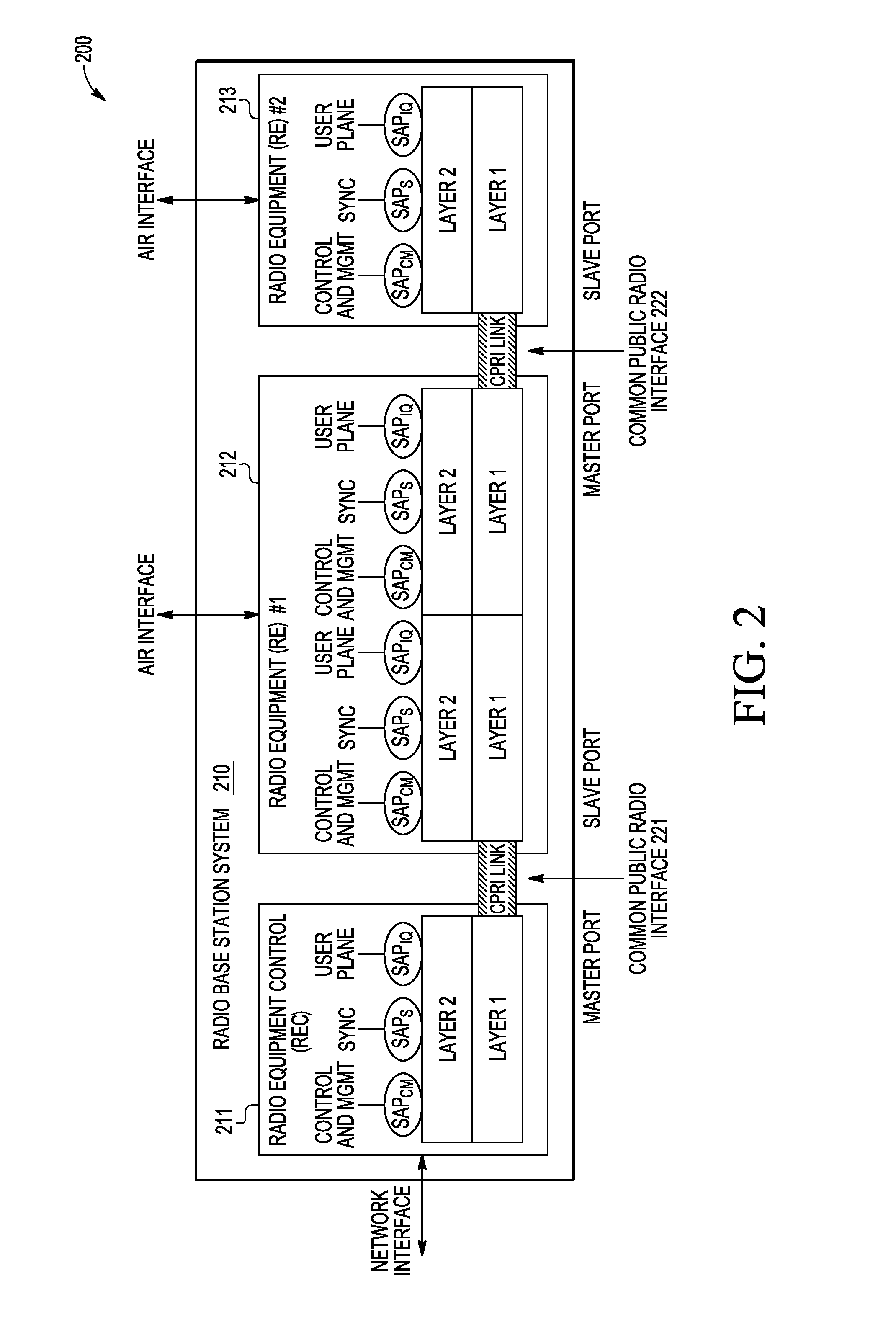

Method and System for Automatically Controlling the Insertion of Control Word in CPRI Daisy Chain Configuration

A method and apparatus automatically controls the insertion of information flow data over a shared CPRI link (561) by providing a hardware control mechanism (504-509) at a local radio base station subsystem (501) connected in a CPRI daisy chain configuration between a downstream RE device (570) and an upstream REC device (560) for determining whether the control word being transmitted is sourced from a downstream device (e.g., forwarded data from a downstream RE device) or from the local device.

Owner:NXP USA INC

Double-disk type magnetorheological clutch

InactiveCN102080692ASpeed up the flowIncrease the magnetic field strengthFluid clutchesRing deviceDrive shaft

The invention relates to a double-disk type magnetorheological clutch which comprises a driving disk, a driven disk, a magnetorheological fluid, a transmission shaft, a rotating blade, a magnetic conduction shell, a magnet exciting coil, an insulation ring, a fluid inlet, a fluid outlet, a bearing and a sealing element, wherein the driving disk is connected to a driving shaft; the driven disk is connected to a driven shaft; the magnetorheological fluid is filled between primary and secondary magnetic conduction disks through the fluid inlet; a sealing ring device is rotated so as to keep the magnetorheological fluid between the two disks; the magnet exciting coil is fixed in the magnetic conduction shell with no need of an electric brush; and the magnetorheological fluid is sealed between the two disks, and the rotating blade is arranged on the transmission shaft. The rotating blade is rotated under the driving of the transmission shaft, so air is guided to circularly flow through an air vent, and the excellent radiating property is maintained. The double-disk type magnetorheological clutch has the advantages of compact structure and good radiation property, and can be used for natural air cooling.

Owner:CHINA UNIV OF MINING & TECH

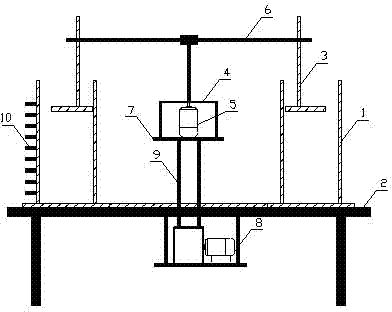

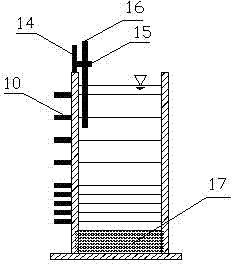

Annular water tank device for simulating sediment pollutant resuspension release

InactiveCN103869048AHighlight substantiveEasy to sampleEarth material testingTesting waterRing deviceWater flow

The invention relates to an annular water tank device for simulating sediment pollutant resuspension release. The annular water tank device comprises an annular water tank main body, a base, a rotary power device, a lifting power device and a flow velocity measurement and sampling device, wherein the annular water tank main body is arranged on the base; the lifting power device is arranged in the center of the base; the rotary power device is arranged at the upper end of the lifting power device; the flow velocity measurement and sampling device is arranged on the upper part of an outer wall of the annular water tank main body. The annular water tank device is small in size and can be conveniently moved even can be transported to be subjected to field sampling for test, a storage reservoir is not needed, a water pump is not needed, a small number of needed samples are needed, the flow velocity is conveniently and feasibly adjusted, observation and operation are convenient, mechanical interference is avoided, and infinitely long water flow can be simulated. An eccentric shear ring device floating on water surface is adopted in the device, and water flow in the annular water tank can be kept horizontal, so that secondary flow development is effectively suppressed.

Owner:SHANGHAI UNIV

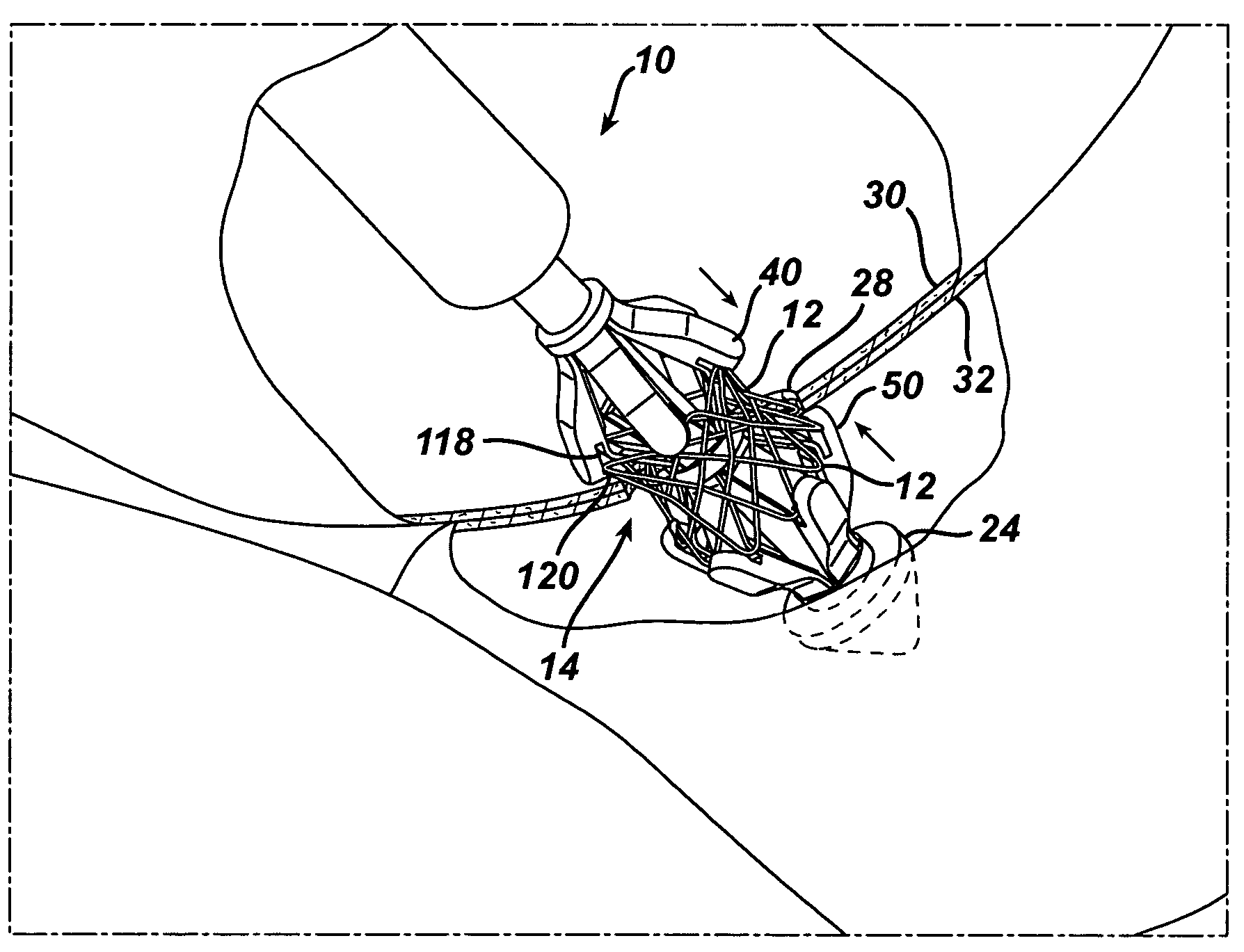

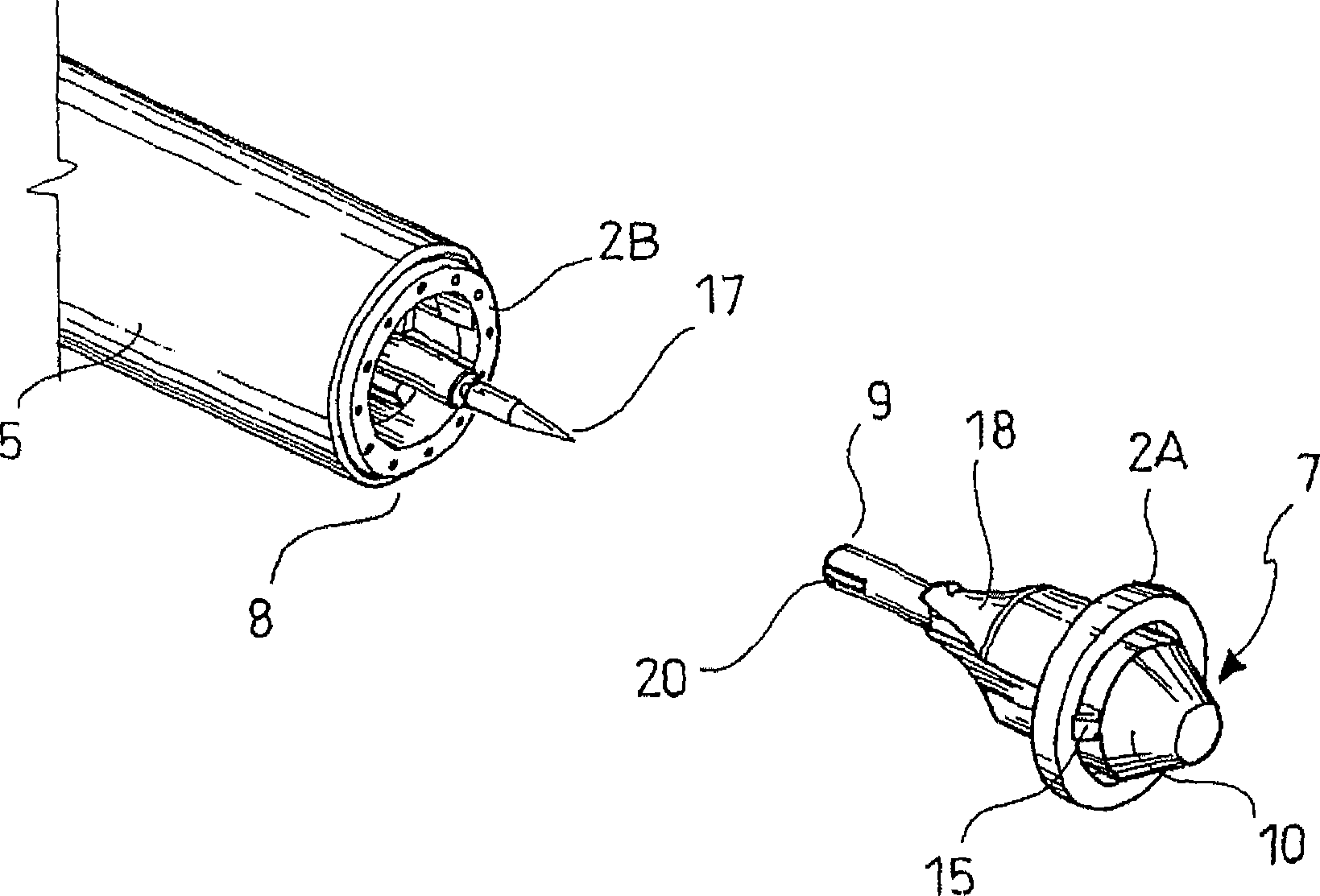

An anastomotic applier

ActiveCN101522112ANo added complexityLow dexterity requirementsSurgical staplesRing deviceEngineering

A surgical instrument (1) for implanting an anastomotic ring device (2) comprises an anvil (7) including a first connecting part (9) and a seat (15) for receiving a distal compression ring (2A), an actuating member (8) comprising: - one or more seats (22,24) for receiving a proximal compression ring (28) and a retention element (2C); - a second connecting part (17) configured to engage the first connecting part (9) for connecting the anvil (7) with the actuating member (8), wherein the second connecting part (17) is movable to approximate the distal compression ring (2A) towards the proximal compression ring (2B); - an actuating part (24) configured to act on the retention element (2C), the actuating part (24) being movable for moving the retention element (2C) towards and in engagement with the distal compression ring (2A) to connect the compression rings.

Owner:ETHICON ENDO SURGERY INC

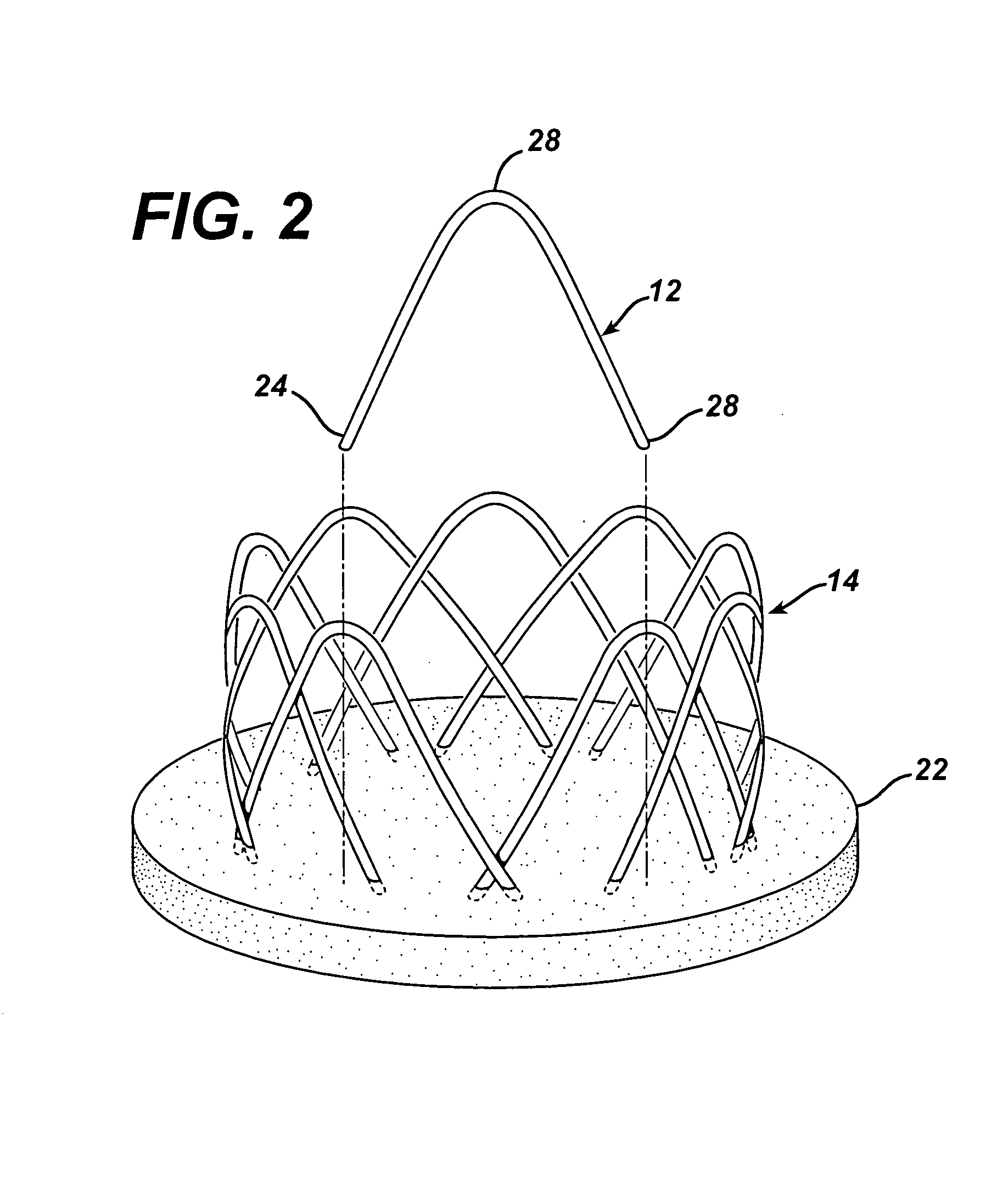

Unfolding anastomosis ring device

An anastomotic ring device for forming a hollow rivet (ring) attachment between tissue lumens facilitates laparoscopic or endoscopic implantation by including features that facilitate assembly, specifically by forming from constituent arcuate members or petals that join with one another at a circular midpoint. Automated assembly is thereby facilitated with each longitudinal half including a “crown” of these arcuate members arranged in a cylindrical pattern with equally spaced curved points and overlapping ends. Molded arcuate members with integral hinges further enhance assembly and provide other advantages, especially when implanted with an applier capable of actuating the anastomotic ring device.

Owner:ETHICON ENDO SURGERY INC

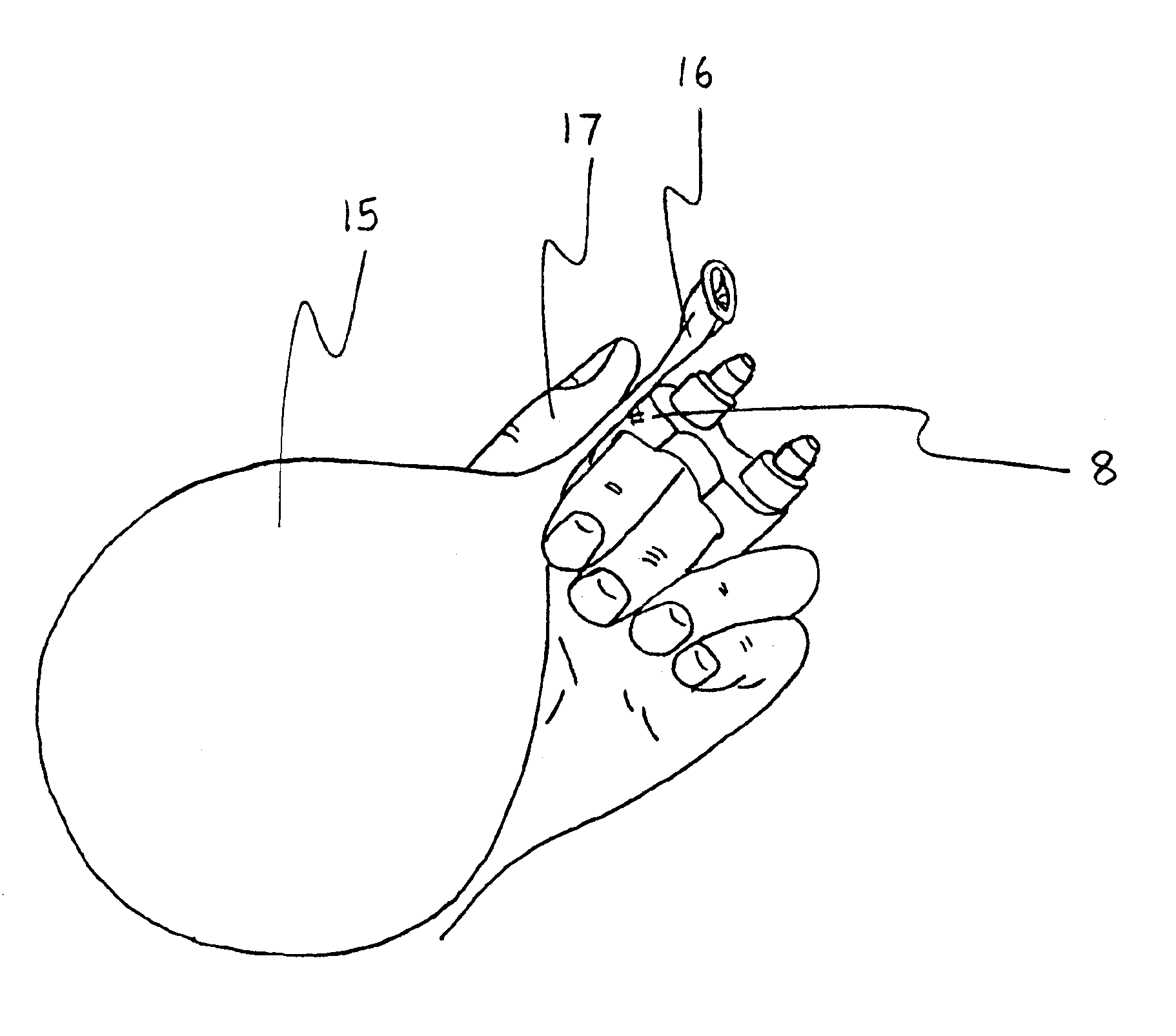

Hand held balloon tier

A balloon knot tying device that has a base with dual rods provided for stretching the leading end of an inflated balloon around to assist in tying a permanent knot. Each rod having at least two diameters to provide a retaining edge so the balloon will not slide down onto the base during the knot tying operation. The base with dual rods can be attached to different holding devices such as a ring shaped device for inserting at least 1 finger or a handle shaped device for gripping. The knot tying operation consisting of holding the balloon against the side of the device and stretching the leading end around the rods to form a loop. The leading end is then crossed under the loop through a relief area and up between the two rods. The leading end is then pulled off of the rods to form a permanent knot.

Owner:MIZE KAREN JENNIFER

Pulse oximetry ring

A biometric sensor can be disposed within a wearable finger ring. The ring device can provide a variety of different biometric and health measurements. The ring device can also be in communication with the Internet. Information from the ring device can be saved in the cloud, accessed by remote smart devices, accessed by remote computers, or otherwise accessed and saved. Various users, such as doctors and EMS personnel, can access the information provided by the ring device.

Owner:OWLET BABY CARE INC

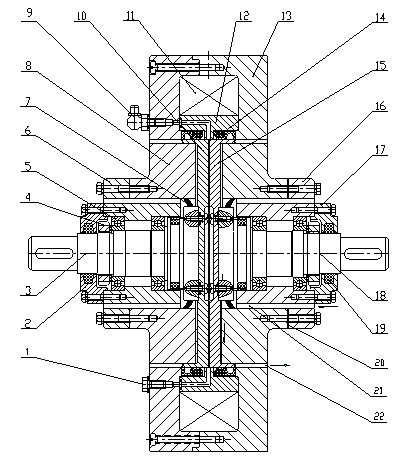

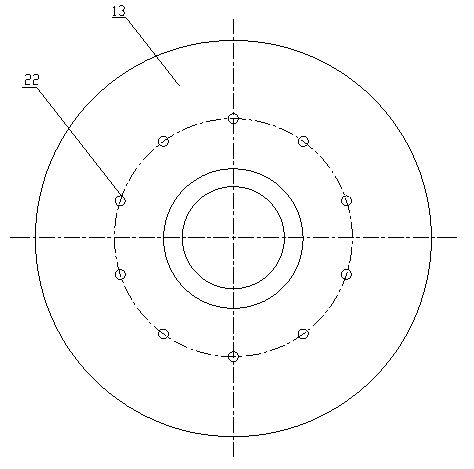

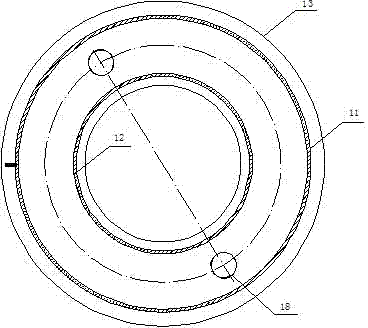

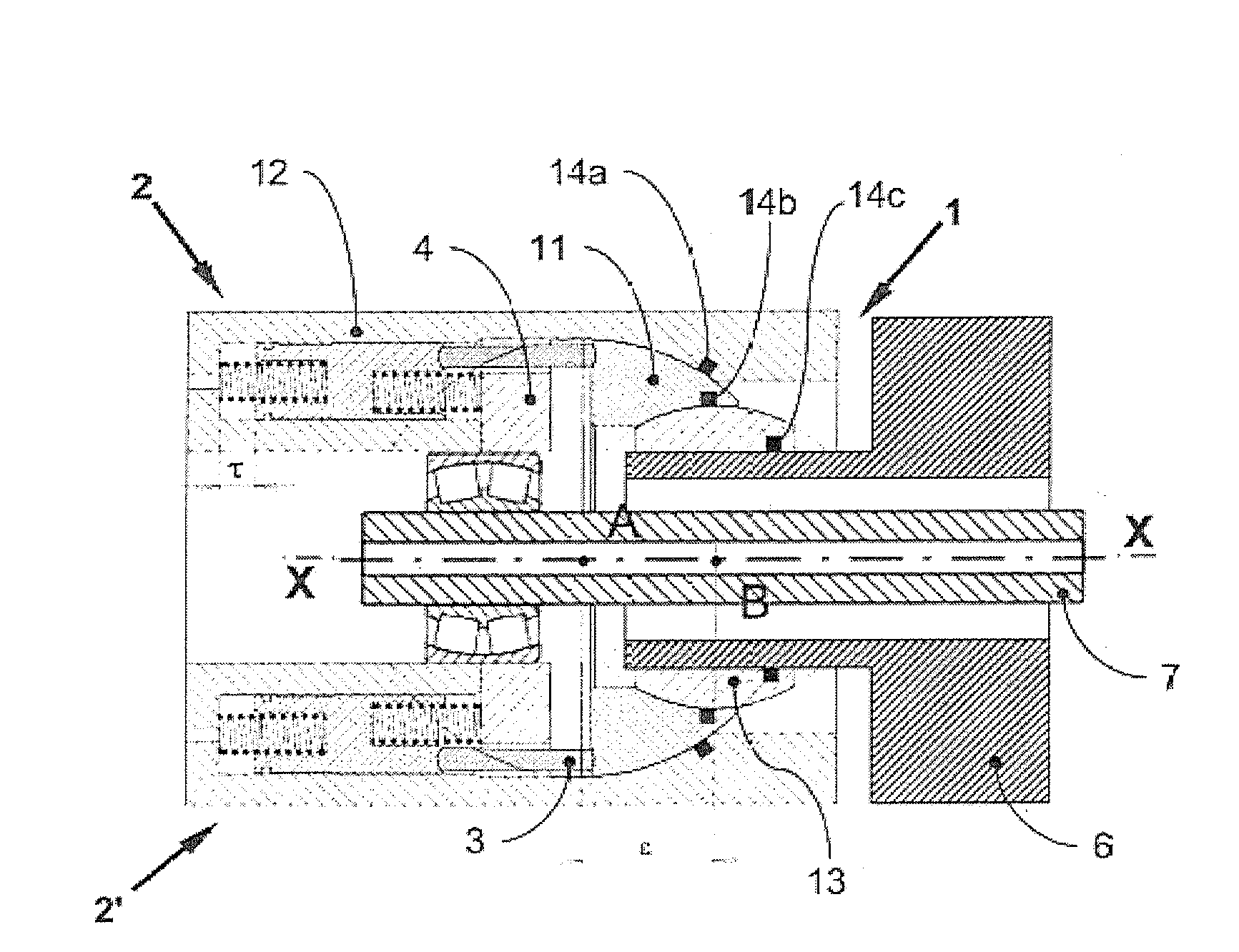

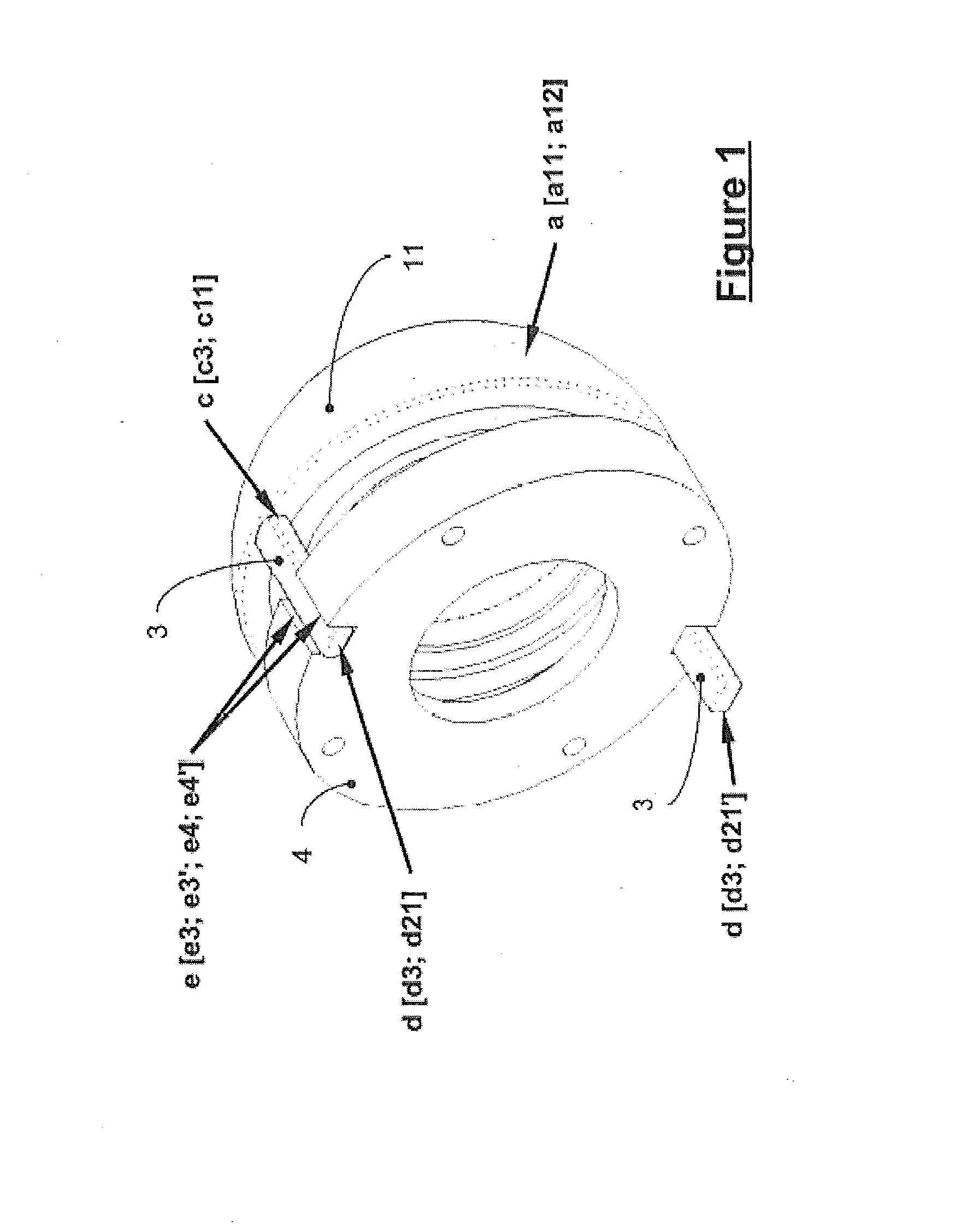

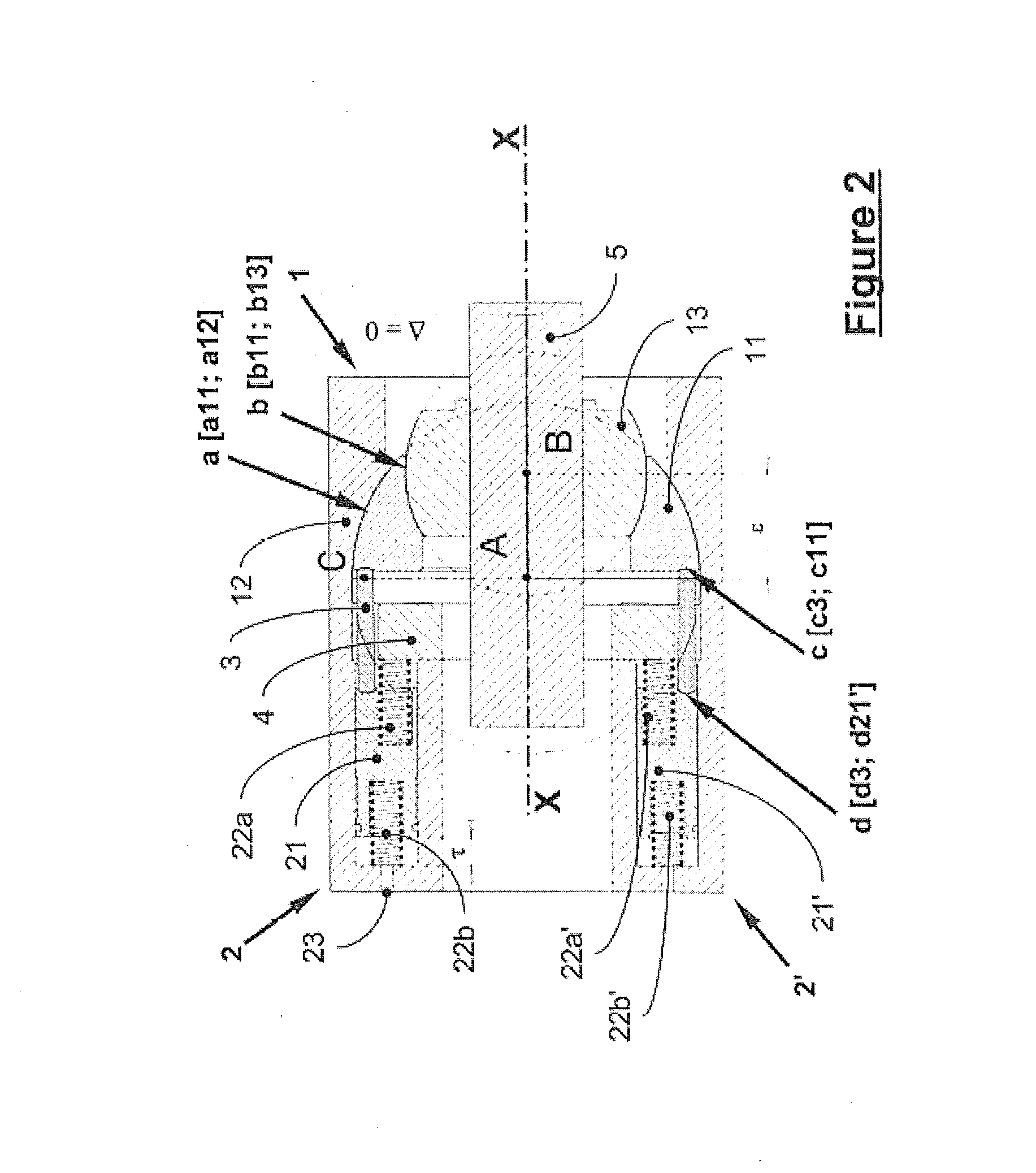

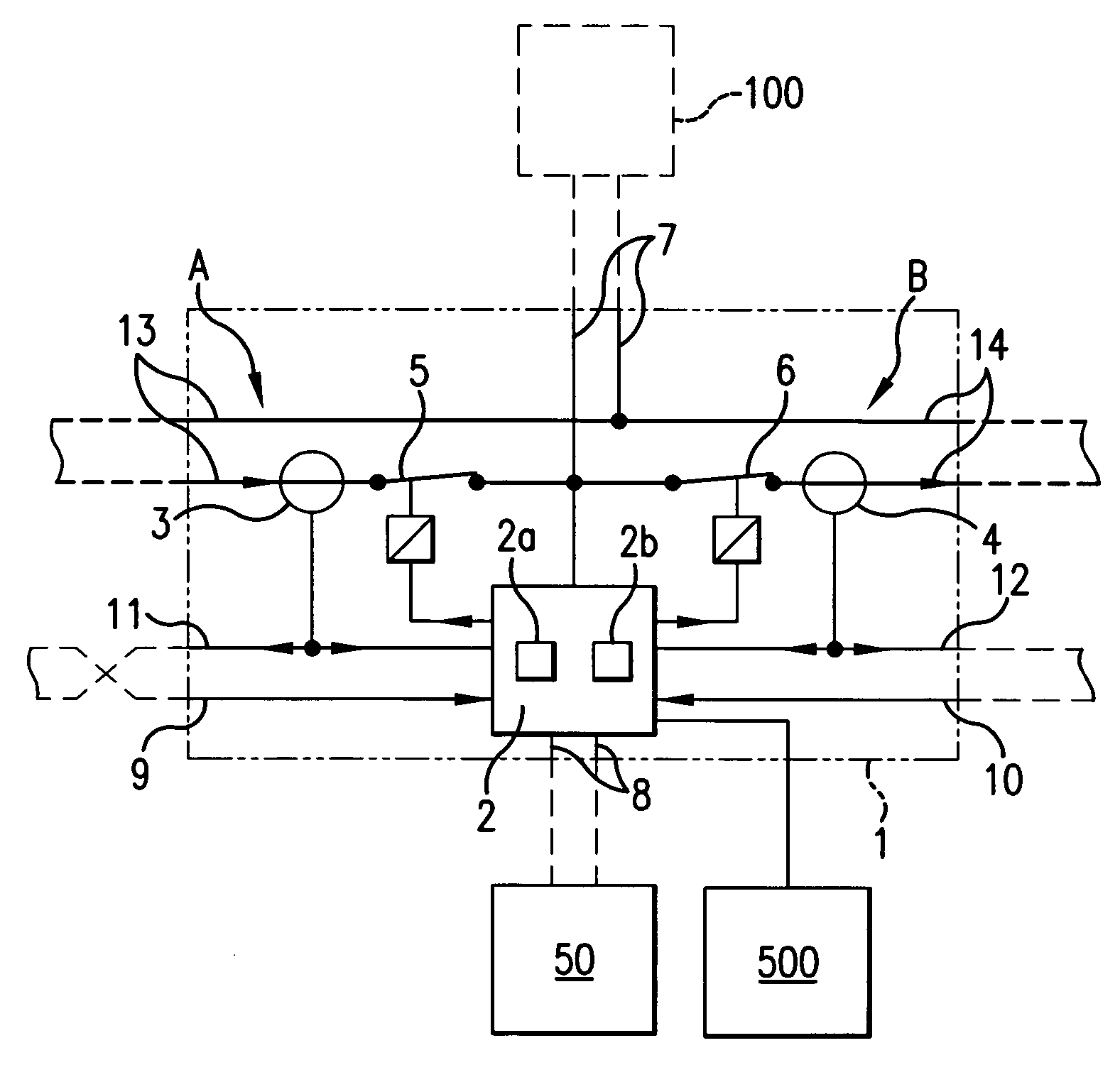

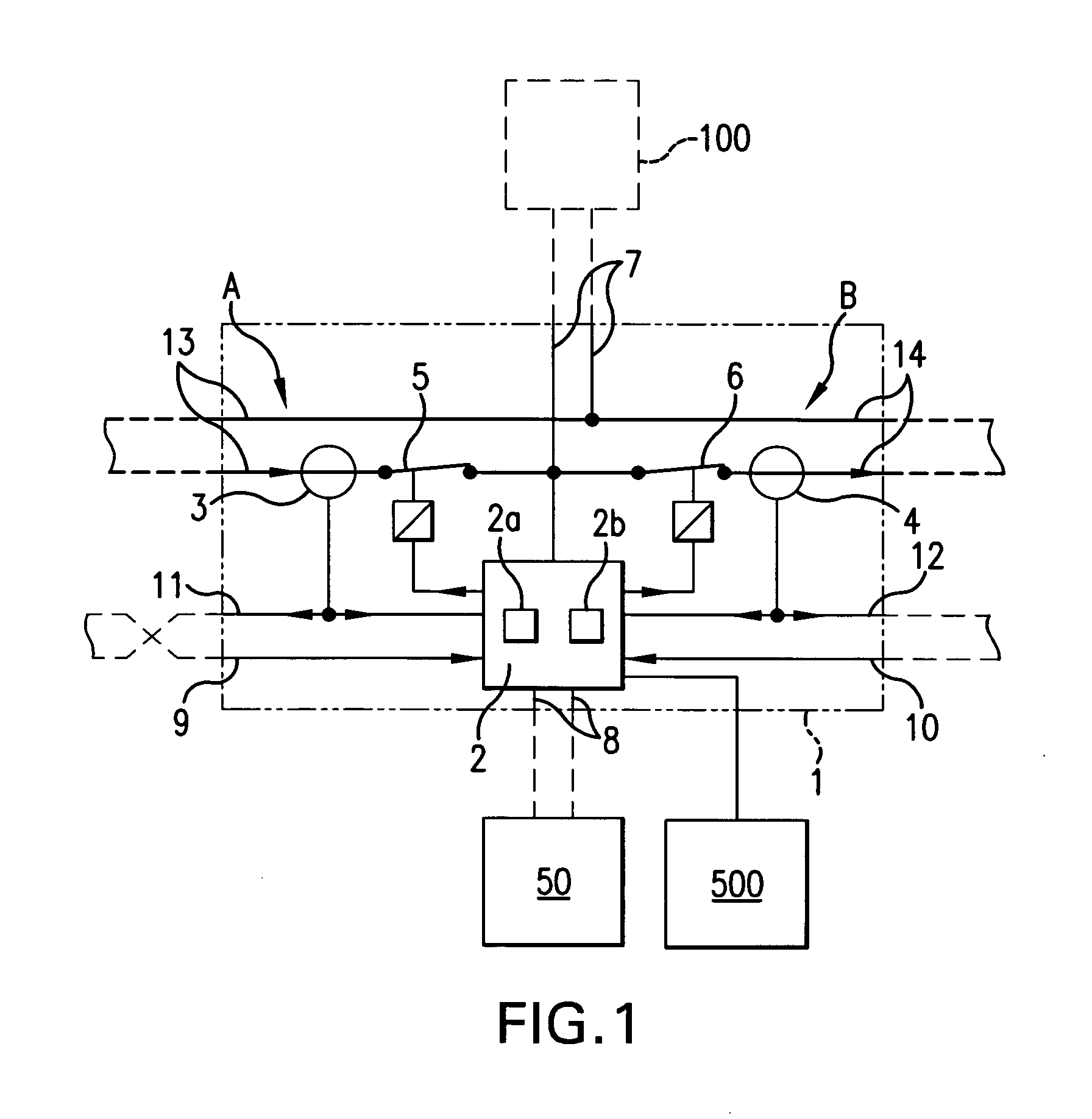

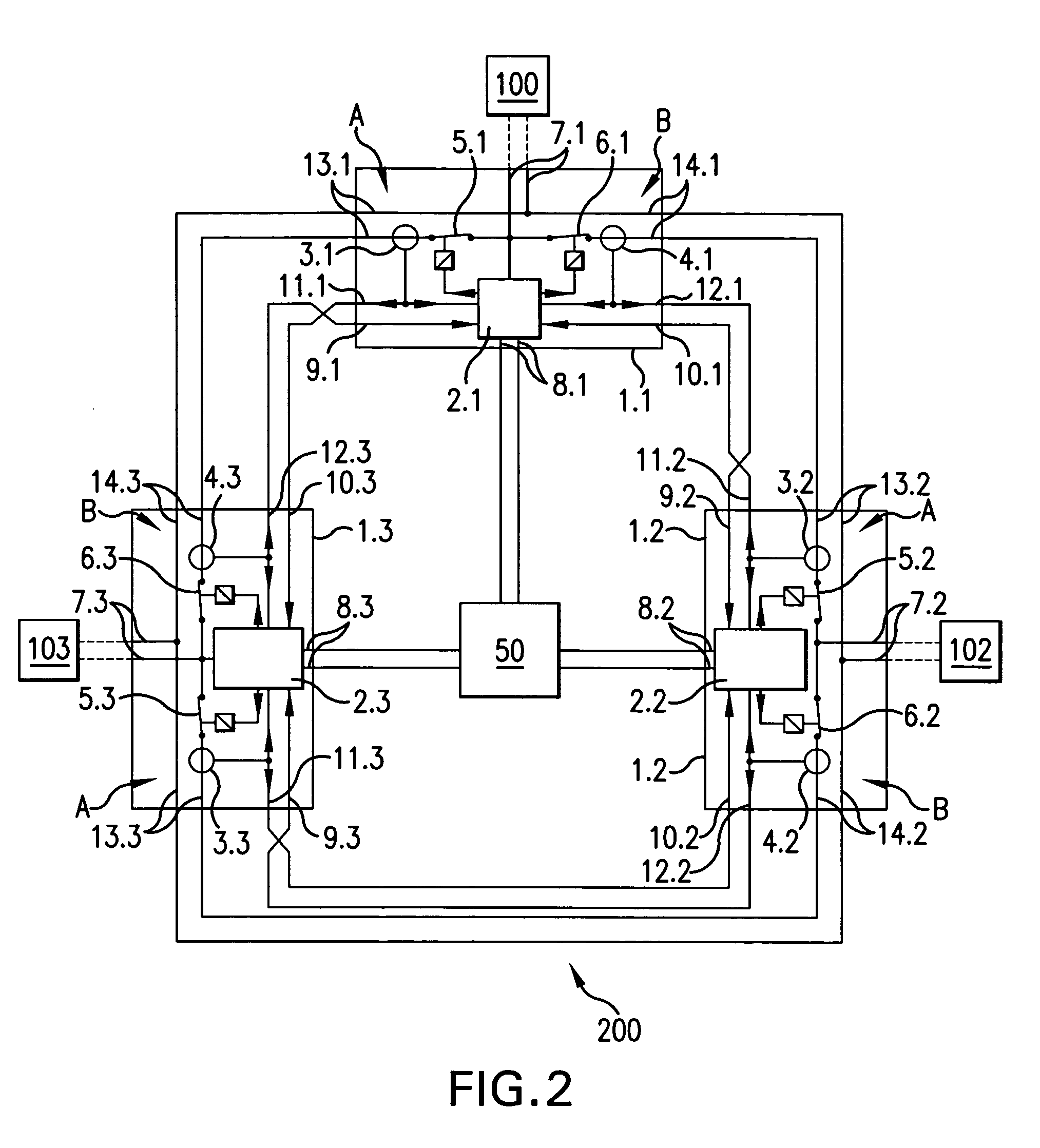

Annular Device for Radial Displacements of Interconnected Parts

The invention relates to a device for generating essentially radial displacements and / or stresses of at least one mechanical part with respect to its X-X axis common with that of at least one other mechanical part functionally connected to the first one, said device comprising:(I) a frame, a swivelling ring (11) and an internal ring producing two nested ball joint connections (a) and (b) with respective centres A and B, eccentric by a distance or value ε along said X-X axis common to the two rings in a position said to be neutral,(II) one or more actuators in a barrel arrangement about the X-X axis for driving the mechanism, each actuator acting on the swivelling ring (11) via a guided push rod (3), and(III) a guide ring (4) for guiding the push rods (3) via a bidirectional planar link (e),while the swivelling rings (11, 13) are steerable by means of push rods (3) displaced by the actuators (2) and guided by the guide ring (4), andwhile said swivelling rings are rotatable in their respective housings (a) and (b),Application in particular for drilling trajectory control devices.

Owner:BREAKTHROUGH DESIGN

Error recognition for power ring

InactiveUS20050001431A1Long delayMaintain stable transmissionElectric devicesEmergency protective circuit arrangementsData connectionRing device

A power ring device that includes: a ring conductor; a plurality of controllers, each controller being connected to the ring conductor and includes a first control unit; a plurality of paired pick ups, wherein each pair connects either an electrical consumer device or an electrical power supply to the ring conductor and to one of the plurality of controllers, wherein a first pair of pick ups of a first controller is connected to a first power supply; and a plurality of current sensor signal lines connecting each control unit to form a data connection; wherein each controller has a right and left side, a right sided and left sided switch elements; and a right sided and left sided current sensors connected so that a first current value measured by the left sided current sensor of the first controller is transmitted as data to the first control unit of a second controller.

Owner:RHEINMETALL LANDSYST

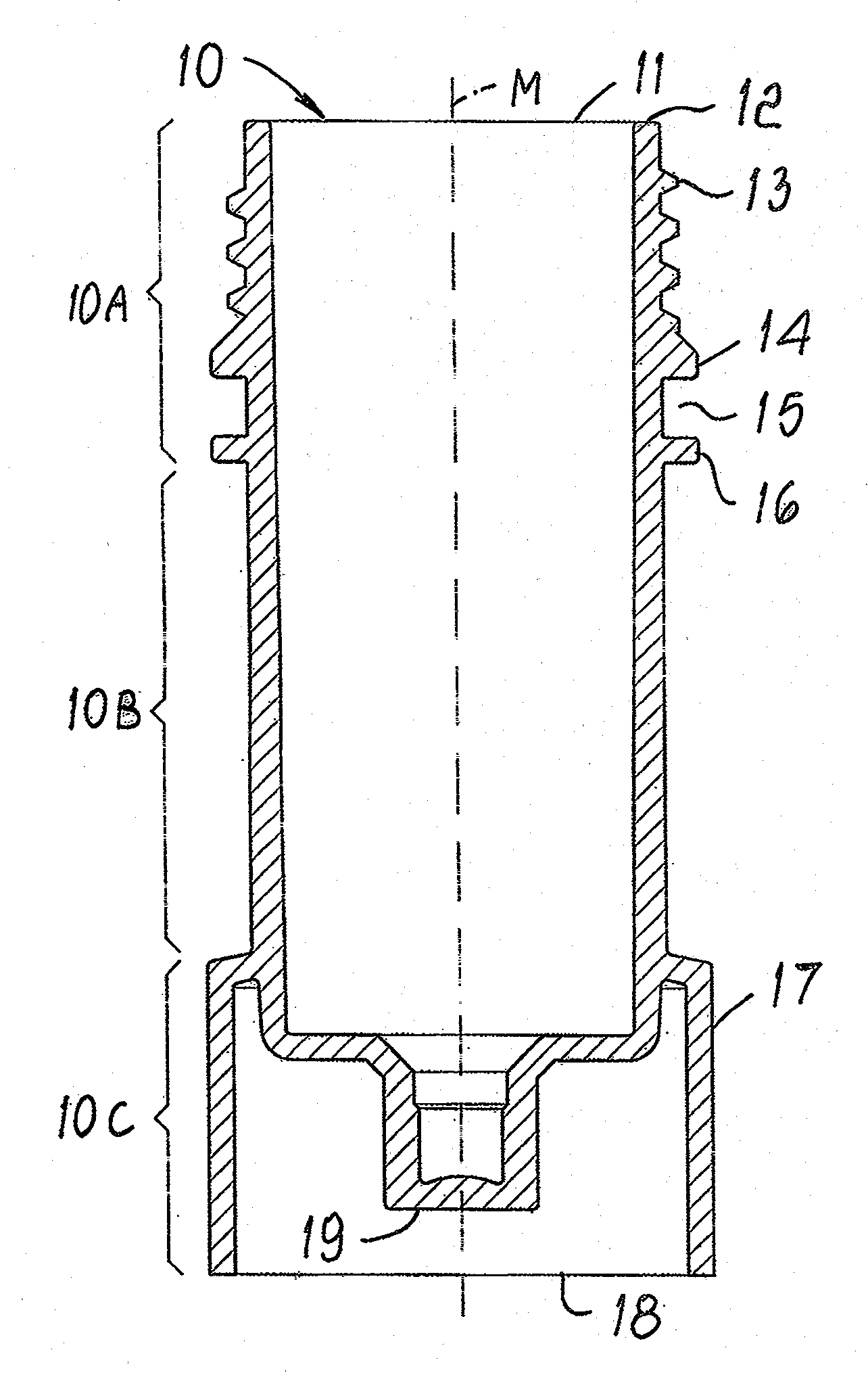

External Container for an Implant Carrier

InactiveUS20090065387A1Increase storage spaceAvoid material fatigueDental implantsSurgical furnitureRing deviceBiomedical engineering

The present invention refers to an external container (1) for an implant carrier (20), comprising a cylindrical body portion (10) and a lid (50) closing the cylindrical body portion (10), the lid (50) being provided with a truncated cone-like element (74) which protrudes into the cylindrical body portion (10) and has on its surface at least one annular means (73) for fixing an implant carrier (20) into place which is adapted such as to fix the implant carrier (20) releasably into place in a stable position in the center of the interior of the cylindrical body portion (10).

Owner:STRAUMANN HLDG AG

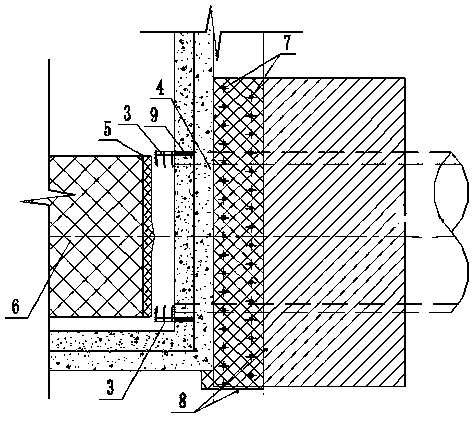

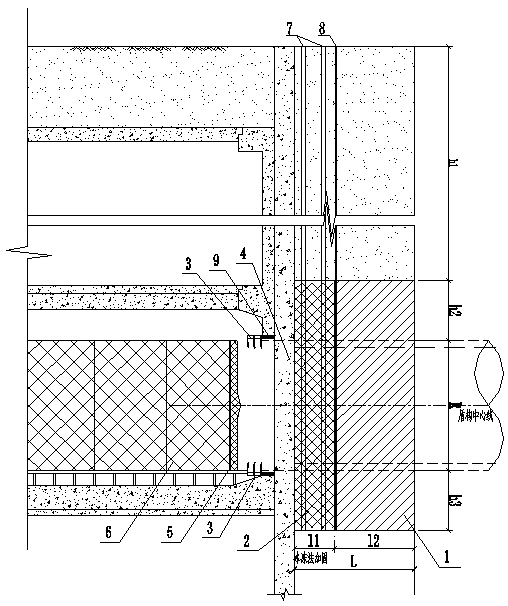

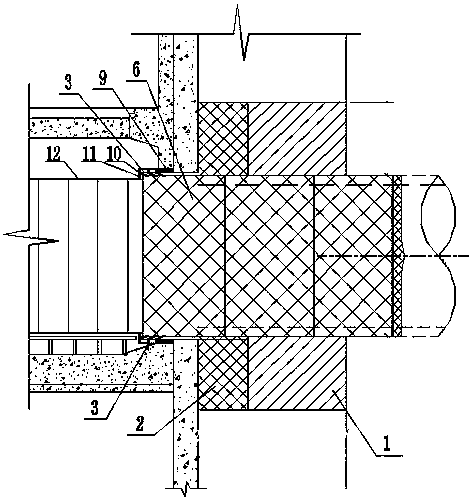

High water pressure soft soil stratum HFE combined type shield starting method

ActiveCN107676097AMake sure it's safeImprove self-stabilityUnderground chambersTunnel liningRing deviceEngineering

The invention relates to the field of shield construction, in particular to a high water pressure soft soil stratum HFE combined type shield starting method. The technical problem of receiving of starting of a soft soil stratum shield tunneling machine under a condition of high water pressure is solved. The shield starting method comprises the following steps that rotary jetting reinforcing is constructed according to design drawing requirements; freezing pipes and temperature measuring holes are constructed, temperature measuring lines are arranged, and freezing is conducted after freezing equipment and a freezing pipeline are mounted and debugged; shield starting preparation is conducted; the outer portion of a door opening steel ring is connected with an externally connected steel ringdevice through a bolt; after shield starting preparation work is completed and freezing and reinforcing are conducted, a door opening fencing structure is broken and removed; the shield tunneling machine jacks and marches forwards; pressure buildup is conducted on a working face of the shield tunneling machine; the freezing pipe in a tunneling outline is pulled and removed, and other freezing pipes continue to work and conduct freezing; an arc-shaped plate is welded to the outer vertical face of the externally connected steel ring device, after the shield tunneling machine completely enters the externally connected steel ring device, synchronous grouting is started, and starting tunneling is completed. The high water pressure soft soil stratum HFE combined type shield starting method has obvious advantages when being particularly applied to a soft soil stratum which is high in waterhead, large in water yield and not equipped with a starting rainfall condition, and has good popularization prospects.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Manufacturing method for high-strength low-elongation type dacron industrial yarn

ActiveCN102787378AReduce cooling rateReduce solidification point downshiftArtificial thread manufacturing machinesMelt spinning methodsYarnDry heat

The invention relates to a manufacturing method for high-strength low-elongation type dacron industrial yarn. The manufacturing method comprises compress flows of hyper-viscous melting of a dacron raw material, metering, yarn spraying, cooling, oiling, drawing, heat setting and winding forming. An adopted dacron slice is a hyper-viscous slice obtained by solid phase tackifying. A cooling device sequentially comprises slow cooling, pre-cooling, windless region cooling and air-blowing cooling, wherein the pre-cooling is initiative outer ring pre-cooling and refers to enabling hot air to be conveyed and flow through an initiative outer ring device so as to cool yarn strips. The initiative outer ring device is a hollow annular belt, the air passing area ratio of the initiative outer ring device is 20-50%, and the height is 30-80mm. The temperature of the hot air is 60-80 DEG C, the humidity is 60-80%, and the conveying speed is 0.2-0.8m / s. The obtained dacron filament has the advantages of being high in breaking strength, low in breaking elongation and linear density deviation rate and reasonable in dry heat shrinkage rate, and can meet the application requirements well.

Owner:JIANGSU HENGLI CHEM FIBER

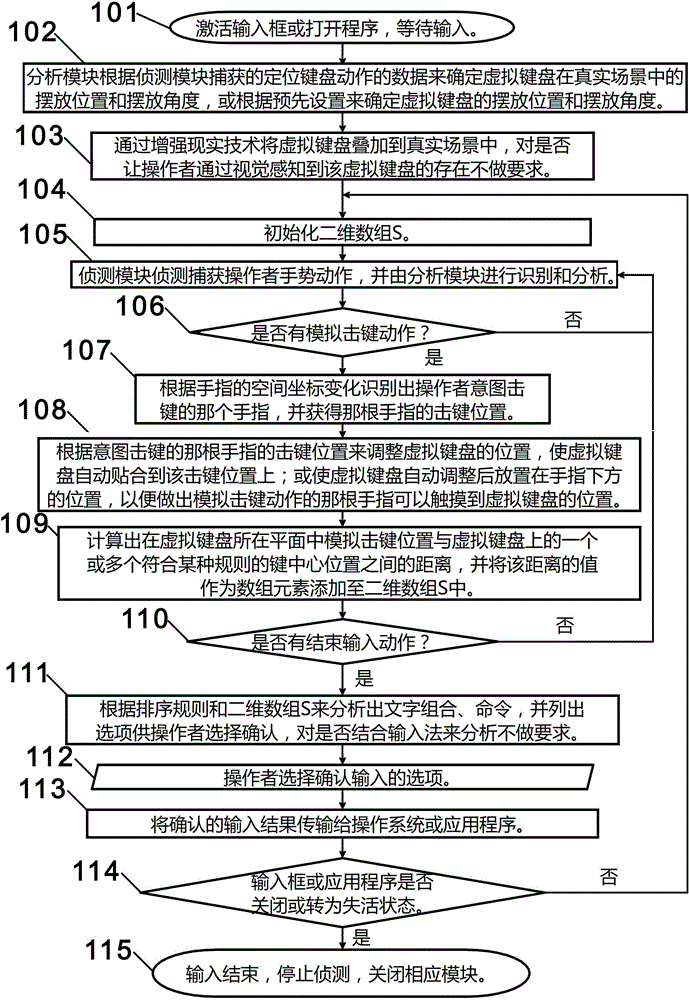

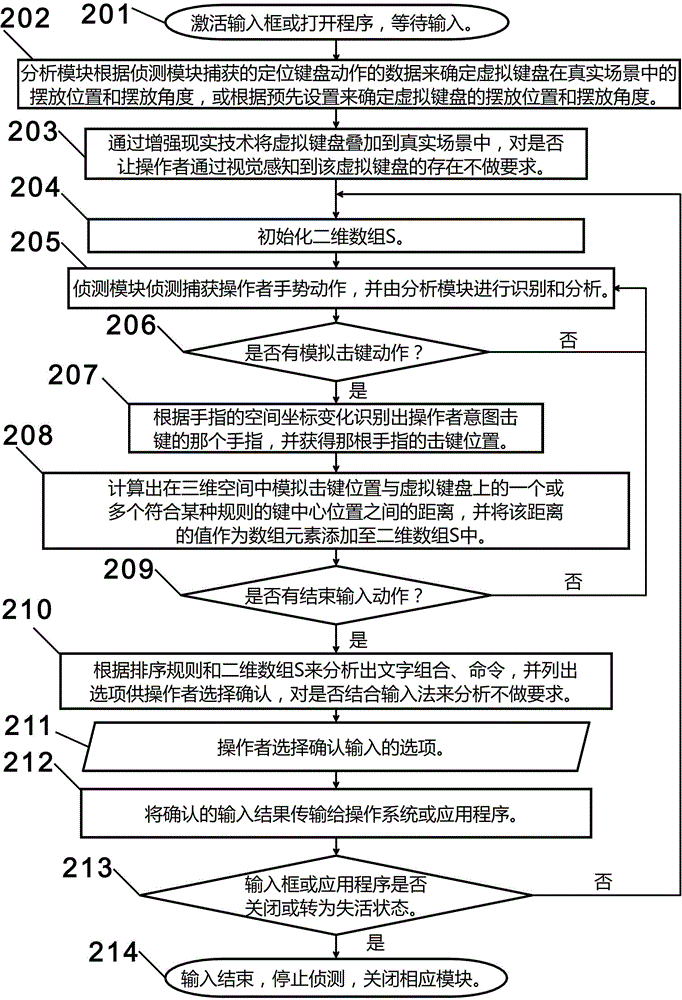

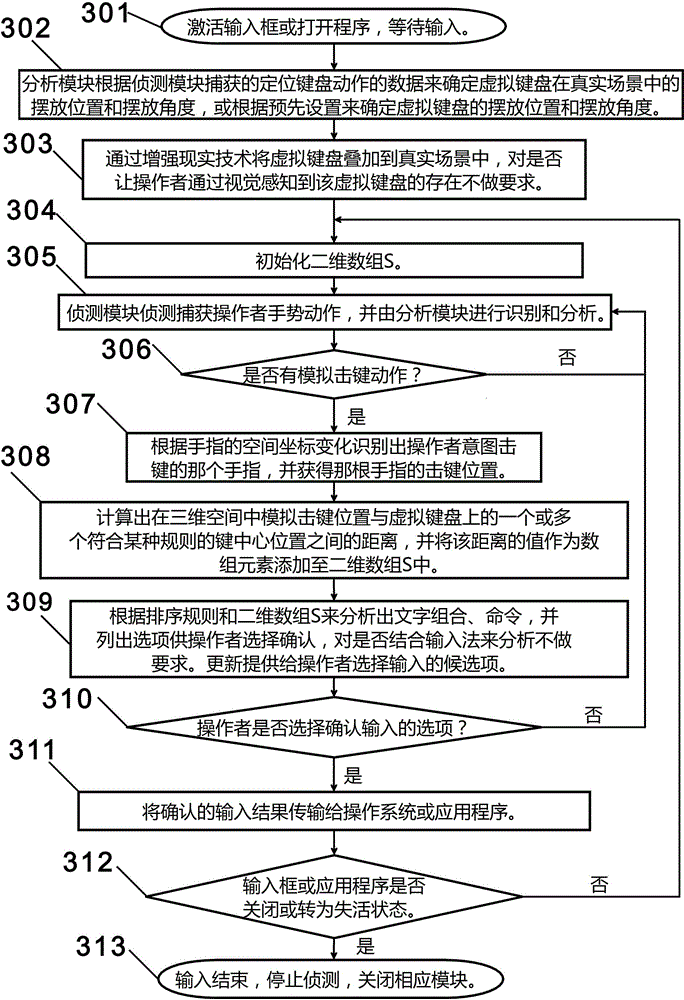

Augmented reality virtual keyboard input method and apparatus using same

ActiveCN105224069AImprove handlingEasy to operateInput/output for user-computer interactionGraph readingMicrocontrollerSmartglasses

The present invention discloses an augmented reality virtual keyboard input method and an apparatus using the same. The method comprises: according to a gesture action by which an operator locate a virtual keyboard or presetting, determining placing location and angle of the virtual keyboard; by an augmented reality technology, superposing the virtual keyboard into a real scene, so that the virtual keyboard induces the action of the operator; and analyzing the gesture action by which the operator operates the virtual keyboard to obtain an input result and feeding back the input result to an operating system or an application. An operation mode is simple. During inputting, a user does not need to make any voice and wear a ring device, and no integration of projection equipment is required. The method and the apparatus can adapt to various input gestures, and no training system is required. The method and the apparatus can be suitable for various devices which need keyboards to input information, such as mobile phones, single-chip microcomputer devices, intelligent furniture, intelligent electric appliances and computers, especially wearable devices that perform input by using keyboards and touch screens inconveniently, such as intelligent glasses. The method and the apparatus greatly expand the operation performance of an intelligent device during inputting by using the virtual keyboard.

Owner:王登高

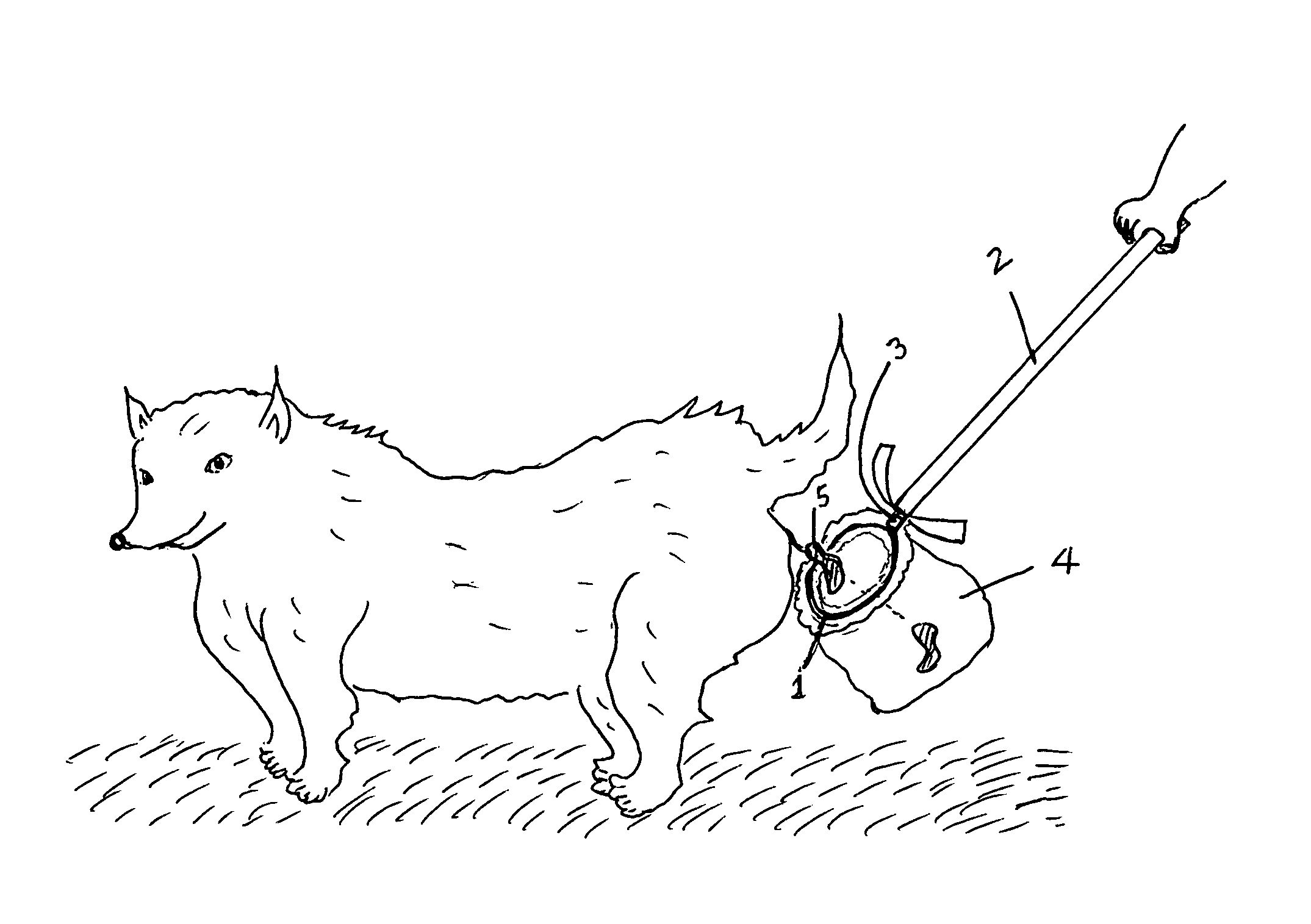

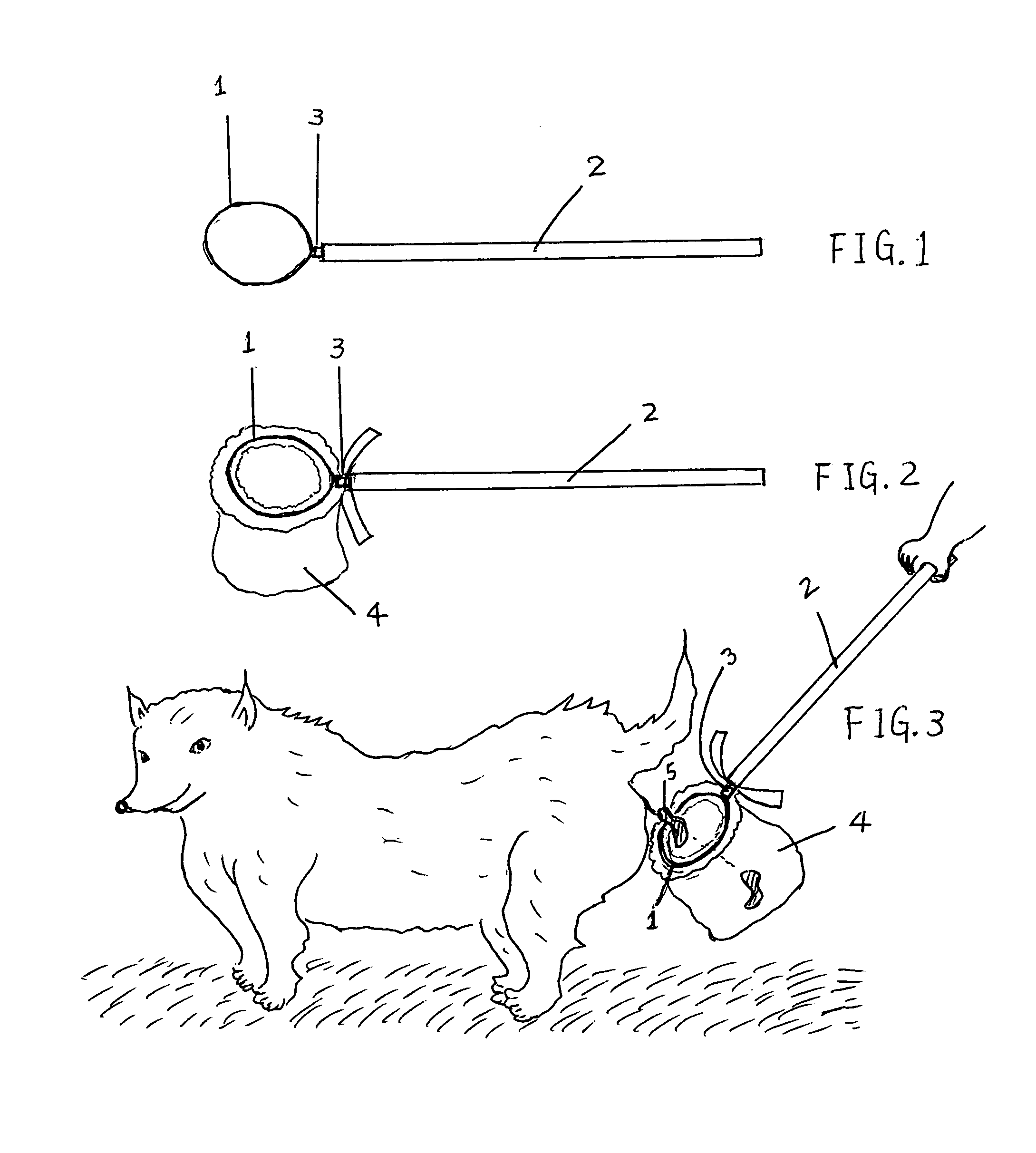

Dog waste catcher and holder

A dog waste catcher and holder is a very simple, light-weight and economical portable device designed to catch and hold a dog's droppings before they fall on the ground or grass. It is carried by a dog's owner or caretaker while he or she walks the dog. This is a device comprised of a loop shaped device to hold a plastic bag, a carrying rod of which one end is attached to the loop shaped device, a securing device such as a bracket to attach the loop shaped device to one end of the carrying rod, and a plastic bag, preferably a plastic bag such as a grocery bag, etc. placed inside the loop shaped device with its upper portion folded over the loop and its ends tied to the rod where the loop shaped device is attached. As soon as the dog shows the motion to excrete, this device can be placed under the dog's bottom and catches the waste in the plastic bag as it excretes. Once the dog has finished excreting, the plastic bag is removed and discarded. This is a very simple and sanitary way of catching and discarding the dog waste.

Owner:BORMAN SETSUKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com