Long-chain dicarboxylic acid with centralized granularity distribution and preparation method thereof

A long-chain dibasic acid and particle size distribution technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of concern about the particle size of long-chain dibasic acid separation and purification products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

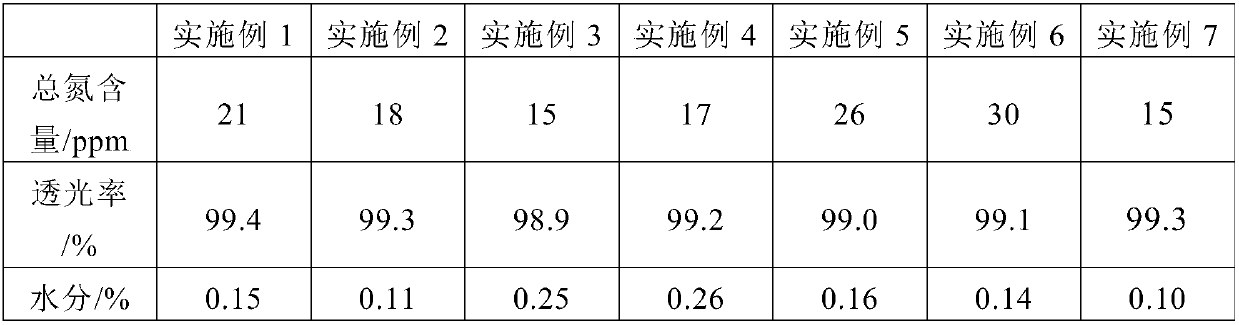

Examples

Embodiment 1

[0089] Dodecane dibasic acid crude product (purity is 95%) is placed in the decolorization tank, adds the activated carbon of 3.5% of dodecane dibasic acid crude product quality, and content is 95wt.% acetic acid, and this 95wt.% acetic acid conversion content is The mass ratio of 100wt.% acetic acid to the crude product of dodecanedibasic acid is 3:1, then decolorize at 80°C for 20min, and filter to obtain the dodecanedibasic acid solution. In the crystallizer, keep the dodecane dibasic acid solution at a constant temperature of 80°C for 1h.

[0090] The temperature was lowered to 60°C at a rate of 2min / °C. Particles were precipitated in the solution and the number of particles continued to increase. Raise the temperature to 67°C at a rate of 3min / °C, the number of particles in the solution decreases continuously, and the first temperature cycle ends; the second temperature cycle cools down to 52°C at a rate of 2min / °C, and then raises the temperature to 59°C at a rate of 3mi...

Embodiment 2

[0106] Dodecane dibasic acid (purity is 99%) and content is that 98wt.% acetic acid is placed in the crystallizer, and this 98wt.% acetic acid is converted into content and is after the acetic acid of 100wt.% and dodecane dibasic acid (purity is 99%) with a mass ratio of 2.2:1, heated to 85° C. to obtain a dodecanedioic acid solution.

[0107] In the crystallizer, keep the dodecanedibasic acid solution at a constant temperature of 85°C for 1h. Cooling down to 60°C at a rate of 2min / °C, particles precipitated in the solution and the number of particles continued to increase. Then the temperature was raised to 67°C at a rate of 3min / °C, the number of particles in the solution continued to decrease, and the first temperature cycle ended; the second temperature cycle was cooled to 52°C at a rate of 2min / °C, and then heated to 59°C at a rate of 3min / °C ℃,; for the third temperature cycle, cool down to 44°C at a rate of 2 min / °C, then raise the temperature to 51°C at a rate of 3 mi...

Embodiment 3

[0123] Undecane dibasic acid (purity is 99.1%) and content is that 95wt.% acetic acid is placed in the crystallizer, and this 95wt.% acetic acid is converted into the content after being 100wt.% acetic acid and purity is 99.1% The mass ratio of the basic acid is 2.8:1, heated to 80°C to obtain an undecanedibasic acid solution, and kept at a constant temperature of 80°C for 1 hour. Cool down to 55°C at a rate of 3min / °C, and keep at this temperature for 10min. Particles are precipitated in the solution and the number of particles continues to increase. Raise the temperature to 60°C at a rate of 5min / °C, keep at this temperature for 10min, the number of particles in the solution decreases continuously, and the first temperature cycle ends; the second temperature cycle cools down to 50°C at a rate of 3min / °C, at this temperature Keep warm for 10 minutes, heat up to 55°C at a rate of 5min / °C, and hold at this temperature for 10 minutes; for the third temperature cycle, cool down t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com