Steam turbine oil

A technology of turbine oil and base oil, applied in the field of lubricating oil, can solve the problems of insufficient anti-rust and anti-corrosion ability, insufficient extreme pressure lubrication performance, and reduced surface quality of workpieces, so as to eliminate the impact on health, reduce the frequency of suffering, and eliminate the The effect of charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

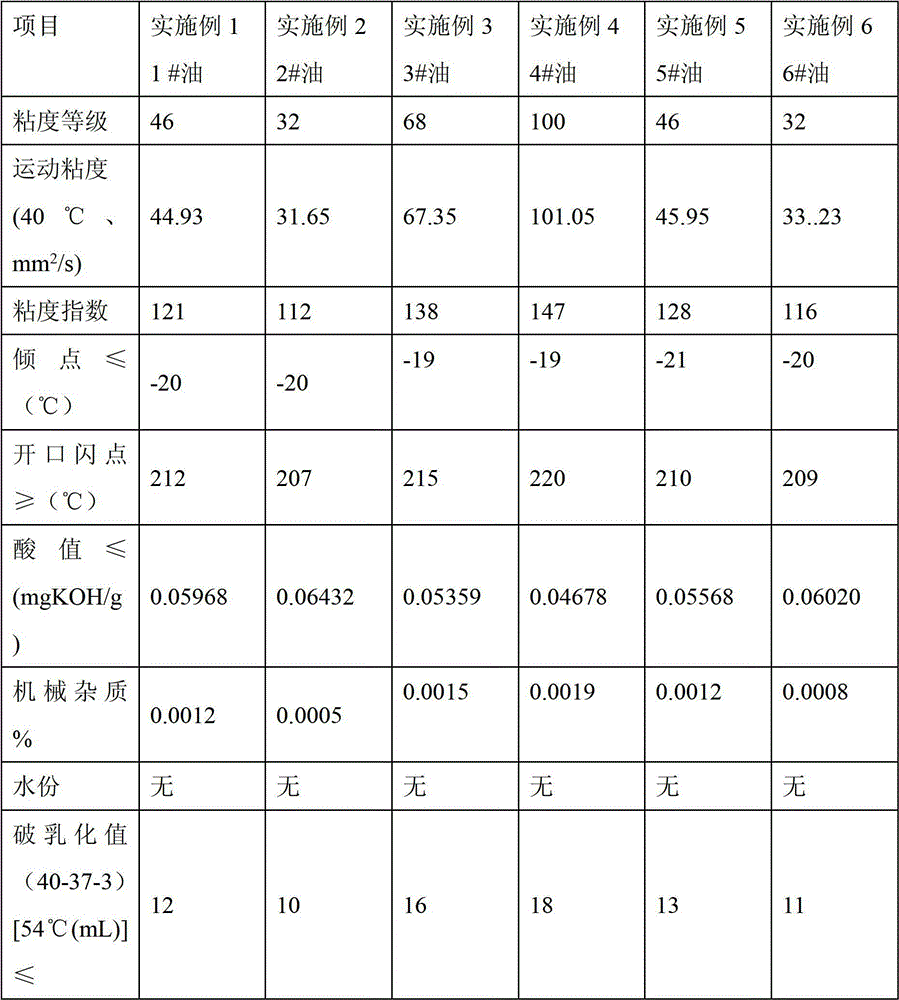

Examples

Embodiment 1

[0021] 1# turbine oil consists of the following components by weight:

[0022] Amine Antioxidant: Dioctyldiphenylamine 0.4%

[0023] Extreme pressure antiwear additive: Alkyl dithioaminomethyl ester 0.3%

[0024] Ashless rust inhibitor: Phosphate amine salt 0.02%

[0025] Metal deactivator: Tolyltriazole derivative 0.04%

[0026] Defoamer: Methylsilane mixture 0.002%

[0027] Group III base oil 99.238%

[0028] Product preparation method and steps are as follows:

[0029] Heat the base oil to about 50-80°C, add amine antioxidants, extreme pressure and anti-wear agents, anti-rust and anti-corrosion additives, metal passivators, defoamers in turn, stir and mix for 1-5 hours, after cooling, The product was obtained by fine filtration.

Embodiment 2

[0031] 2# turbine oil consists of the following components by weight:

[0032] Amine Antioxidant: Ethyl / methyl styryl alkylated diphenylamine blend 0.5%

[0033] Extreme pressure antiwear agent: di-n-butyl phosphite 0.2%

[0034] Ashless Rust Inhibitor: Alkenyl Succinic Acid 0.4%

[0035] Metal deactivator: Tolyltriazole derivative 0.04%

[0036] Defoamer: Methylsilane mixture 0.001%

[0037] Group III base oil 98.859%

[0038] Product preparation method is with embodiment 1.

Embodiment 3

[0040] 3# turbine oil consists of the following components by weight:

[0041] Amine Antioxidant: Butyl / Styrene Alkylated Diphenylamine Blend 0.4%

[0042] Extreme pressure antiwear additive: Alkyl dithioaminomethyl ester 0.7%

[0043] Ashless rust inhibitor: Phosphate amine salt 0.03%

[0044] Metal deactivator: thiadiazole derivatives 0.04%

[0045] Defoamer: Methylsilane mixture 0.002%

[0046] Group III base oil 98.828%

[0047] Product preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com