A method, product and application for preparing composite adsorbent by utilizing chlorosilane raffinate and chitosan

A chlorosilane residual liquid, composite adsorption technology, applied in silicon compounds, chemical instruments and methods, adsorption water/sewage treatment, etc. It can achieve the effect of excellent hydrophobicity, excellent adsorption performance and hydrophobicity, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

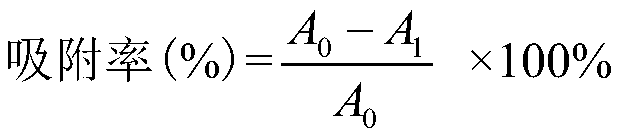

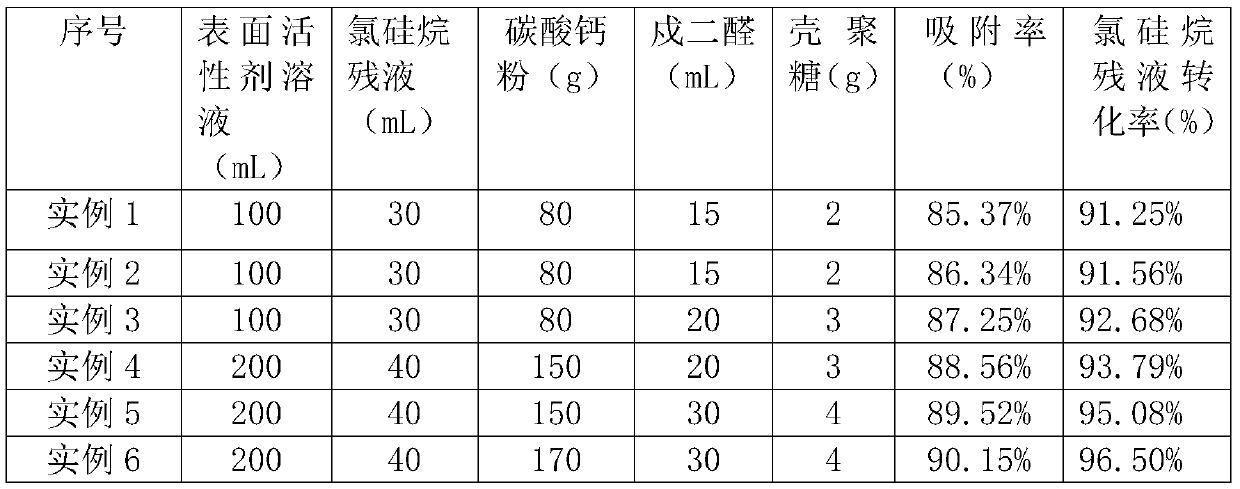

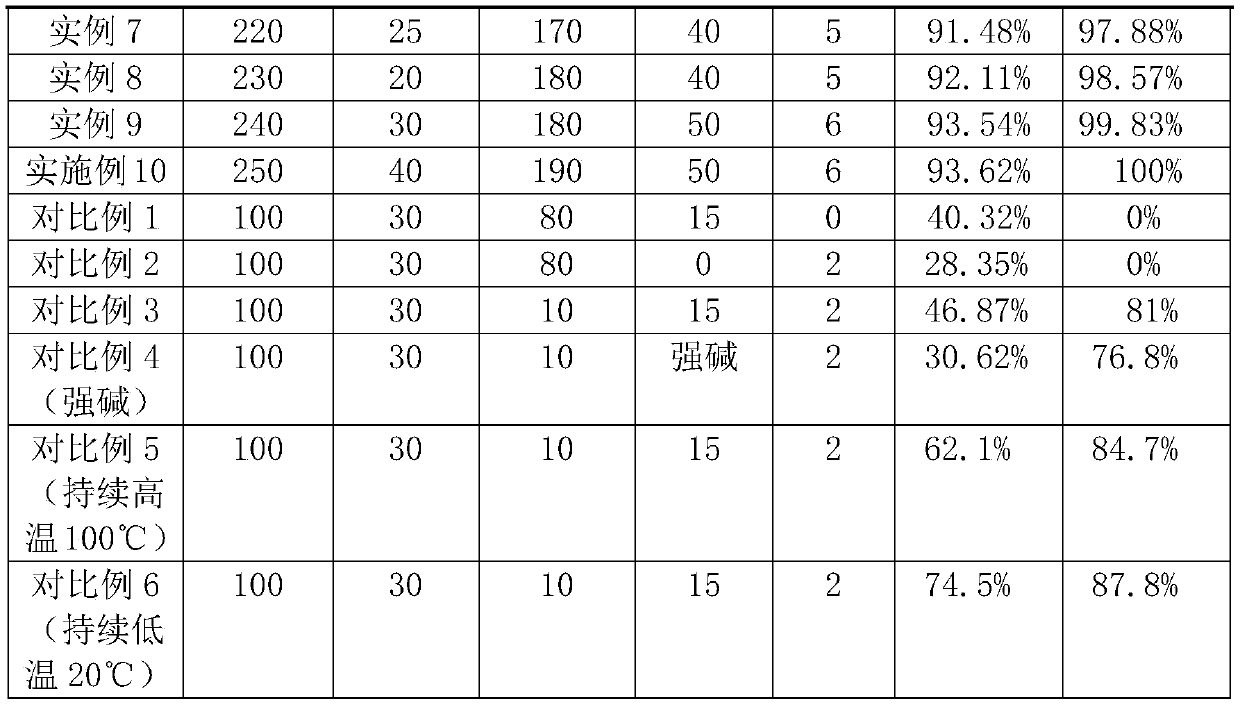

[0032] This embodiment provides a method for preparing a modified silica adsorbent, which specifically includes the following steps:

[0033] Prepare 100ml of 0.08% surfactant aqueous solution in a 1000ml four-necked flask with deionized water and Tween 20; then alternately add 30ml of chlorosilane residue to the four-necked flask containing the surfactant solution And 80g calcium carbonate powder, control the alternate addition speed, so that the pH of the reaction mixture in the four-neck flask is controlled between 0.5-3, and the reaction temperature is controlled to 40-50 ℃, and react for 3 hours under stirring conditions. After the addition is complete, add 2g of chitosan and 15ml of glutaraldehyde, heated to 50°C and continued to stir and react for 2h, and then kept at 60°C for 3h. After the precipitation in the reaction mixture is complete, the reaction in the four-necked flask The mixture is filtered, and the filtered cake is repeatedly washed with deionized water until t...

Embodiment 2

[0035] This embodiment provides a method for preparing a composite adsorbent using chlorosilane residual liquid and chitosan, which specifically includes the following steps:

[0036] First prepare 100ml of 0.09% surfactant aqueous solution with deionized water and Tween 80 in a 1000ml four-necked flask; then alternately add 30ml of chlorosilane residue to the four-necked flask containing the surfactant solution And 80g calcium carbonate powder, control the alternate addition speed, so that the pH of the reaction mixture in the four-neck flask is controlled between 0.1-3, and the reaction temperature is controlled to 40-50℃, and react for 4h under stirring conditions. After the addition is complete, add 2g of chitosan and 20ml of glutaraldehyde, heated to 60°C and continued to stir and react for 3h, then kept at 60°C for 3h, and after the precipitation in the reaction mixture is complete, the reaction in the four-necked flask The mixture is filtered, and the filtered cake is repe...

Embodiment 3

[0038] This embodiment provides a method for preparing a composite adsorbent using chlorosilane residual liquid and chitosan, which specifically includes the following steps:

[0039] Firstly, in a 1000ml four-necked flask, use deionized water and sodium dodecylbenzene sulfonate surfactant (SDBS) to prepare 100ml of a 0.1% surfactant aqueous solution; then to the four-necked flask containing the surfactant solution In the flask, alternately add 30ml of chlorosilane residue and 80g of calcium carbonate powder, and control the alternate addition speed so that the pH of the reaction mixture in the four-neck flask is controlled between 1.5-2.5, and the reaction temperature is controlled to 40-50°C, stirring React for 5h under the conditions. After the dripping is completed, add 3g chitosan and 20ml glutaraldehyde, increase the temperature to 70℃ and continue to stir the reaction for 4h, and then keep it at 60℃ for 3h, and wait until the precipitation in the reaction mixture is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com