Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

188results about How to "Improve profit margins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

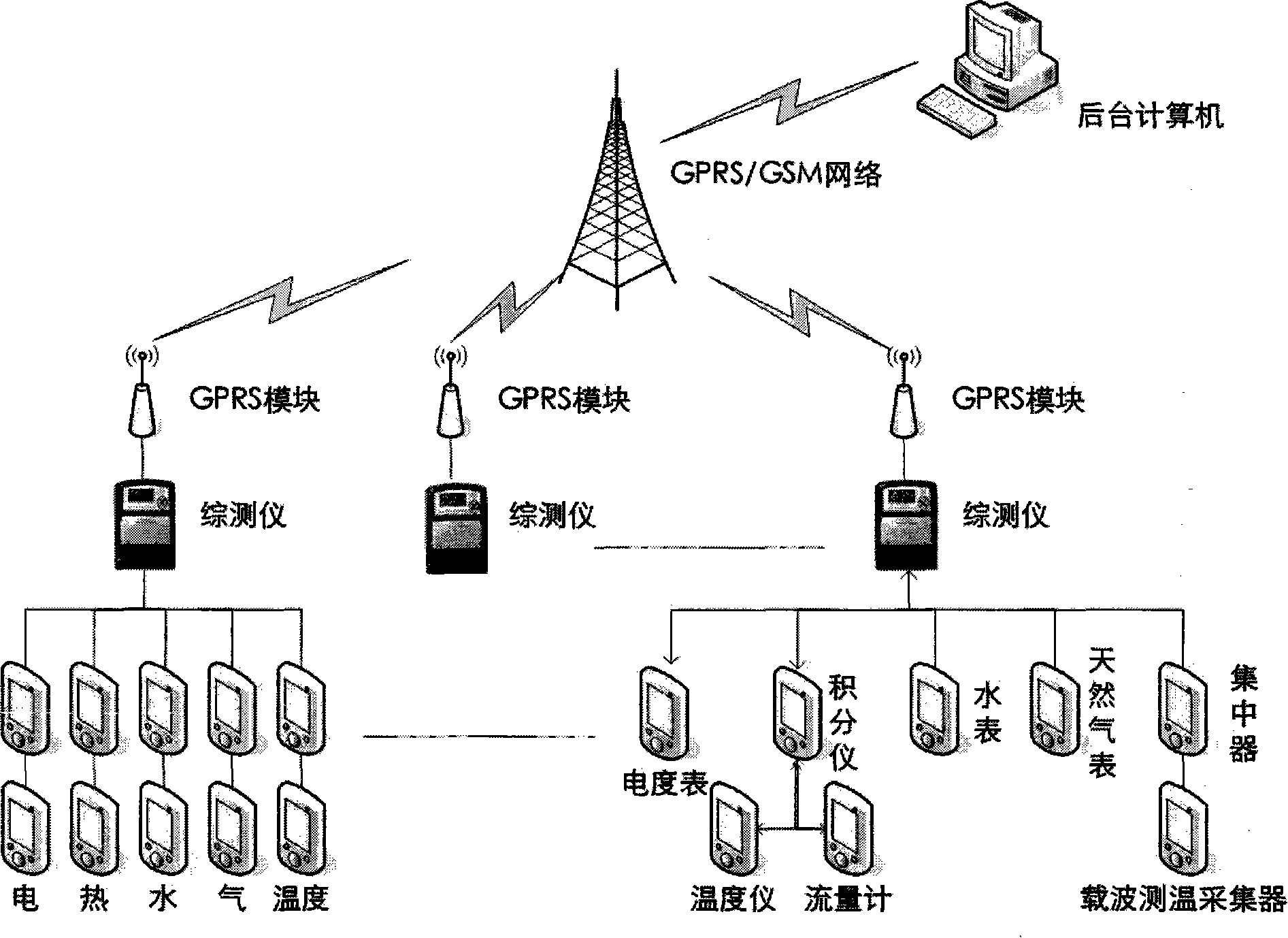

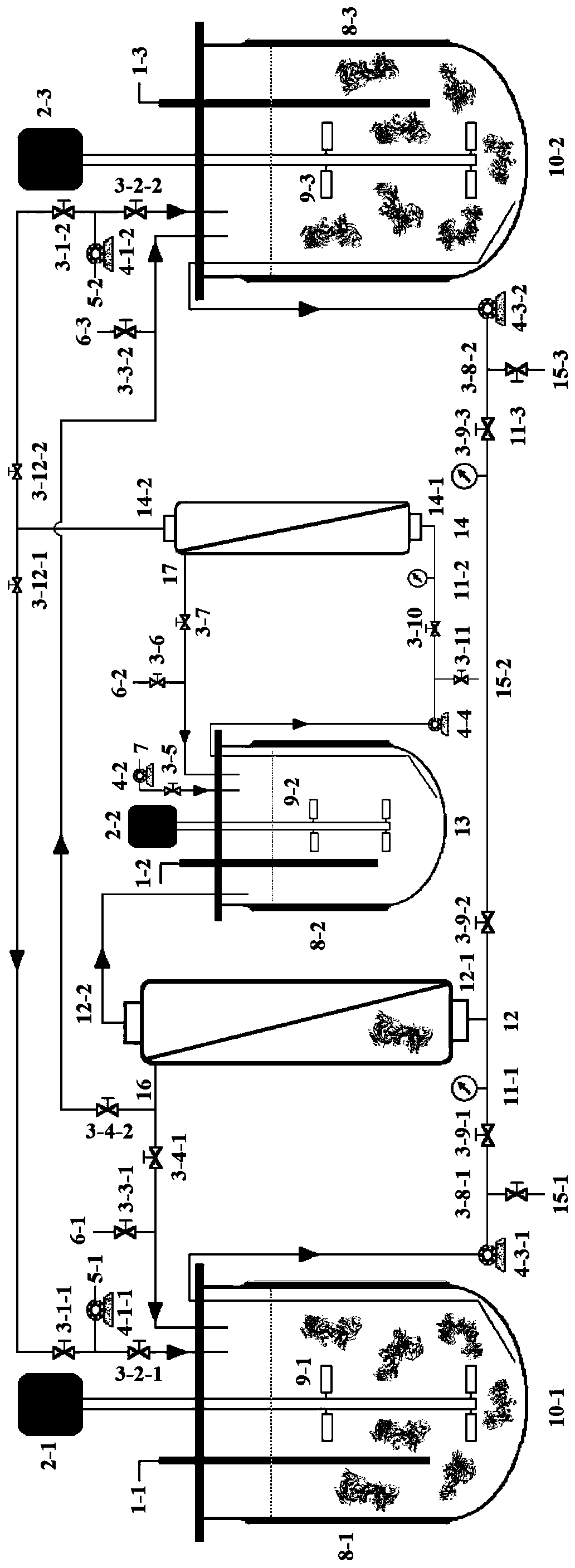

Energy-saving monitoring system

ActiveCN101174364AHigh energy consumptionGood compensationEnergy efficient ICTElectric signal transmission systemsThermal energyData acquisition

The invention discloses an energy-saving monitoring system, which comprises a plurality of data acquisition devices, a synthesis tester connected with the data acquisition devices, and a background computer connected with the synthesis tester; the data acquisition devices comprise electric data acquisition devices, heat energy data acquisition devices, and other devices, and are connected with the synthesis tester through bus lines; the synthesis tester comprises a CPU unit, and a data storage unit, a data statistic unit, data computing unit, a bus interface unit, and a long-distance data transmission unit which are connected with the CPU unit; the background computer comprises a data collecting unit, a data storage Unit, and an energy-saving analysis unit connected with the long-distance data transmission unit of the synthesis tester through the data collecting unit by adopting long-distance transmission means. The invention can effectively reduce the energy source waste through the monitoring to the energy consumption condition, thus realizing the preliminary behavior energy conservation; and completes energy saving renovation and realizes technical energy conservation by using technical means.

Owner:BEIJING JIUZHOU HENGSHENG CONSTR ENG

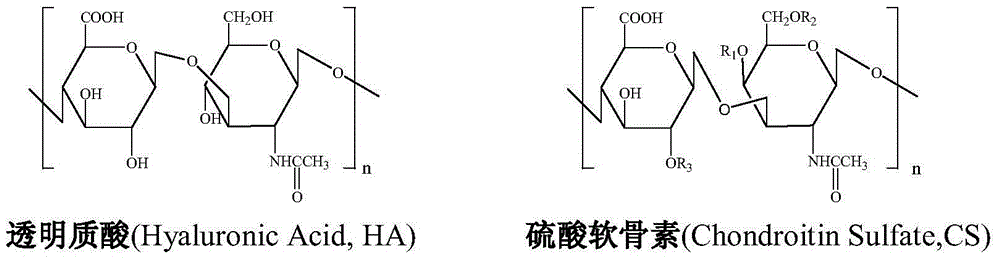

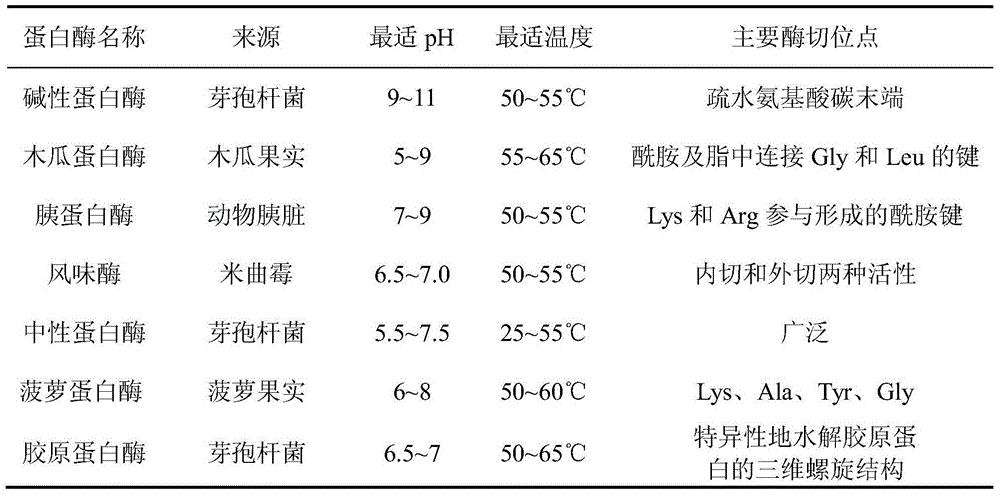

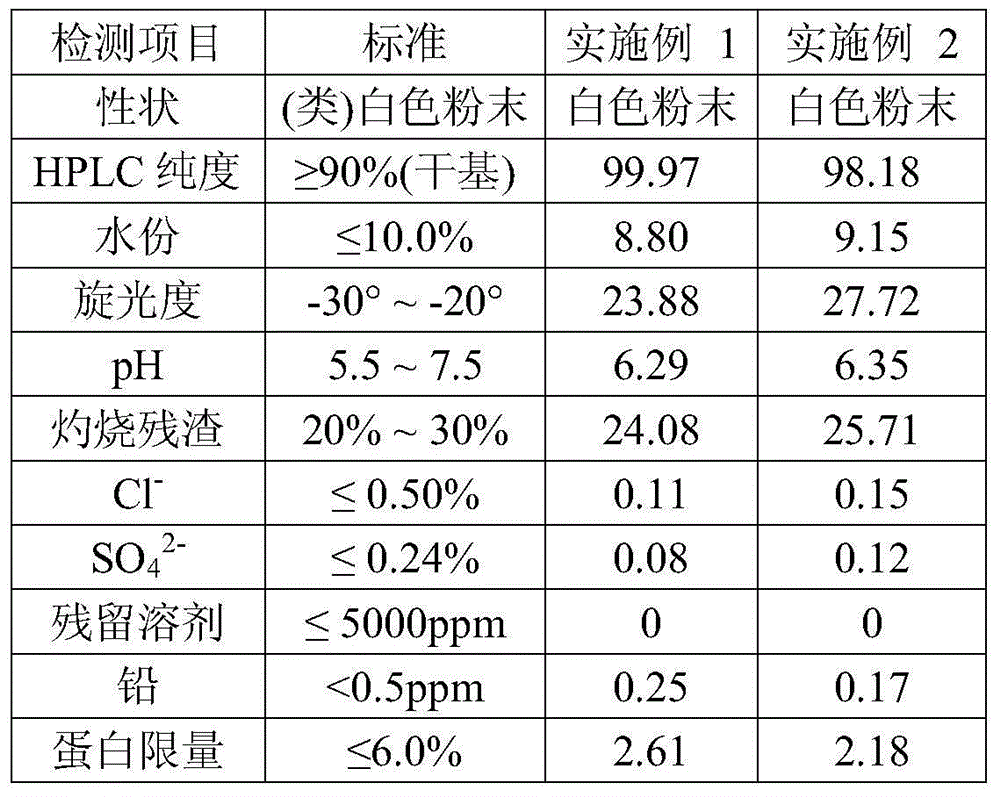

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method for manufacturing medium-temperature Longquan powder celadon

The invention relates to a method for manufacturing medium-temperature Longquan powder celadon. In the method, a green body and a glaze are mixed with common mineral materials and chemical materials in specific ratios, calcined zinc oxide and calcined talcum are added in the glaze, the Longquan powder celadon is fired at 1,220 to 1,240 DEG C at one time, the problems of high production cost, serious environmental pollution and the like, which are caused by high firing temperature and large energy consumption, of the conventional powder celadon production are solved, the jade textural quality of medium-temperature powder greenish glaze is strengthened.

Owner:JINGDEZHEN CERAMIC UNIV

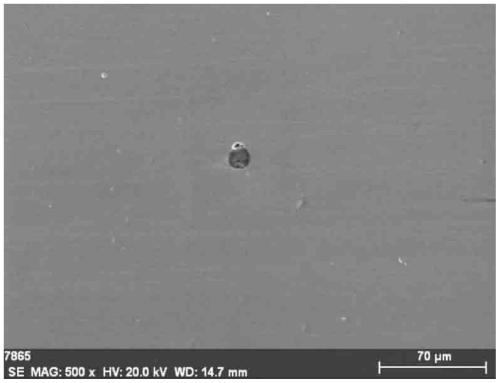

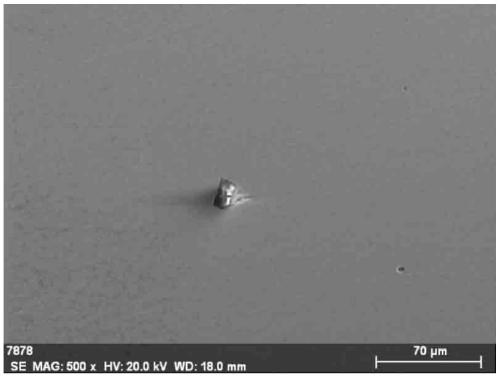

Additive for electrolytic copper foil and production process of electrolytic copper foil for 7-mu. m double-light lithium ion battery

The invention relates to an additive for an electrolytic copper foil. The additive is aqueous solution containing a brightening agent DPS and industrial gelatin, wherein the concentration of the DPS in the additive is 5-15g / L, and the concentration of the industrial gelatin is 1-4g / L. The invention further discloses a production process for preparing the electrolytic copper foil for a 7-mu. m double-light lithium ion battery by adopting the additive. The cost of the additive is lower, the performance index of the produced electrolytic copper foil meets a specified requirement, and the electrolytic copper foil can be taken as a copper foil special for a lithium battery.

Owner:LINGBAO WASON COPPER FOIL

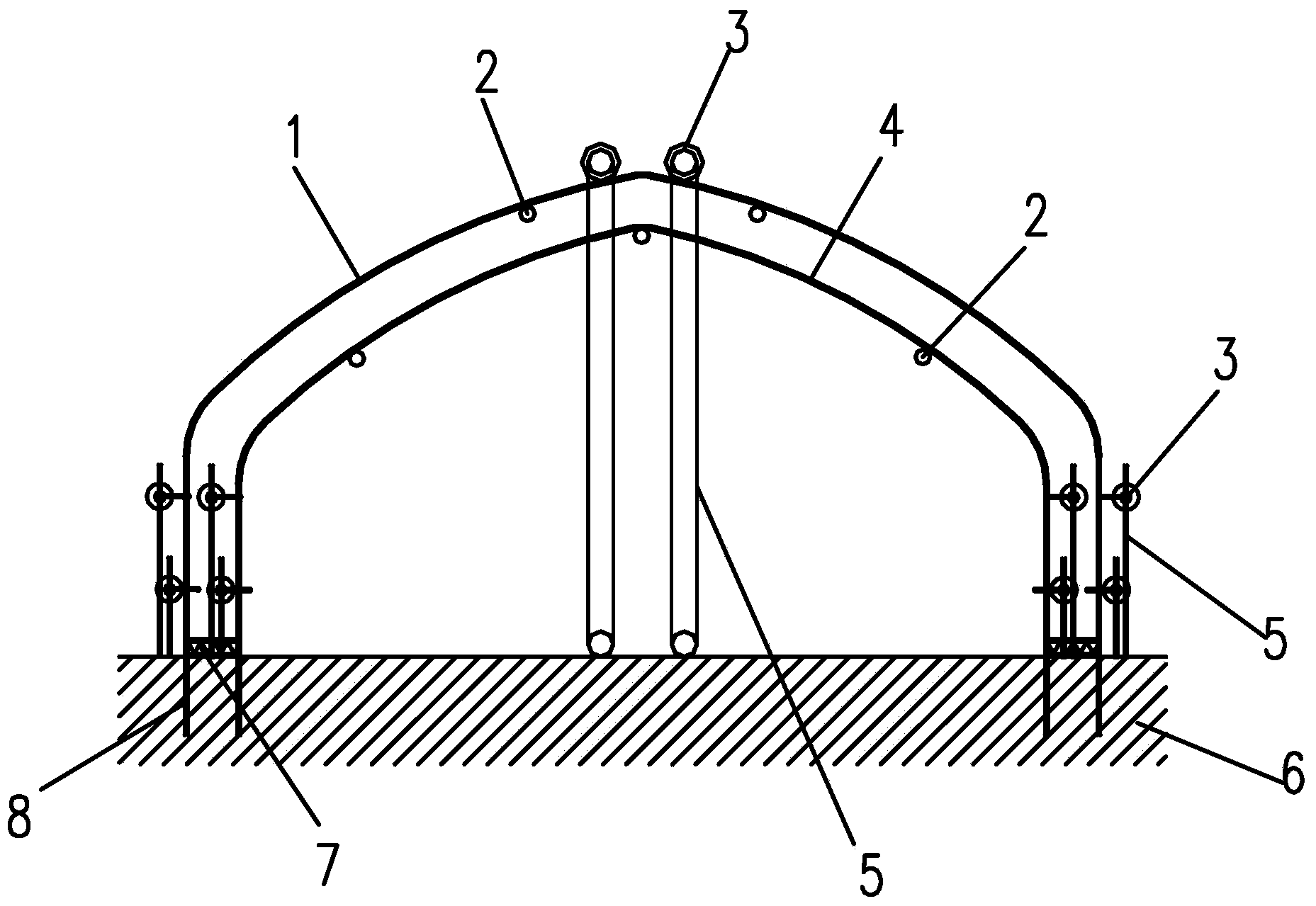

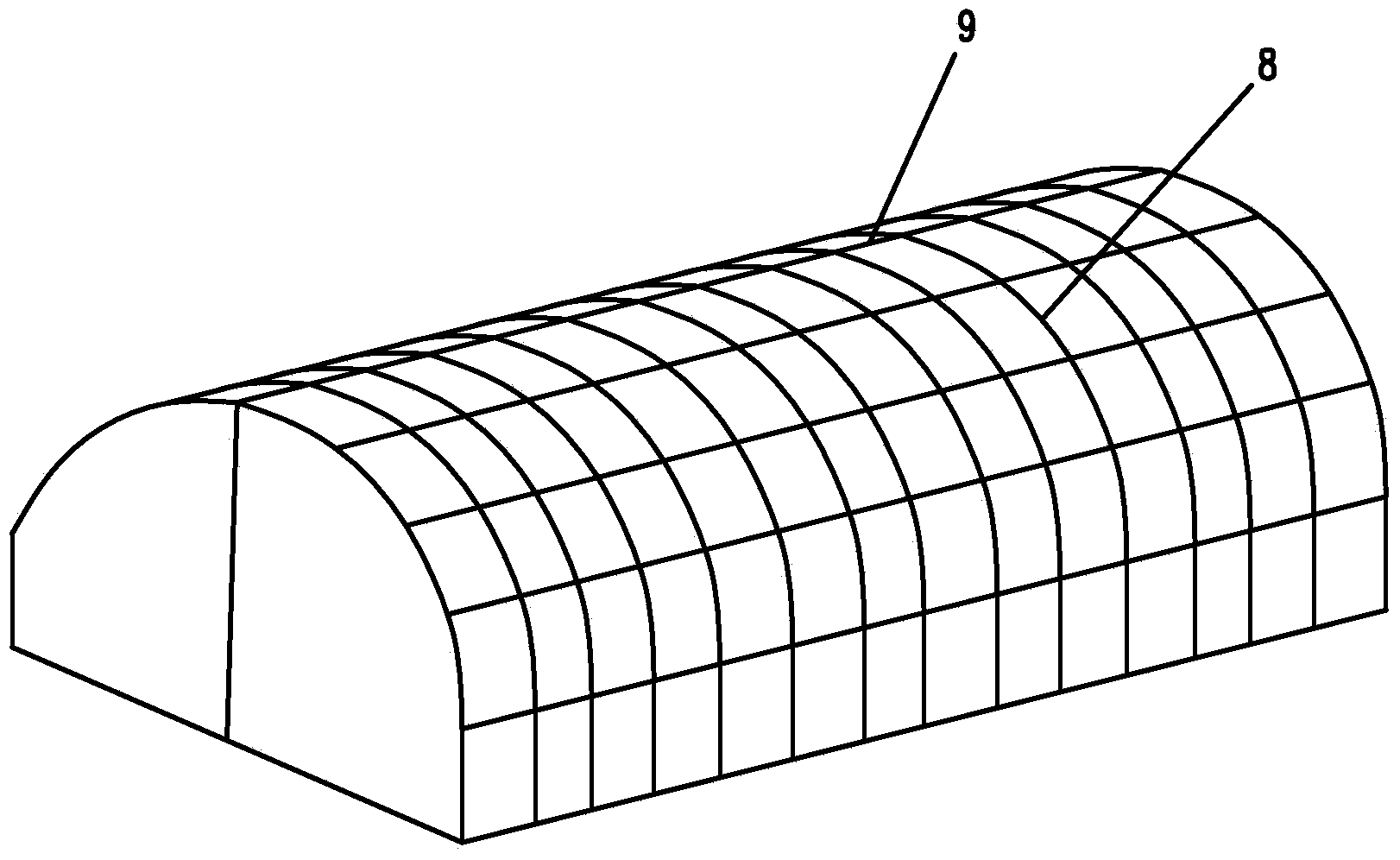

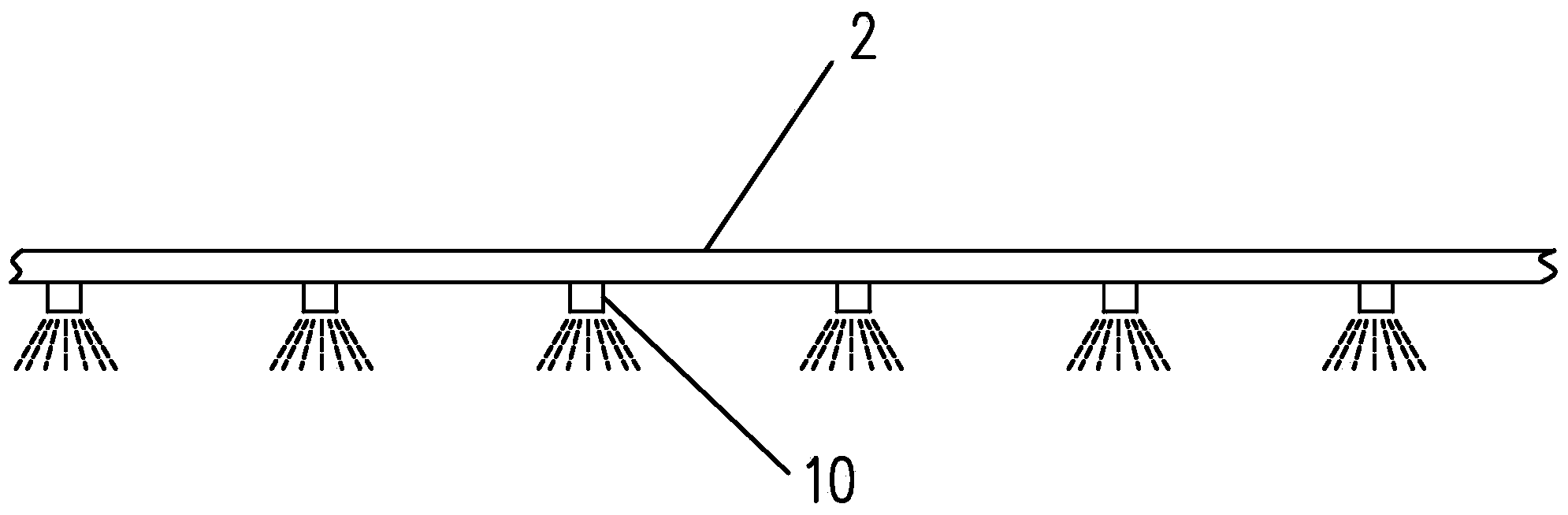

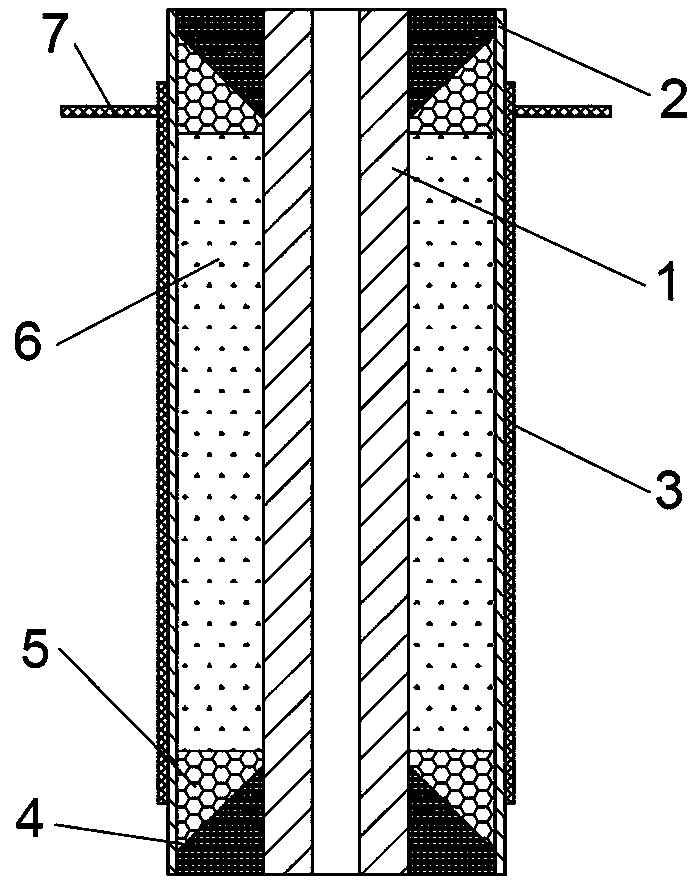

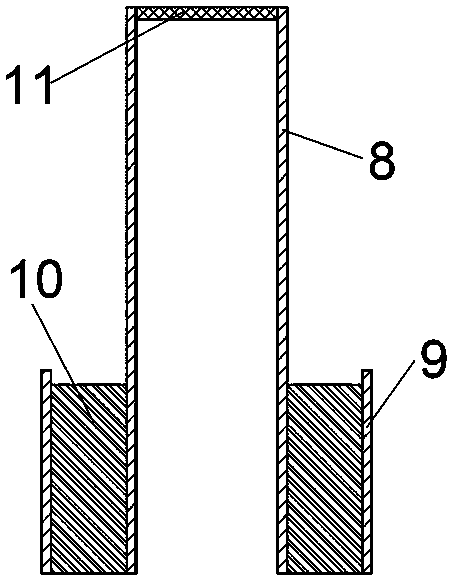

Dual-net dual-film shed

InactiveCN104255302AIncrease profitAchieve annual bacteriaClimate change adaptationGreenhouse cultivationSprayerEdible mushroom

The invention relates to a dual-net dual-film shed. The dual-net dual-film shed comprises a large arch shed and a small arch shed located inside the large arch shed; each of the large arch shed and the small arch shed comprises a steel structure shed framework composed of transverse steel pipes and longitudinal steel pipes which are all connected with each other; the longitudinal steel pipes on the two sides of each shed framework are inserted into soil; each shed framework is orderly covered with a plastic film and a shading net from inside to outside; the plastic film and the shading net are connected with rollers, respectively; the rollers are fixed by use of supports; a spraying water pipe is arranged at the lower end of each shed framework and sprayers are arranged on the spraying water pipes at intervals; a cushion film is arranged on the ground between the large arch shed and the small arch shed. The dual-net dual-film shed is capable of annual mushroom output due to the mutual cooperation of the large arch shed and the small arch shed, and therefore, the utilization rate of the shed is greatly increased and the income can be increased. The dual-net dual-film shed is capable of automatically regulating the temperature and the humidity inside the shed and the illumination condition and thus capable of producing high-quality edible mushrooms. The dual-net dual-film shed is lower than the existing sheds in cost, and therefore, the profit margin of the product is further increased.

Owner:QINGDAO HUASHENG GREEN ENERGY AGRI TECH

Material for high-wear-resistant rare earth rubber shoes and preparation method thereof

ActiveCN107216504AIncrease the amount addedGuaranteed basic physical propertiesSolesDomestic footwearVulcanizationPolymer science

The invention discloses a material for high-wear-resistant rare earth rubber shoes and a preparation method thereof. The material is prepared from rare earth polybutadiene rubber (NdBR), isoprene rubber (IR), solution polymerized butadiene styrene rubber (SSBR), a softening agent, an activating agent, a coupling agent, a vulcanizing agent, a vulcanization accelerator, an anti-aging agent and surface modified ground rubber. The invention adopts a die pressing method to prepare a series of rubber shoe sole materials with wear resistance (DIN wear is 30 to 120mm<3>), slip limit (dry slip is 0.6 to 1.1, and wet slip is 0.3 to 0.6), and moderate hardness (Shore A) 60 to 70; the material has the following advantages that (1) the wear resistance is better; (2) the slip limit is improved; (3) the comfort is increased; (4) the production cost can be remarkably reduced, the profit space is improved, and the energy is saved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST JINJIANG CO LTD +1

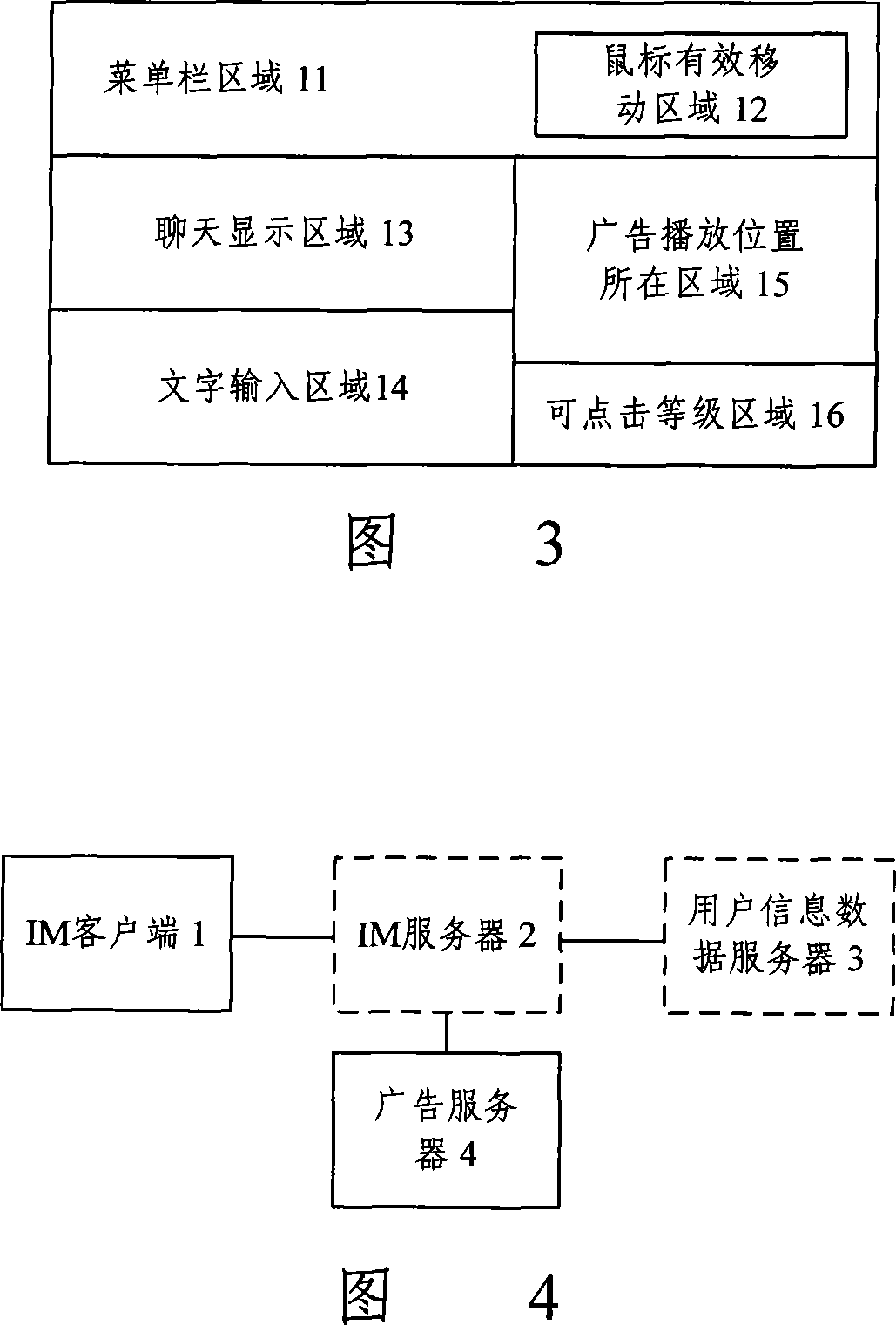

Method, system and instant communication client terminal of implementing feedback of advertisement grade

ActiveCN101141414AImprove profit marginsImprove effectivenessData switching networksMarketingOnline advertisingClient-side

The present invention discloses a realization method for feeding back an advertisement rank. The method comprises the procedures that an instant messaging (IM) client side gains an advertisement list, and downloads corresponding advertisement resources from an advertisement server according to the advertisement indicating information obtained in the advertisement list; the IM client side selects the advertisement rank data corresponding to the advertisement resources, and feeds back the advertisement rank data to the advertisement server. The present invention also discloses a system and an instant messaging client side for feeding back the advertisement rank, by adopting the method, the system and the instant messaging client side of the present invention, not only the experience process of a user to actively participate in feedback is increased, but also the interaction of a user and an IM operator, and the IM operator can appropriately meet the needs of users to gain income from an network advertisement.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Pineapple-flavored wax gourd soft sweets with health-care function and preparation process of pineapple-flavored wax gourd soft sweets

InactiveCN104970171AThe production process is simpleImprove profit marginsConfectionerySweetmeatsWaxMaltitol

The invention discloses pineapple-flavored wax gourd soft sweets with a health-care function. The pineapple-flavored wax gourd soft sweets with the health-care function are characterized by being prepared from the following raw materials in parts by weight: 400-450 parts of wax gourds, 2-3 parts of carrageenan, 18-22 parts of gelatin, 45-55 parts of maltitol, 1-2 parts of aspartame, 40-50 parts of pineapples, 10-14 parts of lotus powder, 14-16 parts of konjaku flour, 4-8 parts of cinnamon and 8-10 parts of pericarpium citri reticulatae. The preparation process of the pineapple-flavored wax gourd soft sweets disclosed by the invention are simple, the edible value of the wax gourds is developed and utilized to the maximum extent, and the profit margin of the wax gourds is improved. The prepared wax gourd soft sweets not only have a special faint scent of the wax gourds, but also have a certain health-care effect. The wax gourd soft sweets are agreeable in sweetness and suitable for people of all ages and have a good application prospect and economical benefit.

Owner:余朝霞

Preparation method of breast-milk patterned structured oil and breast-milk patterned structured oil prepared by preparation method and use of breast-milk patterned structured oil

ActiveCN105441492APromote absorptionPromote growth and developmentMilk preparationFermentationCarbon numberTriglyceride

The present invention provides a preparation method of breast-milk patterned structured oil and the breast-milk patterned structured oil prepared by the preparation method and use of the breast-milk patterned structured oil. More specifically, according to the method, palmitic-acid-rich oil, oil rich in saturated fatty acids having the carbon number of 6-14, and oil rich in unsaturated fatty acids are used as raw materials for preparation of the breast-milk patterned structured oil by combination of random ester exchange reaction and directional ester exchange reaction. The Sn-2 position of the breast-milk patterned structured oil is the saturated fatty acid, the saturated fatty acid accounts for 50wt%-70wt% of the weight of total saturated fatty acids in the breast-milk patterned structured oil, and the Sn-1 position and the Sn-3 position of the breast-milk patterned structured oil are unsaturated fatty acids, so that the breast-milk patterned structured oil is in close proximity to the structure of breast milk triglyceride, and the breast-milk patterned structured oil prepared by the preparation method can be more easily absorbed by infants and young children, and is more conducive to promoting of growth and development of the infants and young children.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Method for filtering and centrifugally separating mixture containing aluminum, silicon, iron and the like, removing impurities and carrying out purification

InactiveCN110846513ALow costImprove profit marginsProcess efficiency improvementSilicon compoundsSilicon alloyLiquid state

The invention relates to a method for filtering and centrifugally separating a mixture containing aluminum, silicon, iron and the like, removing impurities and carrying out purification. The method includes the steps that (1), the liquid-state mixture containing the aluminum and the silicon is put in an insulated bag container; (2), the temperature operation interval of the mixture is controlled,and pure silicon crystals are precipitated and grow; (3), intermetallic compounds and other impurities are enriched and settle on the outer layer under the effect of centrifugal supergravity or pressurization, aluminum-silicon alloys on an interlayer are purified, and silicon solid phases are collected in a filtering and filtering and centrifuging manner; (4), the remaining liquid-state mixture issubjected to supergravity centrifuging and gradually cooled and solidified; and (5), solidified products are stripped in a mechanical or manual manner, and the multiple high-grade products are obtained at low cost.

Owner:刘旭

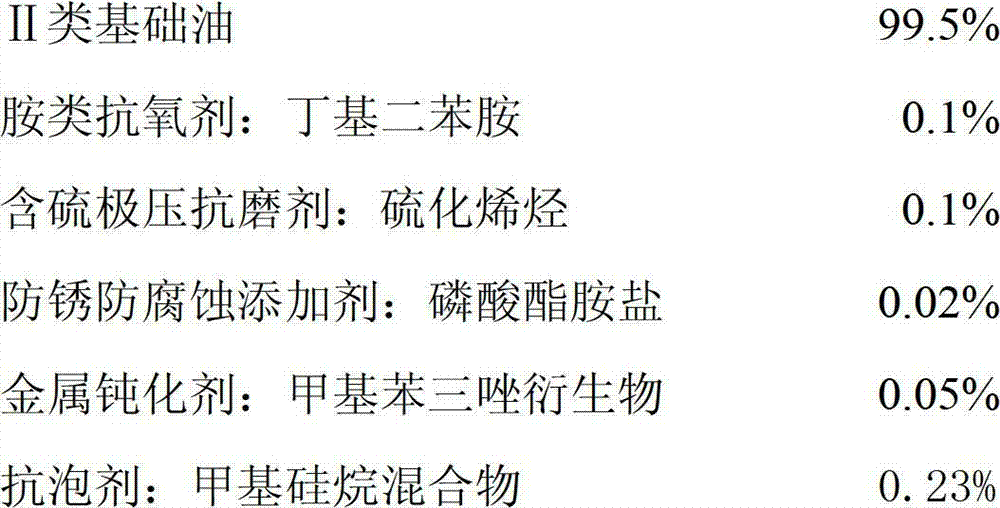

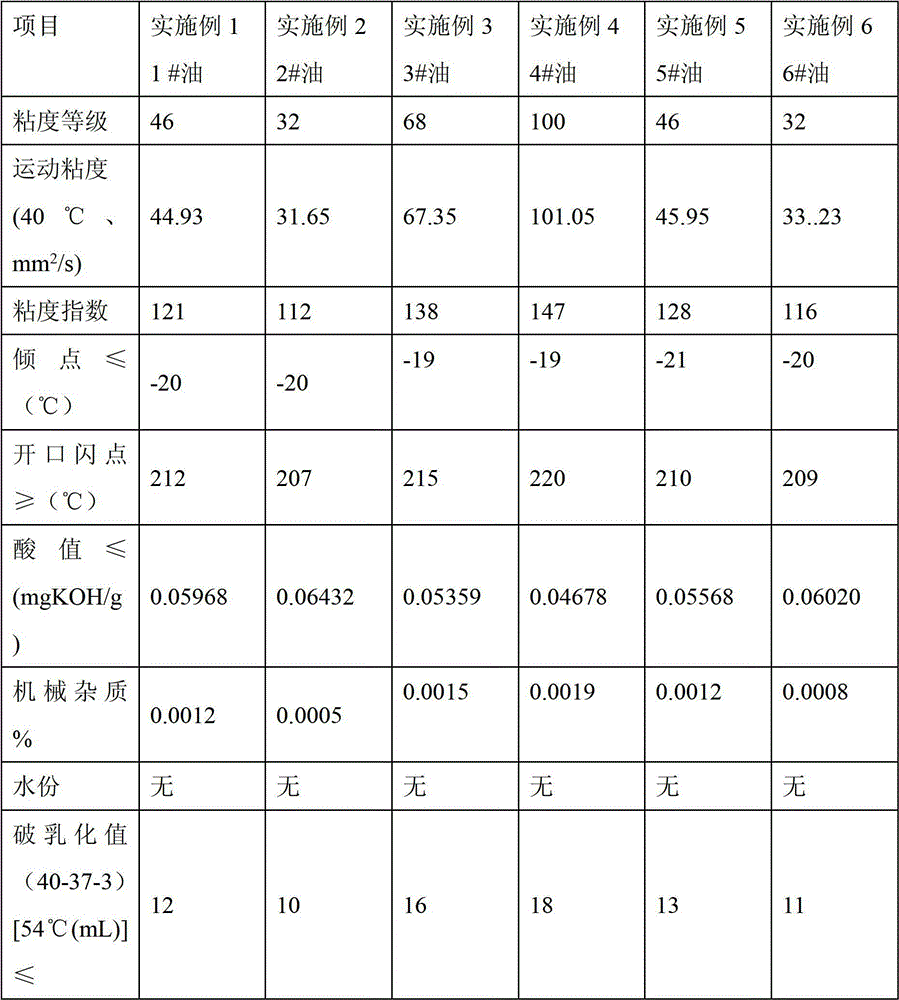

Industrial gear oil

ActiveCN102776055ASolution to short lifeNo pollution in the processLubricant compositionGear wheelAntioxidant

The invention discloses industrial gear oil, which contains the following components by weight percent: 98-99.5 percent of base oil with saturated hydrocarbon content being more than 90 percent and sulfur content being less than 0.03 percent, 0.1-0.5 percent of amine antioxidant, 0.1-0.9 percent of sulfur-containing extreme pressure antiwear agent, 0.02-0.1 percent of antirust and anticorrosion additive, 0.01-0.05 percent of metal deactivator and 0.001-0.5 percent of anti-foaming agent. The industrial gear oil provided by the invention has good extreme pressure lubricating performance and good antirust and anticorrosion performance, and has the advantages of high quality, long service life, no pollution and the like; by formulating the high-quality base oil and novel environmental-friendly gear oil additives and by using the unique extreme pressure antiwear agent, not only can the bearing capacity of the gear oil be greatly improved, but also the impact caused by the traditional lead-containing formula to the health of operating workers is precluded and the surfaces of steel and copper parts can be effectively prevented from being worn; and due to proper adhesiveness and extremely low friction coefficient, the noise produced by gears during operation and the temperature of a machine body can be effectively reduced, the energy consumption is reduced and the service life of the gears is prolonged.

Owner:上海福岛新材料科技有限公司

Method for preparing methyl chlorosilane by cracking organic silicon high boiling point substance

InactiveCN101824047AHigh selectivitySolve the use problemGroup 4/14 element organic compoundsBoiling pointMethyltrichlorosilane

The invention discloses a method for preparing methyl chlorosilane by cracking organic silicon high boiling point substance, which takes the organic silicon high boiling point substance produced by organic silicon mixed monomer as raw material, and comprises the steps of: when the organic silicon high boiling point substance is forged to 2 / 3 of the liquid level in a cracking kettle by a pump, adding catalyst triethylamine and tributylamine; filling chloromethane gas into the cracking reaction kettle with rising temperature, and preparing methyl chlorosilane mixed monomer; and cooling the mixed monomer, leading the mixed monomer enter a rectifying tower, and then preparing monomethyl dichlorsilane, dimethyl dichlorsilane, monomethyl trichlorosilane and trimethyl monochlorosilane. The method can improve the selectivity of the dimethyl dichlorsilane, increases the product yield, generates less residual waste, solves the problem of the utilization of the high boiling point substance, reduces the environmental pollution, is low in cost, has higher profit space, can be used for continuously cracking the high boiling point substance, and is suitable for popularization and application.

Owner:山东中创钢构有限公司

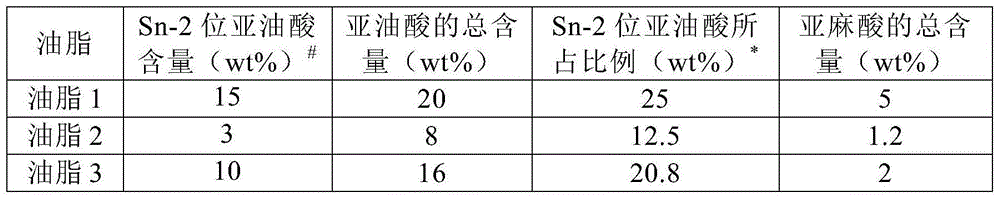

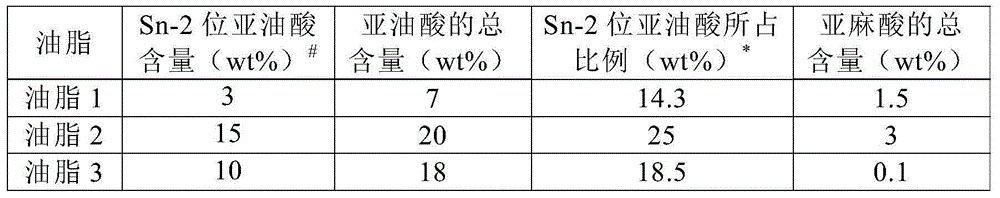

Preparation method of human milk fat substitute, human milk fat substitute prepared by method, and use of milk fat substitute

The invention relates to a preparation method of a human milk fat substitute, the human milk fat substitute prepared by the method, and use of the milk fat substitute. Specifically, edible fat is used as a raw material, and a random ester exchange reaction, a physical mixed reaction and a directed ester exchange reaction are performed, so that the human milk fat substitute is prepared. In the human milk fat substitute disclosed by the invention, compared with the total weight of fatty acid residues at an Sn-2 site of triglyceride of the human milk fat substitute, the content of palmitic acid residues at the Sn-2 site is 20wt%-60wt%, and the content of linoleic acid at the Sn-2 site is 3wt%-15wt%; compared with the total weight of the fatty acid residues in the triglyceride of the human milk fat substitute, the total content of the linolenic acid is 1wt%-5wt%. According to the method disclosed by the invention, the edible fat with broad sources is used as the raw material, and the technology is simple, so that the mass production of the human milk fat substitute of which the structure is similar to that of breast milk triglyceride in industry at a low cost can be realized. The human milk fat substitute prepared by the method disclosed by the invention is easy to absorb by babies, and promotion of the growth and the development of the babies is facilitated.

Owner:COFCO NUTRITION & HEALTH RES INST +1

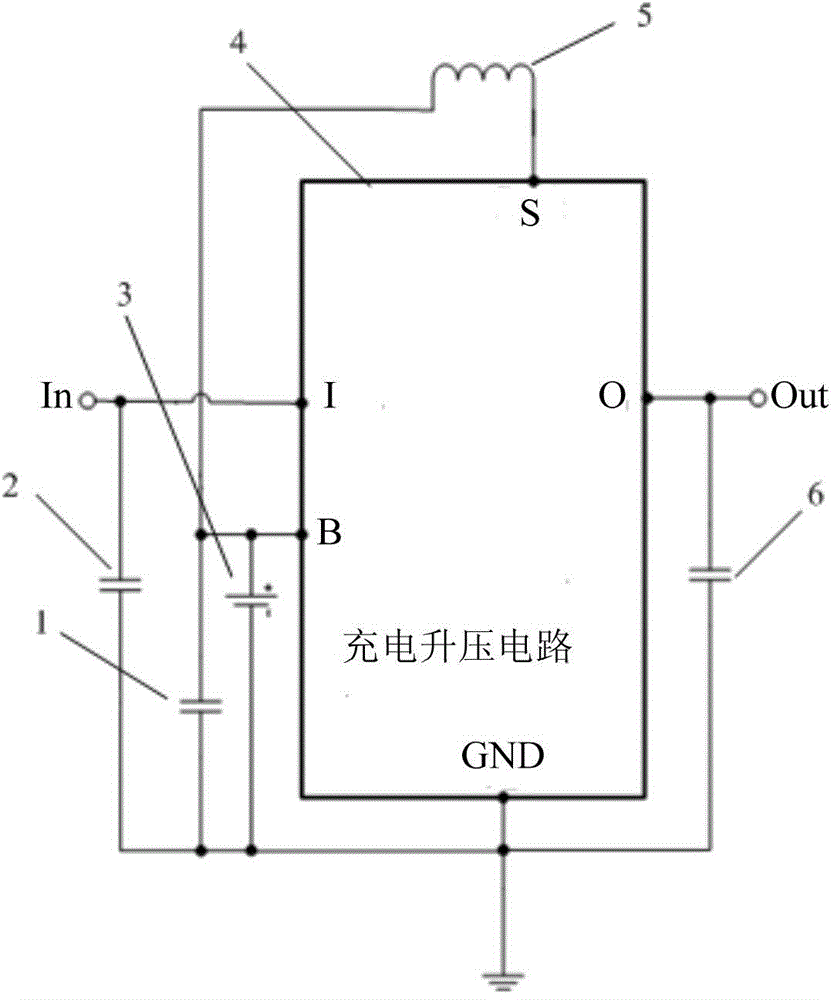

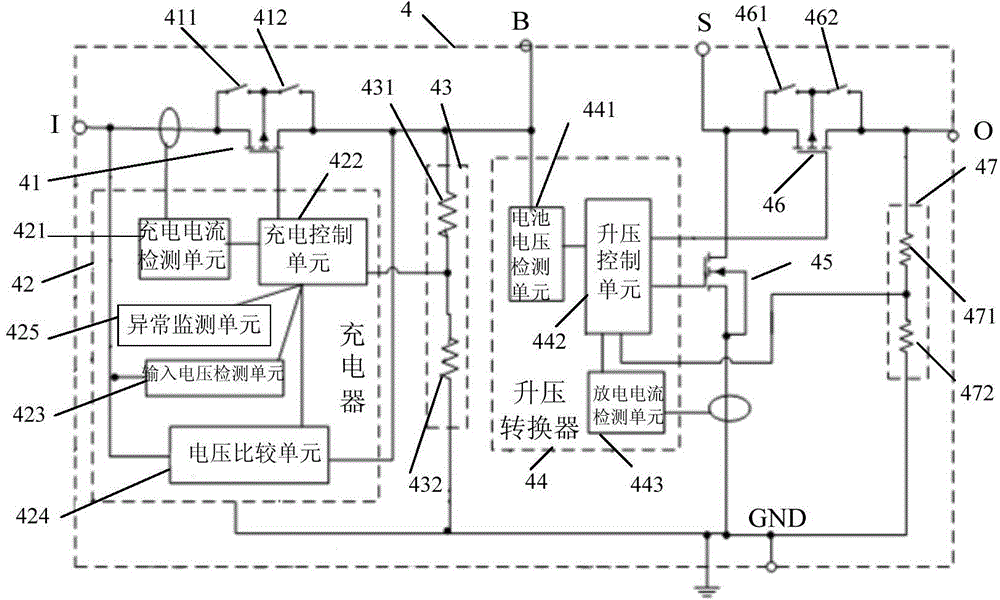

Charging and discharging circuit with automatic protecting function

ActiveCN103607009ALow costImprove profit marginsBatteries circuit arrangementsElectric powerElectrical batteryCharge and discharge

The invention provides a charging and discharging circuit with an automatic protecting function. The charging and discharging circuit comprises a power source input end, a power source output end, a battery, a charging module and a voltage boost module, wherein the charging module comprises a charger, a battery voltage feedback unit and a first switch unit, the charger comprises a charging current detecting unit, an input voltage detecting unit, a voltage comparison module and a charging control unit, and the first switch unit is connected between the power source input end and the battery; the voltage boost module comprises a voltage boost converter, an output voltage feedback unit, a power switch tube and a second switch unit, and the voltage boost converter comprises a battery voltage detecting unit, a discharging current detecting unit and a voltage boost control unit. The charging and discharging circuit achieves the automatic protecting function and meanwhile can reduce the number of components, and therefore the overall area of the circuit is reduced, cost is saved, the complexity of the circuit is reduced, and the reliability of the circuit is improved.

Owner:钰泰半导体股份有限公司

Technological method for comprehensively recovering vanadium and potassium through acid leaching of pulverized fuel ash

ActiveCN104131169AHigh recovery rateEfficient use ofProcess efficiency improvementPotassiumPulverized fuel ash

The invention relates to a technological method for comprehensively recovering vanadium and potassium through acid leaching of pulverized fuel ash. The technological method comprises the following steps: (1) leaching-flying ash neutralization operation; (2) aluminum potassium sulfate crystallization operation; (3) lime neutralization operation; (4) reduction operation; (5) extraction-reextraction operation; (6) crystallization-vanadium precipitation operation; and (7) bichromate calcination operation. Potassium can be recovered by crystallization through using leached supernate, and partial impurity aluminum can be effectively utilized; ammonium alum can be prepared from return water through crystallization, thus further recovering impurity aluminum and also providing a guarantee for quality of finally produced up-to-standard refined vanadium; an extraction raffinate returns to the leaching operation after being treated, no waste water is emitted, and simultaneously the recovery rate of potassium can also be improved. The method is low in running cost, capable of guaranteeing the smoothness of the whole vanadium extraction technology, and less in environmental pollution.

Owner:SHAANXI COAL & CHEM CONSTR GRP CO LTD +1

Low-temperature high-toughness V-N alloyed ship plate steel and manufacturing method thereof

The invention discloses a low-temperature high-toughness V-N alloyed ship plate steel and a manufacturing method thereof. The steel comprises the following chemical elements in percentage by weight: 0.055% to 0.15% of C, 0.1% to 0.25% of Si, 1.55% to 1.65% of Mn, 0.035% to 0.045% of V, 0.003% to 0.013% of Ti, 0.006% to 0.0095% of N, not more than 0.02% of P, not more than 0.02% of S, not more than 0.03% of Als, and the balance being Fe and inevitable impurities. The steel is prepared by the following steps: smelting in vacuum environment, introducing nitrogen gas into the furnace after the refinement, casting ingots, heating the ingots to a temperature of 1150 to 1250 DEG C, and maintaining the temperature for 0.5 to 2.5 hours; wherein the rolling temperature is 1050 DEG C to 1130 DEG C, the cooling temperature is 850 DEG C to 950 DEG C, and the re-reddening temperature is 500 to 800 DEG C. The formula of the steel is re-designed, thus the carbon content of the steel is effectively reduced, and the welding performance of the steel is improved. At the same time the cheap nitrogen element is fully utilized to optimize the precipitate of V, so the strength and toughness of the steel are both improved, and the cost of the steel is reduced too.

Owner:ANGANG STEEL CO LTD

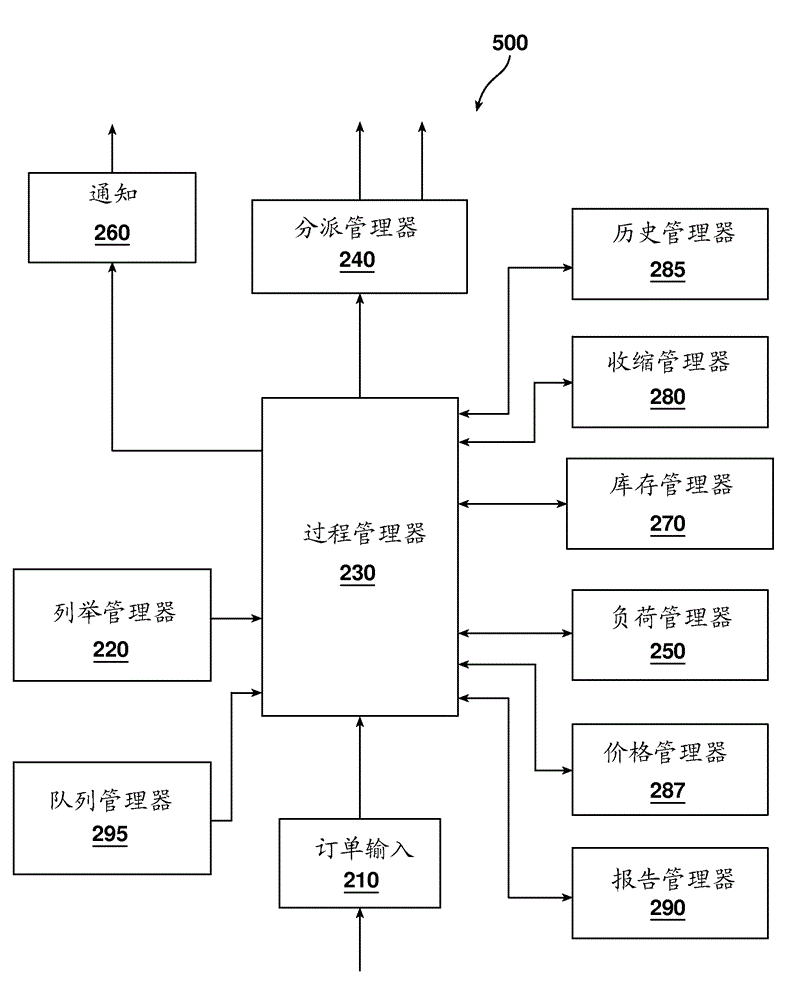

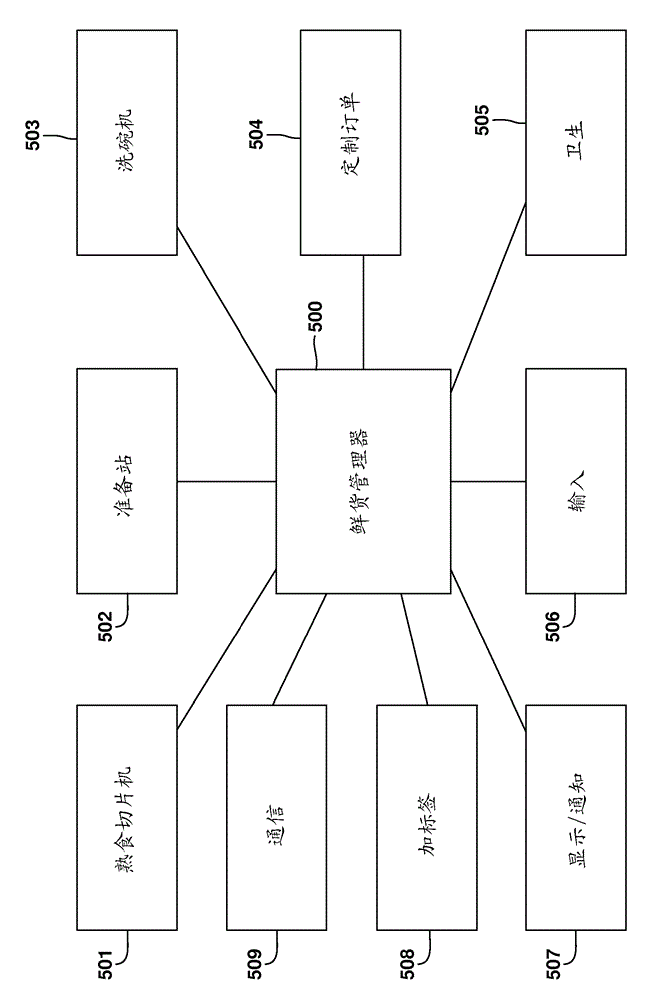

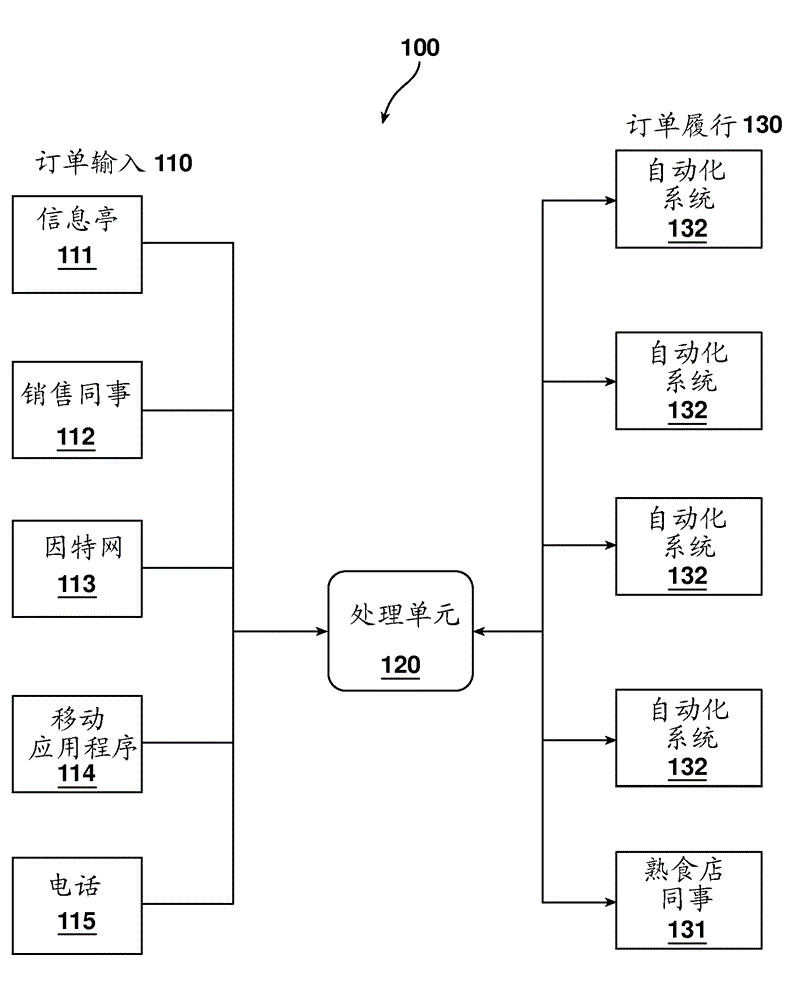

Fresh departments management system

InactiveCN104380320AReduce errorsImprove shopping experiencePayment architectureApparatus for meter-controlled dispensingHuman interactionOrder fulfillment

The system comprises a central processing module that is configured to interconnect the fresh departments and operational functions. These tasks can include facilitated order fulfillment, inventory and accounting functions, sanitation, maintenance, traceability and others. This is a system that integrates various sub-systems within the fresh departments, as well as integrating the fresh departments together. The system may also utilize a plurality of slicing machines that communicate with the centralized processing unit. The software modules resident in the processing unit receive inputs that represent customer orders, and dispatch these orders to the plurality of slicing machines. The slicing machines are in communication with the software modules such that the modules are aware of the food product that is currently placed on the slicer. In this way, the software modules are able to direct specific orders to a particular slicing machine, minimizing human interaction and customer wait time.

Owner:SEALED AIR SAS

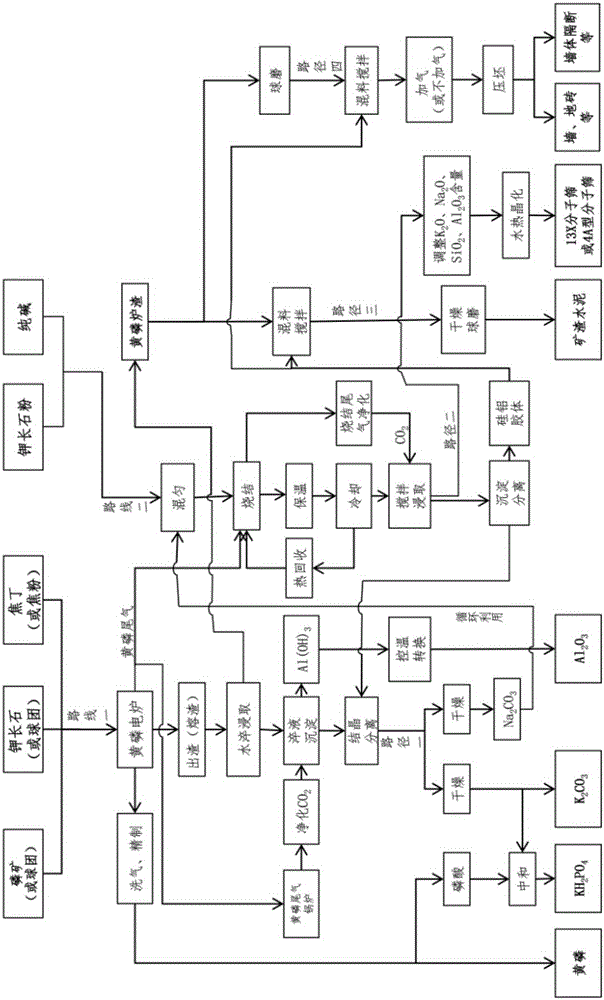

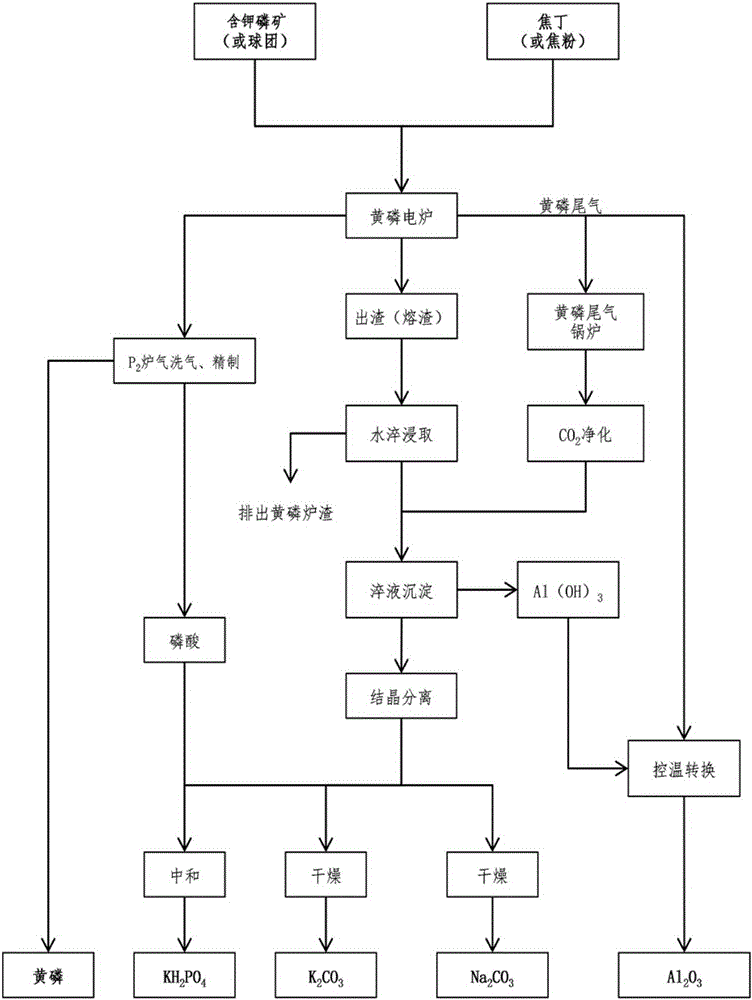

Circular clean production method for yellow phosphorus with co-production of potassium salt, aluminium oxide, molecular sieve, blast furnace slag cement and architectural profile

ActiveCN105217588AConsumption is not affectedReduce manufacturing costCement productionFaujasite aluminosilicate zeoliteSlagMaterials science

The invention relates to a circular clean production method for yellow phosphorus with co-production of potassium salt, aluminium oxide, a molecular sieve, blast furnace slag cement and an architectural profile. The method comprises two lines: 1, replacing externally added silica by potassium feldspar, and preparing high quality yellow phosphorus with phosphorite and coke nuts by virtue of an electric heating method; quenching yellow phosphorus slag, dissolving out KAlO2, filtering the mixture, introducing CO2, and precipitating Al(OH)3 and preparing a first filtrate; and carrying out temperature-controlled conversion on Al(OH)3 to obtain Al2O3. and 2, uniformly mixing potassium feldspar and Na2CO3, calcining the mixture with yellow phosphorus tail gas, and the leaching the mixture by water, introducing CO2, precipitating a silica-alumina gel body and preparing a second filtrate. then the line is divide into four using paths: (1) crystallizing the first and second filtrates in a centralized manner and drying the first and second filtrates to prepare K2CO3 and Na2CO3, returning Na2CO3 to a line 2 to be recycled, and continuously processing K2CO3 to potassium salt such as KH2PO4 and K2SO4 and the like; (2) carrying out hydrothermal crystallization on the unprecipitated silica-alumina gel body and the filtrate to prepare a molecular sieve; (3) preparing slag cement by the silica-alumina gel body and yellow phosphorus slag; and (4) preparing the architectural profile by the silica-alumina gel body and yellow phosphorus slag.

Owner:黄钰雪

Calcium treatment-free production process of low-carbon silicon-containing killed clean steel

The invention discloses a calcium treatment-free production process of low-carbon silicon-containing killed clean steel, and belongs to the technical field of iron and steel metallurgy. The process ischaracterized in that the production of the molded low-carbon low-aluminum killed clean steel is carried out under the condition that calcium treatment is not used, and the specific flow comprises the steps of processing molten iron, performing combined oxygen blowing to a converter from the top and the bottom, LF refining (adjusting the aluminum component of the molten steel, feeding aluminum for three times, and feeding aluminum-iron-rare earth core-spun yarn), performing argon soft blowing to the bottom of a ladle, continuous casting and continuous rolling. Compared with the prior art, a calcium treatment process is not adopted, so that the calcium treatment cost is saved, the problem that high-melting-point aluminate is prone to generate floccule flow is avoided, the forming performance of a steel sheet is improved, and the occurrence probability of cold bending cracking is reduced.

Owner:RIZHAO STEEL HLDG GROUP

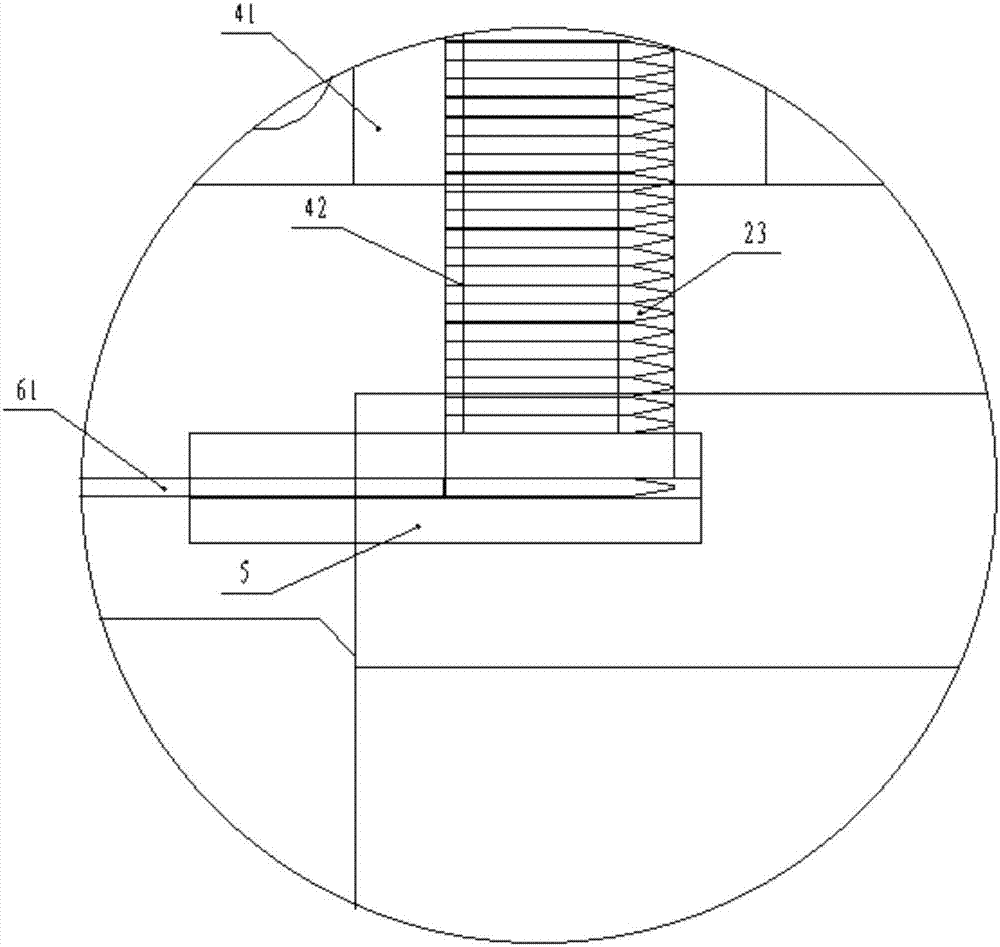

Isostatic pressing forming mold of rotating target

ActiveCN108556135AImprove the situation of sharp deformationAvoid tearingMouldsCeramic shaping coresTransition layerMaterials science

The invention discloses an isostatic pressing forming mold of rotating target. The mold comprises an elastic outer mold, a rigid inner mold and end plugs, the rigid inner mold is arranged in the innercavity of the elastic outer mold, the end plugs are arranged at the two ends of a tubular mold cavity between the elastic outer mold and the rigid inner mold correspondingly, and plastic transition layers capable of being radially compressed with a to-be-formed powder material and can be retracted and deformed along with the elastic outer mold is arranged on a position between one sides, facing the tubular mold cavity, of the end plugs and the to-be-formed powder material, one faces of the plastic transition layers which connected with the end plugs are conical concave surfaces, and conical protrusion matched and cooperate with the conical concave surfaces are arranged on the end plugs. The problems of the trumpet-shape deformation and non-uniform density are solved through the plastic transition layers; a rigid supporting sleeve and a positioning device enable the powder material to be more uniformly filled, an arc-shaped metal clamping plate and a flexible layer are combined to enable the elastic clamping device to tightly wrap round a tubular biscuit all the time, so that the shape of the tubular biscuit is regular, the wall thickness is uniform, the size precision is high; andthe obtaining of the high-performance target is facilitated by sintering, and meanwhile, the later turning amount is reduced, the material utilization rate is increased, and the production cost is reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Steam turbine oil

The invention discloses steam turbine oil which comprises the components by weight percent: 0.1-2% of amine antioxidant, 0.1-0.9% of anti-wear reagent at extreme pressure, 0.02-0.5% of ashless rust inhibitor, 0.01-0.05% of metal deactivator, 0.001-0.01% of anti-foaming agent and the balance of base oil; the base oil is III type base oil, wherein the content of saturated hydrocarbon is more than 90%, and the content of sulphur is less than 0.03%; the amine antioxidant is selected from alkylated diphenylamine, phenyl naphthylamine or a mixture of the alkylated diphenylamine and the phenyl naphthylamine; the anti-wear reagent at extreme pressure is one or a mixture of more than one of alkyl phosphorothioate, alkyl phosphate, alkyl phosphate amine salt and alkyl sulfo-carbamic acid ester, wherein alkyl group is C2-C20 hydrocarbyl; and the ashless rust inhibitor is vinyl succinic acid, or phosphate amine salt, or a compound mixture of the vinyl succinic acid and the phosphate amine salt. The steam turbine oil has the advantages of being excellent in quality, long in service life, free from pollution and the like, is suitable for lubricating bearings and circulation adjusting systems of large-sized, medium-sized and small-sized steam turbines (water turbines), and is mainly used for a steam turbine or gas turbine with the power more than 300MW.

Owner:上海福岛新材料科技有限公司

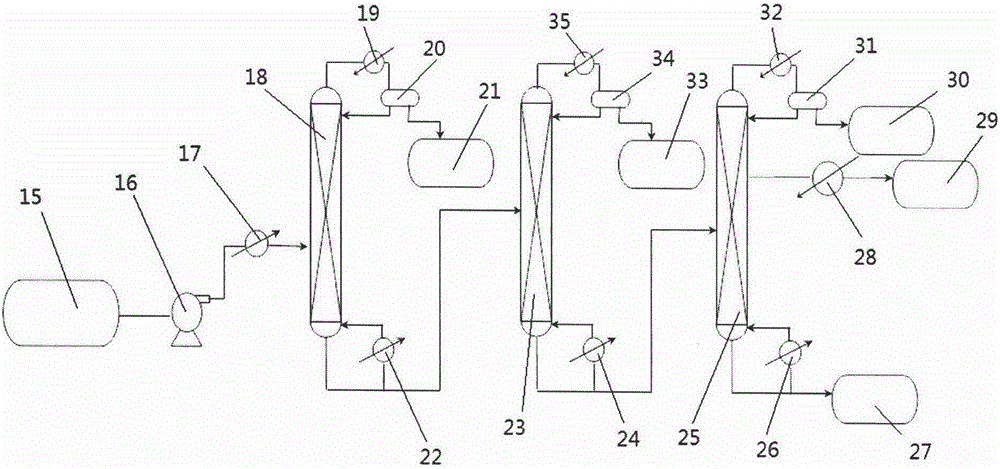

A process for continuously producing m-toluic acid

InactiveCN105061187AImprove reaction efficiencyIncrease production capacityOrganic compound preparationCarboxylic compound separation/purificationM-tolualdehydeWork flow

The invention discloses a process for continuously producing m-toluic acid. The process comprises a synthesizing production process corresponding to a synthesizing workshop section and a rectifying production process corresponding to a rectifying workshop section. The process for continuously producing m-toluic acid comprises a work flow of (1) synthesizing process, namely synthesizing by adopting a multi-level outer-loop serial connection process; and (2) rectifying process, namely rectifying by utilizing an m-xylene recovery tower, a m-tolualdehyde recovery tower and a m-toluic acid rectifying tower. The process has the advantages of reasonable structural design and continuous operation, a gaseous phase and a liquid phase are sufficiently contacted by means of countercurrent to react, so that the reaction efficiency can be greatly improved, the product production capacity in unit interval can be improved, and operation energy consumption can be reduced. Furthermore, the continuous rectification process can be used for greatly shortening the time for heating a to-be-separated mixture and remarkably inhibiting generation of deep byproducts, so that the once through yield can be greatly improved, and the production benefit can be remarkably increased.

Owner:JIANGSU PANOXI CHEM

Double-spray one-sintering low-temperature sintering spraying technology

The invention belongs to the technical field of the production of an enamel product, and particularly relates to a double-spray one-sintering low-temperature sintering spraying technology. The spraying technology is characterized in that a ground coat is firstly coated on a metal blank in the production process of the enamel product, then a cover glaze is coated, and finally the enamel product is sintered in one step, therefore, the one-time sintering procedure can be simplified, the production cost of the enterprise can be effectively reduced, the production efficiency of the enamel product can be increased, the production flow can be saved, and the national requirement of energy conservation and emission reduction also can be met. Clay and different electrolytes are unnecessary to add in the ground coat and the cover glaze, the sintered enamel surface is smooth and compact, the porous rate is low, miscellaneous points and different colors can be obviously reduced, the situation that the exhaust direction is gradually escaped and dispersed from the non-enamel surface in the traditional technology and an air passage directly leading to the enamel surface is difficult to form can be well solved, and the appearance defects such as pin holes, bubbles and the like can be avoided.

Owner:郸城县英耐姆复合材料有限公司

Artificial hatching method for pigeon eggs

The invention provides an artificial hatching method for pigeon eggs. The artificial hatching method comprises the following steps: selecting a nanny pigeon; picking up pigeon eggs; sterilizing; choosing the hatching temperature and the hatching humidity; ventilating; candling the pigeon eggs; turning over the pigeon eggs and performing later period management of hatching. The hatching yield of the pigeon eggs is improved by 5-20% by adopting the artificial hatching than that by a natural hatching; the pigeon egg-laying period of the breed pigeon is ahead of time for 10-15 days; the number of broken pigeon eggs is reduced by about 10-20%; the hatchability of fertilized pigeon eggs is improved by about 10-25%; therefore, the artificial hatching method for the pigeon eggs is high in application value.

Owner:LIUZHOU DAJIN AGRI TECH

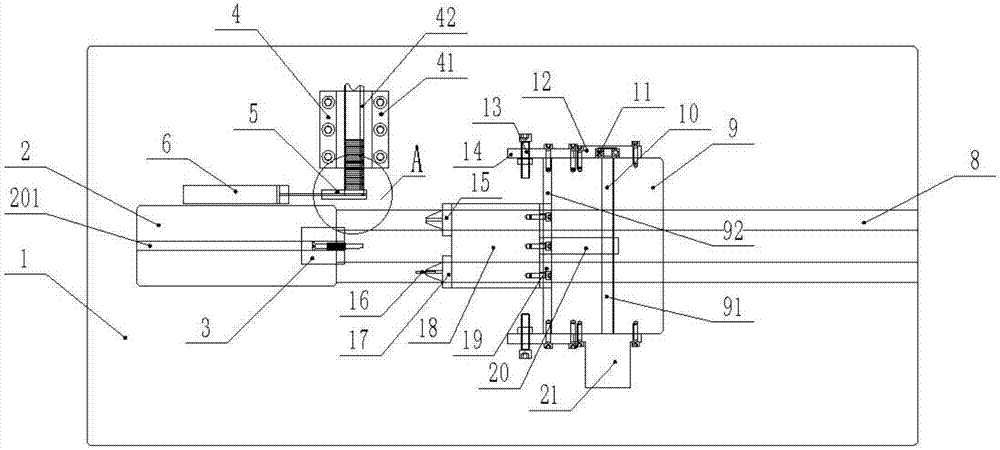

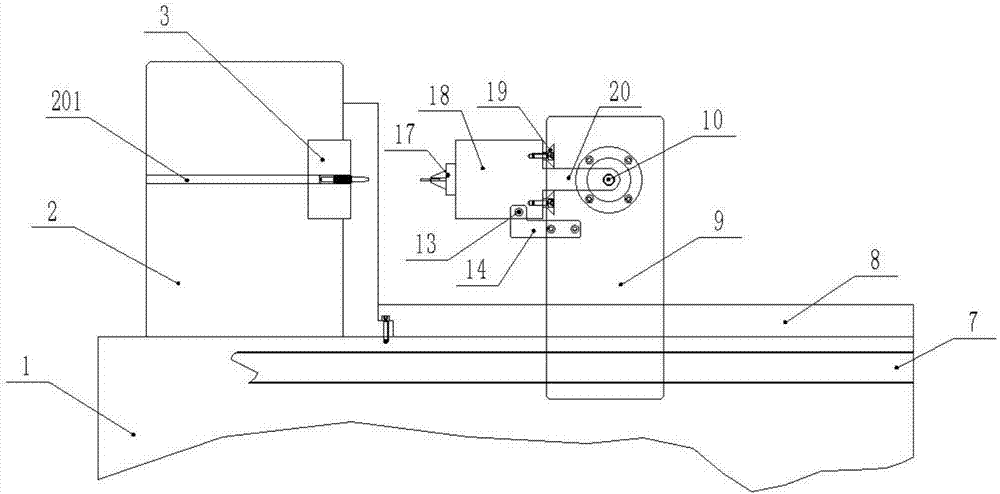

Automatic processing assembling device for screwdriver

ActiveCN107214503AImprove profit marginsImprove installation accuracyMetal working apparatusPositioning apparatusTool bitEngineering

The invention discloses an automatic processing assembling device for a screwdriver. A machine head is fixedly arranged above the left side of a machine base; a discharge tube is processed in the machine head; a pneumatic chuck is fixedly arranged at the right side of the machine head; a horizontal feeding mechanism is mounted at one side of the machine head, and comprises a horizontal feeder and a horizontal feeding rail; a discharge block is fixedly arranged between the horizontal feeder and the machine head, and abuts against the horizontal feeding rail; an air cylinder is arranged at the left side of the discharge block; a slide path is mounted at the right side of the machine base; a knife rest is positioned on the slide path and is driven by a power lead screw; a processing through hole in the knife rest is used for mounting the lead screw; the inner side of the lead screw is limited by a cover plate, and the outer side of the lead screw is connected with a motor; a dovetail slot is processed in the wall surface at the left side of the knife rest; a tool bit is embedded into the dovetail slot from a slide bock, and is connected with the lead screw through a connecting block; a pneumatic chuck I and a pneumatic chuck II are mounted on the tool bit; a reducing drill bit is fixedly arranged on the pneumatic chuck I; a PLC controls the knife rest to move; after the reducing drill bit drills, the pneumatic chuck II drives out a screw cutter bar from a discharge block and is inserted into a cutter bar hole in an interference mode; and the automatic processing assembling device is compact in structure, realizes once positioning of the screw cutter shank, and is high in assembly precision.

Owner:舟山市敏瑞科技咨询有限公司

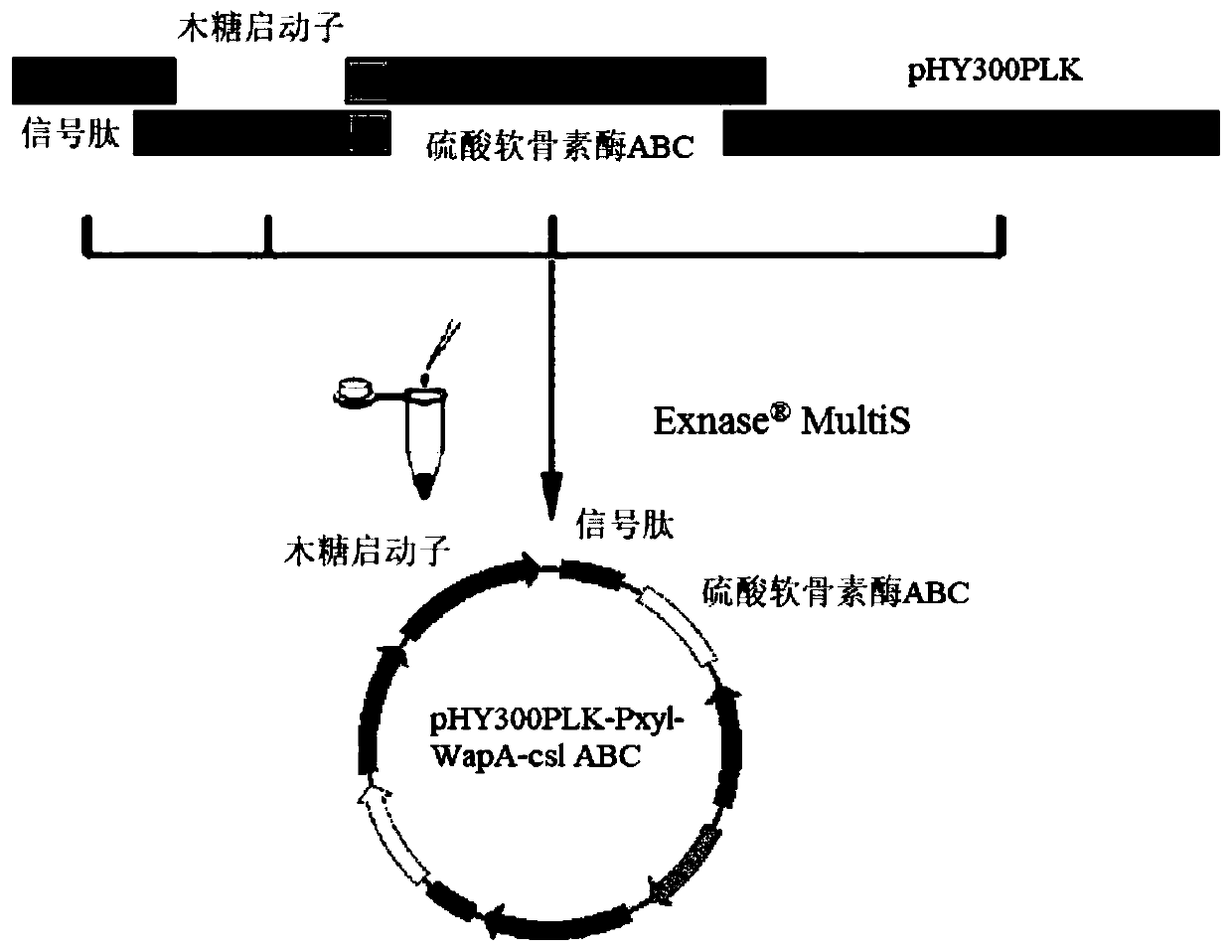

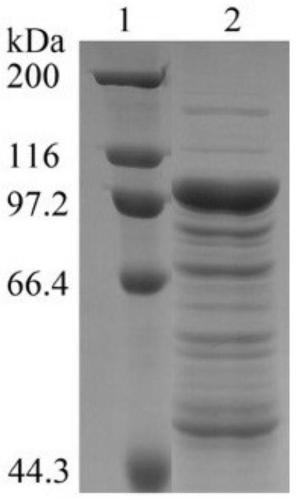

Method for efficiently preparing micromolecular chondroitin sulfate and micromolecular hyaluronic acid by one step

ActiveCN109988739AEasy to operateAvoid immobilizationBacteriaMicroorganism based processesHeterologousEnzyme membrane

The invention discloses a method for efficiently preparing micromolecular chondroitin sulfate and micromolecular hyaluronic acid by one step, and belongs to the technical field of bioengineering. According to the method, chondroitin sulfate ABC lyase derived from proteus vulgaris ATCC33420 is heterologously expressed, a signal peptide wapA is selected, and constitutive xylose promoter Pxyl and pHY300PLK vectors are used, and secreted expression of the chondroitin sulfate ABC lyase in bacillus subtilis is realized through induction by xylose; the micromolecular chondroitin sulfate and the micromolecular hyaluronic acid can be produced efficiently and continuously by a designed chondroitin lyase-enzyme membrane reactor. The method has the advantages that the food-grade bacillus subtilis serves as a host strain, and safety and reliability are realized; effective reference is provided for industrial green production of the micromolecular chondroitin sulfate and the micromolecular hyaluronic acid; energy conservation and emission reduction are realized, and economic and social benefits are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite

ActiveCN105197901AReduce manufacturing costTake advantage ofChemical industryAlkali metal carbonatesFiltrationQuenching

The invention relates to an energy-saving method for preparing yellow phosphorus, sylvite, sodium carbonate and aluminum oxide through potassium-bearing phosphorite. The method comprises the steps that the potassium-bearing phosphorite and coke nuts are added into a yellow phosphorus electric furnace to be reacted to obtain furnace gas containing P2; washing is conducted on the furnace gas, crude phosphorous is collected, refining is conducted, and high quality yellow phosphorus is obtained; water quenching is conducted on yellow phosphorus slags, the slags are removed, KAlO2 is dissolved out, filtration is conducted, Al(OH)3 is settled after CO2 is added, and water quench filtrate is obtained. The Al(OH)3 is converted through temperature control to obtain Al2O3, crystal separation and drying are conducted on the water quench filtrate, and K2CO3 and Na2CO3 are obtained. According to the energy-saving method for preparing the yellow phosphorus, the sylvite, the sodium carbonate and the aluminum oxide through the potassium-bearing phosphorite, series of problems that for a traditional electrothermal method that the potassium-bearing phosphorite is used for producing the yellow phosphorus through the yellow phosphorus electric furnace, the reaction is complex, the efficiency is low, furnace ore is unstable, and the benefit is poor are solved; compared with preparing K2CO3 through a traditional orthoclase sintering method, a high-temperature melting method, a hydrothermal method, a blast furnace smelting method and a low-temperature decomposition method, the energy consumption, material consumption and production cost can be greatly reduced, product profit margins are improved, and meanwhile environmental pollution is reduced.

Owner:黄钰雪

Method and system for analysing a blend of two or more hydrocarbon feed streams

ActiveUS20170023485A1Low costLow of opportunityAnalysis using chemical indicatorsDistillation corrosion inhibitionHydrocarbonMethod evaluation

The invention relates to a method for analysing a blend of two or more hydrocarbon feed streams such as crude oils. These crude oils are blended in a facility such as a refinery. The method assesses the compatibility of a hydrocarbon feed in a blend to calculate the blend stability such that organic deposition is minimised. The method uses all of a plurality of hydrocarbon feeds to be blended for analysis. The method either selects a neat hydrocarbon feed, from a plurality of the hydrocarbon feeds included in a blend, as a titrant, wherein the or each other hydrocarbon in the hydrocarbon feed are used to make a pseudo-blend and titrating the pseudo-blend with said selected neat hydrocarbon feed for a plurality of different blend ratios. Alternatively the method involves preparing a reference hydrocarbon and making a blend from the plurality of hydrocarbon feeds and titrating the blend with the reference hydrocarbon. Measurements associated with the change in characteristics of the titrated blend are made and data recorded. The method then calculates, using said data, the stability of the blend.

Owner:INTERTEK GRP

Human milk fat substitute preparing method, human milk fat substitute prepared by the method, and uses of the milk fat substitute

InactiveCN105433120APromote absorptionEasy to absorb and useFatty acid esterificationEdible oils/fatsButterfatTriglyceride

The invention relates to a human milk fat substitute preparing method, a human milk fat substitute prepared by the method, and uses of the milk fat substitute. In particular, the human milk fat substitute is prepared by adopting edible fat and oil as a raw material, and by random interesterification, directed interesterification and physical mixing. In the human milk fat substitute, based on the total weight of fatty acid residues at the Sn-2 site in triglyceride in the human milk fat substitute, the content of palmitic acid residues at the Sn-2 site is 20-60 wt% and the content of linoleic acid at the Sn-2 site is 3-15 wt%. The total content of linolenic acid is 1-5 wt% based on the total weight of fatty acid residues in triglyceride in the human milk fat substitute. The method adopts the edible fat and oil wide in source as the raw material and is simple in process, and therefore the human milk fat substitute the composition of which is similar to that of human milk triglyceride can be produced in a large scale at a low cost in the industry. The human milk fat substitute prepared by the method can be easily absorbed by infants and is beneficial to growth and development of the infants.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com