Full-automatic multi-decoration strip sewing equipment

A fully automatic and decorative strip technology, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of affecting product quality, easy deviation, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

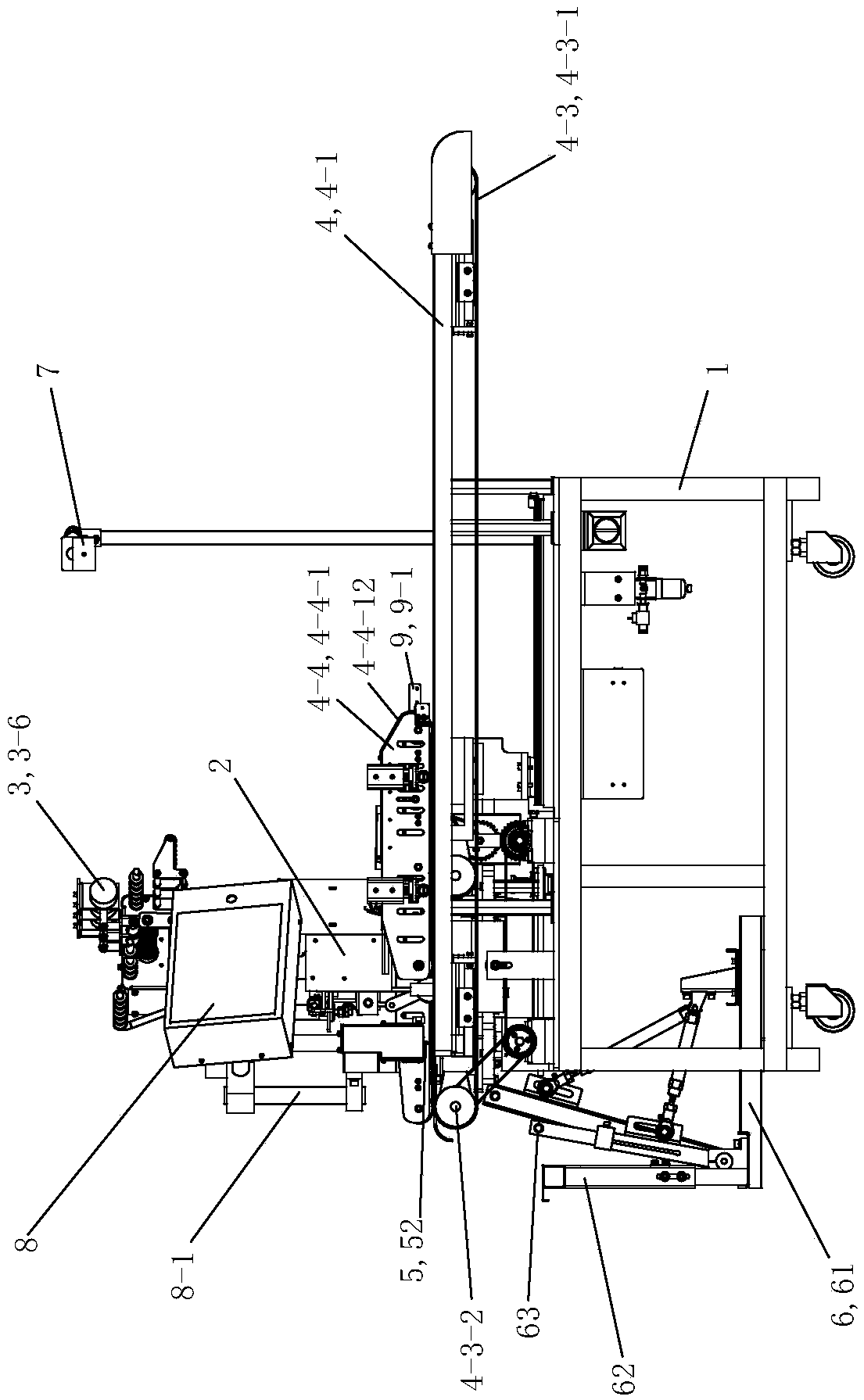

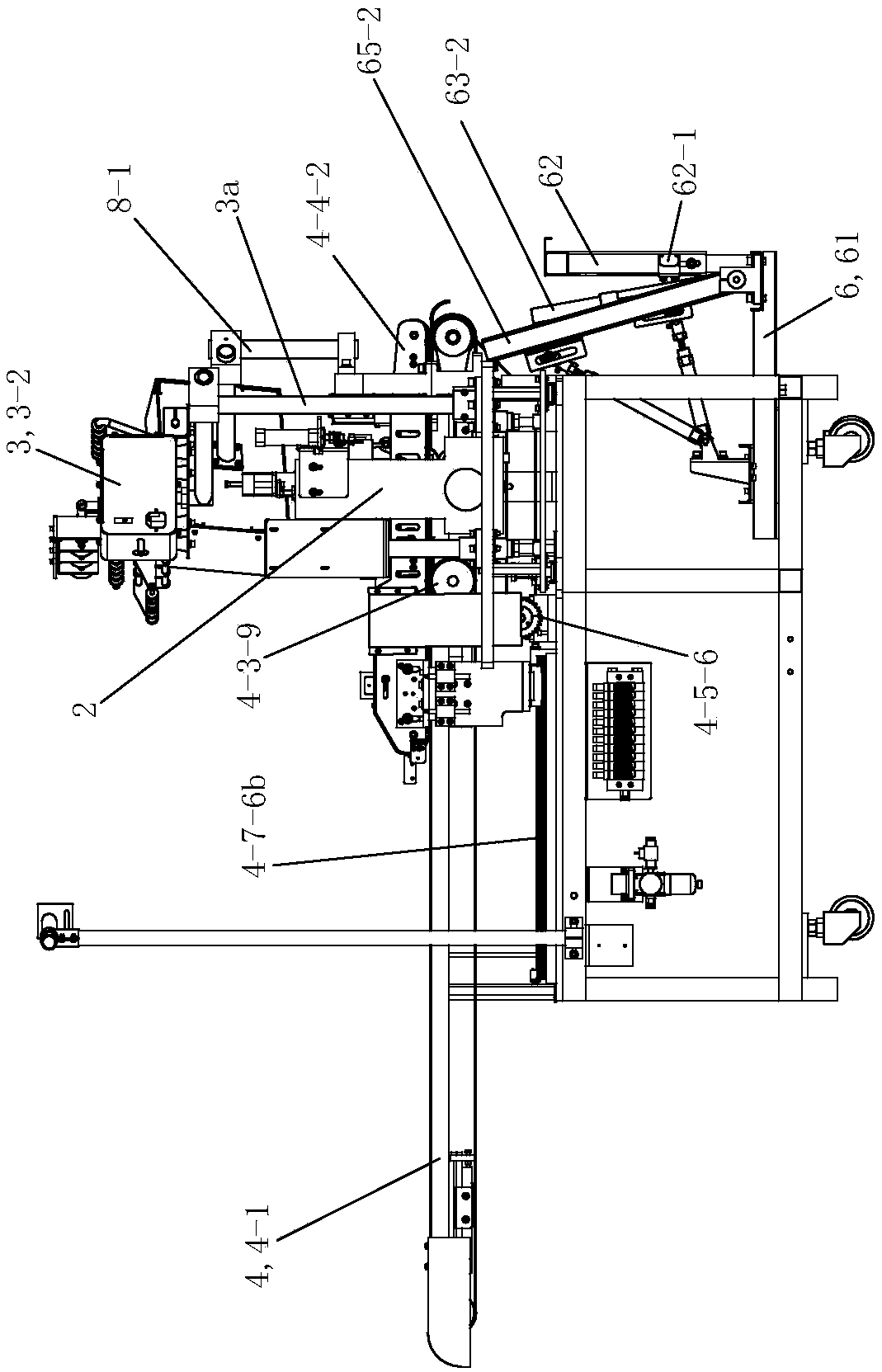

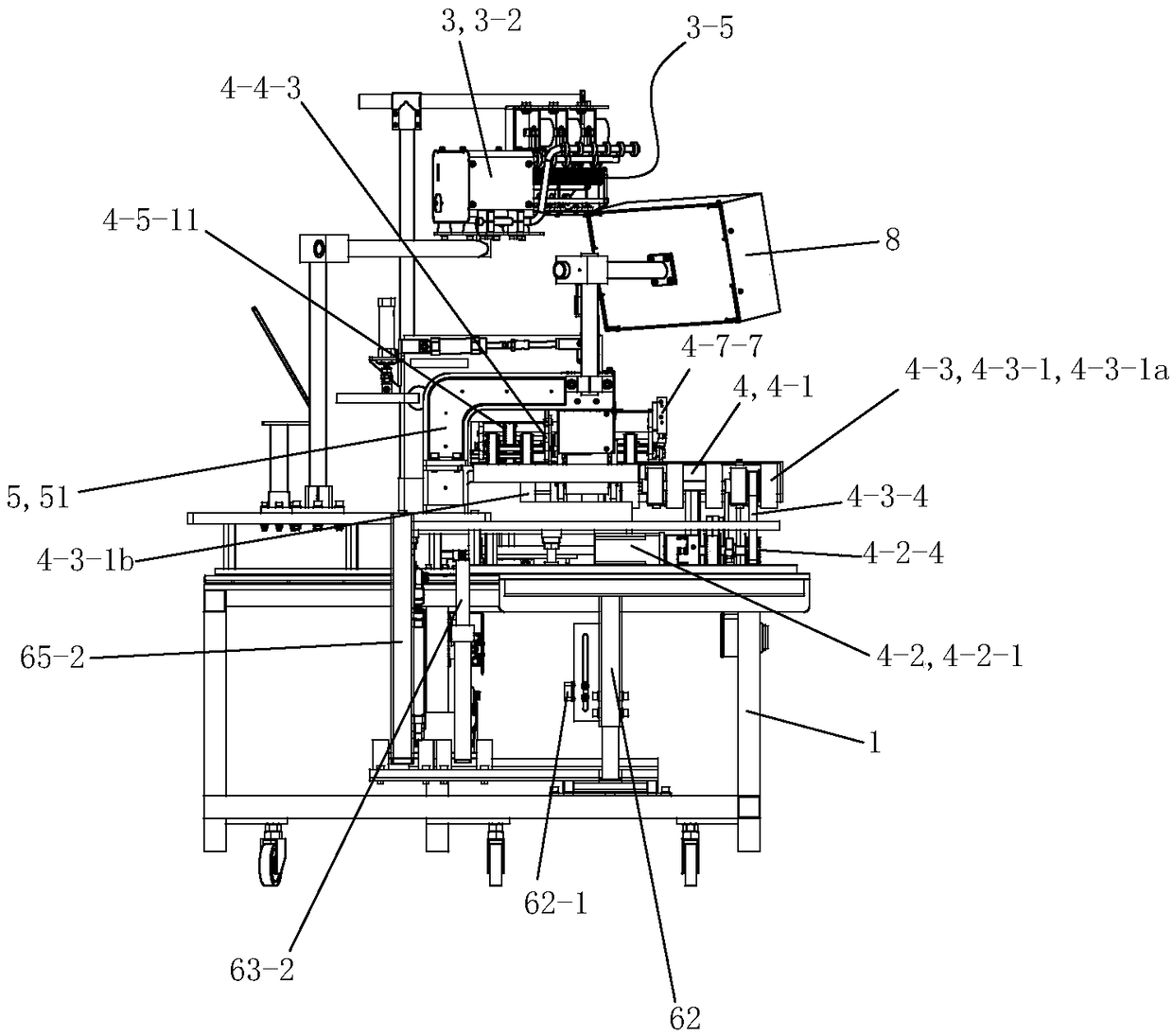

[0076] See Figure 1 to Figure 29 , the fully automatic multi-strip sewing equipment of the present invention includes a frame 1, a multi-needle sewing machine 2, a strip feeding device 3, a feeding device 4, a shearing device 5, a receiving device 6, a positioning device 7, and a control panel 8 And the first auxiliary feeding assembly 9. Corresponding casters are provided on the lower side of the frame 1 for easy movement. The control panel 8 is provided with a human-computer interaction interface for displaying device status and controlling the device.

[0077] See Figure 1 to Figure 8 , Figure 10 and Figure 11, Multi-needle sewing machine 2 adopts Morimoto's DLR-1509P multi-needle sewing machine. The multi-needle sewing machine 2 is fixedly arranged on the left rear side of the frame 1. The multi-needle sewing machine 2 is provided with a presser foot adjusting assembly 21, a pull tube 22 and a head blowing pipe 23. The presser foot adjustment assembly 21 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com