Thread drawing device of sewing machine

A sewing machine and thread puller technology, applied in the field of sewing machines, can solve the problems of difficult assembly and maintenance, low working stability, complex overall structure, etc., and achieve the effects of low manufacturing cost, beautiful stitches, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

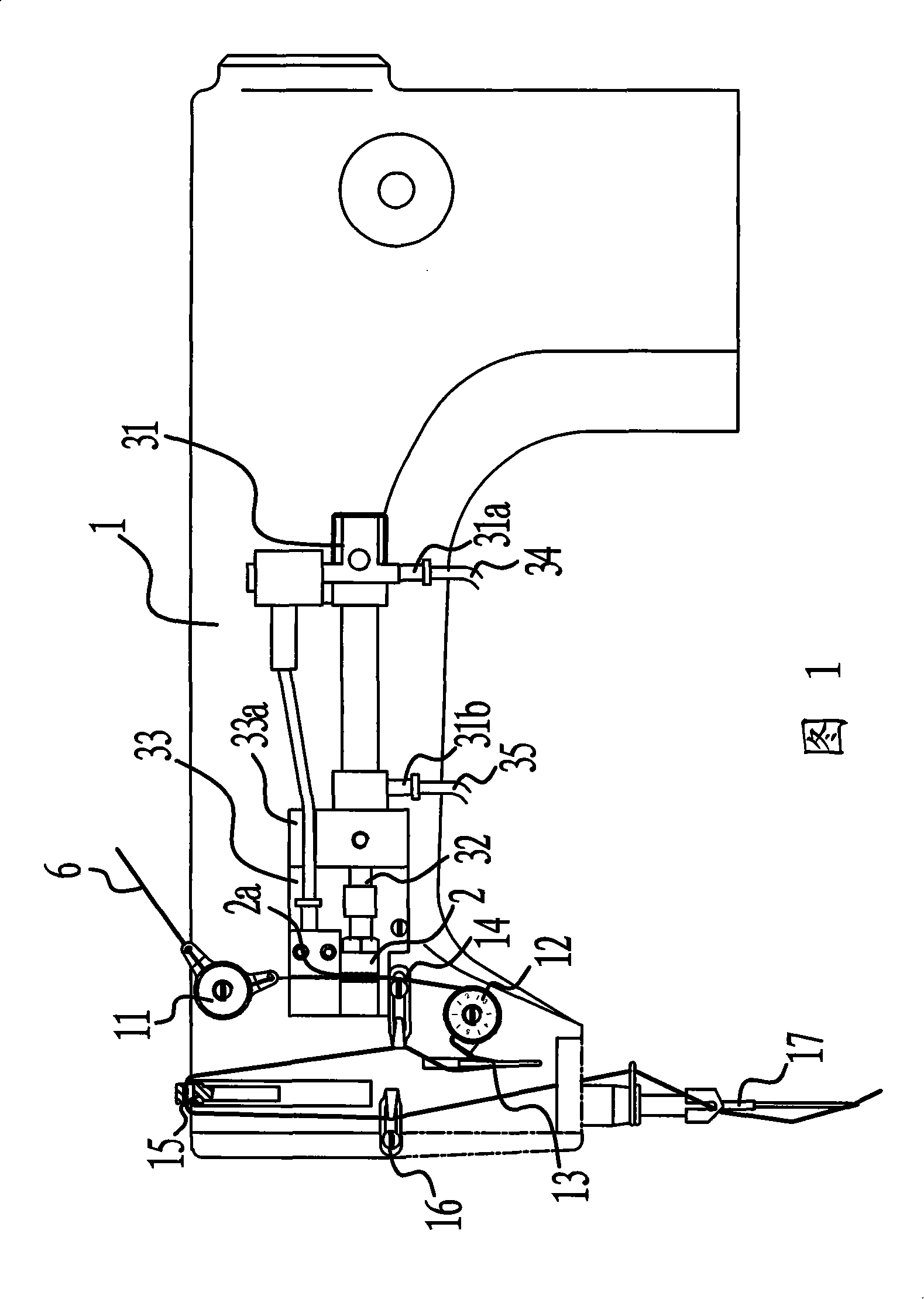

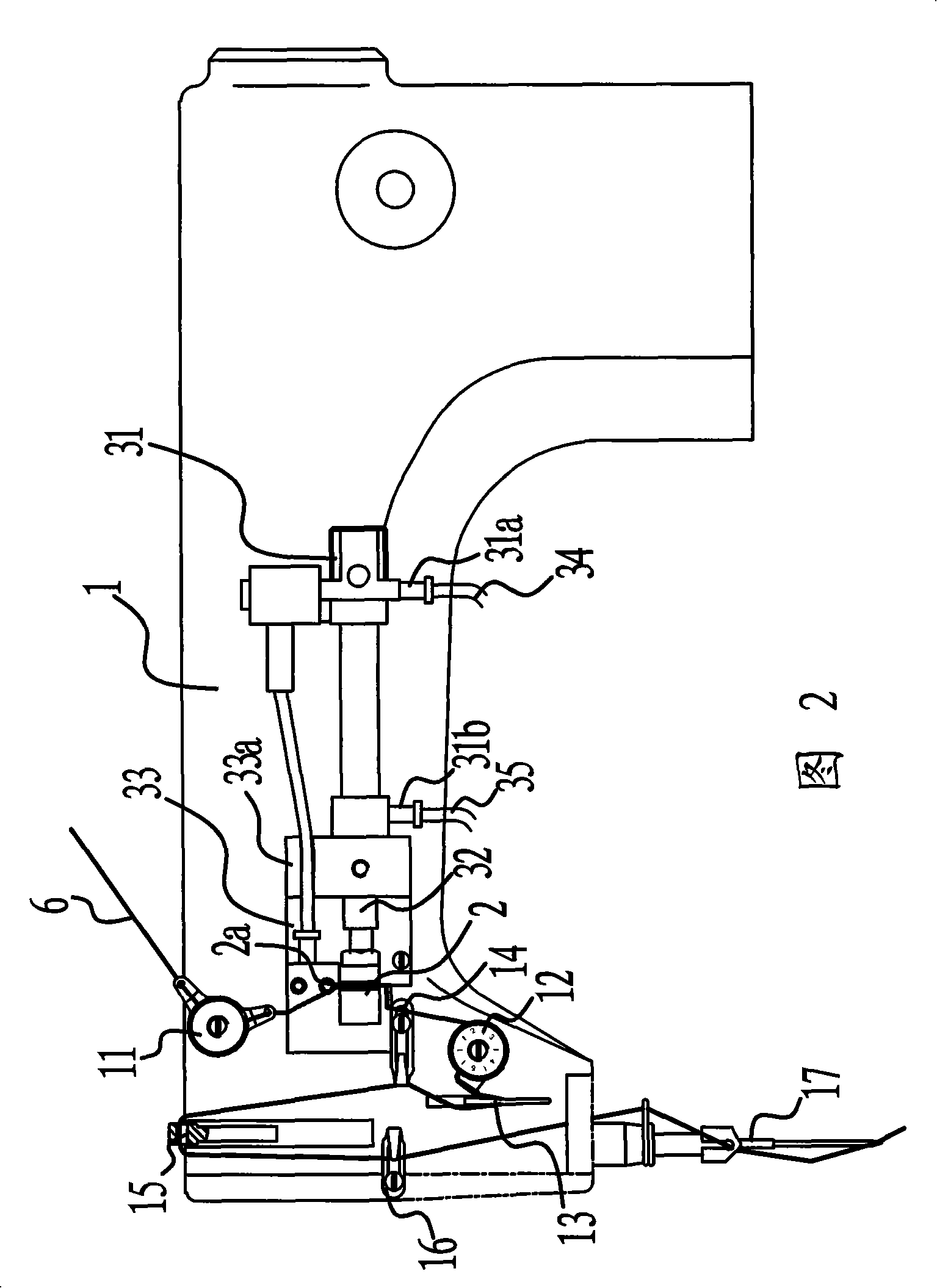

[0028] As shown in Figures 1 and 2, the machine head 1 of the sewing machine is provided with a small thread clamp nut 11, a thread clamp 12, a slow thread hook 13, a right thread 14, and a thread take-up lever 15 for the suture 6 to pass through in sequence. , and cross thread 16 to the left, and finally reach machine needle 17. The thread puller of the sewing machine is arranged on the machine head 1 of the sewing machine, and is located between the small thread clamping nut 11 and the thread clamping device 12 . The wire puller is composed of a wire pull head 2 arranged on the machine head 1 and a driving device that makes the wire pull head 2 slide back and forth in the horizontal direction. After the suture 6 comes out from the small thread clamp nut 11, it leads to the thread clamp 12 through the thread pulling head 2.

[0029] The driving device includes an air cylinder 31 fixed on the machine head 1 , and a wire drawing head 2 fixed on the top end of a piston rod 32 o...

Embodiment 2

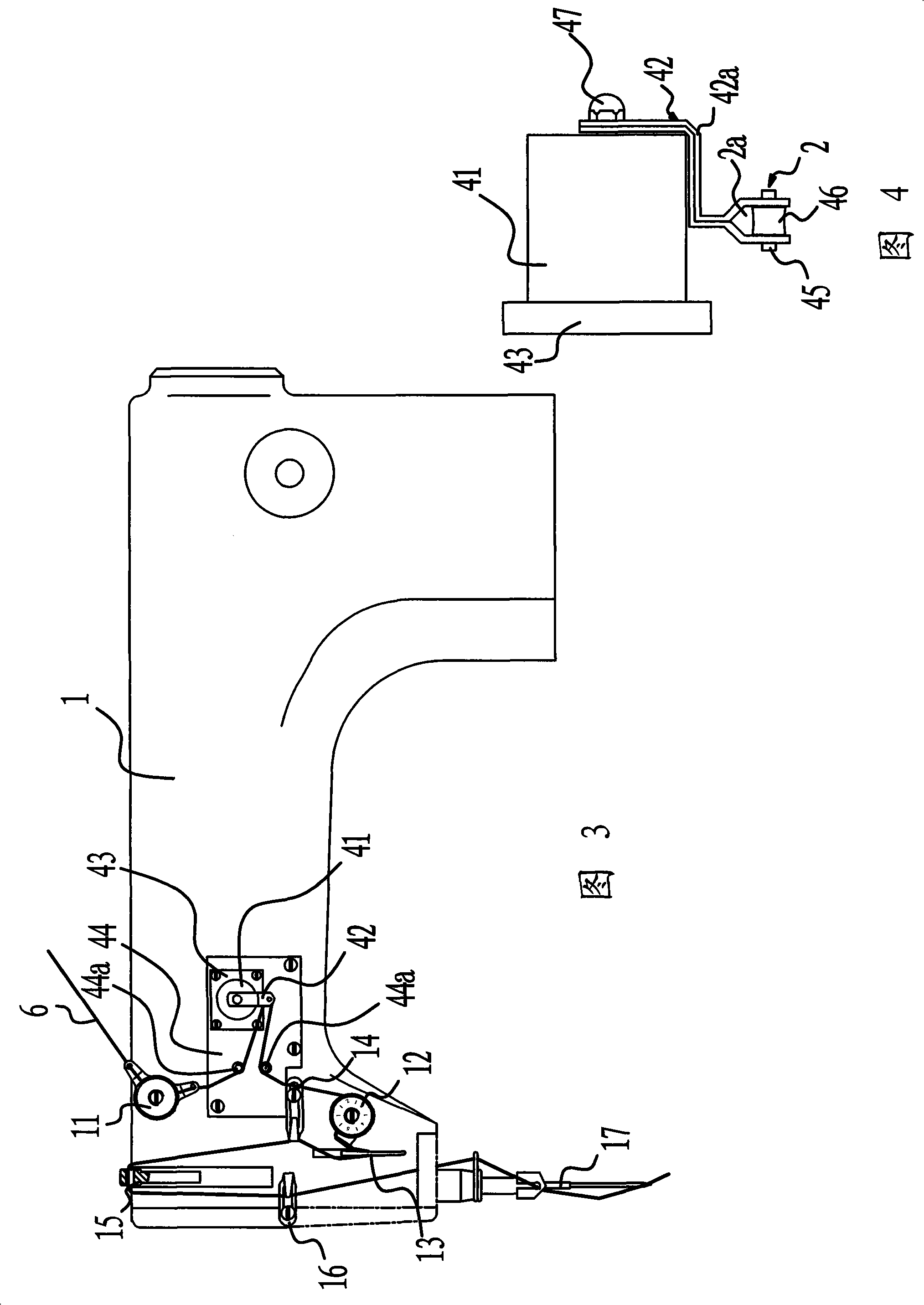

[0035] As shown in Figure 3, in the present embodiment, the driving device includes a stepper motor 41 fixed on the machine head 1, the motor shaft of the stepper motor 41 is fixedly connected with one end of the fork 42, and the above-mentioned pull head 2 is provided with At the other end of the swing rod 42.

[0036] More specifically, the stepping motor 41 is fixed on the seat plate 43 by screws, and the seat plate 43 is fixed on the side of the machine head 1 by a support plate 44 . The support plate 44 is fixedly connected with the machine head 1 by screws. As shown in FIG. 4 , the swing rod 42 in this embodiment is bent into a Z shape by two side-by-side rods 42a, one end of which is fixedly connected to the motor shaft through a nut 47, and the other end is bifurcated to form a fork. The fork 42 is buckled on the periphery of the stepper motor 41 . A bearing pin 45 is installed on the fork, and a roller 46 for suture bypassing is sleeved on the bearing pin 45 . A pi...

Embodiment 3

[0041] As shown in FIG. 5 , in this embodiment, the driving device includes an electromagnet 51 fixed on the machine head 1 , and the above-mentioned wire pulling head 2 is fixed on the top end of the armature rod 52 of the electromagnet 51 . More specifically, the electromagnet 51 is fixed on the machine head 1 through a mounting plate 53, and the mounting plate 53 and the machine head 1 are fixedly connected by screws. The pull head 2 is a slider that can slide back and forth on the mounting plate 53 in the horizontal direction. In order to make the sliding smoother and more stable, the support frame 33 and the pull head 2 can be connected by slide rails.

[0042] The working process of this embodiment is as follows:

[0043] When the sewing machine was working normally, this wire puller was not working, and the wire puller 2 was positioned between the small thread clamp nut 11 and the thread clamp 12, and the suture 6 between the two was not bent. When the sewing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com