Fibre optic sensor for measuring temperature and refractive index of liquid contemporarily

A refractive index sensor and optical fiber sensing technology, which is applied in the direction of measuring devices, using optical devices to transmit sensing components, thermometers, etc., can solve the problems of temperature sensitivity of optical fiber refractive index sensors, and achieve easy production, high sensitivity and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

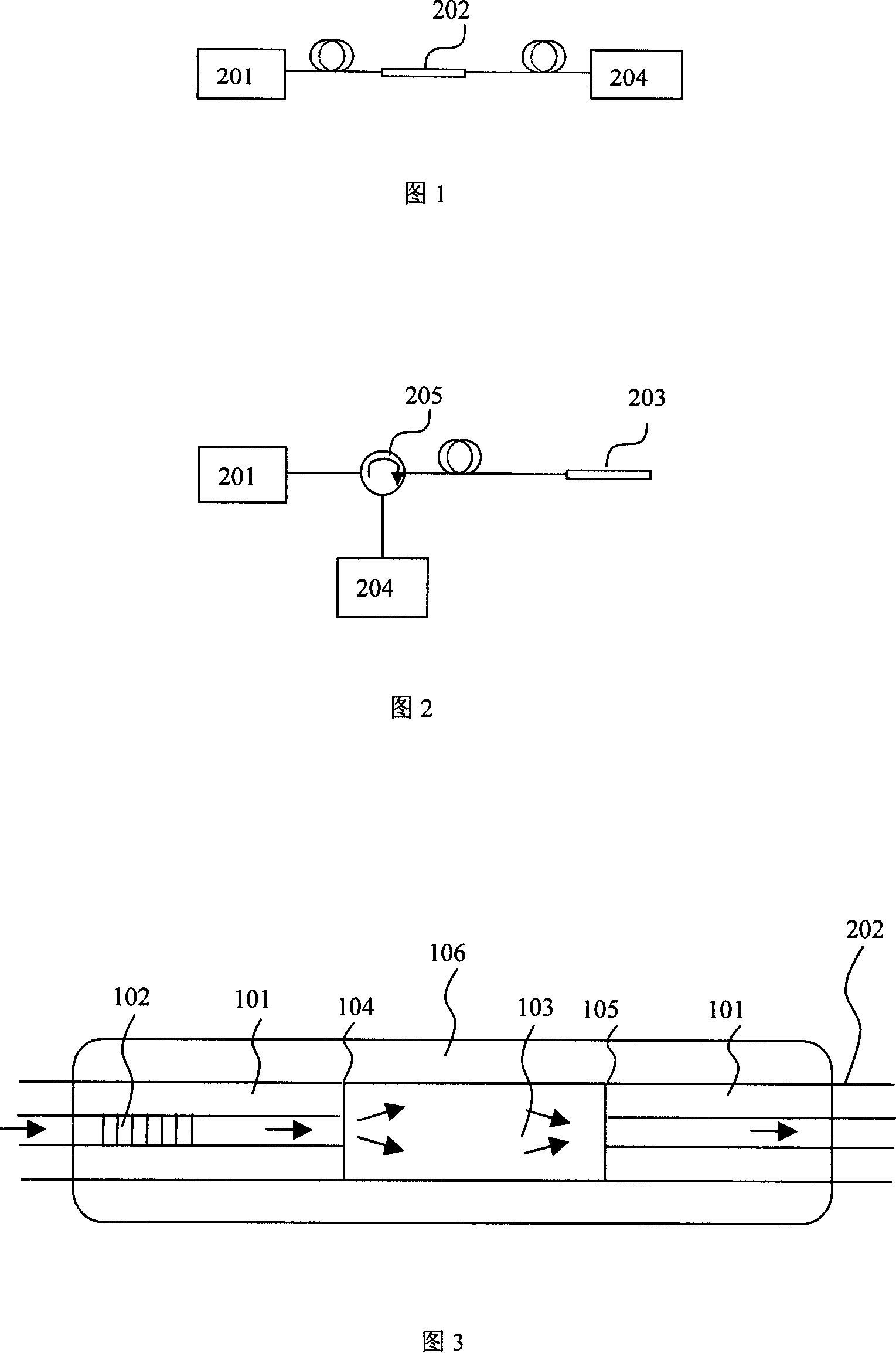

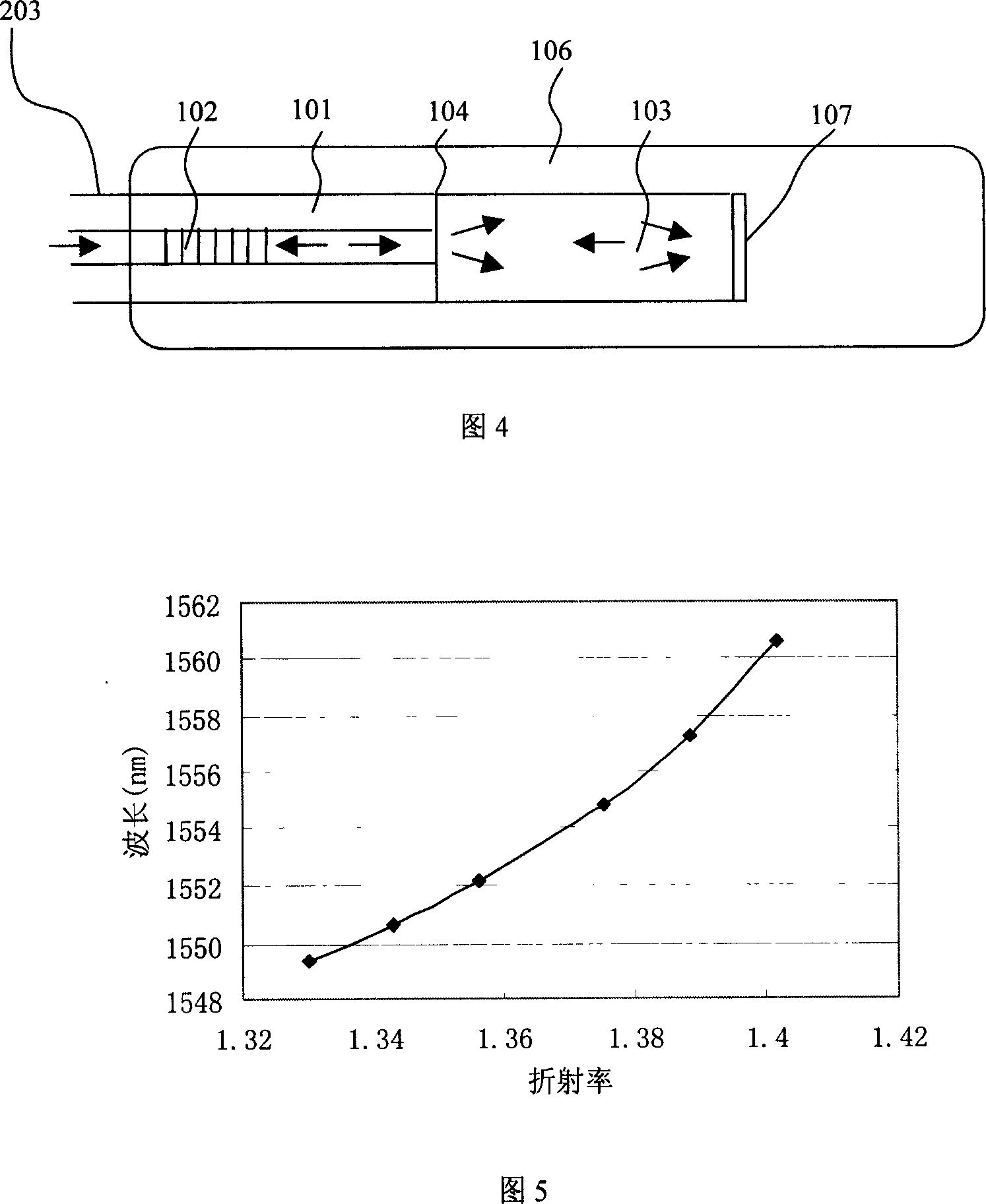

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in Figure 1, the single-mode optical fiber 101 is a standard single-mode optical fiber (G652), the diameter of the core (105) is 8.2 μm, the diameter of the cladding (104) is 125 μm, and the numerical aperture is 0.14. First remove its protective coating, and then use a fiber optic cutter to cut its end face perpendicular to its axis. The coreless optical fiber 103 has a diameter of 125 μm, and its end face is cut perpendicular to its axis using a fiber cutter. Afterwards, the single-mode optical fiber 101 and the coreless optical fiber 103 after the end face treatment are put into an optical fiber fusion splicer to fuse the two optical fibers together. Use a fiber cutter to cut the coreless fiber at 100 mm, and fuse it with another section of single-mode fiber 101 to form a fiber-optic multi-mode interferometer as a ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com