Preparation method of spherical high-capacity lithium-rich positive electrode material

A lithium-rich positive electrode material and high-capacity technology, which is applied in the field of preparation of high-capacity spherical lithium-rich positive electrode materials, can solve the problems of difficulty in preparing high-vibration-density positive electrode materials and difficult control of particle size, and meet market needs and long service life , good safety effect

Active Publication Date: 2014-07-30

TIANJIN UNIVERSITY OF TECHNOLOGY

View PDF5 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional co-precipitation method-high temperature solid phase method to prepare lithium-rich cathode materials is difficult to prepare cathode materials with high vibration density, and the particle size is not easy to control to a certain extent, which limits the application of such materials to a large extent.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

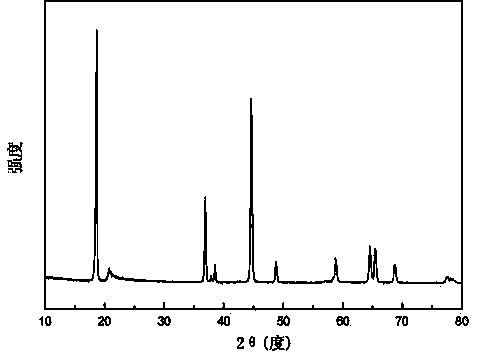

The invention discloses a preparation method of a spherical high-capacity lithium-rich positive electrode material. A sintering process is improved through regulating a coprecipitation reaction mode. The preparation method comprises the following steps: 1, preparing a nickel-cobalt-manganese sulfate solution; 2, performing a coprecipitation reaction on the nickel-cobalt-manganese sulfate solution and a mixed solution of a carbon carbonate solution and ammonia water at a pH value of 7-9 to obtain a solid-liquid mixture of a precursor; 3, filtering, separating, washing and drying to obtain a carbonate precursor; 4, performing gradient temperature rise on the carbonate precursor in a tubular furnace and keeping the temperature, cooling, crushing and sieving to obtain a nickel-cobalt-manganese oxide; and 5, mixing the nickel-cobalt-manganese oxide with lithium carbonate powder, and performing multi-section ventilation roasting in the tubular furnace to obtain the target object. The preparation method has the advantages that the sintering process is improved through regulating the coprecipitation reaction mode, the granularity of the precursor is effectively controlled, and the high-capacity lithium-rich lithium ion positive electrode material with a layered crystal structure, which is high in energy density, good in rate capability, low in cost, good in safety and long in service life, is prepared, and the market demand is met.

Description

technical field [0001] The invention belongs to the preparation of positive electrode materials of lithium ion batteries, in particular to a preparation method of high-capacity spherical lithium-rich positive electrode materials. Background technique [0002] With the world's increasing energy demand, under the influence of fluctuations in crude oil prices and the pressure of environmental issues, green and renewable energy has gained more and more attention. Without available energy storage and conversion systems, these new sources of energy cannot be well exploited, yet highly efficient lithium-ion batteries could, in principle, serve this purpose. Among them, the first-generation lithium-ion power battery under the background of major applications such as electric vehicles and grid energy storage, under the basic conditions of safety, environmental protection, low cost, and long life, the key performance indicators are high energy density and stable cycle performance. ....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/505H01M4/525

CPCH01M4/366H01M4/505H01M4/525H01M10/0525Y02E60/10

Inventor 张联齐张彦涛宋大卫时喜喜郭建

Owner TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com