Decorating sewing machine

A sewing machine and machine head technology, applied in the field of sewing machines, can solve the problems of low degree of automation, poor pattern consistency on the pockets, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

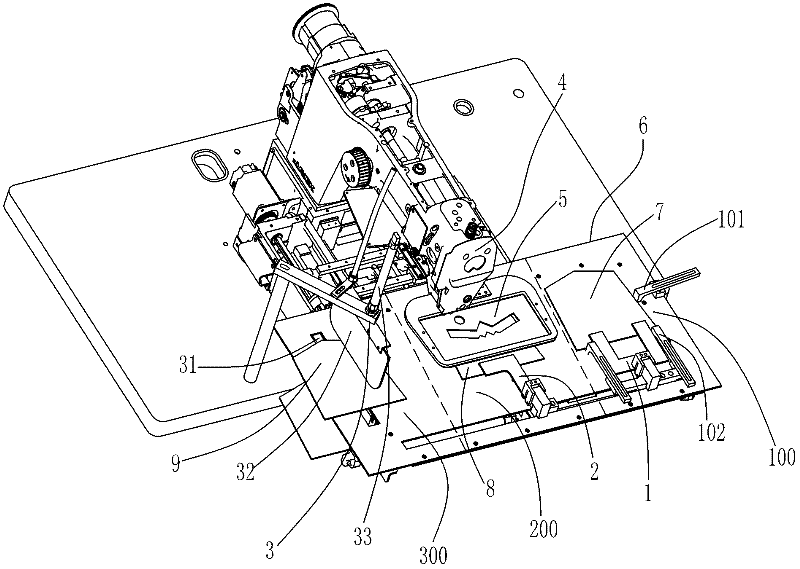

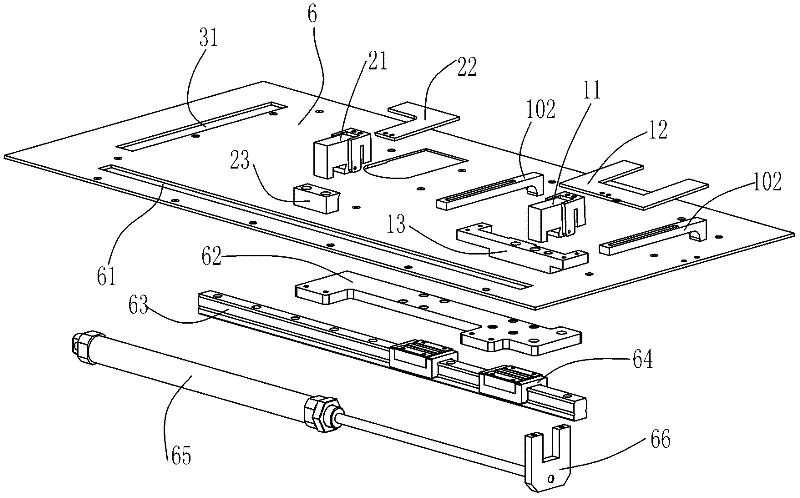

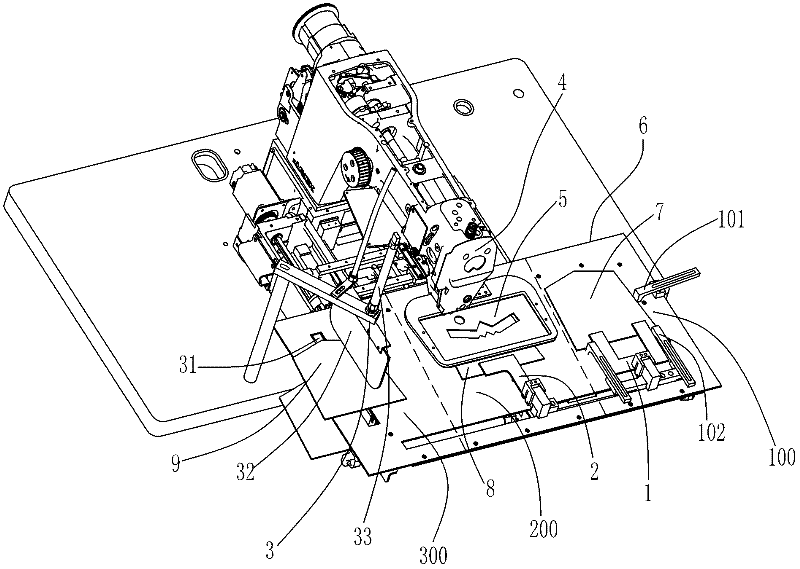

[0025] Such as figure 1 As shown, the decorative sewing machine of the present invention comprises a machine head 4 and a machine plate 6 positioned below the machine head, a template mechanism 5 is also provided below the machine head 6, and is divided into three stations along the longitudinal direction of the machine plate 6—from From right to left, there are loading position 100, sewing position 200 and unloading position 300. The template mechanism 5 is located on the sewing position 200, and a first feeding mechanism 1 is provided corresponding to the loading position 100, corresponding to the sewing position. The position 200 is provided with a second feeding mechanism 2 , corresponding to the unloading position 300 is provided with a unloading mechanism 3 , wherein the first feeding mechanism 1 and the second feeding mechanism 2 can move synchronously along the longitudinal direction of the board 6 .

[0026] The working principle and design concept of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com